Audi 4.2-liter V8 FSI Service Training

Self-Study Program 921603

Audi 4.2-liter V8 FSI Engine

Service Training

Audi of America, Inc.

Service Training

Printed in U.S.A.

Printed 07/2006

Course Number 921603

©2006 Audi of America, Inc.

All rights reserved. All information contained in this manual is

based on the latest information available at the time of printing

and is subject to the copyright and other intellectual property

rights of Audi of America, Inc., its affiliated companies and its

licensors. All rights are reserved to make changes at any time

without notice. No part of this document may be reproduced,

stored in a retrieval system, or transmitted in any form or by

any means, electronic, mechanical, photocopying, recording or

otherwise, nor may these materials be modified or reposted to

other sites without the prior expressed written permission of

the publisher.

All requests for permission to copy and redistribute

information should be referred to Audi of America, Inc.

Always check Technical Bulletins and the latest electronic

repair information for information that may supersede any

information included in this booklet.

Trademarks: All brand names and product names used in

this manual are trade names, service marks, trademarks, or

registered trademarks; and are the property of their respective

owners.

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Engine Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Oil Circulation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Air Circulation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Engine Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Knowledge Assessment . . . . . . . . . . . . . . . . . . . . . . . . . . .43

The Self-Study Program provides introductory information regarding the design

and function of new models, automotive components or technologies.

The Self-Study Program is not a Repair Manual!

All values given are intended as a guideline only and refer

to the software version valid at the time of publication of the SSP.

For maintenance and repair work, always refer to the current technical literature.

