Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder)

Engine ID

Edition 05.2005

ARY AUM AUQ BVP BVR

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

01 - Self-diagnosis

24 - Mixture preparation - injection

28 - Ignition system

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A0357085920

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Contents

01 - Self-diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Self-diagnosis of Motronic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Technical data of self-diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Connecting vehicle diagnostic, testing and information system VAS 5051 A . . . . . . . . . . 2

2 Interrogating fault memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Interrogating fault memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Fault tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Fault tables for faults 16395 / P0011 to 17608 / P1200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Fault tables for faults 17621 / P1231 to 19534 / P3078 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Final control diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Basic setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 Erasing fault memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 Ending output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 Coding control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8 Reading measured value block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9 Readiness code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.1 Reading out readiness code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.2 Generating readiness code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

24 - Mixture preparation - injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1 Servicing Motronic injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1.2 Rules for cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1.3 Overview of fitting locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

1.4 Dismantling and assembling air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1.5 Removing and installing air filter element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1.6 Removing and installing air mass meter G70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.7 Wiring and component check with adapter cable, 121-pin V.A.G 1598/31 (test box) . . . . 58

1.8 Procedure following interruption of voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1.9 Removing and installing engine control unit without protective housing . . . . . . . . . . . . . . 59

1.10 Removing and installing engine control unit with protective housing . . . . . . . . . . . . . . . . . . 61

1.11 Exhaust emissions warning lamp K83 in instrument cluster . . . . . . . . . . . . . . . . . . . . . . . . 63

1.12 Checking exhaust emissions warning lamp K83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

1.13 Checking idling speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

1.14 Checking system pressure, fuel pressure regulator and residual pressure . . . . . . . . . . . . 67

1.15 Checking injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

1.16 Dismantling and assembling fuel rail with injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

1.17 Removing and installing injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

1.18 Checking injection quantity and spray pattern of injectors; checking for leaks . . . . . . . . . . 75

1.19 Checking fuel pump relay J17 and activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

1.20 Checking air mass meter G70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

1.21 Checking intake system for leaks (unmetered air) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

2 Checking Lambda control function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2.1 Checking Lambda probe and Lambda control before catalytic converter . . . . . . . . . . . . . . 86

2.2 Checking ageing of Lambda probe before catalytic converter . . . . . . . . . . . . . . . . . . . . . . 90

2.3 Checking Lambda probe heating Z19 for Lambda probe before catalytic converter . . . . . . 93

2.4 Checking Lambda probe and Lambda control after catalytic converter . . . . . . . . . . . . . . . . 95

2.5 Checking Lambda probe heating Z29 for Lambda probe after catalytic converter . . . . . . . . 101

2.6 Removing and installing Lambda probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3 Checking fuel tank breather system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

3.1 Checking solenoid valve 1 for activated charcoal filter N80 . . . . . . . . . . . . . . . . . . . . . . . . 105

4 Checking electronic engine power control (electronic throttle) . . . . . . . . . . . . . . . . . . . . . . 108

4.1 Operation of electronic throttle system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

4.2 Electronic power control fault lamp K132 in instrument cluster . . . . . . . . . . . . . . . . . . . . . . 108

4.3 Checking electronic power control fault lamp K132 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

4.4 Checking throttle valve module J338 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

4.5 Performing adaption of throttle valve module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

4.6 Checking angle senders for throttle valve drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

4.7 Checking accelerator position senders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

4.8 Adapting kickdown function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

4.9 Checking brake light switch and brake pedal switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

4.10 Checking clutch pedal switch F36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

5 Checking auxiliary signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

5.1 Checking engine speed signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

5.2 Checking road speed signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

5.3 Checking air conditioner compressor cut-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

5.4 Checking power assisted steering pressure switch F88 . . . . . . . . . . . . . . . . . . . . . . . . . . 135

5.5 Checking crash signal wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

5.6 Checking fuel consumption signal for on-board computer . . . . . . . . . . . . . . . . . . . . . . . . . . 140

5.7 Checking tank level signal wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

6 CAN bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

6.1 Checking CAN bus wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

7 Vacuum system layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

28 - Ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

1 Checking ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

1.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

1.2 Checking ignition coils with output stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

1.3 Checking Motronic current supply relay J271 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

1.4 Checking intake air temperature sender G42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

1.5 Checking engine speed sender G28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

1.6 Checking coolant temperature sender G62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

1.7 Checking voltage supply of engine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

1.8 Checking knock control limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

1.9 Checking knock sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

1.10 Checking Hall sender G163 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

1.11 Checking misfiring detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

01 – Self-diagnosis

1 Self-diagnosis of Motronic system

Note

Certain tests may lead to a fault being detected by the control unit

and stored in the memory. The fault memory must therefore be

interrogated and if necessary erased on completion of all tests

and repair work. The readiness code must then be generated af‐

ter erasing the fault memory ⇒ page 37 .

1.1 Technical data of self-diagnosis

♦ Data are transmitted between engine control unit and vehicle

diagnostic, testing and information system -VAS 5051 A- in

“self-diagnosis” mode.

♦ The fault memory is a non-volatile memory and therefore does

not depend on the power supply.

♦ Faults related to the “electronic throttle” are additionally indi‐

cated by the electronic power control fault lamp -K132- (“EPC

lamp”) in the instrument cluster.

♦ If the engine control unit detects faults which result in deteri‐

oration of emission levels, these are indicated by activation of

the exhaust emissions warning lamp -K83- in the instrument

cluster. For operation of the exhaust emissions warning lamp

-K83- , refer to ⇒ page 63 .

Audi TT 1999 ➤

1. Self-diagnosis of Motronic system 1

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

1.2 Safety precautions

Note the following if testers and measuring instruments have to

be used during a road test:

WARNING

♦ To avoid any risk of accident, observe the following pre‐

cautions when using test instruments while road testing

the vehicle:

Audi TT Coupé:

♦ To read measured value blocks, use only the vehicle di‐

agnostic, testing and information system -VAS 5051 A- or

the vehicle diagnostic and information system VAS 5052- . Test equipment must always be secured on

the rear seat and operated from that position by a second

person.

♦ Due to the limited space, slide the front passenger's seat

forwards as far as it will go and (without pulling the release

lever) incline the backrest as far forwards as possible by

turning the adjuster knob. Do not operate the release lever

to tilt the backrest forward.

Audi TT Roadster:

♦ In the Audi TT Roadster, only use the vehicle diagnostic

and information system -VAS 5052- with the passenger's

airbag deactivated.

♦ Deactivate the front passenger's airbag by means of the

key switch in the glove box or via the self-diagnosis func‐

tion ⇒ Body, self-diagnosis; Rep. Gr. 01 .

♦ Reactivate front passenger's airbag on completion of

work.

Note the following to avoid possible injury and/or the destruction

of electrical and electronic components:

♦ Always switch off ignition before disconnecting and connecting

measuring equipment and testers.

♦ Always switch off the ignition before connecting or discon‐

necting the battery, otherwise the engine control unit may be

damaged.

