Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine

(165-176 kW), mechanics

Engine ID

Edition 12.2005

AMU APX BAM BEA BFV

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

00 - Technical data

10 - Removing and installing engine

13 - Crankshaft group

15 - Cylinder head, valve gear

17 - Lubrication

19 - Cooling

21 - Turbocharging/supercharging

26 - Exhaust system

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A0057006320

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Engine number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Engine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

10 - Removing and installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 Removing and installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Removing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Separating engine and gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.3 Securing engine to assembly stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.4 Installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2 Adjusting assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.1 Checking adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2 Adjusting assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

13 - Crankshaft group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1 Servicing work on pulley end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1.1 Poly V-belt drive - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1.2 Removing and installing poly V-belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1.3 Removing and installing vibration damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1.4 Removing and installing bracket for ancillaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1.5 Toothed belt - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1.6 Removing and installing toothed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1.7 Removing toothed belt from camshaft sprocket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.8 Positioning crankshaft at “TDC” with engine installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.9 Positioning crankshaft at “TDC” with engine removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2 Removing and installing sealing flanges and dual-mass flywheel . . . . . . . . . . . . . . . . . . . . 57

2.1 Sealing flanges and dual-mass flywheel - exploded view of components . . . . . . . . . . . . . . 57

2.2 Renewing crankshaft oil seal (pulley end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.3 Removing and installing sealing flange (front) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2.4 Removing and installing dual-mass flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3 Removing and installing crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.1 Crankshaft - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.2 Crankshaft dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.3 Removing and installing drive chain sprocket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4 Dismantling and assembling pistons and conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.1 Pistons and conrods - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.2 Piston and cylinder dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.3 Measuring radial clearance of conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

15 - Cylinder head, valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

1 Removing and installing cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

1.1 Cylinder head - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

1.2 Removing and installing cylinder head cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

1.3 Removing and installing cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

1.4 Removing and installing intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

1.5 Checking compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

2 Servicing valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2.1 Valve gear - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2.2 Checking axial clearance of camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

2.3 Renewing exhaust camshaft oil seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

2.4 Renewing inlet camshaft oil seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

2.5 Removing and installing camshafts and hydraulic chain tensioner/camshaft adjuster . . . . 101

2.6 Checking hydraulic bucket tappets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

2.7 Renewing valve stem oil seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

2.8 Valve dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

2.9 Checking valve guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

2.10 Machining valve seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

2.11 Checking valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

3 Checking variable valve timing - vehicles with engine code BAM, BEA, BFV . . . . . . . . . . 116

3.1 Checking function of variable valve timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

3.2 Checking inlet camshaft control valve 1 N205 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

17 - Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

1 Removing and installing parts of lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

1.1 Lubrication system - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

1.2 Removing and installing sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

1.3 Removing and installing oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

1.4 Oil filter and oil cooler - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

1.5 Checking oil pressure and oil pressure switch F1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

1.6 Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

1.7 Checking oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

19 - Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

1 Removing and installing parts of cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

1.1 Diagram of coolant hose connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

1.2 Draining and filling cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

1.3 Removing and installing coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

1.4 Removing and installing thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

1.5 Checking thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.6 Removing and installing coolant pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.7 Checking continued coolant circulation pump V51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

1.8 Radiator and radiator fan - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . 148

1.9 Removing and installing radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

1.10 Checking cooling system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

21 - Turbocharging/supercharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

1 Servicing charge air system with turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

1.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

1.2 Test requirements for checking turbocharging system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

1.3 Diagram of connections for charge pressure control system and vacuum system . . . . . . 157

1.4 Effects of leaks in charge air system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

1.5 Checking turbocharger and charge pressure control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

1.6 Checking mechanical air recirculation valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

1.7 Checking air recirculation valve for turbocharger N249 . . . . . . . . . . . . . . . . . . . . . . . . . . 167

1.8 Checking solenoid valve for charge pressure control N75 . . . . . . . . . . . . . . . . . . . . . . . . 171

1.9 Checking charge pressure sender G31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

2 Servicing charge air system with turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

2.1 Rules for cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

2.2 Turbocharger - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

2.3 Removing and installing turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

2.4 Charge air cooler - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

2.5 Removing and installing charge air cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

26 - Exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

1 Removing and installing parts of exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

1.1 Exhaust system - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

1.2 Separating centre and rear silencers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

1.3 Removing and installing catalytic converter with front exhaust pipe . . . . . . . . . . . . . . . . . . 196

1.4 Removing and installing exhaust manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

1.5 Stress-free alignment of exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

1.6 Checking exhaust system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

2 Exhaust gas temperature monitoring - vehicles with engine code BAM, BEA, BFV . . . . . . 204

2.1 Checking exhaust gas temperature sender 1 G235 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

3 Secondary air system - vehicles with engine code AMU, APX, BEA . . . . . . . . . . . . . . . . . . 208

3.1 Principle and function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

3.2 Checking secondary air inlet valve N112 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

3.3 Checking secondary air pump relay J299 and secondary air pump motor V101 . . . . . . . . 216

3.4 Checking combination valve for secondary air system for proper operation and leakage . . 221

3.5 Removing and installing combination valve for secondary air system . . . . . . . . . . . . . . . . 222

3.6 Removing and installing secondary air pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Contents iii

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

iv Contents

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

00 – Technical data

1 Technical data

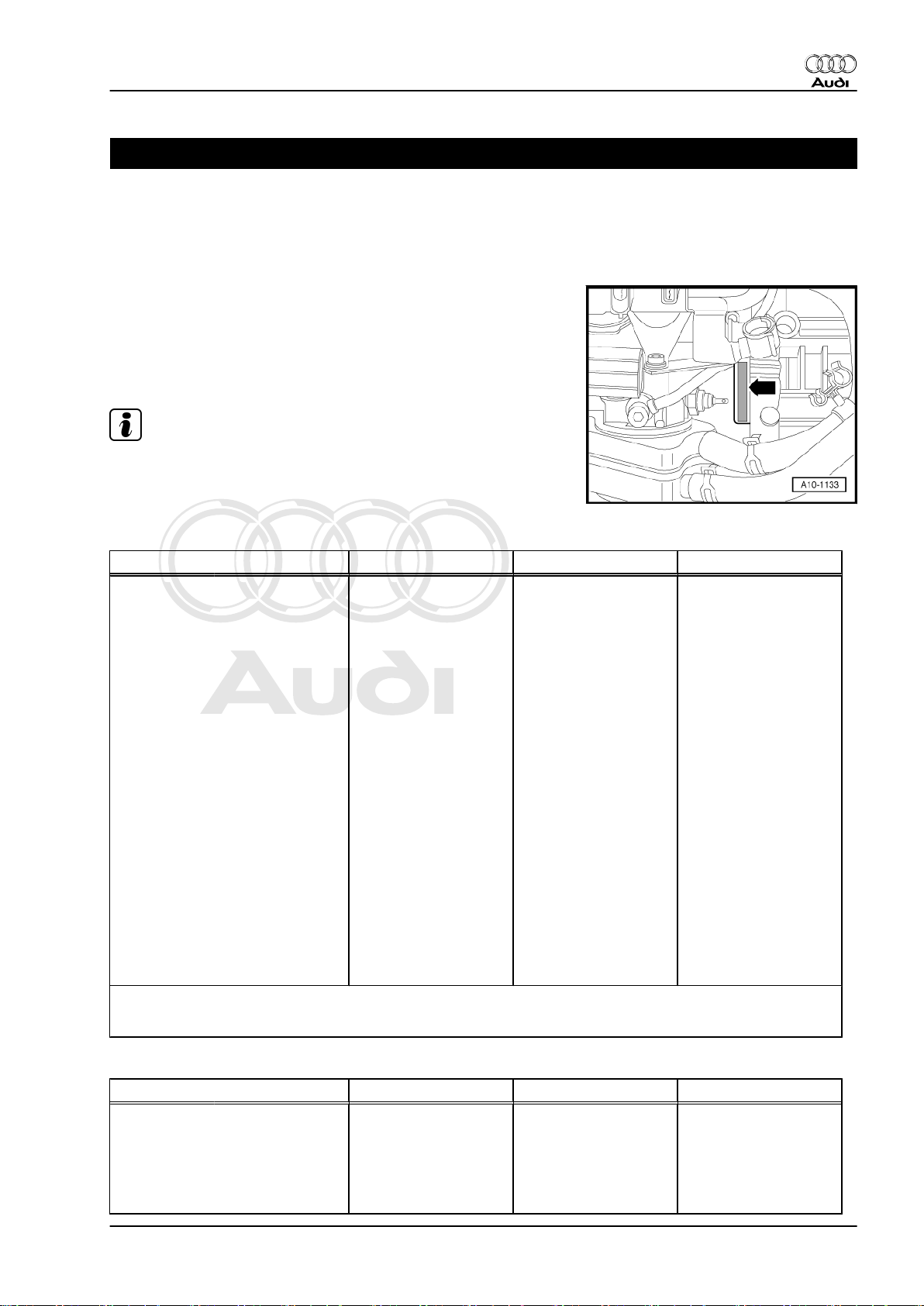

1.1 Engine number

♦ The engine number (“Engine code” and “Serial number”) can

be found at the front of the joint between engine and gearbox.

♦ There is also a sticker on the cylinder head cover showing the

“engine code” and “serial number”.

♦ The engine code is also included on the vehicle data sticker.

Note

The engine code is additionally marked at the engine lifting eye

(right-side).

Audi TT 1999 ➤

1.2 Engine data

Code letters AMU APX BAM

Capacity ltr. 1.781 1.781 1.781

Power output kW at rpm 165/5900 165/5900 165/5900

Torque Nm at rpm 280/2200 … 5500 280/2200 … 5500 280/2200 … 5500

Bore ∅ in mm 81.0 81.0 81.0

Stroke mm 86.4 86.4 86.4

Compression

ratio

RON at least

Injection/ignition system Motronic Motronic Motronic

Firing order 1-4-3-2 1-4-3-2 1-4-3-2

Emissions standard TLEV EU2+D3 EU3

Exhaust gas temperature control no no yes

Turbocharging/supercharging yes yes yes

Catalytic converter yes yes yes

Knock control yes yes yes

Charge air cooling yes yes yes

Lambda control 2 probes 1 probe 2 probes

Variable valve timing no no yes

Secondary air system yes yes no

1)

•

In exceptional circumstances, fuel with not less than 95 RON can also be used, but this will cause a

loss of power.

9.0 9.0 9.0

98

1)

98

1)

98

1)

Code letters BEA BFV

Capacity ltr. 1.781 1.781

Power output kW at rpm 165/5900 176/5700

Torque Nm at rpm 280/2200 … 5500 320/2300 … 5000

Bore ∅ in mm 81 81

Stroke mm 86.4 86.4

1. Technical data 1

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

Code letters BEA BFV

Compression

9.0 9.0

ratio

RON at least

98

1)

98

1)

Injection/ignition system Motronic Motronic

Firing order 1-4-3-2 1-4-3-2

Emissions standard LEV EU3

Exhaust gas temperature control yes yes

Turbocharging/supercharging yes yes

Catalytic converter yes yes

Knock control yes yes

Charge air cooling yes yes

Lambda control 2 probes 2 probes

Variable valve timing yes yes

Secondary air system yes no

1)

•

In exceptional circumstances, fuel with not less than 95 RON can also be used, but this will cause a

loss of power.

