Audi V6 BITURBO, 2.7-litre V6 Biturbo User Manual

Service.

For internal use only

198

All rights reserved. Subject

to change.

AUDI AG

Dept.I/GS-5

D-85045 Ingolstadt

Fax +49.841/89-6367

740.2810.17.20

Technical status: 01/98

Printed in Germany

The 2.7-litre V6 Biturbo

Design and Function

Self-study Programme 198

2

The 2.7-litre V6 biturbo .......

Turbocharged engines are already something

of a tradition at AUDI. The task now facing

AUDI’s engineers was to develop a worthy

successor to the 5-cylinder turbocharged

engine.

One of the key development goals for the

turbocharged engine was to achieve a good

level of dynamic response, particularly at the

bottom end of the rev band.

........ a further milestone in engine development by Audi!

The goal of AUDI’s engineers was to realise a

high “basic torque level“ and a torque

characteristic that rises in direct proportion to

engine speed to its peak.

The term “basic torque level“

describes the torque which is

immediately available when the

throttle is opened (e.g. at part

throttle or in overrun).

SSP 198/77

3

This Self-study Programme provides you with information

regarding design and function.

The Self-study Programme is not a Workshop Manual!

Please refer to the Service Literature for all the relevant

maintenance and repair instructions.

Page

Engine .........................................................

Technical data, crankshaft, cylinder head,

camshaft timing, cooling circuit, engine

lubrication, overview of components, air ducting,

charging, exhaust system, pneumatically

controlled systems, charge pressure control, air

divert control in overrun, ACF system, crankcase

breather

4

Motronic ME 7.1..........................................

Subfunctions, system overview

31

Subsystems of the Motronic .....................

Torque-oriented engine management, torqueoriented functional structure, Electronic throttle,

exhaust gas temperature control

33

Sensors .......................................................

Additional sensors of the Motronic

49

Auxiliary signals/interfaces ...................... 57

Functional diagram..................................... 62

Self-diagnosis .............................................

Vehicle diagnosis, test and information system

VAS 5051, test box V.A.G 1598/31

64

Transmission ..............................................

Self-adjusting clutch, gearbox

66

Contents

Important!/Note!

New!

4

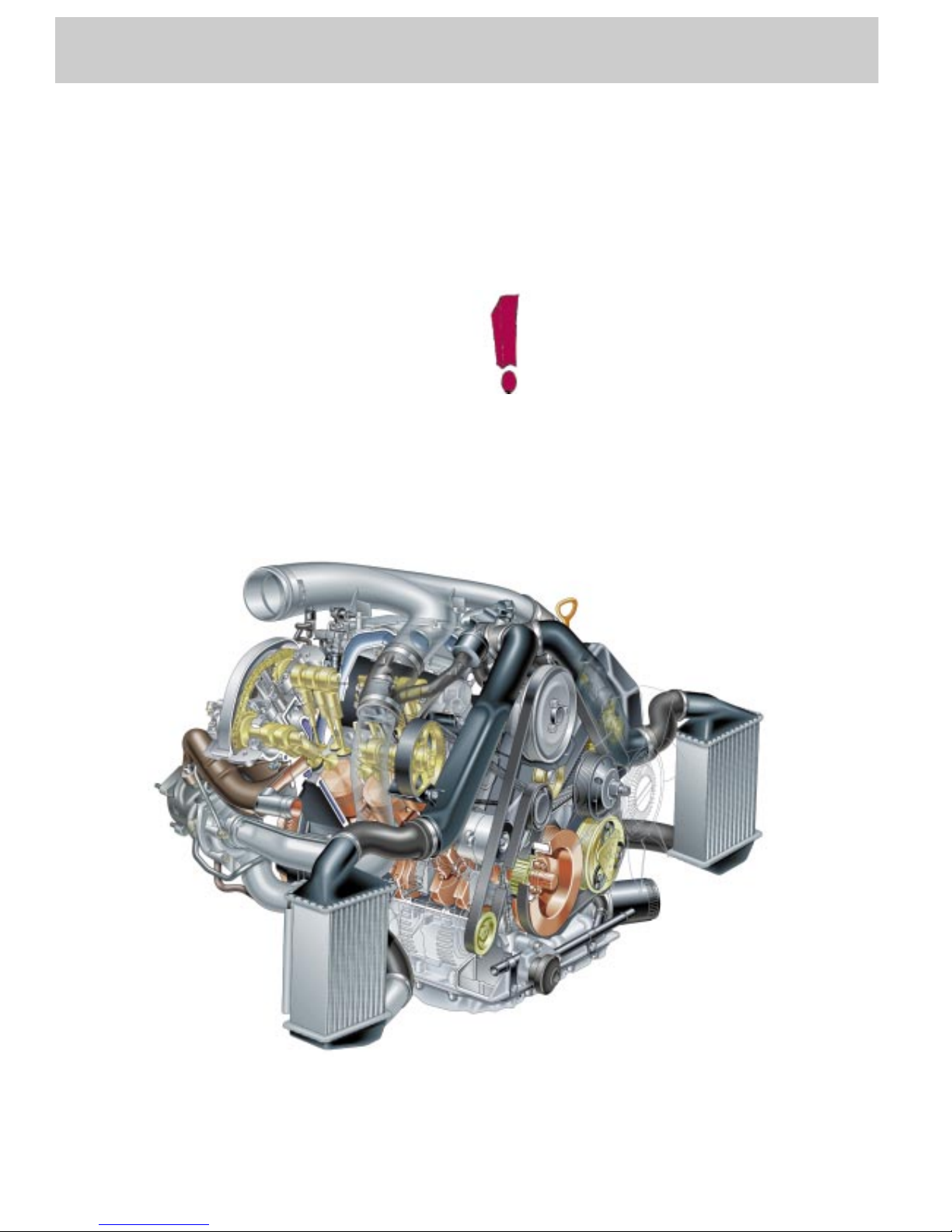

Engine

The 2.7-litre V6 biturbo

This engine will also be used in the Audi S4

and Audi A6.

The engine used in the A6 has a comfortoriented setup, which means that it has

different torque and power output.

This effect was principally achieved by

modifying the software configuration of the

engine control unit.

A tuning protective device prevents

the S4 engine control unit being

installed in the A6!

This prevents misuse, which can

result in damage to the drivetrain!

An auxiliary heater is not available

as an option for the S4 and the A6,

due to the constraints on space.

BITURBO

SSP 198/01

5

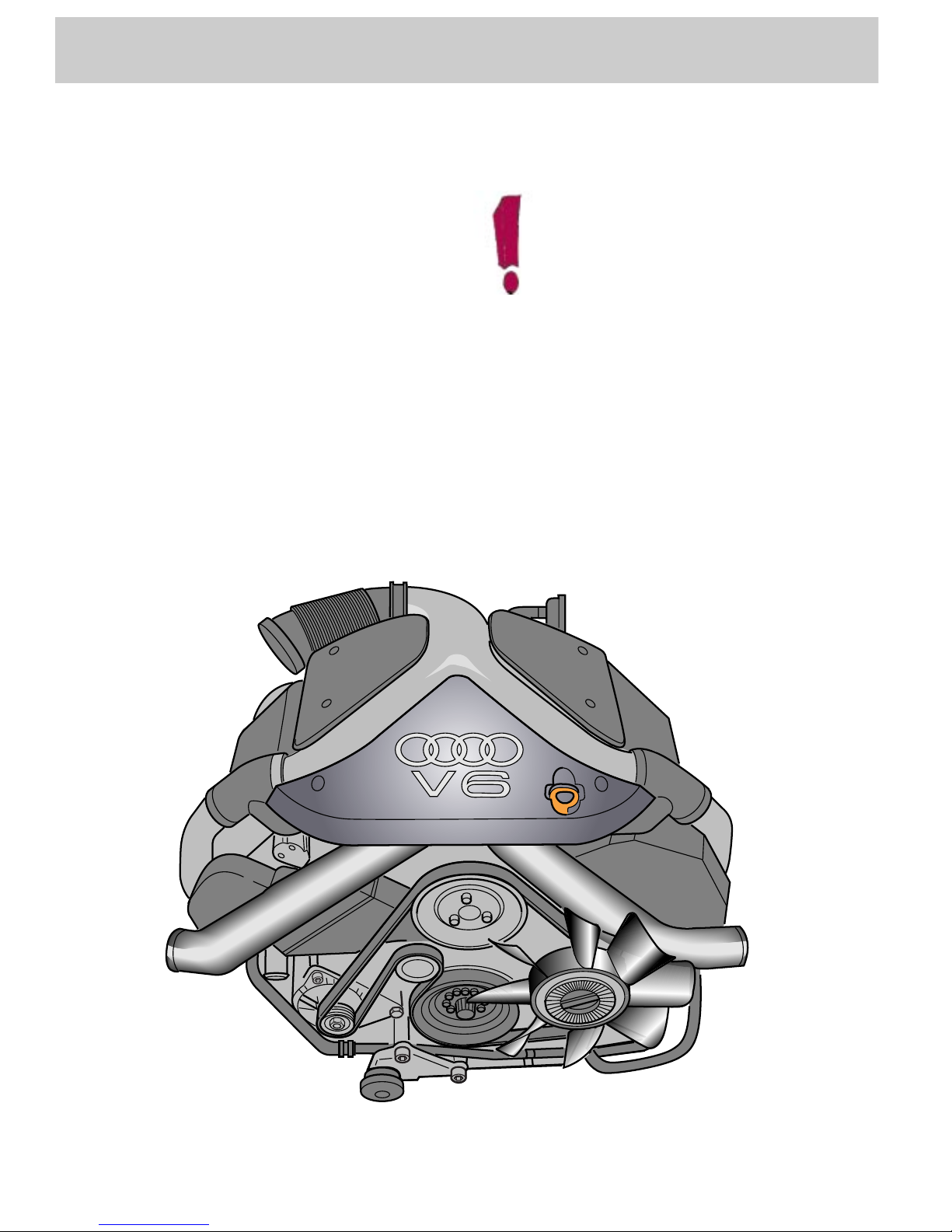

The technical data

•

Configuration:

