Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve

turbo), mechanics

Engine ID

Edition 11.2006

BWA BPY

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

00 - Technical data

10 - Removing and installing engine

13 - Crankshaft group

15 - Cylinder head, valve gear

17 - Lubrication

19 - Cooling

21 - Turbocharging/supercharging

26 - Exhaust system

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A005TT00520

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Engine number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Engine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4 Rules for cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

10 - Removing and installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 Removing and installing engine, detaching from gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Removing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Separating engine and gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3 Securing engine to assembly stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.4 Installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 Assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.1 Assembly mountings - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.2 Checking adjustment of assembly mountings (engine/gearbox mountings) . . . . . . . . . . . . 26

2.3 Adjusting assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

13 - Crankshaft group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1 Cylinder block (pulley end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1.1 Poly V-belt, bracket for ancillaries - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1.2 Removing and installing poly V-belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1.3 Removing and installing bracket for ancillaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1.4 Removing and installing vibration damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1.5 Front sealing flange - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1.6 Renewing crankshaft oil seal - pulley end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1.7 Removing and installing sealing flange (front) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2 Cylinder block (gearbox end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2.1 Rear sealing flange and dual-mass flywheel - exploded view . . . . . . . . . . . . . . . . . . . . . . 48

2.2 Removing and installing dual-mass flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.3 Removing and installing sealing flange (rear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3 Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.1 Crankshaft - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.2 Crankshaft dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.3 Measuring axial clearance of crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.4 Measuring radial clearance of crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.5 Extracting and driving in needle bearing for crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.6 Removing and installing chain sprocket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4 Pistons and conrods - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.1 Piston and cylinder dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

15 - Cylinder head, valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1 Toothed belt drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1.1 Toothed belt drive - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1.2 Removing and installing toothed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

2 Cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2.1 Cylinder head - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2.2 Removing and installing inlet camshaft control valve 1 N205 . . . . . . . . . . . . . . . . . . . . . . 80

2.3 Removing and installing cylinder head cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

2.4 Removing and installing cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

2.5 Checking compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3 Valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

3.1 Valve gear - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

3.2 Removing and installing camshaft adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.3 Removing and installing camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.4 Checking axial clearance of camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

3.5 Renewing valve stem oil seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

3.6 Checking valve guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

3.7 Renewing exhaust camshaft oil seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

17 - Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

1 Oil pump and sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

1.1 Sump - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

1.2 Removing and installing sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

1.3 Balance shaft assembly with oil pump - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

1.4 Removing and installing balance shaft assembly with oil pump . . . . . . . . . . . . . . . . . . . . . . 127

2 Oil filter bracket and oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

2.1 Oil filter bracket - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

2.2 Draining oil filter housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

2.3 Removing and installing oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

2.4 Removing and installing oil filter bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

2.5 Checking oil pressure and oil pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

19 - Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

1 Removing and installing parts of cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

1.1 Cooling system components (on engine) - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.2 Continued coolant circulation pump V51 - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . 145

1.3 Diagram of coolant hose connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

1.4 Draining and filling cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

1.5 Checking cooling system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

1.6 Removing and installing coolant pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

1.7 Removing and installing coolant distributor housing with map-controlled engine cooling

thermostat F265 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

1.8 Removing and installing coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

1.9 Radiator and radiator fans - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

1.10 Removing and installing radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

1.11 Removing and installing radiator cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

1.12 Removing and installing radiator fan V7 and radiator fan 2 V177 . . . . . . . . . . . . . . . . . . . . 163

21 - Turbocharging/supercharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

1 Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

1.1 Fitting hose connections with plug-in connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

1.2 Turbocharger - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

1.3 Removing and installing turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

1.4 Checking vacuum unit for turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

1.5 Removing and installing vacuum unit for turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

1.6 Adjusting vacuum unit for turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

2 Charge air system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

2.1 Charge air cooler - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

2.2 Turbocharging diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

2.3 Removing and installing charge air cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

2.4 Checking charge air system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

26 - Exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

1 Parts of exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

1.1 Exhaust system - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

1.2 Removing and installing front exhaust pipe with catalytic converters and front silencer . . 191

1.3 Aligning exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

1.4 Checking exhaust system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Contents iii

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

iv Contents

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

00 – Technical data

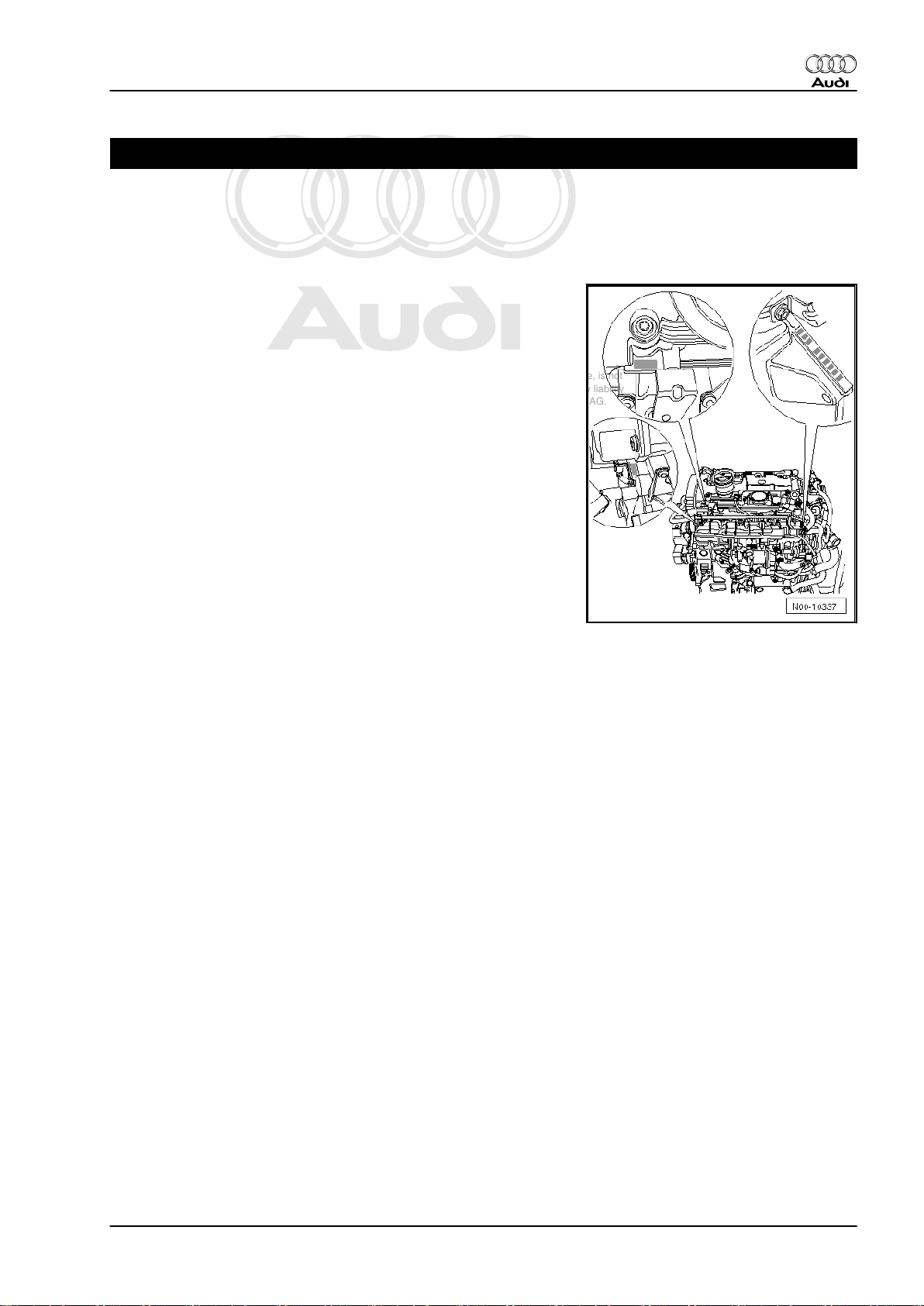

1 Engine number

The engine number (including “Engine code” and “Serial num‐

ber”) can be found on the left of the joint between engine and

gearbox.

The engine code is also stamped on the right of the cylinder head

and on the cylinder block.

The engine number consists of up to nine characters (alphanu‐

meric). The first part (up to 3 code letters) represents the “engine

code letters”, the second part (6 digits) the “serial number”. If more

than 999 999 engines were produced with the same code letters,

the first of the 6 digits is replaced by a letter.

Additionally there is a sticker on the toothed belt cover showing

the “engine code” and “serial number”.

The engine code is also to be found on the vehicle data sticker.

Audi TT 2007 ➤

1. Engine number 1

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

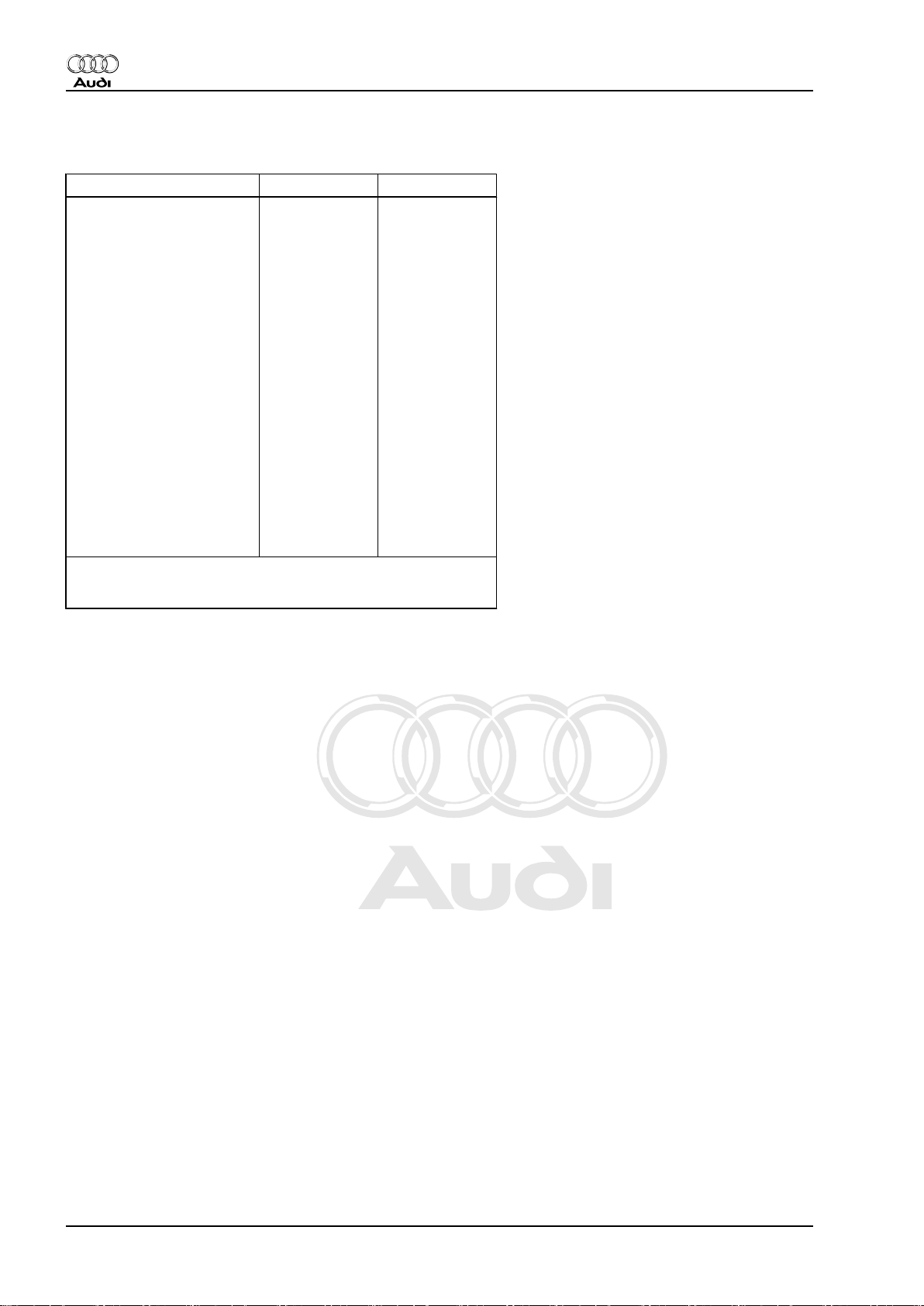

2 Engine data

Code letters BWA BPY

Capacity ltr. 1.984 1.984

Power output kW at rpm 147/5100 147/5700

Torque Nm at rpm 280/1800 280/2000

Bore ∅ in mm 82.5 82.5

Stroke mm 92.8 92.8

Compression ratio 10.3 10.5

RON

98

1)

Injection/ignition system FSI FSI

Firing order

1-3-4-2 1-3-4-2

Knock control yes yes

Turbocharging/super‐

yes yes

charging

Exhaust gas recirculation no no

Intake manifold change-

no no

over

Variable valve timing yes yes

Secondary air system no no

1)

•

Unleaded petrol RON 95 can also be used, but results in

reduced power

98

1)

2 Rep. Gr.00 - Technical data

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

3 Safety precautions

When working on the fuel system please note the following warn‐

ings:

WARNING

The fuel system is pressurised. Before opening the system

place a clean cloth around the connection. Then release pres‐

sure by carefully loosening the connection.

Observe the following to avoid injuries to persons and/or damage

to the injection and ignition system:

♦ Always switch off the ignition before connecting or discon‐

necting electrical wiring for the injection or ignition system or

tester cables.

♦ Certain tests may lead to a fault being detected by the engine

control unit and stored in the memory. You must therefore in‐

terrogate the fault memory and erase it if necessary after

completion of all tests and repair work. If you erase the fault

memory, you must then generate the readiness code in the

engine control unit in “Guided Fault Finding” mode ⇒ Vehicle

diagnosis, testing and information system VAS 5051.

♦ Always switch off the ignition before cleaning the engine.

Audi TT 2007 ➤

♦ Observe notes on procedure for disconnecting the battery

Caution

⇒ Rep. Gr. 27 .

♦ Always switch off the ignition before connecting or dis‐

connecting the battery, otherwise the engine control unit

may be damaged.

When working on the cooling system note the following warnings:

WARNING

Hot steam or hot coolant can escape when expansion tank is

opened; cover filler cap with cloth and open carefully.

Note the following if testers and measuring instruments have to

be used during a road test:

WARNING

♦ Test equipment must always be secured on the rear seat

and operated from that position by a second person.

♦ If test and measuring instruments are operated from front

passenger's seat and the vehicle is involved in an acci‐

dent, the person sitting in this seat could be seriously

injured when the airbag is triggered.

3. Safety precautions 3

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

4 Rules for cleanliness

Injection system/fuel system

Even small amounts of dirt can cause faults in the injection sys‐

tem. When working on the fuel supply/injection system, please

pay careful attention to the following basic rules:

♦ Carefully clean connection points and the surrounding area

with engine cleaner or brake cleaner and dry thoroughly before

opening.

♦ Plug open lines and connections with suitable protective caps

immediately.

♦ Place parts that have been removed on a clean surface and

cover them over. Use only lint-free cloths.

♦ Only install clean components; replacement parts should only

be unpacked immediately prior to installation. Do not use parts

that have been previously unpacked and stored away loose

(e.g. in toolboxes, etc.).

♦ When the system is open: Do not work with compressed air.

Do not move the vehicle unless absolutely necessary.

♦ Unplugged electrical connectors must be kept clean and dry.

Make sure connections are dry when attaching.

Turbocharger

When working on the turbocharger, pay careful attention to the

following “5 rules”:

♦ Thoroughly clean all unions and surrounding areas before dis‐

connecting.

♦ Place parts that have been removed on a clean surface and

cover them over. Use only lint-free cloths.

♦ Carefully cover or seal open components if repairs cannot be

carried out immediately.