Reference Note

i

ii

Introduction

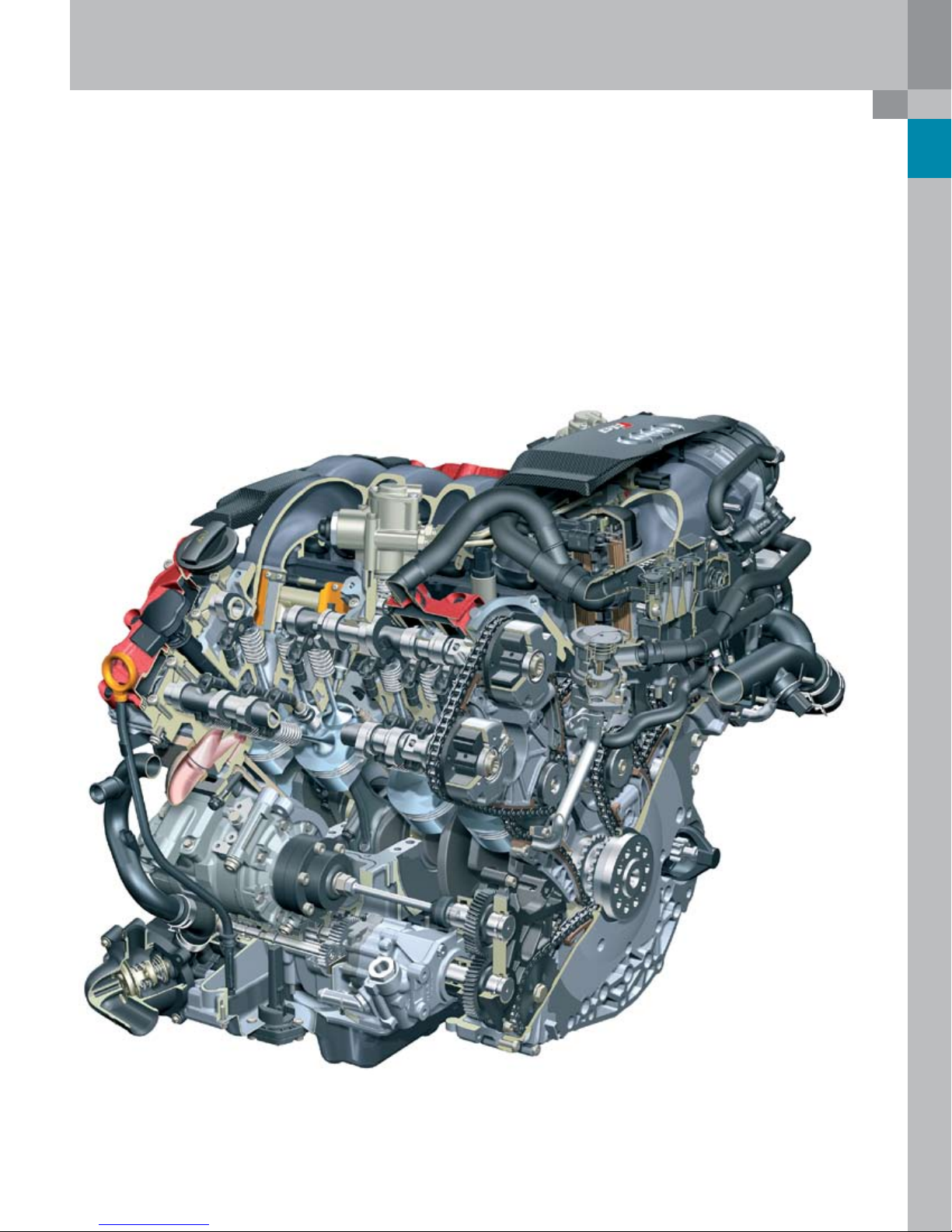

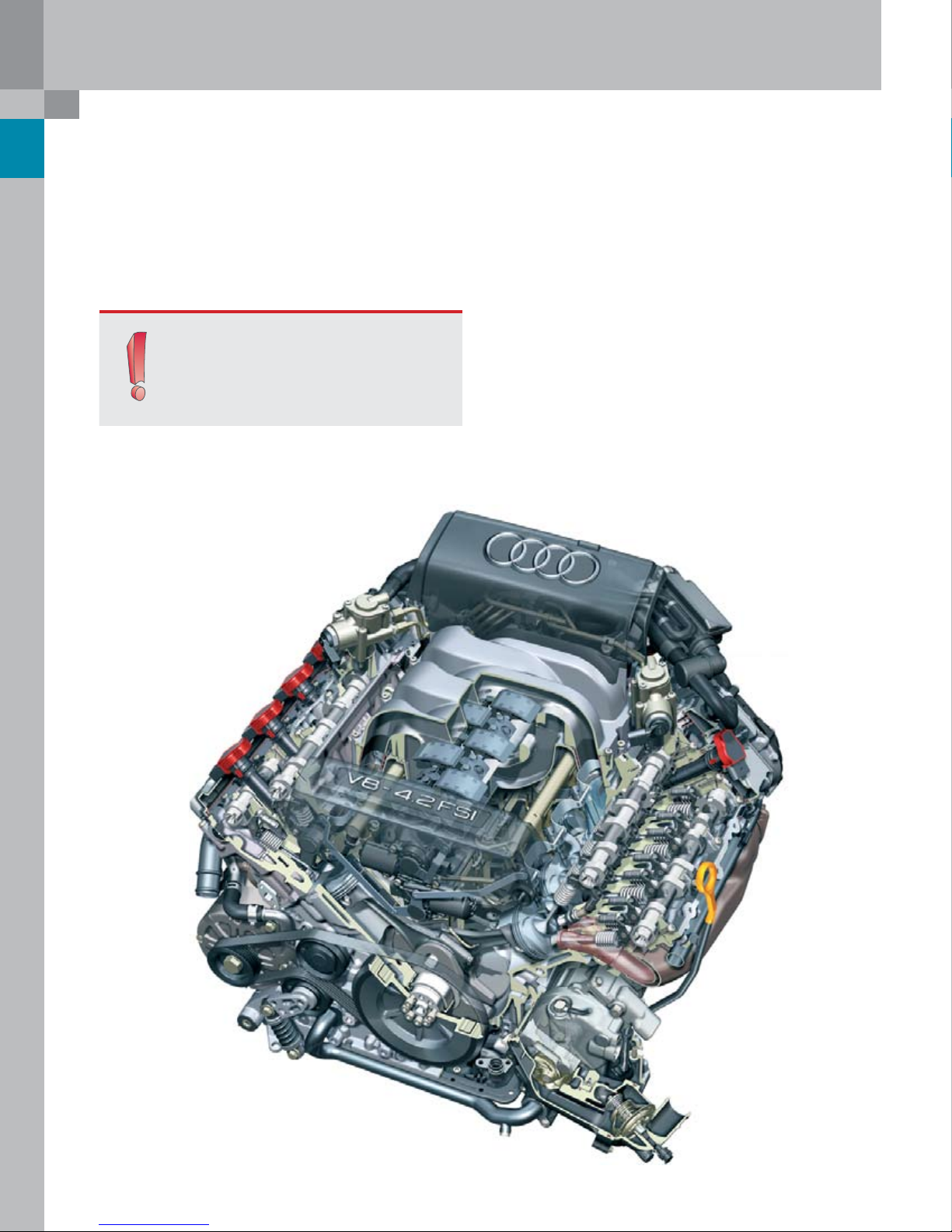

The first member of the current Audi V family of engines was the 3.2-liter V6 FSI engine.

Special features of the Audi V-engine family are the 90-degree angle between the cylinder banks and the 90 mm spacing

between the cylinders.

The 4.2-liter V8 FSI engine is also a member of this family.

It is available in two versions – a comfort-oriented version (used for the first time in the Audi Q7) and a sporty high-revving

version for the new RS4. A 5.2L V10 FSI will also be available in the near future.

RS4 4.2L V8 FSI High-revving Engine

377_045

1

Introduction

The 4.2-liter V8 FSI engine is supplied in the new Audi Q7

and RS4. In the future, the engine will be used in the Audi

A6 and A8.

Note:

The technical descriptions of this engine

refer mainly to the 4.2L V8 FSI engine in the

Audi Q7 and the high-revving engine in the

Audi RS4.

Audi Q7 4.2L V8 FSI Engine

The following main objectives were set for the

development of the Audi Q7 engine:

High specific engine power:

–

350 bhp out of 4.2 liters (15 bhp more than MPI

●

engines)

High torque: 325 lb. ft. out of 4.2 liters

–

Reduction of fuel consumption by approximately 5 %

–

(at 2000 rpm and 2 bar)

Short and compact design

–

Modular engine concept based on the V6 FSI engine

–

for V8 and V10 FSI

High idling quality

–

High standard of comfort with regard to acoustics and

–

running quality

Low engine weight

–

Off-road capability of Audi Q7 engine

–

2

377_003

Technical Features

Introduction

Fuel Straight Injection

–

Roller cam rocker arms with hydraulic lifters

–

Chain drives for camshafts and accessories

–

Variable camshaft adjustment for intake and exhaust

–

camshafts

Two-stage magnesium variable inlet manifold with

–

integrated tumble flap (not fitted in RS4)

