Page 1

Service Training

Audi TT Coupé ‘07

Self-Study Programme 380

Page 2

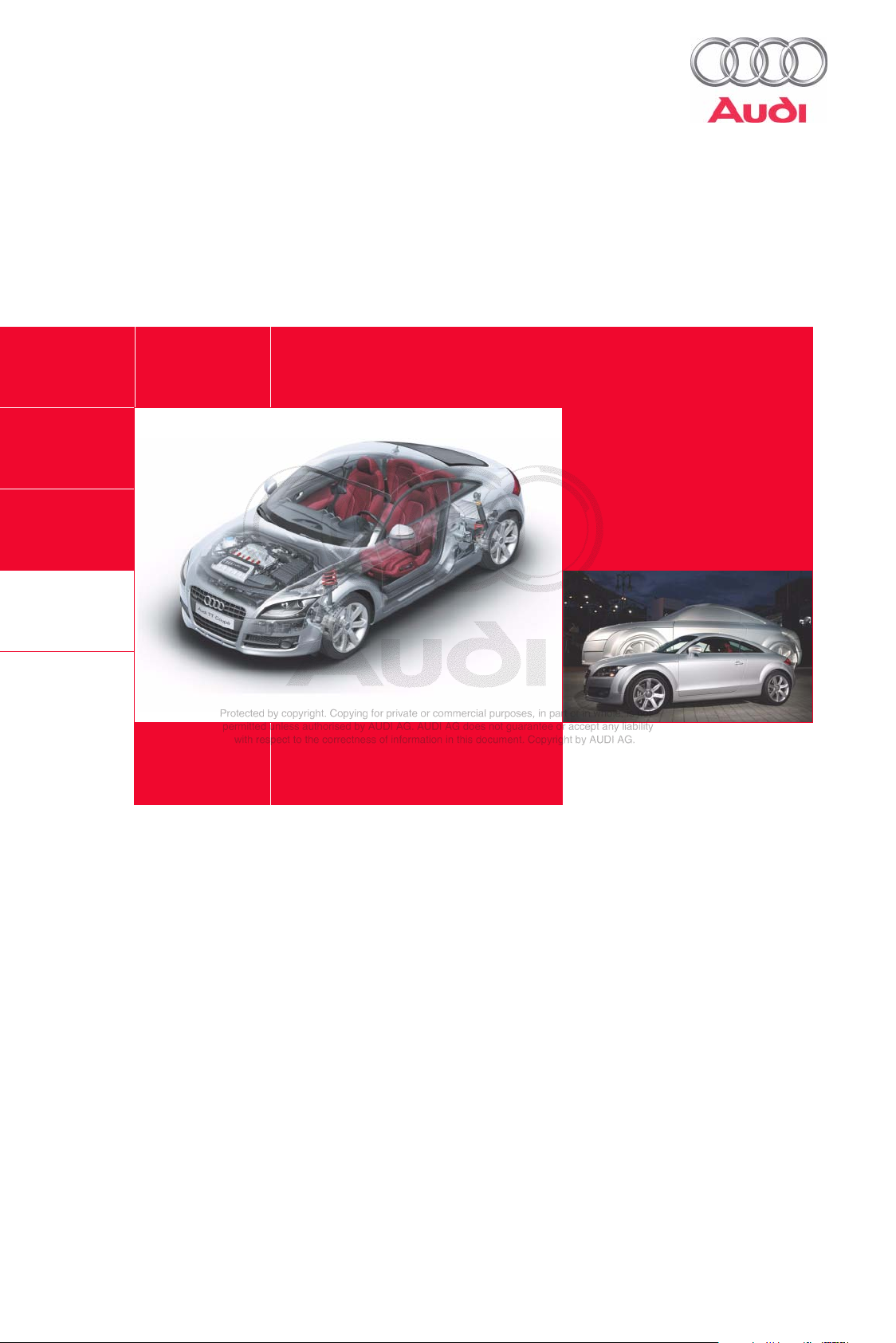

Introduction

The first generation of the Audi TT Coupé, named after the legendary "Tourist Trophy" race in the UK, was

a milestone in automotive design.

The design followed the pure geometry, with central motives being the circle, particularly distinctive on the

wheel arches, the arches of the roofline, the front end and the rear end.Audi has taken this genetic code and

developed it in authentic style.

In the new TT, the geometric shapes merge fluidly with one another.The concave and convex arches radiate

dynamism and movement while lending the TT Coupé the character of an athletic sculpture thrusting

forwards.

The front end of the new TT Coupé has gained in expressiveness and resoluteness, the most distinctive

element being the singelframe radiator grille.

Unlike the predecessor model, the rear end has a completely different outline to the front end. The rear lights

create a three-dimensional effect by virtue of their visual depth. The trapezoidal cut-out around the license

plate continues the flowing lines of the boot lid. The powerful exhaust tailpipes, wide diffusor and central rear

fog light are borrowed straight from motorsport.

The dynamic impression conveyed by the Audi TT Coupé also stems from its modified proportions.

On the exterior it is now: - 137 mm longer

- 78 mm wider

Excellence in design & performance

380_043

Page 3

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Occupant protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Running gear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Air conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Infotainment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

The self-study programme teaches the design and function of new vehicle models,

new automotive components or new technologies.

The self-study programme is not a repair manual!

All values given are intended as a guideline only, and refer

to the software version valid at the time of publication of the SSP.

For maintenance and repair work, always refer to the current technical literature.

NoteReference

Page 4

Introduction

Overview

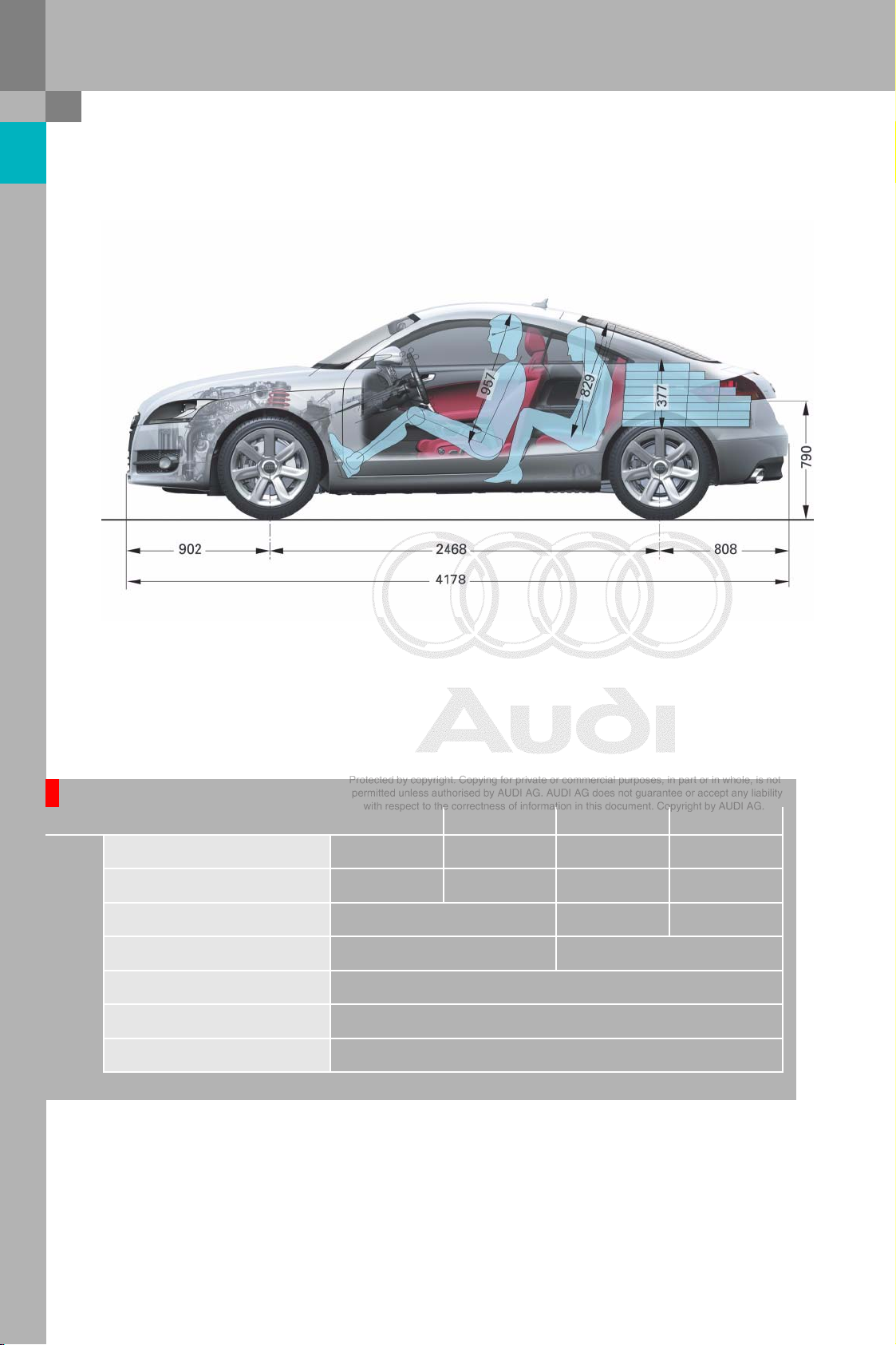

Dimensions of the Audi TT Coupé ‘07.

Audi TT Coupé ‘07 2.0l HS 2.0l s-tronic 3.2l HS qu 3.2l s-tronic qu

Permissible gross weight in kg 1660 1680 1810 1830

Kerb weight without driver in kg 1260 1280 1410 1430

Drag coefficient Cw 0.30 0.30 0.31

Fuel tank capacity in litres 55 60

Body type Audi Space Frame (ASF)

Height of loading sill in mm 790

Luggage compartment volume in l 290 (700l with rear-seat back folded forward)

