Page 1

Service Training

Audi TT Coupé ´07 - Body

Self-Study Programme 383

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi-Space-Frame ASF® of the Audi TT Coupé

The development targets for the bodyshell of the Audi TT

With a weight advantage of 48 % over a comparable all-steel bodyshell, in addition to an optimised weight

distribution, the new composite aluminium-steel spaceframe body of the Audi TT marks yet another milestone in the development of modern Audi bodyshells.

Crash safety of the bodyshell is enhanced by means of load-bearing structures at the front end, sides and rear

end, with a heavy emphasis on pedestrian safety.

To ensure efficient volume bodyshell production, various new joining and production techniques are

employed.

The repair concept is based heavily on the well-known aluminium repair concept. However, of course, the

materials combination of aluminium and steel necessitated that new approaches be taken.

383_001

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Contents

Audi Space Frame of the Audi TT

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Technological concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Contact corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Combination of steel and aluminium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Comparison of ASF concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Joining techniques and production processes

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Punch riveting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Clinching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

MIG welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Resistance spot welding and MAG welding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Structural bonding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

New joining technique: solid punch riveting (Kerb-Konus riveting) . . . . . . . . . . 16

New joining technique: Flow Drill screwing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

New joining technique: aluminium laser welding . . . . . . . . . . . . . . . . . . . . . . . . . 18

Repair concept

Aluminium repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Steel repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Aluminium-steel repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Workshop equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Qualification of aluminium. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bodyshell safety concept

Head-on collision, side impact and rear collision . . . . . . . . . . . . . . . . . . . . . . . . . 26

Pedestrian safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Electromechanical rear spoiler

The self-study programme teaches the design and function of new vehicle models,

new automotive parts or new technologies.

The self-study programme is not a repair manual!

All values given are intended as a guideline only and refer to the software version valid at the time of

preparation of the SSP.

For maintenance and repair work, always refer to the current technical literature.

NoteReference

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi Space Frame of the Audi TT

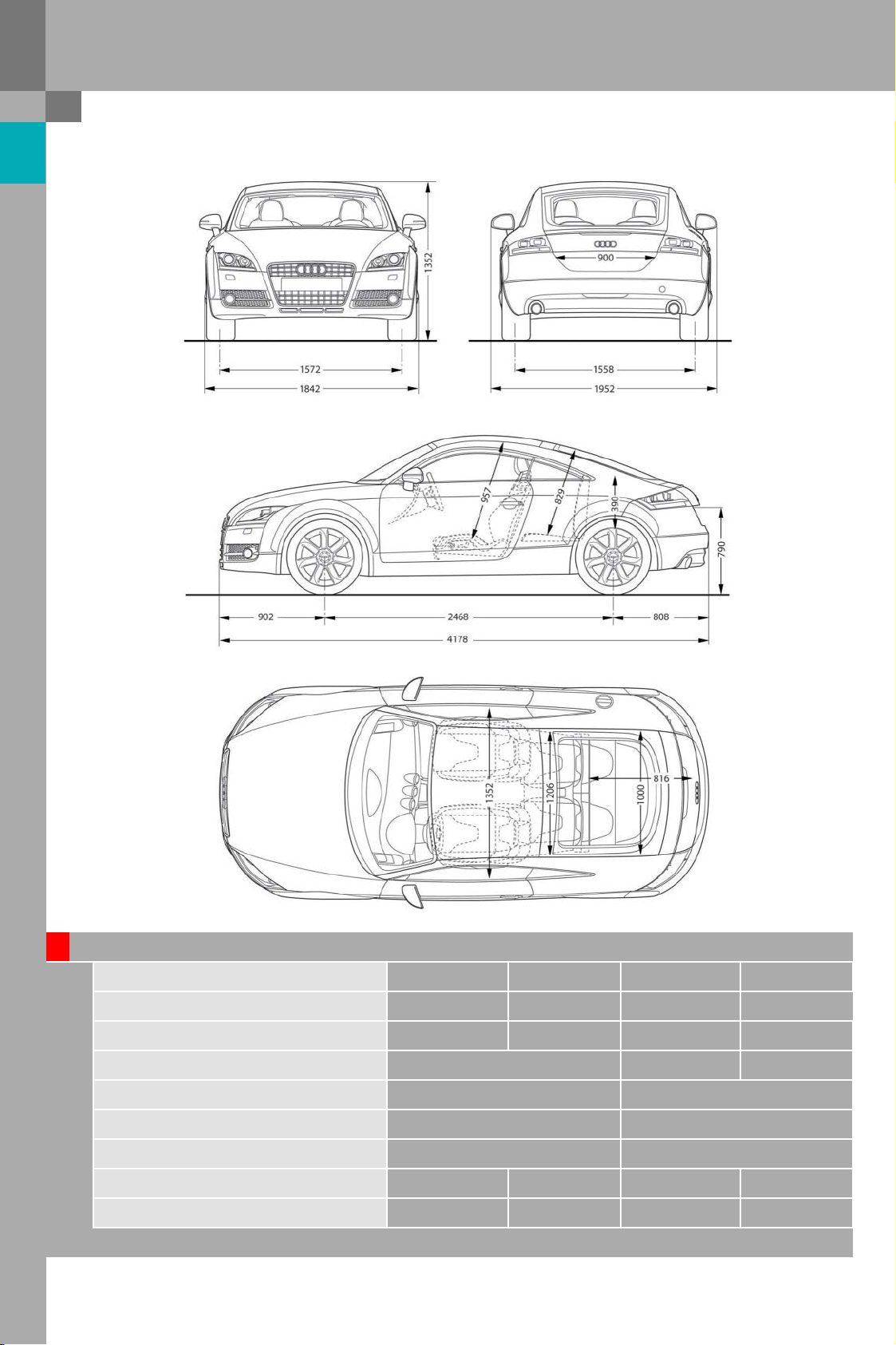

Dimensions

383_002

Audi TT Coupé ’ 07 2,0 3,2 quattro

Transmission Manual gearbox S tronic Manual gearbox S tronic

Kerb weight without driver in kg 1260 1280 1410 1430

Max. perm. gross weight in kg 1660 1680 1810 1830

cw (rear spoiler extended) 0.3 0.3 0.31

Boot capacity in l 290 (700*) 290 (700*)

