Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi A1 2011 ➤ , Audi A2 2001 ➤ ,

Audi A3 2004 ➤ , Audi A4 2001 ➤ ,

Audi A4 2008 ➤ ,

Audi A4 Cabriolet 2003 ➤ ,

Audi A5 Cabriolet 2009 ➤ ,

Audi A5 Coupé 2008 ➤ , Audi A6 1998 ➤ ,

Audi A6 2005 ➤ ,

Audi A7 Sportback 2011 ➤ ,

Audi A8 2003 ➤ , Audi A8 2010 ➤ ,

Audi Q5 2008 ➤ , Audi Q7 2007 ➤ ,

Audi R8 2007 ➤ , Audi TT 1999 ➤ ,

Audi TT 2007 ➤

Electrical system; General information

Edition 10.2010

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

27 - Starter, current supply, CCS

92 - Windscreen wash/wipe system

94 - Lights, bulbs, switches - exterior

96 - Lights, bulbs, switches - interior

97 - Wiring

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A005AA00420

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

Contents

27 - Starter, current supply, CCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Battery - general notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Safety measures and procedures to be followed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Warnings and safety procedures when handling lead-acid batteries . . . . . . . . . . . . . . . . . . 1

2 Non maintenance-free batteries (without „magic eye“) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Central gas venting system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Battery terminal screw connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Checking non maintenance-free batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Visual inspection of battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Checking electrolyte level in battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Measuring relative density of electrolyte in all battery cells . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Maintenance-free batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Battery with „magic eye“ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Checking battery with „magic eye“ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Valve-regulated lead acid (VRLA) or absorbent glass mat (AGM) battery without „magic eye“

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 Checking valve-regulated lead acid or AGM battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5 Central gas venting system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.6 Battery terminal screw connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.7 Visual inspection of battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.8 Checking colour indicator (electrolyte level in battery) - batteries with „magic eye“ . . . . . . 15

3.9 Checking electrolyte level in battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Checking battery - vehicles without battery monitor control unit J367 or energy management

control unit J644 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Checking battery using battery tester with printer VAS 6161 . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Checking battery using battery tester with printer VAS 5097A . . . . . . . . . . . . . . . . . . . . . . 21

4.3 Measuring no-load voltage - vehicles without battery monitor control unit J367 or energy

management control unit J644 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4 Checking battery by measuring current draw - vehicles without battery monitor control unit

J367 or energy management control unit J644 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 Checking battery - vehicles with battery monitor control unit J367 or energy management

control unit J644 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1 Checking battery using vehicle diagnostic tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2 Checking battery by measuring current draw - vehicles with battery monitor control unit J367

or energy management control unit J644 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.3 Measuring no-load voltage - vehicles with battery monitor control unit J367 or energy

management control unit J644 „transport mode not active“ . . . . . . . . . . . . . . . . . . . . . . . . 32

5.4 Measuring no-load voltage - vehicles with battery monitor control unit J367 or energy

management control unit J644 „transport mode active“ . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6 Charging battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.1 Charging battery with battery charger VAS 5095A , VAS 5900 , VAS 5903 , VAS 5904 or VAS

5906 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2 Totally discharged battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3 Rapid-charging battery - vehicles without battery monitor control unit J367 or energy

management control unit J644 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4 Back-up power supply of battery via battery charger VAS 5095A , VAS 5900 , VAS 5903 ,

VAS 5904 or VAS 5906 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.5 Maintaining battery charge with solar panel VAS 6102 A . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7 Checking and servicing alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1 Checking alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2 Bosch alternator up to 2000 - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3 Bosch alternator from 2001 onwards - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.4 Removing and installing voltage regulator - Bosch alternator from 2001 onwards . . . . . . 46

7.5 Bosch alternator from 2007 onwards - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

7.6 Removing and installing voltage regulator - Bosch alternator from 2007 onwards . . . . . . 48

7.7 Checking carbon brushes - all types of Bosch alternators from 2001 onwards . . . . . . . . . . 48

7.8 Valeo alternator up to 2000 - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.9 Valeo alternator from 2001 onwards - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.10 Removing and installing voltage regulator - Valeo alternator from 2001 onwards . . . . . . . . 51

7.11 Checking carbon brushes - Valeo alternator from 2001 onwards . . . . . . . . . . . . . . . . . . . . 51

7.12 Removing and installing voltage regulator - Valeo alternator from 2007 onwards . . . . . . . . 52

7.13 Checking carbon brushes - Valeo alternator from 2007 onwards . . . . . . . . . . . . . . . . . . . . 52

7.14 Removing and installing poly V-belt pulley without free-wheel . . . . . . . . . . . . . . . . . . . . . . 53

7.15 Removing and installing poly V-belt pulley with free-wheel . . . . . . . . . . . . . . . . . . . . . . . . 54

8 Cruise control system - vehicles with electronic throttle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

92 - Windscreen wash/wipe system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1 Washer fluid hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.1 Disconnecting and connecting washer fluid hose connectors . . . . . . . . . . . . . . . . . . . . . . 57

1.2 Servicing a smooth washer fluid pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

1.3 Servicing a washer fluid hose with corrugated tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

94 - Lights, bulbs, switches - exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

1 Safety precautions when handling gas discharge bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . 61

96 - Lights, bulbs, switches - interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1 Immobilizer for vehicles without entry and start authorisation switch E415 (mechanical

ignition lock) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1.2 Defective transponder or loss of key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1.3 Renewing reader coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1.4 Procedure for renewing lock set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2 Immobilizer for vehicles with entry and start authorisation switch E415 (electronic ignition

lock) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3 Heated steering wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4 Towing bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.1 Removing and installing socket for towing bracket - version 1 . . . . . . . . . . . . . . . . . . . . . . 66

4.2 Removing and installing socket for towing bracket - version 2 . . . . . . . . . . . . . . . . . . . . . . 67

4.3 Removing and installing socket for towing bracket - version 3 . . . . . . . . . . . . . . . . . . . . . . 69

4.4 Pin assignment at socket for towing bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

97 - Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

1 Repairing wiring harnesses and electrical connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

1.1 General information on repairs to the vehicle electrical system . . . . . . . . . . . . . . . . . . . . . . 72

1.2 ESD (electrostatic discharge) workplace VAS 6613 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

1.3 Notes on repairing wiring harnesses and electrical connectors . . . . . . . . . . . . . . . . . . . . . . 74

1.4 Repairing wiring for pyrotechnic components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

1.5 Repairing CAN bus wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

1.6 Repairing FlexRay wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

1.7 Repairing an 0.25 mm2 wire with a single crimp connector . . . . . . . . . . . . . . . . . . . . . . . . 76

1.8 Repairing a wire of 0.35 mm2 section or thicker with a single crimp connector . . . . . . . . . . 78

1.9 Repairing an 0.25 mm2 wire by connecting in an additional wire . . . . . . . . . . . . . . . . . . . . 80

1.10 Repairing a wire of 0.35 mm2 section or thicker by connecting in an additional wire . . . . 83

2 Repairing connector housings and electrical connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2.1 Notes on repairing connector housings and electrical connectors . . . . . . . . . . . . . . . . . . . . 86

2.2 Repairing contacts in connector housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2.3 Fitting seals for individual wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

2.4 Repairing connector housings with insulation displacement technology (IDC) . . . . . . . . . . 88

3 Releasing and dismantling connector housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

3.1 Notes on releasing and dismantling connector housings . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.2 Secondary locking device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.3 Primary locking device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

3.4 Primary locking device with round connector systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.5 Primary locking device with flat connector systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.6 Primary locking device with special connector systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4 Cleaning contact surfaces with contact surface cleaning set VAS 6410 . . . . . . . . . . . . . . 96

4.1 Servicing wiring lugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

4.2 Servicing screw connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4.3 Cleaning battery terminal clamps and battery terminals . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.4 Corrosion protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5 Repairing aerial wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6 Fibre optic cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.1 Repairing fibre optic cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.2 Separating fibre optic cable from wiring harness connector . . . . . . . . . . . . . . . . . . . . . . . . 107

7 Vehicle diagnostic, testing and information systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.1 Notes on operation and safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.2 Connecting vehicle diagnostic tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Contents iii

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

iv Contents

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

27 – Starter, current supply, CCS

1 Battery - general notes

WARNING

Risk of injury.

♦ Observe warnings and safety regulations ⇒ page 1 .

Caution

Risk of damage to battery or vehicle.

♦ Vehicles with batteries that are not maintenance-free: Ob‐

serve notes

⇒ „2.4 Visual inspection of battery“, page 6 .

♦ Vehicles with maintenance-free batteries: Observe notes

⇒ „3.7 Visual inspection of battery“, page 13 .

♦ To ensure a long service life, the battery must be checked,

serviced and maintained according to the instructions in this

Workshop Manual.

♦ Apart from starting the engine, the battery also acts as an

electrical buffer and supplies power to all parts of the vehicle's

electrical system.

Note

Additional information ⇒ Self-study programme No. 234 ; Vehicle

batteries

1.1 Safety measures and procedures to be followed

Before starting work, employees must be informed of the possible

hazards involved with handling batteries.

Caution

Non-qualified personnel such as trainees and junior staff must

only be allowed to perform work on vehicle batteries under the

supervision of skilled workers such as qualified vehicle me‐

chanics or electricians.

1.2 Warnings and safety procedures when handling lead-acid batteries

Knowing and avoiding dangers

Handling batteries is dangerous. Such dangers can be avoided

by paying attention to the warnings on the battery, in the Owner's

Manual and in the Workshop Manual.

