Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail),

mechanics

Engine ID

Edition 04.2010

CBB

B

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

00 - Technical data

10 - Removing and installing engine

13 - Crankshaft group

15 - Cylinder head, valve gear

17 - Lubrication

19 - Cooling

21 - Turbocharging/supercharging

26 - Exhaust system

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A005TT02220

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Engine number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Engine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4 General repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Rules for cleanliness when working on fuel supply system, injection system and

turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 Checking for leaks in the fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.3 Contact corrosion! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.4 Checking vacuum system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.5 Routing and attachment of pipes, hoses and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

10 - Removing and installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1 Removing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Separating engine from manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3 Securing engine to engine and gearbox support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4 Installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5 Assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 Assembly mountings - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2 Checking adjustment of assembly mountings (engine/gearbox mountings) . . . . . . . . . . . . 38

5.3 Adjusting assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

13 - Crankshaft group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1 Cylinder block (pulley end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1.1 Poly V-belt drive with tensioner and air conditioner compressor - exploded view . . . . . . . . 43

1.2 Removing and installing poly V-belt - vehicles with tensioner and air conditioner

compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1.3 Removing and installing tensioner for poly V-belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1.4 Poly V-belt drive without air conditioner compressor - exploded view . . . . . . . . . . . . . . . . 48

1.5 Removing and installing poly V-belt - vehicles without air conditioner compressor . . . . . . 48

1.6 Removing and installing vibration damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1.7 Removing and installing bracket for ancillaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

1.8 Sealing flange (pulley end) - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.9 Renewing crankshaft oil seal (pulley end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1.10 Removing and installing sealing flange (pulley end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2 Cylinder block (gearbox end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.1 Dual-mass flywheel and sealing flange (gearbox end) - exploded view . . . . . . . . . . . . . . . . 59

2.2 Removing and installing dual-mass flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.3 Renewing sealing flange (gearbox end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3 Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.1 Crankshaft - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.2 Crankshaft dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.3 Measuring axial clearance of crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.4 Measuring radial clearance of crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.5 Extracting and driving in needle bearing for crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3.6 Pulling spur gear off crankshaft and shrink-fitting new spur gear . . . . . . . . . . . . . . . . . . . . 74

4 Pistons and conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.1 Pistons and conrods - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.2 Measuring piston projection at “TDC” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.3 Piston and cylinder dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.4 Measuring radial clearance of conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

15 - Cylinder head, valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

1 Toothed belt drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

1.1 Toothed belt - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

1.2 Removing and installing toothed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2 Cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

2.1 Cylinder head cover - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

2.2 Removing and installing cylinder head cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.3 Cylinder head - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

2.4 Removing and installing cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

2.5 Checking compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

3 Valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

3.1 Valve gear - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

3.2 Measuring axial clearance of camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

3.3 Measuring radial clearance of camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

3.4 Renewing camshaft oil seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

3.5 Removing and installing camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

3.6 Checking hydraulic tappets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

3.7 Renewing valve stem oil seals with cylinder head installed . . . . . . . . . . . . . . . . . . . . . . . . 127

3.8 Renewing valve stem oil seals with cylinder head removed . . . . . . . . . . . . . . . . . . . . . . . . 130

3.9 Valve dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

3.10 Machining valve seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

3.11 Checking valve guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

3.12 Checking valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

17 - Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

1 Oil pump, sump, balance shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

1.1 Oil pump, sump, balance shaft assembly - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . 136

1.2 Removing and installing oil level and oil temperature sender G266 . . . . . . . . . . . . . . . . . . 139

1.3 Removing and installing sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

1.4 Removing and installing oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.5 Removing balance shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.6 Installing a new balance shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

1.7 Re-installing a used balance shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

2 Oil filter bracket and engine oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

2.1 Oil filter bracket and engine oil cooler - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

2.2 Removing and installing oil filter bracket with engine oil cooler . . . . . . . . . . . . . . . . . . . . . . 153

2.3 Removing and installing oil pressure switch F1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

2.4 Checking oil pressure switch F1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

2.5 Checking oil pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

2.6 Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

2.7 Checking oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

19 - Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

1 Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

1.1 Diagram of coolant hose connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

1.2 Draining and filling cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

2 Coolant pump and thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

2.1 Coolant pump and thermostat - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

2.2 Removing and installing coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

2.3 Removing and installing thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

2.4 Removing and installing 4/2-way valve with thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

2.5 Checking thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

3 Coolant pipes, coolant temperature senders, coolant circulation pump . . . . . . . . . . . . . . . . 175

3.1 Coolant pipes, coolant temperature senders, coolant circulation pump - exploded view . . 175

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

3.2 Removing and installing coolant temperature sender G62 . . . . . . . . . . . . . . . . . . . . . . . . 176

3.3 Removing and installing radiator outlet coolant temperature sender G83 . . . . . . . . . . . . 178

3.4 Removing and installing pump for exhaust gas recirculation cooler V400 . . . . . . . . . . . . 178

3.5 Removing and installing coolant pipe (front) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

3.6 Removing and installing coolant pipe (left-side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

3.7 Removing and installing coolant pipe (right-side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

4 Radiator and radiator fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

4.1 Radiator and radiator fans - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

4.2 Removing and installing radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

4.3 Removing and installing radiator cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

4.4 Removing and installing radiator fans V7 / V177 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

4.5 Checking cooling system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

21 - Turbocharging/supercharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

1 Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

1.1 Diagram of vacuum connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

1.2 Turbocharger - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

1.3 Removing and installing turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

1.4 Renewing vacuum unit with position sender for charge pressure positioner G581 . . . . . . 202

2 Charge air cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

2.1 Charge air cooler - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

2.2 Removing and installing charge pressure sender G31 / intake air temperature sender G42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

2.3 Removing and installing charge air cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

2.4 Checking charge air system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

26 - Exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

1 Silencers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

1.1 Silencers - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

1.2 Removing and installing particulate filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

1.3 Stress-free alignment of exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

1.4 Aligning tailpipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

1.5 Checking exhaust system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

2 Exhaust gas temperature control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

2.1 Exhaust gas temperature control - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

2.2 Removing and installing exhaust gas temperature sender 1 G235 . . . . . . . . . . . . . . . . . . 223

2.3 Removing and installing exhaust gas temperature sender 3 G495 . . . . . . . . . . . . . . . . . . 224

2.4 Removing and installing exhaust gas temperature sender 4 G648 . . . . . . . . . . . . . . . . . . 225

3 Exhaust gas recirculation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

3.1 Diagram of vacuum connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

3.2 Exhaust gas recirculation with exhaust gas recirculation cooler - exploded view . . . . . . . . 227

3.3 Removing and installing exhaust gas recirculation valve N18 with exhaust gas recirculation

potentiometer G212 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

3.4 Checking exhaust gas recirculation cooler change-over . . . . . . . . . . . . . . . . . . . . . . . . . . 230

3.5 Removing and installing exhaust gas recirculation cooler . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Contents iii

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

iv Contents

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

00 – Technical data

1 Engine number

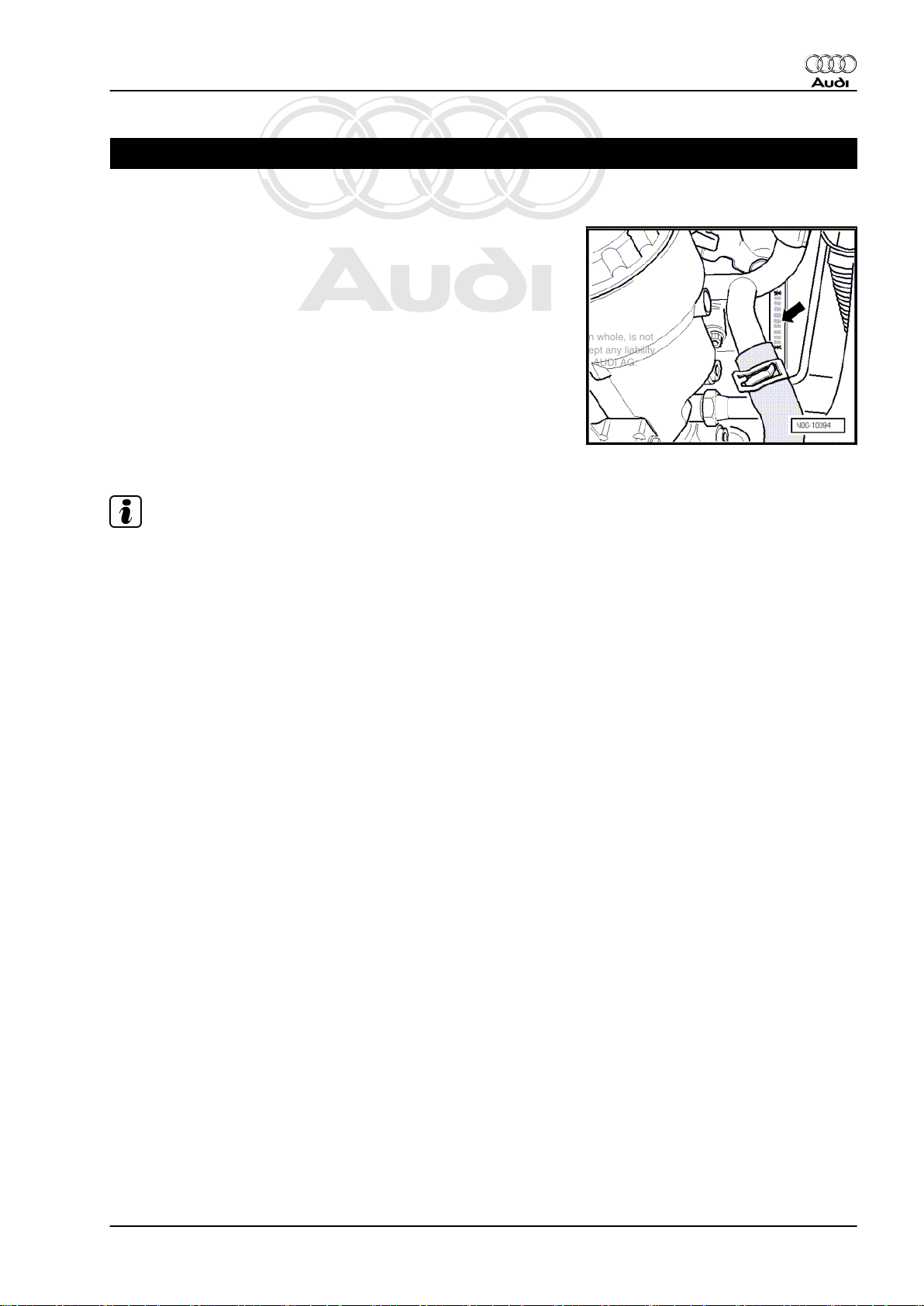

♦ The engine number (“Engine code” and “Serial number”)

-arrow- can be found at the front of the joint between engine

and gearbox.

♦ There is also a sticker on the toothed belt cover showing the

“Engine code” and “Serial number”.

♦ Starting with the letter “C”, the engine codes consist of 4 let‐

ters.

♦ The first 3 characters of the engine code stand for the engine

capacity and the mechanical construction and design. They

are stamped on the cylinder block, together with the serial

number.

♦ The 4th character indicates the power output and torque of the

engine, and is determined by the engine control unit.

Audi TT 2007 ➤

Note

♦

The 4-character engine code can be found on the type plate

(in versions for some countries only) and on the vehicle data

sticker and the engine control unit.

♦

Fitting locations of the type plate (certain countries only) and

the vehicle data sticker ⇒ Maintenance ; Booklet 810 .

1. Engine number 1

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

2 Engine data

Code letters CBBB

Capacity ltr. 1.968

Power output kW at rpm 125/4200

Torque Nm at rpm 350/1750 … 2500

Bore ∅ in mm 81.0

Stroke mm 95.5

Compression ra‐

tio

CN not less than 51

Firing order

Emission standards EU4 plus

Exhaust gas recirculation yes

Exhaust gas temperature control yes

Turbocharging/supercharging Turbocharger

Glow plugs Steel glow plugs

Charge air cooling yes

Lambda control 1 Lambda probe

Particulate filter yes

Valves per cylinder 4

16.5

1-3-4-2

Note

Audi TT models with a TDI engine (2.0 ltr. 4-valve common rail)

are always equipped with steel glow plugs.

2 Rep. Gr.00 - Technical data

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

3 Safety precautions

When working on the fuel system note the following warnings:

WARNING

Risk of injury - fuel system operates under pressure.

♦ Wrap a clean cloth around the connection before opening

the fuel system. Then release pressure by carefully loos‐

ening the connection.

♦ Wear protective gloves.

♦ Wear safety goggles.

The fuel can become extremely hot. This can cause injuries.

♦ In extreme cases the temperature of the fuel lines and the

fuel can be up to 100 °C after the engine is switched off.

Allow the fuel to cool down before disconnecting the lines

- danger of scalding.

♦ Wear protective gloves.

♦ Wear safety goggles.

Audi TT 2007 ➤

Observe the following points to prevent personal injuries and

damage to the injection and glow plug system:

♦ Always switch off the ignition before connecting or discon‐

necting tester cables or electrical wiring for the injection or

glow plug system.

♦ Always switch off ignition before washing engine.

♦ Faults are stored in engine control unit if electrical connectors

have been unplugged:

– “Interrogate fault memory” in “Vehicle self-diagnosis”.

Caution

To prevent damage to the electronic components when dis‐

connecting the battery:

♦ Observe notes on procedure for disconnecting the battery.

♦ Always switch off the ignition before disconnecting the

battery.

– Disconnect battery ⇒ Rep. Gr. 27 .

3. Safety precautions 3

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

When working on the cooling system note the following warnings:

WARNING

Hot steam/hot coolant can escape - risk of scalding.

♦ The cooling system is under pressure when the engine is

hot.

♦ To allow pressure to dissipate, cover filler cap coolant on

expansion tank with cloth and open carefully.

Risk of injury as the radiator fans may start up automatically.

♦ Unplug electrical connectors before starting to work in the

area of radiator cowl.

Caution

Overheating can occur if the filler cap is not fitted properly.

♦ Firmly close filler cap on coolant expansion tank.