Max. power output in kW 147 (200 bhp) 184 (250 bhp)

vmax in kph 240 250

Acceleration 0-100 kph in s 6.6 6.4 5.9 5.7

Fuel consumption in l/100 km 7.7 7.7 10.3 9.4

* with the rear-seat back folded forward

4

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

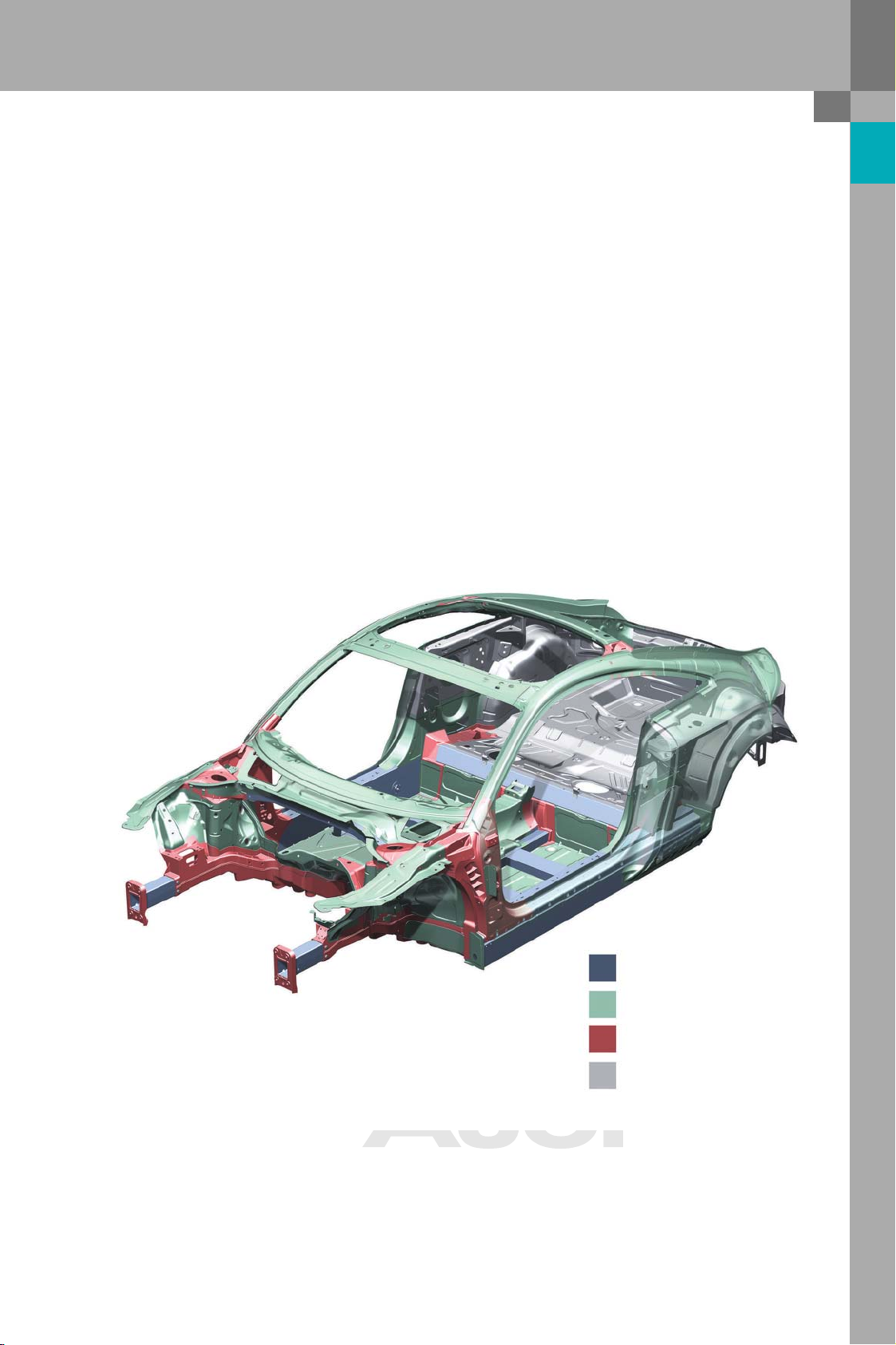

Technological concept

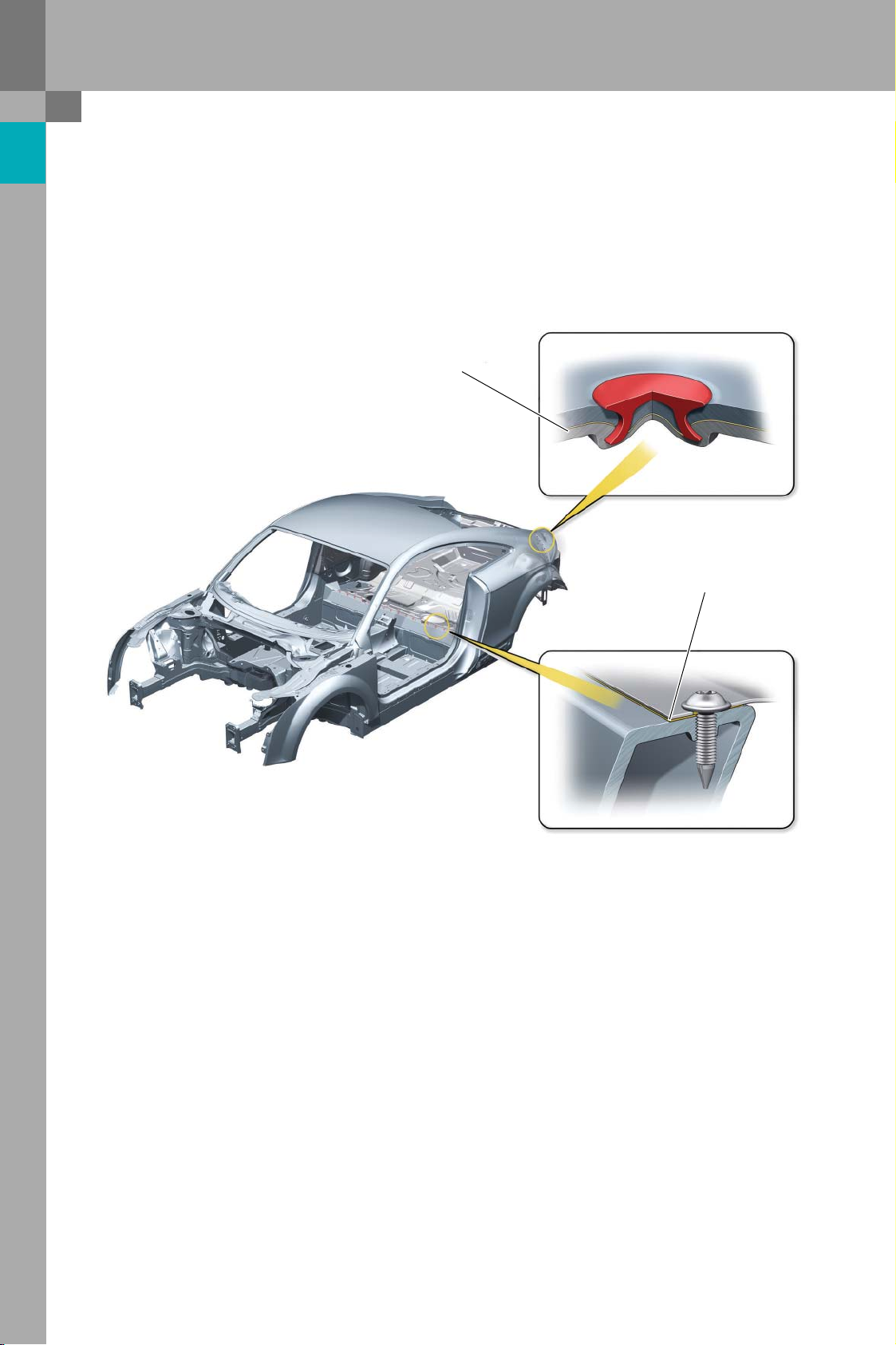

Sheet-steel parts are used for the first time in the

ASF of the new Audi TT in addition to aluminium

castings, aluminium extruded sections and aluminium sheet-metal parts. Collectively, they make up

the body structure. Vehicle weight distribution has

been optimised by using sheet-steel parts in the

rear body section. This has a direct bearing on

sporting characteristics, such as driving dynamics

and acceleration as well as safety characteristics,

such as stopping distance and driving stability