380_054

4

Page 5

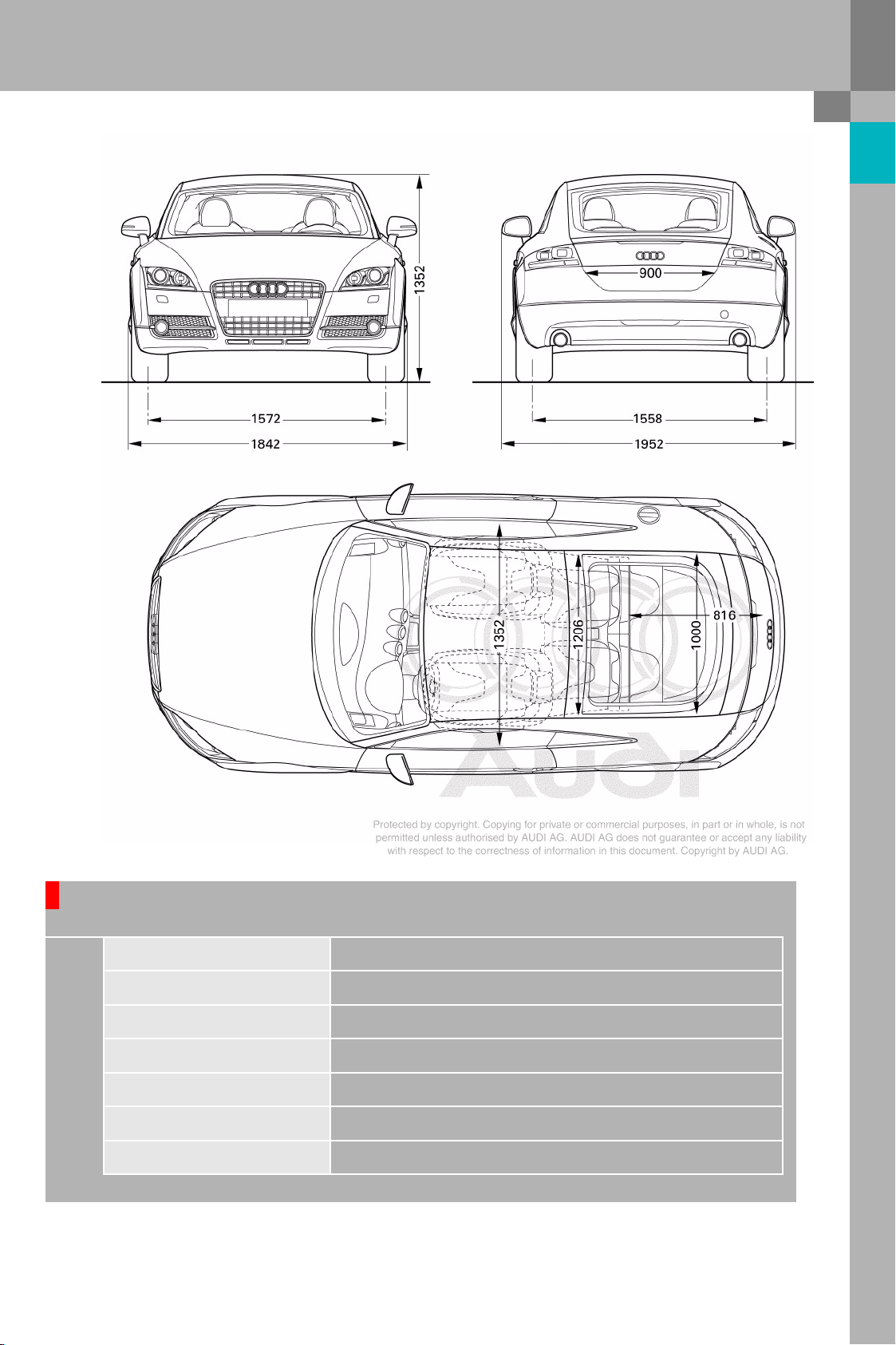

Body / dimensions

Length in mm 4178 + 137

Width in mm 1842 + 78

Height in mm 1352 + 6

Wheelbase in mm 2468 + 46

Front track width in mm 1572 + 26

Rear track width in mm 1558 + 30

Number of seats 2 + 2

380_040

5

Page 6

Body

Audi Space Frame ASF of the Audi TT Coupé ´07

The development targets for the bodyshell of the Audi TT Coupé ‘07

With a weight advantage of 48 % over a comparable all-steel bodyshell, not to mention the optimised weight

distribution, the new composite aluminium-steel spaceframe body of the TT Coupé marks yet another

milestone in the development of modern Audi bodyshells.

Crash safety of the bodyshell is enhanced by load-bearing structures at the front, sides and rear end with

a heavy emphasis on pedestrian safety.

To ensure efficient volume bodyshell production, various new joining and production techniques are

employed.

The repair concept is to a large extent based on the well-known aluminium repair concept, although

combining the materials aluminium and steel meant, of course, that new approaches had to be taken.

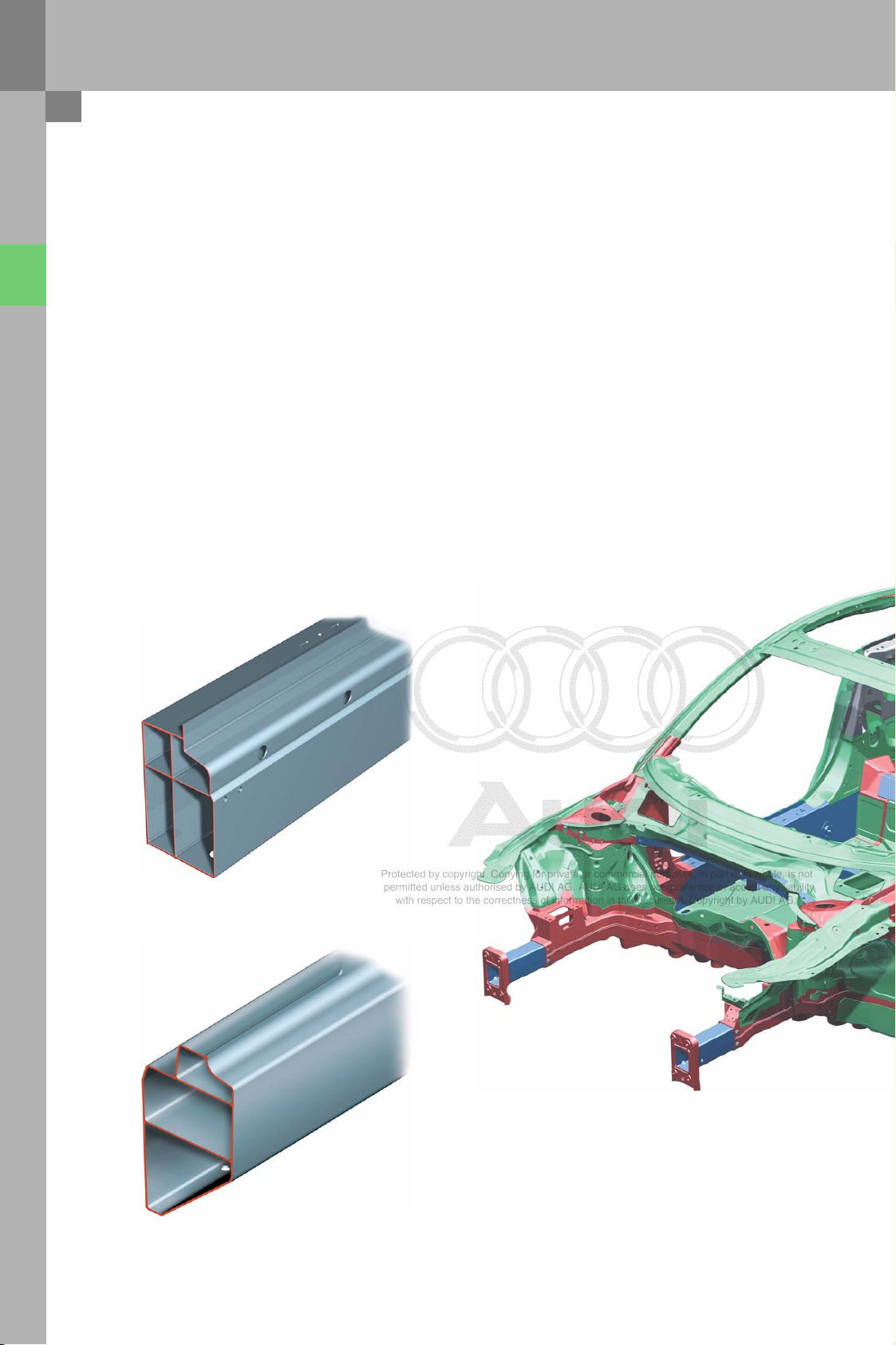

Sill section Audi TT Coupé ‘07

Four-chamber extruded section

Sill section Audi A8

Three-chamber extruded section

380_062

380_063

6

Page 7

Technological concept

Sheet-steel parts are used for the first time in the ASF of the Audi TT Coupé ‘07, in addition to aluminium

castings, aluminium extruded sections and aluminium sheet-metal parts. Collectively they form the body

structure. Vehicle weight distribution is optimised by using sheet-steel parts at the rear end of the body.

This has a direct bearing on sporting characteristics such as driving dynamics and acceleration, as well as

safety characteristics such as stopping distance and driving stability Despite the partial use of sheet-steel

parts, the total body weight of 277 kg including attachments, such as doors and lids, is approx. 48 % less than

that of a comparable full steel body. Although the TT Coupé has grown considerably in size, the overall weight

of the vehicle has been reduced through the use of the aluminium steel bodyshell.

The body structure of the Audi TT Coupé ‘07 has higher strength and 50 % higher torsional rigidity than its

predecessor.

380_061

Component parts overview

22 Aluminium castings

129 Sheet-aluminium parts

19 Extruded aluminium sections

107 Sheet-steel parts (galvanised)

Reference

For details of design and function,

refer to Self-Study Programme 383

Audi TT Coupé ‘07 - Body.