Note the following if testers and measuring instruments have to

be used during a road test:

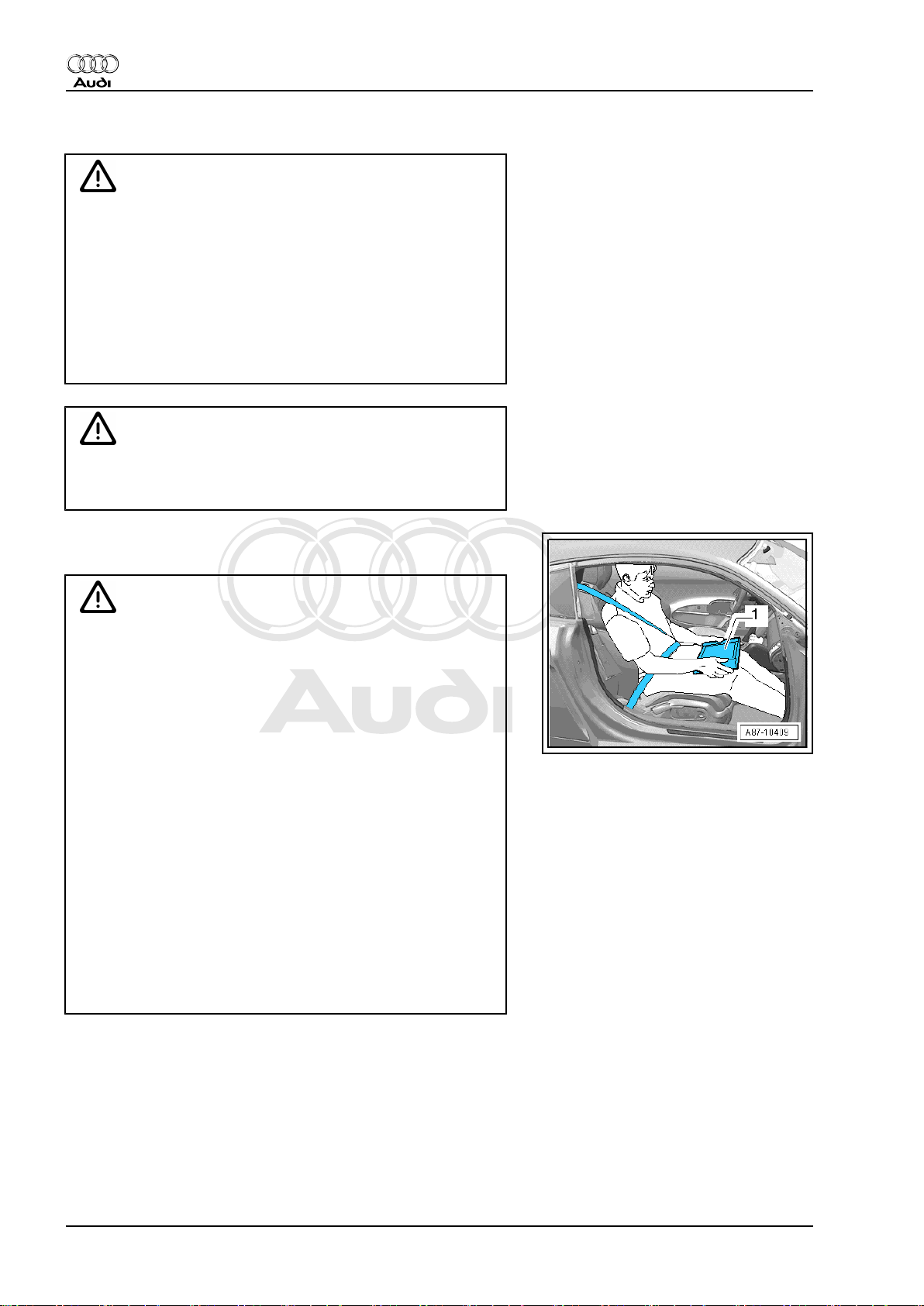

WARNING

Accidents can be caused if the driver is distracted by test

equipment while road-testing, or if test equipment is not prop‐

erly secured.

Persons sitting in the front passenger's seat could be injured if

the airbag is triggered in an accident.

• The use of test equipment while driving causes distraction.

• There is an increased risk of injury if test equipment is not

secured.

TT Coupé:

Test equipment must always be secured on the rear seat with

a strap and operated from the rear seat by a second person.

TT Roadster:

♦ Move the passenger's seat back as far as it will go.

♦ Use only vehicle diagnosis and service information sys‐

tem -VAS 5052- or diagnosis system -VAS 5053- .

♦ The test equipment -1- must rest flat on the passenger's

thighs (as shown in illustration) and must be operated by

the passenger.

4 Rep. Gr.00 - Technical data

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

4 General repair instructions

4.1 Rules for cleanliness when working on fuel supply system, injection system and turbocharger

Even small amounts of dirt can cause malfunctions. For this rea‐

son, please observe the following rules when working on the fuel

supply system, injection system and turbocharger:

♦ Carefully clean connection points and the surrounding area

with engine cleaner or brake cleaner and dry thoroughly before

opening.

♦ Seal off open pipes/lines and connections using engine bung

set -VAS 6122- .

♦ Place parts that have been removed on a clean surface and

cover them over. Do not use fluffy cloths.

♦ Carefully cover or seal open components if repairs cannot be

carried out immediately.

♦ Only install clean components; replacement parts should only

be unpacked immediately prior to installation. Do not use parts

that have not been stored in the proper packaging (e.g. in tool

boxes etc.).

♦ When the system is open: Do not work with compressed air.

Do not move the vehicle unless absolutely necessary.

♦ Protect unplugged electrical connectors against dirt and mois‐

ture and make sure connections are dry when attaching.

Audi TT 2007 ➤

4.2 Checking for leaks in the fuel system

Procedure

– Allow engine to run for several minutes at moderate rpm.

– Switch off ignition.

– Check complete fuel system for leaks.

– If leaks are found although the connections have been tight‐

ened to the correct torque, the relevant component must be

renewed.

– Road-test vehicle and accelerate with full throttle at least once.

– Then inspect high-pressure section of fuel system again for

leaks.

4.3 Contact corrosion!

Contact corrosion can occur if unsuitable fasteners are used (e.g.

bolts, nuts, washers, etc.).

For this reason, only fasteners with a special surface coating are

used.

Additionally, all rubber and plastic parts and all adhesives are

made of non-conductive materials.

Always install new parts if you are not sure whether used parts

can be re-fitted ⇒ Electronic parts catalogue .

Note the following:

♦ We recommend using only genuine replacement parts; these

have been tested and are compatible with aluminium.

4. General repair instructions 5

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

♦ We recommend the use of Audi accessories.

♦ Damage caused by contact corrosion is not covered under

warranty.

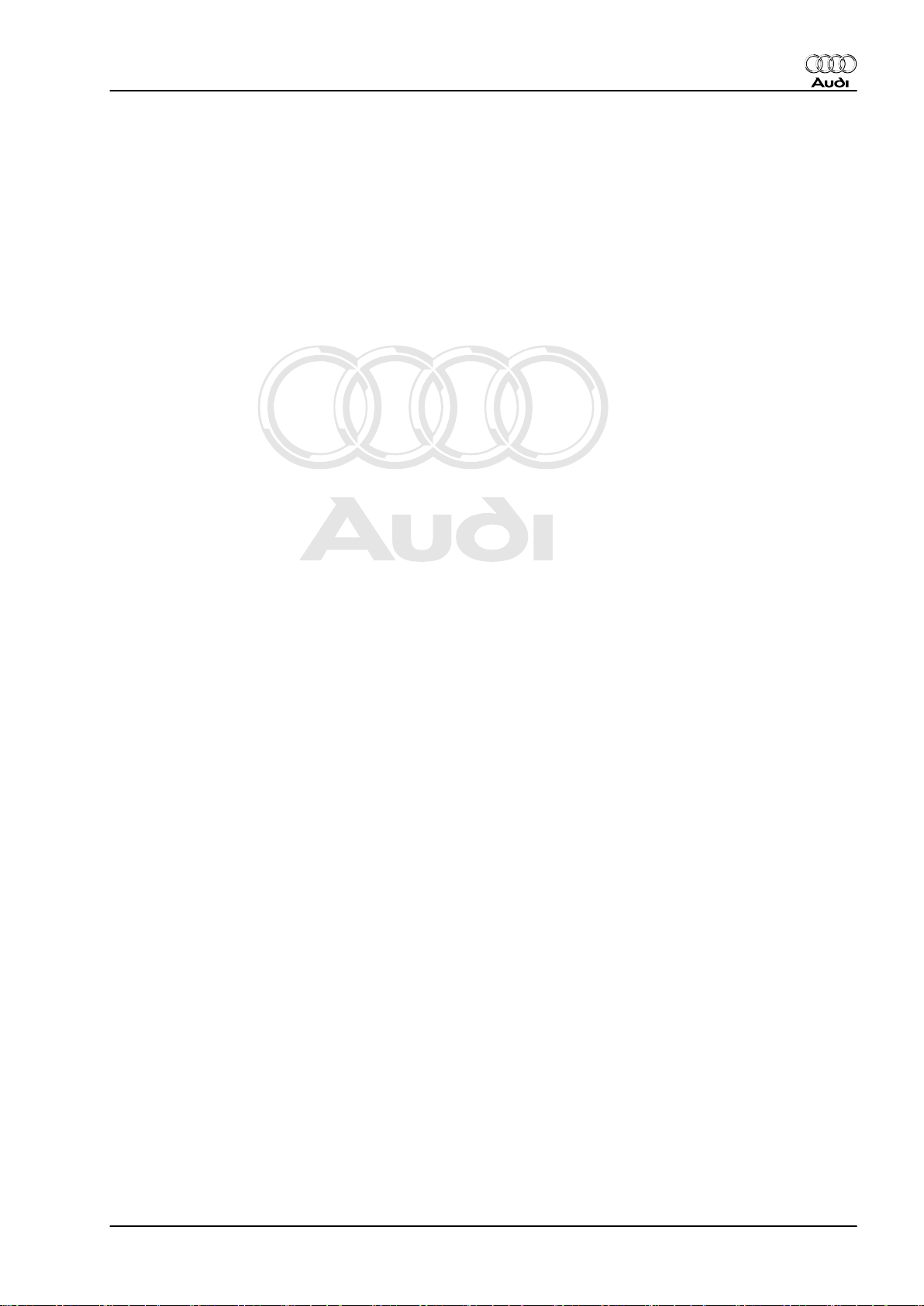

4.4 Checking vacuum system

Special tools and workshop equipment required

♦ Hand vacuum pump -VAS 6213-

Procedure

– Check all vacuum lines in the complete vacuum system for:

♦ Cracks

♦ Traces of animal bites

♦ Kinked or crushed lines

♦ Lines porous or leaking

– Check vacuum line to solenoid valve and from solenoid valve

to corresponding component.

– If a fault is stored in the fault memory, check the vacuum lines

leading to the corresponding component and also check the

remaining vacuum lines in the system.

– If it is not possible to build up pressure with the hand vacuum

pump -VAS 6213- or if the pressure drops again immediately,

check the hand vacuum pump and connecting hoses for leaks.

4.5 Routing and attachment of pipes, hoses and wiring

Mark hydraulic lines, vacuum lines and electrical wiring before

removal so they can be re-installed in the original positions and

correctly connected. Make sketches or take photographs if nec‐

essary.

