Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Maintenance

Audi TT 2007 ➤

Edition 04.2010

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Maintenance

He ad in g

1. Overview of engines

2. Delivery Service

3. Description of work

4. Type plate, vehicle identification number

5. Lifting the vehicle

6. Tow-starting/towing

7. Vehicle tests carried out as part of inspection services and maintenance

Service

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A00IGTT0220

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

Contents

1 Overview of engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Delivery Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Description of work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Cap for suspension strut protective tube: greasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Reading out: measured value block 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Battery: checking "no load" voltage before engine is started for first time . . . . . . . . . . . . . . 6

3.4 Battery: checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5 Battery: checking that battery cables are securely fitted . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6 Battery: performing battery test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.7 Tyres: checking condition, wear pattern, tread depth and correcting tyre pressures . . . . . . 14

3.8 Brake system: visual check for leaks and damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.9 Lights: checking function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.10 Brake pads: checking thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.11 Brake fluid level (depends on brake pad wear): checking . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.12 Brake fluid: changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.13 S tronic gearbox: changing oil and renewing oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.14 Electric windows: checking positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.15 G17 additive: adding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.16 Ignition keys: checking operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.17 Diesel particulate filter: reading out ash deposit mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.18 Data memory: interrogating with vehicle diagnostic, testing and information system

VAS 5051/ 5052 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.19 Noise insulation: removing and installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.20 Haldex coupling: changing oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.21 Poly V-belt: renewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.22 Fuel filter: renewing (2.0 ltr. TDI CR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.23 Cooling system: checking coolant additive level and topping up with coolant if necessary

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.24 Instrument cluster: setting the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.25 Air cleaner: cleaning housing and renewing filter element . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.26 Bonnet arrester hook: lubricating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.27 Engine cover panel: removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.28 Engine and engine compartment (from below): visual check for leaks and damage . . . . . . 38

3.29 Engine oil: draining or extracting, changing oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.30 Bonnet hinges: lubricating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.31 Engine oil: filling up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.32 Engine: checking oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.33 Navigation system: releasing eject button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.34 Radio: activating anti-theft coding by entering fixed code number . . . . . . . . . . . . . . . . . . . . 44

3.35 Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.36 Wheel bolts: tightening to specified torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.37 Tyre pressure monitoring system: updating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.38 Manual gearbox/final drive: checking oil level, topping up with oil if necessary . . . . . . . . . . 47

3.39 Windscreen wiper/washer system: checking jet settings, adjusting jets if necessary . . . . 47

3.40 Headlight washer system: checking jet settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.41 Wiper blades: checking park position and checking for damage . . . . . . . . . . . . . . . . . . . . 50

3.42 Service interval display: resetting or adapting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.43 Fuse for headlight washer system: fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.44 Dust and pollen filter: removing and installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.45 Track rods, track control links, swivel joints, guide links and drive shafts on front and rear

axle: checking boots, play, and secure fit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.46 Transport mode: deactivating (using vehicle diagnostic, testing and information system VAS

5051/5052 ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.47 Door arresters, door hinges and lock cylinders: lubricating . . . . . . . . . . . . . . . . . . . . . . . . 57

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

3.48 Transport locks: removing locking elements for front and rear suspension struts . . . . . . . . 57

3.49 Underseal: visual check for damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.50 Plenum chamber: checking and cleaning water drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.51 Winter tyres (factory-fitted) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.52 Toothed belt for camshaft drive: renewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.53 Clock: setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.54 Spark plugs: renewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4 Type plate, vehicle identification number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5 Lifting the vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6 Tow-starting/towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7 Vehicle tests carried out as part of inspection services and maintenance . . . . . . . . . . . . . . 71

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

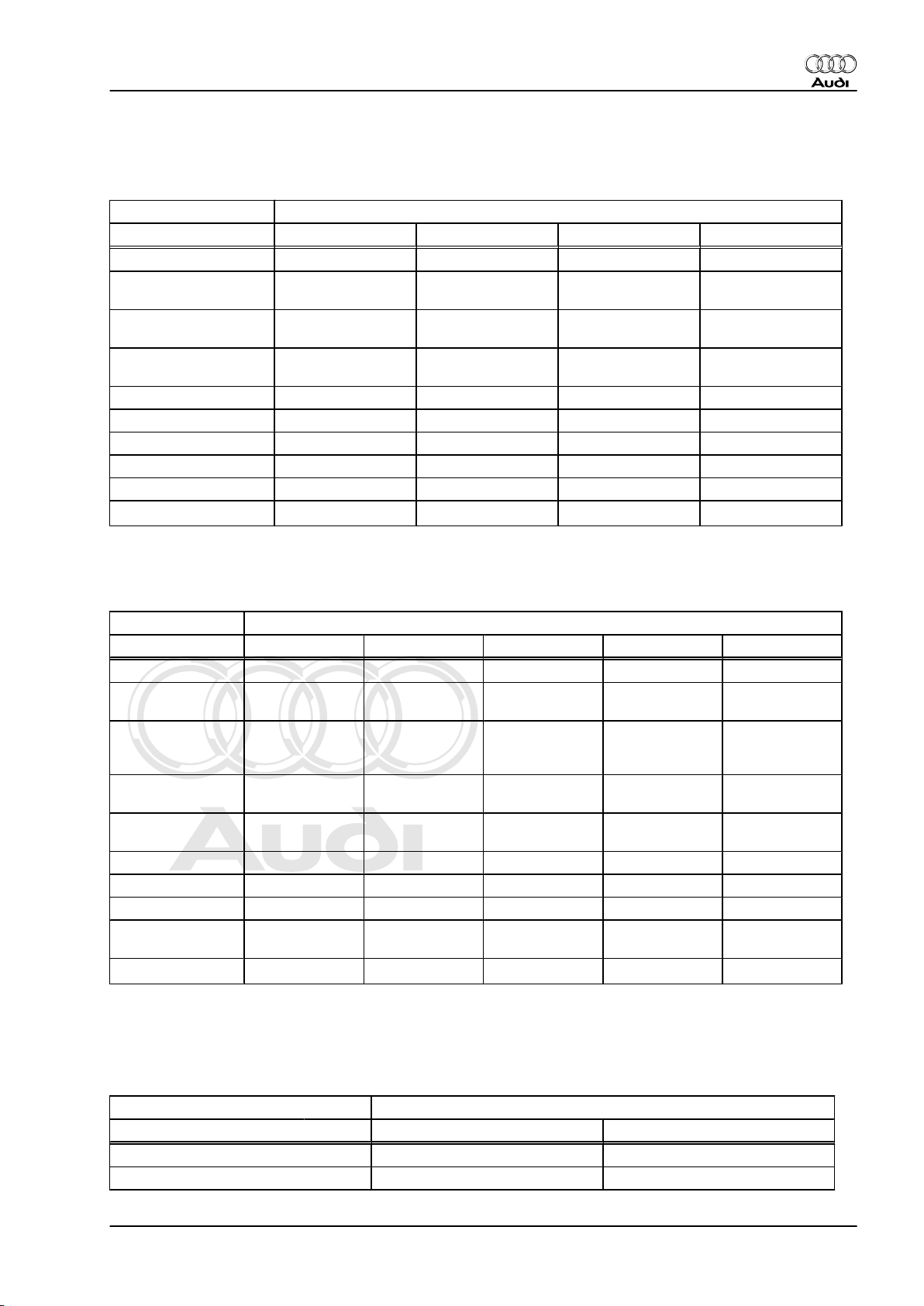

1 Overview of engines

Petrol engines

Engines ⇒ Petrol engines

Engine code BWA CDLA CDLB BUB

Capacity 2.0 ltr. 2.0 ltr. 2.0 ltr. 3.2 ltr.

No. of cylinders /

valves per cylinder

Exhaust emissions

standard

Power output (kW at

147 / 5100 - 6000 195 / 6000 199 / 6000 184 / 6333

rpm)

Torque (Nm at rpm) 280 / 1800 - 5000 350 / 2500 … 5250 350 / 2500 … 5250 320 / 2500

Bore (∅ mm) 82.5 82.5 82.5 84.0

Stroke (mm) 92.8 92.8 92.8 95.5

Compression ratio 10.5:1 9.8:1 9.8:1 10.85:1

Fuel injection / ignition TFSI TFSI TFSI MPI

RON at least

4/4 4/4 4/4 6/4

EU IV EU IV EU IV EU IV

98 unleaded

1)

98 unleaded

1)

98 unleaded

1)

98 unleaded

1)

1)

Unleaded RON 95 can also be used, but will result in a slight

loss of power.

Engines ⇒ Petrol engines

Engine code CCZA CESA CDAA CDMA CEPA

Capacity 2.0 ltr. 2.0 ltr. 1.8 ltr. 2.0 ltr. 2.5 ltr.

No. of cylinders /

4/4 4/4 4/4 4/4 5/4

valves per cylinder

Exhaust

EU V EU V EU V EU IV EU V

emissions

standard

Power output (kW

at rpm)

Torque (Nm at

rpm)

147 / 5100 -

6000

280 / 1800 -

5000

155 / 4300 -

6000

350 / 1600 -

4200

118 / 4500 -

6200

250 / 1500 -

4500

195 / 6000 250 / 5400 -

6500

350 /

2500 … 5250

450 / 1600 -

5300

Bore (∅ mm) 82.5 82.5 82.5 82.5 82.5

Stroke (mm) 92.8 92.8 84.1 92.8 92.8

Compression ratio 9.8:1 9.8:1 9.8:1 9.8:1 10:1

Fuel injection / ig‐

TFSI TFSI TFSI TFSI TFSI

nition

RON at least

98 unleaded 1)98 unleaded

1)

95 unleaded

98 unleaded 1)98 unleaded

1)

1)

Unleaded RON 95 can also be used, but will result in a slight

loss of power.

Diesel engines

Engines ⇒ Diesel engines

Engine code CBBB CFGB

Capacity 2.0 ltr. 2.0 ltr.

No. of cylinders / valves per cylinder 4/4 4/4

1. Overview of engines 1

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

Engines ⇒ Diesel engines

Engine code CBBB CFGB

Exhaust emissions stand‐

EU V EU V

ard

Power output (kW at rpm) 125 / 4200 125 / 4200

Torque (Nm at rpm) 350 / 1750 - 2500 350 / 1750 - 2500

Bore (∅ mm) 81 81

Stroke (mm) 95.5 95.5

Compression ratio 16.5 :1 16.5 :1

Fuel injection / ignition TDI

CR II

TDI

CR II

CN at least 51 51

Diesel particulate filter

1)

Unleaded RON 95 can also be used, but will result in a slight

X X

loss of power.

2 1. Overview of engines

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

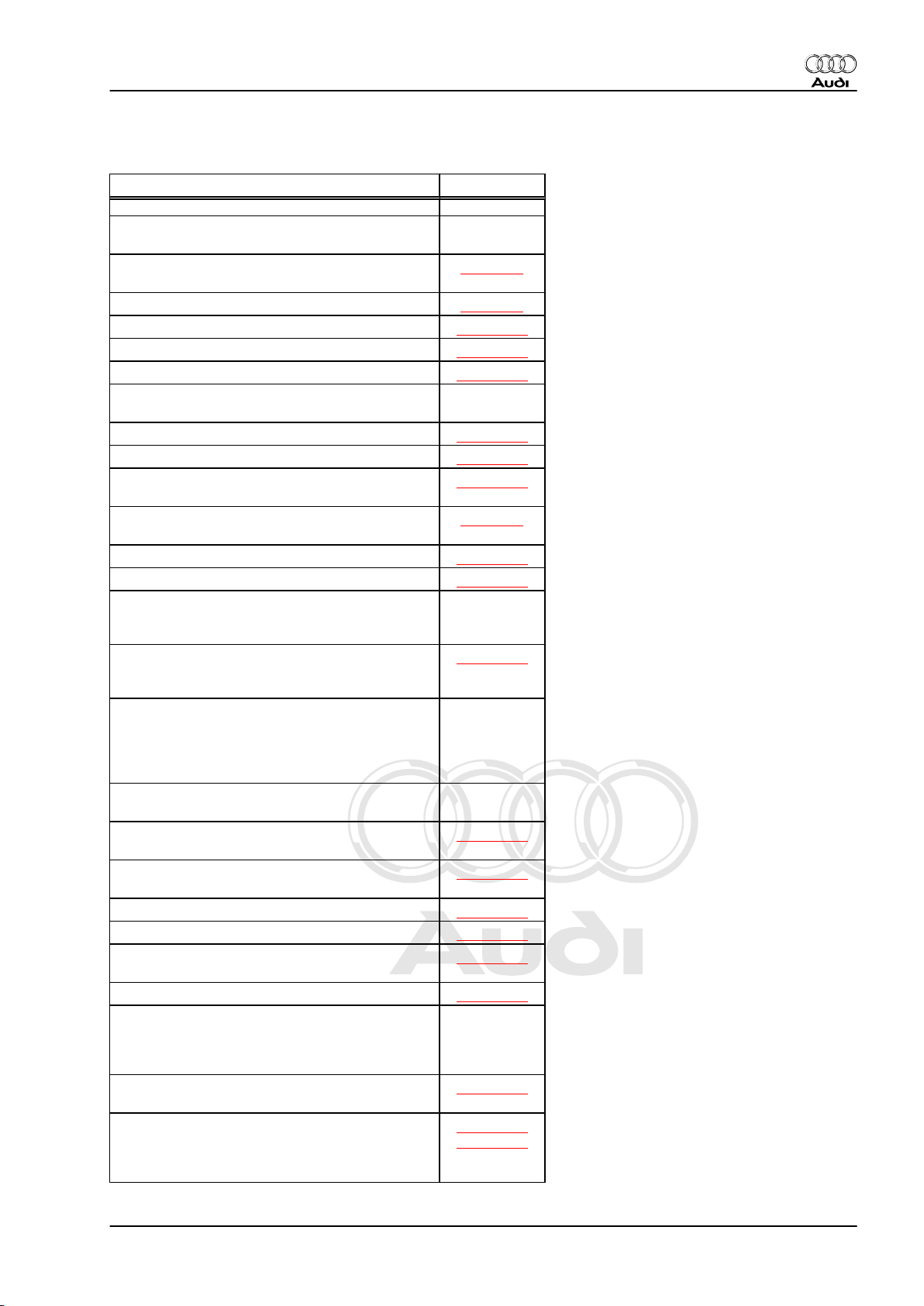

2 Delivery Service

Work to be completed Page

In the case of stock vehicles: performing steps

specified in maintenance table “stock vehicles”

