Page 1

Service Training

Audi New Technology 2009 – 2010

Self-Study Program 990193

Page 2

Audi of America, LLC

Service Training

Printed in U.S.A.

Printed 11/2009

Course Number 990193

©2009 Audi of America, LLC

All rights reserved. Information contained in this manual is

based on the latest information available at the time of printing

and is subject to the copyright and other intellectual property

rights of Audi of America, LLC., its affi liated companies and its

licensors. All rights are reserved to make changes at any time

without notice. No part of this document may be reproduced,

stored in a retrieval system, or transmitted in any form or by

any means, electronic, mechanical, photocopying, recording or

otherwise, nor may these materials be modifi ed or reposted to

other sites without the prior expressed written permission of

the publisher.

All requests for permission to copy and redistribute

information should be referred to Audi of America, LLC.

Always check Technical Bulletins and the latest electronic

repair literature for information that may supersede any

information included in this booklet.

Page 3

Table of Contents

R8 with 5.2L V10 FSI Engine . . . . . . . . . . . . . . . . . . . . . . . . . 1

Packaged Ultrasonic Level Sensor (PULS) . . . . . . . . . . . .17

0B5 S Tronic Transmission . . . . . . . . . . . . . . . . . . . . . . . . . .20

Sport Differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Indirect Tire Pressure Monitoring . . . . . . . . . . . . . . . . . . . .69

MMI 3G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Knowledge Assessment . . . . . . . . . . . . . . . . . . . . . . . . . . .93

The Self-Study Program provides introductory information regarding the design

and function of new models, automotive components or technologies.

The Self-Study Program is not a Repair Manual!

All values given are intended as a guideline only.

Refer to the software version valid at the time of publication of the SSP.

For maintenance and repair work, always refer to the current technical literature.

Reference Note

i

Page 4

Notes

ii

Page 5

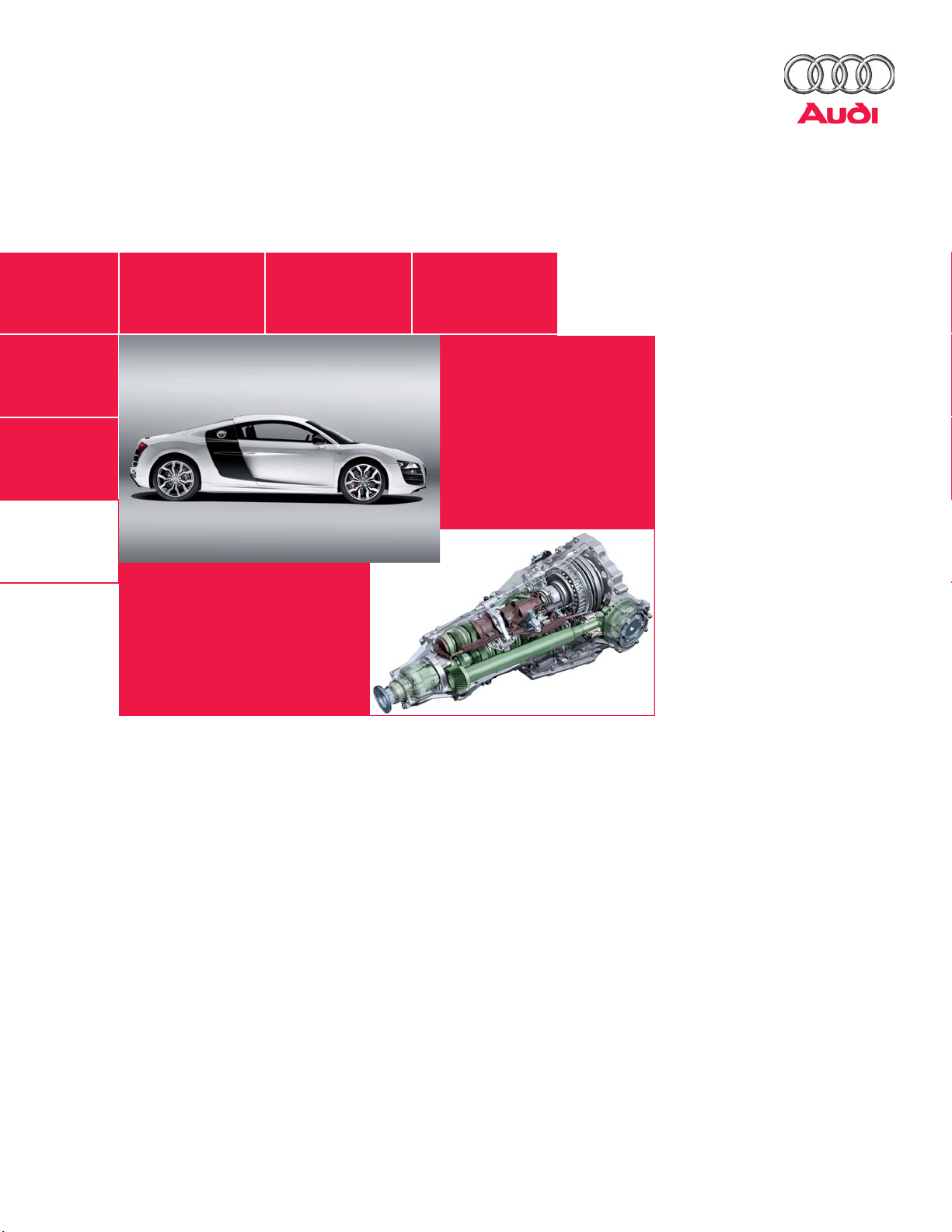

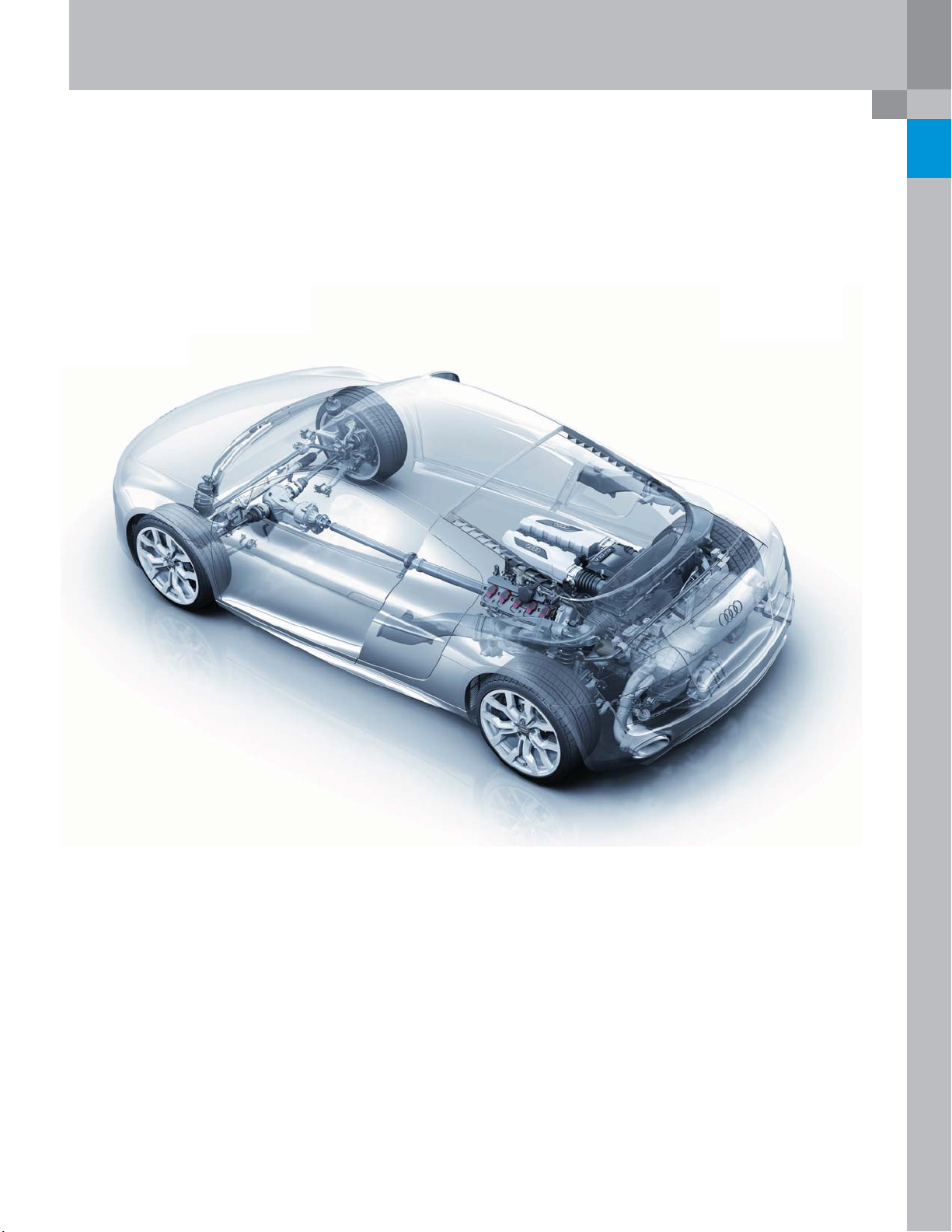

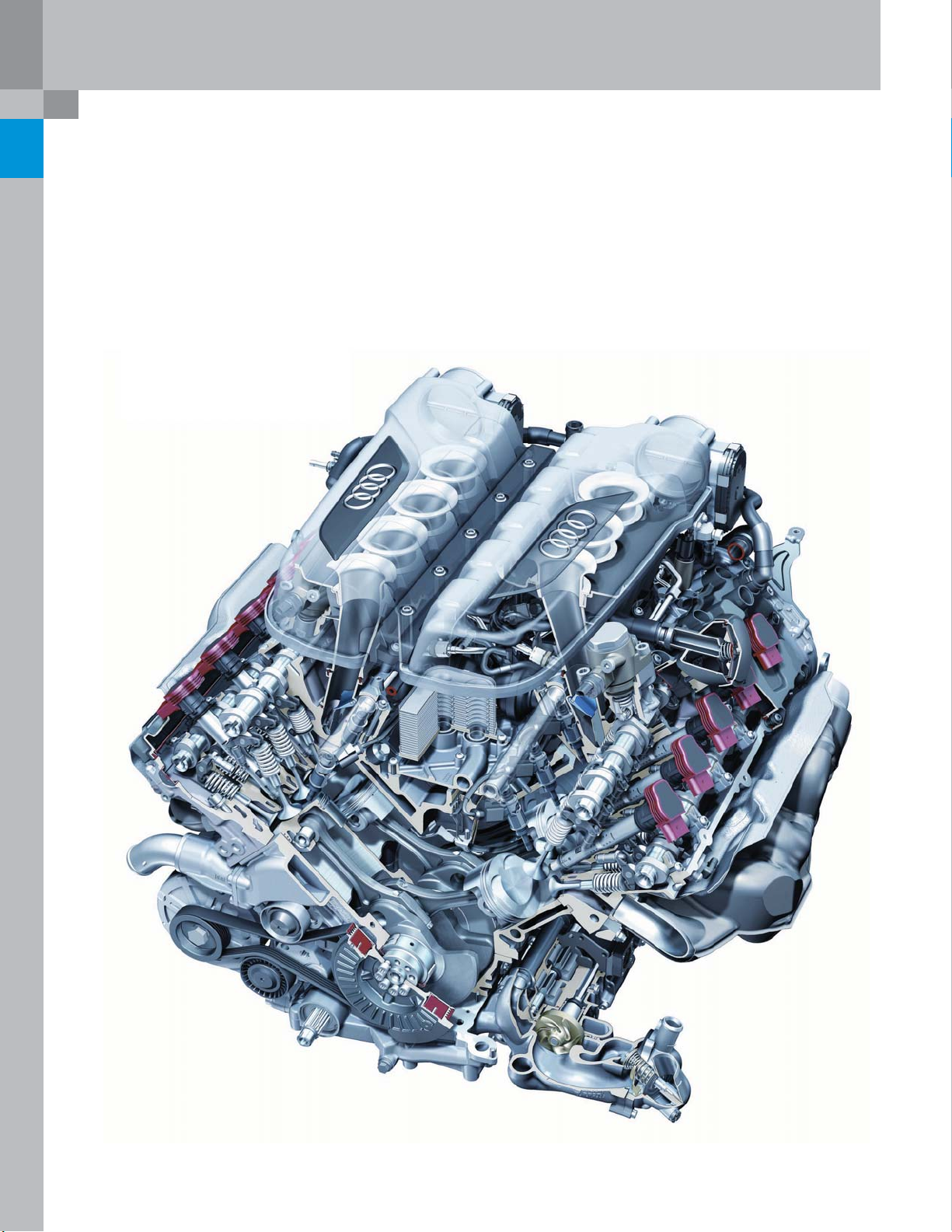

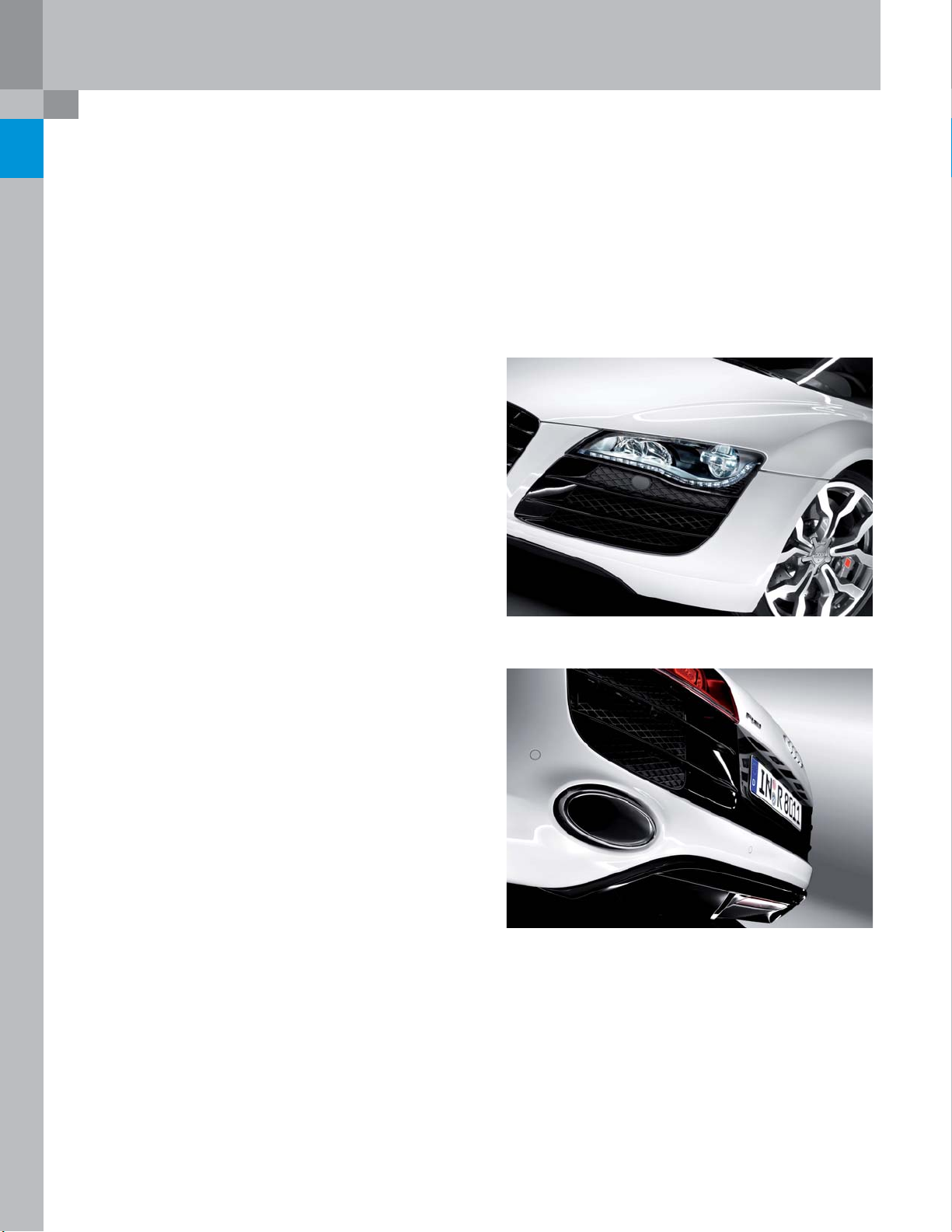

R8 with 5.2L V10 FSI Engine

Audi continues to build on its leadership position in the

high-performance sports car segment with the

R8 5.2L V10 FSI quattro. The top-of-the-line model of

the R8 model series was developed jointly with quattro

GmbH. Its ten-cylinder engine develops 525 hp (386 kW)

which is capable of delivering breathtaking performance.

Audi technologies such as quattro permanent all wheel

drive, lightweight aluminum body (ASF) and innovative

all-LED lights propel the R8 5.2L V10 to the top of its

competitive fi eld.

