Service.

For internal use only

Pneumatic suspension system Part 2

4-level air suspension

in the Audi allroad quattro

Design and function

Self-study programme 243

243

2

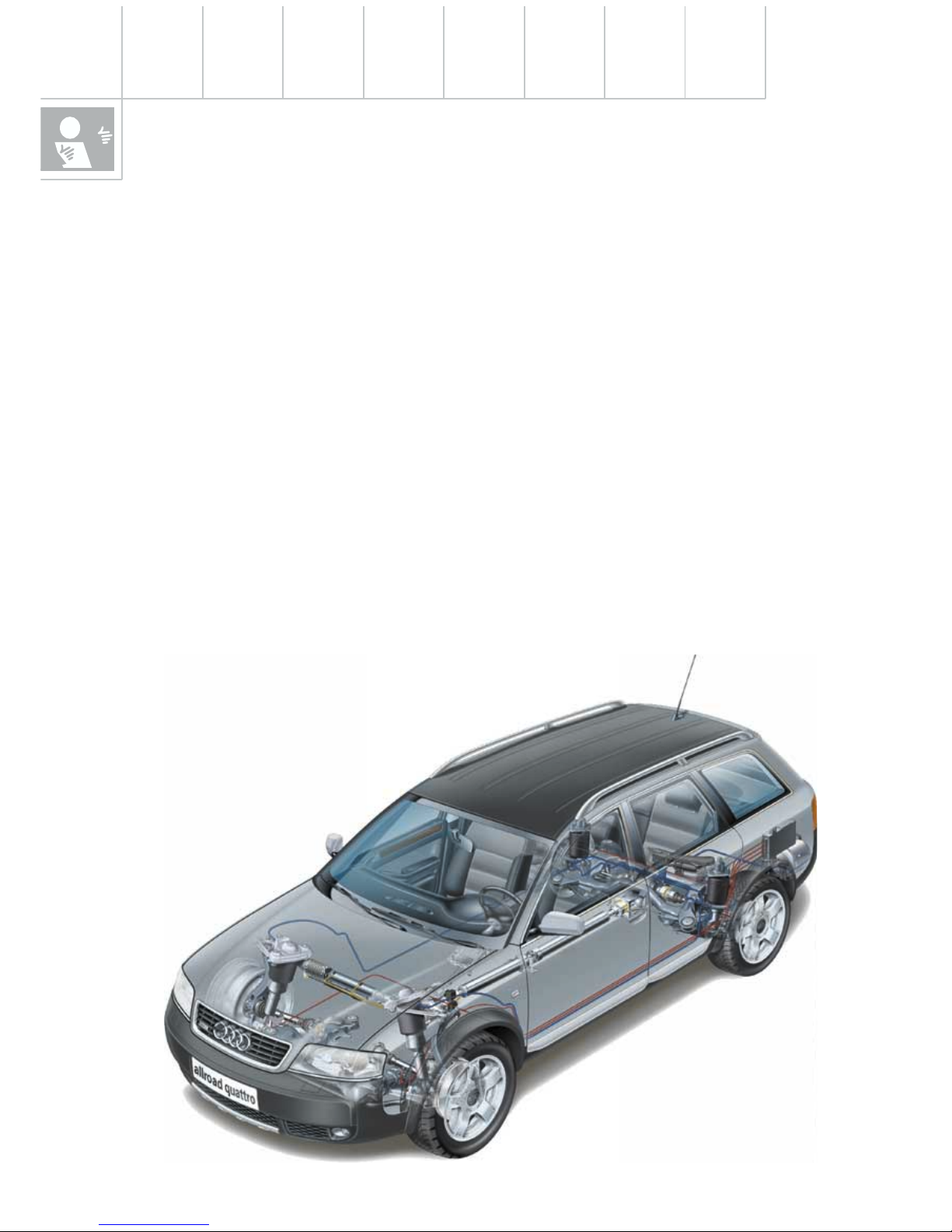

The 4-level air suspension system in the allroad quattro is a logical development of the selflevelling system in the Audi A6.

The principles of the suspension/air suspension system and the description of those system

components which are identical in the 4-level air suspension system are described in SSP 242.

The contents of this self-study program are supplementary to the contents of SSP 242.

The 4-level air suspension system in the Audi allroad quattro

Introduction

Designing a vehicle this perfect for on and

off-road use sounds like squaring the circle.

Usually the strengths of an off-road vehicle

are decided weaknesses when it comes to

road use.

A high ground clearance, crucial for rough

terrain, gives the vehicle a correspondingly

high centre of gravity.

243_001

243_002

243_003

When it comes to fast cornering, however,

this is as disadvantageous as it is for driving

stability at higher speeds. In addition, the air

resistance is increased, which significantly

affects fuel consumption.

In contrast, the shorter spring travel and the

firmer running gear matching of an “on-road

running gear” offer inadequate driving

comfort off-road.

A variable ground clearance is the solution for

all road use and it’s called

4-level air suspension .

The air suspension realised in the allroad

quattro is based on the familiar self-levelling

system of the Audi A6.

3

Contents

System description . . . . . . . . . . . . . . . . . . . . 4

The self-study programme is not intended as a workshop manual.

The self-study programme will provide you with information on

the design and functions of the different assemblies/systems.

New

Note

Important:

Note

Page

For maintenance and repairs please refer to the current technical

literature.

Operation and display

Operation ................................................................................. 7

Display ..................................................................................... 8

Self-levelling suspension control unit J197 ....................... 34

Modes .................................................................................... 35

Control concepts

Service

Special tools .......................................................................... 38

Basic system settings .......................................................... 39

Self-diagnosis ....................................................................... 40

General overview .................................................................. 41

Control strategies

System components

Air springs .............................................................................. 14

Air suspension ...................................................................... 17

Diagram of pneumatic system............................................. 20

Solenoid valves...................................................................... 21

Temperature sensor G290..................................................... 22

Pressure sensor G291............................................................ 22

Level senders G76, G77, G78, G289 ..................................... 23

Warning lamp K134 ............................................................... 27

Operating unit E281 .............................................................. 28

CAN information exchange ................................................. 29

Additional interfaces............................................................. 30

Function diagram ................................................................... 32

Interfaces

Control strategies, control unit 4Z7 907 553A ................... 10

Control strategies, control unit 4Z7 907 553B ................... 12

ESP safety switching ............................................................ 13

Order No.:

507.5320.01.00

This figure can be ordered as a size A0 poster through

Bertelsmann Distribution for a net price of DM

15.00 DM/7.50 EUR

.

Direct ordering through Bertelsmann only applies to Germany.

Dealers in export markets are requested to contact their importer.

