Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive

Edition 12.2006

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

00 - Technical data

30 - Clutch

34 - Controls, housing

35 - Gears, shafts

39 - Final drive - front differential

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A0057108920

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Gearbox identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Code letters, gearbox allocation, ratios, equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Calculating ratio “i” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 Notes on the direct shift gearbox 02E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.2 Safety functions of gearbox control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6 Notes on tow-starting and towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7 Repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.1 Contact corrosion! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.2 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8 Rules for cleanliness when working on the gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

30 - Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1 Servicing multiple clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.1 Multiple clutch - exploded view of components (replacement parts) . . . . . . . . . . . . . . . . . . 13

1.2 Removing and installing multiple clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

34 - Controls, housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2 Servicing selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.1 Checking selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2 Checking selector lever cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.3 Adjusting selector lever cable - vehicles with vehicle ID No. to 8N 41013847 . . . . . . . . . . 30

2.4 Adjusting selector lever cable - vehicles with vehicle ID No. from 8N 41013848 . . . . . . . . 31

2.5 Checking adjustment of selector lever cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.6 Checking function of ignition key removal lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.7 Dismantling and assembling selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.8 Removing and installing selector lever handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.9 Removing and installing selector mechanism cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.10 Removing and installing selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.11 Removing and installing tiptronic switch F189 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.12 Removing and installing selector lever lock solenoid N110 . . . . . . . . . . . . . . . . . . . . . . . . 40

2.13 Removing and installing selector lever cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.14 Removing and installing locking cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2.15 Adjusting locking cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.16 Checking connectors on selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3 Removing and installing gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.1 Removing gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.2 Installing gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3.3 Removing and installing gearbox mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3.4 Removing and installing pendulum support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.5 Transporting the direct shift gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.6 Securing gearbox to assembly stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4 Gear oil in direct shift gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.1 Checking and topping up gear oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.2 Checking and topping up gear oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.3 Changing gear oil or filling up after performing repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.4 Removing and installing gear oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

4.5 Removing and installing gear oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5 Removing and installing bevel box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6 Checking and topping up gear oil in bevel box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.1 Draining oil in bevel box and filling up after repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

35 - Gears, shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

1 Oil pan, mechatronic unit and gear oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

1.1 Oil pan, mechatronic unit and gear oil pump - exploded view of components . . . . . . . . . . 97

1.2 Removing and installing oil pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

1.3 Removing and installing mechatronic unit for direct shift gearbox J743 . . . . . . . . . . . . . . 102

1.4 Removing and installing gearbox input speed sender G182 / oil temperature sender for multi-

plate clutch G509 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

1.5 Removing and installing gear oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

39 - Final drive - front differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

1 Flange shaft and oil seals on gearbox - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

1.1 Removing and installing flange shaft (left-side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

1.2 Renewing flange shaft oil seal (left-side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

1.3 Renewing oil seal between bevel box and gearbox (on gearbox) . . . . . . . . . . . . . . . . . . . . 112

1.4 Renewing selector shaft oil seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

2 Flange shafts and oil seals on bevel box - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . 117

2.1 Removing and installing flange shaft (right-side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

2.2 Renewing flange shaft oil seal (right-side) at bevel box (outer) . . . . . . . . . . . . . . . . . . . . . . 119

2.3 Renewing needle bearings (polygon bearings) for flange shaft (right-side) . . . . . . . . . . . . 121

2.4 Renewing oil seal between gearbox and bevel box (on bevel box) . . . . . . . . . . . . . . . . . . 122

2.5 Renewing oil seal for bevel box output flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

3 Propshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

4 Rear final drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

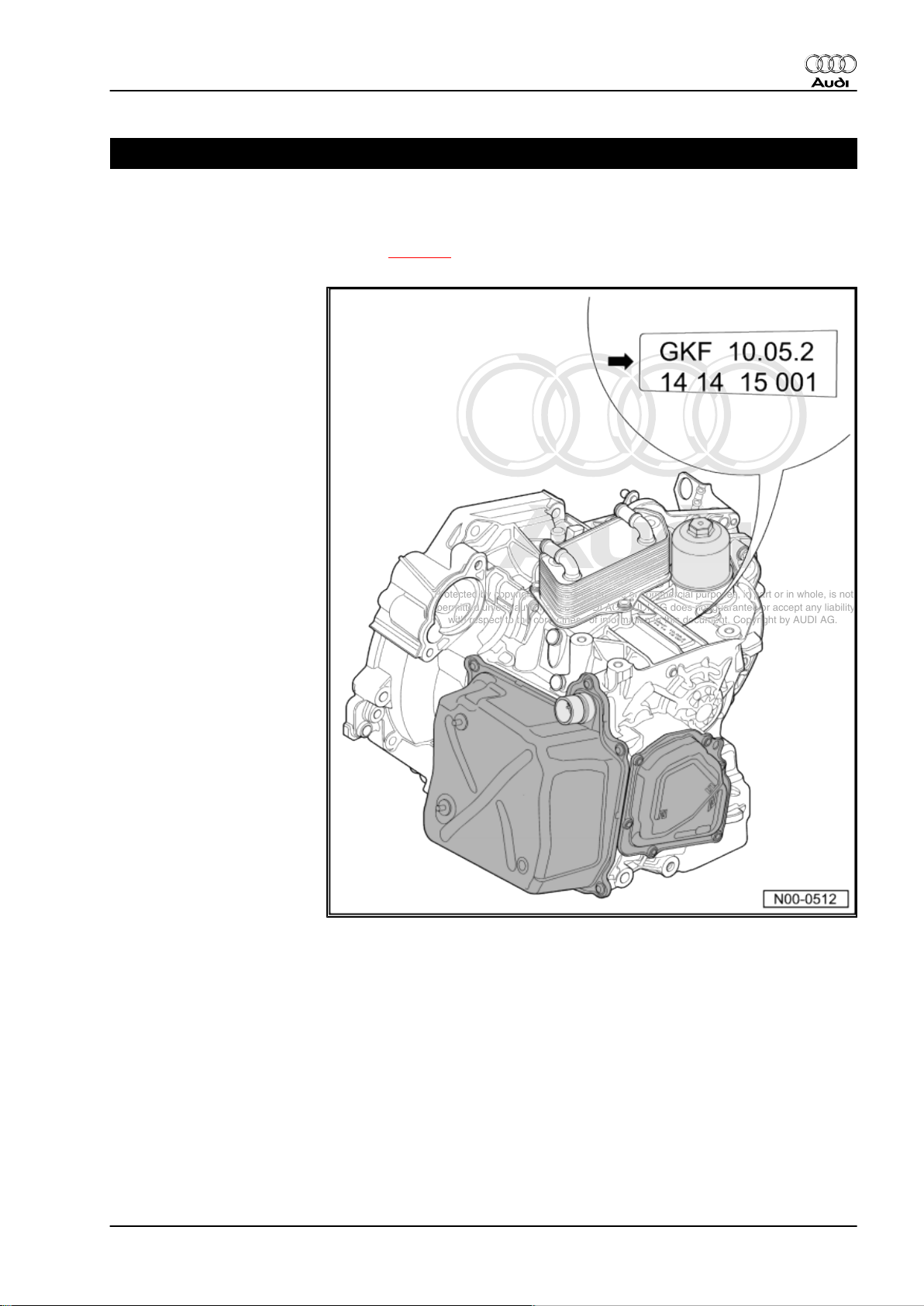

00 – Technical data

1 Gearbox identification

The “6-speed direct shift gearbox 02E (four-wheel drive)” is in‐

stalled in the Audi TT 1999 ▸. Allocation ⇒ page 2 .

Audi TT 1999 ➤

The gearbox code is located on the top of the gearbox, near the

oil cooler.

Example of a gearbox:

♦ GKF = gearbox code

♦ 10.05.2 = date of production: 10th May 2002

The code letters of the gearbox are also given on the vehicle data

stickers.

1. Gearbox identification 1

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

2 Code letters, gearbox allocation, ratios, equipment

Direct shift gearbox 02E four-wheel drive

Gearbox Code letters GVF GVG GYU

Allocation Model

Ratios Final drive I

Z2 : Z

1

Overall ratio i

Allocation: rear final drive Designation: 02D

Manufac‐

tured

fro

m

03.03 03.03 07.03

to

Engine

Audi TT 1999 ▸ Audi TT 1999 ▸ Audi TT 1999 ▸

3.2 ltr. - 184 kW

6 cylinders

3.2 ltr. - 184 kW

6 cylinders

3.2 ltr. - 184 kW

6 cylinders

69 : 17 = 4.059 69 : 17 = 4.059 69 : 17 = 4.059

for 1st to 4th gear

Final drive II

69 : 22 = 3.136 69 : 22 = 3.136 69 : 22 = 3.136

for 5th/6th gear

and reverse gear

1st gear

2nd gear

3rd gear

4th gear

5th gear

6th gear

Reverse

gear

in top gear 2.889 2.889 2.889

ov.

45 : 13 = 3.462 45 : 13 = 3.462 45 : 13 = 3.462

45 : 22 = 2.045 45 : 22 = 2.045 45 : 22 = 2.045

45 : 31 = 1.452 45 : 31 = 1.452 45 : 31 = 1.452

41 : 38 = 1.079 41 : 38 = 1.079 41 : 38 = 1.079

39 : 35 = 1.114 39 : 35 = 1.114 39 : 35 = 1.114

35 : 38 = 0.921 35 : 38 = 0.921 35 : 38 = 0.921

22 : 14 x 33 : 13 =

3.989

22 : 14 x 33 : 13 =

3.989

22 : 14 x 33 : 13 =

05.04

3.989

Direct shift gearbox 02E four-wheel drive

Gearbox Code letters GYV GYW HAH

Manufac‐

tured

fro

m

03.03 07.03

03.04

06.04

10.05

to

Allocation Model

Engine

Ratios Final drive I

Audi TT 1999 ▸ Audi TT 1999 ▸ Audi TT 1999 ▸

3.2 ltr. - 184 kW

6 cylinders

3.2 ltr. - 184 kW

6 cylinders

3.2 ltr. - 184 kW

6 cylinders

69 : 17 = 4.059 69 : 17 = 4.059 69 : 17 = 4.059

for 1st to 4th gear

Z2 : Z

1

Final drive II

69 : 22 = 3.136 69 : 22 = 3.136 69 : 22 = 3.136

for 5th/6th gear

Overall ratio i

and reverse gear

1st gear

2nd gear

3rd gear

4th gear

5th gear

6th gear

Reverse

gear

in top gear 2.889 2.889 2.889

ov.

45 : 13 = 3.462 45 : 13 = 3.462 45 : 13 = 3.462

45 : 22 = 2.045 45 : 22 = 2.045 45 : 22 = 2.045

45 : 31 = 1.452 45 : 31 = 1.452 41 : 28 = 1.464

41 : 38 = 1.079 41 : 38 = 1.079 41 : 38 = 1.079

39 : 35 = 1.114 39 : 35 = 1.114 35 : 32 = 1.094

35 : 38 = 0.921 35 : 38 = 0.921 35 : 38 = 0.921

22 : 14 x 33 : 13 =

3.989

22 : 14 x 33 : 13 =

3.989

22 : 14 x 33 : 13 =

3.989

Allocation: rear final drive Designation: 02D

2 Rep. Gr.00 - Technical data

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

Direct shift gearbox 02E four-wheel drive

Gearbox Code letters HQB

Manufac‐

tured

fro

m

11.05

to

Allocation Model

Engine

Audi TT 1999 ▸

3.2 ltr. - 184 kW

6 cylinders

Ratios Final drive I

69 : 17 = 4.059

for 1st to 4th gear

Z2 : Z

1

Final drive II

69 : 22 = 3.136

for 5th/6th gear

and reverse gear

Overall ratio i

1st gear

2nd gear

3rd gear

4th gear

5th gear

6th gear

Reverse

gear

in top gear 2.889

ov.

45 : 13 = 3.462

45 : 22 = 2.045

41 : 28 = 1.464

41 : 38 = 1.079

35 : 32 = 1.094

35 : 38 = 0.921

22 : 14 x 33 : 13 =

3.989

Allocation: rear final drive Designation: 02D

Audi TT 1999 ➤

2.1 Calculating ratio “i”

Example:

Drive gear ZG1 = 38 ZA1 = 22

Driven gear ZG2 = 35 ZA2 = 69

i = Z2 : Z1 (Z1 = number of teeth on drive gear, Z2 = number of

teeth on driven gear)

iG = gear ratio = ZG2 : ZG1 = 35 : 38 = 0.92

iA = axle ratio = ZA2 : ZA1 = 69 : 22 = 3.136

iov = overall ratio = iG x iA = 0.92 x 3.136 = 2.89

6th gear Final drive

2. Code letters, gearbox allocation, ratios, equipment 3

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

3 Capacities

Gearbox capacity

Capacities Direct shift gearbox 02E

Initial filling 6.9 ltr.

Oil change approx. 5.5 ltr.

Change interval ⇒ Maintenance tables

Lubricant, specification Gear oil for direct shift gearbox 02E

Part No.: ⇒ Parts catalogue

Only the gear oil available as a replacement part may be used for

the direct shift gearbox 02E. Other types of oil cause malfunctions

and/or failure of the gearbox.

When changing gear oil always renew the gear oil filter

⇒ page 86 .

Checking gear oil level and changing gear oil ⇒ page 74 .

Bevel box capacity

Capacities Bevel box

Initial filling 0.9 ltr.

Oil change Filled for life, no change

Lubricant For gear oil refer to ⇒ Parts cata‐

logue

Only the gear oil available as a replacement part may be used for

the bevel box. Other oils cause faults and/or failure of the bevel

box.

Checking oil level in bevel box ⇒ page 94 .