2 Rep. Gr.00 - Technical data

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

10 – Removing and installing engine

1 Removing and installing engine

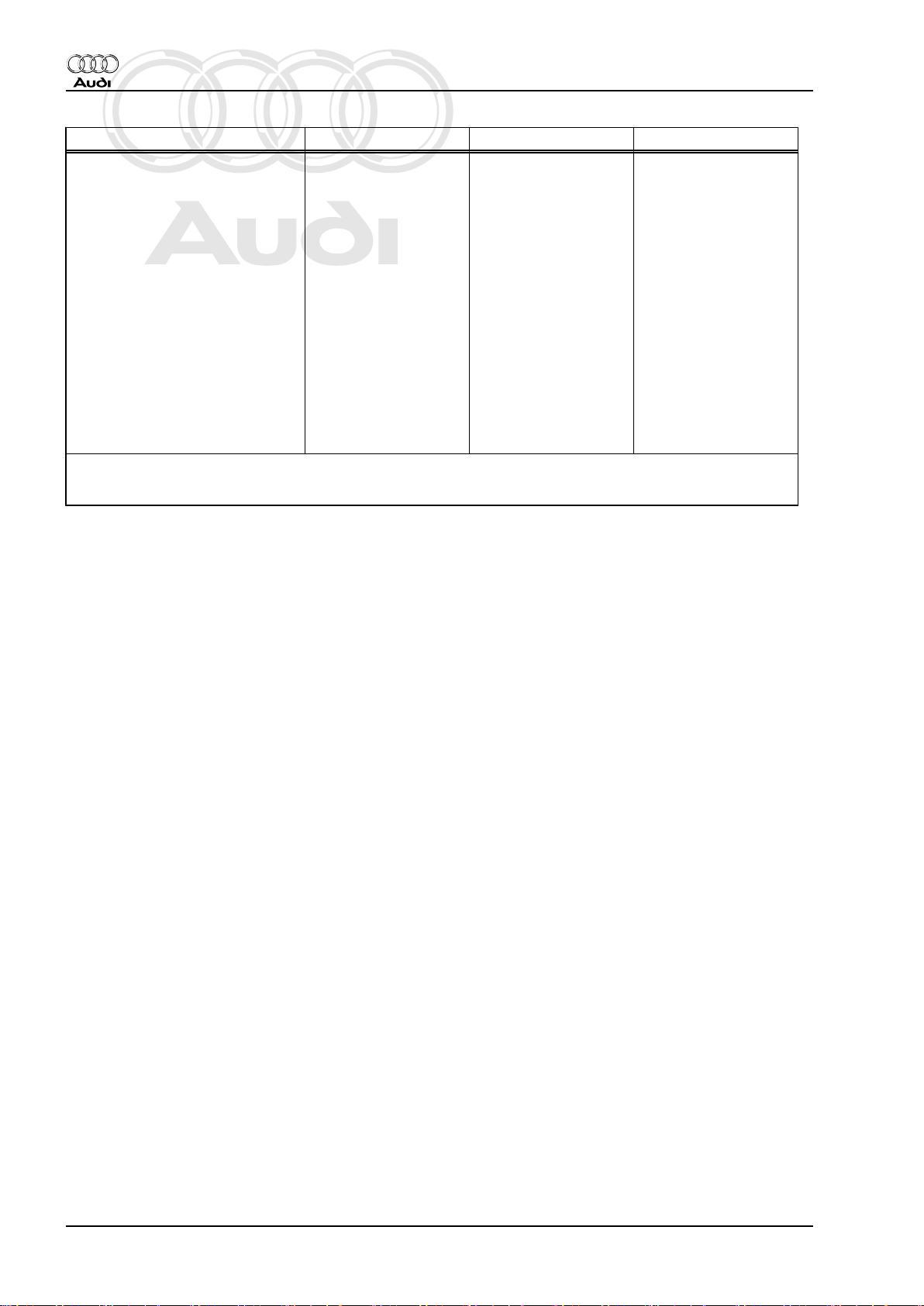

1.1 Removing engine

♦ Hose clamps for hoses up

to 25 mm Ø -3094-

♦ Drip tray for workshop hoist

-VAS 6208- or V.A.G 1306-

♦ Engine and gearbox jack -

V.A.G 1383 A-

♦ Hose clip pliers -V.A.G

1921-

♦ Stepladder -VAS 5085-

♦ Engine bracket -T10012-

Audi TT 1999 ➤

♦ Locking pin -T10060 A-

1. Removing and installing engine 3

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

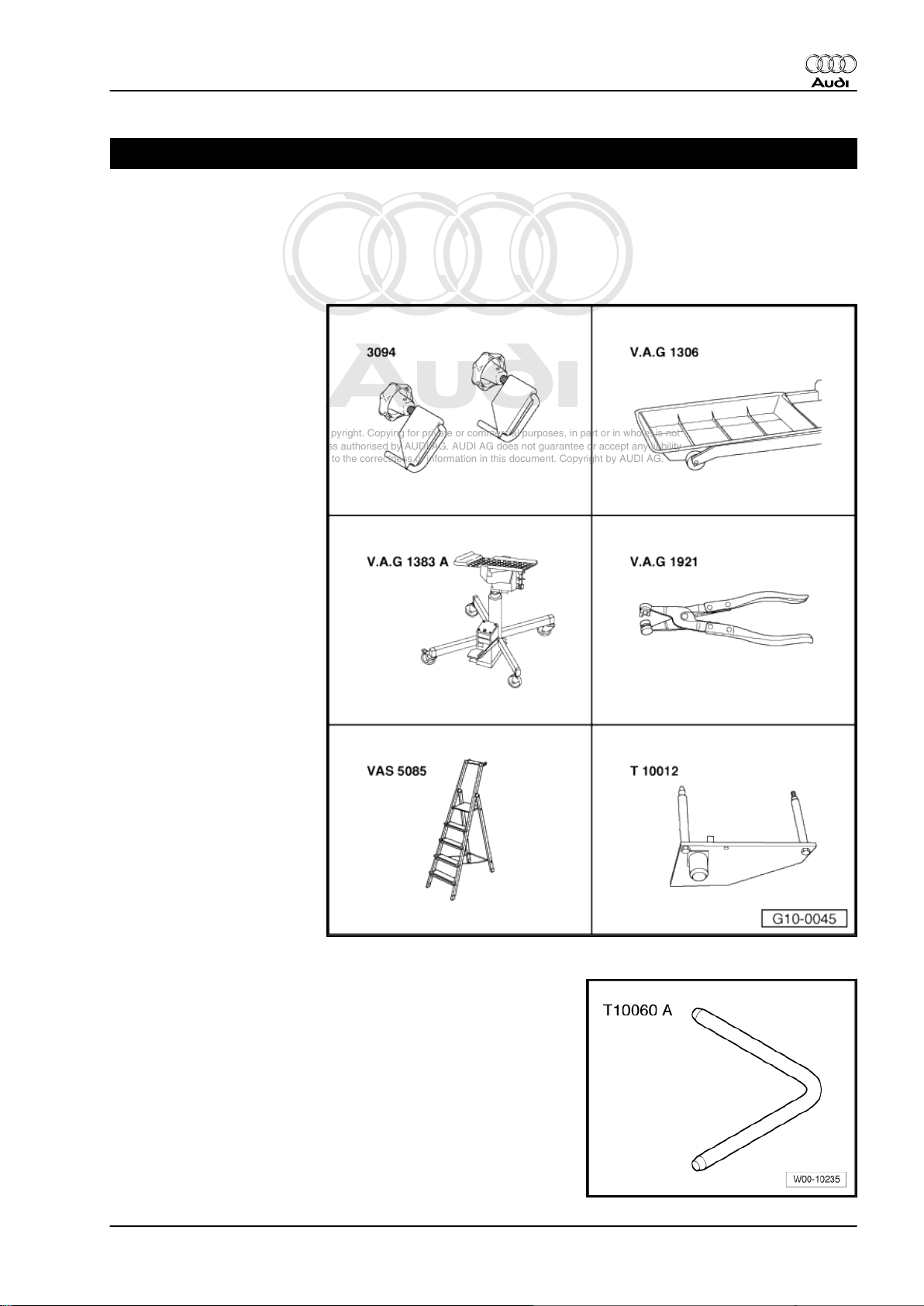

♦ Used oil collection and extraction unit -V.A.G 1782-

Procedure

Note

♦

The engine is removed from underneath together with the

gearbox.

♦

The following description corresponds to the removal and in‐

stallation on vehicles with secondary air system. Certain work

steps may not apply to vehicles without secondary air system.

♦

All heat insulation sleeves which are removed must be fitted

in the same position when installing.

♦

All cable ties which are released or cut open when removing

must be fitted in the same position when installing.

♦

Collect drained coolant in a clean container for re-use or dis‐

posal.

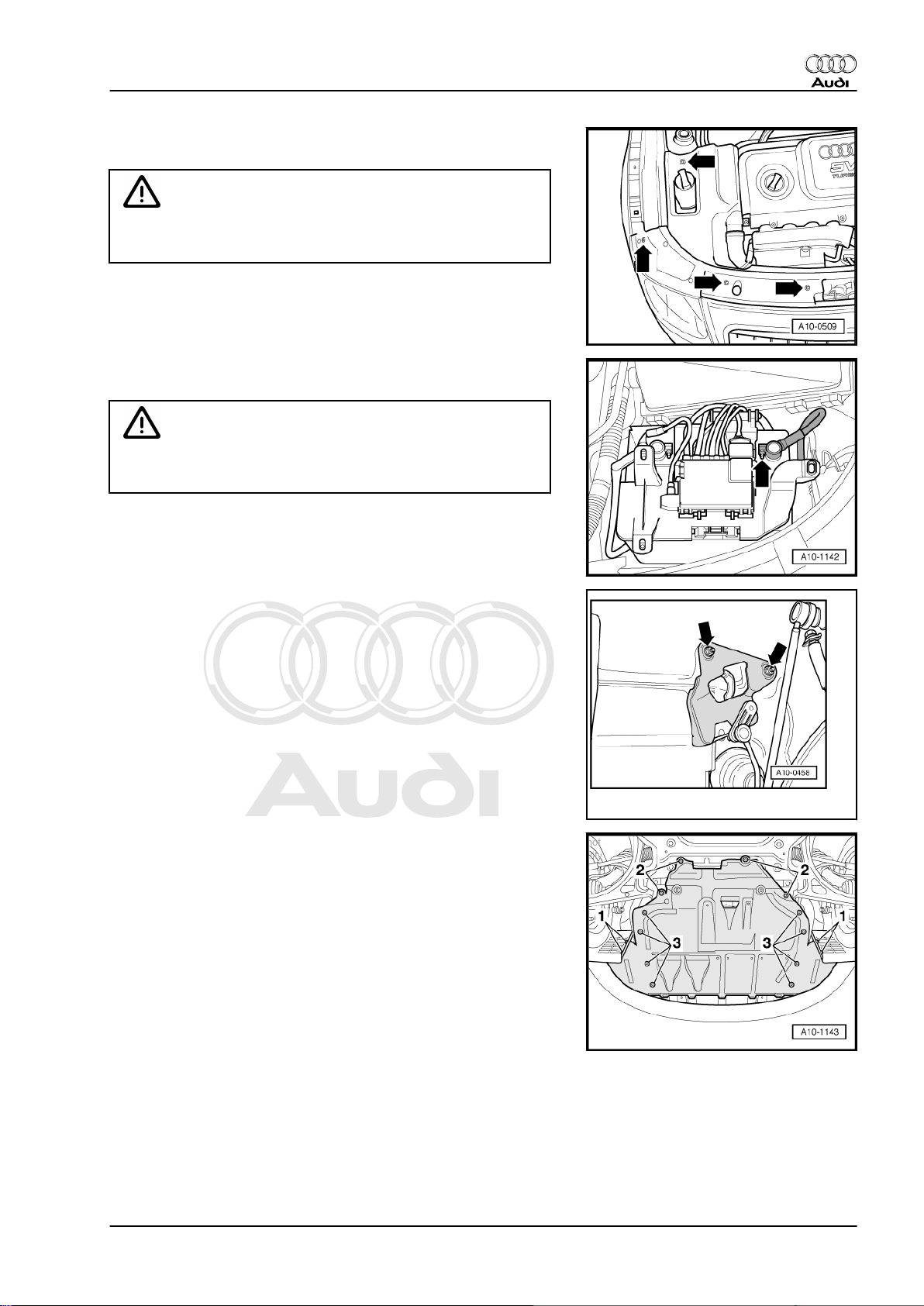

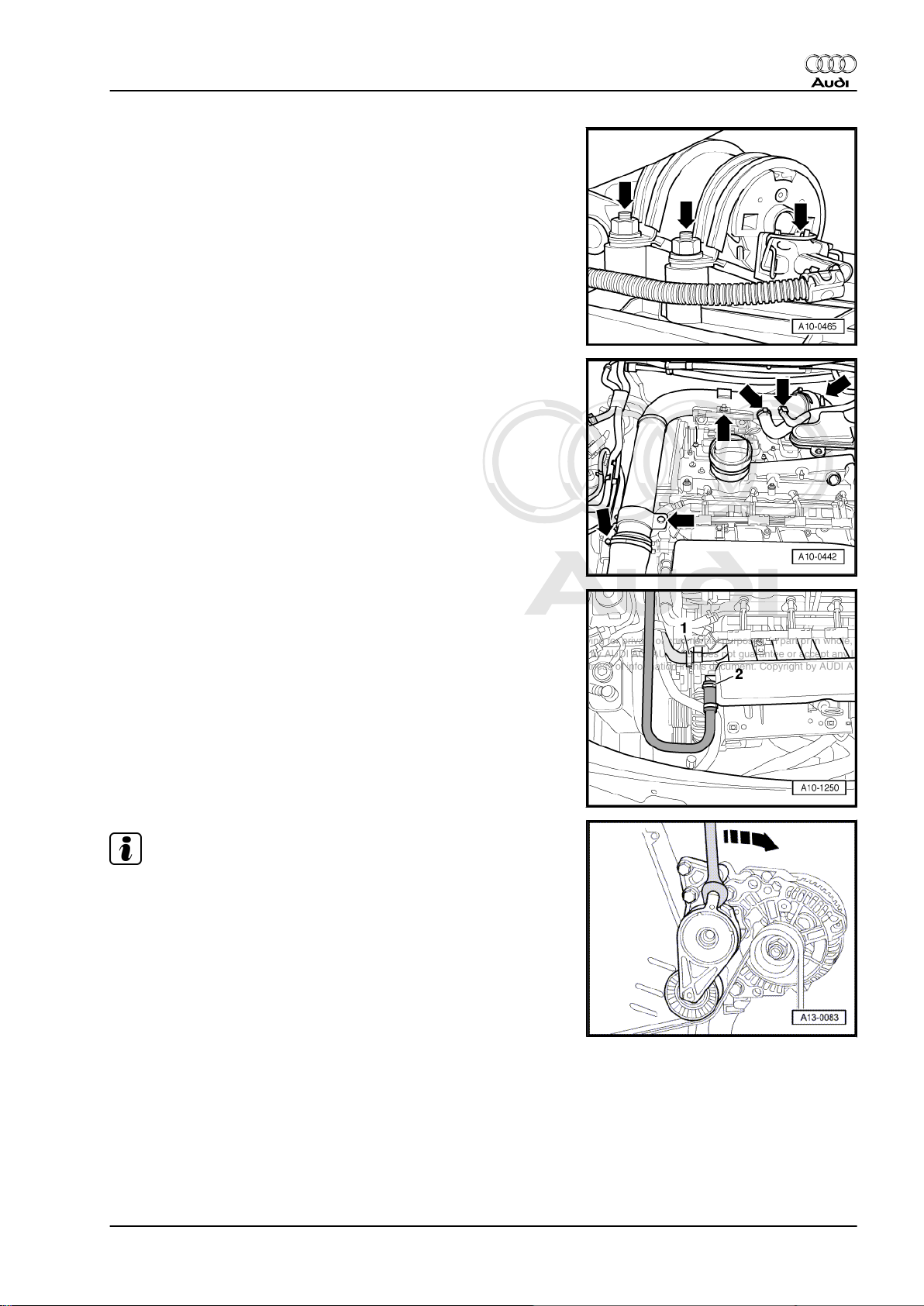

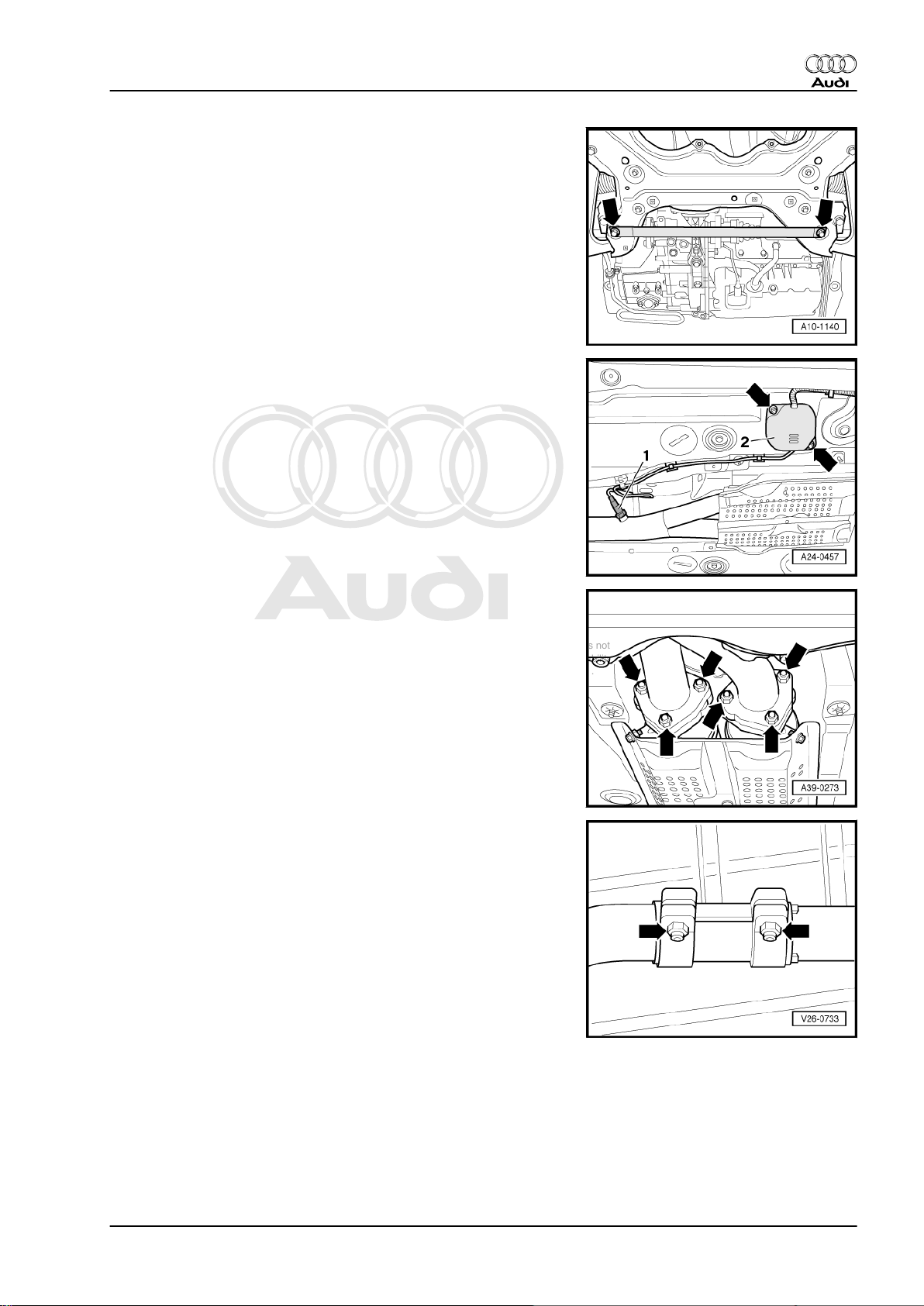

– Remove engine cover -arrows- and cover in front of intake

manifold.

– Remove covers -1- and -2- at lock carrier (left-side) and above

battery -arrows-.

4 Rep. Gr.10 - Removing and installing engine

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Remove covers -1- and -2- at lock carrier (right-side) and

above coolant expansion tank -arrows-.

Caution

Observe notes on procedure for disconnecting the battery ⇒

Rep. Gr. 27 .

– With ignition switched off, disconnect battery earth cable

-arrow-.

WARNING

Hot steam or hot coolant can escape when expansion tank is

opened; cover filler cap with cloth and open carefully.

Audi TT 1999 ➤

– Open filler cap on coolant expansion tank.

– Remove both front wheels.

– Unbolt bracket for headlight range control sender in wheel

housing (left-side, top) -arrows-.

– Remove centre noise insulation -1 ... 3-.

