Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive

Edition 12.2004

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

00 - Technical data

30 - Clutch

34 - Controls, housing

35 - Gears, shafts

39 - Final drive - front differential

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A0057006420

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Gearbox identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Code letters, allocation, transmission ratios, capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Calculating ratio “i” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Transmission layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 General repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Contact corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Special tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

30 - Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1 Servicing clutch mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Pedal cluster - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 Removing and installing clutch pedal switch F36 (square housing) . . . . . . . . . . . . . . . . . . 13

1.3 Removing and installing clutch pedal switch F36 (round housing) . . . . . . . . . . . . . . . . . . . . 13

1.4 Removing and installing over-centre spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5 Removing and installing clutch pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.6 Hydraulics - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.7 Removing and installing clutch master cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.8 Removing and installing clutch slave cylinder (release bearing with hydraulic actuator) . . 21

1.9 Bleeding clutch system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 Servicing clutch release mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1 Clutch release mechanism - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2 Renewing input shaft oil seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3 Servicing conventional clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Conventional clutch - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Removing and installing conventional clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 Servicing self-adjusting clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1 Self-adjusting clutch (Sachs version) - exploded view of components . . . . . . . . . . . . . . . . 30

4.2 Removing and installing self-adjusting clutch (Sachs version) . . . . . . . . . . . . . . . . . . . . . . 33

4.3 Self-adjusting clutch (LuK version) - exploded view of components . . . . . . . . . . . . . . . . . . 36

4.4 Removing and installing clutch (LuK version) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

34 - Controls, housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1 Servicing selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1.1 Installation position of selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1.2 Gear lever knob and boot - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . 42

1.3 Gear lever and selector housing - exploded view of components . . . . . . . . . . . . . . . . . . . . 43

1.4 Selector cables to 06.2001 - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . 45

1.5 Selector cables from 07.2001 - exploded view of components . . . . . . . . . . . . . . . . . . . . . . 47

1.6 Removing and installing selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1.7 Adjusting selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2 Removing and installing gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2.1 Removing gearbox - vehicles with 4-cylinder engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2.2 Installing gearbox - vehicles with 4-cylinder engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

2.3 Removing gearbox - vehicles with 6-cylinder engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

2.4 Installing gearbox - vehicles with 6-cylinder engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

2.5 Transporting gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

2.6 Removing and installing gearbox mounting - vehicles with 4-cylinder engine . . . . . . . . . . 95

2.7 Removing and installing gearbox mounting - vehicles with 6-cylinder engine . . . . . . . . . . 98

2.8 Removing and installing pendulum support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3 Removing and installing bevel box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

3.1 Removing and installing bevel box - vehicles with 4-cylinder engine . . . . . . . . . . . . . . . . . . 103

3.2 Removing and installing bevel box - vehicles with 6-cylinder engine . . . . . . . . . . . . . . . . . . 109

4 Gear oil in manual gearbox with bevel box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

4.1 Checking gear oil level in manual gearbox with bevel box and filling up. . . . . . . . . . . . . . . 115

5 Dismantling and assembling gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

5.1 Gearbox - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

5.2 Gearbox - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

5.3 Dismantling and assembling gearbox housing and selector mechanism - gearboxes to

approx. 04.2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

5.4 Removing and installing input shaft, output shafts (pinion shafts), differential, bevel box and

selector rods - gearboxes to approx. 04.2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

5.5 Dismantling and assembling gearbox housing, selector mechanism, input shaft, output shafts

(pinion shafts), differential, bevel box and selector rods - gearboxes to approx. 04.2003 . . 122

5.6 Removing and installing gearbox housing and selector mechanism - gearboxes from approx.

04.2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

5.7 Dismantling and assembling input shaft, output shafts (pinion shafts), differential, bevel box

and selector rods - gearboxes from approx. 04.2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

5.8 Dismantling and assembling gearbox housing, selector mechanism, input shaft, output shafts

(pinion shafts), differential, bevel box and selector rods - gearboxes from approx. 04.2003

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

6 Servicing gearbox housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

6.1 Dismantling and assembling gearbox housing - gearboxes to approx. 04.2003 . . . . . . . . 142

6.2 Servicing gearbox housing - gearboxes from approx. 04.2003 . . . . . . . . . . . . . . . . . . . . . . 147

7 Servicing clutch housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

7.1 Dismantling and assembling clutch housing - gearboxes to approx. 04.2003 . . . . . . . . . . 156

7.2 Servicing clutch housing - gearboxes from approx. 04.2003 . . . . . . . . . . . . . . . . . . . . . . . . 160

8 Servicing selector mechanism in gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

8.1 Dismantling and assembling selector mechanism in gearbox - gearboxes to approx.

04.2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

8.2 Dismantling and assembling selector mechanism in gearbox - gearboxes from approx.

04.2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

9 Servicing selector forks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

9.1 Dismantling and assembling selector forks - gearboxes to approx. 04.2003 . . . . . . . . . . . . 170

9.2 Servicing selector forks - gearboxes from approx. 04.2003 . . . . . . . . . . . . . . . . . . . . . . . . 172

35 - Gears, shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

1 Servicing input shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

1.1 Dismantling and assembling input shaft - gearboxes to approx. 04.2003 . . . . . . . . . . . . . . 175

1.2 Adjusting input shaft - gearboxes to approx. 04.2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

1.3 Dismantling and assembling input shaft - gearboxes from approx. 04.2003 . . . . . . . . . . . . 186

2 Servicing output shaft for 1st - 4th gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

2.1 Dismantling and assembling output shaft for 1st - 4th gear . . . . . . . . . . . . . . . . . . . . . . . . 191

2.2 Adjusting output shaft for 1st - 4th gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

3 Servicing output shaft for 5th, 6th and reverse gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

3.1 Dismantling and assembling output shaft for 5th, 6th and reverse gear . . . . . . . . . . . . . . 208

3.2 Adjusting output shaft for 5th, 6th and reverse gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

39 - Final drive - front differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

1 Renewing oil seals and needle bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

1.1 Renewing flange shaft oil seal (left-side) - vehicles with 4-cylinder engine . . . . . . . . . . . . 226

1.2 Renewing flange shaft oil seal (left-side) - vehicles with 6-cylinder engine . . . . . . . . . . . . 228

1.3 Renewing flange shaft oil seal (right-side) - vehicles with 4-cylinder engine . . . . . . . . . . . . 231

1.4 Renewing flange shaft oil seal (right-side) - vehicles with 6-cylinder engine . . . . . . . . . . . . 235

1.5 Renewing oil seal for bevel box output flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

1.6 Renewing needle bearings (polygon bearings) for flange shaft (right-side) - vehicles with 4-

cylinder engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

1.7 Renewing needle bearings (polygon bearings) for flange shaft (right-side) - vehicles with 6-

cylinder engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

2 Servicing differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

2.1 Dismantling and assembling differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

2.2 Table of adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

2.3 Adjusting differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Contents iii

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

iv Contents

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

00 – Technical data

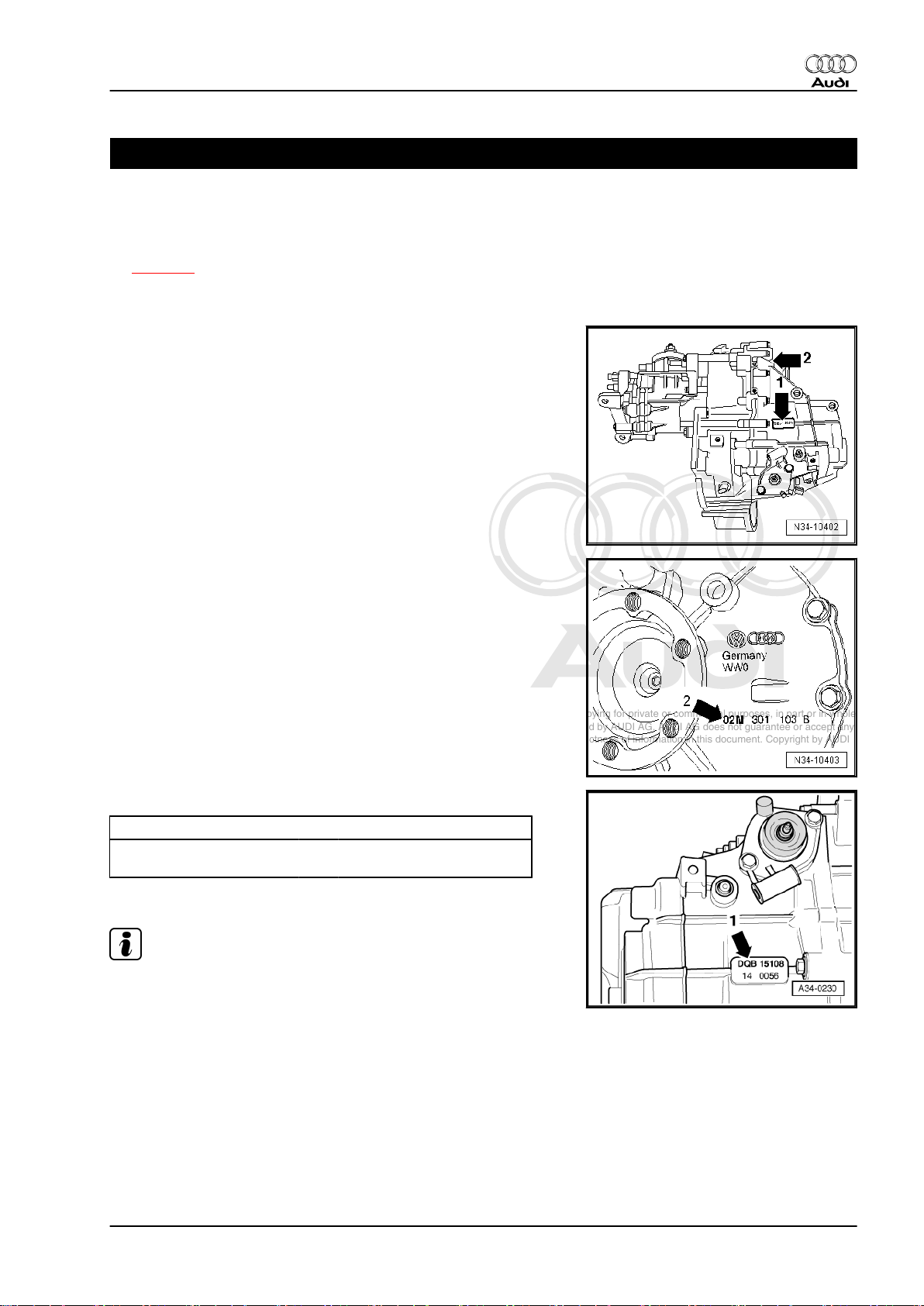

1 Gearbox identification

♦ The manual gearbox 02M/02Y, four-wheel drive is installed in

the Audi TT 1999 ▸ as 5/6-speed gearbox. Allocation

⇒ page 2 .

♦ The components of manual gearbox 02M, four-wheel drive

and 02Y, four-wheel drive are the same.

Location on gearbox

♦ Code letters and date of manufacture of gearbox -arrow 1-

♦ Manual gearbox 02M/O2Y, four-wheel drive -arrow 2-

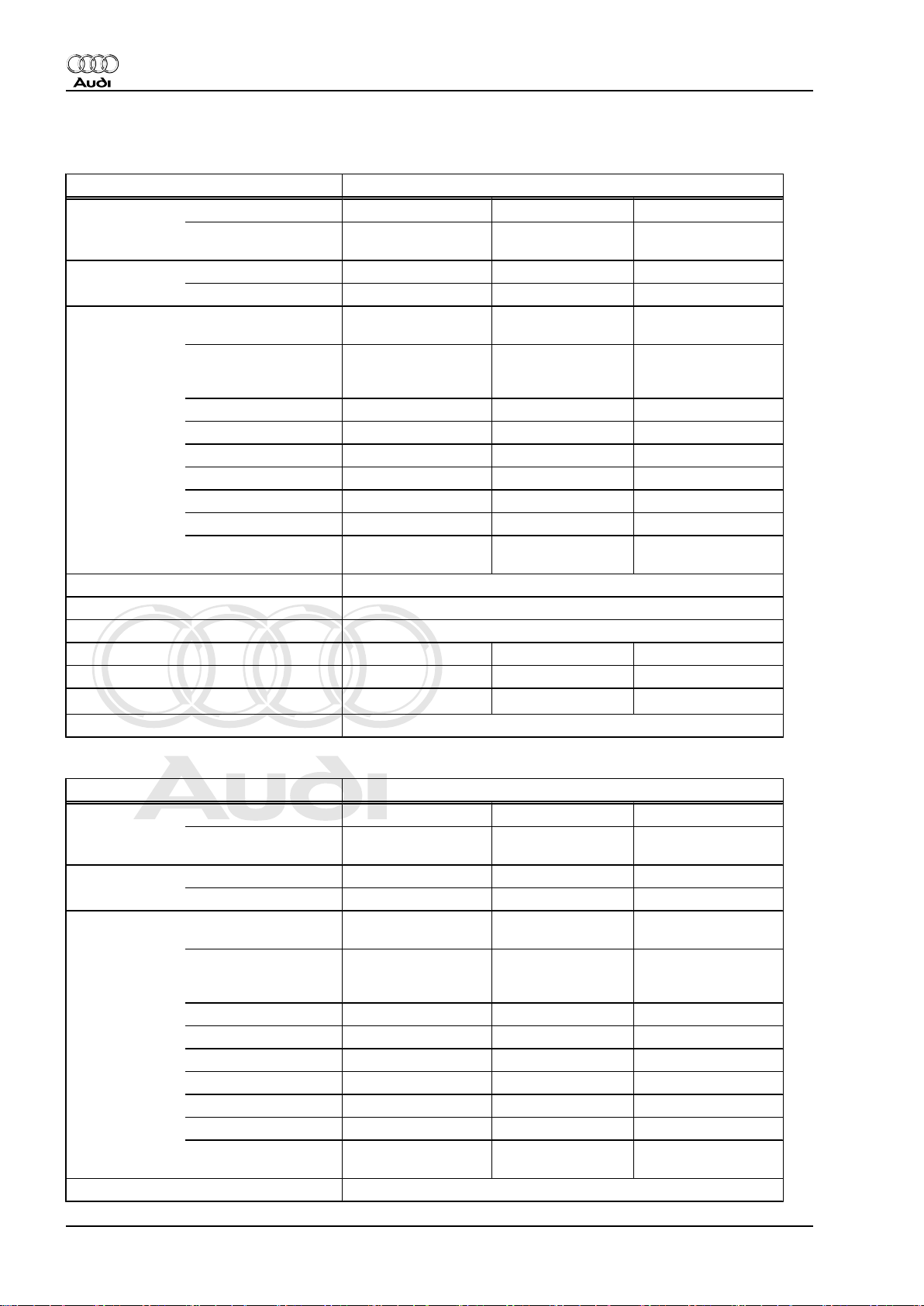

Audi TT 1999 ➤

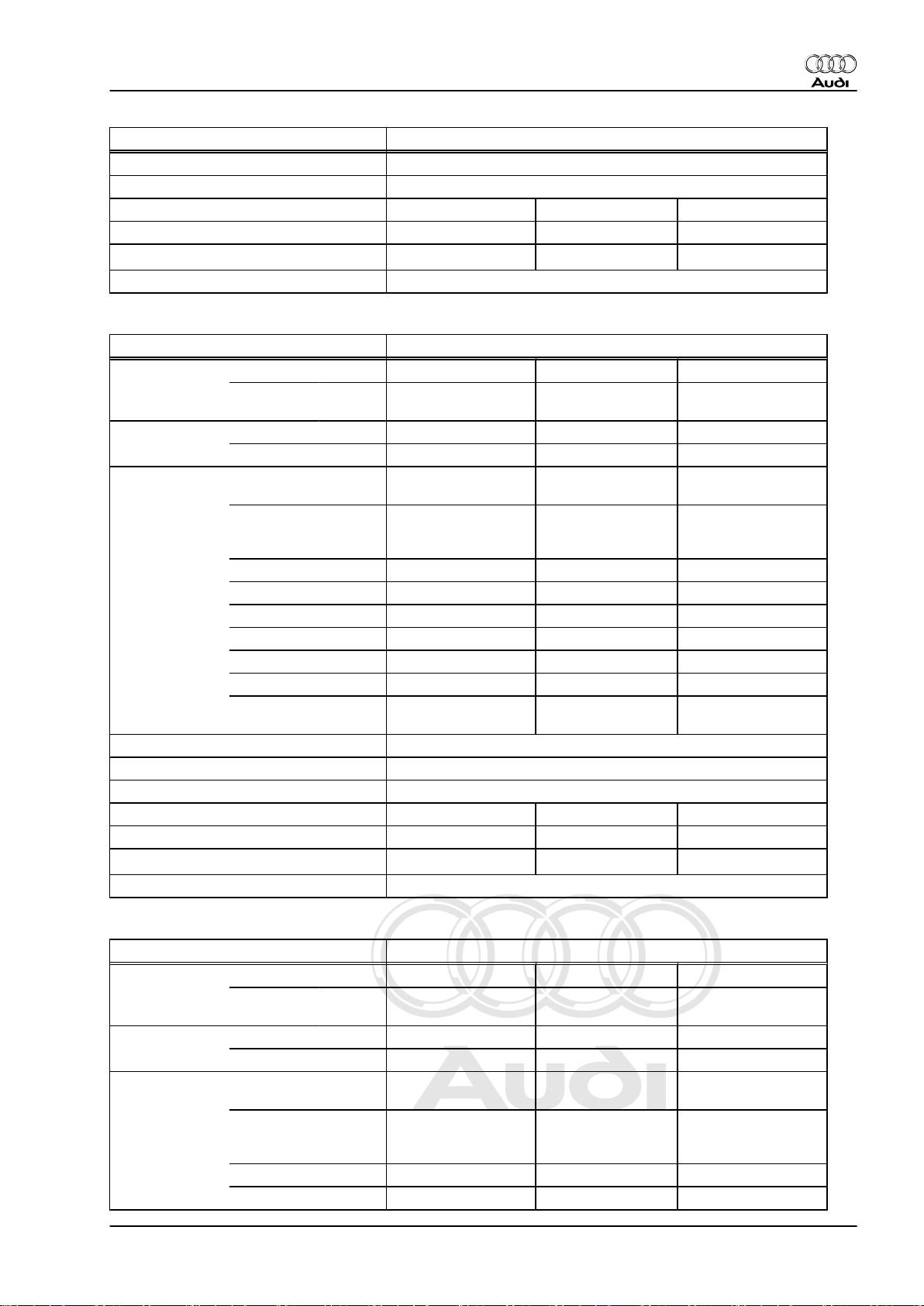

Manual gearbox 02M, four-wheel drive -arrow 2-

Code letters and date of manufacture of gearbox -arrow 1-

Example: DQB 15 10 8

Additional data are production-related.