Battery: checking that battery cables are se‐

curely fitted

Battery: checking no load voltage ⇒ page 6

Data memory: reading out ⇒ page 23

Service interval display: resetting ⇒ page 50

Instrument cluster: setting the language ⇒ page 28

Daytime running lights: activating (see MMI Op‐

erating Manual)

Fuse for headlight washer system: fitting ⇒ page 53

Transport mode: deactivating ⇒ page 56

Transport locks: removing locking elements for

suspension struts

Cap for suspension strut protective tube: greas‐

ing

G17 additive: adding into tank ⇒ page 21

Clock: setting ⇒ page 58

Front passenger's airbag: checking key switch

on / off, must be set to “on” (see Owner's Man‐

ual)

Ignition keys: checking operation. Enter the

number of ignition keys which have been

checked and handed over to the customer: ____

Service Schedule: removing vehicle data sticker

from supplied pack on front passenger's side

and sticking into Service Schedule under “War‐

ranty entitlement record”

Entering record of Delivery Service

Owner's literature: checking that it is complete

and preparing for handover to customer

Cooling system: coolant must be filled to max.

level

Engine: checking oil level and topping up if nec‐

essary

Headlight washer system: fitting fuse ⇒ page 53

Navigation system: releasing eject button ⇒ page 44

Brake system: brake fluid must be filled to max.

level

Wheel bolts: tightening to specified torque ⇒ page 46

Radio or radio/navigation system: disposing of

label with serial number and fixed code number

(supplied pack on front passenger's side) after

entering fixed code number

Radio and radio/navigation system: activating

anti-theft coding by entering fixed code number

Tyre pressure on all 4 wheels and spare wheel:

checking (note: 3.5 bar when car leaves factory)

Saving pressures in tyre pressure monitoring

system

ELSA mainte‐

nance table

⇒ page 9

⇒ page 57

⇒ page 5

⇒ page 22

⇒ page 26

⇒ page 44

⇒ page 18

⇒ page 44

⇒ page 14

⇒ page 46

Audi TT 2007 ➤

Maintenance - Edition 04.2010

2. Delivery Service 3

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

Work to be completed Page

Accessories: installing (components stored in

luggage compartment, glove box, supplied

pack); keep puller or plastic clip in vehicle tool

kit.

Vehicle (from below): checking for damage

(without removing noise insulation)

Protective seat covers, plastic sheeting for car‐

pet: removing

Floor mats: fitting

Cleanliness of vehicle interior: checking front

and rear seats, interior trim, carpeting/mats,

windows

Cleanliness of vehicle exterior: checking paint‐

work, trims, windows, wiper blades

Transport protection: removing protective edge

strips on doors

Interior mirror with compass: calibrating (if “C” is

⇒ Rep. Gr. 68

displayed on mirror)

Road test and reset DIS ⇒ page 45

4 2. Delivery Service

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

3 Description of work

The following chapters describe the work steps necessary for

performing the services listed in the maintenance tables.

Please refer to the relevant maintenance table for information on

when a service is due.

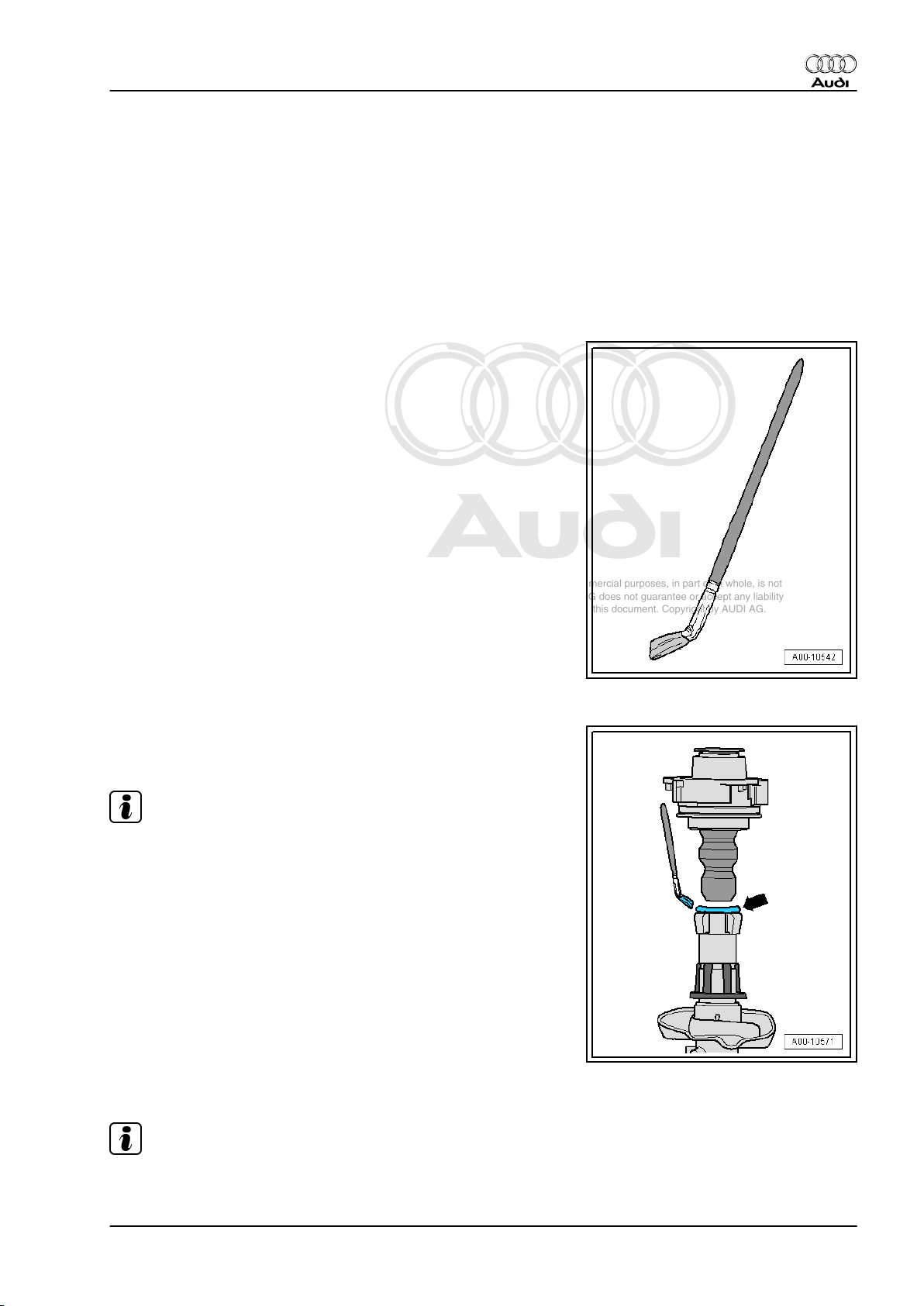

3.1 Cap for suspension strut protective tube: greasing

Special tools and workshop equipment required

♦ Lubricant G 000 405 A2

Audi TT 2007 ➤

Maintenance - Edition 04.2010

♦ Brush

Coat contact surface -arrow- of plastic cap at suspension strut

protective tube with G 000 405 A2.

Note

After removing the spring inserts/spacers and greasing the cap

for the suspension strut protective tube, make sure that the boot

is correctly seated in the suspension strut mounting and at the

shock absorber tube.

3.2 Reading out: measured value block 32

Note

Only applies in certain countries. For the countries affected, refer

to maintenance table.

3. Description of work 5

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

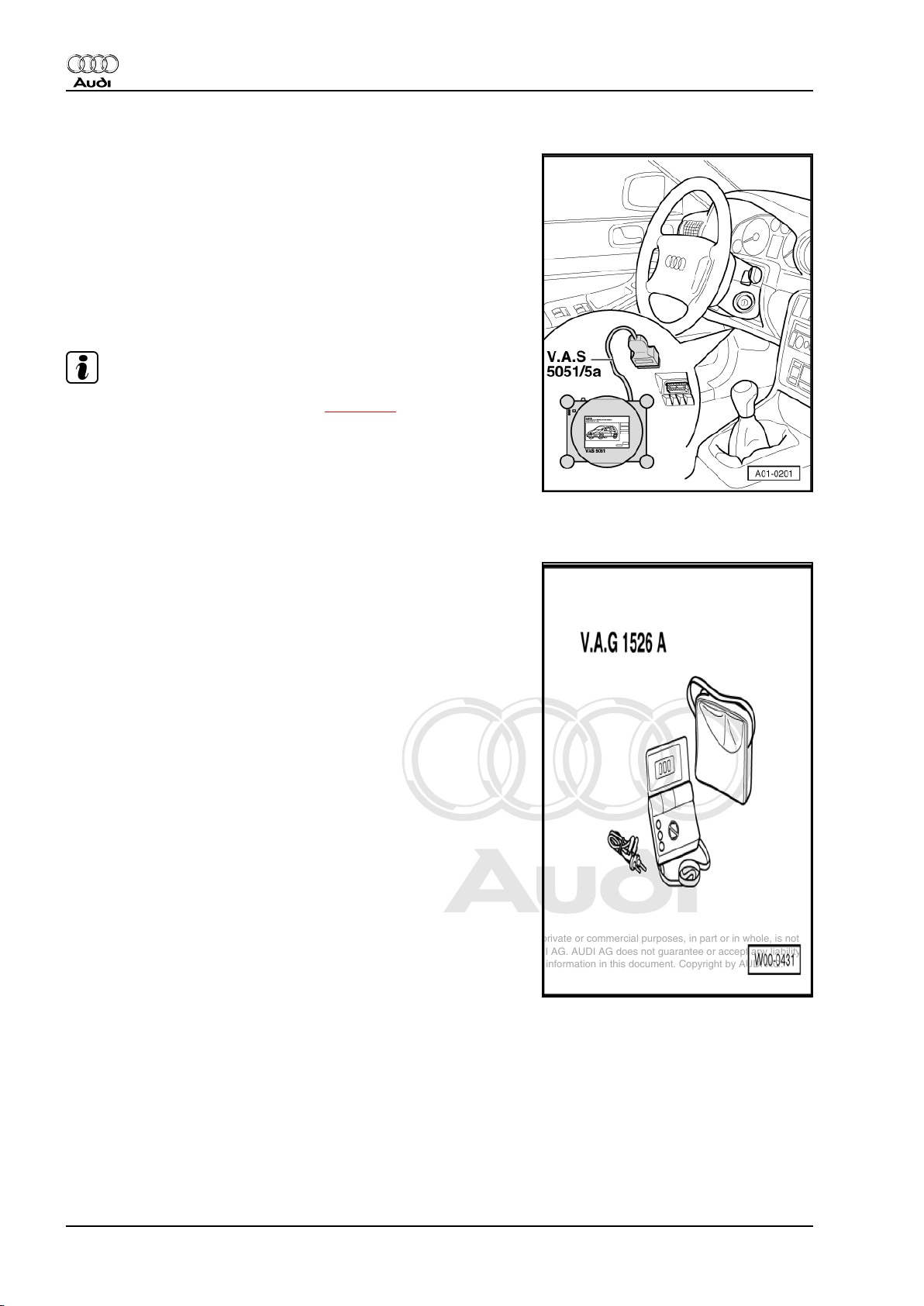

– Carry out the following steps, one after the other.

♦ Connect -VAS 5051/5052-

♦ Self-diagnosis

♦ Engine electronics

♦ Measured value blocks

♦ Select measured value block 32

♦ Display zone 2 (4-cyl. engines)

♦ Display zones 2 and 4 (V6 and V8 engines)

Note

Add four times as much G17 additive ⇒ page 21 if there is a

deviation of > 15% in the values.

3.3 Battery: checking "no load" voltage be‐

fore engine is started for first time

3.3.1 Special tools and workshop equipment

required

♦ Hand-held multimeter -V.A.G 1526C-

– Ensure that the following rules are observed, otherwise correct

measurements cannot be guaranteed.

6 3. Description of work

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

♦ The battery must not be placed under load from connected

electrical equipment for at least 12 hours before the test.

♦ The battery must not be charged for at least 12 hours before

test.