In spite of the partial use of sheet-steel parts, the

total body weight of 277 kg, including attachments

such as doors and lids, is considerably less than

that of a comparable all-steel body.

Although the new TT has grown in size, the gross

weight of the vehicle has been reduced through the

use of the aluminium-steel bodyshell.

The body structure of the new Audi TT has higher

strength and 50 % higher torsional rigidity than its

predecessor.

Aluminium extruded sections

Sheet-aluminium parts

Aluminium castings

Sheet-steel parts

383_003

5

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi Space Frame of the Audi TT

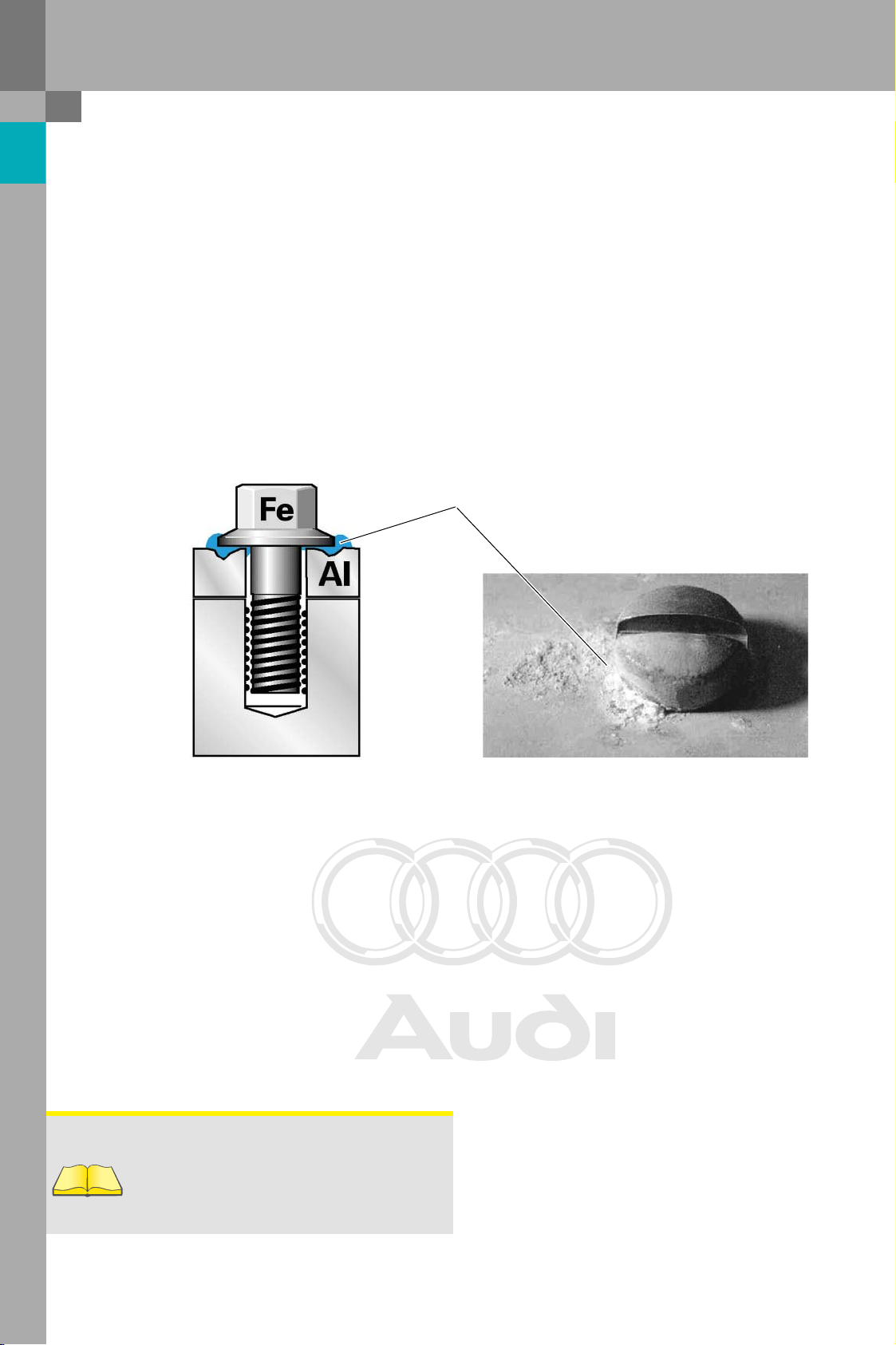

Contact corrosion

Aluminium has a passivating oxide surface layer

which protects the material underneath from corrosion. This is why an unpainted aluminium part normally does not corrode.