6 Rep. Gr.00 - Technical data

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

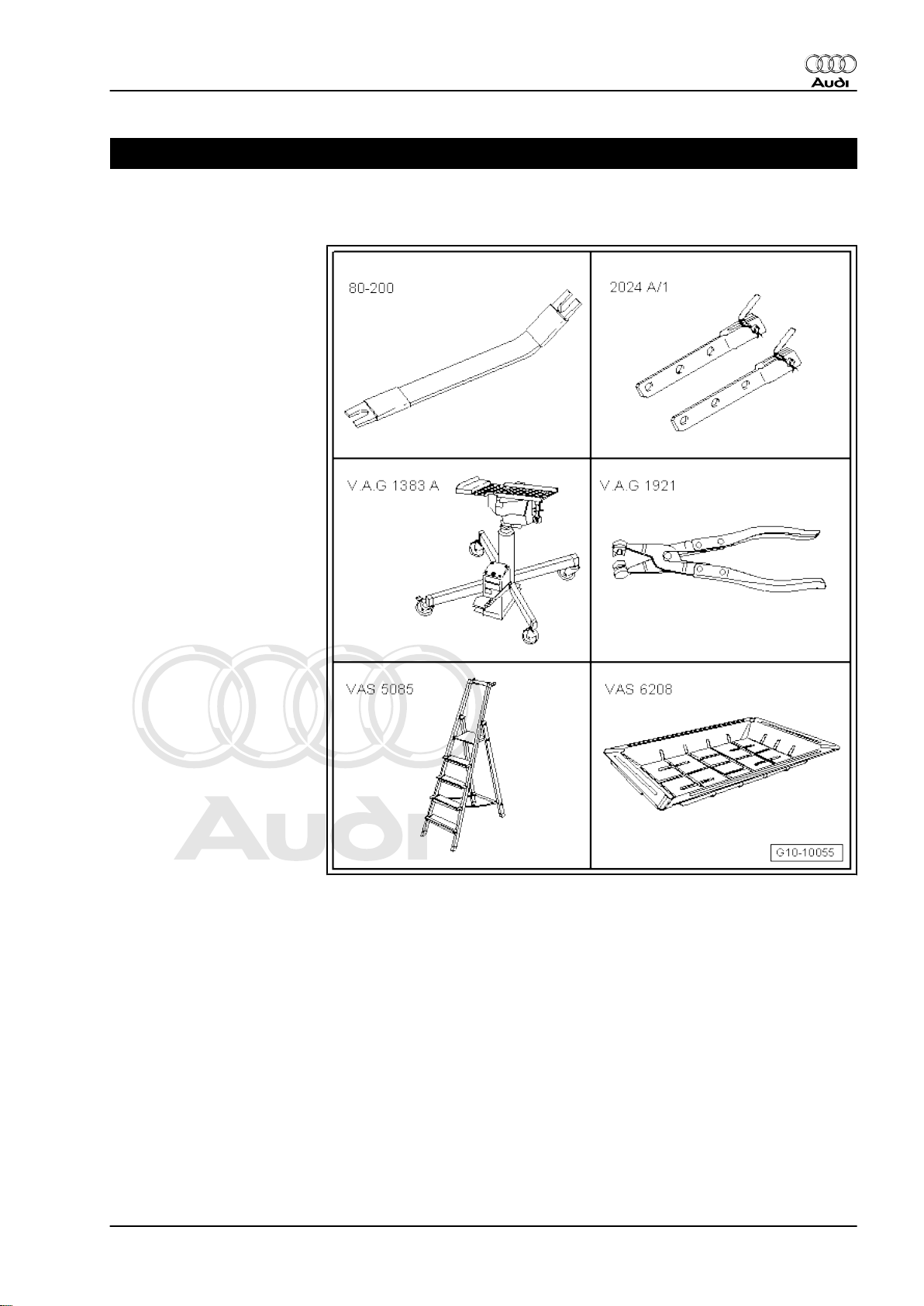

10 – Removing and installing engine

1 Removing engine

Special tools and workshop

equipment required

♦ Removal lever -80 - 200-

♦ Extension -2024 A /1-

♦ Engine and gearbox jack -

V.A.G 1383 A-

♦ Hose clip pliers -

V.A.G 1921-

♦ Stepladder -VAS 5085-

♦ Drip tray for workshop hoist

-VAS 6208-

Audi TT 2007 ➤

1. Removing engine 7

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

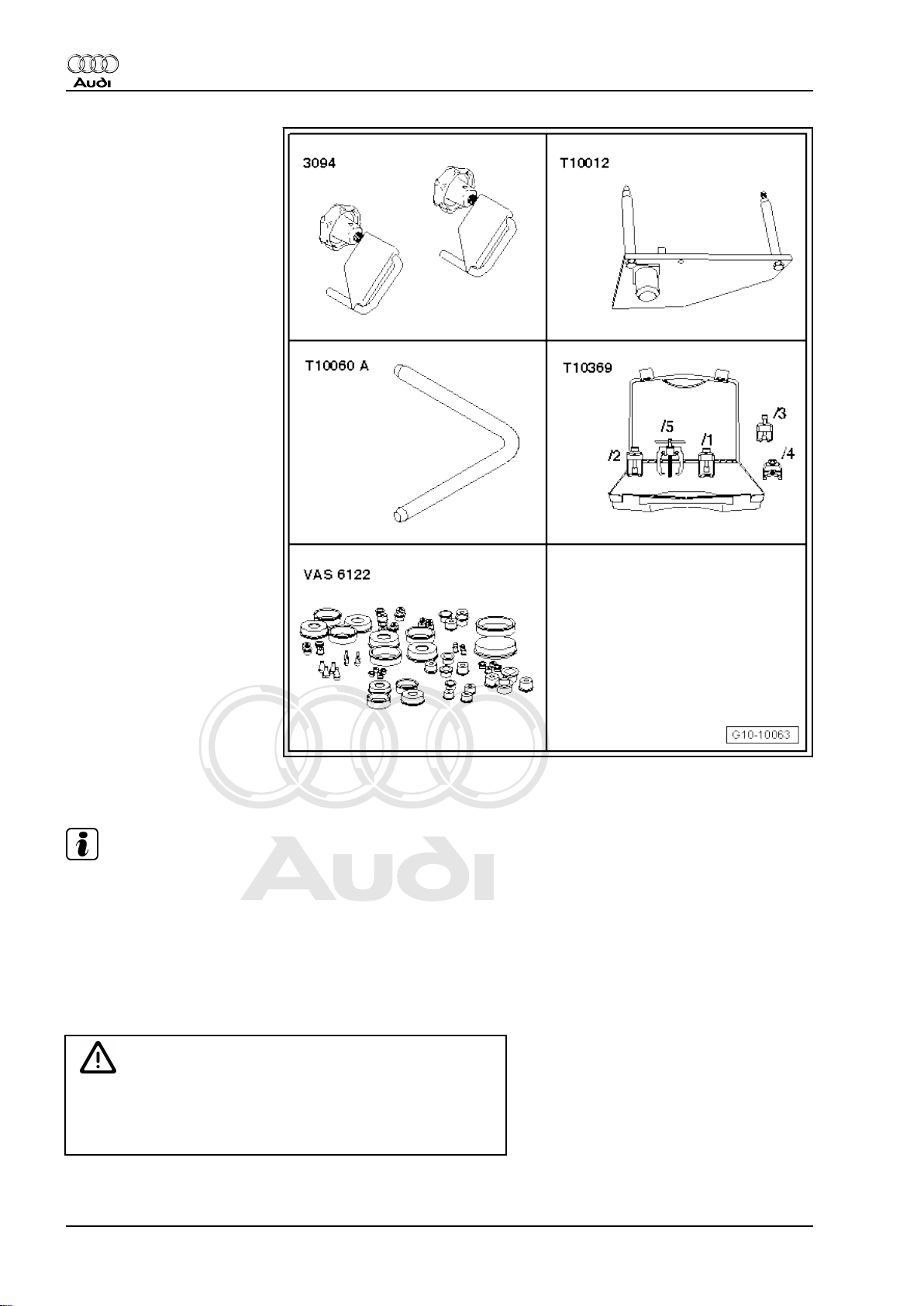

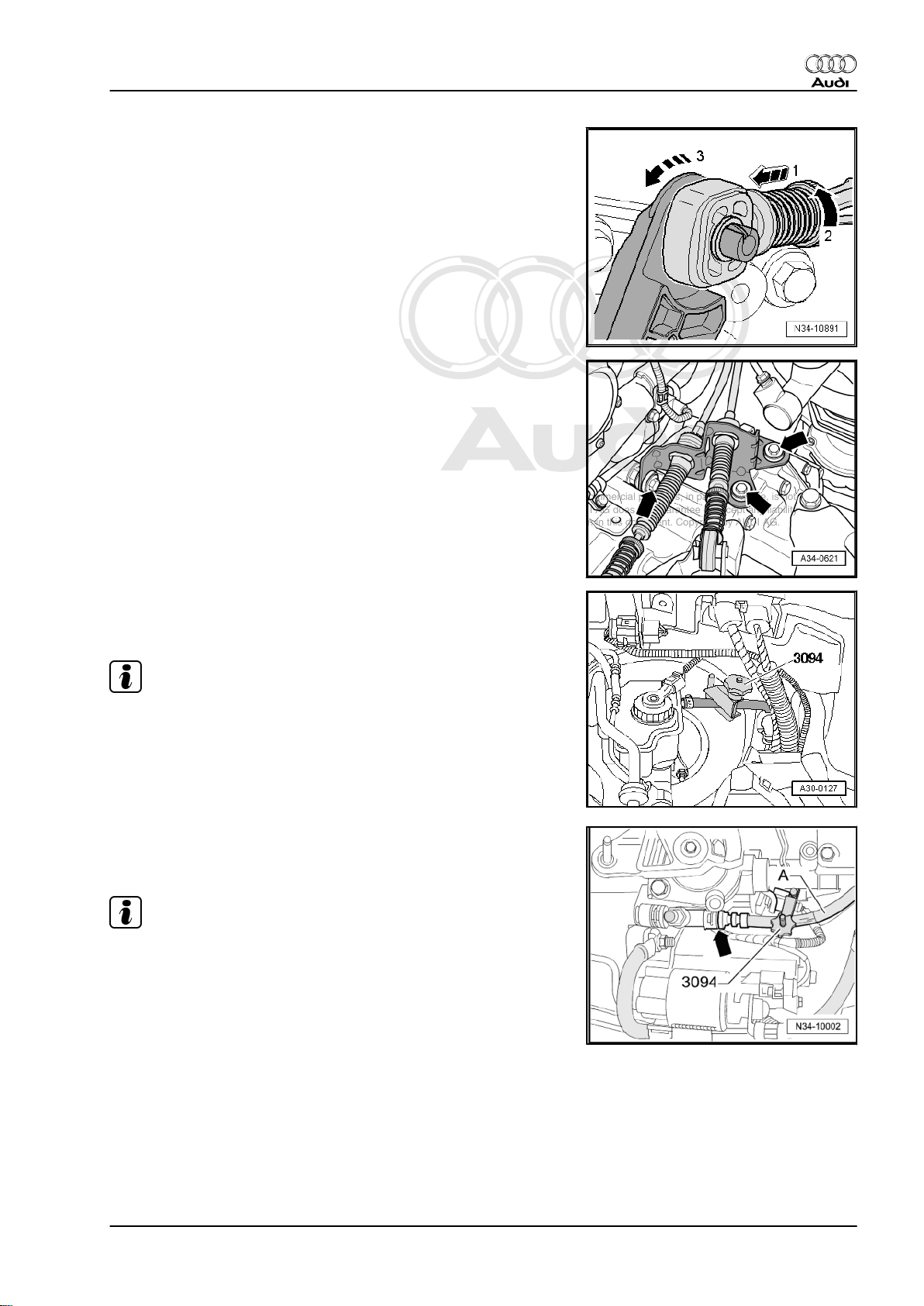

♦ Hose clamps for hoses up

to 25 mm -3094-

♦ Engine bracket -T10012-

♦ Locking pin -T10060 A-

♦ Puller -T10369-

♦ Engine bung set -VAS

6122-

♦ Safety goggles

♦ Protective gloves

Procedure

Note

♦

The engine is removed from underneath together with the

gearbox.

♦

Collect drained coolant in a clean container for re-use or dis‐

posal.

♦

Fit cable ties in the original positions when installing.

♦

Fit heat insulation sleeves in the original positions when in‐

stalling.

Caution

To prevent damage to the electronic components when dis‐

connecting the battery:

♦ Observe notes on procedure for disconnecting the battery.

8 Rep. Gr.10 - Removing and installing engine

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

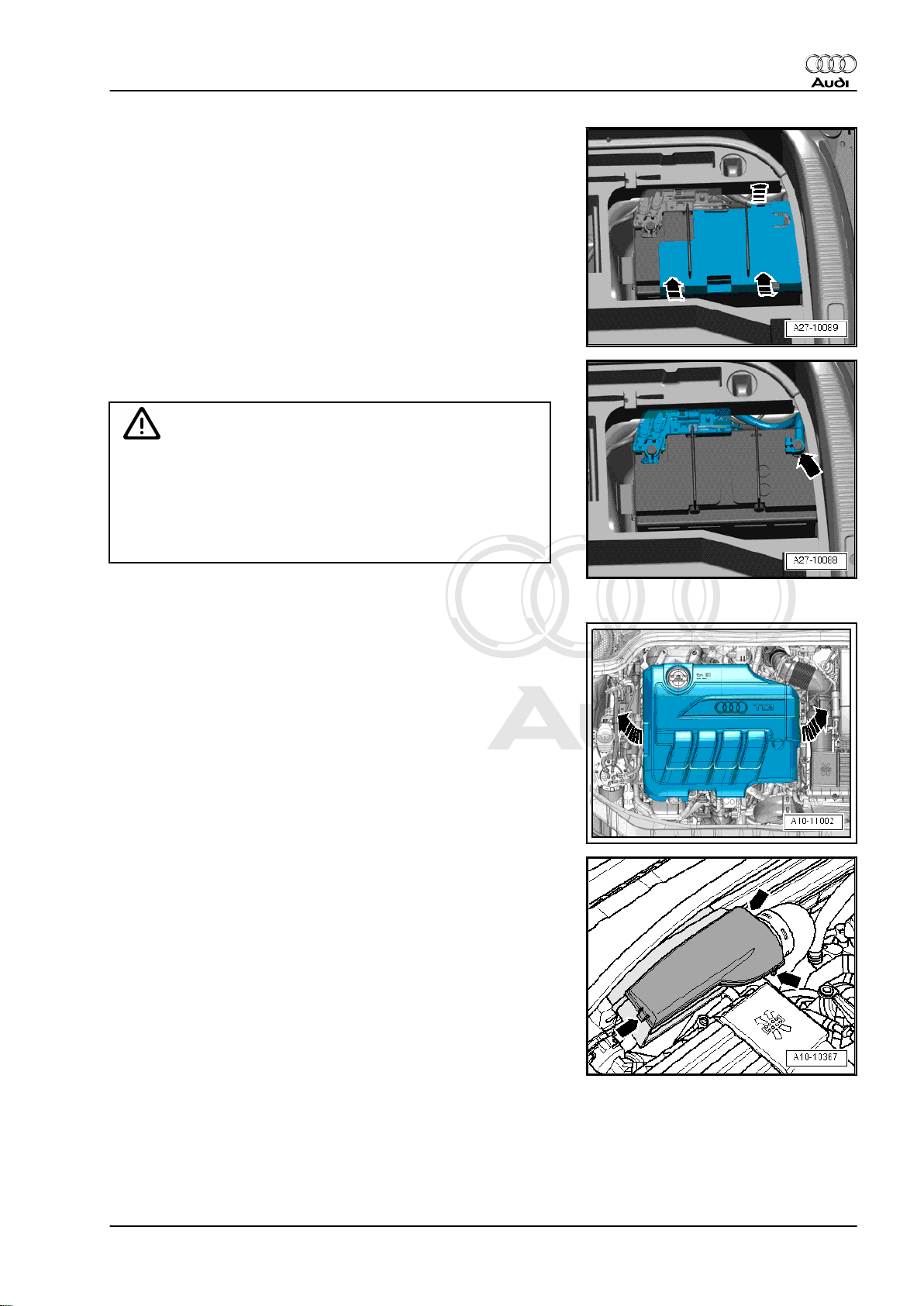

– Take out luggage compartment floor covering.

– Take out luggage compartment floor mat.

– Remove rear cross panel trim if cover for negative battery ter‐

minal is located behind rear cross panel trim ⇒ Rep. Gr. 70 .

– Release retaining clips -arrows- and detach cover for negative

terminal.

– Loosen nut a few turns and disconnect battery clamp on earth

wire -arrow- from battery terminal.

WARNING

Hot steam/hot coolant can escape - risk of scalding.

♦ The cooling system is under pressure when the engine is

hot.

♦ To allow pressure to dissipate, cover filler cap on coolant

expansion tank with cloth and open carefully.

Audi TT 2007 ➤

– Open filler cap on coolant expansion tank.

– Remove engine cover panel -arrows-.

– Pull cover off air duct (release clips on sides) -arrows-.