1. Battery - general notes 1

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

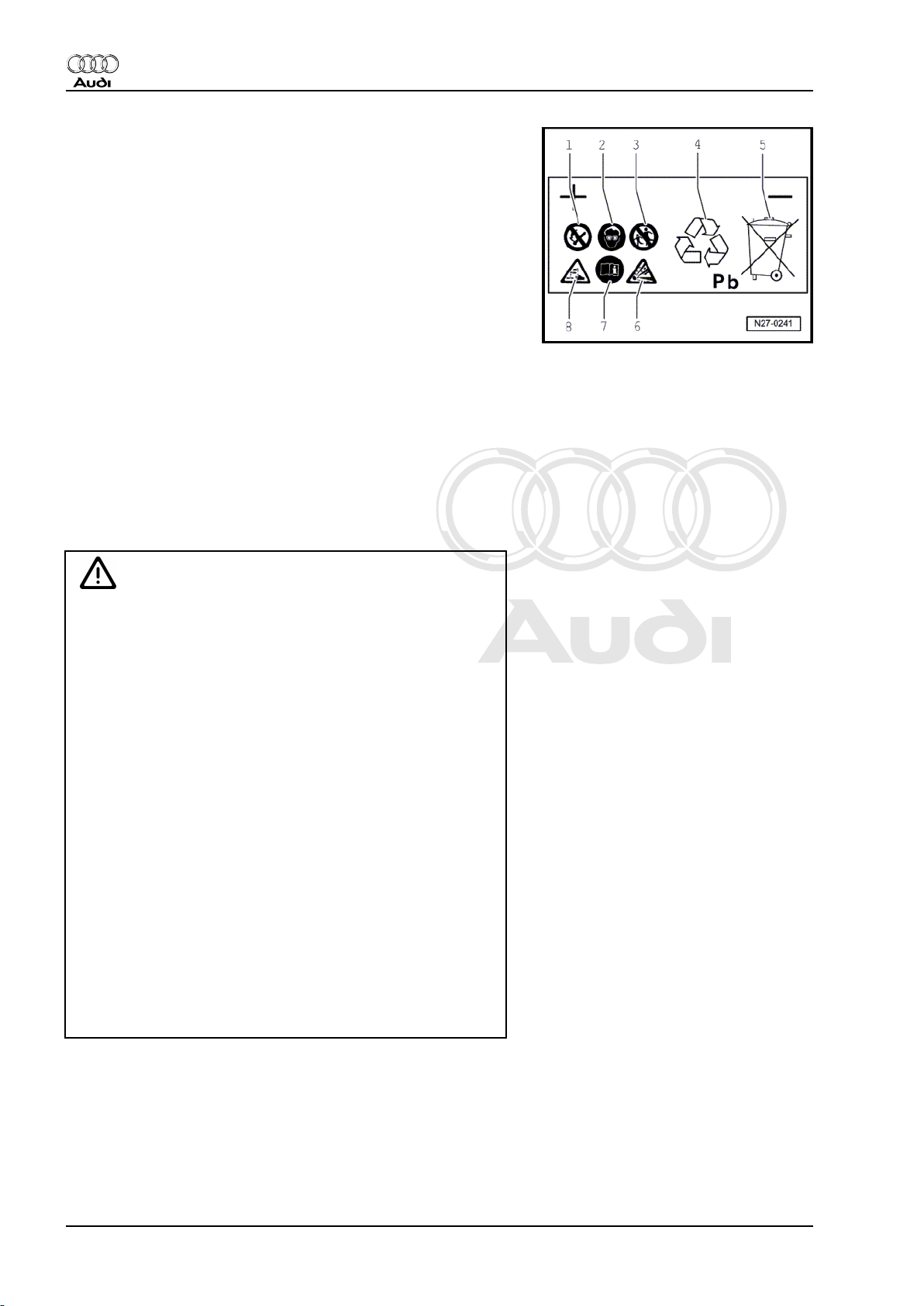

Explanatory notes on battery symbols

1 - Fires, sparks, naked flames and smoking are prohibited

when handling batteries. Avoid sparks and static discharge

when handling wires and electrical equipment. To avoid

short circuits, never place tools on the battery.

2 - Wear eye protection when working on the battery.

3 - Keep children away from acid and batteries.

4 - Disposal: Old batteries are hazardous waste. They are only

to be disposed of at an official collection point; all legal re‐

quirements must be observed.

5 - Do not dispose of old batteries with household waste.

6 - There is a risk of explosion when handling batteries. A highly

explosive gas mixture is given off when batteries are under

charge.

7 - Observe the instructions on the battery, in the Workshop

Manual „Electrical system; General information“ and in the

Owner's Manual.

8 - Danger of acid burns: Electrolyte is highly corrosive; pro‐

tective gloves and eye protection should therefore always

be worn when working on the battery. Do NOT tilt the battery

as electrolyte can leak out of the gas vents.

WARNING

Risk of injury due to electrolyte.

♦ Can cause severe injury to the eyes, skin and mucous

membranes.

♦ Inhalation can damage the respiratory system.

♦ Swallowing is harmful to the digestive system.

♦ First aid: Rinse eyes and immediately consult first aid sta‐

tion or inform doctor.

♦ Never tilt battery. Acid can leak out of the gas vents.

♦ Soak up spilt electrolyte with binding agent and neutralise

any residual electrolyte. Use e.g. soap solution for neu‐

tralising.

♦ Never allow electrolyte to come into contact with hands.

♦ Avoid contact with skin.

♦ Never touch mouth, nose or eyes with soiled hands.

♦ Immediately change any clothing affected by electrolyte

and place in water if necessary.

♦ Do not eat, drink or store foodstuffs at workplace.

♦ Wash thoroughly before breaks and on completion of

work.

2 Rep. gr.27 - Starter, current supply, CCS

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

WARNING

Wear eye protection and protective clothing to reduce the risk

of injury.

♦ Wear safety goggles and an acid-resistant apron or alter‐

natively electrolyte-proof overalls.

♦ Wear electrolyte-proof gloves.

WARNING

Risk of explosion due to gas produced when charging battery.

♦ The gas given off during charging and sometimes emitted

by the battery at rest even after charging is explosive. In

the worst case, improper handling of the battery can lead

to explosion caused by escaping gas.

♦ Smoking, naked flames and sparks (caused by grinding,

welding or cutting) are prohibited when working in the vi‐

cinity of the battery.

♦ Take care to avoid short circuits when handling wires and

electrical equipment. Never place tools on the battery.

♦ To avoid sparks as a result of electrostatic discharge, al‐

ways touch the vehicle body before handling the battery.

WARNING

Avoid explosion risks.

♦ If the display is colourless or light yellow on batteries with

„magic eye“, do not check or charge the battery. Do NOT

boost start the vehicle. There is a risk of explosion when

checking or charging the battery or boost starting the ve‐

hicle. The battery must be renewed.

♦ Old batteries (in use for 6 months or more) must be treated

with an anti-static spray (currently „Neostatic Antistatikum

HB 155“) prior to handling.

♦ Sealing plugs of batteries which are not maintenance-free

must be firmly screwed in when charging.

♦ Charging of batteries removed from the vehicle is only

permitted in vented cubicles with extraction system.

♦ After charging, the battery must be left in the charging area

with extraction system for an appropriate length of time.

♦ Only work on batteries in suitable, well ventilated areas.

♦ Batteries must always be transported in conductive metal

containers.

♦ Do not use electrostatically chargeable materials for se‐

curing purposes.

1. Battery - general notes 3

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

WARNING

Risk of damage to vehicle.

♦ Escaping electrolyte could cause acid corrosion and dam‐

age to safety-relevant vehicle components.

WARNING

Risk of environmental pollution.

♦ Old batteries are hazardous waste. They contain toxic

lead (Pb) and sulphuric acid.

♦ Observe disposal regulations. Old batteries should only

be disposed of in appropriate containers at an official col‐

lection point.

4 Rep. gr.27 - Starter, current supply, CCS

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

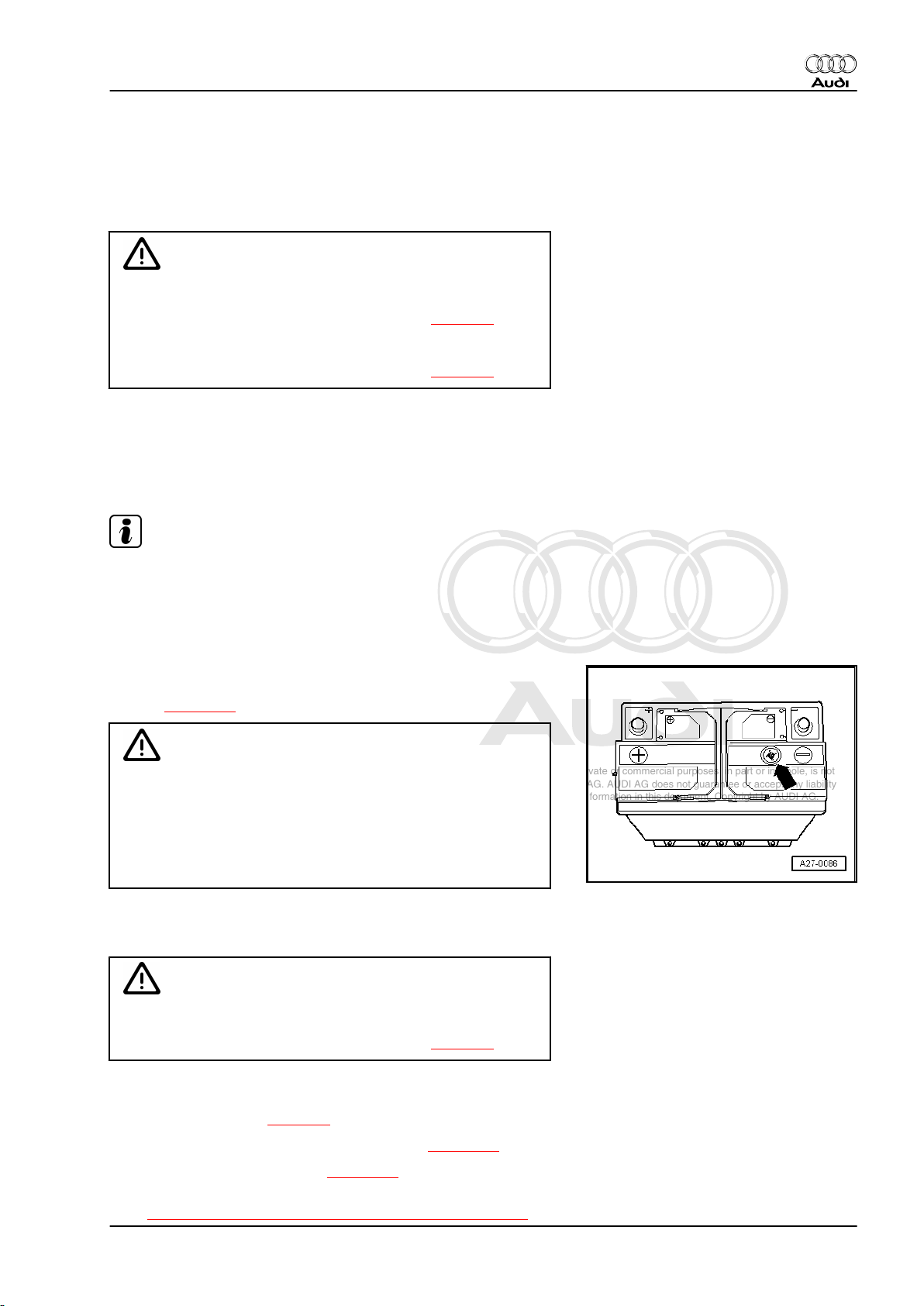

2 Non maintenance-free batteries

(without „magic eye“)

Lead-acid batteries which are not maintenance-free are filled with

liquid electrolyte (wet battery). They are fitted with sealing plugs.