At a glance:

Engine

– Newly developed V10 with 5.2 liters displacement, FSI

direct injection and dry sump lubrication

– Superior performance 525 hp (386 kW) and 390 lb ft

(530 Nm) of torque

Power train

– Six-speed manual transmission; optional sequential

R tronic with paddle shifters on steering wheel and

“Launch Control” function

– quattro permanent all wheel drive with rear-wheel bias

990193_100

Chassis

– Dual aluminum wishbone suspension

– High-performance brakes, optional with ceramic discs

– 19-inch wheels

– Audi magnetic ride adaptive suspension

Body and design

– Lightweight, extremely rigid aluminum ASF body

weighs only 436 lb (210 Kg)

– Spacious interior and high level of everyday utility

– Exterior and interior design with distinctive new

elements

– All-LED lights as standard

1

Page 6

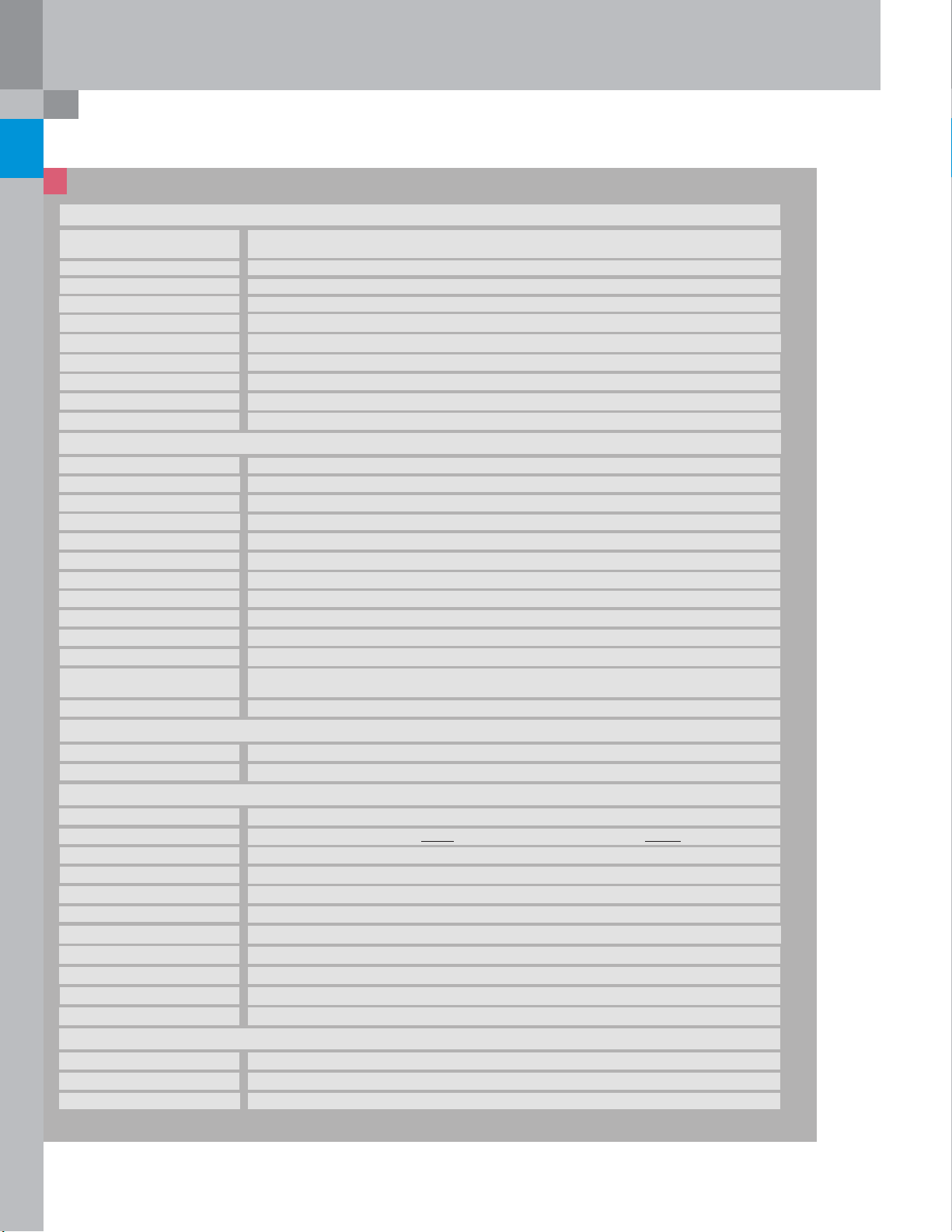

R8 with 5.2L V10 FSI Engine

Technical Specifi cations

Engine:

Naturally aspirated 5.2 liter V10 spark ignition engine with FSI, 90° cylinder angle, 4-valve per cylinder,

Type

double overhead camshafts (DOHC), intake manifold with charge movement flaps

8700 rpm

rpm

Arrangement

Displacement

Compression ratio

Fuel requirement

Horsepower

Torque

Engine design:

Cylinder block

Connecting rods

Pistons

Crankcase

Crankshaft

Cylinder head

Valve train

Firing order

Cooling system

Lubrication system

Fuel injection

Emission system

Electrical system:

Battery

Alternator

Drive train:

Transmission

Gear ratios: 1st

Reverse

Final drive

Center differential

Steering:

Turning circle (curb to curb)

Mid-mounted, longitudinal

Bore

Stroke

3.65 in (92.8 mm)

12.5 : 1

Premium unleaded

525 hp (386 kW) @ 8000 rpm

391 lb ft (530 Nm) @ 6500 rpm

Aluminum alloy incorporating silicon crystals

Forged steel / large ends cracked

Aluminum

High strength aluminum alloy casting

Forged steel, 5 main bearings

Aluminum alloy casting

Chain-driven DOHC, continuous intake and exhaust camshaft adjustment

1–6–5–10–2–7–3–8–4–9

Water-cooled, thermostatically controlled radiator fan

Dry sump oil system

FSI

Two metal primary catalytic converters, two metal main catalytic converters, four heated oxygen sensors,

secondary air injection system

Super Plus ROZ 98 (Premium unleaded — 9 AKI)

Fuel

110 amp/hour

14.0 volts 190 amp

6-speed manual with launch control / optional R tronic with launch control

Manual R tronic

Type

2nd

3rd

4th

5th

6th

3.077 3.077

Viscous clutch

Hydraulically assisted rack-and-pinion

Type

17.3

Ratio

3.33 in (84.5 mm)

317.6 cu in (5,204 ccm)

4.373

2.709

1.925

1.502

1.239

1.035

3.713

38.7 ft (11.8 m)

2.709

1.925

1.502

1.239

1.035

4,373

3.713

2

Page 7

R8 with 5.2L V10 FSI Engine

Suspension:

Double aluminum wishbone

Front

Double aluminum wishbone

Rear

Brakes:

Service brake: Discs/calipers

Parking brake

Wheels (standard only):

Tire (standard only):

Body:

Corrosion protection

Capacity:

Engine oil

Fuel tank

Reserve

Cooling system

Exterior dimensions: [see next page]

Interior dimensions:

Seating capacity

EPA class

Head room

Shoulder room

Leg room

Interior volume (EPA)

Luggage capacity trunk / behind seats

Performance:

0 - 60 mph

0 - 100 km/h

0 - 200 km/h

Top speed

Lateral acceleration

Fuel economy (EPA estimate): Manual R-tronic

Highway

Combined

Disc brakes, internally vented / eight piston calipers at front, 4 piston calipers at rear

Front

14.4 in (365 mm)

Rear

14.4 in (365 mm)

Mechanically actuated at the rear wheels

Size

Front: 8.5J x 19, Rear: 11J x 19 Alloy

Size

Front: 235/35 91Y, Rear: 295/30 100Y

Material

Multi-step anti-corrosion protection

Audi Space Frame (ASF)

12.7 qt (12.0L)

23.8 gal (90L)

2.6 gal (10L)

5.3 gal (24.0l)

2

n/a

n/a

n/a

n/a

n/a

3.5 cu ft (100L) / 3.18 cu ft (90L)

5.2 FSI quattro - manual 5.2 FSI quattro - R tronic

3.7 seconds 3.7 seconds

3.9 seconds 3.9 seconds

12.0 seconds 12.0 seconds

196 mph (316 km/h) 196 mph (316 km/h)

1.2 g

12.0 mpg 13.0 mpg

City

20.0 mpg 20.0 mpg

15.0 mpg 15.0 mpg

3

Page 8

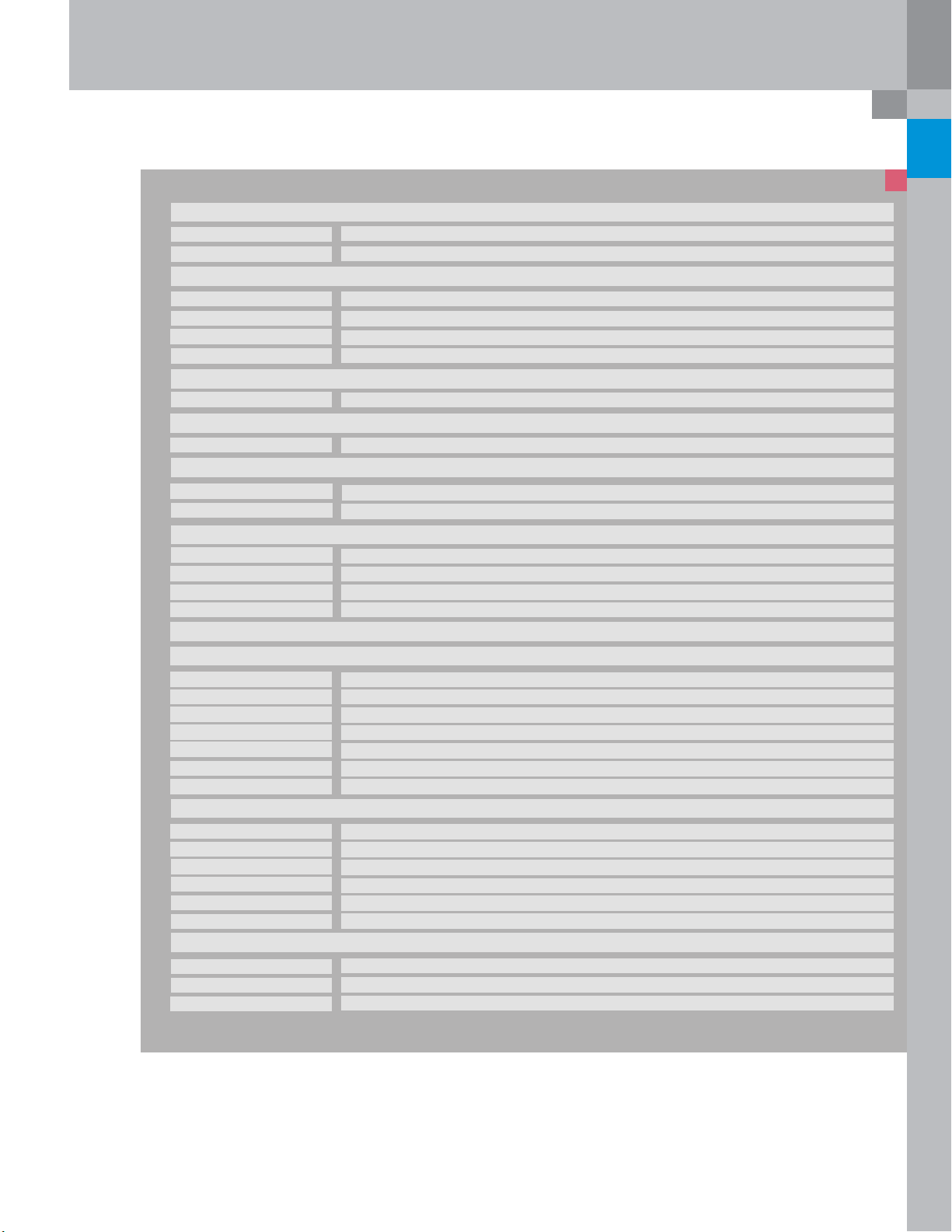

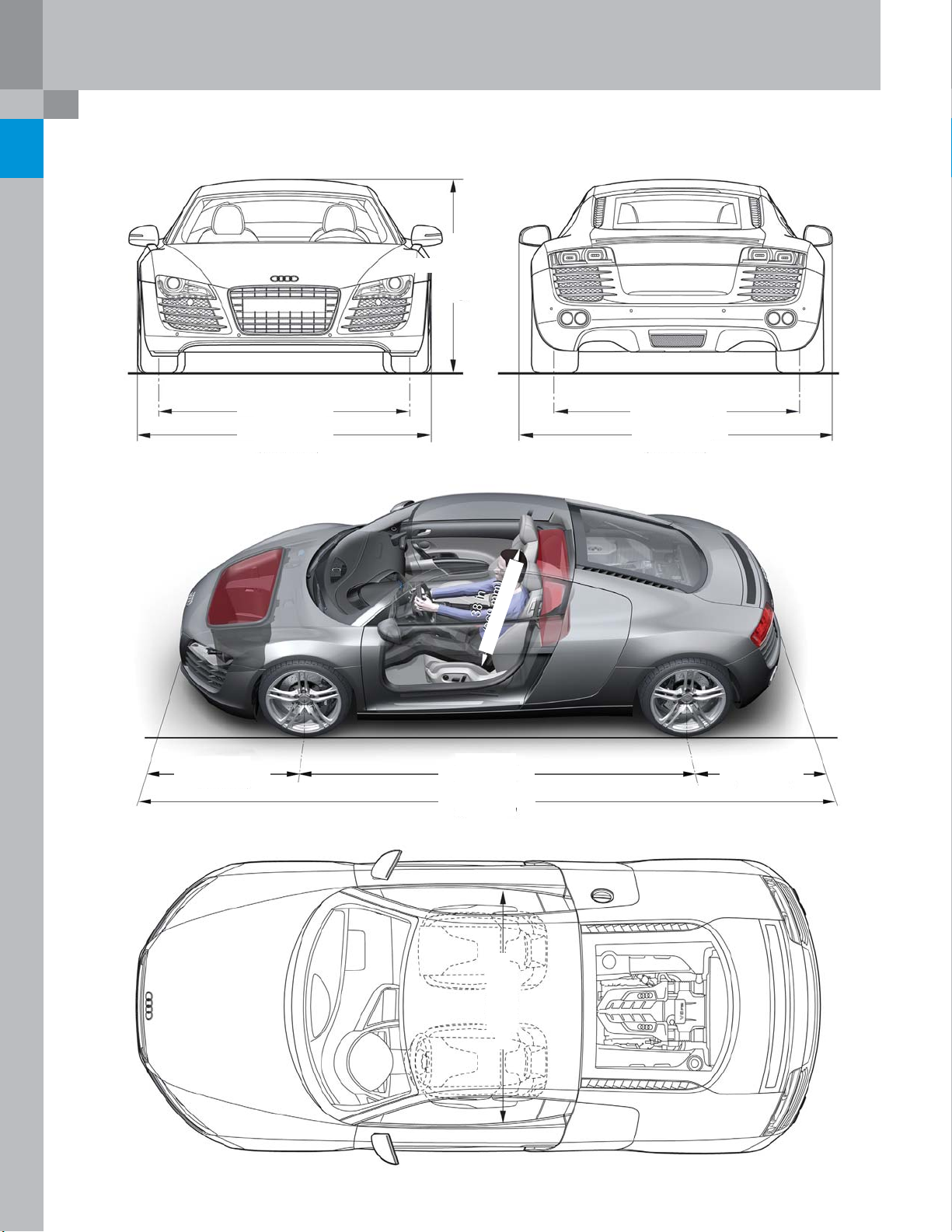

R8 with 5.2L V10 FSI Engine

Dimensions

49.2 in (1252 mm)

64.4 in (1638 mm)

75.9 in (1930 mm)

39.4 in (1003 mm)

37.7 in (958 mm)

104.3 in (2650 mm)

174.6 in (4435 mm)

62.7 in (1595 mm)

79.8 in (2029 mm)

30.7 in (782 mm)

54.8 in (1392 mm)

4

990193_101

Page 9

Like the R8 4.2L, the R8 5.2L V10, uses an Audi Space

Frame of aluminum and ultra-light magnesium.

It is produced largely by hand in the Neckarsulm

manufacturing plant of quattro GmbH.

Maximum precision and the use of the most advanced

joining techniques are employed. This includes: 325 ft

(99 meters) of welding seams, 782 rivets, and 308 selftapping screws that hold the body together.

A fully automatic measuring system checks the

dimensions of every body with precision in the one-tenth

of a millimeter range.

R8 with 5.2L V10 FSI Engine

990193_102

990193_103

Casting (aluminum)

Section (aluminum)

Sheet metal (aluminum)

Magnesium

5

Page 10

R8 with 5.2L V10 FSI Engine

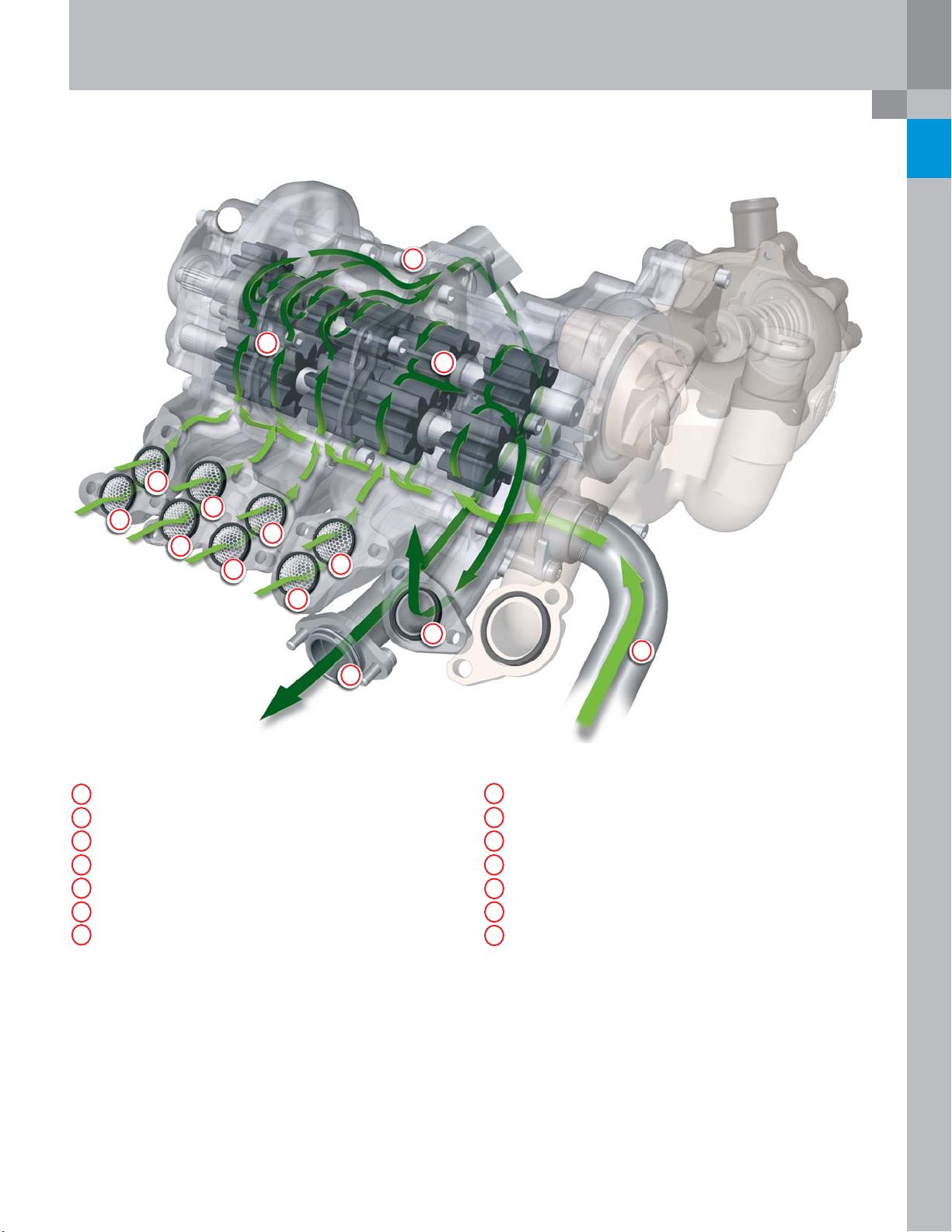

5.2L V10 FSI Engine

The V10 for the R8 has a total displacement of 5,204 cc

and is designed for high-performance.