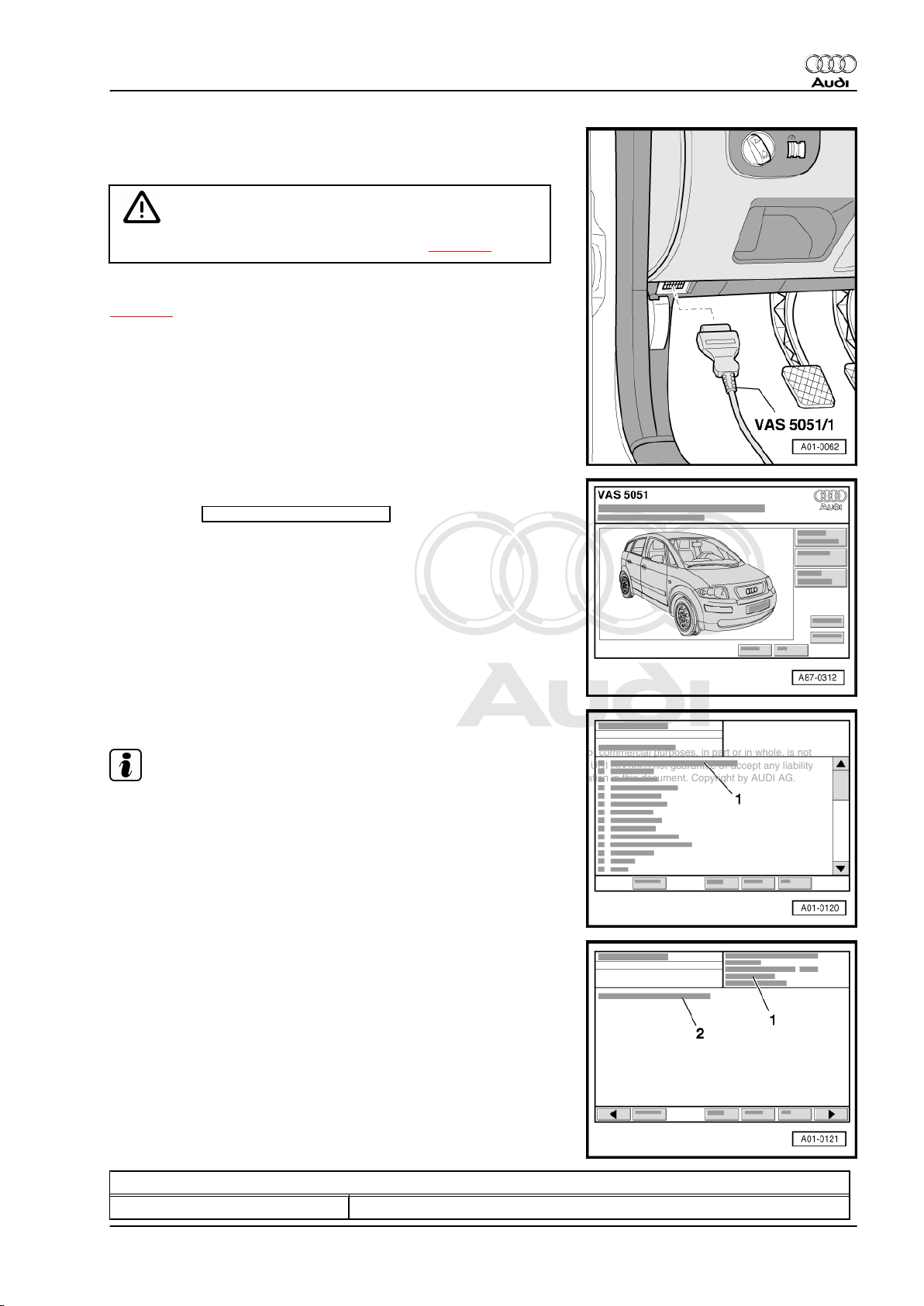

1.3 Connecting vehicle diagnostic, testing and information system -VAS 5051 A-

Procedure

• Fuses for engine electronics okay ⇒ Current flow diagrams,

Electrical fault finding and Fitting locations.

• Fuel pump relay OK; checking ⇒ page 77 .

• Battery voltage at least 12.5 V.

• Earth connections on engine and gearbox OK

2 Rep. Gr.01 - Self-diagnosis

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

– With ignition switched off, connect up vehicle diagnostic, test‐

ing and information system -VAS 5051 A- with diagnosis lead

-VAS 5051 A/1- to diagnosis connection.

WARNING

Make sure to observe the safety precautions ⇒ page 2 .

Depending on the function required ⇒ Table “Diagnosis functions”

⇒ page 4 :

– Switch on ignition.

or

– Start engine.