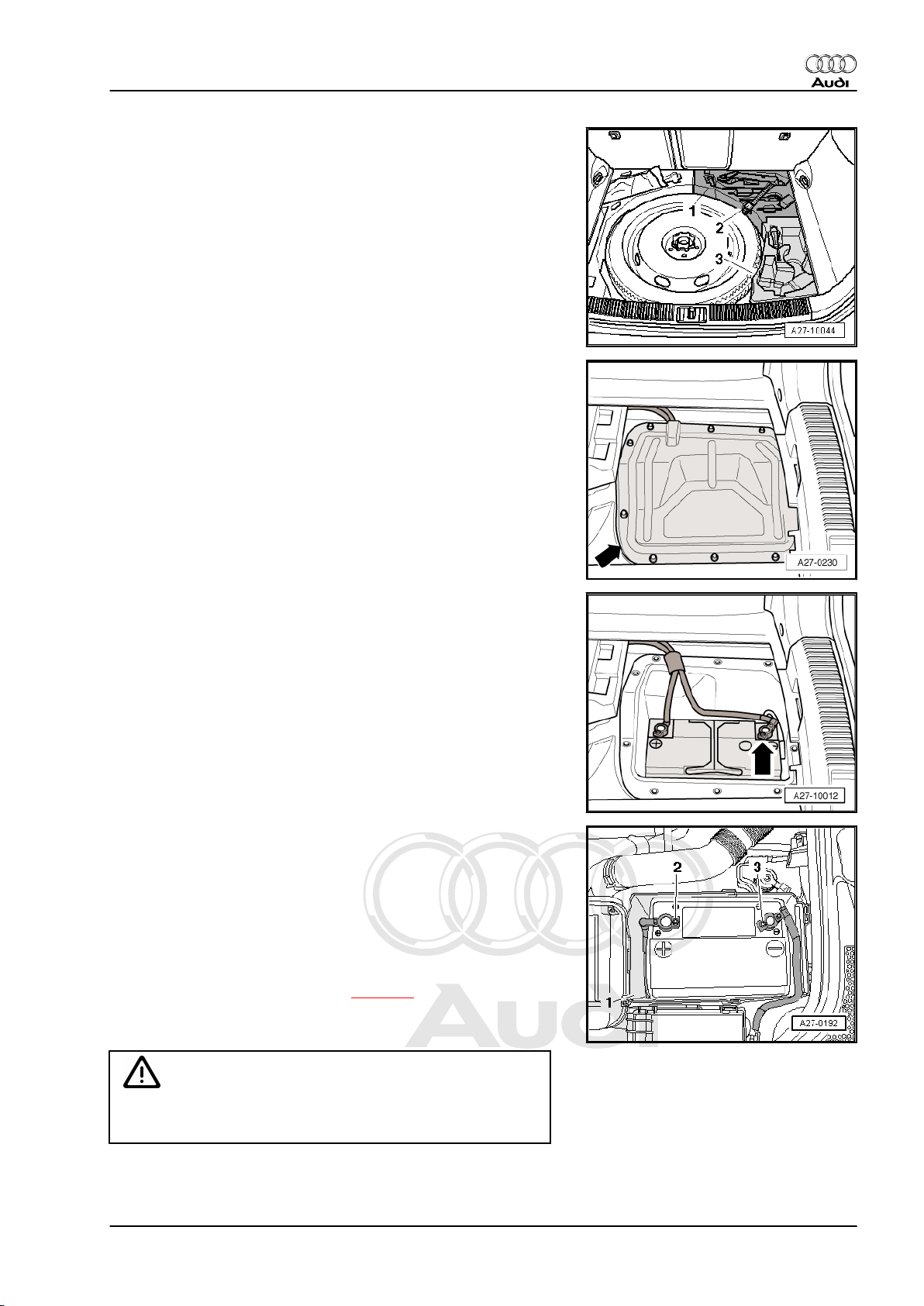

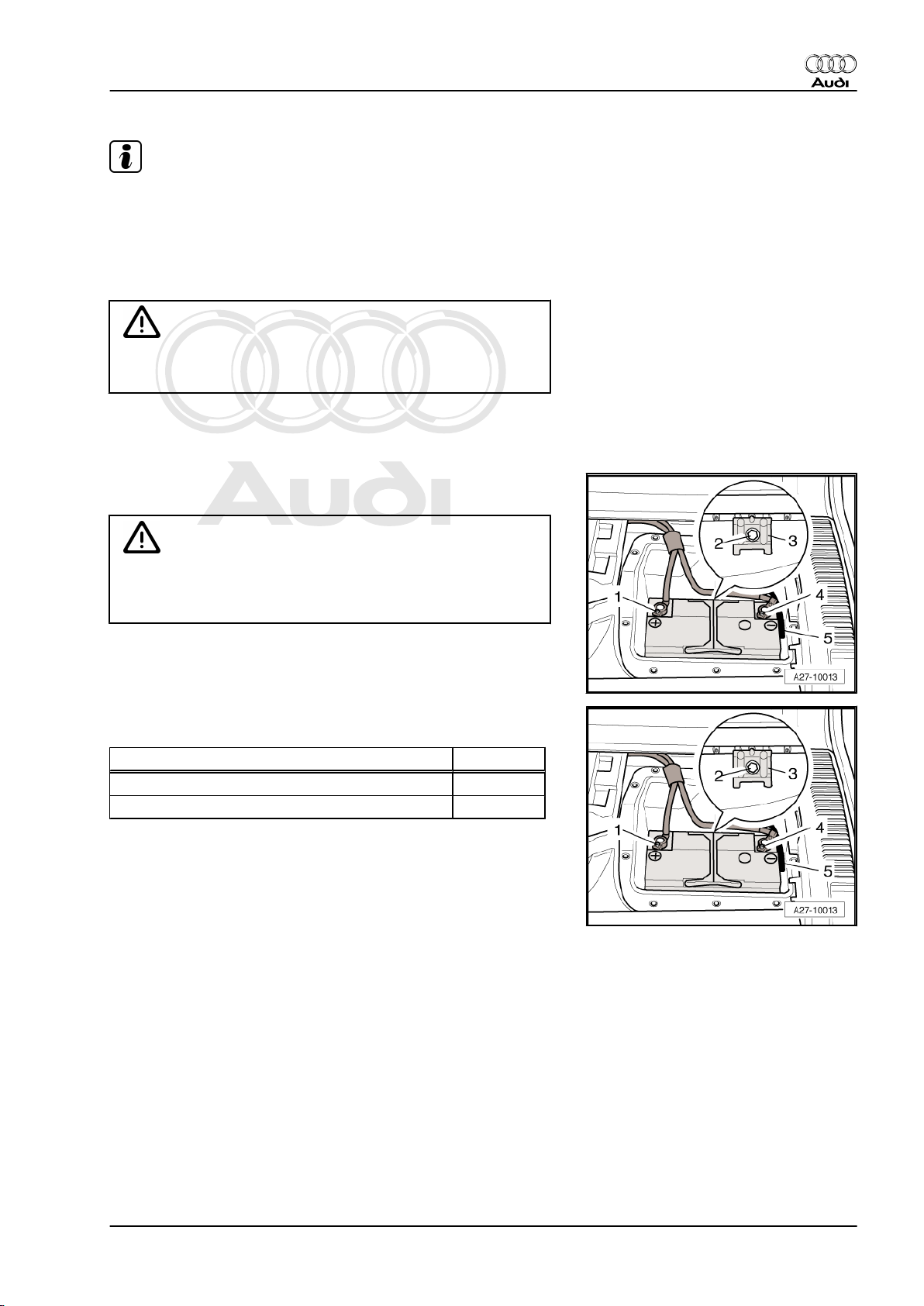

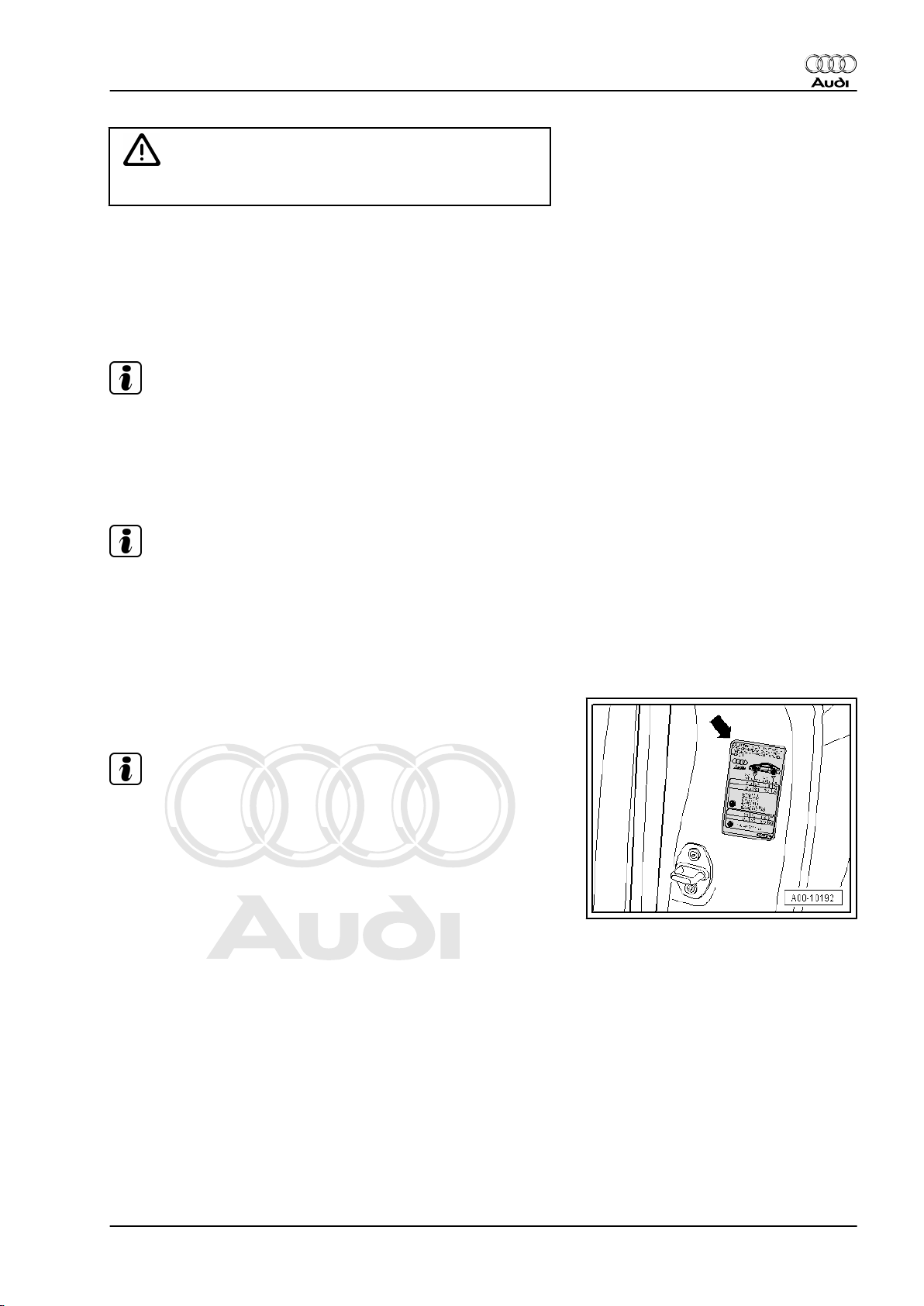

Remove rear moulded insert -3- for tools below luggage com‐

partment floor covering.

– Detach cover -arrow- for battery compartment.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Detach moulded insert above battery.

– With ignition switched off, measure voltage between battery

clamps -2- and -3-.

1 - If the tester indicates 12.5 V or more, then the battery is OK.

2 - If the tester indicates 12.2 to 12.5 V the battery must be

charged ⇒ Rep. Gr. 27 .

3 - If the tester indicates between 11.6 and 12.2 V proceed as

follows: Charge battery ⇒ Rep. Gr. 27 . After charging bat‐

tery allow to stand with no load for 24 hours. Then carry out

battery test / battery load test ⇒ page 9 .

4 - If tester indicates 11.6 V or less the battery must be renewed

⇒ Rep. Gr. 27 .

WARNING

Always adhere to correct procedure, otherwise measurements

will be falsified.