However, if there is contact between aluminium and

a metal higher up in the electrochemical series than

aluminium and if an electrolyte, such as salt water,

is present in this region, contact corrosion will

occur.

Contact corrosion

The greater the difference in potential, the greater

the contact corrosion. As aluminium is normally the

lesser noble metal, it degrades.

383_005

Schematic of contact corrosion with example

Contact corrosion can only be prevented by taking

measures to stop the flow of electrical current

induced by the potential difference between

the two metals. This is best achieved by painting the

surfaces. However, the risk of corrosion is high even

if a tiny amount of paint damage occurs.

Reference

For detailed information on contact corrosion,

please refer to Self-Study Programme 239 "Audi

A2 - Body" .

383_004

In the case of the Audi TT, the following anti-corrosion measures have been taken:

– coating of all steel screws and fasteners such as

self-piercing rivets

– Galvanising of all sheet-metal parts (zinc and alu-

minium have a smaller potential difference than

steel and aluminium)

– Insulation by means of adhesive

– Sealing of aluminium-steel joints

6

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

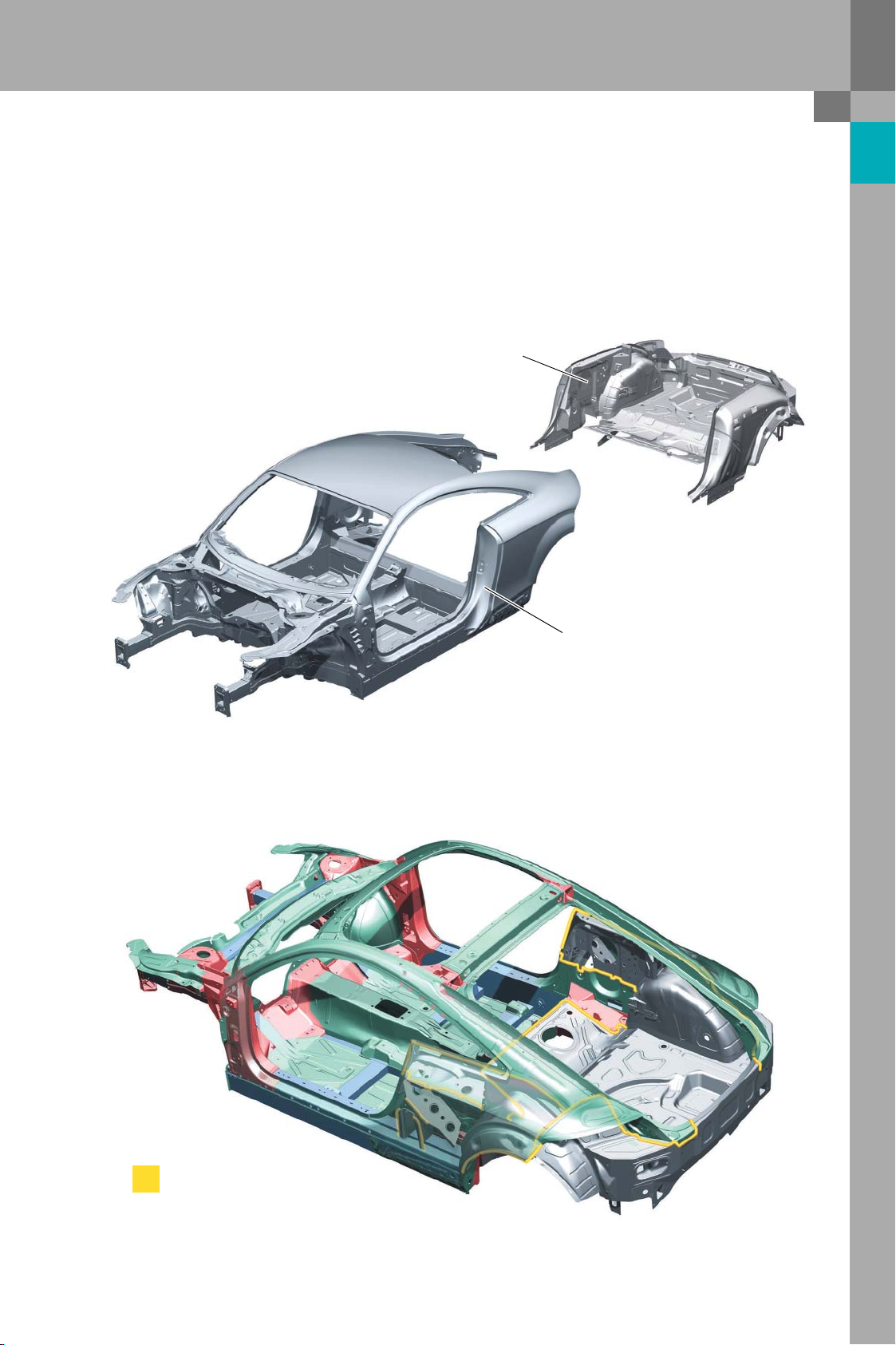

Joining steel and aluminium

One of the challenges for the development of the

Audi TT bodyshell was the attachment of the sheetsteel rear-end parts to the aluminium body assemblies.

Thermal joining processes such as MIG welding can

be ruled out because it is not possible by these

means to make a joint which has the requisite structural and dynamic strength and will not result in

contact corrosion.

Steel

Aluminium

383_011

Aluminium-steel connections

383_006

7

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi Space Frame of the Audi TT

Special requirements are made with regard to the

strength and corrosion protection of the joints

between aluminium body parts and steel parts.