WARNING

Risk of injury when handling electrolyte.

♦ Observe warnings and safety regulations ⇒ page 2 .

Risk of explosion due to gas produced when charging battery.

♦ Observe warnings and safety regulations ⇒ page 3 .

2.1 Central gas venting system

To prevent the gas produced when charging the battery from

causing damage or becoming a health hazard, the gas is dis‐

charged through a central opening in the top of the battery cover.

– Make sure that the central gas venting system hose or pipe is

always attached to the battery.

– Make sure the central gas venting system hose or pipe is not

obstructed. Only then is the battery able to vent freely.

Note

More modern batteries are equipped with a fine-mesh flame trap

at the central gas venting outlet. This circular glass-fibre mesh

with a diameter of approx. 15 mm and a thickness of 2 mm oper‐

ates like a valve. It allows the gas given off during battery charging

to escape and at the same time prevents ignition of the explosive

gas in the battery.

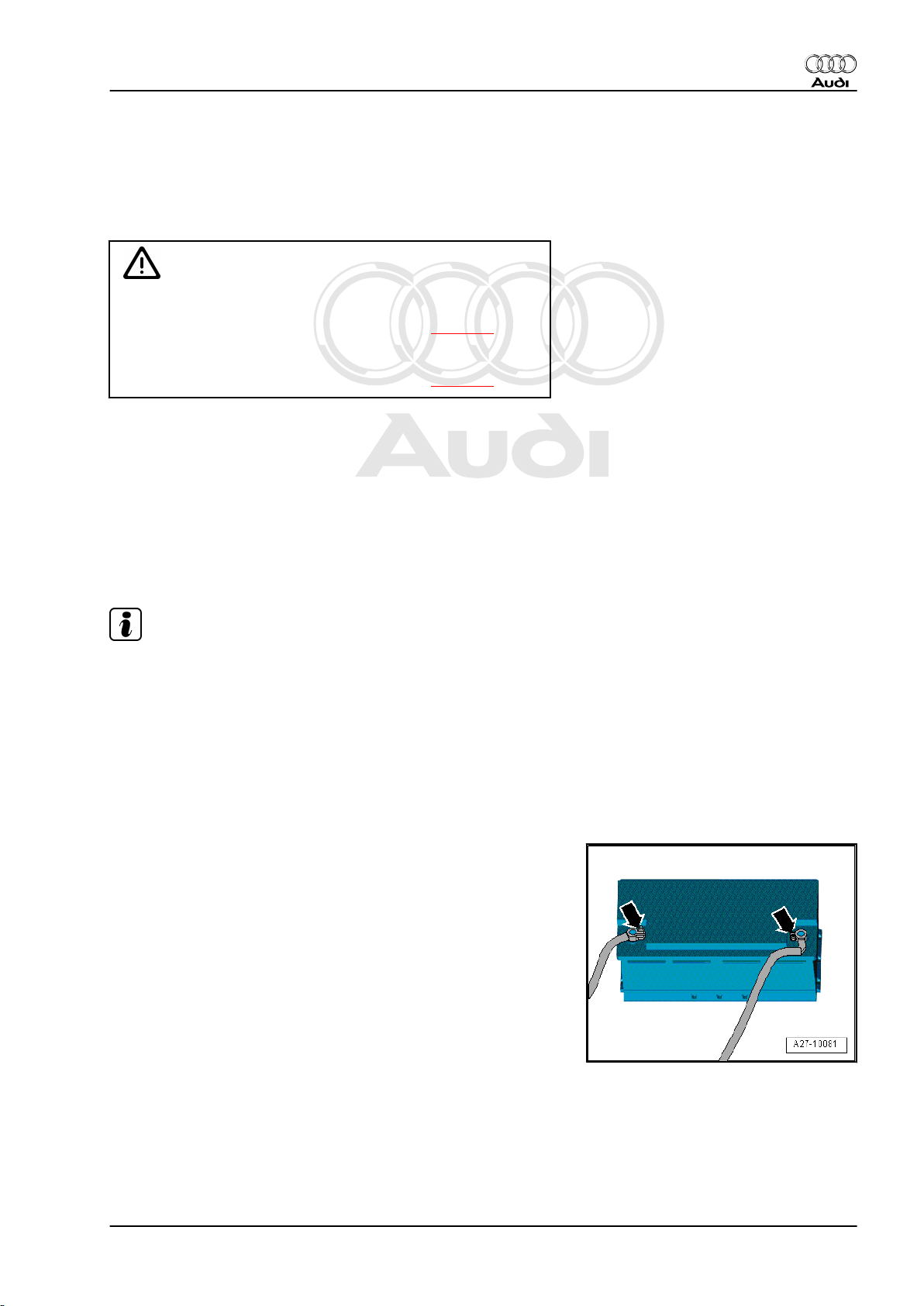

2.2 Battery terminal screw connection

Observe the following to avoid damaging the battery terminals

and battery housing:

♦ Battery terminal posts must not be greased.

♦ Only connect battery terminal clamps -arrows- by hand without

exerting force.

♦ Fit battery terminal clamps in such a way that the battery ter‐

minal post is flush with the terminal clamp or protrudes from it.

♦ Tightening torque for battery terminal clamps and additional

clamps ⇒ Electrical system; Rep. gr. 27 .

♦ Never re-tighten screw connections after tightening battery

terminal clamps to specified torque.

2. Non maintenance-free batteries (without „magic eye“) 5

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

2.3 Checking non maintenance-free batter‐

ies

WARNING

Risk of injury and explosion.

♦ Observe warnings and safety regulations ⇒ page 1 .

Perform tests in the following order:

1. Visual inspection ⇒ page 6

2. Checking electrolyte level ⇒ page 7

3. Checking battery using battery tester with printer -

VAS 6161- ⇒ page 17 or using battery tester with printer

-VAS 5097A- ⇒ page 21 or measuring relative density of

electrolyte ⇒ page 7 .

4. Further procedure depending on result of battery check us‐

ing battery tester.

2.4 Visual inspection of battery

– Visually inspect battery before performing comprehensive

measurements:

♦ External condition of battery

♦ Battery connections

♦ Secure fit of battery

Caution

Risk of explosion, poor crash safety, risk of corrosion, short‐

ened service life.

♦ If the retainer plate is loose, this may damage the battery

housing and allow electrolyte to escape.

♦ If not properly secured, the battery may be subject to vi‐

bration damage and the plates in the battery will be dam‐

aged.

♦ Tighten bolt for retainer plate; for tightening torque refer to

⇒ Electrical system; Rep. gr. 27 .

Risk of malfunctions in electrical system or cable fire.

♦ The wiring connections may not make proper contact if the

battery terminals are damaged or the battery terminal

clamps are loose. Check condition of battery terminals; for

tightening torques for battery terminal clamps and addi‐

tional clamps refer to ⇒ Electrical system; Rep. gr. 27 .

♦ Risk of corrosion due to escaping electrolyte.

♦ The battery openings must be fitted with the correct type

of genuine sealing plugs to ensure proper sealing of the

battery cover (different types). Only use genuine sealing

plugs of the same type when renewing missing or dam‐

aged sealing plugs.

♦ The plugs must be fitted with an O-ring.

6 Rep. gr.27 - Starter, current supply, CCS

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

2.5 Checking electrolyte level in battery

Procedure

The correct electrolyte level is an important factor in ensuring long

battery service life.

WARNING

Risk of injury when handling electrolyte.

♦ Observe safety instructions when handling battery elec‐

trolyte ⇒ page 2 .

♦ Wear eye protection and protective clothing ⇒ page 3 .

Risk of explosion due to naked flames, fires and smoking.

♦ Use only an electric hand torch to illuminate the inside of

the battery housing.

♦ Never illuminate the inside of the battery housing with a

naked flame.

♦ Never bring a naked flame or a burning cigarette into the

vicinity of the battery.

– If the „min“ and „max“ marks are visible on the outside of the

battery, only perform an external visual inspection.

• The electrolyte level must be above the „min“ mark, but may

not exceed the „max“ mark.

– If it is difficult to detect the „min“ and „max“ marks on the out‐

side of the battery or they cannot be seen through the battery

housing , unscrew the sealing plugs.

– Check the electrolyte level by making a visual inspection of the

inside of the battery.

• The electrolyte level must coincide with the internal level mark

(plastic moulding). This corresponds to the „max“ marking on

the outside.

Caution

Risk of corrosion due to escaping electrolyte.

♦ The battery openings must be fitted with the correct type

of genuine sealing plugs to ensure proper sealing of the

battery cover (different types). Only use genuine sealing

plugs of the same type when renewing missing or dam‐

aged sealing plugs.

♦ The plugs must be fitted with an O-ring.

♦ If the electrolyte level is too low, the battery must be re‐

newed. Do not top up with distilled water.

– Screw sealing plugs of battery cells back in again.