3. Description of work 7

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

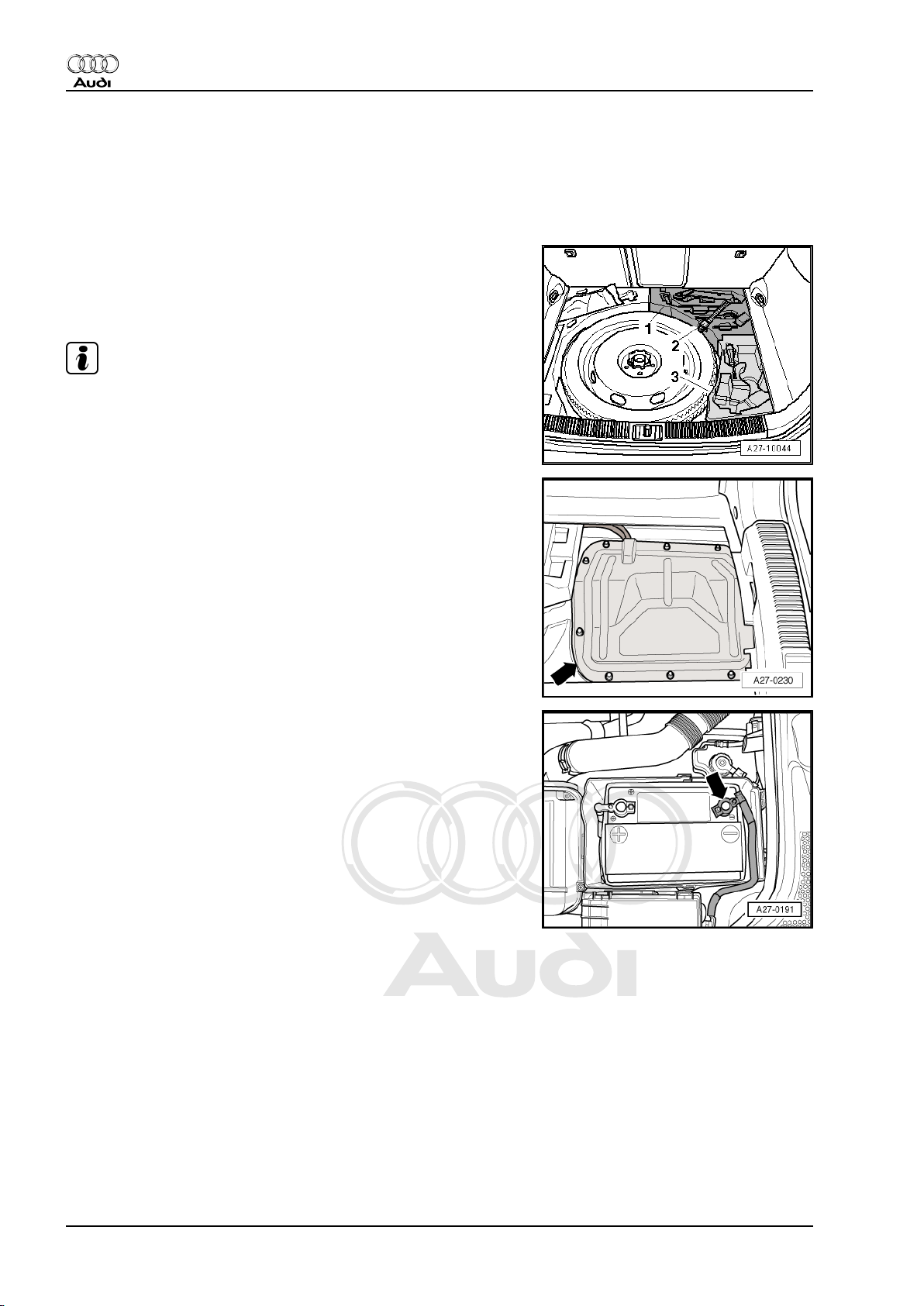

3.4 Battery: checking

3.4.1 Batteries with “magic eye”

The battery is located in the luggage compartment (rear right).

– Switch off the ignition and remove the ignition key from the

lock.

– Remove rear moulded insert -3- for tools below luggage com‐

partment floor covering.

Note

-Item 1- and -item 2- can be disregarded.

– Detach cover -arrow- for battery compartment.

– Detach moulded insert above battery.

♦ The magic eye -arrow- indicates the electrolyte level and the

charge level of the battery to be checked.

♦ Three different colours are used as indicators:

– Green → the battery is sufficiently charged.

– Black → no charge or charge too low

– Colourless or yellow → critical electrolyte level has been

reached. Battery must be renewed.

3.4.2 Battery with sealing plugs

♦ A visual check of the battery is sufficient for batteries with

clearly visible external min. and max. marks.

♦ The electrolyte level must be above the minimum marking, but

must not exceed the maximum marking.

♦ If the external min. and max. marks on the battery are not

clearly visible or if the electrolyte level cannot be checked

properly due to an opaque battery housing, the sealing plugs

must be unscrewed. It is then possible to visually check the

electrolyte level from the inside.

♦ The electrolyte level must align with the marking inside the

battery (plastic moulding). This corresponds to the max. mark‐

ing on the outside.

8 3. Description of work

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Note

If electrolyte level is too low, the cell plates dry out, resulting in a

loss of battery capacity (loss of power). The cell plates must be

fully covered by electrolyte (sulphuric acid) in order to prevent

corrosion of plates, plate bridges and cell connectors. Corrosion

of these parts will impair battery function and make it unreliable.

It will be rendered unusable.

WARNING

If the electrolyte level is below the min. marking the battery

must be renewed! ⇒ Rep. Gr. 27

3.5 Battery: checking that battery cables are securely fitted

– Check that battery clamps are securely fitted. If necessary,

tighten nuts -1- and -4-.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

WARNING

If the battery clamp on the positive terminal is not fitted se‐

curely, disconnect the battery earth strap from the battery

negative terminal first to avoid possible accidents.

– Check that battery is securely installed. If necessary tighten

securing bolt -2- on retainer plate -3-.

Tightening torque Nm

Battery clamps to battery terminals 5

Bolt on retainer plate 22

3.6 Battery: performing battery test

Special tools and workshop equipment required

3. Description of work 9

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

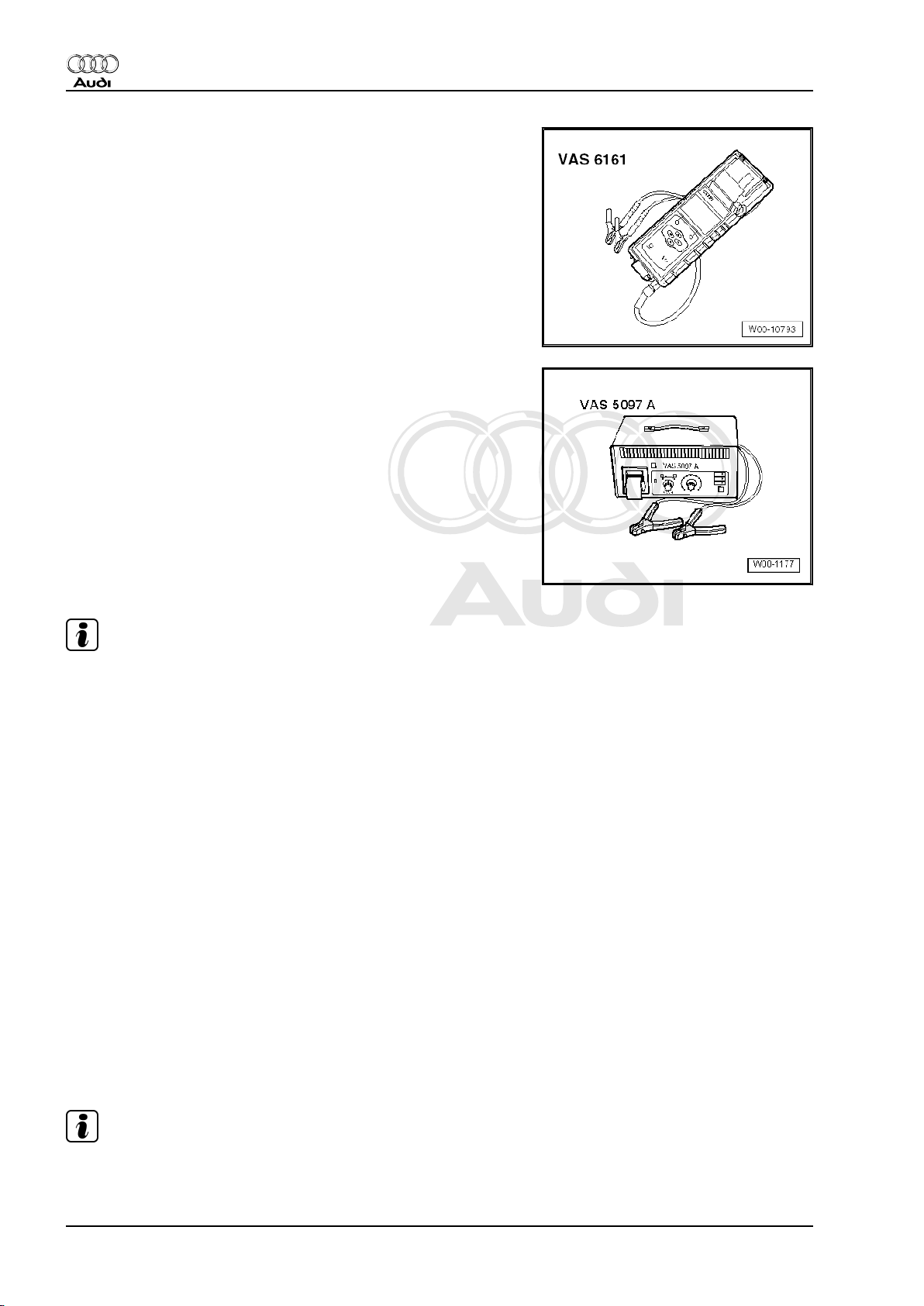

♦ Battery tester -VAS 6161- (with printer)

♦ Battery tester -VAS 5097 A-

Note

♦

During battery test with battery tester -VAS 6161- (with print‐

er), battery earth wire does not have to be disconnected.

♦

It is not necessary to remove the battery when using battery

tester -VAS 5097A- . The battery does not have to be discon‐

nected.

3.6.1 Performing battery test using battery tester -VAS 6161- (with printer)

♦ The battery tester with printer -VAS 6161- no longer puts the

battery under load, but works by measuring the dynamic con‐

ductivity. For this reason it is possible to perform several

measurements without re-charging the battery.

♦ "No-load" voltage measurement can be performed without de‐

lay.

♦ All battery types are stored in the tester. These data can be

updated.

♦ The battery bar code can be directly read off with the optionally

available 2D scanner.

♦ The integrated temperature sensor improves the quality of

measurements.

♦ The data can be stored on an SD card.

Note

For more information on the battery tester -VAS 6161- (with print‐

er), refer to the tester's ⇒ operating instructions .

10 3. Description of work

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

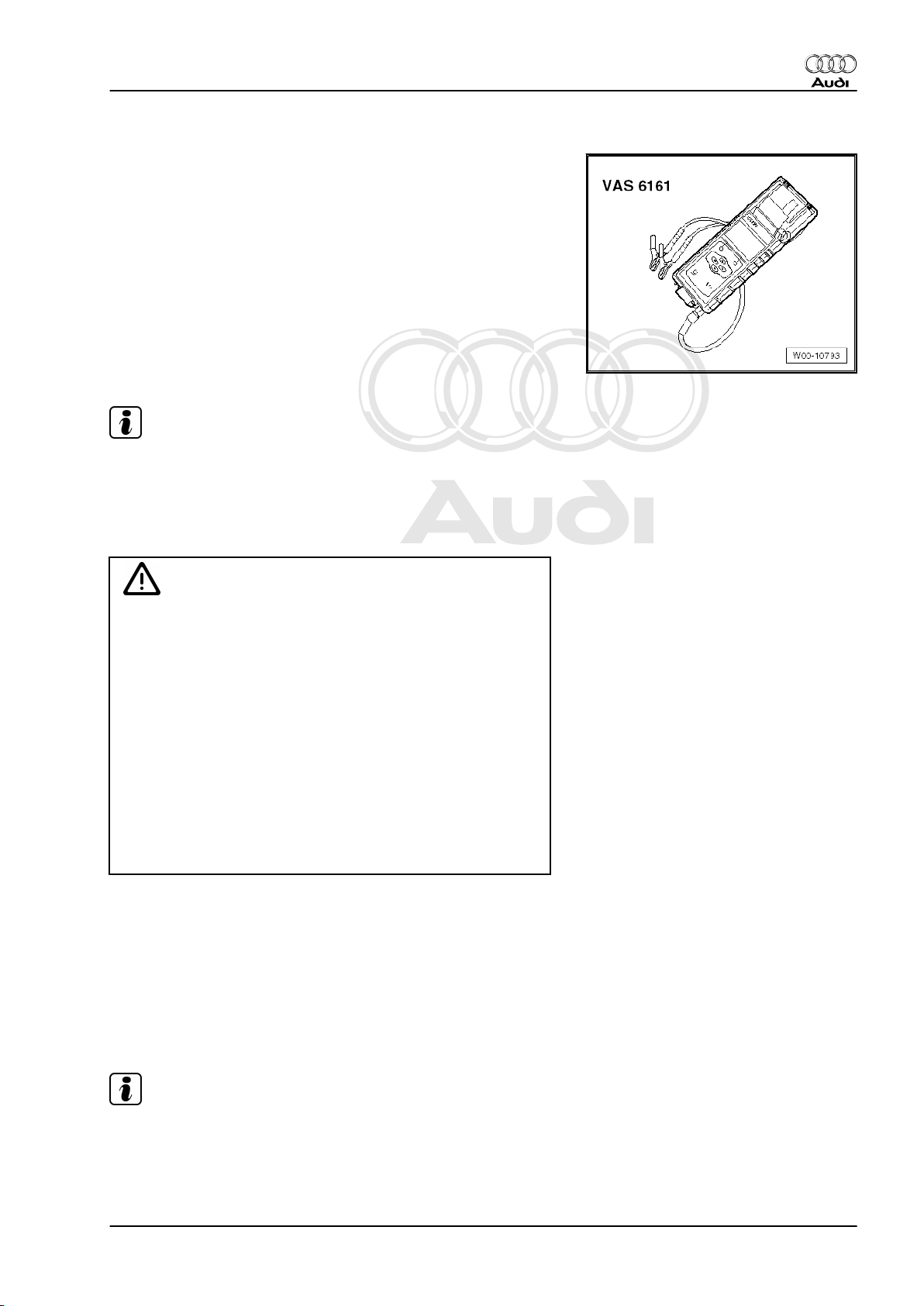

Special tools and workshop equipment required

♦ Battery tester (with printer) -VAS 6161-

Note

For instructions on how to use the battery tester -VAS 6161- refer

to its ⇒ operating instructions .