Adhesive

This is ensured by non-thermal joining of parts

using coated self-piercing rivets and special screws

in combination with bonding.

Adhesive

Aluminium and steel joints with faulty corrosion protection can exhibit much higher corrosion rates than

all-aluminium joints or all-steel joints.When making

aluminium-steel joints, therefore, highest standards

of quality must be maintained at all times during the

production process and in the service workshop.

383_012

Adhesive bonding is the basis for the corrosion protection of corrosion-susceptible aluminium/galvanised steel joints in the bodyshell of the Audi TT.In

this way, the mating materials are superficially insulated, thus suppressing corrosion processes at the

point of contact. As a further measure, all composite joints either sealed with PVC or coated with wax

preservative after the cataphoretic dip coating (KTL)

process.

8

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

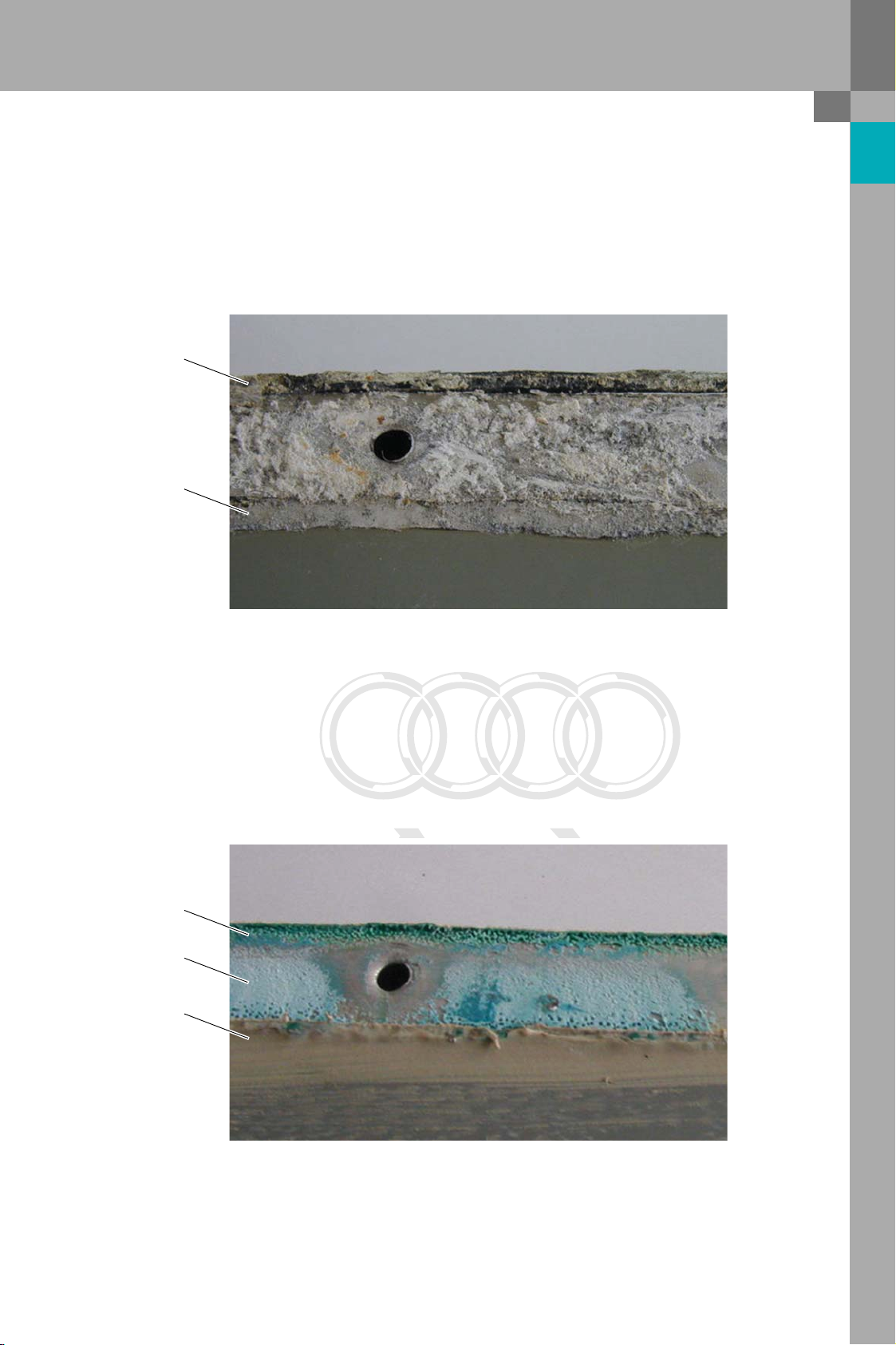

This illustration shows clearly what effects contact

corrosion can have if adequate corrosion protection

is not provided. A this joint, the flange was sealed in

the bodyshell without using adhesive.

Seal

Seal

The aluminium sheet shown here exhibits severe

contact corrosion, which has resulted in mechanical

failure of the punch riveted joint.

383_007

By way of a comparison, this illustration shows the

same flange with an adhesive bond and sealing.

Seal

Adhesive

Seal

In this case, the aluminium sheet showed no damage due to contact corrosion after exposure to identical environmental conditions.

383_008

9

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi Space Frame of the Audi TT

Comparison of ASF concepts

Audi A8 (2003 ➔)