4

Description of the system

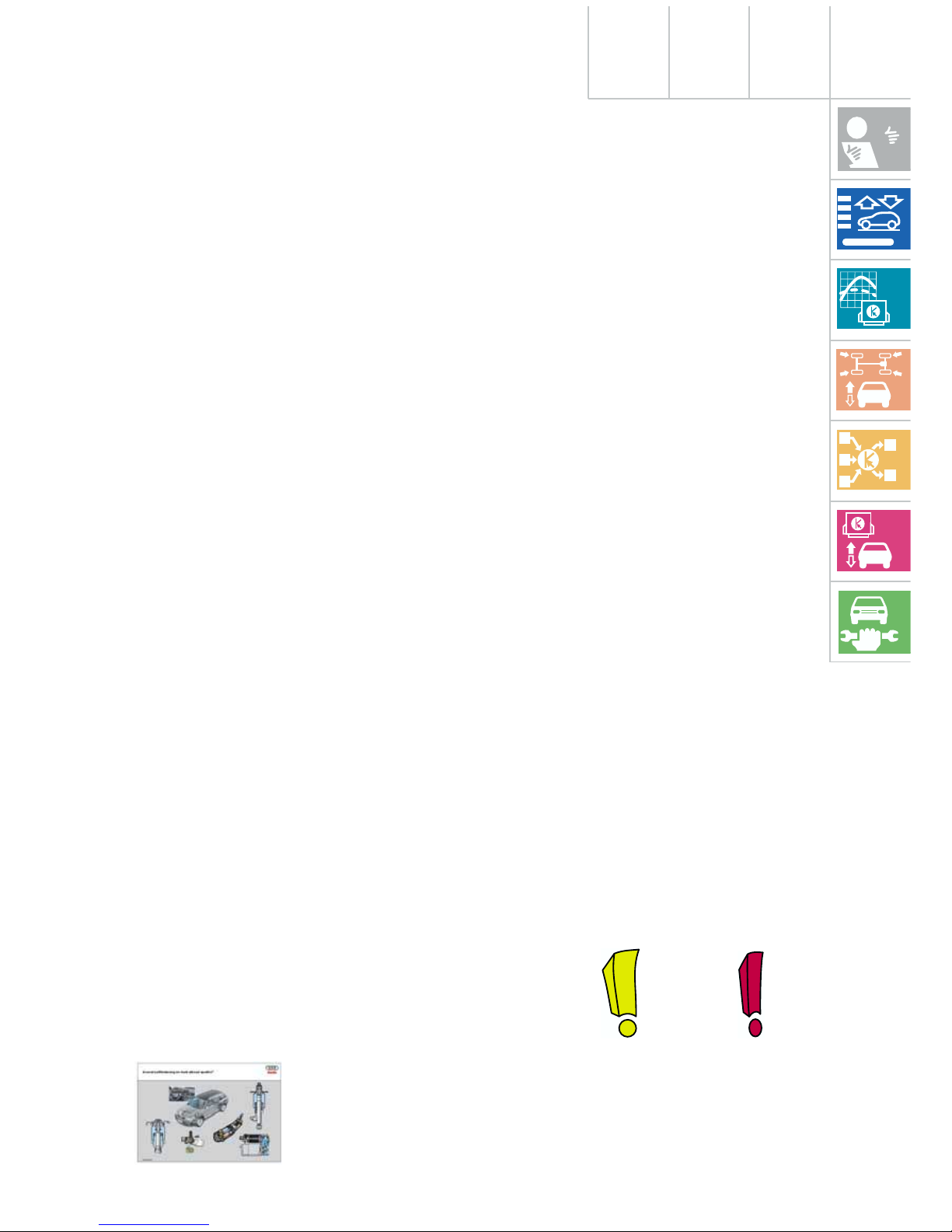

The vehicle level is determined separately at

each axle side by means of 4 level sensors.

Each air suspension strut is allocated a socalled air spring valve (transverse check valve)

so that each axle can be controlled

individually.

Front right air

suspension strut

Rear left suspension strut with load-

dependant damping.

Rear left vehicle

level sender

Control unit

Pressure accumulator

Operating unit

Rear left suspension strut

with load-dependant

damping.

Air supply unit with: Compressor

Discharge valve

Transverse check valves

Temperature sender

Pressure sender

Rear right vehicle

level sender

Electrical/pneumatic

lines

Front left air

suspension strut

Front left vehicle

level sender

Front right vehicle

level sender

The 4-level air suspension system is a fullysupporting level control system with

conventional shock absorbers at the front

axle and load dependent shock absorbers

(PDC dampers) on the rear axle.

243_021

5

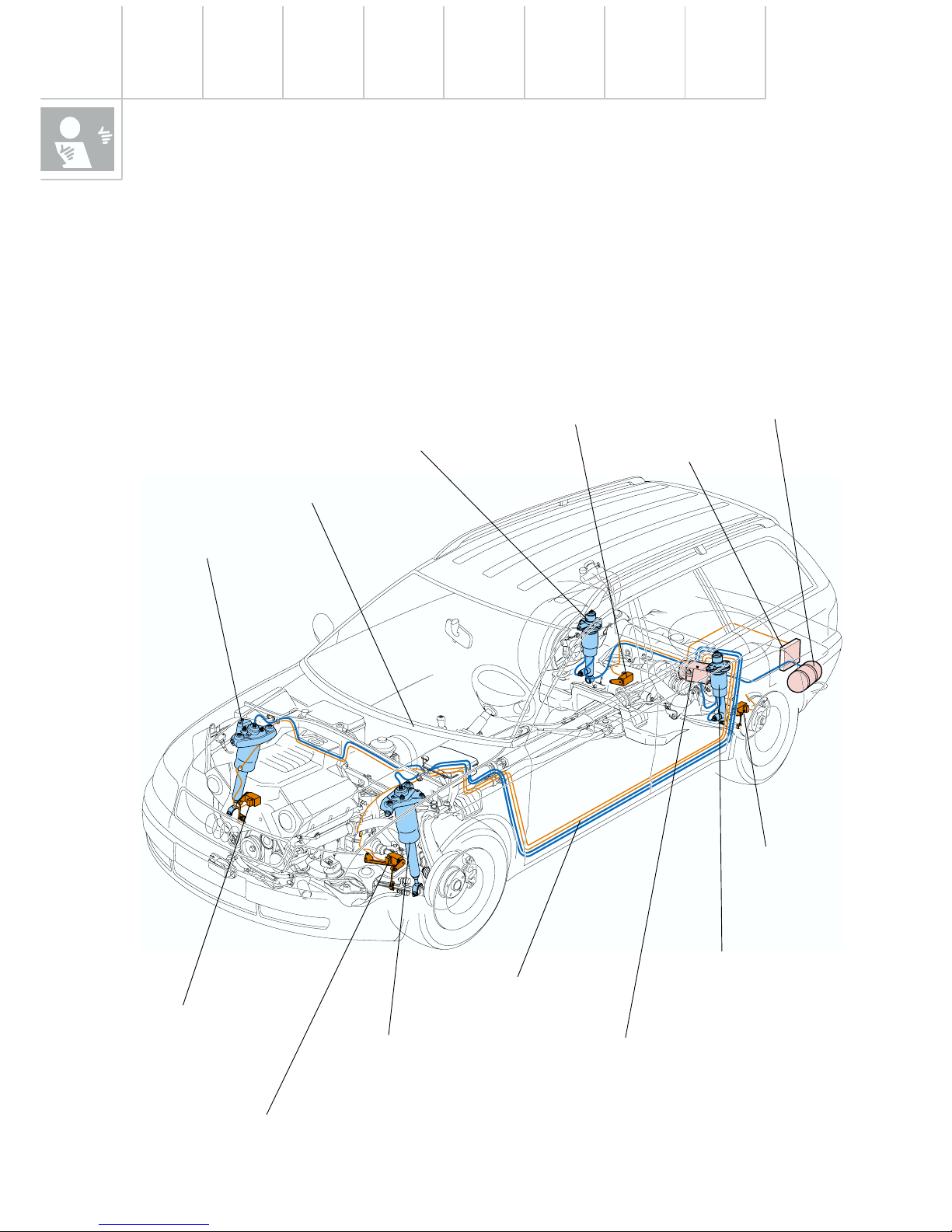

The 4-level air suspension system is designed

as what is known as a pressure accumulator

system.