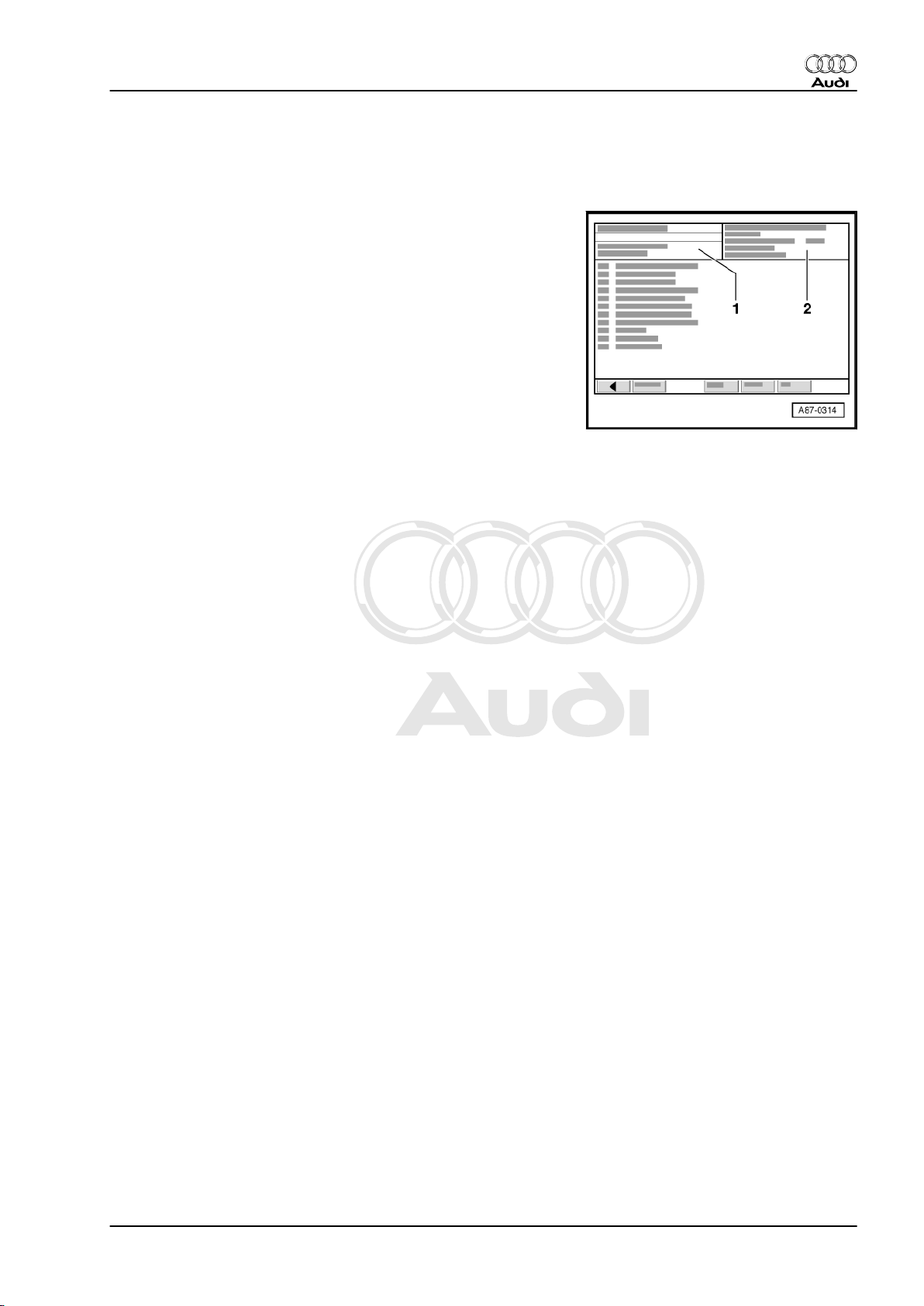

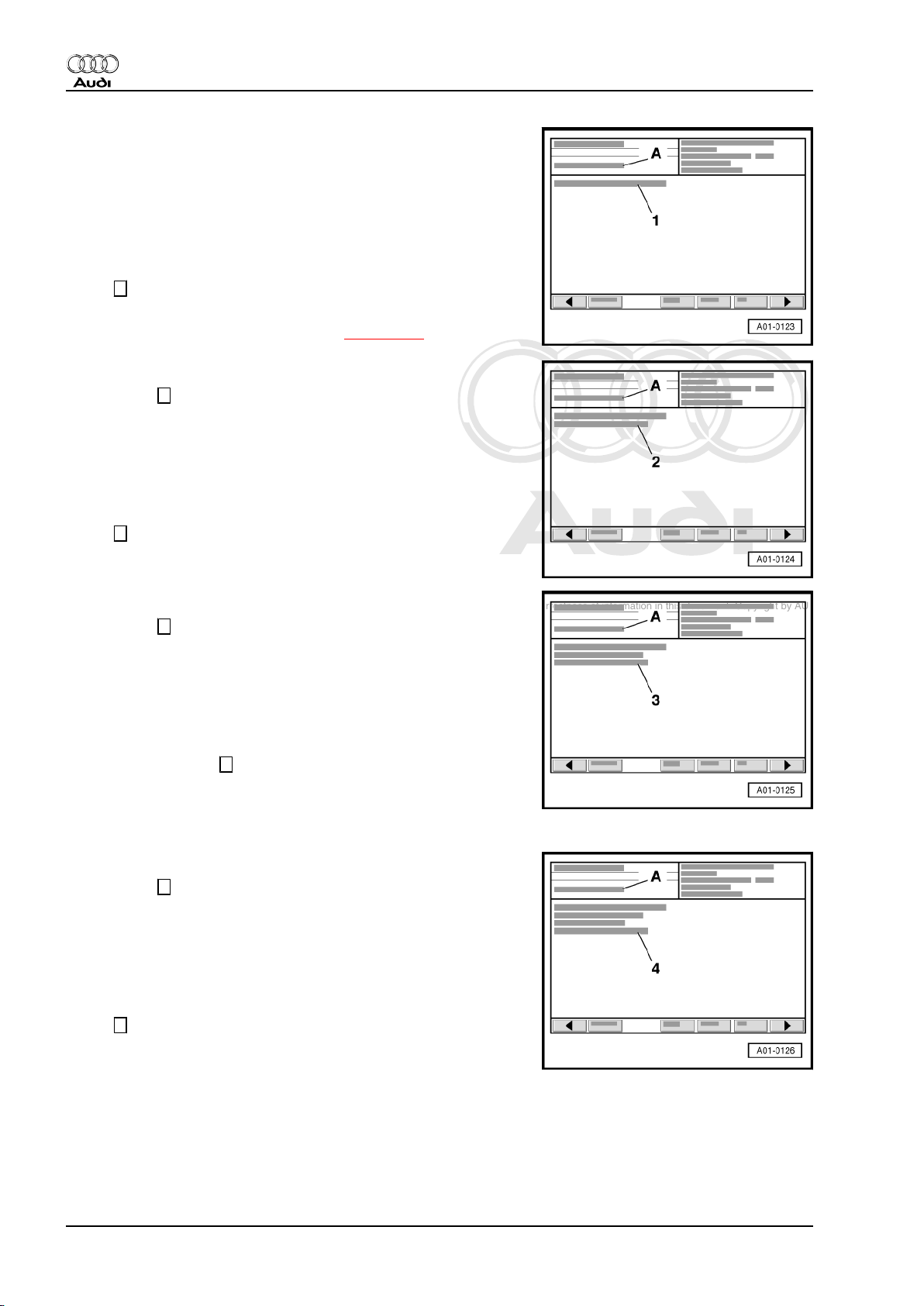

Display on -VAS 5051 A- :

– Press the vehicle self-diagnosis key.

Audi TT 1999 ➤

Display on -VAS 5051 A- :

Note

Touching the function “00 - Interrogating fault memory - Overall

system” in the list -1- implements the automatic test sequence,

i.e. the fault memories of all systems with self-diagnosis capability

in the vehicle are interrogated.

– From list -1- select vehicle system “01 Engine electronics”.

– Wait until next readout appears in the display.

Display on -VAS 5051 A- :

1 - Engine control unit identification

2 - Immobilizer control unit identification

Engine control unit identification (example)

01 - Engine electronics Vehicle system

1. Self-diagnosis of Motronic system 3

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Engine control unit identification (example)

06A906032.. Part no.; assignment ⇒ Parts catalogue

1.8 ltr. 1) R4/5VT 2) G 3) 0003

4)

Engine capacity

2)

In-line engine, 4-cylinder/5-valve turbo

3)

♦ G = Cruise control system activated

1)

♦ No display = No cruise control system fitted or system not activated

4)

Data level (software version) of control unit

Code 11500 Control unit coding (checking ⇒ page 31 )

Workshop code 12345 Workshop code of -VAS 5051 A- which was used to perform the last cod‐

ing

Immobilizer control unit identification (example)

TRUZZZ8NZ11018983 1) AUZ5Z0Y9122017

2)

1)

17-position vehicle identification No. (chassis num‐

ber)

2)

14-position immobilizer identification number

– Press the → key.