Specifi c power output for the R8 V10 is 100.9 hp per liter

of displacement. Each horsepower of the engine only

needs to move 6.81 lb (3.09 kilograms) of weight. When

equipped with a manual transmission, the vehicle only

weighs 3571 lb (1,620 kilograms).

The 10-cylinder layout is an ideal design solution for

maximum performance. Compared to a V8 with the same

displacement, a V10 has smaller and lighter pistons and

connecting rods, which makes it a free-revving engine.

Compared to a V12, it has fewer components, resulting in

lower moving masses and less internal friction. Even with

all attached components, the 10-cylinder engine is only

25 inches (646 mm) long, 29 inches (737 mm) wide, and

27 inches (696 mm) high.

990193_104

6

Page 11

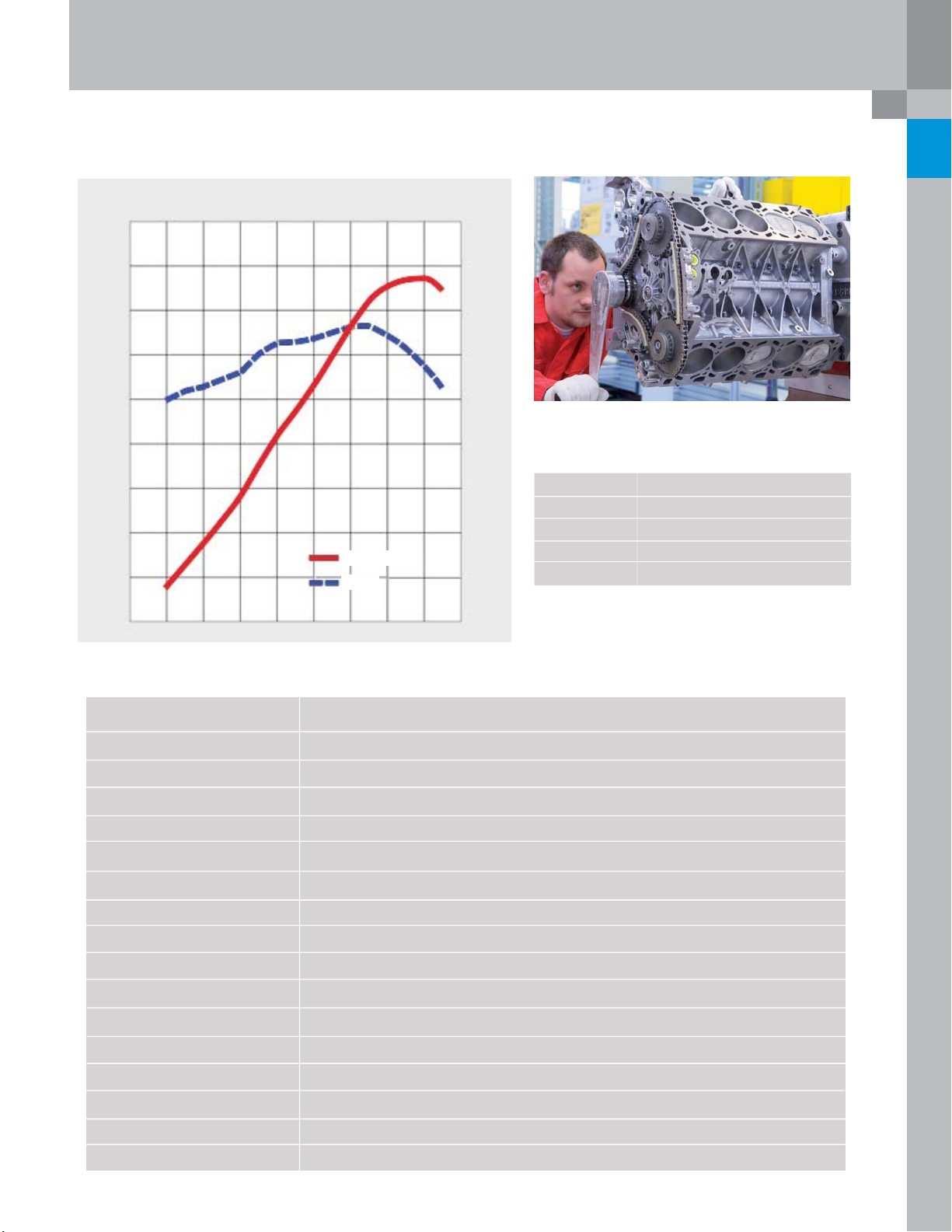

R8 with 5.2L V10 FSI Engine

Specifi cations

hp (kW) lb ft (Nm)

600 (450)

540 (400)

470 (350)

400 (300)

340 (250)

270 (200)

200 (150)

130 (100)

70 (50)

530 (720)

470 (640)

410 (560)

350 (480)

300 (400)

230 (320)

180 (240)

120 (160)

Power output

Torque

0

60 (80)

0

990193_110

Displacement:

Horsepower:

Maximum torque:

Maximum rpm:

Fuel requirement:

317.8 cubic inches (5204 cc)

525 hp SAE (386 kW) @ 8000 rpm

391 lb ft (530 Nm) @ 6500 rpm

8700

Premium unleaded

990193_113

Type:

Arrangement:

Bore:

Stroke:

Compression ratio:

Cylinder block:

Connecting rods:

Pistons:

Crankcase:

Cylinder head:

Valve train:

Firing order:

Cooling system:

Lubrication system:

Fuel injection/ignition system:

Emission system:

Fuel:

5.2 liter V10 spark-ignition with FSI, 90° cylinder angle, 4 valve technology, DOHC, intake manifold

with charge movement flaps, naturally aspirated

Longitudinal, mid-engine installation

3.33 inches (84.5 mm)

3.65 inches (9.28 mm)

12.5:1

Aluminum alloy

Forged steel

Aluminum

High strength aluminum alloy casting

Aluminum alloy

DOHC chain driven, continuously variable intake and exhaust camshaft adjustment

1-6-5-10-2-7-3-8-4-9

Water cooled, thermostatically controlled radiator fans

Dry sump oil system

FSI direct injection

Two metal primary converters, two main converters, four heated O

Super Plus ROZ 98 / Premium unleaded (91 AKI)

sensors, secondary air system

2

7

Page 12

R8 with 5.2L V10 FSI Engine

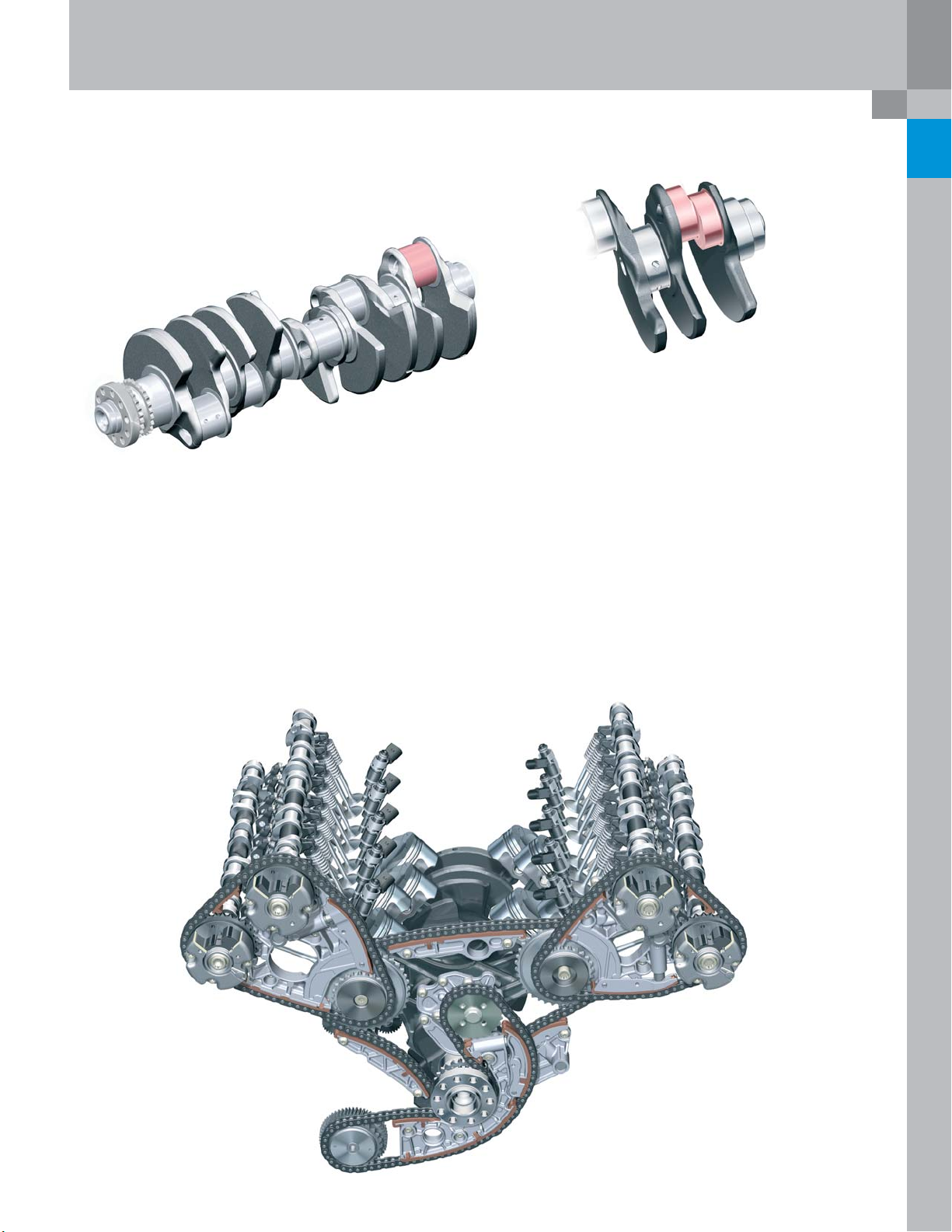

The crankcase is produced by a low-pressure die-casting

method. It is made from hypereutectic aluminum-silicon

alloy — a high-tech material that combines low weight

with high strength. The high silicon content of this alloy

gives the cylinder walls the necessary wear resistance to

withstand very high average piston velocity.

The bedplate design — the lower bearing brackets for the

crankshaft are integrated into a single frame — provides

the crankcase with maximum rigidity and optimal

vibration behavior. Integrally cast iron bearing brackets

reduce thermal expansion of the aluminum housing

and minimize play in the main crankshaft bearings. The

forged crankshaft and forged-steel con rods combine

high strength with low weight. The pistons are forged of

a high-strength aluminum alloy.

431_046

With the dry-sump lubrication system there is no oil pan.

The engine has an intake module connected directly to

the external oil pump via intake ports.

8

This intake module does not have a large oil reservoir.

Instead it serves as a baffl e plate and collects the outfl owing oil generated by the rotation of the crankshaft.

431_074

Page 13

The crankshaft has been designed as a common-pin type

crank pin, and not a split-pin type as on the 5.2L V10

engine used in the Audi S6.

Common-pin

crankshaft

R8 with 5.2L V10 FSI Engine

431_066

Split-pin

431_044

crankshaft

The camshafts, as well as the oil pump, the water pump,

and parts of the accessory sub-systems, are driven by

maintenance-free chains located on the rear wall of the

engine. All four camshafts are adjustable through a 42°

crank angle, which provides a wide range of control

timing. The valves are actuated by roller-mounted cam

followers. The exhaust valves are subject to a high

thermal load and are lined with sodium to assist in

cooling.

431_042

9

Page 14

R8 with 5.2L V10 FSI Engine

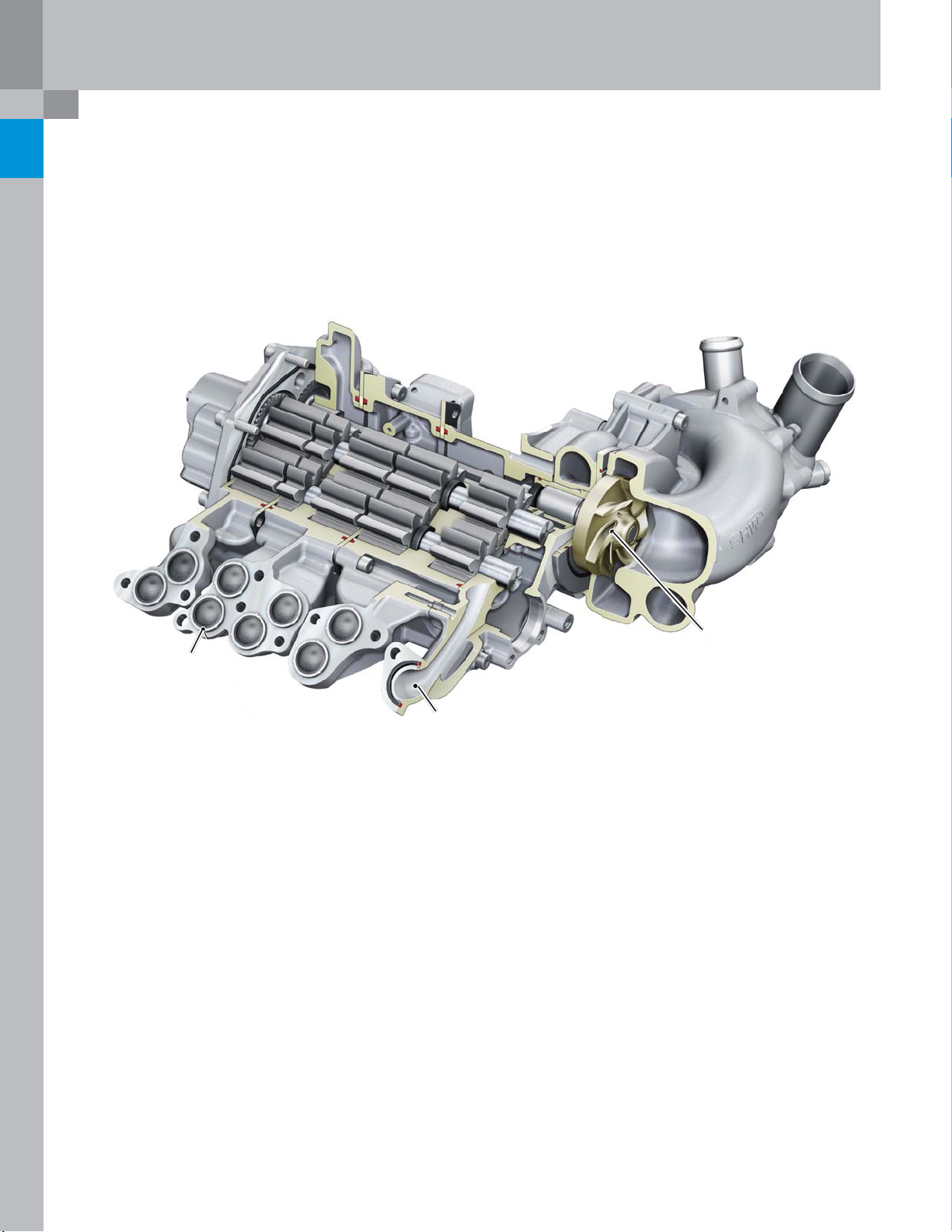

Dry Sump Lubrication System

The oil pump module is external to the engine and is

chain-driven. The pump consists of a suction and feed

pump for fi lling the oil reservoir, and a suction and

pressure pump for supplying oil to the engine.

The oil pump and coolant pump are paired to form a

single unit, so they can only be replaced as a unit.

Only the thermostat housing and integrated coolant

thermostat can be replaced separately.

990193_105

Oil return from

right cylinder head

To main oil port

Water

pump

10

Page 15

R8 with 5.2L V10 FSI Engine

14

12

13

2

1

4

3

6

5

8

431_025

7

Legend

1 Crankshaft chamber 5

2 Chain case return line

3 Oil return from right cylinder head

4 Oil return from left cylinder head

5 Crankshaft chamber 4

6 Crankshaft chamber 3

7 Crankshaft chamber 2

10

11

9

8 Crankshaft chamber 1

9 To oil thermostat

10 To main oil port

11 From oil reservoir

12 Suction pump

13 Pressure pump

14 Crankcase divider

11

Page 16

R8 with 5.2L V10 FSI Engine

In combination with an oil-to-water heat exchanger

located in the inner V of the engine, the 5.2L V10 uses

a thermostatically controlled airfl ow-type oil cooler to

regulate engine oil temperature. It is mounted behind the

left side-blade the body.

