Page 1

220

Service.

Audi TT Roadster

Design and Function

For internal use only

Self-Study Programme 220

Page 2

2

Page 3

Page

Body

Body Overview ....................................................................... 4

Roll bar ................................................................................... 6

Occupant protection ............................................................ 7

Gantry gauge ......................................................................... 8

Soft top control

Semiautomatic soft top ...................................................... 10

Soft top design .................................................................... 12

Hydraulic diagram ............................................................... 14

Fitting locations

Manual soft top ..................................................... 18

Semiautomatic soft top ........................................ 19

System overview .................................................................. 20

Function diagram ................................................................ 25

Contents

Bulkhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Central locking . . . . . . . . . . . . . . . . . . . . . . . 28

Interior monitor . . . . . . . . . . . . . . . . . . . . . . 29

The Self-Study Programme provides you with information regarding designs and functions.

The Self-Study Programme is not a Workshop Manual!

For maintenance and repair work, always refer to the current

Technical Literature.

New! Important!

Note!

3

Page 4

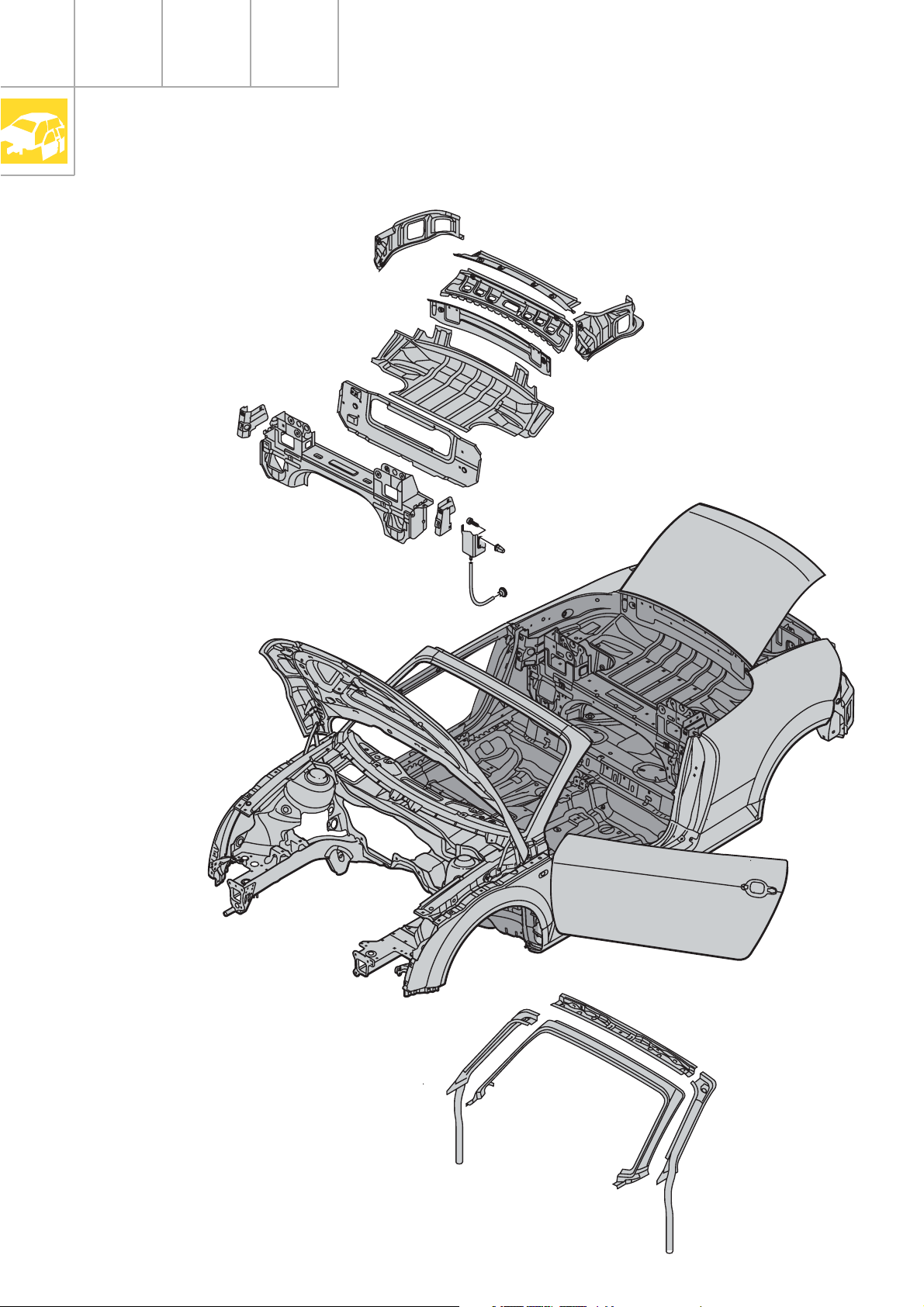

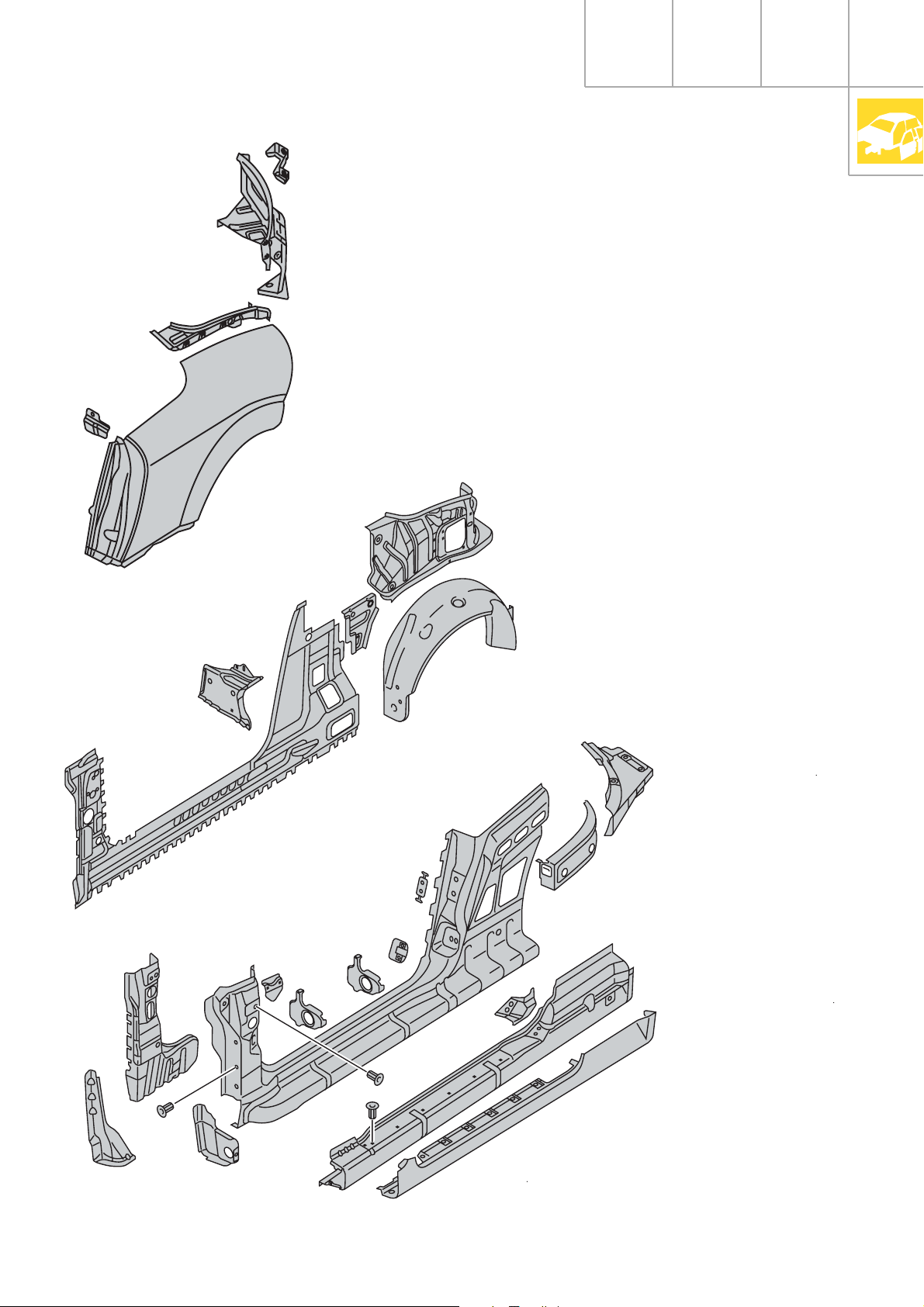

Body

Body Overview

4

Page 5

SSP220_001

5

Page 6

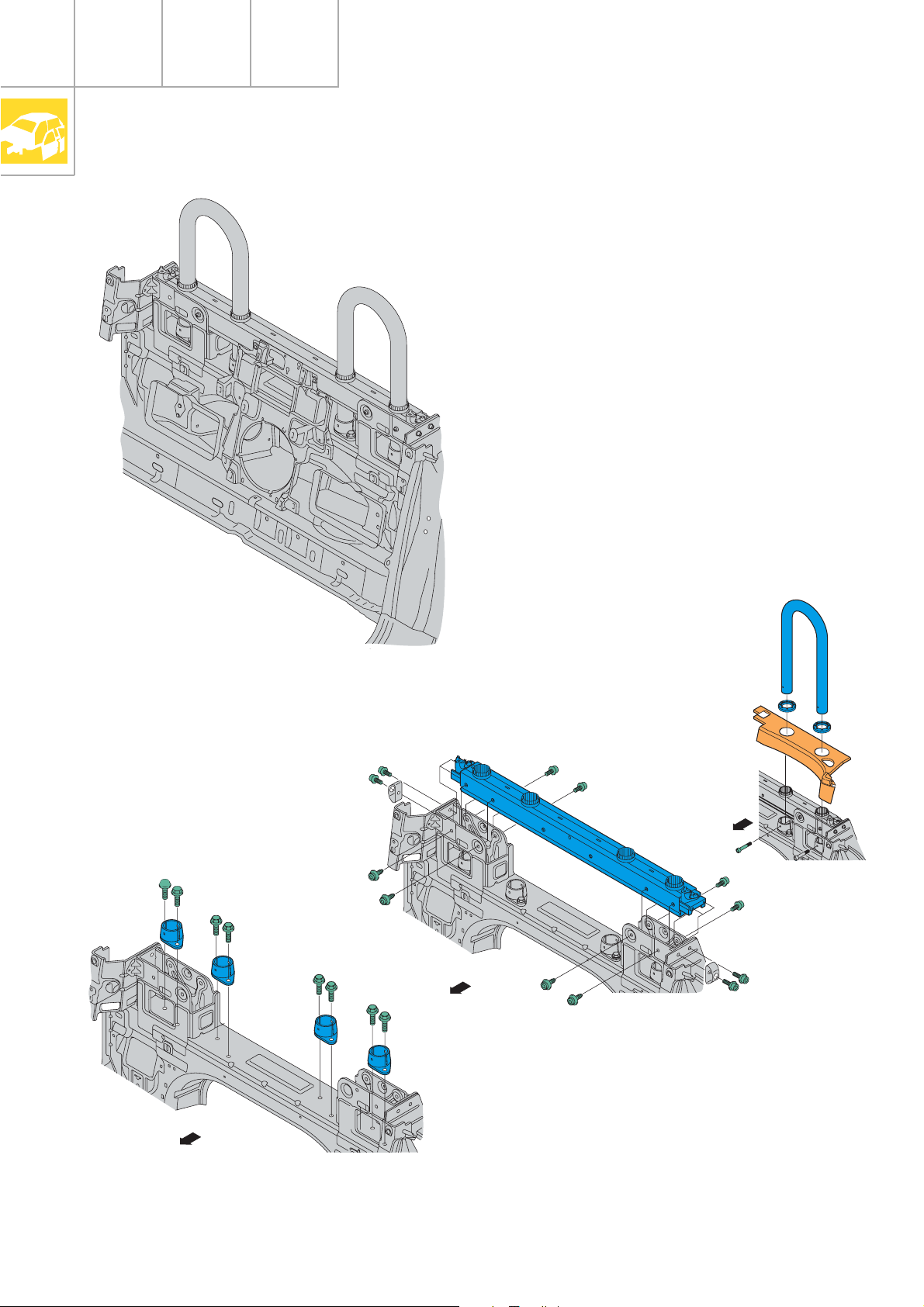

Body

Roll bar

SSP220_002

6

Page 7

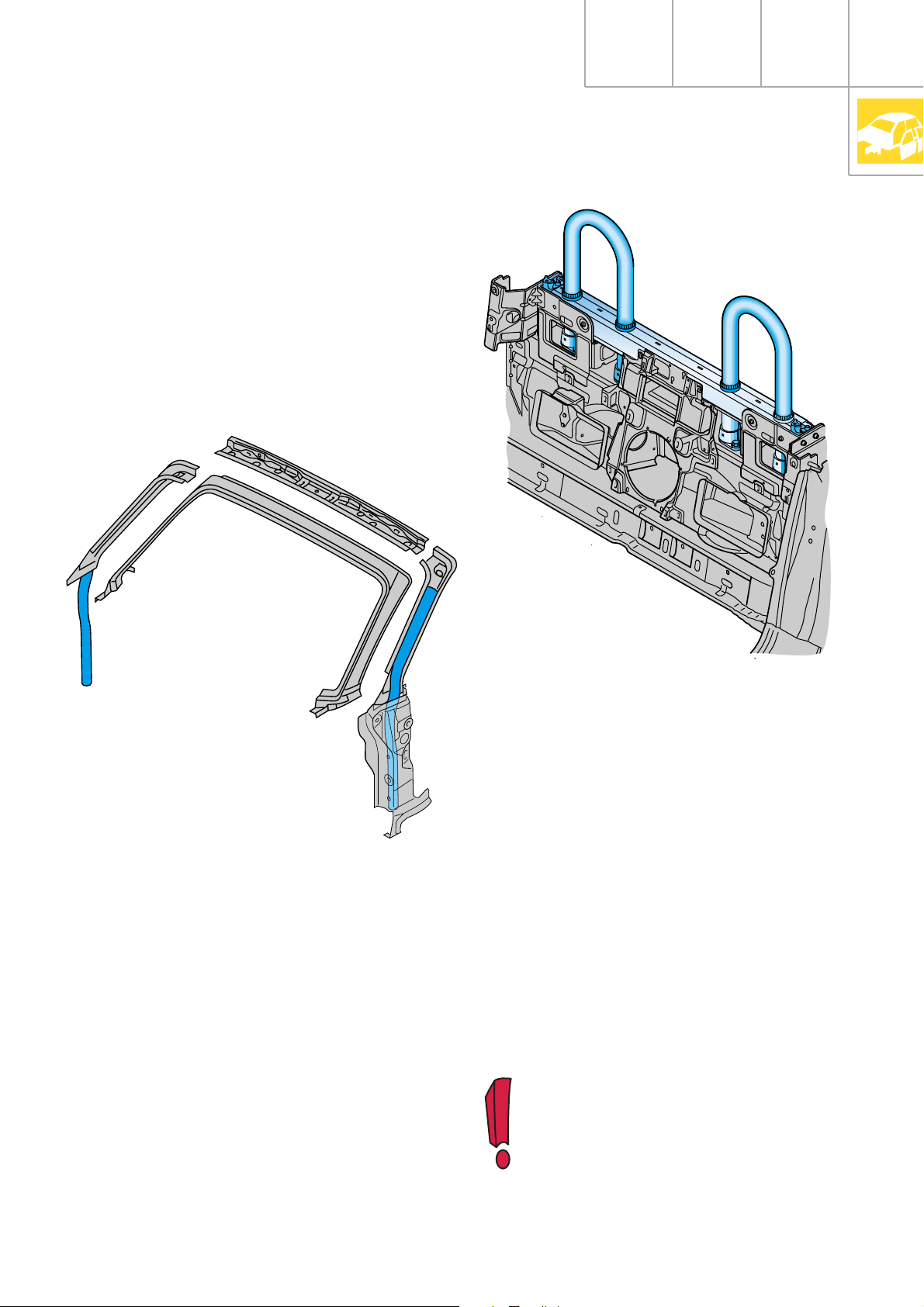

Occupant protection

Despite the lack of a roof structure, the

convertible driver is provided with sufficient

protection in the event of a rollover, and a

saloon-like survival space is preserved.