1. Removing engine 9

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

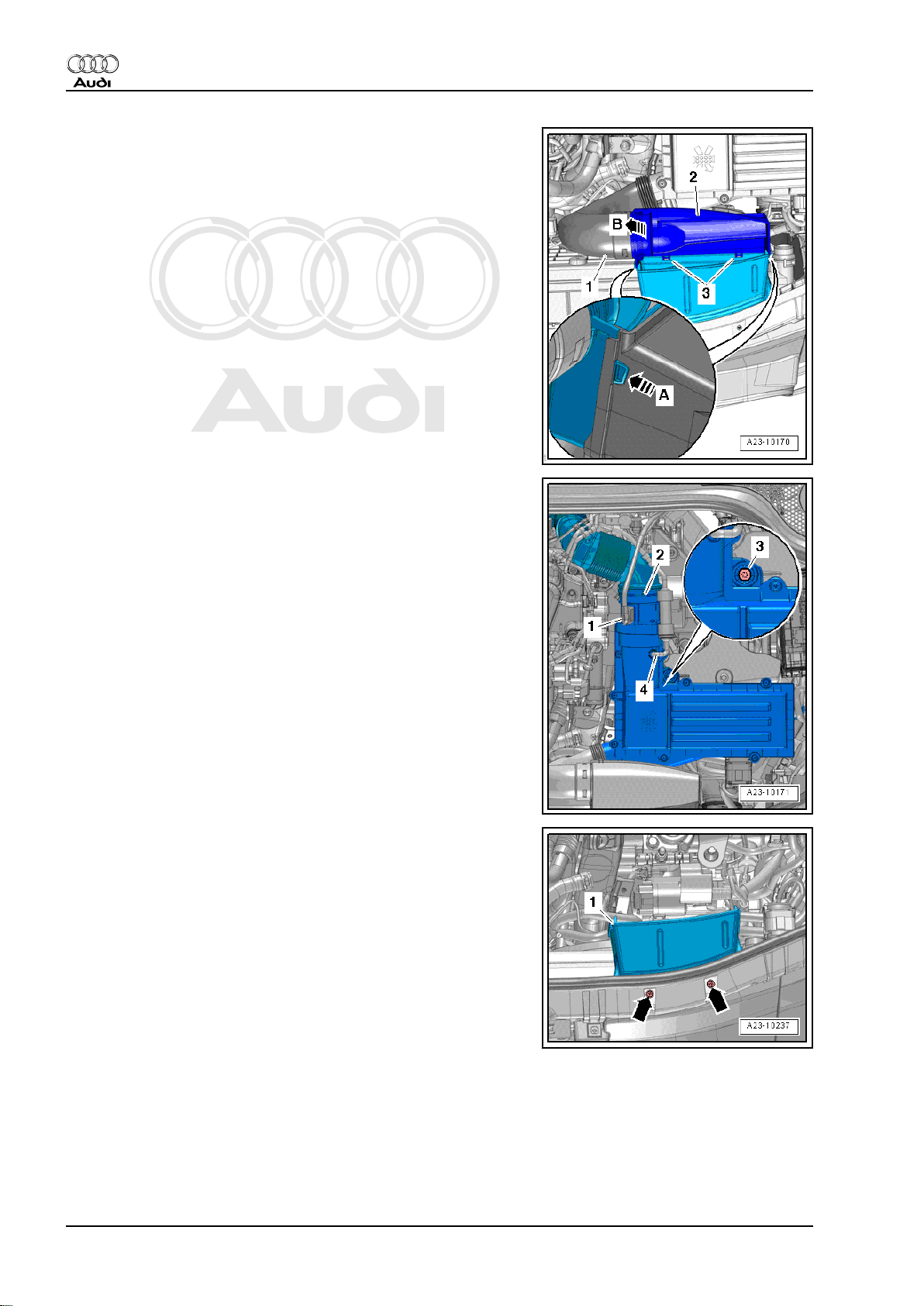

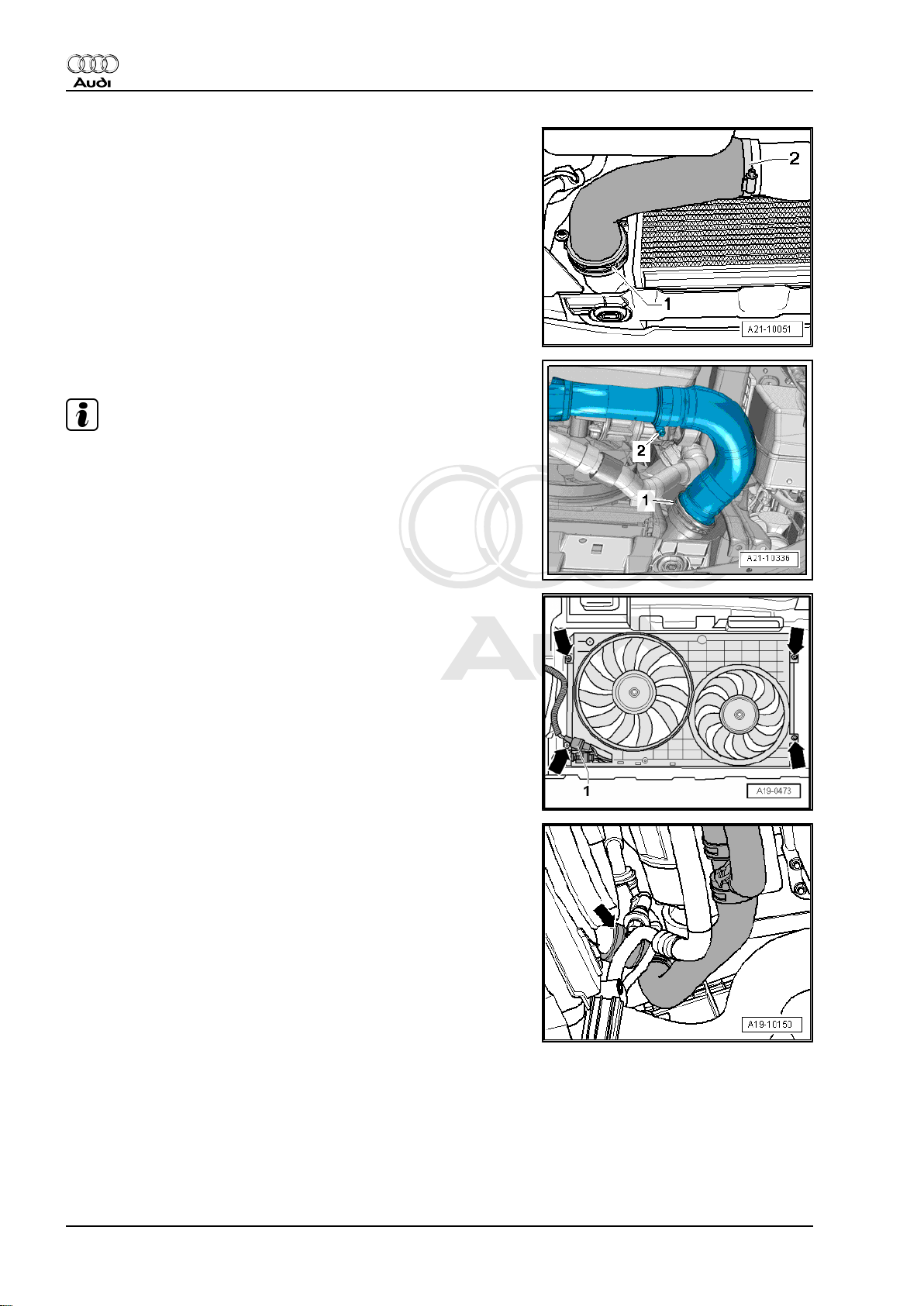

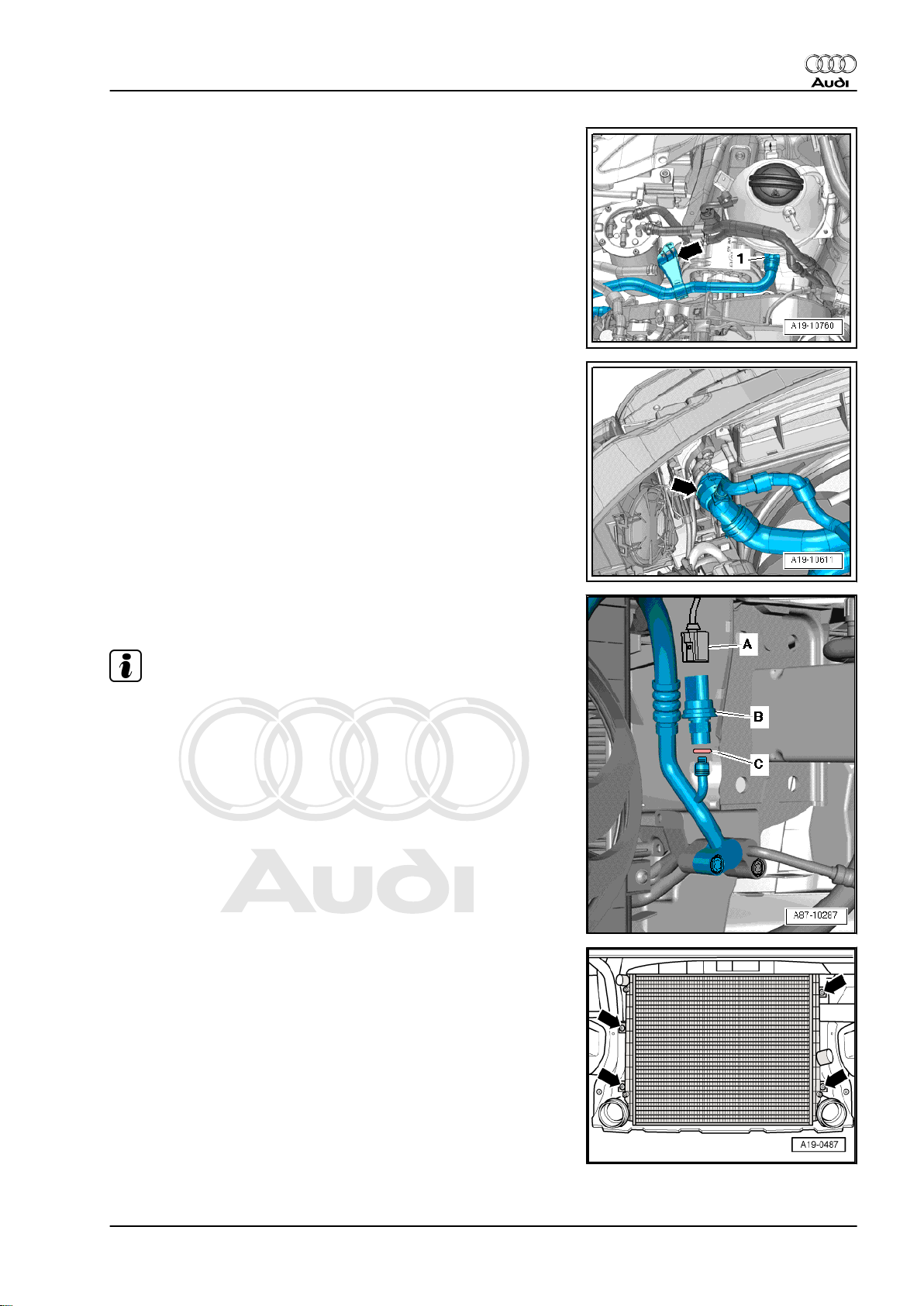

– Release clips on left and right -arrow A- and unclip air duct at

bottom -2-.

– Swivel air duct (bottom) slightly to the rear and detach air duct

(bottom) from retainers -3-.

– Detach air pipe -1- from air duct (bottom) -arrow B-.

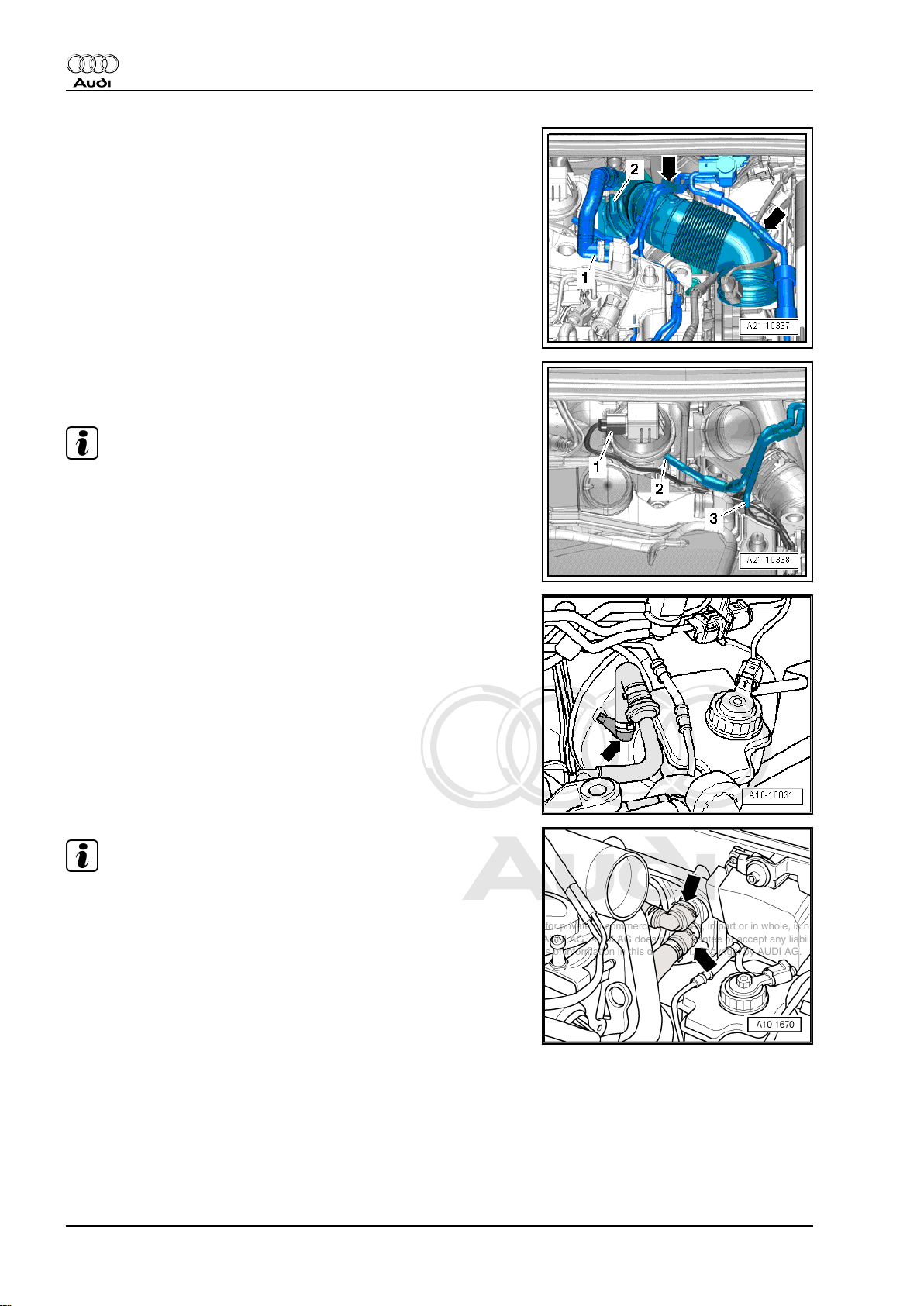

– Unplug electrical connector -1- from air mass meter -G70- .

– Detach hose -4-.

– Release hose clip -2- and detach air hose.

– Unscrew bolt -3- and remove air cleaner housing.

– Remove bolts -arrows- and detach air duct -1- from lock car‐

rier.