V6 engine with 90° V-angle and twin

turbochargers

•

Engine code:

S4: AGB

A6: AJK

•

Output:

S4: 195 kW at 5800 rpm

A6: 169 kW at 5800 rpm

•

Torque:

S4: 400 Nm at 1850 to 3600 rpm

A6: 310 Nm at 1700 to 4600 rpm

•

Maximum speed:

6800 rpm

•

Compression ratio:

9.3 : 1

•

Displacement:

2671 cm

3

•

Bore:

81 mm

•

Stroke:

86.4 mm

•

Weight:

approx. 200 kg

•

Engine management:

Motronic ME 7.1

•

Firing order:

1-4-3-6-2-5

•

Fuel type:

S4: 98/95/91 RON

A6: 95/91 RON

•

Compliant with emission standard:

EU III-D

Figures obtained using 98 RON

unleaded premium fuel to

89/491/EEC.

Figures obtained using 95 RON

unleaded premium fuel to

89/491/EEC.

500

450

400

350

300

250

200

150

100

50

0

200,0

180,0

160,0

140,0

120,0

100,0

80,0

60,0

40,0

20,0

0,0

0 1000 2000 3000 4000 5000 6000 7000

SSP 198/02

Speed [rpm]

Torque [Nm]

Output [kW]

S4

500

450

400

350

300

250

200

150

100

50

0

180,0

160,0

140,0

120,0

100,0

80,0

60,0

40,0

20,0

0,0

0 1000 2000 3000 4000 5000 6000 7000

SSP 198/46

Speed [rpm]

Torque [Nm]

Output [kW]

A6

6

Engine

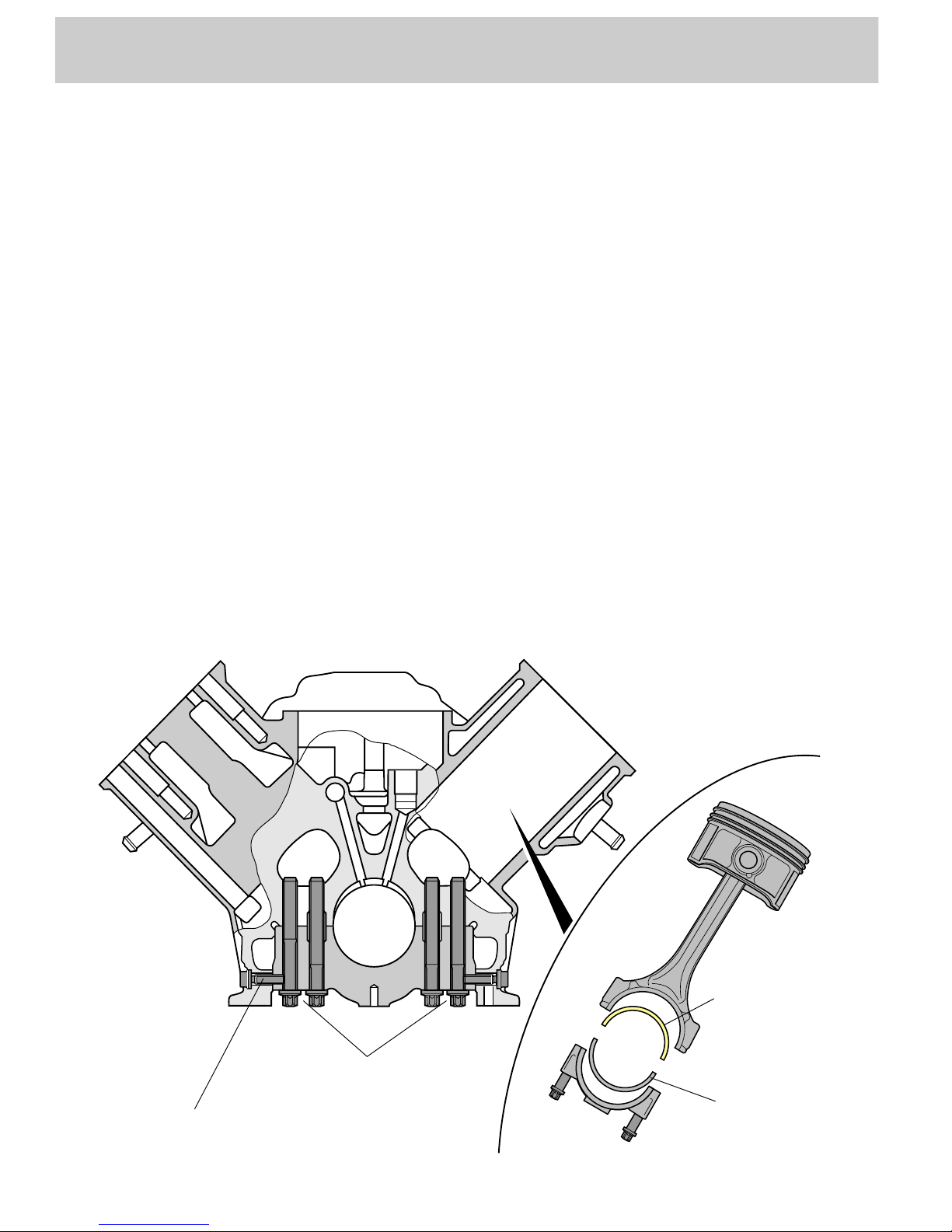

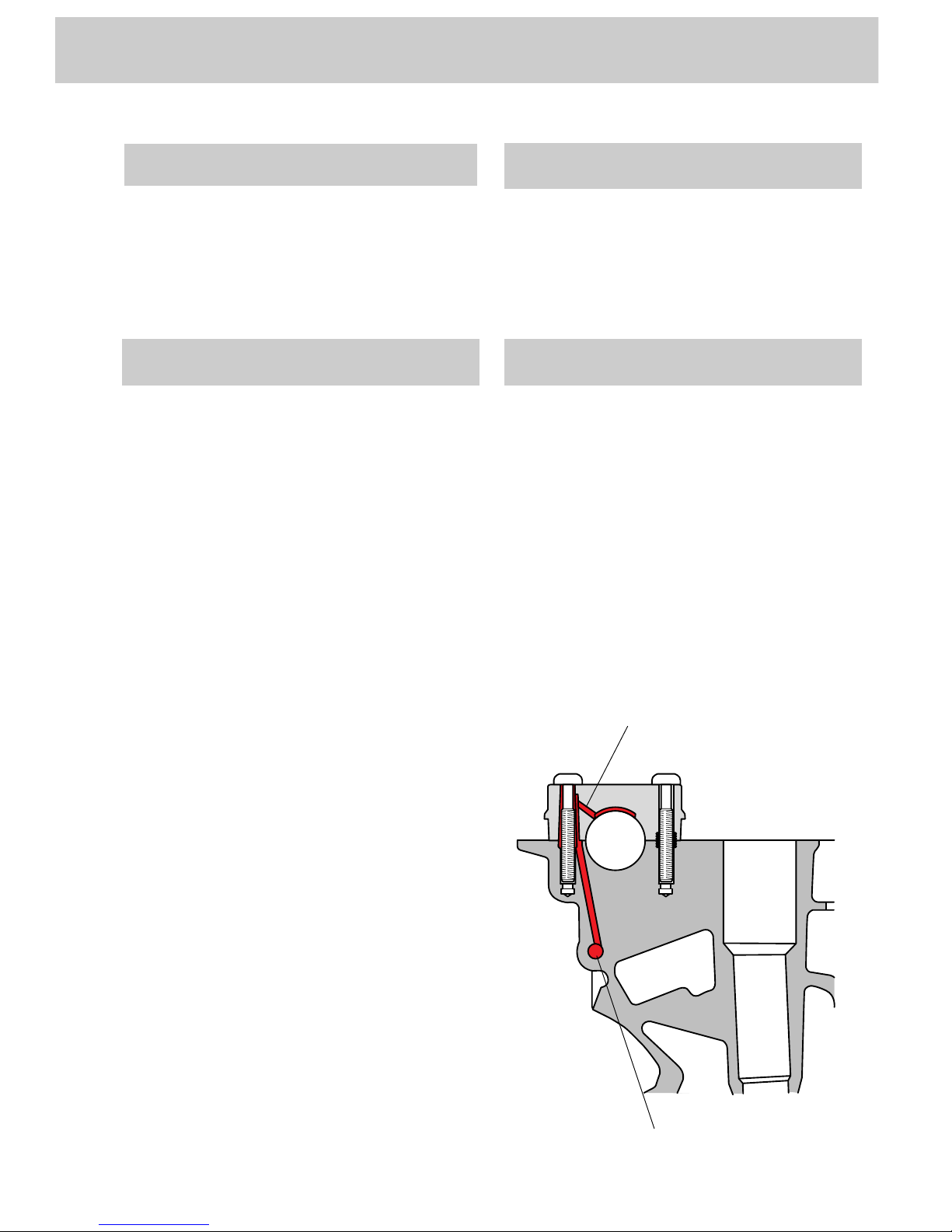

The crankshaft

The crankshaft is identical to that used in the

2.8-litre V6 engine.