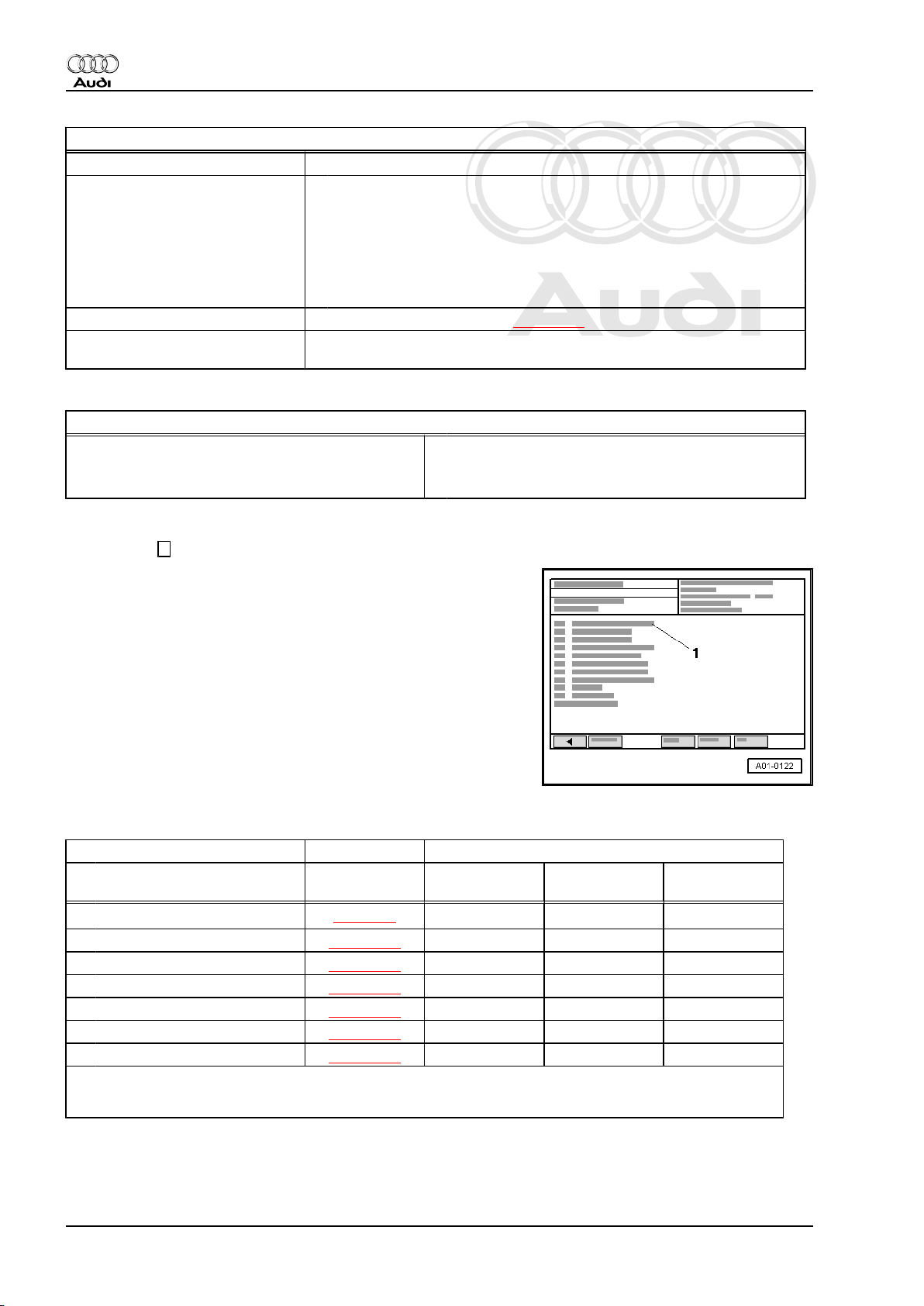

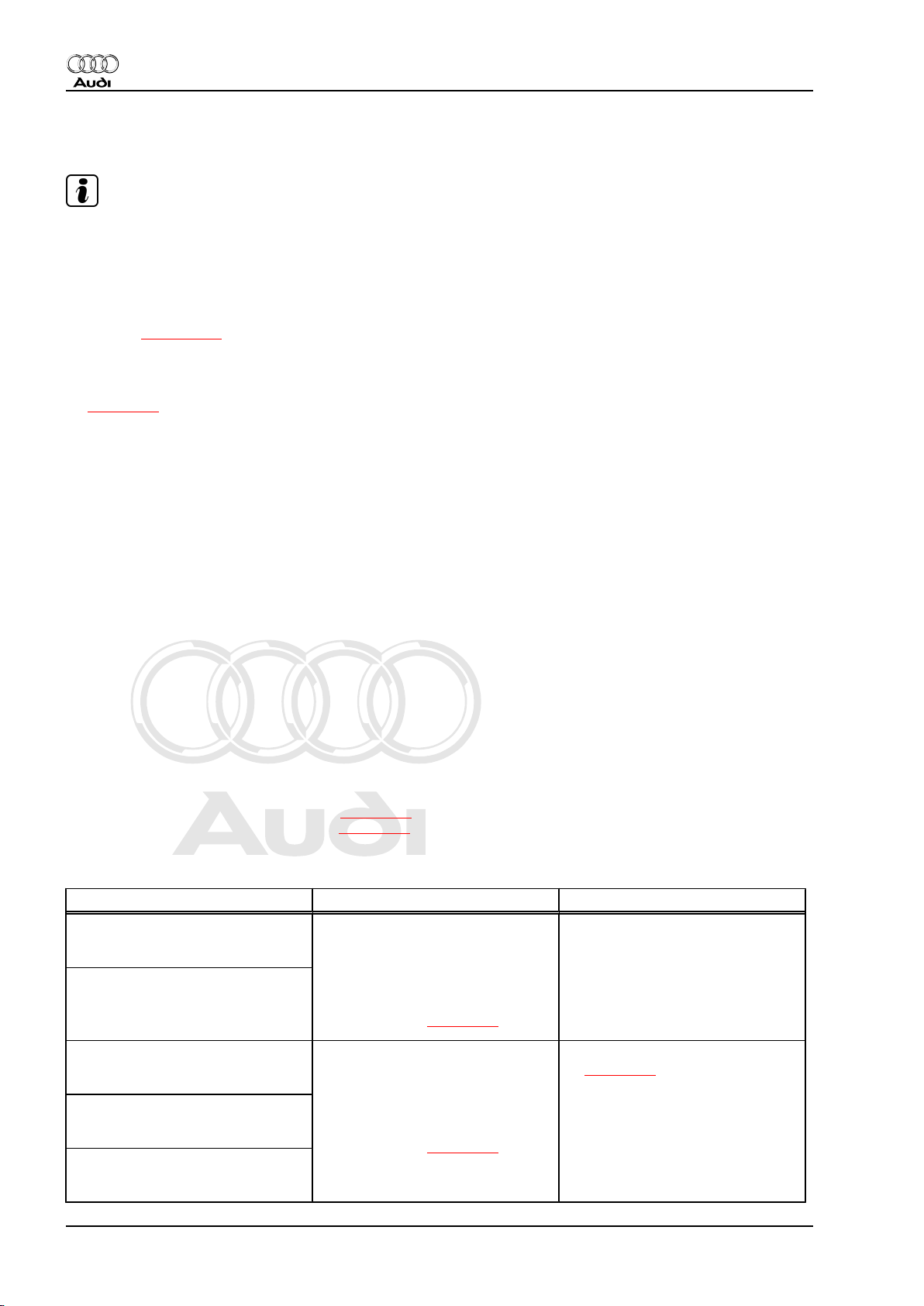

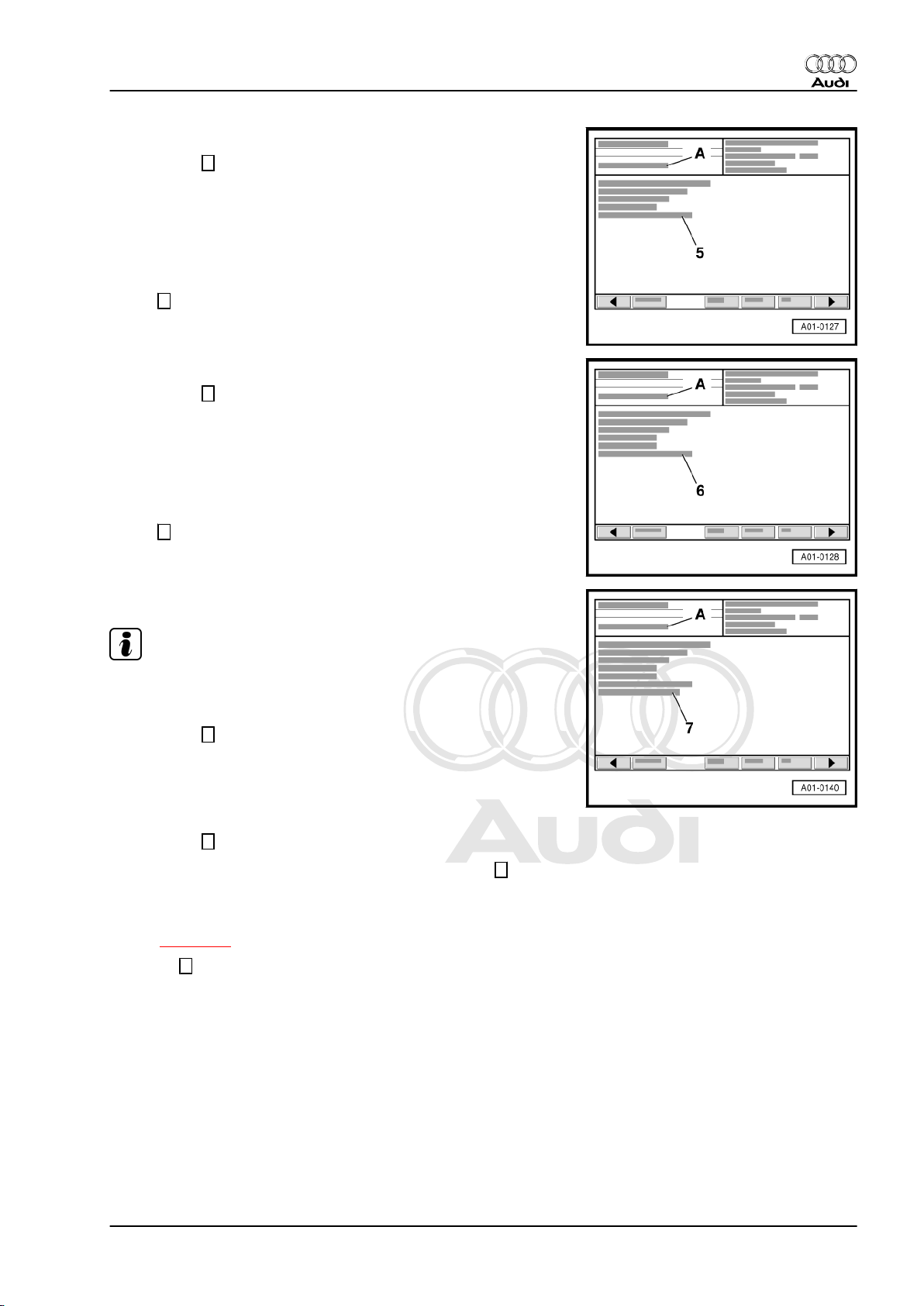

Display on -VAS 5051 A- :

1 - Selection of diagnostic functions:

The following diagnosis functions shown in the display -1- are

available:

Diagnosis functions Page Conditions

02 Interrogate fault memory ⇒ page 6

Ignition on, en‐

gine not running

1)

no

Engine idling Vehicle being

driven

yes yes

03 Final control diagnosis ⇒ page 23 yes no no

04 Basic setting ⇒ page 27 yes yes yes

05 Erase fault memory ⇒ page 29 yes yes yes

06 End output ⇒ page 30 yes yes yes

07 Code control unit ⇒ page 31 yes no no

08 Read measured value block ⇒ page 33 yes yes yes

1)

•

If the engine does not start, turn the engine over for at least 5 seconds using the starter. After doing

this, do not switch off the ignition.

All other functions displayed cannot be selected or can be ignored

in this case.

4 Rep. Gr.01 - Self-diagnosis

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Fault messages on -VAS 5051 A-

If a fault message appears on the display, refer to ⇒ Operating

instructions of vehicle diagnostic, testing and information system

-VAS 5051 A- .

If display zone -1- shows “Vehicle system not available”:

– Check:

♦ Voltage supply to diagnostic connection ⇒ Current flow dia‐

grams, Electrical fault finding and Fitting locations

♦ Wiring between diagnostic connection and engine control unit

⇒ Current flow diagrams, Electrical fault finding and Fitting lo‐

cations.

Audi TT 1999 ➤

1. Self-diagnosis of Motronic system 5

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

2 Interrogating fault memory

2.1 Interrogating fault memory

– Connect vehicle diagnostic, testing and information system -

VAS 5051 A- ⇒ page 2 and select vehicle system “01 - Engine

electronics” from list. When doing this, the engine must be

running at idling speed.

Note

If the engine does not start, turn the engine over for at least 5

seconds using the starter. After doing this, do not switch off the

ignition.