Procedure:

• The battery temperature must be at least +10 °C.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

WARNING

Risk of injury due to electrolyte.

♦ The accident prevention procedures must be observed

when handling electrolyte.

♦ Wear eye protection and protective clothing.

♦ Sealing plugs of batteries which are not maintenance-free

must be firmly screwed in when measuring voltage under

load.

Risk of explosion due to a discharged battery with “magic eye”.

♦ If the “magic eye” is colourless or light yellow, do not test

or charge the battery. Do not attempt to jump-start the ve‐

hicle! There is a danger of explosion if you test or charge

the battery or jump-start the vehicle! The battery must be

renewed.

– Switch off ignition and all electrical equipment.

– On vehicles with “magic eye” check colour of “magic eye”.

– Switch on battery tester -VAS 6161- (with printer).

– Connect red test clamp “+” of battery tester to positive battery

terminal or jump start terminal in engine compartment.

– Connect black test clamp “–” of battery tester to negative bat‐

tery terminal or jump start terminal in engine compartment.

Note

Make sure the test clamps make proper contact.

– Select one of the following functions:

♦ Maintenance test

3. Description of work 11

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

♦ Service test

♦ Warranty test

Maintenance test

– Select “Maintenance test” from the menu.

– Connect scanner and scan in vehicle identification number.

– Select connection point: “at battery post” or “at jump start

post”.

– Select vehicle model.

– Scan in battery's bar code.

– Determine temperature by holding temperature sensor at a

distance of approx. 5 cm over battery or jump start post until

a constant temperature is displayed.

– Start test.

– If required, print out test log.

Service test

– Select “Service test” from the menu.

– Select vehicle model.

– Determine temperature by holding temperature sensor at a

distance of approx. 5 cm over battery until a constant temper‐

ature is displayed.

– Select battery type: “Regular”, “AGM”, “2*6V” or “Gel”.

– Select rating units: “CCA”, “JIS”, “DIN”, “SAE”, “IEC” or “EN”.

– Start test.

– If required, print out test log.

Warranty test

– Select “Warranty test” from the menu.

– Select fitting location: “in vehicle” or “out of vehicle”.

– Select vehicle model.

– Determine temperature by holding temperature sensor at a

distance of approx. 5 cm over battery until a constant temper‐

ature is displayed.

– Select battery type: “Regular”, “AGM”, “2*6V” or “Gel”.

– Select corresponding rating using arrow buttons.

– Start test.

– If required, print out test log.

Note

The test log is required for warranty processing.

– Switch off battery tester.

– Detach test clamps.

12 3. Description of work

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

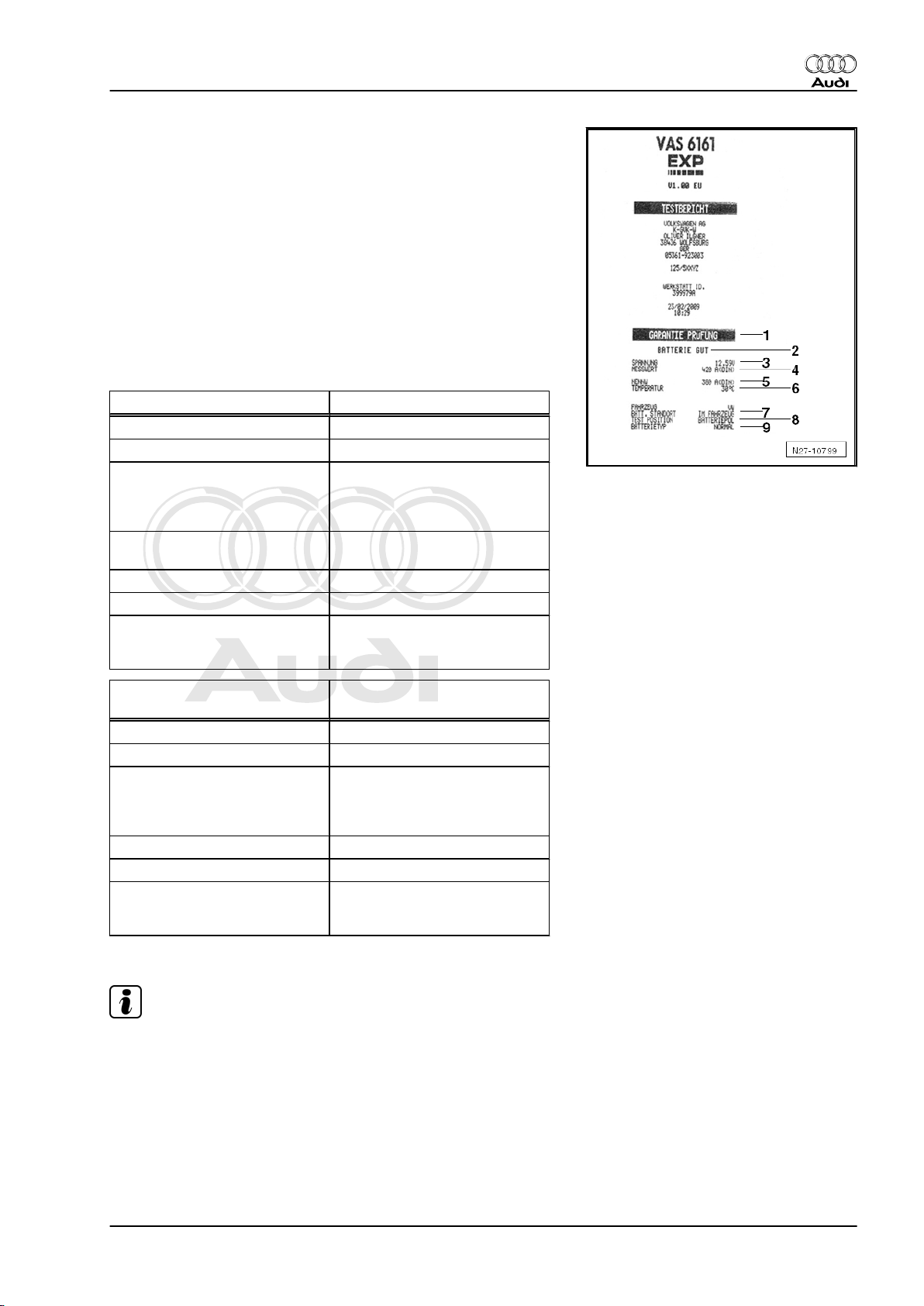

Test result on printout:

1 - Test mode

2 - Test result

3 - Measured voltage

4 - Measured nominal value of battery

5 - Nominal value of battery set on tester

6 - Temperature measured above battery

7 - Fitting location of battery

8 - Position of battery clamp set on tester

9 - Selected battery type

Result of maintenance test Measures

Battery good Battery OK

Charge battery Charge battery

Charge battery instantly Charge battery completely and

repeat test. Faults can occur if

battery is not completely charg‐

ed when test is repeated

Mark as defect Mark as “defect” and remove

from vehicle

Check tester connection Remove battery and repeat test

Battery frozen Thaw battery and repeat test

Check connection Connect cable directly to bat‐

tery and not to jump-start termi‐

nal

Audi TT 2007 ➤

Maintenance - Edition 04.2010

Result of service test and war‐

Measures

ranty test

Battery good Battery OK

Battery good - recharge Charge battery completely

Replace battery Remove battery and repeat

test. Result "Replace battery"

can arise if cables do not make

proper contact

Bad cell - replace Renew battery

Battery frozen Thaw battery and repeat test

Check connection Connect cable directly to bat‐

tery and not to jump-start termi‐

nal

– Renew battery ⇒ Rep. Gr. 27 .

Note

If the battery has to be renewed, observe disposal regulations.

3.6.2 Performing battery load test using VAS 5097 A

– Switch off ignition.

– Read operating instructions for battery tester.

3. Description of work 13

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Connect the clamps of the test leads to battery terminals as

described in operating instructions for the tester.

The clamps must make good contact with the battery terminals.

– As the load current differs depending on the battery, the cur‐

rent must be set on the tester according to battery capacity ⇒

Operating instructions for battery test equipment.

– Perform a battery load test as described in the operating in‐

structions.

Please note the test results shown on the display of the tester.

Display on bat‐

tery tester

Battery Very

Delivery Inspection Inspection Service

LongLife Service

Battery OK Battery OK

Good

Battery Good Battery OK Battery OK

Battery Sufficient Renew battery

Battery Not Good Renew battery

Battery Faulty Renew battery

Cannot be tested Renew battery

Charge battery

Charge battery

Renew battery

Renew battery

1)

1)

2)

2)

1) - Perform battery load test again after recharging the battery.

If tester shows “Battery Good” after charging, battery is OK. How‐

ever, if tester still shows “Battery Not Good”, battery must be

renewed.

2) - Agree battery replacement with customer.

– Renew battery ⇒ Rep. Gr. 27 .

Notes on battery load test:

The battery voltage will decrease during the test due to the high

load (high current flow).

If a battery is in working order battery voltage will only drop to

minimum voltage.

If the battery is defective or only insufficiently charged, battery

voltage will very quickly drop below minimum voltage.

After carrying out the load test the voltage will remain at this low

level for quite a while; voltage will only rise again slowly.

3.7 Tyres: checking condition, wear pattern,

tread depth and correcting tyre pres‐

sures

Note

All tyres and wheels (front and rear) must be of same type and

size. On four-wheel drive vehicles you must also ensure that all

tyres are made by the same manufacturer and have the same

tread pattern.

Delivery Inspection

– Check tyre tread surfaces and sidewalls for damage and re‐

move any foreign bodies.

Inspection Service

– Check tyres for scuffing, one-sided wear, porous sidewalls,

cuts and fractures.

14 3. Description of work

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

WARNING

Any defects must be reported to the customer.

Checking tyre wear pattern

– The wear pattern of the front tyres indicates, for example,

whether the toe and camber have to be checked.

♦ Feathering on tread indicates incorrect toe setting.

♦ One-sided tread wear is usually due to incorrect camber.

Note

If the above types of wear are found, check wheel alignment to

determine the cause (repair measure).

Checking tyre tread depth

♦ Minimum depth: 1.6 mm

Audi TT 2007 ➤

Maintenance - Edition 04.2010

Note

♦

This figure may vary for individual countries due to different

legislation.

♦

If the tread depth is approaching the minimum permissible

tread depth, the customer must be informed.

3.7.1 Inflating to correct pressures

The correct inflation pressures are listed on the sticker inside the

B-pillar.

Note

Please note that the tyre pressures listed on the sticker apply to

cold tyres. When the tyres are warm, the actual pressures will be

higher, but must not be reduced.

3.7.2 Spare wheel

• Collapsible spare wheel

The correct tyre pressure is indicated on the sidewall.

3.8 Brake system: visual check for leaks and damage

– Check following components for leaks and damage:

♦ Brake master cylinder

♦ Brake servo

♦ ABS hydraulic unit

♦ Brake calipers

3. Description of work 15

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Ensure that brake hoses are not twisted.

– Make sure that brake hoses do not touch any components

when steering is on full lock.

– Check brake hoses for porosity, blistering and brittleness.

– Check brake hoses and pipes for chafing.

– Check brake pipe connections and mountings for correct seat‐

ing, leaks and corrosion.

WARNING

Any faults found must be rectified (repair measure).