The pressure accumulator system increases

system availability, reduces noise

development and protects the power supply.

One of the special features of the system is

the ability to alter the ground clearance by 66

mm in 4 stages. The 4 stages can be

controlled manually or automatically (see

page 7 onwards).

The levels are designated as follows:

Level 1 = low level ( LL)

Level 2 = normal level ( NL )

Level 3 = high level 1 ( HL1)

Level 4 = high level 2 ( HL2)

Parking level PL = high level 1

High level 2 (HL2)

+41 mm from normal

level

Ground clearance

208 mm

High level 1 (HL1)

+25 mm from normal

level

(=parking level)

Normal level (NL)

± 0 mm

Low level (TL)

-25 mm from normal

level

Ground clearance

192 mm

Ground clearance

167 mm

Ground clearance

142 mm

241_063

6

Description of the system

• The 4 level stages can be controlled

manually or automatically within defined

limits (see page 8 onwards).

• Individual automatic functions or the

entire system can be switched off via the

control system.

• LEDs in the operating unit indicate the

operating status and the control

procedures to the driver.

• Pressure accumulator system for

maximum comfort.

The newly developed fully-supporting air

suspension system on all four wheels was

designed specifically for the allroad quattro .

As well as the advantages of air suspensionbased self-levelling, as described for the A6

(see SSP 242), this system offers additional

benefits.

• The 4-level air suspension is a

sophisticated electronically controlled air

suspension system at both axles. The

system enables variation of the floor level

by 66 mm and offers four defined height

levels with between 142 and 208 mm

ground clearance.

• Depending on the driving conditions and

requirements you can select greater

ground clearance or a low vehicle centre

of gravity and a good c

w

value.

• The 4-level air suspension keeps the preset vehicle level constant, regardless of

load and weight distribution.

242_067

7

Operation and display

Operation

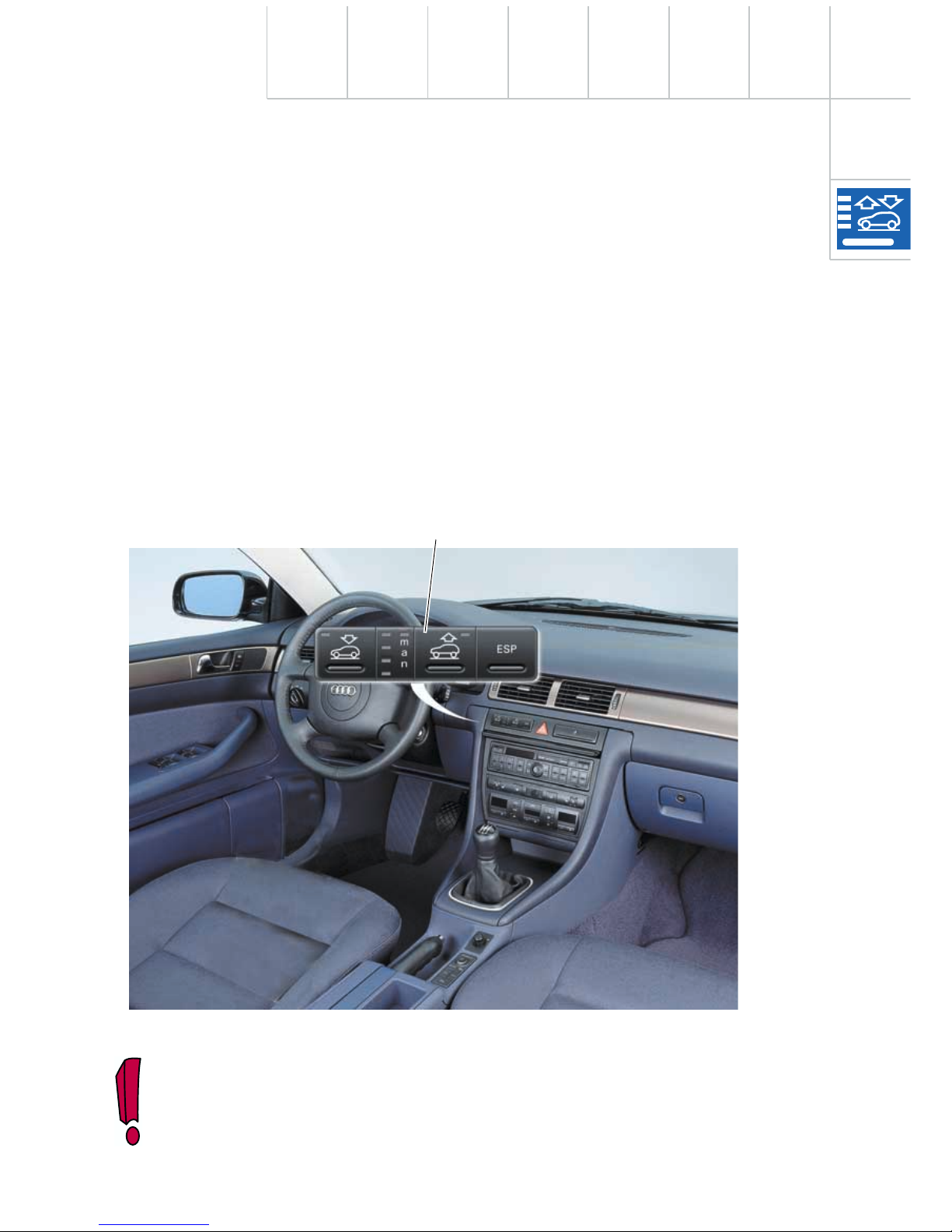

The self-levelling control unit E281 is used to

control the 4-level air suspension and the

display/monitor the system status.

Certain level changes occur automatically

during normal driving (see Control strategy).

Within defined conditions (see Control

strategy) the driver can use the “raise” or

“lower” buttons to select an appropriate level

at any time.

Pressing the “raise” button once selects the

next highest level. By pressing the button

repeatedly, it is possible to change, e.g.

directly from low level to high level 1. High

level 2 cannot be selected until high level 1

has already been set.

