Audi TT 45 User Manual

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail generation II), mechanics

Engine ID

Edition 05.2010

CFG

B

Service Department. Technical Information

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

00 - Technical data

10 - Removing and installing engine

13 - Crankshaft group

15 - Cylinder head, valve gear

17 - Lubrication

19 - Cooling

21 - Turbocharging/supercharging

26 - Exhaust system

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt D3E8029FA9E

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Engine number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Engine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.1 Working on the fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2 Working on the cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3 Working on vehicles with start/stop system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.4 Using testers and measuring instruments during a road test . . . . . . . . . . . . . . . . . . . . . . . . 5

3.5 Working on the exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 General repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Rules for cleanliness when working on fuel supply system, injection system and

turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Checking for leaks in the fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.3 Contact corrosion! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.4 Routing and attachment of pipes, hoses and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.5 Installing radiators, condensers and charge air coolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.6 Checking vacuum system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

10 - Removing and installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 Removing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Separating engine from manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3 Securing engine to engine and gearbox support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4 Installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 Assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 Assembly mountings - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2 Removing and installing engine mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.3 Checking adjustment of assembly mountings (engine/gearbox mountings) . . . . . . . . . . . . 41

5.4 Adjusting assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

13 - Crankshaft group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1 Cylinder block (pulley end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1.1 Poly V-belt drive without air conditioner compressor - exploded view . . . . . . . . . . . . . . . . 46

1.2 Removing and installing poly V-belt - vehicles without air conditioner compressor . . . . . . 47

1.3 Poly V-belt drive for vehicles with air conditioner compressor and tensioner - exploded

view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1.4 Removing and installing poly V-belt - vehicles with air conditioner compressor and

tensioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1.5 Removing and installing tensioner for poly V-belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.6 Poly V-belt drive for vehicles with air conditioner compressor and tensioning roller - exploded

view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.7 Removing and installing poly V-belt - vehicles with air conditioner compressor and tensioning

roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1.8 Removing and installing vibration damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1.9 Removing and installing bracket for ancillaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.10 Sealing flange (pulley end) - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1.11 Renewing crankshaft oil seal (pulley end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1.12 Removing and installing sealing flange (pulley end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2 Cylinder block (gearbox end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.1 Dual-mass flywheel and sealing flange (gearbox end) - exploded view . . . . . . . . . . . . . . . . 65

2.2 Removing and installing dual-mass flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

2.3 Renewing sealing flange (gearbox end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3 Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Contents i

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

3.1 Crankshaft - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.2 Crankshaft dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.3 Measuring axial clearance of crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.4 Measuring radial clearance of crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.5 Extracting needle bearing for crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.6 Pulling spur gear off crankshaft and shrink-fitting new spur gear . . . . . . . . . . . . . . . . . . . . 78

4 Pistons and conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.1 Pistons and conrods - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.2 Measuring piston projection at “TDC” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4.3 Piston and cylinder dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.4 Measuring radial clearance of conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

15 - Cylinder head, valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

1 Toothed belt drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

1.1 Toothed belt - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

1.2 Removing and installing toothed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2 Cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

2.1 Cylinder head cover - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

2.2 Removing and installing cylinder head cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

2.3 Renewing injector seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

2.4 Cylinder head - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

2.5 Removing and installing cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

2.6 Checking compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

3 Valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

3.1 Valve gear - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

3.2 Measuring axial clearance of camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

3.3 Measuring radial clearance of camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

3.4 Renewing camshaft oil seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.5 Removing and installing camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

3.6 Checking hydraulic valve compensation elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

3.7 Renewing valve stem oil seals with cylinder head installed . . . . . . . . . . . . . . . . . . . . . . . . 135

3.8 Renewing valve stem oil seals with cylinder head removed . . . . . . . . . . . . . . . . . . . . . . . . 139

3.9 Valve dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

3.10 Machining valve seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

3.11 Checking valve guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

3.12 Checking valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

17 - Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1 Oil pump, sump, balance shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.1 Oil pump, sump, balance shaft assembly - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.2 Removing and installing oil level and oil temperature sender G266 . . . . . . . . . . . . . . . . . . 147

1.3 Removing and installing sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

1.4 Removing and installing oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

1.5 Removing balance shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

1.6 Installing a new balance shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

1.7 Re-installing a used balance shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

2 Oil filter bracket and engine oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

2.1 Oil filter bracket and engine oil cooler - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

2.2 Removing and installing oil filter bracket with engine oil cooler . . . . . . . . . . . . . . . . . . . . . . 160

2.3 Removing and installing oil pressure switch F1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

2.4 Checking oil pressure switch F1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

2.5 Checking oil pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

2.6 Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

2.7 Checking oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

ii Contents

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

19 - Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

1 Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

1.1 Diagram of coolant hose connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

1.2 Draining and filling cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

1.3 Checking cooling system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

2 Coolant pump and thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

2.1 Coolant pump and thermostat - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

2.2 Removing and installing coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

2.3 Removing and installing 4/2-way valve with thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

2.4 Checking thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

3 Coolant pipes, coolant temperature senders, coolant circulation pump . . . . . . . . . . . . . . . . 184

3.1 Coolant pipes, coolant temperature senders, coolant circulation pump - exploded view . . 184

3.2 Removing and installing coolant temperature sender G62 . . . . . . . . . . . . . . . . . . . . . . . . 185

3.3 Removing and installing radiator outlet coolant temperature sender G83 . . . . . . . . . . . . 187

3.4 Removing and installing pump for exhaust gas recirculation cooler V400 . . . . . . . . . . . . 188

3.5 Removing and installing coolant pipe (front) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

3.6 Removing and installing coolant pipe (top front) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

3.7 Removing and installing coolant pipe (left-side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

3.8 Removing and installing coolant pipe (right-side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

4 Radiator and radiator fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

4.1 Radiator and radiator fans - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

4.2 Removing and installing radiator cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

4.3 Removing and installing radiator fans V7 and V177 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

4.4 Removing and installing radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

21 - Turbocharging/supercharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

1 Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

1.1 Diagram of vacuum connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

1.2 Turbocharger - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

1.3 Removing and installing turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

2 Charge air cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

2.1 Charge air cooler - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

2.2 Removing and installing charge pressure sender G31 / intake air temperature sender G42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

2.3 Removing and installing charge air cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

2.4 Checking charge air system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

26 - Exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

1 Silencers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

1.1 Silencers - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

1.2 Removing and installing particulate filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

1.3 Stress-free alignment of exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

1.4 Aligning tailpipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

1.5 Checking exhaust system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

2 Exhaust gas temperature control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

2.1 Exhaust gas temperature control - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

2.2 Removing and installing exhaust gas temperature sender 1 G235 . . . . . . . . . . . . . . . . . . 225

2.3 Removing and installing exhaust gas temperature sender 3 G495 . . . . . . . . . . . . . . . . . . 226

2.4 Removing and installing exhaust gas temperature sender 4 G648 . . . . . . . . . . . . . . . . . . 227

3 Exhaust gas recirculation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

3.1 Diagram of vacuum connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

3.2 Exhaust gas recirculation with exhaust gas recirculation cooler - exploded view . . . . . . . . 229

3.3 Checking exhaust gas recirculation cooler change-over . . . . . . . . . . . . . . . . . . . . . . . . . . 230

3.4 Removing and installing exhaust gas recirculation cooler . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Contents iii

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

iv Contents

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

00 – Technical data

1 Engine number

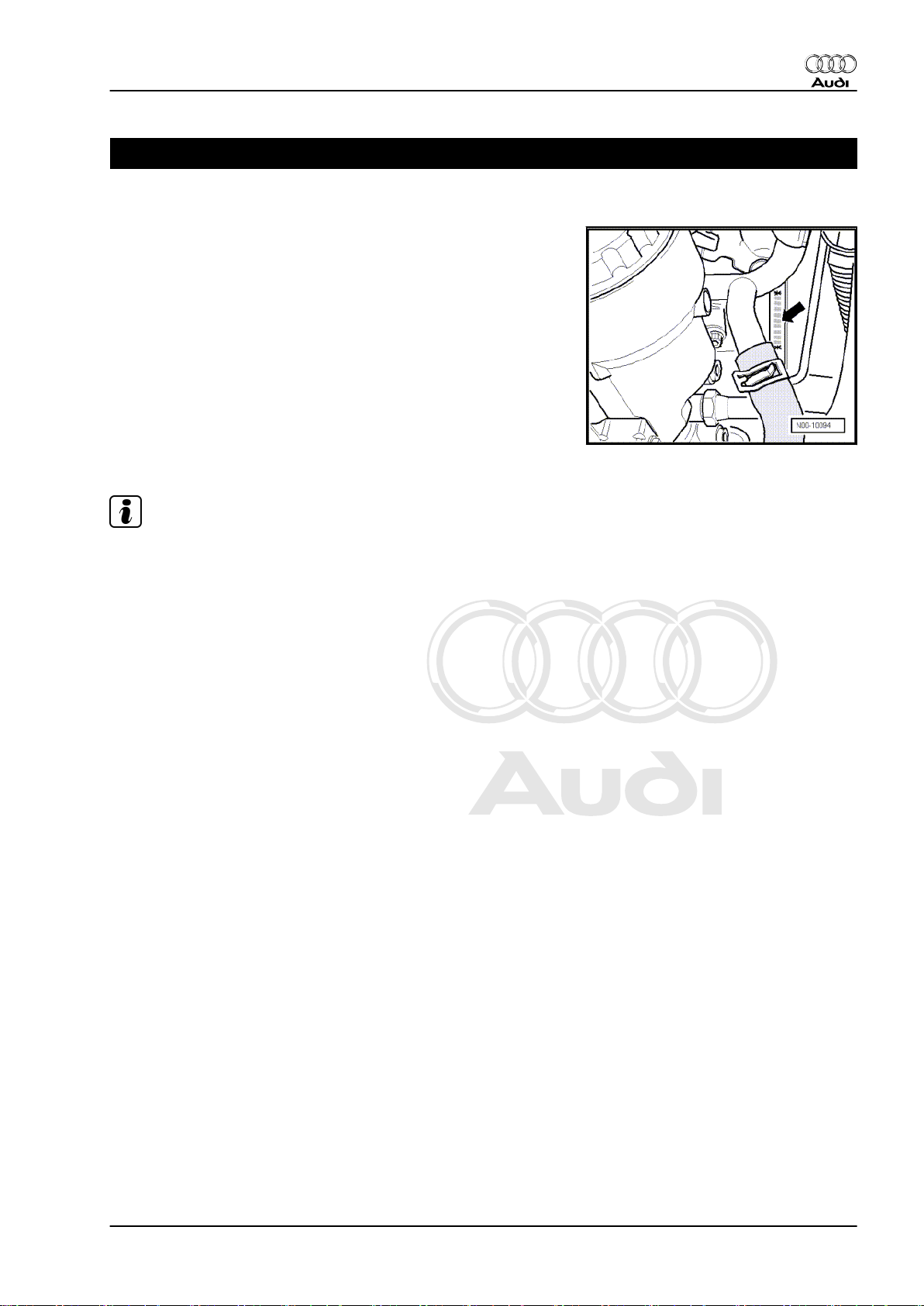

♦ The engine number (“Engine code” and “Serial number”)

-arrow- can be found at the front of the joint between engine

and gearbox.

♦ There is also a sticker on the toothed belt cover showing the

“Engine code” and “Serial number”.

♦ Starting with the letter “C”, the engine codes consist of 4 let‐

ters.

♦ The first 3 characters of the engine code stand for the engine

capacity and the mechanical construction and design. They

are stamped on the cylinder block, together with the serial

number.

♦ The 4th character indicates the power output and torque of the

engine, and is determined by the engine control unit.

Note

♦

The 4-character engine code can be found on the type plate

(in versions for some countries only) and on the vehicle data

sticker and the engine control unit.

♦

Fitting locations of the type plate (certain countries only) and

the vehicle data sticker ⇒ Maintenance ; Booklet 810 .