2.6 Measuring relative density of electrolyte

in all battery cells

Special tools and workshop equipment required

2. Non maintenance-free batteries (without „magic eye“) 7

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

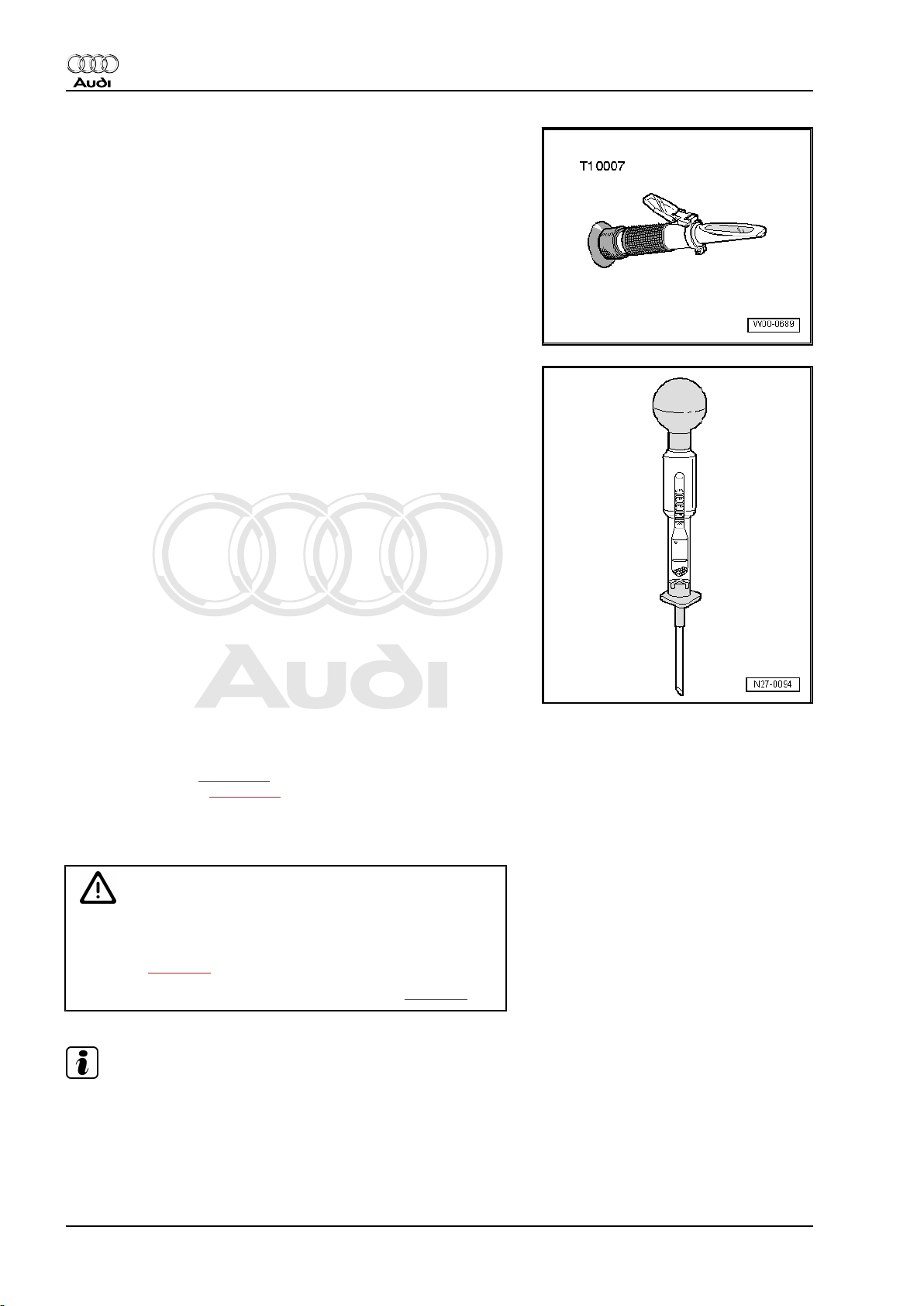

♦ Refractometer -T10007- or

♦ Hydrometer (commercially available)

Procedure

In conjunction with the battery check using the battery tester with

printer -VAS 6161- ⇒ page 17 or using the battery tester with

printer -VAS 5097A- ⇒ page 21 , the relative density test pro‐

vides information on the charge state of the battery.

• The temperature of the battery electrolyte must be at least +10

°C.

WARNING

Risk of injury when handling electrolyte.

♦ Observe safety instructions when handling battery elec‐

trolyte ⇒ page 2 .

♦ Wear eye protection and protective clothing ⇒ page 3 .

Note

The relative density of the electrolyte can be checked immediately

after charging the battery.

– Unscrew all battery cell sealing plugs.

8 Rep. gr.27 - Starter, current supply, CCS

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

– Dip hydrometer into battery cell and draw in electrolyte until

the float is floating freely in the electrolyte.

♦ The greater the relative density of the electrolyte drawn in, the

higher the float will ride.

♦

The relative density in kg/dm3 (specific density of electrolyte)

can be read off the hydrometer scale.

– Take reading on hydrometer and compare it to values given

in table:

Charge state

Relative density of electrolyte in kg/dm

In normal climatic

In tropical countries

3

zones

discharged 1.12 1.08

half charged 1.20 1.16

well charged 1.28 1.23

The relative density in normal climatic zones must be at least 1.24

kg/dm3. If relative density is too low in all battery cells:

– Charge battery and then repeat electrolyte relative density

test.

Example 1

Battery cell 1 2 3 4 5 6

Relative density per battery cell in

3

kg/dm

1)

•

Relative density in battery cell 4 is too low (difference greater than 0.03 kg/dm3).

Example 2

Battery cell 1 2 3 4 5 6

Relative density per battery cell in

3

kg/dm

1)

•

Relative density in battery cells 4 and 5 is too low (difference greater than 0.03 kg/dm3).

1.24 1.25 1.25

1.26 1.26 1.25

1.10

1.14

1)

1)

1.24 1.25

1)

1.18

1.24

– Renew the battery if the specified values are not attained.

Note

The battery must be renewed if the relative density of the elec‐

trolyte measured in the individual battery cells varies by more than

0.03 kg/dm3.

2. Non maintenance-free batteries (without „magic eye“) 9

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

Caution

Danger from escaping electrolyte.

♦ The battery openings must be fitted with the correct type

of genuine sealing plugs to ensure proper sealing of the

battery cover (different types). Only use genuine sealing

plugs of the same type when renewing missing or dam‐

aged sealing plugs.

♦ The plugs must be fitted with an O-ring.

– If specified values have been attained, screw sealing plugs of

battery cells back in.

Note

Observe disposal regulations if battery has to be renewed

⇒ page 4 .

10 Rep. gr.27 - Starter, current supply, CCS

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

3 Maintenance-free batteries

Only install maintenance-free batteries with the specifications

„TL82506“ (from December 1997 onwards) and „VW75073“ (from

August 2001 onwards).

WARNING

Risk of injury when handling electrolyte.

♦ Observe warnings and safety regulations ⇒ page 2 .

Risk of explosion due to gas produced when charging battery.

♦ Observe warnings and safety regulations ⇒ page 3 .

3.1 Battery with „magic eye“

Lead-acid batteries with „magic eye“ are filled with liquid electro‐

lyte (wet battery). They are not fitted with sealing plugs for topping

up with distilled water.

Note

♦

If batteries with „magic eye“ are fitted with sealing plugs for

production reasons, these are covered with plastic foil.

♦

Do not remove plastic foil and do not top up with distilled water.

♦

Only perform visual inspections.

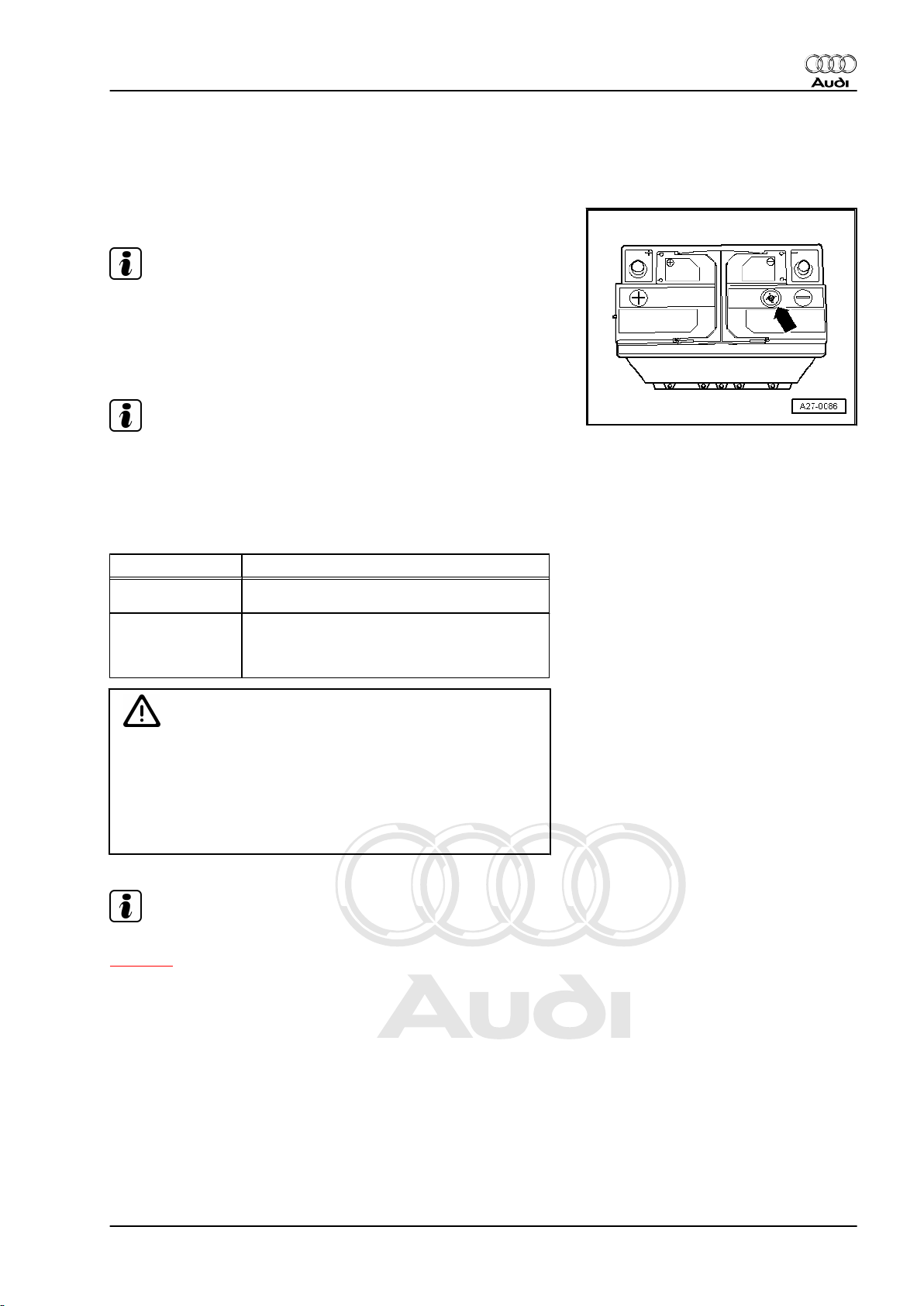

The „magic eye“ -arrow- provides information on the electrolyte

level and battery charge via a colour indicator. Possible indicator

colours ⇒ page 11 .