4 Rep. Gr.00 - Technical data

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

4 Safety precautions

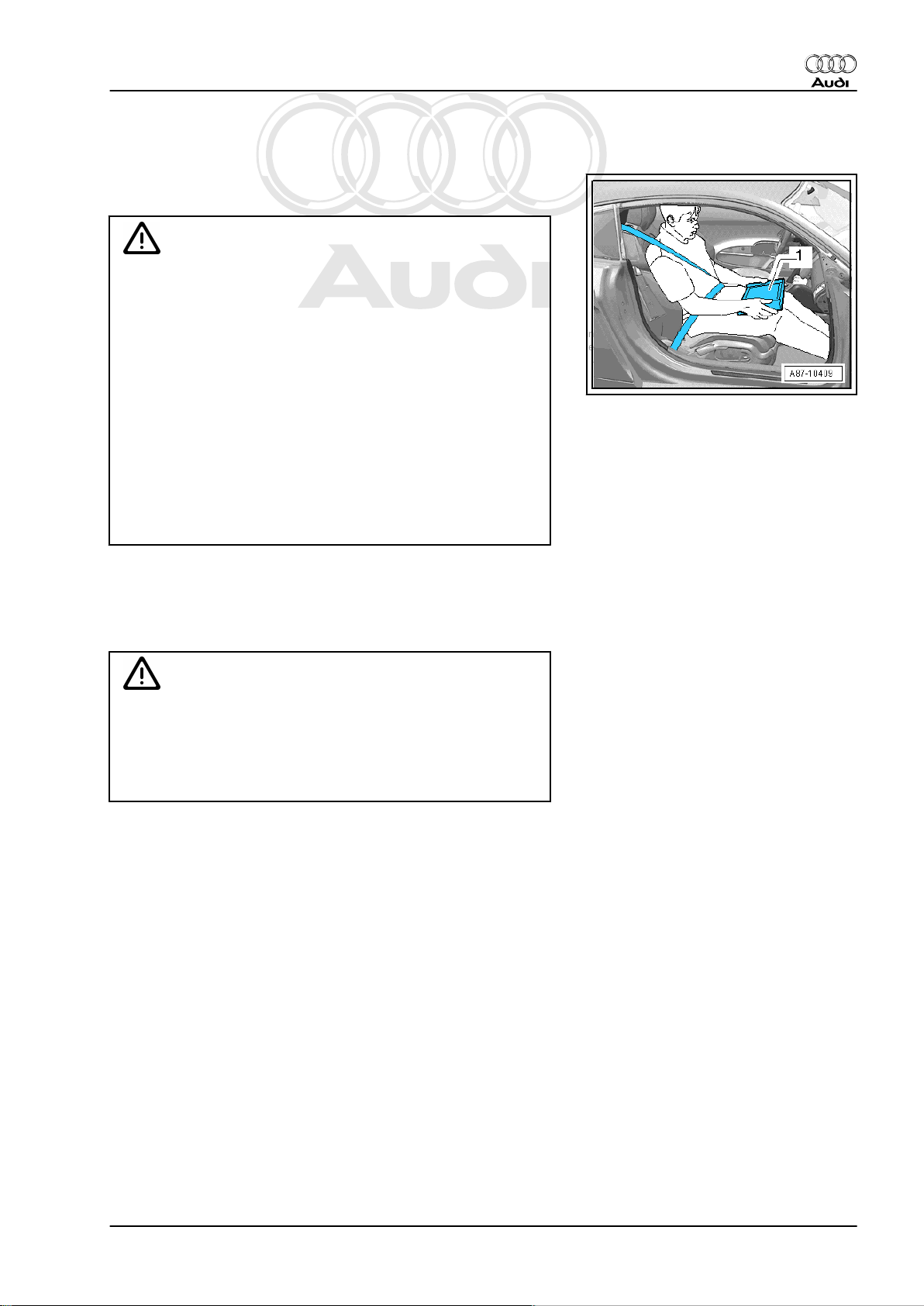

Observe the following precautions if test and measuring instru‐

ments are required during a test drive:

WARNING

Accidents can be caused if the driver is distracted by test

equipment or if test equipment is not secured.

Injuries can also be caused if the passenger's airbag is trig‐

gered in a collision.

• The use of test equipment while driving causes distraction.

• There is an increased risk of injury if test equipment is not

secured.

♦ Move the passenger's seat to the rearmost position.

♦ Use only vehicle diagnosis and service information sys‐

tem -VAS 5052- or diagnosis system -VAS 5053- .

♦ Test equipment may only be operated by the passenger;

the tester -1- must be placed flat on the passenger's lap

as illustrated.

Audi TT 1999 ➤

Observe the following precautions to avoid possible injury and/or

the destruction of electrical and electronic components:

♦ Switch off ignition before disconnecting and connecting test

equipment.

Caution

♦ Follow steps required when disconnecting battery ⇒ Elec‐

trical system; Rep. Gr. 27 .

♦ Always switch off ignition before disconnecting or con‐

necting the battery to ensure gearbox control unit is not

damaged.

4. Safety precautions 5

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

5 Notes on the direct shift gearbox 02E

5.1 General notes

Gearbox

The direct shift gearbox 02E is also referred to as a dual-clutch

gearbox. The engine torque is transferred to the gearbox via the

dual-mass flywheel. The layout of the gearbox is basically similar

to that of a 6-speed manual gearbox. The two multi-plate "wet"

clutches are regulated hydraulically and actuated alternately so

that the gearbox is operated like an automatic gearbox, i.e. the

gears are engaged automatically (or manually via the tiptronic

function). There is no clutch pedal. For further information please

refer to ⇒ Self-study programme No. 308 ; Direct shift

gearbox 02E .

Selector mechanism

The selector lever position is no longer transmitted mechanically

via the selector lever cable and multi-function switch (driving

range sensor) as on the automatic gearbox. The selector lever

positions and gear changes are transmitted to the gearbox control

unit by a separate selector mechanism control unit via CAN bus.

This means that gear shifts are effected without a cable. Excep‐

tion: In selector lever position “P” the selector lever cable is used

to mechanically engage the parking lock.

Gear oil

The gear oil level in gearbox and final drive (front) is checked and

topped up together ⇒ page 74 .

♦ Only the oil available as a replacement part may be used in

the direct shift gearbox 02E. Other types of oil will cause mal‐

functions and/or failure of the gearbox; for Part No. refer to

⇒ page 4 .

The oil level in the bevel box is checked and topped up separately

⇒ page 94 .

♦ Only the gear oil available as a replacement part may be used

for the bevel box. Other oils cause faults and/or failure of the

bevel box.

Regulations for the disposal of oil

Make sure that used oil is taken to the appropriate collection cen‐

tre for recycling.

♦ Improper disposal of used oil endangers the environment.

♦ It is forbidden to add solvents, brake fluid, coolant or similar.

♦ Please observe the information shown on the packaging of the

oil.

Variation of gear-change points for gradients

An additional gear change map automatically selects gear

changes for gradients depending on accelerator pedal position

and driving speed.

• Gear change map for extreme uphill gradients is matched to

engine output

• Gear change map for extreme downhill gradients is matched

to the braking effect of the engine

• Increased engine braking effect can also be obtained by di‐

rectly selecting a specific gear via the tiptronic function, e.g.

when towing a trailer on downhill gradients.

6 Rep. Gr.00 - Technical data

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

5.2 Safety functions of gearbox control unit

In the event of a failure of one or more components/sensors, the

gearbox control unit will activate appropriate backup functions.

This ensures that the gearbox will not be damaged, however, the

function and quality of the gear shifts will be impaired.

Faults detected by the gearbox are classified in four different cat‐

egories.

♦ 1) The fault is stored and a backup programme enables the

vehicle to drive on (in some cases with restrictions). The driver

will not be made aware of the problem, as it is not critical to

driving safety or to the gearbox itself. The gear selection indi‐

cator in the instrument cluster will continue to show the selec‐

tor lever position currently engaged in the normal way. If at all,

the driver will only notice the fault if he experiences driveability

problems, and will then automatically contact an Audi Service

Partner to identify the cause.

♦ 2) Certain positions on the gear selection indicator in the in‐

strument cluster start to flash. This is to inform the driver that

this particular selector lever position is currently not available.

Example: position “D” is not available when selector lever is in

position “R” and vehicle is still rolling backwards. In this case,

selector lever position “D” will start to flash on the gear selec‐

tion indicator in the instrument cluster. The gearbox control

unit prevents the 1st gear from being engaged in order to avoid

damage to the gearbox. 1st gear will be engaged once the

vehicle has come to a standstill.

♦ 3) The complete gear selection indicator in the instrument

cluster is lit up and flashing. The current selector lever position

is indicated in the instrument cluster (e.g. “D” is highlighted).

This is an indication that the gearbox has been overloaded or

the maximum temperature in the gearbox has been exceeded

(overheating), e.g. towing a load that was too heavy.

♦ 4) If the complete gear selection indicator in the instrument

cluster is lit up and flashing, this means that a serious fault in

the gearbox has been identified. The display in the instrument

cluster no longer shows the current selector lever position. The

defect is critical with regard to driving safety or the gearbox

itself. It may no longer be possible to use all gears. The driver

is made aware by the flashing gear selection indicator that he

should immediately contact an Audi Service Partner.

Audi TT 1999 ➤

5. Notes on the direct shift gearbox 02E 7

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

6 Notes on tow-starting and towing

WARNING

If the vehicle has to be towed, the selector lever must be set to

position N and the vehicle must not to be towed further than

50 km or at a speed in excess of 50 km/h, as the gearbox would

otherwise suffer irreparable damage.

Note

It is not possible to start the engine by means of tow-starting, for

instance in the case of insufficient battery charge or if the starter

is not working.

8 Rep. Gr.00 - Technical data

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

7 Repair instructions

7.1 Contact corrosion!

Contact corrosion can occur if non-approved fasteners are used

on the vehicle (bolts, nuts, washers etc.).

For this reason, only fasteners with a special surface coating are

fitted.

Rubber or plastic parts and adhesives also consist of non-con‐

ductive materials.

If you are not sure whether used parts can be re-installed, always

fit new parts ⇒ Parts catalogue .

Please note:

♦ Use only genuine spare parts: these have been fully tested

and are compatible with aluminium.

♦ We recommend the use of accessories approved by Audi.

♦ Damage resulting from contact corrosion is not covered by the

warranty.

Audi TT 1999 ➤

7.2 General notes

Proper tools and the maximum possible care and cleanliness are

essential for satisfactory gearbox repairs. The usual basic safety

precautions also naturally apply when carrying out repair work.

To avoid repetition, a number of generally applicable instructions

for the various repair procedures are summarised here. They ap‐

ply to the work described in this Manual.

7. Repair instructions 9

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

Guided fault finding, vehicle self-diagnosis and testing system

♦ Before servicing the gearbox, the exact cause of the failure

must be determined using the functions “Guided Fault Find‐

ing”, “Vehicle Self-diagnosis” and “Test Instruments” ⇒ Vehicle

diagnosis, testing and information system VAS 5051.

Special tools

For a complete list of special tools used in this Workshop Manual

⇒ "Special tools, Workshop equipment"

Gearbox

♦ Do not run the engine or tow the vehicle with the oil pan re‐

moved or when there is no gear oil in the gearbox.

♦ When renewing the gearbox the gear oil ⇒ page 74 must be

checked and topped up, if necessary. Filling quantities and

specification ⇒ page 4 .

♦ Thoroughly clean all joints and surrounding areas before dis‐

mantling.

♦ When installing gearbox, ensure that dowel sleeves are fitted

correctly.

O-rings, oil seals and gaskets

♦ Always renew O-rings, oil seals and gaskets.

♦ After removing gaskets and seals, always inspect the contact

surface on the housing or shaft for burrs resulting from removal

or for other signs of damage.

♦ Always replace paper gaskets. Completely remove old gasket

and clean sealing surfaces thoroughly.

♦ Lightly lubricate the outer circumference and sealing lip of oil

seals with gear oil before installing.

♦ Lightly lubricate O-rings with gear oil or vaseline before instal‐

lation to prevent them from getting crushed during assembly.

♦ Do not use any other lubricants where gear oil is used. Oth‐

erwise, there is a risk of problems occurring in the gearbox

hydraulics.

♦ The open side of the oil seals faces toward the side with fluid

filling.

♦ Observe rules for cleanliness ⇒ page 12 .

♦ After installing, check gear oil level, adjust to correct level if

necessary ⇒ page 74 .

Locking elements

♦ Do not overstretch circlips; renew if necessary.

♦ Circlips must be properly seated in the base of the groove.

Nuts, bolts

♦ Loosen bolts in reverse sequence to the specified tightening

sequence.

♦ Nuts and bolts which secure covers and housings should be

loosened and tightened in diagonal sequence and in stages if

no tightening sequence is specified.

♦ Renew self-locking nuts.

♦ Use a wire brush to clean the threads of bolts which are se‐

cured with locking fluid. Then apply locking fluid AMV 185 101 A1- to bolt threads before installing.

10 Rep. Gr.00 - Technical data

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

♦ The tightening torques stated apply to non-oiled nuts and

bolts.

Audi TT 1999 ➤

7. Repair instructions 11

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

8 Rules for cleanliness when working

on the gearbox

♦ Thoroughly clean all joints and surrounding areas before dis‐

mantling.

♦ Place removed parts on a clean surface and cover them over.

Use sheeting and paper. Use lint-free cloths.

♦ Carefully cover or seal open components if repairs cannot be

carried out immediately.

♦ Only install clean components: do not remove replacement

parts from packaging until just before installation.

♦ Always renew O-rings, oil seals and gaskets.

♦ Always replace paper gaskets. Completely remove old gasket

and clean sealing surfaces thoroughly.

♦ Use a wire brush to clean the threads of bolts which are se‐

cured with locking fluid. Then apply locking fluid AMV 185 101 A1- to bolt threads before installing.