Note

Code letters Day Month Year “1998” of

manufacture

The code letters of the gearbox are also given on the vehicle data

stickers.

1. Gearbox identification 1

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

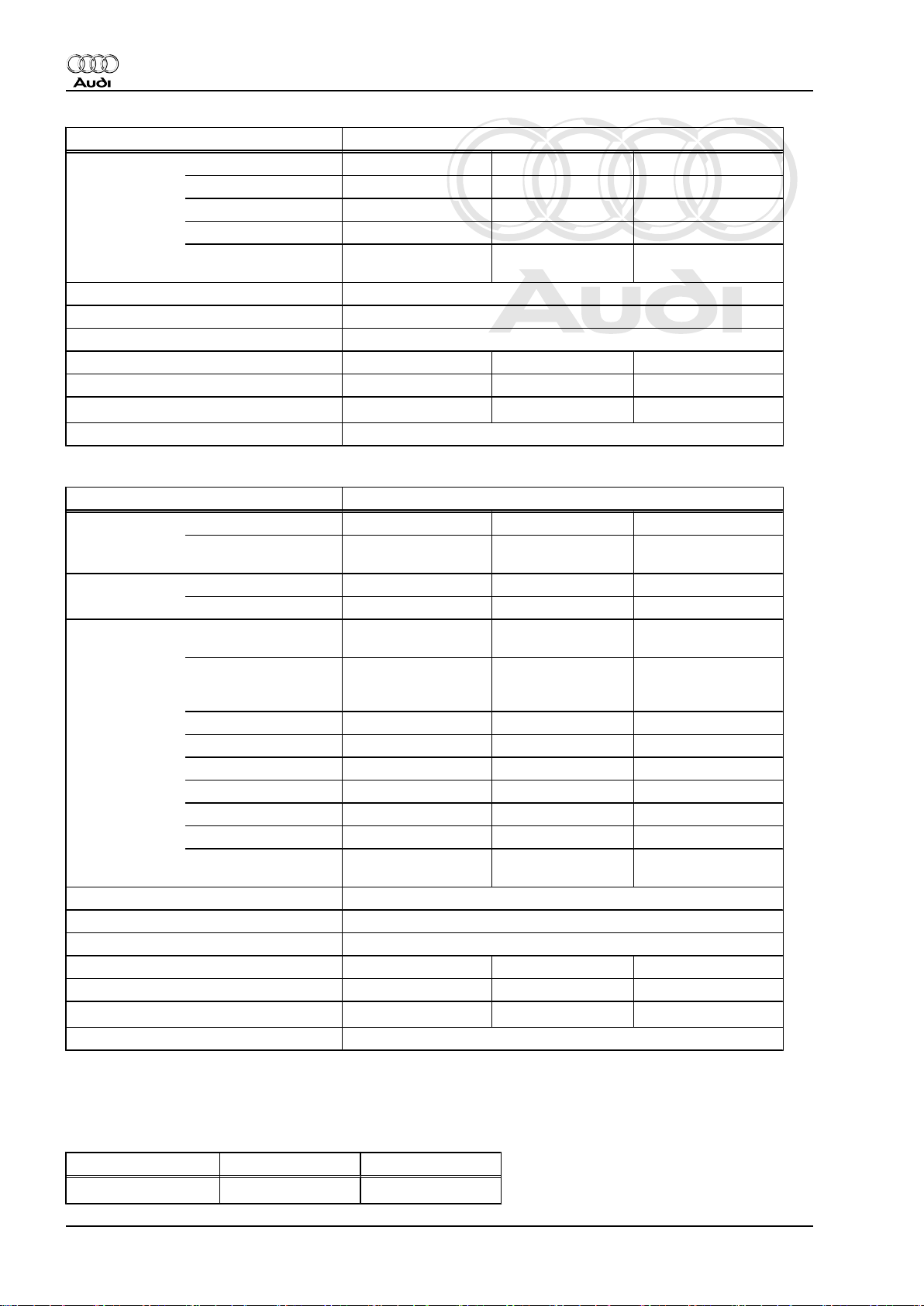

2 Code letters, allocation, transmission ratios, capacities

Manual gearbox 5/6-speed 02M, four-wheel drive

Gearbox Code letters DQB DXW EFY

Allocation Model Audi TT 1999 ▸ Audi TT 1999 ▸ Audi TT 1999 ▸

Ratios Final drive I

Z2 : Z

1

Capacity 2.6 litres

Specification ⇒ Parts catalogue

Clutch actuation Hydraulic

Clutch plate ∅ 240 mm 240 mm 240 mm

Drive shaft flange ∅ 108 mm 108 mm 108 mm

Overall ratio i

Allocation: rear final drive Designation 02D ⇒ Parts catalogue

Manufac‐

tured

from

to

09.00

02.01

09.0

01.01

09.00

02.01

Engine 1.8 ltr. - 165 kW 1.8 ltr. - 132 kW 1.8 ltr. - 132 kW

63 : 15 = 4.200 63 : 15 = 4.200 63 : 15 = 4.200

for 1st to 4th gear

Final drive II

63 : 19 = 3.316 63 : 19 = 3.316 63 : 19 = 3.316

for 5th/6th gear and

reverse gear

1st gear 41 : 12 = 3.417 42 : 11 = 3.818 41 : 12 = 3.417

2nd gear 40 : 19 = 2.105 40 : 19 = 2.105 40 : 19 = 2.105

3rd gear 40 : 28 = 1.429 39 : 29 = 1.345 40 : 27 = 1.481

4th gear 37 : 34 = 1.088 35 : 36 = 0.972 38 : 33 = 1.152

5th gear 34 : 31 = 1.097 32 : 33 = 0.970 35 : 30 = 1.167

6th gear 31 : 34 = 0.912 – 32 : 33 = 0.970

Reverse gear 30 : 12 x 23 : 14 =

4.108

in top gear 3.023 3.215 3.215

ov.

31 : 11 x 23 : 14 =

4.630

30 : 12 x 23 : 14 =

4.108

Manual gearbox 5/6-speed 02M, four-wheel drive

Gearbox Code letters FHA FHB FHC

Allocation Model Audi TT 1999 ▸ Audi TT 1999 ▸ Audi TT 1999 ▸

Ratios Final drive I

Manufac‐

tured

from

to

02.01

04.02

08.01

04.02

02.01

04.02

Engine 1.8 ltr. - 132 kW 1.8 ltr. - 165 kW 1.8 ltr. - 132 kW

63 : 15 = 4.200 63 : 15 = 4.200 63 : 15 = 4.200

for 1st to 4th gear

Z2 : Z

1

Final drive II

63 : 19 = 3.316 63 : 19 = 3.316 63 : 19 = 3.316

for 5th/6th gear and

reverse gear

1st gear 41 : 12 = 3.417 41 : 12 = 3.417 42 : 11 = 3.818

2nd gear 40 : 19 = 2.105 40 : 19 = 2.105 40 : 19 = 2.105

3rd gear 40 : 27 = 1.481 40 : 28 = 1.429 39 : 29 = 1.345

4th gear 38 : 33 = 1.152 37 : 34 = 1.088 35 : 36 = 0.972

5th gear 35 : 30 = 1.167 34 : 31 = 1.097 32 : 33 = 0.970

6th gear 32 : 33 = 0.970 31 : 34 = 0.912 –

Reverse gear 30 : 12 x 23 : 14 =

4.108

30 : 12 x 23 : 14 =

4.108

31 : 11 x 23 : 14 =

4.630

Capacity 2.6 litres

2 Rep. Gr.00 - Technical data

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

Manual gearbox 5/6-speed 02M, four-wheel drive

Specification ⇒ Parts catalogue

Clutch actuation Hydraulic

Clutch plate ∅ 240 mm 240 mm 240 mm

Drive shaft flange ∅ 108 mm 108 mm 108 mm

Overall ratio i

in top gear 3.215 3.023 3.215

ov.

Allocation: rear final drive Designation 02D ⇒ Parts catalogue

Manual gearbox 5/6-speed 02Y, four-wheel drive

Gearbox Code letters FMN FMR FMT

Manufac‐

tured

from

to

09.02

04.03

05.02

08.02

05.02

08.02

Allocation Model Audi TT 1999 ▸ Audi TT 1999 ▸ Audi TT 1999 ▸

Ratios Final drive I

Engine 1.8 ltr. -165 kW 1.8 ltr. - 132 kW 1.8 ltr. - 132 kW

72 : 17 = 4.235 72 : 17 = 4.235 72 : 17 = 4.235

for 1st to 4th gear

Z2 : Z

1

Final drive II

72 : 22 = 3.273 72 : 22 = 3.273 72 : 22 = 3.273

for 5th/6th gear and

reverse gear

1st gear 47 : 14 = 3.357 49 : 13 = 3.769 47 : 14 = 3.357

2nd gear 48 : 23 = 2.087 48 : 23 = 2.087 48 : 23 = 2.087

3rd gear 47 : 32 = 1.469 45 : 34 = 1.324 47 : 32 = 1.469

4th gear 45 : 41 = 1.098 42 : 43 = 0.977 46 : 40 = 1.150

5th gear 41 : 37 = 1.108 39 : 40 = 0.975 43 : 36 = 1.194

6th gear 38 : 41 = 0.927 – 39 : 40 = 0.975

Reverse gear 23 : 14 x 34 : 14 =

3.990

23 : 14 x 36 : 13 =

4.549

23 : 14 x 34 : 14 =

3.990

Capacity 2.6 litres

Specification ⇒ Parts catalogue

Clutch actuation Hydraulic

Clutch plate ∅ 240 mm 240 mm 240 mm

Drive shaft flange ∅ 108 mm 108 mm 108 mm

Overall ratio i

in top gear 3.033 3.191 3.191

ov.

Allocation: rear final drive Designation 02D ⇒ Parts catalogue

Manual gearbox 5/6-speed 02Y, four-wheel drive

Gearbox Code letters FZL FZP GQT

Manufac‐

tured

from

to

04.03 04.03 01.04

Allocation Model Audi TT 1999 ▸ Audi TT 1999 ▸ Audi TT 1999 ▸

Ratios Final drive I

Engine 1.8 ltr. - 165 kW 1.8 ltr. - 132 kW 3.2 ltr. - 184 kW

72 : 17 = 4.235 72 : 17 = 4.235 72 : 17 = 4.235

for 1st to 4th gear

Z2 : Z

1

Final drive II

for 5th/6th gear and

reverse gear

72 : 22 = 3.273 72 : 22 = 3.273 72 : 22 = 3.273

1st gear 47 : 14 = 3.357 47 : 14 = 3.357 47 : 14 = 3.357

2nd gear 48 : 23 = 2.087 48 : 23 = 2.087 48 : 23 = 2.087

2. Code letters, allocation, transmission ratios, capacities 3

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

Manual gearbox 5/6-speed 02Y, four-wheel drive

3rd gear 47 : 32 = 1.469 47 : 32 = 1.469 47 : 32 = 1.469

4th gear 45 : 41 = 1.098 46 : 40 = 1.150 37 : 34 = 1.088

5th gear 41 : 37 = 1.108 43 : 36 = 1.194 41 : 37 = 1.108

6th gear 38 : 41 = 0.927 39 : 40 = 0.975 31 : 34 = 0.912

Reverse gear 23 : 14 x 34 : 14 =

3.990

23 : 14 x 34 : 14 =

3.990

23 : 14 x 34 : 14 =

3.990

Capacity 2.6 litres

Specification ⇒ Parts catalogue

Clutch actuation Hydraulic

Clutch plate ∅ 240 mm 240 mm 240 mm

Drive shaft flange ∅ 108 mm 108 mm 108 mm

Overall ratio i

in top gear 3.033 3.191 2.984

ov.

Allocation: rear final drive Designation 02D ⇒ Parts catalogue

Manual gearbox 5/6-speed 02Y, four-wheel drive

Gearbox Code letters GQV

Manufac‐

tured

from

to

01.04

Allocation Model Audi TT 1999 ▸

Ratios Final drive I

Z2 : Z

1

Engine 3.2 ltr. - 184 kW

for 1st to 4th gear

Final drive II

72 : 17 = 4.235

72 : 22 = 3.273

for 5th/6th gear and

reverse gear

1st gear 47 : 14 = 3.357

2nd gear 48 : 23 = 2.087

3rd gear 47 : 32 = 1.469

4th gear 37 : 34 = 1.088

5th gear 41 : 37 = 1.108

6th gear 31 : 34 = 0.912

Reverse gear 23 : 14 x 34 : 14 =

3.990

Capacity 2.6 litres

Specification ⇒ Parts catalogue

Clutch actuation Hydraulic

Clutch plate ∅ 240 mm

Drive shaft flange ∅ 108 mm

Overall ratio i

in top gear 2.984

ov.