1. Removing and installing engine 5

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

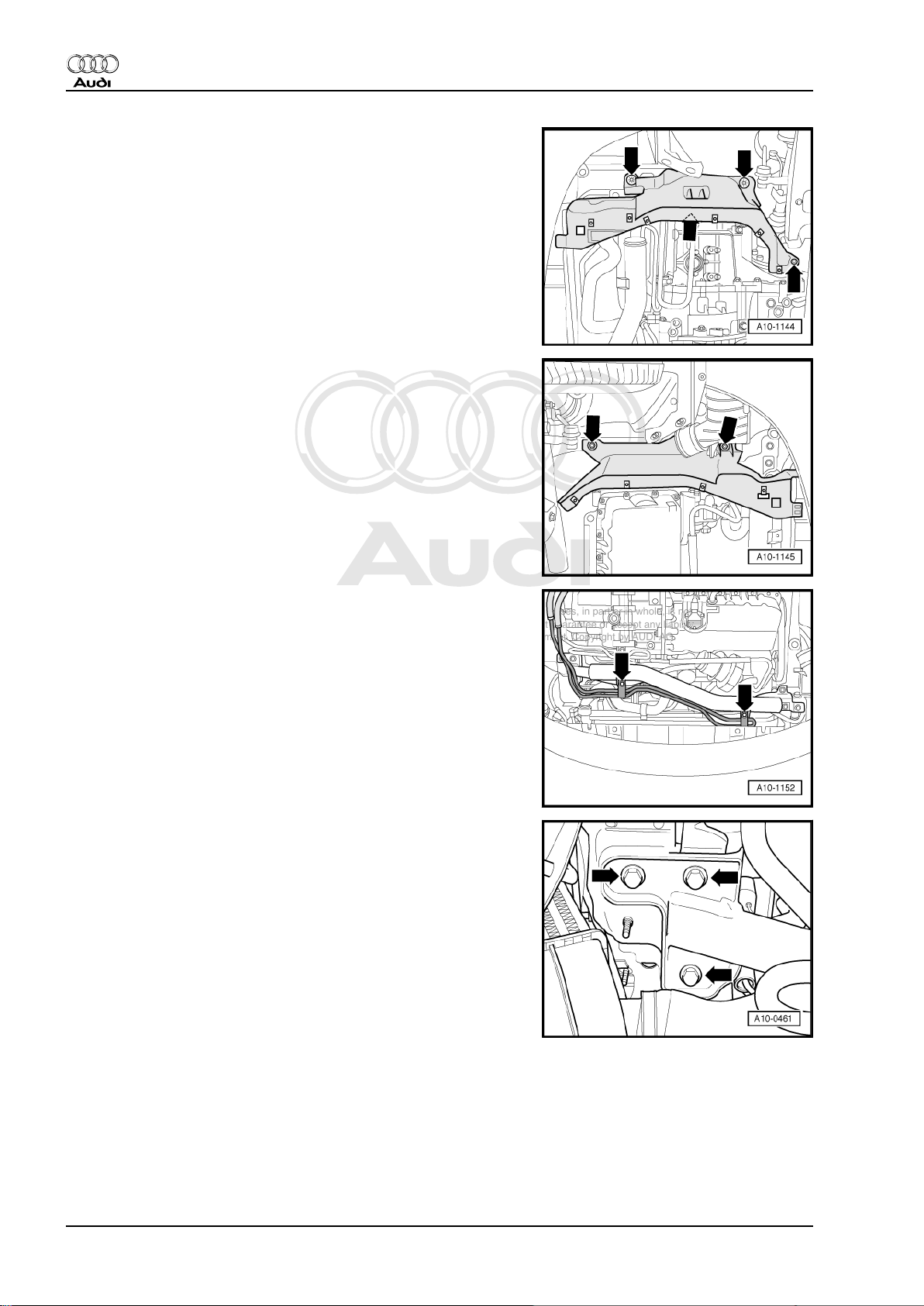

– Remove left noise insulation -arrows-.

– Remove right noise insulation -arrows-.

– If fitted, detach power steering line from connecting pipe for

charge air coolers -arrows-.

– Unbolt connecting pipe for charge air coolers on left side

-arrows-.

6 Rep. Gr.10 - Removing and installing engine

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Unbolt connecting pipe for charge air coolers on right side and

detach air intake hoses from charge air coolers -arrows-.

– Remove connecting pipe for charge air coolers.

– Place drip tray for workshop hoist -VAS 6208- under engine.

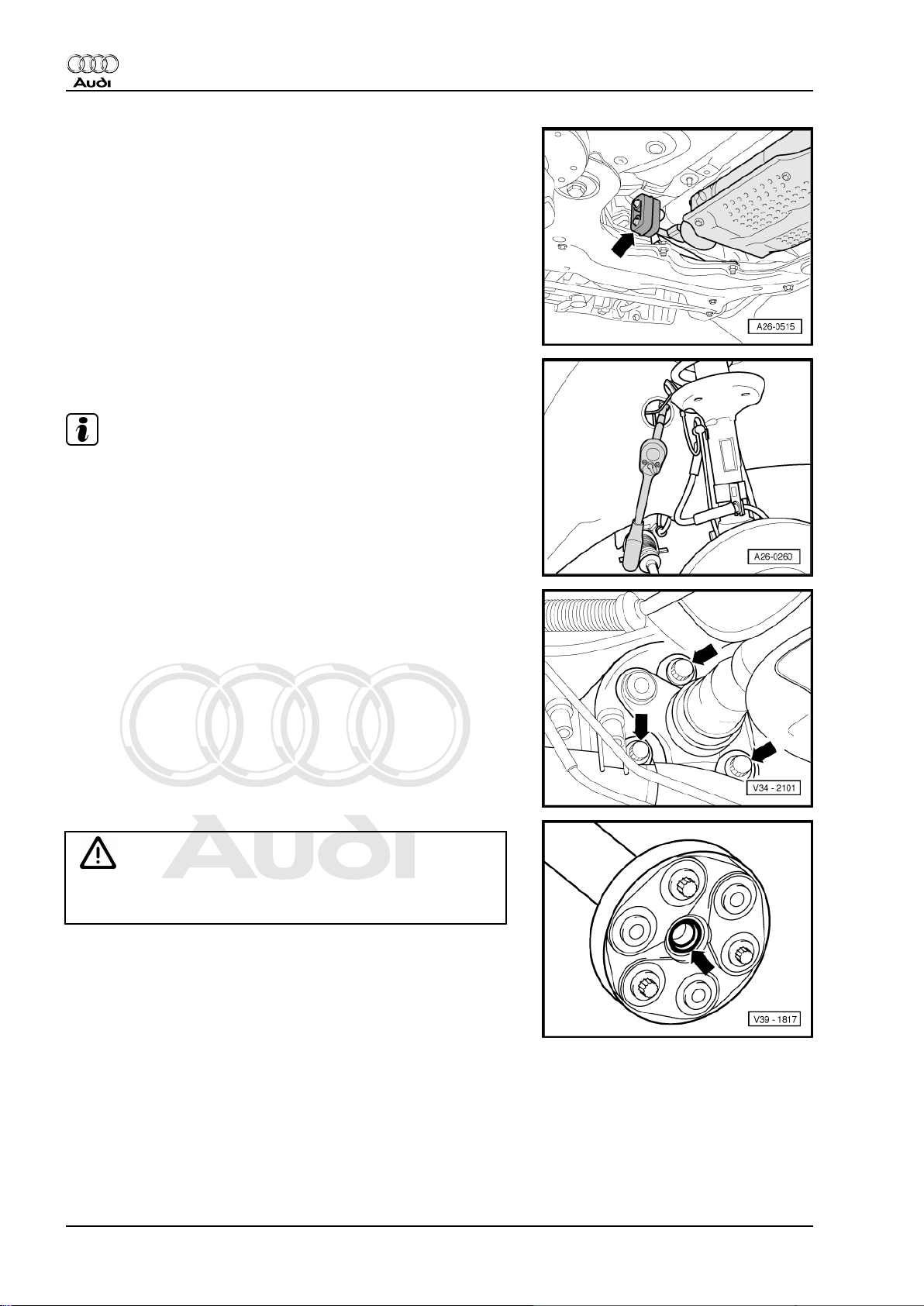

– Turn drain plug -1- on radiator anti-clockwise and drain coolant

(attach hose to connection if necessary).

– Disconnect coolant hose from radiator by pulling off retaining

clip -2- at bottom.

Audi TT 1999 ➤

– Disconnect bottom coolant hose from oil cooler -arrow-, and

drain off remaining coolant.

– Remove cross piece -1- for suspension strut -arrows-, if fitted.

1. Removing and installing engine 7

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

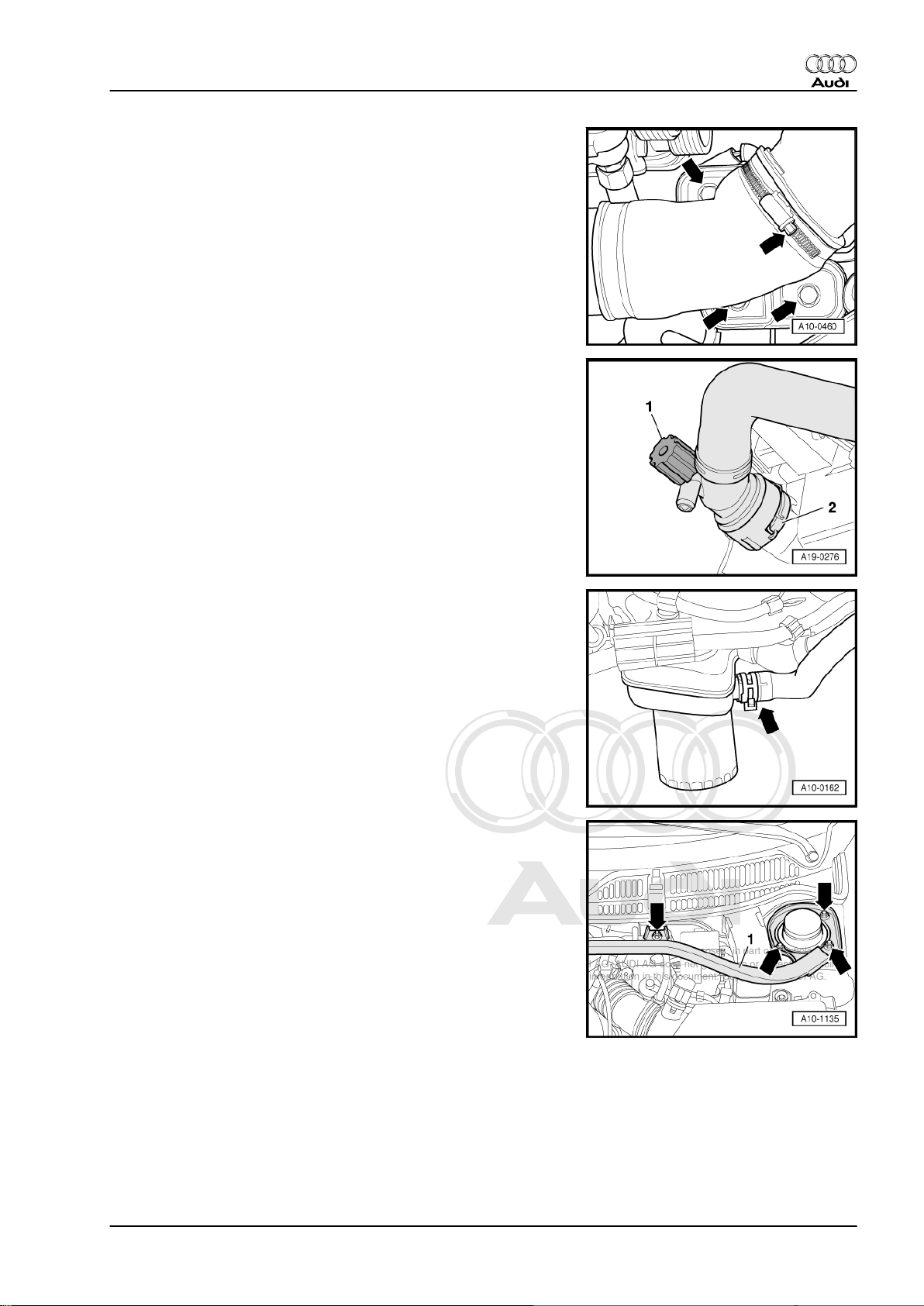

– Disconnect vacuum line and coolant pipe at locations marked

with -arrows-.

– If fitted, detach air intake hose -1- leading to secondary air

pump at air cleaner housing.

– Release hose clip -2- and detach air intake hose from air mass

meter -G70- .

– Unplug electrical connector at air mass meter -G70-

-item 3-.

– Unscrew bolts -4- and -5- and remove air cleaner housing.

Detach air duct between air cleaner and turbocharger as follows:

– Remove pressure control valve of crankcase breather -1- and

mechanical air recirculation valve -2- from air duct.

– Detach hose going to activated charcoal filter at non-return

valve -3-.

– Disconnect electrical connector -4- at charge pressure control

solenoid valve -N75- .

– Detach hoses -5- and -6- from charge pressure control sole‐

noid valve -N75- .

– Detach air duct -7- from connection on turbocharger and pull

out hose -5-, guiding as required.

– Detach coolant hoses going to to heat exchanger at bulkhead

-arrows- by releasing retaining clips.

8 Rep. Gr.10 - Removing and installing engine

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

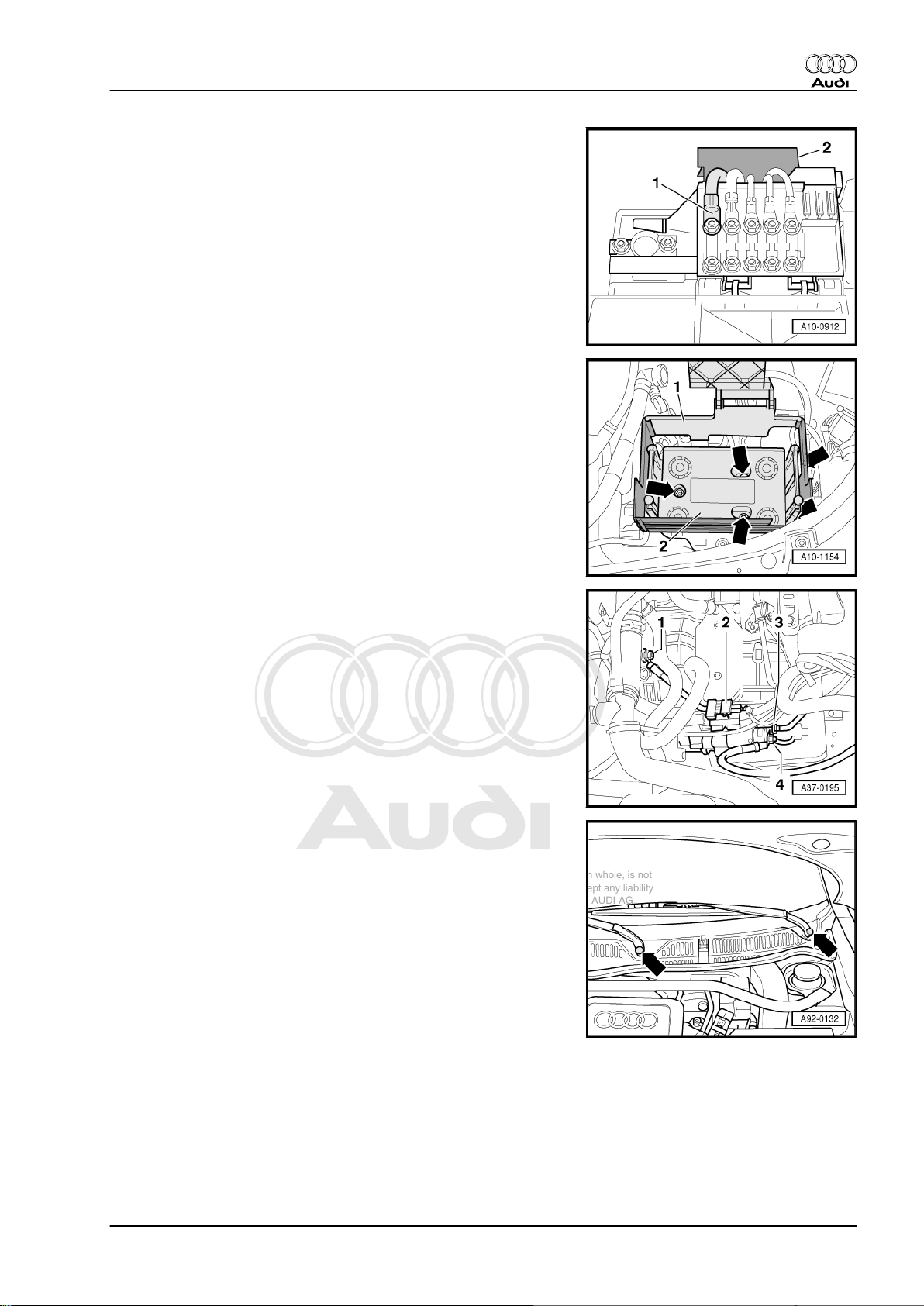

– Open cover of main fuse box.

– Unclip protective cover -2- for electrical cables.

– Unscrew black wire -1- at fuse block.

– Remove battery.

– Lift off side wall -1- together with main fuse box.

– Remove battery tray -arrows-.