12 Rep. Gr.00 - Technical data

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

30 – Clutch

1 Servicing multiple clutch

♦ The clutch in the direct shift gearbox 02E consists of two sets

of plates, and is therefore referred to as a “multiple clutch”. The

larger set of plates (located on the outside) is designated

“K 1” (clutch 1), and controls the torque flow for reverse gear

and gears “1”, “3” and “5”. The smaller set of plates (on the

inside) is designated “K 2” (clutch 2), and controls the torque

flow for gears “2”, “4” and “6”.

♦ Any work performed on the multiple clutch requires extra care:

all the parts are balanced and matched together in production.

If the components are rotated out of their original positions

when repairing, this will cause imbalance and impair the

smoothness of the gearchanges and reduce the service life of

the unit.

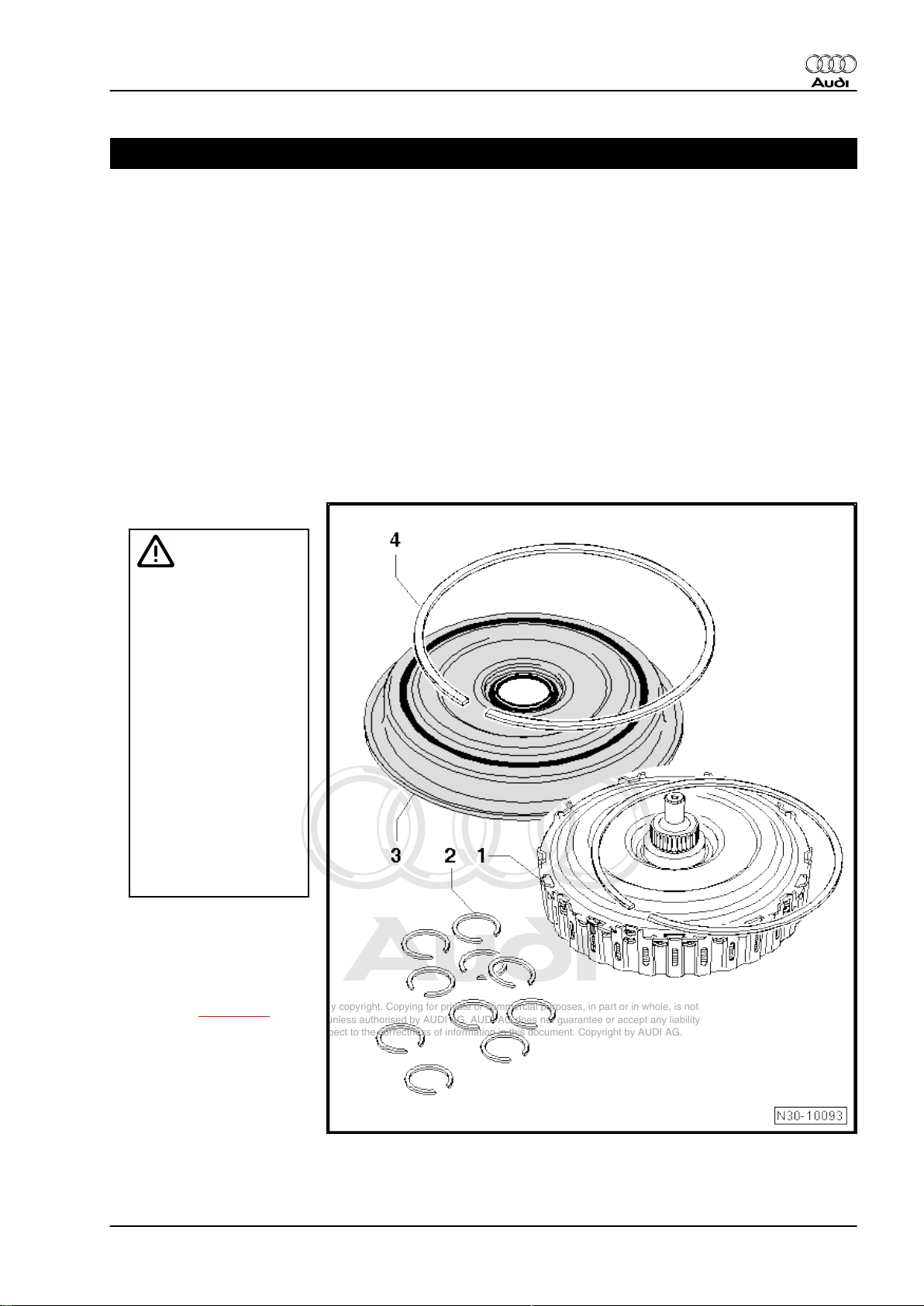

1.1 Multiple clutch - exploded view of components (replacement parts)

1 - Multiple clutch with circlip

Caution

♦The drive plate (top sec‐

tion of multiple clutch) of

a new clutch is not se‐

cured with the circlip, it is

only a “close fit” in the

clutch.

♦The drive plate must re‐

main engaged between

the splines of the outer

plate carrier.

♦If the drive plate comes

loose, the clutch plates

can slip out of position in‐

side the multiple clutch

unit. If this happens, it

may not be possible to

adjust the multiple clutch

correctly during installa‐

tion.

2 - Circlip

❑ 10 x, with different thick‐

nesses for adjusting

❑ Determine circlip thick‐

ness when installing

clutch ⇒ page 20

3 - Clutch end cover

4 - Circlip for clutch end cover

1. Servicing multiple clutch 13

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

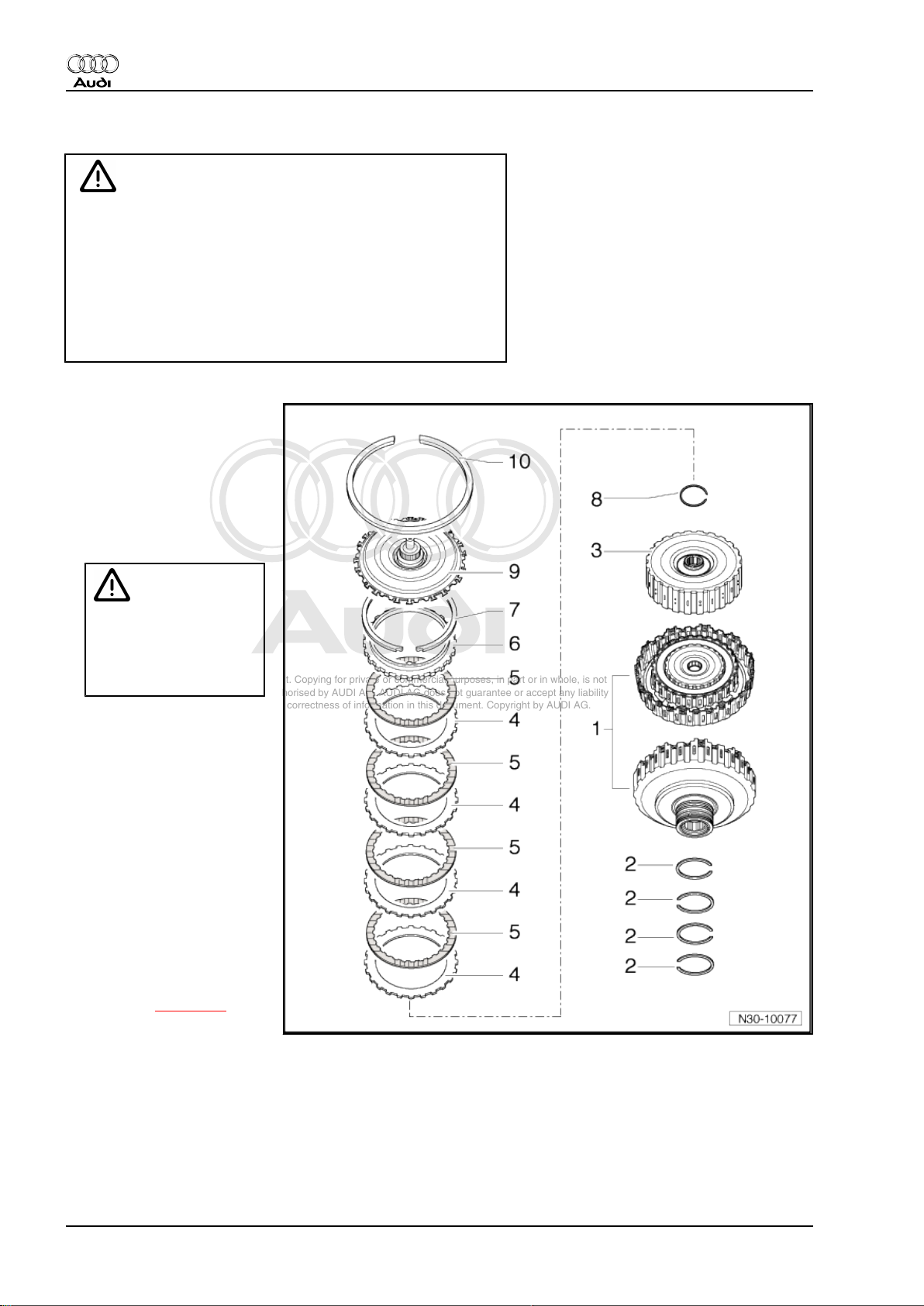

Dismantled multiple clutch - exploded view of components

Caution

♦ This illustration serves only as an overview of compo‐

nents; at the present time the multiple clutch must NOT be

dismantled, as all outer and inner plates are matched and

balanced before installation.

♦ If the drive plate is loosened, the plates can slip out of

position inside the multiple clutch unit. If this happens, it

may not be possible to adjust the multiple clutch correctly

during installation.

1 - Multiple clutch/clutch hous‐

ing

❑ Outer plate carrier

2 - Oil seals

❑ 4x

3 - Inner plate carrier

❑ Do not remove

Caution

DO NOT remove or lift up

the inner plate carrier.

This could cause the

plates to move out of

their original positions.

4 - Outer plates

❑ 4x

5 - Inner plates

❑ 4x

6 - Thrust washer

7 - Circlip

❑ Fit a new circlip of the

same thickness if the

original circlip is re‐

moved in order to re-in‐

stall the clutch plates.

8 - Circlip

❑ Re-determine thickness

when installing a new

clutch ⇒ page 20

9 - Drive plate

10 - Circlip

❑ Renew

1.2 Removing and installing multiple clutch

Special tools and workshop equipment required

14 Rep. Gr.30 - Clutch

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

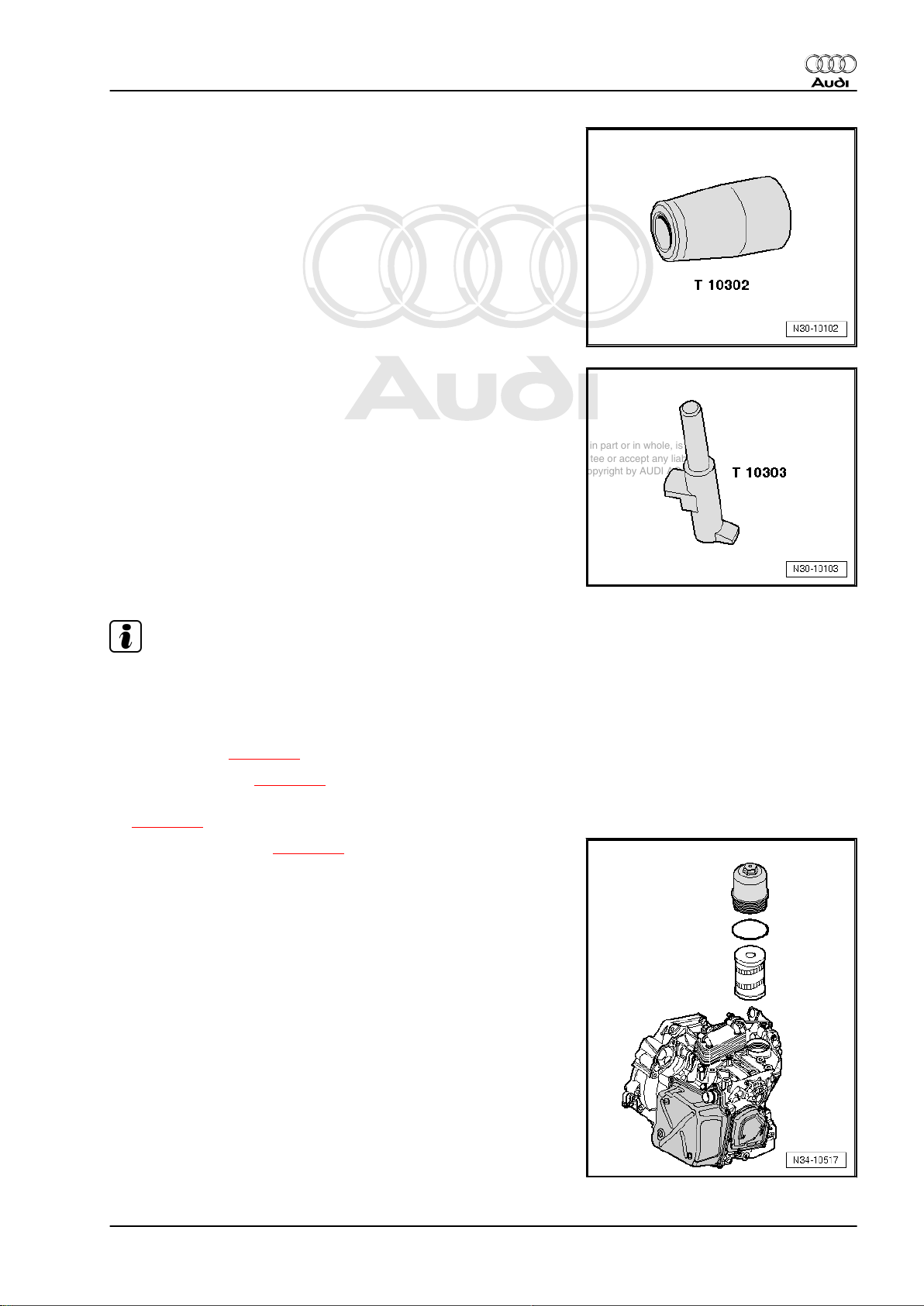

♦ Assembly sleeve -T10302-

♦ Retaining pin -T10303-

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

Note

Assembly sleeve -T10302- must be cleaned before use; do not

use an assembly sleeve if it is scratched.