The crankshaft bearing caps are attached to

the central crankcase by 4 bolts.

•

The 4-bolt connection reduces the load on

the bearing caps considerably.

The middle two crankshaft bearing caps are

also bolted to the side of the crankcase.

•

The lateral bolted connection helps to

improve acoustics.

The pistons are forged to enable them to

withstand the high loads to which they are

subjected.

Due to the high combustion pressures, a 2material bearing shell is installed on the

connecting rod side. The bearing cap has a 3material bearing shell.

Advantage:

The bearing shell has a high load-bearing

capacity

SSP 198/11

Lateral bolted connection

4-bolt connection

2-material

bearing shell

3-material

bearing shell

7

Cylinder head

The cylinder heads are largely identical to

those used in the V6 naturally aspirated

engine. Common parts are used for both banks

of cylinders.

The mounting position of the right-hand

cylinder head is rotated through an angle of

180° in relation to the left-hand cylinder head.

The timing of the inlet camshafts is enginedependent.

To improve heat dissipation, the exhaust

valves are sodium-filled.

The shape of the inlet duct causes the drawnin air to tumble.

Advantages:

•

A good degree of swirl and high ignitability

fuel-air mixture are achieved

•

The tumble effect allows more efficient

combustion

For a turbocharged engine, the compression

ratio of 9.3 : 1 is high.

Advantage:

•

High ”basic torque level“ and fuel

economy

Tumble duct

In combination with five-valveper-cylinder technology, the inlet

duct is shaped as a so-called

“tumble duct“.

Tumble duct

Tumble effect

SSP 198/78

8

Engine

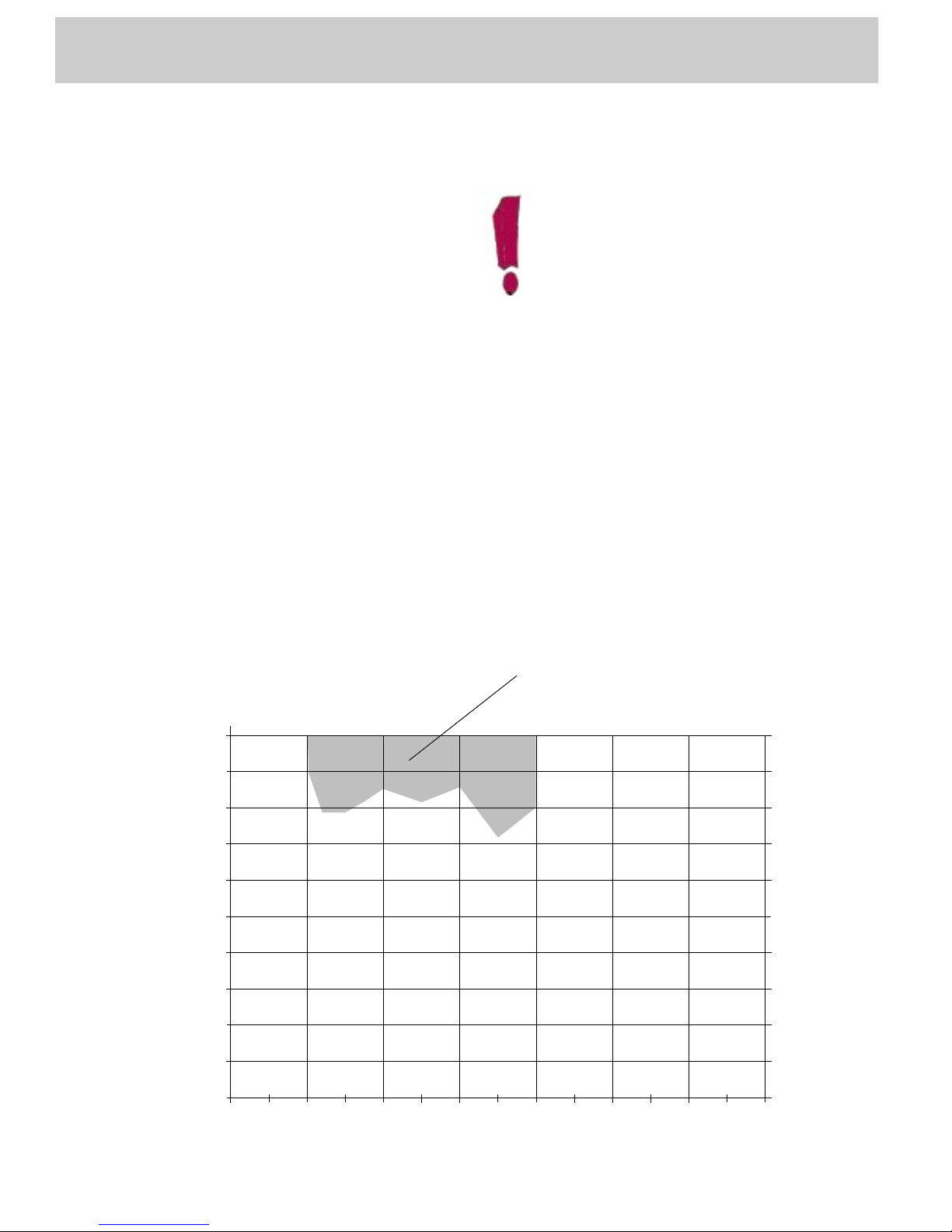

The variable valve timing

The camshaft timing has been modified

compared to the 2.8-litre V6 engine to meet the

demands of turbocharging technology.

Variable valve timing with an adjustment angle

of 22° is used here for the first time in

turbocharged engines .

Advantage:

•

A torque increase of approx. 10% is

achieved at the bottom and top ends of the

engine speed range.

•

Better emission levels and fuel

consumption figures.

The variable valve timing is activated by the

Motronic by means of camshaft adjustment

valves N205 and N208.

The design and function of the

variable valve timing are already

described in Self-study Programmes

182 and 192.

Activation of the variable valve timing is

dependent on engine load and speed.

In the self-diagnosis, you can find out whether

the variable valve timing is active or not by

reading out the relevant measured value block

(refer to Workshop Manual).

0

0 1000 2000 3000 4000 5000 6000 7000

SSP 198/45

Diagram of variable valve timing

(shown using the 265 bhp engine as an

example)