Audi TT 1999 ➤

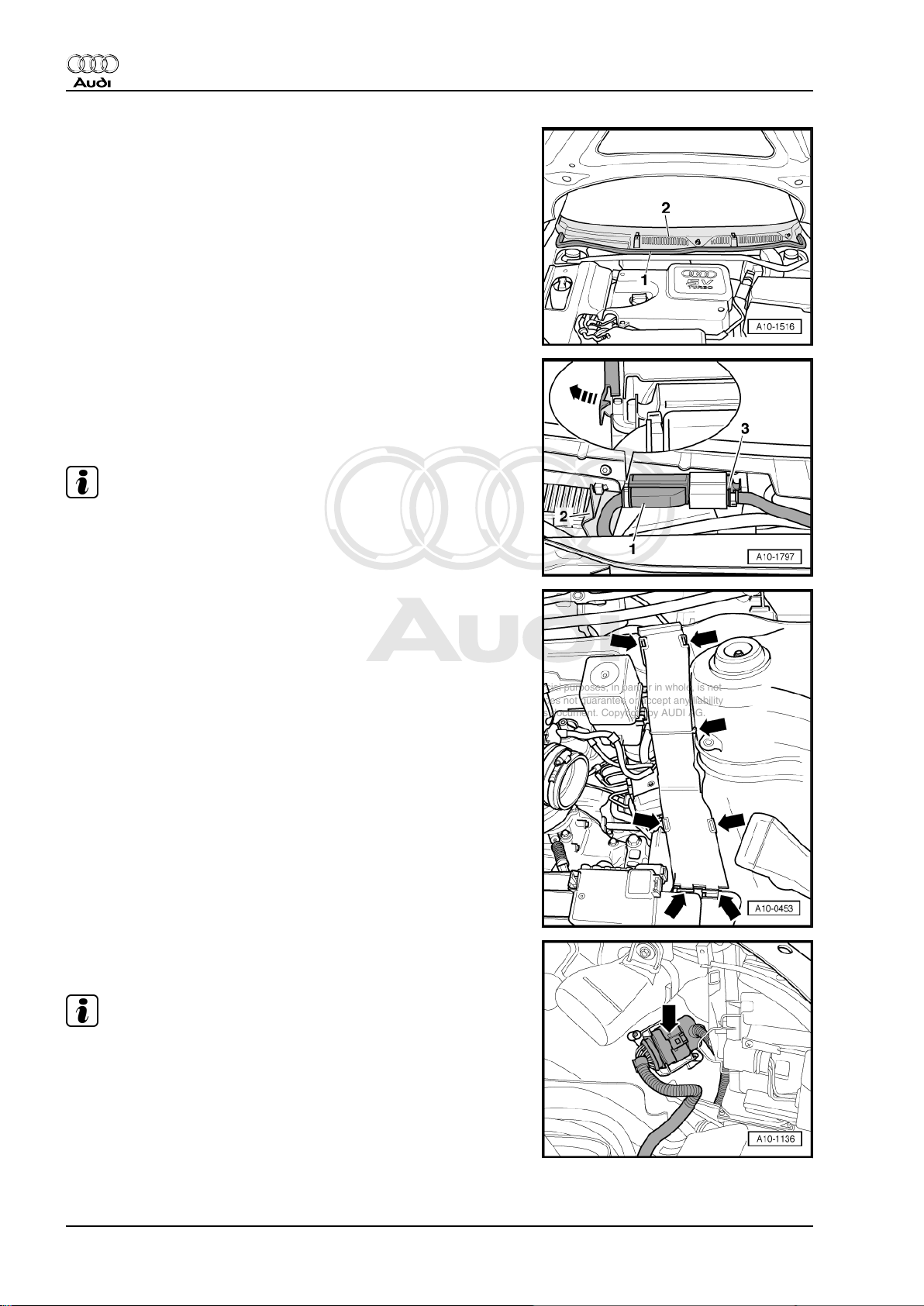

– Unscrew earth wire -1- at engine/gearbox connection.

– Detach electrical wiring -3- and -4- at starter.

– Detach electrical connector -2- from bracket and unplug.

– Disengage wiring from bracket on starter and move it clear to

the side.

– Use screwdriver to pry off caps on wiper arms -arrows- and

slacken off nuts several turns.

– Loosen wiper arms -1- from wiper shafts by tilting slightly.

– Remove nuts completely and take off wiper arms.

1. Removing and installing engine 9

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Pull off rubber seal -1- on plenum chamber cover.

– Pull off rubber seal -2- and plenum chamber cover -3-.

– Detach the washer hose and electrical connectors at wind‐

screen washer jets.

– Lay aside plenum chamber cover (towards windscreen).

– Unclip cover -2-.

– Detach multi-pin connector -1- at engine control unit.

– Release retaining tab -arrow- and pull engine control unit for‐

wards out of the bracket.

Note

The multi-pin connector -3- remains attached to the engine control

unit.

– Open cable duct (left-side) in engine compartment -arrows-.

– Unplug electrical connector in cable duct.

– Take electrical connector out of bracket (near left-side head‐

light) and unplug connector -arrow-.

Note

On some vehicles the connector is obstructed by the headlight

(left-side). In this case, remove the headlight ⇒ Rep. Gr. 94 .

– Release wiring harness leading to engine control unit.

– Place engine control unit with wiring harness on top of engine.

– Secure the engine control unit to prevent it falling.

10 Rep. Gr.10 - Removing and installing engine

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Unbolt cable support bracket from gearbox -arrows-.

Vehicles to 06.2001:

– Press locking sleeve in direction of -arrow 1- as far as stop and

lock by turning anti-clockwise in direction of -arrow 2- to re‐

lease cable end-piece for gate selector cable and gear selec‐

tor cable.

– Disengage cables from cable end-piece.

Audi TT 1999 ➤

Vehicles from 07.2001:

– Unclip retaining clip -1- from gear selector cable and retaining

clip -2- from gate selector cable.

– Pull selector cable end-pieces with selector cables off selector

shaft lever and relay lever.

All models:

– Clamp off hydraulic line to clutch slave cylinder using a hose

clamp -3094- .

– Pull out retainer towards the top -arrow- and disconnect hy‐

draulic line -1- from hose connector.

Caution

Do not press clutch pedal after disconnecting hydraulic line.

1. Removing and installing engine 11

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

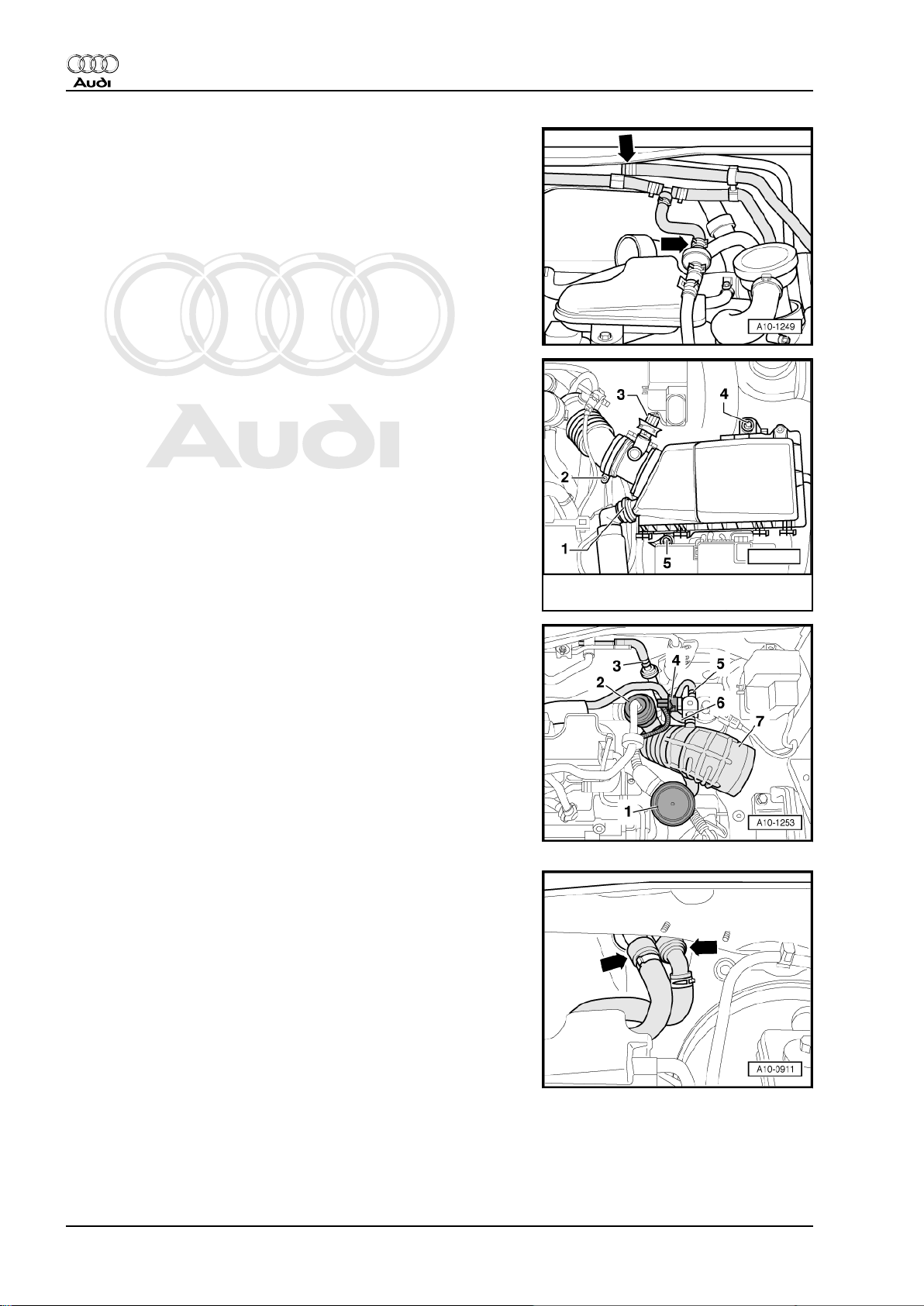

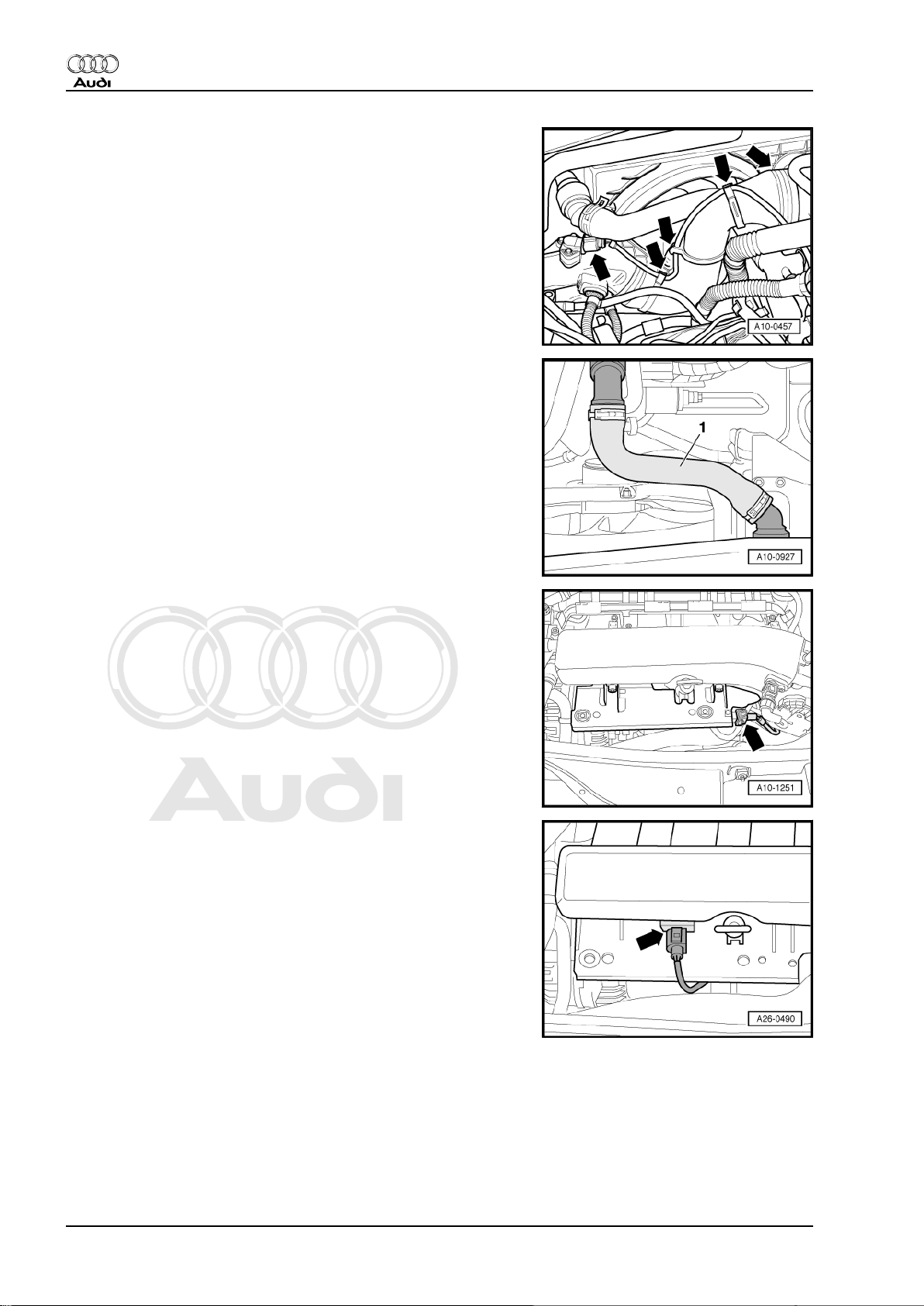

– Unplug electrical connector at charge pressure sender -G31-

and unclip wiring from air intake hose.

– Detach air intake hose from throttle valve module -J338- .

– Remove coolant hose -1- between engine and radiator.

Vehicles with secondary air system:

– Unplug electrical connector -arrow- at secondary air inlet valve

-N112- .

Vehicles with exhaust temperature control:

– Unplug electrical connector -arrow- at exhaust gas tempera‐

ture sender 1 -G235- .

12 Rep. Gr.10 - Removing and installing engine

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

All models:

– Unplug electrical connector -right arrow- at continued coolant

circulation pump -V51- .

– Unbolt continued coolant circulation pump -V51- from radiator

cowl -left arrows- (coolant hoses remain connected).

– Unscrew bolts for radiator cowl which are accessible from

above.

– Remove air pipe -arrows-.

Audi TT 1999 ➤

– Detach vacuum line -2- from intake manifold.

– Detach coolant hose -1- from coolant pipe/coolant expansion

tank.

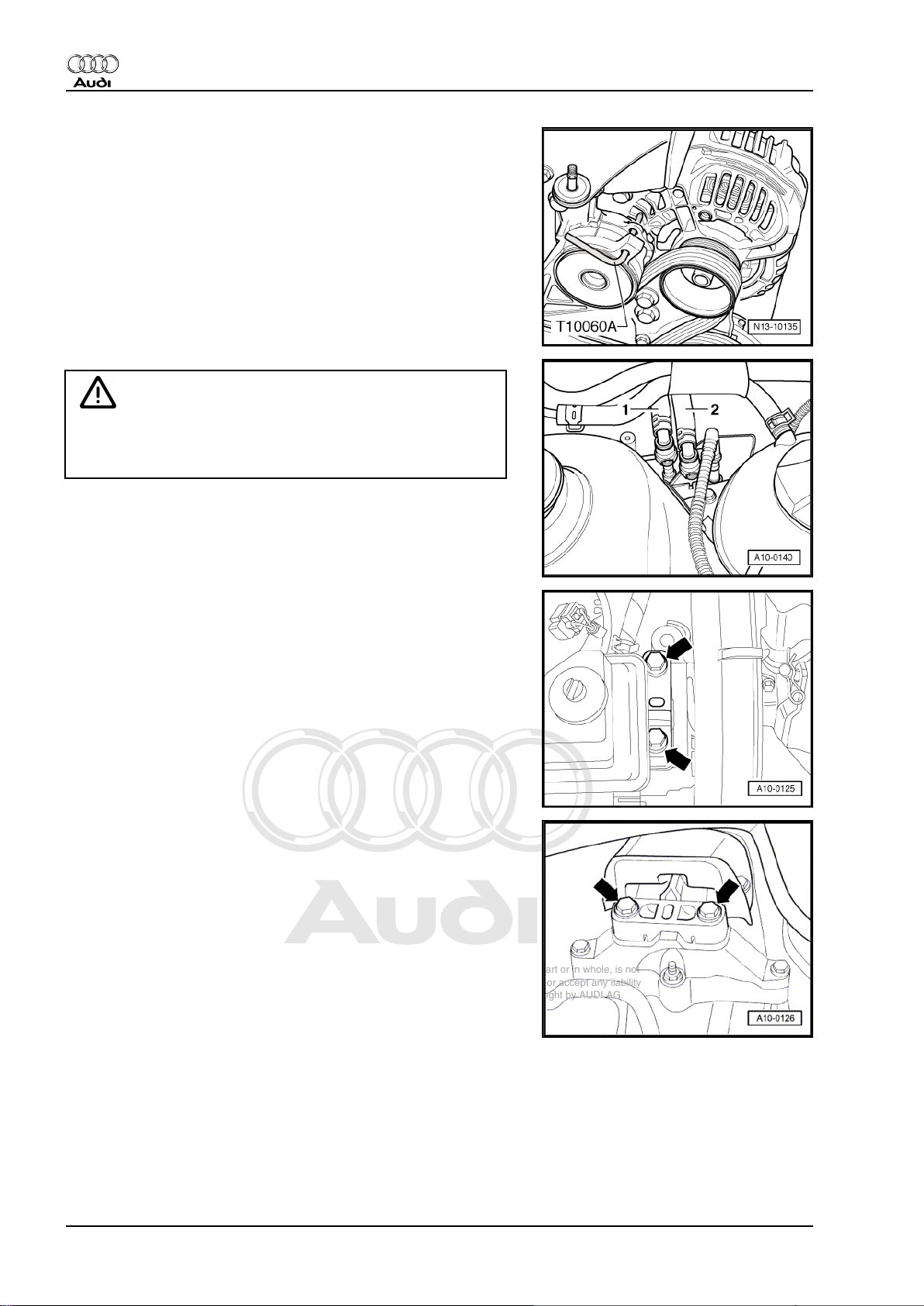

Note

Before removing, mark direction of rotation of poly V-belt with

chalk or felt-tipped pen. If the belt runs in the opposite direction

when it is refitted, this can cause breakage.