1. Engine number 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

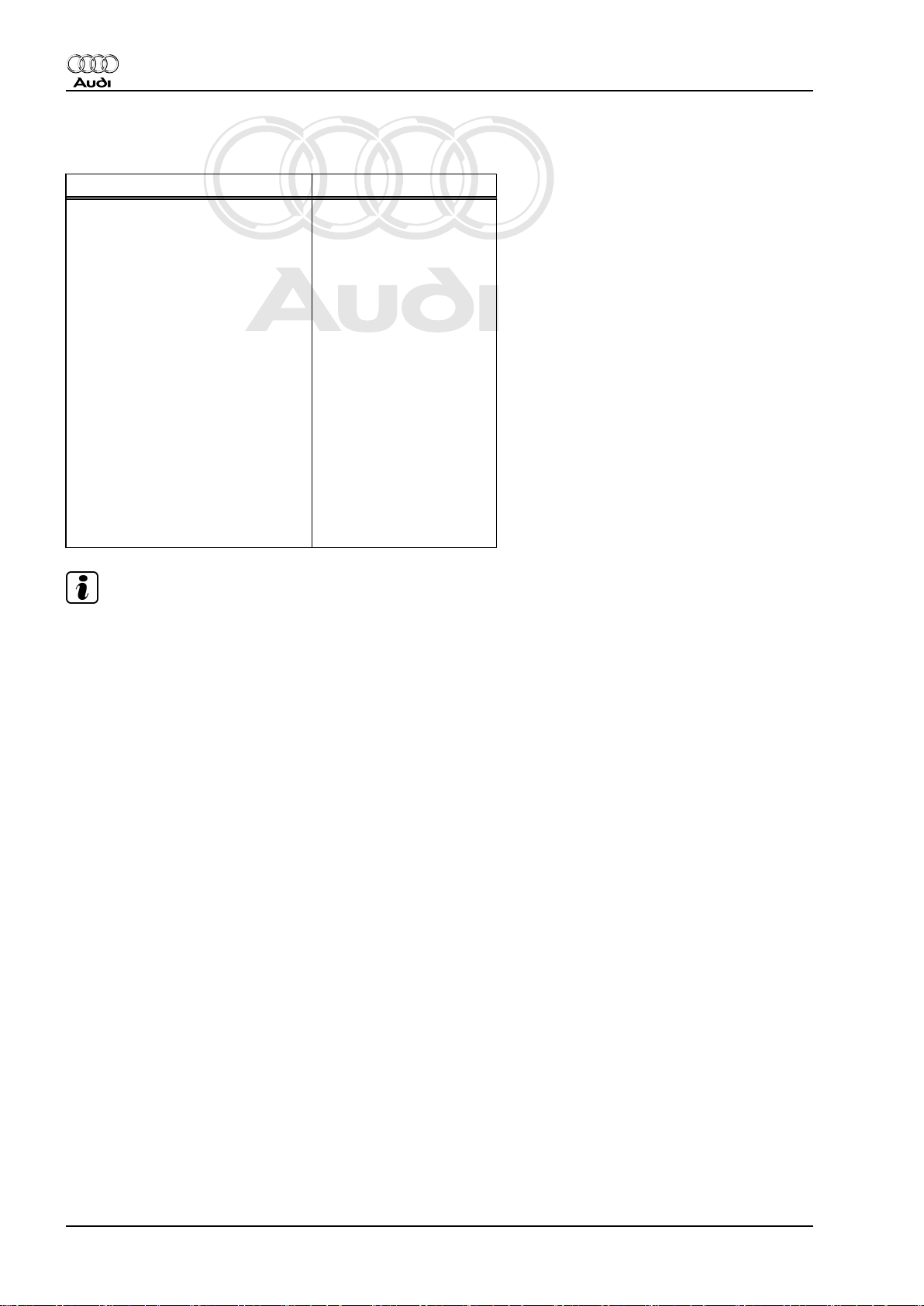

2 Engine data

Code letters CFGB

Capacity ltr. 1.968

Power output kW at rpm 125/4200

Torque Nm at rpm 350/1750 … 2500

Bore ∅ in mm 81.0

Stroke mm 95.5

Compression ratio

CN not less than 51

Firing order

Exhaust gas recirculation yes

Exhaust gas temperature control yes

Turbocharging/supercharging Turbocharger

Glow plugs Steel glow plugs

Charge air cooling yes

Lambda control 1 Lambda probe

Particulate filter yes

Valves per cylinder 4

16.5

1-3-4-2

Note

Audi TT models with a TDI engine (2.0 ltr. 4-valve common rail)

are always equipped with steel glow plugs.

2 Rep. Gr.00 - Technical data

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

3 Safety precautions

3.1 Working on the fuel system

When working on the fuel system note the following warnings:

WARNING

Risk of injury - fuel system operates under pressure.

♦ Wrap a clean cloth around the connection before opening

the fuel system. Then release pressure by carefully loos‐

ening the connection.

♦ Wear protective gloves.

♦ Wear safety goggles.

The fuel can become extremely hot. This can cause injuries.

♦ In extreme cases the temperature of the fuel lines and the

fuel can be up to 100 °C after the engine is switched off.

Allow the fuel to cool down before disconnecting the lines

- danger of scalding.

♦ Wear protective gloves.

♦ Wear safety goggles.

Observe the following points to prevent personal injuries and

damage to the injection and glow plug system:

♦ Always switch off the ignition before connecting or discon‐

necting tester cables or electrical wiring for the injection or

glow plug system.

♦ Always switch off ignition before washing engine.

♦ Entries are stored in event memory of engine control unit if

electrical connectors were unplugged and engine was started:

Interrogate event memory in Vehicle self-diagnosis

⇒ vehicle diagnostic tester .

Caution

To prevent damage to the electronic components when dis‐

connecting the battery:

♦ Observe notes on procedure for disconnecting the battery.

♦ Always switch off the ignition before disconnecting the

battery.

– Disconnect battery ⇒ Electrical system; Rep. Gr. 27 .

3. Safety precautions 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

3.2 Working on the cooling system

When working on the cooling system note the following:

WARNING

Hot steam/hot coolant can escape - risk of scalding.

♦ The cooling system is under pressure when the engine is

hot.

♦ To allow pressure to dissipate, cover filler cap on coolant

expansion tank with cloth and open carefully.

Risk of injury as the radiator fans may start up automatically.

♦ Unplug electrical connectors before starting to work in the

area of radiator cowl.

Caution

Overheating can occur if the filler cap is not fitted properly.

♦ Close filler cap on coolant expansion tank (make sure it

engages).

3.3 Working on vehicles with start/stop sys‐

tem

When performing repairs on vehicles with start/stop system, note

the following:

WARNING

Risk of injury due to automatic engine start on vehicles with

start/stop system.

♦ On vehicles with activated start/stop system (this is indi‐

cated by a message in the instrument cluster display), the

engine may start automatically on demand.

♦ Therefore it is important to ensure that the start/stop sys‐

tem is deactivated when performing repairs (switch off

ignition, if required switch on ignition again).

4 Rep. Gr.00 - Technical data

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

3.4 Using testers and measuring instru‐

ments during a road test

Note the following if testers and measuring instruments have to

be used during a road test:

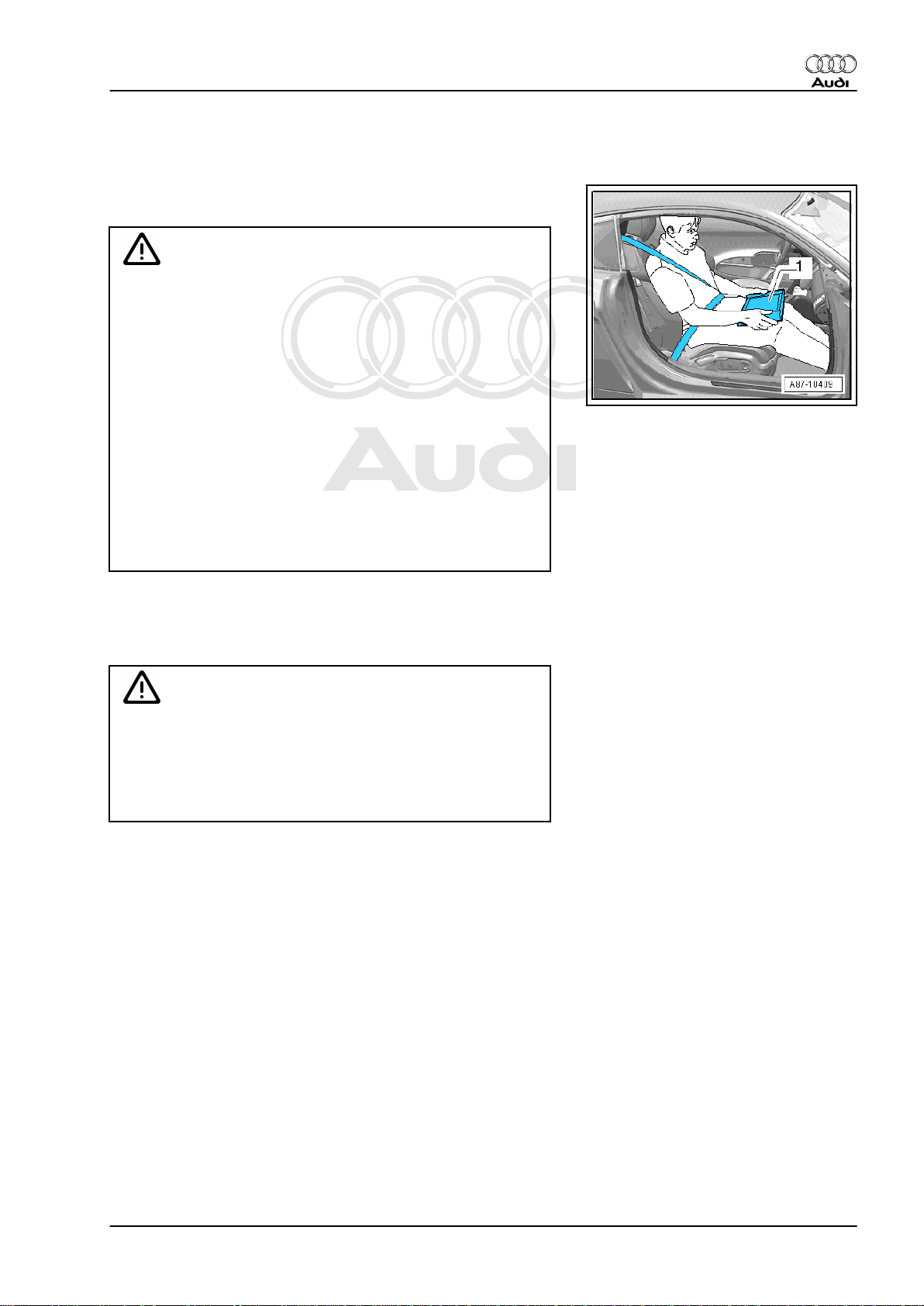

WARNING

Accidents can be caused if the driver is distracted by test

equipment while road-testing, or if test equipment is not prop‐

erly secured.

Persons sitting in the front passenger's seat could be injured if

the airbag is triggered in an accident.

• The use of test equipment while driving causes distraction.

• There is an increased risk of injury if test equipment is not

secured.

♦ Move the passenger's seat back as far as it will go.

♦ Use only vehicle diagnosis and service information sys‐

tem -VAS 5052 A- or diagnosis system -VAS 5053- .

♦ The test equipment -1- must rest flat on the passenger's

thighs (as shown in illustration) and must be operated by

the passenger.

3.5 Working on the exhaust system

When working on the exhaust system note the following:

Caution

Avoid damage to flexible joint.

♦ Do not bend flexible joint more than 10°.

♦ Install flexible joint so that it is not under tension.

♦ Take care not to damage wire mesh on flexible joint.

3. Safety precautions 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

4 General repair instructions

4.1 Rules for cleanliness when working on fuel supply system, injection system and turbocharger

Even small amounts of dirt can cause malfunctions. For this rea‐

son, please observe the following rules when working on the fuel

supply system, injection system and turbocharger:

♦ Carefully clean connection points and the surrounding area

with engine cleaner or brake cleaner and dry thoroughly before

opening.

♦ Seal off open pipes/lines and connections using engine bung

set -VAS 6122- .

♦ Place parts that have been removed on a clean surface and

cover them over. Do not use fluffy cloths.

♦ Carefully cover or seal open components if repairs cannot be

carried out immediately.

♦ Only install clean components; replacement parts should only

be unpacked immediately prior to installation. Do not use parts

that have not been stored in the proper packaging (e.g. in tool

boxes etc.).

♦ When the system is open: Do not work with compressed air.

Do not move the vehicle unless absolutely necessary.

♦ Protect unplugged electrical connectors against dirt and mois‐

ture and make sure connections are dry when attaching.

4.2 Checking for leaks in the fuel system

Procedure

– Allow engine to run for several minutes at moderate rpm.

– Switch off ignition.

– Check complete fuel system for leaks.

– If leaks are found although the connections have been tight‐

ened to the correct torque, the relevant component must be

renewed.

– Road-test vehicle and accelerate with full throttle at least once.

– Then inspect high-pressure section of fuel system again for

leaks.

4.3 Contact corrosion!

Contact corrosion can occur if unsuitable fasteners are used (e.g.

bolts, nuts, washers, etc.).

For this reason, only fasteners with a special surface coating are

used.

Additionally, all rubber and plastic parts and all adhesives are

made of non-conductive materials.

Always install new parts if you are not sure whether used parts

can be re-fitted ⇒ Electronic parts catalogue .

Note the following:

♦ We recommend using only genuine replacement parts; these

have been tested and are compatible with aluminium.

6 Rep. Gr.00 - Technical data

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

♦ We recommend the use of Audi accessories.

♦ Damage caused by contact corrosion is not covered under

warranty.

4.4 Routing and attachment of pipes, hoses and wiring

♦ Mark fuel lines, hydraulic lines, vacuum lines, lines for activa‐

ted charcoal filter system and electrical wiring etc. before

removal so they can be re-installed in the original positions

and correctly connected. Make sketches or take photographs

if necessary.

♦ To prevent damaging pipes, hoses and wiring, ensure suffi‐

cient clearance from all moving or hot components in engine

compartment (little space in engine compartment).

4.5 Installing radiators, condensers and charge air coolers

Even when the radiator, condenser and charge air cooler are cor‐

rectly installed, slight impressions may be visible on the fins of

these components. This does not mean that the components are

damaged. If the fins are only very slightly distorted, this does not

justify renewal of the radiator, charge air cooler or condenser.