Removing clutch end cover

– Drain gear oil ⇒ page 80 .

– Remove gearbox ⇒ page 61 .

– Secure gearbox to assembly stand in vertical position

⇒ page 72 .

– Renew gear oil filter ⇒ page 86 .

1. Servicing multiple clutch 15

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

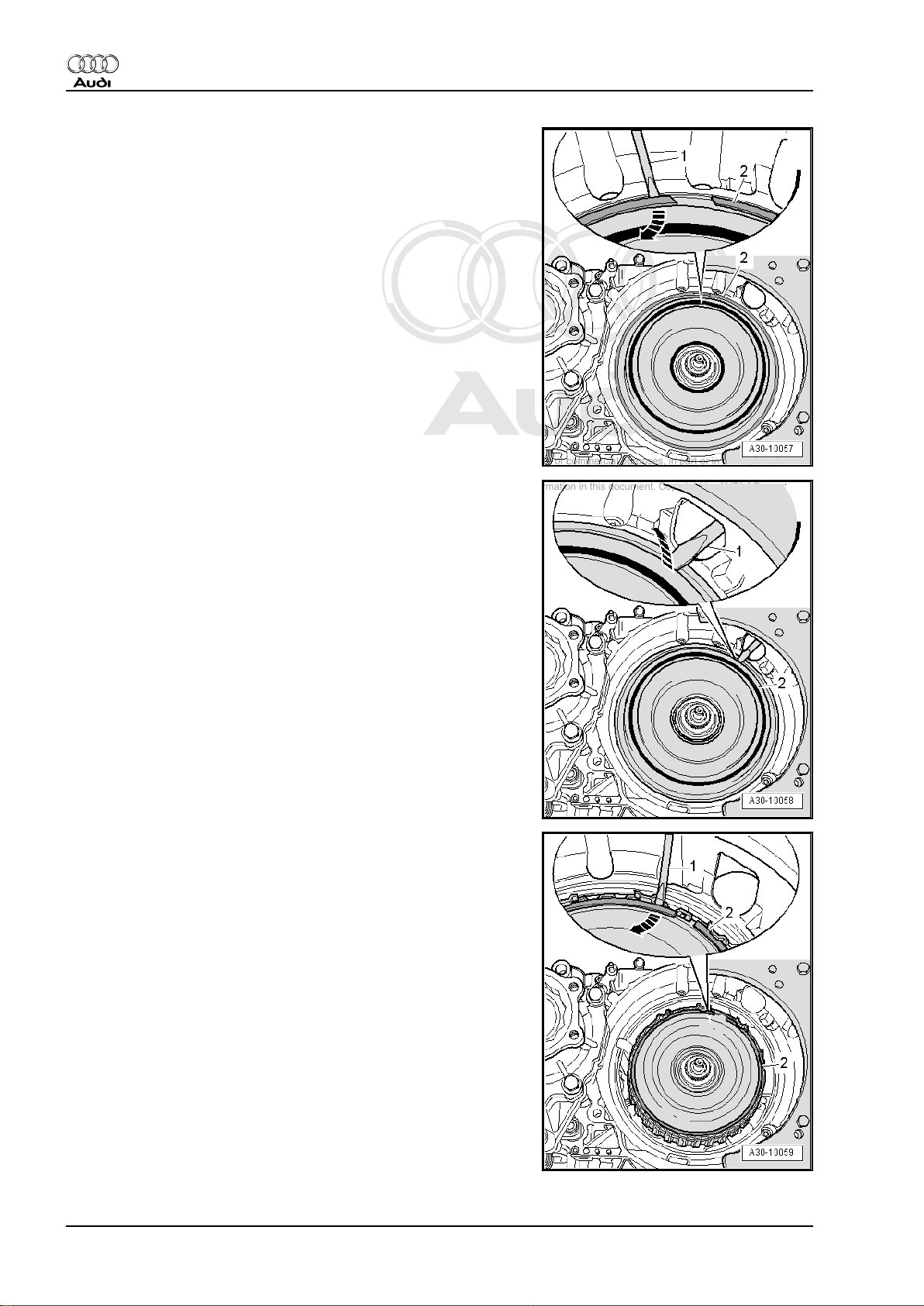

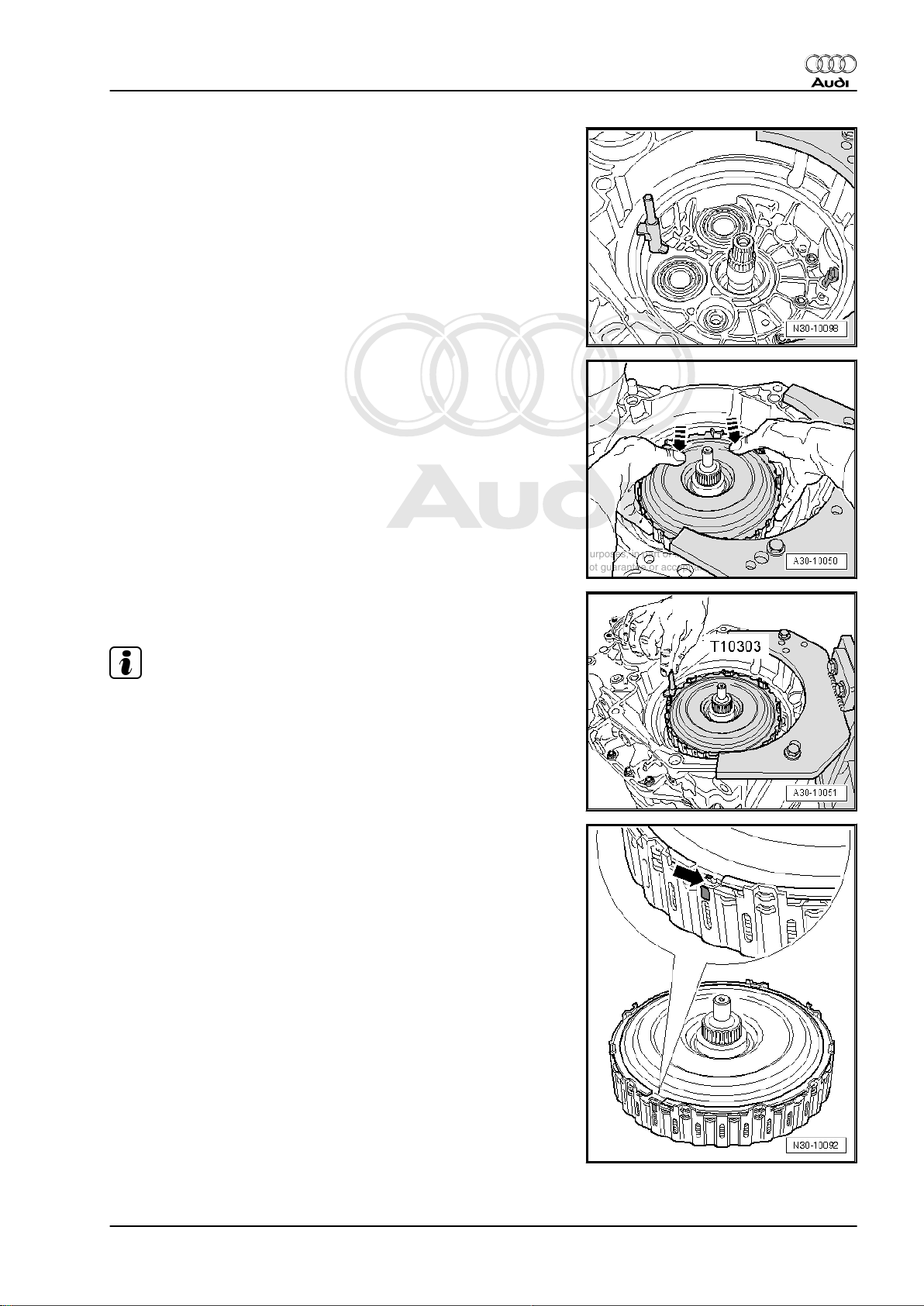

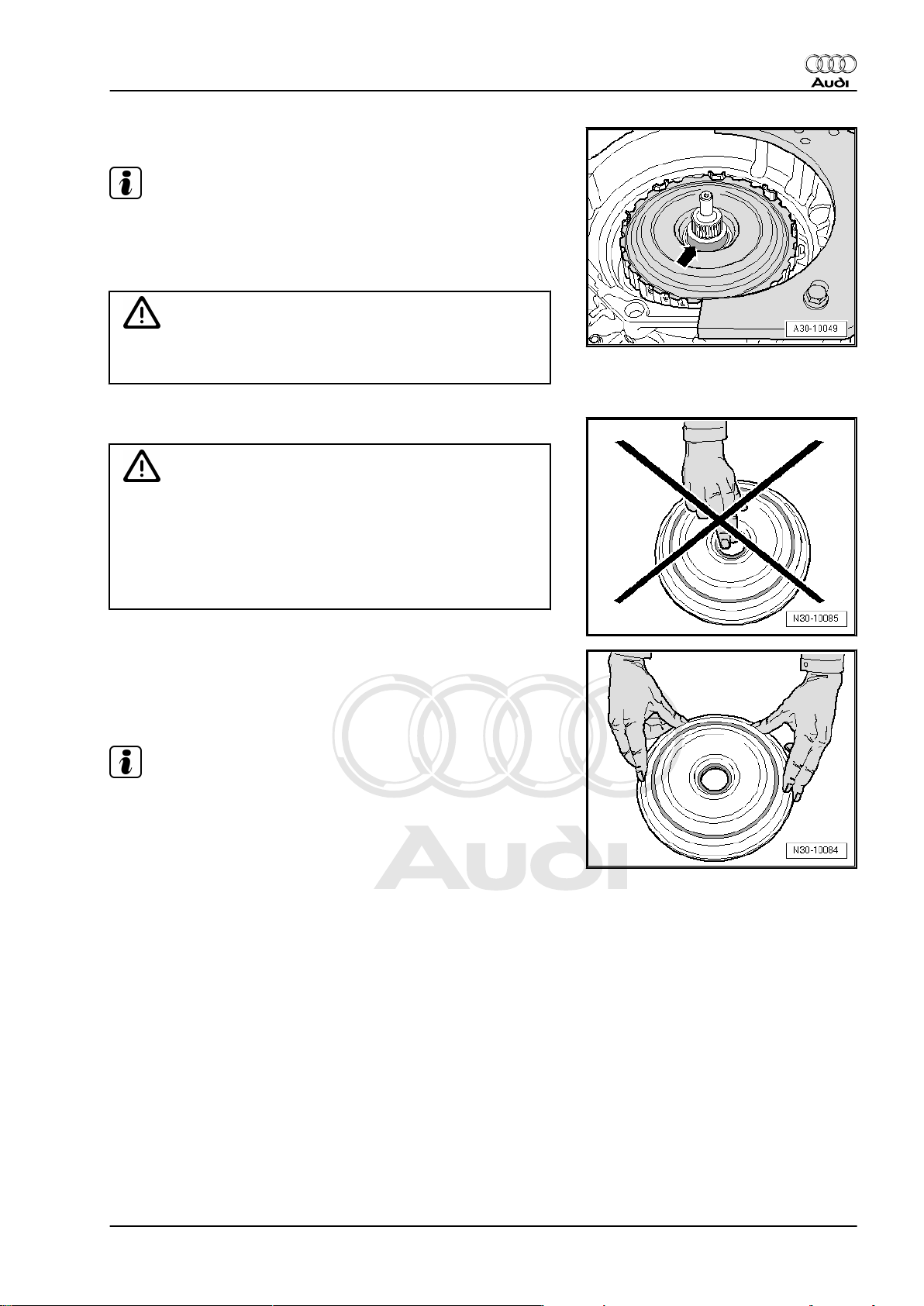

– Using a screwdriver -1-, pry out circlip -2- for clutch end cover

-arrow- and take out circlip.

– Working through opening for starter motor, pry off clutch end

cover -2- using a screwdriver -1- or suitable lever -arrow- and

take off clutch end cover.

Removing multiple clutch

– Pry out circlip -2- using a screwdriver -1- -arrow-.