3.9 Lights: checking function

– The following components must be checked:

♦ Front lights: side lights, dipped beam, main beam, front fog

lights, turn signals, hazard warning lights

♦ Tail light cluster: brake lights (incl. 3rd brake light), rear lights,

reversing lights, rear fog light, number plate light, turn signals,

hazard warning lights

♦ Horn, glove box light and luggage compartment light

3.10 Brake pads: checking thickness

Special tools and workshop equipment required

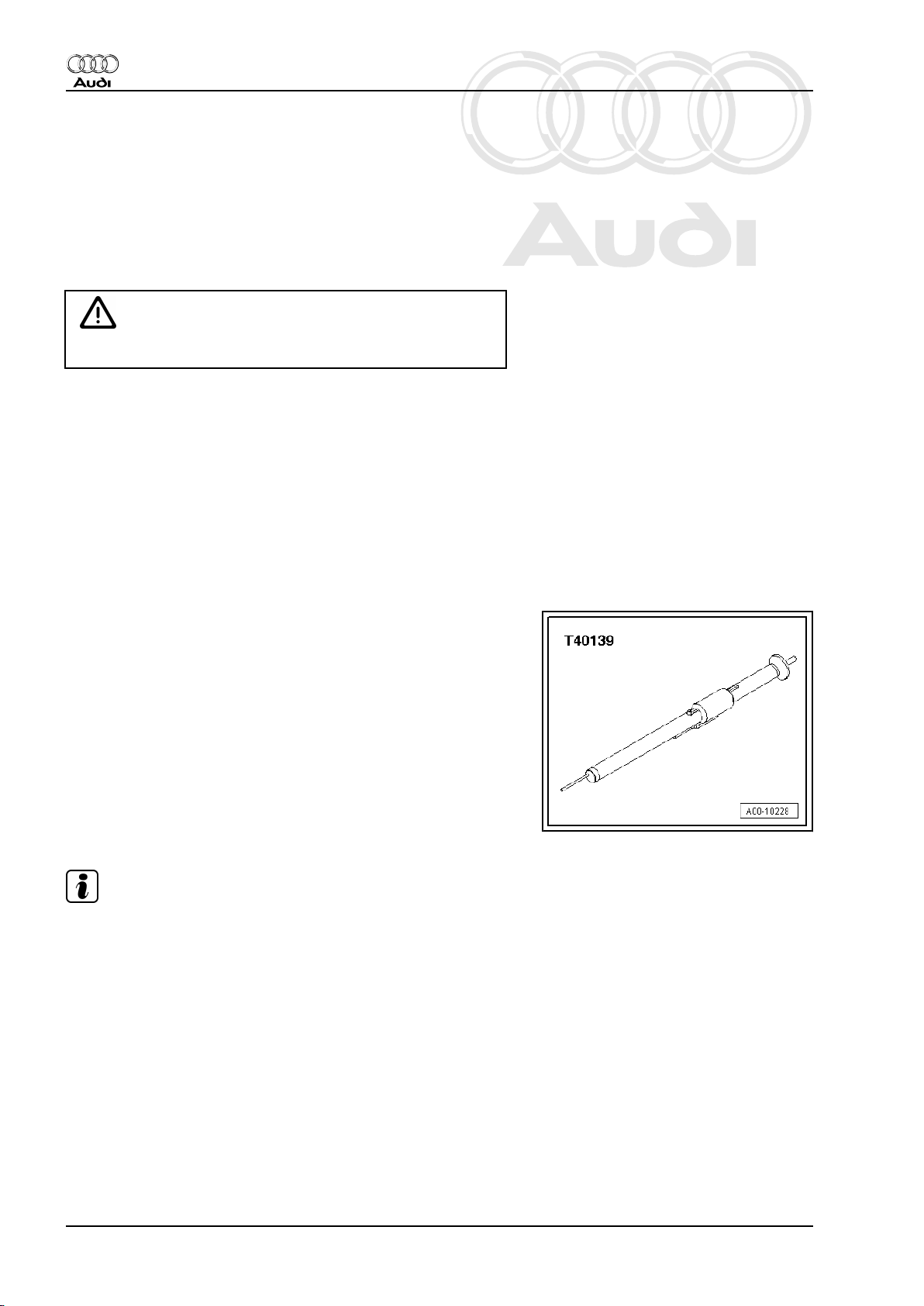

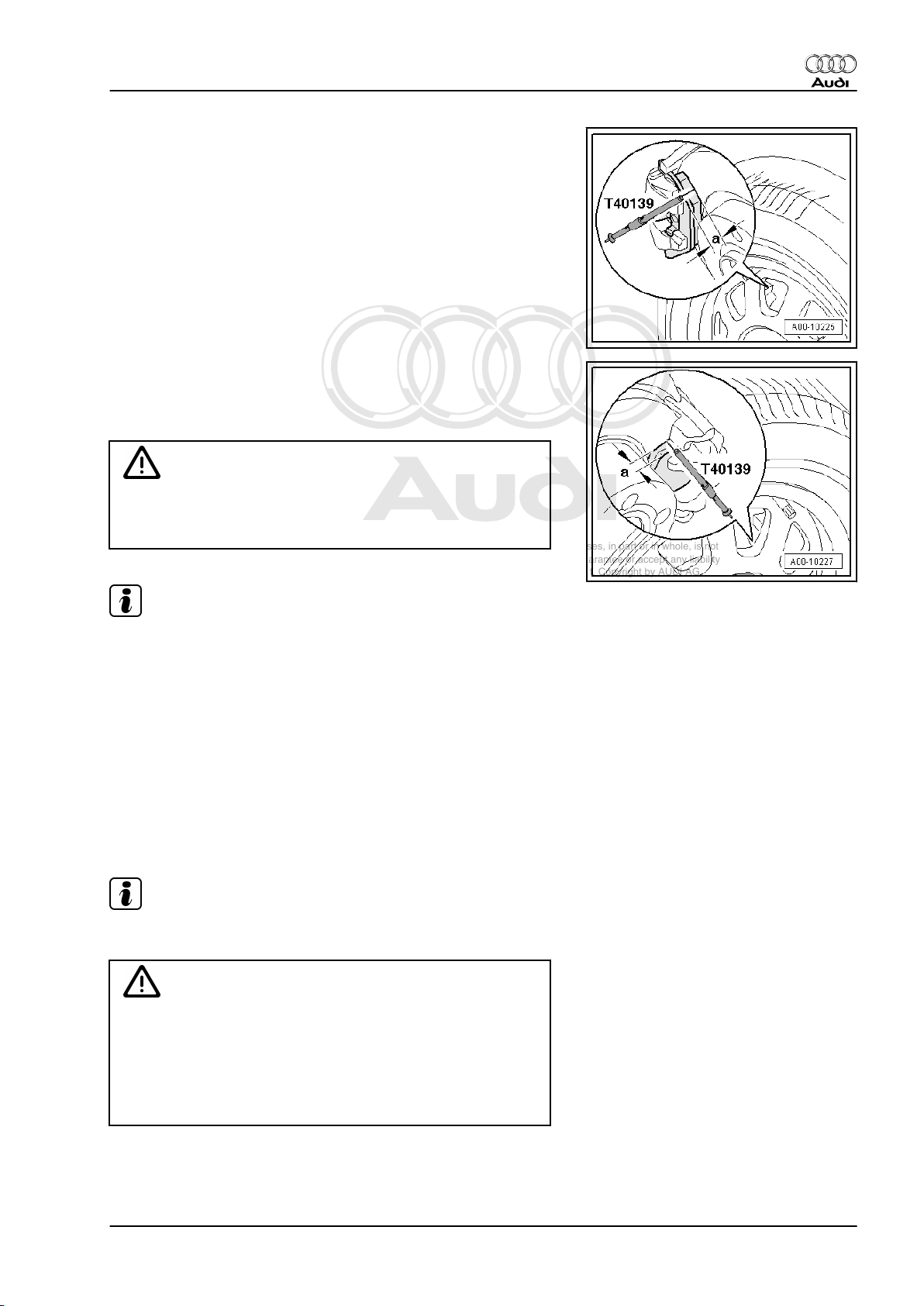

♦ Test pin T40139

Test pin

Before using the test gauge to check the pad thickness, push the

sliding ring towards the tip of the gauge as far as it will go.

Then insert the test gauge through the wheel rim and bring the tip

of the gauge into contact with the brake disc. Then slide the body

of the gauge uniformly towards the brake pad until the gauge

makes contact with the backplate of the brake pad.

Then take out the test pin and read off the value on the scale

marked with the brake symbol.

Note

♦

When removing the test pin, take care not to move the sliding

ring. This would give an incorrect measurement.

♦

The second scale on the test pin (with the tyre symbol) can be

used for checking tread depth.

16 3. Description of work

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Front disc brake pads:

a - Pad thickness including backplate

- Wear limit: 7

Rear disc brake pads:

a - Pad thickness including backplate

- Wear limit: 7

WARNING

When brake pad thickness (including backplate) is down to 7,

the brake pads have reached their wear limit and must be re‐

newed (repair measure). The customer must be informed.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

Note

♦

On some vehicles (fitted with aftermarket rims) it may not be

possible to insert the test pin through the wheel rim and bring

it into contact with the brake disc or the brake pad, due to the

shape of the rim. In this case proceed as follows:

♦

Determine thickness of outer pads by checking visually (using

electric torch through cut-out in rim).

♦

Determine thickness of inner pads by checking visually (with

help of electric torch and mirror).

3.11 Brake fluid level (depends on brake pad wear): checking

Note

Only use new genuine VW/Audi brake fluid, refer to ETKA.

WARNING

♦ Brake fluid is poisonous. It also has caustic properties and

must therefore not be allowed to come into contact with

paintwork.

♦ Brake fluid is hygroscopic, i.e. it absorbs moisture from the

surrounding air. It must therefore always be stored in airtight containers.

– Note the following:

3. Description of work 17

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

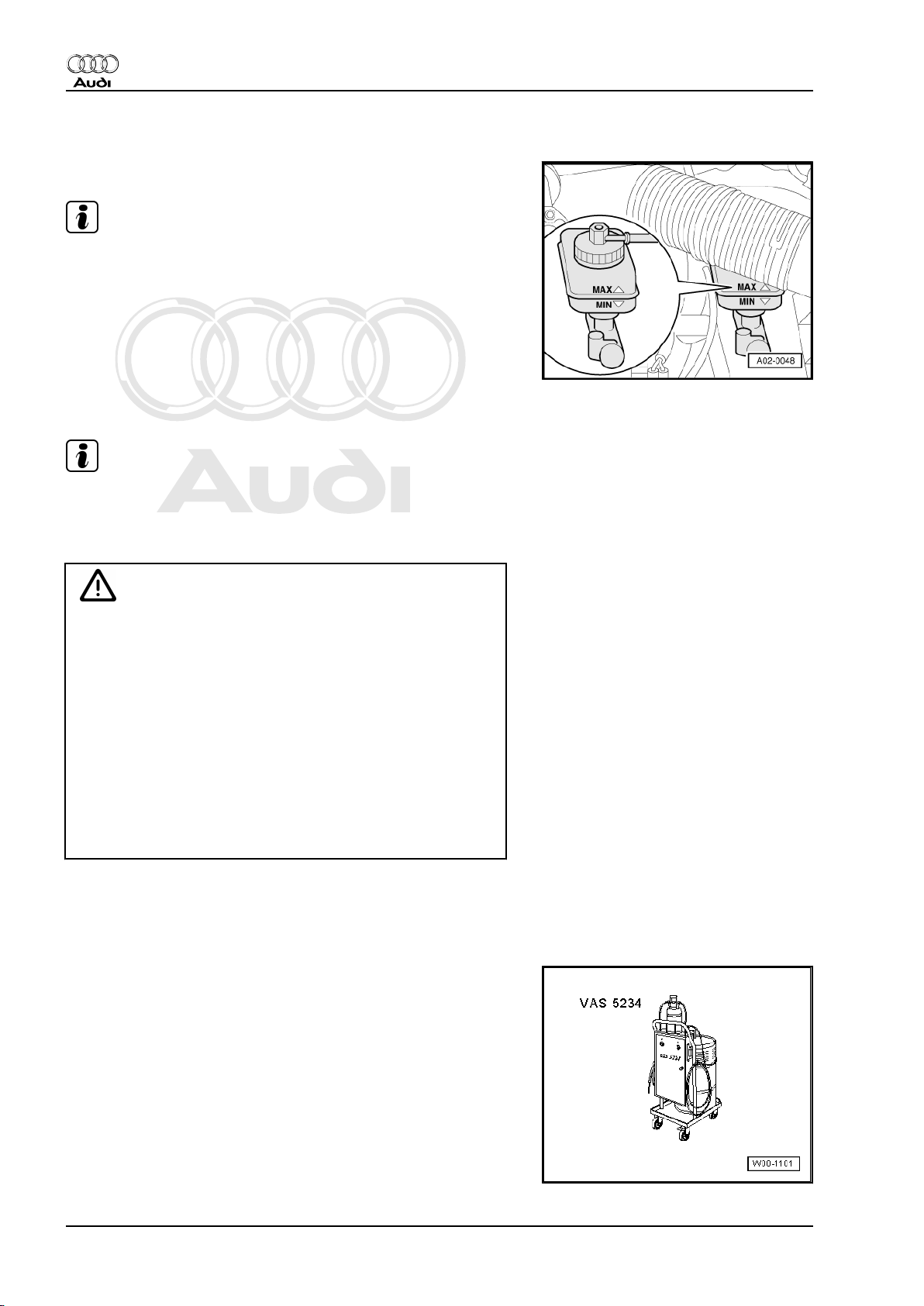

3.11.1 Delivery Inspection

♦ The fluid level must be at the MAX mark.

Note

The fluid level must not exceed the MAX marking, otherwise the

fluid will overflow.

3.12 Brake fluid: changing

Note

Only use new genuine VW/Audi brake fluid, refer to ETKA.

Changing brake fluid with brake filling and bleeding equipment VAS 5234-

WARNING

♦ Brake fluid must on no account come into contact with liq‐

uids containing mineral oils (oil, petrol, cleaning agents).

Mineral oils damage the plugs and sleeves in the brake

system.

♦ Brake fluid is poisonous and must under no circumstances

be sucked through a tube using the mouth. Because of its

caustic properties it must also not come into contact with

paintwork.

♦ Brake fluid is hygroscopic, i.e. it absorbs moisture from the

surrounding air. It must therefore always be stored in airtight containers.

♦ Always observe the relevant environmental regulations for

disposal.