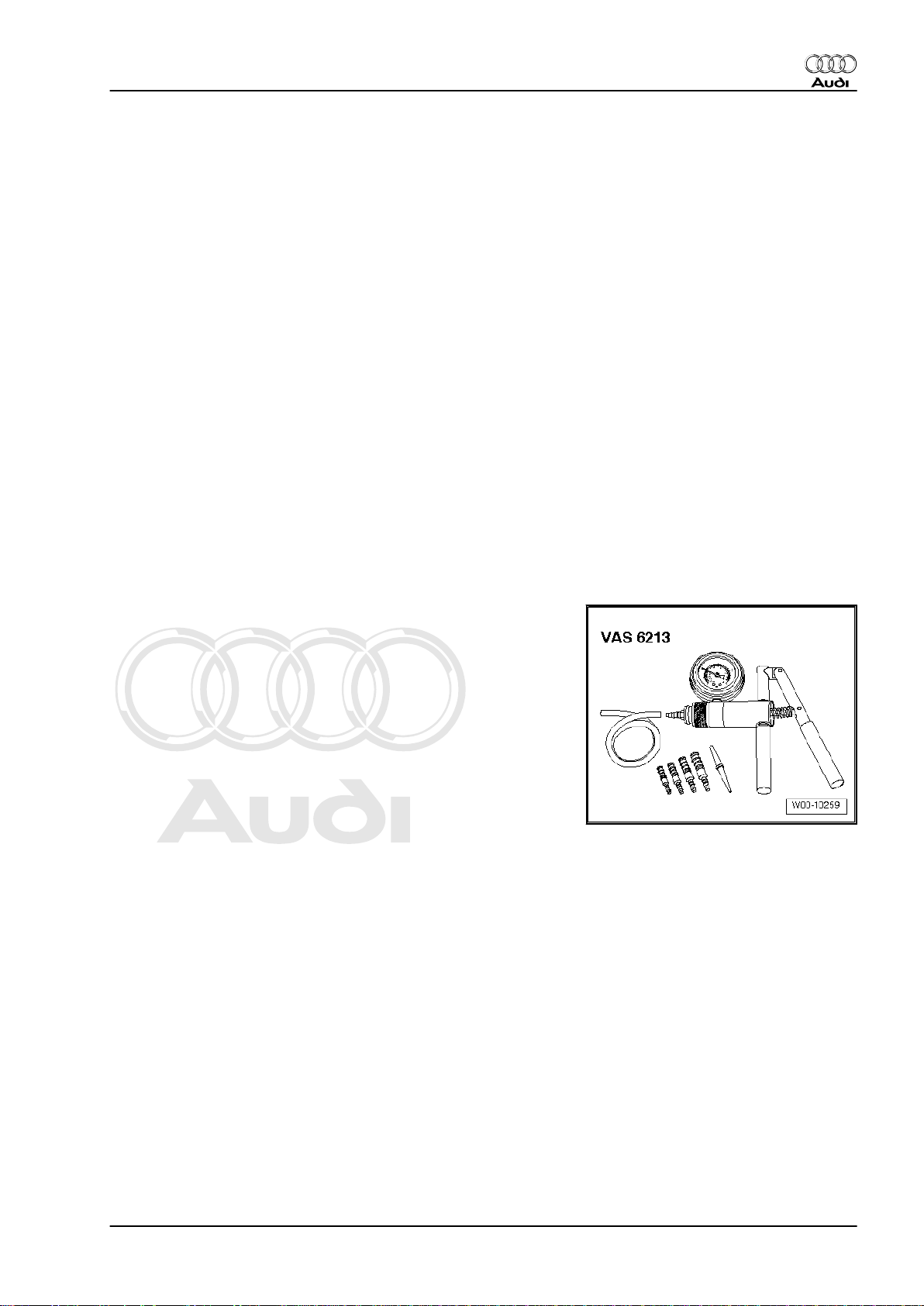

4.6 Checking vacuum system

Special tools and workshop equipment required

♦ Hand vacuum pump -VAS 6213-

Procedure

– Check all vacuum lines in the complete vacuum system for:

♦ Cracks

♦ Traces of animal bites

♦ Kinked or crushed lines

♦ Lines porous or leaking

– Check vacuum line to solenoid valve and from solenoid valve

to corresponding component.

– If a fault is stored in the event memory, check the vacuum lines

leading to the relevant component and also check the remain‐

ing vacuum lines in the system.

– If it is not possible to build up a vacuum with the hand vacuum

pump -VAS 6213- or if the vacuum pressure drops again im‐

mediately, check the hand vacuum pump and connecting

hoses for leaks.