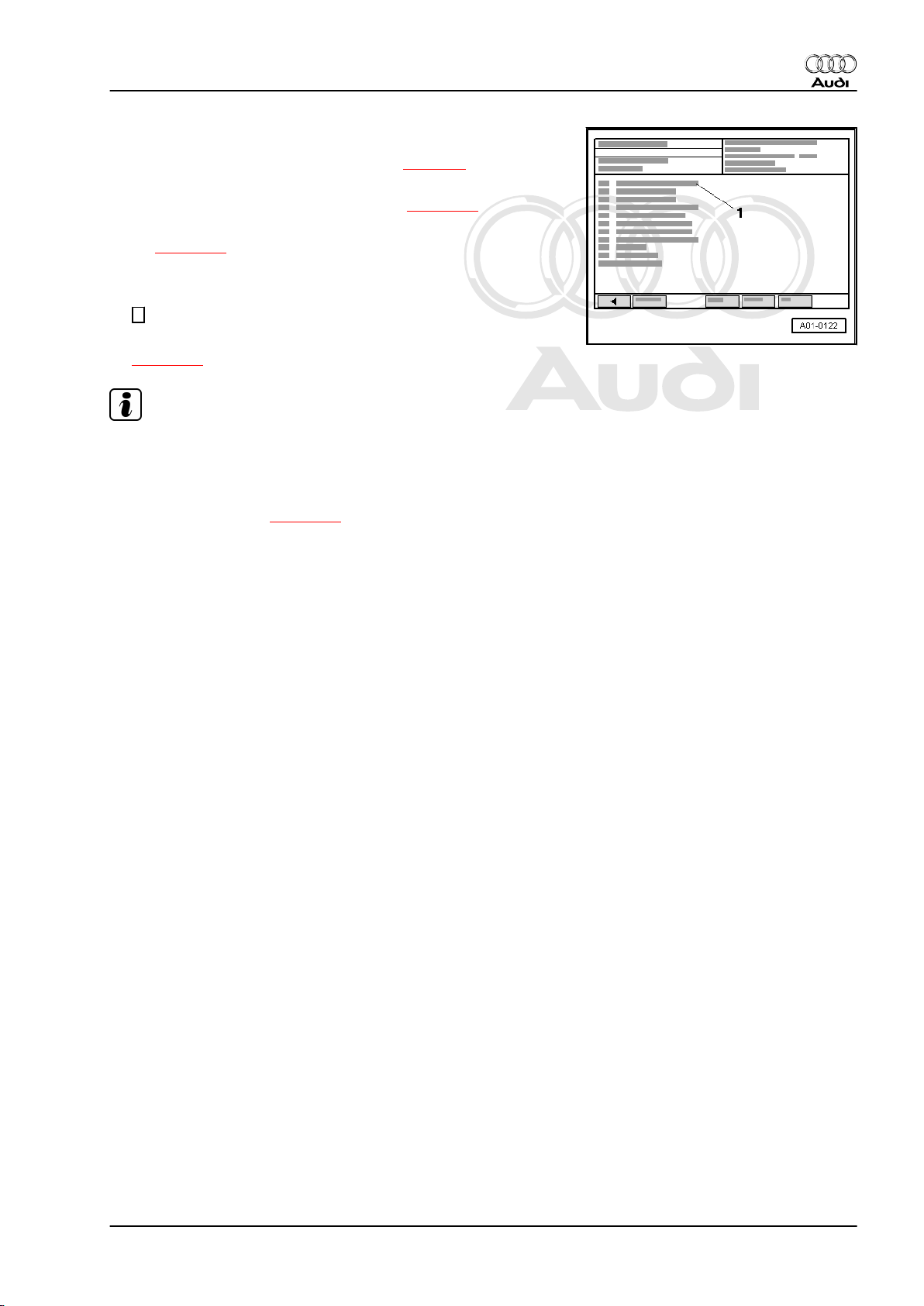

Display on -VAS 5051 A- :

– From list -1-, select diagnosis function “02 - Interrogate fault

memory”.

Display on -VAS 5051 A- :

-1- Content of fault memory No faults detected

or

X faults detected

-2- Fault Fault code

Fault location

Type of fault

A - If faults are detected:

– Print out information on screen or self-diagnosis log.

– Terminate function “02 - Interrogate fault memory” by touching

← key.

6 Rep. Gr.01 - Self-diagnosis

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- :

– Rectify fault(s) according to fault tables ⇒ page 8 .

– From list -1-, select diagnosis function “02 - Interrogate fault

memory” again and erase fault memory ⇒ page 29 .

– Select diagnosis function “06 - End output” from the menu

-1- ⇒ page 30 .

B - If no faults are detected:

– Terminate function “02 - Interrogate fault memory” by touching

← key.

– Select diagnostic function “06 - End output” from list

⇒ page 30 .

Note

♦

If no faults have been stored in the fault memory, do not erase

the fault memory unnecessarily otherwise the readiness code

will be reset.

♦

If the fault memory has been erased, the readiness code must

be generated again ⇒ page 37 .

Audi TT 1999 ➤

2. Interrogating fault memory 7

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

2.2 Fault tables

Note

♦

If faults occur in the monitored sensors or components, these

are stored in the fault memory together with an indication of

the type of fault.

♦

Faults related to the “electronic throttle” are additionally indi‐

cated by the electronic power control fault lamp -K132- (“EPC

lamp”) in the instrument cluster. Notes on electronic throttle

system ⇒ page 108 .

♦

Faults which cause a deterioration in emission levels are in‐

dicated by the exhaust emissions warning lamp -K83- in the

instrument cluster. Notes on exhaust emissions warning lamp

⇒ page 63 .

♦

The fault table is sorted according to the 5-digit fault code in

the left-hand column and the P code.

♦

If a fault is stored in the fault memory and then does not occur

again during the next 40 engine warm-up cycles, the fault will

be automatically erased.

♦

Sporadic faults (temporary faults) are marked “sporadic” on

the display. The word “sporadic” means “intermittent” or “oc‐

curring at irregular intervals”.

♦

The components shown to be defective by the -VAS 5051should not be replaced immediately. Start by using the current

flow diagram to check the wiring and connectors to these com‐

ponents. Also test the earth connections using the current flow

diagram. This is particularly important in the case of “sporadic”

faults.

♦

All adaption values in the control unit are erased if the multipin connectors at the engine control unit are unplugged or the

battery is disconnected. The contents of the fault memory will

remain intact. The next time the engine is started the idling

may be rough at first. In this case, allow the engine to run at

idle for several minutes until the adaption process has been

completed.

♦

If the fault memory has been erased ⇒ page 29 , the readi‐

ness code must be generated again ⇒ page 37 .

2.3 Fault tables for faults 16395 / P0011 to 17608 / P1200

Display on -VAS 5051 A- Explanatory notes Fault remedy

16395 / P0011

Bank 1 camshaft timing control

Specification not attained

16396 / P0012

Bank 1 camshaft timing control

Specification not attained

16485 / P0101

Air mass meter -G70Implausible signal

16486 / P0102

Air mass meter -G70Signal too small

16487 / P0103

Air mass meter -G70Signal too large

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check ⇒ Rep. Gr. 15

– Check air mass meter

⇒ page 80

8 Rep. Gr.01 - Self-diagnosis

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

16490 / P0106

Intake manif.press./air press ⇒ G71- / -F96Implausible signal

♦ The intake manifold pressure is

determined by the charge air

pressure sender -G31- (instead

of -G71- displayed); the atmos‐

– Check charge air pressure

sender -G31- ⇒ Rep. Gr. 21

pheric pressure is determined

by the altitude sender -F96- (in

the engine control unit)