Changing to a lower level is performed in the

same manner as described above using the

“lower” button. By pressing several times (x3)

it is possible to shift directly from high level 2

to the low level.

Operating unit for self-levelling E281

241_062

It is possible to switch to a higher level

only when the engine is running or

when sufficient pressure is present in

the pressure accumulator.

It is possible to change to a lower level even

when the engine is switched off.

8

Operation and display

If the actual level deviates greatly from the

reference level, this is indicated to the driver

with flashing LEDs (according to a level

change).

Significant deviations are:

– at least one axle level is below the next

level down.

– both axle levels are above the next level up.

Display

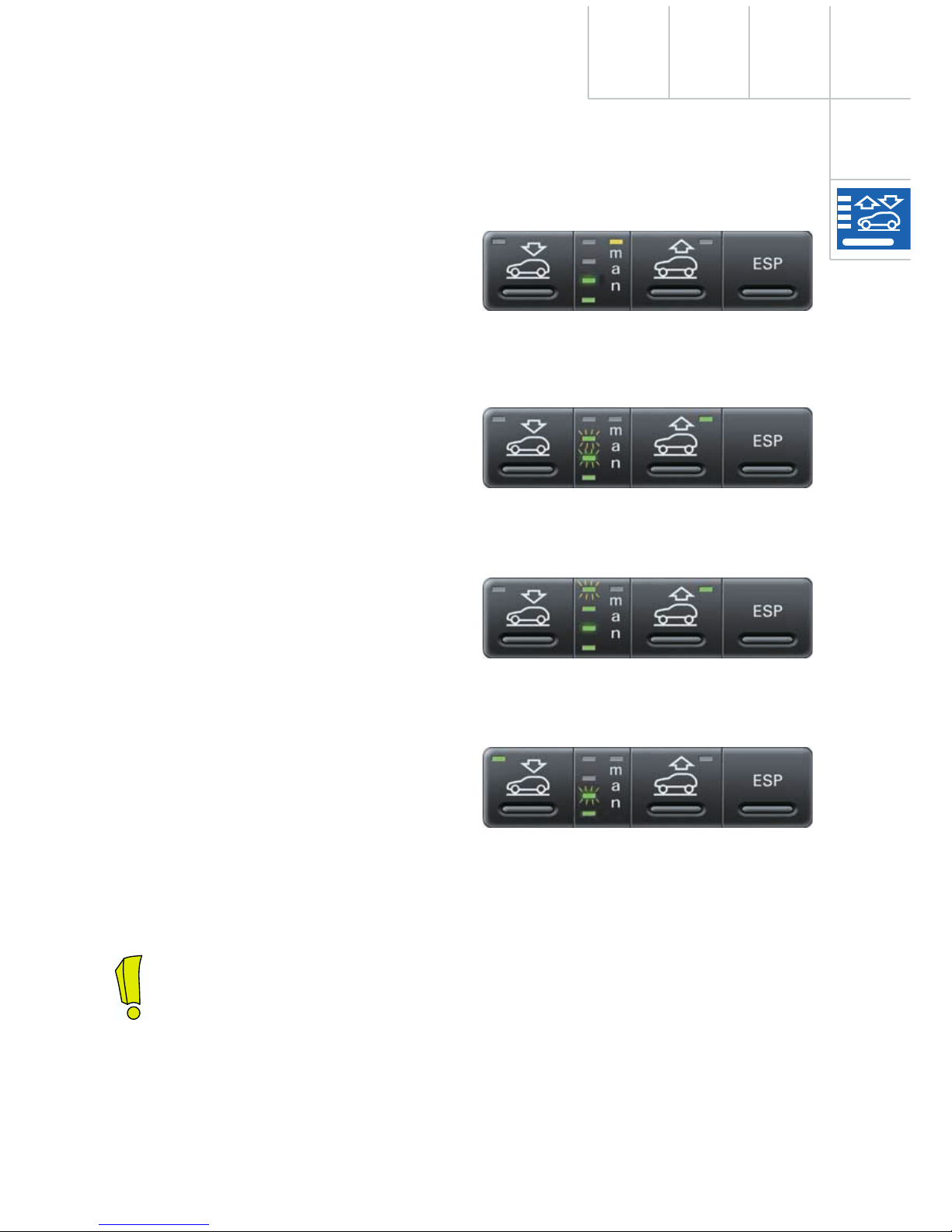

The four LEDs which are arranged one on top

of the other in the display zone illuminate

continuously to indicate the current level

status.

Only the control procedure which has been

triggered by a level change (whether

automatically or manually) is indicated by one

or several flashing LEDs. Once the target level

has been reached, the flashing changes to

continuous illumination.

The LEDs in the “raise” and “lower” buttons

indicate actuation and the control direction. If

the LED flashes, a level request has been

denied (e.g. if the driving speed is too high)

243_020

Lower button Raise button ESP button

Manual mode display

Display zone with 4 level-indicating LEDs

Actuation/control direction display Actuation/control direction display

9

243_022

243_023

243_024

243_025

Other button functions

Automatic switching

The so-called “manual mode” can be

switched on or off by pressing the “raise” or

“lower” button for at least 3 sec. The yellow

LED marked “man” indicates to the driver that

the vehicle is in manual mode.

The automatic “parking level control” and

“motorway mode” functions are deactivated

in manual mode.

Switching off control system

The control system is switched on or off by

pressing both level buttons for longer than

5 seconds.

When the control system is switched off, the

LEDs in the operating unit for manual mode,

both level buttons and the warning lamp K134

are illuminated.

The level-indicating LEDs show the level set.

The corresponding LED is continuously

illuminated.

A control system that has been switched off

will be automatically switched back on again

when the driving speed exceeds approx.

10 km/h (unless the lifting platform mode is

recognised).

The control system can also be switched off

using the diagnostic testers (see Workshop

Manual).

It is often advisable to switch off the

system during repair work (e.g. during

axle measurement or if the pressure

lines have been detached) in order to

prevent the compressor from running

unnecessarily.