4. General repair instructions 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

10 – Removing and installing engine

1 Removing engine

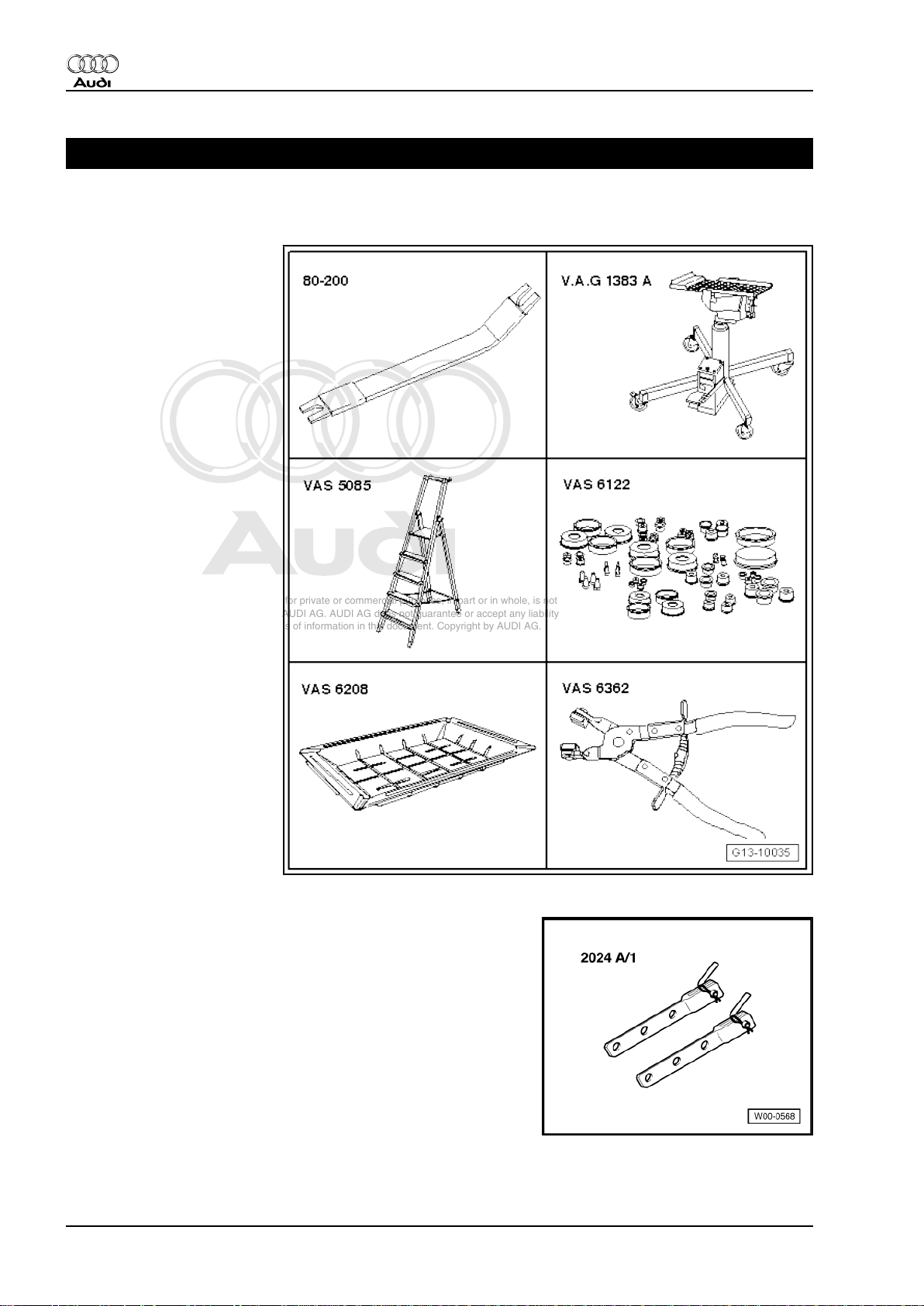

Special tools and workshop

equipment required

♦ Removal lever -80 - 200-

♦ Engine and gearbox jack -

V.A.G 1383 A-

♦ Stepladder -VAS 5085-

♦ Engine bung set -VAS

6122-

♦ Drip tray for workshop hoist

-VAS 6208-

♦ Hose clip pliers -VAS 6362-

♦ Hook -2024 A /1- of lifting tackle -2024 A-

8 Rep. Gr.10 - Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

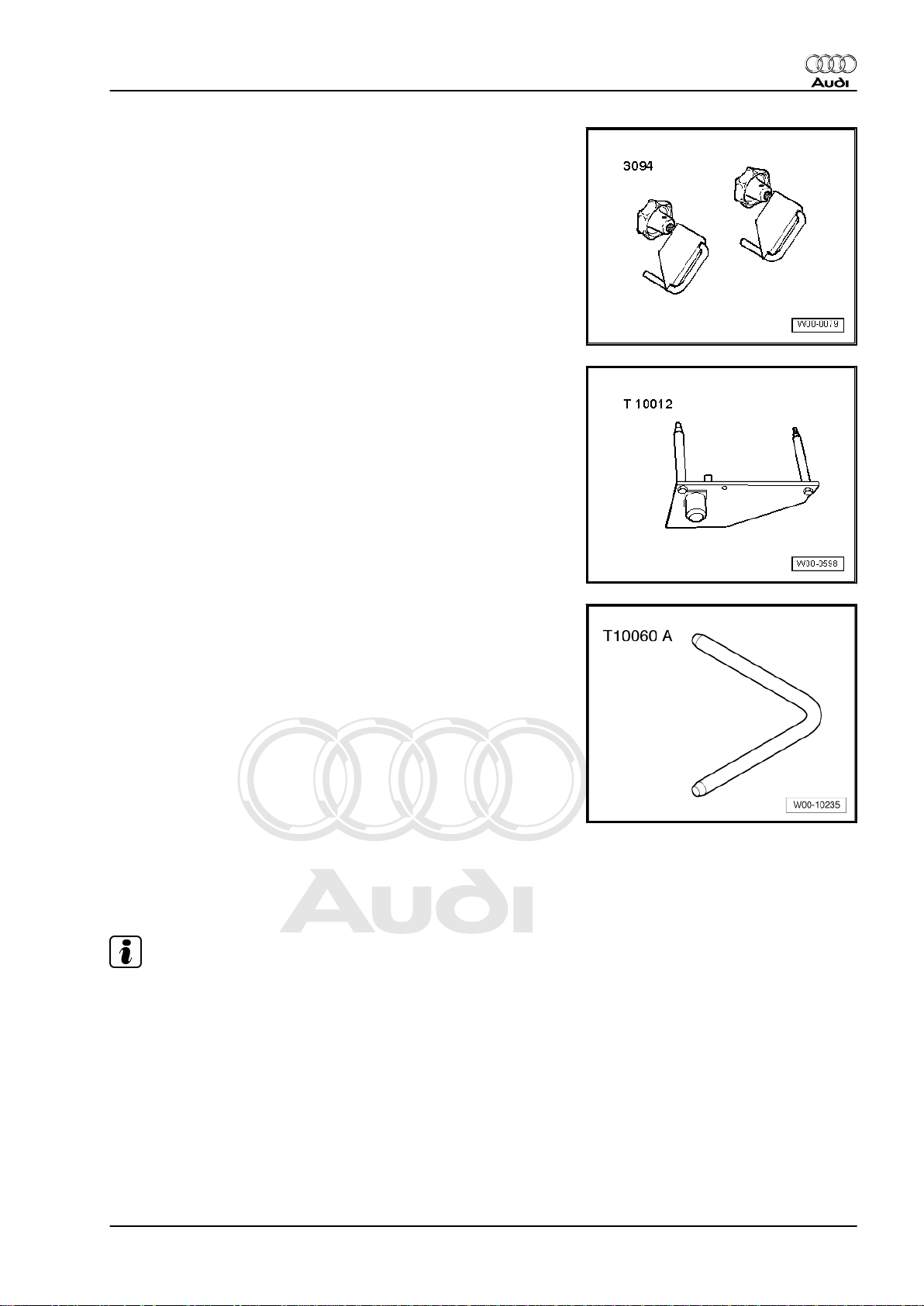

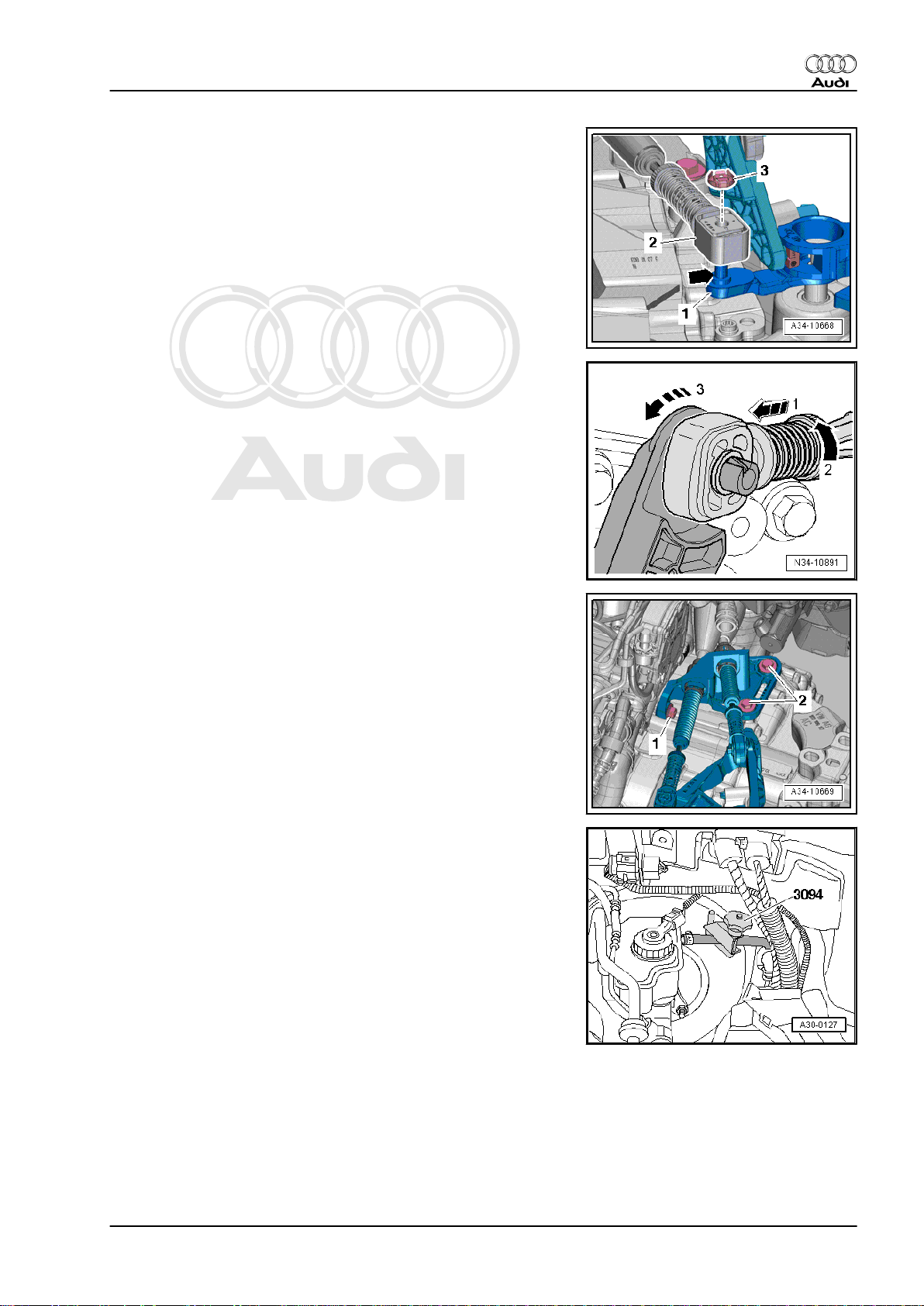

♦ Hose clamps for hoses up to 25 mm -3094-

♦ Engine bracket -T10012-

♦ Locking pin -T10060 A- for vehicles with air conditioner com‐

pressor and tensioner

♦ Safety goggles

♦ Protective gloves

Procedure

Note

♦

The engine is removed from underneath together with the

gearbox.

♦

Fit all cable ties in the original positions when installing.

♦

Fit heat insulation sleeves in the original positions when in‐

stalling.

1. Removing engine 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

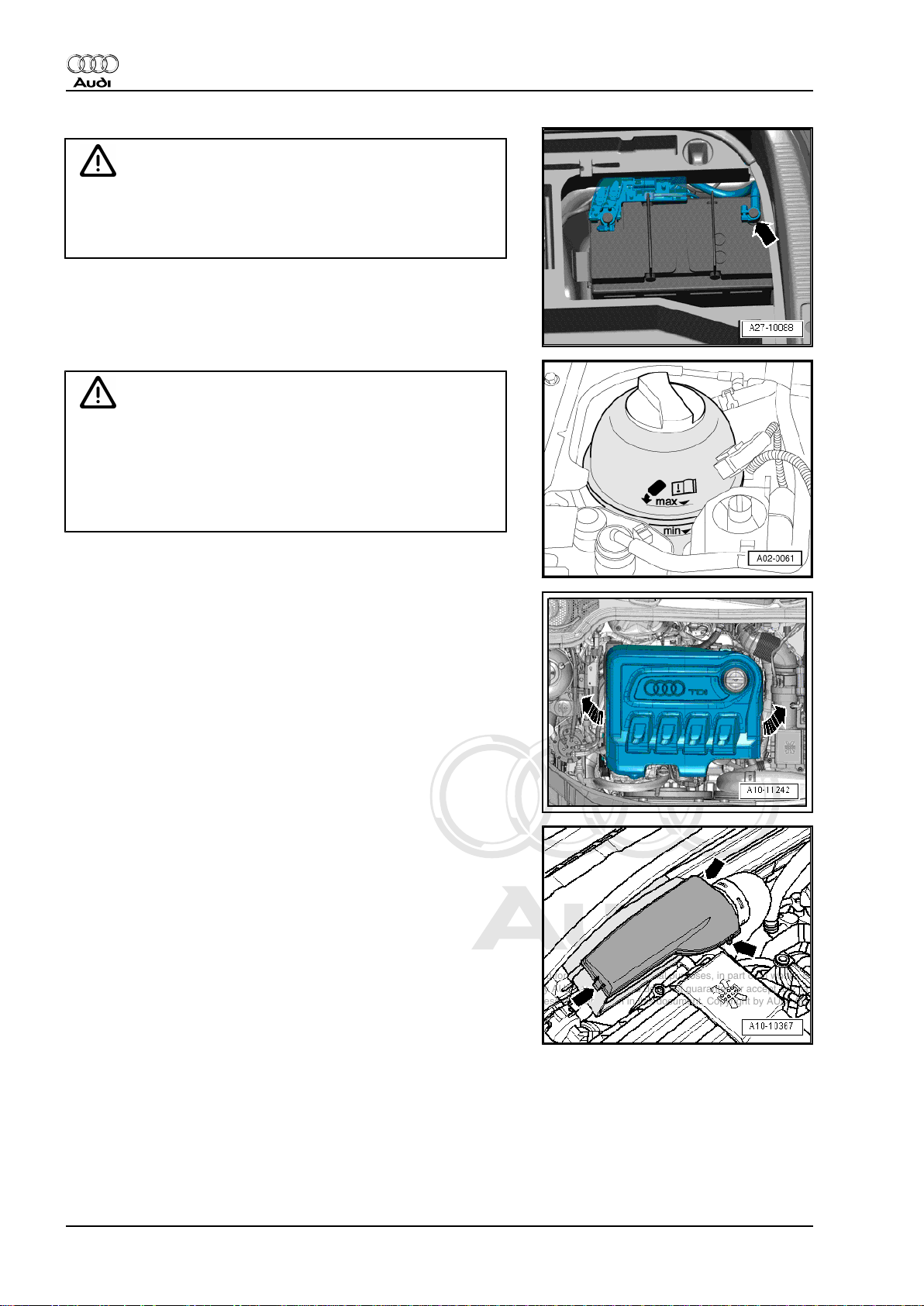

Caution

To prevent damage to the electronic components when dis‐

connecting the battery:

♦ Observe notes on procedure for disconnecting the battery.

– Disconnect earth cable -arrow- from battery terminal ⇒ Elec‐

trical system; Rep. Gr. 27 .

WARNING

Hot steam/hot coolant can escape - risk of scalding.

♦ The cooling system is under pressure when the engine is

hot.

♦ To allow pressure to dissipate, cover filler cap on coolant

expansion tank with cloth and open carefully.

– Open filler cap on coolant expansion tank.

– Remove engine cover panel -arrows-.

– Pull cover off air duct (release clips on sides) -arrows-.