10 Rep. Gr.10 - Removing and installing engine

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

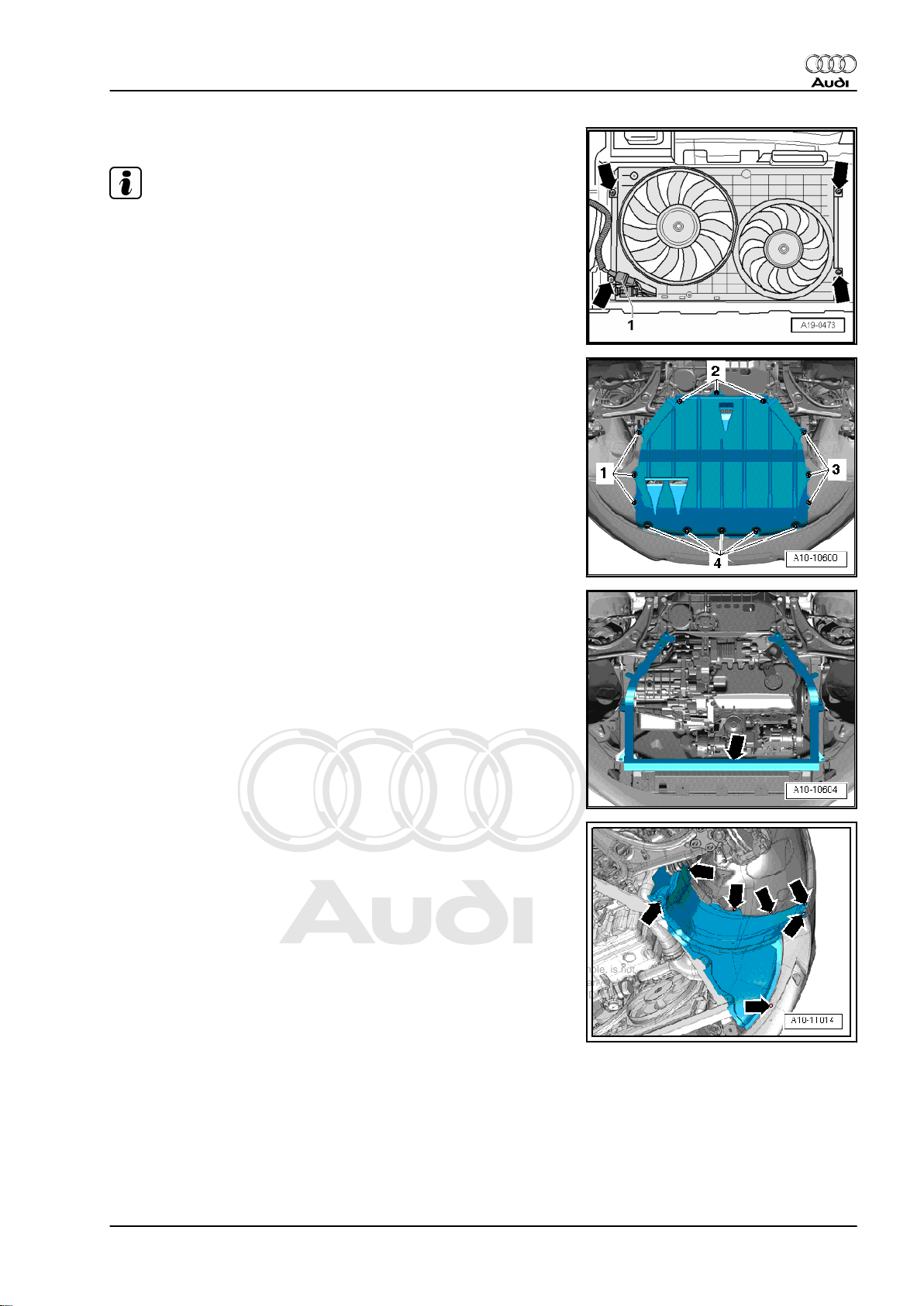

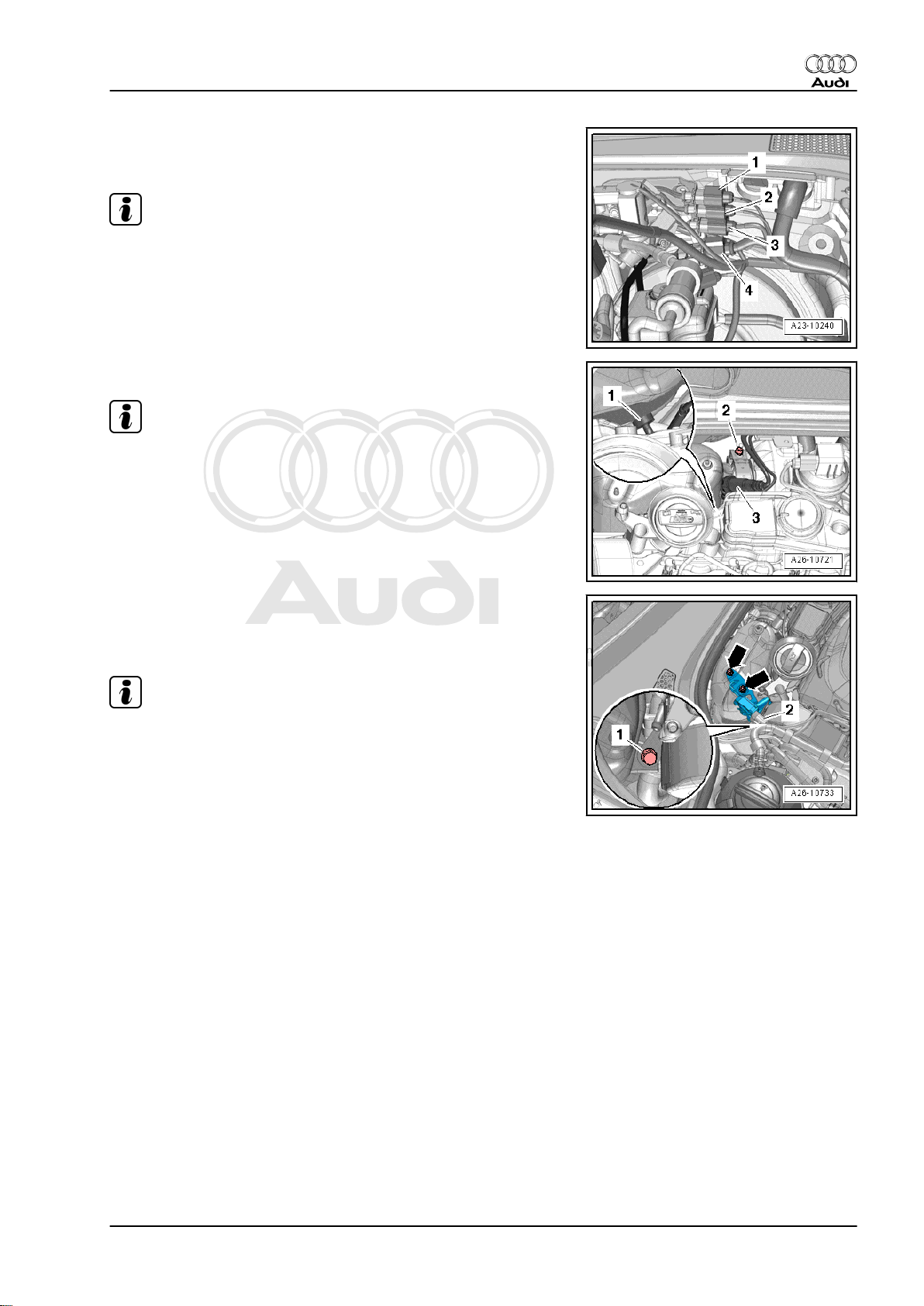

– Remove bolts -top arrows- for radiator cowl.

Note

The bolts -bottom arrows- are removed at a later stage.

– Remove both front wheels.

– Release fasteners -1 ... 4- and remove centre noise insulation.

Audi TT 2007 ➤

– Only on TT Roadster: Remove noise insulation frame

-arrow- ⇒ Rep. Gr. 50 .

– Release fasteners -arrows- and remove wheel housing liner

(bottom section) on both sides.

1. Removing engine 11

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Release hose clip -2-, lift retaining clip -1- and remove air hose.

– Release hose clip -2-, lift retaining clip -1- and remove air hose.

Note

To prevent coolant from entering, seal off connection on charge

air cooler with a clean plug from engine bung set -VAS 6122- .

– Unplug electrical connector -1-.

– Remove bolts -bottom arrows- and take out air cowl down‐

wards.

– Place drip tray for workshop hoist -VAS 6208- beneath engine.

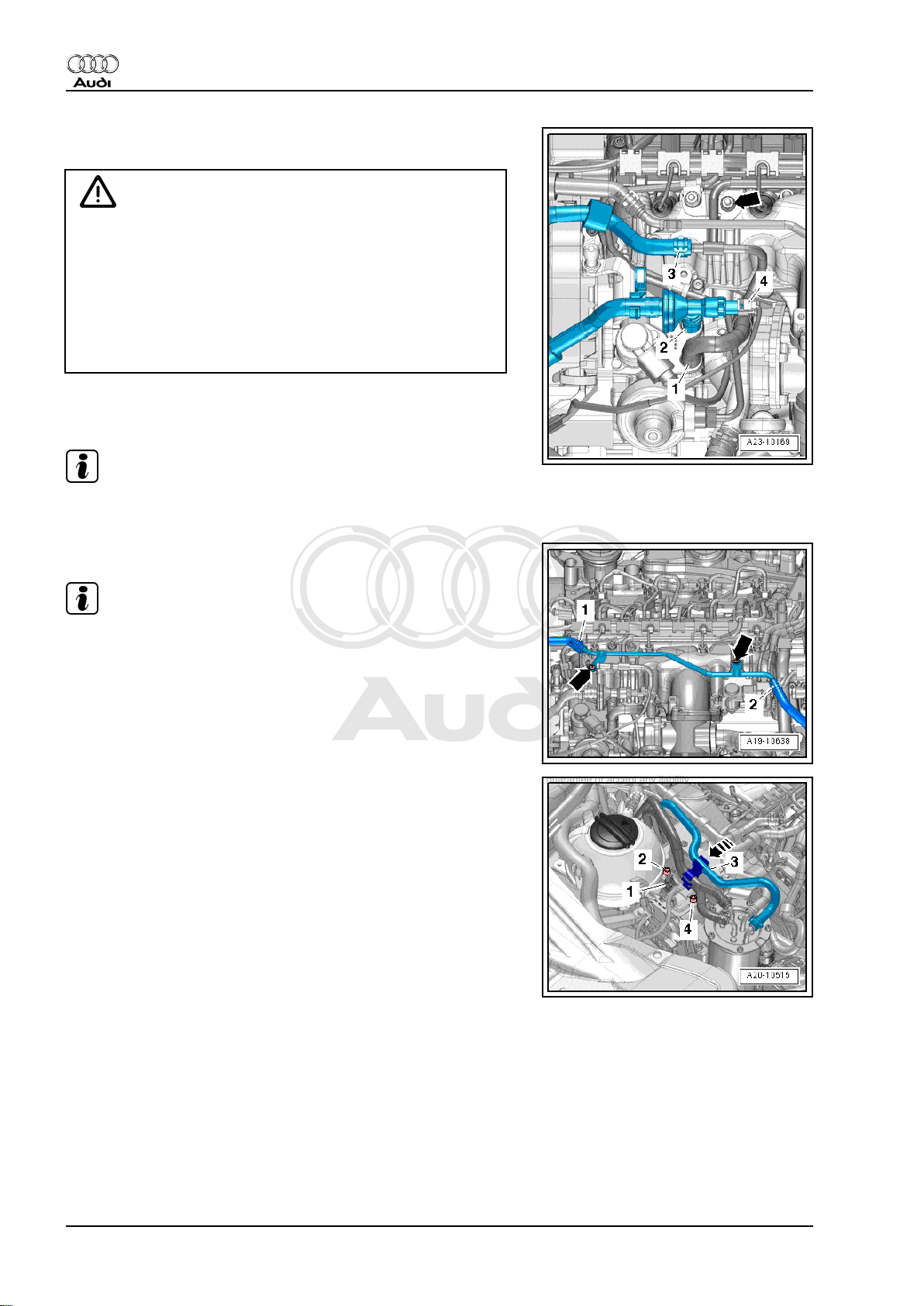

– Lift retaining clip -arrow-, disconnect coolant hose (bottom

right) from radiator and drain off coolant.

12 Rep. Gr.10 - Removing and installing engine

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Open hose clip -arrow-, disconnect coolant hose (bottom)

leading to pump for exhaust gas recirculation cooler -V400and drain off coolant.

– Remove bolts -bottom arrows- on rear side of radiator.

Note

The bolts -top arrows- are removed at a later stage.

Audi TT 2007 ➤

– As an additional step, open hose clip -arrow-, disconnect cool‐

ant hose at top of engine oil cooler and drain off remaining

coolant.

– Remove bolts -arrows- and detach bracket -1- for air cleaner

housing.

1. Removing engine 13

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

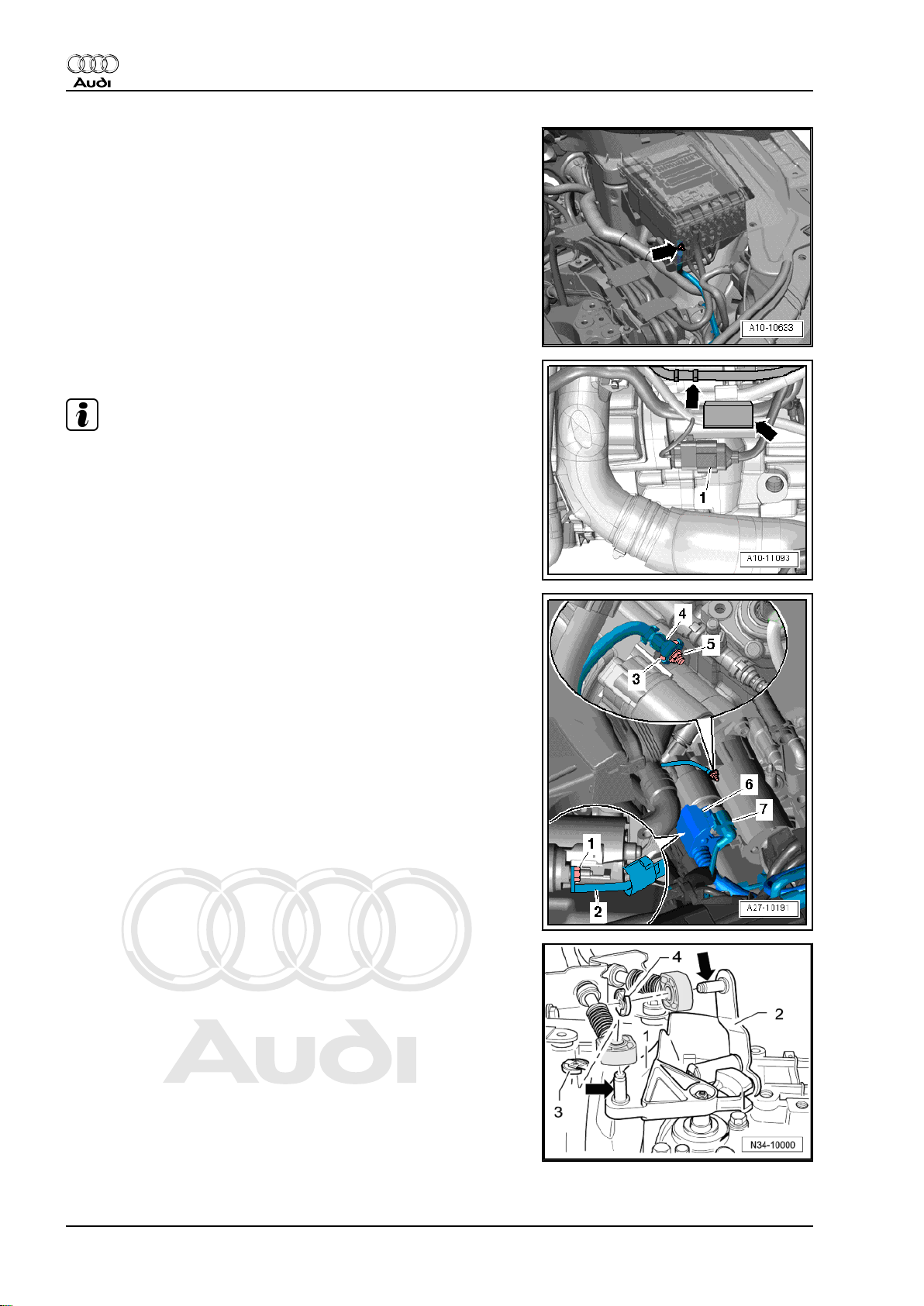

– Press release tabs and disconnect crankcase breather hose

-1- from cylinder head cover.

– Move clear vacuum hoses -arrows- at air pipe.

– Loosen hose clip -2- and detach air pipe.

– Detach vacuum hose -2- from vacuum unit of turbocharger.

– Disconnect vacuum hose -3-.

Note

Disregard -item 1-.

– Detach vacuum hose -arrow- from brake servo.

Note

Place a cloth underneath heat exchanger to catch escaping cool‐

ant.

– Lift retaining clips -arrows- and detach coolant hoses from

heat exchanger.

14 Rep. Gr.10 - Removing and installing engine

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Detach electrical connector -1- from bracket and unplug.

– Move clear electrical wiring.

Note

Disregard -items 2, 3 and 4-.

– Slacken bolt -2- and remove clamp.

Note

Disregard -items 1, 3-.

Audi TT 2007 ➤

– Unplug electrical connector -2- on exhaust gas pressure sen‐

sor 1 -G450- .

– Remove bolt -1-.

Note

Disregard -arrows-.

1. Removing engine 15

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Unplug electrical connector -4- on fuel temperature sender -

G81- .

WARNING

The fuel can become extremely hot. This can cause injuries.

♦ In extreme cases the temperature of the fuel lines and the

fuel can be up to 100 °C after the engine is switched off.

Allow the fuel to cool down before disconnecting the lines

- danger of scalding.

♦ Wear protective gloves.

♦ Wear safety goggles.

– Release hose clips -2- and -3- and disconnect fuel supply hose

and fuel return hose.

Note

Disregard items marked -1- and -arrow-.

– Release hose clip -1- and detach coolant hose.

Note

Ignore items marked -2- and -arrows-.