Drive-by-wire throttle control

–

For compliance with exhaust emission standards

●

LEV II

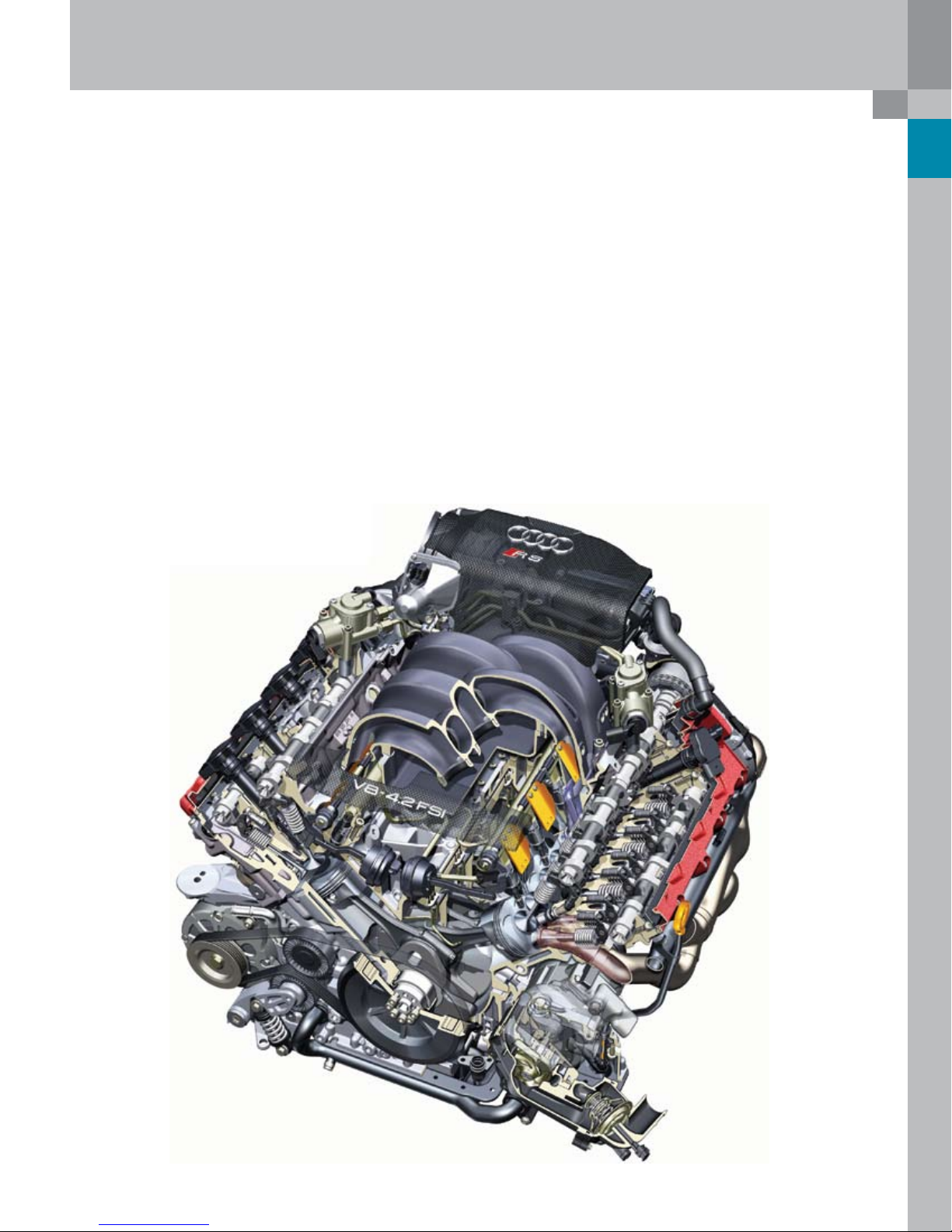

RS4 4.2L V8 FSI Engine

The main technical differences between the base engine

and the high-revving engine lie in the following:

Crankshaft/connecting rods/pistons

–

Timing gear

–

Cylinder head

–

Oil supply

–

Engine cooling

–

Intake path

–

Exhaust system

–

Engine management

–

For an exact description of the differences, please refer to

the relevant sections in this SSP.