7

Page 8

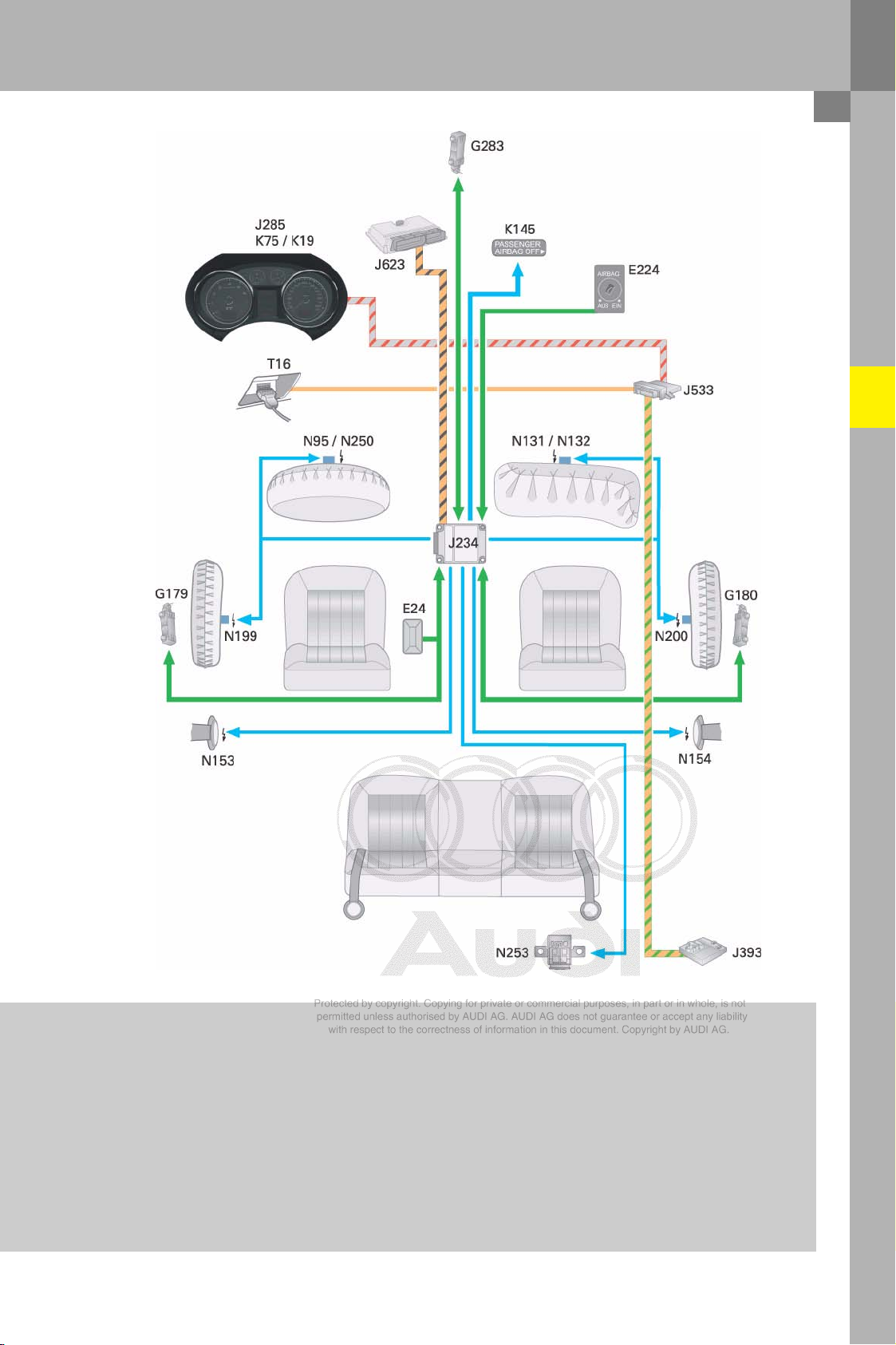

Occupant protection

Occupant protection system in the Audi TT Coupé ‘07

The Audi TT Coupé ‘07 is a high-end sports car. However, the occupant protection system matches the

vehicle's driving dynamics in every respect. Creating a sports car with a high occupant protection potential is

always a big challenge. This challenge was met by the TT Coupé development team.

The occupant protection system of the Audi TT Coupé ‘07 is composed of the following components and

systems:

–Airbag control unit

– Dual-stage driver and front passenger airbags

–Front side airbags

– Central crash sensor for front airbag, so-called "upfront" sensor for head-on collision detection

– Side impact detection sensors in the front doors

– Front belt tensioners

– Battery isolation igniter

– Belt switch, driver side

–Belt-on indicator

Due to the different criteria and statutory requirements set by the various markets, the equipment

specifications can vary. This applies particularly to the US market.

Legend

E24 Driver side belt switch

E224 Front passenger side airbag deactivation key

switch

G179 Side airbag crash sensor, driver side

G180 Side airbag crash sensor, front passenger

side

G283 Driver side front airbag crash sensor (central)

8

Page 9

380_005

J234 Airbag control unit

J285 Control unit with display in dash panel insert

J393 Convenience system central control unit

J533 Data bus diagnostic interface (Gateway)

J623 Engine control unit

K19 Seat belt warning system warning lamp

K75 Airbag warning lamp

K145 Front passenger side airbag deactivated

warning lamp (PASSENGER AIRBAG OFF)

N95 Airbag igniter, driver side

N250 Driver side airbag igniter -2N131 Front passenger side airbag igniter 1

N132 Front passenger side airbag igniter 2

N153 Driver seat belt tensioner igniter -1N154 Front passenger seat belt tensioner igniter -1N199 Side airbag igniter, driver side

N200 Side airbag igniter, front passenger side

N253 Battery isolation igniter

T16 16-pin connector, diagnosis connection

9

Page 10

Occupant protection

Airbag control unit J234

Airbag control unit J234 and integrated electronics have the task of detecting a collision.

In the Audi TT Coupé ‘07 the airbag control unit is attached to the vehicle body in the area of the handbrake

lever.

The airbag control unit is integrated in the CAN powertrain data bus so that it can exchange information with

other control units.

The airbag electronics basically have the following

main tasks:

– Collision detection (front, side, rear)

– Defined deployment of the belt tensioners,

airbags and battery disconnect

– Defined deployment of the second front airbag

stage

– Evaluation of all input information

– Permanent monitoring of the complete airbag

system

– Independent energy supply via capacitor for

a defined period of time

(approx. 150 ms)

– Fault display via failure warning lamp

– Storage of error / and crash information

– Indication of a collision event to other system

components via the powertrain CAN bus or

discrete collision output (conventionally wired)

–Activate seat belt reminder

380_008

To find out which components need replacing after an accident, refer to the valid Workshop Manual in

ElsaWin.

An airbag control unit can only be replaced with a VAS tester running the "Guided Fault Finding" or "Guided

Functions" application.

Reference

For more information about the

airbag control unit J234, refer to SelfStudy Programmes 323 Audi A6 `05

and 361 Audi Q7.

10

Page 11

Belt-on warning

The Audi TT Coupé ‘07 has a belt-on warning function for the driver.

The airbag control unit evaluates the information from the driver side belt switch E24 after ignition "on". If the

driver is not wearing a seat belt, a visual warning is given by the seat belt warning system warning lamp K19

integrated in the dash panel insert.If the system determines that the vehicle is moving, an audio warning is

given in addition to the visual warning.As long as the ignition is on, the airbag control unit monitors the

switched condition of seat belt switch E24. If seat belt status changes while terminal 15 is "on", the seat belt

reminder will be reactivated.

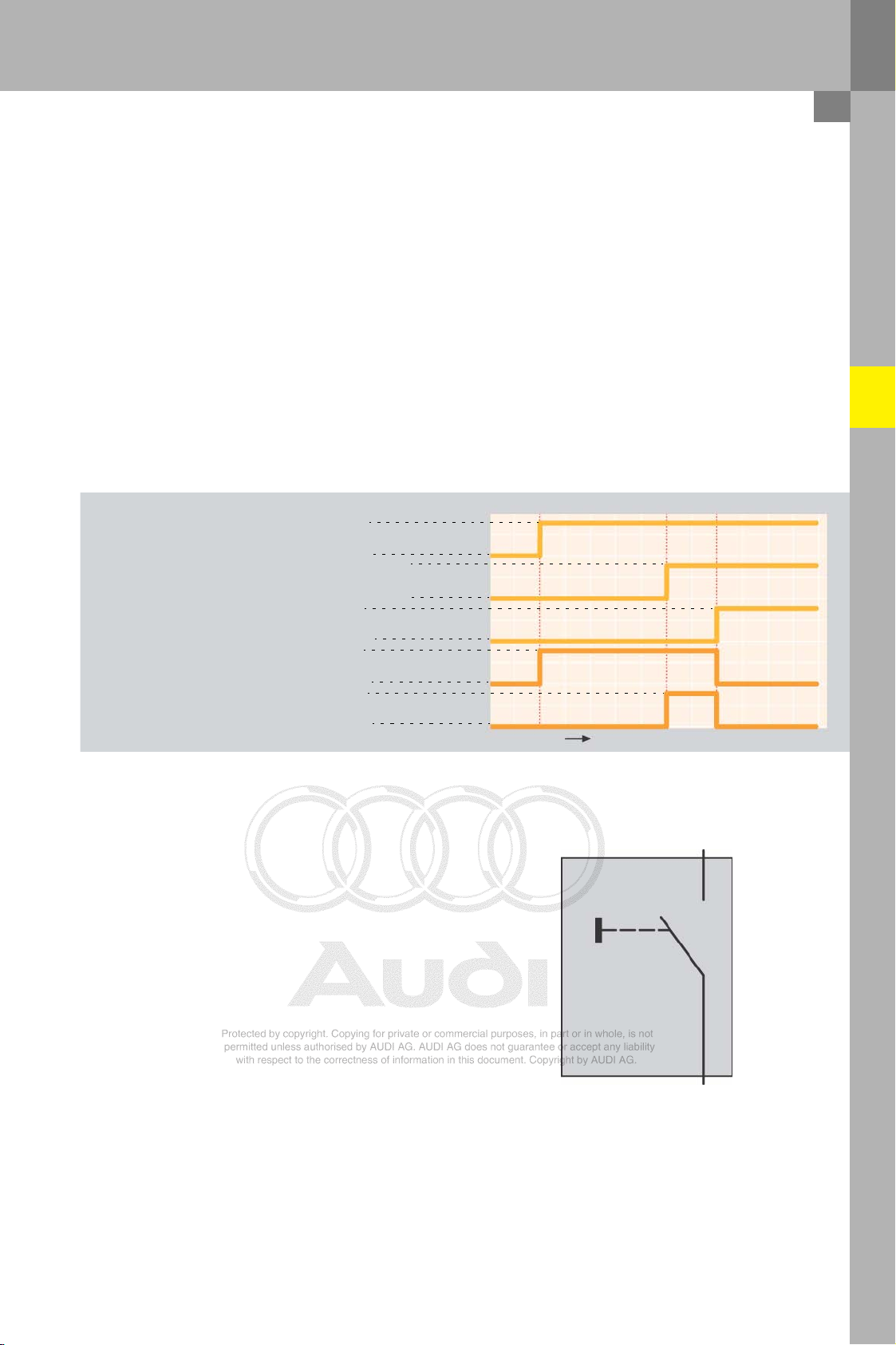

Time diagram for seat belt reminder

Visual and audio signals

- Delayed seat belt fastening

Term i n a l 1 5

Road speed

Seat belt fastened

Seat belt warning system warning lamp

Audio signal

ON

OFF

V > 25 kph

v < 25 kph

yes

No

ON

OFF

ON

OFF

Driver side belt switch E24

The "belt-on warning" function needs information

on whether the driver's seat belt is fastened or not.

Seat belt switch E24 in the belt buckle is

a mechanically actuated open-close switch.

The airbag control unit uses a resistance

measurement to establish whether the seat belt is

fastened or not.

Time

361_016

380_065

11

Page 12

Occupant protection

Airbag

The Audi TT Coupé ‘07 has two-stage front airbags on the driver and front passenger sides.

The airbag control unit selects the time interval between the two ignition stages (approx. 5 ms to 30 ms)

according to severity and type of crash.

The loads acting on the driver or front passenger during an accident can be reduced through time-staggered

ignition of the propellant charges.

Both propellant charges are always ignited. This ensures that no propellant charge remains active after the

airbag is deployed.