16 Rep. Gr.30 - Clutch

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

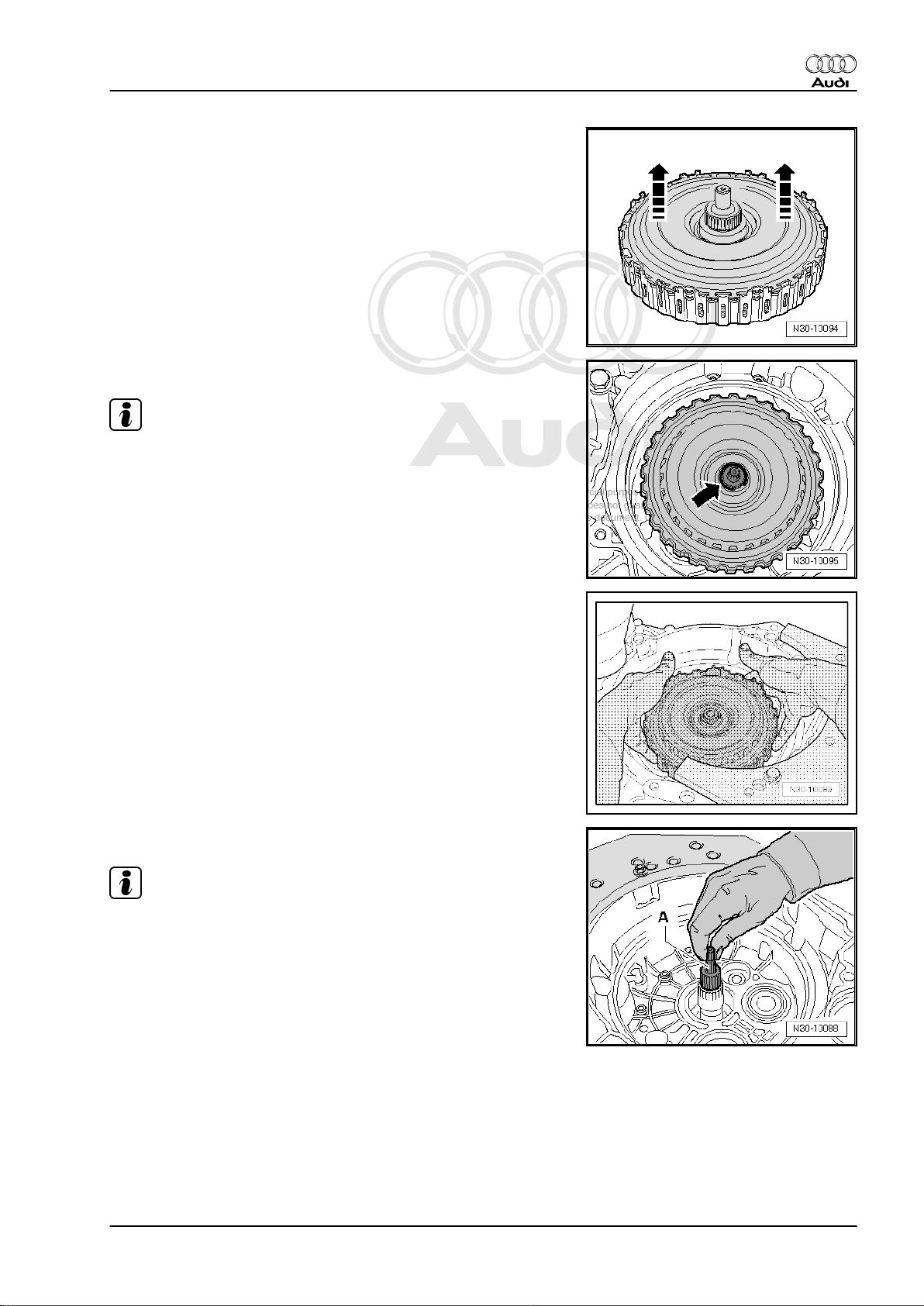

– Remove drive plate -arrows-.

– Use screwdriver or suitable pliers to pry out circlip -arrow-.

Note

This circlip must be replaced with a new circlip of the correct

thickness when re-assembling.

Audi TT 1999 ➤

– Take out multiple clutch.

– After removing multiple clutch, check clutch bellhousing for

damage caused during removal.

– Pull out pump shaft -A-.

Note

The pump shaft is not re-installed until after the new clutch has

been fitted. Keep the shaft in a suitable place until it is required.

1. Servicing multiple clutch 17

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

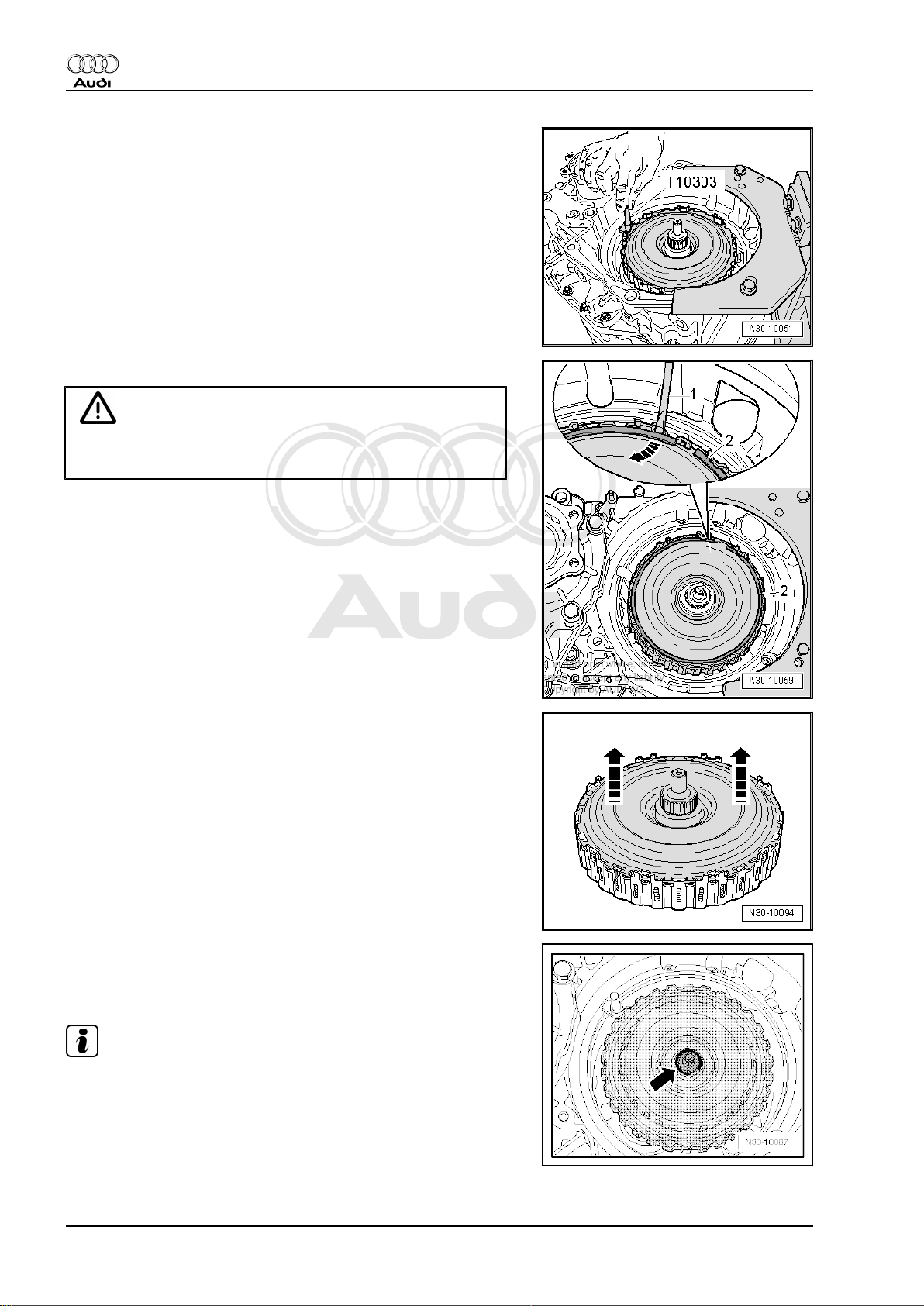

Installing multiple clutch

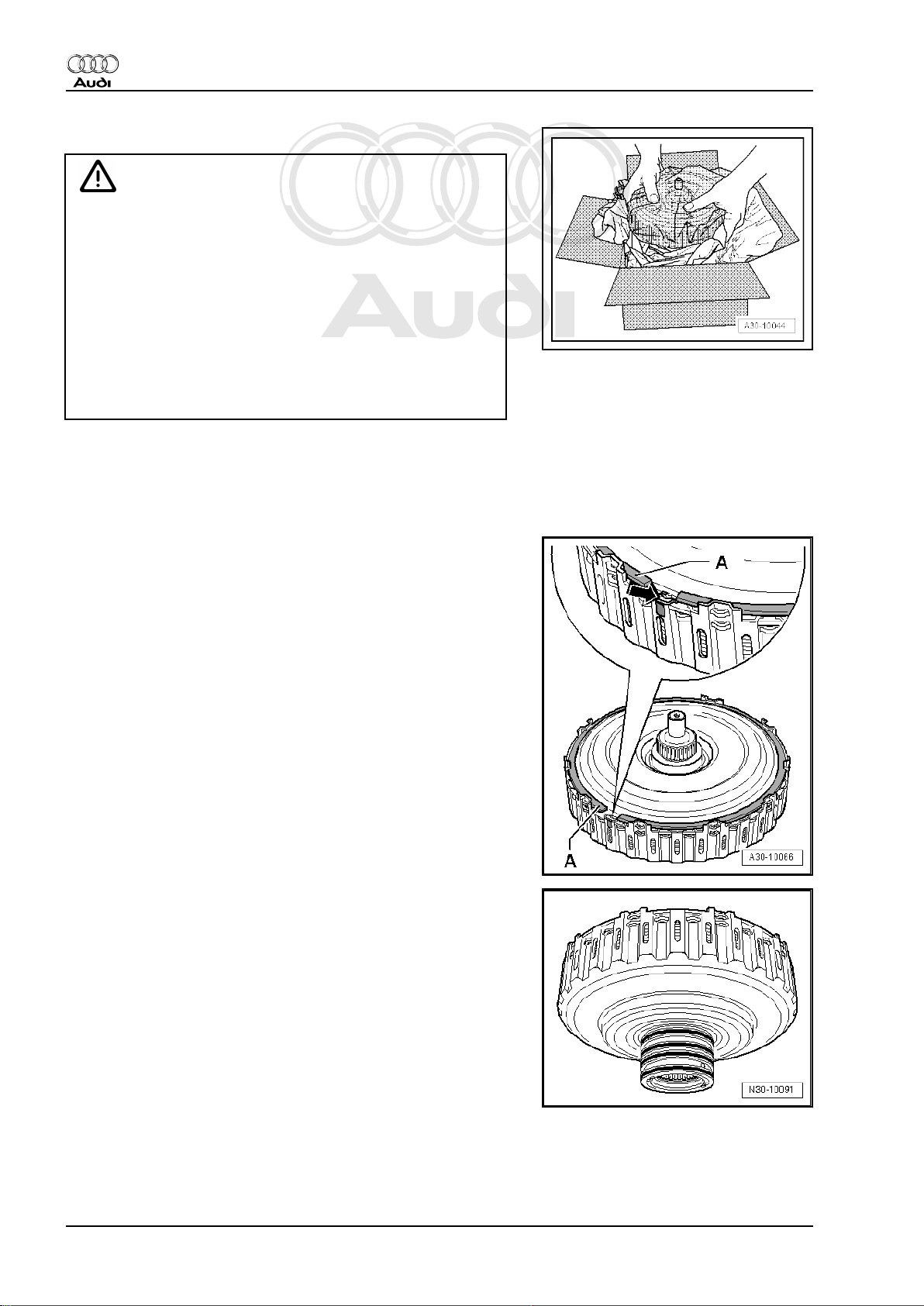

Caution

♦ The drive plate of a new clutch is not secured with a circlip;

it is only a “close fit” in the clutch.

♦ While carrying out the following steps you must therefore

hold the drive plate by pressing it into the outer plate car‐

rier with both thumbs.

♦ The drive plate must remain engaged between the splines

of the outer plate carrier.

♦ If the drive plate comes loose, the clutch plates can slip

out of position inside the multiple clutch unit. If this hap‐

pens, it may not be possible to adjust the multiple clutch

correctly during installation.

– Take the circlip out of the packaging.

– Take the clutch for direct shift gearbox out of the packaging,

at the same time pressing the drive plate into the outer plate

carrier with both thumbs.

– Secure drive plate in outer plate carrier with “old” circlip -A-

from removed clutch.

• Do NOT use the new circlip supplied when carrying out this

installation.

• The circlip must be installed so that the lug on the drive plate

-arrow- and the colour-marked splines on the outer plate car‐

rier are located between the two ends of the circlip.

• The circlip must be fully engaged all round.

– Check that the 4 oil seals on the hub on the underside of the

multiple clutch are correctly seated; engage in position if nec‐

essary.

• The joints of the seals should be offset and not aligned one

above the other.

18 Rep. Gr.30 - Clutch

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

– Apply retaining pin -T10303- to seat of clutch end cover as

illustrated.

– Install multiple clutch in clutch bell housing (turn and move up

and down as required); do not allow clutch to drop into place.

While doing this, keep the drive plate pressed into the outer

plate carrier with both thumbs -arrows-.

Audi TT 1999 ➤

• During this procedure the retaining pin -T10303- must be held

in place by a 2nd mechanic.

Note

♦

The retaining pin remains in position until the clutch end cover

is installed.

♦

The multiple clutch must not be turned from this point onwards,

as this would turn the retaining pin -T10303- out of position.

– Check whether the projecting lug -arrow- on the drive plate is

positioned between the colour-marked splines on the outer

plate carrier.

If no markings are provided:

– Mark position of projecting lug in relation to outer rim of outer

plate carrier with waterproof pen as illustrated.

1. Servicing multiple clutch 19

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

• When re-assembling, the lug on the drive plate must be loca‐

ted again at this marked position.

• While carrying out the following two steps the retaining pin T10303- must be held in place by a 2nd mechanic.