377_002

3

Introduction

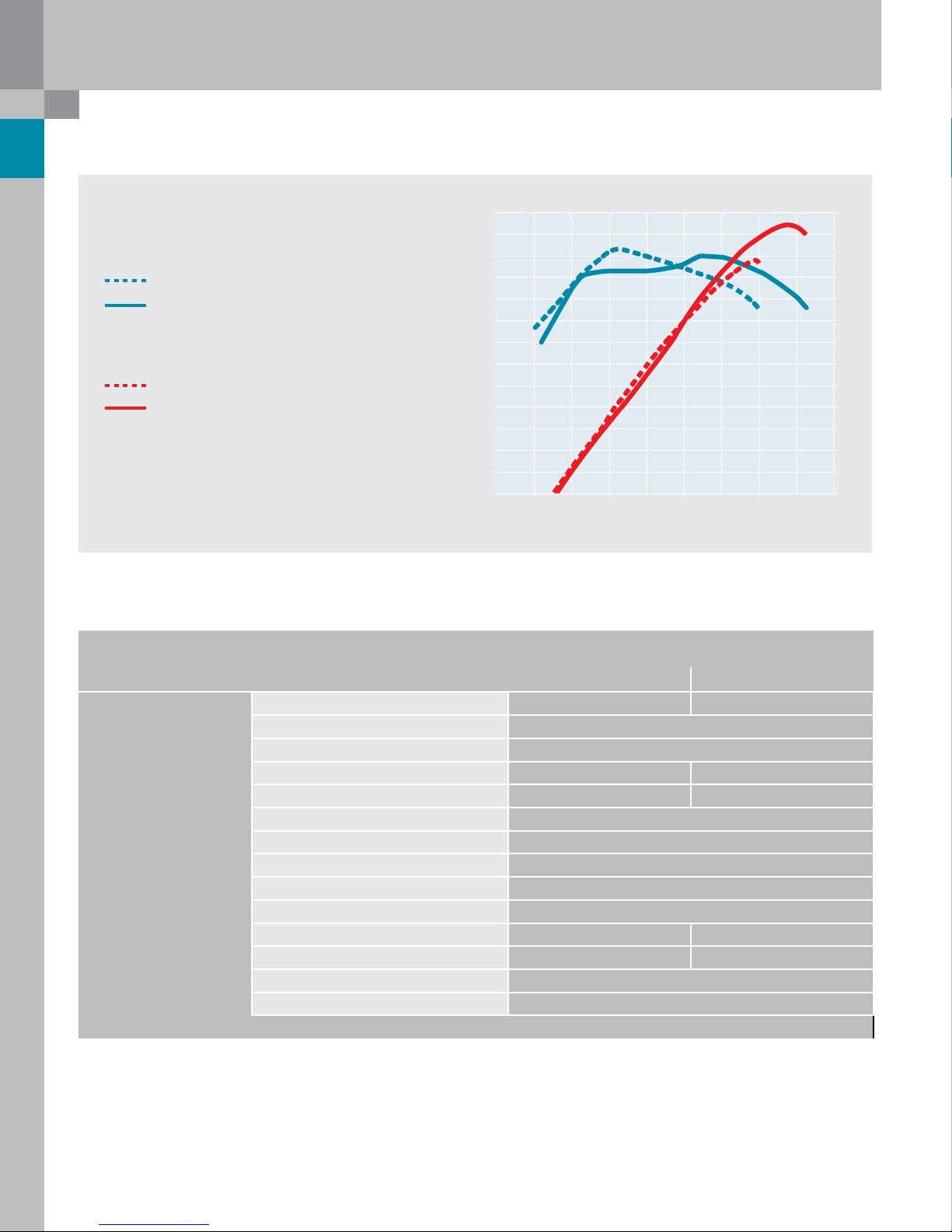

215

268

322

375

429

107

HP

lb ft

340

221

280

310

20000

5000

7000 9000

Torque/Power Curve

Maximum Torque in lb ft

V8 FSI Basic Engine in Audi Q7

V8 FSI High-revving Engine in RS4

Maximum Power Output in Horsepower (HP)

V8 FSI Basic Engine in Audi Q7

V8 FSI High-revving Engine in RS4

Engine Speed in RPM

Specifications

Audi Q7 RS4

Engine Code BAR BNS

Type of Engine V8 90° V angle 4V FSI

Displacement in cm

Maximum Power Output in bhp 350 @ 6800 rpm 420 @ 7800 rpm

Maximum Torque in lbft 325 @ 3500 rpm 317 @5500 rpm

Valves per Cylinder 4

Bore in mm (in) 84.5 (3.33)

Stroke in mm (in) 92.8 (3.66)

Compression Ratio 12.5/-0.4 : 1

Firing Order 1–5–4–8–6–3–7–2

Engine Weight in lbs approximately 437* approximately 467**

Engine Management Bosch MED 9.1.1 Bosch 2x MED 9.1

Fuel Grade 98 / 95 RON (91 octane)

Exhaust Emission Standard LEV II

3

4163

4

* with automatic transmission

** manual transmission including clutch and dual-mass flywheel

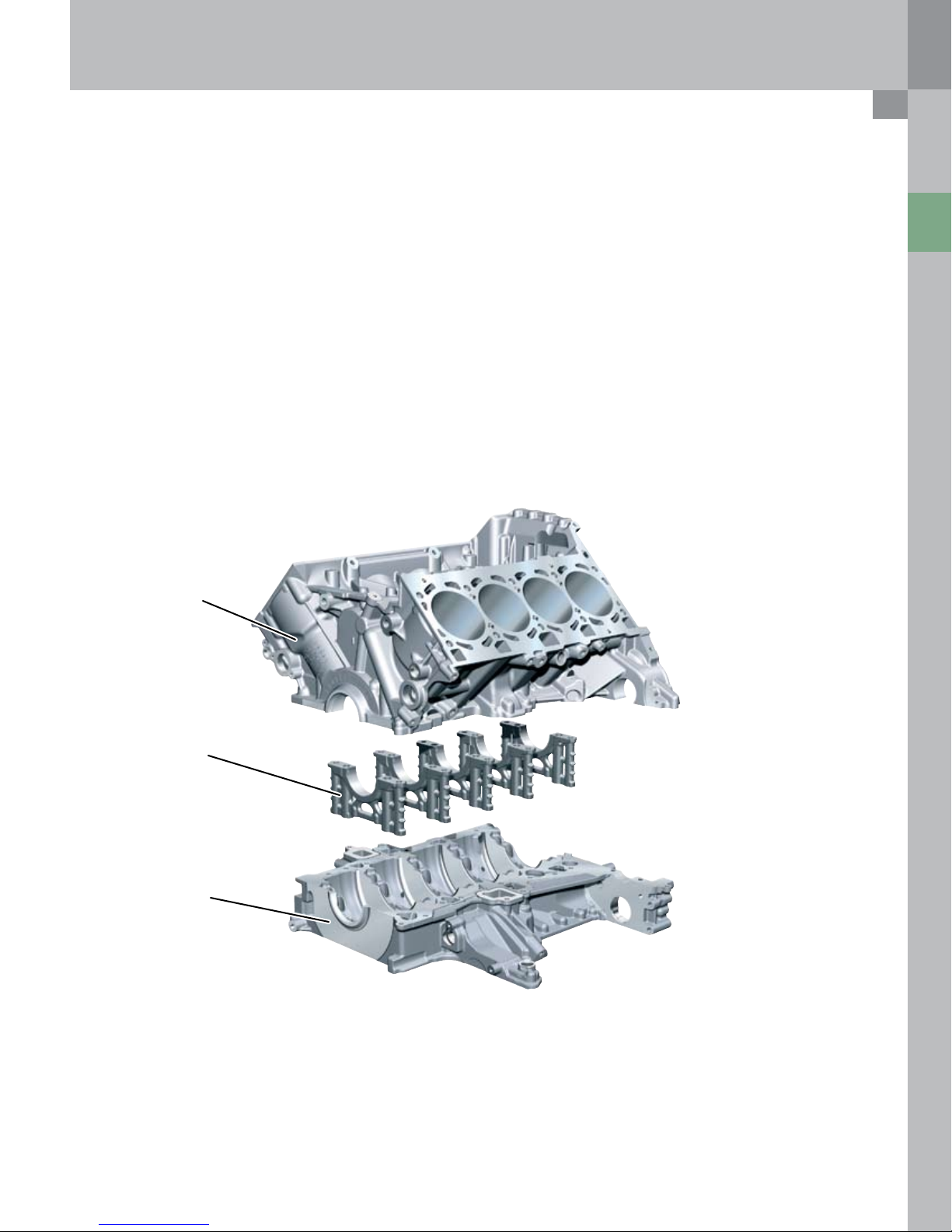

Cylinder Block

Engine Mechanical

The cylinder crankcase has a closed-deck design, which is

stronger than the open-deck design.