Engine speed

Engine load in %

Variable valve timing active

= advance position

Full throttle

9

SSP 198/03

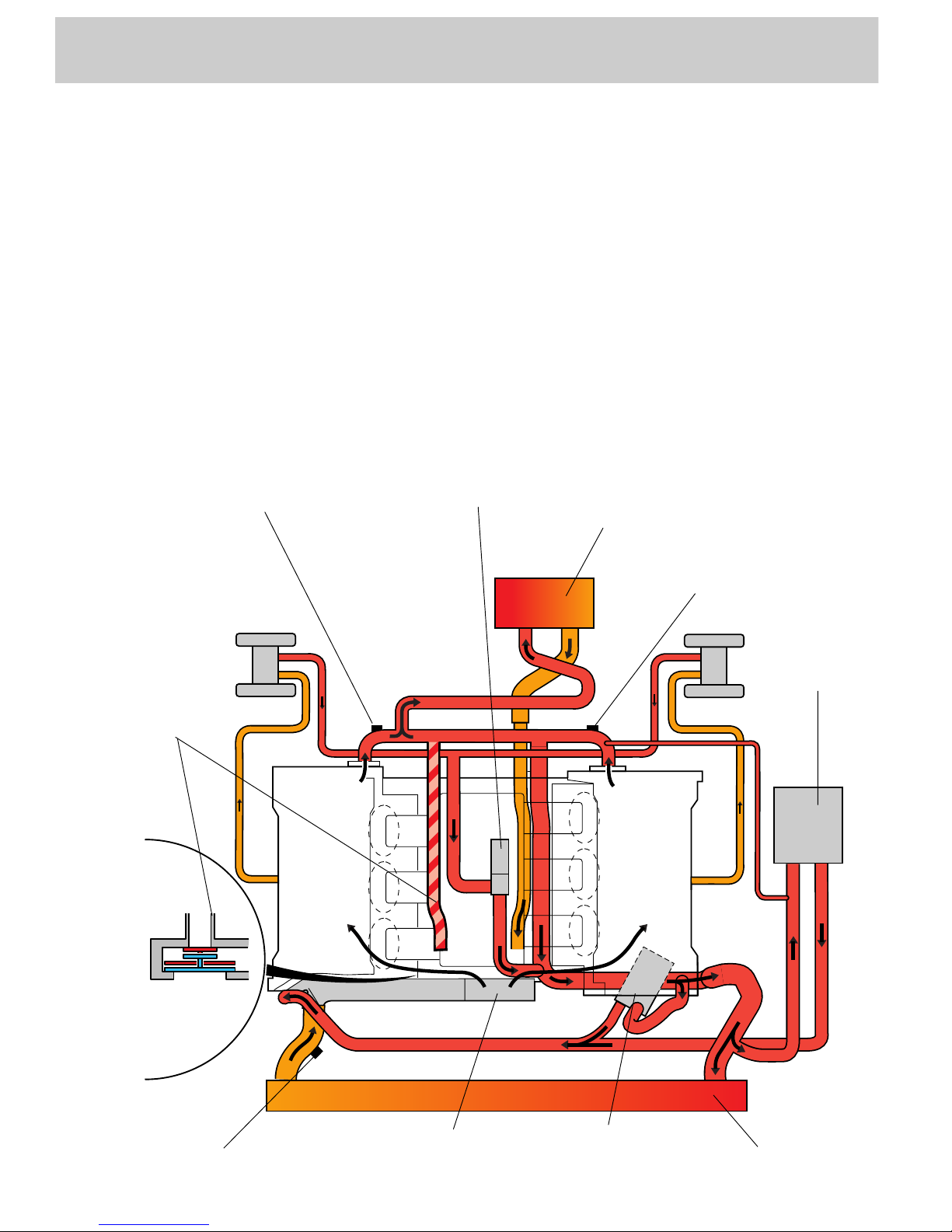

Cooling circuit

Both exhaust gas turbochargers are watercooled and integrated in the cooling circuit.

When the coolant thermostat is closed, the

coolant flows back to the coolant pump along

the short-circuit line as well as the heat

exchanger.

When the coolant thermostat is open, the

coolant flows back to the coolant thermostat

through the radiator (primary flow) or through

the oil cooler and expansion tank (secondary

flow).

Located in the cooling circuit is a electrical

coolant pump.

This pump is required as a means of

protection against overheating of the coolant

under high thermal load, e.g. when the hot

engine is turned off.

Short-circuit

line

Continued coolant function pump

Heat exchanger

Coolant

Expansion

tank

Radiator fan thermoswitch F18/F54

Oil cooler

Radiator

Thermoswitch for F95

Coolant temperature

senders G2 and G62

Coolant pump

10

SSP 198/10

Engine

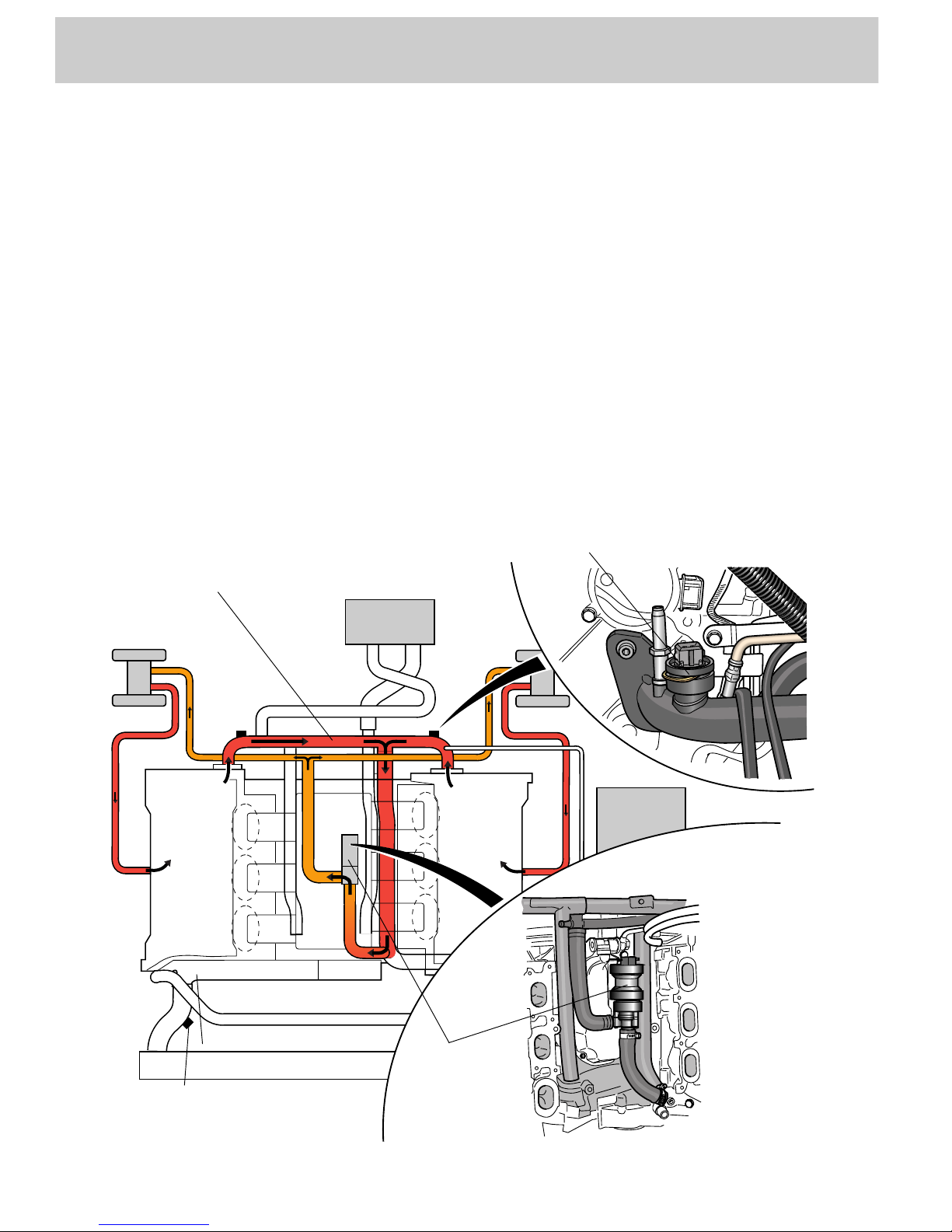

Electrical coolant circulation pump V51

Electrical coolant circulation pump V51 is

located in the engine’s V angle.

If the coolant temperature is too high,

thermoswitch for coolant circulation run-on

F95 activates the additional coolant function.

The high temperatures which occur at the

exhaust gas turbocharger produce vapour

bubbles which prevent coolant being drawn in

by pump V51.

When pump V51 starts up, the coolant flows

through the exhaust gas turbocharger and the

cylinder heads. The direction of flow in the

turbocharger cooling circuit is reversed by

this.

Due to this reversal of the direction of coolant

flow, coolant is drawn in via the cylinder heads

(large cross-sections), which means that any

vapour bubbles which develop are expelled

from the exhaust gas turbocharger lines.

The electrical coolant circulation pump again

draws in coolant along the rear coolant pipe,

thereby recirculating the coolant.

Rear coolant pipe

Electrical

coolant

circulation pump

V51

Thermoswitch for additional coolant

function F95

Radiator fan thermoswitch

F18/F54

11

Fan control

The control unit for radiator fan V293 regulates

the output of the radiator fan and controls the

continued coolant circulation. The induced-air

fan V7 and the forced-air fan V177 are

activated simultaneously.

Forced-air fan V177 is located upstream of the

condenser, water cooler and visco fan. It

assists the visco fan.

The electronic power control

The various fan settings are executed by an

electronic power control.

The fan motors are operated periodically, the

length of the operating cycle depending on the

fan setting selected. Fan output level is

controlled via pulse-width-modulated outputs.

Should a fan fail, the radiator fan control unit

increases the speed of the fan motor still

available.

Advantages of the power control:

•

The series resistors previously used for

power control are no longer required.

•

Lower power consumption in lower fan

settings.

•

Safety functions.

The power supply is protected by a

fuse on the 8-socket relay plate. For

the correct fuse rating, please refer

to wiring diagram.

Vehicles equipped with an air

conditioner require a higher fuse

rating than vehicles without an air

conditioner.

SSP 198/50

8-socket relay plate

SSP 198/55

Control unit for radiator fan

attached to front right

vehicle side member

Fuse, terminal 30

Fuse, terminal 61

12

Electric circuit of fan control:

Engine

for vehicles with air-conditioning system:

Integrated in the pressure switch for air

conditioner F129 is the high-pressure switch

for activating a higher fan setting.

The pressure switch is mounted below the

right-hand headlight behind the bumper.