The conceptual drawback of open-top convertibles is offset in the Audi TT roadster by a

highly effective and yet exceedingly aesthetic

solution.

Two roll bars anchored to the vehicle body

and projecting beyond the two head

restraints, in combination with the ultra-rigid

A pillar / windscreen cross-member combination, afford the vehicle occupants highly

effective protection even in the event of a

rollover.

SSP220_003

SSP220_004

The A pillar comprises a pipe-in-pipe system

reinforced with high-tensile steel.

In addition, tubular aluminium roll bars

adapted from the body contours of the

vehicle occupants give the roadster a special,

sporty look.

You can find information regarding further occupant protection measures in

SSP 207.

7

Page 8

Body

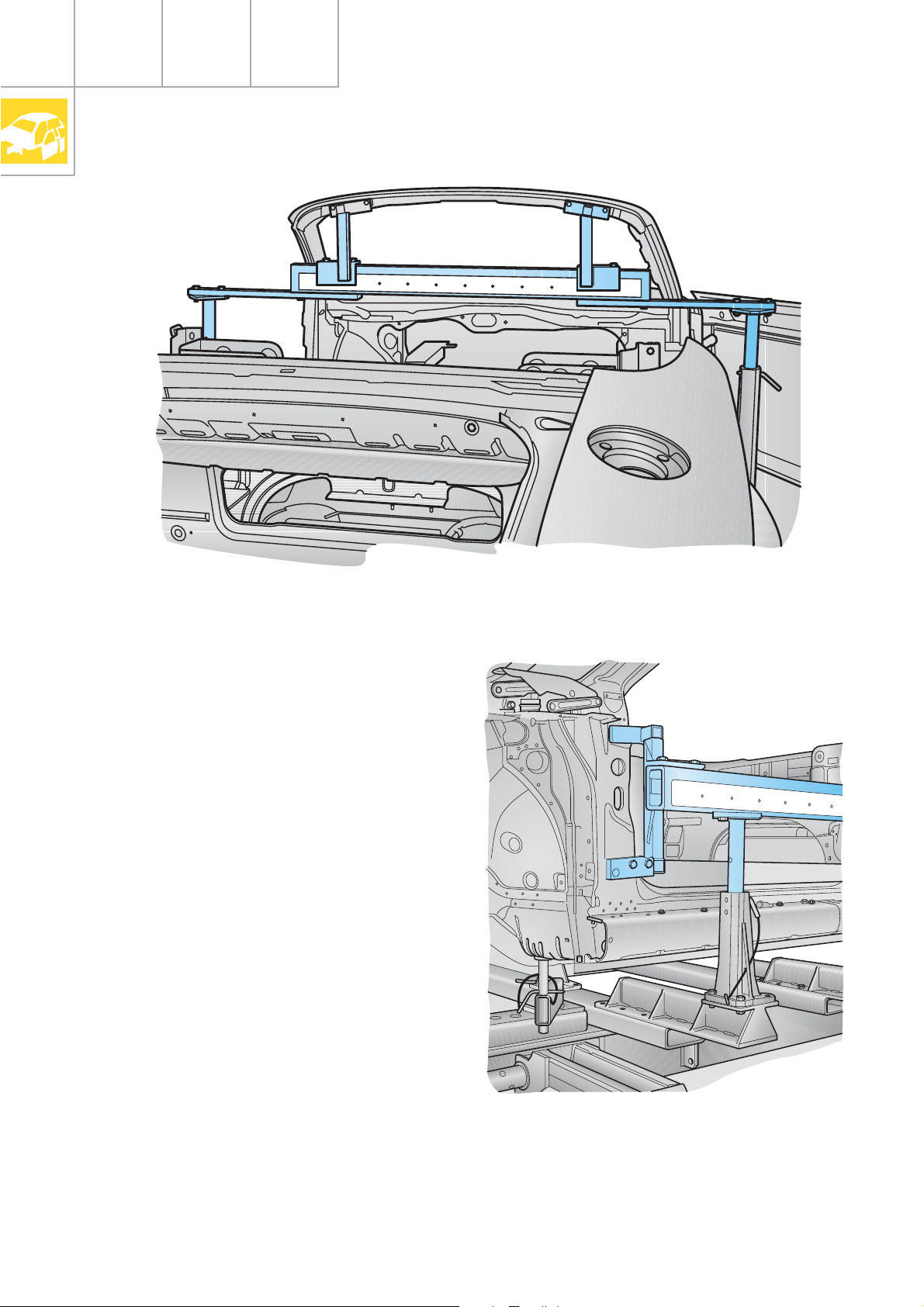

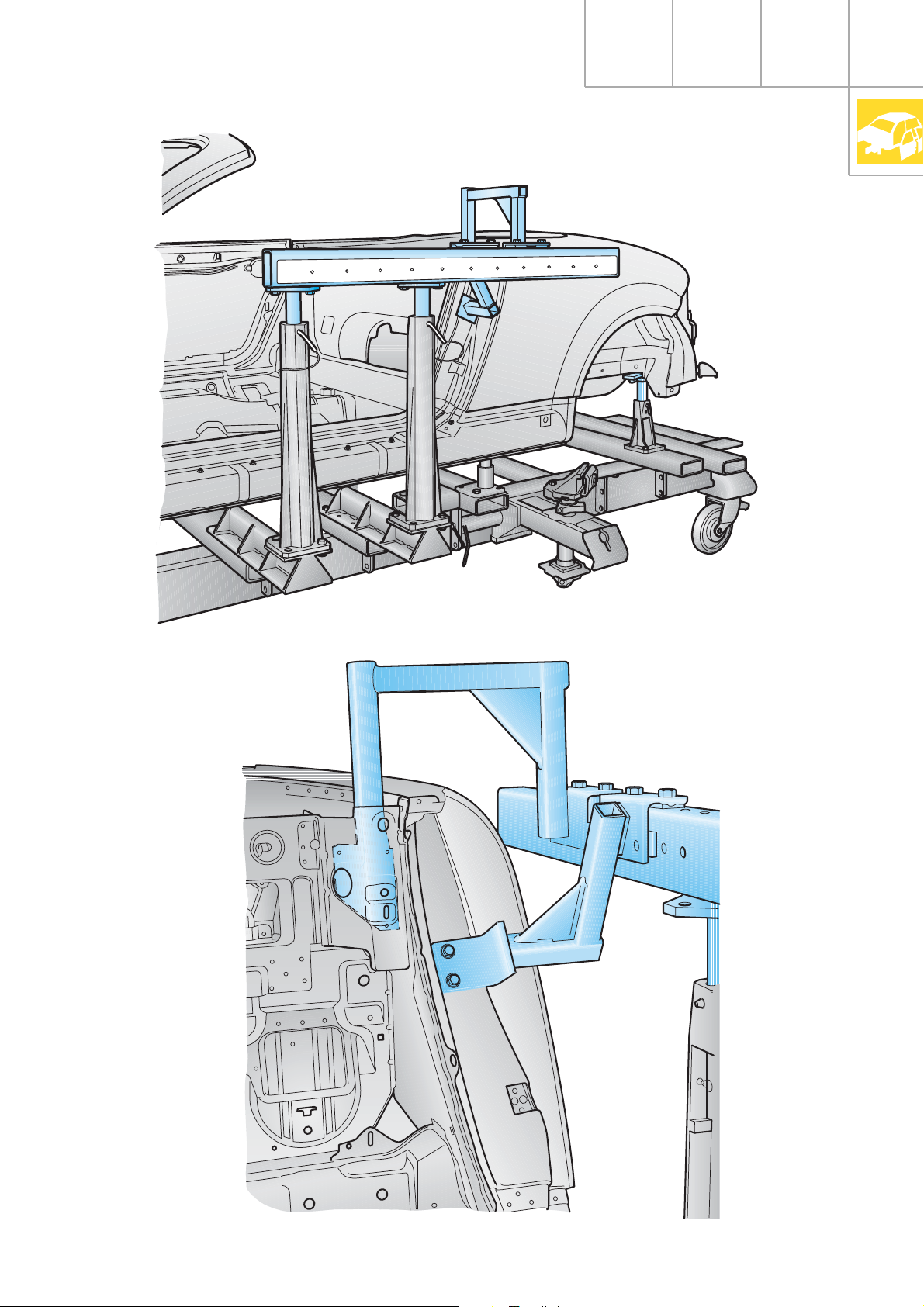

Gantry gauge

1

12

3

4

5

11

10

9

6

8

7

As with the Audi TT Coupé, the alignment

bracket set VAS 5020/6 is also used in the

Audi TT roadster.

In connection with the known gantry gauge

VAS 5007, the TT roadster requires alignment

bracket set supplement VAS 5007/8.

The following locating points are measured:

7

8

9

6

5

10

4

3

12

2

1

SSP220_026

1

2

3

4

5

12

11

10

9

6

8

7

– Soft top locks at left/right on windscreen

frame

– A pillar

– Striker plate mount, B pillar

– Soft top main bearing mount, left/right

Correctly positioned on the vehicle body, the

locating points ensure an ideal soft top

geometry.