In an open-deck cylinder block, the water jacket for

cooling the cylinders is open at the top. The cylinder

crankcase is made of a low-pressure gravity diecast

aluminum-silicon alloy, is hypereutectic* and has a

silicon content of 17 % (AlSi17Cu4Mg).

The cylinder crankcase underwent special heat

treatment to increase its strength. The cylinder liners are

mechanically stripped.

The cylinder crankcase of the high-revving engine was

machined to higher specifications due to the higher

stresses in this component. To minimize warping of the

cylinder manifolds, the crankcase is honed under stress.

For this purpose, a honing template is attached to the

crankcase before the honing process in order to simulate

the warping of the bolted-on cylinder manifold.

Cylinder Block

Top Section

*Aluminum alloys are classed as hypoeutectic or

hypereutectic, depending on their silicon content.

“Alusil” has a hypereutectic silicon content of 16 to 18 %

so that primary silicon is precipitated on solidification of

the molten metal.

A multistage honing process is applied. The silicon grains

in the cylinder bores in the form of microscopically small,

very hard particles are stripped to give the necessary

wear resistance of the cylinder surfaces for the piston

and piston rings.

Cylinder spacing: 90 mm

–

Cylinder bank offset: 18.5 mm

–

Overall engine length: 464 mm

–

Cylinder block height: 228 mm

–

Press-fit

Main Bearings

Cylinder Block

Bottom Section

The cylinder crankcase lower section (bedplate bearing

cross-member) is made of aluminum with press-fitted

iron main bearing covers made of grade 50 nodular cast

iron. It is centered using centering pins, sealed with

liquid sealant and bolted to the cylinder crankcase.

The main bearing is symmetric with the center of the

main bearing, attached by four bolts. The bedplate type

design provides high stability. The bedplate has the same

stabilizing effect as a ladder frame.

5

Engine Mechanical

Crankshaft/Connecting Rods/

Pistons

Crankshaft

The crankshaft runs on five bearings and is made of highalloy tempered steel (42CrMoS4). It is 90° cranked and

has no connecting rod journal offset.

The vibration damper is a vulcanized single-mass damper

with unbalance.

Main bearing diameter: 65 mm

–

Main bearing width: 18.5 mm

–

–

Big-end bearing diameter: 54 mm

–

Big-end bearing width: 15.25 mm

RS4 Crankshaft

Modifications to High-revving Engine

At very high engine speeds, axial vibration occurs due to

the unbalance in the single-mass damper. This can cause

the crankshaft to break.

To avoid this vibration, a dual-mass damper without

unbalance is employed in the high-revving engine.

To compensate for unwanted engine vibration, heavy

metal inserts are integrated in the first and eighth crank

journals by way of unbalance.

6

377_035

Heavy Metal Inserts

Connecting Rod

Cracked connecting rods made of 36MnVS4 are

used in the basic engine, while the conventionally

split connecting rods in the RS4 engine are made of

34CrNiMo8, for strength.

In addition, the geometry and tolerances of the

connecting rods were reduced on the high revving

version of the 4.2L V8 FSI engine.

Bearing journals diameter: 54 mm

–

Bearing bushings: 1.4 mm thick,

–

15.25 mm wide

–

Length of bushing: 0.20 mm diameter rolled

–

Connecting rod length: 154 mm

Engine Mechanical

Cracking

During the cracking process, the connecting rod is split

at a predetermined breaking point using a special tool.

The resultant unique breaking surface ensures the high

joining precision of the two mating parts.

Piston

For strength reasons, forged pistons with a slightly higher

weight than conventional pistons, are used. Both engines

have the same piston geometry.

377_058

Breaking surface

Predetermined

breaking point

377_062

Piston weight

–

without rings: approximately 290 g (10 oz)