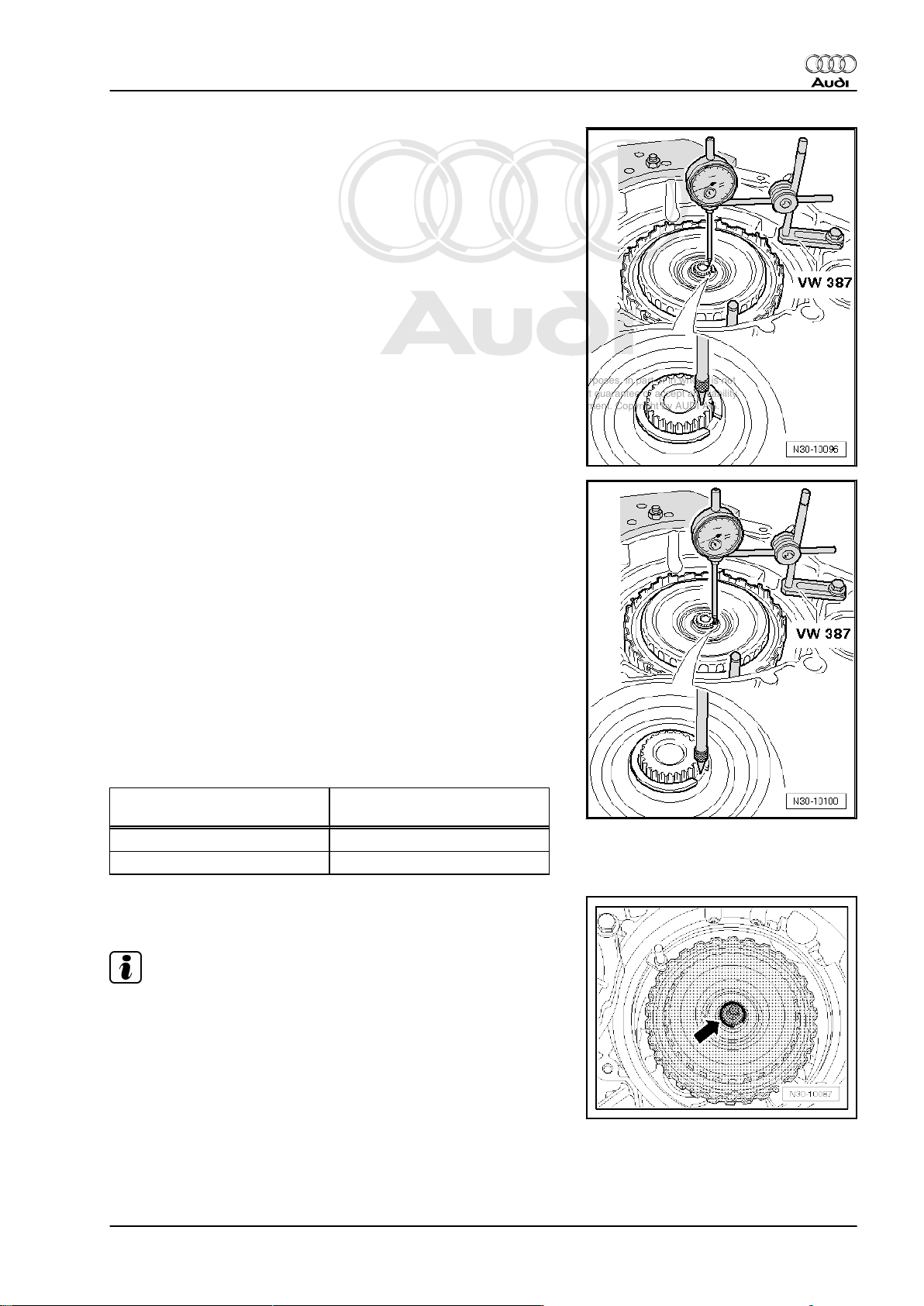

– Pry out the old circlip -2- using a screwdriver -1- -arrow-.

Caution

DO NOT remove or lift up the inner plate carrier. This could

cause the plates to move out of their original positions.

– After installing clutch, lift out drive plate -arrows-; if necessary

pry drive plate carefully out of splines on outer plate carrier

using a screwdriver.

– Lay drive plate aside.

Determining thickness of circlip for multiple clutch

– Select the 2 mm thick circlip from the circlips supplied with the

clutch and fit this circlip as shown -arrow-.

Note

This circlip is installed provisionally in order to measure the axial

play.

20 Rep. Gr.30 - Clutch

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

– Bolt universal dial gauge bracket -VW 387- onto gearbox

flange.

– For 1st measurement, apply tip of dial gauge to end of input

shaft as shown in illustration.

– Set dial gauge to “0” with a preload of 2 mm.

– Lift up clutch as far as it will go and note dial gauge reading (=

axial play of input shaft).

– For 2nd measurement, apply tip of dial gauge to hub of inner

plate carrier as shown in illustration.

• The tip of the dial gauge must not contact the circlip.

– Set dial gauge to “0” with a preload of 2 mm.

– Lift up clutch again as far as it will go and note dial gauge

reading.

The thickness of the new circlip is calculated according to the fol‐

lowing formula:

2nd measurement – 1st measurement + 1.85 mm = thickness

of circlip

The thickness of the new circlips -02E 311 321- is graduated in

steps of 0.1 mm. When selecting the required circlip, round up or

down to the nearest 10th of a millimetre as required. In other

words, values up to 0.049 are rounded down and values of 0.05

and above are rounded up.

Audi TT 1999 ➤

Calculated thickness of new cir‐

New circlip

clip

2.27 mm 2.3 mm

2.24 mm 2.2 mm

– Remove provisionally fitted circlip (2.0 mm) and fit new circlip

with thickness as calculated above.

Note

♦

If the calculated thickness of the new circlip is exactly 2.0 mm,

the circlip fitted previously for taking the measurement does

not have to be removed.

♦

All remaining circlips should be disposed of.

♦

Circlips may not be used more than once.

1. Servicing multiple clutch 21

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

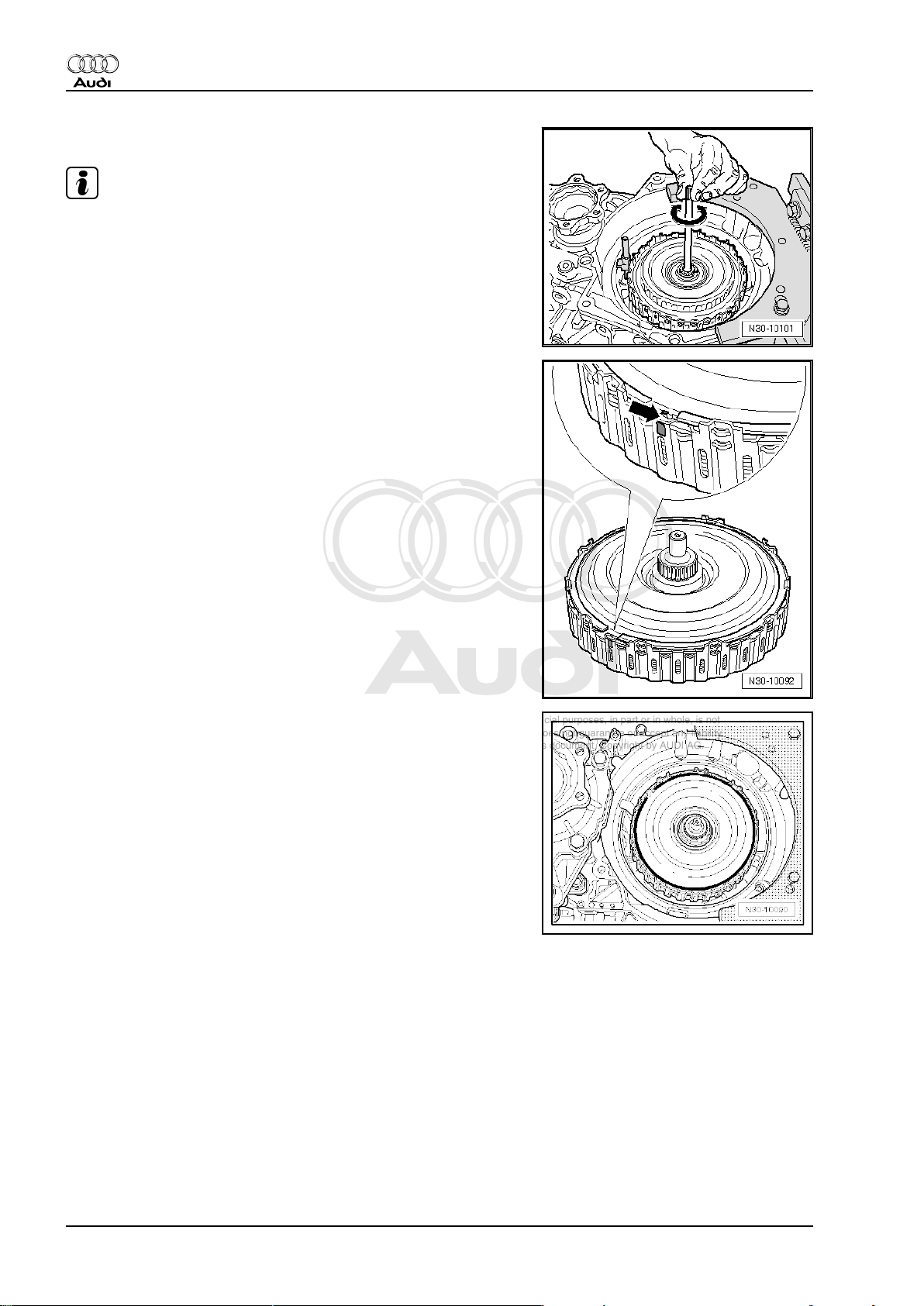

– Insert pump shaft.

Note

When installing, lift the shaft and turn it slightly -arrow- so that it

slides in and engages fully in the splines.

– Install drive plate in multiple clutch.

• The projecting lug on the drive plate must be positioned be‐

tween the colour-marked splines on the outer plate carrier.

Alternatively, align the new markings made earlier in this pro‐

cedure.

– Install new circlip securing drive plate.

• The circlip must be installed so that the lug on the drive plate

and the colour-marked splines on the outer plate carrier are

located between the two ends of the circlip.

• The circlip must be fully engaged all round.

– Use a screwdriver to check that the circlip is properly seated

and fully engaged.

– Take out retaining pin -T10303- between multiple clutch and

housing.

22 Rep. Gr.30 - Clutch

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

Installing clutch end cover

Note

Renew clutch end cover and circlip.

– Thoroughly degrease running surface -arrow- on drive plate

for oil seal of clutch end cover.

Caution

The contact surfaces of the clutch end cover must be cleaned

very thoroughly, otherwise leaks can occur.

– Clean contact surface for outer seal of clutch end cover.

Caution

♦ Do not touch the seal inside the opening in the clutch end

cover. This seal will only seal properly if the running sur‐

face is absolutely free of grease when installed.

Audi TT 1999 ➤

♦ Do not apply hammer blows directly to the clutch end cov‐

er. Any force applied to the inner part of the clutch end

cover will cause malfunctions.

– Take the new clutch end cover out of its packaging. Always

take hold of the outside of the clutch end cover, as illustrated.

DO NOT touch the seal inside the cover.

– Clean end of gearbox shaft if necessary.

Note

♦

Lightly lubricate the outer seal only.

♦

If there are any stickers on the inside or the outside of the end

cover, remove them thoroughly.

1. Servicing multiple clutch 23

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

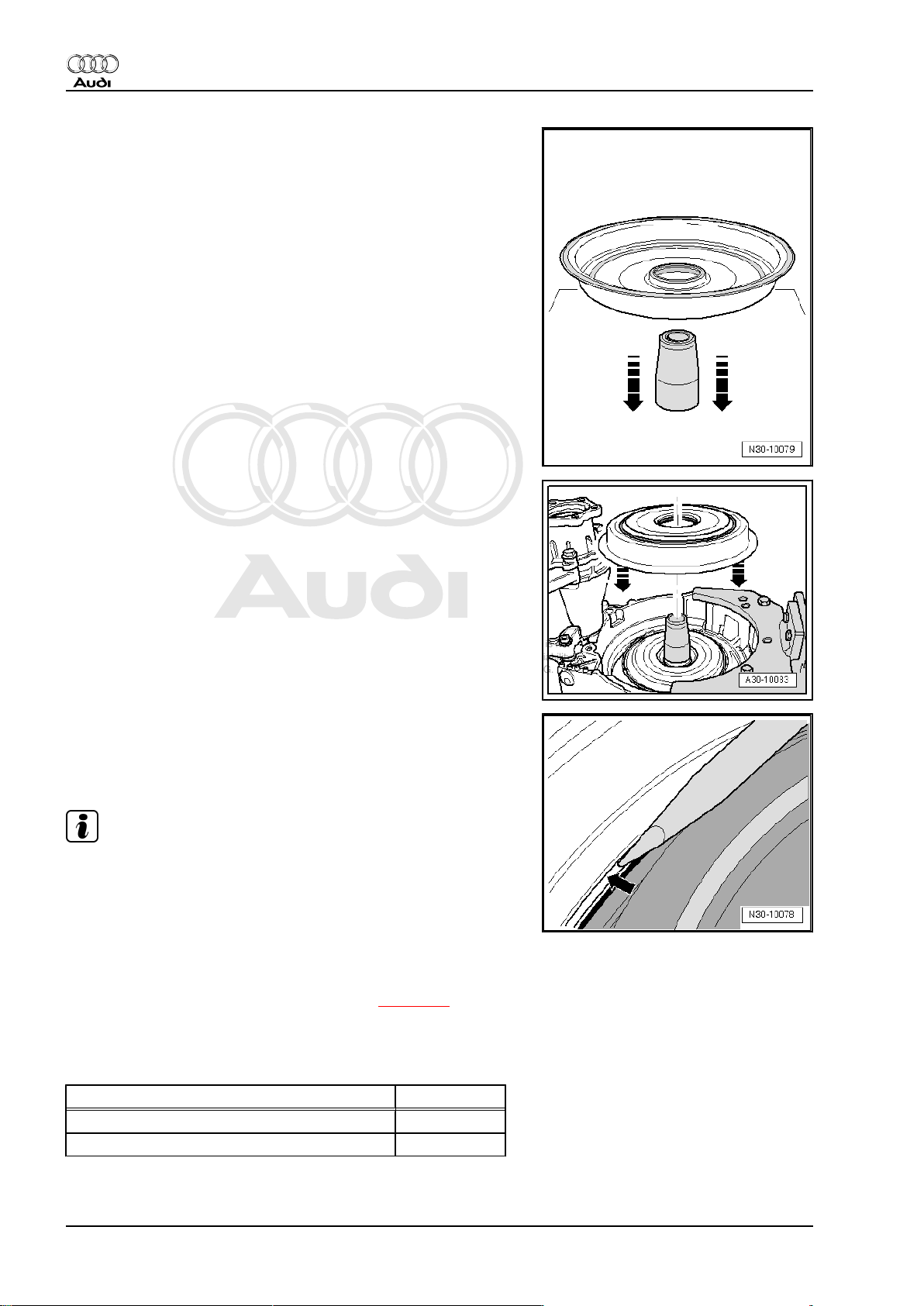

– Place assembly sleeve -T10302- on a flat surface.