8

SSP220_025

Page 9

1

12

10

11

8

9

6

7

4

5

1

2

3

12

11

10

9

8

7

6

5

4

3

2

SSP220_023

SSP220_024

9

Page 10

30

40

50

60

90

°C

50

70

13

Soft top control

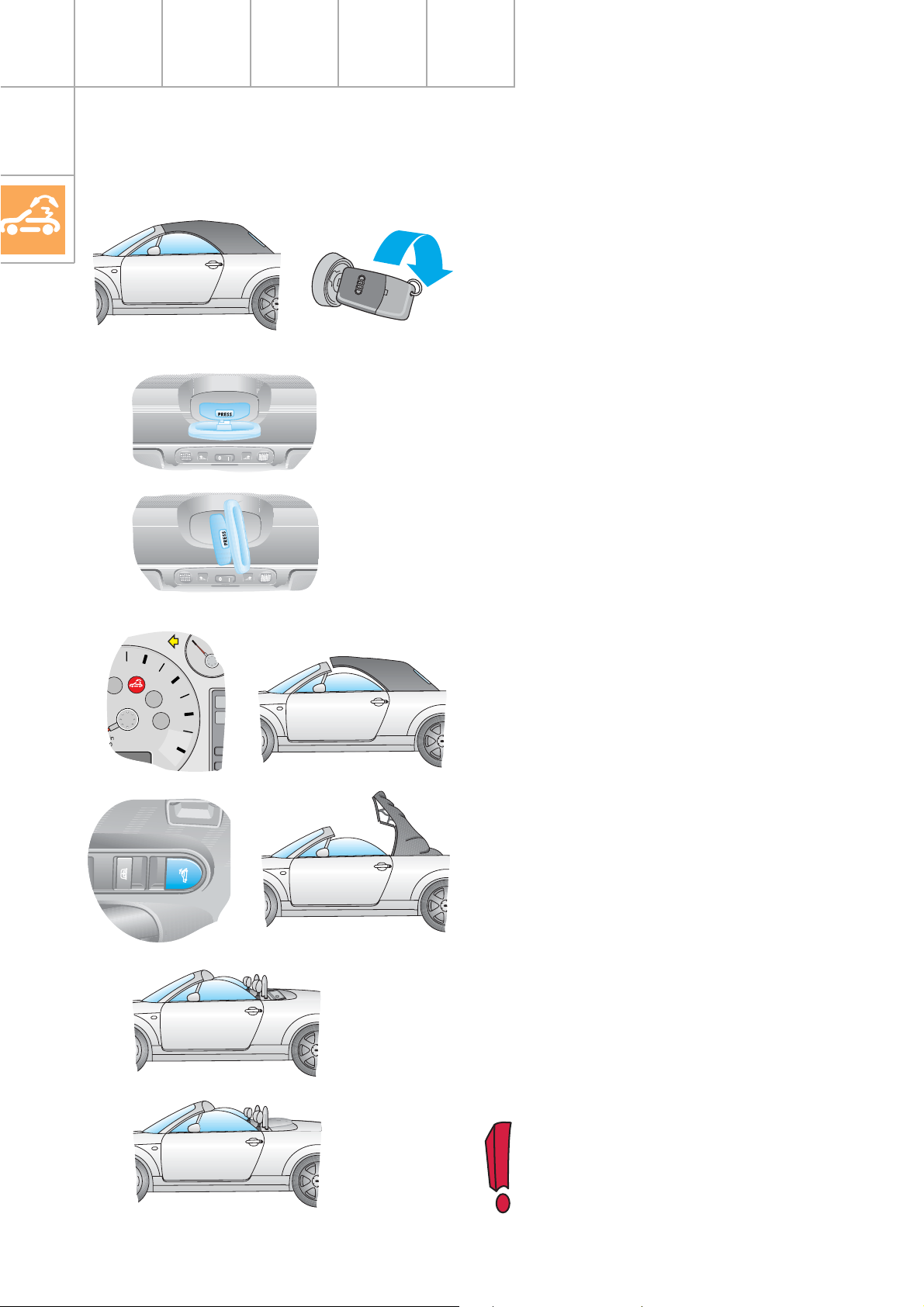

Semiautomatic soft top

Open soft top:

1.

– Vehicle stationary (< 5 kph)

– Ignition "On"

2.

– Press down the release knob and fold

down the locking handle.

3.

– Turn the handle anticlockwise as far as the

stop and push the soft top up out of the

interlock.

(turn back handle and fold in)

4.

– The warning lamp for the soft top comes

on, and the door window panes are lowered automatically by approx. 30 mm.

5.

– Pull switch in central console.

– The soft top is opened and stowed in the

soft top box by means of two hydraulic

cylinders.

– The door window panes close automati-

cally.

– The warning lamp goes out.

6.

– Fit tonneau cover.

(refer to Operating Manual)

For safety reasons, the vehicle should

10

only be driven with the tonneau cover

fitted when the soft top is open.

Page 11

30

40

50

60

90

°C

50

70

13

Close soft top

1.

– Remove the tonneau cover and stow it

away in the luggage compartment.

(refer to Operating Manual)

2.

– Vehicle stationary (< 5 kph)

– Ignition "On"

When the tonneau cover is fitted, the

soft top function is deactivated or

disabled.

– Press down the switch in the central

console in order to close the soft top.

– The warning lamp for the soft top comes

on and the door window panes are

lowered automatically by approx. 30 mm.

3.

– Press down the release knob and fold

down the locking handle.

4.

– Turn the handle anticlockwise as far as the

stop, then pull the soft top down into the

lock and close.

– The door window panes close automati-

cally.

– The warning lamp goes out.

11

Page 12

Soft top control

Soft top design

Soft top fabric

Tension clamp

The weave and tensioning of the soft top

fabric are designed to maintain an air

stream for as long as possible.

The soft top fabric is secured to the

bracing hoops by tension clamps.

For visual reasons, these bracing hoops

have plastic linings.

Soft top frame

(mechanism)

Raising the front roof rail allows the soft

top to be stowed away in the soft top box

by means of a kinematic chain (roof links 1

and 2 plus the main link) . The tensioning

strut simultaneously folds down from its

“stretched” position into the stowed

position in the soft top box.