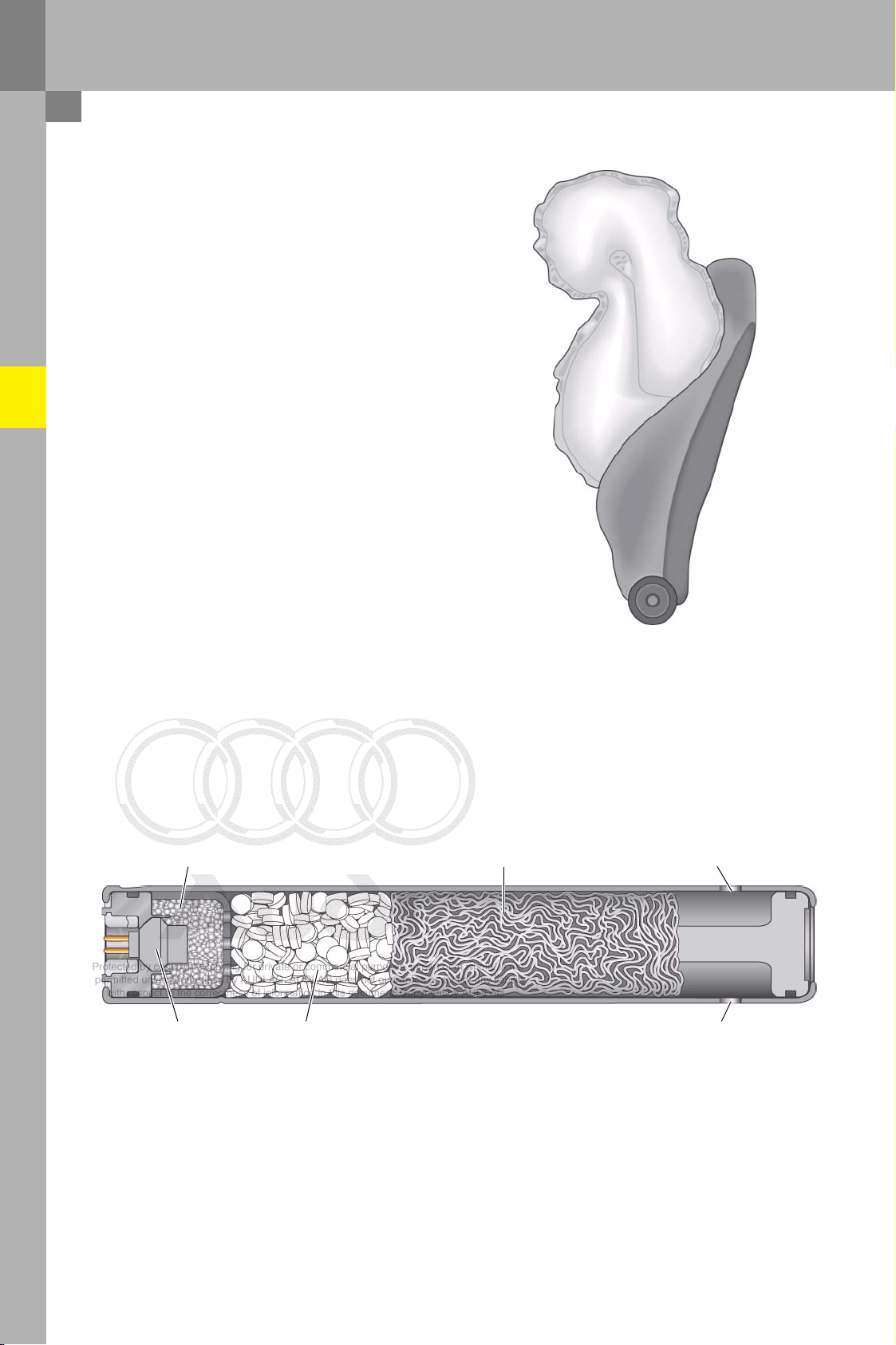

Driver airbag

Airbag igniter I, driver side N95

Airbag igniter II, driver side N250

A gas generator with two pyrotechnic propellant charges is integrated in the driver's airbag.

Igniter I is activated electrically by the airbag control unit J234. The igniter flame passes through the container

and ignites the ignition charge in the container. If the pressure produced by the ignition of the ignition charge

is high enough, the flame will break through the container and reach the propellant charge through the

perforated tube. Propellant charge I ignites and combusts. The developing gas destroys the foil seal, and

filtered gas flows through the air outlet into the airbag. After a defined interval has expired, the airbag control

unit activates igniter II, which in turn ignites propellant charge II directly. The gas produced by combustion of

the propellant material flows through the raised end cap into the combustion chamber of propellant charge I.

From here the gas flows through the filter into the airbag.

Perf ora ted tu be

Casing

Foil seal

Air outlet

Filter

Igniter I

12

Ignition charge container Propellant charge II

Propellant charge I

Igniter II

End cap

Foil seal

Air outlet

Filter

380_003

Page 13

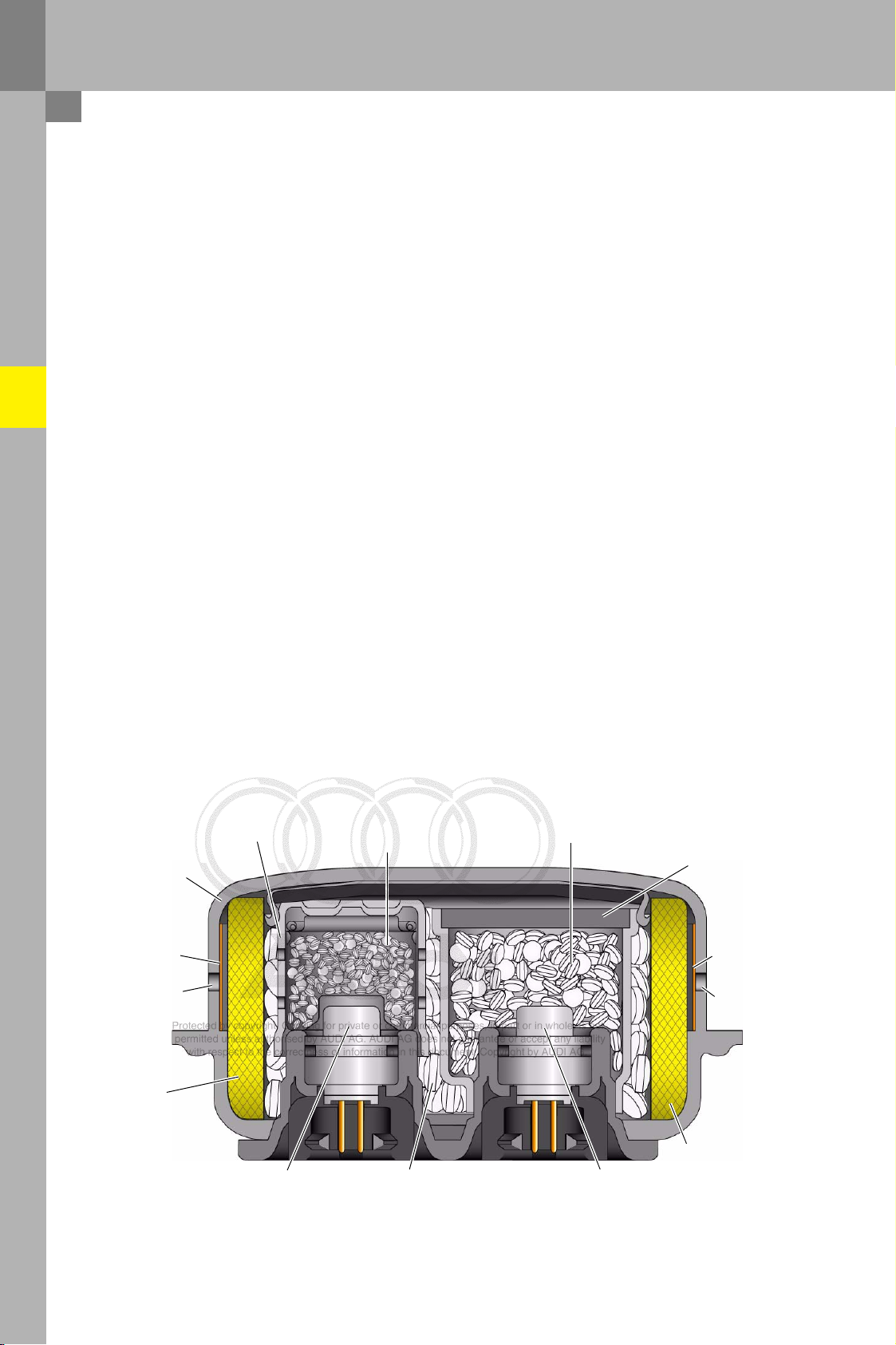

Front passenger airbag

Airbag igniter 1, front passenger side N131

Airbag igniter 2, front passenger side N132

An airbag module with a two-stage hybrid gas generator is used in the Audi TT Coupé ‘07 on the front

passenger side.This module is already in use in the Audi Q7. However, it has been adapted for the TT Coupé.

Two pyrotechnic propellant charges integrated in a pressurised gas bottle are activated separately by the

airbag control unit.

The so-called cold gas in the pressurised gas bottle is under approx. 250 bar of pressure and is a mixture of

approx. 98 % argon and approx. 2 % helium.

Igniter I

Igniter II

Ignition charge I

Ignition charge II Propellant charge II Coil spring Rupture disc

Propellant charge I Coil spring

Filter

Pressurised gas bottle

Gas: approx. 98 % argon

approx. 2 % helium

Pressure: approx. 250 bar

361_002

Reference

For more information about the

function of the front passenger front

airbag, refer to Self-Study Programme

361 Audi Q7.

13

Page 14

Occupant protection

Side airbags

Side airbag igniter, driver side N199

Side airbag igniter, front passenger side N200

Airbag modules which cover both the body and

head areas - so-called head-thorax airbags - are

used as side airbags.

Tubular gas generators filled with solid propellant

inflate the airbags with gas in the event of a crash.

380_004

The airbag control unit J234 energises the corresponding side airbag igniter. The ignition charge which is

ignited by the igniter in turn ignites the actual propellant charge. The developing gas is treated and cooled by

the metal filter, whereupon it unfolds and inflates the airbag.

Metal filterIgnition charge

Propell ant chargeDetonator

Air outlet

Air outlet

361_022

14

Page 15

Driver seat belt tensioner igniter -1- N153

Front passenger seat belt tensioner igniter -1- N154

The Audi TT Coupé ‘07 is equipped with redesigned

belt tensioners for the driver and front passenger.

These belt tensioners are so-called "band

tensioners".

The TT Coupé for the North American market is also

equipped with these belt tensioners.

If the rear seats in the TT Coupé are equipped with

Isofix fixing eyelets, belt tensioners are also

installed for these seats.

The workshop manual (ElsaWin) applicable to the

vehicle describes the tests which must be made to

detect an activated belt tensioner (band tensioner).

An activated belt tensioner can be detected, among

other things, by virtue of the fact that the foil

located on the side of the belt tensioner housing is

detached from the housing.

Seat belt Inertia-reel seatbelt

Foil

Belt tensioner unit

380_030

A metal band is wrapped around the seat belt

retractor shaft.

Both open ends are connected to the seat belt

retractor shaft.

The closed end is looped around the belt tensioner

igniter.

Metal band

Seat belt retractor

shaft

Electrical connector

Detonator

Metal band loop

380_027

15

Page 16

Occupant protection

The belt tensioner igniter is located inside the metal

band loop.