–

Piston pin: 0.20 mm x 0.11.5 mm x 40 mm

377_057

7

Engine Mechanical

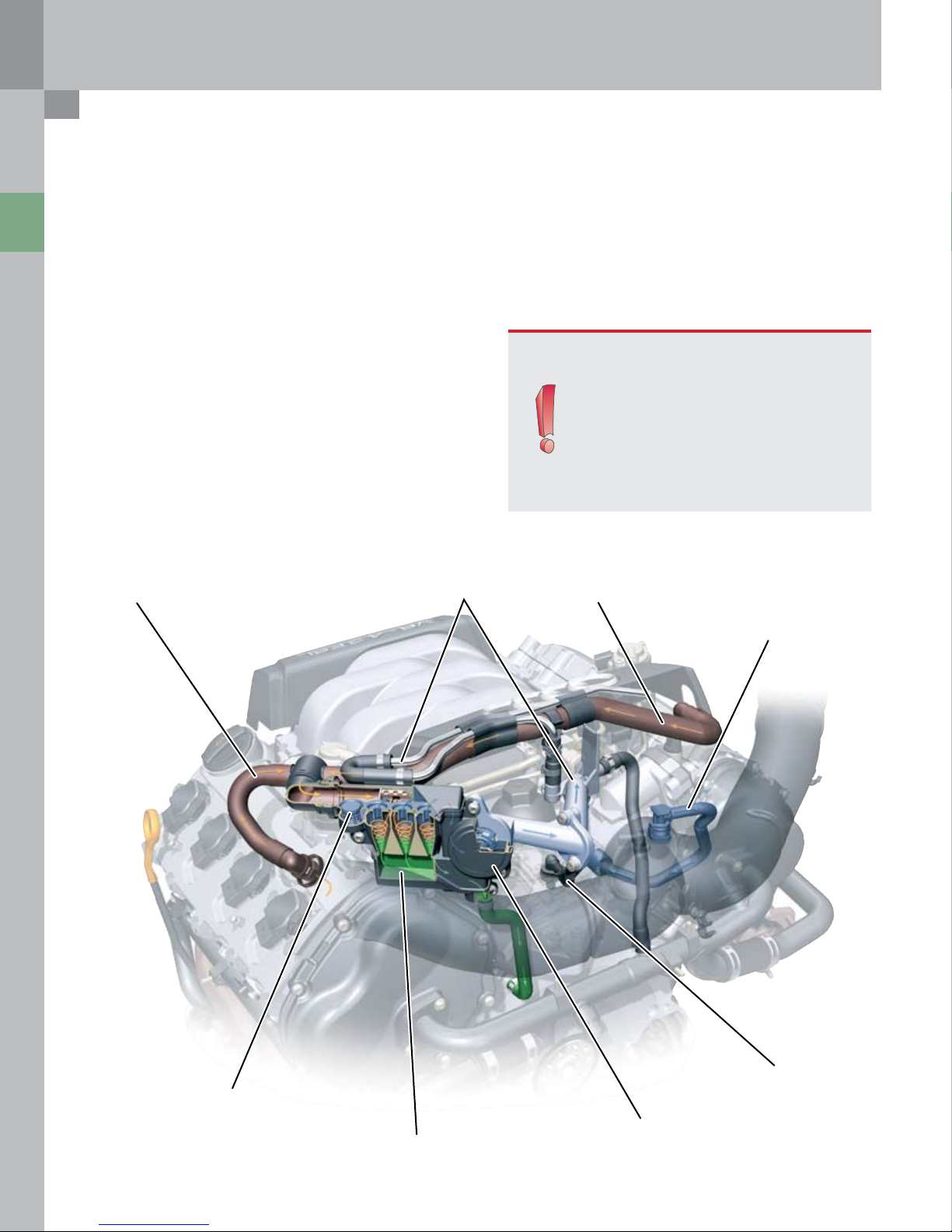

Crankcase Ventilation

The crankcase is ventilated through both cylinder heads.

The valve covers incorporate a large settling space.

This space acts as a gravity-type oil separator. A fine oil

separator is connected to the valve covers by means of

plastic hoses.

A control piston, a bypass valve, a two-stage pressure

limiting valve and an oil drain valve are integrated in the

oil separator housing.

Breather Pipe Heater

After the blow-by gas has passed through the fine

oil separator, the gas flows into the intake manifold

downstream of the throttle valve.

This inlet point is integrated in the coolant circulation

system and heated. This prevents the crankcase breather

from freezing up.

Note:

Modifications after start of production

In both engines, the separated oil flows

into the crankcase through the cover in the

inner V, adjacent the crankcase breather

(no longer through the chain housing).

In the Audi Q7 engine, the crankcase is

vented through a single chamber, i.e.,

via bank 2 only. Better icing protection is

achieved in this way.

Breather Pipe

Bypass Valve

Fine Oil Separator

Pressure Limiting Valve

Crankcase Breather System

377_009

Non-return Valve

(crankcase breather)