Display example: Manual mode and NL

Display example: Raising from LL to HL1

Display example: Raising from HL1 to HL2

Display example: Lowering from NL to LL

10

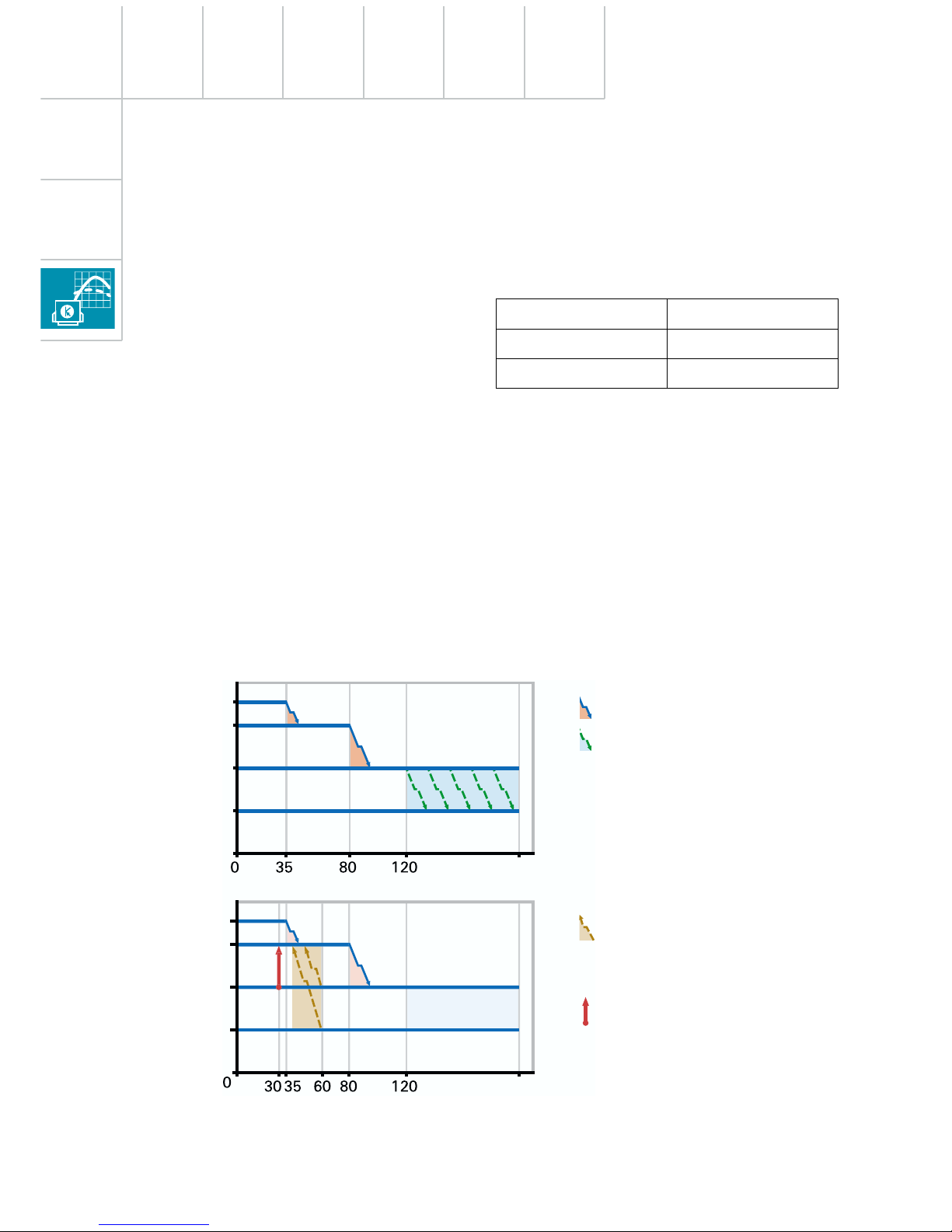

If the vehicle is at high level 2, it will lower

automatically to high level 1 at a speed of

> 35 km/h. The system will respond to a

request to shift to high level 2 only up to a

speed of < 30 km/h.

At a speed of > 80 km/h in high level 1, the

system will automatically lower the vehicle to

normal level.. The system will respond to a

(manual) request to shift to high level 1 only

up to a speed of < 75 km/h.

During driving operation, no automatic

raising to high level 1 or 2 is performed. It

must be selected manually by the driver.

The parking level is an exception. In this

mode the vehicle automatically rises to high

level 1 once it has been parked and locked

(see parking level control).

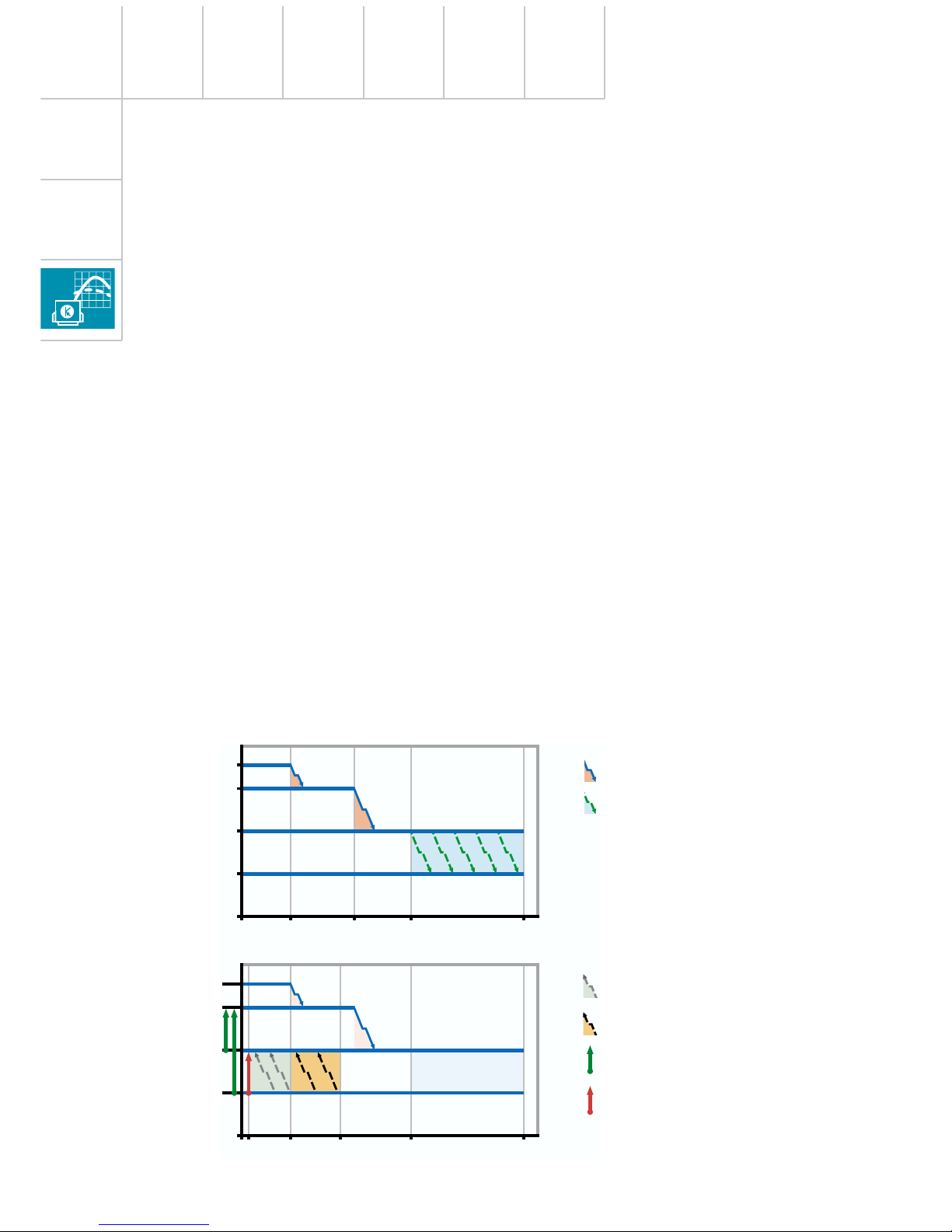

There are two control units currently in use,

depending on the country.