When the igniter is activated by the airbag control

unit, the resultant pressure causes the

loop of the metal band to expand.The movement of

the metal band exerts a pull on the seat belt

retractor shaft, which thereupon begins to rotate,

tensioning the seat belt.

Metal band

Seat belt retractor

shaft

Electrical connector

Detonator

Metal band loop

380_028

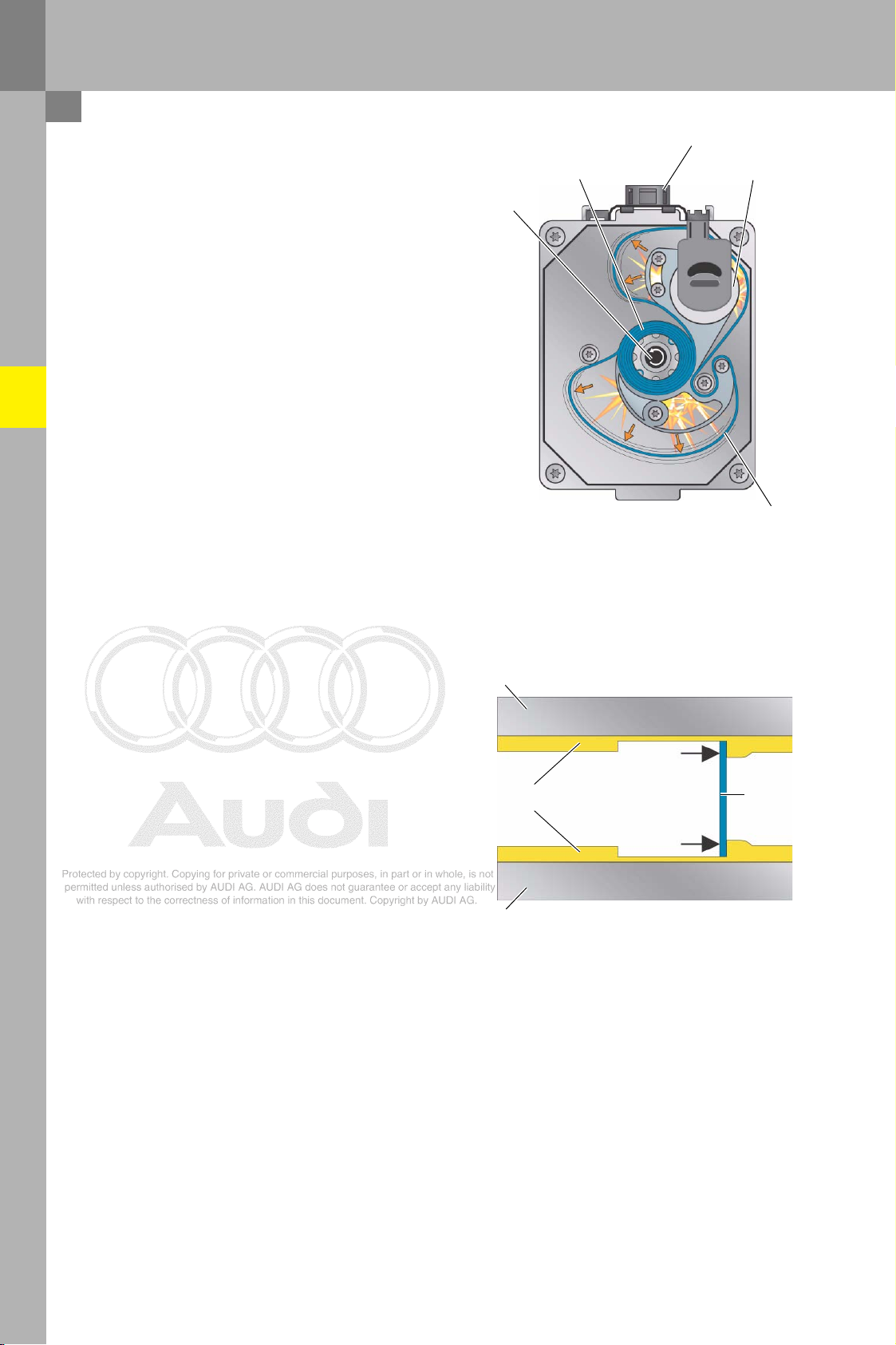

The casing and casing cover surface between which

the metal band moves are coated in a layer of

silicon. When the metal band moves, it thrusts

a part of this silicon layer ahead of itself and

thereby ensures that a tight seal is maintained.

Pressure losses are thus reduced.

Casing

Silicon layer

Casing cover

Metal band

380_026

16

Page 17

Battery isolation igniter N253

The battery isolation igniter has the task of

disconnecting the starter and alternator leads from

the vehicle battery in the event of a crash.

Use is made of a pyrotechnic component which is

activated by the airbag control unit J234 whenever

the airbag is deployed.

During a rear collision, only the belt tensioner and

the battery isolation igniter are activated.

If the pyrotechnic propellant charge is ignited, the

resultant gas pressure displaces the pin on a piston

and disconnects the two terminals.

After deployment of the airbag, the battery isolation

igniter must be replaced.

Battery isolation igniter

Pin

Connecting

element with

terminals

Detonator

332_030

361_024

Reference

Further information on the function

of the battery isolation igniter, refer

to Self-Study Programme 361

Audi Q7.

17

Page 18

Occupant protection

Additional functions and components of the occupant

protection system for the North American market

The additional functions and components of the occupant protection system for the North American market

are described on the following pages.

The occupant protection system is equipped with additional functions and components,

e.g. second crash sensor for front airbag, so that the Audi TT Coupé ‘07 meets the statutory and marketspecific requirements for the US market.

Seat occupied detection, front passenger side

The front passenger side seat occupied recognition system was largely adopted from the Audi Q7.

The system basically comprises the following components:

– Seat squab

– Sensor mat for seat occupied recognition

– Pressure sensor for seat occupied recognition G452

– Seat occupied recognition control unit J706

– Front passenger side belt switch E25

– Seat belt force sensor for seat occupied recognition G453

– Front passenger side airbag deactivated warning lamp

K145 (PASSENGER AIRBAG OFF)

–Airbag control unit J234

These components form a single

unit and must not be separated

from each other.

Driver side belt switch E24

Front passenger side belt switch E25

The Audi TT Coupé ‘07 for the North American

market is equipped with seat belt switches for beltfastened recognition on the driver and front

passenger sides.

Seat belt switches E24 and E25 are integrated in the

belt buckles on the front seats So-called "reed

switches" are used. The reed switch remains open

until the occupants have fastened their seat belts.

The airbag control unit J234 performs a resistance

measurement from which it can determine whether

the occupants have fastened their seat belts or not.

Depending on the position of the reed switch, the

measurement is made using one or both resistors.

361_029

Reference

For further information about the

seat occupied recognition system

and the seat belt switch, refer to SelfStudy Programme 361 Audi Q7.

18

Page 19

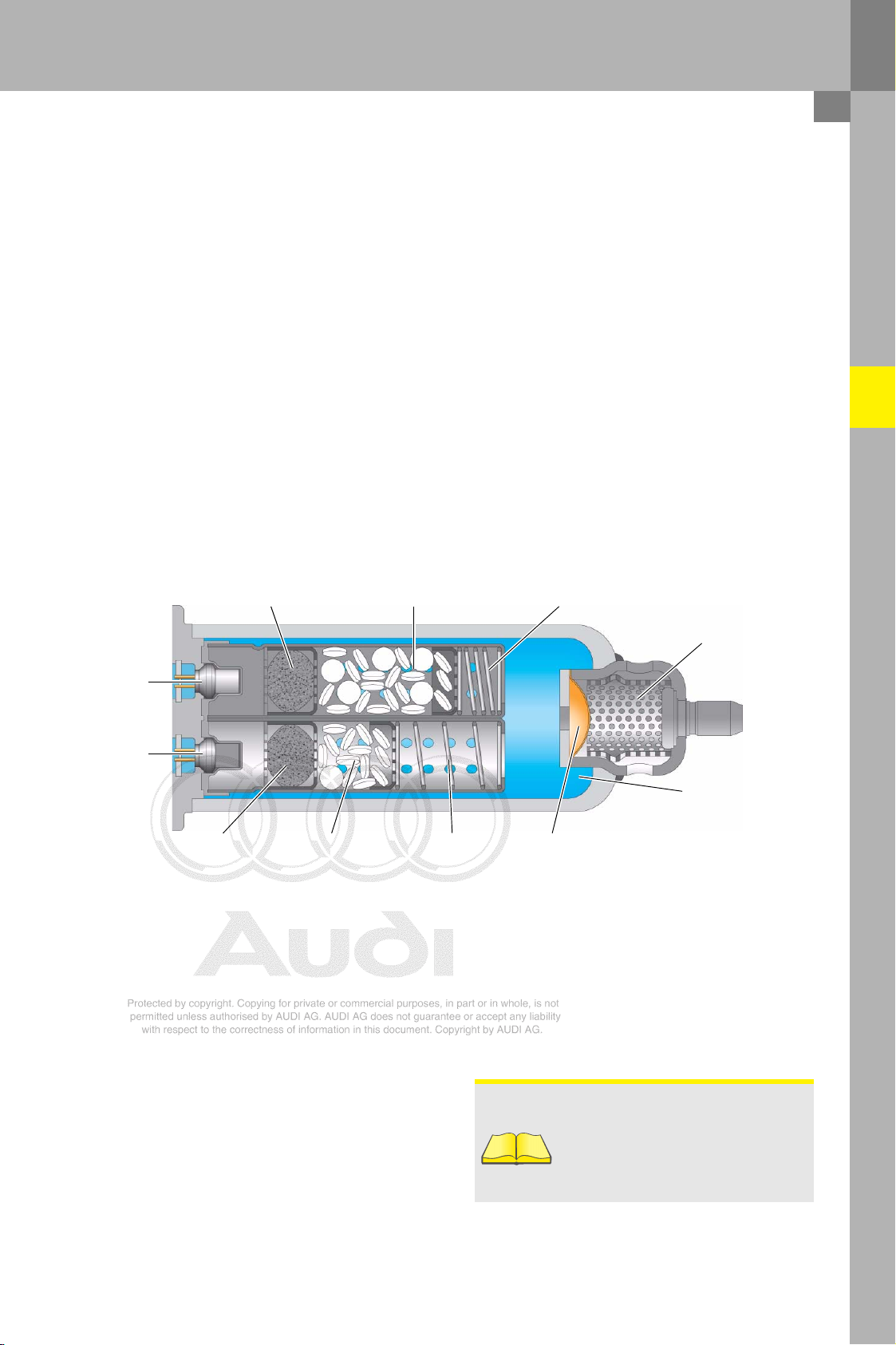

Knee airbag igniter, driver side N295

Knee airbag igniter, front passenger side N296

The Audi TT Coupé ‘07 for the North American market is equipped with knee airbags for the driver and front

passenger sides.