– Turn the tensioner in the direction of the -arrow- to slacken the

poly V-belt.

– Remove poly V-belt.

1. Removing and installing engine 13

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Lock tensioner in position with locking pin -T10060 A- .

WARNING

The fuel system is pressurised. Before opening the system

place a clean cloth around the connection. Then release pres‐

sure by carefully loosening the connection.

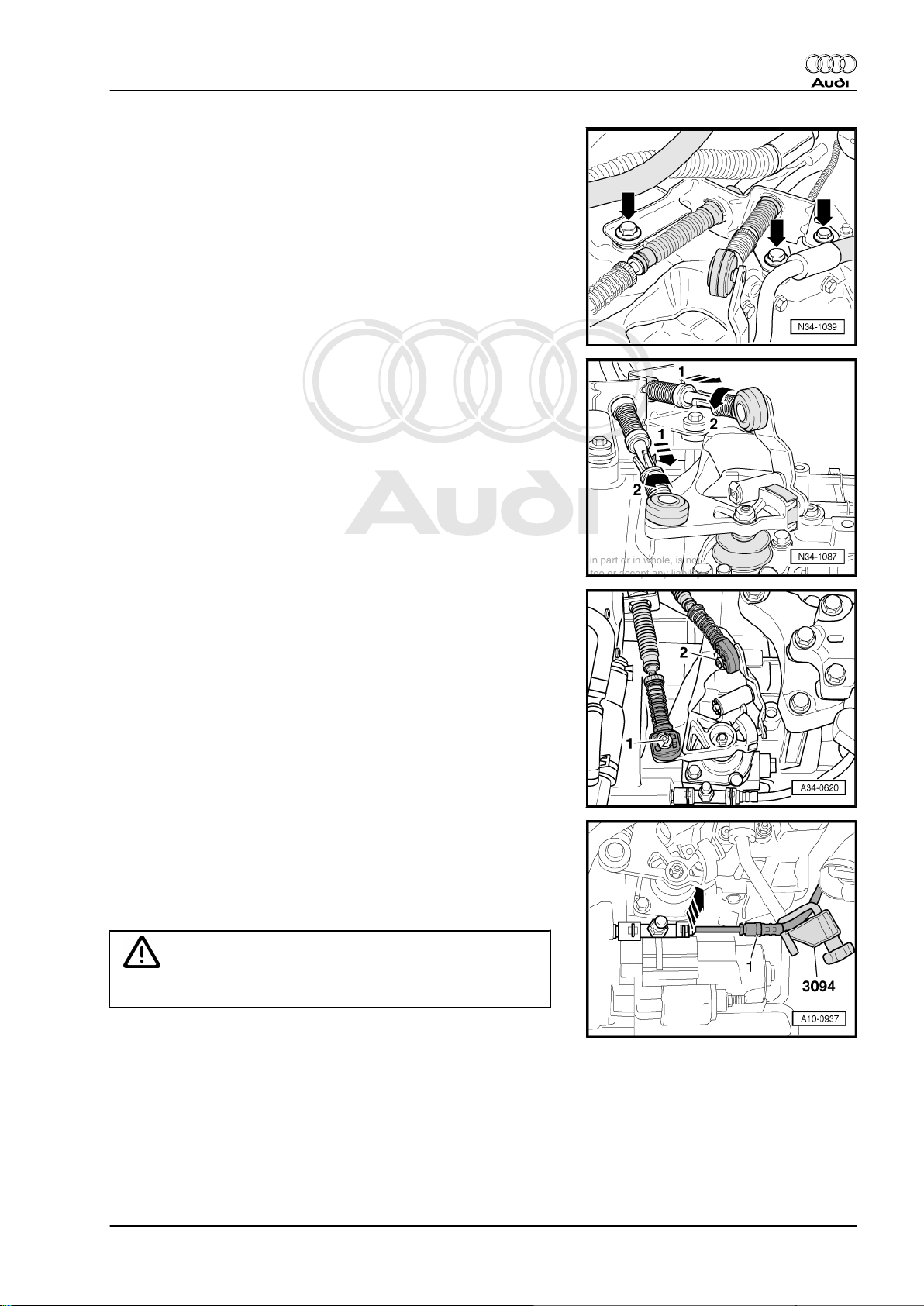

– Disconnect fuel supply pipe -1- and fuel return pipe -2- by

pressing release tabs.

– Loosen bolts -arrows- of assembly mounting for engine ap‐

prox. 2 turns.

– Loosen bolts -arrows- of assembly mounting for gearbox ap‐

prox. 2 turns.

14 Rep. Gr.10 - Removing and installing engine

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

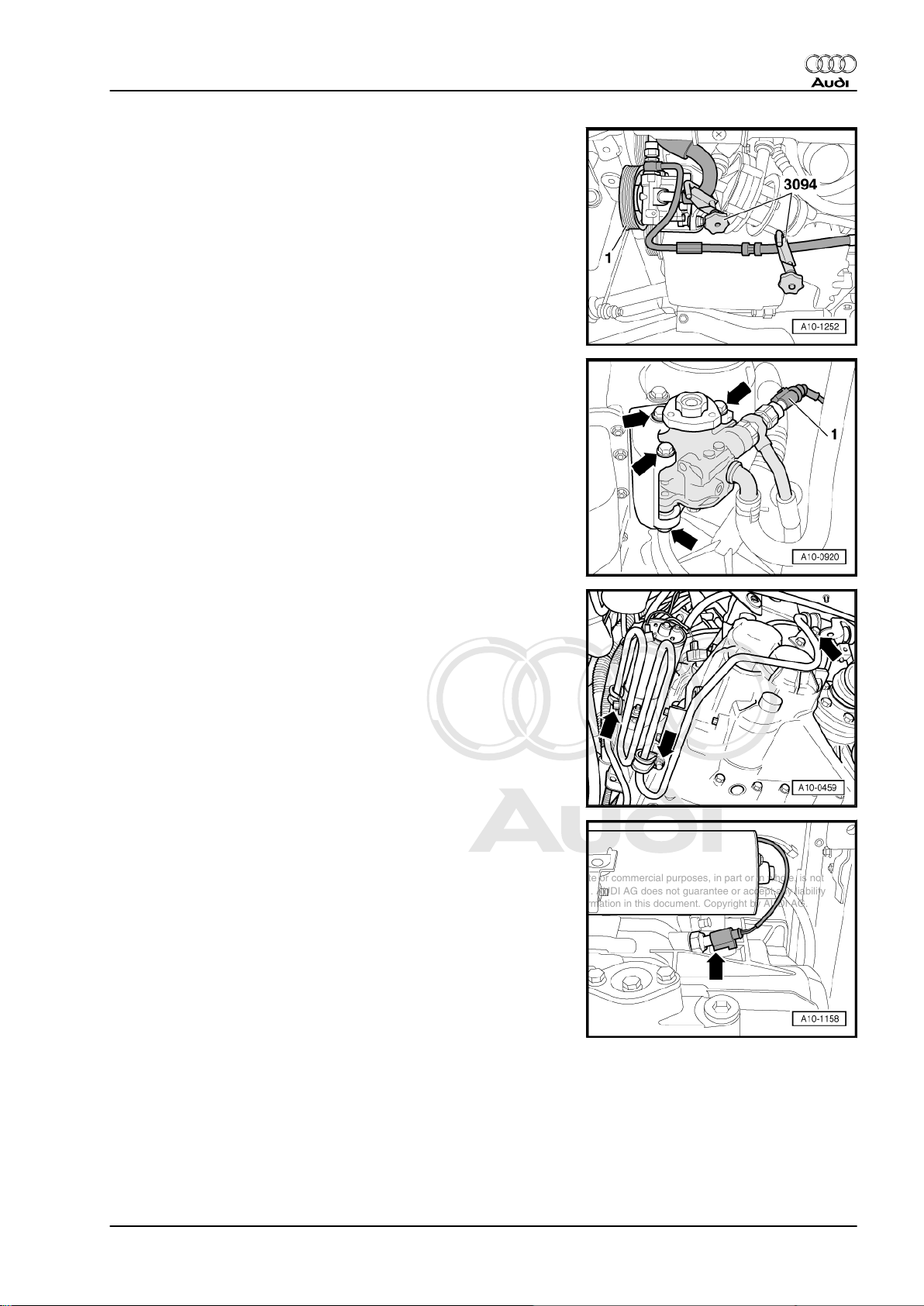

– Unbolt pulley -1- for power steering pump.

– Use hose clamps -3094- to clamp off both hydraulic hoses to

power steering pump.

– Unplug electrical connector -1- at power assisted steering

pressure switch -F88- .

– Place used oil collection and extraction unit -V.A.G 1782- un‐

der power steering pump.

– Disconnect hydraulic hoses from power steering pump.

– Unscrew power steering pump from bracket -arrows-.

Audi TT 1999 ➤

– Detach power steering cooling pipe from gearbox -arrows-.

– Unplug electrical connector -arrow- for reversing light switch -

F4- on gearbox.

1. Removing and installing engine 15

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

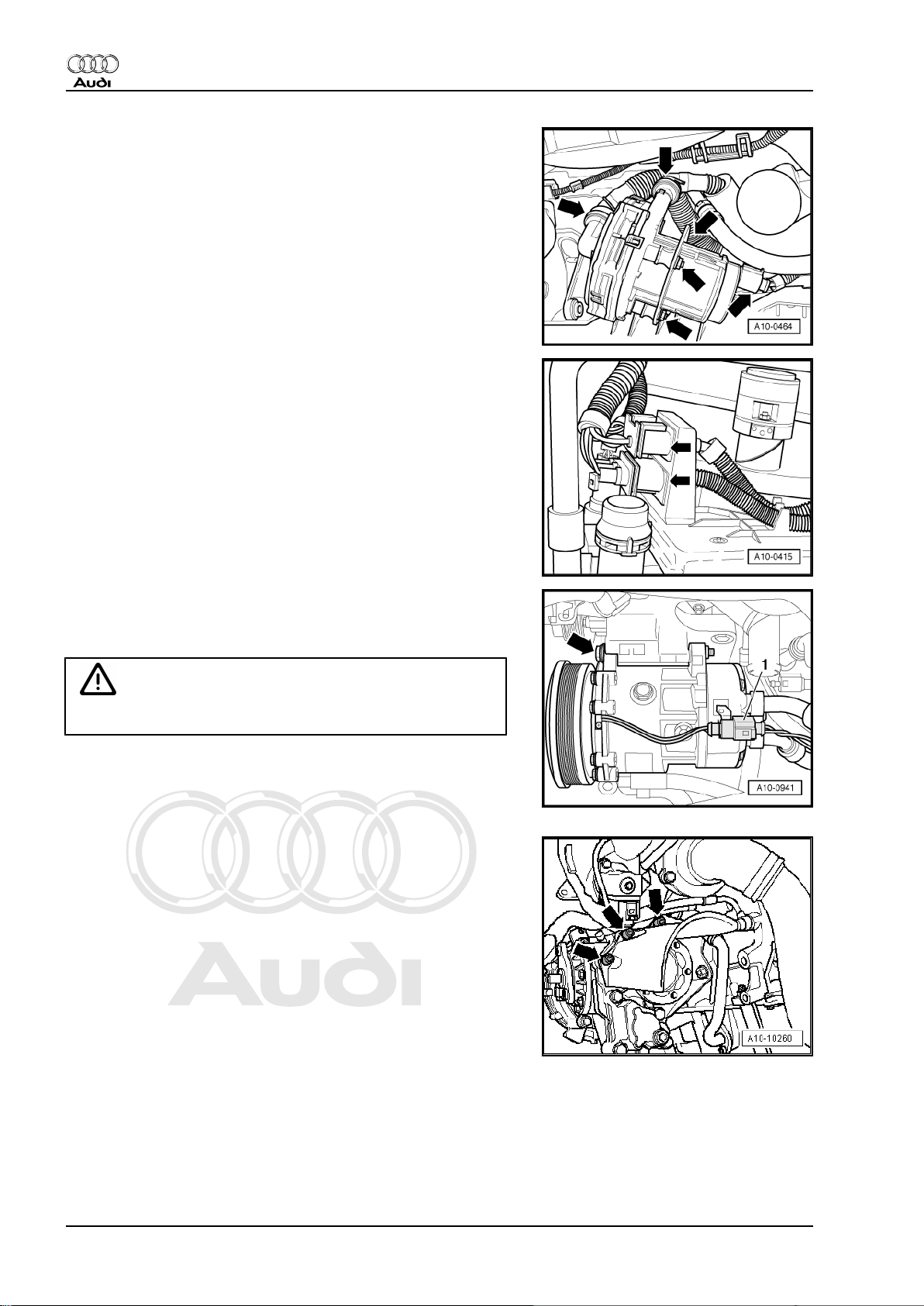

Vehicles with secondary air system:

– Unplug electrical connector at secondary air pump motor -

V101- , detach hoses and remove nuts -arrows-.

– Detach secondary air pump.

– Release wiring harness leading to body from retainers, etc.

All models:

– Detach electrical connectors -arrows- for radiator fan on bot‐

tom left of radiator cowl.

– Unscrew bolts on radiator cowl (accessible from below) and

remove radiator cowl with both fans from below.

Vehicles with air conditioning:

– Unplug electrical connector -1- for magnetic clutch of air con‐

ditioner compressor.

WARNING

The air conditioner refrigerant circuit must not be opened.

– Unscrew bolts -arrow- for air conditioner compressor.

– Tie up air conditioner compressor together with refrigerant ho‐

ses to radiator (refrigerant hoses remain connected).

– Unscrew heat shield for drive shaft (right-side) from bevel box

-arrows-.

– Unbolt drive shafts (left and right) from gearbox flange shafts.

16 Rep. Gr.10 - Removing and installing engine

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Remove cross piece -arrows-.

Vehicles with 2 Lambda probes:

– Unbolt protective cover -2- -arrows-.

– Unplug electrical connector for Lambda probe after catalytic

converter -G130- -item 1- and move wiring clear.

Audi TT 1999 ➤

All models:

– Unbolt catalytic converter from front exhaust pipe -arrows-.

– Separate exhaust system at clamp -arrows-.

– Push the clamp back and remove the catalytic converter.

1. Removing and installing engine 17

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Remove rubber mounting -arrow- for front exhaust pipe.

– Unbolt front exhaust pipe from turbocharger connection and

move to rear.

Note

♦

The top bolts securing the front exhaust pipe are accessible

through the brake pipe opening in the right wheel housing (re‐

move plug).

♦

To avoid any damage, the flexible joint in the front exhaust

pipe must not be bent more than 10°.

– Mark position of flexible coupling on bevel box.

– Unscrew propshaft with flexible coupling from bevel box

-arrows- (counter-hold using a suitable lever at the triangular

flange).

Caution

Avoid damaging the seal -arrow- in the propshaft flange when

removing. If a seal is damaged the propshaft must be renewed.

– Push propshaft horizontally as far back as possible.