When the engine oil is cold, the re-circulating, extracted

oil is pumped into the oil thermostat housing. When

the thermostat is in a closed state, it seals off the inlet

leading to the oil cooler, while the oil in the thermostat

housing is redirected to the oil reservoir.

When the temperature of the oil exceeds 212°F (100°C),

the oil thermostat opens the inlet to the oil cooler.

An expanding element in the thermostat exerts pressure

against the thermostat housing. Due to the pressure

of the expanding element, the thermostat is displaced

against the force of a spring, opening the channel, and

simultaneously closing off the inlet leading directly to the

oil reservoir.

Oil fl ows through this port and into the oil cooler,

returning from there to the oil thermostat housing before

entering the oil reservoir.

Oil cooler, located

behind left side blade

990193_107

12

Page 17

Notes

13

Page 18

R8 with 5.2L V10 FSI Engine

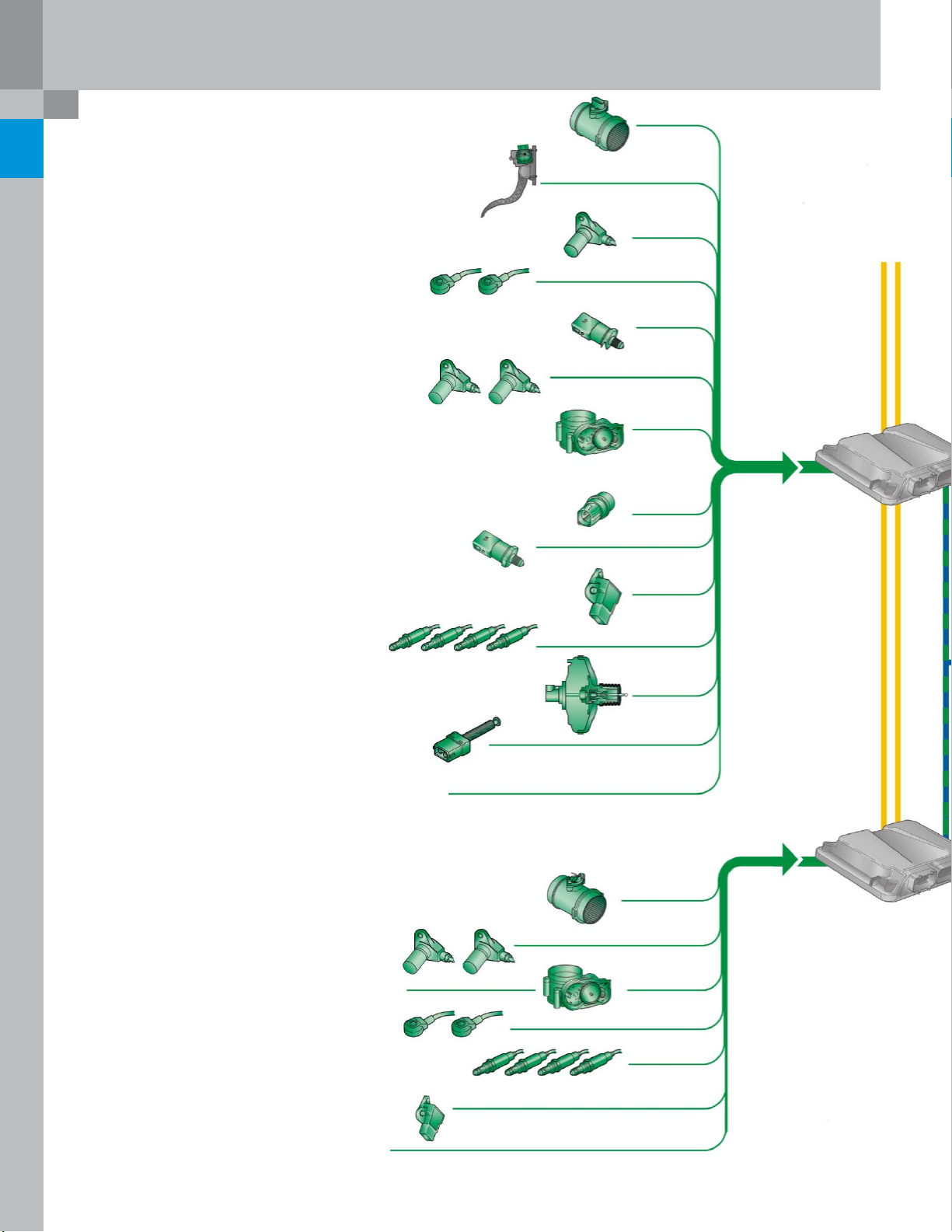

Mass Air Flow Sensor G70

Intake Air Temperature Sensor G42

Throttle Position Sensor G79

Accelerator Pedal Position Sensor -2- G185

Engine Speed Sensor G28

Knock Sensors -1- and -2- G61, G62

Fuel Pressure Sensor G247

Camshaft Position Sensor G40

Camshaft Position Sensor -3- G300

Throttle Valve Control Module J338

Throttle Drive Angle Sensors -1- and -2- G187, G188

Throttle Drive G186

Engine Coolant Temperature Sensor G62

Low Fuel Pressure Sensor G410

Intake Manifold Runner Position Sensor G336

Heated Oxygen Sensor G39

Oxygen Sensor Behind 3-Way Catalytic Converter

G130 Heated Oxygen Sensor -2- G108

Oxygen Sensor -2- Behind 3-Way Catalytic Converter G131

Powertrain

CAN-Bus

Engine Control

Module J623

Brake Booster Pressure Sensor G294

Brake Light Switch F

Brake Pedal Switch F47

Additional Signals:

Oil Temperature Sensor -2- G664 Secondary Injection

Sensor -1- G609

Clutch Position Sensor G476

Cruise Control ON/OFF

Park/Neutral Signal

Terminal 50

Wake Up Signal from Driver’s Door Switch via J393

Mass Air Flow Sensor G246

Intake Air Temperature Sensor -2- G299

Camshaft Position Sensor -2- G163

Camshaft Position Sensor -4- G301

Throttle Valve Control Module -2- J544

Throttle Drive Angle Sensors -1- and -2- G297, G298

Knock Sensors -3- and -4- G198, G199

Heated Oxygen Sensor -3- G285

Oxygen Sensor -3- Behind 3-Way Catalytic Converter G287

Heated Oxygen Sensor -4- G286

Oxygen Sensor -4- Behind 3-Way Catalytic Converter G288

Intake Manifold Runner Position Sensor -2- G512

Secondary Air Injection Sensor -2- G610

Fuel Pressure Sensor -2- G624

14

Engine Control

Module -2- J624

Page 19

R8 with 5.2L V10 FSI Engine

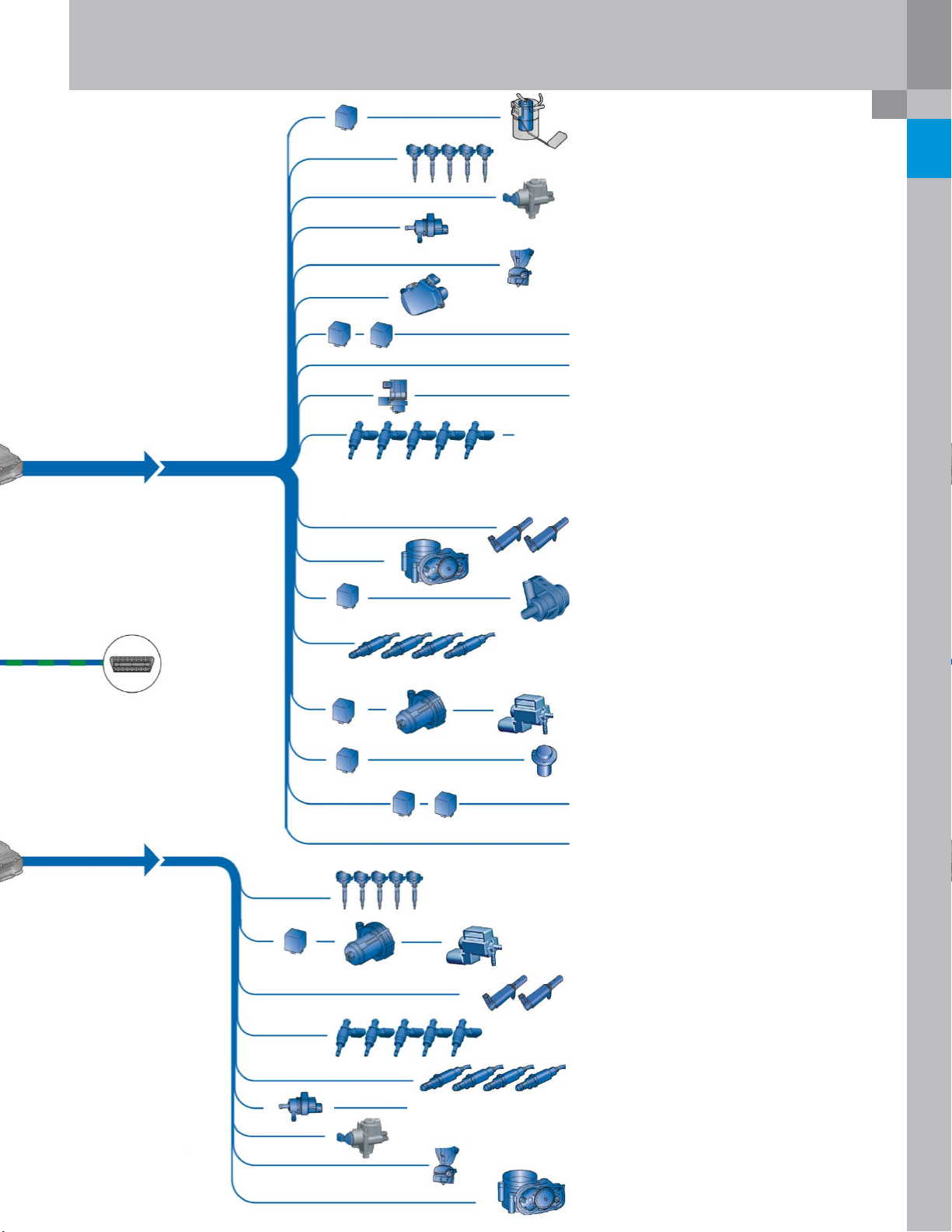

Fuel Pump Control Module J538

Transfer Fuel Pump G6

Ignition Coils 1-5 with Power Output Stage

N70, N291, N292, N323, N127; Cylinders 1-5

Fuel Metering Valve N290

Evaporative Emission Canister Purge Regulator Valve N80

Right Electro-Hydraulic Engine Mount Solenoid

Valve N145

Intake Manifold Runner Control (IMRC) Valve N316

Starter Relay J53; Starter Relay -2- J695

Leak Detection Pump V144

Exhaust Flap Valve -1- N321

Fuel Injectors N30, N31, N32, N33, N83

Cylinders 1-5

Data Link

Connector

990193_114

Camshaft Adjustment Valve -1- N205

Camshaft Adjustment Valve -1- (exhaust) N318

Throttle Drive (for EPC) G186

Coolant Recirculation Pump Relay J151

After-Run Coolant Pump V51

Oxygen Sensor Heater Z19; Oxygen Sensor -1- Behind

3-Way Catalytic Converter Heater Z29; Oxygen Sensor

-2- Heater Z28; Oxygen Sensor -2- Behind 3-Way Catalytic

Converter Heater Z30

Secondary Air Injection Pump Relay J299

Secondary Air Injection Pump Motor V101

Secondary Air Injection Solenoid Valve N112

Brake Booster Relay J569

Brake System Vacuum Pump V192

Engine Component Power Supply Relay J757

Engine Control Module Power Supply Relay J271

Additional Signals:

Coolant Fan Control (FC) Control Module J293

Coolant Fan Control (FC) Control Module -2- J671

Ignition Coils 6-10 with Power Output Stage N324-N328

Cylinders 6-10

Secondary Air Injection Pump Relay -2- J545; Secondary

Air Injection Pump Motor -2- V189; Secondary Air

Injection Solenoid Valve -2- N320

Camshaft Adjustment Valve -2- N208

Camshaft Adjustment Valve -2- (exhaust) N319

Fuel Injectors N84-N86, N299-N300; Cylinders 6-10

Oxygen Sensor -3- Heater Z62; Oxygen Sensor -3- Behind

3-Way Catalytic Converter Heater Z64; Oxygen Sensor

-4- Heater Z63; Oxygen Sensor -4- Behind 3-Way Catalytic

Converter Z65

Evap. Emission Canister Purge Regulator Valve -2- N333

Fuel Metering Valve -2- N402

Left Electro-Hydraulic Eng. Mount Solenoid Valve N144

Throttle Drive -2- G296

15

Page 20

R8 with 5.2L V10 FSI Engine

Distinguishing Features of the 5.2L V10 R8

Audi is the world’s fi rst automaker to use LEDs for high

beam, low beam, daytime running lights, and turn

signals. In this highly complex technology, lens and

refl ector systems, intelligent ballasts, and fan driven

coolers interact. Although the LEDs emit cool light, they

heat up, and their temperature must be kept within a

defi ned range.

With a color temperature of 6,000 Kelvin, the LED light

closely resembles white daylight, which is less tiring to

the eyes when driving at night.

Excellent light distribution and virtually unlimited

LED service life are additional benefi ts. Their energy

consumption is also substantially lower than halogen

lights.

The rear fascia of the R8 5.2L V10 features high-gloss

black as the dominant color.

LEDs mounted in tubular housings create a threedimensional lighting effect.

The rear fascia air outlets have only two cross braces,

and the exhaust system terminates in two large, oval

tailpipes.

The fully enclosed underbody ends in a diffuser with a

pronounced upward sweep.

The rear spoiler automatically deploys at 62 mph (100

km/h.)

990193_112

990193_111

16

Page 21

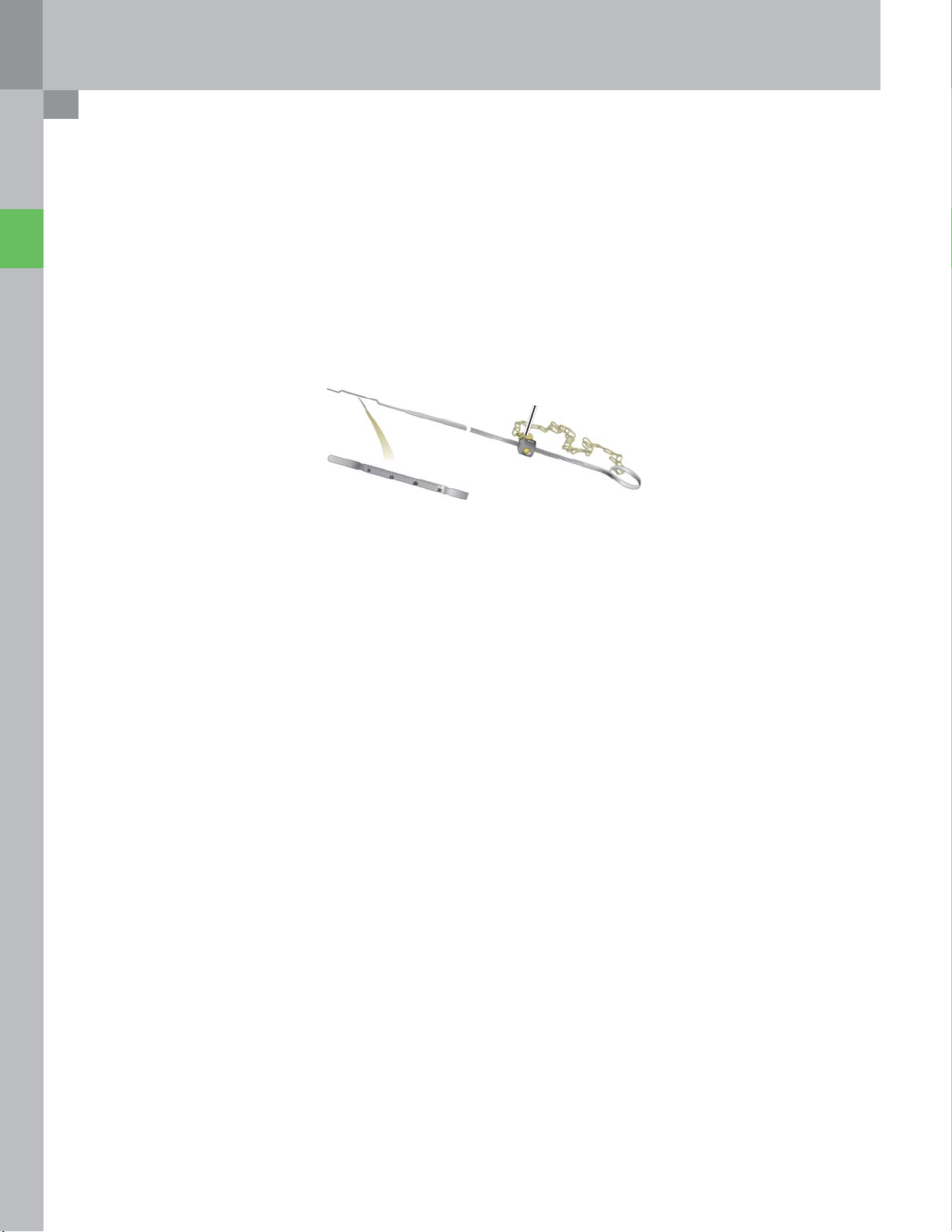

Packaged Ultrasonic Level Sensor (PULS)

New Oil Level Sensor

A new generation engine oil level sensing system has

been introduced by Audi. It is referred to in the technical

literature and VAS Scan Tool as: PULS — Packaged

Ultrasonic Level Sensor. Vehicles using this system can

be identifi ed by the absence of an oil dipstick.

PULS operates on an ultrasonic principle. Ultrasound

pulses generated by the oil level sensor are refl ected

by the oil-air boundary layer. This type of level sensor

replaces the older Thermal Oil Level Sensor (TOLS) that

used the hot-wire principle.

Upper

oil pan

With PULS, oil level is calculated by the engine

control module, which factors the difference between

transmitted and refl ected pulses of the oil level sensor,

and the speed of sound.