Allocation: rear final drive Designation 02D ⇒ Parts catalogue

2.1 Calculating ratio “i”

Example:

6th gear Final drive

Drive gear ZG1 = 34 ZA1 = 19

4 Rep. Gr.00 - Technical data

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

6th gear Final drive

Driven gear ZG2 = 31 ZA2 = 63

i = Z2 : Z1 (Z1 = number of teeth on drive gear, Z2 = number of

teeth on driven gear)

iG = gear ratio = ZG2 : ZG1 = 31 : 34 = 0.912

iA = axle ratio = ZA2 : ZA1 = 63 : 19 = 3.316

iov = overall ratio = iG x iA = 0.912 x 3.316 = 3.023

2. Code letters, allocation, transmission ratios, capacities 5

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

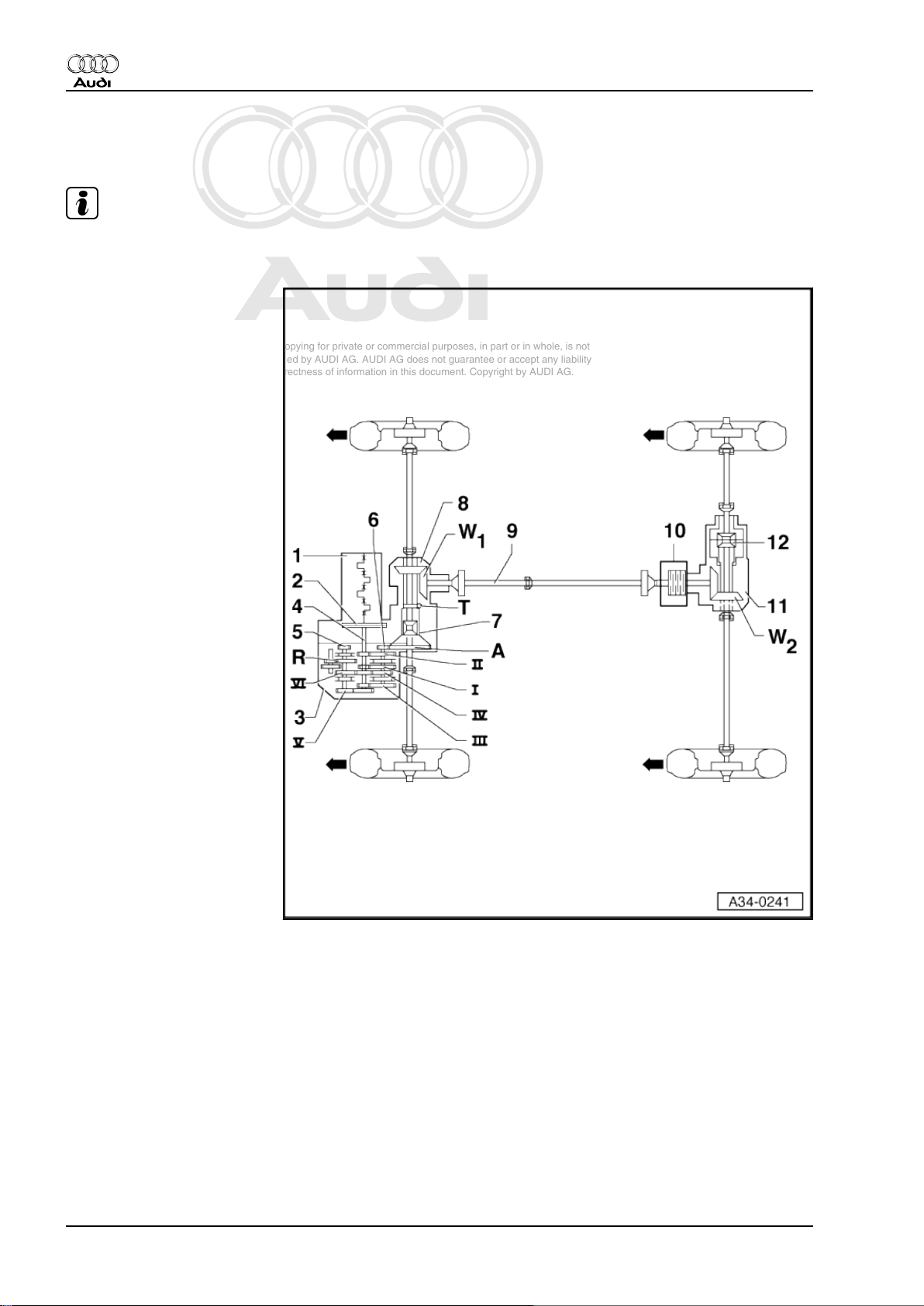

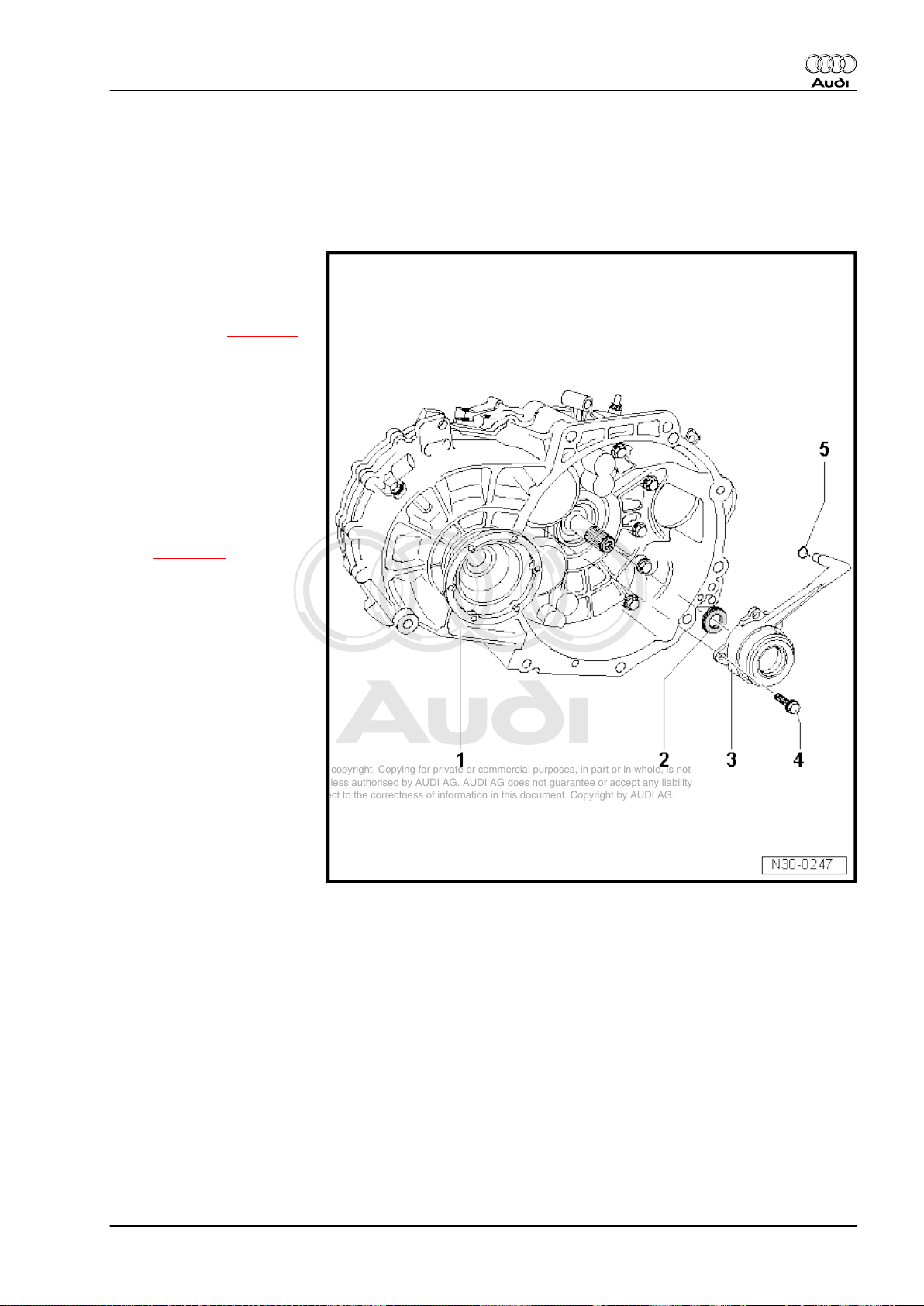

3 Transmission layout

Note

Arrows point in direction of travel

1 - Engine

2 - Clutch

3 - Manual gearbox

4 - Input shaft

5 - Output shaft for 5th/6th/re‐

verse gear (pinion shaft II)

6 - Output shaft for 1st-4th gear

(pinion shaft I)

7 - Differential

8 - Bevel box

9 - Propshaft

10 - Haldex coupling

11 - Rear final drive

12 - Differential

I - 1st gear

II - 2nd gear

III - 3rd gear

IV - 4th gear

V - 5th gear

VI - 6th gear

R - Reverse gear

A - Final drive

T - Speedometer drive

W1 - Front bevel gears

W2 - Rear bevel gears

6 Rep. Gr.00 - Technical data

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

4 General repair instructions

Proper tools and the maximum possible care and cleanliness are

essential for satisfactory gearbox repairs. The usual basic safety

precautions also naturally apply when carrying out repair work.

A number of generally applicable instructions for the various re‐

pair procedures - which were previously repeated at numerous

places in the Workshop Manual - are summarised here. They ap‐

ply to the work described in this Manual.

4.1 Contact corrosion

♦ The housing of the manual gearbox in the Audi TT is made of

a magnesium alloy.

♦ Bolts and other components which are in direct contact with

the gearbox casing are surface treated for compatibility with

magnesium.

♦ If the incorrect components are used (bolts, nuts, washers

etc.), this will cause contact corrosion. The gearbox housing

will be damaged.

♦ If you are not sure whether used parts can be re-installed, al‐

ways fit new parts.

Audi TT 1999 ➤

Caution

♦ Only use Genuine Audi parts.

♦ Damage resulting from contact corrosion is not covered

by the warranty.

4.2 Special tools

For a complete list of special tools used in this Workshop Manual

⇒ Special tools, Workshop equipment .

4.3 Components

Gearbox

♦ When installing, ensure that the dowel sleeves between the

engine and gearbox are correctly located.

♦ When assembling mounting brackets as well as other waxed

components, the contact surfaces must be cleaned. The con‐

tact surfaces must be free of wax and grease.

♦ When installing a new gearbox or bevel box fill with gear oil.

♦ Capacities and specifications ⇒ page 2 .

O-rings, oil seals, gaskets

♦ Always install new O-rings, oil seals and gaskets.

♦ After removing gaskets and seals, always inspect the contact

surface on the housing or shaft for burrs resulting from removal

or for other signs of damage.

♦ Clean joints thoroughly and apply sealant -AMV 188 200 03- .

♦ Apply sealant evenly and not too thickly.

Before installing:

4. General repair instructions 7

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

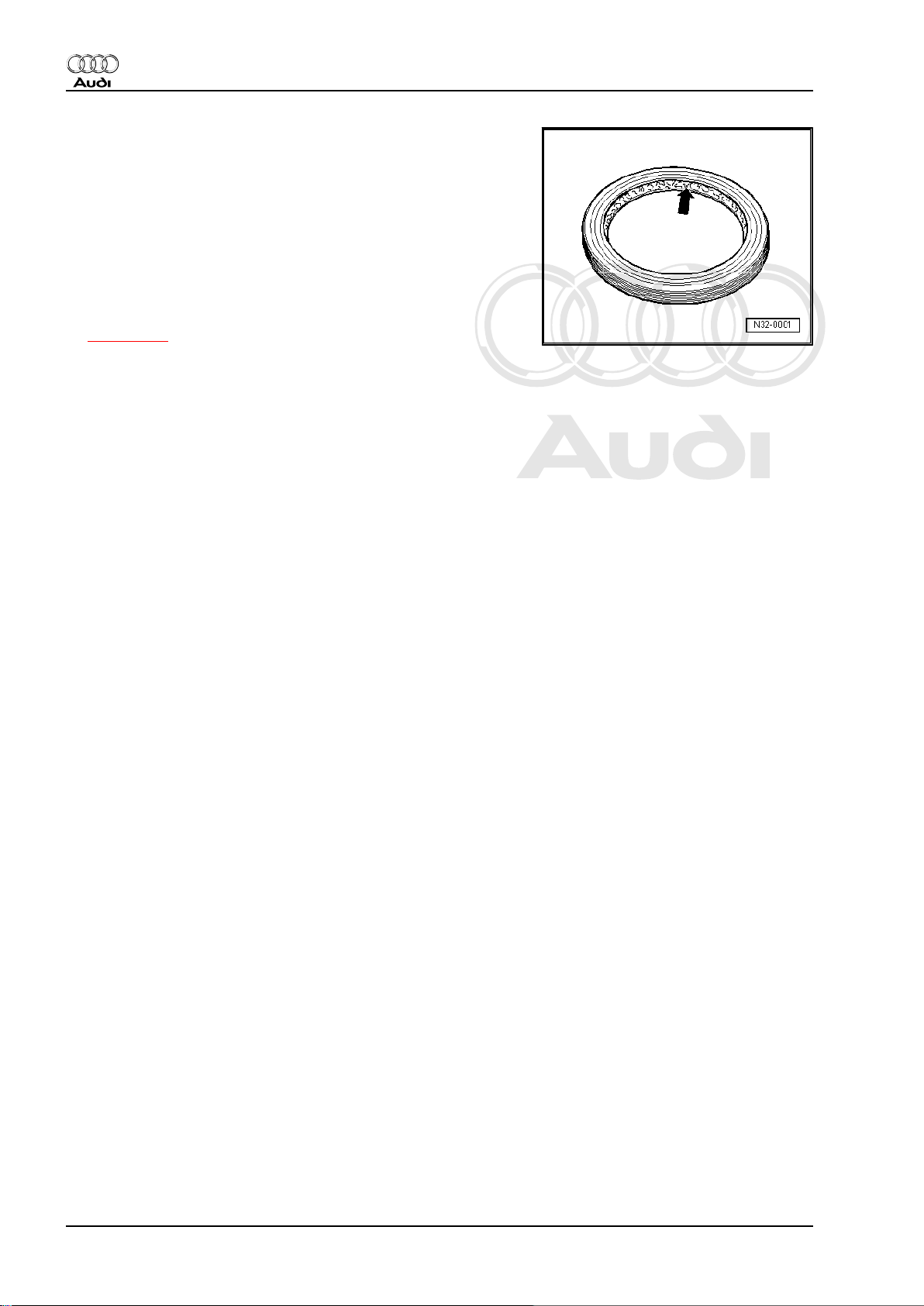

♦ Lightly oil the outer circumference of oil seals and fill the space

between the sealing lips -arrow- about half full with grease -G

052 128 A1- .

♦ The open side of the oil seals faces toward the side with fluid

filling.

♦ When installing a new oil seal, position the seal in the housing

so that sealing lip does not contact the shaft in the same place

as the old seal (make use of insertion depth tolerances).

After installation:

♦ Check gear oil level in manual gearbox with bevel box

⇒ page 115 .

8 Rep. Gr.00 - Technical data

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

Locking elements

♦ Do not over-stretch circlips.

♦ Always renew circlips which have been damaged or over-

stretched.

♦ Circlips must be properly seated in the base of the groove.