The control strategies described below relate

to the control unit 4Z7 907 553A.

The differences in control units with part

numbers 4Z7 907 553B are described

subsequently.

See also page 34, “Self-levelling control unit

J197”.

Control strategies

4Z7 907 553A

Automatic lowering

As mentioned previously, the driver can select

the appropriate level by actuating the “raise”

or “lower” buttons.

The following preconditions relating to

driving speed apply for high level 1 and high

level 2.

Control strategies

0 35 80 120

0

5 35 70 120

Automatic lowering

Lowering processes

after 30 seconds

after 30 seconds

Raising processes

after 120 seconds

Raising to parking level

Immediate raising

Speed km/h

Speed km/h

243_026

LL

NL

HL1

HL2

LL

NL

HL1

HL2

11

Motorway mode

If the vehicle travels for longer than

30 seconds at over 120 km/h (vehicle is

already at normal level), it will automatically

be lowered to low level.

This reduces air resistance (saves fuel) and

lowers the vehicle’s centre of gravity

(improved driving dynamics).

PL (=HL1) is only cancelled when a

driving speed of 80 km/h is exceeded

(see automatic lowering) or when

switching to a lower level manually.

If the vehicle is already in HL2 it is not

lowered to parking level.

Manual mode

The motorway mode and parking level

control functions are deactivated in

manual mode (see Automatic

switching page 9).

The vehicle rises automatically to normal level

at the following speeds and time thresholds:

Vehicle speed Time

<70 km/h >120 seconds

<35 km/h >30 seconds

<5 km/h immediately

Parking level control

The parking level ensures that the vehicle is

maintained at a suitable level after parking for

a long period of time (normal volumetric

reduction due to cooling or diffusion).

It also facilitates entering and loading the

vehicle and optimises the appearance of the

stationary vehicle.

The parking level corresponds to high level 1

(HL1).

The vehicle is set to parking level

– when the system is in run-on mode and the

vehicle is locked from the outside.

– when sufficient pressure is present in pres-

sure accumulator.

– when the system is not switched to manual

mode.

12

Control strategies

The vehicle rises automatically to high level 1

at the following speeds and time thresholds:

If the system has lowered the vehicle to low

level (motorway mode), it will automatically

raise it to high level 1 when its speed drops

below 60 km/h for longer than 30 seconds.

Vehicle speed Time

<60 km/h >30 seconds

<30 km/h immediately

Control unit strategies

4Z7 907 553B

Variations to the description of control unit

4Z7 907 553A are outlined below:

• No parking level control

• Automatic raising to high level 1

Preconditions for automatic raising to high

level 1:

• The system must not be switched to

manual mode.

• Between ignition ON and OFF, the driver

must select high level 1 or high level 2

once.

243_019

Automatic lowering

Lowering processes

after 30 seconds

Automatic raising to HL1 after

30 seconds

Raising processes

Immediate raising

Speed km/h

Speed km/h

LL

NL

HL1

HL2

LL

NL

HL1

HL2

13

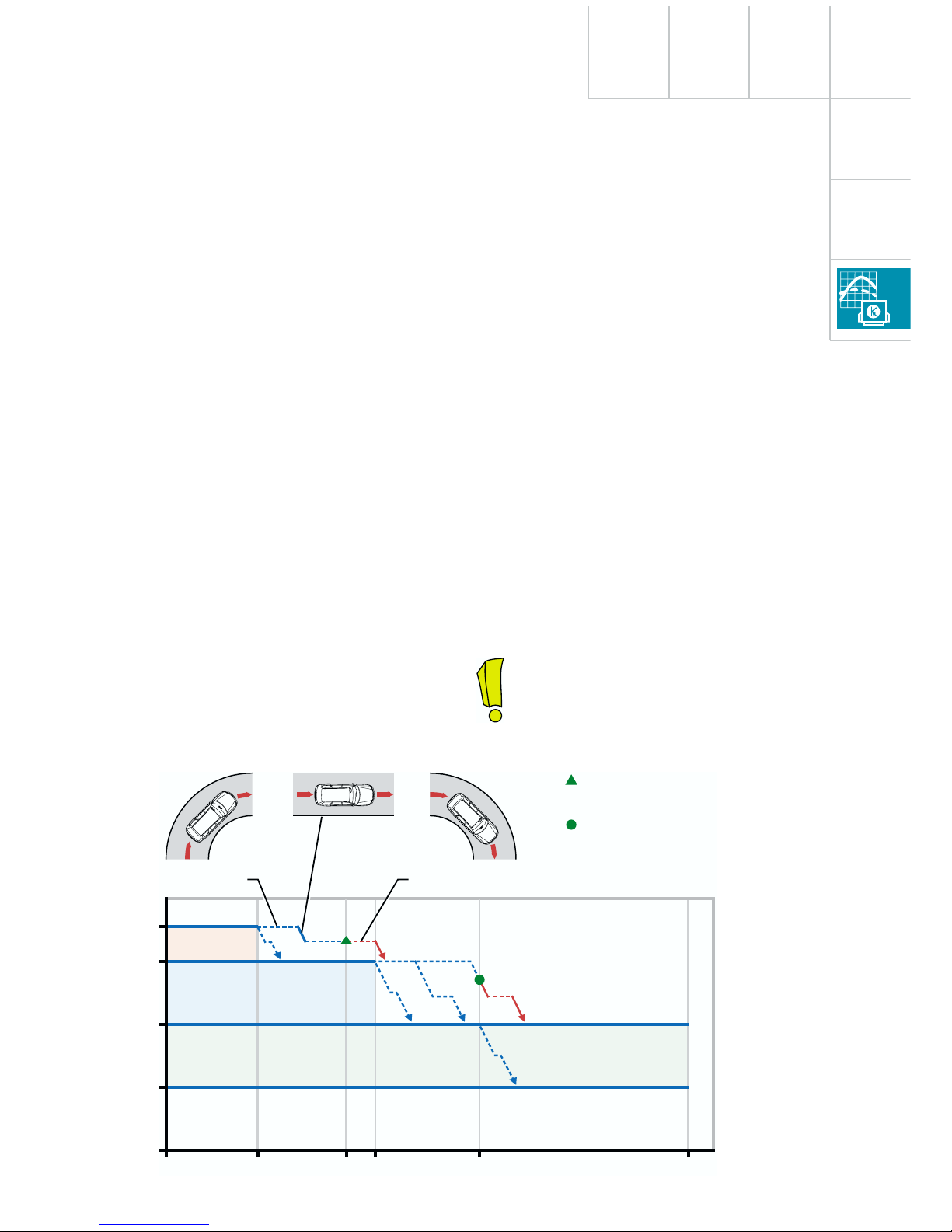

If, for example, the vehicle is at high level 2

with active ESP influences and the driver

accelerates sharply on a very winding route,

speeds of > 35 km can be achieved in high

level 2. In order to guarantee maximum safety

in such driving conditions, ESP influences are

automatically deactivated at a speed of

> 70 km/h, despite the high centre of gravity

of the vehicle (ESP-safety switching).