18 Rep. Gr.10 - Removing and installing engine

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

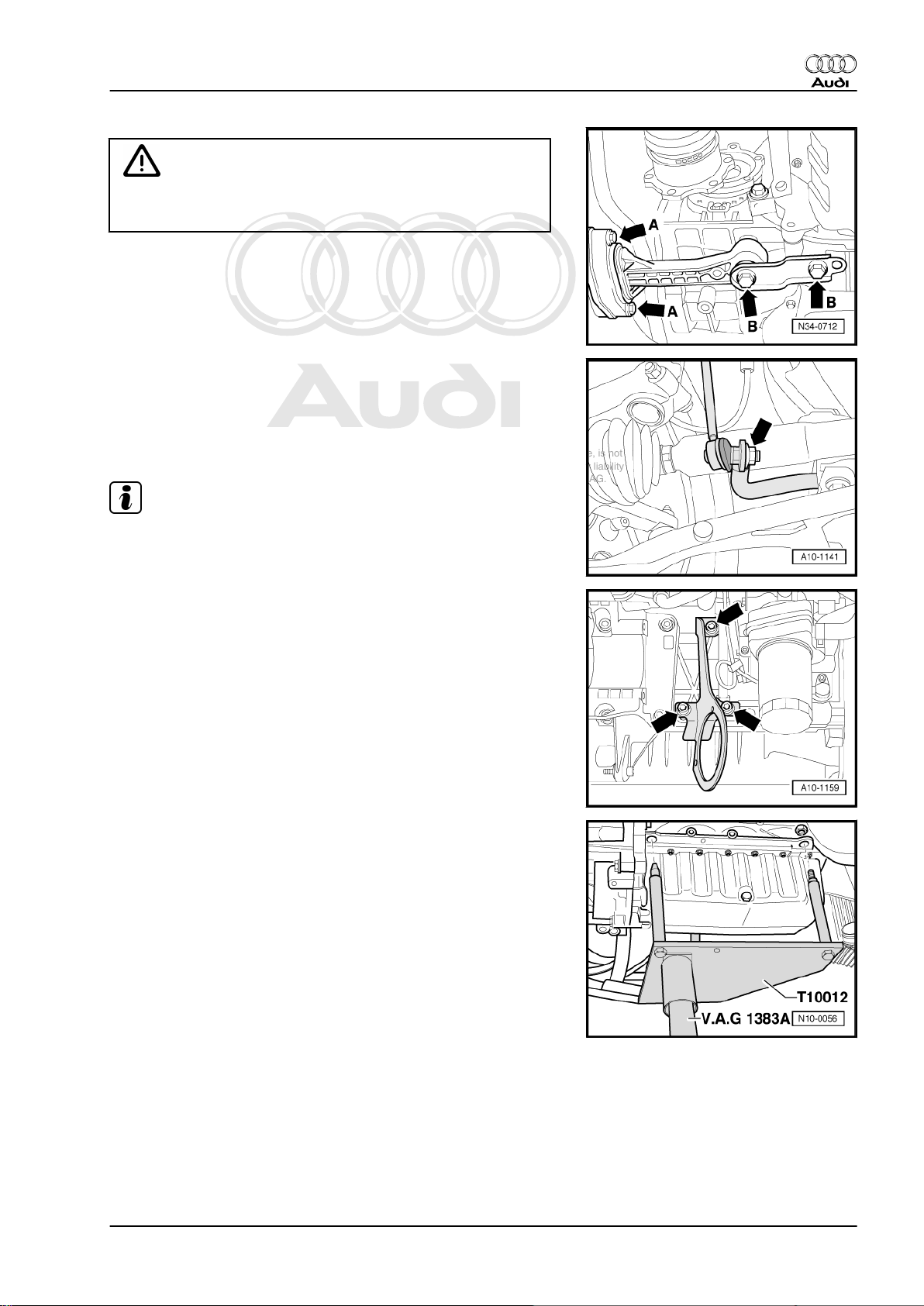

Caution

After unscrewing the bolts -A-, the engine/gearbox assembly

swings slightly forward.

– First remove bolts -A-, then bolts -B- and remove pendulum

support.

– Unbolt coupling rod from anti-roll bar -arrow- on left and right

side of vehicle.

– Push engine forward. At the same time swivel right drive shaft

towards front and tie up with wire.

– Tie up left-side drive shaft with wire.

Note

Audi TT 1999 ➤

Take care not to damage the surface coating of the drive shafts.

Vehicles with secondary air system:

– Remove bracket for secondary air pump -arrows-.

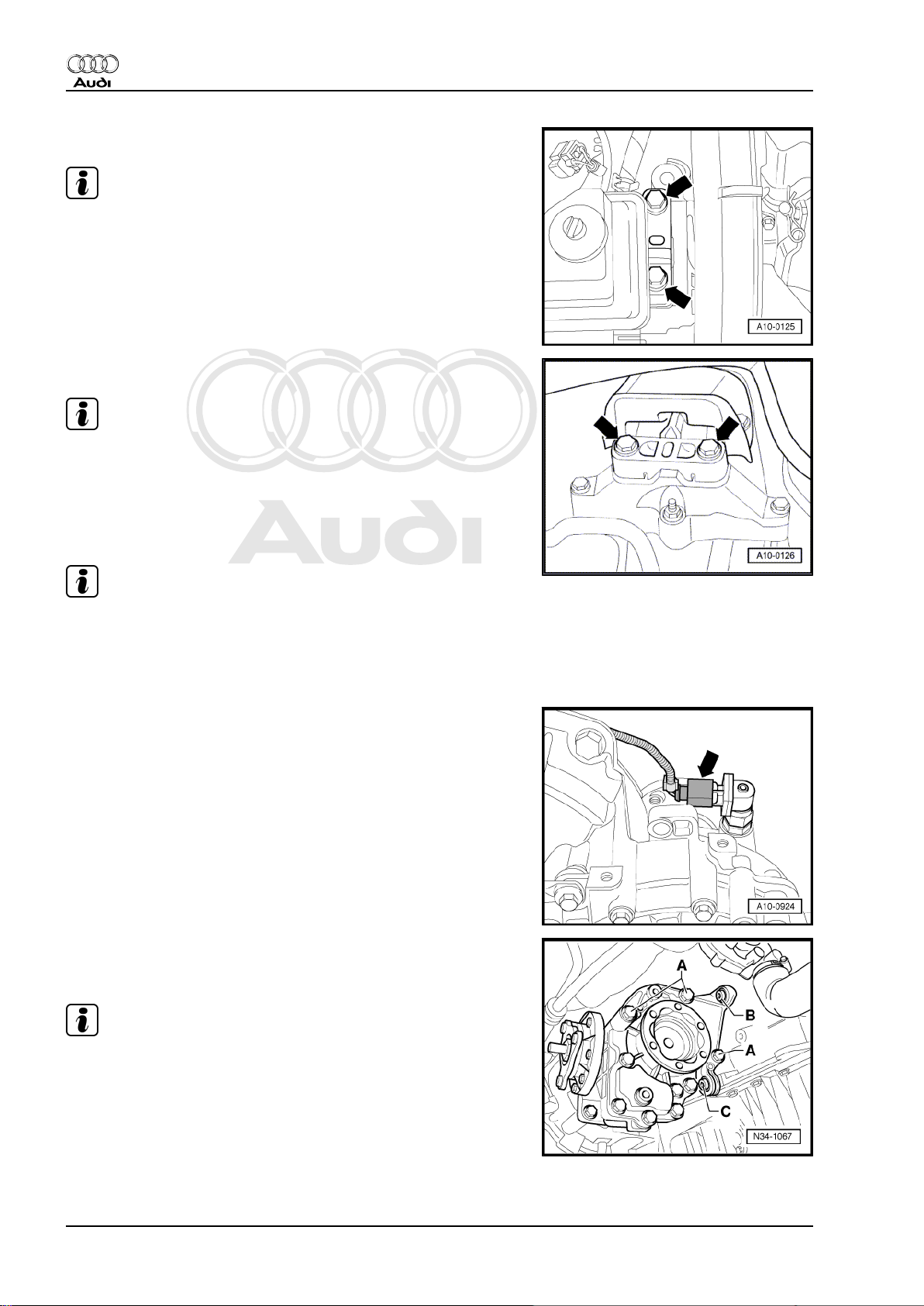

All models:

– Attach engine bracket -T10012- with nut and bolt to cylinder

block: approx. 20 Nm.

– Insert engine and gearbox jack -V.A.G 1383 A- in engine

bracket -T10012- and raise engine slightly.

1. Removing and installing engine 19

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Remove bolts -arrows- of assembly mounting on engine.

Note

To unscrew bolts for assembly mounting use stepladder VAS 5085- .

– Remove bolts -arrows- of assembly mounting on gearbox.

Note

Check that all hoses, pipes and wiring connections between en‐

gine, gearbox and body have been detached.

– Pull engine/gearbox assembly as far forward as possible, and

lower gradually using engine and gearbox jack V.A.G 1383 A- .

Note

Carefully guide engine/gearbox assembly when lowering to avoid

damage.

1.2 Separating engine and gearbox

Procedure

• Engine/gearbox assembly removed and attached to engine

bracket -T10012- .

– Unplug electrical connector -arrow- at speedometer sender -

G22- on gearbox and release wiring from retainers, etc.

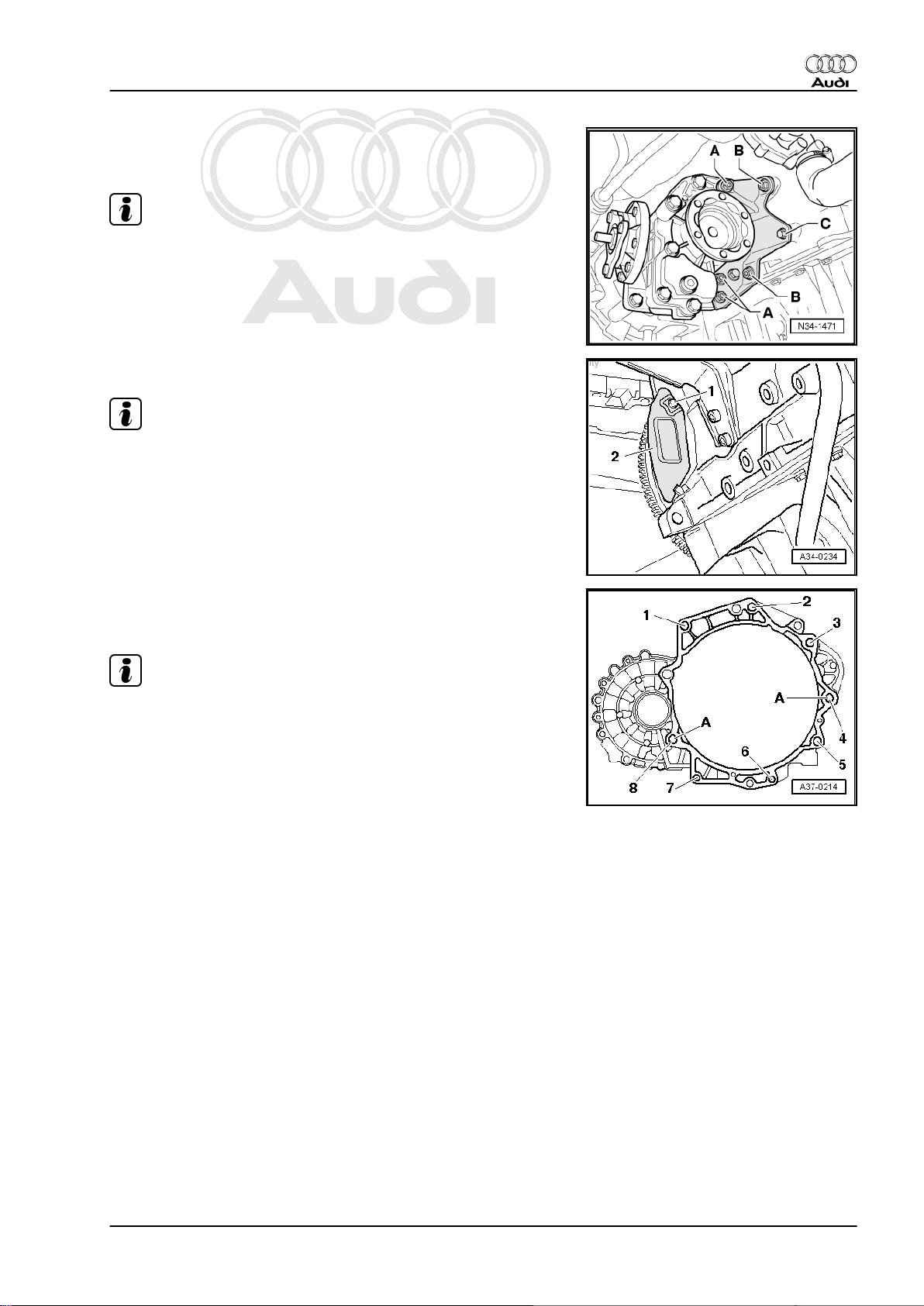

Vehicles with cast bracket for bevel box:

– Remove bolts -A ... C- on bracket for bevel box.

Note

Leave bracket in position. It cannot be removed at this stage.

20 Rep. Gr.10 - Removing and installing engine

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

Vehicles with pressed steel bracket for bevel box:

– Remove bolts -A ... C- on bracket for bevel box.

Note

Leave bracket in position. It cannot be removed at this stage.

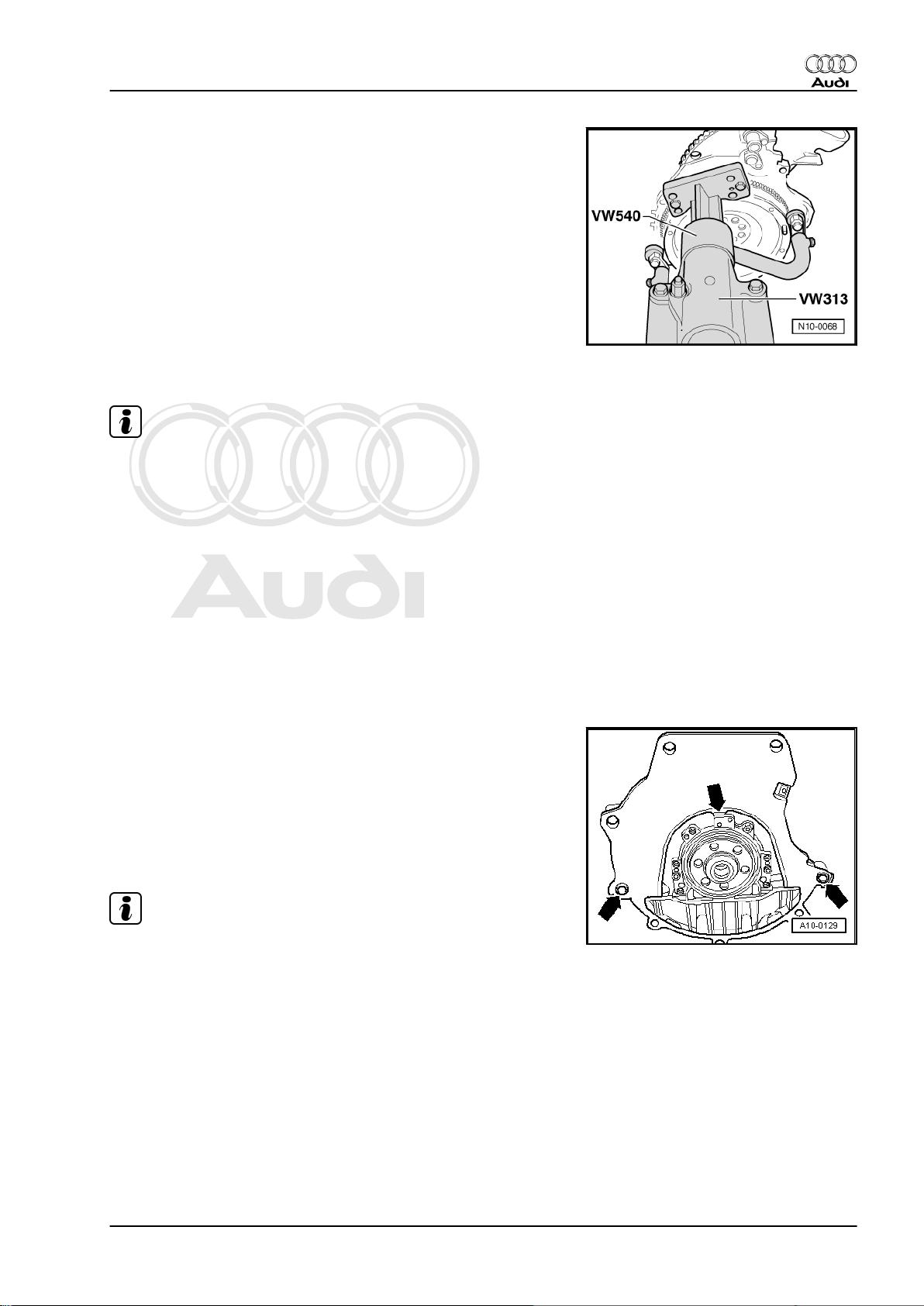

All models:

Note

The small cover plate -2- for the flywheel is located behind the

bevel box and is not visible with the bevel box installed. Shown in

illustration with gearbox removed.

Audi TT 1999 ➤

– Unscrew bolt -1- and lift out cover plate.

– Remove bottom engine/gearbox securing bolts -1 ... 8-.

– Separate gearbox from engine.

Note

Second mechanic is required to separate engine/gearbox as‐

sembly.