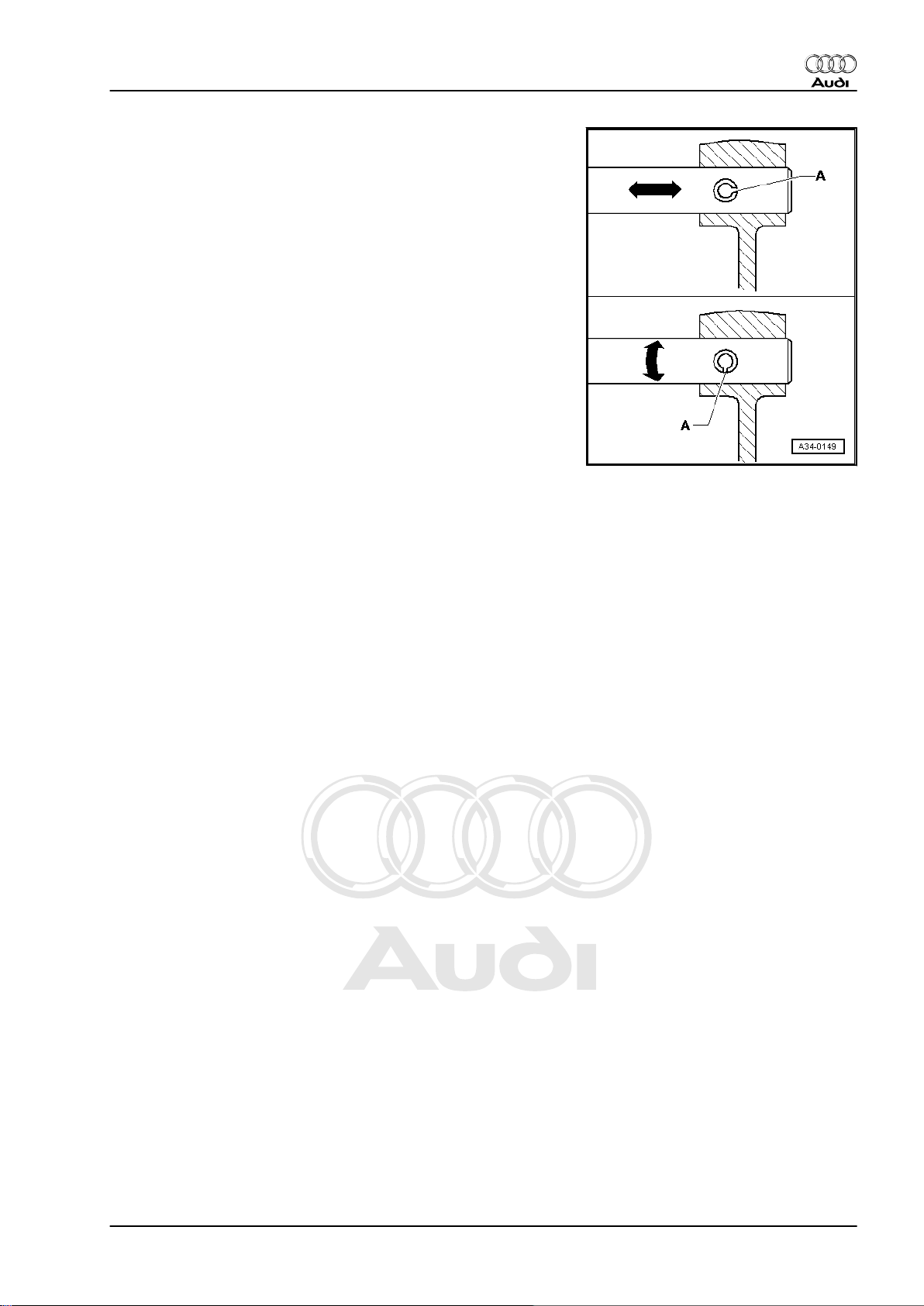

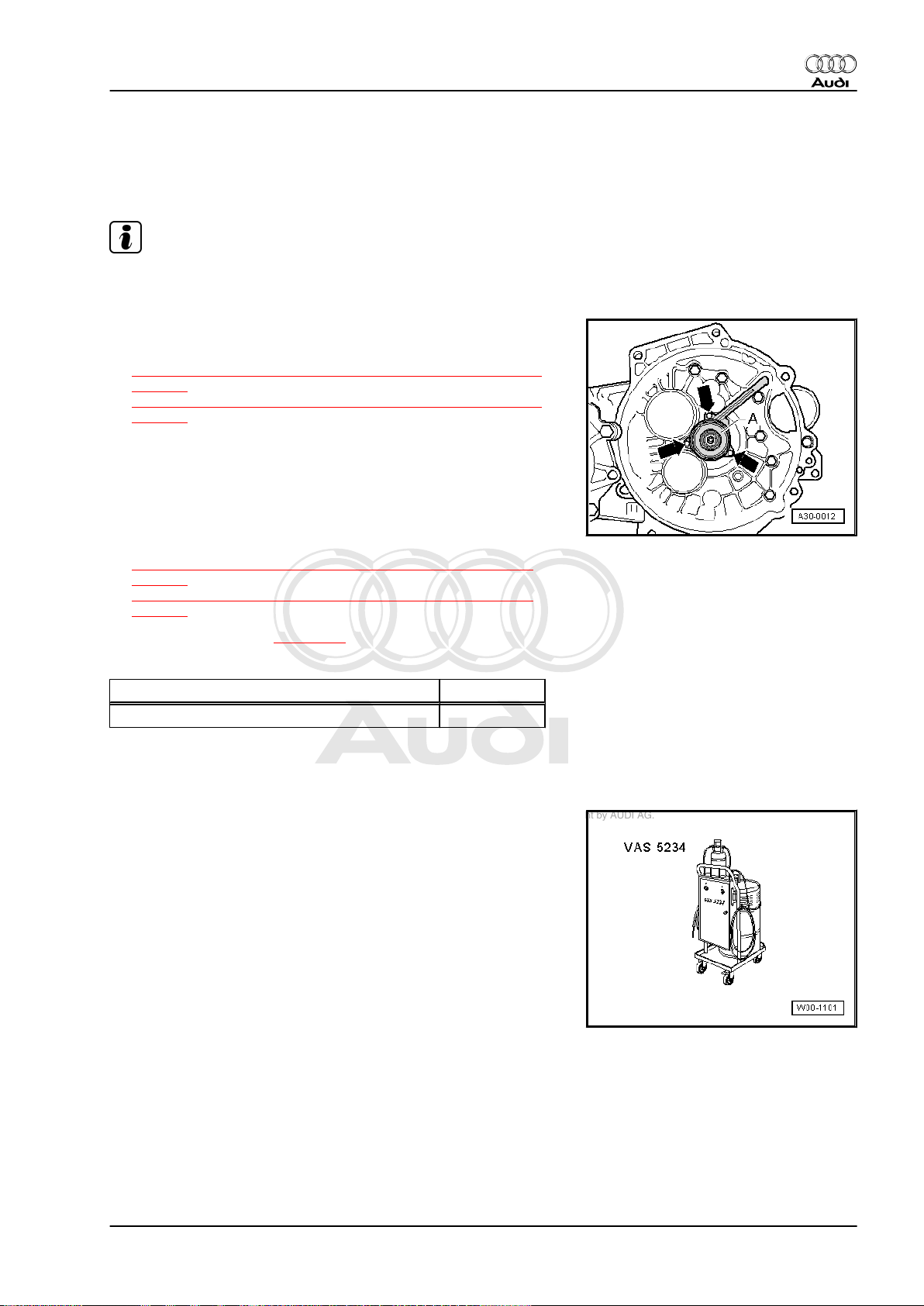

♦ Renew spring pins. Position: the slit -A- should be in line with

the line of force -arrow-.

Nuts, bolts

♦ Nuts and bolts for securing covers and housings must be

slackened and tightened in diagonal sequence.

♦ Parts which are particularly sensitive (e.g. clutch pressure

plates) must be kept straight. Slacken and tighten them in

stages and in diagonal sequence.

♦ The tightening torques stated apply to non-oiled nuts and

bolts.

♦ Always renew self-locking bolts and nuts.

♦ For all threaded connections, ensure that (where applicable)

the contact surfaces and the nuts and bolts are not coated with

wax until after assembly is completed.

Bearings

♦ Install new tapered roller bearings as supplied; do not lubricate

additionally with oil.

♦ Lubricate all bearings (except tapered roller bearings) with

gear oil before installing in gearbox.

♦ Always renew the tapered roller bearings on one shaft togeth‐

er as a set and use new bearings from a single manufacturer.

♦ Heat inner races of tapered roller bearings to approx. 100°C

before installing. Press in onto stop when installing so there is

no axial clearance.

♦ Do not interchange the outer or inner races of bearings of the

same size (the bearings are paired).

♦ Install needle bearings so the lettering (side with thicker metal)

faces towards the installing tool.

Shims

♦ Measure shims at several points with a micrometer. Tolerance

variations make it possible to obtain the exact shim thickness

required.

♦ Check for burrs and damage.

♦ Install only shims which are in perfect condition.

Synchroniser rings

♦ Do not interchange. When reusing synchroniser rings, always

fit to the same gear wheel.

♦ Check for wear; renew if necessary.

♦ Lubricate with gear oil before installing.

Gear wheels

♦ Before installing, clean and heat on a hotplate to approx. 100°

C.

♦ The temperature can be checked with Temperature tester -

V.A.G 1558- .

Audi TT 1999 ➤

4. General repair instructions 9

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

Selector gears

♦ After installing, check 1st to 6th speed selector gears for min‐

imal axial play and freedom of movement.

Clutch actuation

♦ Ensure that the pressure plate is kept straight: loosen and

tighten bolts in a diagonal sequence and in several gradual

stages.

♦ If the clutch has burnt out, thoroughly clean the bell housing,

flywheel and parts of the engine facing the gearbox in order to

prevent odours.

10 Rep. Gr.00 - Technical data

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

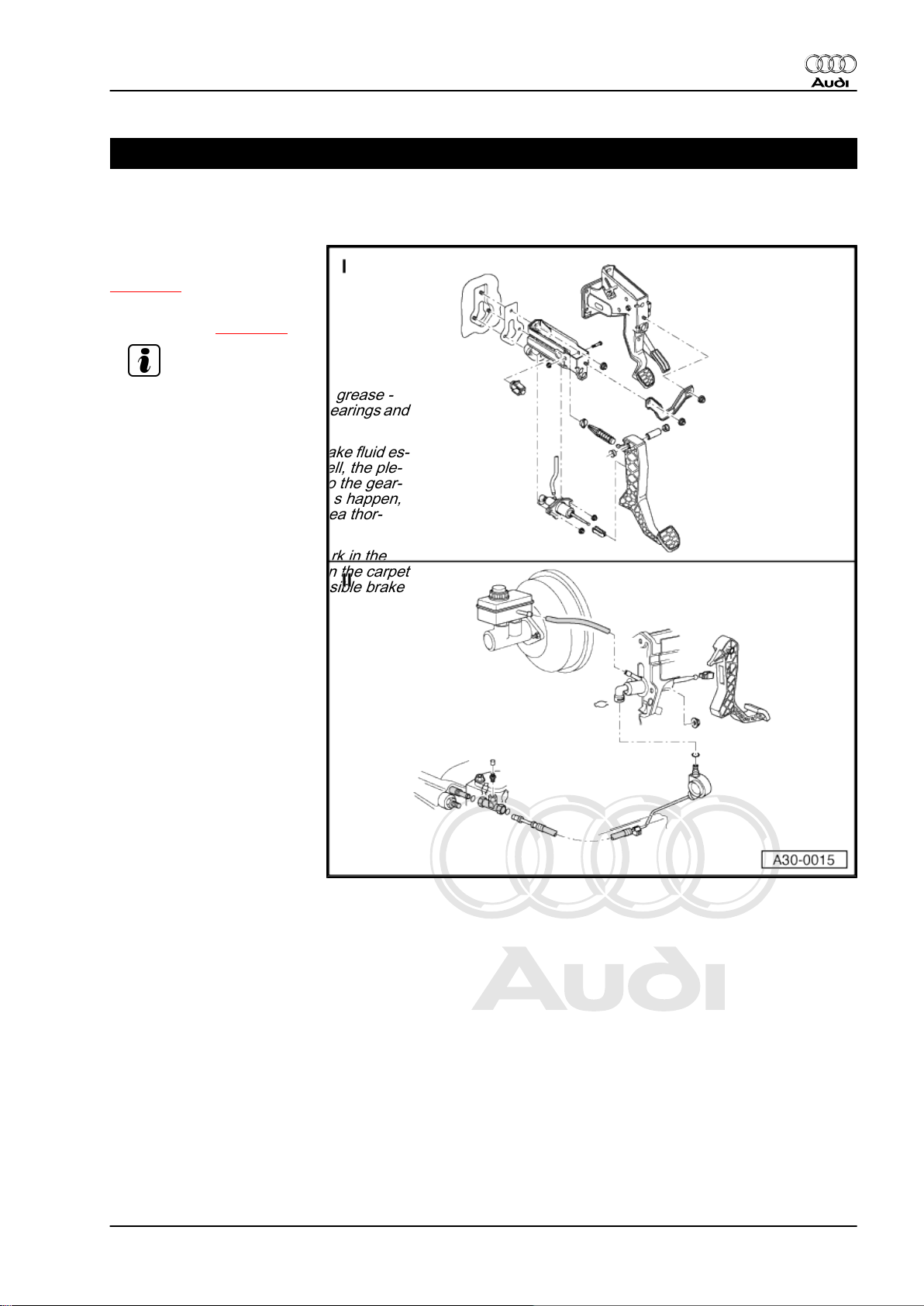

30 – Clutch

1 Servicing clutch mechanism

I - Pedal cluster - exploded

view of components

⇒ page 12

II - Hydraulics - exploded view

of components ⇒ page 16

Note

♦

Apply polycarbamide grease -

G 052 142 A2- to all bearings and

contact surfaces.

♦

Make sure that no brake fluid es‐

capes into the footwell, the ple‐

num chamber or onto the gear‐

box below. If this does happen,

clean the affected area thor‐

oughly.

♦

When performing work in the

footwell, put cloths on the carpet

to protect it from possible brake

fluid spills.

Audi TT 1999 ➤

1. Servicing clutch mechanism 11

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

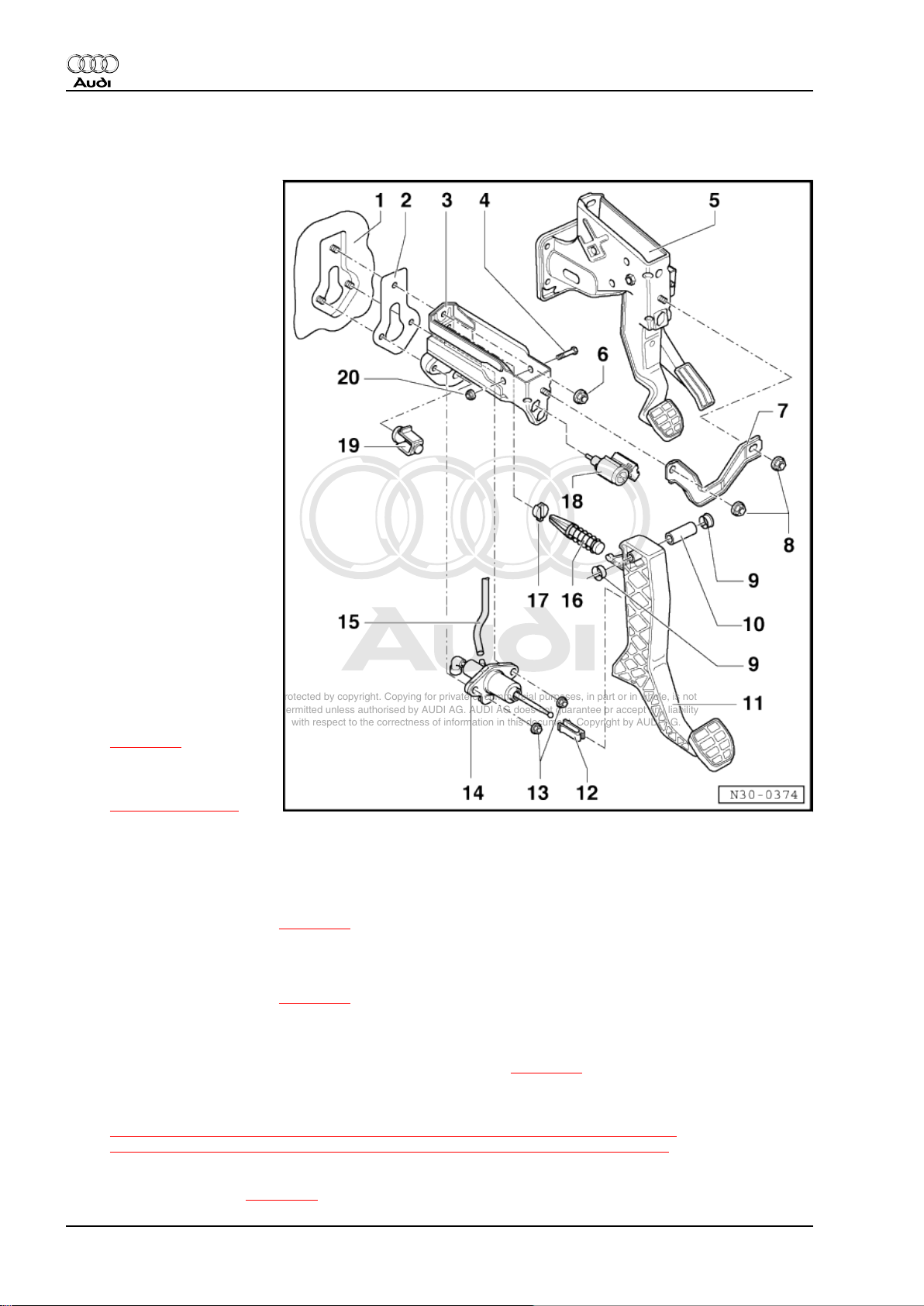

1.1 Pedal cluster - exploded view of components

1 - Cross panel

❑ With mounting for

mounting bracket and

master cylinder

2 - Gasket

❑ Always renew

3 - Mounting bracket

❑ For mounting clutch

pedal

4 - Bolt

5 - Mounting bracket

❑ For mounting accelera‐

tor pedal and brake ped‐

al

6 - Hexagon nut, 25 Nm

❑ Self-locking

❑ Renew

7 - Connecting plate

8 - Hexagon nut, 25 Nm

❑ Self-locking

❑ Renew

9 - Mounting bush

10 - Pivot pin

11 - Clutch pedal

❑ Removing and installing

⇒ page 15

12 - Retaining clip

❑ Removing and installing

⇒ Item 4 (page 16)

13 - Hexagon nut, 25 Nm

❑ Self-locking

❑ Renew

14 - Clutch master cylinder

❑ Removing and installing ⇒ page 18

15 - Supply hose

16 - Over-centre spring

❑ Removing and installing ⇒ page 14

17 - Mounting for over-centre spring

❑ Install in mounting bracket

❑ When renewing: remove and install clutch master cylinder ⇒ page 18

18 - Clutch pedal switch -F36-

❑ Removing and installing

⇒ “1.2 Removing and installing clutch pedal switch F36 (square housing)”, page 13 or