♦ Only install clean components; replacement parts should only

be unpacked immediately prior to installation. Do not use parts

that have been stored loose (e.g. in tool boxes etc.).

♦ When the system is open: Do not work with compressed air if

this can be avoided. Do not move the vehicle unless absolutely

necessary.

4 Rep. Gr.00 - Technical data

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

10 – Removing and installing engine

1 Removing and installing engine, de‐

taching from gearbox

1.1 Removing engine

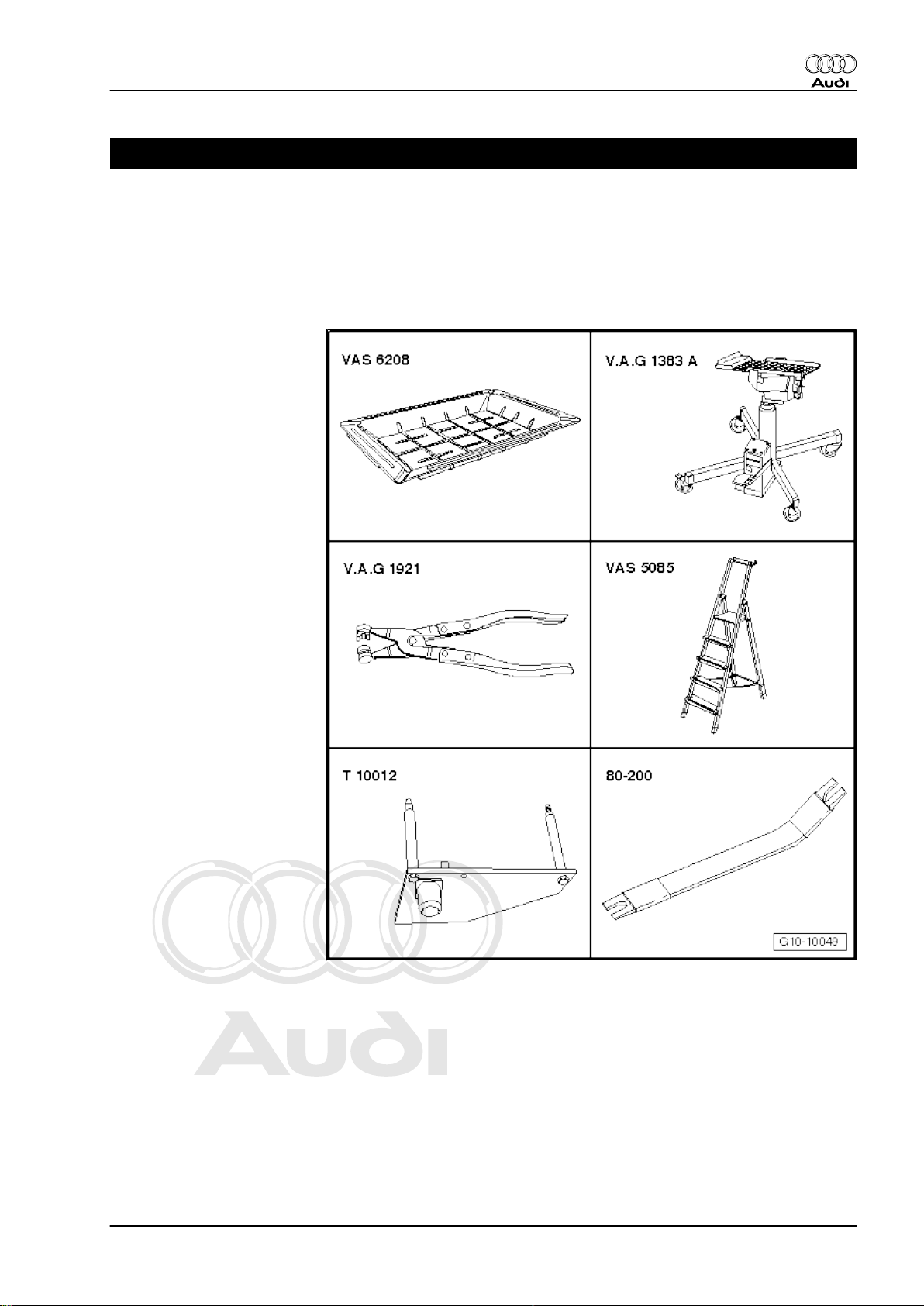

Special tools and workshop

equipment required

♦ Drip tray for workshop hoist

-VAS 6208-

♦ Engine and gearbox jack -

V.A.G 1383 A-

♦ Hose clip pliers -V.A.G

1921-

♦ Stepladder -VAS 5085-

♦ Engine bracket -T10012-

♦ Removal lever -80 - 200-

Audi TT 2007 ➤

1. Removing and installing engine, detaching from gearbox 5

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

Lambda probe open ring spanner set -3337-

Engine bung set -VAS 6122-

Note

♦

The engine is removed from underneath together with the

gearbox.

♦

Renew all cable ties which are released or cut open when re‐

moving the engine. Refit in the same position when installing

the engine.

♦

Heat insulation sleeves removed when taking out the engine

are to be reinstalled in the original position.

♦

Collect drained coolant in a clean container for re-use or dis‐

posal.

WARNING

Observe notes on procedure for disconnecting the battery. ⇒

Electrical system; Rep. Gr. 27

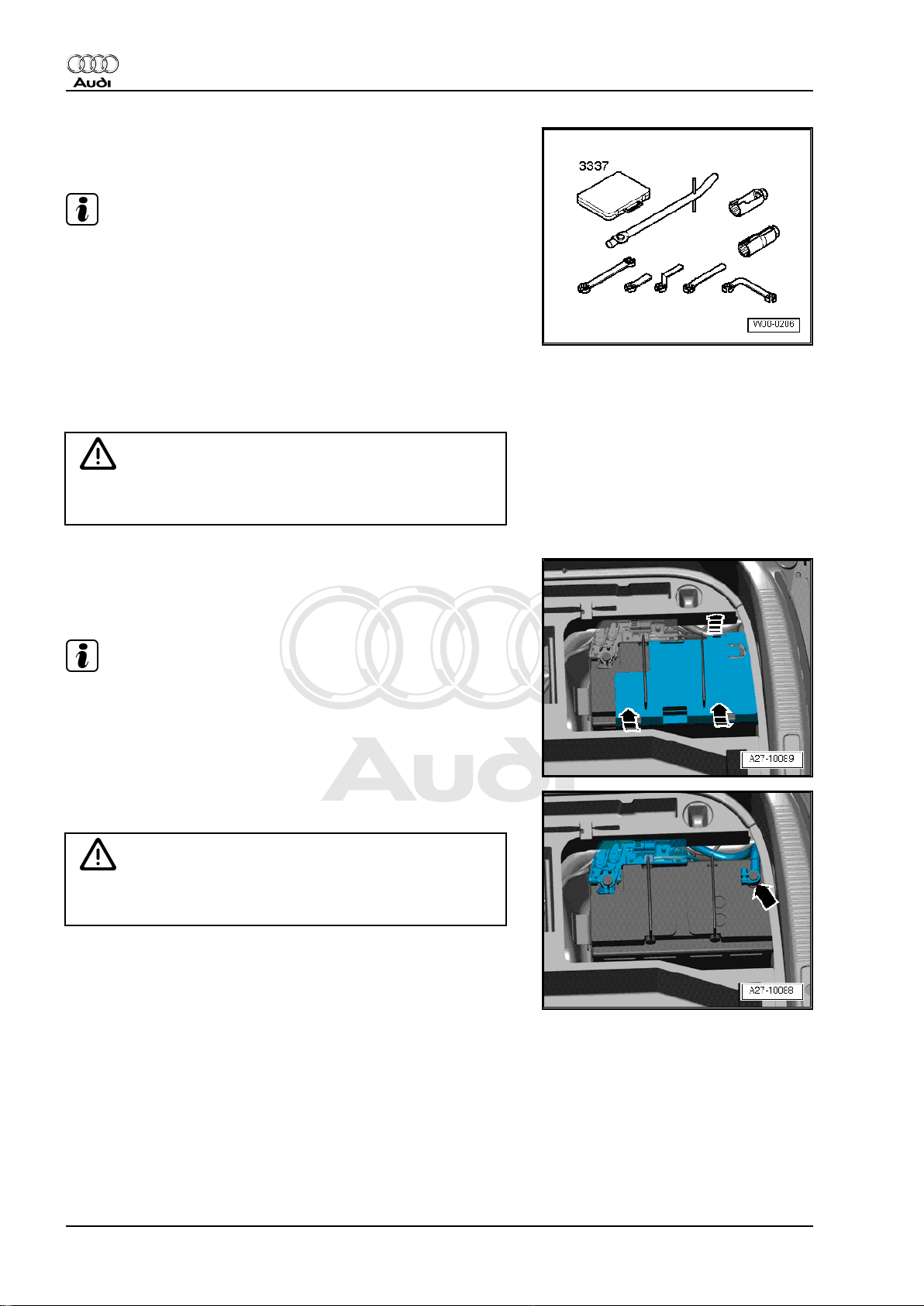

– Remove luggage compartment floor covering.

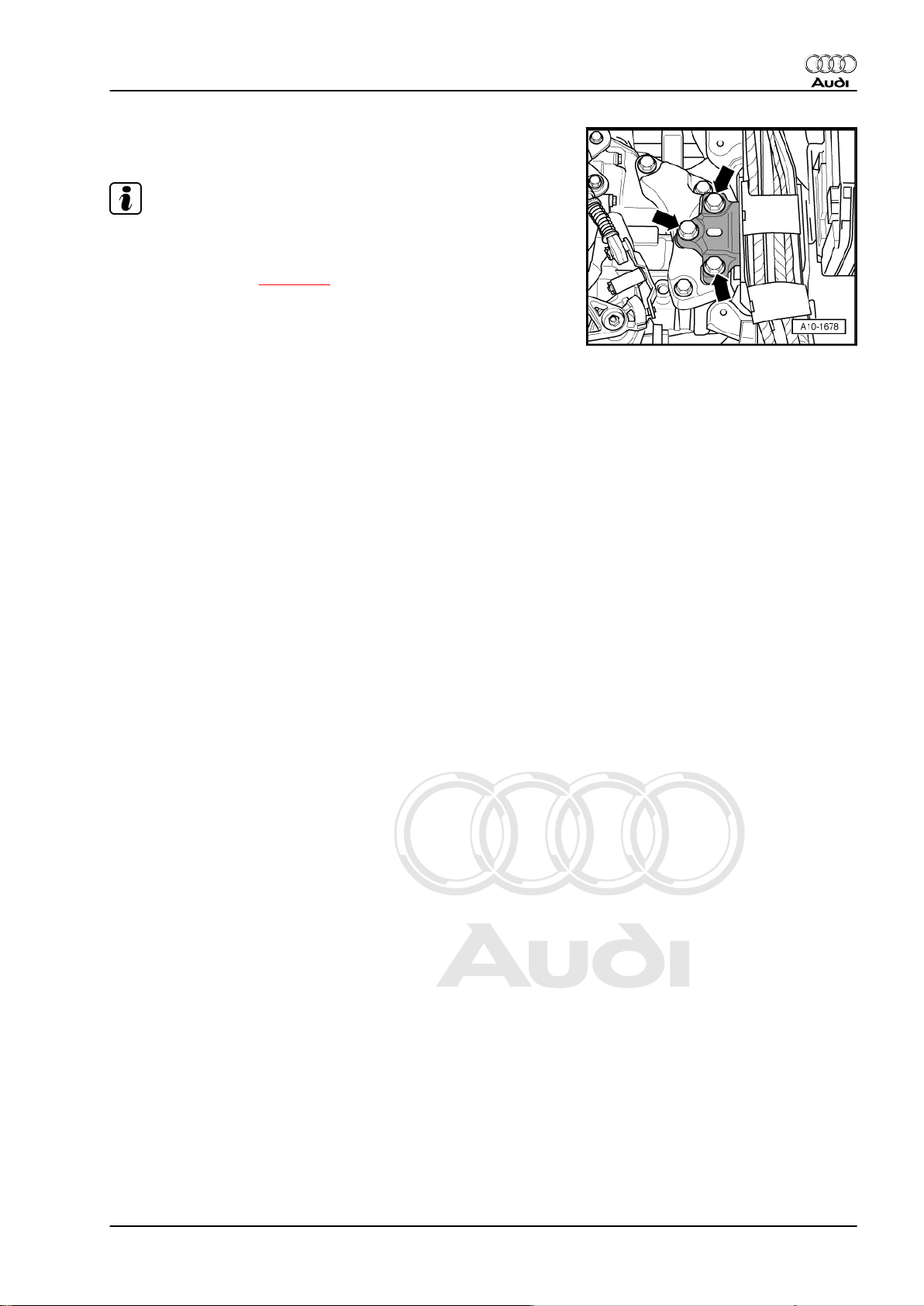

– Release retaining clips -arrows- and detach cover for negative

terminal.

Note

Remove rear cross panel trim if cover for negative terminal of

battery is located under rear cross panel trim ⇒ Rep. Gr. 70 .

– With ignition switched off, disconnect earth wire -arrow- at

battery.

WARNING

Hot steam/hot coolant may escape when opening expansion

tank. Cover cap with cloth and open carefully.

– Open filler cap on coolant expansion tank

– Remove both front wheels.

6 Rep. Gr.10 - Removing and installing engine

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

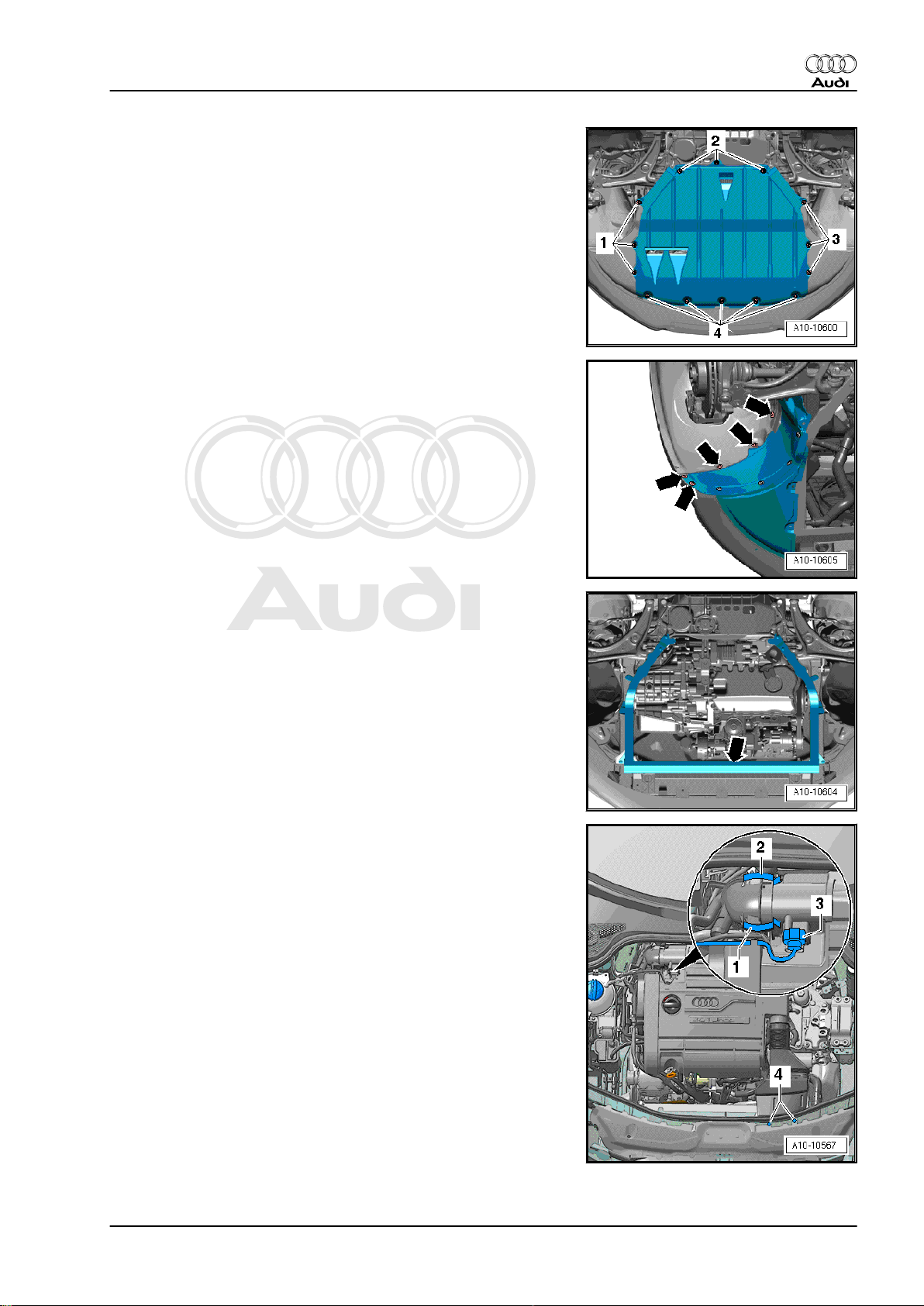

– Remove centre noise insulation -fasteners 1 ... 4-.