The driver can view oil level information via the MMI

under the heading CAR. In addition, minimum and

maximum oil level warnings are displayed in the Driver

Information Display of the instrument cluster.

Virtual cylinder

0.7 in (20 mm) diameter

free of refl ective surfaces

Oil level

sensor

Lower

oil pan

Static

measurement

range

2.9 – 4.7 in

(75 – 120 mm)

measurement

0.6 – 2.9 in

(15 – 75 mm)

Ultrasonic signals are processed electronically by

circuitry in the oil level sensor and are transmitted to

the instrument cluster through a Pulse Width Modulated

(PWM) signal.

Dynamic

range

Zero reference

point of system

411_100

Advantages of the PULS versus a Thermal Oil Level

System (TOLS):

– The sensor signal is available quickly (approx. 100 ms

for ignition ON)

– Low electrical power consumption (approx. 0.5A)

17

Page 22

Packaged Ultrasonic Level Sensor (PULS)

Oil Level Scale

The Engine Control Module calculates oil level in the

engine. This information is transmitted to the Powertrain

CAN-bus where it is read by the instrument cluster and

MMI, which then pass this information on to other subsystems via Data Bus On Board Diagnostic Interface J533.

Because the dipstick has been eliminated, the customer

can only check the oil level via the instrument cluster or

MMI displays.

Oil level scale

T40178

Dynamic Measurement

This measurement method is preferred because it

provides more accurate results. The measurement

process is interrupted when:

– Vehicle acceleration rate is greater than 6.7 mile/hour

seconds (3 meter/sec

– Oil temperature is greater than 284°F (140°C)

– Engine hood has been opened

2

)

Checking the oil in the workshop requires special tool

T40178. The tool must be calibrated for each individual

engine. The adjustment ring is fi rst set to the correct

position, then the oil level is read on the oil level scale.

The correct setting position value for T40178 can be

found in the repair manual maintenance section.

Oil level is calculated both dynamically (vehicle moving)

and statically (vehicle stationary).

Adjustment

ring

411_105

Static Measurement

This measurement is performed:

– At ignition ON (however, the signal is transmitted as

soon as the driver’s door is opened in order to obtain

a level signal quickly

– Engine speed less than 100 rpm

– Engine at standstill for longer than 60 seconds

– Engine temperature over 104°F (40°C)

The following criteria are evaluated:

– Engine speed

– Longitudinal and transverse acceleration

– Engine temperature

– Engine Hood Switch F266 position (open/closed)

– Number of miles (km) driven since the last opening of

Engine Hood Switch F266 (more than 30 miles [50 km])

– Number of measurement values generated within the

driving cycle

18

The longitudinal and transverse acceleration values,

as well as the parking brake position are also used to

determine vehicle status when measurements are made.

Page 23

Packaged Ultrasonic Level Sensor (PULS)

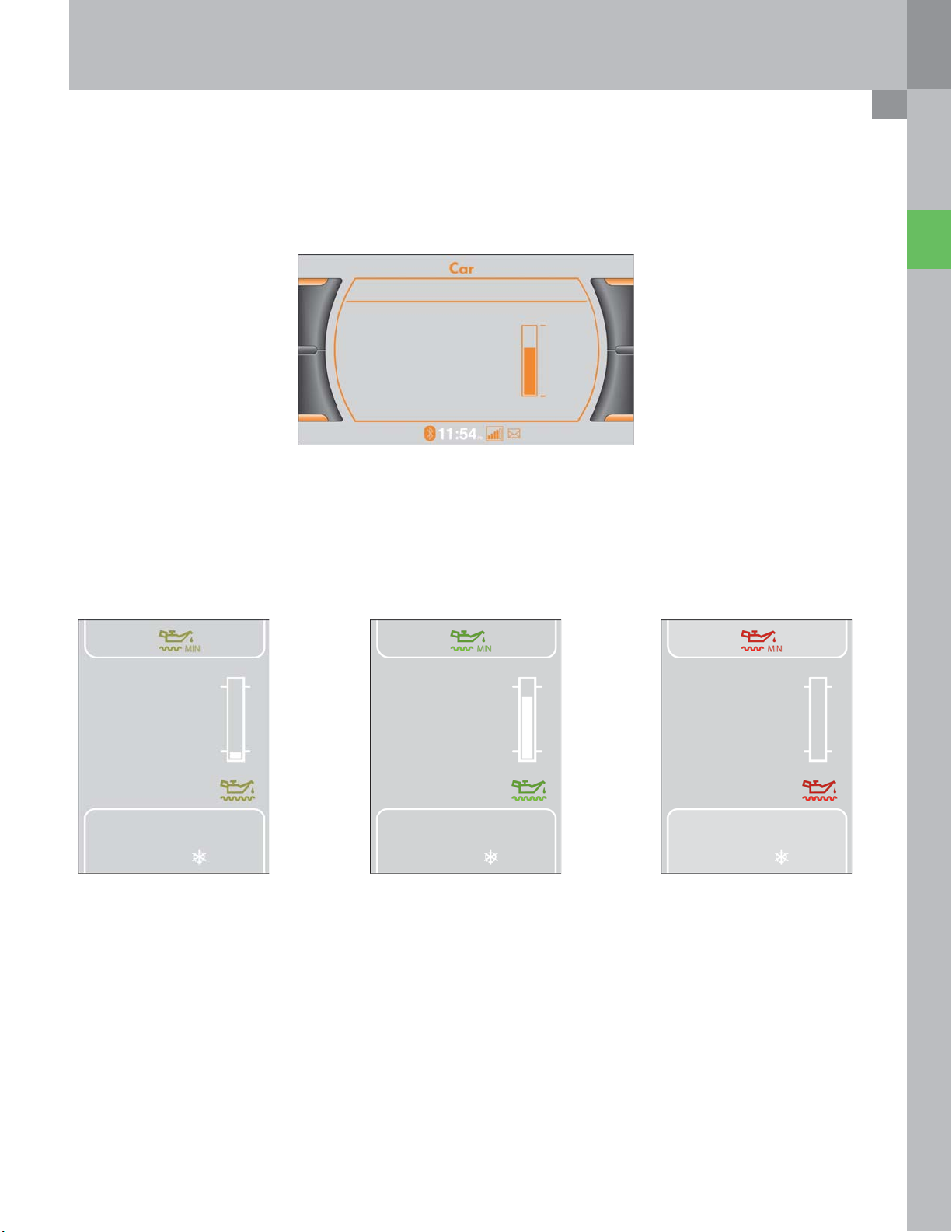

Oil level can be checked by the customer using the MMI,

under the CAR menu.

Oil Level

Engine oil level o.k.

Max

Min

411_096

The following graphics can be displayed in the DIS of the

instrument cluster.

Max

Please add

max. 1 qt oil.

Continued

driving possible.

35540

D4 27° F

m 1975.5

Min

411_097

Oil level is o.k.

35540

D4 27° F

In addition, there is a display that indicates overfi lling

of the system, and a display that indicates if the oil level

sensor has failed.

Max

Min

m 1975.5

411_098

Urgent:

Please

add oil.

35540

D4 27° F

Max

Min

m 1975.5

411_099

19

Page 24

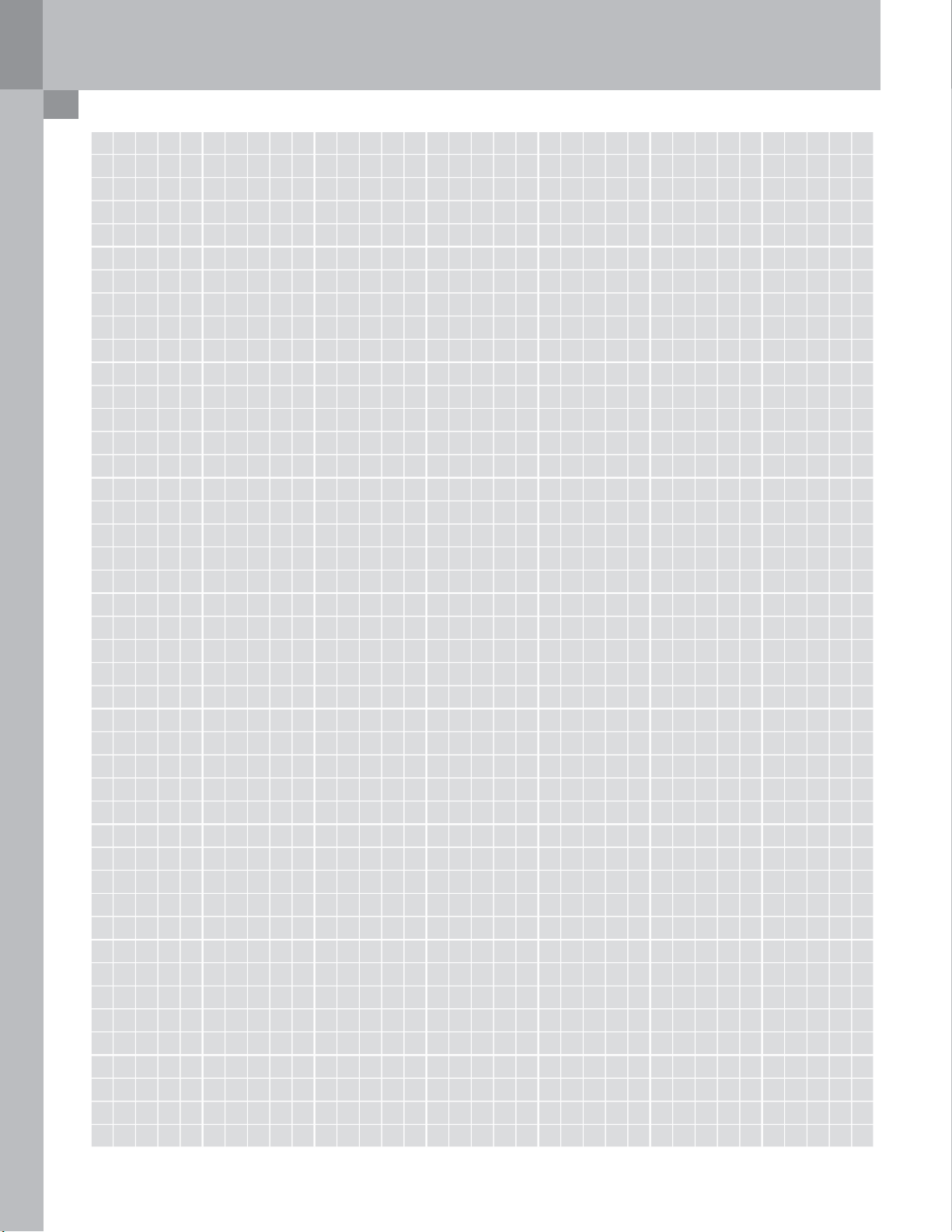

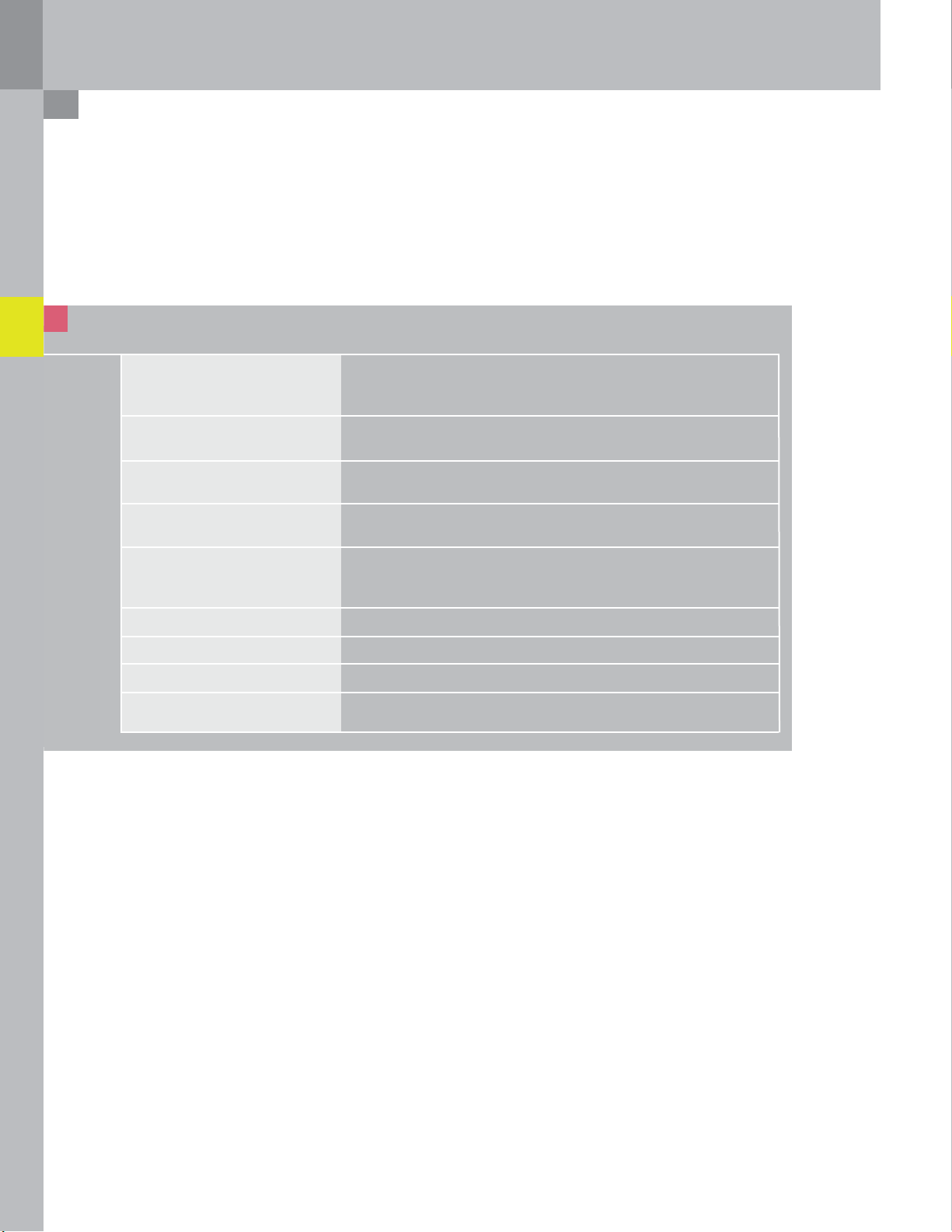

0B5 S Tronic Transmission

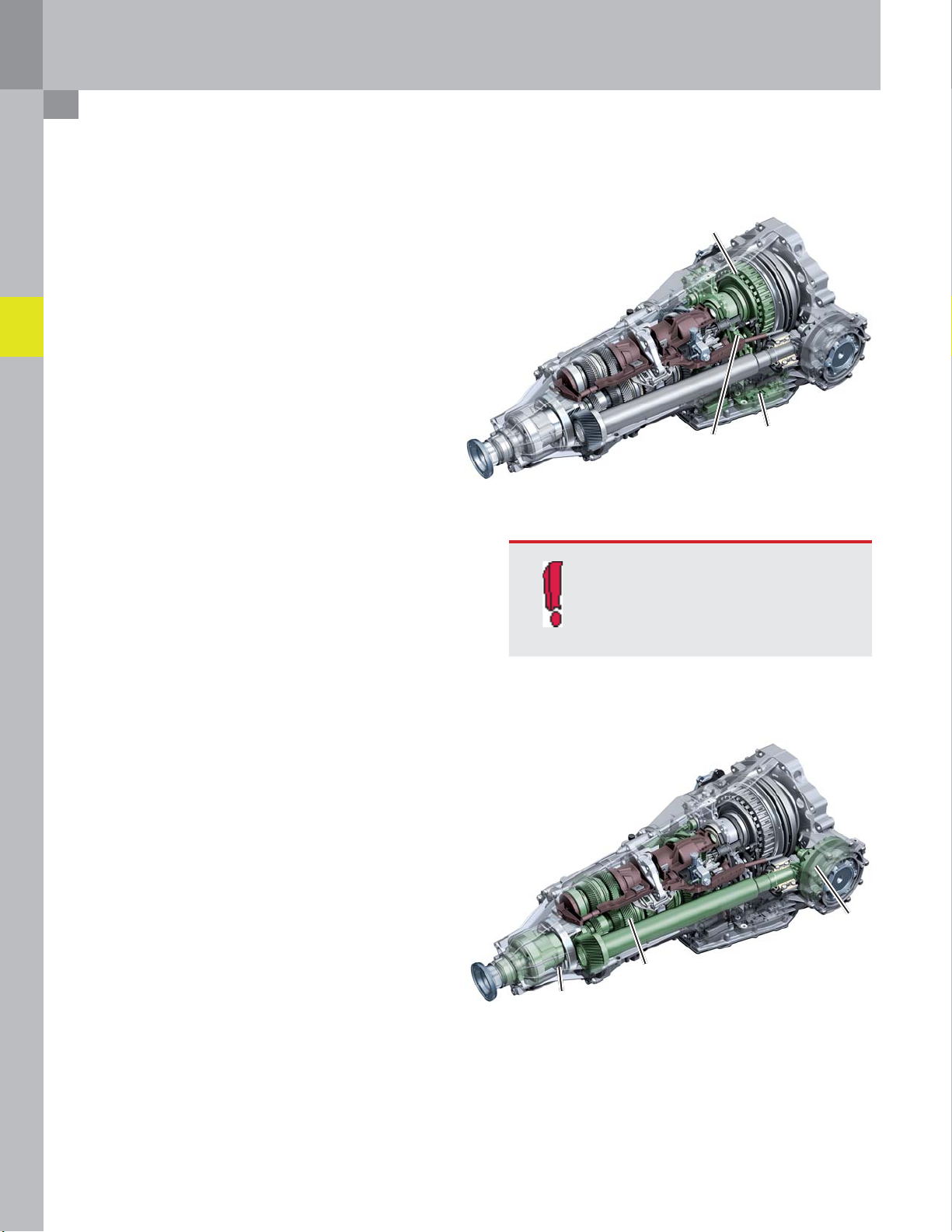

0B5 7-Speed Dual Clutch

Transmission

Following the success of the six-speed S tronic on the

Audi A3 and Audi TT models, a seven-speed dual-clutch

transmission, combined with the quattro powertrain,

is now available for the fi rst time in a longitudinal

confi guration.