Hydraulic cylinder with main bearing

Front roof rail

SSP220_046

Roof link 1

12

Guide part

For better stowage of the soft top, there

is a guide part on the tensioning strut at

the point of anchoring to the main

bearing.

SSP220_047

Page 13

Tonneau cover

Use the tonneau cover to protect the

stowed soft top.

Bracing hoop 1

Roof link 2

Bracing hoop 2

Bracing hoop 3

SSP220_020

Bracing hoop 4

Main link

Main bearing

Tension strap

Tensioning strut

SSP220_022

13

Page 14

Soft top control

Hydraulic diagram

Depending on the direction of rotation of the

electric motor, the rotor piston pump forces

oil through a 2-way valve into the corresponding pressure lines routed to the hydraulic

cylinders.

"Open“ soft top

To open the soft top, the extended piston

rods are pushed back into the hydraulic

cylinder and the soft top is opened via the

main bearing.

"Close“ soft top

SSP220_005

14

To close the soft top, the piston rods are pushed

out of the cylinders and the soft top is closed via

the main bearing.

SSP220_006

Page 15

Position "soft top stowed“

Double-action, bidirectional hydraulic

cylinder.

Limit switch

Fuse

Sealing ring

Hydraulic line

connection

Hydraulic cylinder

Coil spring

Piston base

Piston rod

Hydraulic line

connection

Fuse

SSP220_007

15

Page 16

Soft top control

Hydraulic pump unit

2/2-way valve

Hydraulic pump

Electric motor

Changeover relay

Hydraulic pump

The pump is designed as a rotor piston pump.

The pump draws hydraulic fluid out of the

tank through bore E. The cylinders are filled

under the centrifugal force exerted by the

pistons.

The rotor, together with the pistons, rotates

around an excentrically mounted stator. Thus,

the pistons are pushed back in and the

hydraulic fluid is pumped through bore A into

the lines of the individual hydraulic cylinders

at a pressure not exceeding 100 bar.

Pressure line

"Close“

Rotor

SSP220_009

Pressure line

"Open“

Bore A

(pressure connection)

Pump housing

16

SSP220_053

Piston

Bore E

(suction connection)

Stator

SSP220_054

Page 17

Open soft top

Hydraulic cylinder

2/2-way valve

Hydraulic pump

Close soft top

Pressure limiting

valve

Pressure limiting

valve

SSP220_066

Expansion tank

Non-return valve

SSP220_065

17

Page 18

Soft top control

Fitting locations

Manual soft top

To enhance ease of use, the soft top is

equipped with two gas-filled springs which

make it easier to lift the soft top out of the the

soft top box. In addition, a set of compression

springs is installed in the main bearing (left/

right) in order to make the soft top easier to

open and close.

Central locking and anti-theft

alarm control unit J 379

Bulkhead (optional)

Microswitch

Soft top stowed

Microswitch

Soft top released

18

Page 19

Semiautomatic soft top

Hydraulic pump

Central locking and anti-theft

alarm control unit J 379

Hydr. cylinder

Microswitch

Soft top stowed

Microswitch

Tonneau cover, right

Soft top operating

switch

Bulkhead operating

switch

Microswitch

Tonneau cover, left

Soft top released

(autom. air conditioner off)

Soft top released

19

Page 20

Soft top control

Semiautomatic soft top

System overview

Ignition "On"

Road speed signal, dash panel

insert

Switch for soft top control

90

1/2

0

130

1/1

50

R

30

20

10

°C

40

50

60

70

80

100

120

70

60

140

160

50

40

180

200

30

220

20

240

10

260

0

Air conditioner operating and

display unit

(no automatic operation)

Microswitch

(Soft top released)

Microswitch

(soft top released)

Microswitch

(Soft top stowed)

Microswitch

(tonneau cover, left)

Operation

Operation

ECON

OTUA

OFF

Microswitch

(tonneau cover, right)

Hydraulic cylinder switch,

left

20

Page 21

30

40

50

60

90

°C

50

70

13

Central locking and anti-theft

alarm control unit J 379

Hydraulic pump

(with changeover relay)

Power windows

Soft top warning light

SSP220_059

21

Page 22

30

40

50

60

90

°C

50

70

13

Soft top control

Semiautomatic soft top

The soft top is controlled via central locking

control unit J379.

Self-diagnosis: Address word 35

Combination processor in instrument cluster

J218

90

1/2

0

130

30

20

10

50

40

50

60

70

1/1

°C

80

100

120

70

60

140

50

40

30

20

10

0

160

180

200

220

240

260

Signal utilisation:

Central locking control unit J379 receives the

vehicle road speed signal from the combination processor. This is a criterion for enabling

the switch for soft top operation at road

speeds of less than 5 kph.

Microswitch - soft top released

The left catch hook on the soft top operates

the microswitch integrated in the lock. This

signal is utilised for:

– Activating the soft top warning lamp

– Lowering the door window panes

(30 mm)

– Switching off the automatic air

conditioning mode

The signal supplied by the sender for interior

temperature sensor G65 in the air conditioner/Climatronic operating and display unit is

suppressed and the previously set temperature and fresh-air blower values are retained.

The short-stroke function (10 mm) for

raising and lowering the door window

panes is executed via the door contact

switch.