Normal ESP functions are available again and

the ESP warning lamp extinguishes.

This ESP safety switching takes place as of

70 km/h at high level 2 and as of 120 km/h at

high level 1.

There is no ESP safety switching at normal

level or low level.

ESP safety switching

For technical reasons it is not possible to

change levels/self-level during cornering. If

cornering is recognised, no control functions

are performed and control functions already

running are interrupted. The target level

remains stored and is reset when straightahead driving is recognised.

In the Audi allroad quattro it is possible to

influence certain ESP functions using the ESP

button.

You can find further information about this in

SSP 241, from page 67 onwards.

If ESP influences have been activated (via ESP

button, ESP warning lamp illuminated), the

transverse dynamics control (anti skid

function) is passive (not during braking).

0 35 80 12070

ESP switching at high level 2

No self-levelling while

cornering

ESP switching at high level 1

Speed km/h

No self-levelling while

cornering

243_027

Cornering is detected by the J197 selflevelling control unit by evaluation of

the signals from the four level sensors.

LL

NL

HL1

HL2

14

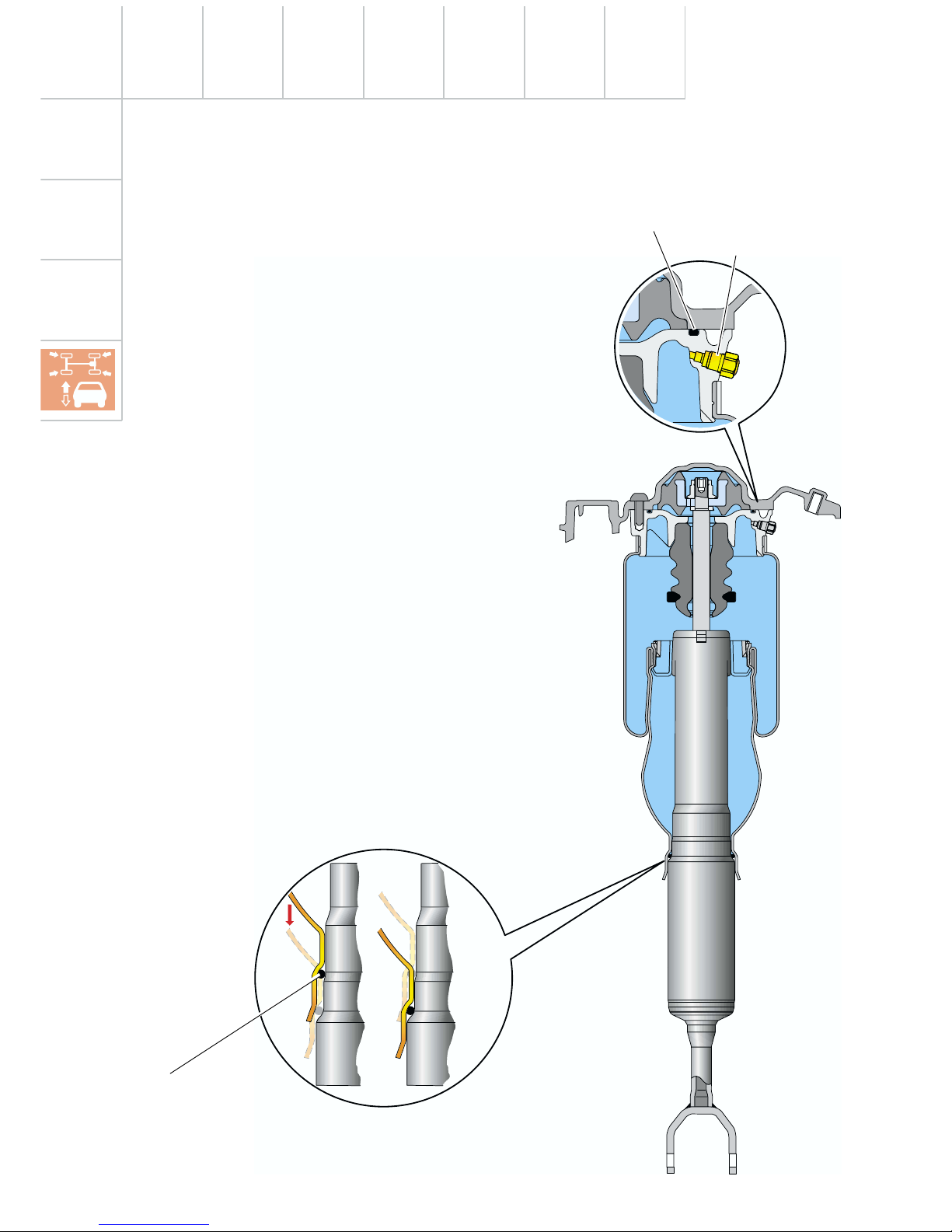

The air springs

The front air spring is a new design.

As on the rear axle, the air springs are combined

coaxially with the dampers as a suspension strut.

The rear air springs are identical in design and

function to those of the Audi A6 with self-levelling.

Design

While in the case of the rear suspension strut, the

connection/seal from the air spring (piston) to the

damper is made via a double-seal bayonet

connection, on the front suspension strut it takes the

form of a single-seal N17 connector.

The differences in design require a different

assembly.

Front suspension strut

The assembly of the front air spring with the damper

is carried out without lubrication. The N17 connector

and the O ring must be absolutely dry and free from

grease.

Before assembly of the air spring, the O-ring

is placed onto the second shoulder of the damper,

ensuring an even perimeter. The air spring (piston) is

positioned onto the damper and pushed together

with adequate force. The O-ring is forced onto

shoulder 3 by the movement of the piston, where it

supports and seals the air spring.

System components

243_004

Installation

O-ring

O-ring

Air connection

15

Rear suspension strut

The bayonet connection must be absolutely

clean and is greased with a special lubricant

before installation (see Workshop Manual).

For installation, the air spring is pushed on

and then turned.

Operating pressure of the air springs

front rear

Minimum

operating

pressure

6.0 bar 6.1 bar

Nominal

operating

pressure

6.4 bar 8.5 bar

Maximum

operating

pressure

9.0 bar 10.9 bar

Always check for leaks on the O-ring

seals at the raised areas. The sealing

surfaces must be clean, free from

corrosion and pitting (aluminium parts)

and greased as required (see Workshop

Manual).

Design and function of the rear air

springs, see SSP 242, from page 40

onwards.

Full description of the PDC damper, see

SSP 242, from page 33 onwards.

243_005

O-ring

Locking cap

16

System components

243_006

243_007

Wrong

Correct

Air springs must not be moved when

pressureless because the air bellows

cannot unroll on the piston and would

be damaged.

In a vehicle with depressurised air

springs, the relevant air springs must

be filled with the aid of the diagnostic

tester (see Workshop Manual) before

raising or lowering the vehicle (e.g. on a

vehicle lifting platform or vehicle jack).