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

16496 / P0112

Intake air temperature sender G42Signal too small

16497 / P0113

Intake air temperature sender G42Signal too large

16500 / P0116

Coolant temperature sender -G62Implausible signal

16501 / P0117

Coolant temperature sender -G62Signal too small

16502 / P0118

Coolant temperature sender -G62Signal too large

16514 / P0130

Bank 1, probe 1

Electrical fault in current circuit

16515 / P0131

Bank 1, probe 1

Voltage too low

16516 / P0132

Bank 1, probe 1

Voltage too high

16517 / P0133

Bank 1, probe 1

Signal too slow

16518 / P0134

Bank 1, probe 1

No activity

16519 / P0135

Bank 1, probe 1

Electrical fault in heating element

circuit

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check intake air temperature

sender ⇒ page 157

– Check coolant temperature

sender ⇒ page 162

– Check Lambda probe and

Lambda control before catalytic

converter ⇒ page 86

2. Interrogating fault memory 9

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

16520 / P0136

Bank 1, probe 2

Electrical fault in current circuit

16521 / P0137

Bank 1, probe 2

Voltage too low

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check Lambda probe and

Lambda control after catalytic

converter ⇒ page 95

16522 / P0138

Bank 1, probe 2

Voltage too high

16523 / P0139

Bank 1, probe 2

Signal too slow

16524 / P0140

Bank 1, probe 2

No activity

16620 / P0236

Charge pressure sender -G31Implausible signal

16621 / P0237

Charge pressure sender -G31Signal too small

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check charge air pressure

sender⇒ Rep. Gr. 21

16622 / P0238

Charge pressure sender -G31Signal too large

16684 / P0300

Misfiring recognised

16685 / P0301

Cyl. 1 Misfiring recognised

16686 / P0302

Cyl. 2 Misfiring recognised

16687 / P0303

Cyl. 3 Misfiring recognised

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check fuel pressure

⇒ page 67

– Check injectors ⇒ page 70

– Check spark plugs and ignition

cables with connectors

– Check ignition coils with output

stages ⇒ page 149

16688 / P0304

Cyl. 4 Misfiring recognised

– Check misfiring detection

⇒ page 173

16705 / P0321

Engine speed sender -G28Implausible signal

16706 / P0322

Engine speed sender -G28No signal

10 Rep. Gr.01 - Self-diagnosis

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ This fault causes the engine

control unit to activate the EPC

lamp in the instrument cluster

⇒ page 108

– Put fuel in fuel tank

– Check engine speed sender

⇒ page 159

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

16711 / P0327

Knock sensor 1 -G61Signal too small

16712 / P0328

Knock sensor 1 -G61Signal too large

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check for corrosion in connec‐

tion between knock sensor and

wiring harness

– Check knock sensor

⇒ page 168

16716 / P0332

Knock sensor 2 -G66Signal too small

16717 / P0333

Knock sensor 2 -G66Signal too large

16725 / P0341

Camshaft pos. sensor ⇒ sender G40Implausible signal

16726 / P0342

Camshaft pos. sensor ⇒ sender G40Signal too small

16727 / P0343

Camshaft pos. sensor ⇒ sender -

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ The Hall sender is referred to as

-G163- in the current flow dia‐

grams.

– Check Hall sender -G163-

⇒ page 170

G40Signal too large

16795 / P0411

Secondary air system

Through-flow defective

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

– Check hoses (secondary air in‐

let valve); check intake system

for leaks (unmetered air)

⇒ page 83

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check secondary air system ⇒

Rep. Gr. 26

16804 / P0420

Bank 1, catalytic converter system

Efficiency too low

16806 / P0422

Bank 1, main catalytic converter

Efficiency too low

16825 / P0441

Tank breathing system

Flow rate faulty

16885 / P0501

Vehicle speed signal

Implausible signal

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Generate readiness code

⇒ page 37 . If the same fault is

displayed again, renew catalytic

converter ⇒ Rep. Gr. 26

– Check solenoid valve 1 for acti‐

vated charcoal filter -N80-

⇒ page 105

– Check vehicle speed signal

⇒ page 131

2. Interrogating fault memory 11

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

16890 / P0506

Idling speed control

Revs below specification

16891 / P0507

Idling speed control

Revs above specification

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check throttle valve module -

J338- ⇒ page 109

– Check hoses (secondary air in‐

let valve); check intake system

for leaks (unmetered air)

⇒ page 83

16944 / P0560

Voltage supply

Implausible signal

16946 / P0562

Voltage supply

Voltage too low

16947 / P0563

Voltage supply

Voltage too high

16955 / P0571

Brake light switch -FImplausible signal

16985 / P0601

Control unit defective

16988 / P0604

Control unit defective

16989 / P0605

Control unit defective

16990 / P0606

Control unit defective

17069 / P0685

Main relay ⇒ -J271Open circuit

17070 / P0686

Main relay ⇒ -J271Short to earth

17071 / P0687

Main relay ⇒ -J271Short to positive

17072 / P0688

Main relay, load circuit ⇒ -J271Open circuit

17510 / P1102

Bank 1, probe 1, heating element

circuit

Short to positive

♦ In addition to the brake light

switch -F- , the brake pedal

switch -F47- is also monitored

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check voltage supply of engine

control unit ⇒ page 165

– Check brake light switch and

brake pedal switch ⇒ page 121

– Renew engine control unit

⇒ “1.9 Removing and installing

engine control unit without pro‐

tective housing”, page 59 or

⇒ “1.10 Removing and installing

engine control unit with protec‐

tive housing”, page 61

– Check Motronic current supply

relay -J271- ⇒ page 152

– Check Lambda probe heating

before catalytic converter

⇒ page 93

17511 / P1103

Bank 1, probe 2, heating element

circuit

Performance too low

17513 / P1105

Bank 1, probe 2, heating element

circuit

Short to positive

12 Rep. Gr.01 - Self-diagnosis

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check Lambda probe heating

after catalytic converter

⇒ page 101

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

17519 / P1111

Lambda control (bank 1)

– Check Lambda control before

catalytic converter ⇒ page 86

System too lean

17520 / P1112

Lambda control (bank 1)

System too rich

17521 / P1113

Bank 1, probe 1

Internal resistance too high

– Start by checking for contact re‐

sistance in signal wires

⇒ page 90 ; if there is no con‐

tact resistance: renew Lambda

probe

17522 / P1114

Bank 1, probe 2

Internal resistance too high

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

– Start by checking for contact re‐

sistance in signal wires

⇒ page 100 ; if there is no con‐

tact resistance: renew Lambda

probe

sions warning lamp in the instru‐

ment cluster ⇒ page 63

17523 / P1115

Bank 1, probe 1, heating element

circuit

Short to earth

17524 / P1116

Bank 1, probe 1, heating element

circuit

Open circuit

17525 / P1117

Bank 1, probe 2, heating element

circuit

Short to earth

17526 / P1118

Bank 1, probe 2, heating element

circuit

Open circuit

17535 / P1127

Bank 1, mixture adaption (mult.)

System too rich

17536 / P1128

Bank 1, mixture adaption (mult.)

System too lean

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ “mult.” (= multiplicative) indi‐

cates that the fault takes effect

over the entire engine speed

and load range

– Check Lambda probe heating

before catalytic converter

⇒ page 93

– Check Lambda probe heating

after catalytic converter

⇒ page 101

– Perform road test (fuel in oil)

– Check fuel system pressure

⇒ page 67

– Check air mass meter

⇒ page 80

– Check intake system for leaks

(unmetered air) ⇒ page 83

– Check Lambda probe before

catalytic converter ⇒ page 86

– Check Lambda probe after cat‐

alytic converter ⇒ page 95

– Check injectors ⇒ page 70

2. Interrogating fault memory 13

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

17544 / P1136

Bank 1, mixture adaption (add.)

System too lean

17545 / P1137

Bank 1, mixture adaption (add.)

System too rich

♦ “add.” = additive, i.e. the fault

only occurs at idling speed

– Perform road test (fuel in oil)

– Check fuel system pressure

⇒ page 67

– Check air mass meter -G70-

⇒ page 80

– Check intake system for leaks

(unmetered air) ⇒ page 83

– Check Lambda probe after cat‐

alytic converter ⇒ page 95

– Check solenoid valve 1 for acti‐

vated charcoal filter -N80-

⇒ page 105

17551 / P1143

Load determination

Level exceeded

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

– Check air mass meter -G70-

⇒ page 80

– Check throttle valve module -

J338- ⇒ page 109

sions warning lamp in the instru‐

ment cluster ⇒ page 63

17557 / P1149

Lambda control bank 1

Implausible control value

17579 / P1171

Angle sens. 2 for throt. valve drive G188Implausible signal

17580 / P1172

Angle sens. 2 for throt. valve drive G188Signal too low

17581 / P1173

Angle sens. 2 for throt. valve drive G188Signal too high

17584 / P1176

Bank 1, Lambda corr. after catalytic

converter

Control limit reached

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ This fault causes the engine

control unit to activate the EPC

lamp in the instrument cluster

⇒ page 108

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check Lambda probe learnt val‐

ues and Lambda control

⇒ page 88

– Check fuel system pressure

⇒ page 67

– Check intake system for leaks

(unmetered air) ⇒ page 83

– Check angle sender for throttle

valve drive ⇒ page 112

– Check ageing of Lambda probe

before catalytic converter

⇒ page 90

– Check Lambda probe and

Lambda control after catalytic

converter ⇒ page 95

17606 / P1198

Bank 1, probe 2, heating element

circuit

Electrical fault

17608 / P1200

Air recirculation valve for turbo‐

charger -N249Mechanical fault

14 Rep. Gr.01 - Self-diagnosis

– Check Lambda probe heating

after catalytic converter

⇒ page 101

– Check vacuum system for leaks

– Check air recirculation valve for

turbocharger -N249- ⇒ Rep. Gr.