Components:

F18/F54 Radiator fan thermoswitch

F95 Thermoswitch for continued coolant

function

F129 Pressure switch for air conditioner

(only for vehicles with air conditioner)

V293 Control unit for radiator fan

V7 Radiator fan (induced-air fan)

V51 Continued coolant circulation pump

V177 Fan 2 for radiator (forced-air fan)

(only for vehicles with air conditioner)

1 Terminal 30, positive supply via fuse

on 8-socket relay plate

2 Terminal 61, D+ (alternator) via fuse on

8-way relay

3 Fan activation (only for vehicles with

air conditioner)

M

_

V293

F18

F54

F129

V177

V7

V51

M

_

M

_

SSP 198/17

*

*

F95

*

P

P

1 23

only for vehicles with air conditioner

Air-conditioning pressure switch F129

13

Function of fan circuit

(for vehicles with air-conditioning

system)

4 fan settings are possible:

is activated by coolant pump thermoswitch

F95.

The fan motors and continued coolant

circulation pump V51 are activated.

The fan motors run at min. output (40%).

is requested by radiator fan thermoswitch F18

or by the air-conditioning control panel.

The fan motors run at 50% output.

is activated by air-conditioning system

pressure switch F129.

The fan motors run at 85 % output.

is activated by radiator fan thermoswitch F54.

The fan motors run at full output.

Fan speeds 1, 2 and 3 are only

activated if the “engine running“

signal is picked up at terminal 61.

The electrical coolant function.....

The continued coolant function is

only activated if the “engine not

running“ signal is picked up at

terminal 61. The continued coolant

function period is limited to 10

minutes.

Fan speed 1......

Fan speed 2......

Fan speed 3......

14 15

SSP 198/49

Engine

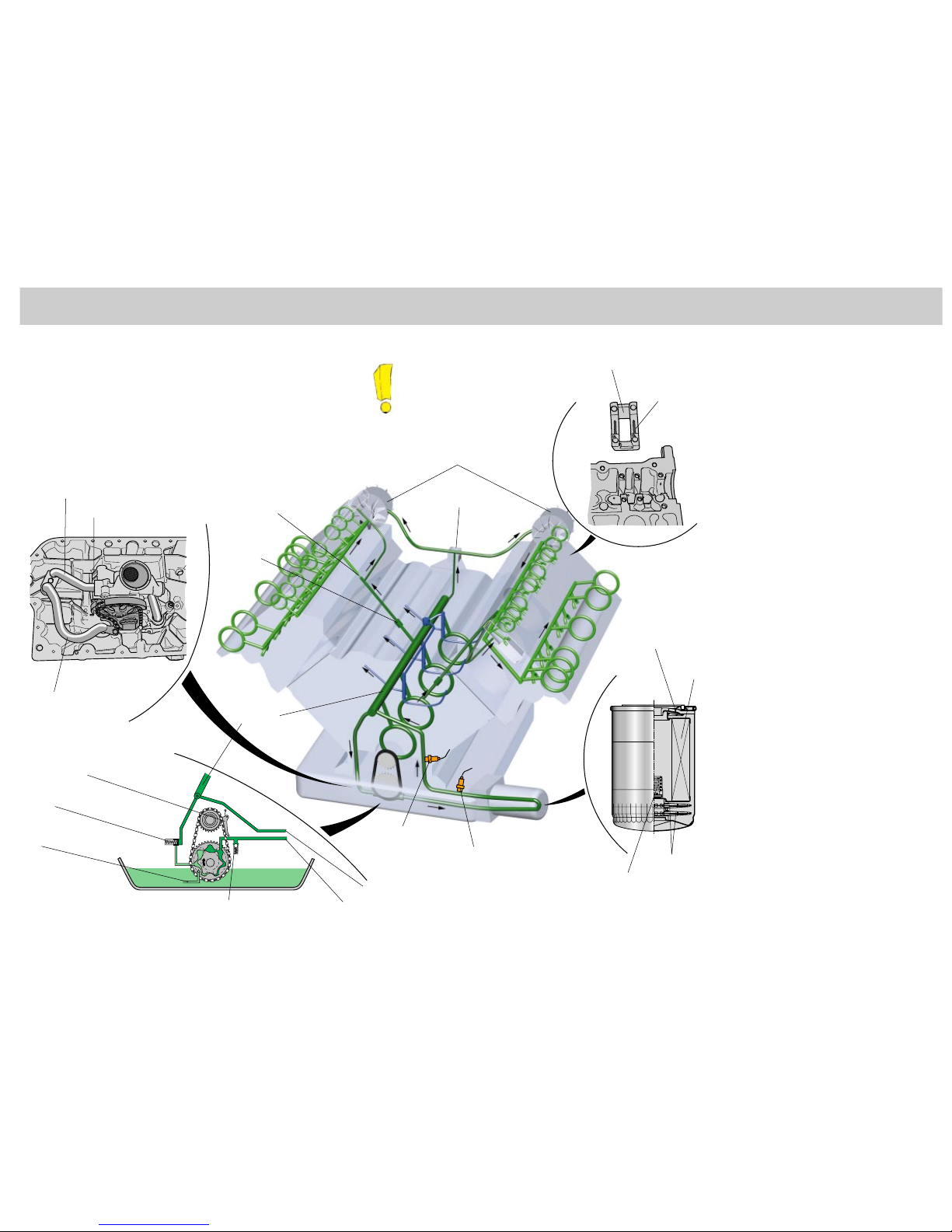

Engine lubrication

The oil circuit of the 2.7-litre V6 biturbo engine largely corresponds to that

of the 3rd V6 engine generation.

In addition, the two exhaust gas turbochargers are supplied with

pressurised oil from the main oil gallery via a distributor piece. The oil is

returned directly to the oil sump.

The oil cooler was adapted to withstand the higher thermal stresses in

comparison with a naturally aspirated engine.

A new feature of the biturbo is

the “integrated oil supply“ (see

next page).

to oil filter/oil cooler

Spring-loaded slipper

(chain tensioner)

Main oil gallery

Oil retention valves

Bypass valve

Filter element

Bearing cap

Oil groove

Oil temperature

sender

Oil pressure switch

Restrictor

Oil retention

valve

distributor piece

The oil circuit

A duocentric oil pump draws in the oil

through a coarse filter. Located in the

pressure chamber of the pump is a

pressure relief valve which protects

downstream components against

pressure peaks during cold starts.

The oil is fed to the oil filter via the oil

cooler. After passing an oil retention

valve, the oil flows through the filter

element. A bypass filter is connected in

parallel with the filter element.

The oil subsequently reaches the main

oil gallery. A branch line is routed to the

oil pressure control valve (clean oil

side).

The following components are supplied

with oil from the main oil gallery:

- the four crankshaft bearings

- the two exhaust gas turbochargers

via an oil distributor line

- the three pairs of piston spray jets via

a spray jet valve

- the cylinder head of cylinder bank 1

via an oil retention valve

The cylinder head of cylinder bank 2 is

supplied through a separate bore from

crankshaft bearing 2 via an oil retention

valve also.

First of all, the camshaft adjustment

valve is supplied with oil from the inlet

drilling in the cylinder head. After the oil

has passed by a restrictor, it is

channeled via the cylinder head main

gallery to the hydraulic valve tappets

and the camshaft bearings.