8

Engine Mechanical

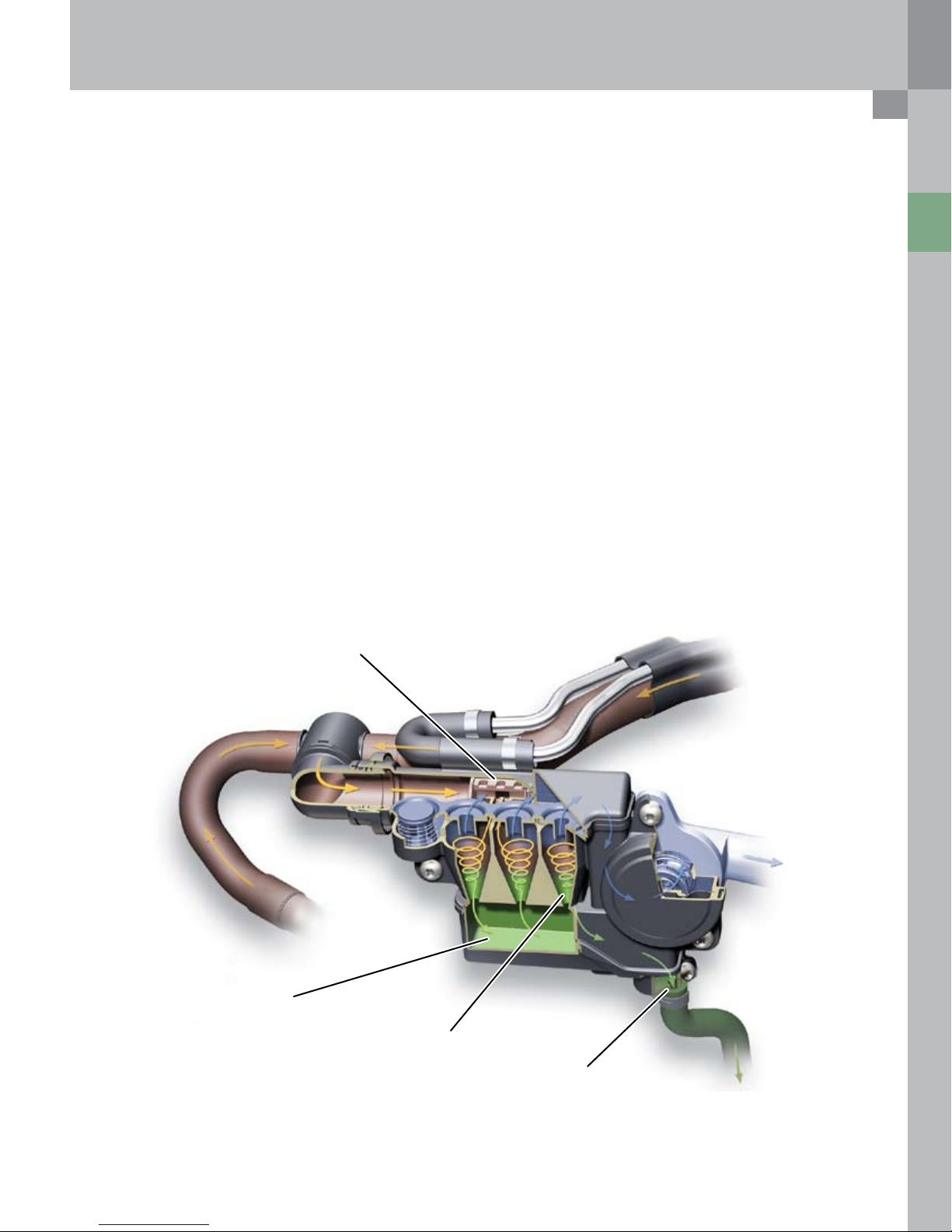

Fine Oil Separator

Blow-by gas volume is dependent on engine load and

RPM. The fine oil (“oil spray”) is separated by means

of a cyclone separator. Cyclone separators have a high

separation efficiency over only a small volumetric range.

For that reason, one, two, or three cyclones of the fine oil

separator operate in parallel, depending on the gas-flow

rate.

The cyclones are released by the control piston. The

displacement of the control piston against its spring

force is dependent on the gas-flow rate. Piston ring

flutter at very high engine RPMs and low engine load can

result in a very high gas-flow rate.

The crankcase internal pressure is set by the two-stage

pressure control valve. The bypass valve, together with

the control piston, ensures that the cyclones operate at

the optimum operating point (if the volumetric flow rate

is too high or too low, it will impair the functioning of the

cyclones).

When the bypass valve opens, a fraction of the blow-by

gas flows to the engine untreated, but the remainder is

optimally treated by the cyclones.

The separated oil is collected in an oil reservoir beneath

the cyclones. The oil cannot drain out of the reservoir

until the oil drain valve is opened. The oil drain valve

is closed as long as the pressure in the crankcase, i.e.,

below the valves, is higher than in the oil separator. The

valve opens automatically due to gravity only at very

low engine RPMs or when the engine is at a standstill,

because the pressure conditions above and below the

valve are in equilibrium.

The crankcase ventilation system also includes the

crankcase breather. Air is extracted downstream of the

air filter and flows through a non-return valve into the

crankcase from above.

The non-return valve is located at the end of the vent

line and is bolted between the two cylinder banks in the

engine block.

A damping chamber is located below the non-return

valve in the engine block. This prevents non-return valve

flutter and eliminates noise.

A restrictor bore connects this chamber to the inner

chamber of the crankcase. It has the task of supplying

only a defined volume of fresh air to the crankcase.

Oil Reservoir

Control Piston

Triple Cyclones

Oil Drain Valve

377_011

9

Engine Mechanical

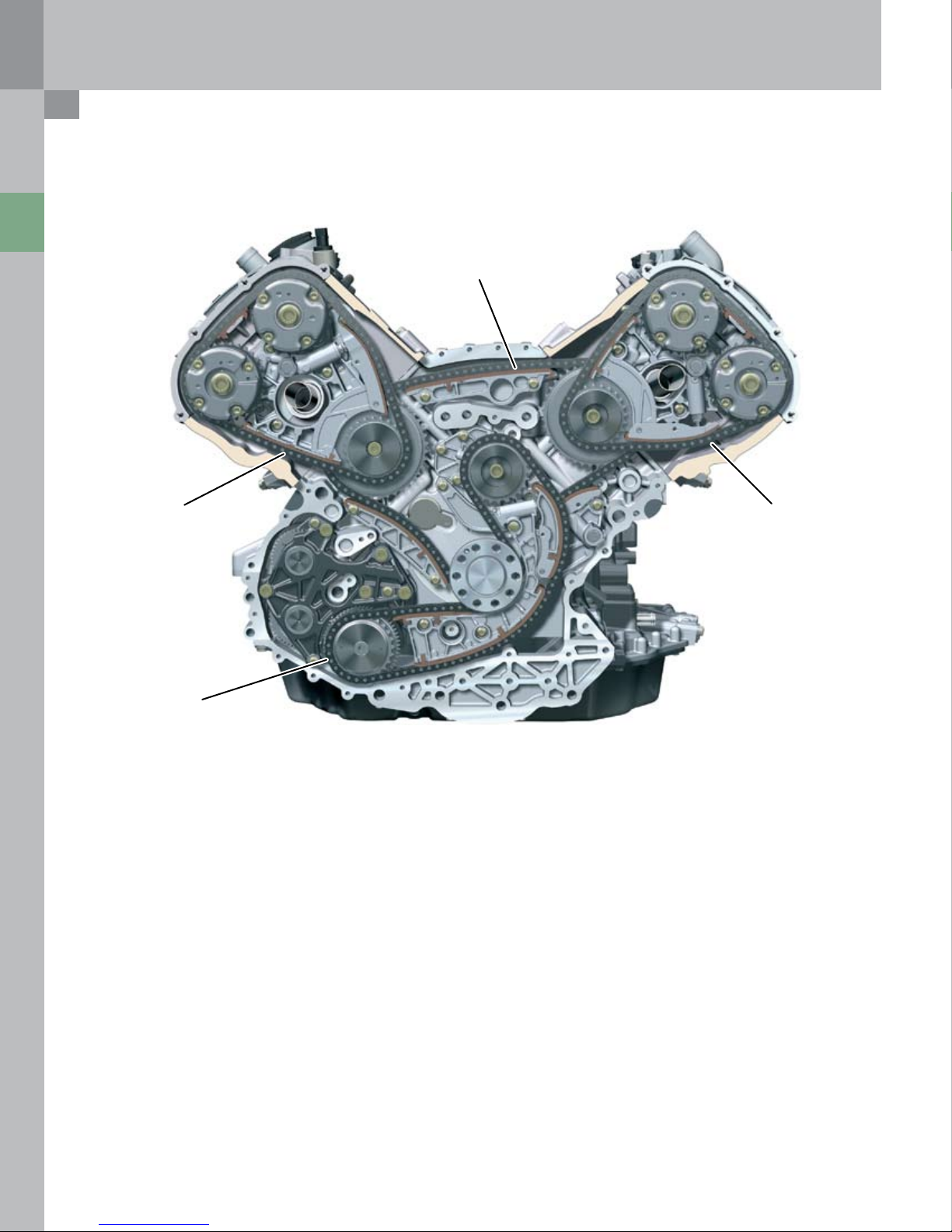

Chain Drives

Audi Q7 4.2L V8 FSI Engine

Chain Drive A

Chain Drive B Chain Drive C

Chain Drive D

The timing gear concept is identical in all Audi V-engine

series.