1. Removing and installing engine 21

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

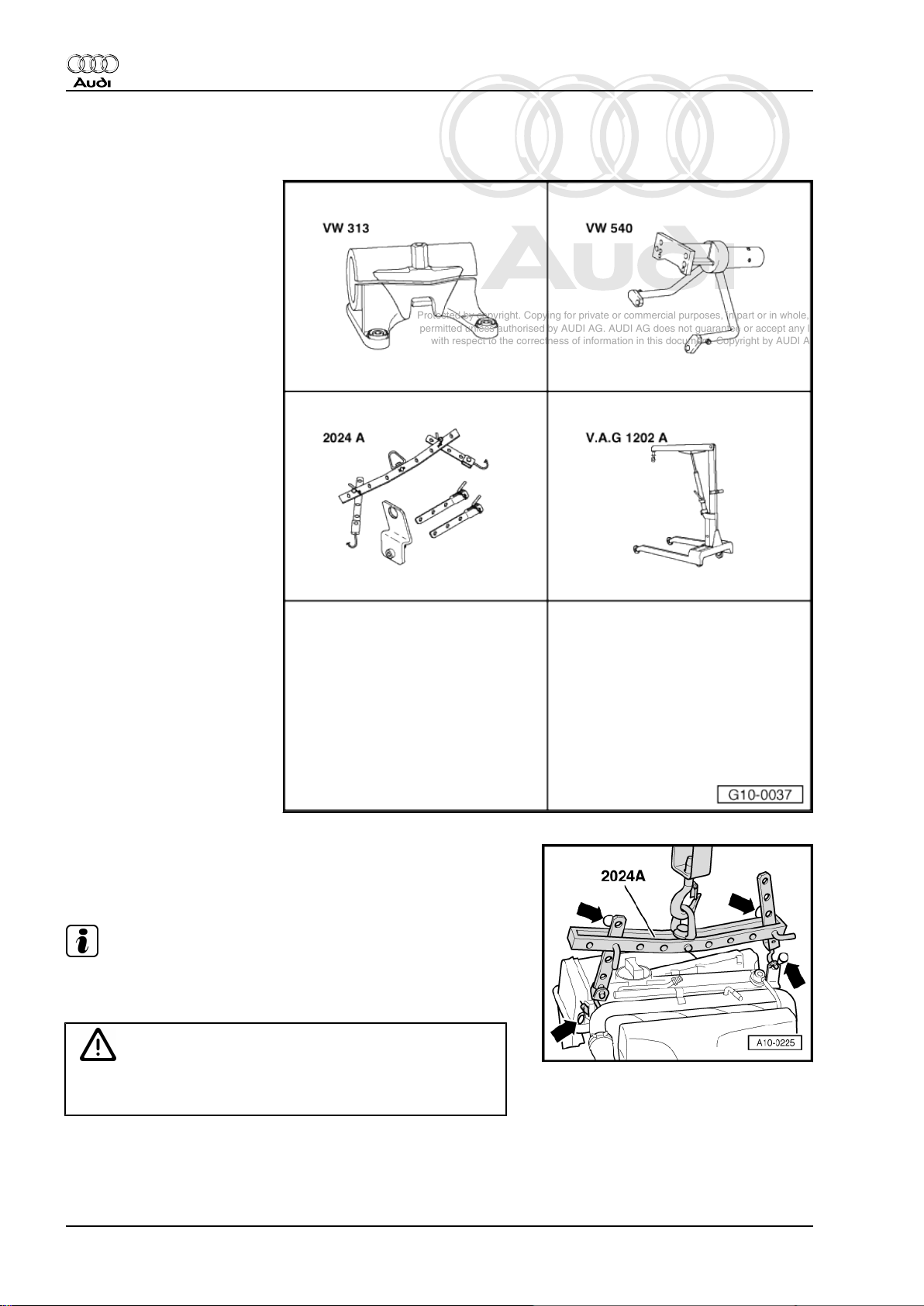

1.3 Securing engine to assembly stand

Special tools and workshop

equipment required

♦ Support clamp -VW 313-

♦ Engine and gearbox sup‐

port -VW 540-

♦ Lifting tackle -2024 A-

♦ Workshop hoist -6100- or -

V.A.G 1202 A-

Procedure

– Hook lifting tackle -2024 A- onto engine and workshop hoist

-6100- .

Note

To adjust to the centre of gravity of the assembly, the perforated

rails of the support hooks must be positioned as shown.

WARNING

The support hooks and retaining pins on the lifting tackle must

be secured with locking pins -arrows-.

– Lift engine off engine and gearbox jack -V.A.G 1383 A- using

workshop hoist -6100- .

22 Rep. Gr.10 - Removing and installing engine

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– When carrying out repairs, secure engine to assembly stand

with engine and gearbox support -VW 540- .

1.4 Installing engine

Note

♦

On assembly, renew oil seals and gaskets as well as selflocking nuts and bolts that are tightened by turning through to

a specified angle.

♦

Hose connections and hoses for charge air system must be

free of oil and grease before assembly.

♦

Fit all heat insulation sleeves in the original position when in‐

stalling.

♦

Secure all hose connections with the correct type of hose clips

(same as original equipment) ⇒ Parts catalogue.

♦

Fit all cable ties in the original positions when installing.

– Check whether dowel sleeves for centring the engine/gearbox

assembly are fitted in the cylinder block; install dowel sleeves

if necessary.

– Engage intermediate plate on sealing flange and slip onto

dowel sleeves -arrows-.

Audi TT 1999 ➤

– Check that clutch plate is correctly centred.

– Check clutch release bearing for wear, renew if necessary.

– Lightly grease clutch release bearing, release bearing guide

sleeve and splines on input shaft with grease for clutch plate

splines -G 000 100- .

Note

♦

Tightening torques apply only to lightly greased, oiled,

phosphated or black-finished nuts and bolts.

♦

Additional lubricant such as engine oil or gearbox oil may be

used, but do not use lubricant containing graphite.

♦

Do not use degreased parts.

♦

Tolerance for tightening torques ± 15 %.

– Fit bracket for bevel box before fitting engine/gearbox securing

bolts.

– Use new securing bolts.

1. Removing and installing engine 23

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

Securing engine to gearbox

Item

1, 2

3 1), 4

1)

1)

Bolt

2

Nm

M12x55 80

M12x165 80

5 M10x105 40

6, 7 M10x50 40

8 M12x70 80

A Dowel sleeves for centralising

1)

•

Bolt with M8 stud

2)

•

Renew bolts.

– Install new engine/gearbox securing bolts accessible from be‐

low.

– Push in small cover plate -2- for flywheel behind bevel box in

such a way that lug at bottom engages into cylinder block and

secure with bolt -1-.

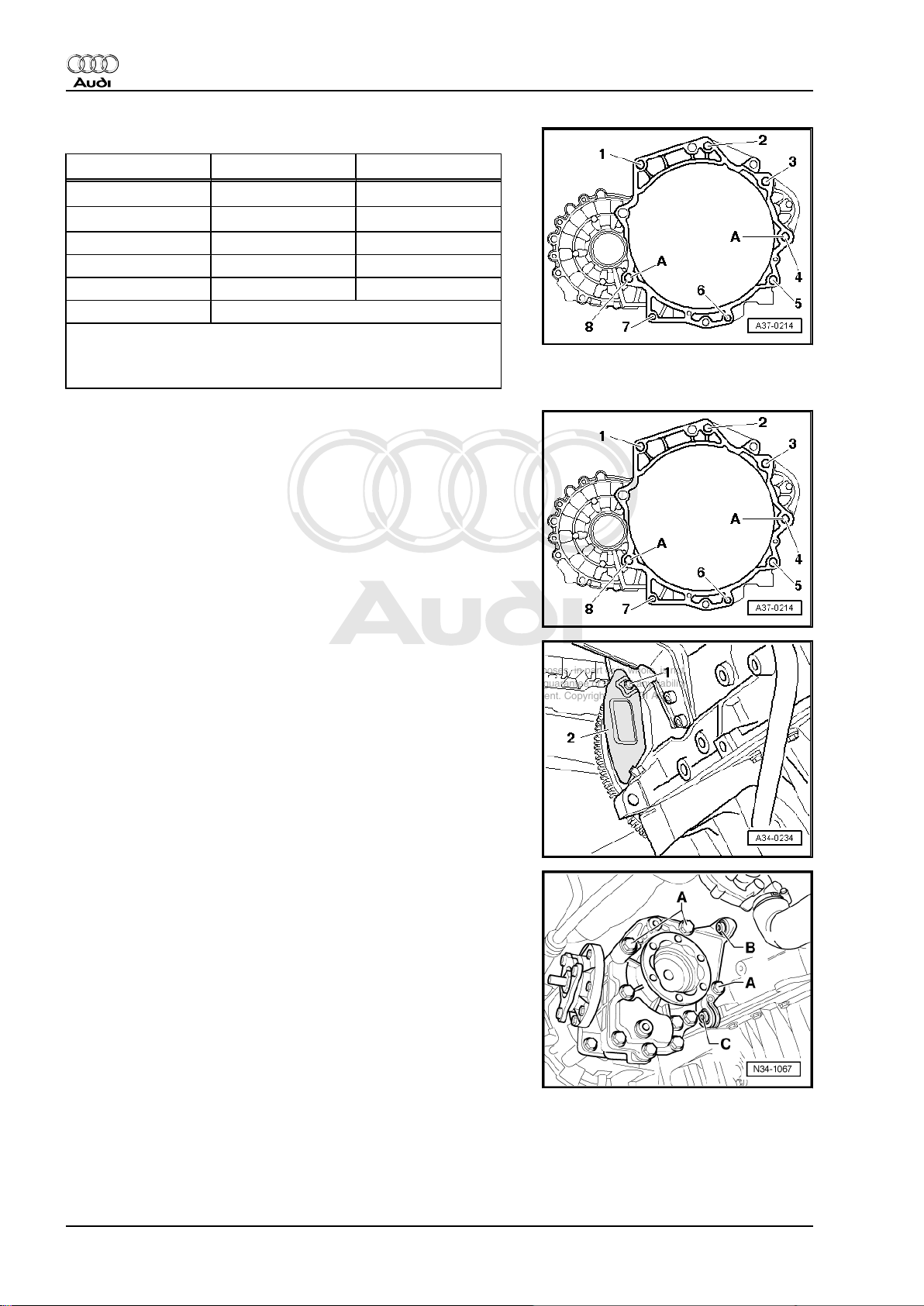

Vehicles with cast bracket for bevel box:

– Fit bolts -A ... C- for bevel box bracket. Note tightening se‐

quence:

1. Initially tighten bolts -A- to 3 Nm.

2. Tighten bolts -B- and -C- to 35 Nm.

3. Tighten bolts -A- to 45 Nm.

24 Rep. Gr.10 - Removing and installing engine

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

Vehicles with pressed steel bracket for bevel box:

– Fit bolts -A ... C- for bevel box bracket. Note tightening se‐

quence:

1. Initially tighten bolts -A- to 3 Nm.

2. Tighten bolts -B- to 35 Nm.

3. Tighten bolt -C- to 22 Nm.

4. Tighten bolts -A- to 45 Nm.

All models:

– Guide engine/gearbox assembly into the body.

– Tighten bolts securing engine mounting to engine support

-arrows- initially hand-tight.

Audi TT 1999 ➤

– Tighten bolts securing gearbox mounting to gearbox support

-arrows- initially hand-tight.

– Use new securing bolts.

Note

The bolts are tightened to final torque only after adjusting the en‐

gine mountings ⇒ page 29 .

– Remove engine bracket -T10012- from engine.

– Bolt drive shafts to flange shafts of gearbox ⇒ Rep. Gr. 40 .

Note

Drive shafts must be installed prior to further assembly.

– Secure coupling rod to anti-roll bar ⇒ Rep. Gr. 40 .

– Secure pendulum support at gearbox -arrows B-.

– Use new securing bolts.

1. Removing and installing engine 25

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

Caution

Avoid damaging the seal -arrow- in the propshaft flange when

installing. If a seal is damaged the propshaft must be renewed.

– Push engine/gearbox assembly towards bulkhead; the journal

of the bevel box must be simultaneously inserted horizontally

and carefully into the flange of the propshaft.

– Secure pendulum support to subframe -arrows A-.

– Use new securing bolts.

– Secure propshaft with flexible coupling to bevel box -arrows-

⇒ Rep. Gr. 39 .

– Install catalytic converter and front exhaust pipe

⇒ page 196 .

– Install exhaust system and align it free of stress

⇒ page 201 .

– Install cross piece; note marking “L” or “Links” for left side of

vehicle.

– Use new securing bolts.

– Knock back bushes for securing bolts slightly to facilitate in‐

stallation of power steering pump and air conditioner com‐

pressor.

– Install power steering pump ⇒ Rep. Gr. 48 .

– Install secondary air pump ⇒ page 223 .

– Install air conditioner compressor ⇒ Rep. Gr. 87 .

26 Rep. Gr.10 - Removing and installing engine

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Push the hydraulic line -1- for clutch slave cylinder into the

hose connector and lock it with the catch.

Caution

The clutch pedal must not be depressed prior to bleeding the

clutch system.

– Detach hose clamp -3094- .

– Bleed clutch hydraulics ⇒ Rep. Gr. 30 .

Remaining installation steps are carried out in reverse sequence;

note the following:

– Install cable support bracket and selector cables ⇒ Rep. Gr.

34 .

– Adjust selector cables ⇒ Rep. Gr. 34 .

– Install battery tray and battery ⇒ Rep. Gr. 27 .

– Install poly V-belt ⇒ page 34 .

– Adjust assembly mountings ⇒ page 29 .

– Connect vacuum hoses ⇒ page 157 .

– Install cross piece for suspension strut ⇒ Rep. Gr. 40 .

– Electrical connections and routing ⇒ Current flow diagrams,

Electrical fault finding and Fitting locations.

– Observe notes on procedures required after connecting bat‐

tery ⇒ Rep. Gr. 27 .

– Install and adjust wiper arms ⇒ Rep. Gr. 92 .

– Check oil level ⇒ page 133 .

– Fill cooling system ⇒ page 138 .

Audi TT 1999 ➤

Note

♦

Drained-off coolant may only be used again if the original cyl‐

inder head and cylinder block are re-installed.

♦

Contaminated or dirty coolant must not be used again.

Caution

Never use battery charging equipment for boost starting. There

is danger of damaging the vehicle's control units.

1. Removing and installing engine 27

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

Tightening torques

Component Nm

Bolts/nuts M6 9

M8 20

M10 45

M12 65

Except for the following:

Radiator cowl to radiator 10

Pendulum support to: Gearbox

Subframe

40 + 90°

20 + 90°

Drive shaft heat shield to bevel box 25

Rear cross piece to subframe

Connecting pipe for charge air coolers to lon‐

30 + 90°

20

gitudinal member

Hose clips for air hoses 3.5

1)

•

Renew bolts.

2)

•

90° = one quarter turn.

3)

•

Install using locking fluid; for locking fluid refer to ⇒ Parts

catalogue .

1)2)

1)2)

1)2)3)

28 Rep. Gr.10 - Removing and installing engine

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

2 Adjusting assembly mountings

2.1 Checking adjustment

Procedure

– Take off engine cover panel -arrows-.

– Unscrew bolt -1- and remove cover over coolant expansion

tank -arrow-.

Audi TT 1999 ➤

– Remove air pipe -arrows-.

2. Adjusting assembly mountings 29

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Detach power steering reservoir above engine mounting

(right-side) and move to side.

• Both bolt heads -b- must be flush with the edge of the support

arm -2-.

• The distance -a- between engine mounting -1- and support

arm -2- must be 13 mm.

– Check gap -a- with 12 mm iron bar (or support bridge -2011- ).

• The bar must be easy to insert.

Installation is carried out in the reverse order; note the following:

Note

♦

Hose connections and hoses for charge air system must be

free of oil and grease before assembly.

♦

Secure all hose connections with the correct type of hose clips

(same as original equipment) ⇒ Parts catalogue.

Tightening torque

Component Nm

Hose clips for air hoses 3.5

2.2 Adjusting assembly mountings

Special tools and workshop equipment required

♦ Support bracket -10-222 A-

Procedure

If the distance measured is too small or too great, proceed as

follows:

– Remove covers -1- and -2- at lock carrier (left-side) and above

battery -arrows-.

30 Rep. Gr.10 - Removing and installing engine

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Remove cover -1- (right-side) on lock carrier

-bottom arrows-.

Note

Disregard -item 2-.

– If fitted, detach air intake hose -1- leading to secondary air

pump at air cleaner housing.

– Release hose clip -2- and detach air intake hose from air mass

meter -G70- .

– Unplug electrical connector at air mass meter -G70-

-item 3-.

– Unscrew bolts -4- and -5- and remove air cleaner housing.

Audi TT 1999 ➤

– Set up support bracket -10-222 A- on top surface of panel

flange.

• The spindles face forwards.

– Attach hooks of spindles to engine lifting eyes.

– Lift the engine evenly a short distance with both spindles.

– Remove bolts -arrows- of assembly mounting on engine.

2. Adjusting assembly mountings 31

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Remove bolts -arrows- of assembly mounting on gearbox.