– Remove noise insulation panels (left and right) -arrows-.

Audi TT 2007 ➤

– Remove noise insulation frame -arrow-.

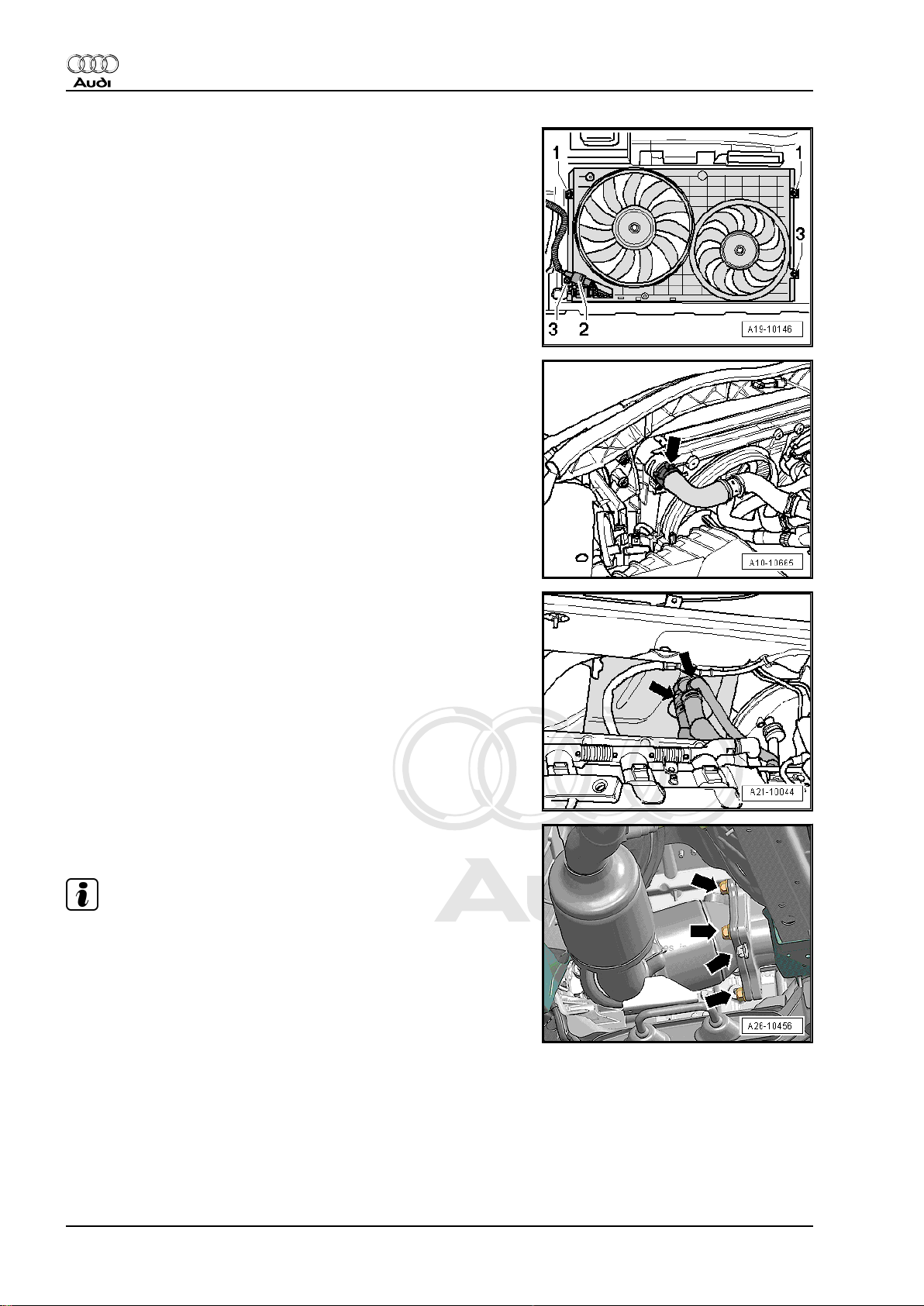

– Unplug electrical connector at air mass meter -G70- -3-.

– Open clamps -1 and 2- and disconnect air intake hose from

air mass meter.

– Detach air intake connection at lock carrier -4-.

– Pull off engine cover panel.

1. Removing and installing engine, detaching from gearbox 7

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

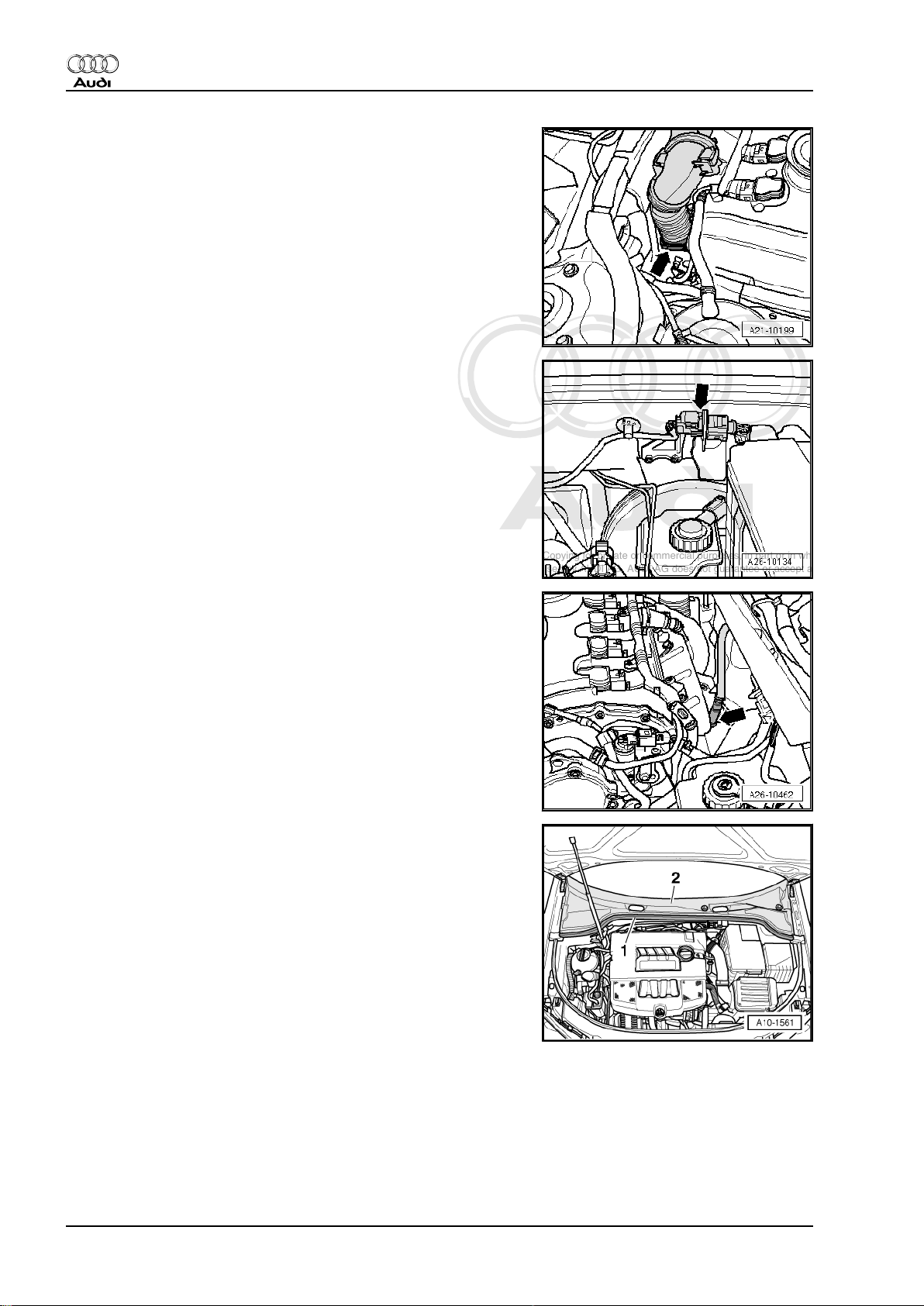

– Remove air intake hose -arrow- using hose clip pliers -V.A.G

1921- .

– Remove electrical connector -arrow- for Lambda probe (be‐

fore catalytic converter) from bracket, unplug and move clear.

– Unscrew Lambda probe -G39- -arrow- using tool from Lambda

probe open ring spanner set -3337- .

– Use screwdriver to pry off cover caps on wiper arms and un‐

screw hexagon nuts.

– Pull wiper arms off wiper shafts and remove.

– Pull off rubber seal -1- on plenum chamber cover.

– Detach plenum chamber cover -2-.

– Move engine wiring harness in plenum chamber clear.