Ignited knee airbags allow the occupants to participate earlier in the vehicle deceleration process. The airbag

system of driver and front passenger front airbags in combination with knee airbags reduces the injury risk

for the occupants.

On the driver side, the knee airbag is located in the footwell trim panel below the dash panel.On the front

passenger side, the knee airbag is located behind the glove box lid.

After the airbags are activated, the airbag unfolds

between the dash panel and the occupants' legs.

Gas generator

View inside the dash panel

Airbag

380_006

Hybrid gas generators have the task of inflating the airbags with gas.

The airbag control unit J234 activates the igniter in the gas generator. The resultant pulsation wave is directed

to the rupture disc. The rupture disc breaks and the helium from the pressurised gas bottle flows into the

airbag.

Filter Air outlet

Detonator

Filter Air outlet Rupture disc Pressurised gas bottle

Gas: Helium

Pressure: approx. 600 bar

380_009

19

Page 20

Occupant protection

Belt force limiter, driver side G551

Belt force limiter, front passenger side G552

The front inertia-reel seatbelts have a two-stage belt

force limiter. In the event of a collision, the belt

tensioners (band tensioners) are ignited first. The

inertia-reel seatbelt blocks the seat belt retractor

shaft and prevents the seat belt from unreeling,

which would occur due to the forwards movement

of the occupants. The seat belt retractor shaft is

designed as a torsion shaft. To limit the load which

the seat belt places on the occupants, two torsion

shafts allow controlled unreeling of the seat belt;

belt force limiter.

After a defined interval, the airbag control unit

activates the belt force limiter igniter.

The second torsion shaft is decoupled. The seat belt

retractor shaft now counteracts the force which the

seat belt exerts.

To ensure that the occupants are afforded a good

level of protection, the belt tensioning function, the

belt force limiting function and the front airbags are

coordinated with each other.

Detonator

Spline end

Gear II

Seat belt

retractor shaft

Gear I

Torsion shaft II

380_013

Gears I and II are permanently connected to the seat

belt retractor shaft and the second torsion shaft

respectively.

In the initial state, both gears are in mesh with one

another.

Tor sio n s h a f t II

Spline end

Gear II

Seat belt retractor shaft

Gear I

380_012

20

Page 21

The belt tensioner retracts the seat belt to the extent

possible, and the inertia-reel seatbelt locks the seat

belt retractor shaft. The seat belt can no longer be

pulled out.

If the occupant's body now accelerates forwards

due to centrifugal force, the belt force limiter allows

the seat belt to unreel as of a certain force.Both

torsion shafts are rotated.

Seat belt retractor shaft

Tor sio n s h a ft II

Gear I

Spline end

Gear II

380_011

After a defined period of time, the belt force limiter

igniter is activated. The spline end decouples gear II

from gear I.

The belt force is now limited by the seat belt

retractor shaft alone.The occupant can plunge into

the fully inflated airbag.

Detonator

Spline end

Seat belt retractor shaft

Tor sio n s h a ft II

Gear I

Tors io n s h a f t I I

Spline end

Gear II

380_010

Gear II

Seat belt

retractor shaft

Gear I

380_016

21

Page 22

Engine

Engine-gearbox combination

2.0l 4 cyl. TFSI MQ 350 6F / DQ 250 6F

380_045

380_042

380_044

380_060

MQ 350 6A / DQ 250 6A3.2l VR6 MPI

380_045

380_060

Reference

For information about the design and

function on the s-tronic, please refer

to Self-Study Programme 386

6-speed Direct Shift Gearbox 02E.

22

Page 23

2.0l TFSI

The engine number is located at the rear left of the

engine block in the area of the gearbox flange.

Tec h ni c al f eat ur es

– Toothed belt drive with CTC toothed belt

sprocket

– Selective petrol direct injection system (FSI)

–Turbocharging

– Pencil ignition coils

– 1 primary catalytic converter and 1 main catalytic

converter

– 1 primary catalytic converter and 1 post-cat

sensor

Tor q u e/ po we r c ur v e

Max. torque in Nm

Max. power output in kW

380_042

Engine speed in RPM

Specifications

Engine code BWA

Typ e of eng ine 4-cylinder petrol engine

Displacement 1984 cm

Powe r outp ut 147 kW (200 bhp) at 5100 RPM

To rq ue 280 Nm at 1800 - 5000 RPM

Bore 82.5 mm

Stroke 92.8 mm

Compre ssion ratio 10.5 : 1

Cylinder spacing 90 mm

Weight approx. 152 kg

Firing order 1 – 3 – 4 – 2

Engine management Bosch Motronic MED 9.1

Exhaust gas recirculation Internal exhaust gas recirculation

Exhaust emission control 1 ceramic pre-catalytic converter with heating function via homogeneous

Exhaust emission standard EU 4 / ULEV

3

split dual injection, 1 main catalytic converter

380_047

23

Page 24

Engine

3.2l VR6 MPI

Tec h ni c al f eat ur es

– Chain drive on the transmission side

– Cylinder-selective injection system

– Fully variable adjustment of both camshafts

– Pencil ignition coils

– 2 primary catalytic converters and 2 main

catalytic converters

Tor q u e/ po we r c ur v e

Max. torque in Nm

380_044

Max. power output in kW

Engine speed in RPM

Specifications

Engine code BUB

Typ e of e ngine VR6 petrol engine 15° vee angle

Displacement 3,189 cm

Power out pu t 184 kW (250 bhp) at 6,300 RPM

To rq ue 320 Nm from 2500 to 3000 RPM

Bore 84.0 mm

Stroke 95.9 mm

Compre ssio n rati o 11.3 : 1

Offset 15°

Firing orde r 1 – 5 – 3 – 6 – 2 – 4

Engine management Bosch ME 7.1.1

Camshaft adjustment range Intake camshaft 52° crank angle

Exhau st ga s recirculation Internal exhaust gas recirculation

Exhaust emission control 2 primary catalytic converters and 2 main catalytic converters

Exhaust emission standard EU 4

3

Exhaust camshaft 42° crank angle

380_046

24

Page 25

Fuel supply

The fuel system is basically adopted from the A3 `04.

The fuel tanks differ from one another in terms of their shape, which is dependent on the vehicle's drive

concept.

They are made of HPPE (high-pressure polyethylene). To safeguard the fuel tank against destruction in the

event of an accident, it is mounted in front of the rear axle. Here it is fixed to the underbody by means of

ratchet straps. It is not necessary to disassemble the rear axle to remove the fuel tank. The front tank has

a capacity of 55 litres, the quattro tank 60 litres.The US spec quattro tank has a capacity of 55 litres, because

a different breather system is used due to the different statutory requirements which apply.

Front tank

Breather pipe

quattro tank

Fuel tank

breather pipe

Fuel tank

breather pipe

Fuel filter

Fuel filter

Breather pipe

Breather pipe

Fuel delivery

unit

to tank

Fuel delivery unit

to tank

Breather pipe

Suction jet pump

(entrainment pump)

+ 2nd fuel tank sender

380_020

380_001

25

Page 26

Engine

Pressure regulation

The fuel filter is bolted to the exterior of the fuel tank. The pressure regulator is integrated in the fuel filter.

In case of excess pressure, the governed fuel is returned to the tank. The pressure regulator in the FSI engine

cuts off fuel delivery at 6.4 bar (relative). In the case of the MPI engine, fuel cut-off is at 4 bar (relative). Both

systems are returnless, with the distinction being that the pressure in the MPI engine is maintained at

a constant 4 bar, while the FSI engine utilises a supply-on-demand fuel system.

Reference

Pressure regulation in the 3.2l and

2.0l engines is described in SelfStudy Programme 290 and Self-Study

Programme 332 respectively.

Fuel gauge sender

For the MPI and FSI engines, a fuel delivery unit with

integrated fuel gauge potentiometer and a suction

jet pump are arranged inside the fuel tank.

In the case of the quattro tank, a second fuel gauge

potentiometer is arranged inside the second half of

the fuel tank.The second half of the fuel tank also

houses the suction jet pump, which pumps the fuel

into the fuel delivery unit reservoir. The suction jet

pump is attached securely to the sender flange by

means of clips. The thin line is the propulsion jet

line. It is driven by the suction jet pump. The thicker

line is the mixing tube, in which the intake fuel is

pumped to the fuel delivery unit.

The fuel gauge senders are configured as slider

potentiometers.

Suction jet pump

Fuel pump

380_021

Suction jet pump

Fuel gauge sender

380_023

26

Page 27

Fuel tank breather system, ROW spec (2.0l and 3.2l engines)

Tank connection, fuel

Tank connection, breather

Activated charcoal canister

Engine connection, fuel

on 3.2l engine only

Fuel tank breather system, US spec (2.0l and 3.2l engines)

Tank connection, breather

380_034

Activated charcoal canister

Fuel system diagnostic pump

Engine connection, fuel on 3.2l engine only

Tank c o n n e c t i o n , f u e l

380_033

27

Page 28

Engine

Soundpipe

A soundpipe is used on the 3.2l V6 engine to give the engine a sportier sound. The intake noise is transmitted

to the vehicle body via a connecting line from the intake manifold to the plenum chamber and via a resonator.

The soundpipe has been developed to accentuate the dynamism and sportiness of the 3.2l engine

The soundpipe produces a sporty sound in the vehicle interior without impairing comfort. The pressure

pulsations are amplified by the gas exchange cycle via the soundpipe without exceeding the exterior noise

limits. Unwanted noise emission from ancillary units and tire noise are to a large extent avoided by the fact

that the occupant cell is well-insulated. As a result, comfortable travelling is still possible.

Secondary pipe Sound generator Primary pipe

Air filter

380_014

28

Page 29

Function

A soundpipe is connected between the air mass meter and the throttle valve unit in the air intake tract.

The soundpipe made up of three parts: the primary pipe, which is connected to the air intake tract, the sound

generator and the secondary pipe, which is connected to the vehicle interior via the engine bulkhead. The

primary and secondary pipes as well as the sound generator are configured in such a way that it is possible to

influence the "bandpass characteristic"*, and hence the acoustic transmission range. However, the sound

generator is the key component.The system is designed such that the sound becomes meatier when the

driver demands more power from the engine.

The pressure pulsations which during the gas exchange cycle are transmitted to the membranes in the sound

generator, where they are amplified by the sound generator and relayed to the vehicle interior. Another further

task the membranes is to seal the gas flow between the air intake tract and the vehicle interior. The foam core

in the sound generator has the task of maintaining the shape and position of the membranes.

* A bandpass characteristic is produced, for example, by connecting the highpass and lowpass filters in

series. Only a defined range of frequencies is allowed to pass, depending on the circuit configuration.

Sound generator

Securing clip

to vehicle

interior

Secondary pipe

Prim ary pi pe

O-ringFoam co re Membranes

from intake

manifold

380_076

29

Page 30

Suspension system

Suspension system

Overview

The Audi TT Coupé ‘07 is available with three different suspension systems. The dynamic suspension system

represents the basic specification. The semi-active "Audi magnetic ride" suspension is optional. The driver can

select between comfort and sport suspension settings at the touch of a button.

quattro GmbH is also offering an S-Line suspension system, which is sportier than the dynamic suspension

system.The main axle components are identical to those of the Audi A3 in respect of their design and

function.