10 Rep. Gr.10 - Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

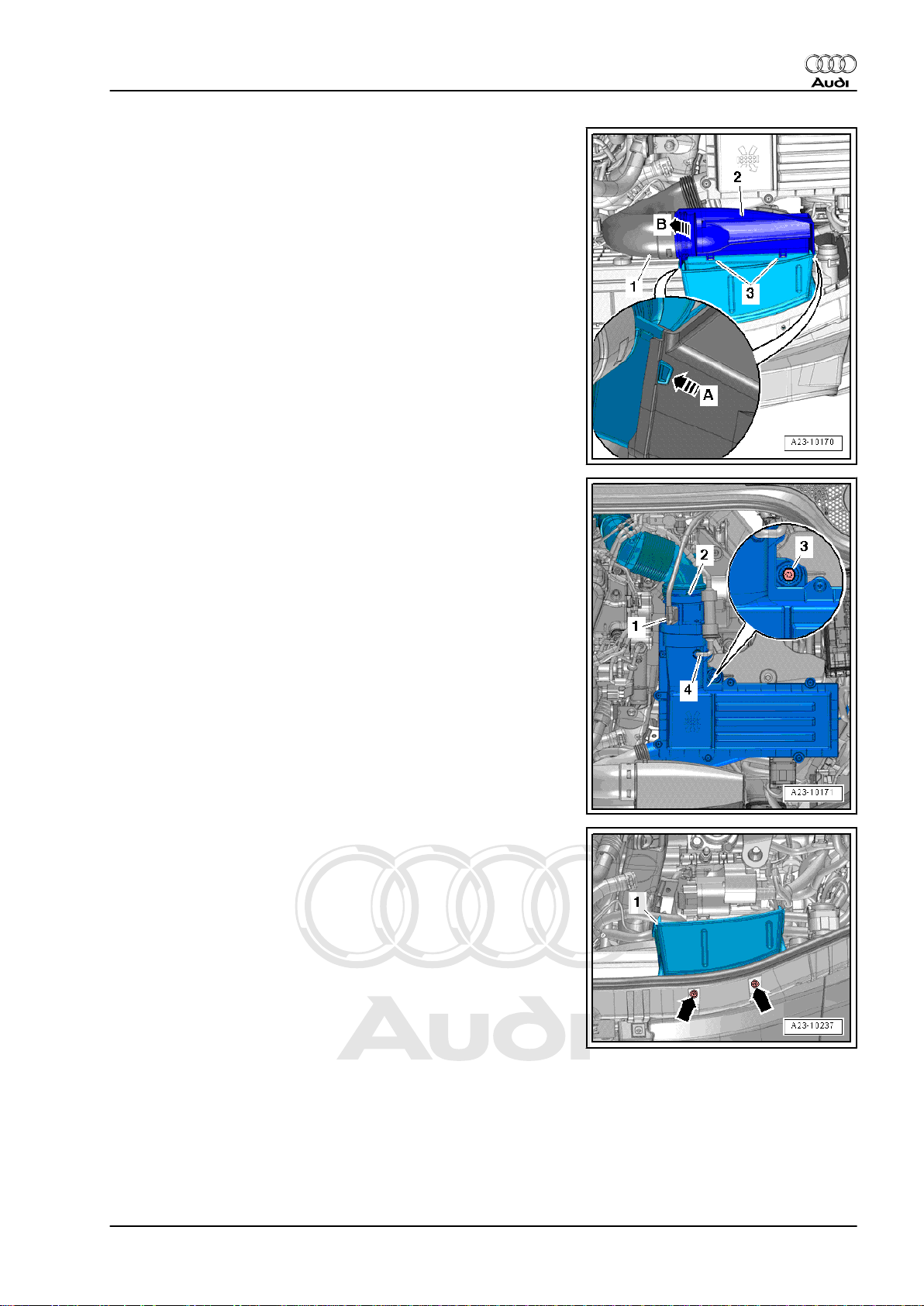

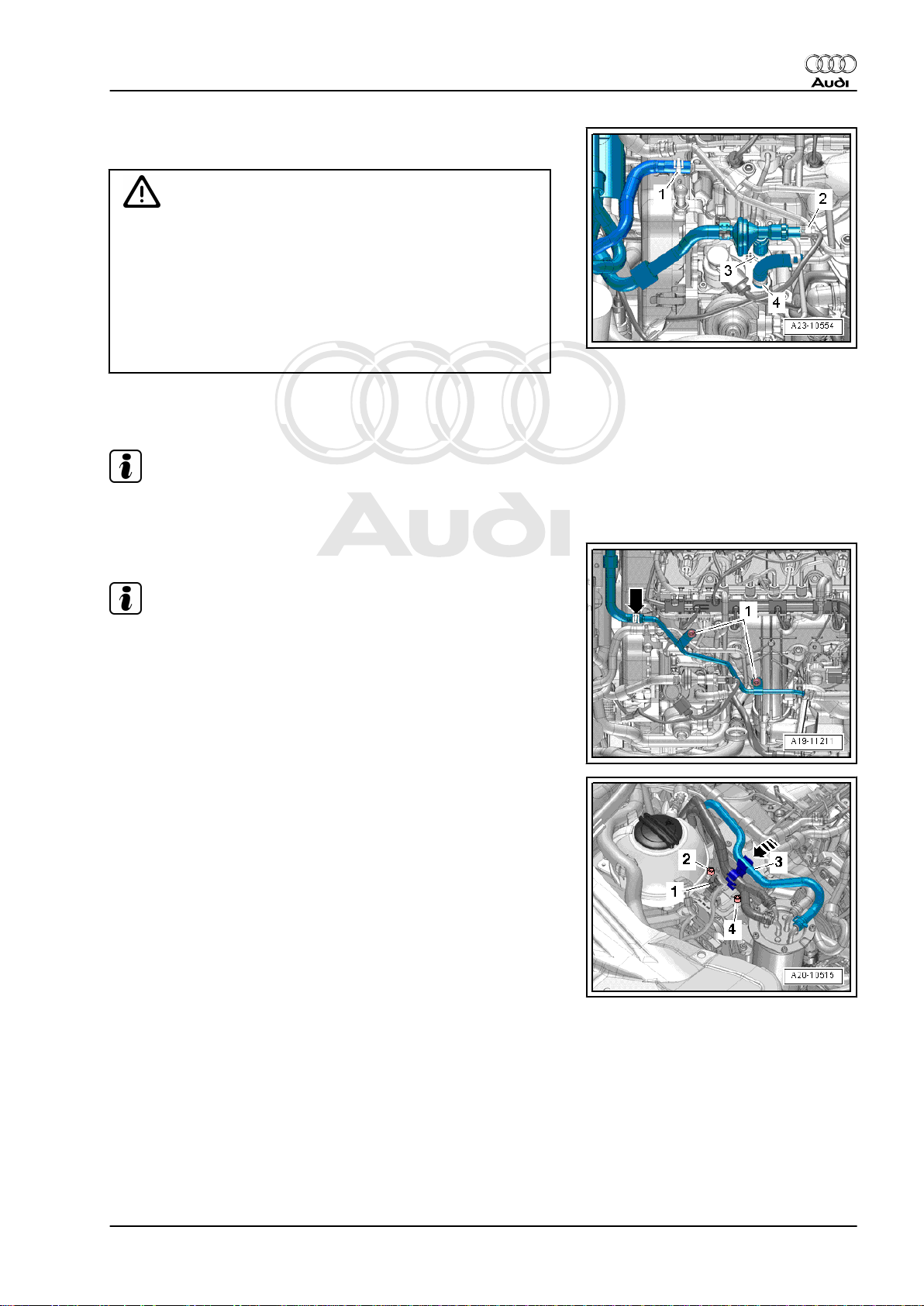

– Release clips on left and right -arrow A- and unclip air duct at

bottom -2-.

– Swivel air duct (bottom) slightly to the rear and detach air duct

(bottom) from retainers -3-.

– Detach air pipe -1- from air duct (bottom) -arrow B-.

– Unplug electrical connector -1- from air mass meter -G70- .

– Detach hose -4-.

– Release hose clip -2- and detach air hose.

– Unscrew bolt -3- and remove air cleaner housing.

– Remove bolts -arrows- and detach air duct -1- from lock car‐

rier.

1. Removing engine 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

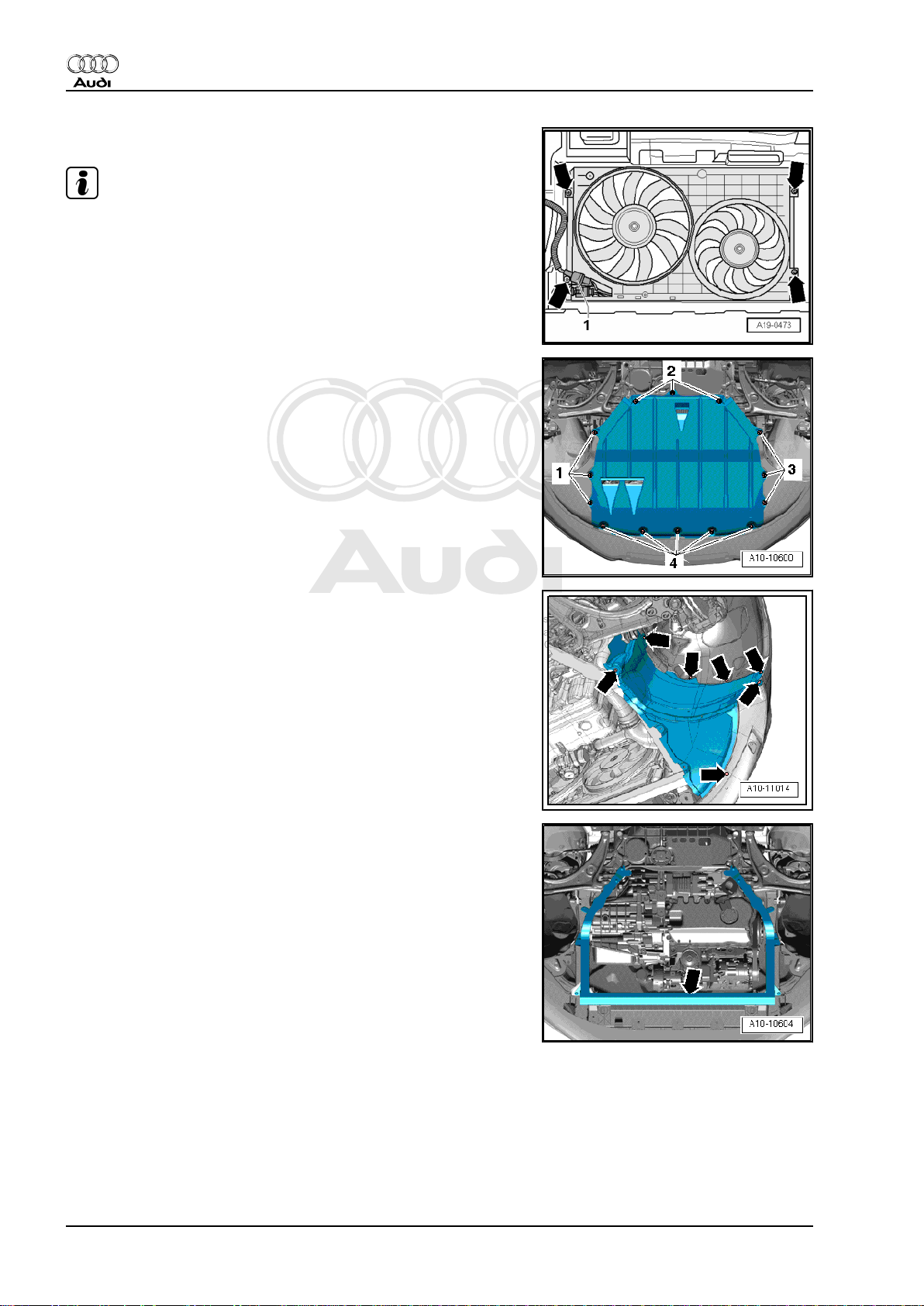

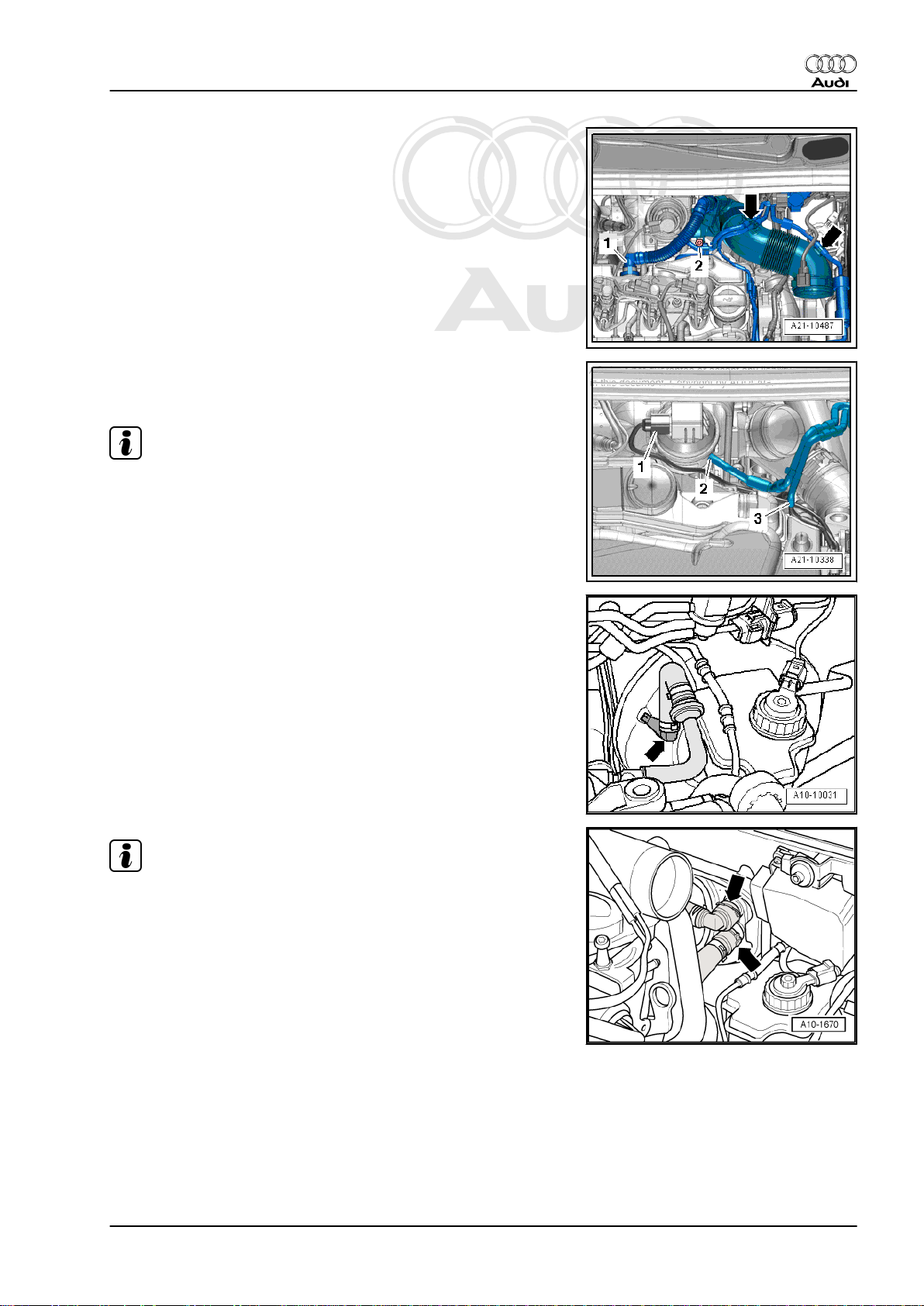

– Remove bolts -top arrows- for radiator cowl.

Note

The bolts -bottom arrows- are removed at a later stage.

– Remove both front wheels.

– Remove noise insulation ⇒ Rep. Gr. 66 .

– Remove bottom sections of wheel housing liners (left and

right) ⇒ Rep. Gr. 66 .

– TT Roadster: Remove noise insulation frame -arrow- ⇒ Rep.

Gr. 50 .