– Remove engine control unit. ⇒ Rep. Gr. 24

8 Rep. Gr.10 - Removing and installing engine

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

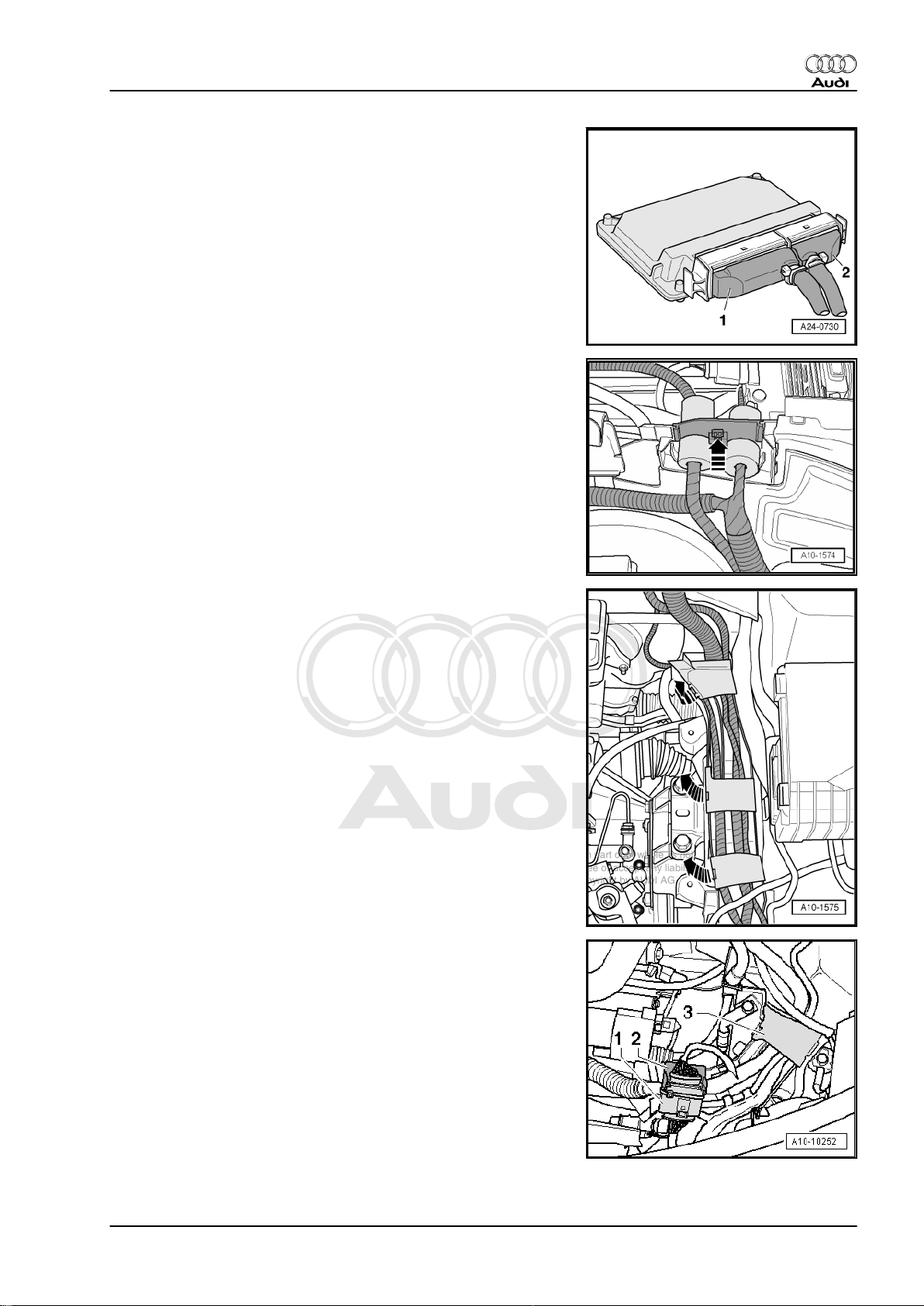

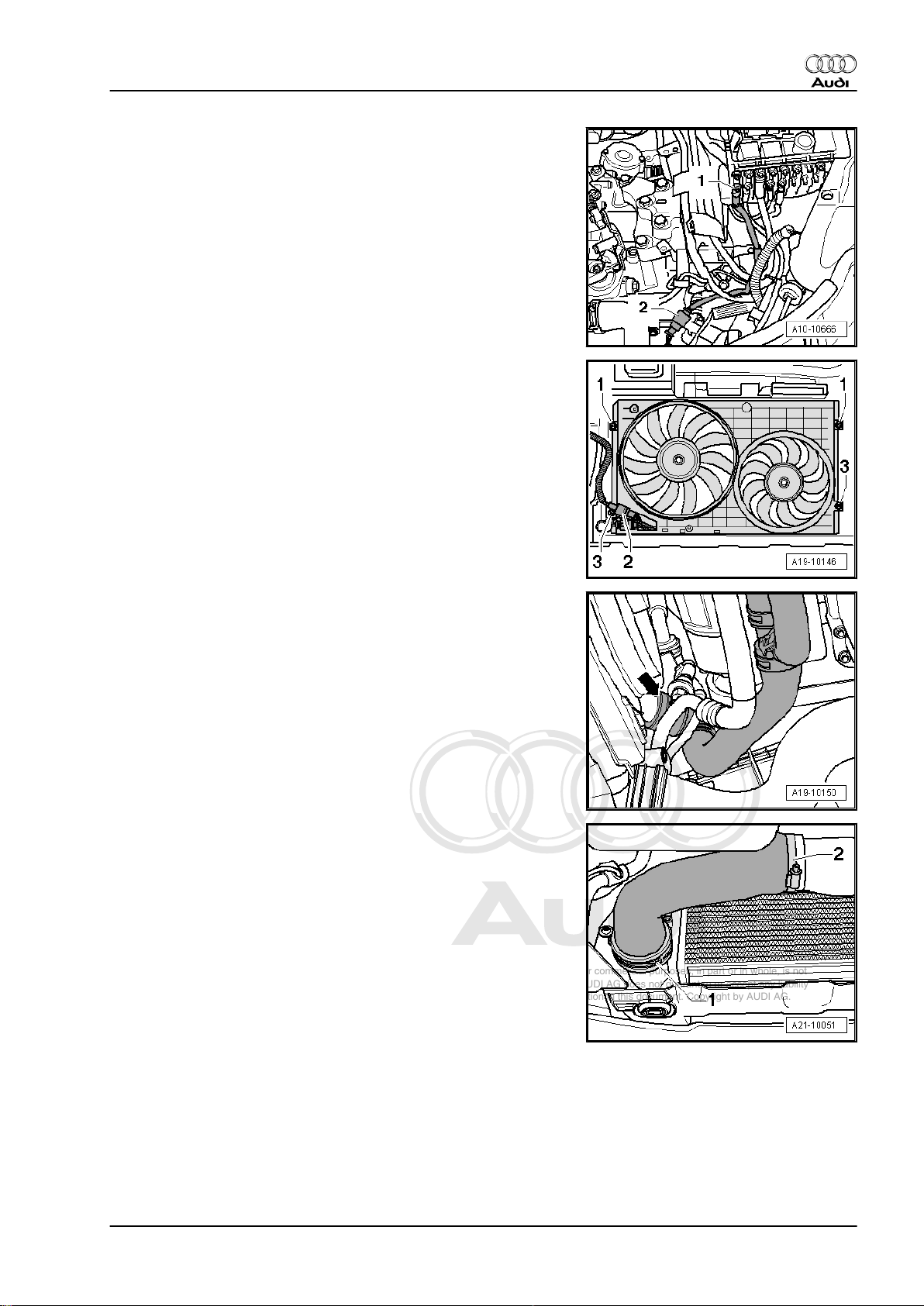

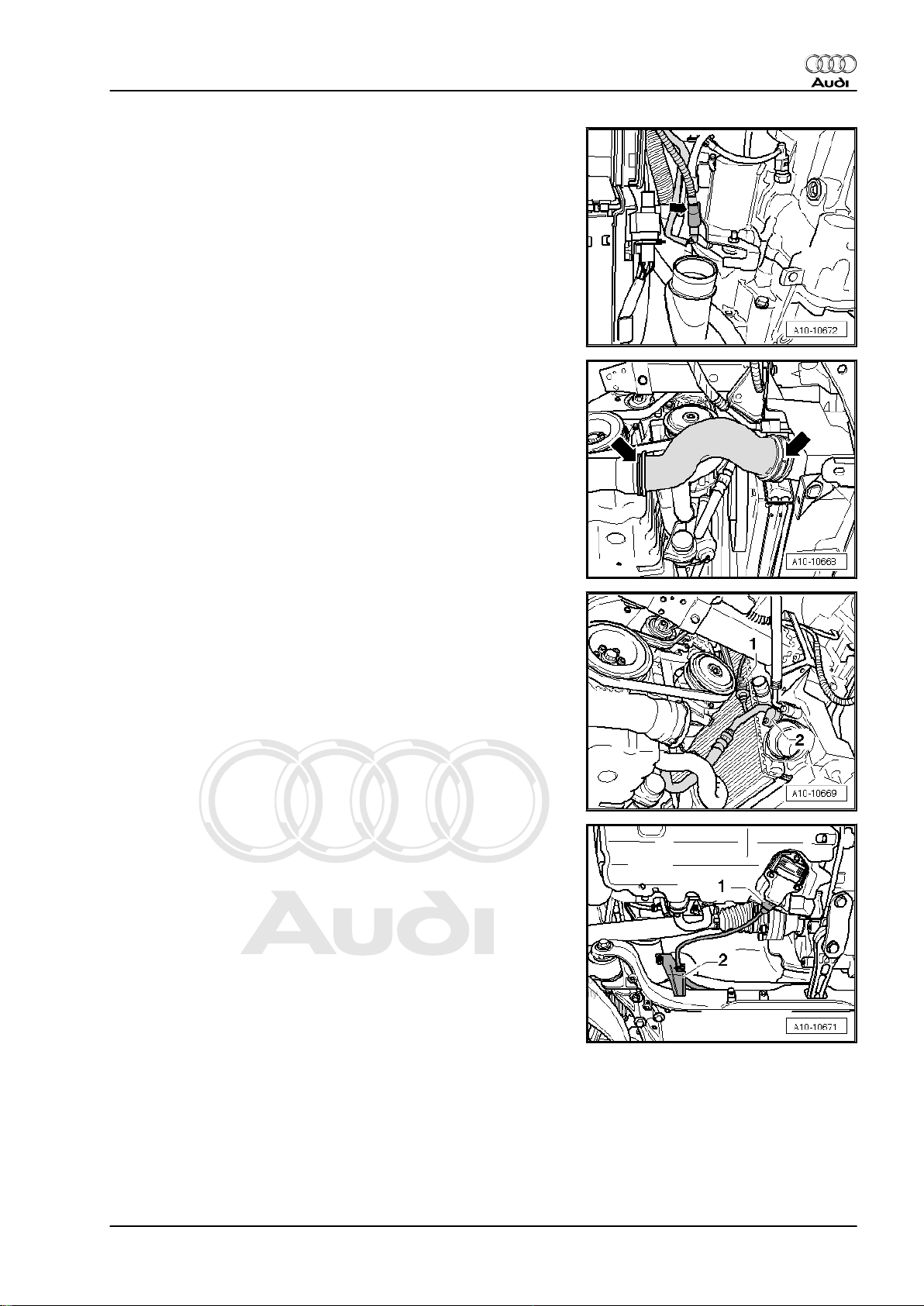

– Unplug engine wiring harness connector -1-.

– Release wiring protector for engine wiring harness -arrow- and

lift off.

Audi TT 2007 ➤

– Open wiring duct brackets -arrows-.

– Move electrical connector -1- clear and unplug connector.

– Open wiring duct bracket located below -2-.

– Open wiring duct bracket -3-.

– Remove engine control unit wiring harness from wiring duct.

1. Removing and installing engine, detaching from gearbox 9

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

Note

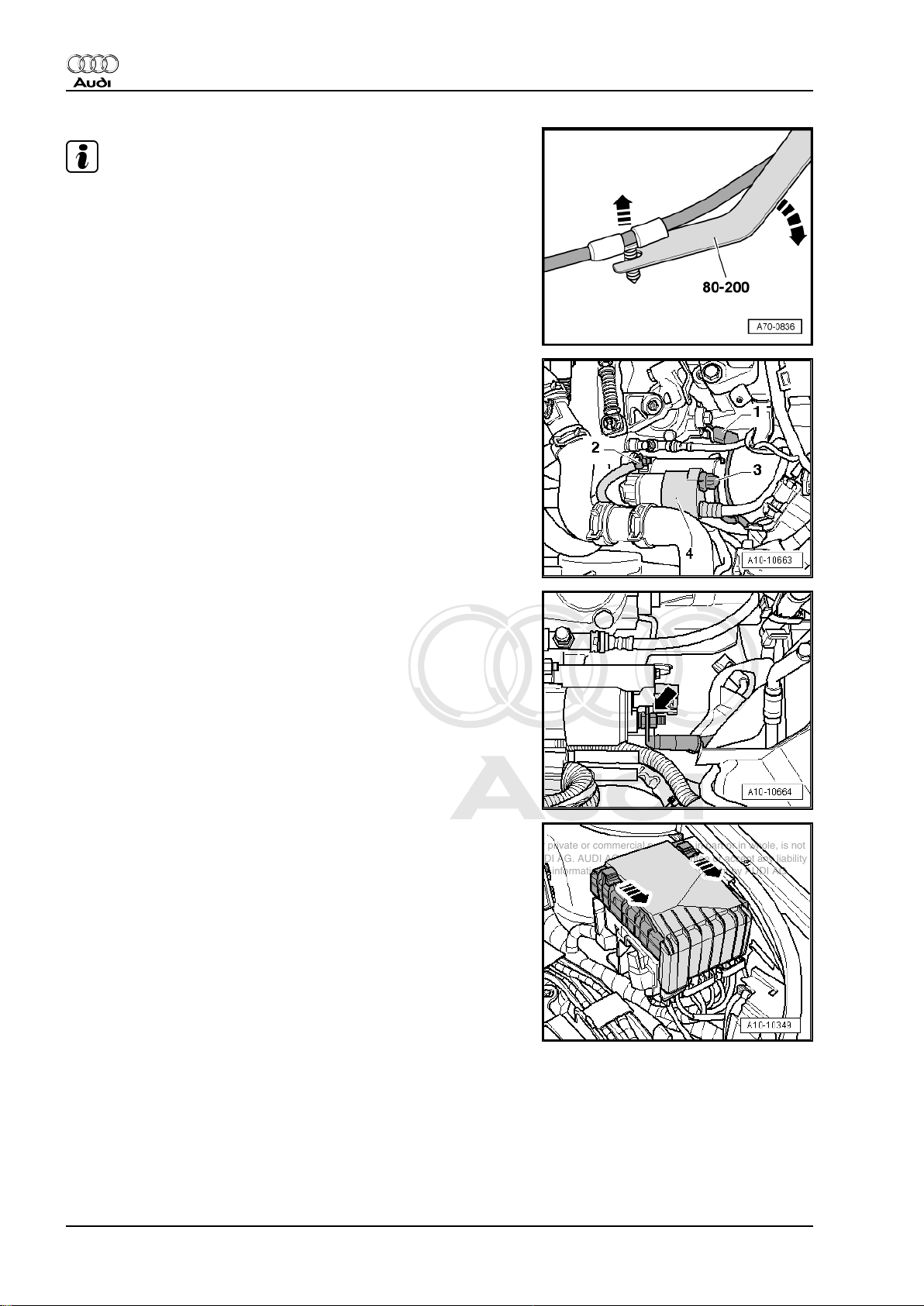

Use removal lever -80 - 200- to lever out the wiring clips.

– Unplug electrical connector -1- for reversing light switch.

– Disconnect earth cable -2-.

– Unplug electrical connector -3-.

– Slide cover -4- to rear.

– Detach wire -arrow- at starter and move clear.

– Press the two clips in direction of the -arrows- and remove

cover from electronics box in engine compartment.

10 Rep. Gr.10 - Removing and installing engine

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Unscrew electrical wire -1- and move clear up to engine.

– Unplug electrical connector -2-.

– Unscrew bolts -1- from above.

Audi TT 2007 ➤

– Place drip tray for workshop hoist -VAS 6208- beneath engine.

– To drain off coolant, detach bottom coolant hose -arrow-.

– Remove air pipe -1 and 2- for charge air cooler.

1. Removing and installing engine, detaching from gearbox 11

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Unplug electrical connector -2-.

– Unscrew the bolts -3- and remove radiator cowl from below.

– Detach top coolant hose from radiator -arrow-.

– Detach coolant hoses going to heat exchanger -arrows-.

– Unscrew securing bolts -arrows- for front exhaust pipe/turbo‐

charger accessible from above.

Note

Shown in illustration from rear with engine removed.

12 Rep. Gr.10 - Removing and installing engine

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

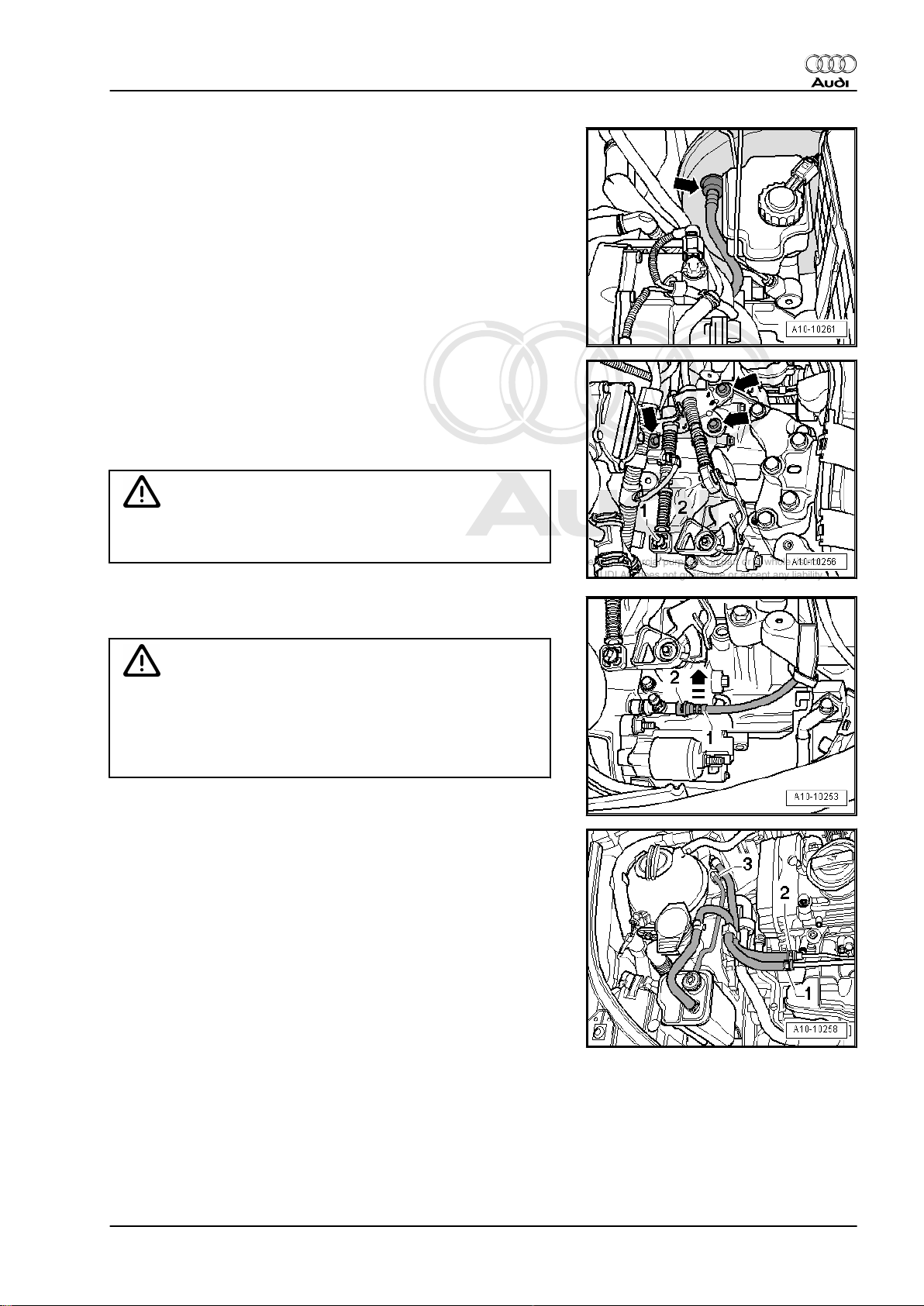

– Disconnect vacuum hose -arrow- leading to brake servo.

– Unclip securing clips -1- and -2- on both selector cables.

– Pull off selector cable end-pieces from gearbox selector lever

and relay lever.

– Detach cable support bracket from gearbox -arrows- and

place to one side.

WARNING

Audi TT 2007 ➤

Do not press clutch pedal after disconnecting hose leading to

slave cylinder.

– Pull out clip -2- as far a stop in -direction of arrow- and detach

hose -1-.

WARNING

Fuel supply line is pressurised. Wear safety goggles and pro‐

tective clothing to avoid possible injury and skin contact. Before

removing from hose connection wrap a cloth around the con‐

nection. Then release pressure by carefully pulling hose off

connection.

– Mark fuel line -2- and line going to ACF -1-.

– Disconnect fuel line -2- and move clear.

– Disconnect ACF line -1- and move clear.

– Disconnect vacuum line -3- going to activated charcoal filter

(press release tabs).

– Lift out ACF.