Exhaust gas turbocharger

Bypass filter

Oil pressure relief valve

from oil filter/oil cooler

Oil pressure

control valve

Induction filter

Oil pressure relief valve

from oil filter/oil cooler

to oil filter/oil cooler

16

Engine

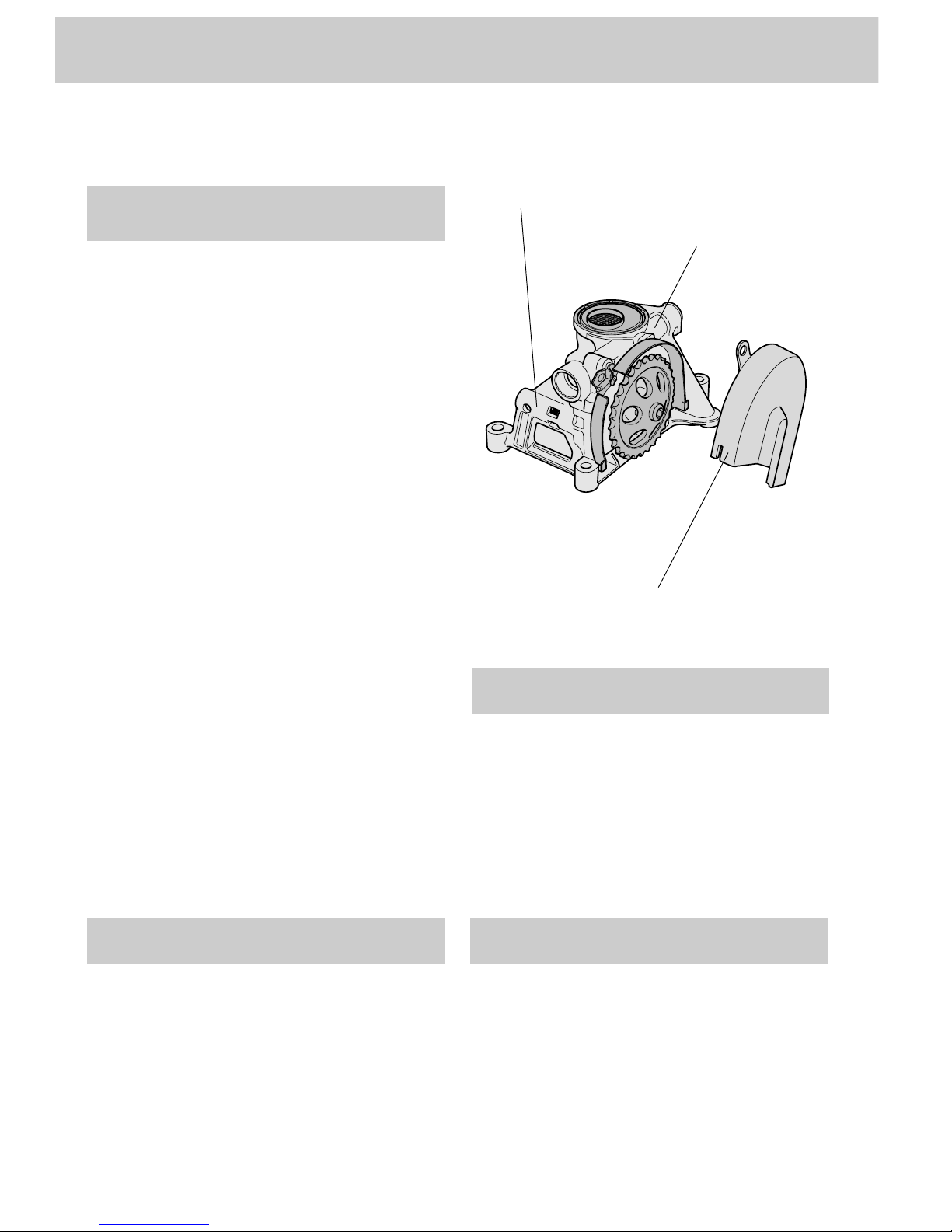

The component parts of the oil circuit

is integrated in the primary flow. By increasing

the capacity and optimising the flow

resistance, the entire oil flow can be routed

through the oil cooler. Unlike the V6 naturally

aspirated engine, a bypass is not required.

The oil cooler ......

contains an oil retention valve, the filter

element, a bypass filter and the filter bypass

valve. The latter has the task of maintaining

engine lubrication via the bypass filter if the

filter element becomes clogged up or if the oil

has a high viscosity.

The oil filter ......

opens up the oil flow to the piston spray jets if

the oil pressure is greater than 1.8 bar.

Reason: at low oil viscosity and low engine

speeds, the oil pressure would otherwise drop

below the minimum permissible level. That

aside, piston cooling is not necessary at low

engine speeds.

The spray jets valve ......

SSP 198/57

Oil pressure control valve

Oil pressure limiting valve

Chain guard

is an internal gear pump. It is attached to the

crankcase as a separate component.

The oil pump is designed in such a way that it

projects deep down into the oil sump and is

immersed completely in the engine oil when

the oil level is correct. This prevents the oil

pump running dry.

The oil pump, in combination with the

extremely short intake path, enables oil

pressure to build up more quickly and safely,

particularly during cold starts.

The oil pump is driven by the crankshaft by

means of a single chain.

A spring-loaded flat plate produces the

necessary tension.

A new feature of the oil pump is the chain

guard made from sheet steel. It encapsulates

both the chain wheel and the chain over a large

area.

This reliably prevents oil frothing and the

problems associated with this.

The oil pump ......

17

is a pressure relief valve. It is located inside the

oil pump housing and opens when the oil

pressure rises too high (cold start). If an

excessively high oil pressure builds up,

various component parts of the oil circuit (e.g.

oil filter, oil cooler) may be damaged. Also,

there is the possibility of the inlet and exhaust

valves opening or no longer closing, due to

“bulking“ of the hydraulic tappets. The knockon effect of this is that the engine can no

longer be started or cuts out.

The oil pressure limiting valve ......

regulates the engine oil pressure. It is

integrated in the oil pump housing. The oil

quantity “regulated“ by the oil pressure

control valve is fed to the suction side of the

oil pump.

This helps to optimise efficiency.

The oil pressure control valve ......

prevent the oil running out of the oil filter and

the cylinder heads and back into the oil sump

while the engine is stationary.

The oil retention valves ......

The “integrated oil supply“ ...

will also be adopted for all V6 5V naturally

aspirated engines.

Each camshaft bearing is supplied via a

drilling stemming from the cylinder head main

gallery.

The oil is fed along a bolt shaft in the bearing

cap to a transverse drilling.

A lubrication groove distributes the oil

throughout the camshaft bearing. It is no

longer necessary to run a pipe to the

individual bearing caps.

Advantages:

•

Fewer components

•

Quick and even oil supply

•

No additional installation work necessary

•

Lower cost

SSP 198/58

Cylinder head main gallery

Transverse drilling

prevent “flooding“ of the cylinder heads. At

high engine speeds, an excessively large

amount of oil enters the cylinder heads and

has to be returned to the oil sump via the oil

return drillings. The restrictors reduce the oil

flow and thereby ensure that return flow takes

place.

The restrictors ......