Microswitch - soft top released

The microswitch integrated in the right lock in

the windscreen frame closes as soon as the

22

centring pin leaves the lock when raising the

soft top. The second criterion for enabling the

switch for soft top control is fulfilled.

Page 23

Switch for soft top control

If the previous two criteria have been fulfilled,

the hydraulic pump is activated via central

locking control unit J379 when the soft top

switch is operated.

Microswitch - soft top stowed

(in the left-hand main bearing)

Signal utilisation:

– Switches the hydraulic pump off

– Rear window heating off

– Soft top warning light off

– Door window panes being raised

If the soft top is open and stored, the

short-stroke function is not executed

when opening and closing the doors.

Microswitch - tonneau cover, left/right

If the tonneau cover is fitted properly, the

microswitches are closed. The central locking

control unit uses this signal to suppress the

function of the switch for soft top operation.

Consequently, it is not possible to close the

soft top.

Switch at left-hand hydraulic cylinder

The switch closes as soon as the piston of the

hydraulic cylinder reaches the upper stop and

the soft top begins to close. The incoming

signal is utilised to switch off the hydraulic

pump.

Switch statuses can be exported to

measured value blocks 9 and 10 by

means of the Diagnostic Testing and

Information System.

23

Page 24

Soft top control

Function diagram

Semiautomatic soft top

E87 Signal for air conditioner

operating and display unit

(no automatic operation)

E137 Soft top operation button

F171 Soft top stowed switch

F172 Soft top released switch

F202 Soft top switch, front

F205 Soft top released switch

F254 Tonneau cover left switch

F267 Tonneau cover right switch

J321 Relay for hydraulic pump soft top

operation

J379 Central locking and

anti-theft alarm control unit

J531 Bulkhead control unit

K98 Soft top released warning lamp

N272 Solenoid valve for hydraulic pump

S Fuse

V118 Soft top hydraulic pump

30

X

31

in out

58s

01 10

E137

J379

1 Road speed signal from combination

processor in dash panel insert J218

24

1

K98

F267F254

31

Page 25

30

S

30

X

31

J321

M

N272

J379

V118

J531

E87

F205F202

F171 F172

31

SSP220_048

25

Page 26

Bulkhead

The bulkhead can only be raised if the soft top

is stowed;the latter is detected via the "Soft

top stowed“ microswitch.

Glass pane

Electric motor

SSP220_011

SSP220_036

26

Page 27

Function diagram

30

X

31

75x

S227

0110

J531

58s

in out

E278

J379

30

X

31

M

V186

31

E87

E278 Button for bulkhead operation

F171 Soft top stowed switch

F172 Soft top released switch

J379 Central locking and

anti-theft alarm control unit

J531 Bulkhead control unit

S227 Fuse

V186 Motor for bulkhead operation

F172

F171

31

SSP220_012

27

Page 28

Central locking

6-

DISK

Stowage compartment

The stowage compartment is locked and

unlocked by the central locking system.

SSP220_017

SSP220_016SSP220_015

28

Emergency release, luggage compartment

Operating the handle activates the luggage

compartment emergency release by means

of a bowden cable.

The compartment must be locked with the

ignition key.

CD changer tray

The CD changer tray is locked and released

by the central locking system.

CD player optional

Page 29

Interior monitor

Megawave interior

monitor

R 900

J347

J347

R 900

SSP220_042

Audi has developed a new interior monitoring

system which is ideal for such open-topped

vehicles as the Audi TT Roadster.

The system requirement is a precisely

demarcated theoretical "protective sheath“ in

the form of a hemispherical shell whose

intrusion is detectable at any time. However,

the system must not pick up movements

outside this protective sheath irrespective of

their velocity, object size and reflectivity.

SSP220_041

The radius of the "protective sheath“ is defined by the distance between the ultrasonic

sensor module and the shortest point within

the bounds of the vehicle.

The megawave interior protection

system is implemented by pulse radar.

29

Page 30

Interior monitor

Theoretical protective

sheath

When the system is active, the module

1

R = t

cyclically emits radar pulses with a very low

wattage (t

).

1

Pulse generator

t

= t

1

2

< t

t

1

2

t

2

J347

SSP220_043

do not activate alarm

1

R = t

t

2

J347

SSP220_044

activate alarm

The same pulse is supplied to a so-called

delay line within the control unit (t

).

2

A measuring process in parallel with actual

measurement in the defined vehicle interior is

therefore simulated.

If the propagation time of the radar pulse

from the transmitter antenna to the reflecting

object and back to the receiver antenna equates to at least the period set in the control

unit (t

), then the signal is evaluated in the

2

control unit and the alarm is triggered if

necessary.

30

The interior monitor can still be switched off

using the switch in the central console.

SSP220_014

Page 31

Dear Reader,

In this Self-Study Programme you will have been able to familiarise

yourself with the Audi TT Roadster.

Our objective is to make our Self-Study Programmes interesting

for you!

That is why we are giving you the opportunity to submit your views or

suggestions for future Self-Study Programmes.

To help you, we have provided the following questionnaire.

We will take into consideration suggestions sent to us under the fax

number +49 841/ 89-36367.

Thank you for your support.

With kind regards,

Service Technology TrainingTeam

31

Page 32

220

All rights reserved.

Technical specifications subject

to change without notice.

AUDI AG

Dept. I/VK-5

D-85045 Ingolstadt

Fax +49 841/89-36367

940.2810.39.20

Technical status 03/99

Printed in Germany

Loading...

Loading...