1. Removing and installing engine, detaching from gearbox 13

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

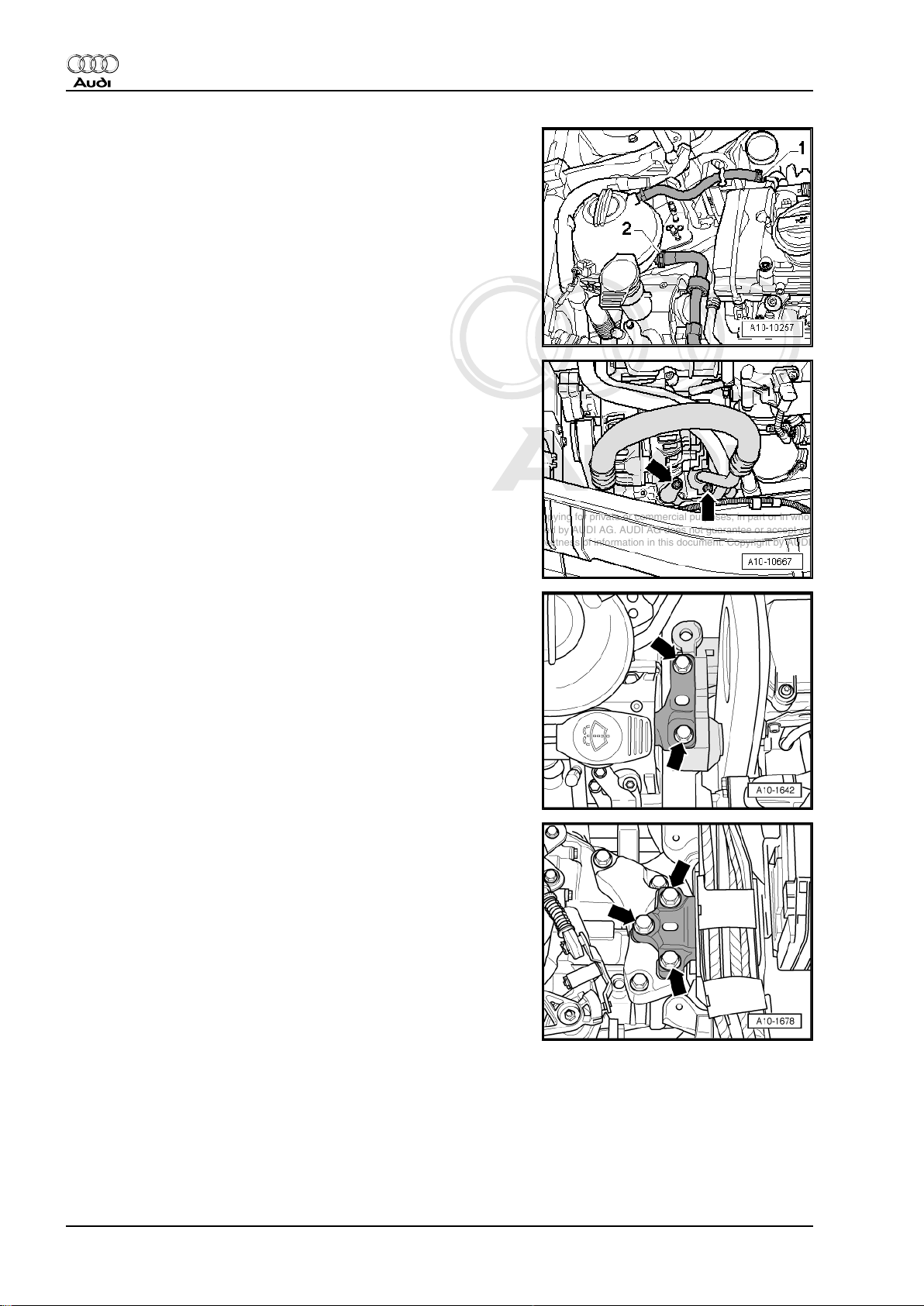

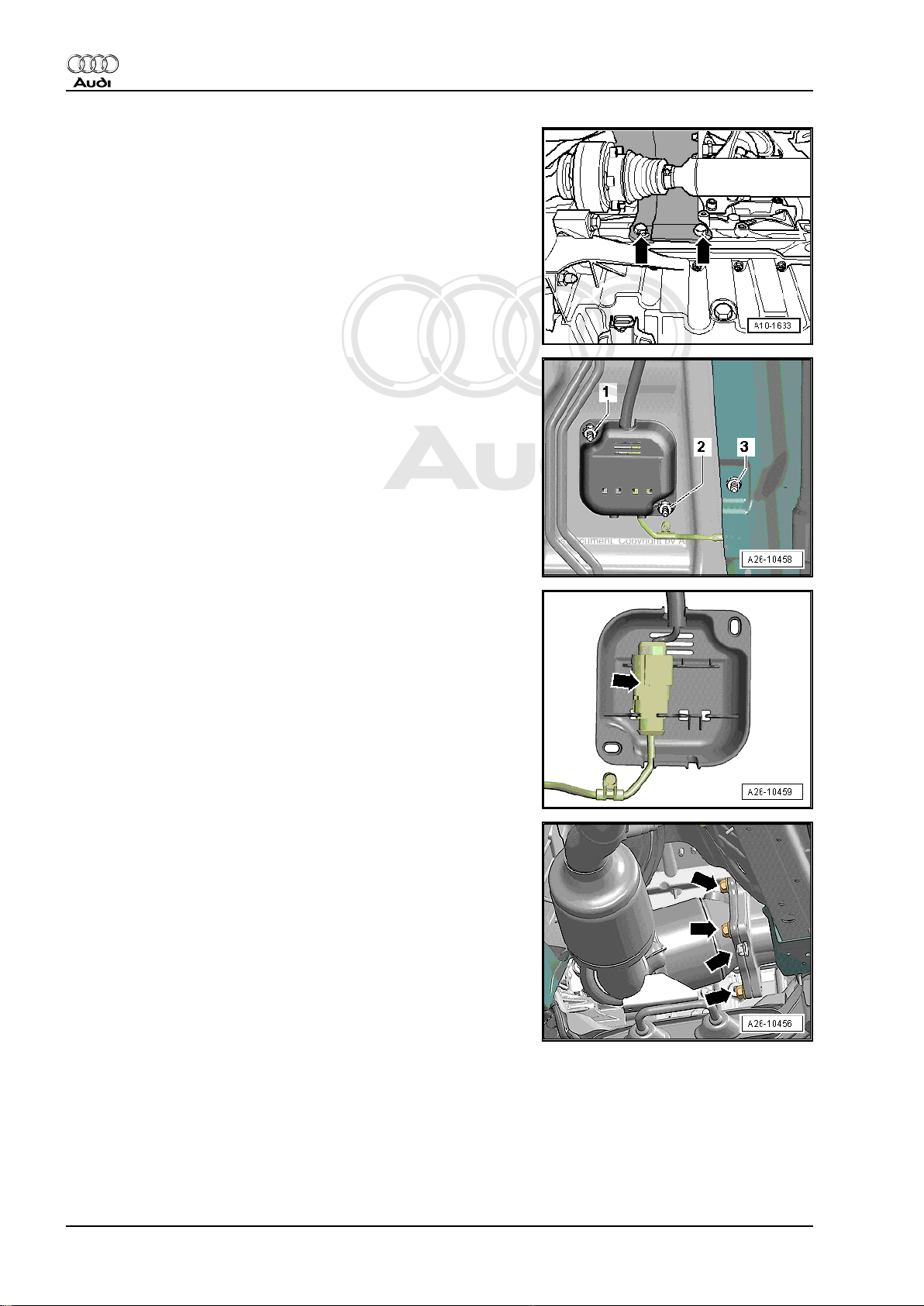

– Detach coolant hoses -1 and 2-.

– Discharge the refrigerant system ⇒ Rep. Gr. 87 ; Air condi‐

tioner system with refrigerant R134a .

– Disconnect air conditioner pipes -arrows- at compressor.

– Plug the openings with sealing plugs from engine bung set -

VAS 6122- .

– Loosen bolts -arrows- of assembly mounting for engine ap‐

prox. 2 turns.

– Loosen bolts -arrows- of assembly mounting for gearbox ap‐

prox. 2 turns.

14 Rep. Gr.10 - Removing and installing engine

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Unplug electrical connector -arrow-.

– Remove air pipe -arrows-.

Audi TT 2007 ➤

– Unplug electrical connector -1- for high-pressure sender -

G65- .

– Detach air conditioner pipe from condenser -2-.

– Unplug electrical connector at oil level sender -1-.

– Unclip bracket -2-.

1. Removing and installing engine, detaching from gearbox 15

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Unbolt heat shield for drive shaft (right-side) -arrows-.

– Remove drive shafts (left and right) ⇒ Rep. Gr. 40 .

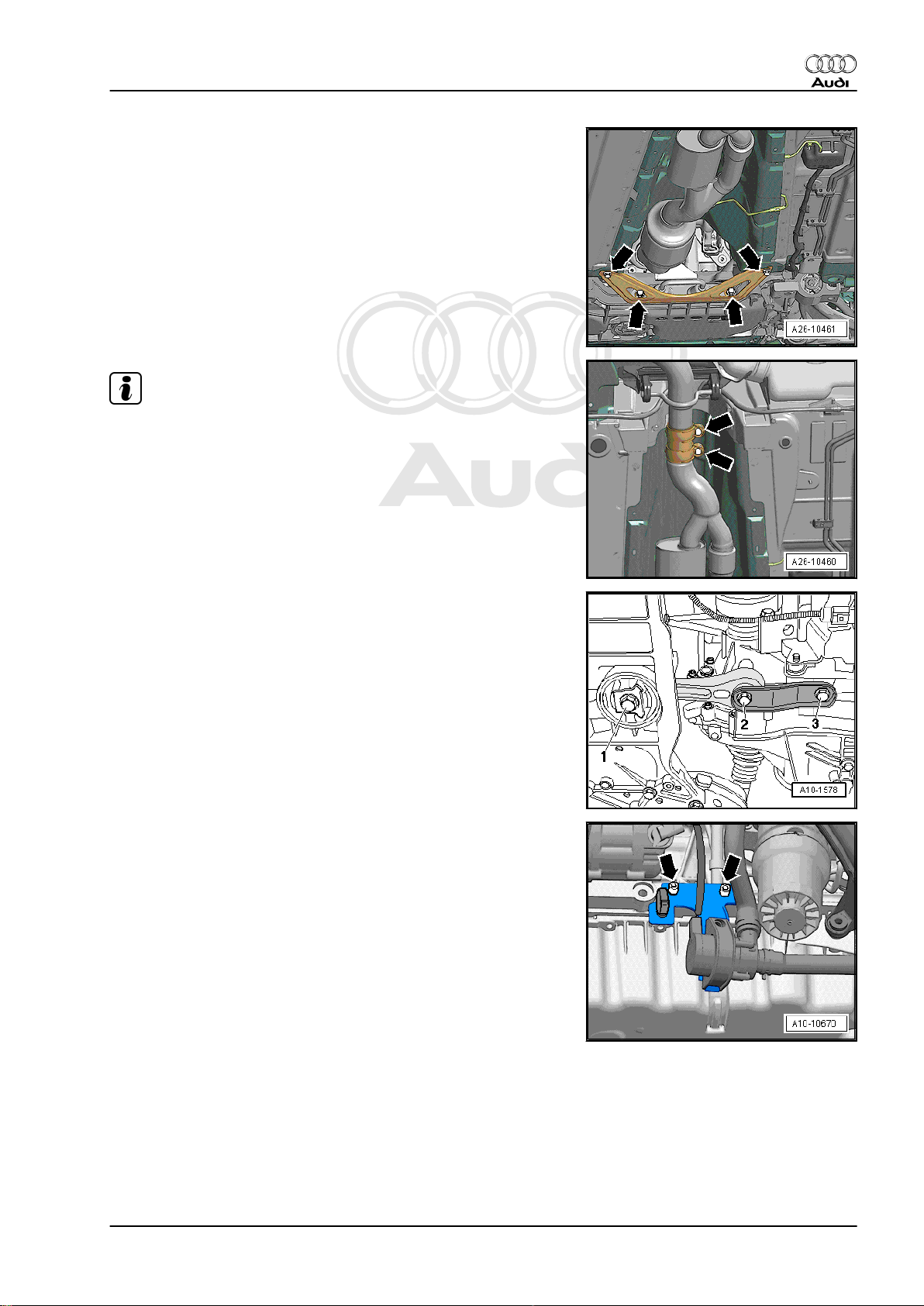

– Remove nuts -1- and -2- on bracket for electrical connector for

Lambda probe on underside of vehicle and remove cover.

– Unscrew bolt -3- and move electrical wire for Lambda probe

clear.

– Detach plug connector from bracket -arrow-.

– Unplug connector for Lambda probe after catalytic converter

-G130- .

– Unscrew remaining securing nuts -arrows- for front exhaust

pipe/turbocharger from below.

16 Rep. Gr.10 - Removing and installing engine

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Unbolt bracket for exhaust system and tunnel brace -arrows-.

Note

To avoid any damage, the flexible joint in the front exhaust pipe

must not be bent more than 10°.

– Separate exhaust system at clamp -arrows-.

– Remove front exhaust pipe with catalytic converter and front

silencer.

Audi TT 2007 ➤

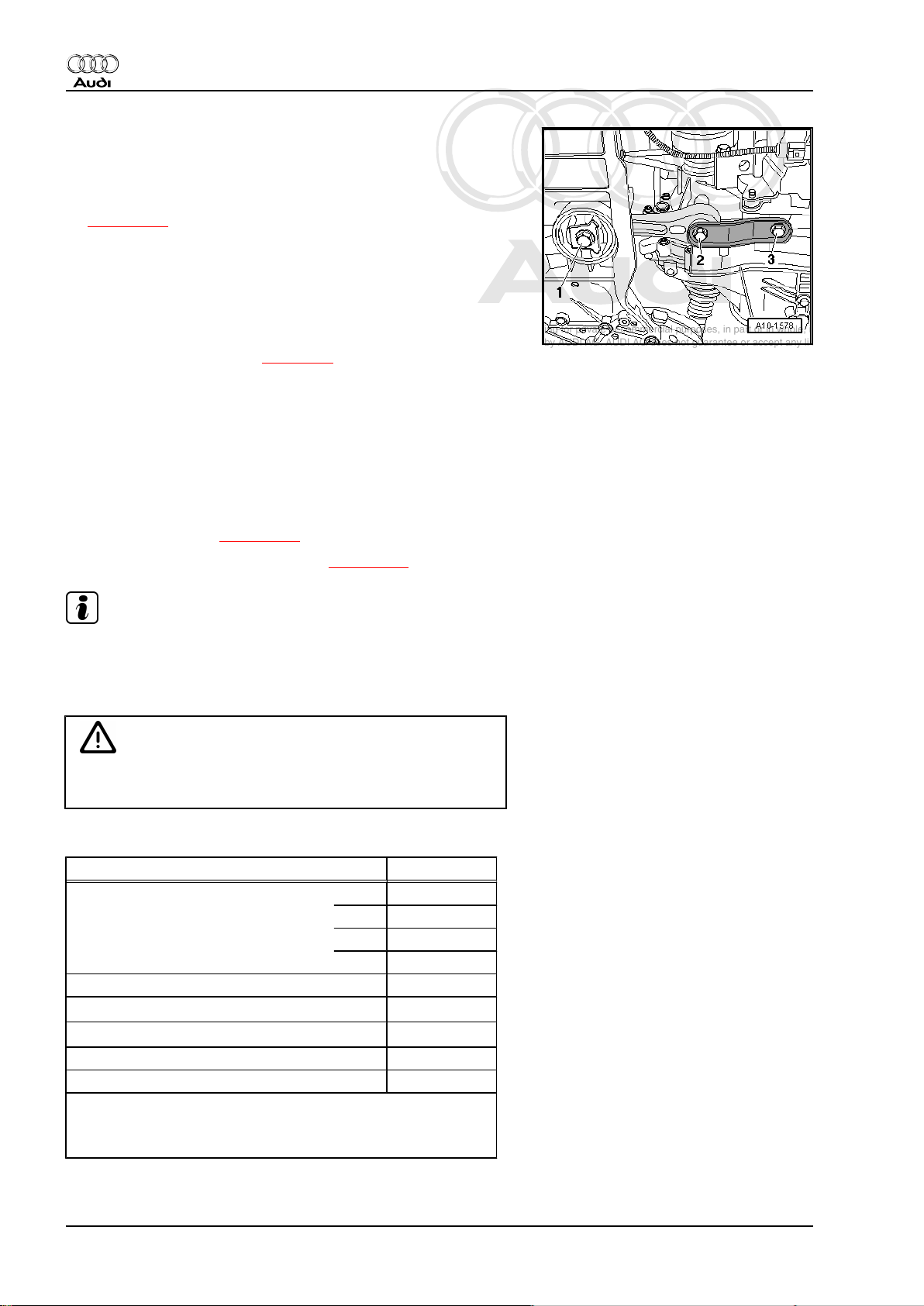

– Remove bolts -1 ... 3- and take out pendulum support.