WARNING

Risk of explosion due to a discharged battery with „magic eye“.

♦ The battery must NOT be checked or charged if the indi‐

cator of the „magic eye“ is colourless or yellow. Do NOT

boost start the vehicle. There is a risk of explosion when

checking or charging the battery or boost starting the ve‐

hicle. The battery must be renewed.

3.2 Checking battery with „magic eye“

WARNING

Risk of injury and explosion.

♦ Observe warnings and safety regulations ⇒ page 1 .

Perform tests in the following order:

1. Visual inspection ⇒ page 6

2. Checking colour indicator of „magic eye“ ⇒ page 15

3. Checking electrolyte level ⇒ page 15

4. Checking battery

⇒ „4 Checking battery - vehicles without battery monitor

3. Maintenance-free batteries 11

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

control unit J367 or energy management control unit J644

“, page 17 or

⇒ „5.2 Checking battery by measuring current draw - vehi‐

cles with battery monitor control unit J367 or energy man‐

agement control unit J644 “, page 30 .

5. Further procedure depending on result of battery check us‐

ing battery tester.

3.3 Valve-regulated lead acid (VRLA) or ab‐

sorbent glass mat (AGM) battery without

„magic eye“

♦ VLRA or AGM batteries are deep-cycle resistant and leak-

proof.

♦ VRLA or AGM batteries are filled with electrolyte which is held

in place in an „A“bsorbent „G“lass „M“at. The battery is sealed

and equipped with valves.

♦ As the electrolyte is absorbed in the mat, these batteries can‐

not have a „magic eye“. Absorbent glass mat batteries are

marked with „AGM“ on the battery.

Note

♦

VLRA or AGM batteries cannot and must not be opened and

must not be topped up with distilled water.

♦

Only perform visual inspections.

Caution

Fitting a wrong battery will result in poor crash safety.

♦ If a vehicle was originally equipped with a VRLA or AGM

battery, only replace the battery with another VRLA or

AGM battery.

3.4 Checking valve-regulated lead acid or

AGM battery

WARNING

Risk of injury and explosion.

♦ Observe warnings and safety regulations ⇒ page 1 .

Perform tests in the following order:

1. Visual inspection ⇒ page 6

2. Checking battery

⇒ „4 Checking battery - vehicles without battery monitor

control unit J367 or energy management control unit J644

“, page 17 or

⇒ „5.2 Checking battery by measuring current draw - vehi‐

cles with battery monitor control unit J367 or energy man‐

agement control unit J644 “, page 30 .

3. Further procedure depending on result of battery check us‐

ing battery tester.

12 Rep. gr.27 - Starter, current supply, CCS

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

3.5 Central gas venting system

To prevent the gas produced when charging the battery from

causing damage or becoming a health hazard in the engine or

passenger compartment, the gas is discharged through a central

opening in the top of the battery cover.

– Make sure that the central gas venting system hose or pipe is

always attached to the battery.

– Make sure the central gas venting system hose or pipe is not

obstructed. Only then is the battery able to vent freely.

Note

More modern batteries are equipped with a fine-mesh flame trap

at the central gas venting outlet. This circular glass-fibre mesh

with a diameter of approx. 15 mm and a thickness of 2 mm oper‐

ates like a valve. It allows the gas given off during battery charging

to escape and at the same time prevents ignition of the explosive

gas in the battery.

3.6 Battery terminal screw connection

Observe the following to avoid damaging the battery terminals

and battery housing:

♦ Battery terminal posts must not be greased.

♦ Only connect battery terminal clamps -arrows- by hand without

exerting force.

♦ Fit battery terminal clamps in such a way that the battery ter‐

minal post is flush with the terminal clamp or protrudes from it.

♦ Tightening torque for battery terminal clamps and additional

clamps ⇒ Electrical system; Rep. gr. 27 .

♦ Never re-tighten screw connections after tightening battery

terminal clamps to specified torque.

3.7 Visual inspection of battery

– Visually inspect battery before performing comprehensive

measurements:

♦ External condition of battery

♦ Battery connections

♦ Secure fit of battery

3. Maintenance-free batteries 13

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

Caution

Risk of explosion, poor crash safety, risk of corrosion, short‐

ened service life.

♦ If the retainer plate is loose, this may damage the battery

housing and allow electrolyte to escape.

♦ If not properly secured, the battery may be subject to vi‐

bration damage and the plates in the battery will be dam‐

aged.

♦ Tighten bolt for retainer plate; for tightening torque refer to

⇒ Electrical system; Rep. gr. 27 .

Risk of malfunctions in electrical system or cable fire.

♦ The wiring connections may not make proper contact if the

battery terminals are damaged or the battery terminal

clamps are loose. Check condition of battery terminals; for

tightening torques for battery terminal clamps and addi‐

tional clamps refer to ⇒ Electrical system; Rep. gr. 27 .

14 Rep. gr.27 - Starter, current supply, CCS

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

3.8 Checking colour indicator (electrolyte level in battery) - batteries with „magic eye“

Procedure

Note

As the „magic eye“ is only located in one battery cell, the electro‐

lyte level is only checked for this battery cell.

– Prior to visual inspection, use a screwdriver handle to tap gen‐

tly and carefully on the magic eye -arrow-.

Note

When charging the battery and while driving, air bubbles may

form under the „magic eye“ and falsify the colour indicator. Tap‐

ping on the „magic eye“ will disperse the air bubbles underneath.

– Read off electrolyte level in battery from colour indicator. Two

different displays are possible:

Colour indicator Battery charge state

Black or green • Electrolyte level in battery OK

Colourless or light

yellow

WARNING

• Electrolyte level in battery too low. Risk of

explosion; do not check or charge bat‐

tery.

Risk of explosion due to a discharged battery with „magic eye“.

♦ The battery must NOT be checked or charged if the indi‐

cator of the „magic eye“ is colourless or yellow. Do NOT

boost start the vehicle. There is a risk of explosion when

checking or charging the battery or boost starting the ve‐

hicle. The battery must be renewed.

Note

Observe disposal regulations if battery has to be renewed

⇒ page 4 .

3.9 Checking electrolyte level in battery

Procedure

The correct electrolyte level is an important factor in ensuring long

battery service life.

3. Maintenance-free batteries 15

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

WARNING

Danger of injury when handling electrolyte.

♦ Observe safety instructions when handling battery elec‐

trolyte ⇒ page 2 .

♦ Wear eye protection and protective clothing ⇒ page 3 .

♦ If the electrolyte level is too low, the battery must be re‐

newed. Do not open battery and do not top up with distilled

water.

Risk of explosion due to naked flames, fires and smoking.

♦ Never bring a naked flame or a burning cigarette into the

vicinity of the battery.

– If the „min“ and „max“ marks are visible on the outside of the

battery, perform an external visual inspection.

• The electrolyte level must be above the „min“ mark, but may

not exceed the „max“ mark.

16 Rep. gr.27 - Starter, current supply, CCS

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

4 Checking battery - vehicles without

battery monitor control unit -J367- or

energy management control unit J644-

Do not open maintenance-free batteries; this would invalidate the

warranty.