21

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

2.4 Fault tables for faults 17621 / P1231 to 19534 / P3078

Display on -VAS 5051 A- Explanatory notes Fault remedy

17621 / P1213

Injector Cyl. 1 -N30Short to Positive

17622 / P1214

Injector Cyl. 2 -N31Short to Positive

17623 / P1215

Injector Cyl. 3 -N32- Short to Posi‐

tive

17624 / P1216

Injector Cyl. 4 -N33Short to Positive

17633 / P1225

Injector Cyl. 1 -N30Short to Earth

17634 / P1226

Injector Cyl. 2 -N31Short to Earth

17635 / P1227

Injector Cyl. 3 -N32Short to Earth

17636 / P1228

Injector Cyl. 4 -N33Short to Earth

17645 / P1237

Injector Cyl. 1 -N30Open circuit

17646 / P1238

Injector Cyl. 2 -N31Open circuit

17647 / P1239

Injector Cyl. 3 -N32Open circuit

17648 / P1240

Injector Cyl. 4 -N33Open circuit

17658 / P1250

Fuel status too low

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ The fault “fuel status too low” is

stored in conjunction with misfir‐

ing or faults relating to Lambda

control if there is or has been in‐

sufficient fuel in the tank; the

fault remains static in the fault

memory and is not set to spora‐

dic even if (for example) the ve‐

hicle has been re-fuelled in the

meantime

– Check injectors ⇒ page 70

– Fault resulting from earlier prob‐

lem ⇒ “Explanatory notes”

– Fill fuel tank and erase fault

memory

– Interrogate fault memory of in‐

strument cluster ⇒ Electrical

system, self-diagnosis; Rep.

Gr. 01

2. Interrogating fault memory 15

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

17695 / P1287

Air recirc. valve for turbocharger N249Open circuit

17696 / P1288

Air recirc. valve for turbocharger N249-

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check air recirculation valve for

turbocharger ⇒ Rep. Gr. 21

Short to positive

17697 / P1289

Air recirc. valve for turbocharger N249Short to earth

17704 / P1296

– Check ⇒ Rep. Gr. 19

Fault in cooling system

17705 / P1297

– Check ⇒ Rep. Gr. 21

Turbocharger/throttle valve con‐

nection

Drop in pressure

17733 / P1325

Knock control Cylinder 1

– Check knock control

⇒ page 166

Control limit reached

17734 / P1326

Knock control Cylinder 2

Control limit reached

17735 / P1327

Knock control Cylinder 3

Control limit reached

17736 / P1328

Knock control Cylinder 4

Control limit reached

17743 / P1335

Engine torque monitoring 2

Control limit surpassed

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

– Major leak; check intake system

for leaks (unmetered air)

⇒ page 83

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

– Check intake air temperature

sender -G42- ⇒ page 157

ment cluster ⇒ page 63

– Check air mass meter -G70-

⇒ page 80

– Check coolant temperature

sender -G62- ⇒ page 162

17744 / P1336

♦ This fault causes the engine

control unit to activate the EPC

lamp in the instrument cluster

⇒ page 108

Engine torque monitoring

Control limit surpassed

17748 / P1340

Camshaft pos./crankshaft pos.

sens.

Wrong allocation

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

– Unscrew Hall sender and check

proper installation of rotor ring at

camshaft. (If incorrectly instal‐

led, the retainer tab will be

squashed on tightening the bolt)

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Also check valve timing ⇒ Rep.

Gr. 13

16 Rep. Gr.01 - Self-diagnosis

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

17763 / P1355

Ignition circuit, cylinder 1

Open circuit

17764 / P1356

Ignition circuit, cylinder 1

Short to Positive

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check ignition coils with output

stages ⇒ page 149

17765 / P1357

Ignition circuit, cylinder 1

Short to Earth

17766 / P1358

Ignition circuit, cylinder 2

Open circuit

17767 / P1359

Ignition circuit, cylinder 2

Short to Positive

17768 / P1360

Ignition circuit, cylinder 2

Short to Earth

17769 / P1361

Ignition circuit, cylinder 3

Open circuit

17770 / P1362

Ignition circuit, cylinder 3

Short to Positive

17771 / P1363

Ignition circuit, cylinder 3

Short to Earth

17772 / P1364

Ignition circuit, cylinder 4

Open circuit

17773 / P1365

Ignition circuit, cylinder 4

Short to Positive

17774 / P1366

Ignition circuit, cylinder 4

Short to Earth

17794 / P1386

Control unit defective

17795 / P1387

Control unit defective

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Renew engine control unit

⇒ “1.9 Removing and installing

engine control unit without pro‐

tective housing”, page 59 or

⇒ “1.10 Removing and installing

engine control unit with protec‐

tive housing”, page 61

17796 / P1388

Control unit defective

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ This fault causes the engine

control unit to activate the EPC

lamp in the instrument cluster

⇒ page 108

2. Interrogating fault memory 17

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

17818 / P1410

Tank breathing valve -N80Short to positive

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

– Check solenoid valve 1 for acti‐

vated charcoal filter -N80-

⇒ page 105

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

17829 / P1421

Secondary air inlet valve -N112Short to earth

17830 / P1422

Secondary air inlet valve -N112Short to positive

17832 / P1424

Bank 1, Secondary air system

Leak recognised

17833 / P1425

Tank breathing valve -N80Short to earth

17834 / P1426

Tank breathing valve -N80Open circuit

17835 / P1427

Activation, vacuum pump for

brakes

Short to positive

17836 / P1428

Activation, vacuum pump for

brakes

Short to positive

17837 / P1429

Activation, vacuum pump for

brakes

Open circuit

17840 / P1432

Secondary air inlet valve -N112Open circuit

17841 / P1433

Relay for secondary air pump J229Open circuit

17842 / P1434

Relay for secondary air pump J229Short to Positive

17843 / P1435

Relay for secondary air pump J229Short to earth

17909 / P1501

Fuel pump relay -J17Short to earth

17910 / P1502

Fuel pump relay -J17Short to positive

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check secondary air inlet valve

-N112- ⇒ Rep. Gr. 26

– Check hoses and components

of secondary air system ⇒ Rep.

Gr. 26

– Check solenoid valve 1 for acti‐

vated charcoal filter -N80-

⇒ page 105

– Check brake vacuum pump ⇒

Rep. Gr. 47

– Check secondary air inlet valve

-N112- ⇒ Rep. Gr. 26

– Check secondary air pump relay

-J229- ⇒ Rep. Gr. 26

– Check fuel pump relay

⇒ page 77

18 Rep. Gr.01 - Self-diagnosis

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

17927 / P1519

Bank 1, camshaft timing control

Faulty

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

– Check ⇒ Rep. Gr. 15

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

17931 / P1523

Crash signal from airbag control

unit

Implausible signal

17937 / P1529

Variable valve timing

Short to positive

17938 / P1530

Variable valve timing

Short to earth

17939 / P1531

Variable valve timing

Open circuit

17947 / P1539

Clutch pedal switch -F36Implausible signal

17949 / P1541

Fuel pump relay -J17Open circuit

♦ This fault is stored if the corre‐

sponding signal is received from

the airbag control unit

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check ⇒ Body, self-diagnosis;

Rep. Gr. 01

– Check ⇒ Rep. Gr. 15

– Check clutch pedal switch

⇒ page 125

– Check fuel pump relay

⇒ page 77

17950 / P1542

Angle sender for throt. val. drive G187Implausible signal

17951 / P1543

Angle sender for throt. val. drive G187Signal too low

17952 / P1544

Angle sender for throt. val. drive G187Signal too high

17953 / P1545

Throttle valve control

Faulty

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ This fault causes the engine

control unit to activate the EPC

lamp in the instrument cluster

⇒ page 108

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ This fault causes the engine

control unit to activate the EPC

lamp in the instrument cluster

⇒ page 108

– Check angle sender for throttle

valve drive ⇒ page 112

– Check throttle valve module -

J338- ⇒ page 109

2. Interrogating fault memory 19

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

17954 / P1546

– Check ⇒ Rep. Gr. 21

Charge press. control solenoid

valve -N75Short to positive

17955 / P1547

Charge press. control solenoid

valve -N75Short to earth

17956 / P1548

Charge press. control solenoid

valve -N75Open circuit

17958 / P1550

Charge pressure

Control difference

17963 / P1555

Maximum charge pressure sur‐

passed

17964 / P1556

Charge pressure control

Regulating limit not reached

17965 / P1557

Charge pressure control

Regulating limit surpassed

17966 / P1558

Throttle valve drive -G186Fault in electrical circuit

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

– Check throttle valve module -

J338- ⇒ page 109

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ This fault causes the engine

control unit to activate the EPC

lamp in the instrument cluster

⇒ page 108

17967 / P1559

Throttle valve module -J338Fault in basic setting

17968 / P1560

Maximum engine revs

surpassed

17972 / P1564

Throttle valve module -J338Low voltage in basic setting

17973 / P1565

Throttle valve module -J338Lower stop not reached

17976 / P1568

Throttle valve module -J338Mechanical fault

♦ If this fault occurs within 3 con‐

– Perform adaption ⇒ page 110

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ Engine has been overrevved – Repair mechanical damage