– Unscrew the additional coolant pump -arrows-.

1. Removing and installing engine, detaching from gearbox 17

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

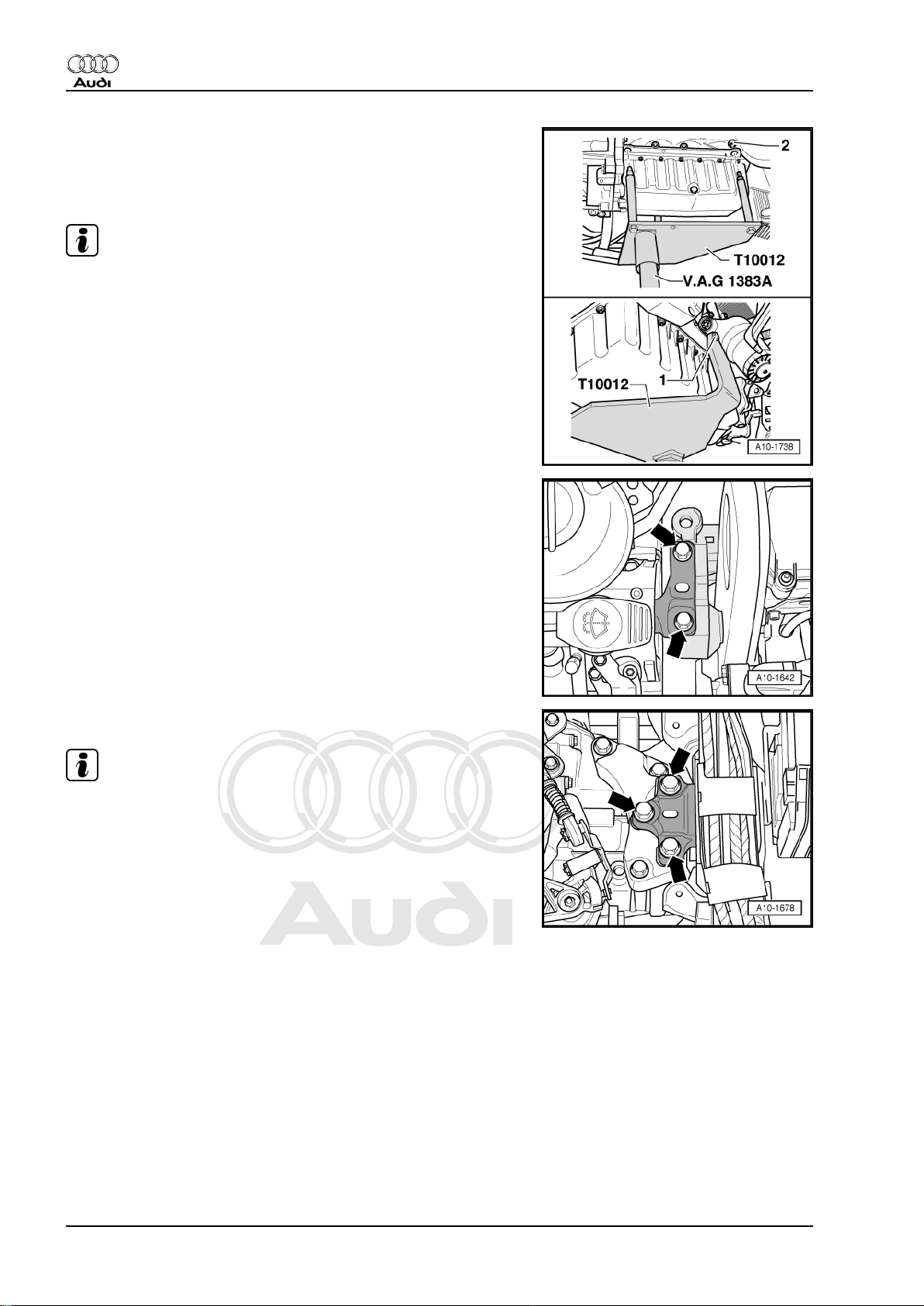

– Bolt engine bracket -T10012- with securing bolt -1- and nut

-2- to cylinder block (tightening torque: approx. 20 Nm).

– Insert engine and gearbox jack -V.A.G 1383 A- in engine

bracket -T10012- and raise engine slightly.

Note

To unscrew bolts for assembly mounting use stepladder -VAS

5085- .

– Remove bolts -arrows- of assembly mounting on engine.

– Remove bolts -arrows- of assembly mounting for gearbox.

Note

♦

Check that all hoses, pipes and wiring connections between

engine, gearbox and body have been detached.

♦

Carefully guide engine/gearbox assembly when lowering to

avoid damage.

– Pull engine/gearbox assembly as far forward as possible, and

lower gradually.

1.2 Separating engine and gearbox

• Engine/gearbox assembly removed and attached to engine

bracket -T10012- .

18 Rep. Gr.10 - Removing and installing engine

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

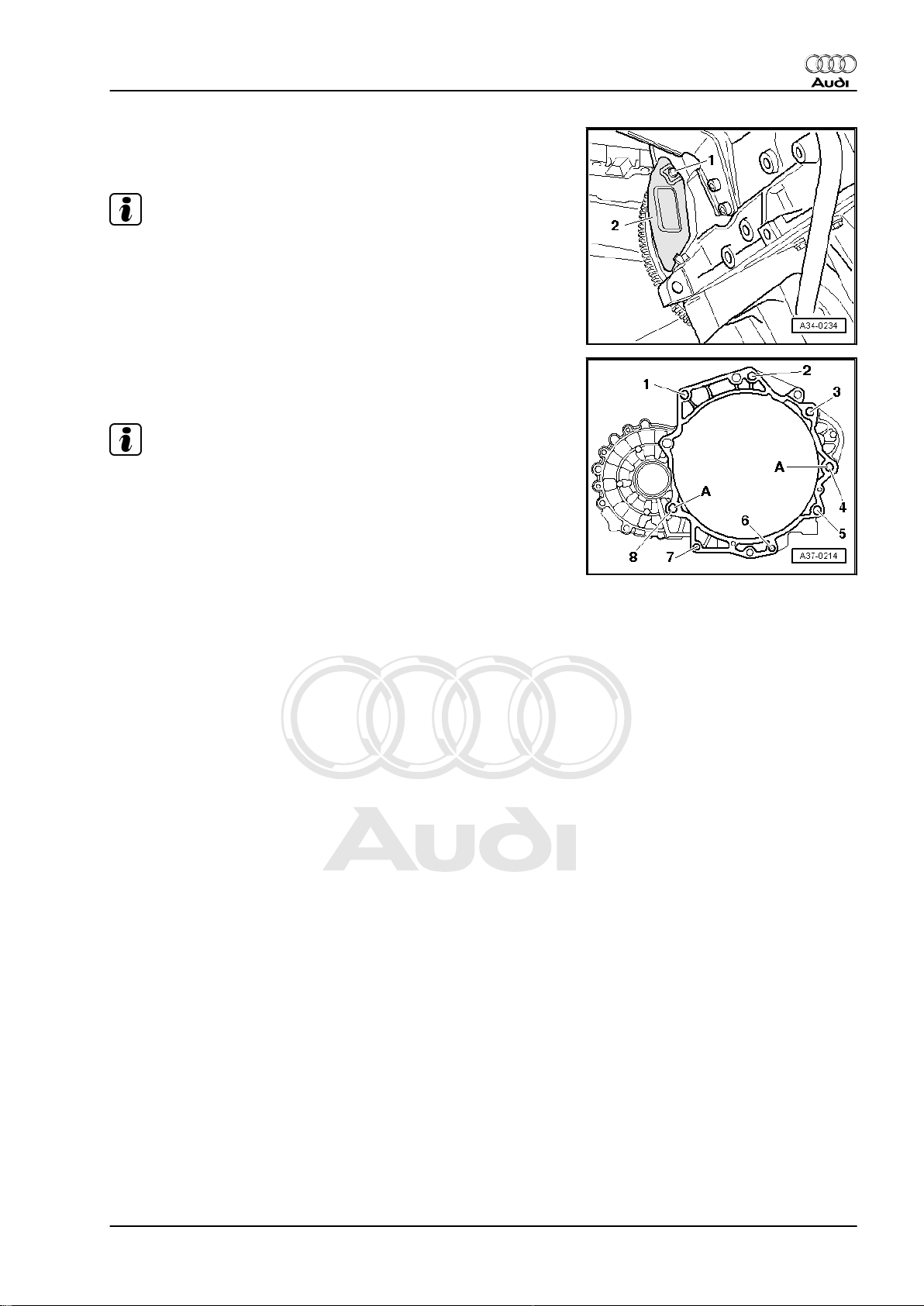

– Unscrew bolt -1- with gearbox installed.

– Pull up cover plate -2- and remove.

Note

Shown in illustration with gearbox removed.

– Remove bolts -1 ... 8- on engine/gearbox flange.

– Detach starter.

Note

The manual gearbox can be detached from the engine without a

workshop hoist, a 2nd mechanic is required for this purpose.

Audi TT 2007 ➤

– Separate gearbox from engine.

1. Removing and installing engine, detaching from gearbox 19

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

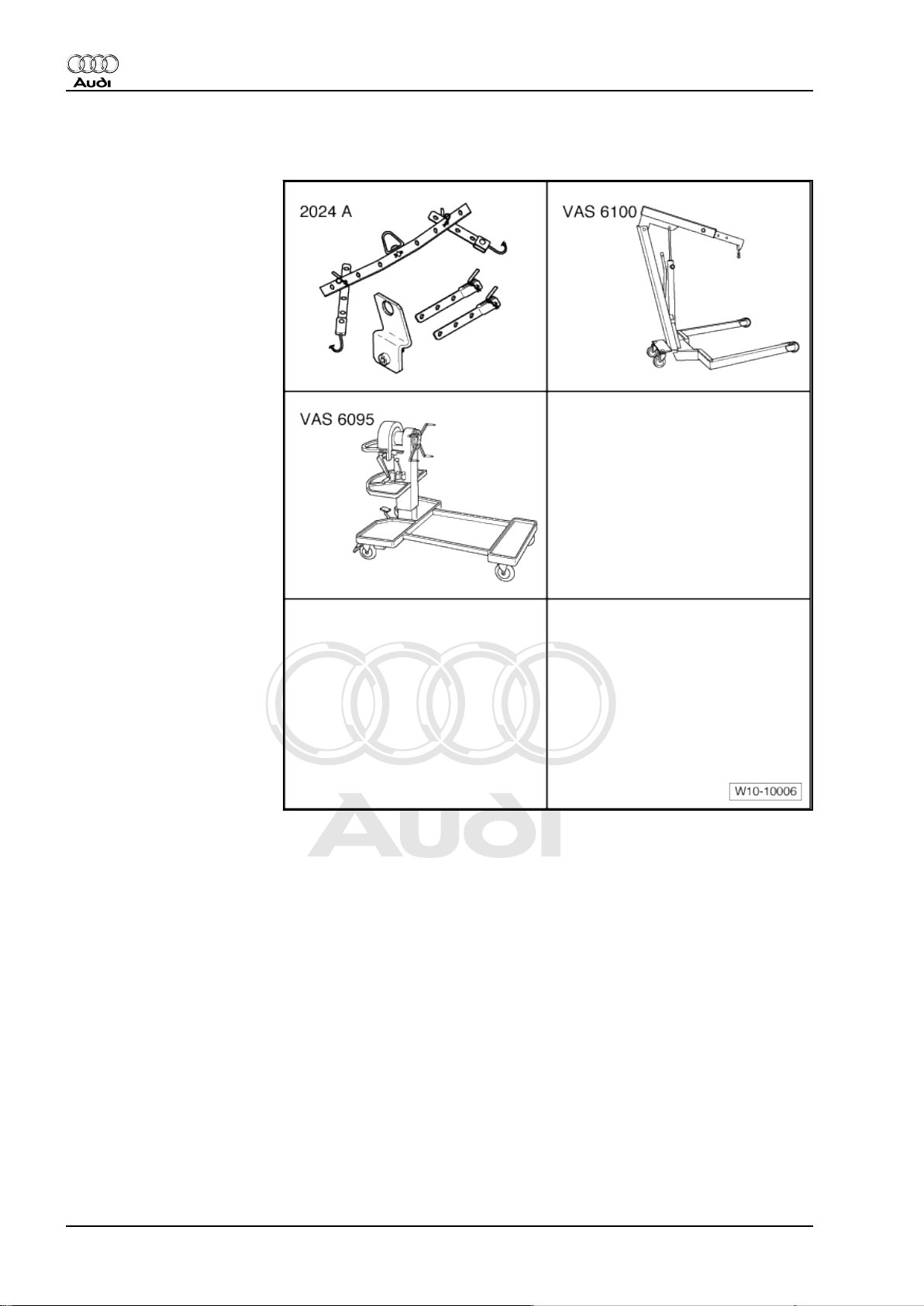

1.3 Securing engine to assembly stand

Special tools and workshop

equipment required

♦ Lifting tackle -2024 A-

♦ Workshop hoist -VAS

6100-

♦ Engine and gearbox sup‐

port -VAS 6095-

• Gearbox detached from engine.

20 Rep. Gr.10 - Removing and installing engine

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Engage lifting tackle -2024 A- on engine and workshop hoist

-VAS 6100- .

Note

To adjust to the centre of gravity of the assembly, the perforated

rails of the support hooks must be positioned as shown.

WARNING

The support hooks and locating pins on the lifting tackle must

be secured with locking pins (arrows in illustration).

– Lift engine off engine bracket -T10012- using workshop hoist

-VAS 6100- .

Secure engine to engine and gearbox support -VAS 6095- when

dismantling/assembling engine.

1.4 Installing engine

Audi TT 2007 ➤

• Engine installed on engine bracket -T10012- .

Installation is carried out in the reverse order; note the following:

Note

♦

Reinstall all cable ties in the same locations when assembling.

♦

Secure all hose connections with the correct type of hose clips

(same as original equipment): ⇒ Parts catalogue

♦

Renew self-locking nuts and bolts when performing assembly

work.

♦

Renew bolts which are tightened to a specified angle as well

as oil seals and gaskets.

♦

Clean input shaft splines and (in the case of used clutch plates)

the hub splines. Remove corrosion and apply only a very thin

coating of grease (⇒ Parts catalogue ) to the splines. Then

move clutch plate back and forth on input shaft until the hub

moves smoothly on the shaft. Remove any excess grease.

– Check whether dowel sleeves for centring the engine/gearbox

assembly are fitted in the cylinder block; install dowel sleeves

if necessary.