18

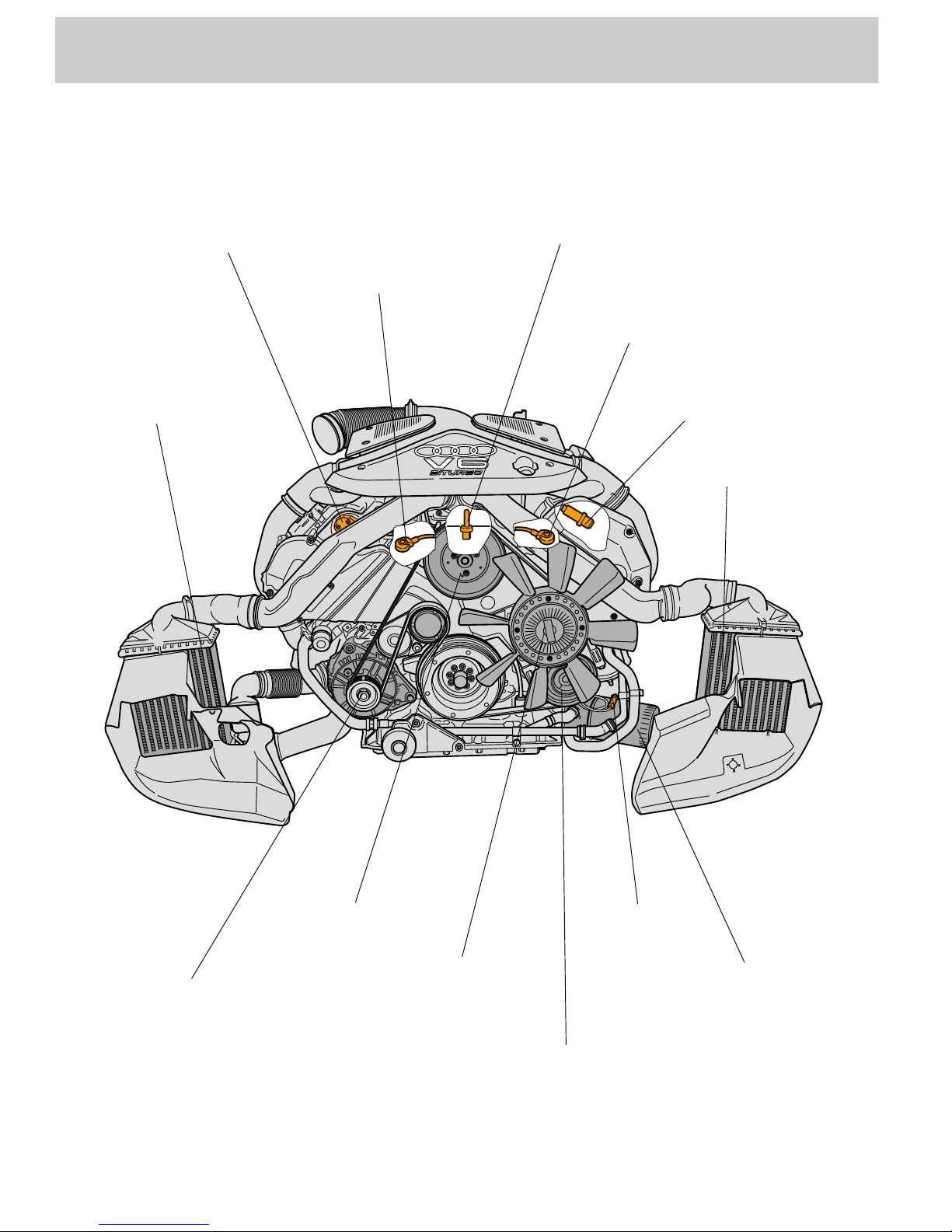

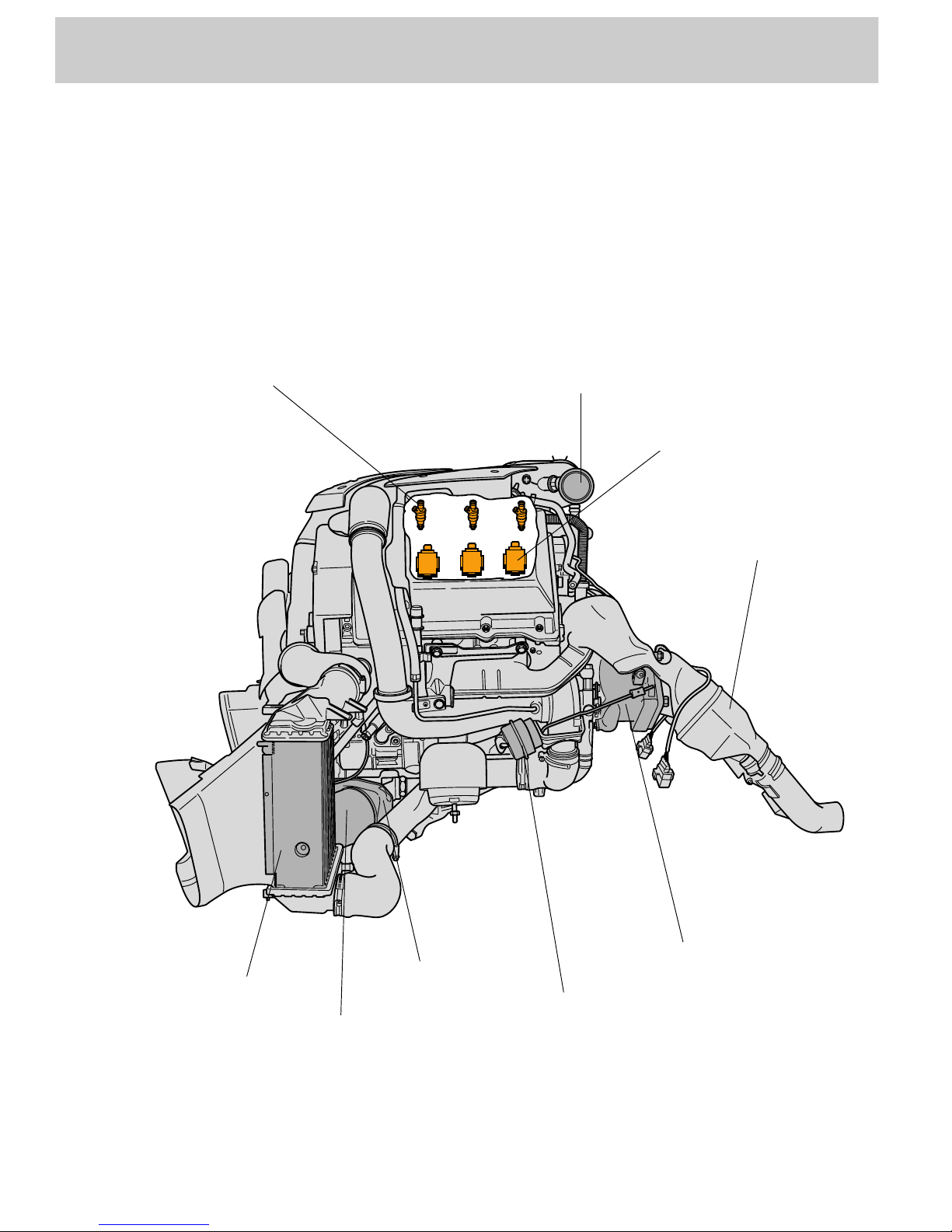

Front view of engine

SSP 198/51

Engine

Camshaft adjustment

valve N208

Knock sensor G66

Intake-air temperature

sender G42

Knock sensor G61

Hall sender G163

Charge air cooler

Charge air cooler

Oil filter

Oil pressure

switch

Air-cond. compressor

Visco fan

Alternator

Power assisted steering

pump drive

19

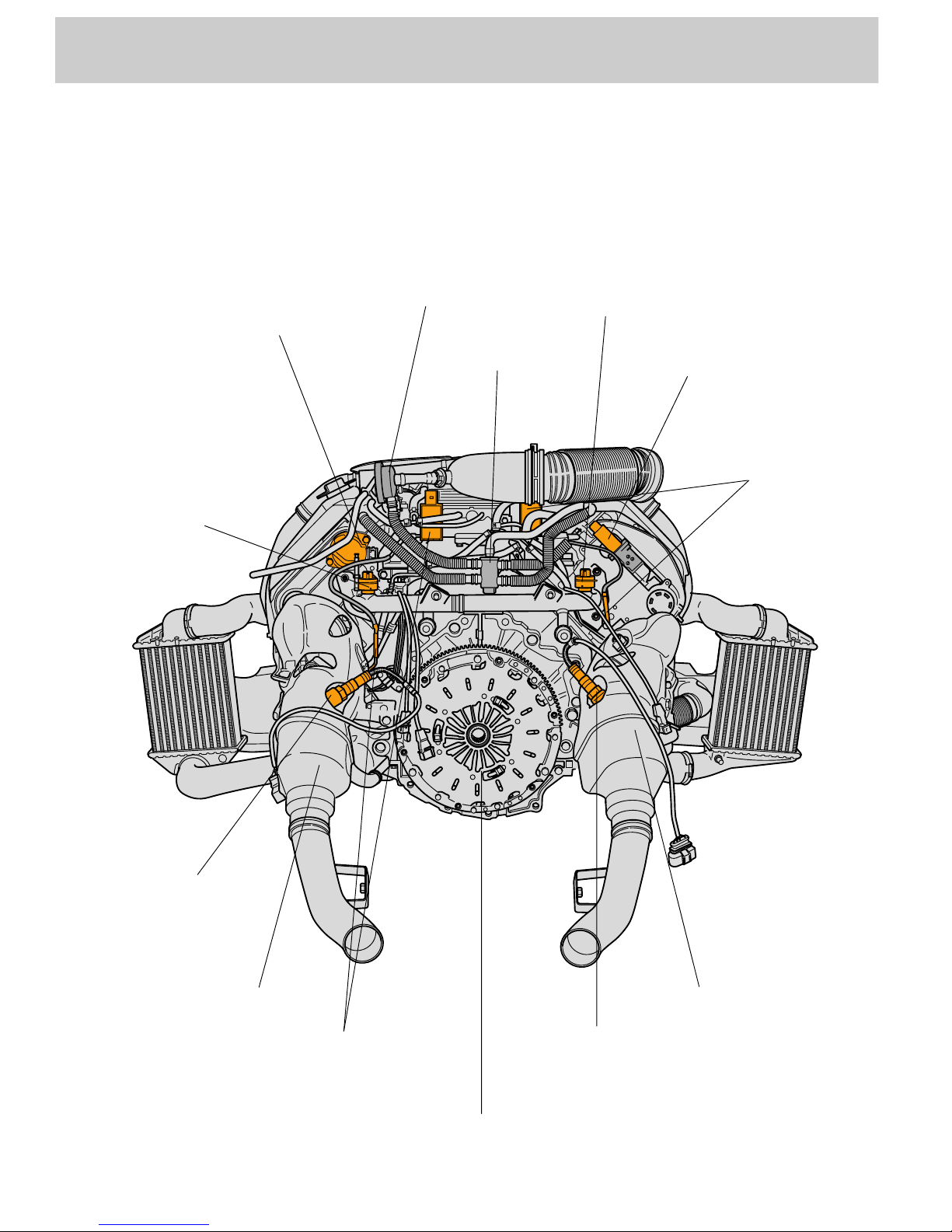

Rear view of engine

SSP 198/52

Hall sender G40

Thermoswitch for

continued cooling

function F95

Pressure limiting

valve

Distributor piece

Coolant temperature sender F18/F54

Camshaft adjustment

valve N205

Exhaust gas

temperature sender

G235 (with evaluation

electronics)

Lambda probe

G108

Exhaust gas temperature

sender G236 (with

evaluation electronics)