– Renew all 4 bolts one after the other and hand-tighten.

– Loosen bolts -b- for support arms on right and left sides ap‐

prox. 2 turns.

– Use lever to adjust engine until distance -a- between engine

mounting -1- and support arm -2- is 13 mm.

• It should be possible to insert the 12 mm iron bar (or support

bridge -2011- ) easily.

• Both bolt heads -b- must be flush with the edge of the support

arm.

– Tighten the bolts -b- for engine assembly mounting.

– Ensure that the edges of the support arm (on the gearbox as‐

sembly mounting) -a- and gearbox mounting -b- are parallel.

– Tighten the bolts for gearbox assembly mounting.

Installation is carried out in the reverse order; note the following:

Note

Secure all hose connections with the correct type of hose clips

(same as original equipment) ⇒ Parts catalogue.

Tightening torques

Component Nm

Support arm to: Gearbox support

Engine support

1)

•

Renew bolts.

2)

•

90° = one quarter turn.

60 + 90°

60 + 90°

1)2)

1)2)

32 Rep. Gr.10 - Removing and installing engine

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

13 – Crankshaft group

1 Servicing work on pulley end

1.1 Poly V-belt drive - exploded view of components

Note

The illustration shows the poly V-belt drive on vehicles with air conditioner.

1 - Poly V-belt

❑ Routing of belt on vehi‐

cles without air condi‐

tioner ⇒ page 34

❑ Routing of belt on vehi‐

cles with air conditioner

⇒ page 34

❑ Double-sided poly V-

belt on vehicles with air

conditioner

❑ Before removing, mark

direction of rotation with

chalk or felt-tipped pen.

If the belt runs in the op‐

posite direction when it

is refitted, this can

cause breakage.

❑ Check for wear

❑ Do not kink

❑ Removing and installing

⇒ page 34

Audi TT 1999 ➤

2 - 23 Nm

3 - Poly V-belt tensioner

❑ Turn with open-end

spanner to slacken poly

V-belt ⇒ page 36

4 - Vibration damper

❑ With pulley for poly V-

belt

❑ Removing and installing

⇒ page 37

5 - 45 Nm

6 - 23 Nm

7 - Alternator

❑ Removing and installing ⇒ Rep. Gr. 27

❑ To facilitate attachment of alternator, knock back threaded bushes for alternator securing bolts slightly

8 - Air conditioner compressor

❑ Removing and installing ⇒ Rep. Gr. 87

❑ After detaching, secure compressor to lock carrier using wire or similar. Do not leave it suspended from

refrigerant pipes.

❑ Do not unscrew or disconnect refrigerant hoses or pipes.

1. Servicing work on pulley end 33

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

❑ To facilitate attachment of air conditioner, knock back threaded bushes for securing bolts slightly

9 - Spacer bush

10 - Bracket for ancillaries

❑ Removing and installing ⇒ page 38

11 - 45 Nm

12 - 23 Nm

13 - 23 Nm

14 - Power steering pump

❑ Removing and installing ⇒ Rep. Gr. 48

❑ To facilitate positioning of power steering pump, drive back threaded bush for securing bolt slightly at

bracket

15 - Pulley for power steering pump

16 - 23 Nm

17 - Special bolt

❑ For correct version refer to ⇒ Parts catalogue

❑ If bolt strength rating is 8.8, renew bolt and tighten to 10 Nm + 90° further

❑ If bolt strength rating is 10.9, tighten to 40 Nm

Routing of poly V-belt on vehicles without air conditioner

Routing of poly V-belt on vehicles with air conditioner

Note

A double-sided poly V-belt is fitted on engines with A/C compres‐

sor.

1.2 Removing and installing poly V-belt

Special tools and workshop equipment required

34 Rep. Gr.13 - Crankshaft group

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

♦ Locking pin -T10060 A-

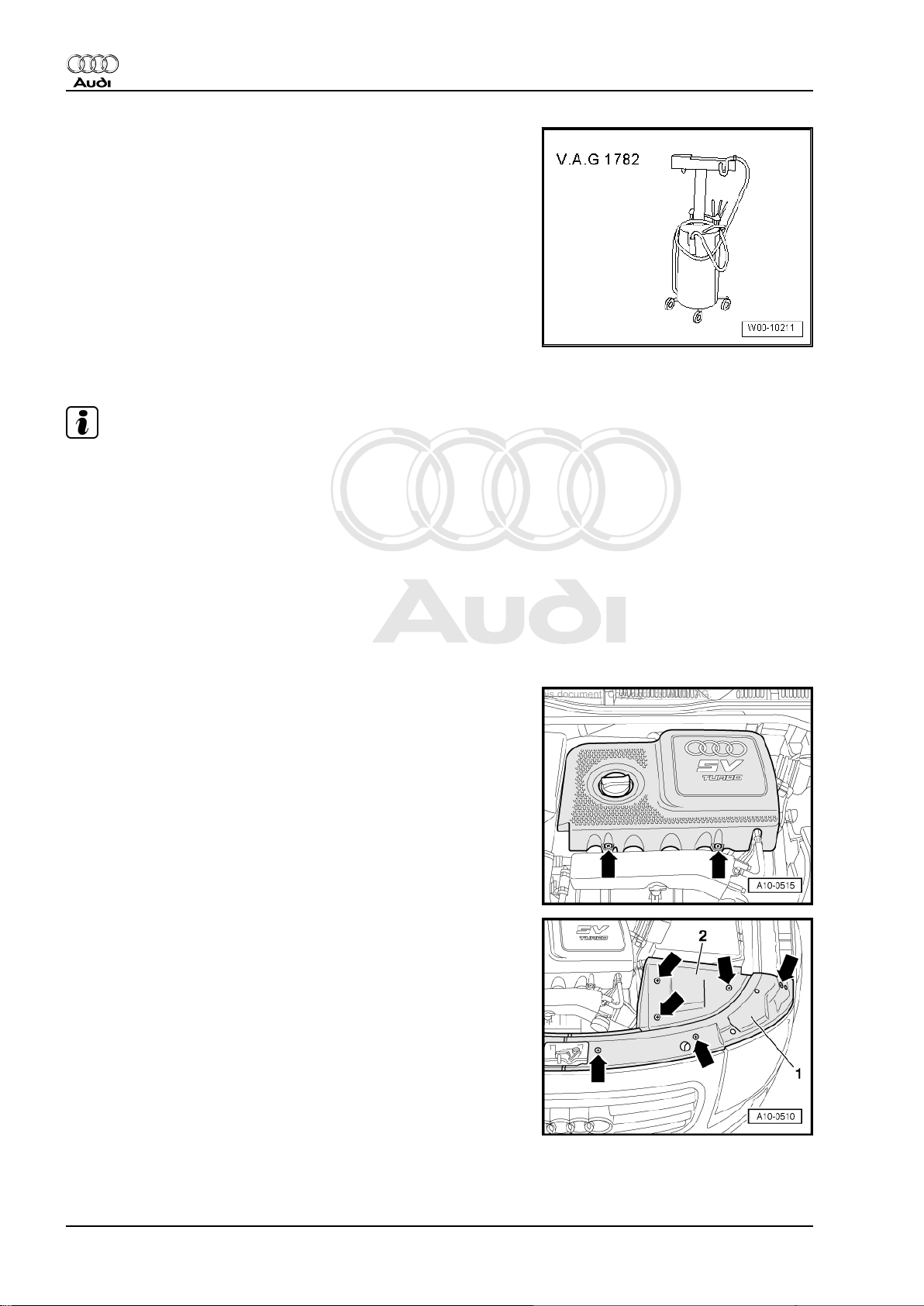

Removing

– Take off engine cover panel -arrows-.

Audi TT 1999 ➤

– Unscrew bolt -1- and remove cover over coolant expansion

tank -arrow-.

– Remove air pipe -arrows-.

1. Servicing work on pulley end 35

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

Note

Before removing, mark direction of rotation of poly V-belt with

chalk or felt-tipped pen. If the belt runs in the opposite direction

when it is refitted, this can cause breakage.

– Turn the tensioner in the direction of the -arrow- to slacken the

poly V-belt.

– Lock tensioner in position with locking pin -T10060 A- .

– Remove centre noise insulation -1 ... 3-.

36 Rep. Gr.13 - Crankshaft group

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Remove right noise insulation -arrows-.

– Remove poly V-belt.

Installing

Installation is carried out in the reverse order; note the following:

Note

♦

Before fitting poly V-belt, make sure all mechanical units (al‐

ternator, air conditioner compressor, power steering pump)

are firmly in position.

♦

Hose connections and hoses for charge air system must be

free of oil and grease before assembly.

♦

Secure all hose connections with the correct type of hose clips

(same as original equipment) ⇒ Parts catalogue.

– Fit poly V-belt onto crankshaft pulley, power steering pump

pulley and then onto alternator pulley.

– Release pressure from tensioner and remove locking pin -

T10060 A- .

– Check poly V-belt for proper seating.

• Routing of poly V-belt on vehicles without air conditioner

⇒ page 34 .

• Routing of poly V-belt on vehicles with air conditioner

⇒ page 34 .

– Start engine and check that belt runs properly.

Tightening torque

Audi TT 1999 ➤

Component Nm

Hose clips for air hoses 3.5

1.3 Removing and installing vibration damp‐

er

Removing

– Remove poly V-belt ⇒ page 34 .

– Unbolt vibration damper; counterhold on centre bolt with ring

spanner.

1. Servicing work on pulley end 37

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

Installing

Installation is carried out in the reverse order; note the following:

– When installing the vibration damper, use only genuine bolts

(same as original equipment): ⇒ Parts catalogue .

• The vibration damper can only be installed in one position. The

hole -arrow- in the vibration damper must be located over the

projection on the toothed belt sprocket.

– Install poly V-belt ⇒ page 34 .

Tightening torque

Component Nm

Vibration damper

to crankshaft

1)

•

Renew bolts.

Bolt strength rating 8.8

10 + 90°

Bolt strength rating 10.9 40

1)2)

• 90° equals a 1/4 turn.

1.4 Removing and installing bracket for an‐

cillaries

Special tools and workshop equipment required

♦ Hose clamps for hoses up to 25 mm Ø -3094-

♦ Used oil collection and extraction unit -V.A.G 1782-

38 Rep. Gr.13 - Crankshaft group

Page 45

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

Removing

– Remove engine cover -arrows- and cover in front of intake

manifold.

– Remove covers -1- and -2- at lock carrier (left-side) and above

battery -arrows-.

Audi TT 1999 ➤

– Remove covers -1- and -2- at lock carrier (right-side) and

above coolant expansion tank -arrows-.

Caution

Observe notes on procedure for disconnecting the battery ⇒

Rep. Gr. 27 .

– Disconnect earth wire at battery with ignition switched off.

– Remove poly V-belt ⇒ page 34 .

– Unbolt bracket for headlight range control sender in wheel

housing (left-side, top) -arrows-.

1. Servicing work on pulley end 39

Page 46

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Remove left noise insulation -arrows-.

– If fitted, detach power steering line from connecting pipe for

charge air coolers -arrows-.

– Unbolt connecting pipe for charge air coolers on left side

-arrows-.

– Unbolt connecting pipe for charge air coolers on right side and

detach air intake hoses from charge air coolers -arrows-.

– Remove connecting pipe for charge air coolers.

40 Rep. Gr.13 - Crankshaft group

Page 47

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Unbolt pulley -1- for power steering pump.

– Use hose clamps -3094- to clamp off both hydraulic hoses to

power steering pump.

– Unplug electrical connector -1- at power assisted steering

pressure switch -F88- .

– Place used oil collection and extraction unit -V.A.G 1782- un‐

der power steering pump.

– Disconnect hydraulic hoses from power steering pump.

– Detach power steering pump from bracket for ancillaries

-arrows-.

Audi TT 1999 ➤

Vehicles with secondary air system:

– Unplug electrical connector at secondary air pump motor -

V101- , detach hoses and remove nuts -arrows-.

– Detach secondary air pump.

Vehicles with exhaust temperature control:

– Unplug electrical connector -arrow- at exhaust gas tempera‐

ture sender 1 -G235- .

1. Servicing work on pulley end 41

Page 48

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

All models:

– Remove bolts -2- and -3- and detach retaining plate -4- from

dipstick guide tube.

– Disengage coolant hose -1- from retaining plate.

– Move retaining plate to the side (hoses remain connected).

– Detach vacuum line -2- from intake manifold.

Note

Disregard -item 1-.

– Unplug electrical connector -2-.

– Unscrew electrical wire -1- from alternator.

– Unscrew clamp and move electrical wiring clear.

– Unscrew bolts -arrows-.

– Detach alternator and guide it towards right out of engine com‐

partment.

42 Rep. Gr.13 - Crankshaft group

Page 49

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

Vehicles with air conditioning:

– Unscrew radiator fan (right-side) from radiator cowl, take out

downwards and tie up to body (wiring remains connected).

– Unplug electrical connector -1- for magnetic clutch of air con‐

ditioner compressor.

WARNING

The air conditioner refrigerant circuit must not be opened.

– Unscrew bolts -arrow- for air conditioner compressor.

Note

To prevent damage to the refrigerant lines, ensure that the pipes

and hoses are not stretched, kinked or bent.

– Lower air conditioner compressor and tie up to lock carrier.

Audi TT 1999 ➤

All models:

– Remove poly V-belt tensioner -arrows-.

1. Servicing work on pulley end 43

Page 50

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

– Unscrew bolts -A ... F- and remove bracket for ancillaries.

Installing

Installation is carried out in the reverse order; note the following:

Note

♦

Hose connections and hoses for charge air system must be

free of oil and grease before assembly.

♦

Secure all hose connections with the correct type of hose clips

(same as original equipment) ⇒ Parts catalogue.

– Tighten bolts in the sequence -A ... F-.

– Drive back the respective bushes for securing bolts slightly to

facilitate installation of alternator, power steering pump and air

conditioner compressor.

– Install power steering pump ⇒ Rep. Gr. 48 .

– Install air conditioner compressor ⇒ Rep. Gr. 87 .

– Install alternator ⇒ Rep. Gr. 27 .

– Install secondary air pump ⇒ page 223 .

– Observe notes on procedures required after connecting bat‐

tery ⇒ Rep. Gr. 27 .

– Install poly V-belt ⇒ page 34 .

Tightening torques

Component Nm

Bracket for ancillaries to cylinder block 45

Tensioner for poly V-belt to bracket for ancilla‐

23

ries

Radiator fan to radiator cowl 10

Connecting pipe for charge air coolers to longi‐

tudinal member

20

Pulley to power steering pump 23

44 Rep. Gr.13 - Crankshaft group

Page 51

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

1.5 Toothed belt - exploded view of components

1 - Engine support

2 - 45 Nm

3 - Toothed belt cover (top)

❑ To remove toothed belt

cover, it may be neces‐

sary to unbolt bracket

for coolant return line

(for turbocharger).

❑ Engage carefully in cen‐

tre toothed belt cover

when installing

4 - Toothed belt

❑ Before removing, mark

direction of rotation with

chalk or felt-tipped pen.

If the belt runs in the op‐

posite direction when it

is refitted, this can

cause breakage

❑ Check for wear

❑ Removing ⇒ page 47

❑ Installing (adjusting

valve timing)

⇒ page 51

5 - Idler roller

6 - 27 Nm

7 - 65 Nm

❑ Use counterhold tool

-3036- when loosening

and tightening

⇒ page 46

8 - Camshaft sprocket for ex‐

haust camshaft

❑ Remove toothed belt prior to removing and installing ⇒ page 47

❑ Installation position ⇒ page 46

9 - Tensioning roller

10 - Washer

11 - Tensioner for toothed belt

12 - O-ring

❑ Renew

❑ Lubricate with coolant additive Plus -G 012 A8F A1- prior to installing

13 - Coolant pump

❑ Removing and installing ⇒ page 141

14 - 15 Nm

15 - Crankshaft sprocket

❑ Contact surface between sprocket and crankshaft must be free of oil

❑ Can only be installed in one position

Audi TT 1999 ➤

16 - 90 Nm + 90° (1/4 turn) further

❑ Renew

1. Servicing work on pulley end 45

Page 52

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

4-cylinder 1.8 ltr. 5-valve turbocharged engine (165-176 kW), mechanics - Edition 12.2005

❑ Do not lubricate with oil

❑ Use counterhold tool -3415- when loosening and tightening ⇒ page 46

17 - 15 Nm

18 - 25 Nm

19 - Toothed belt cover (centre)

20 - Toothed belt cover (bottom)

21 - 10 Nm

❑ Install using locking fluid; for locking fluid refer to ⇒ Parts catalogue

Loosening and tightening bolt for camshaft sprocket

– Use counterhold tool -3036- when loosening and tightening

central bolt.

Installation position of camshaft sprocket

• The thinner web of the camshaft sprocket faces outwards

-arrows- and the marking “OT” for TDC is visible from the front.