1. Removing and installing engine, detaching from gearbox 21

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

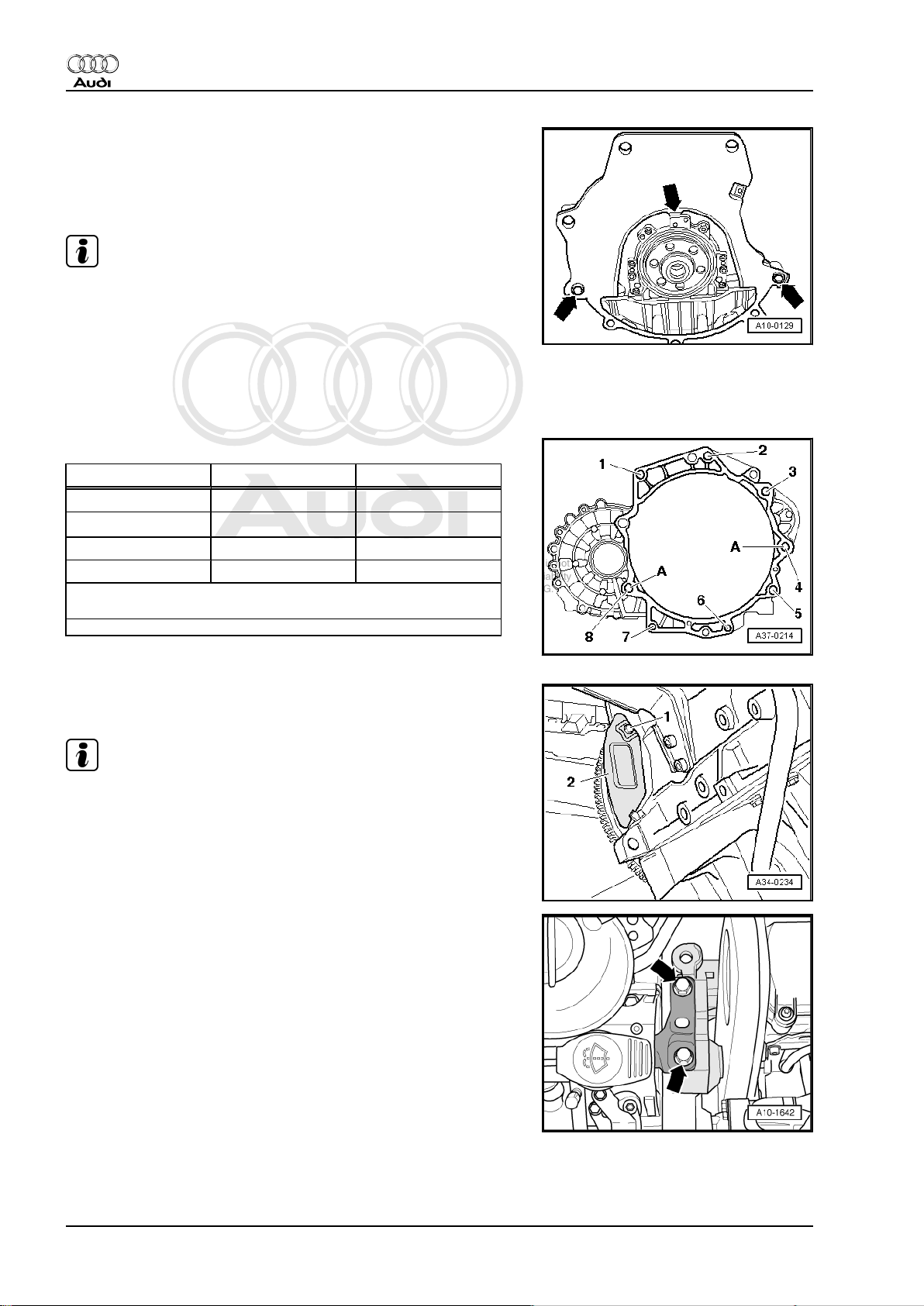

– Ensure that the intermediate plate is engaged on the sealing

flange and pushed onto the dowel sleeves -arrows-.

– Check clutch release bearing for wear; renew if necessary.

– Bolt gearbox to engine.

Note

♦

Tightening torques apply only to lightly greased, oiled,

phosphated or black-finished nuts and bolts.

♦

Additional lubricant such as engine oil or gearbox oil may be

used, but do not use lubricant containing graphite.

♦

Do not use degreased parts.

♦

Tolerance for tightening torques: 15%.

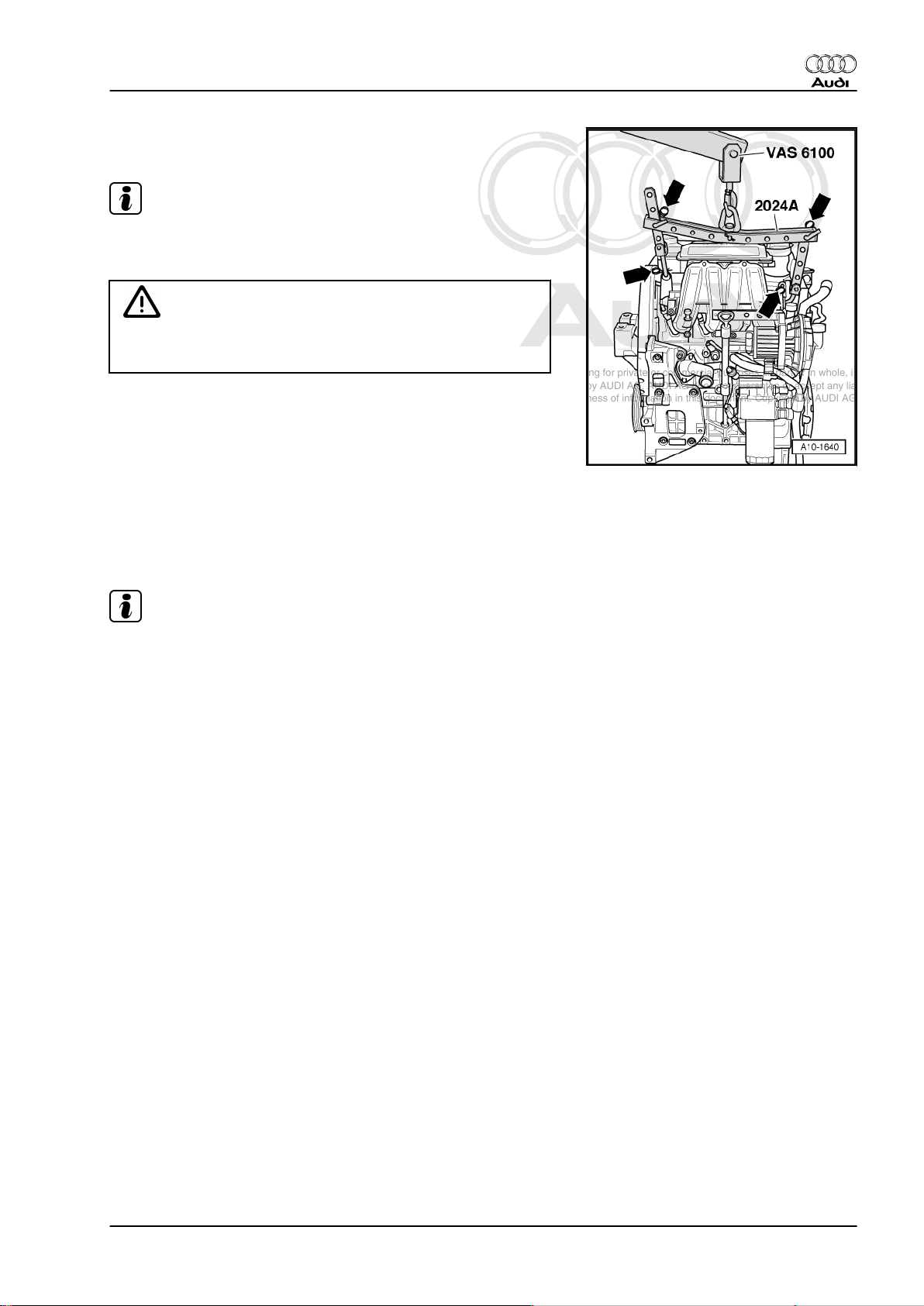

Securing engine to gearbox

Item Bolt Nm

1, 2 M12×65 80

3 1), 4

1)

M12×135 80

5 ... 7 M10×60 40

8 M12×90 65

1)

•

Bolt with M8 stud

A: Centring sleeves

– Push in splash plate -2- in such a way that the lower lug en‐

gages into the cylinder block and secure on top with bolt -1-.

Note

Shown in illustration with gearbox removed.

– Guide engine/gearbox assembly into the body.

– Tighten bolts -arrows- of assembly mounting for engine initially

hand-tight.

22 Rep. Gr.10 - Removing and installing engine

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Tighten bolts of assembly mounting for gearbox -arrows- ini‐

tially hand-tight.

Note

♦

Use new securing bolts.

♦

The bolts are tightened to final torque only after adjusting the

engine mountings ⇒ page 25 .

– Remove engine bracket -T10012- from engine.

Audi TT 2007 ➤

1. Removing and installing engine, detaching from gearbox 23

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Secure pendulum support to gearbox and subframe -1 ... 3-.

– Install drive shafts ⇒ Running gear, front-wheel drive and four-

wheel drive; Repair group 40

– Install exhaust system and align it free of stress

⇒ page 194 .

– Install Lambda probe -G39- ⇒ Rep. Gr. 24 .

– Charge refrigerant circuit ⇒ Air conditioning system; Repair

group 87

– Attach and adjust selector mechanism at gearbox: ⇒ Rep. Gr.

34 .

– Adjust engine mountings ⇒ page 27 .

– Electrical connections and routing: ⇒ Current flow diagrams,

Electrical fault finding and Fitting locations

– Bleed fuel system ⇒ Motronic direct injection and ignition sys‐

tem (4-cylinder); Repair group 24; Servicing fuel injection sys‐

tem

– Check oil level ⇒ Maintenance ; Booklet 810 .

– Connect battery ⇒ Electrical system; Rep. Gr. 27 .

– Fill up with coolant ⇒ page 147 .

– Installing air pipes with connectors ⇒ page 164

Note

♦

Drained-off coolant may only be used again if the original cyl‐

inder head and cylinder block are re-installed.

♦

Contaminated or dirty coolant must not be used again.

WARNING

Never use battery charging equipment for boost starting. There

is danger of damaging the vehicle's control units.

Tightening torque

Component

Nm

Bolts/nuts M6 10

Except for the following:

Pendulum support to gearbox

Pendulum support to subframe

M8 20

M10 45

M12 65

40 + 90°

100 + 90°

1)2)

1)2)

Terminal B+ to starter 16

Earth wire to gearbox 23

1)

•

Renew bolt

2)

•

90° = one quarter turn.

24 Rep. Gr.10 - Removing and installing engine

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

2 Assembly mountings

2.1 Assembly mountings - exploded view

1 - Bolt

❑ Gearbox support to

gearbox

❑ Tightening torque ⇒

Rep. Gr. 34

2 - Bolts

❑ Pendulum support to

gearbox

❑ Renew

❑

40 Nm + 90° (1/4 turn

further).

3 - Engine support

❑ With support arm

4 - Bolt

❑ Engine support to en‐

gine

❑ 45 Nm

5 - Engine mounting

6 - Bolt

❑ Engine mounting to

body

❑ Renew

❑

40 Nm + 90° (1/4 turn

further).

7 - Connecting bracket

8 - Bolt

❑ Connecting bracket to

engine mounting

❑ Renew

❑

20 Nm + 90° (1/4 turn

further).

9 - Bolt

❑ Connecting bracket to body

❑ Renew

❑

20 Nm + 90° (1/4 turn further).

Audi TT 2007 ➤

10 - Bolt

❑ Engine mounting to body

❑ Renew

❑

40 Nm + 90° (1/4 turn further).

11 - Bolts

❑ Engine mounting to engine support

❑ Renew

❑

60 Nm + 90° (1/4 turn further).

2. Assembly mountings 25

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

12 - Pendulum support

13 - Bolt

❑ Pendulum support to subframe

❑ Renew

❑

100 Nm + 90° (1/4 turn further).

14 - Bolt

❑ Gearbox mounting to gearbox support

❑ Tightening torque ⇒ Rep. Gr. 34

15 - Bolt

❑ Gearbox mounting to body

❑ Tightening torque ⇒ Rep. Gr. 34

16 - Gearbox mounting

❑ With support arm

17 - Bolt

❑ Gearbox support to gearbox

❑ Tightening torque ⇒ Rep. Gr. 34

18 - Bolt

❑ Gearbox support to gearbox

❑ Tightening torque ⇒ Rep. Gr. 34

19 - Gearbox support

2.2 Checking adjustment of assembly mountings (engine/gearbox mountings)

Procedure

– Lift out activated charcoal filter from retainer

-in direction of arrow- with pipes connected and lay aside.

26 Rep. Gr.10 - Removing and installing engine

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

Proceed as follows:

– Check distances at mounting (right-side) for engine and gear‐

box:

• The two bolt heads -2- must be parallel with edge of support

arm -3- for engine mounting.

• There must be a distance of -x- = 16 mm between engine

mounting -1- and engine support -4-.

Note

Distance -x- = 16 mm can also be checked with a metal rod of

suitable size, or similar.

– If the distance measured is too large or small, the assembly

mountings must be adjusted ⇒ page 27 .

2.3 Adjusting assembly mountings

Special tools and workshop

equipment required

♦ Support bracket -10 - 222

A-

♦ 2x spindle -10 - 222 A /11-

♦ Adapter -10 - 222 A /20-

(2x)

♦ Hooks -10 - 222 A /2-

♦ Engine support bracket

(basic set) -T40091-

♦ Engine support bracket

(supplementary set) T40093- with -T40093/3-2and -T40093/3-3-

Audi TT 2007 ➤

Proceed as follows:

• Tightening torques ⇒ page 25 .

2. Assembly mountings 27

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Unplug electrical connector at air mass meter -G70- -3-.

– Open clamps -1 and 2- and disconnect air intake hose from

air mass meter.

– Detach air intake connection at lock carrier -4-.

– Pull off engine cover panel.

– Pull activated charcoal filter with hoses attached upwards out

of the retainer -arrow- and place to side.

– Remove bracket for activated charcoal filter.

– Disconnect coolant pipe -arrows-.

– Detach gear selector cable -arrow-.

28 Rep. Gr.10 - Removing and installing engine

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Position support bracket -10 - 222 A- on bolted flanges of wing

panels using the following tools:

♦ 2x Rack -10 - 222 A /1-

♦ Support bracket -10 - 222 A-

♦ Spindle -10 - 222 A /11- (spindle faces front)

♦ Hooks -10 - 222 A /2-

♦ Adapter -10 - 222 A /20-

♦ Connecting piece -T40091/3- (2x)

– Attach spindle -10 - 222 A /11- with hook -10 - 222 A /2- and

adapter -10 - 222 A /20- to gearbox lifting eye.

– Tighten spindle slightly to take up weight of engine/gearbox

assembly.

– Fit adapter -T40092/3-2- (left-side) and -T40093/3-3- (right-

side) to supports -T40093/3- .

– Unbolt earth wire from longitudinal member (left-side).

– Remove connecting bolt for front section of longitudinal mem‐

ber on left and right.

– Secure adapter -T40092/3-2- (left-side) and -T40093/3-3-

(right-side) to longitudinal members using the removed bolts

-arrow-.

Note

Audi TT 2007 ➤

The illustration shows the left side of the vehicle.

– Fit square-section pipes -T40091/1- with connecting pieces -

T40093/4- into connecting pieces -T40091/3- and supports T40093/3-- as shown in illustration.

2. Assembly mountings 29

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Push support -T40091/2- with sliding support -T40093/5- into

the two connecting pieces -T40093/4- .

WARNING

Accident risk from loose components of support bracket.

♦ Secure support -T10091/2- with pins and split pins of con‐

necting pieces -T40093/4- .

♦ Secure connecting pieces and supports with clamping

bolts.

– Fit spindle -10 - 222 A /11- with adapter -10 - 222 A /20- onto

sliding support and onto engine lifting eye.