⇒ “1.3 Removing and installing clutch pedal switch F36 (round housing)”, page 13

19 - Stop for clutch pedal

❑ Installation position ⇒ page 20

12 Rep. Gr.30 - Clutch

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

20 - Hexagon nut, 25 Nm

❑ Self-locking

❑ Renew

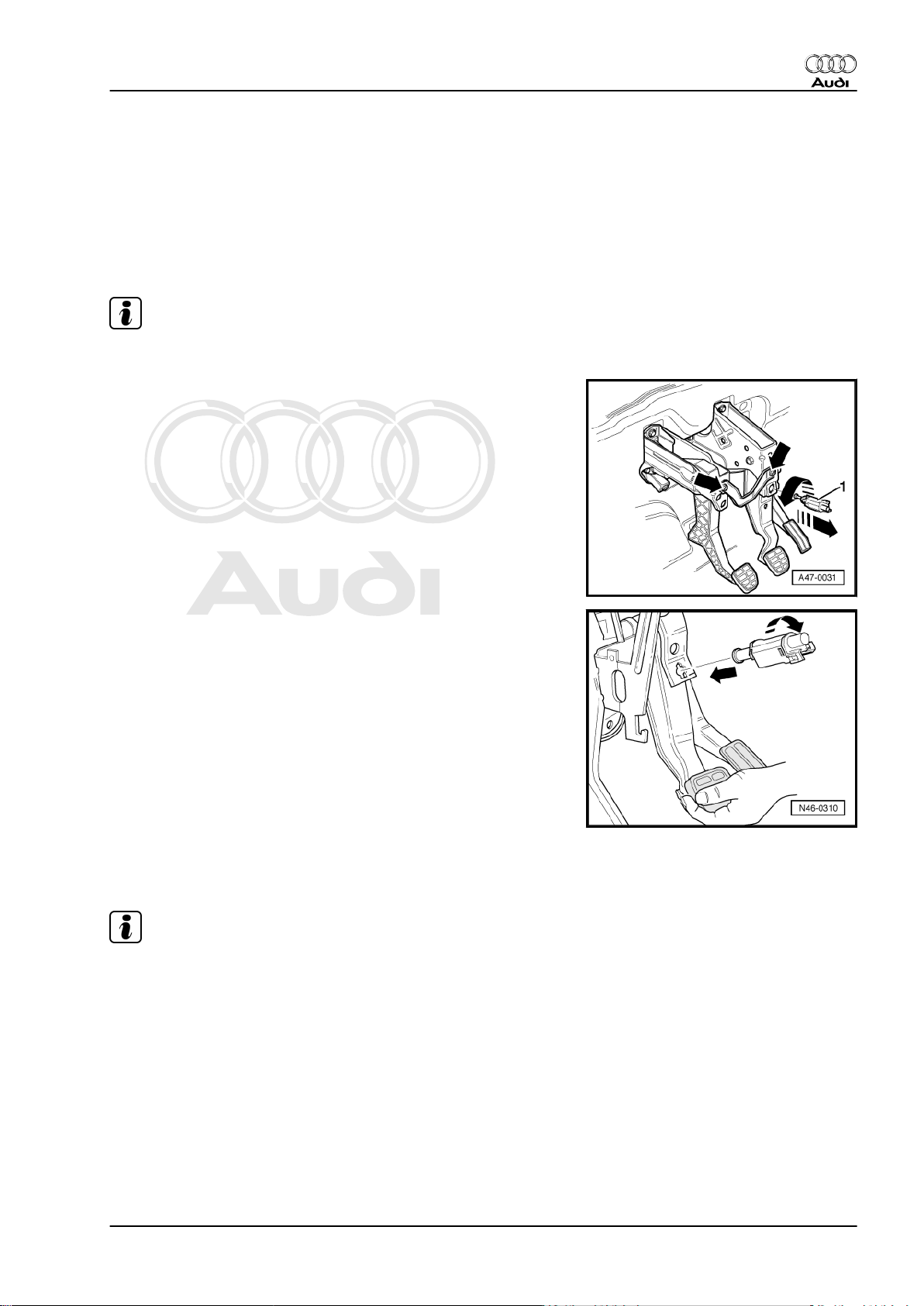

1.2 Removing and installing clutch pedal switch -F36- (square housing)

Note

Switch may only be fitted once so as to ensure a firm fit.

Removing

– Remove storage compartment on driver's side ⇒ General

body repairs, interior; Rep. Gr. 68 .

– Unplug electrical connector from clutch pedal switch.

– Remove clutch pedal switch -1- by turning 90° anti-clockwise.

Audi TT 1999 ➤

Installing

Installation is carried out in reverse sequence; note the following:

– Pull operating rod of clutch pedal switch out onto stop.

– Push clutch pedal down by hand.

– Insert switch in mounting hole and secure by turning clockwise

through 90° -arrows-.

– Release clutch pedal

– Install storage compartment on driver's side ⇒ General body

repairs, interior; Rep. Gr. 68 .

1.3 Removing and installing clutch pedal switch -F36- (round housing)

Note

Clutch pedal switch may only be fitted once so as to ensure a firm

fit.

Removing

– Remove storage compartment on driver's side ⇒ General

body repairs, interior; Rep. Gr. 68 .

– Unplug electrical connector from clutch pedal switch.

– Remove clutch pedal switch by turning in anti-clockwise di‐

rection through 45°.

1. Servicing clutch mechanism 13

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

Installing

Installation is carried out in reverse sequence; note the following:

– Pull out operating rod -arrow- all the way before installing

clutch pedal switch.

• The clutch pedal should be in the normal position (i.e. not

pressed down).

– Guide clutch pedal switch through mounting hole, press oper‐

ating rod against clutch pedal and attach switch by turning 45°

clockwise.

– Install storage compartment on driver's side ⇒ General body

repairs, interior; Rep. Gr. 68 .

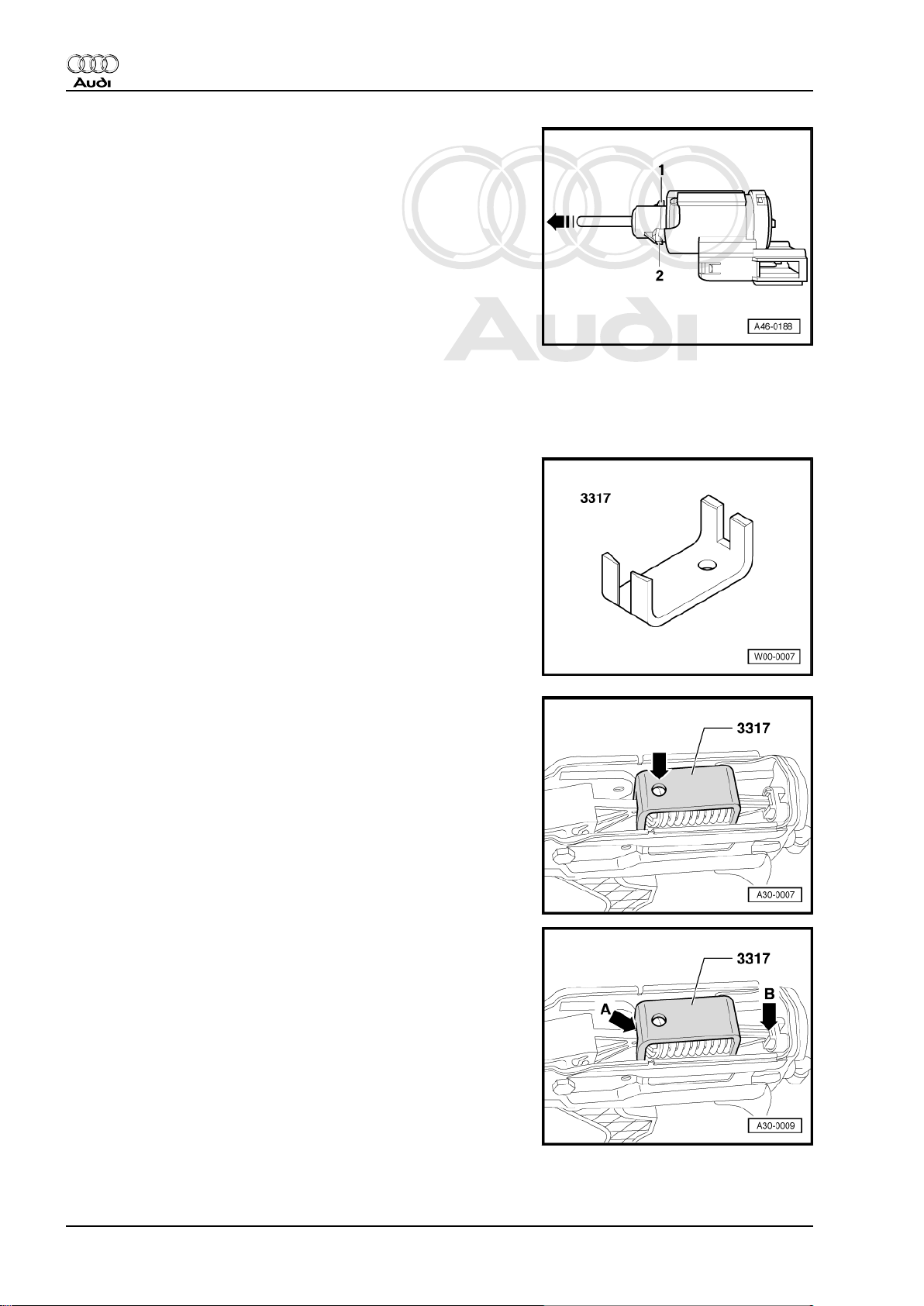

1.4 Removing and installing over-centre

spring

Special tools and workshop equipment required

♦ Assembly clip -3317-

Removing

– Remove storage compartment on driver's side ⇒ General

body repairs, interior; Rep. Gr. 68 .

– Press down clutch pedal to compress the over-centre spring

and fit assembly clip -3317- from the top onto over-centre

spring.

• The drilling -arrow- faces towards clutch pedal.

– Return clutch pedal to normal position and remove over-centre

spring together with assembly clip -3317- .

Installing

– Pull clutch pedal into passenger compartment.

– Insert over-centre spring into rear mounting -arrow B- first,

then operate clutch pedal until the assembly clip -3317- seats

against the mounting lug -arrow A- of the clutch pedal.

–

– Return clutch pedal to normal position and remove assembly

clip -3317- .

14 Rep. Gr.30 - Clutch

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

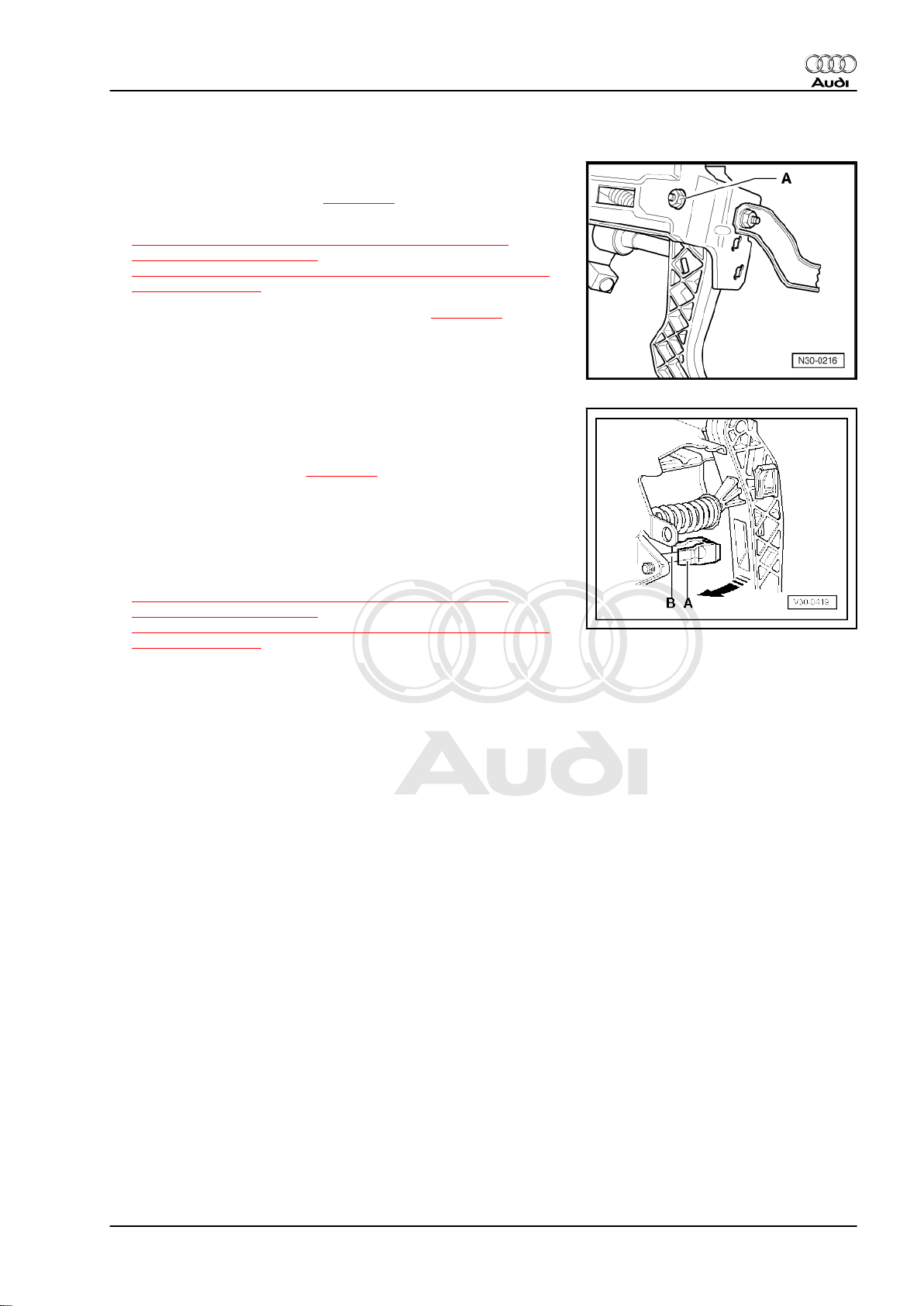

1.5 Removing and installing clutch pedal

Removing

– Remove over-centre spring ⇒ page 14 .

– Remove clutch pedal switch

⇒ “1.2 Removing and installing clutch pedal switch F36

(square housing)”, page 13 or

⇒ “1.3 Removing and installing clutch pedal switch F36 (round

housing)”, page 13 .

– Separate clutch pedal from master cylinder ⇒ page 18 and

push operating rod towards bulkhead onto stop.

– Remove nut -A-.

– Pull bolt out until the clutch pedal can be removed.

Installing

Installation is carried out in reverse sequence; note the following:

– Install over-centre spring ⇒ page 14 .

• The retaining clip -A- must be fitted on the master cylinder op‐

erating rod -B-.

– Press clutch pedal in direction of -arrow- to engage. Ensure

that pedal is correctly located.

– Install clutch pedal switch

⇒ “1.2 Removing and installing clutch pedal switch F36

(square housing)”, page 13 or

⇒ “1.3 Removing and installing clutch pedal switch F36 (round

housing)”, page 13 .