Aluminium extruded sections

Sheet aluminium parts

Aluminium castings

383_013

383_014

Sill section Audi A8

Three-chamber extruded section

10

383_017

A-post, Audi A8

Single-chamber extruded section

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

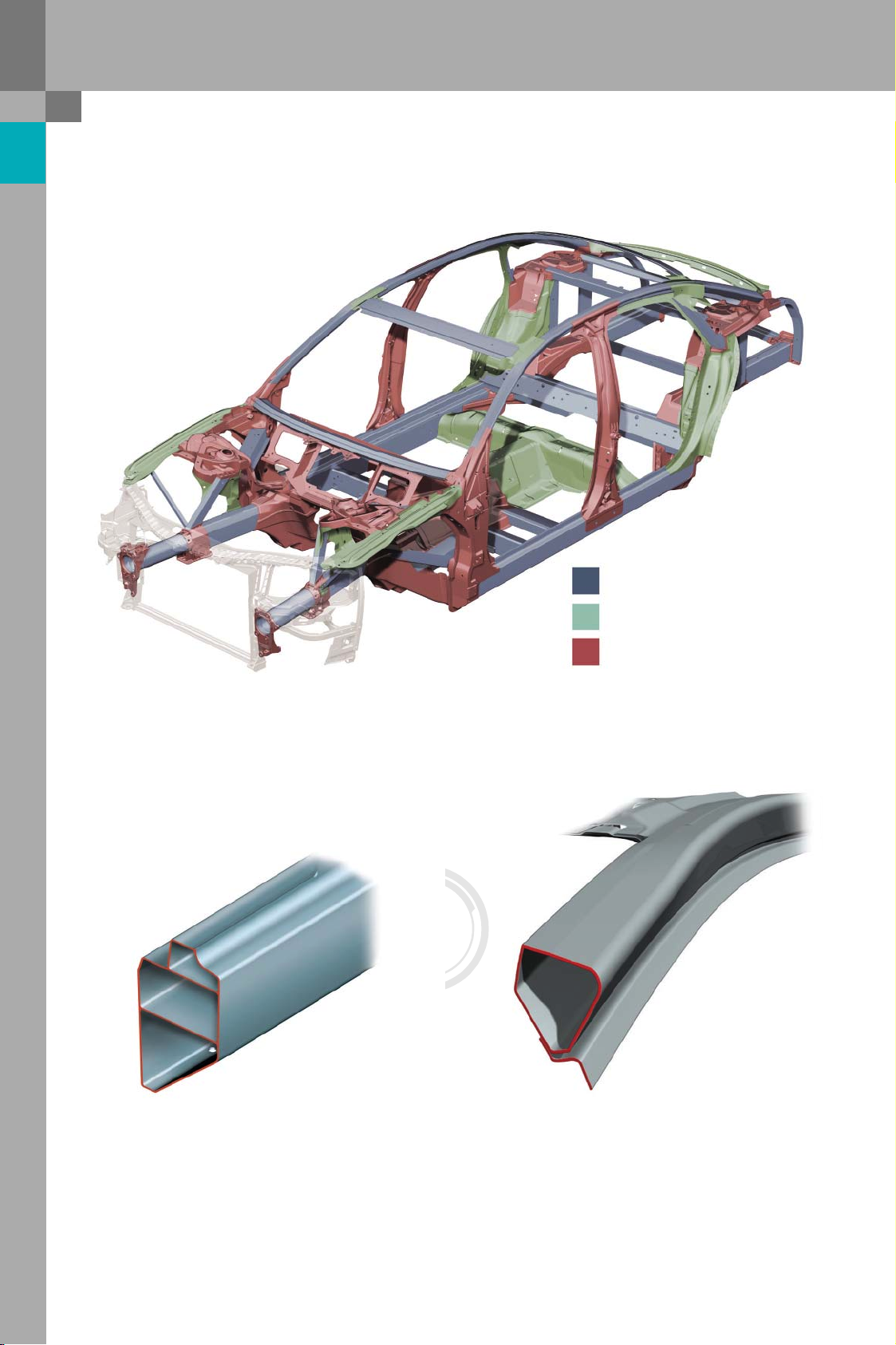

Audi TT (2006 ➔)

Aluminium extruded sections

383_016

Sill section, Audi TT

Four-chamber extruded section

Sheet aluminium parts

Aluminium castings

Sheet-steel parts

383_009

383_015

A-post, Audi TT

Sheet-aluminium sections (interior/exterior)

11

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Joining techniques and production processes

Overview

In addition to well-known processes such as MIG welding or punch riveting, the joining techniques of Flow

Drill screwing and Kerb-taper riveting are used for the first time on the Audi TT.

In the production process, a laser cleaning method is used for cleaning before the roof drip moulding is

attached by welding.

Riveted joint

383_019

Flow-Drill screw connection

Clean Laser

Technology Process Quantity per vehicle

383_018

383_020

Mechanical

joining techniques

Thermal

joining techniques

Punch riveting

Flow Drill screwing

Solid punch riveting (Kerb-Konus)

Clinching

MIG welding

Laser welding

Resistance spot welding

MAG welding

Stud welding

1615 pce.

229 pce.

96 pce.

164 pce.

21462 mm

5309 mm

1287 spots

809 mm

234 pce.

Bonding technology Bonding 97156 mm

Machining technology Milling

12

Drilling

Thread cutting

Brushing

Roll seaming

Clean lasering

188 mm

16 pce.

8 pce.

2300 mm

26737 mm

4000 mm

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Punch riveting

Punch riveting is one of the principal joining techniques used on the bodyshell of the new Audi TT. This technique is used for joining aluminium body parts and for joining aluminium body parts to steel body parts.

The process has been in use since launch of the Audi A2. Self piercing rivets with two different diameters and

lengths are used in the Audi TT.

383_032

Punch riveting process

Applications of punch riveting

383_051

Clinching

With clinching, the metal sheets to be joined are clamped between a die and a blankholder. The sheets are

then pushed down into the die by a punch to form an interlocking joint. However, joints produced in this way

is not as strong as joints produced by punch riveting, for example.

In the Audi TT, this technology is used on attachments such as doors and lids. Several clinched joints are also

located in the area of the B-post and rear wheel arch. In this area, aluminium sheets as well as steel and aluminium sheets are clinched together.

Clinching process

383_052

Applications of clinching

383_053

13

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Joining techniques and production processes

MIG welding

Aluminium parts have largely been joined by means of metal inert gas welding since the launch of the Audi

aluminium bodyshell in the Audi A8 (1994) . This technique is principally used to make joints between castings

and extruded sections, as well as sheet-metal parts.

This joining technique is notable for producing high-strength joints, but it introduces a great deal of heat into

the joint and has a relatively slow process speed.

383_054

MIG welding process

Applications of MIG welding

383_055

Resistance spot welding and MAG welding

The usual techniques of resistance spot welding and, to a lesser extent, metal active gas welding (MAG welding) are used for joining sheet steel body parts in steel body manufacturing.

383_056

Resistance spot welding process

Applications of MAG welding

Applications of resistance spot welding

14

383_057

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Structural bonding

In certain areas, adhesive bonding is used supplementary to clinched joints and punch riveted joints, solid

punch riveted joints, Flow Drill screw connections and resistance spot welds. This improves joint strength.