There are four chain drives arranged in two layers.

Layer 1

Chain drive A drives the camshafts idler gears from

–

the crankshaft

Layer 2

Top drives B and C drive the camshafts from the idler

–

gears

Chain drive D drives the accessory drive module from

–

the crankshaft

Correct chain tension is ensured by hydraulic tensioners.

The chain drive is maintenance-free and designed for

lifetime service.

The two engine types differ in terms of the type of chains

used and the reduction ratios in drives A, B and C. The

load on the roller chains was reduced in the basic engine

version by selecting a greater number of teeth.

10

377_012

Audi Q7

The camshafts in the basic engine are driven by 3/8”

simplex roller chains.

Due to their acoustic advantages, the chains were

developed to meet the high comfort requirements.

In this case, the idler gears have 40 and 24 teeth. The

camshaft sprockets have 30 teeth.

High-revving Engine

3/8“ simplex sleeve-type chains are used here. Their

advantage is their reduced wear and higher stress

resistance at high engine speeds.

In this case the idler gears have 38 and 19 teeth. The

camshaft sprockets have 25 teeth.

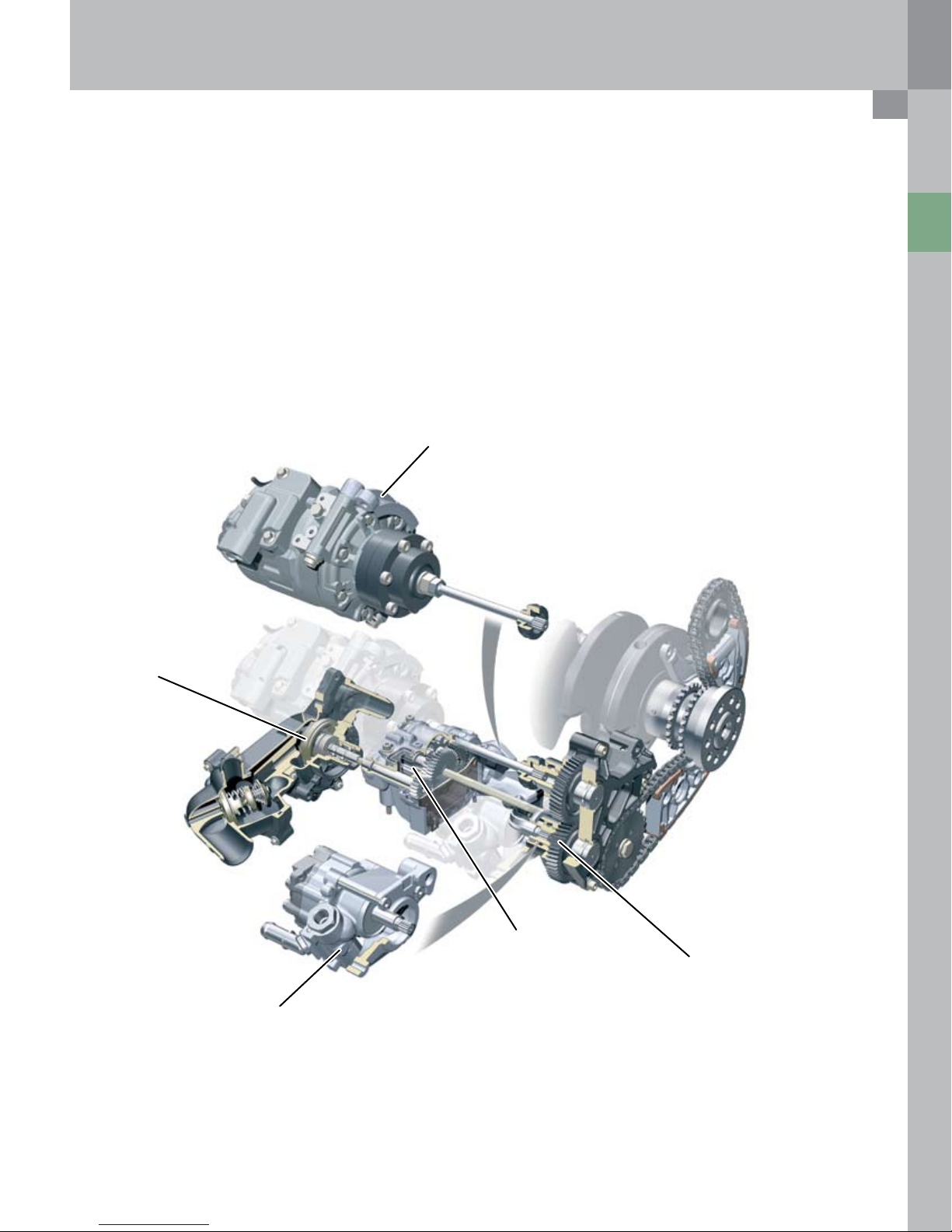

Accessory Drive

The oil pump, water pump, power steering pump and the

compressor are driven by chain drive D.

The chain is driven directly by the crankshaft, deflected

by an idler gear and drives the chain sprocket seated on

the gear module.

Air Conditioner Compressor

Engine Mechanical

Coolant Pump

377_013

Oil Pump

Gear Module

Power Steering Pump

11

Loading...

Loading...