Audi TT 1999 ➤

1. Servicing clutch mechanism 15

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

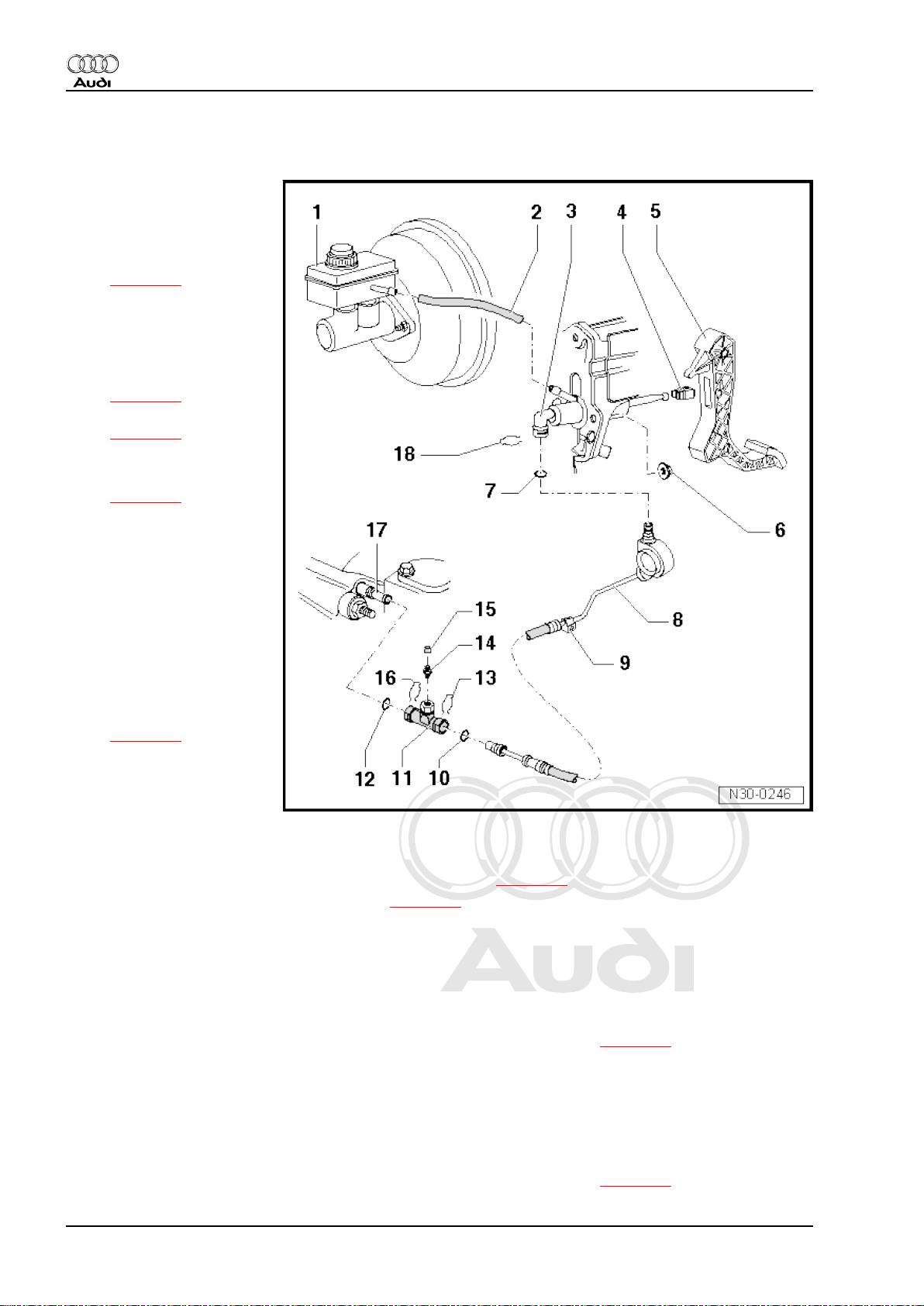

1.6 Hydraulics - exploded view of components

1 - Brake fluid reservoir

2 - Supply hose

3 - Clutch master cylinder

❑ Removing and installing

⇒ page 18

4 - Retaining clip

❑ Only renew when clutch

master cylinder has

been removed

❑ Lever off to remove

⇒ page 17

❑ Pressing on

⇒ page 17

5 - Clutch pedal

❑ Removing and installing

⇒ page 15

6 - Hexagon nut, 25 Nm

❑ 2 x

❑ Self-locking

❑ Renew

7 - Seal/O-ring

❑ Renew; for correct ver‐

sion refer to ⇒ Parts

catalogue

❑ Whether a seal or an O-

ring is used depends on

the type of connection

⇒ page 17 .

❑ Lubricate with brake flu‐

id before installing

❑ Push onto pipe connec‐

tion

8 - Pipe/hose assembly

❑ With frequency modulator

❑ Disconnecting from clutch master cylinder and installing ⇒ page 19

❑ Disconnecting from clutch slave cylinder ⇒ page 62

❑ For correct version refer to ⇒ Parts catalogue

9 - Retainer

❑ Attached to body

10 - Seal/O-ring

❑ Renew; for correct version refer to ⇒ Parts catalogue

❑ Whether a seal or an O-ring is used depends on the type of connection ⇒ page 17 .

❑ Lubricate with brake fluid before installing

❑ Push onto pipe connection

11 - Bleeder connection

12 - Seal/O-ring

❑ Renew; for correct version refer to ⇒ Parts catalogue

❑ Whether a seal or an O-ring is used depends on the type of connection ⇒ page 17 .

❑ Lubricate with brake fluid before installing

16 Rep. Gr.30 - Clutch

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

❑ Push onto pipe connection

13 - Clip

❑ To remove pipe, pull out clip as far as limit stop ⇒ page 19

14 - Bleeder valve

❑ Bleeding clutch system ⇒ page 21

15 - Dust cap

16 - Clip

❑ To remove pipe, pull out clip as far as limit stop ⇒ page 19

17 - Clutch slave cylinder (release bearing with hydraulic actuator)

❑ Can only be removed after removing gearbox

❑ Removing and installing ⇒ page 21

18 - Clip

❑ To remove pipe, pull out clip as far as limit stop ⇒ page 19

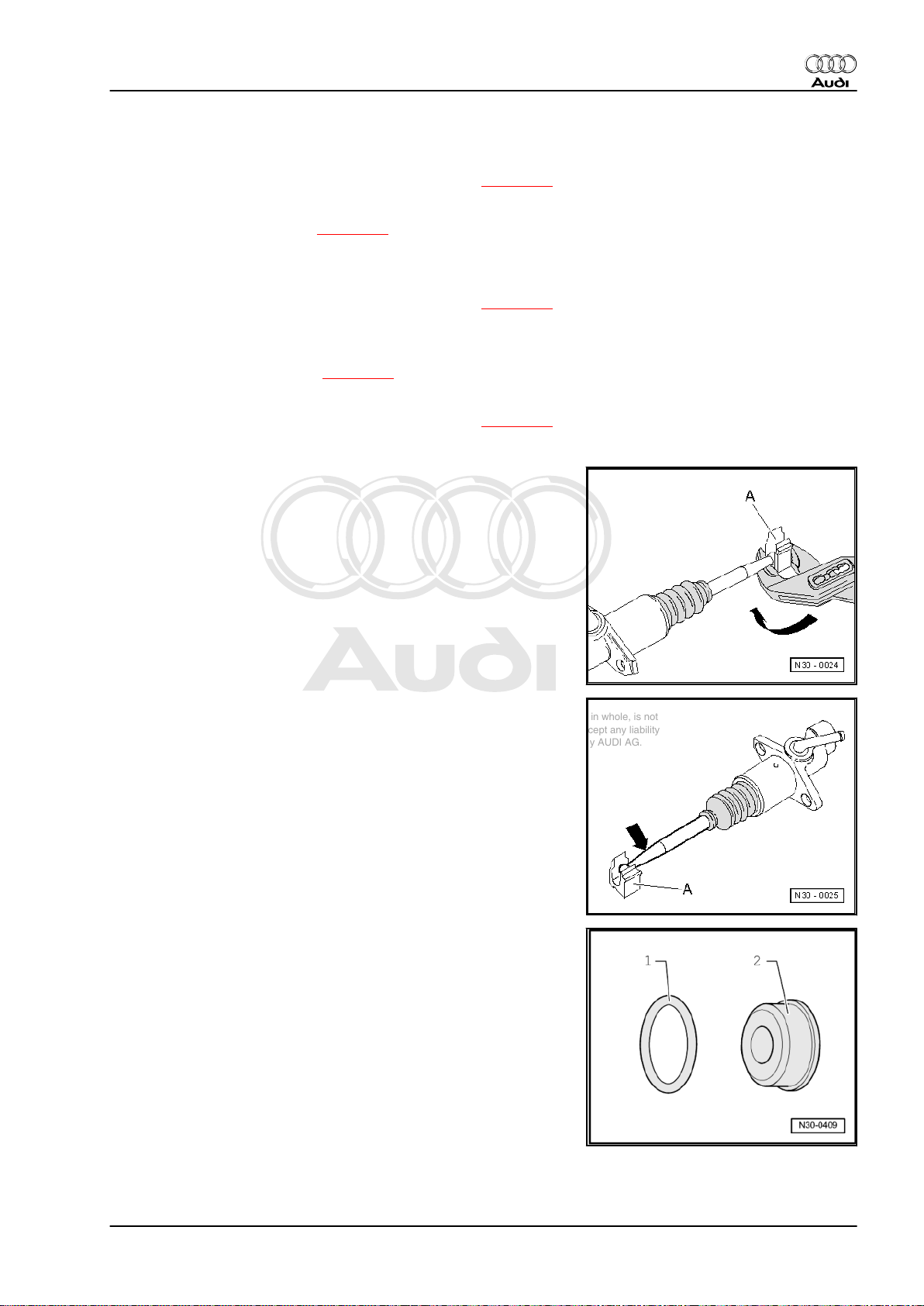

Levering off retaining clip

– Lever retaining clip -A- off in direction of -arrow- using pliers.

Audi TT 1999 ➤

Pressing master cylinder operating rod into retaining clip

– Press master cylinder operating rod into retaining clip -A-

-arrow-.

Seals/O-rings for pipe/hose assemblies

1 - For metal pipe/hose assemblies

2 - For synthetic pipe/hose assemblies

1. Servicing clutch mechanism 17

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

1.7 Removing and installing clutch master cylinder

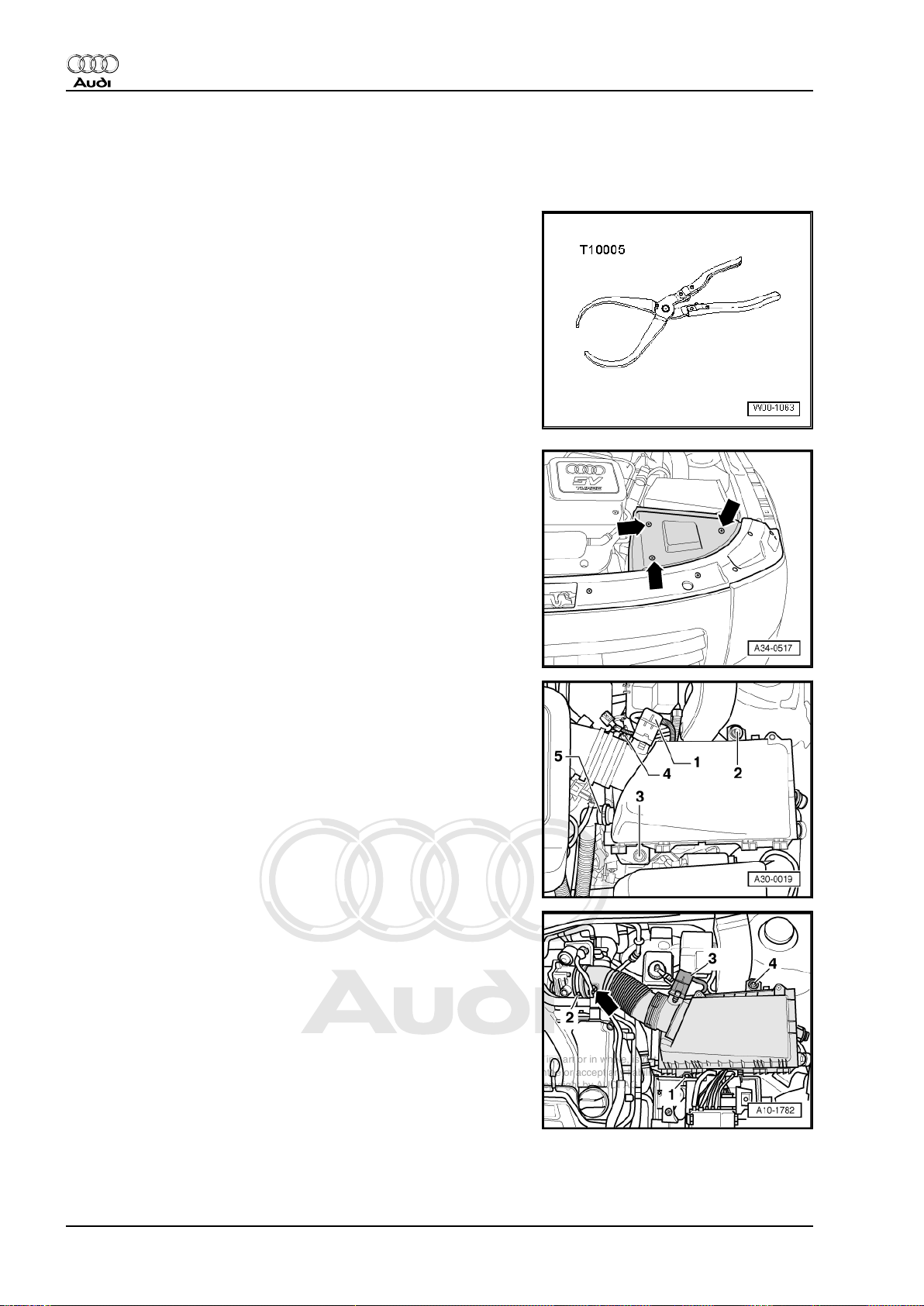

Special tools and workshop equipment required

♦ Pliers -T10005-

Removing

– Remove cover panel (front left) -arrows-.

Vehicles with 4-cylinder engine:

– Detach air intake hose at throttle valve module -J338- (slacken

hose clip -4-).

– Unplug electrical connector for air mass meter -G70- -1-.

– If fitted, detach hose -5- from air cleaner housing.

– Remove bolts -2- and -3-.

– Take out air cleaner housing.

Vehicles with 6-cylinder engine:

– Detach air intake hose -2- at throttle valve module -J338- .

– Unplug electrical connector for air mass meter -G70- -3-.

– Remove bolts -1- and -4-.

– Move electrical wire -arrow- clear.

– Take out air cleaner housing.

18 Rep. Gr.30 - Clutch

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

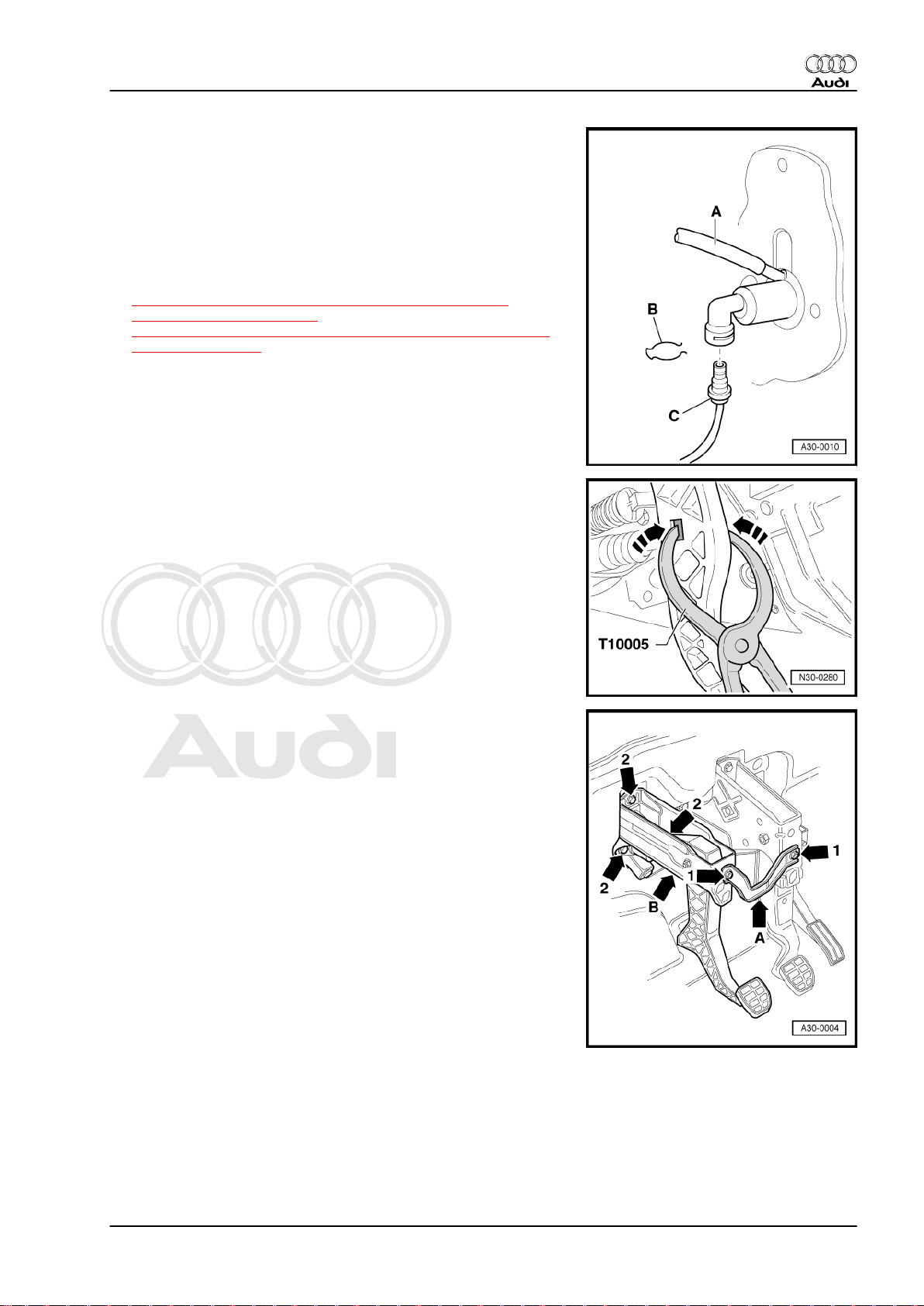

All models:

– Pull off supply hose -A- going to brake fluid reservoir and seal.