– Disengage fuel hose -3- at bracket.

– Pull off bracket for fuel lines towards right -arrow- and move

clear to one side.

– Unplug electrical connector -1- at supplementary fuel pump -

V393- .

– Remove bolts -2- and -4-, detach bracket with supplementary

fuel pump -V393- and move clear to one side.

16 Rep. Gr.10 - Removing and installing engine

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Release hose clip -1-, detach coolant hose from coolant ex‐

pansion tank and move coolant hose clear -arrow-.

– Lift retaining clip -arrow- and disconnect coolant hose (top left)

from radiator.

Audi TT 2007 ➤

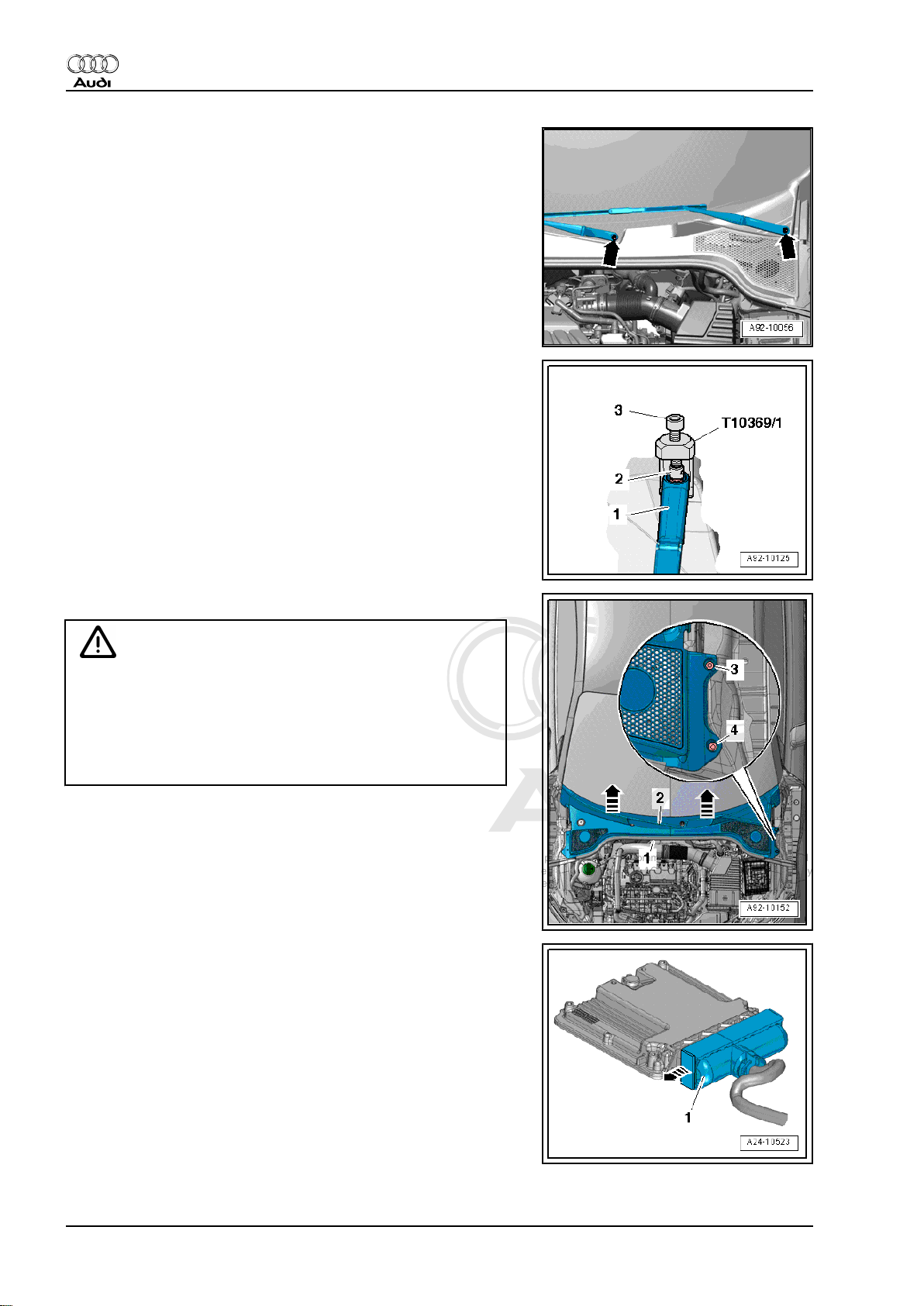

– Unplug electrical connector -A- at high-pressure sender -G65-

-item B-.

Note

Disregard -item C-.

– Remove bolts -top arrows- at rear and lift out radiator.

1. Removing engine 17

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

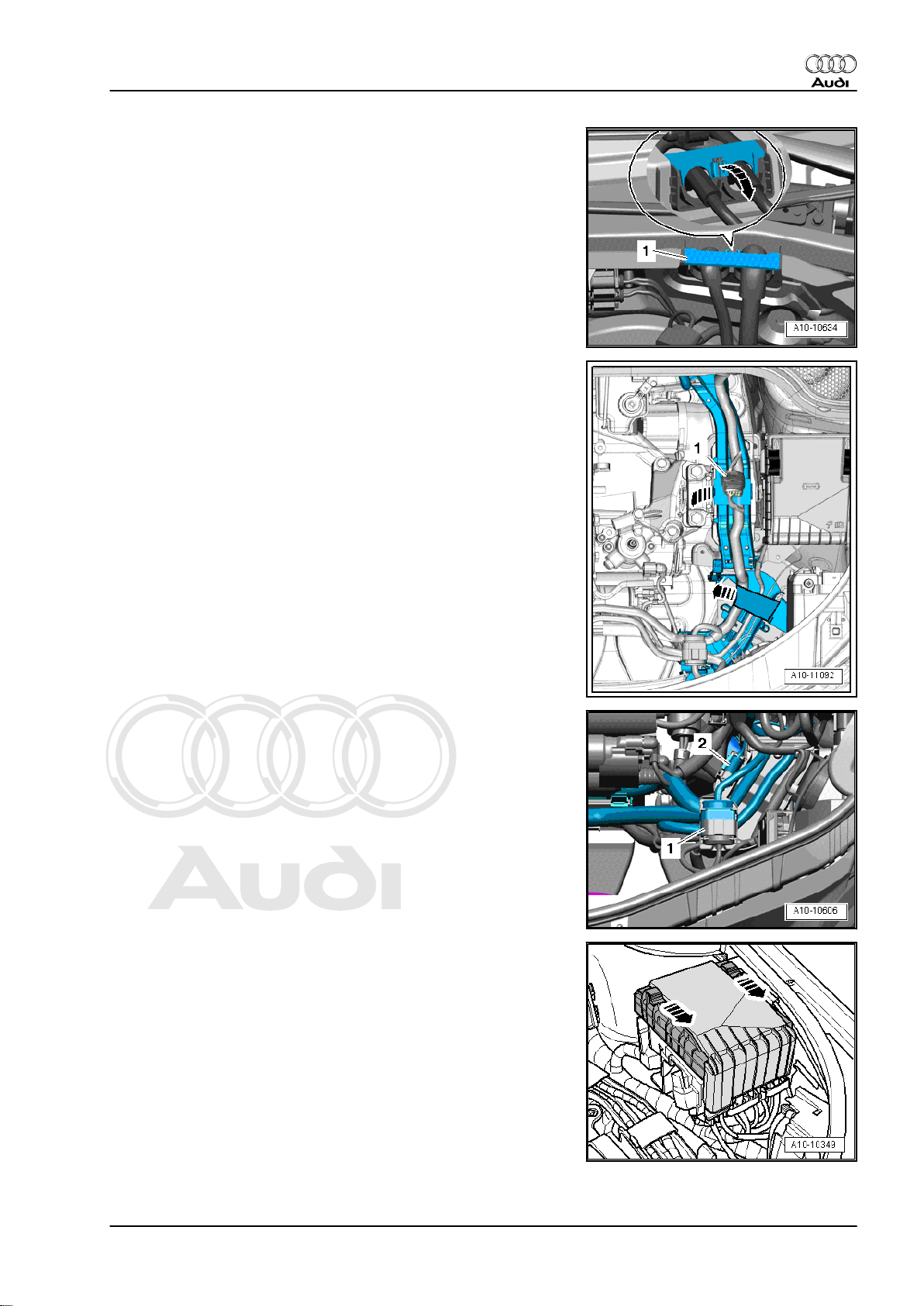

– Pry off caps on windscreen wiper arms with a screwdriver.

– Slacken nuts -arrows- one turn.

– Apply puller -T10369/1- to wiper arm -1- as shown in illustra‐

tion.

– Apply thrust piece -2- onto wiper shaft.

– Turn bolt -3- in clockwise direction until wiper arm is pulled off

wiper shaft.

– Remove nuts and detach windscreen wiper arms.

– Remove seal -1-.

Caution

Risk of damage to plenum chamber cover.

♦ Apply a small quantity of soap solution to transition be‐

tween windscreen and plenum chamber cover -2-. Then,

starting at edge of windscreen, carefully pull plenum

chamber cover upwards off retainer at windscreen

-arrows-.

– Detach plenum chamber cover by pulling it carefully off re‐

tainer at windscreen.

– Move clear engine wiring harness at rear of plenum chamber

partition panel.

– Remove engine control unit ⇒ Rep. Gr. 23 .

– Release electrical connector -1- for engine wiring harness

-arrow- and detach.

18 Rep. Gr.10 - Removing and installing engine

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Release wiring protector -1- for engine wiring harness

-arrow- and lift off.

– Move clear and unplug electrical connector -1-.

– Open wiring duct bracket -arrows-, use removal lever -80 -

200- to unclip wiring and press wiring to side.

– Unclip wiring duct.

Audi TT 2007 ➤

– Unclip electrical connector -1- from bracket and unplug.

– Open wiring duct bracket located underneath.

– Unclip wiring harness for engine control unit from wiring duct.

– Place engine wiring harness with engine control unit on top of

engine.

– Secure engine control unit to prevent it falling.

– Unclip electrical connector -2- from bracket and unplug.

– Slide the two clips in the direction of the -arrows- and remove

cover from electronics box in engine compartment.

1. Removing engine 19

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Remove nut -arrow-, detach terminal 30 wire from electronics

box in engine compartment and move it clear.

– Unplug electrical connector -1-.

Note

Disregard -arrows-.

– Unplug electrical connector -7- (push retainer to the rear and

press down release catch).

– Push back protective sleeve -6-.

– Remove nut -1- and detach B+ wire -item 2- from starter sol‐

enoid switch.

– Remove nut -5- and detach earth wire -4-.

– Remove top starter bolt -3-.

– Detach securing clip -3- for gear selector cable from gearbox

selector lever -1- and pull cable off pin -arrow-.

Metal selector relay lever:

– Detach securing clip -4- for gate selector cable from selector

relay lever -2- and pull cable off pin -arrow-.

20 Rep. Gr.10 - Removing and installing engine

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

Plastic selector relay lever:

• To prevent damage to gate selector cable, cable end-piece

must be detached from gate selector cable before removing.

– Pull locking device forwards onto stop -arrow 1- and lock by

turning anti-clockwise -arrow 2-.

– Press selector relay lever towards front -arrow 3-.

All vehicles (continued):

– Remove cable support bracket -arrows- from gearbox and

place to one side (selector cables remain fitted).

Audi TT 2007 ➤

– If a plastic pipe is installed between clutch master cylinder and

slave cylinder, clamp off supply hose to clutch master cylinder

using hose clamp -3094- .

Note

♦

Make sure brake fluid does not come into contact with starter

or gearbox when performing the following operations. If it

does, clean affected area thoroughly.

♦

Seal off open pipes/lines and connections with clean plugs

from engine bung set -VAS 6122- to prevent dirt from entering.

– If a pipe/hose assembly is installed between clutch master

cylinder and slave cylinder, clamp off hose -A- using hose

clamp for hoses up to 25 mm -3094- .

Note

Disregard -arrow-.

1. Removing engine 21

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

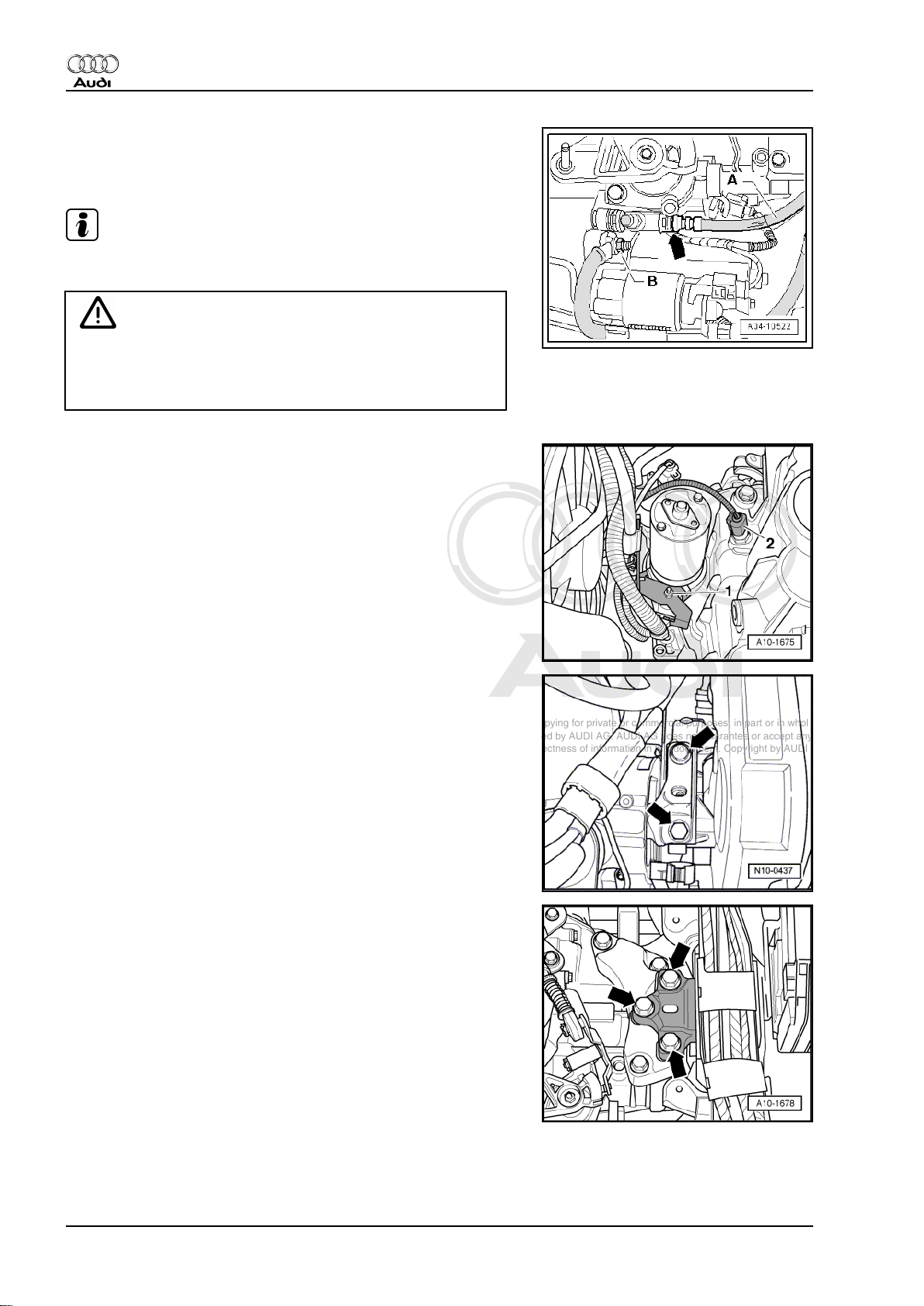

– Pull out clip -arrow- as far as stop.