Specifications of the 0B5 transmission

Designations Manufacturer: DL501-7Q

Service: 0B5

Distribution: S tronic

Development production Audi AG Ingolstadt

VW plant, Kassel

Type Seven-speed, dual-clutch gearbox;

fully synchronized, electro-hydraulically controlled

Dual clutch Dual oil-cooled multi-plate clutches,

electro-hydraulically controlled

Control Mechatronic system — integrating the hydraulic control module,

electronic control module, some sensors and actuators; sport

program and “tiptronic” shift program for manual gear shifting

Ratio spread Up to 8.1 : 1*

The 0B5 S tronic transmission combines the positive

features of an automatic transmission with the sportiness

and effi ciency of a manual gearbox. It provides extremely

short shift times without interruption of tractive power to

provide a special driving experience.

Shaft spacing 3.503 in (89.0 mm)

Torque capacity Up to 406.6 lb ft (550 Nm) at 9000 rpm

Weight Approx. 313.0 lb (142 kg), including dual-mass flywheel and

oil fill

* 7th gear is confi gured as an overdrive gear. Top speed is in 6th gear.

20

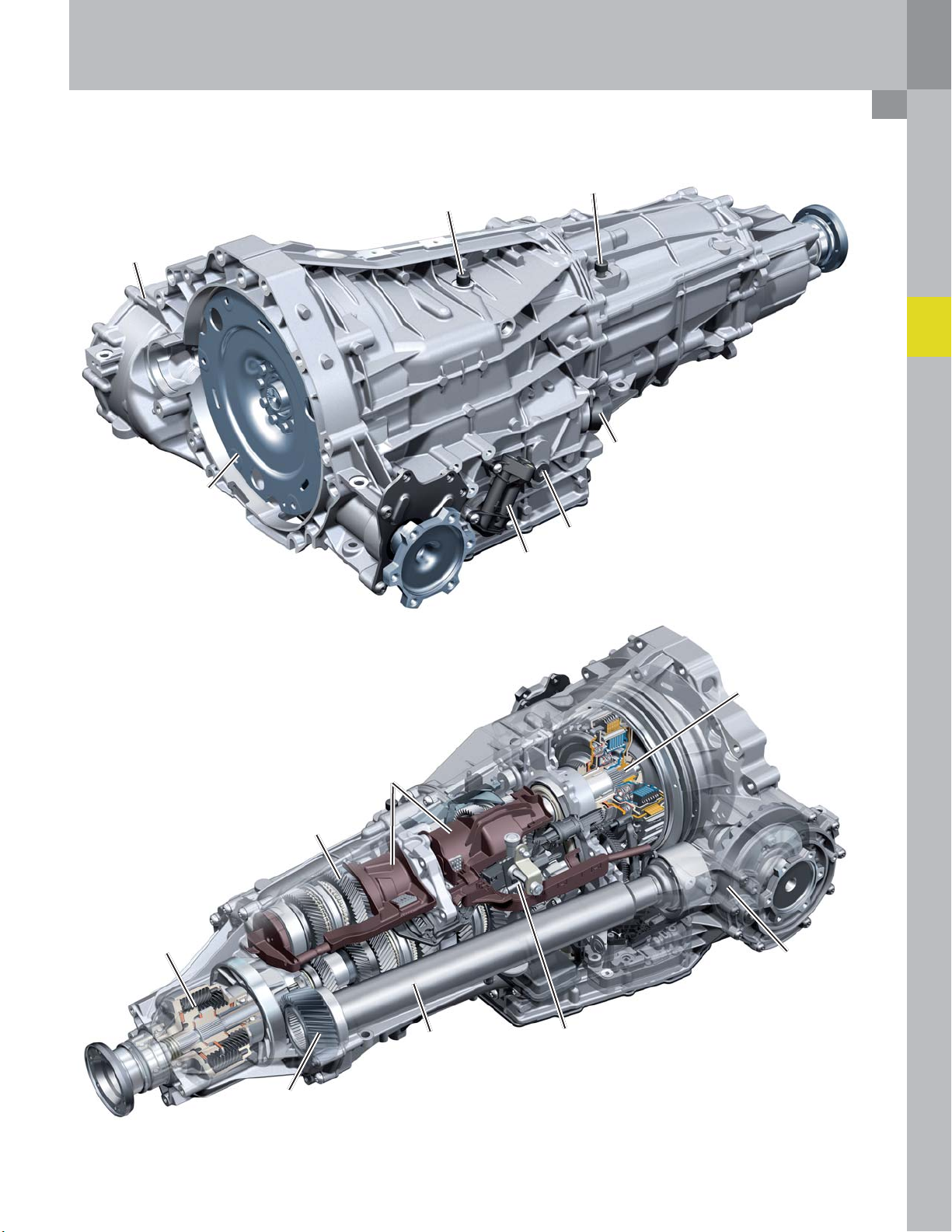

Page 25

Final drive/

differential (forward

of the dual clutch)

Transmission

plate with dual-

mass fl ywheel

0B5 S Tronic Transmission

Vent for ATF system

(hydraulic controls/

dual clutch)

Vent for gear oil system

(gears/transfer case/

front axle drive)

Connection

to ATF cooler

Connection for

ATF, fi ller

and oil level

checking bolt

Mechatronic

module

429_124

Center

differential

Seven-speed

gearbox

assembly

Spur pinion with special tooth

geometry which allows the

shaft to rotate at an angle in

two planes (beveloid gearing)

Oil drip

pans

Bi-planar

angled

side shaft

Gear

lever

429_128

Dual clutch

(K1, K2)

Final drive with

welded ring gear

and special tooth

geometry to

accommodate the

angled side shaft

21

Page 26

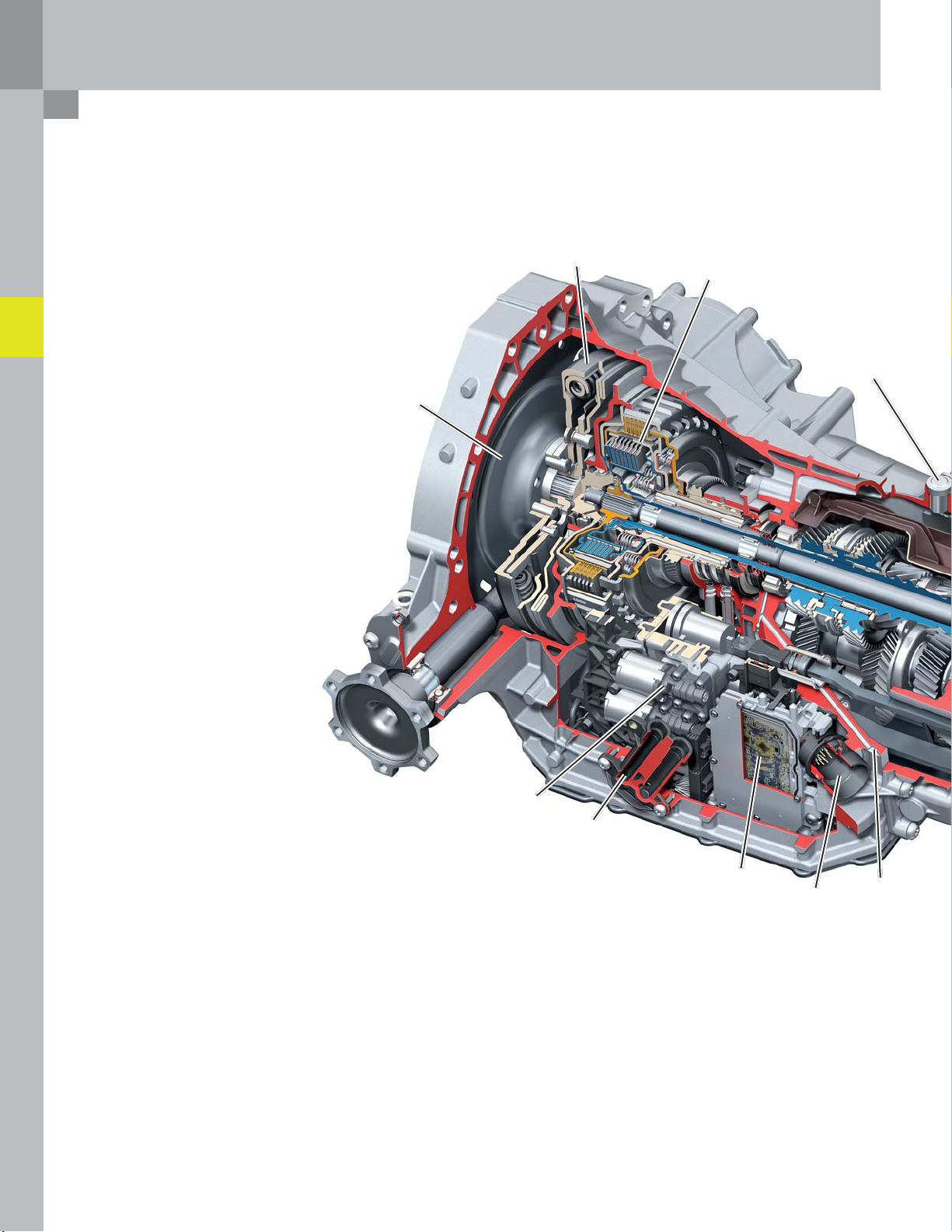

0B5 S Tronic Transmission

Component Parts Overview

Transmission

plate

Dual mass

fl ywheel

Dual clutch

(K1, K2)

Stop

Hydraulic control

(Mechatronic

system)

22

Connection

module for

ATF cooler

Direct Shift

Gearbox (DSG)

Mechatronic J743

Electric

connection

Oil drain

port

Page 27

Advantages of Seven Gear Ratios

Seven forward gears provide a wide ratio spread that

boosts initial acceleration, while also lowering fuel

consumption via the 7th (overdrive) gear.

Gear

lever

0B5 S Tronic Transmission

Selector

rail

Oil drip

pan

Gear oil fi ll

and level

checking bolt

Self-locking center differential with 40/60

asymmetric/dynamic torque split. The

asymmetric-dynamic power distribution

provides sporty and agile driving

characteristics with slight emphasis to the

rear axle. When needed, the center differential

can deliver up to 85% power to the rear axle

or a maximum of 65% power to the front axle.

Serviceable

offset depth for

all shaft oil seals

when replaced

429_116

23

Page 28

0B5 S Tronic Transmission

Gearbox Design — Function

Drive is transmitted to the dual mass fl ywheel through

the transmission plate. From there, torque is transmitted

to electro-hydraulically controlled clutches (K1, K2) which

operate even or odd numbered gears.

The gear arrangement of the 05B transmission can be

viewed as two separate gear boxes.

Sub-Gearbox 1

Odd numbered gears (1, 3, 5, 7) are driven through

central input shaft 1 by clutch K1.

Clutch K1

Clutch K2

Sub-Gearbox 2

Even numbered gears (2, 4, 6) and the reverse gear are

driven through input shaft 2 (a hollow shaft) by clutch K2.

Power output is through the common output shaft, with

torque transmitted directly to the center differential.

Torque distribution is approx. 60% to the fl ange shaft

connected to the rear axle, and approx. 40% to the spur

pinion and side shaft connected to the front axle drive

(not shown here).

Input

shaft 2

Transmission

plate

Dual mass

fl ywheel

Design Features of the Dual Clutch

The dual clutch serves two tasks:

– To engage the engine at initial acceleration and to

disengage the engine when stopping

– To shift the gears

The dual clutch was designed so that clutch K1 is located

on the outside, making it a larger diameter. This meets

the higher demands placed on K1 as the starting clutch

(in fi rst gear).

24

Parking

lock gear

6th gear

4th gear

2nd gear

Reverse

(R) gear

Small pressure cylinders and coil spring assemblies

on both clutches provide good control during initial

acceleration and when changing gears.

Hydraulic pressure equalization is no longer required.

Clutch control corrects dynamic pressure build-up

caused by centrifugal forces at high engine speeds in any

situation.

Page 29

Gear Shifting Sequence

0B5 S Tronic Transmission

Initial Acceleration

In selector lever position P or N, only 1st gear and reverse

are engaged. This allows immediate acceleration from a

standing stop. Regardless of whether the driver decides

to drive in reverse or to go forward, the correct gears are

already pre-selected.

Input

shaft 1

Spur pinion/

output to front

axle (beveloid

gearing)

Shifting

To drive forward, the driver shifts the selector lever into

D and drives away in 1st gear. When a defi ned speed

threshold of approx. 10 mph (15 km/h) is exceeded, 2nd

gear is engaged in sub-gearbox 2 (reverse was previously

engaged).

When the shift point for upshifting from 1st to 2nd gear

is reached, the gearshift is made by the rapid opening

of clutch K1 and simultaneous rapid closing of clutch K2

without any interruption in tractive power. To enhance

shift comfort and preserve the clutch, engine torque is

reduced during the gearshift (overlap).

The gear shifting process is completed within a few

hundredths of a second. 3rd gear is now pre-selected

in sub-gearbox 1. The process described above repeats

itself alternately during the subsequent gearshifts from

2-3 up to 6-7.

Output to rear

axle differential

1st gear

3rd gear

7th gear

5th gear

Center

differential

429_134

Synchromesh

To facilitate extremely short shift times, all gear

synchronizers are carbon coated.

Gears one, two, and three are also triple cone

synchronizers due to the high stresses to which they are

subjected.

Gears 4, 5, 6, and 7 use single cone synchronizers.

25

Page 30

0B5 S Tronic Transmission

Transmission Oil Systems

ATF Oil System

The 0B5 transmission has two separate oil systems.

The fi rst oil system accommodates the dual clutch,

Mechatronic system, and oil supply. These components

use an ATF developed specifi cally for the 0B5

transmission.

This ATF system enables rapid shifting even at low

temperatures, while also lubricating and cooling the

dual clutch.

Dual

clutch

ATF

pump

Mechatronic

system

429_126

Gear Oil System

The second oil system incorporates the gear assembly,

the transfer case (center differential), and the front axle

drive.

Lubrication is by means of a hypoid gear oil with a special

oil additive for the center differential. Separating these

oil chambers made it possible to design the individual

component parts of the transmission optimally. It was not

necessary to make any compromises due to confl icting

demands on the lubricants.

Note

ATF oil is subject to a fi xed replacement

interval (refer to maintenance).

Hypoid gear oil is designed for

lifetime use.

Gear

Transfer

case

assembly

429_127

Front axle

differential

26

Page 31

Gear Oil System

The oil chambers must be reliably sealed off from one

another.

The ingress of gear oil into the ATF oil chamber (the

ATF mixes with the gear oil) would adversely affect the

performance of the dual clutch.

To prevent this from occurring, special sealing elements

are fi tted in relevant places.

0B5 S Tronic Transmission

Double oil seal ring

Input shaft 1

Transverse

bore

Double oil

seal ring

Input shaft 2

Oil drain port,

refer to Fig. 116

on page 23

The 4 selector rails are sealed

by means of double-sided

axial sealing elements.

429_121

Axial

seal

Input shafts 1 and 2 are sealed by a double oil seal ring.

In total, four radial sealing rings are used. If a radial seal

is leaking, a oil drain port allows the leaking oil to drain

off and prevents it from entering the other oil chamber.

The transverse bore in input shaft 2 establishes a

connection between input shaft 1 and the oil drain port.

27

Page 32

0B5 S Tronic Transmission

ATF Oil Supply — Lubrication

ATF Pump with Rotating Port and Dual Clutch Bearing

A suffi cient supply of ATF oil is essential for the operation

of the transmission.

An external gear pump driven by the dual clutch through

a gear step provides necessary oil fl ow and oil pressure.

Pressure

line K1

The ATF pump supplies the Mechatronic system with the

oil pressure required to perform the following functions:

– Control of the multi-plate clutch (engagement and

disengagement)

– Cooling and lubrication of the multi-plate clutch

– Control of gearbox hydraulics

Suction

fi lter

Pressure

line K2

429_138

Suction

jet pump

Rotating

port

Oil pump

drive

429_122

Dual

clutch

A suction jet pump, operating on the Venturi principle,

increases the cooling oil fl ow for the clutch cooling

system. Because this pump doubles the cooling oil fl ow

rate without the need for increasing oil pump capacity, it

is smaller and more effi cient.

28

ATF pump

(external gear pump)

Page 33

ATF Cooling

0B5 S Tronic Transmission

ATF cooling is provided by a heat exchanger integrated

into the engine cooling system (ATF cooler).

The supply line running to the ATF cooler accommodates

a pressure fi lter, which, in conjunction with the suction

fi lter, provides effective fi ltering of the ATF. Both fi lters

are designed for lifetime use in the transmission, and are

not subject to a replacement interval.

ATF

cooler

Engine cooling

system with

ATF cooler

A differential pressure valve is integrated in the pressure

fi lter. It opens when the fl ow resistance rises above a

threshold value, for example when the fi lter is clogged

or the ATF is very cold. Therefore, circulation to the ATF

cooler is always assured.

Notes on the ATF cooler:

If the ATF cooler is leaking, coolant will mix

with the ATF. Even the smallest amounts

of coolant in the ATF will impair clutch

control. The new glycol test 8E0 398 998

can be used to determine whether the ATF

contains glycol.

Notes on the ATF fi lter:

It is only necessary to replace the pressure

fi lter if the ATF has been contaminated due

to transmission damage. If swarf (metal

chips), abraded matter, or other foreign

material is found mixed in with the ATF,

the ATF cooler must be fl ushed, and if

necessary, replaced.

The illustration on this page shows the ATF cooling

system connected to the 2.0L TFSI engine. This

confi guration is representative of all Audi engines, with

the exception of different wiring harnesses.

Connection

module

* In the future, the pressure fi lter will be integrated

into the connection module.