– The seal in the centre of the clutch end cover must be pre-

formed before installation; this is done by guiding the new

clutch end cover with the outside pointing downwards hori‐

zontally and evenly over the entire length of the assembly

sleeve -arrows-.

– Remove assembly sleeve upwards from clutch end cover and

fit assembly sleeve onto end of clutch shaft.

– Guide clutch end cover with the outside pointing upwards hor‐

izontally over sleeve -arrows- and press cover evenly onto its

seat.

– If necessary use a screwdriver to lever the clutch end cover

carefully into its seat, as illustrated, so that the new circlip can

be fitted.

– Install “new” circlip for clutch end cover into gearbox housing.

Note

To make sure circlip remains in groove always counterhold on

opposite side if necessary.

• The circlip must be fully engaged all round and must be prop‐

erly seated in the base of the groove.

– Use a screwdriver to check that the circlip is properly seated

and fully engaged.

– Fill up with gear oil for direct shift gearbox ⇒ page 80 .

– After installing gearbox, perform basic setting of mechatronic

unit for direct shift gearbox -J743- .

Tightening torques

Component Nm

Drain plug to gearbox, M24 45

Oil filter housing to gearbox 20

24 Rep. Gr.30 - Clutch

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

34 – Controls, housing

1 Electrical/electronic components and fit‐

ting locations

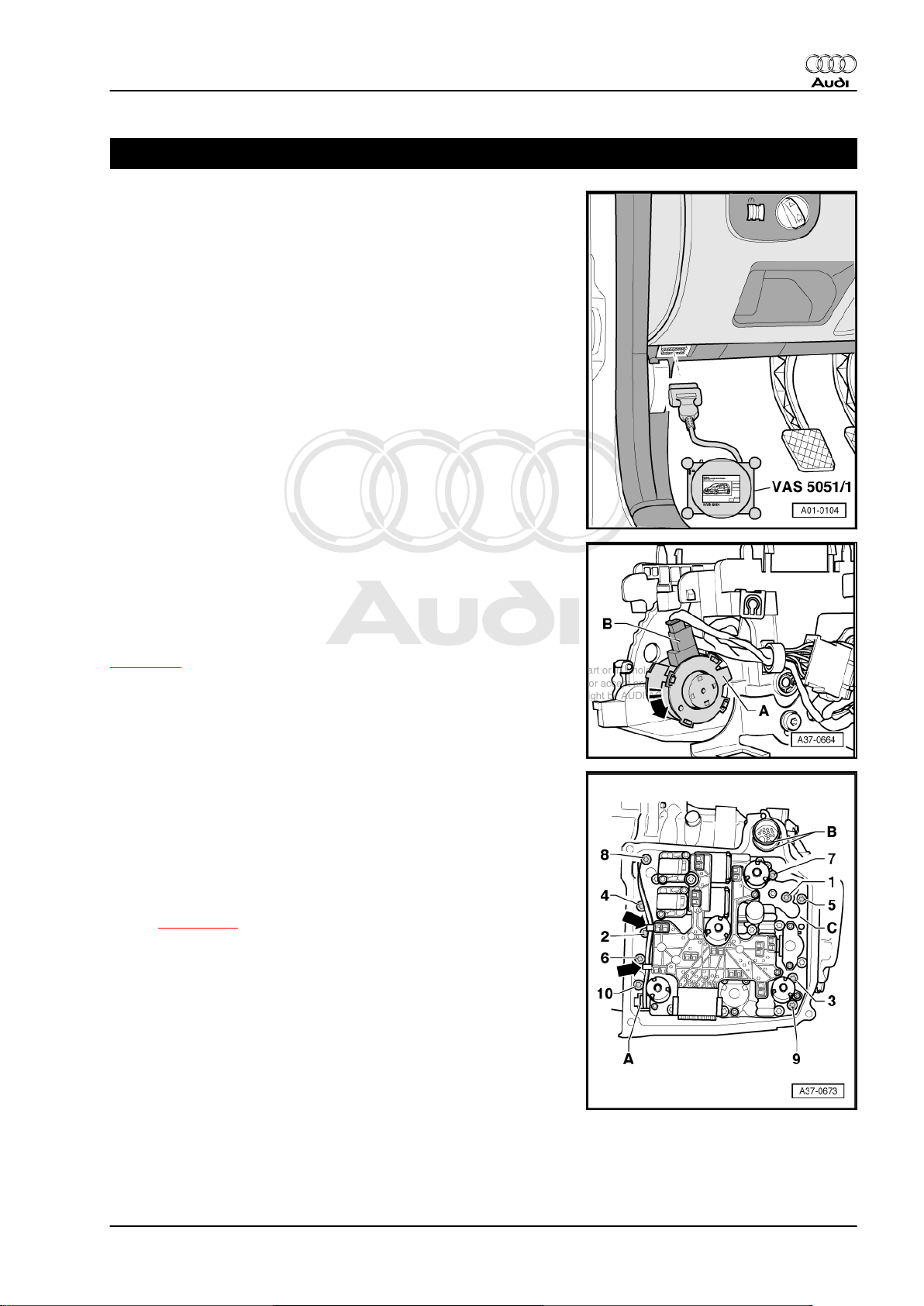

Diagnostic connector

Fitting location: below knee padding on left side of steering wheel.

Audi TT 1999 ➤

Selector lever lock solenoid -N110-

Fitting location: the selector lever lock solenoid -N110- -item A- is

located in the selector mechanism.

♦ Checked via self-diagnosis

Removing and installing selector lever lock solenoid -N110-

⇒ page 40

Mechatronic unit for direct shift gearbox -J743-

Fitting location: the mechatronic unit for direct shift gearbox J743- is bolted to the front of the gearbox housing and covered

by the gearbox oil pan.

The control unit is an integrated component of the mechatronic

unit for direct shift gearbox -J743- .

Removing and installing mechatronic unit for direct shift gearbox

-J743- ⇒ page 102 .

1. 25

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

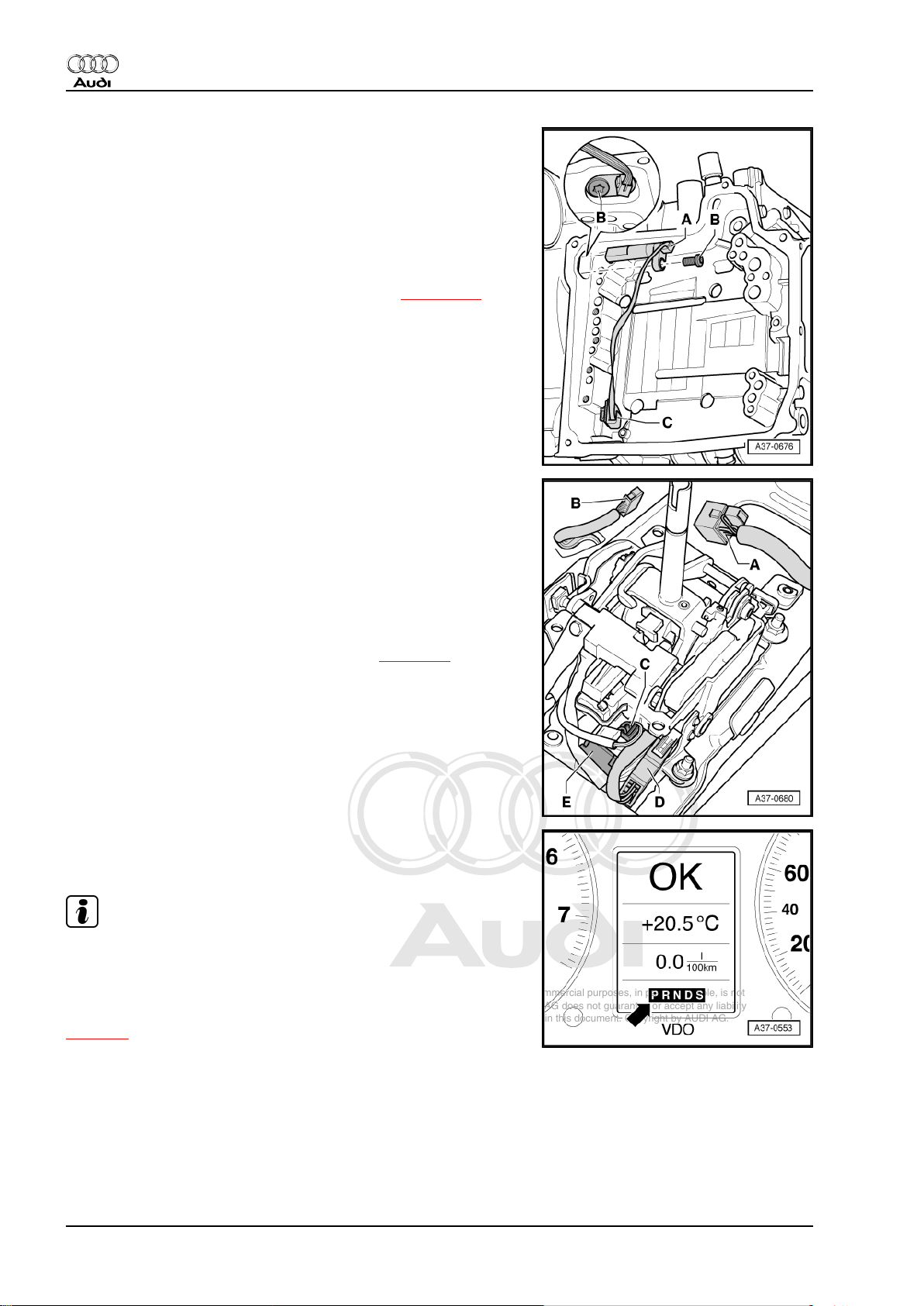

Gearbox input speed sender -G182- / oil temperature sender for

multi-plate clutch -G509-

Fitting location: the gearbox input speed sender -G182- / oil tem‐

perature sender for multi-plate clutch -G509- -item A- is bolted to

the gearbox housing below the mechatronic unit for direct shift

gearbox -J743- .

♦ Checked via self-diagnosis

Removing and installing gearbox input speed sender -G182- / oil

temperature sender for multi-plate clutch -G509- ⇒ page 106 .

Selector lever -E313- with tiptronic switch -F189-

Fitting location: the selector lever -E313- with tiptronic switch F189- is integrated in the selector mechanism. These compo‐

nents cannot be renewed separately. Several versions available.

For correct allocation refer to ⇒ Parts catalogue .

♦ Checked via self-diagnosis

D - Electrical connector for tiptronic switch -F189-

Remove and install selector lever -E313- with tiptronic switch F189- only together with selector mechanism ⇒ page 38 .

Selector lever position display -Y6-

Fitting location: integrated into instrument cluster

Note

The selector lever position display can only be renewed together

with the instrument cluster.

If the selector lever position display flashes or is illuminated, take

note of the safety functions of the gearbox control unit

⇒ page 7 .

Removing and installing instrument cluster ⇒ Electrical system;

Rep. Gr. 90

26 Rep. Gr.34 - Controls, housing

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

Brake light switch -F-

Fitting location: the brake light switch -arrow- is located on pedal

cluster.

♦ Signal transmission from engine control unit to gearbox control

unit via CAN bus

♦ Checked via self-diagnosis

Removing and installing brake light switch ⇒ Brake system; Rep.

Gr. 46 .

Note

Switch may only be fitted once so as to ensure a firm fit.

Kickdown switch -F8-

An adapted value from accelerator position sender -G79- and ac‐

celerator position sender 2 -G185- (integrated in accelerator ped‐

al module) is stored in the engine control unit as the kickdown

signal.

♦ Checked via self-diagnosis

♦ Signal transmission from engine control unit to gearbox control

unit via CAN bus

Removing and installing accelerator pedal module: ⇒ Fuel supply

system, petrol engines; Rep. Gr. 20 .

Audi TT 1999 ➤

1. 27

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

2 Servicing selector mechanism

WARNING

Before working on vehicle while engine is running, shift selec‐

tor lever into position “P” and apply handbrake.

Overview:

♦ Checking selector mechanism ⇒ page 28

♦ Checking and adjusting selector lever cable ⇒ page 29

♦ Checking function of ignition key removal lock ⇒ page 33

♦ Dismantling and assembling selector mechanism

⇒ page 35

♦ Removing and installing selector lever handle ⇒ page 37

♦ Removing and installing selector mechanism cover

⇒ page 37

♦ Removing and installing selector mechanism ⇒ page 38

♦ Removing and installing tiptronic switch -F189- ⇒ page 40

♦ Removing and installing selector lever lock solenoid -N110-

⇒ page 40

♦ Removing and installing selector lever cable ⇒ page 41

♦ Removing and installing locking cable ⇒ page 48

♦ Adjusting locking cable ⇒ page 50

♦ Overview of connectors on selector mechanism ⇒ page 51

2.1 Checking selector mechanism

♦ It should not be possible to operate the starter while the se‐

lector lever is in position “S”, “D” or “R” or in the tiptronic

position.

♦ When travelling at speeds above 5 km/h and shifting into se‐

lector lever position “N”, the solenoid for the selector lever lock

must not engage and block the selector lever. The selector

lever can be shifted into a driving gear.

♦ When travelling at speeds below 5 km/h (almost stationary)

and shifting into selector lever position “N”, the solenoid for the

selector lever lock should only engage after about 1 second.