Adhesive bonding is also used for strengthening of seam joints, e.g. in the rear wheel arch. In other areas of

the body, adhesive beads are used for sealing and insulation between aluminium and steel sheets, as well as

for noise reduction.

Structural bonding process in production

383_058

Applications of structural adhesive

383_059

15

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Joining techniques and production processes

New joining technique: solid punch riveting (Kerb-Konus riveting)

Solid punch riveting or Kerb-Konus riveting involves the use of aluminium or coated stainless steel rivets. In

contrast to punch riveting, the rivet is punched through both sheets to be joined.

Unlike steel rivets, aluminium solid punch rivets can be reworked mechanically. This is the case with the joint

between the body side section and the drip moulding. However, the strength of solid punch riveted joints is

inferior to that of punch riveted joints.

383_060

383_073

Solid punch riveting process in production

Solid punch riveting process

383_061

Micrograph of a solid punch riveted joint

Information on the repair concept

Aluminium solid punch rivets are used in the C-post drip moulding area, while coated stainless steel solid

punch rivets are used in the region of the roof frame. Stainless steel rivets must not be drilled out or ground,

due to the risk of corrosion.

Applications of solid punch riveting

16

383_048

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

New joining technique: Flow Drill screwing

Automatic direct screwing enables joints to be made between any materials, even if these materials can be

accessed from one side only. A special coated screw is driven under high surface pressure through a hole in

the outer part to be joined. The lower part is not predrilled. The pressure and rotational speed soften the

material and allow the screw to be inserted.

383_062

Flow Drill screwing process

Flow Drill

Screw

383_074

Screwing process in production

383_063

Micrograph of a Flow Drill screw connection

Information on the repair concept

Flow Drill screws can be removed in the service workshop and replaced with new screws. In case of thread

damage, screws are also available in oversize (M6 instead of M5) . For use in new parts, it may be necessary to

predrill the material.

Applications of Flow Drill screwing

383_064

17

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Joining techniques and production processes

New joining technique: aluminium laser welding

(invisible roof seam)

Laser welding has been used for joining aluminium body parts since the launch of the Audi A2. In most cases,

sheet-metal parts are welded onto castings or extruded parts. The invisible joint in the roof area is joined

using a new joining technique: laser welding.

Laser beam

Evaporating metal vapour

Laser-induced plasma

Liquid melt zone

Solid melt zone

Welding wire

Vapour / plasma / channel

Direction of welding

383_066

Laser welding process in production

Micrograph of the roof frame and roof panel joint

383_065

383_025

Applications of laser beam welding

Invisible roof seam

Applications of laser beam welding

18

383_067

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

To ensure consistent laser welding of aluminium parts, the parts to be welded must have a perfectly clean surface. This is achieved either by washing the component parts followed by chemical pickling or by using the

new Laser Clean process.

A controlled laser beam removes all residues from the surface by heating it for a short time. Parts cleaned

using this method can be directly laser-welded.

383_069

383_068

Laser Clean process in production

Micrograph of a laser-welded seam with

Laser Clean (above) and without cleaning (below)

383_075

The joint between the roof frame and roof panel is reworked and surface finished automatically in the production line by means of a brushing process.

383_071

Brushing process in production

383_070

383_072

Laser weld seam before (above) and

after the brushing process (below)

19

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Repair concept

Aluminium repair

The repair concept for the all-aluminium body parts

is similar to that for the repair of previous Audi aluminium-bodied vehicles.

The front end of the vehicle is designed in such a

way that the bumper beams and bolted crash boxes

can be replaced after minor collisions up to approx.

15 kph.

Bumper beam 1

Crash box

If the vehicle structure is damaged, beam 1 can also

be replaced by undoing the screw connection. All further damage to the vehicle front end can only be

repaired by welding suitable genuine parts into place.

Bumper beam

Screw connections

Bumper beam 2

383_023

383_024

Joint between beam 1 and beam 2

20

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

The four-chamber extruded section is located

beneath the sill moulding.A special repair method

was developed for damaged outer chambers. When

repair work is needed, the extruded section is split

vertically so that the two rear chambers including

the centre ridge of the four-chamber profile remain.

A dual-chamber genuine part developed specially

for this repair solution is welded to the remainder of

the sill profile using a continuous MIG weld seam at

the top and bottom. In addition, the U-shaped channel in the genuine part is filled with an adhesive

bead which provides additional strength and eliminates noise transmission between the two sills.

New part

MIG weld seam

Adhesive bead

383_039

21

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Repair concept

Steel repairs

The rear end of the Audi TT is only area where it is

possible to carry out repair work involving only steel

parts and where the aluminium-steel joint is fully

intact.

This repair work can be carried out on the

– rear end section

– rear side member (body side section undamaged)

– rear floorpan

Basically, the repair procedure is the same as for allsteel-bodied vehicles. Due to the danger of contact

corrosion in aluminium body parts, however, special

safety precautions must be taken. Grinding dust of

steel parts, particularly flying sparks caused by cutting or welding work, must not be allowed to drop

onto the aluminium parts.

This also applies to painted aluminium parts! Red

hot steel parts can damage the paintwork and steel

particles can come into contact with the aluminium

body parts, leading to contact corrosion on the

undamaged aluminium body.

Therefore, the complete bodyshell must be protected carefully when carrying out steel repairs. This

is done by using suitable protective covers and by

masking the body with masking tape. Furthermore,

cutting work may only be performed using a body

saw. If grinding work is needed, this must be done

using grinding discs which produce little or no flying sparks. The spot welding machine should be

used for welding work where possible, because it

produces less weld spatter during the welding process.

body parts which must be covered when carrying out steel repairs

Damage to be

repaired

383_040

22

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Aluminium-steel repairs

In the case of body side or rear-end damage, both

aluminium and steel body parts may become damaged. This is the case, for example, when the body

side section (aluminium) and rear wheel arch (steel)

are damaged. After removing the damaged parts,

the new genuine parts are installed in accordance

with the repair procedures described in the previous

sections. Joining of steel and aluminium parts must

be carried out with the greatest care in order to

eliminate the possibility of future contact corrosion.