– Charge battery and repeat basic

setting

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

– Check throttle valve module

⇒ page 109

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ This fault causes the engine

control unit to activate the EPC

lamp in the instrument cluster

⇒ page 108

20 Rep. Gr.01 - Self-diagnosis

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

17977 / P1569

CCS switch -E45-

– Check ⇒ Electrical system, self-

diagnosis; Rep. Gr. 01

Implausible signal

17978 / P1570

Engine control unit

blocked

– Adapt electronic immobilizer to

engine control unit ⇒ Electrical

system, self-diagnosis; Rep.

Gr. 01

17987 / P1579

Throttle valve module -J338Adaption not started

– Perform adaption of throttle

valve module in accordance

with test requirements

⇒ page 110

18010 / P1602

Voltage supply term. 30

– Check voltage supply of engine

control unit ⇒ page 165

Voltage too low

18011 / P1603

Control unit defective

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Renew engine control unit

⇒ “1.9 Removing and installing

engine control unit without pro‐

tective housing”, page 59 or

⇒ “1.10 Removing and installing

engine control unit with protec‐

tive housing”, page 61

18012 / P1604

Control unit defective

18017 / P1609

Crash switch-off triggered

(crash triggered)

18018 / P1610

Control unit defective

18020 / P1612

Engine control unit wrong coding

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ This fault causes the engine

control unit to activate the EPC

lamp in the instrument cluster

⇒ page 108

♦ This fault is stored in the event

of a corresponding signal from

the airbag control unit (also dur‐

ing final control diagnosis of air‐

bag system)

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check ⇒ Body, self-diagnosis;

Rep. Gr. 01

– After completing final control di‐

agnosis of airbag system, erase

fault memory of engine control

unit ⇒ page 29

– Renew engine control unit

⇒ “1.9 Removing and installing

engine control unit without pro‐

tective housing”, page 59 or

⇒ “1.10 Removing and installing

engine control unit with protec‐

tive housing”, page 61

– Code engine control unit

⇒ page 31

2. Interrogating fault memory 21

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Display on -VAS 5051 A- Explanatory notes Fault remedy

18038 / P1630

Accelerator position sender -G79Signal too low

18039 / P1631

Accelerator position sender -G79Signal too high

18041 / P1633

Accelerator position sender 2 G185Signal too low

18042 / P1634

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

♦ This fault causes the engine

control unit to activate the EPC

lamp in the instrument cluster

⇒ page 108

– Check accelerator position

sender ⇒ page 116

Accelerator position sender 2 G185Signal too high

18047 / P1639

Accelerator position sender 1/2 G79- + -G185Implausible signal

18048 / P1640

Control unit defective

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Renew engine control unit

⇒ “1.9 Removing and installing

engine control unit without pro‐

tective housing”, page 59 or

⇒ “1.10 Removing and installing

engine control unit with protec‐

tive housing”, page 61

18056 / P1648

Drive train data bus

defective

18057 / P1649

Drive train data bus

Message from ABS control unit

missing

18058 / P1650

Drive train data bus

Message from instrument cluster

missing

18062 / P1654

Please interrogate fault memory of

instrument cluster

18090 / P1682

Drive train data bus

Implausible message from ABS

control unit

18261 / P1853

Drive train data bus

Implausible message from ABS

control unit

♦ If this fault occurs within 3 con‐

secutive driving cycles (engine

operation for at least 5 sec‐

onds), the engine control unit

switches on the exhaust emis‐

sions warning lamp in the instru‐

ment cluster ⇒ page 63

– Check CAN bus wiring

⇒ page 141

– Interrogate fault memory ⇒

Electrical system, self-diagno‐

sis; Rep. Gr. 01

– Check CAN bus wiring

⇒ page 141

22 Rep. Gr.01 - Self-diagnosis

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

3 Final control diagnosis

Note

♦

Final control diagnosis can only be performed when engine is

not running and ignition is switched on.

♦

The electric fuel pump runs continuously throughout the final

control diagnosis.

♦

During final control diagnosis, the individual control elements

(except for injectors) are operated for about one minute in turn

unless the next control element is selected by pressing the

→

key.

♦

The control elements can be checked either by listening for

audible clicks, etc. or by touching the component.

♦

The final control diagnosis is terminated if the engine is started

or if an engine speed pulse is detected.

♦

Before restarting the final control diagnosis the engine must

be started and the ignition must be switched off and on again.

Audi TT 1999 ➤

Activation sequence

1. Activated charcoal filter solenoid valve 1 -N80-

2. Secondary air inlet valve -N112-

3. Secondary air pump relay -J299-

4. Solenoid valve for charge pressure control -N75-

5. Variable valve timing

6. Turbocharger air recirculation valve -N249-

7. Injector, cylinder 1 -N30-

8. Injector, cylinder 3 -N32-

9. Injector, cylinder 4 -N33-

10. Injector, cylinder 2 -N31-

11. Brake vacuum pump - only for vehicles with automatic gear‐

box

Procedure

• Fuses for engine electronics okay ⇒ Current flow diagrams,

Electrical fault finding and Fitting locations.

– Connect vehicle diagnostic, testing and information system -

VAS 5051 A- ⇒ page 2 and select vehicle system “01 - Engine

electronics”. When doing this the ignition must be switched on.

Display on -VAS 5051 A- :

– From menu -1- select diagnosis function “03 - Final control

diagnosis”.

Note

The fuel pump relay -J17- should pick up and the fuel pump

should run. There will be a clearly audible fuel flow at the fuel

pressure regulator. If the fuel pump does not run, check activation

⇒ page 78 .

3. Final control diagnosis 23

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Activating solenoid valve 1 for activated charcoal filter -N80- (tank

breather valve)

Display on -VAS 5051 A- :

A - 1st control element in test

1 - Fuel tank breather valve -N80-

• The valve is activated (clicks) intermittently for 1 minute unless

the next control element is selected beforehand by touching

the → key.

If the valve is not activated (does not click), check activated char‐

coal filter system solenoid valve 1 -N80- ⇒ page 105 .

Activating secondary air inlet valve -N112-

– Press the → key.

Display on -VAS 5051 A- :

A - 2nd control element in test

2 - Secondary air inlet valve -N112-

• The valve is activated (clicks) intermittently for 1 minute unless

the next control element is selected beforehand by touching

the → key.

If the valve is not activated (does not click) ⇒ Rep. Gr. 26 .

Activating secondary air pump relay -J299-

– Press the → key.

Display on -VAS 5051 A- :

A - 3rd control element in test

3 - Secondary air pump relay -J299-

• The secondary air pump relay -J299- switches the secondary

air pump motor -V101- on and off intermittently for about 1

minute, or until the → key is pressed to advance the pro‐

gramme to the next control element.

If the motor is not activated (does not run intermittently), check

secondary air pump relay -J299- ⇒ Rep. Gr. 26 .

Activating charge pressure control solenoid valve -N75-

– Press the → key.

Display on -VAS 5051 A- :

A - 4th control element in test

4 - Solenoid valve for charge pressure control -N75-

• The valve is activated (clicks) intermittently for 1 minute unless

the next control element is selected beforehand by touching

the → key.

If the valve is not activated (does not click) ⇒ Rep. Gr. 21 .

24 Rep. Gr.01 - Self-diagnosis

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (4-cylinder) - Edition 05.2005

Activating inlet camshaft control valve 1 -N205-

– Press the → key.

Display on -VAS 5051 A- :

A - 5th control element in test

5 - Variable valve timing

• The valve is activated (clicks) intermittently for 1 minute unless

the next control element is selected beforehand by touching

the → key.

If the valve is not activated (does not click) ⇒ Rep. Gr. 15 .

Activating turbocharger air recirculation valve -N249-

– Press the → key.