ATF fi lter

(pressure fi lter)*

429_135

29

Page 34

0B5 S Tronic Transmission

Gear Assembly Lubrication

Selective lubrication, conducted via special oil passages

and oil drip pans, results in lower oil level requirements.

This innovative lubrication design reduces churning

losses and enhances overall transmission effi ciency.

The bearings for the input shaft change gears are

lubricated through the hollow drilled input shaft 1.

Transverse bores in the shafts direct the oil to the

bearing points.

Oil drip

pans

Oil passage in

input shaft 1

Lubricant is supplied to the

center differential through the

hollow drilled output shaft

Bi-planar

angled

side shaft

Oil passage

to front

axle drive

429_125

30

Page 35

Parking Lock

0B5 S Tronic Transmission

The 0B5 transmission requires a parking lock since both

clutches are open (disengaged) whenever the engine is

not running.

The parking lock gear is connected to the output shaft.

The pawl is actuated mechanically by the selector lever

via the selector lever cable.

Gear

lever

Drive Position

Sensor G676

Permanent

magnet

Drive Position Sensor G676 is also actuated through the

selector shaft and the parking lock lever.

For this purpose, a permanent magnet exerting a

magnetic fi eld on the sensor is located on the parking

lock actuating lever.

Utilizing the signals generated by Drive Position Sensor

G676, the Mechatronic module recognizes the position of

the selector lever (P, R, N, D, or S).

Stop

Direction of Travel

Note

The parking lock gear and pawl lock all

four gears through the center differential,

but can compensate through the center

differential if a raised wheel is able to

turn freely, for example, when changing a

wheel.

Therefore, as a precaution, the parking

brake must always be applied, in these

situations.

Locking

pawl

Parking lock in selector lever position P

(locking pawl engaged)

Parking

lock gear

429_117

31

Page 36

0B5 S Tronic Transmission

Transmission Control

Direct Shift Gearbox Mechatronic J743

The transmission is controlled by a newly developed

Mechatronic system. It enables precision control of gear

engagement speed and force when changing gears. This

means that regardless of the driving situation, rapid gear

shifts are also smooth.

Gear

selector

module

Gear Position Distance

Sensor 4 G490 (for

gear selector 4-6)

Gear Position Distance

Sensor 3 G489 (for

gear selector 7-5)

Gear Position Distance

Sensor 2 G488 (for

gear selector 1-3)

X

X

The Mechatronic system acts as the central transmission

control module. It combines the electro-hydraulic control

module (actuators), the electronic control module, and

some of the sensors into a single unit.

Because of the longitudinal confi guration, the rpm

sensors of both gearbox input shafts and the gear sensor

are located on a separate mounting bracket (PCB 3).

X

X

X

Clutch Oil Temperature

Sensor G509

Transmission Input

Speed Sensor 3 G641

(clutch input speed)

Gear Position Distance

Sensor 1 G487 (for

gear selector 2-R)

PCB 1

Electro-hydraulic

control module

Mounting points in the transmission case

X

PCB 2

429_133

32

Page 37

0B5 S Tronic Transmission

The Mechatronic system controls, regulates, and

performs the following functions:

– Adaptation of oil pressure in the hydraulic system to

requirements

– Dual clutch regulation

– Clutch cooling regulation

– Shift point selection

– Transmission control and regulation

– Communication with other control modules

– “Limp home” program circuitry

– Self-diagnostics

X

X

Center

differential

module wiring

Connector

Sensor

harness

Note

When replacing the Mechatronic system,

various adaptations must be made using

the VAS Scan Tool.

Note

When handling the Mechatronic system, it

is important to pay close attention to the

working guidelines regarding electrostatic

discharge!

X

Connector:

Gearbox

Control

Module PCB 2

Connector:

Gearbox

Control

Module PCB 1

X

X

X

Electronic

module

Drive Position

Sensor G676

Transmission

X

Connector:

Mechatronic

wiring harness

Connector:

wiring harness

(sensor module)

Input Speed

Sensor G612

Wiring harness/

cable duct

X

429_130

Transmission

Input Speed

Sensor1 G632

Mounting points in the transmission case

33

Page 38

0B5 S Tronic Transmission

Hydraulic Component Overview

This illustration shows the electro-hydraulic control module,

together with all components activated by the actuators.

N433 Sub Transmission 1 Valve 1 (for gear selector 1-3)

N434 Sub Transmission 1 Valve 2 (for gear selector 7-5)

N435 Sub Transmission 1 Valve 3 (for clutch valve K1, activation)

N436 Sub Transmission 1 Valve 4 (for pressure regulation in sub-gearbox 1)

N437 Sub Transmission 2 Valve 1 (for gear selector 2-R)

N438 Sub Transmission 2 Valve 2 (for gear selector 4-6)

N439 Sub Transmission 2 Valve 3 (for clutch valve K2, activation)

N440 Sub Transmission 2 Valve 4 (for pressure regulation in sub-gearbox 2)

N471 Cooling Oil Valve

N472 Main Pressure Valve

GS = Gear Selector

Shift

fork 4-6

GS 4-6

Shift

fork 7-5

Shift

fork 1-3

Shift

fork 2-R

GS 7-5

GS 1-3

GS 2-R

Note

Before installing the Mechatronic system

into the transmission, the gear selectors

and selector rails must be brought into

alignment with each other. Refer to the

The selector rails/shift forks have no stops, with the

shift forks held in position by gear selectors. The only

stops are in the gear change sleeve and the synchronizer

assembly.

repair manual.

34

Page 39

N437

(2-R)

N434

(7-5)

N433

(1-3)

N438

(4-6)

Electro-hydraulic

control module —

gear selector module

0B5 S Tronic Transmission

Dual

clutch

ATF pump with

rotating port for

the dual clutch

Gear

selector

Electro-hydraulic

control module

N471

N439

N435

N440

N472

N436

429_129

35

Page 40

0B5 S Tronic Transmission

Electronics

Integrated Sensors

The transmission control module, the four distance

sensors and the two hydraulic pressure sensors are

combined as a non-separable unit.

Two temperature sensors are integrated into the

TCM. One sensor is positioned to supply precise ATF

temperatures.

The other sensor is integrated directly into the processor

and measures critical component temperatures.

The two temperature senders monitor each other for

plausibility. Electronics temperature monitoring is very

important so that temperature reduction measures can

be made quickly, as needed.

Besides safety, ATF temperature is relevant to both

clutch control and hydraulic control. For this reason, ATF

temperature is also a key factor in control and adaptation

functions.

Automatic Transmission Hydraulic Pressures Sensors

1 and 2 are utilized for clutch pressure monitoring and

for adaptation of the primary pressure and sub-gearbox

pressures.

Permanent

magnet

Hall

sensor

Distance Sensor

3 G489 (for gear

Gear Position

Distance Sensor

1 G487 (for gear

selector 2-R)

Gear Position

Distance Sensor

4 G490 (for gear

selector 4-6)

Gear Position

selector 7-5)

Automatic

Transmission

Hydraulic

Pressure

Sensor 1 G193

Automatic

Transmission

Hydraulic

Pressure

Sensor 2 G194

Gear Position

Distance Sensor

2 G488 (for gear

selector 1-3)

429_137

Transmission

control

module

Control

module

temperature

sensor

Temperature

sensor in

processor

Selector

rail

429_136

Four distance sensors determine the position of each

selector rail/shift fork. The TCM requires this information

to immediately diagnose non-allowed positions and to

activate a “limp home” program, if necessary.

An exact travel measurement is also essential for

precision gear shifting. The various phases of the

synchronization and gearshifting processes can then be

activated sequentially.

36

Page 41

A distance sensor consists of two Hall sensors and two

permanent magnets which are attached to the selector

rail. Depending on the position of the magnets in relation

to the Hall sensors, the Hall sensors output a voltage

which corresponds to the distance traveled. The travel

signal is generated by evaluating both voltage signals.

Note

To measure the precise distance traveled

by the gear selector, the shift mechanism

must be adapted to the transmission

control module using the VAS Scan Tool.

0B5 S Tronic Transmission

429_171

Separate Sensors

Transmission Input Speed Sensors 1 and 2, as well as

the gear sensor are mounted together on a common

mounting bracket (PCB 3).

Both engine speed senders are “intelligent sensors.”

With three Hall sensors and the corresponding evaluation

electronics, it is possible to distinguish between driving

forward, driving in reverse, and a weak magnetic fi eld.

The control module receives the information from the

senders pre-evaluated in the form of a pulse width

modulated signal.

The various states are indicated to the control module

by different pulse widths. For example, when driving

forward, the engine speed signal has a different pulse

width than when reversing.

Encoder disc,

input shaft 2

Encoder disc,

input shaft 1

Signal Use

– Determination of the clutch output speed for

computing clutch slip

– Determination of the synchronization speed for shift

control

Drive Position

Sensor G676

Connector Sensor

module/wiring

harness

Transmission

Input Speed

Sensor 1 G632

Transmission

Input Speed

Sensor 2 G612

PCB 3

(sensor module)

429_173

37

Page 42

0B5 S Tronic Transmission

Drive Position Sensor G676

G676 is located in the gearbox and is an integral part of

the sensor module. This is a contactless travel sensor

which is used to determine the selector lever positions

(P, R, N, D, and S).

PCB 3

(sensor module)

A permanent magnet exerting a magnetic force on the

gear sensor is located on the parking lock lever. The

parking lock lever is connected to the gear lever by a

shaft. It is actuated by the selector lever by means of a

selector lever cable.

Drive Position

Sensor G676

Connector

Sensor module/

wiring harness to

gearbox control

module

429_167

Permanent

magnet

Parking lock

lever

The transmission control module requires data on

selector lever position to perform the following functions

and generate the following signals and information:

– Information on driver input/vehicle operating state

(forward, reverse, neutral) for activation of the clutches

and gear selectors

– Information for selection of shift program “D” or “S”

– Signal for controlling the starter inhibitor

– Signal for controlling the P/N lock (shift-lock)

– Information for reverse gear (for example, back-up

lights, Park Assist System, etc.)

– Control of the selector lever position indicator in the

instrument cluster and gearshift mechanism

38

The position sensor is a PLCD travel sensor. The

abbreviation PLCD stands for Permanent Magnetic

Linear Contactless Displacement sensor and describes a

contactless sensor which measures linear travel using a

permanent magnet.

The signal generated by this sensor is very important

for gearbox control and is safety-critical. For this reason,

G676 consists of two redundant sensors arranged in

parallel.

The TCM always evaluates both sensors.

Note

The gear sensors must be adapted to the

transmission control module using the

VAS Scan Tool.

Page 43

Transmission Input Speed Sensor -3- G641

and Clutch Oil Temperature Sensor G509

Outer plate

carrier of

clutch K1

X

PCB 2

X

0B5 S Tronic Transmission

Cooling oil

outlets

X = plugged

connection to gear

selector valve

X

Transmission

Input Speed

Connector to

transmission

control module

Sensor -3- G641

Sensors G641 and G509 are integral parts of PCB2. G641

is a Hall sensor. It measures the input speed of the dual

clutch (engine speed after the dual-mass fl ywheel). The

outer plate carrier of clutch K1 serves as an encoder disc.

The clutch input speed signal:

– Allows more precise clutch control

– Is used for adapting the clutches

– Is used for regulating micro-slip

Clutch Oil

Temperature

Sensor G509

G509 measures and monitors the temperature of the

cooling oil emerging from the dual clutch. Clutch

temperature can be derived from this information.

When a defi ned oil temperature is reached, safety

precautions are taken to prevent a further rise in

temperature.

39

Page 44

0B5 S Tronic Transmission

Transmission Protection Functions

Control Module Temperature Monitoring

High temperatures have a negative impact on the useful

life and performance of electronic components. Due

to the integration of the transmission control module

into the transmission housing (lubricated by ATF), it is

very important to monitor the temperature of both the

electronics and ATF.

When the temperature reaches approx. 275°F (135°C)

(measured by one of the two temperature sensors in the

transmission control module), the electronics must be

protected against a further rise in temperature. When

this threshold value is exceeded, the transmission control

module initiates a reduction in engine torque to reduce

heat input.

Up to a temperature of approx. 293°F (145 °C), engine

torque can be reduced gradually until the engine is at

idle. When the engine is at idle, the clutches are open

and there is no power transmission from the engine to

the drive wheels.

When the protective function is activated, an entry is

made in the fault memory and the following text message

is displayed in the instrument cluster: “You can continue

driving to a limited extent.”

Clutch Protection

If the clutch cooling oil temperature exceeds a value

of approx. 320°F (160 °C), as determined by G509, the

clutch is within a critical temperature range that can

damage it. These temperatures occur, for example, when

accelerating on extreme gradients, when towing a trailer,

or when the vehicle is held stationary on an uphill slope

using the accelerator and the clutch without engaging

the brake.

As a safety precaution, engine torque is reduced when

cooling oil temperature exceeds 320°F (160 °C.) If the

cooling oil temperature continues to rise, engine torque

is gradually reduced, sometimes to idle. When the engine

is at idle, the clutches are open and there is no power

transmission from the engine to the drive wheels.

When the protective function is initiated, an entry is

made in the fault memory and the following text message

is displayed in the instrument cluster: “You can continue

driving to a limited extent.”

As an additional safety precaution, the clutch

temperature is determined using a computer model. If

the computed temperature exceeds a pre-defi ned value,

the above mentioned precautions are taken.

40

Page 45

All you need to know about the …

0B5 S Tronic Transmission

… transmission control module

In the B8 series, a new data and diagnostic log is used

for the engine control modules, the TCM, and the

airbag control module. The previous data blocks and

numberings are no longer used. Individual measured

data is now available and listed as full text in alphabetical

order. This required measured data can then be

specifi cally selected.

… clearing the fault memory

The fault memories of the engine and transmission

control module are always cleared jointly. If the fault

memory of the transmission control module is cleared,

then the fault memory in the engine control module will

be cleared as well. The converse applies if the memory of

the engine control module is cleared.

… towing

If a vehicle with S tronic needs towing, the conventional

restrictions of automatic transmissions apply:

– Selector lever in position “N”

– A maximum towing speed of 30 mph (50 km/h) must

not be exceeded

– A maximum towing distance of 30 mi (50 km) must not

be exceeded

Explanation:

When the engine is at standstill, the oil pump is not

driven and certain parts of the transmission are no

longer lubricated. Exceeding a speed of 30 mph (50 km/h)

results in unacceptably high rotational speeds within

the gearbox and dual clutch, because one gear is always

engaged in both sub-gearboxes.

If these towing cautions are not observed, serious

transmission damage can occur.

41

Page 46

0B5 S Tronic Transmission

“Limp Home” Programs

In the event of a malfunction, serious damage can be

prevented and mobility preserved by means of “limp

home” programs initiated by the transmission control

module. In addition, there are also protective functions,

which protect certain components against overload.

In the event of certain pre-defi ned system malfunctions,

the transmission control module shuts down the subgearbox in question and activates the relevant “limp

home” program (driving with intact sub-gearbox).

1. Driving with sub-gearbox 1, sub-gearbox 2 shut down:

– Only gears 1, 3, 5, and 7* can be engaged (with

interruption in tractive power)

– Backing up (reversing) is not possible

2. Driving with sub-gearbox 2, sub-gearbox 1 shut down:

Only gears 2, 4, 6, and R* can be engaged (with

interruption in tractive power).

3. Complete gearbox shutdown:

In the case of serious faults — for example, a faulty

powertrain CAN, no identifi cation by the immobilizer, or

recognition of an incorrect ratio in the gear steps or in

the fi nal drive — the gearbox is completely shut down.

* The nature of the fault dictates which gears are

still available. To be sure that components do not

overspeed, certain gears are disabled depending on

fault type. After ensuring that no gear is engaged in

the deactivated gearbox, all gears of the intact subgearbox are shifted without any further restrictions.

42

Page 47

Displays/Warnings

0B5 S Tronic Transmission

The 0B5 transmission features new information and

warning technology in the instrument cluster, which will

alert the driver to a system malfunction or the initiation

of a protective function.

The following warnings are displayed:

Display 1 appears when faults the driver may not notice

are recognized by the transmission control module,

which then activates a suitable substitute signal.

These faults result in no, or only negligible, loss of

performance. The purpose of the warning is to prompt

the driver to take the vehicle to an Audi dealer at the next

opportunity.

Display 2 appears when gearbox protection functions and

faults result in a loss of performance.

This can have the following effects:

– “Limp home” program: “Driving with sub-gearbox 2”

is active. For example, gearshifts have interruptions in

tractive power (even-numbered gears only)

– Gearbox protective function is active, but engine

power is reduced because the engine torque reduction

function is also active

– No power transmission to the driving wheels after

stopping

– The engine can no longer be started

Display 1

Gearbox fault:

You can continue

driving

Display 2

Gearbox fault:

You can continue

driving to

a limited

extent only

Display 3 appears when the “limp home” program,

“Driving with sub-gearbox 1,” is active because reverse

gear cannot be selected at the same time.

Text messages disappear after fi ve seconds, and are

displayed again for fi ve seconds at “ignition ON.” Yellow

warning symbols are permanently displayed.

Display 3

Gearbox fault:

You can continue

driving to

a limited

extent only No

reverse gear

43

Page 48

Sport Differential

Traditional quattro Drive

Since 1980, quattro has been synonymous with

outstanding driving dynamics. In its basic form, the

torque-sensing center differential delivers 40% of the

tractive force from the engine to the front axle and 60% to

the rear axle.

This degree of rearward bias is now standard on all newer

Audi models because it ensures optimum performance.

The torque-sensing differential redistributes engine

output without delay if road surface conditions change.

The quattro system technology also has distinct

advantages in terms of lateral dynamics. By distributing

traction among all four wheels, each wheel has

greater potential to resist lateral forces, and tire grip is

optimized.

The action of the electronic differential lock (EDL) and

typical Audi settings adopted for the ESP also add to a

high level of stability.

990193_001

44

Page 49

quattro Drive with Sport Differential

Sport Differential

The quattro system with electronically controlled sport

differential distributes input torque variably between the

two rear wheels, with nearly all tractive force directed to

just one wheel, if necessary.