Two-component car body adhesive DA 001 730 A1

and rivets or screws are used for joining. As in

series production, an insulating layer is placed

between the two materials to prevent contact corrosion. When welding steel body parts, the aluminium

parts must be carefully covered and masked!

Reference

All body repair work must be performed in

accordance with the guidelines set out in the

current workshop literature!

23

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Repair concept

Workshop equipment

A special tool is required for repair work on aluminium-bodied vehicles. The basis is work scope 2010.

In addition to the special equipment and machines

for stud welding, dent removal, bonding and riveting, the aluminium welding technology is of special

importance.

383_026

Aluminium body dent removal tools VAS 5196 and VAS 6049

383_028

Aluminium inert gas welder V.A.G 2001B

Aluminium inert gas welder VAS 6388

383_076

Cordless punch riveter VAS 5279A

383_029

There are now two appliances with modern control

systems which

are ideal for welding work on the Audi aluminium

body.

Reference

For further information on the workshop equip-

The welding appliances, when used properly, produce perfect aluminium welded joints which have

optimum strength.

ment for Audi aluminium-bodied vehicles, refer

to the workshop literature and the Audi Service

Net.

24

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Qualification of aluminium

A special knowledge and special skills are required

to repair aluminium bodyshells. A prerequisite for

successful body repairs is participation in the relevant training courses.

Particularly for welding work, certification of

employees according to international standard DIN

EN ISO 9606-2 is important.

EX 351

Welding

Aluminium Certificate

Repeat exam

AB 352

Aluminium technology

BT 350

Welding

Aluminium technology

Welding Certificate

EX 353

Audi TT

Aluminium technology

BT 351

Basics

Body

BT 352

Basics

Vehicle electrical

systems for car body

technology

BS 301 Occupant protection, airbags and belt ten-

sioners

BS 310 Selective use of technical information

BS 360 Vehicle diagnosis, testing and information

system VAS 5051

Reference

For further information on the qualifications in

aluminium technology, refer to the Audi Service

Net.

383_049

25

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Car body safety concept

Head-on collision, side impact and rear collision

Likewise, in terms of crash safety, the new TT makes

no compromises. The front beams consist of aluminium extruded sections and aluminium castings.

In combination with the front beams and a subframe, they reduce and distribute the forces which

act on the car body during a head-on collision.

Large-sized beams in the rear end protect the occupant cell.High-strength aluminium beams in the

doors provide side impact protection. The aluminium bonnet is designed to all requirements for

pedestrian safety.

The simulation provides information on the collision

behaviour of the body structure at a very early stage

in the development process. For this purpose, calculations are done on the basis of the available car

body data using the Finite Elements Method. The

results are incorporated into the ongoing design

process, thus allowing the body structure design to

be optimised in respect of the relevant crash loads.

Simulation Euro NCAP head-on collision

383_031

26

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

To check the theoretical results and to meet statutory requirements, actual tests are conducted.

Euro NCAP head-on collision (64 kph with partial overlap)

Various test conditions are simulated on the basis of

the applicable standard.

383_041

Euro NCAP side impact (50 kph)

383_042

ECE and Japan rear collision (50 kph)

383_043

27

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Car body safety concept

Pedestrian safety

Pedestrian safety is an increasingly important factor. Various measures were implemented in the new

Audi TT in order to meet the safety requirements.

When designing the bonnet, importance was

attached to a stable design which yields to absorb

head impacts. This is achieved by the honeycomblike structure of the car body inner panelling.

The overall concept provides for deformation zones

between the bonnet and the units or car body structural parts.

383_034

To reduce leg impact force at the front end, the

bumper cover has been decoupled and an impactabsorbing foam part has been integrated between

the bumper beam and bumper cover.

383_044

28

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

The development tools "Simulation" and "Testing" were used for design.

Headform

(head impact)

Lower legform

(leg impact)

Head impact

383_035

To test the head impact a hemisphere which represents the head is catapulted onto the bonnet.

The relevant physical variables are determined, on

the basis of which conclusions are drawn regarding

impact loads.

Leg impact

Leg impact is simulated by means of a test configuration in which a test body similar to the actual body

part impacts the vehicle bumper.

383_036

383_037

29

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Electromechanical rear spoiler

The new Audi TT has as standard an electrically

extendable rear spoiler. The extended rear spoiler

significantly increases driving stability at high

speeds. The spoiler extends automatically at a

speed of 120 kph and retracts at a speed of 80 kph.

At speeds of less then 120 kph, the rear spoiler can

be actuated manually with a switch in the centre

console.

The unit consisting of the rear spoiler module and

the spoiler wing is integrated in the boot lid of the

Audi TT. The rear spoiler module with drive unit,

input shaft and reversing mechanism (hinge) is

bolted with self-adjusting elements to the sheetsteel spoiler wing painted in the body colour.

Reference

For further information on operation, function

and diagnosis, refer to Self-study

Programme 382 "Audi TT Coupé ‘07 Electrical and Infotainment Systems“.

383_038

383_045

When repair work is needed, the spoiler wing can

be replaced separately. The rear spoiler module is

replaced completely in case of damage.

30

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

SSP 380 Audi TT Coupé ‘07

–Body

– Occupant protection

–Engine

– Suspension system

– Electrical system

– Air conditioning

– Infotainment

Order number: A06.5S00.25.20

SSP 381 Audi TT Coupé ‘07 - Suspension System

–Front axle

–Rear axle

– Shock absorber system

– Brake system

Order number: A06.5S00.26.20

SSP 382 Audi TT Coupé ‘07 Electrical and Infotainment Systems

–Networking

–Bus topology

– Convenience electronics

– Infotainment

Order number: A06.5S00.27.20

SSP 383 Audi TT Coupé ‘07 - Body

– Audi Space Frame of the Audi TT

– Joining techniques and production processes

– Repair concept

– Car body safety concept

– Electromechanical rear spoiler

Order number: A06.5S00.28.20

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Vorsprung durch Technik www.audi.de

383

All rights reserved. Technical

specifications subject to

change without notice.

Copyright

AUDI AG

I/VK-35

Service.training@audi.de

Fax +49-841/89-36367

AUDI AG

D-85045 Ingolstadt

Technical status: 05/06

Printed in Germany

A06.5S00.28.20

Loading...

Loading...