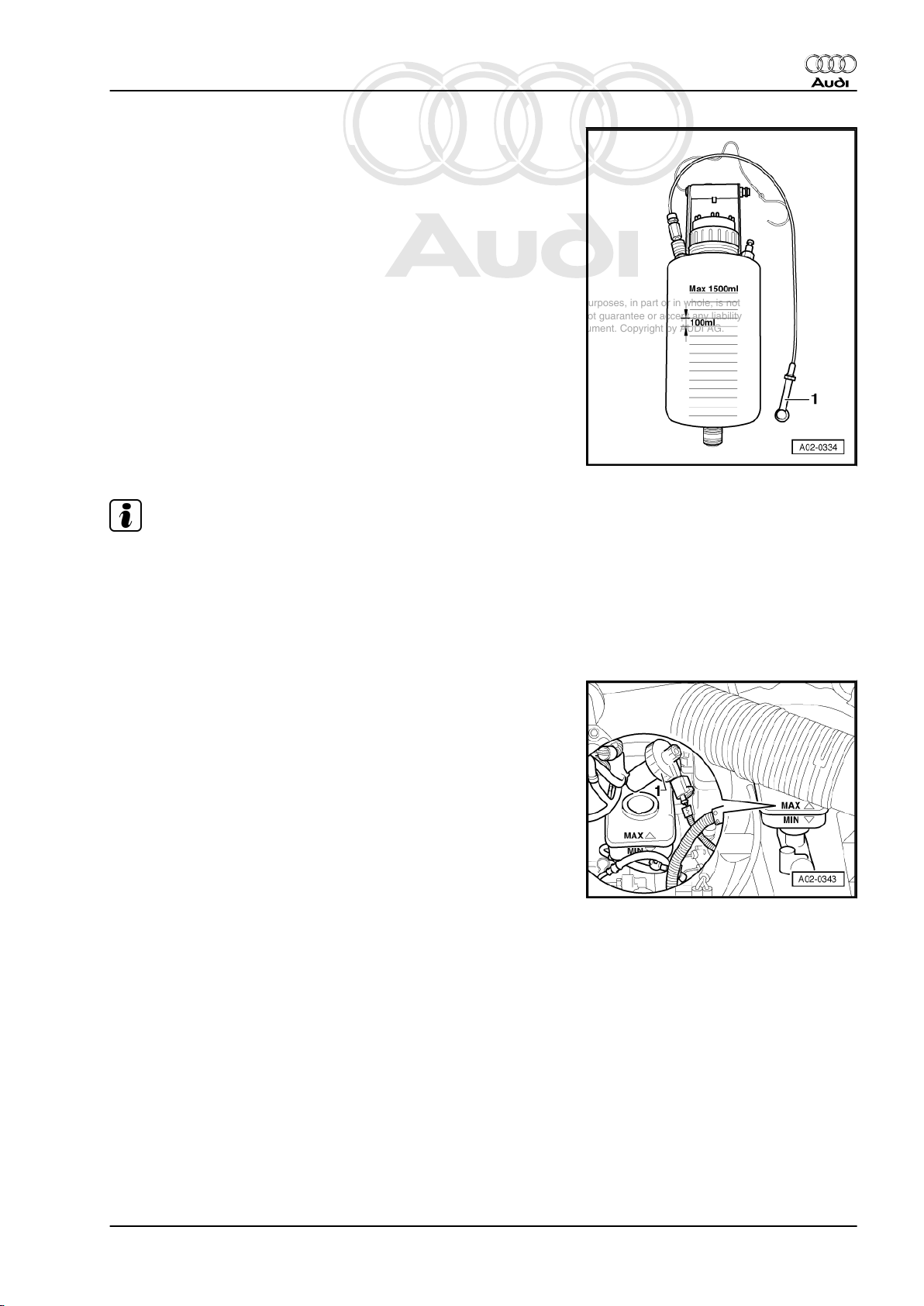

3.12.1 Changing brake fluid with brake filling and bleeding equipment -VAS 5234-

Special tools and workshop equipment required

♦ Brake filling and bleeding equipment -VAS 5234-

18 3. Description of work

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

♦ Container for collecting used fluid

Audi TT 2007 ➤

Maintenance - Edition 04.2010

Note

♦

The brake fluid reservoir must always be adequately filled to

ensure that no air can enter the brake system from the reser‐

voir.

♦

The strainer in the brake fluid reservoir must not be removed.

♦

Observe the instructions given in the operating manual for the

brake filling and bleeding equipment -VAS 5234- .

– Unscrew cap -1- from brake fluid reservoir.

3. Description of work 19

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Use extraction hose included in brake filling and bleeding

equipment -VAS 5234- to extract as much brake fluid as pos‐

sible.

WARNING

Do not reuse the old brake fluid that has been extracted.

– Connect adapter -1- to brake fluid reservoir.

– Connect filling hose -2- included with brake filling and bleeding

equipment -VAS 5234- to adapter.

Vehicles with manual gearbox:

– Remove cap from bleeder screw on clutch slave cylinder.

– Connect bleeder hose -1- attached to collector bottle to bleed‐

er screw on clutch slave cylinder, open bleeder screw and let

approx. 100 ml flow out. Close bleeder screw and fit cap back

on.

– Repeatedly depress the clutch pedal.

Continuation for all vehicles:

– Remove caps from bleeder screws.

– Connect bleeder hose -1- attached to collector bottle to bleed‐

er screw (front left), open bleeder screw and allow approx. 200

ml of brake fluid to flow out. Close bleeder screw.

20 3. Description of work

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

– Repeat the procedure on the other front side of the vehicle.

– Connect bleeder hose -1- attached to collector bottle to bleed‐

er screw (rear left), open bleeder screw and allow approx. 200

ml of brake fluid to flow out. Close bleeder screw.

– Repeat the procedure on the other rear side of the vehicle.

– Fit caps back on bleeder screws on brake calipers.

– Move filling lever on brake filling and bleeding equipment -

VAS 5234- to position -B- (see operating instructions).

– Detach filling hose from adapter.

– Unscrew adapter from brake fluid reservoir.

– Screw cap onto brake fluid reservoir.

– Check brake fluid level and correct as necessary.

– Check pedal pressure and free play of brake pedal. Free play:

no more than 1/3 of pedal travel

3.12.2 Table - sequence for changing brake flu‐

id / quantities

Audi TT 2007 ➤

Maintenance - Edition 04.2010

Front left 200 ml

Front right 200 ml

Rear left 200 ml

Rear right 200 ml

Clutch slave cylinder 200 ml

Total quantity 1000 ml

3.13 S tronic gearbox: changing oil and re‐

newing oil filter

– Change gear oil ⇒ Rep. Gr. 00 ; Direct shift gearbox .

3.14 Electric windows: checking positions

The electric window regulators “forget” their current positions and

the automatic open/close function when the battery is disconnec‐

ted.

– Activate the automatic open/close function as follows:

– Switch on ignition.

– Close the windows all the way to their top positions using the

window switches.

– Then operate all window switches again for at least one sec‐

ond in the “close” direction to activate the automatic one-touch

function.

– Press switch to open window. The side window should move

all the way down automatically.

3.15 G17 additive: adding

Note

Only applies in certain countries. For the countries affected, refer

to maintenance table.

3. Description of work 21

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

♦ When adding G17 additive into the tank, the ratio must be

10 ml of additive per 10 litres of fuel.

♦ The following table lists the quantities to be added depending

on the fuel level indicated on the fuel gauge.

Mixture ratio:

Indicated on fuel gauge G17 fuel additive

approx. 1/4 approx. 15 ml

approx. 1/2 approx. 30 ml

approx. 3/4 approx. 45 ml

approx. 1/1 approx. 60 ml

Note

♦

The quantities listed in the table refer to a fuel tank with a ca‐

pacity of 60 litres.

♦

If the fuel level in the fuel tank is other than quoted in the table,

add additive in steps of 10 ml additive per 10 litres of fuel.

3.16 Ignition keys: checking operation

– Open key ring to check each key individually.

– Insert one ignition key after the other into ignition lock and start

engine with each key.

– If the engine switches off automatically after approx. 3 sec‐

onds and the odometer display shows “safe” the ignition key

has not been matched to the immobiliser.

– Repair measure: Guided Fault Finding (matching ignition

keys).

– Make a note in the delivery record of the number of ignition

keys which have been checked and handed over.

3.17 Diesel particulate filter: reading out ash deposit mass

Note

Engines affected: see Maintenance table.

– Carry out the following steps, one after the other.

22 3. Description of work

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

♦ Connect VAS 5051 or 5052.

♦ Guided Functions

♦ Read measured values

♦ Oil ash deposits

♦ Maximum value for ash deposit mass (4-cyl. engines): 60 g

Note

If ash deposit mass is <= 60 g the vehicle can be driven for a

further 30,000 km (19,000 miles).

WARNING

If ash deposit mass value is 60 g or greater for 4-cyl. engines,

the diesel particulate filter must be renewed.

3.18 Data memory: interrogating with vehicle

diagnostic, testing and information sys‐

tem -VAS 5051/ 5052-

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Carry out the following steps, one after the other.

♦ Connect VAS 5051 or 5052.

♦ Vehicle Self-Diagnosis

♦ Gateway - Fitting list

♦ Read out control units for which entries have been made in

fault memory.

♦ Eliminate relevant faults (when approved by customer).

3.19 Noise insulation: removing and installing

– Remove noise insulation -fasteners 1 ... 4-.

3. Description of work 23

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

3.20 Haldex coupling: changing oil

– Change oil: ⇒ Rep. Gr. 39 .

3.21 Poly V-belt: renewing

Vehicles with 4-cyl. petrol engine 2.0 ltr. TFSI:

– Removing and installing poly V-belt ⇒ Rep. Gr. 13

Vehicles with 6-cyl. petrol engine 3.2 ltr. MPI:

– Removing and installing poly V-belt ⇒ Rep. Gr. 13

Vehicles with 5-cyl. petrol engine 2.5 ltr. TFSI:

– Removing and installing poly V-belt ⇒ Rep. Gr. 13

Vehicles with 4-cyl. diesel engine 2.0 ltr. TDI CR:

– Removing and installing poly V-belt ⇒ Rep. Gr. 13

3.22 Fuel filter: renewing (2.0 ltr. TDI CR)

Special tools and workshop equipment required

♦ Diesel extractor -VAS 5226-

Note

♦

Please ensure that no diesel fuel makes contact with the cool‐

ant hoses.

♦

If necessary, clean hoses immediately.

♦

Observe disposal regulations.

♦

Follow the procedure shown below:

– Unscrew bolt from drain pipe -1-.

– Attach diesel extractor -VAS 5226- to connection.

– Use diesel extractor -VAS 5226- to draw off about 100 ml of

diesel fuel.

– Renew seal and screw bolt into drain pipe.

– Loosen all bolts on cover -arrows- in diagonal sequence (ap‐

prox. 1.5 to 2 turns).

24 3. Description of work

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

– Unscrew bolts completely and remove cover from filter.

– Remove filter element -1- and seals -2 and 3- from filter hous‐

ing -4-.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Renew seals -3-.

– Install new filter element.

– Install new seal -2- on cover of filter.

– Fit cover with seal onto filter housing.

3. Description of work 25

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Pre-tighten bolts in diagonal sequence (2 turns).

Note

The bolts have to be tightened diagonally in correct sequence.

Otherwise, the cover will tilt on the centre pipe and the cover and

seal could get damaged.

– Tighten bolts in sequence shown.

– Start engine and check fuel system for leaks (visual check).

Tightening torques Nm

Bolts on filter housing 5

Note

Observe disposal regulations.

3.23 Cooling system: checking coolant addi‐

tive level and topping up with coolant if

necessary

Note

♦

The coolant additive ratio must be at least 40 % (gives anti‐

freeze protection down to –25 °C), but should not exceed 60 %

(frost protection down to –40 °C); beyond this concentration

both the frost protection and the cooling efficiency are reduced

again.

♦

Frost protection should be ensured down to temperatures of

about –25 °C.

♦

For approved coolant additive, refer to ⇒ ETKA .

Special tools and workshop equipment required

♦ Refractometer -T10007-

26 3. Description of work

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Note

For exact readings for the following tests refer to the light-dark

border. Before carrying out the tests, you can first determine the

light-dark border for water. To do so, use a pipette to place a drop

of water on the glass. The light-dark border will now show up

clearly at the “WATERLINE” marking.

– Check the coolant additive concentration using the refractom‐

eter -T10007- . Observe the instructions in the operating man‐

ual.

Scale -1- on the refractometer applies to coolant additives G 12,

G 12 Plus, G 12 Plus Plus and G 11.

Scale -2- refers only to coolant additive -G 13- (previously called

L80).

Note

♦

Frost protection should be ensured down to temperatures of

about –25 °C.

♦

If greater frost protection is required in very cold climates, the

proportion of coolant additive can be increased, but only up to

60 % (this gives frost protection at temperatures down to ap‐

prox. -40 °C). Beyond this concentration the frost protection

and also the cooling efficiency are reduced again.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

Checking coolant level and topping up with coolant if necessary

– Check coolant level in coolant expansion tank while the engine

is cold.

3. Description of work 27

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

♦ Delivery Inspection: Coolant level should be above “Min.”

marking -arrow-

♦ Inspection Service: Coolant level should be above “Min.”

marking -arrow-

– If coolant level is too low, add required amount (using correct

mixture ratio).

Note

If fluid losses are greater than can be reasonably expected, de‐

termine the cause and rectify faults (repair measure).

Mixture ratio:

Frost protectiontoCoolant additive Water

–25 °C approx. 40 % approx. 60 %

–35 °C approx. 50 % approx. 50 %

–40 °C approx. 60 % approx. 40 %

Note

♦

Coolant additives prevent frost and corrosion damage, scaling

and also raise the boiling point of the coolant. It is therefore

essential to use the correct coolant additive in the cooling sys‐

tem all year round.

♦

Because of its high boiling point, the coolant improves engine

reliability under heavy loads, particularly in countries with trop‐

ical climates.

♦

The coolant concentration must not be reduced by adding wa‐

ter even in warmer seasons and in warmer countries. The

antifreeze ratio must be at least 40 %.