– Pull plastic pipe or pipe/hose assembly -A- out of clutch slave

cylinder and seal end of pipe.

Note

Disregard -item B-.

Caution

Risk of contamination by escaping brake fluid.

♦ Do not operate clutch pedal after detaching pipe from

bleeder screw on clutch slave cylinder.

– Unplug electrical connector -2- for reversing light switch -F4- .

– Remove nut -1- and press bracket to side.

– Remove bottom starter bolt and detach starter.

– Loosen bolts -arrows- for assembly mounting (engine end)

approx. 2 turns.

– Loosen bolts -arrows- for assembly mounting (gearbox end)

approx. 2 turns.

22 Rep. Gr.10 - Removing and installing engine

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

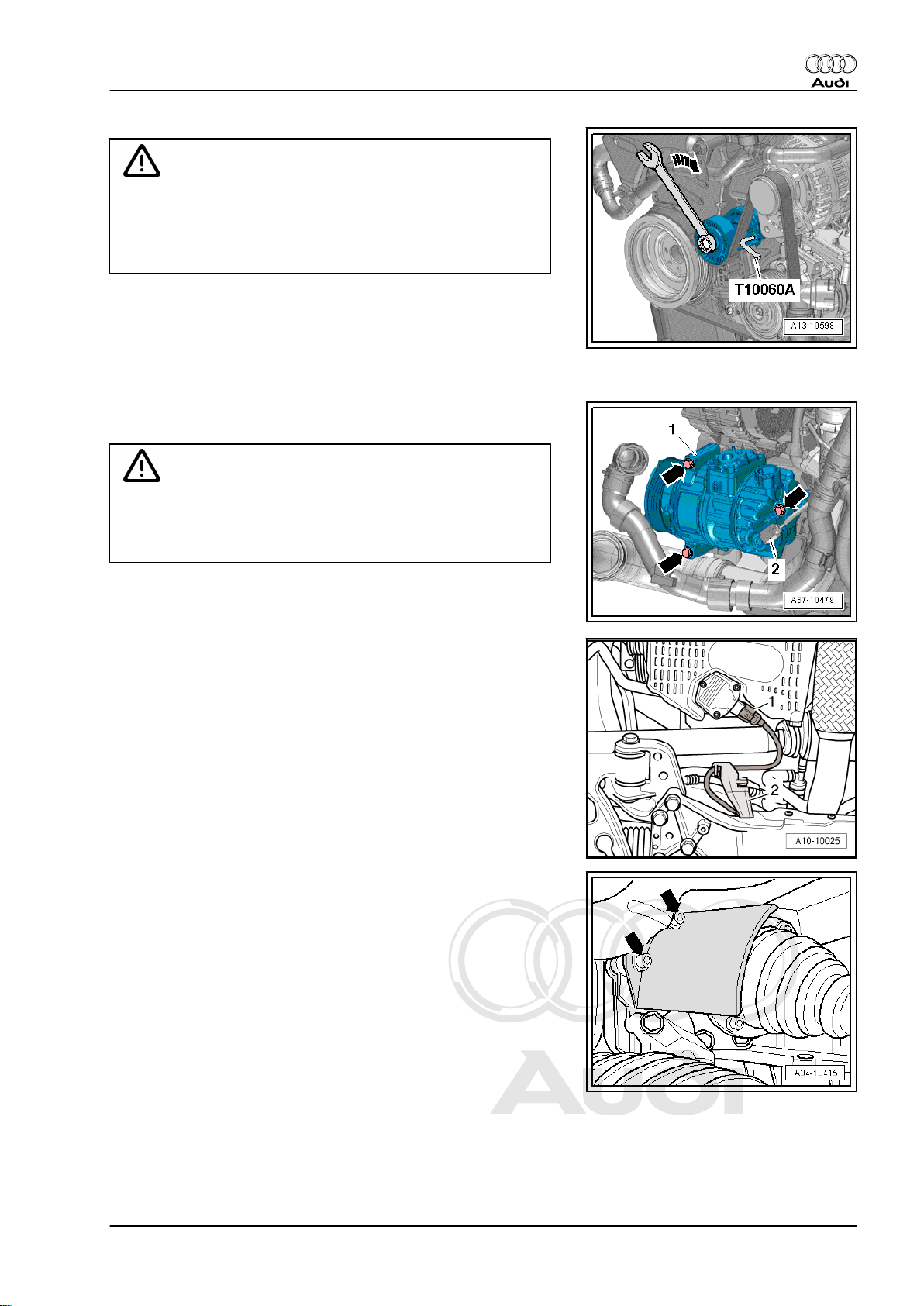

Caution

If a used belt runs in the opposite direction when it is refitted,

this can cause breakage.

♦ Before removing, mark direction of rotation of poly V-belt

with chalk or felt-tipped pen for re-installation.

– To slacken poly V-belt turn tensioner in clockwise direction

-arrow-.

– Lock tensioner with locking pin -T10060 A-

– Take off poly V-belt.

– Unplug electrical connector -2- on air conditioner compressor

regulating valve -N280- .

Caution

Make sure that air conditioner compressor and refrigerant

pipes and hoses are not damaged.

Audi TT 2007 ➤

♦ Do NOT stretch, kink or bend refrigerant lines and hoses.

– Remove bolts -arrow-, detach air conditioner compressor -1-

with refrigerant lines connected and tie up to front.

– Unplug electrical connector -1- at oil level and oil temperature

sender -G266- .

– Unclip bracket -2- for wire to oil level and oil temperature

sender -G266- from subframe.

– Remove bolts -arrows- and detach heat shield for drive shaft

(right-side).

– Detach drive shaft (left-side) from flange shaft of gearbox and

tie up.

– Detach drive shaft (right-side) from flange shaft of bevel box.

1. Removing engine 23

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

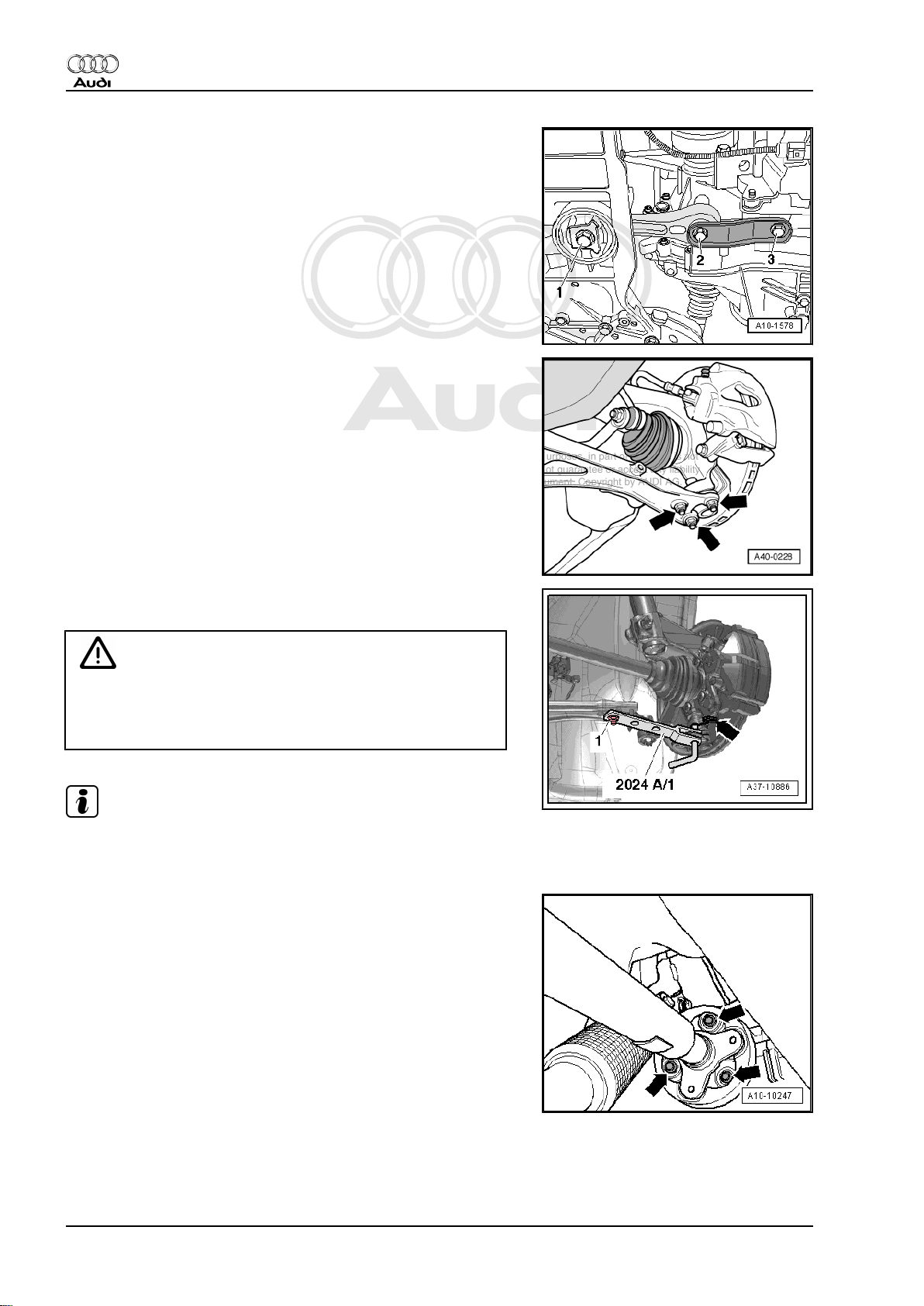

– Remove bolts -1, 2, 3- and remove pendulum support.

– Mark position of nuts -arrows- securing swivel joint.

– Remove nuts for swivel joint (right-side).

– If fitted, remove nut on bracket for front right vehicle level

sender -G289- .

– Detach swivel joint from wishbone.

– Swing suspension strut (right-side) outwards and support with

extension -2024 A /1- as shown in illustration.

WARNING

Accident risk from loose components of support bracket.

♦ Secure retaining pin and swivel joint with locking pin

-arrow- and nut -1-.

Note

The illustration shows the installation position on front suspension

(left-side).

– Mark position of flexible coupling and flange for bevel box in

relation to each other.

– Unbolt flexible coupling for propshaft at bevel box -arrows-

(counterhold using a suitable lever at the triangular flange).

24 Rep. Gr.10 - Removing and installing engine

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Push engine/gearbox assembly forward slightly (towards front

end) and pull propshaft off bevel box.

Caution

Make sure not to damage the seal -arrow- in the propshaft

flange.

♦ Push the propshaft horizontally to the rear and towards the

right side of vehicle as far as possible.

Note

The propshaft must be renewed if oil seal is damaged.

– Unfasten nuts -arrows- for clamp.

Audi TT 2007 ➤

– Remove nuts -1- and -2- and detach bottom bracket for par‐

ticulate filter.

– Tie up particulate filter to rear.

1. Removing engine 25

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Remove bolts -arrows-.

– Move coolant hose -3- clear.

– Loosen hose clip -2-.

– Unplug electrical connector -1- at charge pressure sender -

G31- and detach air pipe.

– Remove bolt -arrow- and push pump for exhaust gas recircu‐

lation cooler -V400- to the side.

Note

Disregard -items 1, 2, 3-.

– Release fasteners -arrows- and remove noise insulation -1-

for sump.

26 Rep. Gr.10 - Removing and installing engine

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Secure engine bracket -T10012- to cylinder block with bolt

-1- and nut -2- (tightening torque: approx. 20 Nm).

– Insert engine and gearbox jack -V.A.G 1383 A- in engine sup‐

port -T10012- and raise engine/gearbox assembly slightly.

Note

Audi TT 2007 ➤

To unscrew bolts for assembly mounting use stepladder VAS 5085- .

– Remove bolts -arrows- for assembly mounting (engine end).

– Remove bolts -arrows- for assembly mounting (gearbox end).

Note

♦

Check that all hoses, pipes and wiring connections between

engine, gearbox and body have been detached.

♦

Carefully guide engine/gearbox assembly when lowering to

avoid damage.

♦

Make sure there is sufficient clearance at air conditioner com‐

pressor and at left-side drive shaft.

– First lower engine/gearbox assembly only slightly.

– Then swing gearbox end of engine/gearbox assembly for‐

wards and only then lower further.

1. Removing engine 27

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

2 Separating engine from manual gear‐

box

Special tools and workshop equipment required

♦ Hooks -10 - 222 A /2-

♦ Workshop hoist -VAS 6100-

♦ Lifting tackle -T40013-

28 Rep. Gr.10 - Removing and installing engine

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

Procedure

• Engine/gearbox assembly removed and attached to engine

bracket -T10012- .

– Attach lifting tackle -T40013- to gearbox and close lock.

– Attach workshop hoist -VAS 6100- with hooks -10 - 222 A /2-

to the lifting tackle.

– Remove bolts -arrows 2, 3- securing bracket for bevel box.

Audi TT 2007 ➤

Note

Disregard -arrows 1-.

– Remove bolts -1, 3, 4, 5- securing gearbox to engine.

– Detach gearbox from engine.

Note

Disregard -items 2, A-.

2. Separating engine from manual gearbox 29

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

3 Securing engine to engine and gearbox support

Special tools and workshop

equipment required

♦ Engine and gearbox sup‐

port -VW 540-

♦ Lifting tackle -3033-

♦ Engine and gearbox sup‐

port -VAS 6095-

♦ Workshop hoist -

VAS 6100-

Procedure

• Gearbox detached from engine ⇒ page 28 .

– Attach lifting tackle -3033- to engine and workshop hoist -

VAS 6100- as shown in illustration.

– Lift engine off engine bracket -T10012- using workshop hoist

-VAS 6100- .

30 Rep. Gr.10 - Removing and installing engine

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Secure engine to engine and gearbox support -VAS 6095- us‐

ing engine and gearbox support -VW 540- .

Audi TT 2007 ➤

3. Securing engine to engine and gearbox support 31

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

4 Installing engine

Tightening torques

Note

♦

Tightening torques apply only to lightly greased, oiled,

phosphated or black-finished nuts and bolts.

♦

Additional lubricants such as engine or gearbox oil may be

used, but do not use lubricants containing graphite.

♦

Do not use degreased parts.

♦

Tolerance for tightening torques ± 15 %.