Front axle

An improved version of the McPherson suspension

is used.The design of the front axle is identical to

that of the Audi A3. Track width is 13 mm wider on

each side than the Audi A3.

Detail modifications have been made to reflect the

particularly sporty character of the Audi TT Coupé

‘07. In addition to the tuning parts (springs,

dampers and anti-roll bars), the same axle

components are used in all TT Coupé suspension

variants.

30

380_074

380_066

Page 31

Rear axle

The rear axle of the Audi TT Coupé ‘07 is basically identical in design and function to the rear axle on the

Audi A3. The wheel carriers, damper bearings and wheel bearings are modifications on the components on

the Audi A3.Track width has been increased by 15 mm on each side compared to the Audi A3. The suspension

and damping components (springs, dampers and anti-roll bars) were adapted to the specific requirements of

the TT Coupé. Additional stone chip protection is provided for certain markets. The trailing arms and spring

links on these models are protected by plastic claddings.

Rear axle for front-wheel drive

Rear axle for quattro models

380_071

380_072

31

Page 32

Suspension system

Brake system

Overview

Front axle brake caliper

16" for all four-cylinder models

17" for all six-cylinder models

ESP

TEVES Mk60E1

with optional low tyre pressure indicator

Brake servo

10", 11", 7/8"

with contactless brake light switch

without dual rate characteristic

32

Page 33

Rear axle brake caliper

16" for all four-cylinder models

17" for all six-cylinder models

380_073

33

Page 34

Suspension system

Steering system

The electromechanical steering system EPS which

has proved successful in the Audi A3 is also

featured in the Audi TT Coupé ‘07. Various detail

modifications have been made to adapt the steering

system for use in the TT Coupé.

A mechanical steering column is fitted in the

Audi TT Coupé ‘07. The steering column is basically

identical in design and function to the steering

column in the Audi A3.

Various detail modifications have been made to

adapt the steering column for use in the TT Coupé.

380_069

A redesigned steering wheel is used in the

Audi TT Coupé ‘07. All models are fitted with threespoke leather-bound steering wheels with an

integral two-stage airbag module. In addition to the

standard version, combinations are also available of

multifunction, Tiptronic and leather stitching in

various colours.

380_067

380_068

34

Page 35

Audi magnetic ride

The Audi TT is the first Audi to feature Audi magnetic ride - a new semi-active suspension system with

magneto-rheologically controlled dampers. A sport or comfort damper set-up can be activated at the touch of

a button.

Damper adjustment button

E387

ECD control unit (electronically

controlled damping)

J250

Shock absorber damping

adjustment warning lamp

K189

Damper adjustment valve

N336-339

Audi magnetic ride improves driving dynamics and

driving comfort for the following reasons:

– reduced body movement (pitch and roll)

– optimised vibration behaviour

– improved road-holding

– improved handling

Vehicle level sender

G76-78, G289

380_064

Reference

For details of the design and function

of the suspension system, refer to

Self-Study Programme 381

Audi TT Coupé ‘07 - Suspension

System.

35

Page 36

Suspension system

Wheels and SST tyres (self supporting tires)

Engine

4-cylinder

6-cylinder

* also available optionally as SST wheel

Basic wheels Optional wheels Winter wheels

7.5J x 126 ET 45 (1)

Cast aluminium

wheel

painted

225/55 R 16

8.5J x 17 ET 50 (2)

Forged al umi niu m

wheel

painted

245/45 R 17 *

8J x 17 ET 47 (3)

Cast aluminium

wheel

painted

225/50 R 17 *

9J x 18 ET 52 (4)

Cast aluminium

wheel

painted

245/40 R 18 *

9J x 18 ET 52 (5)

Cast aluminium

wheel

polished

bi-color

245/40 R 18 *

8.5J x 17 ET 50 (6)

Cast aluminium

wheel

painted

245/40 R 18 *

7J x 16 ET 47 (7)

Cast aluminium

wheel

painted

225/55 R 16

7J x 17 ET 47 (8)

Forged aluminiu m

wheel

painted

225/50 R 17 *

9J x 18 ET 52 (9)

Cast aluminium

wheel

painted

245/40 R 18 *

380_075

SST tyres have run-flat capability because of their modified design compared to conventional tyres.

Much stiffer tyre sidewalls enable the vehicle to drive on for up to 50 km at a maximum speed of 80 kph even

after a total loss of pressure.

Special wheels are used for the SST tyres due to the modified tyre geometry. The special 17" wheels on the

Audi TT Coupé ‘07 can be used both for conventional tyres and for SST tyres. In the case of the 18" wheels,

conventional tyres are available in combination with conventional rims. SST tyres are always combined with

the low tyre pressure indicator.

36

Page 37

Low tyre pressure indicator

In all markets except North America, the

Audi TT Coupé ‘07 comes with an upgraded version

of the low tyre pressure indicator previously

featured in the Audi A3. Being an indirect measuring

system, no tyre pressure sensors are installed in

the wheels.

Using a new evaluation method, it is now possible

to detect simultaneous pressure loss to at multiple

wheels. Tyre pressures are monitored

simultaneously using two different concepts.

380_070

37

Page 38

Electrical system

Topology and networking

Engine control unit

J623

Direct shift gearbox

mechatronics

J743

Selector lever

E313

ABS control unit

J104

Airbag control unit

J234

Four-wheel drive

control unit

J492

Tyre pressu re

monitor control unit 2

J793*

Power steering

control unit

J500

Steering angle

sender

G85

Steering column

electronics control

unit

J527

controlled damping)

Powe r outp ut m od ule

for left headlight

J667

ECD control unit

(electronically

J250

Headlight range

control, control unit

J431

Power output module for

right headlight

J668

Multi-function

steering wheel control

unit

J453

38

Page 39

Diagnostic port

Control unit with display

in dash panel insert

J285

Data bus diagnostic interface

J533

Front passenger

door control unit

Convertible top

operation control unit

heater control unit

Driver door

control unit

J386

J387

Park ing a id

control unit

J446

J256

Auxiliary air

J604

Climatronic

control unit

J255

Anti-theft alarm

system sensor

G578

Telephone transmitter

and receiver unit

R36

Digital satellite

radio tun er

R190

Digital sound package

control unit

J525

TV tuner

R78

Radio

R

Control unit with

display for radio and

navigation

J503

CD changer

R41

Convenience system

central control unit

J393

Onboard power

supply control unit

J619

Tyre pressure monitor

control unit

J502**

Alarm horn

H12

Wiper motor

control unit

J400

Rain and light

detector sensor

G397

* for tyre pressure monitoring system 2 only (ECE = Europe)

** for tyre pressure monitor only (SAE = North America)

Power train CAN bus

infotainment CAN bus

Convenience CAN bus

Dash panel insert CAN bus

Diagnostics CAN bus

LIN bus

Subbus system

Panasonic bus

382_044

39

Page 40

Electrical system

Installation overview - control units

40

Page 41

Legend

382_067

1 Garage door operation control unit J530

2 Direct shift gearbox mechatronics J743

3 Power steering control unit J500

4 Engine control unit J623

5 ABS control unit J104

6 Wiper motor control unit J400

7 Alarm horn H12

8 Onboard power supply control unit J519

Headlight range control, control unit J431

9 Data bus diagnostic interface J533

10 CD changer R41

11 Tyre pressure monitor control unit 2 J793 /

Tyre pressure monitor control unit J502*

12 Control unit with display in dash panel insert

J285

13 Radio R

Control unit with display for radio and

navigation J503

Climatronic control unit J255

14 Steering column electronics control unit J527

Steering angle sender G85

Multi-function steering wheel control unit

J453

15 Rain and light detector sensor G397

16 Driver door control unit J386

17 Front passenger door control unit J387

18 Anti-theft alarm system sensor G578

19 Telephone transmitter and receiver unit R36

20 Airbag control unit J234

21 ECD control unit (electronically controlled

damping) J250

22 Digital satellite radio tuner R190

23 Digital sound package control unit J525

24 Convenience system central control unit J393

Parking aid control unit J446

TV tuner R78

25 Radio controlled clock receiver J489

* for tyre pressure monitor only SAE

41

Page 42

Air conditioning

Overview

The air conditioning system of the

Audi TT Coupé ‘07 is an improved version of the

system used in the Audi A3 ’04. The automatic air

conditioning system is configured as a single-zone

air conditioning system. The TT Coupé has only one

climate zone with no temperature differential

between the driver and front passenger sides.

The TT Roadster is available with a heating-only

system, in addition to the automatic air

conditioning system.

The TT vehicles with petrol engine have no auxiliary

heater and, therefore, no electrical PTC heater

element.

The Climatronic control unit J255 has a rotary knob

for temperature selection, but no digital display.

The system has an air recirculation function, which

can be activated either by the occupants or

automatically as soon as the "on" conditions for air

recirculation have been met.

The automatic air recirculation function by means of

an air quality sensor G238 was not implemented;

no air quality sensor G238 is fitted.

The fresh air intake duct temperature sensor G89 is

not fitted. Information on ambient temperature is

supplied only by the ambient temperature sensor

G17 via CAN data bus from the dash panel insert.

Air conditioner in Audi TT Coupé ‘07

Fresh air/ ram air flap

Air flow flap control motor

V71

Defroster flap

Defroster flap control motor

V107

Air recirculation flap

Air recirculation flap control motor

V113

Chest vent

right

Chest vent

centre

Chest vent

left

Temperature flap

control motor,

right

V159

Temperature flap control motor, left

V158

Central flap control motor

V70

42

380_036

Page 43

Climatronic control unit J255

The setpoint for the temperature flap is set using the "Temperature" rotary knob. The rotary knob is infinitely

variable and activates the "Maximum cool" function in the lowest setting and the "Maximum heat" function in

the highest setting.

Automatic mode of the air conditioning system can be deactivated with the "Air flow" or "Air distribution"

rotary knob or by pressing the DEFROST or AC key.

The air conditioner compressor of the system can be switched on or off by pressing the AC key; the LED is on

or off. The system is active without cooling function when the air conditioner compressor is off.

DEFROST function key REAR WINDOW DEFROSTER function key

"Temperature" rotary knob "Air flow" rotary knob "Air distribution" rotary knob

AUTO function key AIR RECIRCULATION function key SEAT HEATER right function key

SEAT HEATER left function key AC function key

380_049

The seat heater is optional equipment with the Audi TT Coupé ‘07. The three heater settings can be set by

pressing the function keys.

In setting 0 the seat heater is off; setting 0 cannot be selected directly from setting 3; it can only be activated

by pressing the "Minus" key several times.

The function keys are backlit and currently active functions are indicated by integrated LEDs. The control unit

with display in dash panel insert J285 provides the dimming signals terminal 58d for the function LEDs and

terminal 58s for the key backlighting via CAN bus.