Torque input also ensures a neutral road behavior. The

sport differential is active not only under load, but also

on overrun. Its torque distributing action enhances car

agility when the clutch is disengaged.

Depending on steering angle, lateral acceleration, yaw

angle, road speed, and other signals, the control module

calculates the most suitable distribution of torque to the

rear wheels for every driving situation.

When the steering wheel is turned, for example, or when

the car is accelerated in a corner, power is redirected

in a controlled manner to the outer rear wheel. This has

the effect of “forcing” the car into the corner so that the

angle of the front wheels is followed accurately.

The difference in tractive force between the left and

right wheels also exerts a steering effect, so that the

usual corrections by the driver at the steering wheel

are no longer needed. Understeer, the tendency for the

car to run wide at the front when cornering, is virtually

eliminated.

990193_002a

990193_002

45

Page 50

Sport Differential

Traditional quattro Drive

In the illustration below, a car adheres to successive

bends when driven rapidly along a typical country road,

similar to the precise track formed by skis in snow.

The sport differential redistributes the power input

continually and quickly and counteracts any tendency for

the car to understeer or oversteer before either of these

effects can build up. For the driver, this means reduced

effort at the steering wheel and higher maximum lateral

acceleration.

When approaching the car’s handling limits, the sport

differential acts like ESP, but with the principle reversed.

Corrective movements are not initiated solely by altering

the engine settings or applying the brakes, but also by

controlled redistribution of tractive force through the

sport differential. The car’s forward progress becomes

distinctly smoother and free-fl owing because its actual

road dynamics and those sensed subjectively by the

driver are enhanced since ESP comes into action much

less frequently.

Changing direction: depending

Steering into a curve: torque

is redistributed outward to

enhance cornering ability

on driving situation, torque

is redistributed to enhance

agility and/or stability

Since its reaction time is extremely short — less than 100

milliseconds — the sport differential takes effect even

more rapidly than ESP. Furthermore, ESP can only react

to a discrepancy between the car’s steering angle and

its actual body rotation, whereas the sport differential

infl uences the car’s dynamic behavior before any such

discrepancies occur. During sport differential action, ESP

is not active.

Active torque distribution is based on an entirely new

design principle for the rear axle differential. The unit can

also divert torque to the outer wheel on the axle, which

then rotates faster than the inner wheel when cornering.

The rear axle differential has speed modulation units with

multi-plate clutches mounted at the left and right sides.

The clutches are activated by electro-hydraulic actuators

based on input from sensors and other control modules.

Accelerating out of

a curve: torque is

redistributed outward

to avoid acceleration-

induced understeer

990193_003

46

Page 51

Audi Drive Select with Sport Differential

Sport Differential

The quattro driveline with sport differential is also part

of Audi drive select, which integrates key components

that affect each driving experience. These components

include the engine, transmission, steering, shock

absorbers, and sport differential. Drivers can adjust the

characteristics of these systems at any time to suit their

personal preferences.

Buttons on the center console enable drivers to vary the

operation of Audi drive select in three stages ranging

from comfortable to sport mode, or to create a profi le

that suits their personal preferences.

The engine’s throttle response characteristic can be

determined fi rst, followed by that of the servotronic

speed dependent power steering and, if the car has

automatic transmission, its shift points.

The functions of the sport differential can also be varied

to suit the driver’s wishes. In “comfort” mode, driving

safety and vehicle stability have absolute priority, with

optimal damping of load reversals. In “auto” mode, a

balance is achieved between all of the functions. The

“dynamic” mode ensures optimum vehicle agility during

load reversals.

990193_004

47

Page 52

Sport Differential

Component Overview

Breather for

the left speed

modulation unit

Left speed

modulation unit

Breather for

the main

differential

Breather for

the right speed

modulation unit

990193_005

Right speed

modulation unit

Hydraulic

pump

Hydraulic

control

module

990193_006

Specifi cations

Service Designations: Final drive 0BF, internal: HL601

Development: Magna powertrain (Graz, Austria) — Audi AG

Manufacturer: Magna powertrain

Torque Capacity: Up to approx. 480 lb ft (650 Nm) engine torque

Speed Modulation Unit Ratio: i

tot

1.095

Weight: Approx. 95.9 lb (43.5 kg) including oil

48

Page 53

Sport Differential

The sport differential has a conventional pinion shaft and

ring gear. Attached at both sides of the differential are

speed modulation units. These units are made up of two

sun gears and two ring gears and are sometimes referred

to as speed modulation gearboxes or super-position

gearboxes. They provide a step-up (or step-down)

transmission ratio for each axle depending on the driving

situation.

Left speed

modulation unit

The engagement of the speed modulation units is

done electro-hydraulically. Pressure is developed by an

electric motor-driven hydraulic pump and directed to

the multi-plate clutches by a hydraulic control module.

Clutch actuation is determined by All Wheel Drive Control

Module J492.

This ability to change the ratio (dependent on driving

situation) is also referred to as “torque vectoring.”

Right speed

modulation unit

Pinion

shaft

Multi-plate

clutch

Ring

gear

Multi-plate

clutch

990193_008

49

Page 54

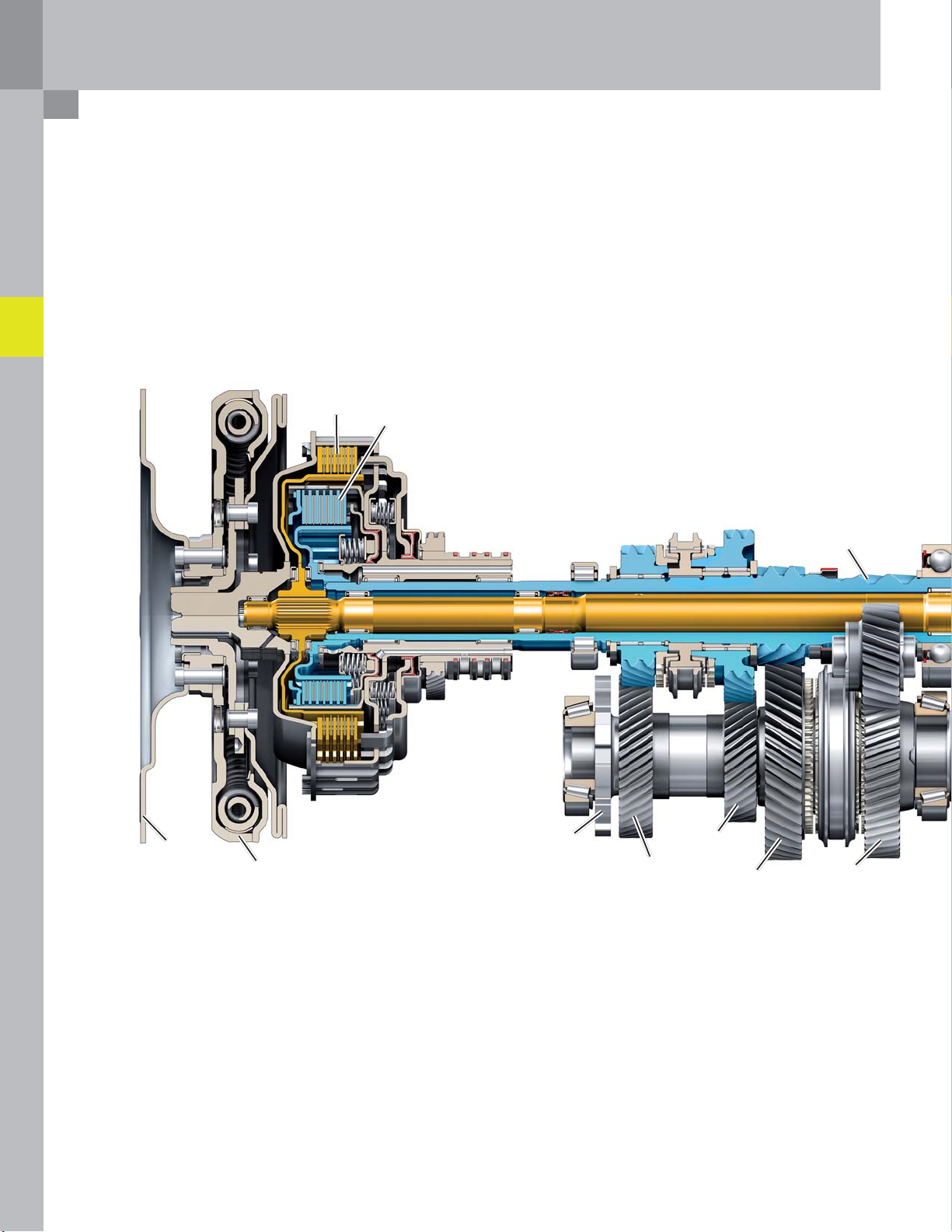

Sport Differential

Speed Modulation Gearbox Component Overview

Differential

pinion shaft

Differential

Clutch

piston

Sun

gear 2

Multi-plate

clutch

Sun

gear 1

Double

shaft seal

Differential

side gears

Differential

ring gear

Ring

gear 1

990193_009

Ring

gear 2

50

Page 55

Sport Differential

Sun gear 1 is integral with the differential housing

and, therefore, turns at the same speed. Sun gear 1 is

internally meshed with ring gear 1 which rotates at a ratio

of 0.868.

Sectional View A - A

i1 = 0.868

Sun gear 1,

Z1 = 33

Ring gear 1,

Z

= 38

2

B

Z = number of teeth per gear

i = gear ratio

990193_010

A

Sun

gear 2

Sun gear 2 is integral with the stub axle. When a multiplate clutch is engaged, ring gear 2 is joined to ring gear

1. Ring gear 2 then drives sun gear 2 which in turn drives

the stub axle. Combining the gear ratios of both sun

gears and ring gears provides the fi nal output ratio to the

stub axle.

Sun

gear 1

Multi-plate

clutch

gear 2

B

Ring

Ring

gear 1

A

i2 = 1.261

Ring gear 2,

Z3 =29

Sun gear 2,

Z

4

=23

990193_012

Sectional View B - B

990193_011

i

= i1 x i

tot

= 0.868 x 1.261

= 1.095

2

51

Page 56

Sport Differential

Power Flow Without Intervention

The sport differential functions as a normal open

differential when the multi-plate clutches of the speed

modulation boxes are not engaged.

Torque is transmitted from the pinion shaft to the ring

gear. The differential transfers the torque to the axles via

the side gears.

Differential

pinion shaft

Side

Differential

gears

ring gear

52

990193_014a

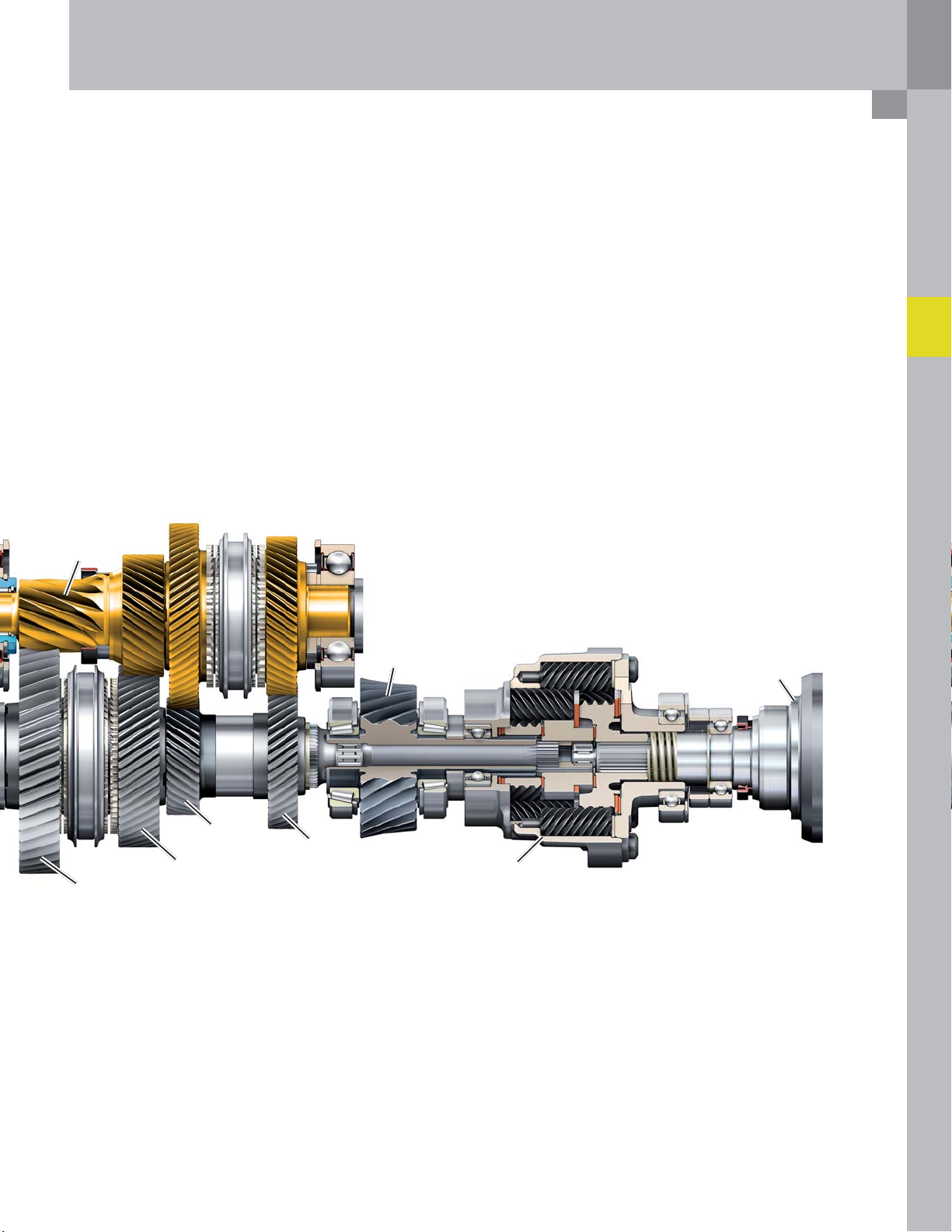

Page 57

Power Flow With Intervention

Sport Differential

The differential ring gear drives sun gear 1 which in turn

drives ring gear 1. With clutch activation, ring gear 1 and

ring gear 2 are joined together. Ring gear 2 drives sun

gear 2 which drives the stub axle.

Only one speed modulation gearbox can be engaged at

a time. When activated, the clutches do not fully engage,

as there is always a defi ned amount of slip between the

plates. This slip is monitored by All Wheel Drive Control

Module J492 and has important service implications.

Differential

pinion shaft

Differential

ring gear

Sun

gear 2

Ring

gear 2

Sun

gear 1

Ring

gear 1

990193_015a

53

Page 58

Sport Differential

Oil Circuits

The sport differential has two oil circuits and three

distinct oil chambers.

The differential pinion and ring gear (conventional

differential components) have a separate oil chamber

fi lled with hypoid oil.

Hypoid oil

ATF

Two speed modulation gearboxes each have their own oil

chamber and are interconnected by an oil passage. This

forms a common oil circuit, which is fi lled with a special

ATF. Both fl uids are lifetime fi lls.

990193_016

54

Page 59

A ball valve integrated in the oil circuit prevents the

ATF oil circuits from overfl owing to one side during

transverse acceleration.

Sport Differential

990193_031

No transverse

acceleration

990193_017

ATF drain

plug

ATF fi ller and

inspection plug

High transverse

acceleration

990193_017a

55

Page 60

Sport Differential

Oil Circuit Separation

A double shaft seal and a special oil seal (rectangular

ring) on each side ensures that the hypoid oil and ATF

circuits are safely separated from each other.

Oil

seal

Double

shaft seal

Oil drain port,

left side

990193_005

990193_018

56

Page 61

Sport Differential

Oil drain ports prevent the mixing of ATF and gear oil if

a seal should fail. If a failure occurs, oil is vented to the

outside of the axle housing via the drain port.

Oil drain port,

right side

990193_019

Double

shaft seal

Oil seal

990193_020

57

Page 62

Sport Differential

Oil Inspection and Drain Plugs

ATF fi ller and

inspection plug

Symbol

for ATF

ATF drain

plug

990193_002a

Hypoid oil

drain plug

Symbol for

fi nal drive

Axle oil fi ller and

inspection plug

990193_006

990193_021

58

Page 63

Hydraulic Control

Oil Pressure/

Temperature

Sensor 2 G640

Pipe to

left clutch

Sport Differential

Oil Pressure/

Temperature

Sensor G437

All Wheel-Drive

Pump V415

V415

Seal with

Screen

Hydraulic

pump

All Wheel Drive

Clutch Valve N445

All Wheel Drive

Clutch Valve 2 N446

Shuttle

valves

990193_006

G437

G640

Check valves

N445

990193_022

N446

59

Page 64

Sport Differential

Basic Confi guration

Pressure for hydraulic operation is supplied by a pump

driven by All Wheel Drive Pump V415. The pump operates

in both directions dependent upon which clutch is to be

activated.

The pressure limiting valves are designed to limit the

extent of coupling force applied to the clutches to

approx. 885 lb ft (1200 Nm). The shuttle valves move to

prevent hydraulic pressure from being applied to both

clutches at the same time.

Oil Pressure/

Temperature

Sensor 2 G640

Left

clutch

Shuttle

valves

Both the oil pressure and temperature sensors measure

the same hydraulic pressure. However, they measure

the pressure opposite from each other during clutch

application. One will display a rising pressure while

the other displays a falling pressure. This is done as a

diagnostic function and plausibility check by All Wheel

Drive Control Module J492.

All Wheel Drive Clutch Valve N445 and All Wheel Drive

Clutch Valve 2 N446 are open until current is supplied.

Pressure

limiting

valves

Right

clutch

Oil Pressure/

Temperature

Sensor G437

All Wheel Drive

Clutch Valve N445

Check

valve

Hydraulic

pump

All Wheel Drive

Clutch Valve 2 N446

Check

valve

M

All Wheel Drive

Pump V415

60

990193_023

Page 65