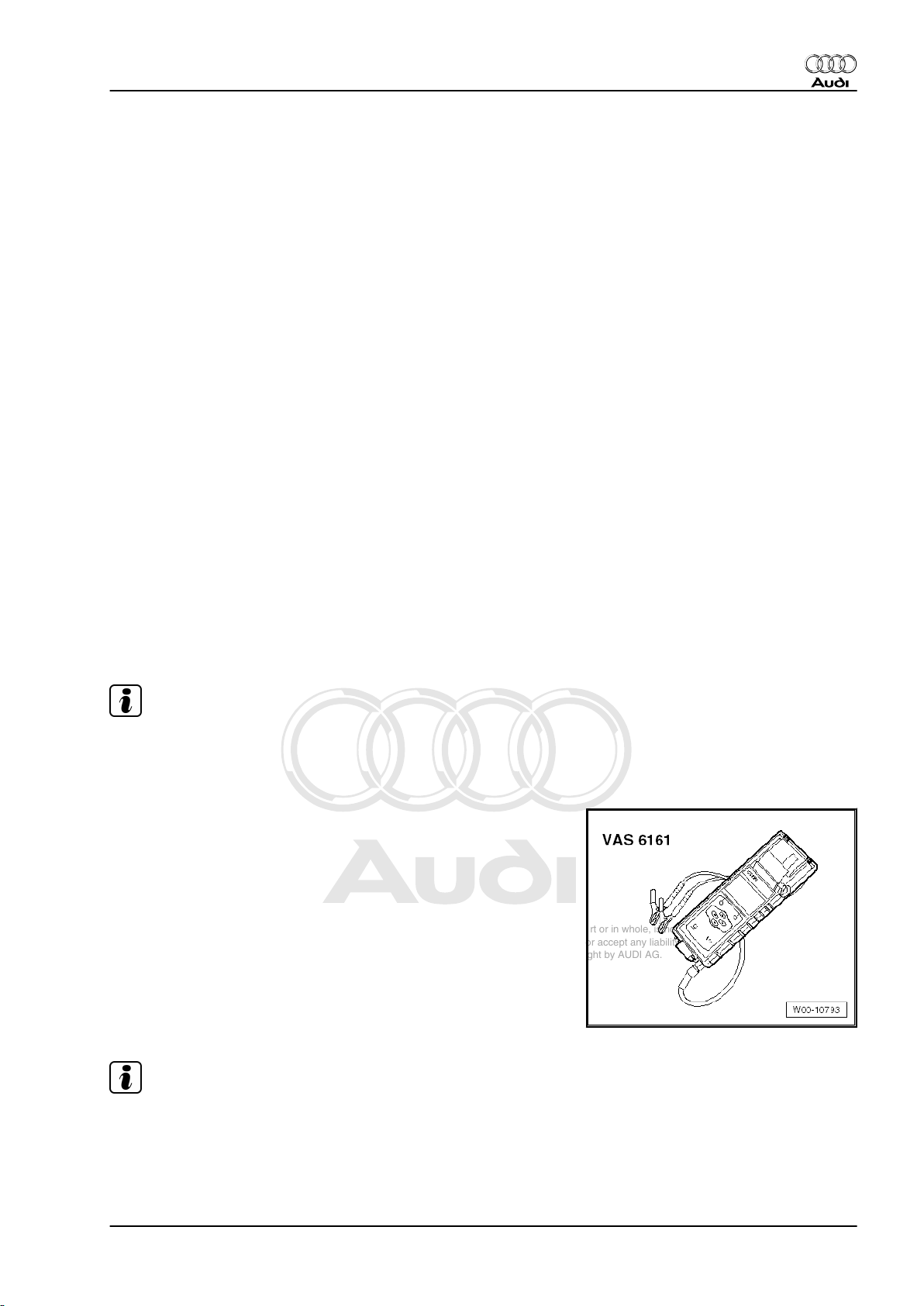

4.1 Checking battery using battery tester with printer -VAS 6161-

♦ When checking the battery using battery tester with printer -

VAS 6161- it is not necessary to disconnect the battery earth

cable.

♦ The battery tester with printer -VAS 6161- no longer puts the

battery under load, but works by measuring the dynamic con‐

ductivity. For this reason it is possible to perform several

measurements without re-charging the battery.

♦ No-load voltage measurement can be performed without de‐

lay.

♦ All types of battery are stored in the tester and they can be

updated.

♦ The battery bar code can be read off directly with the optionally

available 2D scanner.

♦ The integrated temperature sensor improves the quality of

measurements.

♦ Data can be stored on an SD card.

Note

For information on battery tester with printer, refer to ⇒ Instruction

Manual for -VAS 6161- .

Special tools and workshop equipment required

♦ Battery tester with printer -VAS 6161-

Note

For information on how to use the battery tester, refer to ⇒ In‐

struction Manual for -VAS 6161- .

Procedure

• Battery temperature must be at least +10 °C.

4. Checking battery - vehicles without battery monitor control unit J367 or energy management control unit J644 17

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

WARNING

Risk of injury due to electrolyte.

♦ Observe safety instructions when handling battery elec‐

trolyte ⇒ page 2 .

♦ Wear eye protection and protective clothing ⇒ page 3 .

♦ Sealing plugs of batteries which are not maintenance-free

must be firmly screwed in when measuring voltage under

load.

Risk of explosion due to a discharged battery with „magic eye“.

♦ The battery must NOT be checked or charged if the indi‐

cator of the „magic eye“ is colourless or yellow. Do NOT

boost start the vehicle. There is a risk of explosion when

checking or charging the battery or boost starting the ve‐

hicle. The battery must be renewed.

– Switch off ignition and all electrical equipment.

– Check colour indicator of batteries with „magic eye“

⇒ page 15 .

– Switch on battery tester with printer -VAS 6161- .

– Connect red test clamp „+“ of battery tester to positive battery

terminal or jump start terminal in engine compartment.

– Connect black test clamp „–“ of battery tester to negative ter‐

minal of battery or jump start terminal in engine compartment.

Note

Make sure the test clamps make proper contact.

– Select one of the following functions:

♦ Maintenance test

♦ Service test

♦ Warranty test

Maintenance test

– Select „maintenance test“ from the menu.

– Connect scanner and scan in vehicle identification number.

– Select connection point: „at battery post“ or „at jump start

post“.

– Select vehicle model.

– Scan in battery bar code.

– Determine temperature by holding temperature sensor at a

distance of approx. 5 cm over battery or jump start post until

a constant temperature is displayed.

– Start test.

– If required, print out test log.

Service test

– Select „service test“ from the menu.

– Select vehicle model.

18 Rep. gr.27 - Starter, current supply, CCS

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

– Determine temperature by holding temperature sensor at a

distance of approx. 5 cm over battery until a constant temper‐

ature is displayed.

– Select type of battery: „regular“, „AGM“, „2*6V“ or „Gel“.

– Select rating units: „CCA“, „JIS“, „DIN“, „SAE“, „IEC“ or „EN“.

– Start test.

– If required, print out test log.

Warranty test

– Select „warranty test“ from the menu.

– Select fitting location: „in vehicle“ or „out of vehicle“.

– Select vehicle model.

– Determine temperature by holding temperature sensor at a

distance of approx. 5 cm over battery until a constant temper‐

ature is displayed.

– Select type of battery: „regular“, „AGM“, „2*6V“ or „Gel“.

– Select corresponding rating using arrow buttons.

– Start test.

– If required, print out test log.

Note

The test log is required for warranty processing.

– Switch off battery tester.

– Detach test clamps.

4. Checking battery - vehicles without battery monitor control unit J367 or energy management control unit J644 19

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

Test result on printout:

1 - Test mode

2 - Test result

3 - Voltage measured

4 - Nominal value of battery measured

5 - Nominal value of battery as set on tester

6 - Temperature measured above battery

7 - Fitting location of battery

8 - Position of battery clamp as set on tester

9 - Type of battery set

Test result of maintenance test Measures

Good battery Battery OK

Charge battery immediately Charge battery ⇒ page 35

and test again. Faults can occur

if battery is not fully charged

and tested again

Mark as defective Mark as „defective“ and remove

from vehicle

Check tester connection Disconnect battery and test

again. Poor contact of the ca‐

bles can be responsible for the

result „Check tester connec‐

tion“

Check connection Cable must be connected di‐

rectly to battery and not to jump

start post

Test result of service test and

Measures

warranty test

Good battery Battery OK

Good battery - recharge Charge battery ⇒ page 35 ,

trace cause of fault responsible

for discharging, if necessary

Perform current draw test Perform current draw test

⇒ page 26 . Charge battery

⇒ page 35 and test again

Replace battery Disconnect battery and test

again. Poor contact of the ca‐

bles can be responsible for the

result "Replace battery"

Bad cell - replace Replace battery

Frozen battery Thaw battery and test again

Check connection Cable must be connected di‐

rectly to battery and not to jump

start post

Note

Observe disposal regulations if battery has to be renewed

⇒ page 4 .

20 Rep. gr.27 - Starter, current supply, CCS

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

4.2 Checking battery using battery tester with printer -VAS 5097A-

♦ Measuring voltage under load simulates starting engine at low

temperatures. During the test, a high current flows through the

battery, causing the voltage to drop. The amount of the voltage

drop will depend on the state of charge of the battery. The

voltage must not fall below the minimum value specified by the

battery tester.

♦ After the test, the voltage will remain at a low level for a long

time, rising only slowly.

♦ If the battery is defective or only weakly charged, the battery

voltage will drop very rapidly below the specified minimum

voltage level.

♦ The battery must be renewed if the voltage drops below the

specified minimum level.

♦ Only perform the test once. Repeating the test would falsify

the result.

♦ The battery tester must be allowed to cool down for approxi‐

mately 30 minutes before checking another battery.

The battery tester with printer -VAS 5097 A- can be used to check

12 V batteries with the following low temperature test currents:

Low temperature test current in A (Ampere)

1)

According to DIN

2)

According to EN /

3)

SAE

According to IEC

80 – 104 136 – 177 95 – 124

105 – 129 178 – 219 125 – 154

130 – 154 220 – 261 155 – 184

155 – 179 262 – 303 185 – 214

180 – 204 304 – 345 215 – 244

204 – 229 346 – 387 245 – 274

230 – 254 388 – 429 275 – 304

255 – 279 430 – 471 305 – 334

280 – 304 472 – 513 335 – 364

305 –329 514 – 555 365 – 394

330 – 354 556 – 597 395 – 424

355 – 379 598 – 639 425 – 454

380 – 389 640 – 657 455 – 464

390 – 399 658 – 675 465 – 474

400 – 409 676 – 693 475 – 484

410 – 419 694 – 711 485 – 494

420 – 429 712 – 729 495 – 504

430 – 439 730 – 747 505 – 514

440 – 449 748 – 765 515 – 524

450 – 459 766 – 783 525 – 534

460 – 469 784 – 801 535 – 544

470 – 479 802 – 819 545 – 554

480 – 489 820 – 837 555 – 564

490 – 499

4)

838 – 855 565 – 574

4)

4. Checking battery - vehicles without battery monitor control unit J367 or energy management control unit J644 21

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

Low temperature test current in A (Ampere)

1)

According to DIN

2)

1)

•

DIN = Deutsche Industrie Norm (German industrial stand‐

According to EN /

3)

SAE

According to IEC

4)

ard).

2)

•

Batteries with a low temperature test current of 520 A ac‐

cording to DIN can be checked with the setting for 499 A

according to DIN.

3)

•

EN / SAE = European standard / Society of Automotive

Engineers.

4)

•

IEC = International Engineering Consortium.

Note

For information on battery tester with printer, refer to ⇒ Operating

instructions for the -VAS 5097A- or sticker ⇒ Brief operating in‐

structions for battery tester with printer -VAS 5097 A- on unit.

Special tools and workshop equipment required

♦ Battery tester with printer -VAS 5097A-

Note

For information on how to use the battery tester, refer to ⇒ Op‐

erating instructions for -VAS 5097A- .

Procedure

• Battery temperature must be at least +10 °C.

22 Rep. gr.27 - Starter, current supply, CCS

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

WARNING

Risk of injury due to electrolyte.

♦ Observe safety instructions when handling battery elec‐

trolyte ⇒ page 2 .

♦ Wear eye protection and protective clothing ⇒ page 3 .

♦ Sealing plugs of batteries which are not maintenance-free

must be firmly screwed in when measuring voltage under

load.

Risk of explosion due to a discharged battery with „magic eye“.

♦ The battery must NOT be checked or charged if the indi‐

cator of the „magic eye“ is colourless or yellow. Do NOT

boost start the vehicle. There is a risk of explosion when

checking or charging the battery or boost starting the ve‐

hicle. The battery must be renewed.