Lambda probe G39

SAC clutch pressure plate

Prim. catal. converter Prim. catal. converter

20

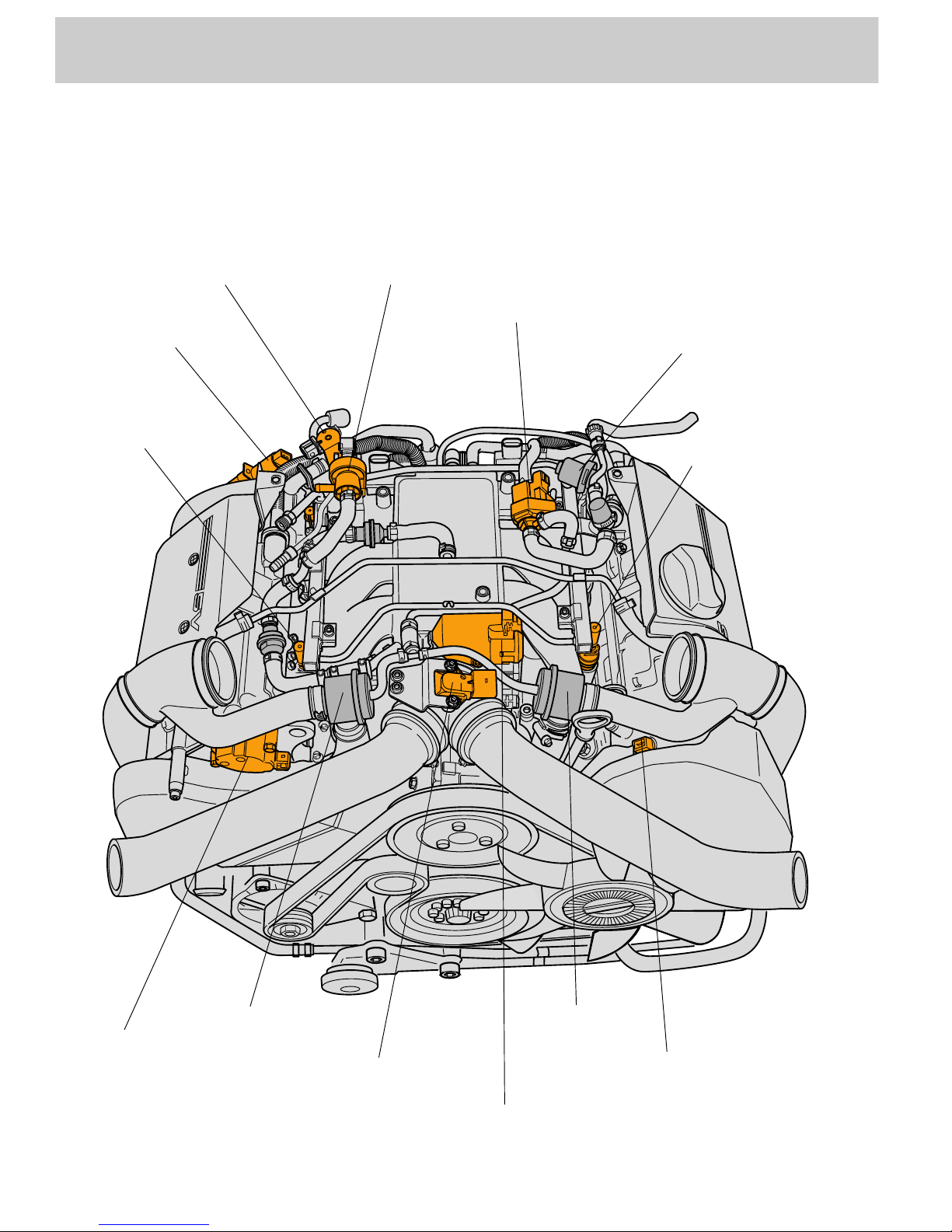

Engine

Top view of engine

SSP 198/54

Divert air valve for

turbocharger N249

Injector

Fuel pressure regulator

Solenoid valve for

activated charcoal

Solenoid valve for charge

pressure control N75

Camshaft

adjustment valve

N205

Injector

Hall sender G163

Divert air valve

Charge pressure

sender G31

Throttle valve

control part

Camshaft adjustment

valve N208

Divert air valve

21

View of engine from left

SSP 198/53

Injector

Individual ignition coil

Pressure control valve

Prim. catal. converter

Exh. gas turbocharger

Pressure unit for

wastegate flap

Oil cooler

Oil filter

Charge air cooler

22

SSP 198/04

Engine

Air ducting

Fresh air is induced by the combined air filter

and air mass meter and distributed to the two

exhaust gas turbochargers by the air

distributor.

The air distributor is made of plastic.

Advantage:

•

Lower weight

•

The intake air is heated to a lesser degree

by the engine

The air, which is compressed and thus heated

by the exhaust gas turbocharger, is fed to the

charge air coolers.

Cooling air intakes in the bumper and air vents

in the wheel housing liners ensure that a

sufficient amount of air flows through the

charge air coolers.

Advantage of charge air cooling:

•

Cooled air has a higher density, and this

means improved volumetric efficiency.

•

The lower temperature reduces knock

tendency also.

The compressed air streams then converge

upstream of the throttle valve control part and

distributed to the individual cylinders in the

intake manifold.

Exhaust gas turbocharger

Throttle valve control part

Charge air cooler

Air distributor

Air mass meter

Air filter

23

SSP 198/32

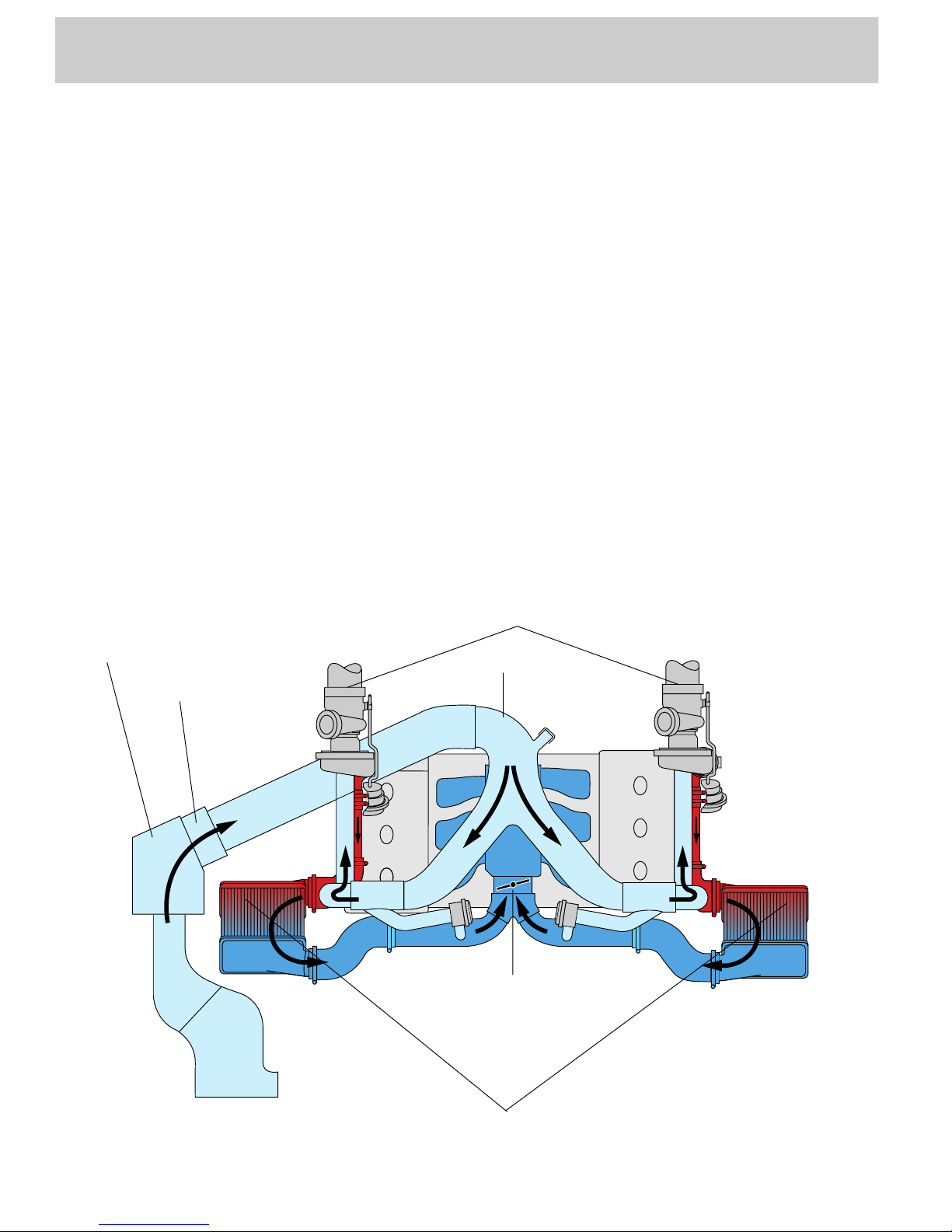

Charging

Two water-cooled exhaust gas turbochargers

with wastegate are used for charging.

The charge pressure of both exhaust gas

turbochargers is controlled via the common

charge pressure control valve N75.

Advantages of the biturbo technology:

•

The exhaust gas turbocharger is smaller,

which means better response due its

reduced mass.

•

Higher charge pressure at low engine

speeds.

•

The exhaust gas turbochargers are located

outside the V-angle due to the high

temperatures they reach. This advantage of

this arrangement is that the intake air is not

heated up additionally and the subassemblies are not subjected to so much

thermal stress.

•

Since the turbochargers are flanged

directly onto the exhaust manifold, the

exhaust gases travel less distance and

there is less temperature loss.

•

As a result, the catalytic converters are able

to heat up more quickly and the efficiency

of the exhaust gas turbocharger is

improved by the favourable air-flow.

Intake side of exhaust

gas turbocharger

Charge press. side

of exh. gas turbocharger

Exhaust manifold

to exhaust system

Pressure unit for actuating

wastegate flap

Control pressure from

solenoid valve for

charge pressure

control

The turbochargers must be replaced

in pairs

To maintain a synchronous air-flow

through the two chargers, it is

important to observe this instruction

to account for manufacturing

tolerances.

Service personnel are not permitted

to adjust the linkage to the wastegate

flap.

Turbine housing

Compressor housing

Loading...

Loading...