12 Rep. Gr.10 - Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

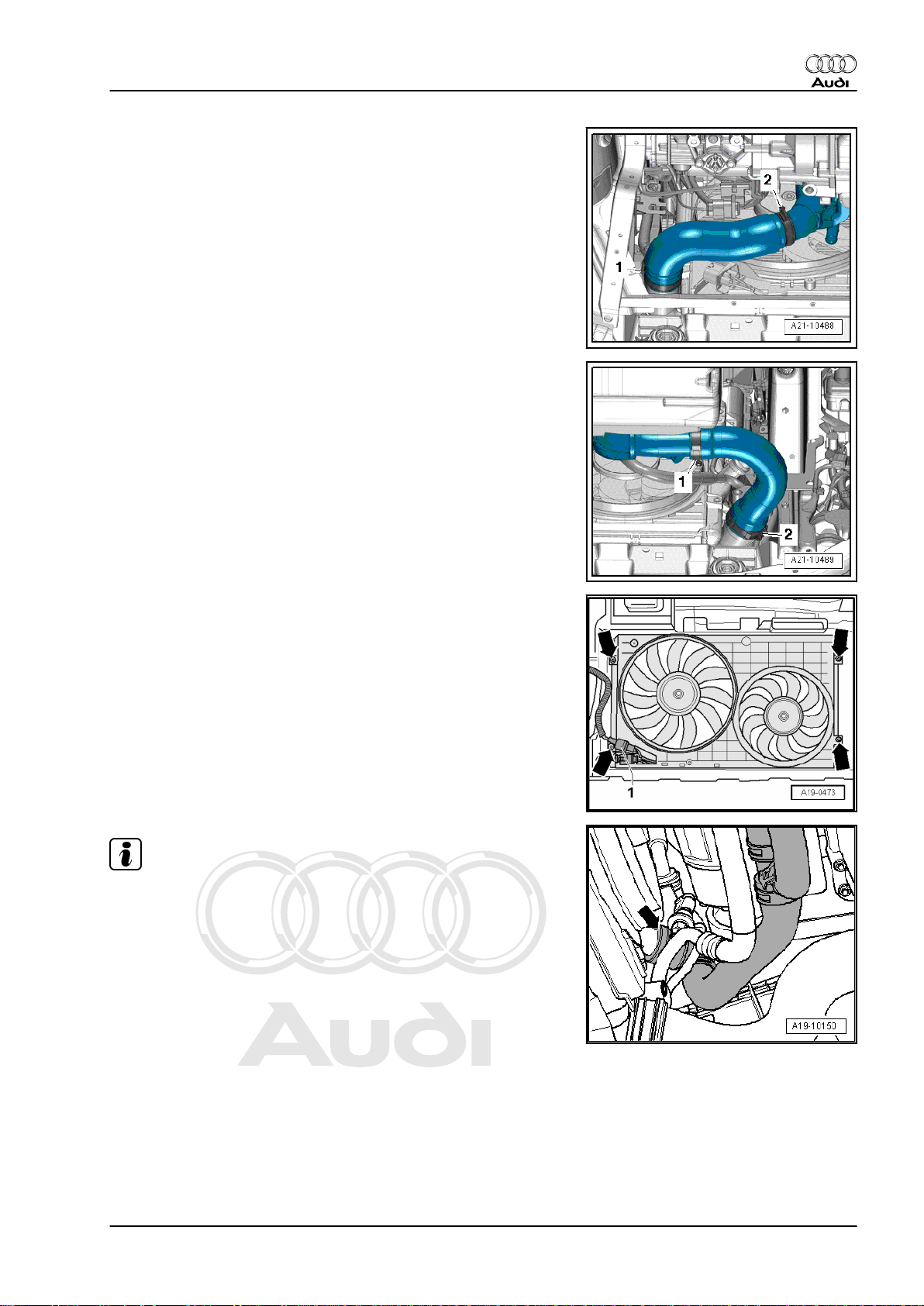

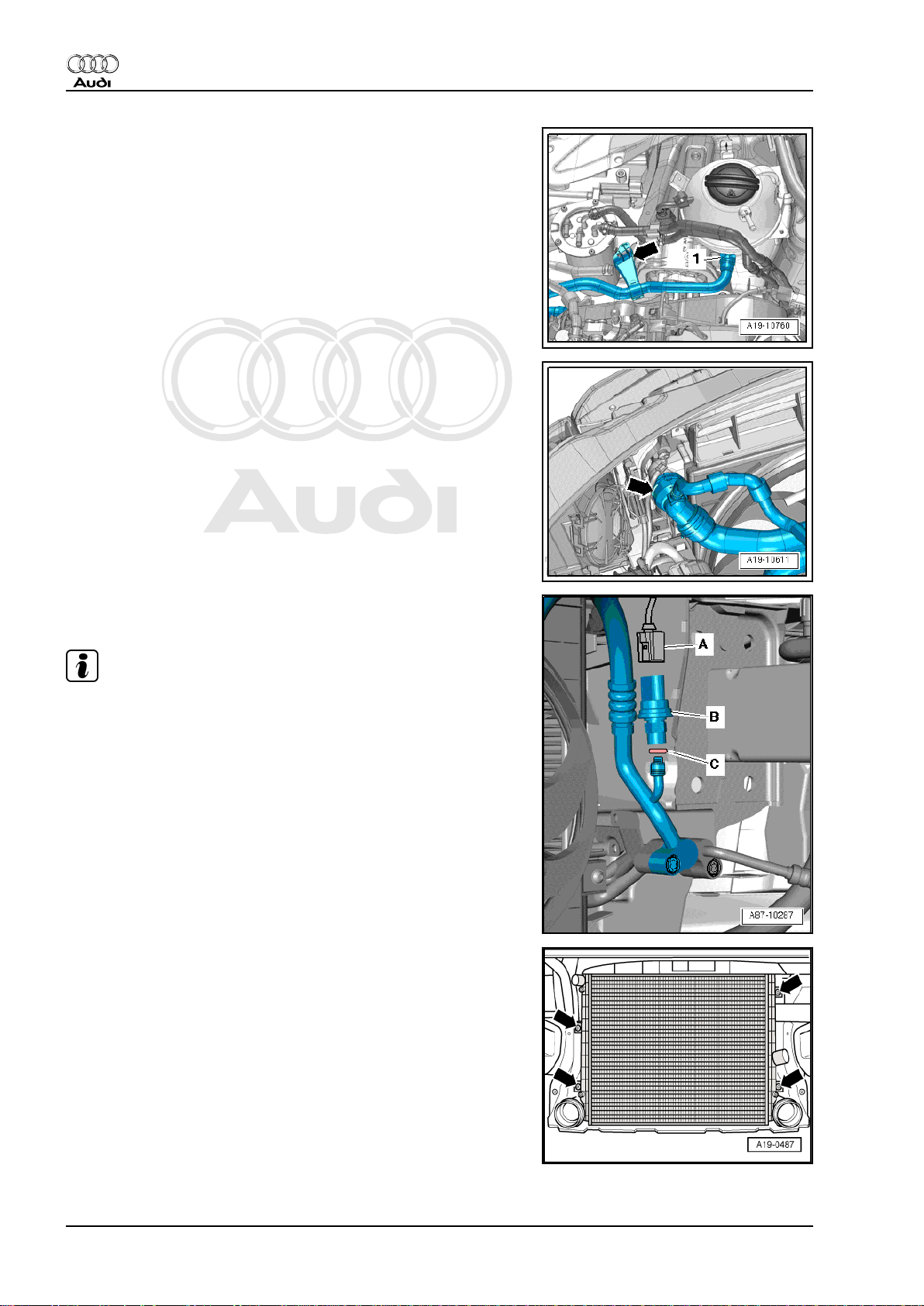

– Release hose clips -1- and -2- and remove air hose.

– Release hose clips -1- and -2- and remove air hose.

– Seal off open pipes/lines and connections with clean plugs

from engine bung set -VAS 6122- .

– Unplug electrical connector -1-.

– Remove bolts -bottom arrows- and take out air cowl down‐

wards.

Note

Collect drained coolant in a clean container for re-use or disposal.

– Place drip tray for workshop hoist -VAS 6208- beneath engine.

– Lift retaining clip -arrow-, disconnect coolant hose (bottom

right) from radiator and drain off coolant.

1. Removing engine 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

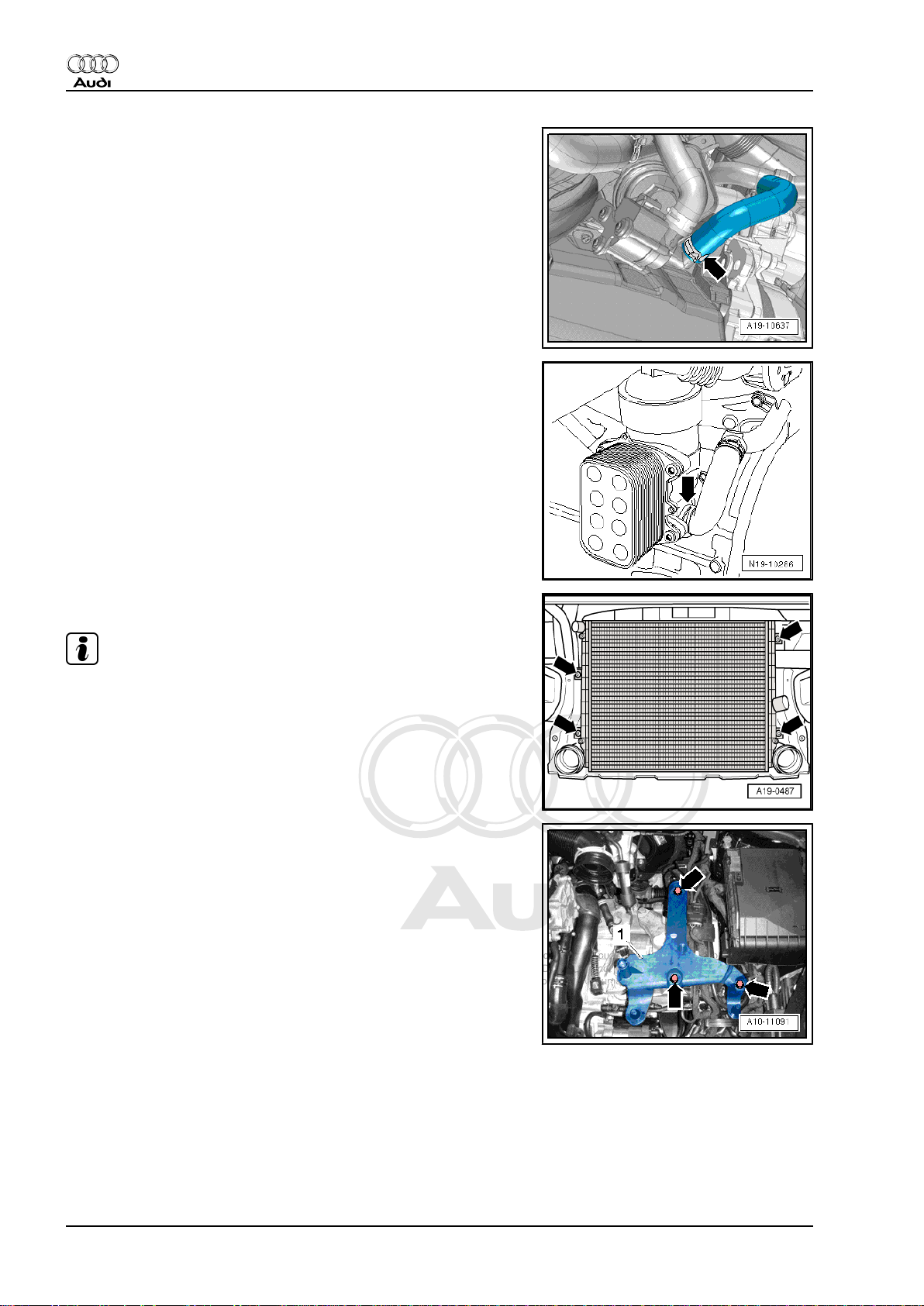

– Open hose clip -arrow-, disconnect coolant hose (bottom)

leading to pump for exhaust gas recirculation cooler -V400and drain off coolant.

– Release hose clip -arrow-, disconnect coolant hose at oil filter

housing and drain off remaining coolant.

– Remove bolts -bottom arrows- on rear side of radiator.

Note

The bolts -top arrows- are removed at a later stage.

– Remove bolts -arrows- and detach bracket -1- for air cleaner

housing.

14 Rep. Gr.10 - Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

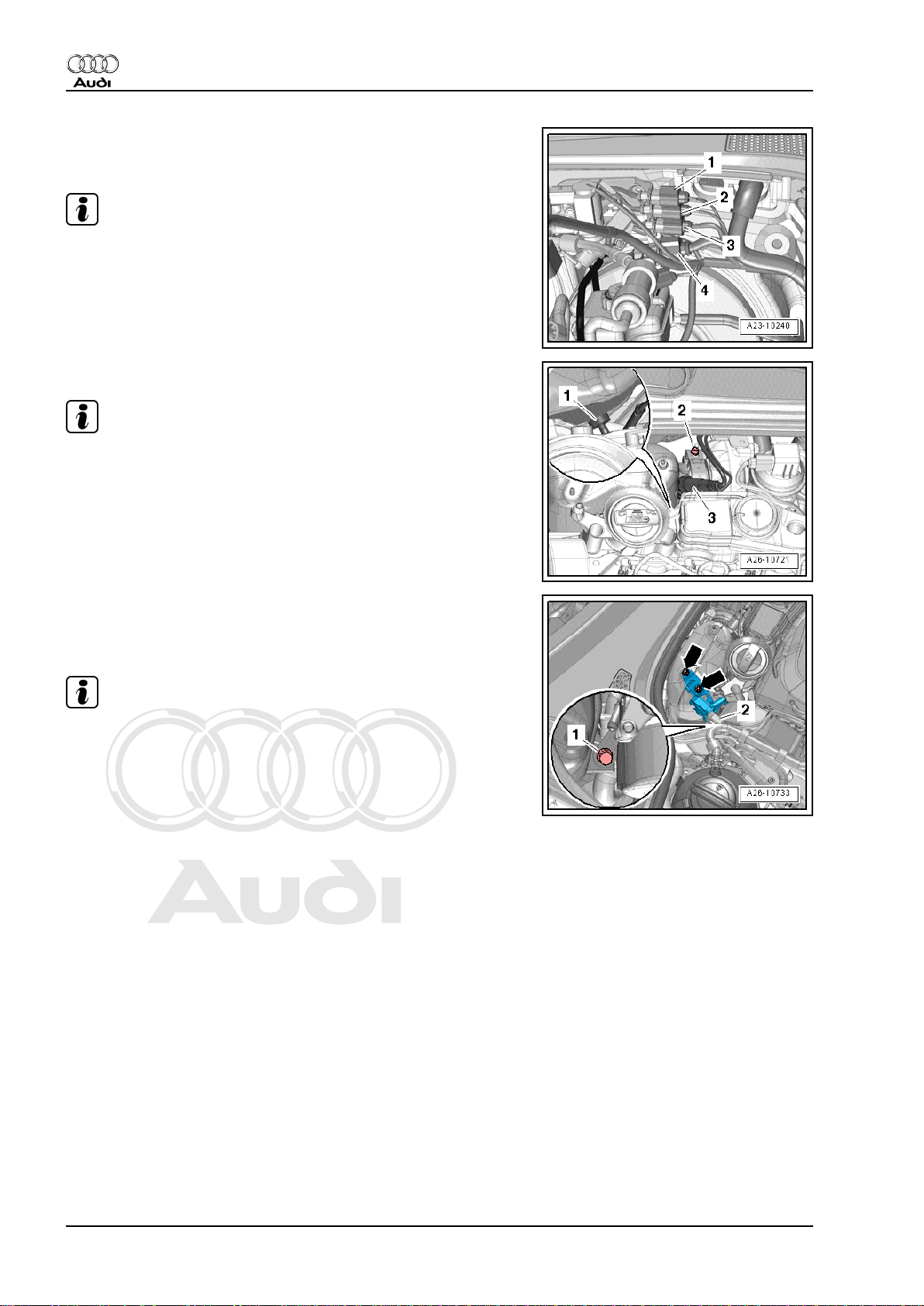

– Press release tabs and disconnect crankcase breather hose

-1- from cylinder head cover.