3.24 Instrument cluster: setting the language

– Carry out the following steps, one after the other.

♦ Connect VAS 5051 or 5052.

♦ Guided Fault Finding/Guided Functions

♦ Go to - Function / component selection

♦ Servicing

♦ Adapting the language

♦ Follow the instructions shown on the screen.

28 3. Description of work

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

3.25 Air cleaner: cleaning housing and re‐

newing filter element

3.25.1 6-cyl. petrol engine 3.2 MPI

– Open hose clip -2- with hose clip pliers -V.A.G 1921- and re‐

move intake hose -1-.

– Release and detach connector -3- from air mass meter.

– Remove securing bolts -arrows-.

– Lift out air cleaner housing (top section).

– Take out old filter element -arrow-.

– Clean filter housing and install new filter element.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Install air cleaner housing (top section) and tighten bolts -ar‐

rows-.

– Fit connector -3- onto air mass meter and make sure it en‐

gages.

– Fit intake hose -1- onto air cleaner housing and secure with

hose clip -2-.

Important: observe general notes at the end of the section

⇒ page 36

3.25.2 4-cyl. petrol engine 2.0 ltr. TFSI

Special tools and workshop equipment required

3. Description of work 29

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

♦ Spring-type clip pliers -VAS 5024-

– Unplug electrical connector -3- from air mass meter -G70- .

– Open clamps -1 and 2- and disconnect air hose from air mass

meter.

– Unclip intake hose -arrows-.

– Release spring-type clips -4- and detach air intake hose from

engine cover panel.

– Carefully pull engine cover panel off at positions

-1 - 2 - 3 - 4- one after another.

Caution

Always observe this sequence (risk of breaking engine cover

panel).

– Cover open intake hose with a clean cloth.

Removing air filter element

– Unscrew all bolts -arrows-.

30 3. Description of work

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

– Detach engine cover panel (note retainers -arrows-).

– Pull air filter element out of engine cover panel.

– Clean filter housing and install new filter element.

Note

♦

Self-tapping screws are used in production to secure the top

section of the air cleaner to the bottom section. If these screws

are tightened or loosened with a power screwdriver the thread

in the top section of the air cleaner housing can be damaged.

♦

For this reason, a power screwdriver must ONLY be used if

the following requirements are met:

♦

Power screwdriver: max. 200 rpm.

♦

It must be possible to set the max. tightening torque to 3 Nm.

♦

To install the engine cover panel, first align it at the four mount‐

ing points. Then use the flat surface of your hands to fit the

cover onto the engine evenly, pressing downwards onto the

four mounting points simultaneously.

♦

When installing the engine cover panel, make sure the rubber

sleeve is properly seated between the air cleaner housing and

the engine intake.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Assembly is conducted in reverse sequence.

Important: observe general notes at the end of the section

⇒ page 36

3. Description of work 31

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

3.25.3 4-cyl. petrol engine 2.0 ltr. TFSI

Removing

– Disconnect air hose -1- from air mass meter -G70- .

– Unplug electrical connector -2- from air mass meter -G70- .

– Detach air cleaner (top section) -arrows- and remove air filter

element.

Installing

Installation is performed in reverse sequence; note the following:

To ensure the correct function of the air mass meter it is important

to observe the following notes and adhere to the procedures de‐

scribed below.

Note

♦

If the air filter element is very dirty or wet, dirt particles or water

can reach the air mass meter and falsify the detected air mass

values. This will cause a loss of power, as the calculated in‐

jection quantities will be too low.

♦

Always use genuine air filter elements (same as original equip‐

ment).

♦

The air cleaner housing must always be clean.

♦

Secure all hose connections with genuine hose clips (same as

original equipment) ⇒ Electronic parts catalogue .

♦

When cleaning the air cleaner housing with compressed air,

cover the critical components of the engine intake system such

as the air mass meter and intake pipes etc. with a clean cloth

to avoid malfunctioning.

♦

Observe disposal regulations.

32 3. Description of work

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

– Blow out water drain (small hole in bottom section of air clean‐

er) with compressed air.

– Clean the air cleaner housing (top and bottom sections) to re‐

move any salt residue, dirt and leaves (if necessary vacuumclean).

– Check air mass meter and air hose (engine intake side) for salt

residue, dirt and leaves.

– Check air duct leading from lock carrier to air cleaner housing

for dirt and leaves.

– When installing the air filter element make sure it is positioned

centrally on the mounting in the bottom section of the air

cleaner.

– Carefully fit the top section of the air cleaner on the bottom

section of the air cleaner, without applying any force. When

fitting the top section of the air cleaner, make sure it is NOT

positioned on the air filter element at an angle (observe sealing

lip of air filter element).

– Make sure that the air hose is correctly seated at the air mass

meter.

Tightening torque Nm

Air cleaner (top section) 5

Audi TT 2007 ➤

Maintenance - Edition 04.2010

Important: observe general notes at the end of the section

⇒ page 36

3.25.4 5-cyl. petrol engine 2.5 ltr. TFSI

Removing

– Pull engine cover panel -1- off upwards -arrows-.

3. Description of work 33

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Loosen hose clips -1- and -2-.

– Remove bolts -arrows- and detach air cleaner (top section).

– Take out air filter element.

Installing

Installation is performed in reverse sequence; note the following:

To ensure the correct function of the air mass meter it is important

to observe the following notes and adhere to the procedures de‐

scribed below.

Note

♦

If the air filter element is very dirty or wet, dirt particles or water

can reach the air mass meter and falsify the detected air mass

values. This will cause a loss of power, as the calculated in‐

jection quantities will be too low.

♦

Always use genuine air filter elements (same as original equip‐

ment).

♦

The air cleaner housing must always be clean.

♦

Secure all hose connections with genuine hose clips (same as

original equipment) ⇒ Electronic parts catalogue .

♦

When cleaning the air cleaner housing with compressed air,

cover the critical components of the engine intake system such

as the air mass meter and intake pipes etc. with a clean cloth

to avoid malfunctioning.

♦

Observe disposal regulations.

– Blow out water drain (small hole in bottom section of air clean‐

er) with compressed air.

– Clean the air cleaner housing (top and bottom sections) to re‐

move any salt residue, dirt and leaves (if necessary vacuumclean).

– Check air mass meter and air hose (engine intake side) for salt

residue, dirt and leaves.

– Check air duct leading from lock carrier to air cleaner housing

for dirt and leaves.

– When installing the air filter element make sure it is positioned

centrally on the mounting in the bottom section of the air

cleaner.

– Carefully fit the top section of the air cleaner on the bottom

section of the air cleaner, without applying any force. When

fitting the top section of the air cleaner, make sure it is NOT

positioned on the air filter element at an angle (observe sealing

lip of air filter element).

– Make sure that the air hose is correctly seated at the air mass

meter.

Tightening torque Nm

Air cleaner (top section) 5

Important: observe general notes at the end of the section

⇒ page 36

34 3. Description of work

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

3.25.5 4-cyl. petrol engine 1.8 ltr. TFSI, 2.0 ltr. TFSI

– Loosen the bolts -arrows- and pull the cover up.

– Remove old filter element.

– Clean filter housing and install new filter element.

– Remove old filter element.

– Clean filter housing and install new filter element.

Important: observe general notes at the end of the section

⇒ page 36

3.25.6 4-cyl. diesel engine 2.0 ltr. CR TDI en‐

gine

– Loosen the bolts -arrows- and pull the cover up.

– Remove old filter element.

– Clean filter housing and install new filter element.

– Remove old filter element.

– Clean filter housing and install new filter element.

Important: observe general notes at the end of the section

⇒ page 36

Audi TT 2007 ➤

Maintenance - Edition 04.2010

3. Description of work 35

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

3.25.7 General notes

Note

♦

If the air filter element is very dirty or soaked with water, dirt

particles or moisture can reach the air mass meter -G70- and

falsify the detected air mass values. This will cause a loss of

power, as the calculated injection quantities will be too low.

♦

Always use genuine air filter elements (same as original equip‐

ment).

♦

Use a lubricant (silicon-free) when installing intake hose.

♦

Secure all hose connections with genuine hose clips (same as

original equipment): refer to ETKA.

♦

Check whether the water drain hose in the bottom section of

the air cleaner is dirty or blocked (clean if necessary).

♦

Clean the air cleaner housing (top and bottom sections) to re‐

move any salt residue, dirt and leaves (if necessary vacuumclean).

♦

Check air mass meter and intake hose (engine intake side) for

salt residue, dirt and leaves.

♦

Check intake duct as far as air filter element for dirt.

♦

When installing the air filter element make sure it is positioned

centrally on the mounting in the bottom section of the air

cleaner.

♦

Carefully fit the top section of the air cleaner on the bottom

section of the air cleaner, without applying any force. When

fitting the top section of the air cleaner, make sure it is NOT

positioned on the air filter element at an angle. Note position

of sealing lip on air filter element (to prevent air leaks).

♦

Then secure top section of air cleaner to bottom section.

3.26 Bonnet arrester hook: lubricating

– Only grease the bonnet arrester hook at the points shown in

the illustration -arrows-.

♦ Lubricant: “G 052 778 A2”

3.27 Engine cover panel: removing

Special tools and workshop equipment required

36 3. Description of work

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

♦ Hose clip pliers -VAS 6340-

4-cyl. petrol engine 2.0 ltr. (TFSI)

– Release clips at air mass meter -A- and at air intake hose

-B- using hose clip pliers -VAS 6340- and push them back.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Unplug air mass meter -2- and move connector to one side.

– Detach engine cover panel first at front -arrows 3-, then at rear

-arrows 4-.

– To do so, reach under the sides of the cover.

Note

♦

To install the engine cover panel, first align it at the four mount‐

ing points. Then use the flat surface of your hands to fit the

cover onto the engine evenly, pressing downwards onto the

four mounting points simultaneously.

♦

When installing the engine cover panel, make sure the rubber

sleeve is properly seated between the air cleaner housing and

the engine intake.

4-cyl. petrol engine 2.0 ltr. TFSI

Removing

– Carefully pull off engine cover panel -arrows-. Do not jerk the

cover panel away, and do not try to pull on one side only.

Installing

– Carefully press engine cover panel back into mountings.

– To avoid causing damage, do not bang the engine cover panel

down with your fist or a tool.

3. Description of work 37

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

4-cyl. petrol engine 1.8 ltr. TFSI, 2.0 ltr. TFSI:

– Pull off engine cover panel -arrows-.

5-cyl. petrol engine 2.5 ltr. TFSI:

– Pull engine cover panel -1- off upwards -arrows-.

4-cyl. CR TDI engine:

– Pull off engine cover panel -arrows-.

3.28 Engine and engine compartment (from

below): visual check for leaks and dam‐

age

– Carry out visual check as follows:

– Check engine and gearbox for leaks and damage.

– Check final drive, drive shaft boots and steering system for

leaks and damage.

WARNING

Any faults found must be rectified (repair measure).

38 3. Description of work

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

3.29 Engine oil: draining or extracting, chang‐

ing oil filter

WARNING

On some engine versions it is NOT permissible to draw off the

engine oil with an oil extractor. Refer to maintenance table.

Note

Oil should always be changed when engine is warm.

Special tools and workshop equipment required

♦ Oil extractor -V.A.G 1782-

Audi TT 2007 ➤

Maintenance - Edition 04.2010

♦ Hazet strap wrench -2171-1-

♦ Oil filter tool -3417-

♦ Oil drain adapter -T 40057-

3. Description of work 39

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

Note

Observe disposal regulations.

3.29.1 4-cyl. petrol engine 1.8 ltr. TFSI, 2.0 ltr. TFSI

– Remove noise insulation ⇒ page 23 .

– Use Hazet strap wrench -2171-1- or oil filter tool -3417- to

slacken oil filter and then remove it.

Note

Observe disposal regulations.

– Open oil drain plug / draw off engine oil.

– Clean sealing surface for oil filter at engine.

– Lightly lubricate rubber seal.

– Screw in new filter and tighten.

– Screw in oil drain plug with new seal.

– Fill up with engine oil, specifications ⇒ page 43 .

Tightening torque Nm

Oil filter 22

Oil drain plug 30

3.29.2 4-cyl. petrol engine 2.0 ltr. TFSI, 2.5 ltr. TFSI

– Remove noise insulation ⇒ page 23 .

Note

Before removing the oil filter you must drain engine oil from the

filter so that it does not spill onto the engine or other components.

40 3. Description of work

Page 45

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

– Unscrew protective cap on base valve -1-.

– Detach hose with ball head from oil drain adapter -T 40057-

and screw stud into base valve on oil filter housing -2- until you

feel a slight resistance.

– Now fit hose with ball head onto stud and screw oil drain

adapter -T 40057- on further as far as it will go; you should

hear the drain valve click.

– Let oil filter drain.

WARNING

Hot engine oil

– Open oil drain plug / draw off engine oil.

– Unscrew the oil drain adapter -T 40057- .

– Now check that base valve -1- is flush and level as shown in

illustration (A02-0423).

– Now screw on the protective cap.

– Unscrew oil filter housing -2- using oil filter tool -3417- or

36 mm socket, e.g. socket, 36 mm -T10125- , and remove oil

filter.

Audi TT 2007 ➤

Maintenance - Edition 04.2010

– Renew filter element -4- and seal -3-.

Note

♦

Note position of service tab on seal -arrow-.

♦

Observe disposal regulations.

– Clean sealing surface on oil filter housing.