– Switch off ignition before disconnecting earth wire at battery

⇒ Electrical system; Rep. gr. 27 .

– Check colour indicator of batteries with „magic eye“

⇒ page 15 .

– Determine the low temperature test current in amps (A) ac‐

cording to DIN from the data on the battery and use the table

⇒ page 21 to read off the setting range for the battery tester

with printer -VAS 5097 A- .

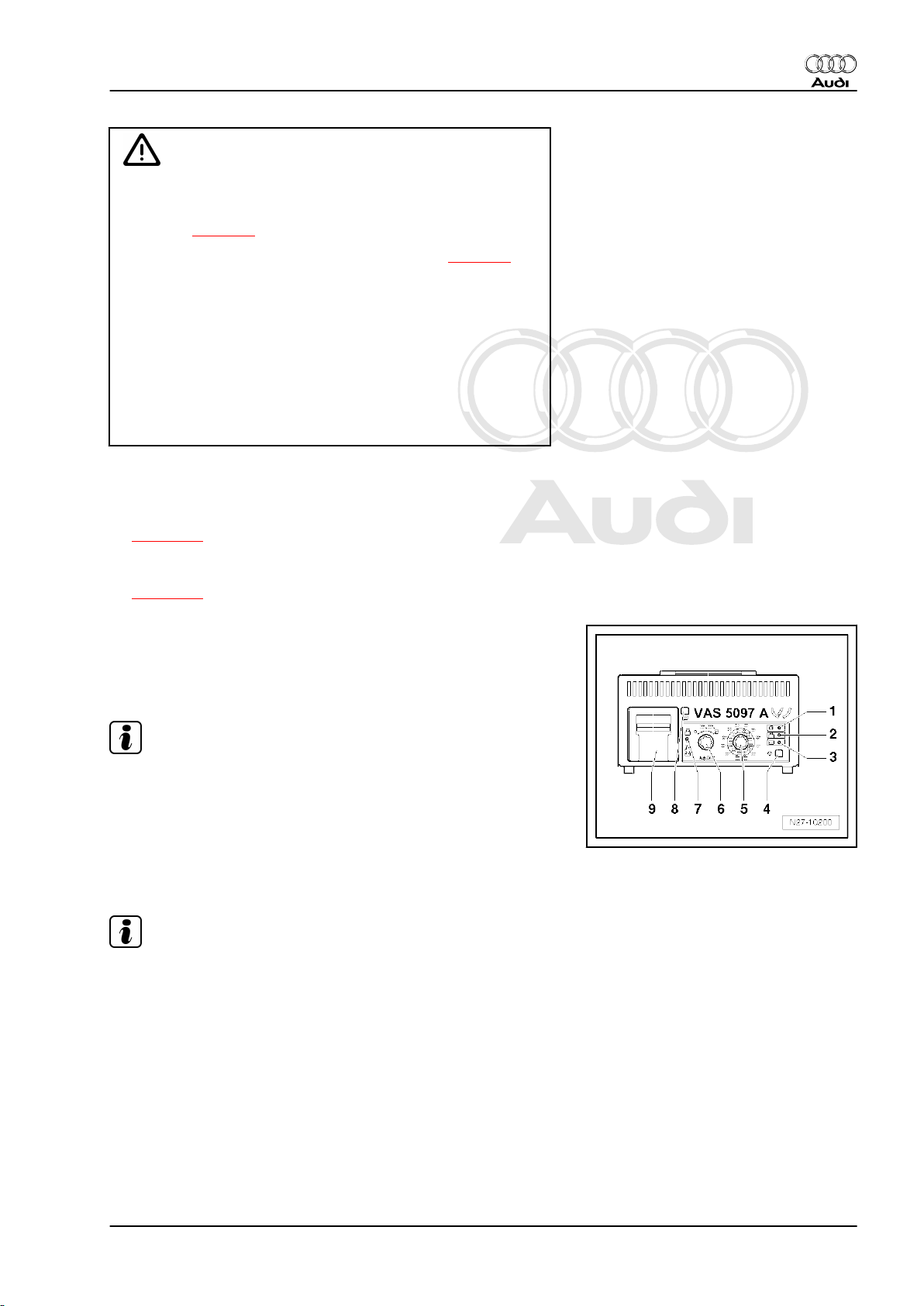

– Set the low temperature test current with the selector switch

-5-.

– Set the measuring range, 80 - 379 A or 380 - 499 A, with the

ON/OFF switch -6-.

Note

Batteries with a low temperature test current of 520 A according

to DIN can be checked with the setting for 499 A according to DIN.

– Connect red test clamp „+“ of battery tester to positive battery

terminal.

– Connect black test clamp „–“ of battery tester to negative bat‐

tery terminal.

Note

♦

Make sure the test clamps make proper contact.

♦

Please note the TPI 2012182 on the battery tester with printer

-VAS 5097 A- .

4. Checking battery - vehicles without battery monitor control unit J367 or energy management control unit J644 23

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

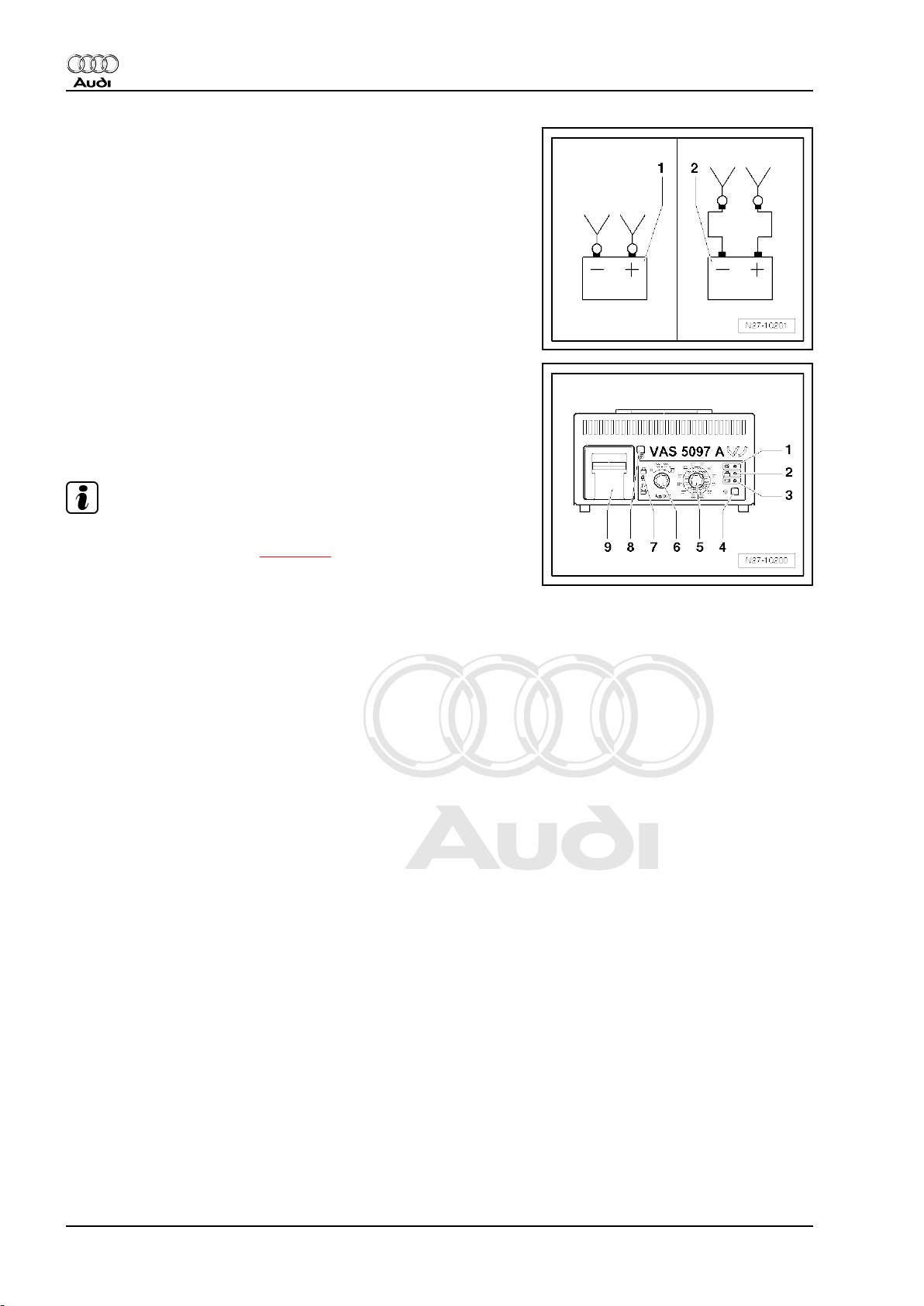

– Use the sliding switch -7- to select the connection point for the

test clamps.

1 - Direct connection to battery

2 - Connection to external test points in engine compartment

– Check whether the low temperature test current indicated on

the battery matches the value set on the battery tester.

– Press start button -4-.

• Green LED -1- lights up.

• The test program runs through automatically.

• The printer -9- will print out the test result after 20 seconds.

Note

♦

If battery tester does not start up (no LED lights, no printout),

battery must be charged ⇒ page 35 .

♦

If red LED -2- lights up, battery tester has been connected with

reverse polarity.

♦

If red LED -3- lights up, battery is not suitable for testing. Re‐

new battery.

– Switch off battery tester with ON/OFF switch -6-.

– Detach test clamps.

24 Rep. gr.27 - Starter, current supply, CCS

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

Test result on printout:

1 - Measuring range set on battery tester

2 - Diagram (-arrow- indicates battery status)

3 - Test result

4 - Battery voltage during load test

5 - Vehicle data and date must be entered by mechanic

Battery tester printout Measures

Battery Very Good Battery OK

Battery Good Battery OK

Battery Sufficient Measure current draw

⇒ page 26

Battery Not Good Measure current draw

⇒ page 26

Battery Faulty Measure current draw

⇒ page 26

Cannot be tested Charge battery ⇒ page 35

and test again

Note

Observe disposal regulations if battery has to be renewed

⇒ page 4 .