– Take up weight of engine/gearbox assembly by evenly tight‐

ening two spindles.

– Unscrew bolts -arrows- on engine assembly mounting one af‐

ter the other, renew them (if not already renewed when engine

was installed) and screw in loosely.

– Unscrew bolts -arrows- on gearbox assembly mounting one

after the other, renew them (if not already renewed when en‐

gine was installed) and screw in loosely.

– Slacken bolts on left and right-hand support arms by about two

turns each.

30 Rep. Gr.10 - Removing and installing engine

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Using a tyre iron, adjust engine/gearbox assembly between

engine mounting -1- and engine support -4- until the specifi‐

cations listed below are obtained:

• The two bolt heads -2- must be parallel with the edge of the

support arm -3-.

• There must be a distance of -x- = 16 mm between engine

mounting -1- and engine support -4-.

Note

Distance -x- = 16 mm can also be checked with a metal rod of

suitable size, or similar.

– Tighten bolts of assembly mounting at gearbox.

– Ensure that the edges of the support arm (on the gearbox as‐

sembly mounting) -1- and gearbox mounting -2- are parallel.

• Dimension -x- must be identical on both sides of mounting.

– Tighten bolts for assembly mounting.

Remaining installation steps are carried out in reverse sequence;

note the following:

– Tighten bolts for front section of longitudinal member ⇒ Rep.

Gr. 50 .

Audi TT 2007 ➤

2. Assembly mountings 31

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

13 – Crankshaft group

1 Cylinder block (pulley end)

1.1 Poly V-belt, bracket for ancillaries - ex‐

ploded view

Note

Before removing, mark direction of rotation of poly V-belt with

chalk or felt-tipped pen. If the belt runs in the opposite direction

when it is refitted, this can cause breakage. Ensure that the belt

is properly seated in the pulleys when installing.

1 - Vibration damper

❑ For poly V-belt

❑ Removing and installing

⇒ page 38

2 - Bolt

❑ 10 Nm + 90°

Renew ⇒ Parts catalogue

3 - Bolt

❑ 23 Nm

4 - Tensioner for poly V-belt

❑ Pivot with open-end

spanner to slacken poly

V-belt

❑ Secure tensioner in po‐

sition using locking pin T10060A-

5 - Bracket for ancillaries

❑ Removing and installing

⇒ page 35

❑ Tightening sequence

⇒ page 33

6 - Bolt

❑ 23 Nm

7 - Nut

❑ 23 Nm

8 - Alternator

❑ Removing and installing

⇒ Electrical system; Re‐

pair group 27

❑ To facilitate attachment

of alternator, knock

back threaded bushes for alternator securing bolts slightly

9 - Bolt

❑ Apply locking fluid when fitting

❑ Locking fluid ⇒ Parts catalogue

32 Rep. Gr.13 - Crankshaft group

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

❑ Tightening sequence ⇒ page 33

10 - Bush

❑ 2 x

11 - Bolt

❑ 25 Nm

12 - Air conditioner compressor

❑ Removing and installing ⇒ Air conditioning; Repair group 87

13 - Poly V-belt

❑ Routing of poly V-belt ⇒ page 33

❑ Check for wear

❑ Do not kink

❑ Removing and installing ⇒ page 33

Routing of poly V-belt

Audi TT 2007 ➤

Tightening sequence on bracket for ancillaries

– Proceed as follows:

1. Screw in bolts -1 ... 6- hand-tight.

2. Tighten bolts -1 ... 6- to 45 Nm.

1.2 Removing and installing poly V-belt

Special tools and workshop equipment required

1. Cylinder block (pulley end) 33

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

♦ Locking pin -T10060A-

Removing

– Unplug electrical connector at air mass meter -G70- -3-.

– Open clamps -1 and 2- and disconnect air intake hose from

air mass meter.

– Detach air intake connection at lock carrier -4-.

– Pull off engine cover panel.

– Lift out activated charcoal filter from retainer with pipes con‐

nected -arrow- and lay aside.

Note

Before removing, mark direction of rotation of poly V-belt with

chalk or felt-tipped pen. If the belt runs in the opposite direction

when it is refitted, this can cause breakage.

– Mark direction of rotation of poly V-belt.

– To slacken poly V-belt, turn tensioner in -direction of arrow-.

34 Rep. Gr.13 - Crankshaft group

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Lock tensioner in position with locking pin -T10060A- .

– Remove poly V-belt.

Installing

Installation is carried out in the reverse order; note the following:

Note

Before fitting poly V-belt, make sure all ancillary units (alternator

and air-conditioner compressor) are firmly secured.

– Fit the poly V-belt onto the crankshaft and air conditioner com‐

pressor pulleys.

– Then position poly V-belt on alternator pulley and release ten‐

sioner.

– Check that poly V-belt is properly seated.

– Start engine and check that belt runs properly.

Audi TT 2007 ➤

1.3 Removing and installing bracket for an‐

cillaries

Special tools and workshop equipment required

♦ Locking pin -T10060A-

1. Cylinder block (pulley end) 35

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

Removing

– Unplug electrical connector at air mass meter -G70- -3-.

– Open clamps -1 and 2- and disconnect air intake hose from

air mass meter.

– Detach air intake connection at lock carrier -4-.

– Pull off engine cover panel.

– Lift out activated charcoal filter from retainer with pipes con‐

nected -arrow- and lay aside.

Note

Before removing, mark direction of rotation of poly V-belt with

chalk or felt-tipped pen. If the belt runs in the opposite direction

when it is refitted, this can cause breakage.

– To slacken poly V-belt, turn tensioner in -direction of arrow-.

– Lock tensioner in position with locking pin -T10060A- .

– Take off poly V-belt.

36 Rep. Gr.13 - Crankshaft group

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Remove tensioner for poly V-belt -arrows-.

– Discharge the refrigerant system ⇒ Rep. Gr. 87 ; Air condi‐

tioner system with refrigerant R134a .

– Remove alternator ⇒ Electrical system; Repair group 27 .

– Remove centre noise insulation -fasteners 1 ... 4-.

Audi TT 2007 ➤

– Remove right noise insulation -arrows-.

– Remove noise insulation frame -arrow-.

– Remove air conditioner compressor ⇒ Rep. Gr. 87 ; Heating,

air conditioning system .

1. Cylinder block (pulley end) 37

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Detach bracket for ancillaries: bolts -1 … 6-.

Installing

Installation is carried out in the reverse order; note the following:

• Tightening torques ⇒ page 32

– Tighten bolts in the sequence -1 ... 6-.

– Install alternator ⇒ Electrical system; Repair group 27 .

– Install air conditioner compressor ⇒ Rep. Gr. 87 ; Heating, air

conditioning system .

– Install poly V-belt ⇒ page 33 .

– Connect battery. Procedures required ⇒ Electrical system;

Repair group 27 .

1.4 Removing and installing vibration damp‐

er

Removing

• Poly V-belt must be removed ⇒ page 33 .

– Remove centre noise insulation -fasteners 1 ... 4-.

38 Rep. Gr.13 - Crankshaft group

Page 45

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Remove right noise insulation -arrows-.

– Remove noise insulation frame -arrow-.

Audi TT 2007 ➤

– Unscrew vibration damper and remove.

Note

To loosen and tighten the vibration damper, counterhold with ring

spanner on centre bolt.

Installing

Installation is carried out in the reverse order; note the following:

• Tightening torques ⇒ page 32

– When installing the vibration damper, use only genuine bolts

(same as original equipment): ⇒ Parts catalogue .

♦ The vibration damper can only be installed in one position. The

hole -arrow- in the crankshaft vibration damper must be loca‐

ted over the projection on the toothed belt sprocket.

1. Cylinder block (pulley end) 39

Page 46

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

1.5 Front sealing flange - exploded view

1 - Bolt

❑

90 Nm + 90° (1/4 turn)

further

❑ Renew

❑ Do not lubricate with oil

❑ Attaching counterhold

tool 3415

2 - Crankshaft sprocket

❑ Contact surface be‐

tween sprocket and

crankshaft must be free

of oil

❑ Can only be installed in

one position

3 - Bolt

❑ Tightening sequence

⇒ page 40

4 - Oil seal

❑ Renewing ⇒ page 41

❑ Do not lubricate with oil

5 - Sealing flange (front)

❑ Must be positioned on

dowel pins

❑ Removing and installing

⇒ page 44

6 - Dowel pins

7 - Diamond-coated washer for

toothed belt sprocket

❑ Renew washer if tooth‐

ed belt sprocket is re‐

moved

8 - Bolt

❑ Tightening sequence ⇒ page 40

9 - Cylinder block

❑ Removing and installing crankshaft ⇒ page 53

❑ Dismantling and assembling pistons and conrods ⇒ page 60

⇒ page 65

Tightening sequence for front sealing flange

– Proceed as follows:

1. Screw in bolts -1 ... 10- hand-tight.

2. Tighten bolts -1 ... 6- in diagonal sequence and in stages to

15 Nm.

3. Tighten bolts -7 ... 10- to 15 Nm.

40 Rep. Gr.13 - Crankshaft group

Page 47

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

1.6 Renewing crankshaft oil seal - pulley end

Special tools and workshop

equipment required

♦ Oil seal extractor -3203-

♦ Counterhold tool -3415-

♦ Assembly tool -T10053-

♦ Torque wrench -V.A.G

1331-

♦ Torque wrench -V.A.G

1332-

Audi TT 2007 ➤

Removing

– Remove poly V-belt ⇒ page 33 .

– Remove toothed belt ⇒ page 63 .

– Remove crankshaft toothed belt sprocket. To do this, counter-

hold sprocket with special tool -3415- .

1. Cylinder block (pulley end) 41

Page 48

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Unscrew central bolt -1- for crankshaft toothed belt sprocket

-2- and remove sprocket.

– Remove diamond-coated washer -3- from toothed belt sprock‐

et.

– To guide oil seal extractor, screw central bolt into crankshaft

onto stop by hand.

– Unscrew inner part of oil seal extractor -3203- nine turns (ap‐

prox. 20 mm) from the outer part and lock in position with the

knurled screw.

– Lubricate threaded head of oil seal extractor -3203- , place it

in position and, while exerting firm pressure, screw it into oil

seal as far as possible.

– Loosen knurled screw and turn inner part against crankshaft

until oil seal is pulled out.

– Clamp flats of oil seal extractor in vice. Remove oil seal with

pliers.

Installing

• Tightening torques ⇒ page 40

– Clean contact surface and sealing surface.

– Remove oil residue from crankshaft journal with a clean cloth.

– Position guide sleeve T10053/1 from assembly tool -T10053-

on crankshaft journal.

– Push oil seal over guide sleeve onto crankshaft journal.

– Press in oil seal with central bolt of toothed belt sprocket and

thrust sleeve of assembly tool -T10053- until flush.

42 Rep. Gr.13 - Crankshaft group

Page 49

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Install crankshaft toothed belt sprocket -2- with new diamond-

coated washer -3- and new central bolt -1-.

Note

♦

Contact surfaces between toothed belt sprocket, diamondcoated washer and crankshaft must be free of oil.

♦

Do not lubricate bolt for crankshaft sprocket.

– Use counterhold tool -3415- to tighten crankshaft toothed belt

sprocket.

Fit toothed belt (adjust valve timing) ⇒ page 66

– Install poly V-belt ⇒ page 33 .

Audi TT 2007 ➤

1. Cylinder block (pulley end) 43

Page 50

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

1.7 Removing and installing sealing flange (front)

Special tools and workshop

equipment required

♦ Counterhold tool -3415-

♦ Assembly tool -T10053-

♦ Torque wrench -V.A.G

1331-

♦ Torque wrench -V.A.G

1332-

♦ Electric drill with plastic

brush attachment

♦ Safety goggles

♦ Sealant ⇒ Parts catalogue

Removing

– Remove poly V-belt ⇒ page 33 .

– Remove toothed belt ⇒ page 63 .

– Remove crankshaft toothed belt sprocket. To do this, counter-

hold sprocket with special tool -3415- .

44 Rep. Gr.13 - Crankshaft group

Page 51

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Unscrew central bolt -1- for crankshaft toothed belt sprocket

-2- and remove sprocket.

– Remove diamond-coated washer -3- from toothed belt sprock‐

et.

– Remove bolts -1 ... 10-.

– Lever off front sealing flange and remove.

– Drive out oil seal with flange removed.

Installing

• Tightening torque ⇒ page 40

Audi TT 2007 ➤

Note

Place a cloth over the exposed section of the sump.

– Carefully remove any sealant residue on the cylinder block

and sump.

WARNING

Wear safety goggles.

– Remove sealant residue from sealing flange with rotating plas‐

tic brush or similar.

– Clean sealing surfaces; they must be free of oil and grease.

– Cut off tube nozzle at front marking (nozzle approx. 2 mm ∅).

1. Cylinder block (pulley end) 45

Page 52

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Apply a thin bead of sealant at the edge of the joint between

the cylinder block and the sump -arrows-.

– Apply the bead of sealant onto the clean sealing surface of the

sealing flange as illustrated -arrow-.

• Thickness of sealant bead: 2 ... 3 mm

Caution

Make sure oil strainer is not clogged by excess sealant.

♦ The bead of sealant must not be thicker than specified.

Note

Sealant bead must not be wider than 3 mm, otherwise excess

sealant could ingress into sump and clog strainer in oil intake pipe.

– Coat the lower sealing surface on the sealing flange lightly with

sealant -hatched area-.

Note

The sealing flange must be installed within 5 minutes after apply‐

ing sealant.

– Push the sealing flange carefully onto the dowel sleeves on

the cylinder block.

Note

Use guide sleeve -T10053/1- to attach sealing flange with oil seal

fitted.

– Tighten sealing flange bolts in three stages as follows:

1. Screw in bolts -1 ... 10- hand-tight.

2. Tighten bolts -1 ... 6- in diagonal sequence and in stages.

3. Tighten bolts -7 ... 10-.

– Install crankshaft oil seal (pulley end) ⇒ page 42 .

46 Rep. Gr.13 - Crankshaft group

Page 53

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

– Install crankshaft toothed belt sprocket -2- with new diamond-

coated washer -3- and new central bolt -1-.

Note

♦

Contact surfaces between toothed belt sprocket, diamondcoated washer and crankshaft must be free of oil.

♦

Do not lubricate bolt for crankshaft sprocket.

– Use counterhold tool -3415- to tighten crankshaft toothed belt

sprocket.

Remaining installation steps are carried out in reverse sequence;

note the following:

Installing toothed belt and adjusting valve timing ⇒ page 66 .

– Install vibration damper ⇒ page 38 .

– Install poly V-belt ⇒ page 33 .

Audi TT 2007 ➤

1. Cylinder block (pulley end) 47

Page 54

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder direct petrol injection engine (2.0 ltr. 4-valve turbo), mechanics - Edition 11.2006

2 Cylinder block (gearbox end)

2.1 Rear sealing flange and dual-mass flywheel - exploded view

Note

Servicing clutch:⇒ Rep. Gr. 30

1 - Bolt

❑ For dual-mass flywheel/

drive plate

❑ 60 + 90° (60 Nm + 90°

(1/4 turn) further

❑ Renew

2 - Dual-mass flywheel

❑ Removing and installing

dual-mass flywheel

⇒ page 49

❑ Can only be installed in

one position. Holes are

off-set

3 - Intermediate plate

❑ Must be positioned on

dowel sleeves

❑ Do not damage/bend

when assembling

❑ Is fitted on sealing

flange ⇒ page 49

4 - Bolt

❑ Tightening sequence

⇒ page 49

5 - Sealing flange with oil seal

(rear)

❑ Renew only as com‐

plete unit

❑ Use guide sleeve provi‐

ded when fitting

❑ Removing and installing

⇒ page 50

❑ Do not lubricate/grease

sealing lip of oil seal

❑ Before installing, remove oil residue from crankshaft journal with a clean cloth.

❑ Guide sleeve is not to be removed until sealing flange has been slipped onto crankshaft journal

6 - Dowel pin