– Pull out clip -B- for pipe/hose assembly.

– Pull pipe/hose assembly -C- out from master cylinder and seal.

– Remove storage compartment on driver's side ⇒ General

body repairs, interior; Rep. Gr. 68 .

– Remove clutch pedal switch

⇒ “1.2 Removing and installing clutch pedal switch F36

(square housing)”, page 13 or

⇒ “1.3 Removing and installing clutch pedal switch F36 (round

housing)”, page 13 .

– Pull clutch pedal lightly towards the passenger compartment

to separate master cylinder operating rod from clutch pedal

and press both sides of retaining clip inwards -arrows- using

pliers -T10005- .

Audi TT 1999 ➤

– Remove connecting plate -A- -arrows 1-.

– Remove nuts -arrows 2- and take off mounting bracket -B-.

1. Servicing clutch mechanism 19

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

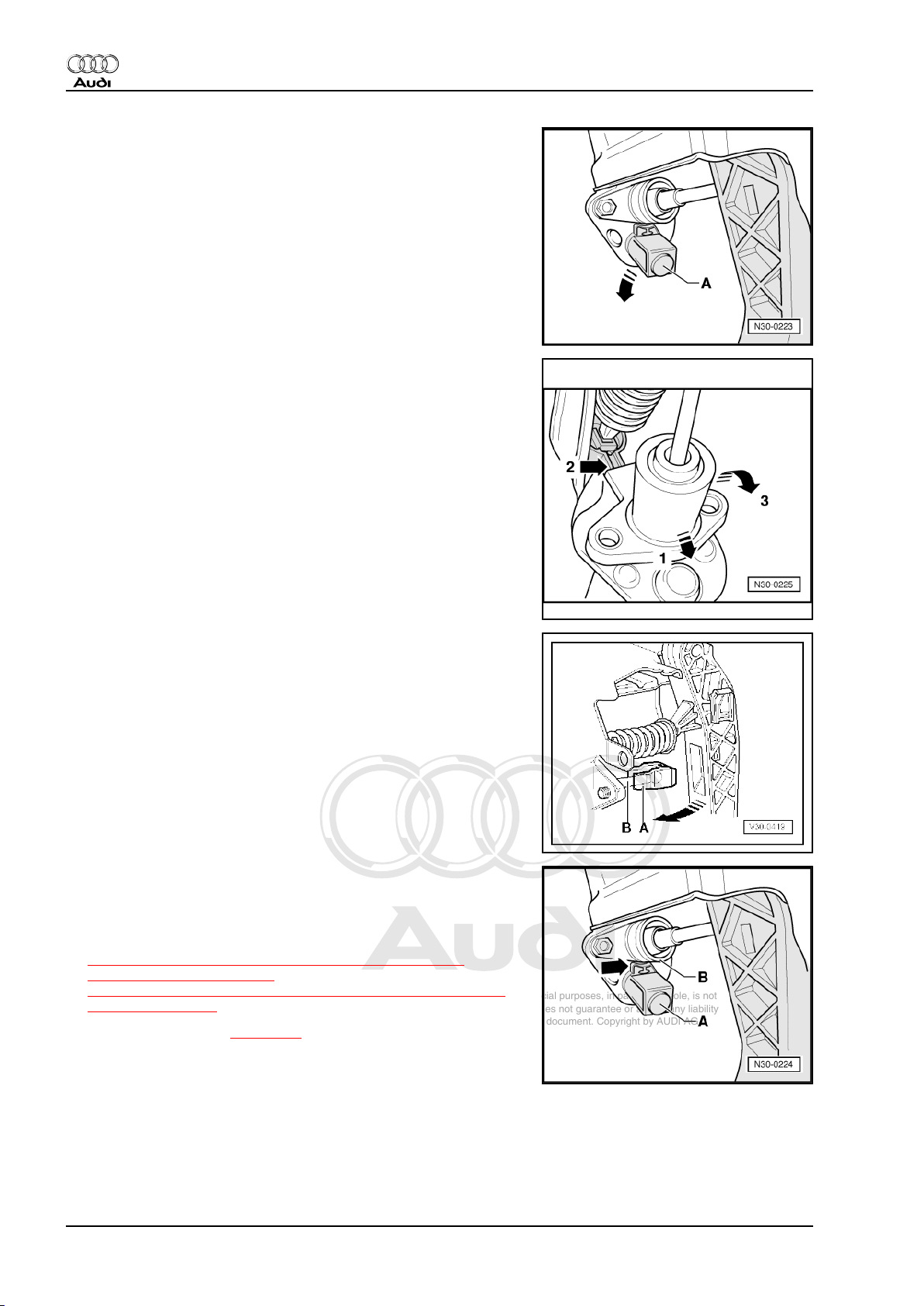

– Turn stop -A- for clutch pedal in direction of -arrow- and re‐

move.

– Then push master cylinder in the direction of -arrow 1- onto

stop.

• It must not be covered in upper area by over-centre spring

mounting -arrow 2-.

– Then swing master cylinder in direction of -arrow 3- out of

mounting bracket.

Installing

Installation is carried out in reverse sequence; note the following:

• The retaining clip -A- must be fitted on the master cylinder op‐

erating rod -B-.

– Press clutch pedal in direction of -arrow- to engage. Ensure

that pedal is correctly located.

– Fit stop -A- for clutch pedal again.

• Installation position: the angled tabs -arrow- point towards the

master cylinder -B-.

– Install clutch pedal switch

⇒ “1.2 Removing and installing clutch pedal switch F36

(square housing)”, page 13 or

⇒ “1.3 Removing and installing clutch pedal switch F36 (round

housing)”, page 13 .

– Bleed clutch system ⇒ page 21 .

20 Rep. Gr.30 - Clutch

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

1.8 Removing and installing clutch slave cylinder (release bearing with hydraulic actuator)

Note

Slave cylinder and release bearing are one unit and can only be

renewed together.

Removing

– Remove gearbox

⇒ “2.1 Removing gearbox - vehicles with 4-cylinder engine”,

page 56 or

⇒ “2.3 Removing gearbox - vehicles with 6-cylinder engine”,

page 75 .

– Remove bolts -arrows-.

– Pull out release bearing -A- together with clutch slave cylinder.

Installing

Installation is carried out in reverse sequence; note the following:

– Install gearbox

⇒ “2.2 Installing gearbox - vehicles with 4-cylinder engine”,

page 67 or

⇒ “2.4 Installing gearbox - vehicles with 6-cylinder engine”,

page 87 .

– Bleed clutch system ⇒ page 21 .

Tightening torque

Audi TT 1999 ➤

Component Nm

Clutch slave cylinder to gearbox 12

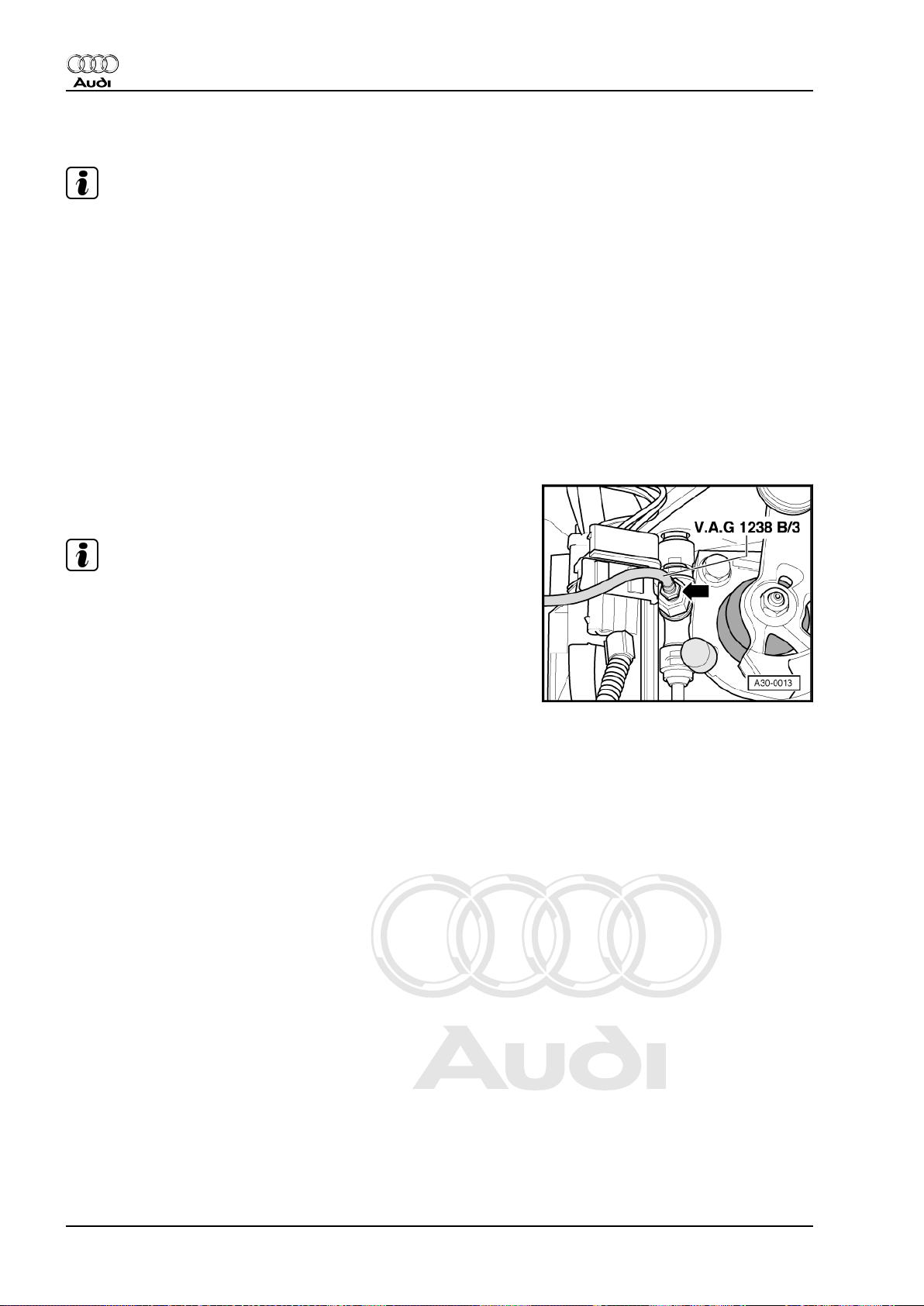

1.9 Bleeding clutch system

Special tools and workshop equipment required

♦ Brake charge and bleed equipment -VAS 5234-

Brake fluid specification ⇒ Brake system; Rep. Gr. 47 .

1. Servicing clutch mechanism 21

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

Procedure

Note

♦

The clutch system must be bled after performing work on the

hydraulic clutch mechanism.

♦

It is not necessary to prefill the system.

♦

When performing the following steps, make sure that no brake

fluid escapes onto the gearbox.

– Pull clutch pedal back to its normal rest position.

– Connect brake charge and bleed equipment -VAS 5234- to

brake fluid reservoir (do not switch on at this stage).

– If necessary, use bleed hose -V.A.G 1238 B/3- (670 mm) to

bleed system.

– Connect bleed hose to collector bottle of brake charge and

bleed equipment -VAS 5234- .

– Connect bleed hose -V.A.G 1238 B/3- to bleeder valve

-arrow-.

Note

Ensure that bleed hose is correctly fitted during bleeding opera‐

tion.

– Open bleeder valve -arrow-.

– Switch on bleeding equipment.

• Operating pressure 2.0 bar

–

Bleed off about 100 cm3 of brake fluid.

– Close bleeder valve.

– Rapidly operate clutch pedal from stop to stop 15 times.

–

Bleed off an additional 50 cm3 of brake fluid.

– Close bleeder valve. Tightening torque 4.5 Nm.

– Depress clutch pedal several times after bleeding process is

completed.

– Bleed system once again if necessary.

– Remove bleed hose and fit protective cap.

– Remove brake charge and bleed equipment -VAS 5234- from

brake fluid reservoir.

22 Rep. Gr.30 - Clutch

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

2 Servicing clutch release mechanism

2.1 Clutch release mechanism - exploded view of components

1 - Gearbox

2 - Oil seal

❑ For input shaft

❑ Renewing ⇒ page 23

3 - Release bearing with hy‐

draulic actuator

❑ One unit; can only re re‐

newed together

❑ Do not wash out bear‐

ing; wipe clean only

❑ Renew complete re‐

lease bearing with hy‐

draulic actuator if noises

occur.

❑ Removing and installing

⇒ page 21

4 - Bolt, 12 Nm

❑ 3 x

❑ For correct version

check engine code and

refer to ⇒ Parts cata‐

logue

5 - Seal/O-ring

❑ Renew; for correct ver‐

sion refer to ⇒ Parts

catalogue

❑ Whether a seal or an O-

ring is used depends on

the type of connection

⇒ page 17 .

❑ Lubricate with brake flu‐

id before installing

❑ Push onto pipe connec‐

tion

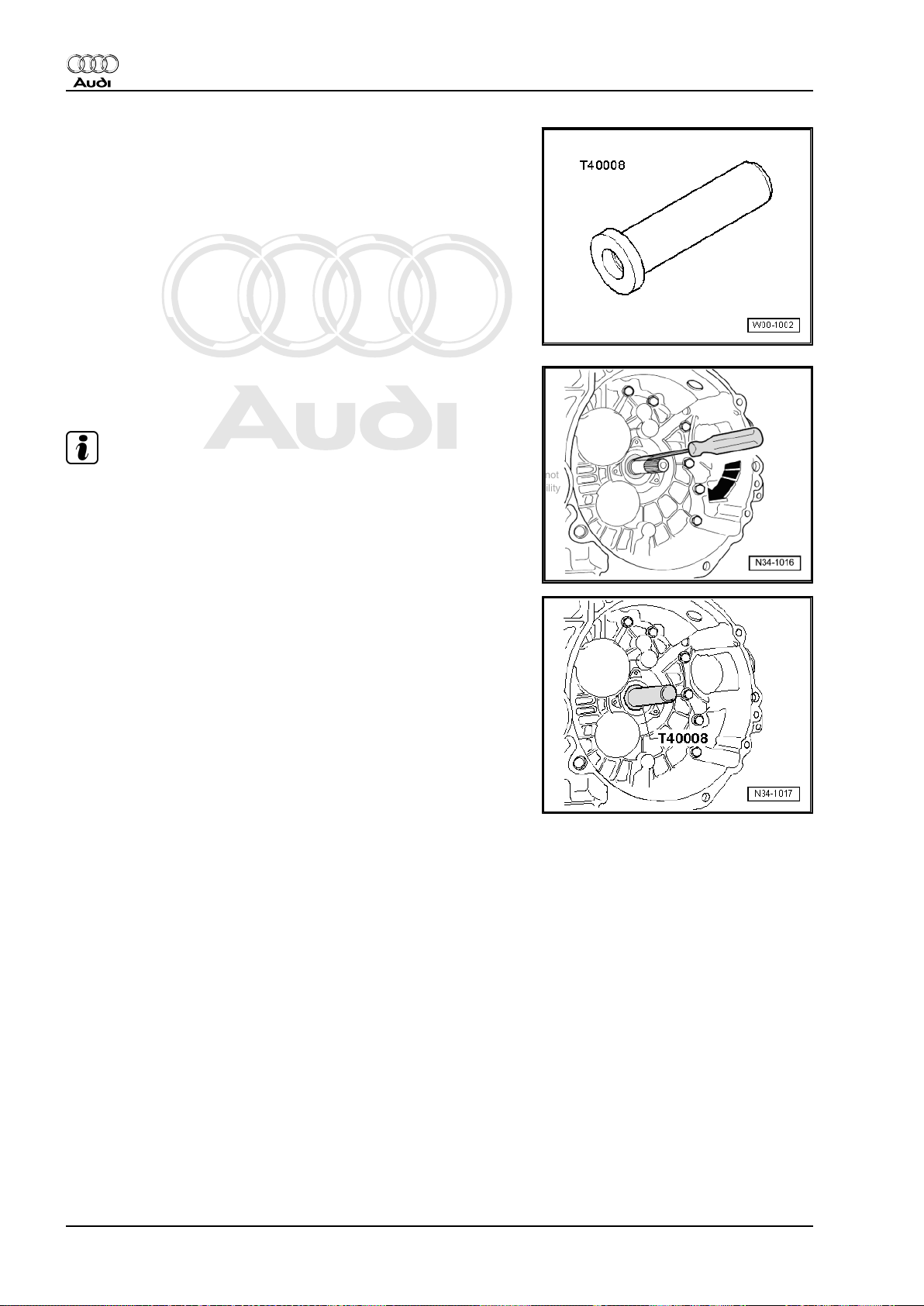

2.2 Renewing input shaft oil seal

Special tools and workshop equipment required

2. Servicing clutch release mechanism 23

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

♦ Thrust piece -T40008-

Procedure

– Prise out input shaft oil seal carefully using a screwdriver.