Selector lever cannot be shifted out of “N” position until brake

pedal is depressed.

Selector lever in position “P”, button on selector lever pressed in

and ignition switched on:

• Brake pedal not depressed:

When button is pressed in, selector lever is locked and cannot be

shifted out of “P” position. Solenoid for selector lever lock blocks

selector lever.

• Brake pedal depressed:

Solenoid for selector lever lock releases selector lever. It is pos‐

sible to shift into a driving gear. Shift selector lever slowly from

“P” position through “R, N, D and S” and check whether the dis‐

play in the dash panel insert shows the correct selector lever

position in each case.

28 Rep. Gr.34 - Controls, housing

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

Selector lever in position “N”, button on selector lever pressed in

and ignition switched on:

• Brake pedal not depressed:

Selector lever is locked and cannot be shifted out of “N”position.

Solenoid for selector lever lock blocks selector lever.

• Brake pedal depressed:

Solenoid for selector lever lock releases selector lever. It is pos‐

sible to shift into a driving gear.

Note

When brake pedal is depressed, it is also possible to shift from

“N” to “D” position without pressing the button on the selector lev‐

er. However, to shift from “N” to “R” you do have to additionally

press the button on the selector lever.

Selector lever in position “D”, ignition switched on:

The selector lever is locked and cannot be shifted from “D” to “S”

position.

• Press button on selector lever:

The selector lever is released and can be shifted from “D” to “S”

position.

Selector lever in position “D”, ignition and lights switched on:

• Shift selector lever into tiptronic gate:

The illuminated “D” symbol in the selector lever position indicator

should go out and the “+” and “-” symbols should light up.

The selector lever position indicator in the instrument cluster

should switch from “PRNDS” to “654321” when the selector lever

is moved into the tiptronic gate.

• Move the selector lever in the tiptronic gate to “+” and “–”.

When you move the selector lever to “+” or “–”, the display

“654321” in the instrument cluster should move one gear up or

down accordingly.

– Check selector lever cable and adjust if necessary

⇒ page 29 .

– Check ignition key removal lock ⇒ page 33 .

Audi TT 1999 ➤

2.2 Checking selector lever cable

– Shift selector lever into position “P”.

– Switch off ignition.

– Loosen clamp -4- and detach intake hose and connector -1-

from air mass meter.

– If fitted, disconnect hose -5- from air cleaner housing.

– Unscrew bolts -2- and -3- to remove complete air cleaner

housing.

2. Servicing selector mechanism 29

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

– Push securing clip -A- upwards and detach it in

-direction of arrow-.

Note

Illustration shows version on vehicles with vehicle ID No. to

8N 41013847.

– Press selector lever cable off selector shaft lever in direction

of arrow and place on top.

– Do not loosen bolt -B-.

– Put the selector lever cable aside in such a way that the end

can move freely.

Note

Do not bend or kink the selector lever cable.

– Move selector lever from “P” to “S”.

– Check protective sleeve on selector mechanism (on front of

selector lever cable) for damage, if necessary renew cable.

– Shift selector lever into position “P”.

• Selector mechanism and selector lever cable should move

smoothly, if necessary renew selector lever cable

( ⇒ page 41 ) or service selector mechanism.

– Carefully press selector lever cable onto selector shaft lever

in opposite direction of -arrow-.

– Fit securing clip -A- and press downwards to secure.

2.3 Adjusting selector lever cable - vehicles

with vehicle ID No. to 8N 41013847

– Shift selector lever into position “P”.

– Switch off ignition.

– Loosen clamp -4- and detach intake hose and connector -1-

from air mass meter.

– If fitted, disconnect hose -5- from air cleaner housing.

– Unscrew bolts -2- and -3- to remove complete air cleaner

housing.

30 Rep. Gr.34 - Controls, housing

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

– Loosen bolt -B-.

– Bring selector shaft lever into position “P” on gearbox.

– Turn both front wheels in one direction, e.g. by pushing the

vehicle forwards, until the detent lever in the gearbox engages

in the parking lock gear and the wheels are blocked (it is not

possible to turn them both in the same direction simultane‐

ously).

Note

The selector lever must remain in “P” position when clamping bolt

-B- is loosened, otherwise adjustment will not be correct.

– Carefully move selector lever slightly forwards and backwards,

without shifting lever into a different selector lever position.

– Tighten bolt -B- smoothly and evenly (tightening torque: 13

Nm).

Note

Audi TT 1999 ➤

When tightening bolt -B-, make sure the selector lever cable does

not move out of position.

2.4 Adjusting selector lever cable - vehicles with vehicle ID No. from 8N 41013848

Special tools and workshop equipment required

♦ Socket and key -T40031-

Procedure

– Shift selector lever into position “P”.

– Switch off ignition.

2. Servicing selector mechanism 31

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

– Loosen clamp -4- and detach intake hose and connector -1-

from air mass meter.

– If fitted, disconnect hose -5- from air cleaner housing.

– Unscrew bolts -2- and -3- to remove complete air cleaner

housing.

– Bring selector shaft lever into position “P” on gearbox.

– Turn both front wheels in one direction, e.g. by pushing the

vehicle forwards, until the detent lever in the gearbox engages

in the parking lock gear and the wheels are blocked (it is not

possible to turn them both in the same direction simultane‐

ously).

– Carefully move selector lever slightly forwards and backwards,

without shifting lever into a different selector lever position.

– Remove selector mechanism cover ⇒ page 37 .

– Insert socket and key -T40031- through access hole in selec‐

tor mechanism to loosen the clamping bolt at the rear of

selector lever cable approx. 1 turn.

Note

♦

Loosen clamping bolt approx. 1 turn - do not remove.

♦

Clamping bolt can only be accessed with selector lever in po‐

sition “P”.

♦

With clamping bolt loosened, selector lever must remain in

position “P”.

– Check exact position of selector lever in position “P”.

Note

Do not pull selector lever back or forward while adjusting as this

would give an incorrect adjustment.

– Tighten clamping bolt to 13 Nm carefully and smoothly in this

position, using socket and key -T40031- .

– Install selector mechanism cover ⇒ page 37 .

Perform remaining installation steps in reverse sequence of re‐

moval.

2.5 Checking adjustment of selector lever cable

– Keep button pressed, while pulling selector lever approx. 5

mm to the rear out of position “P”. Then keep lever in this po‐

sition, do not move it into “R”.

– Release selector lever.

• The selector lever should spring back into “N” position auto‐

matically.

– If necessary, adjust selector lever cable

⇒ “2.3 Adjusting selector lever cable - vehicles with vehicle ID

No. to 8N 41013847”, page 30 and

⇒ “2.4 Adjusting selector lever cable - vehicles with vehicle ID

No. from 8N 41013848”, page 31 .

32 Rep. Gr.34 - Controls, housing

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

– Shift selector lever into position “N”.

– Keep button pressed, while pulling selector lever approx. 5

mm to the rear out of position “N”. Then keep lever in this po‐

sition, do not move it into “D”.

– Release selector lever.

• The selector lever should spring back into “N” position auto‐

matically.

– If necessary, adjust selector lever cable

⇒ “2.3 Adjusting selector lever cable - vehicles with vehicle ID

No. to 8N 41013847”, page 30 and

⇒ “2.4 Adjusting selector lever cable - vehicles with vehicle ID

No. from 8N 41013848”, page 31 .

– Keep button pressed, while pushing selector lever approx. 5

mm to the front out of position “N”. Then keep lever in this

position, do not move it into “R”.

– Release selector lever.

• The selector lever should spring back into “N” position auto‐

matically.

– If necessary, adjust selector lever cable

⇒ “2.3 Adjusting selector lever cable - vehicles with vehicle ID

No. to 8N 41013847”, page 30 and

⇒ “2.4 Adjusting selector lever cable - vehicles with vehicle ID

No. from 8N 41013848”, page 31 .

– Check selector mechanism ⇒ page 28 .

Audi TT 1999 ➤

2.6 Checking function of ignition key removal lock

– Move selector lever to “P”

Start

↓

↓ ← ← ← ← ← ← ← ← ← ← ↑

↓

Defective selector mecha‐

↑

nism or defective steering

– Switch off ignition.

lock

– Renew defective compo‐

– Remove ignition key

Can selector lever be

↓

↓

↓

shifted out of “P” when

the button is pressed?

→

Yes

nents

→

Incorrectly adjusted

locking cable?

↑

No

↑

→

Y

e

→

– Correct adjust‐

ment

s

⇒ page 50

Function OK

– Press brake pedal

↓

No

↓

↓

↓

↑

↑

↑

↑

↑

↑

↑

↑

– Insert ignition key

↑

↑

– Switch on ignition

↓

↑

2. Servicing selector mechanism 33

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

Can selector lever be

→ No → → → → → ↑

shifted out of “P” when

the button is pressed?

– It should be possible to shift se‐

↓

↓

Yes

↓

lector lever to “R, N, D or S”

Can ignition key be removed?

↓

→ →

→ → ↑ ← ← ← ←

Y

↑

↑

↑

↑

↑

↑

↑

↑

↑

e

s

↓

→ → →

No

– Press brake pedal

→

Ignition key can be removed

and selector lever is locked in

– Move selector lever to “P”

“P”.

Ignition key removal lock OK

No

↑

↓

Yes

↓

34 Rep. Gr.34 - Controls, housing

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

2.7 Dismantling and assembling selector mechanism

Note

Lubricate all bearings and moving surfaces with polycarbamide grease -G 052 142 A2- .

1 - Selector lever handle

❑ Removing and installing

⇒ page 37

2 - Sleeve

❑ Clips into selector lever

handle

❑ Prevents the selector

lever handle from being

pulled off

3 - Bolt, 2 Nm

❑ 8x

4 - Retaining ring

5 - Upper cover

❑ Includes symbol insert

❑ Fit onto guides -arrows-

on frame

⇒ Item 8 (page 35) .

6 - Side cover

❑ Fit onto guides -arrows-

on frame

⇒ Item 8 (page 35) .

❑ Removing and installing

⇒ page 37

7 - Printed circuit

❑ Can be checked in “Gui‐

ded fault finding” using

⇒ Vehicle diagnosis,

testing and information

system VAS 5051

❑ Installation position of

printed circuit

⇒ page 36

❑ To remove and install

printed circuit, first dismantle selector mechanism cover

8 - Frame

9 - Selector lever cable

❑ Do not bend or kink

❑ Checking ⇒ page 29

❑ If the protective sleeve is damaged, the selector lever cable must be renewed

❑ Adjusting ⇒ “2.3 Adjusting selector lever cable - vehicles with vehicle ID No. to 8N 41013847”, page 30

and ⇒ “2.4 Adjusting selector lever cable - vehicles with vehicle ID No. from 8N 41013848”, page 31

❑ Removing and installing ⇒ page 41

❑ Do not lubricate cable eye and ball socket

10 - Nut, 10 Nm

❑ For securing cover to selector mechanism

❑ 4x

2. Servicing selector mechanism 35

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

❑ Self-locking

❑ Renew

11 - Cover

❑ For selector mechanism

❑ With glued-on gasket

12 - Washer

13 - Intermediate plate for selector mechanism

14 - Bolt

❑ Inserted into intermediate plate

15 - Selector lever lock solenoid -N110-

❑ Removing and installing ⇒ page 40

❑ Can be checked in “Guided fault finding” using ⇒ Vehicle diagnosis, testing and information system VAS

5051

16 - Retainer for locking cable

17 - Selector mechanism

❑ Removing and installing ⇒ page 38

❑ With integrated tiptronic switch -F189-

18 - Bolt, 6 Nm

❑ 3x

19 - Locking cable

❑ For ignition key removal lock

❑ Must not be kinked

❑ Removing and installing ⇒ page 48

❑ Adjusting ⇒ page 50

❑ Checking operation of the ignition key withdrawal lock ⇒ page 33 .

20 - Steering lock

21 - Clip

❑ Installation position: Fit clip from above. Angled ends of clip must point towards steering lock.

Installation position of printed circuit

– Fit bores in printed circuit onto guides on frame -arrows-.

• When installing cover, make sure wiring harness -A- is not

trapped and that printed circuit is not deformed.

36 Rep. Gr.34 - Controls, housing

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

2.8 Removing and installing selector lever handle

Removing

– Shift selector lever to position “D”.

– Slide sleeve -1- downwards.

– Pull locking button -2- out of handle -3- as far as it will go

-arrow-.

– Use a wire clip or similar -4- to secure the locking button so

that it does not spring back.

– Now pull the handle off the selector lever.

Installing

– Shift selector lever to position “D”.

– Pull locking button -2- out of handle -3- as far as it will go

-arrow-.

– Use a wire clip or similar -4- to secure the locking button so

that it does not spring back.

– Now press the handle onto selector lever as far as it will go.

Audi TT 1999 ➤

Note

Installation position: Button points to driver.

– Remove wire clip.

– Press the button so that the pull lever -5- engages in the pull

rod -6-.

The button should now spring back onto the stop.

– Push sleeve -1- upwards. You should feel the sleeve engage

in the handle.

– Shift selector lever to position “P”.

2.9 Removing and installing selector mech‐

anism cover

Removing

– Shift selector lever to position “D”.

– Switch off ignition.

– Remove selector lever handle ⇒ page 37 .

– Remove centre console (rear) ⇒ General body repairs, inte‐

rior; Rep. Gr. 68 .

2. Servicing selector mechanism 37

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 12.2006

– Carefully release the frame by bending the four hooks out‐

wards -arrows- with a screwdriver. Then remove together with

retaining ring, printed circuit and cover -A-.

– Detach connector -B- from selector mechanism cover and lift

off cover.

Installing

Perform installation in reverse sequence of removal. Note the fol‐

lowing:

– Install centre console (rear) ⇒ General body repairs, interior;

Rep. Gr. 68 .

– Install selector lever handle ⇒ page 37 .