The LEDs of the function keys and the key backlighting cannot be switched individually.

43

Page 44

Air conditioning

Components of the air conditioning system

in the Audi TT Coupé ‘07

Air conditioner compressor

Single acting wobble plate compressor with

6 cylinders and variable delivery rate, without

magnetic coupling, externally controlled.

The air conditioner compressor is not a carry-over

part from the Audi A3.

The compressor stroke volume is regulated via the

air conditioning system compressor regulating

valve N280 by means of the PWM signal, depending

on cooling power requirements.

Ambient temperature sensor G17

Only one ambient temperature sensor is used to

evaluate the ambient temperature.

The ambient temperature sensor G17 is located at

the front end, on the right-hand side behind the

bumper, directly in front of the condenser.

Its value is provide by the control unit with display

in dash panel insert J285 via CAN bus.

If the ambient temperature sensor G17 is faulty,

the ECON function is activated. This means that the

active cooling function is deactivated and the AC

LED goes out.

Dash panel temperature sensor G56

compressor regulating val ve N280

Ambient temperature sensor

(directly before the condenser)

Air conditioning system

380_053

380_048

Dash panel temperature sensor

The dash panel temperature sensor is integrated in

the housing of the Climatronic control unit J255 and

is ventilated by a suction blower. The temperature

sensor can take on values from -50 °C to +77 °C.

The dash panel temperature sensor is deactivated if

the temperature sensor or ventilation motor is

faulty. An entry is made in the data memory, and the

Climatronic control unit J255 uses saved substitute

values depending on the temperature set at the

control panel.

44

380_052

Page 45

Outlet temperature sensor

For the driver side, one outlet temperature sensor is

installed in the air duct of the chest vent and in the

footwell duct. For the front passenger side, only the

outlet temperature sensor is installed in the footwell

duct.

The Climatronic control unit J255 evaluates the

outlet temperature sensor in dependence on the air

distribution and determines from this the actual

outlet temperature.

If an outlet temperature sensor is found to be faulty,

the temperature control is generally not

deactivated. Depending on the operating mode

(Heat or Cool) and the side of the vehicle on which

the fault occurs (the front passenger side has only

one outlet temperature sensor, in the footwell duct),

the Climatronic control unit J255 decides whether

the temperature control can remain active or has to

be deactivated.

If air distribution is in the DEFROST setting, the

outlet temperature control is deactivated.

Outlet temperature sensor

380_050

Combined filter in the Audi TT Coupé ‘07

A combined activated charcoal filter is standard on in the Audi TT Coupé ‘07.

The combined filter is accessible from the front passenger footwell. The filter can be replaced without tools.

The cover in the front passenger footwell is fixed in place with two wing bolts and the pollen filter air duct

cover is located in position using a slide mechanism.

The combined filter has two predetermined bending points.This makes the filter easy to bend and simplifies

installation of the filter into the air conditioner.

Dust and pollen filter

Cover

Fastening bolt s

Pollen filter air duct cover

380_051

45

Page 46

Air conditioning

Function diagram of the automatic air conditioning system

G261 G262 G263 G385* G386** G107

Signal, left

12 V

12 V

12 V

5 V

Signal, right

V70

Evaluation for driver's seat heating

Evaluation for front passenger's seat heating

G112 V71 G113 V107 G135

Legend

G56 Dash panel temperature sensor

G65 High pressure sender

G107 Sunlight penetration photo sensor

G112 Central flap control motor potentiometer

G113 Air flow flap control motor potentiometer

G135 Defroster flap control motor potentiometer

G143 Air recirculation flap control motor

potentiometer

G220 Left temperature flap control motor

potentiometer

J255

G221 Right temperature flap control motor

potentiometer

G261 Vent temperature sender, left footwell

G262 Vent temperature sender, right footwell

G263 Evaporator out-flow temperature sender

*G385 Front left chest vent temperature sender

hand-drive vehicles only)

**G386Front right chest vent temperature sender

(right-hand drive vehicles only)

J126 Fresh air blower control unit

J255 Climatronic control unit

(left-

46

Page 47

N280

G65 V2

Term i n a l 7 5

Term i n a l 3 0

Term i n a l 1 5

Term i n a l 3 1

J126

DiagnosisPWMPWMPWM

V42

V113 G143 V158 G220 V159 G221

N280 Air conditioning system compressor

G56 Dash panel temperature sensor

Input signal for J255

Convenience CAN data bus

regulating valve

Output signal from J255

V2 Fresh air blower

V42 Temperature sensor blower

Positive 5 V / 12 V

V70 Central flap control motor

V71 Air flow flap control motor

Terminal 13 / earth

V107 Defroster flap control motor

V113 Air recirculation flap control motor

CAN data bus

V158 Temperature flap control motor, left

V159 Temperature flap control motor, right

Posi tive 5 V

Earth

Te rm i n

380_037

47

Page 48

Infotainment

Radio navigation systems at a glance

Audi Navigation (BNS 5.0) Audi Navigation plus (RNS-E)

General 6 inch dot matrix display, monochrome 6.5 inch TFT colour display

Light dimming via CAN bus

Display in driver information system

MMI operating logic

can be operated via optional multifunction steering wheel

6 function keys 8 function keys (incl. Name, Car)

CD drive for navigation CD, audio CD or MP3 CD DVD drive for navigation DVD or

German, English, French, Italian, Dutch,

Portuguese, Swedish, Spanish and Czech

Integrated 2 x 20 W power module, Audi sound system with auxiliary amplifier as standard

Radio 2-tuner FM/MW/LW with TMC

CD/MP3 Navigation CD drive reads audio CDs and MP3 CDs

9 languages

can be loaded via CD

Clock in status bar

2-DIN housing

Mute function via Power button (hierarchical mute function)

--- Version display via CAR menu

--- Optional voice recognition system for radio, CD,

Dynamically updated station list

Diversity aerials

--- TP Memo function

6-CD autochanger or iPOD connectivity

--- 2 integrated MMC/SD card slots for MP3 files

--- MP3 playlist support

audio CD or MP3 CD

(German, English, French, Italian, Spanish,

6 languages

Portuguese)

navigation and telephone

48

Page 49

Table c o n t ' d

Audi Navigation (BNS 5.0) Audi Navigation plus (RNS-E)

Navigation CD navigation system incl. Major Roads of Europe DVD navigation system, single-DVD drive

Dynamic navigation system with RDS and TMC

Turning instructions and directional arrow display in driver information system

Destination input options: postcode, place name,

street name, POIs, latitude and longitude

Shortest/optimum/quickest route are selectable max. 3 route options are given

max. 6 intermediate destinations are possible max. 3 intermediate destinations are possible

--- Colour screen incl. Birdview, split screen and POIs

--- Geometric motorway exit display

--- Intersections map

--- List display of the next three route

--- Intelligent Speller (last city history)

Corridor function allows audio or MP3 CDs to be

Te le p ho n e Mute function for hands-free telephone via cable or CAN

Telephone (with

optional Audi mobile

phone adaptor)

Bluetooth symbol appears in the status bar if the mobile phone is connected to the mobile phone adaptor

Voice control functions of mobile phone adaptor

Options BOSE sound system

Service All amplifiers can be encoded for GALA, while

BOSE Sound amplifiers are encoded as standard

System software is flashable by CD in service

played while navigating

Loudspeaker control unit for hands-free telephone, adjustable volume control unit for calls

Display of reception level, network provider and roaming symbol

"accept call", "reject call" and "hang up" functions

Telephone number entry via Speller

Telephone number selection from the mobile phone phonebook

active

--- Telephone number selection from the address

Mobile phone adaptor

--- Analog TV tuner

No auxiliary input (AUX-In)

for Audio-Pilot

Vehicle-specific sound curves can be encoded

Diagnostics via CAN (A3, TT) or L-wire (A4)

4-digit radio code incl. convenience code

Transport mode via CAN Transport mode via adaption channel or CAN

workshops

Destination input options: postcode, place name,

street name, POIs, cursor, address book

recommendations

---

via Bluetooth.

Voice control system integrated in mobile phone

adaptor or voice recognition system

book

Audi Sound System has GALA while the BOSE

Sound System has Audio Pilot

System software is flashable by navigation DVD

49

Page 50

Infotainment

Radio systems at a glance

chorus concert symphony

Three-line graphic display, light dimming via CAN

can be operated via optional multifunction steering wheel

Station frequency display in the driver information system

RDS (Radio Data System) with EON (Enhanced Other Network)

--- --- Traffic Information Messages

Integrated single-CD drive,

CD text capable

Control unit for external 6-disc CD changer or auxiliary iPod adaptor

Integrated 2 x 20 watts power module (not used for concert and symphony radios in the Audi TT)

--- Auxiliary sound amplifier connected

--- Connectivity for optional auxiliary BOSE Surround Sound amplifier

Basic sound set-up via encoding of vehicle type (saloon/Avant/Cabrio), interior trim (fabric/leather) and

Integrated single-CD drive for audio CDs

Loudspeaker control unit for hands-free telephone

Diagnostics via CAN (A3 8P, TT) or L-wire (A4 8E)

Transport mode (reduced power demand)

Anti-theft device with convenience coding

Volume adjustment as a function of road speed (GALA)

2-DIN housing

FM/AM tuner

FM tuner with phase diversity

and MP3 CDs, CD text capable

AUX input (code-activatable)

Mute function for hands-free telephone

engine type (petrol/diesel engine)

(TIM = TP Memo)

Integrated 6-disc CD changer for

audio CDs and MP3 CDs, CD text capable

US variant

RDBS FM/AM radio (FM/MW)

Control unit for optional digital satellite tuner

Reference

For detailed descriptions of radios

and navigation systems,

refer to Self-Study Programme 382

Audi TT Coupé ‘07 - Electrical and

Infotainment Systems

50

Page 51

Self-study programmes on the TT Coupé

SSP 380 Audi TT Coupé ‘07

–Body

– Occupant protection

–Engine

– Suspension system

– Electrical system

– Air conditioning

– Infotainment

Order number: A06.5S00.25.20

SSP 381 Audi TT Coupé ‘07 Suspension System

–Front axle

–Rear axle

– Shock absorber system

– Brake system

Order number: A06.5S00.26.20

SSP 382 Audi TT Coupé ‘07 Electrical and Infotainment Systems

–Networking

–Bus topology

– Convenience electronics

– Infotainment

Order number: A06.5S00.27.20

SSP 383 Audi TT Coupé ‘07 - Body

– Audi Space Frame

– Production processes and joining methods

–Surface finish

– Electromechanical rear spoiler

– Repair concept

– Passive safety concept

Order number: A06.5S00.28.20

Page 52

Vorsprung durch Technik www.audi.de

380

All rights reserved.

Technical specifications

subject to change without

notice.

Copyright

AUDI AG

I/VK-35

Service.training@audi.de

Fax +49-841/89-36367

AUDI AG

D-85045 Ingolstadt

Technical status: 05/06

Printed in Germany

A06.5S00.25.20

Loading...

Loading...