Note

Take care not to damage contact surface for oil seal on input

shaft.

– Drive in new oil seal with thrust piece -T40008- as far as the

stop.

– Pack space between sealing lip and dust lip half-full with seal‐

ing grease -G 052 128 A1- .

24 Rep. Gr.30 - Clutch

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

3 Servicing conventional clutch

3.1 Conventional clutch - exploded view of components

Note

Select the correct pressure plate and clutch plate according to engine code ⇒ Parts catalogue .

1 - Dual-mass flywheel

❑ Observe instructions for

removal ⇒ page 26

❑ Removing and installing

⇒ Rep. Gr. 13

❑ Ensure that dowel pins

fit tightly

❑ Contact surface for

clutch lining must be

free of grooves, oil and

grease

2 - Clutch plate

❑ Removing and installing

⇒ page 27

❑ Installation position:

Shorter end of hub

-arrow- faces towards

pressure plate

❑ Clutch plate diameter

⇒ page 2

3 - Pressure plate

❑ Removing and installing

⇒ page 27

❑ Check ends of dia‐

phragm spring

⇒ page 26

❑ Check spring connec‐

tions and rivet joints

⇒ page 26

4 - M6 = 13 Nm; M7 = 20 Nm;

M8 = 22 Nm

❑ Working clockwise,

slacken all bolts one af‐

ter the other in steps of

90° (1/4 turn) until the

pressure plate is free

❑ Observe instructions for installation ⇒ page 29

❑ For correct version check engine code and refer to ⇒ Parts catalogue

3. Servicing conventional clutch 25

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

Checking ends of diaphragm spring

• Wear up to half the thickness of the diaphragm spring is per‐

missible.

Note

Select the correct pressure plate and clutch plate according to

engine code ⇒ Parts catalogue .

Checking spring connections and rivets

– Check spring connections between pressure plate and cover

for cracks and make sure rivets are seated tightly.

• Renew pressure plate if spring connections are damaged or

rivets are loose -arrows-.

Instructions for removing dual-mass flywheel

Note

Do not use an impact wrench or pneumatic wrench to remove

bolts -B-: this would severely damage the dual-mass flywheel.

The bolts must always be removed by hand.

– Rotate dual-mass flywheel -A- so that the bolts are aligned

centrally behind the holes -arrows-.

– When removing the bolts, make sure that none of the bolt

heads contacts the dual-mass flywheel, as this would damage

the flywheel when the bolts are unscrewed further.

26 Rep. Gr.30 - Clutch

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

3.2 Removing and installing conventional clutch

Special tools and workshop

equipment required

♦ Counterhold tool -3067-

♦ Centring mandrel -3190 A-

♦ Centring mandrel -T10097-

for clutch plate with larger

hub diameter

♦ Grease for clutch plate

splines -G 000 100-

Audi TT 1999 ➤

Removing

– Remove gearbox

⇒ “2.1 Removing gearbox - vehicles with 4-cylinder engine”,

page 56 or

⇒ “2.3 Removing gearbox - vehicles with 6-cylinder engine”,

page 75 .

– Apply counter-hold tool -3067- in order to loosen bolts.

To prevent the pressure plate from becoming distorted during re‐

moval (causes clutch grab when driving off), always adhere to the

following procedure when unbolting the pressure plate:

– Working clockwise, loosen all six bolts consecutively in steps

of 90° (1/4 turn) until the pressure plate is released.

– Take off pressure plate and clutch plate.

Installing

Installation is carried out in reverse sequence; note the following:

3. Servicing conventional clutch 27

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

Note

♦

Select the correct clutch plate and pressure plate according to

engine code: ⇒ Parts catalogue .

♦

If the clutch has burnt out, thoroughly clean the bell housing,

flywheel and parts of the engine facing the gearbox in order to

prevent odours.

♦

Clean input shaft splines and (in the case of a used clutch

plate) the hub splines. Remove corrosion and apply only a very

thin coating of grease for clutch plate splines -G 000 100- to

the splines. Then move clutch plate backwards and forwards

on input shaft until hub moves freely on shaft. It is important

to remove excess grease.

♦

Pressure plates have an anti-corrosion coating and are

greased. Only the contact surface may be cleaned, otherwise

the service life of the clutch will be considerably reduced.

♦

Pressure plate contact surface and clutch plate lining must

make full contact with flywheel. Only then insert bolts.

– Note correct installation position of clutch plate:

• The marking “Getriebeseite” or “Getr.-Seite” (gearbox side)

-arrow- faces pressure plate and gearbox.

– Reverse position of counter-hold tool -3067- when installing.

– Use centring mandrel -3190 A- to centralise clutch plate.

28 Rep. Gr.30 - Clutch

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

– Use centring mandrel -T10097- to centralise clutch plate with

larger hub diameter.

To prevent the pressure plate from becoming distorted during in‐

stallation (causes clutch grab when driving off), always adhere to

the following procedure when installing the pressure plate:

– Fit pressure plate onto dowel pins.

– Screw in all 6 bolts evenly by hand until bolt heads make con‐

tact with pressure plate.

– Working clockwise, tighten all six bolts consecutively in steps

of 90° (1/4 turn) until the housing makes contact with the fly‐

wheel.

– Working clockwise, tighten all 6 bolts to final torque consecu‐

tively.

– Install gearbox

⇒ “2.2 Installing gearbox - vehicles with 4-cylinder engine”,

page 67 or

⇒ “2.4 Installing gearbox - vehicles with 6-cylinder engine”,

page 87 .

Tightening torque

Audi TT 1999 ➤

Component Nm

Pressure plate to dual-mass flywheel M6 13

M7 20

M8 22

3. Servicing conventional clutch 29

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

4 Servicing self-adjusting clutch

4.1 Self-adjusting clutch (Sachs version) - exploded view of components

Caution

On this type of clutch the pressure plate and clutch plate can

only be renewed together.

1 - M6 = 13 Nm; M7 = 20 Nm;

M8 = 22 Nm

❑ Working clockwise,

slacken all bolts one af‐

ter the other in steps of

90° (1/4 turn) until the

pressure plate is free

❑ Observe instructions for

installation ⇒ page 35

❑ For correct version

check engine code and

refer to ⇒ Parts cata‐

logue

2 - Pressure plate

❑ Self-adjusting

❑ Identification

⇒ page 31

❑ Always renew clutch

plate as well

❑ Removing and installing

⇒ page 33

❑ Check ends of dia‐

phragm spring

⇒ page 31

❑ Check spring connec‐

tions and rivets

⇒ page 31

❑ Check wire ring

⇒ page 32

3 - Clutch plate

❑ Always renew pressure

plate as well

❑ Removing and installing

⇒ page 33

❑ Installation position: marking “Getriebeseite”/gearbox side (if provided) goes towards pressure plate and

gearbox; damper assembly (coil springs) (if provided) goes towards pressure plate and gearbox.

❑ Clutch lining must make full contact with flywheel.

❑ Clutch plate diameter ⇒ page 2

4 - Bolt for dual-mass flywheel

❑ Renew

❑ Observe instructions for removal ⇒ page 32

❑ Tightening torque ⇒ Rep. Gr. 13

30 Rep. Gr.30 - Clutch

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

5 - Dual-mass flywheel

❑ Observe instructions for removal ⇒ page 32

❑ Removing and installing ⇒ Rep. Gr. 13

❑ Ensure that dowel pins fit tightly

❑ Contact surface for clutch lining must be free of grooves, oil and grease

6 - Not fitted

Identification of self-adjusting Sachs version clutch

♦ Pressure plate with stop mechanism (position sensor)

-arrow-.

Audi TT 1999 ➤

Checking ends of diaphragm spring

• Wear up to half the thickness of the diaphragm spring is per‐

missible.

Note

Select the correct pressure plate and clutch plate according to

engine code ⇒ Parts catalogue .

Checking spring connections and rivets

– Check spring connections -arrows A- for damage and make

sure riveted joints -arrows B- are seated tightly.

• Renew pressure plate if spring connections are broken or bad‐

ly bent, or if riveted joints are loose.

4. Servicing self-adjusting clutch 31

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

Checking wire ring

– Check that wire ring in pressure plate -arrow- is not damaged.

• Renew pressure plate if wire ring is broken.

Instructions for removing dual-mass flywheel

Note

Do not use an impact wrench or pneumatic wrench to remove

bolts -B-: this would severely damage the dual-mass flywheel.

The bolts must always be removed by hand.

– Rotate dual-mass flywheel -A- so that the bolts are aligned

centrally behind the holes -arrows-.

– When removing the bolts, make sure that none of the bolt

heads contacts the dual-mass flywheel, as this would damage

the flywheel when the bolts are unscrewed further.

32 Rep. Gr.30 - Clutch

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

4.2 Removing and installing self-adjusting clutch (Sachs version)

Special tools and workshop

equipment required

♦ Counterhold tool -3067-

♦ Centring mandrel -3190 A-

♦ Centring mandrel -T10097-

for clutch plate with larger

hub diameter

♦ Grease for clutch plate

splines -G 000 100-

Removing

– Remove gearbox

⇒ “2.1 Removing gearbox - vehicles with 4-cylinder engine”,

page 56 or

⇒ “2.3 Removing gearbox - vehicles with 6-cylinder engine”,

page 75 .

– Apply counter-hold tool -3067- in order to loosen bolts.

To prevent the pressure plate from becoming distorted during re‐

moval (causes clutch grab when driving off), always adhere to the

following procedure when unbolting the pressure plate:

– Working clockwise, loosen all six bolts consecutively in steps

of 90° (1/4 turn) until the pressure plate is released.

4. Servicing self-adjusting clutch 33

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

• Stop -2- with pin -1- should come loose when the bolts are

slackened.

– Take off pressure plate and clutch plate.

Installing

Installation is carried out in reverse sequence; note the following:

Note

♦

Select the correct clutch plate and pressure plate according to

engine code: ⇒ Parts catalogue .

♦

If the clutch has burnt out, thoroughly clean the bell housing,

flywheel and parts of the engine facing the gearbox in order to

prevent odours.

♦

Clean input shaft splines and (in the case of a used clutch

plate) the hub splines. Remove corrosion and apply only a very

thin coating of grease for clutch plate splines -G 000 100- to

the splines. Then move clutch plate backwards and forwards

on input shaft until hub moves freely on shaft. It is important

to remove excess grease.

♦

Pressure plates have an anti-corrosion coating and are

greased. Only the contact surface may be cleaned, otherwise

the service life of the clutch will be considerably reduced.

♦

Pressure plate contact surface and clutch plate lining must

make full contact with flywheel. Only then insert bolts.

– Reverse position of counter-hold tool -3067- when installing.

– Note correct installation position of clutch plate:

• Damper assembly (coil springs) or marking

“Getriebeseite” (gearbox side) faces pressure plate and gear‐

box.

– Use centring mandrel -3190 A- to centralise clutch plate.

– Use centring mandrel -T10097- to centralise clutch plate with

larger hub diameter.

34 Rep. Gr.30 - Clutch

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

To prevent the pressure plate from becoming distorted during in‐

stallation (causes clutch grab when driving off), always adhere to

the following procedure when installing the pressure plate:

– Fit pressure plate onto dowel pins.

– Make sure that the stop pin (position sensor) -arrow- is free to

move.

– Screw in all 6 bolts evenly by hand until bolt heads make con‐

tact with pressure plate.

– Working clockwise, tighten all six bolts consecutively in steps

of 90° (1/4 turn) until the housing makes contact with the fly‐

wheel.

• The stop pin -arrow- should then lift away from the pressure

plate.

– Working clockwise, tighten all 6 bolts to final torque consecu‐

tively.

– Install gearbox

⇒ “2.2 Installing gearbox - vehicles with 4-cylinder engine”,

page 67 or

⇒ “2.4 Installing gearbox - vehicles with 6-cylinder engine”,

page 87 .

Tightening torque

Audi TT 1999 ➤

Component Nm

Pressure plate to dual-mass flywheel M6 13

M7 20

M8 22

4. Servicing self-adjusting clutch 35

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

4.3 Self-adjusting clutch (LuK version) - exploded view of components

1 - Dual-mass flywheel

❑ Observe instructions for

removal ⇒ page 37

❑ Removing and installing

⇒ Rep. Gr. 13

❑ Ensure that dowel pins

fit tightly

❑ Contact surface for

clutch lining must be

free of grooves, oil and

grease

2 - Clutch plate

❑ Removing and installing

⇒ page 38

❑ Always renew SAC

pressure plate as well

❑ Installation position:

marking

“Getriebeseite” (gear‐

box side) faces towards

gearbox

❑ Clutch plate diameter

⇒ page 2

3 - SAC pressure plate

❑ “SAC” = self adjusting

clutch

❑ Removing and installing

⇒ page 38

❑ Check ends of dia‐

phragm spring

⇒ page 37

❑ Check spring connec‐

tions and rivets

⇒ page 37

❑ Always renew clutch

plate as well

4 - M6 = 13 Nm; M7 = 20 Nm; M8 = 22 Nm

❑

Working clockwise, slacken all bolts one after the other in steps of 90° (1/4 turn) until the pressure plate

is free

❑ Observe instructions for installation ⇒ page 39

❑ For correct version check engine code and refer to ⇒ Parts catalogue

36 Rep. Gr.30 - Clutch

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

Checking ends of diaphragm spring

• Wear up to half the thickness of the diaphragm spring

-arrows- is permissible.

Note

If required, pressure plate and clutch plate must always be re‐

newed together. Select the correct pressure plate and clutch plate

according to engine code ⇒ Parts catalogue .

Checking spring connections and rivets

– Check spring connections -arrows A- for damage and make

sure riveted joints -arrows B- are seated tightly.

• Renew pressure plate if spring connections are broken or bad‐

ly bent, or if riveted joints are loose.

Note

Audi TT 1999 ➤

If required, pressure plate and clutch plate must always be re‐

newed together. Select the correct pressure plate and clutch plate

according to engine code ⇒ Parts catalogue .

Instructions for removing dual-mass flywheel

Note

Do not use an impact wrench or pneumatic wrench to remove

bolts -B-: this would severely damage the dual-mass flywheel.

The bolts must always be removed by hand.

– Rotate dual-mass flywheel -A- so that the bolts are aligned

centrally behind the holes -arrows-.

– When removing the bolts, make sure that none of the bolt

heads contacts the dual-mass flywheel, as this would damage

the flywheel when the bolts are unscrewed further.

4. Servicing self-adjusting clutch 37

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

5/6-speed manual gearbox 02M/02Y, four-wheel drive - Edition 12.2004

4.4 Removing and installing clutch (LuK version)

Special tools and workshop

equipment required

♦ Counterhold tool -3067-

♦ Centring mandrel -3190 A-

♦ Centring mandrel -T10097-

for clutch plate with larger

hub diameter

♦ Grease for clutch plate

splines -G 000 100-

Removing

– Remove gearbox

⇒ “2.1 Removing gearbox - vehicles with 4-cylinder engine”,

page 56 or

⇒ “2.3 Removing gearbox - vehicles with 6-cylinder engine”,

page 75 .

– Apply counter-hold tool -3067- in order to loosen bolts.

To prevent the pressure plate from becoming distorted during re‐

moval (causes clutch grab when driving off), always adhere to the

following procedure when unbolting the pressure plate:

– Working clockwise, loosen all six bolts consecutively in steps

of 90° (1/4 turn) until the pressure plate is released.

– Take off pressure plate and clutch plate.