4.3 Measuring no-load voltage - vehicles

without battery monitor control unit J367- or energy management control

unit -J644-

Note

By measuring no-load voltage, for example as part of the speci‐

fied care and maintenance work for vehicles not in use or in

storage, it can be determined if the battery needs re-charging ⇒

Maintenance tables .

Special tools and workshop equipment required

♦ Hand-held multimeter -V.A.G 1526E-

Procedure

Observe the following points to ensure correct measurement.

4. Checking battery - vehicles without battery monitor control unit J367 or energy management control unit J644 25

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

• Battery must NOT be subjected to electrical load within the

next 2 hours prior to measurement.

• After the battery has been charged or the engine has been

running, wait for 12 hours before performing measurements.

• Battery temperature must be at least –10 °C.

After a waiting time of at least 12 hours:

– Measure voltage between battery terminal clamps.

• Specification: 12.5 V or above = battery is OK

– If battery no-load voltage is below 12.5 V, battery must be re-

charged ⇒ page 35 .

– Current draw must be measured after a charging period of

5 minutes ⇒ page 26 .

– If battery no-load voltage is 11.6 V or less, battery is totally

discharged ⇒ page 38 .

4.4 Checking battery by measuring current

draw - vehicles without battery monitor

control unit -J367- or energy manage‐

ment control unit -J644-

Checking the current draw capacity of a battery during charging

allows you to assess quickly whether a partially or totally dis‐

charged battery ⇒ page 38 can be made serviceable again by

re-charging or whether the battery has to be renewed.

Special tools and workshop equipment required

♦ Battery charger -VAS 5095A- and trigger clamp, 100A -VAS

5051B/7- or

♦ Battery charger -VAS 5900- or

26 Rep. gr.27 - Starter, current supply, CCS

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

♦ Battery charger -VAS 5903-

♦ Battery charger -VAS 5904-

Electrical system; General information - Edition 10.2010

♦ Battery charger -VAS 5906-

Note

♦

When charging with battery charger -VAS 5095A- , the current

draw of the battery must be measured using e.g. trigger clamp,

100A -VAS 5051B/7- . Battery chargers -VAS 5900- , -VAS

5903- , -VAS 5904- and -VAS 5906- indicate the current draw

on the unit.

♦

Information on battery chargers ⇒ Operating instructions for

appropriate battery charger.

Procedure

• Battery temperature must be at least +10 °C.

• The battery charger must be capable of supplying a charging

current of at least 30 A, as is the case for example with the

battery chargers -VAS 5095A- , -VAS 5900- , -VAS 5903- , VAS 5904- and -VAS 5906- .

• Battery charger connected and switched on

4. Checking battery - vehicles without battery monitor control unit J367 or energy management control unit J644 27

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

– Measure battery charging current after a charging period of 5

minutes.

• Specification: Charging current must be greater than 10 % of

rated capacity.

• Example: Charging current for a 60 Ah battery after 5 minute

charging period: greater than 6 A.

– If reading matches specification, continue with charging proc‐

ess until battery is fully charged.

– Then check battery using the battery tester:

♦ Using battery tester with printer -VAS 6161- (no waiting time)

⇒ page 17 .

♦ Using battery tester with printer -VAS 5097A- (after charging,

wait for 12 hours) ⇒ page 21 .

– If reading is below specification, renew battery ⇒ Electrical

system; Rep. gr. 27 .

Note

Observe disposal regulations if battery has to be renewed

⇒ page 4 .

28 Rep. gr.27 - Starter, current supply, CCS

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

5 Checking battery - vehicles with bat‐

tery monitor control unit -J367- or en‐

ergy management control unit -J644-

♦ On some models, the electrical system is monitored by the

energy management control unit -J644- or the battery monitor

control unit -J367- in connection with the data bus diagnostic

interface -J533- (allocation ⇒ Current flow diagrams, Electrical

fault finding and Fitting locations). The battery test for these

vehicles is performed via „Guided Fault Finding“.

♦ If is not possible to check the battery in the „Guided Fault

Finding“ because of a partially or totally discharged battery,

the charge status of the battery can be assessed quickly via

„Checking battery by measuring current draw“.

♦ Do not open maintenance-free batteries; this would invalidate

the warranty.

5.1 Checking battery using vehicle diagnos‐

tic tester

Special tools and workshop equipment required

♦ Vehicle diagnostic tester

Procedure

• Battery charger must not be connected during battery test and

engine must not be running.

• Battery temperature must be at least –10 °C.

• Temperature of diagnostic system must be between +5

and 45 °C.

– Connect vehicle diagnostic tester ⇒ page 110 .

Note

If a fault message appears on the display, refer to ⇒ Operating

instructions for vehicle diagnostic tester .

– Select Guided Functions from menu.

5. Checking battery - vehicles with battery monitor control unit J367 or energy management control unit J644 29

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

Electrical system; General information - Edition 10.2010

Display (example):

– Enter vehicle identification by touching the appropriate mes‐

sage line -1- in accordance with the selection prompt -A-.

– Select function or path:

Vehicle brand

Engine code

61 - Battery control or

19 - Data bus diagnostic interface or

Service work

A - Battery, Testing (Repair group 27)

– Continue to follow the instructions on the display of the vehicle

diagnostic tester; the following messages can be displayed:

• Battery OK.

• Re-charge battery.

• Renew battery.

After performing battery test:

– Press Go to button.

– Select „End“ function in list.

– Switch off ignition and separate diagnostic connection.

– If necessary, re-charge ⇒ page 35 or renew battery ⇒ Elec‐

trical system; Rep. gr. 27 .

Note

Observe disposal regulations if battery has to be renewed

⇒ page 4 .

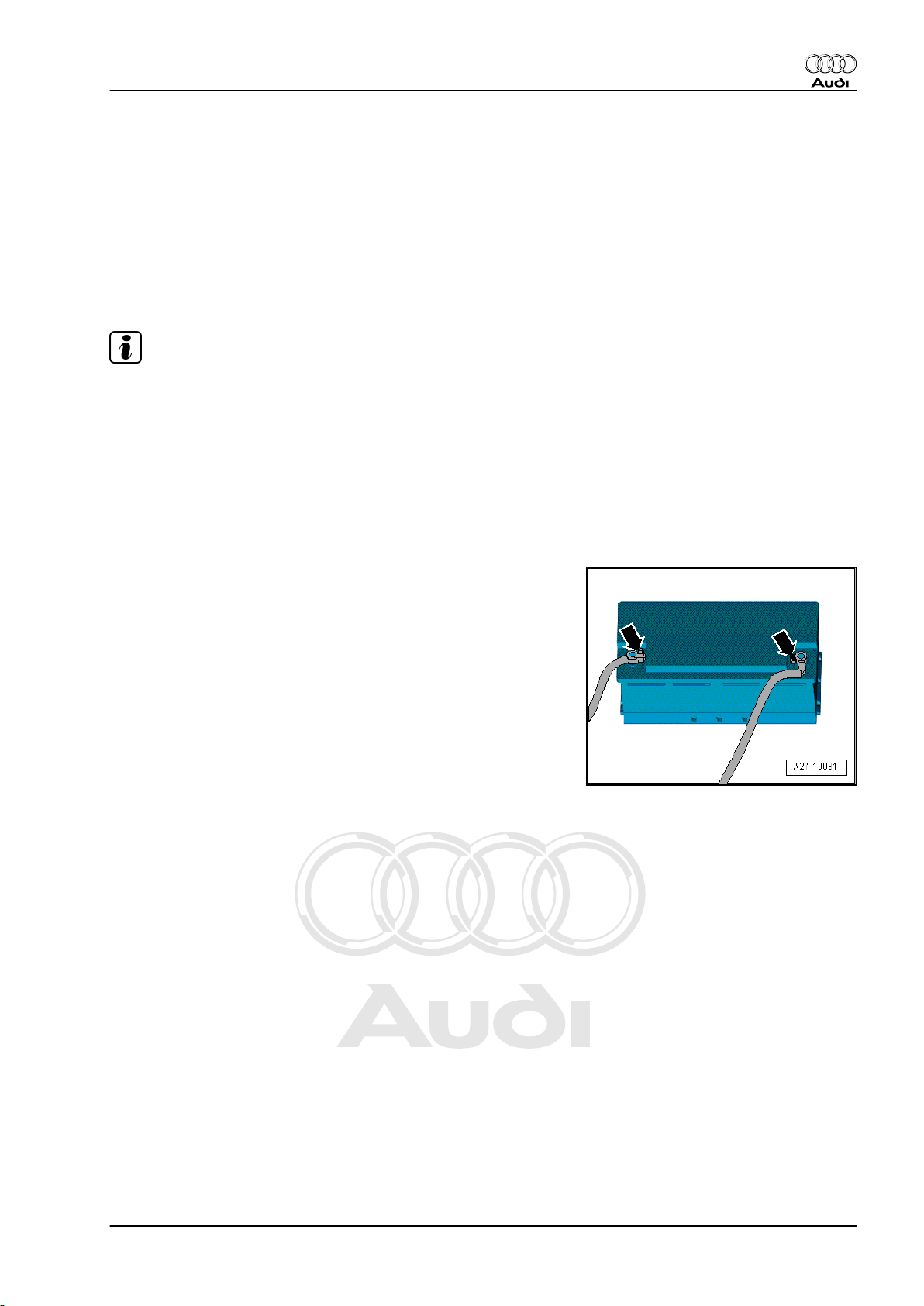

5.2 Checking battery by measuring current

draw - vehicles with battery monitor con‐

trol unit -J367- or energy management

control unit -J644-

Checking the current draw capacity of a battery during charging

allows you to assess quickly whether a partially or totally dis‐

charged battery ⇒ page 38 can be made serviceable again by

re-charging or whether the battery has to be renewed.

Special tools and workshop equipment required

♦ Battery charger -VAS 5095A- and trigger clamp, 100A -VAS

5051B/7- or

30 Rep. gr.27 - Starter, current supply, CCS

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A1 2011 ➤ , Audi A2 2001 ➤ , Audi A3 2004 ➤ , Audi A4 2001 ➤ , Au ...

♦ Battery charger -VAS 5900- or

♦ Battery charger -VAS 5903-

Electrical system; General information - Edition 10.2010

♦ Battery charger -VAS 5904-

♦ Battery charger -VAS 5906-

5. Checking battery - vehicles with battery monitor control unit J367 or energy management control unit J644 31

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not