– Move clear vacuum hoses -arrows- at air pipe.

– Remove bolt -2-, swivel air pipe with connection to rear and

detach from turbocharger.

– Detach vacuum hose -2- from vacuum unit of turbocharger.

– Disconnect vacuum hose -3-.

Note

Disregard -item 1-.

– Detach vacuum hose -arrow- from brake servo.

Note

Place a cloth underneath heat exchanger to catch escaping cool‐

ant.

– Lift retaining clips -arrows- and detach coolant hoses from

heat exchanger.

1. Removing engine 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

– Detach electrical connector -1- from bracket and unplug.

– Move clear electrical wiring.

Note

Disregard -items 2, 3, 4-.

– Slacken bolt -2- and remove clamp.

Note

Disregard -items 1, 3-.

– Remove top bolt -1- at bracket for particulate filter.

– Unplug electrical connector -2- at pressure differential sender

-G505- .

– Remove bolt -1-.

Note

Disregard -arrows-.

16 Rep. Gr.10 - Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

– Unplug electrical connector -2- on fuel temperature sender -

G81- .

WARNING

The fuel can become extremely hot. This can cause injuries.

♦ In extreme cases the temperature of the fuel lines and the

fuel can be up to 100 °C after the engine is switched off.

Allow the fuel to cool down before disconnecting the lines

- danger of scalding.

♦ Wear protective gloves.

♦ Wear safety goggles.

– Release hose clips -1- and -3- and disconnect fuel supply hose

and fuel return hose.

Note

Disregard -item 4-.

– Release hose clip -arrow- and detach coolant hose.

Note

Disregard -item 1-.

– Disengage fuel hose -3- at bracket.

– Pull off bracket for fuel lines towards right -arrow- and move

clear to one side.

– Unplug electrical connector -1- at supplementary fuel pump -

V393- .

– Remove bolts -2- and -4-, detach bracket with supplementary

fuel pump -V393- and move clear to one side.

1. Removing engine 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

– Release hose clip -1-, detach coolant hose from coolant ex‐

pansion tank and move coolant hose clear -arrow-.

– Lift retaining clip -arrow- and disconnect coolant hose (top left)

from radiator.

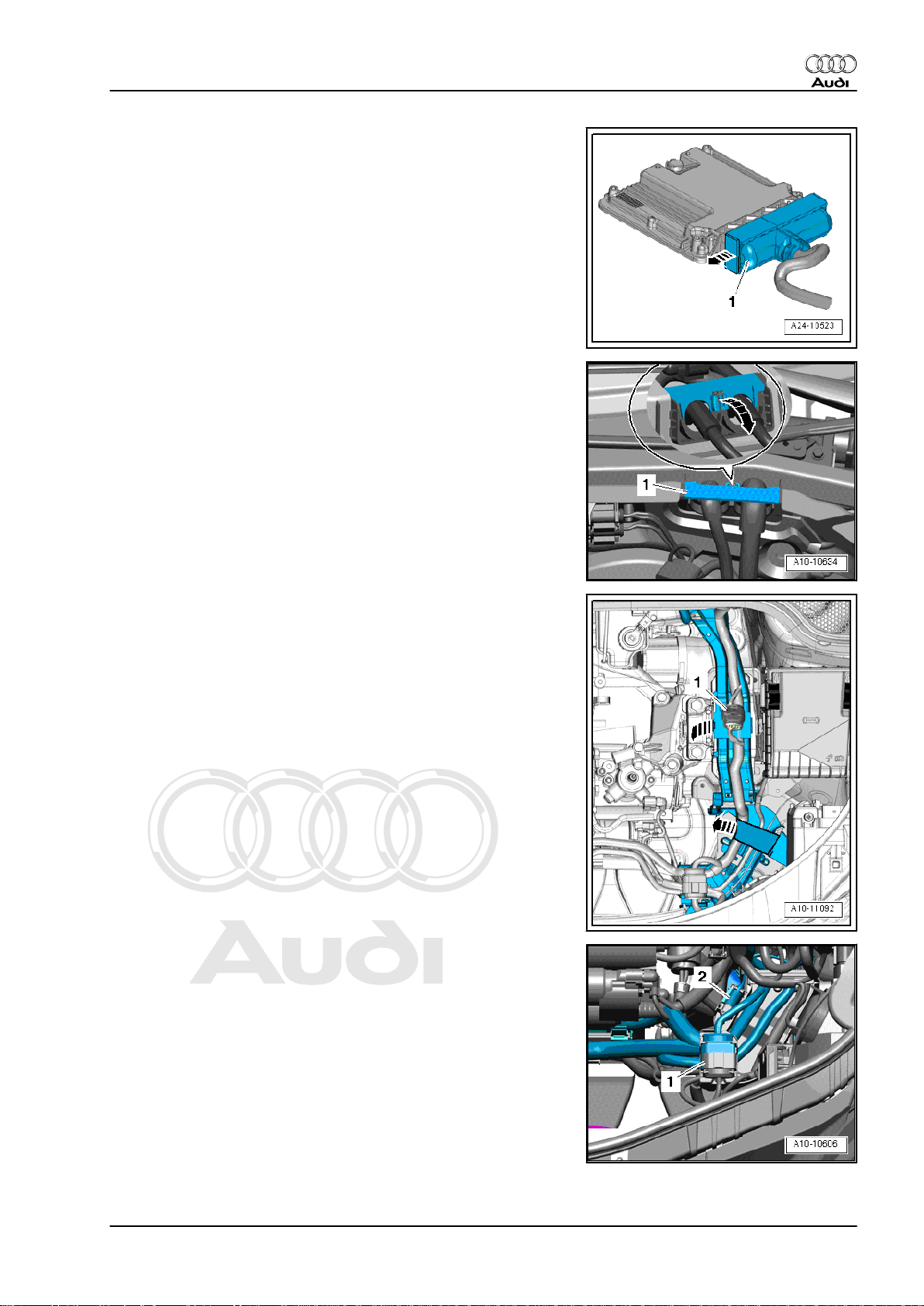

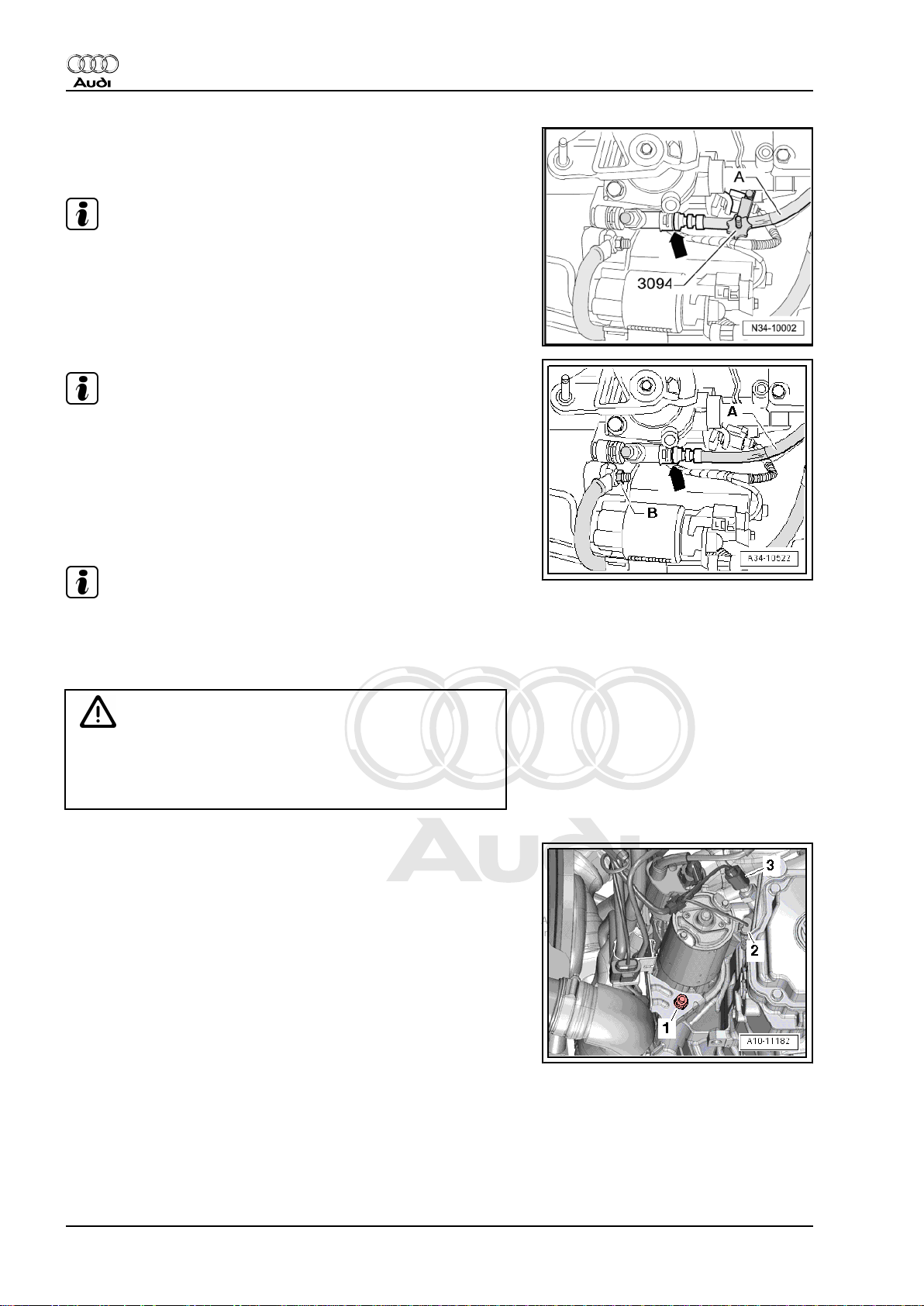

– Unplug electrical connector -A- at high-pressure sender -G65-

-item B-.

Note

Disregard -item C-.

– Detach sealing lip at lock carrier (top).

18 Rep. Gr.10 - Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

– Remove bolts -top arrows- at rear and lift out radiator.

– Release electrical connector -1- for engine wiring harness

-arrow- and detach ⇒ Rep. Gr. 23 ; Removing and installing

engine control unit -J623- .

– Release wiring protector -1- for engine wiring harness

-arrow- and lift off.

– Move clear and unplug electrical connector -1-.

– Open wiring duct bracket -arrows-, use removal lever -80 -

200- to unclip wiring and press wiring to side.

– Unclip wiring duct.

– Unclip electrical connector -1- from bracket and unplug.

– Open wiring duct bracket located underneath.

– Unclip wiring harness for engine control unit from wiring duct.

– Place engine wiring harness with engine control unit on top of

engine.

– Secure engine control unit to prevent it falling.

– Unclip electrical connector -2- from bracket and unplug.

1. Removing engine 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

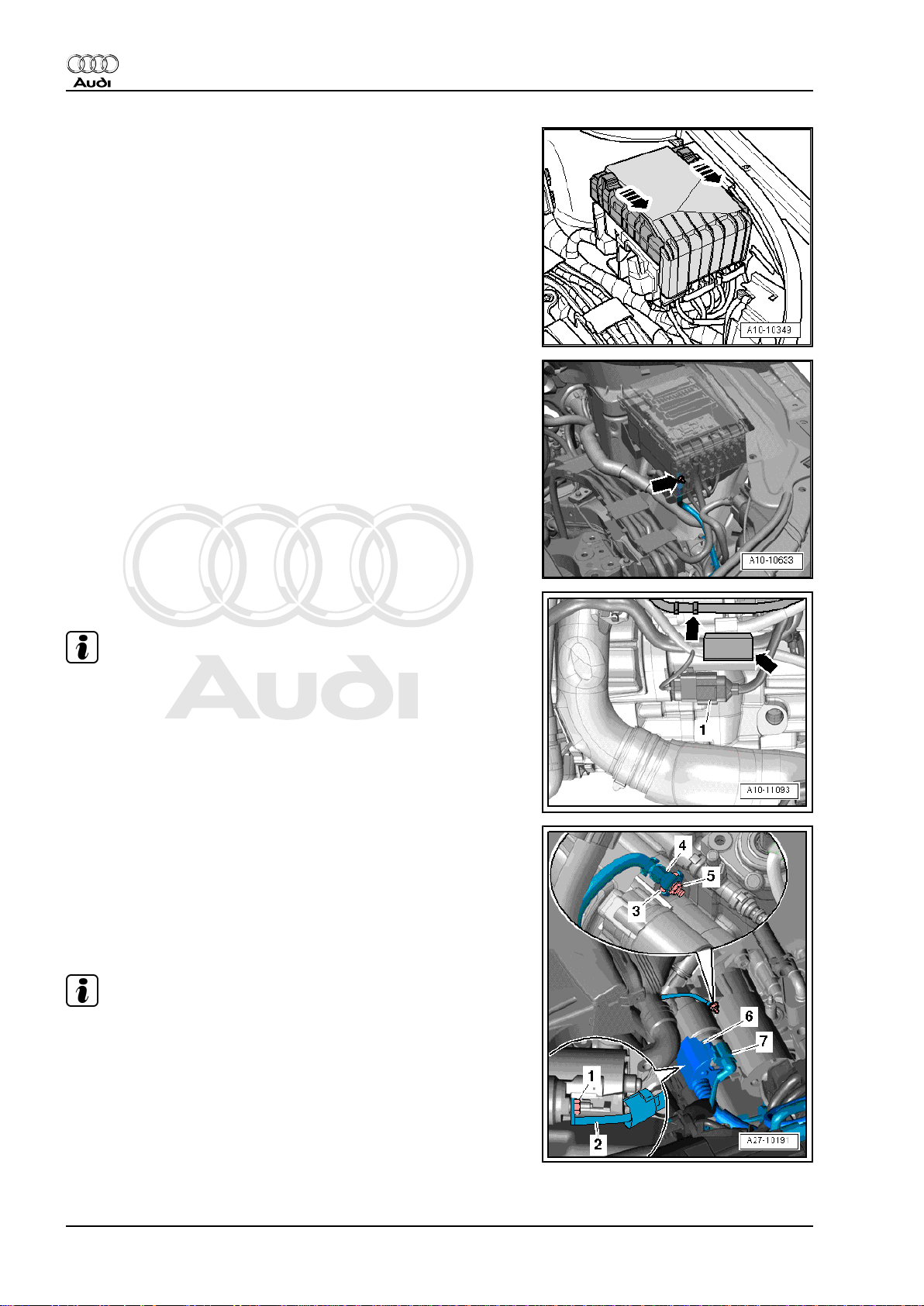

– Slide the two clips in the direction of the -arrows- and remove

cover from electronics box in engine compartment.