Tightening torques ⇒ page 37

Further tightening torques

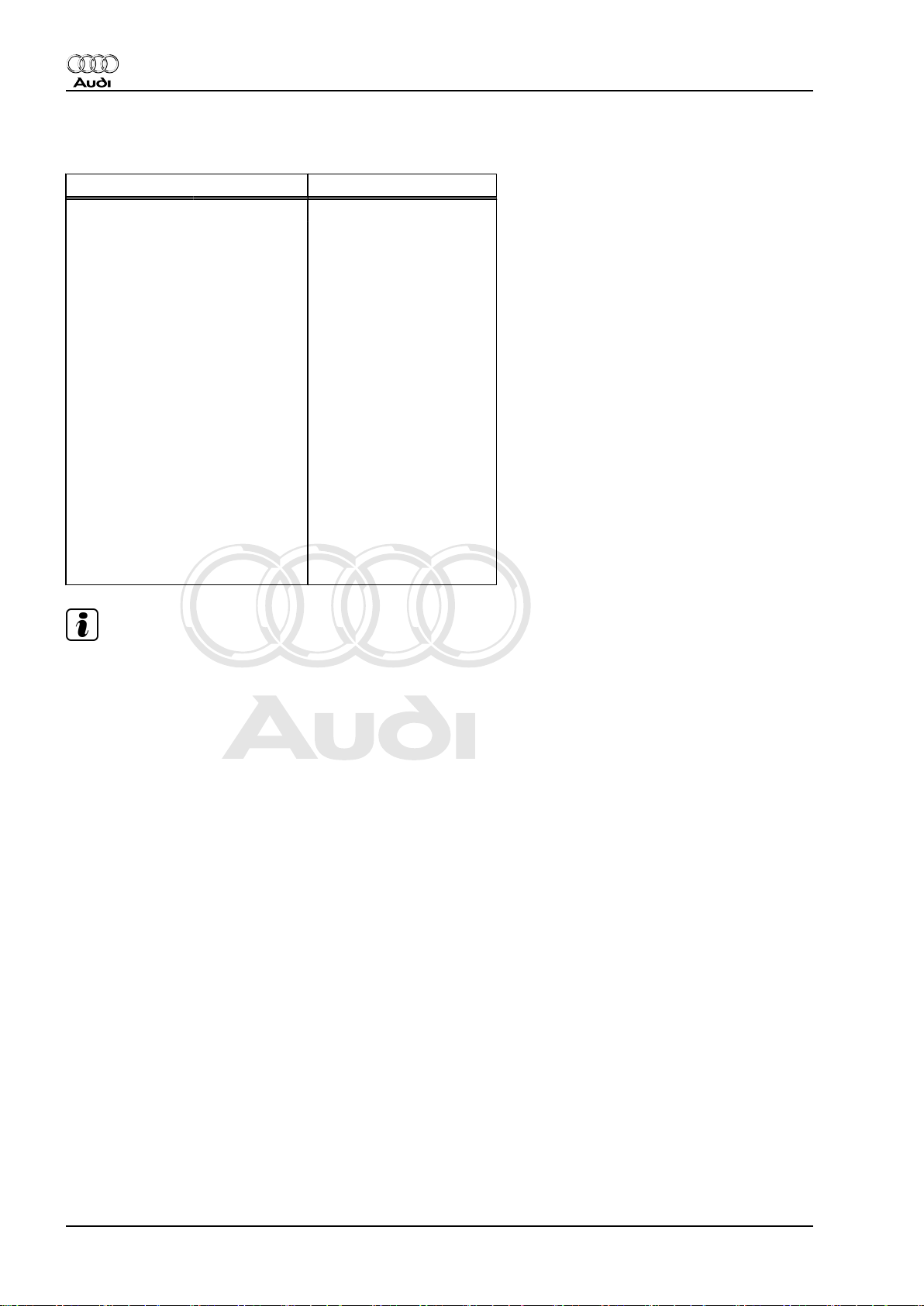

Component Nm

Bolts/nuts M6 10

M7 15

M8 20

M10 40

M12 65

32 Rep. Gr.10 - Removing and installing engine

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

Securing manual gearbox to engine

Audi TT 2007 ➤

Item

2)

1

2)

2

Bolt

1

Nm

M12x55 80

M12x165 80

3 M10x105 40

4 M10x50 40

5

3)

M12x65 80

A Dowel sleeves for centralising

1)

•

Renew bolts.

2)

•

Bolt with M8 threaded pin

3)

•

Screwed into gearbox from engine side

Installation is carried out in the reverse order; note the following:

• Engine/gearbox assembly attached to engine bracket T10012- .

Note

♦

Renew the bolts tightened with specified tightening angle.

♦

Renew self-locking nuts and bolts as well as seals, gaskets

and O-rings.

♦

Hose connections and air pipes and hoses must be free of oil

and grease before assembly.

♦

Secure all hose connections with the correct type of hose clips

(same as original equipment) ⇒ Electronic parts catalogue .

♦

To secure the air hoses at their connections, spray rust re‐

mover onto the worm thread of the used hose clips before

installing.

♦

Fit all cable ties in the original positions when installing.

– If not already fitted, install dowel sleeves for centring engine

and gearbox in cylinder block.

– Ensure that intermediate plate is engaged on sealing flange

and pushed onto dowel sleeves -arrows-.

– Remove needle bearing in crankshaft if fitted ⇒ page 72 .

– Renew clutch release bearing if worn ⇒ Rep. Gr. 30 .

– Lubricate splines of gearbox input shaft lightly with grease for

clutch plate splines ⇒ Electronic parts catalogue .

– Make sure that clutch plate is properly centred.

– Secure gearbox to engine.

– Guide engine/gearbox assembly into body.

4. Installing engine 33

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Initially hand-tighten bolts -arrows- for assembly mounting

(engine end) as far as stop.

.

34 Rep. Gr.10 - Removing and installing engine

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Initially hand-tighten bolts -arrows- for assembly mounting

(gearbox end) as far as stop.

Note

The bolts are tightened to final torque only after adjusting the as‐

sembly mountings ⇒ page 39 .

– Remove engine support -T10012- from engine.

– Install pump for exhaust gas recirculation cooler -V400-

⇒ page 175 .

– Install air pipe ⇒ page 208 .

– Install particulate filter ⇒ page 218 .

– Secure propshaft with flexible coupling to bevel box flange ⇒

Rear final drive 02D/0AV; Rep. Gr. 39 .

– Install wishbone ⇒ Rep. Gr. 40 .

– Install pendulum support ⇒ Rep. Gr. 34 .

– Install drive shafts ⇒ Rep. Gr. 40 .

– Install air conditioner compressor ⇒ Rep. Gr. 87 .

– Install starter ⇒ Rep. Gr. 27

– Install poly V-belt ⇒ page 44 .

– Install engine control unit ⇒ Rep. Gr. 23 .

– Install radiator ⇒ page 191 .

– Install radiator cowl ⇒ page 192 .

– Connect coolant hoses with plug-in connector to heat ex‐

changer ⇒ page 191 .

– Install air cleaner housing ⇒ Rep. Gr. 23 .

– Install air hose with plug-in connector ⇒ page 209 .

– Connect clutch slave cylinder ⇒ Rep. Gr. 30 .

– Install gear selector cable and gate selector cable ⇒ Rep. Gr.

34 .

– Adjust assembly mountings ⇒ page 39 .

– Electrical connections and routing ⇒ Current flow diagrams,

Electrical fault finding and Fitting locations.

– Observe notes on procedure for connecting the battery ⇒ Rep.

Gr. 27 .

Audi TT 2007 ➤

– Install and adjust wiper arms ⇒ Rep. Gr. 92 .

– Install supplementary fuel pump -V393- ⇒ Rep. Gr. 20 .

– Check oil level ⇒ Maintenance ; Booklet 810 .

Caution

Risk of damage to control units because of excessive voltage.

♦ Never use battery charging equipment for boost starting.

– Fill up with coolant ⇒ page 166 .

4. Installing engine 35

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

Note

♦

Do not use drained coolant again if:

♦

the cylinder head or cylinder block have been renewed.

♦

the coolant is contaminated or dirty.

– Install noise insulation frame ⇒ Rep. Gr. 50 .

– Install wheel housing liners (bottom section) and noise insu‐

lation ⇒ Rep. Gr. 66 .

36 Rep. Gr.10 - Removing and installing engine

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

5 Assembly mountings

5.1 Assembly mountings - exploded view

1 - Bolt

❑ Gearbox support to

gearbox

❑ Tightening torque ⇒

Rep. Gr. 34 ⇒ Rep. Gr.

37

2 - Bolts

❑ Pendulum support to

gearbox

❑ Tightening torque ⇒

Rep. Gr. 34 ⇒ Rep. Gr.

37

3 - Engine support

❑ With support arm

❑ Version fitted in vehicle

may differ from illustra‐

tion

4 - Bolt

❑ Engine support to en‐

gine

❑ Observe correct tighten‐

ing sequence

⇒ page 38

❑ 40 Nm + 180°

5 - Engine mounting

6 - Bolt

❑ Engine mounting to

body

❑ Renew

❑ 40 Nm + 90°

7 - Connecting bracket

8 - Bolt

❑ Connecting bracket to engine mounting

❑ Renew

❑ 20 Nm + 90°

9 - Bolt

❑ Connecting bracket to body

❑ Renew

❑ 20 Nm + 90°

10 - Bolt

❑ Engine mounting to body

❑ Renew

❑ 40 Nm + 90°

11 - Bolts

❑ Engine mounting to engine support

Audi TT 2007 ➤

5. Assembly mountings 37

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

❑ Renew

❑ 60 Nm + 90°

12 - Pendulum support

13 - Bolt

❑ Pendulum support to subframe

❑ Tightening torque ⇒ Rep. Gr. 34 ⇒ Rep. Gr. 37

14 - Bolt

❑ Gearbox mounting to gearbox support

❑ Tightening torque ⇒ Rep. Gr. 34 ⇒ Rep. Gr. 37

15 - Bolt

❑ Gearbox mounting to body

❑ Tightening torque ⇒ Rep. Gr. 34 ⇒ Rep. Gr. 37

16 - Gearbox mounting

❑ With support arm

17 - Bolt

❑ Gearbox support to gearbox

❑ Tightening torque ⇒ Rep. Gr. 34 ⇒ Rep. Gr. 37

18 - Gearbox bracket

Tightening sequence for gearbox support

1 - Screw in bolts in the sequence -1, 2, 3- hand-tight.

2 - Tighten bolts in the sequence -1, 2, 3- to 40 Nm.

3 - Turn bolts in the sequence -1, 2, 3- 180° further.

5.2 Checking adjustment of assembly mountings (engine/gearbox mountings)

Procedure

– Remove engine cover panel -arrows-.

38 Rep. Gr.10 - Removing and installing engine

Page 45

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Disengage fuel hose -3- at bracket.

– Pull off bracket for fuel lines towards right -arrow- and move

clear to one side.

– Unplug electrical connector -1- at supplementary fuel pump -

V393- .

– Remove bolts -2- and -4-, detach bracket with supplementary

fuel pump -V393- and move clear to one side.

– Loosen bolt -1-.

– Remove nut -2- and bolt -3-.

– Detach hose retainer -arrow- from fuel filter and move fuel filter

-8- clear to one side with fuel hoses -4 ... 7- connected.

Audi TT 2007 ➤

The following specifications must be obtained:

• There must be a distance of -a- = 13.5 mm between engine

support -2- and longitudinal member (right-side).

• The side of the engine support casting -2- must be aligned

parallel to the support arm -1- (distance -x- = distance -x-).

Note

Distance -a- = 13.5 mm can also be checked with a metal rod of

suitable size, or similar.

– If the distance measured is too large or small, the assembly

mountings must be adjusted ⇒ page 39 .

Assembling

Installation is carried out in the reverse order; note the following:

– Install fuel filter and supplementary fuel pump -V393- ⇒ Rep.

Gr. 20 .

5.3 Adjusting assembly mountings

Special tools and workshop equipment required

5. Assembly mountings 39

Page 46

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

♦ Support bracket -10 - 222 A-

Procedure

• Tightening torques ⇒ page 37

– Remove engine cover panel -arrows-.

– Disengage fuel hose -3- at bracket.

– Pull off bracket for fuel lines towards right -arrow- and move

clear to one side.

– Unplug electrical connector -1- at supplementary fuel pump -

V393- .

– Remove bolts -2- and -4-, detach bracket with supplementary

fuel pump -V393- and move clear to one side.

– Loosen bolt -1-.

– Remove nut -2- and bolt -3-.

– Detach hose retainer -arrow- from fuel filter and move fuel filter

-8- clear to one side with fuel hoses -4 ... 7- connected.

40 Rep. Gr.10 - Removing and installing engine

Page 47

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Remove air cleaner housing ⇒ Rep. Gr. 23 .

– Remove bolts -arrows- and detach bracket -1- for air cleaner

housing.

– Position support bracket -10 - 222 A- with spindles -10 - 222

A /11- on bolted flanges of wing panels as shown in illustration.

– Attach hooks of spindles to engine lifting eyes.

– Take up weight of engine/gearbox assembly evenly with both

spindles (do not raise assembly).

Audi TT 2007 ➤

– Remove bolts -arrows- for assembly mounting (engine end)

one by one and renew (if they were not renewed when instal‐

ling engine).

– Initially fit bolts hand-tight.

– Remove bolts -arrows- for assembly mounting (gearbox end)

one by one and renew (if they were not renewed when instal‐

ling engine).

– Initially fit bolts hand-tight.

5. Assembly mountings 41

Page 48

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

– Using assembly lever, adjust engine/gearbox assembly be‐

tween engine mounting and support arm -1- until specifica‐

tions listed below are attained:

• There must be a distance of -a- = 13.5 mm between engine

support -2- and longitudinal member (right-side).

• The side of the engine support casting -2- must be aligned

parallel to the support arm -1- (distance -x- = distance -x-).

Note

Distance -a- = 13.5 mm can also be checked with a metal rod of

suitable size, or similar.

– Tighten bolts for assembly mounting (engine end).

– Ensure that the edges of the support arm (on the gearbox as‐

sembly mounting) -1- and gearbox mounting -2- are parallel.

• Dimension -x- = dimension -x-.

– Tighten bolts for assembly mounting (gearbox end).

Installation is carried out in the reverse order; note the following:

– Install air cleaner housing ⇒ Rep. Gr. 23 .

– Install fuel filter and supplementary fuel pump -V393- ⇒ Rep.

Gr. 20 .

42 Rep. Gr.10 - Removing and installing engine

Page 49

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

13 – Crankshaft group

1 Cylinder block (pulley end)

1.1 Poly V-belt drive with tensioner and air conditioner compressor - exploded view

1 - Poly V-belt

❑ Check for wear

❑ Before removing, mark

direction of rotation with

chalk or felt-tip pen

❑ Removing and installing

⇒ page 44

❑ Do not kink

❑ When installing, make

sure it is properly seated

on pulleys.

2 - Poly V-belt tensioner

❑ Removing and installing

⇒ page 47

3 - Vibration damper

❑ With poly V-belt pulley

❑ Installation position:

hole in vibration damper

must be positioned over

raised section of crank‐

shaft sprocket

❑ Removing and installing

⇒ page 49

4 - Bolt

❑ Renew

❑ Use only genuine bolts

⇒ Electronic parts cata‐

logue

❑ 10 Nm + 90°

5 - Bolt

❑ Tightening torque ⇒

Rep. Gr. 27

6 - Dowel sleeve

❑ Ensure correct seating in bracket for ancillaries

7 - Bolt

❑ Tightening torque ⇒ Rep. Gr. 23

8 - Bolt

❑ Tightening torque ⇒ Item 20 (page 85)

9 - Idler roller

❑ For toothed belt

10 - Bolt

❑ Tightening torque ⇒ Item 6 (page 84)

1. Cylinder block (pulley end) 43

Page 50

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

4-cylinder TDI engine (2.0 ltr. 4-valve common rail), mechanics - Edition 04.2010

11 - Idler roller

❑ For toothed belt

12 - Bracket for ancillaries

❑ Removing and installing ⇒ page 50

13 - High-pressure pump