– Remove nut -arrow-, detach terminal 30 wire from electronics

box in engine compartment and move it clear.

– Unplug electrical connector -1-.

Note

Disregard -arrows-.

– Unplug electrical connector -7- (push retainer to the rear and

press down release catch).

– Push back protective sleeve -6-.

– Remove nut -1- and detach B+ wire -item 2- from starter sol‐

enoid switch.

– Remove nut -5- and detach earth wire -4-.

Note

Disregard -item 3-.

20 Rep. Gr.10 - Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

– Lift clip and detach retaining clip -3- for gear selector cable

from gearbox selector lever -1-.

– Detach gear selector cable -2- from pin -arrow-.

• To prevent damage to gate selector cable, cable end-piece

must be detached from gate selector cable before removing.

– Pull locking device forwards onto stop -arrow 1- and lock by

turning anti-clockwise -arrow 2-.

– Press selector relay lever towards front -arrow 3-.

– Remove nut -1- and bolts -2-, detach cable support bracket

and place to one side (selector cables remain fitted).

– Vehicles with plastic pipe between clutch master cylinder and

slave cylinder: clamp off supply hose at brake fluid reservoir

using hose clamp -3094- .

1. Removing engine 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

– Vehicles with pipe/hose assembly between clutch master cyl‐

inder and slave cylinder: clamp off hose -A- at pipe/hose

assembly using hose clamp -3094- .

Note

Disregard -arrow-.

Note

Make sure brake fluid does not come into contact with starter or

gearbox when performing the following operations. If it does,

clean affected area thoroughly.

– Pull out clip -arrow- as far as stop.

– Pull plastic pipe or pipe/hose assembly -A- out of bleeder con‐

nection for clutch slave cylinder.

Note

Disregard -item B-.

– Seal off open pipes/lines and connections with clean plugs

from engine bung set -VAS 6122- .

Caution

Risk of contamination by escaping brake fluid.

♦ Do not operate clutch pedal after detaching pipe from

bleeder screw on clutch slave cylinder.

Vehicles with start/stop system:

– Unplug electrical connector -3- for gearbox neutral position

sender -G701- .

All vehicles (continued):

– Unplug electrical connector -2- at reversing light switch -F4- .

– Unscrew nut -1- and detach bracket for electrical connectors.

22 Rep. Gr.10 - Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

– Unscrew bolts -arrows- at engine mounting approx. 2 turns.

– Loosen bolts -arrows- at gearbox mounting approx. 2 turns.

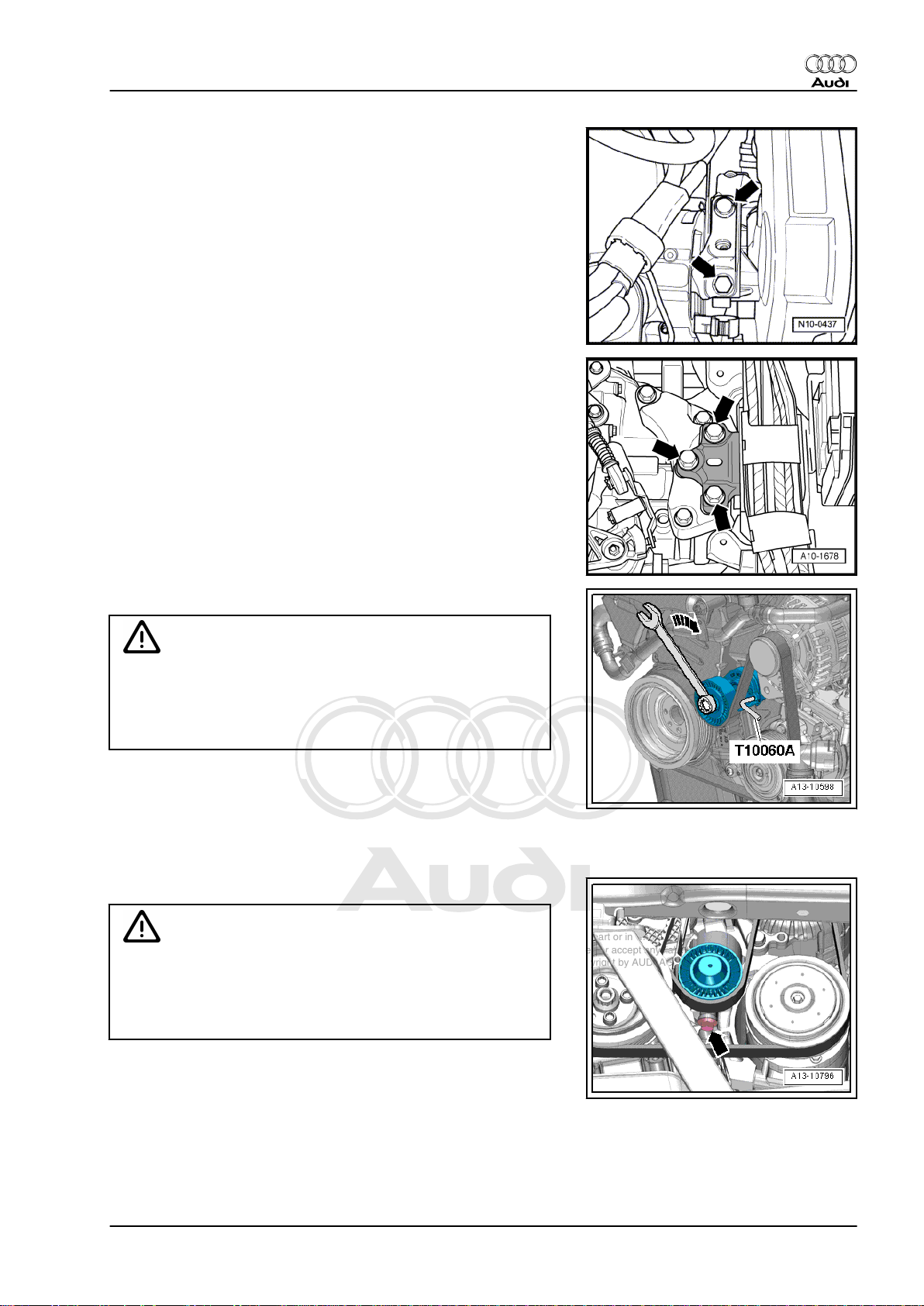

Vehicles with air conditioner compressor and tensioner:

Caution

If a used belt runs in the opposite direction when it is refitted,

this can cause breakage.

♦ Before removing, mark direction of rotation of poly V-belt

with chalk or felt-tipped pen for re-installation.

– To slacken poly V-belt turn tensioner in clockwise direction

-arrow-.

– Lock tensioner with locking pin -T10060 A-

– Take off poly V-belt.

Vehicles with air conditioner compressor and tensioning roller:

Caution

If a used belt runs in the opposite direction when it is refitted,

this can cause breakage.

♦ Before removing, mark direction of rotation of poly V-belt

with chalk or felt-tipped pen for re-installation.

– Remove bolt -arrow- and detach tensioner to slacken poly V-

belt.

– Take off poly V-belt.

1. Removing engine 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail - generation II), mechanics - Edition 05.2010

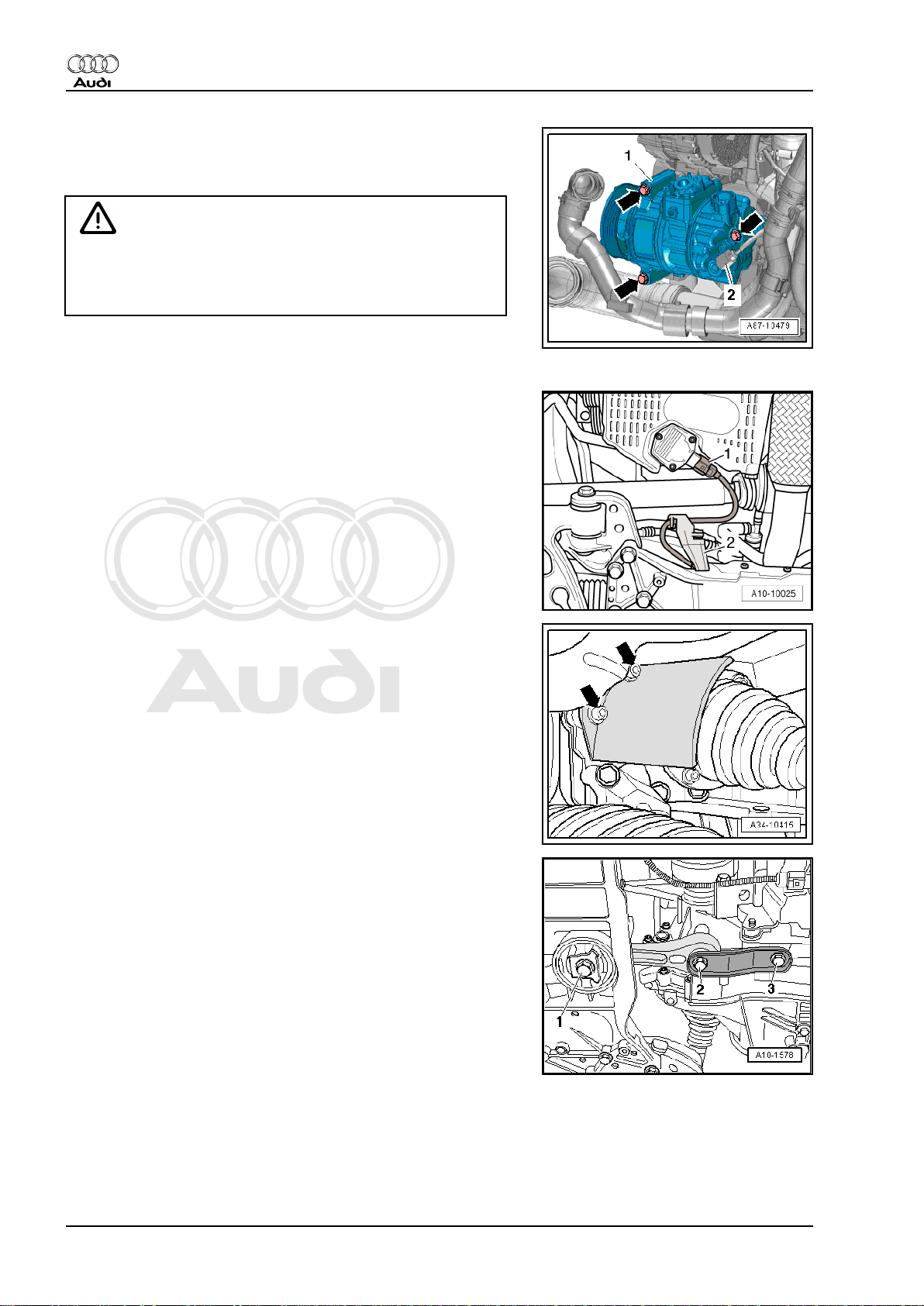

All vehicles with air conditioner compressor (continued):

– Unplug electrical connector -2- on air conditioner compressor

regulating valve -N280- .

Caution

Make sure that air conditioner compressor and refrigerant

pipes and hoses are not damaged.

♦ Do NOT stretch, kink or bend refrigerant lines and hoses.

– Remove bolts -arrow-, detach air conditioner compressor -1-

with refrigerant lines connected and tie up to front.

All vehicles (continued):

– Unplug electrical connector -1- at oil level and oil temperature

sender -G266- .

– Unclip bracket -2- for wire to oil level and oil temperature

sender -G266- from subframe.

– Remove bolts -arrows- and detach heat shield for drive shaft

(right-side).

– Detach drive shaft (left-side) from flange shaft of gearbox and

tie up.

– Detach drive shaft (right-side) from flange shaft of bevel box.

– Remove bolts -1, 2, 3- and remove pendulum support.

24 Rep. Gr.10 - Removing and installing engine

Loading...

Loading...