Warning:

The piston must not be touched during

installation or transport of the

complete suspension strut assembly as

the piston can be easily pushed back

when unpressurised.

If the sealing ring is pushed out of

position (by the air spring pressure) the

air spring will not be sealed correctly.

17

Air supply

The compressor

The construction and function of the

compressor corresponds largely to the unit

described in the self-levelling suspension of

the A6. The following is a description only of

the differences in the 4-level air suspension

system in the Audi allroad quattro

• The fitting location is outside the vehicle

and without noise insulation (in front of

spare wheel well).

• The operating pressure is increased to

16 bar owing to the pressure accumulator

system.

243_028

• Lower speed for reduced noise.

• Suction and discharge of the air is

performed from the spare wheel well via

an air filter/noise damper (passenger

compartment).

• An additional noise damper in the suction/

discharge line ensures minimal through-

flow noise, particularly during discharge.

• Temperature monitoring is performed via

a temperature sensor at the cylinder head

and a simulation formula in the control

unit (temperature model) (more

information, see Temperature sensor

G290).

Compressor

Valve unit with

pressure sensor G291

Pneumatic discharge valve

Discharge valve N11

Air dryer

Temperature sensor G290

Additional noise damper

To the air filter/noise damper

Electric motor

Pressure pipe

Suction/discharge line

Electrical connector

Compressor drive

18

System components

A special mounting consisting of spiral

springs and rubber damping elements

prevents the transfer of vibrations to the

bodywork.

You can find a description of the design and

function of the compressor as well as the

filling and discharging procedure in SSP 242.

243_008

In normal operation the compressor is

allowed to run only when the engine is

running.

Exceptions:

– Final control diagnosis

– Basic system setting

– In pre-run upon recognition of an

extremely low level

Mounting

243_009

Spiral spring

Damping element

Air filter/noise damper

Owing to the fitting location of the air filter/

noise damper in the spare wheel well, it

requires no maintenance.

19

Pressure accumulator

The pressure accumulator allows the vehicle

level to be raised more rapidly with minimal

noise as the pressure accumulator is only

filled while the vehicle is in driving operation

and the compressor noise is less noticeable

(see air supply strategy).

Provided that there is sufficient pressure in

the pressure accumulator, vehicle level

raising can be performed without the

compressor.

Sufficient pressure means that before the

vehicle is raised there must be a pressure

difference of at least 3 bar between the

pressure accumulator and the air springs.

The pressure accumulator is made of

aluminium and has a storage volume of

approx. 6.5 l. The maximum operating

pressure is approx. 16 bar.

243_029

Air supply strategy

At driving speeds of < 36 km/h air supply is

effected primarily by the pressure

accumulator (provided sufficient pressure is

available).

The pressure accumulator is only filled when

driving at speeds of 36 km/h and above.

At a driving speed of > 36 km/h the air supply

is primarily from the compressor.

This supply strategy ensures virtually

noiseless system operation and reduces the

current consumption.

Pressure accumulator

Pressure connector

20

System components

p

Pneumatic diagram

1 Additional noise damper

2 Non-return valve 1

3 Air dryer

4 Non-return valve 3

5 Non-return valve 2

6 Discharge throttle

7 Pneumatic discharge valve

8 Compressor V66

9 Electric discharge valve N111

10 Pressure sensor G291

243_030

1

2

3

4

6

5

7

9

10

11 12 13 14 15

16

17 18 19 20

11 Valve for pressure accumulator N311

12 Valve for FL suspension strut N148

13 Valve for FR suspension strut N149

14 Valve for RL suspension strut N150

15 Valve for RR suspension strut N151

16 Pressure accumulator

17 Front left air spring

18 Front right air spring

19 Rear left air spring

20 Rear right air spring

from the compressor

relay

from control unit

to the

control unit

from the

control unit

8

21

The 4 air spring valves N148, N149, N150,

N151 and accumulator valve N311 are

combined in one valve unit. They are

designed as 2/2 way valves and are closed

without current. The pressure on the air

spring side/accumulator side acts in the

closing direction.

The pressure lines are colour coded to

prevent confusion when connecting.

The colour allocation on the valve block is

echoed by corresponding coloured dots on

the connectors.

Solenoid valves

The 4-level air suspension has 6 electric

solenoid valves.

Discharge valve N111 forms a functional unit

together with the pneumatic discharge valve

and is integrated into the dryer housing (see

page 17).

Discharge valve N111 is a 3/2 way valve and is

closed without current.

The pneumatic discharge valve acts as a

pressure limiter and residual pressure

retaining device.

243_010

Valve unit with

N148, N149, N150, N151

and N311

Compressor

pressure connector

Front left Pressure accumulator

Rear right

Rear left

Front right

22

p

Temperature sensor G290

(Overheat protection)

To enhance system availability, temperature

sensor G290 is attached to the cylinder head

of the compressor.

A temperature model is implemented in

control unit J197 which prevents overheating

of the compressor while simultaneously

utilising the maximum possible raising times.

For this purpose, the control unit calculates a

maximum permissible compressor

temperature based on the compressor

running time and the temperature signal, and

deactivates the compressor or prevents

activation when defined limit values are

exceeded.

System components

Pressure sensor G291

Pressure sensor G291 is integrated into the

valve unit and is used to monitor the pressure

in the pressure accumulator and the air

springs. The information regarding

accumulator pressure is required for checking

the plausibility of the raising functions (see

Pressure accumulator/control strategies,

Page 19) and for self-diagnosis. The individual

pressures of the air springs and pressure

accumulator can be determined by means of

appropriate control of the solenoid valves.

The measurement of individual pressures is

performed during discharging or filling of the

air springs/pressure accumulator. The

pressures determined in this manner are

stored and updated by the control unit.

The accumulator pressure is additionally

determined every 6 minutes (updated) while

the vehicle is in driving operation.

The G291 transmits a voltage signal

proportional to the pressure.

243_011

243_012

Temperature sensor G290

Pressure sensor G291

Valve unit

23

Vehicle level senders G76,

G77, G78, G289 (level

sensors)

The level sensors are so-called angle sensors.

With the aid of the connecting link kinematics

unit, the height changes of the vehicle body

are converted into angle changes.

The angle sensor used in the Audi allroad

quattro is a contact-free sensor which

operates according to the induction principle.

A special feature of the level sensor used is

that it produces two different output signals

proportional to the angle. This allows it to be

used for both 4-level suspension and for

headlamp range control (see pin-assignment

table).

243_031

243_032

One signal output provides a voltage

proportional to the angle (for headlamp range

control) and a second signal output provides

and PWM signal proportional to the angle (for

4-level air suspension).

Level sensor on the front axle

Level sensor installation position

The 4 level sensors are identical in

design, only the brackets and

connecting link kinematics unit vary

according to the side and axle.

The sender arm deflection and thus the

output signal are opposite on the right

and left sides.

For instance, the output during

compression increases on one side and

decreases on the other.

24

System components

243_033

243_037

For technical reasons, the voltage for the lefthand level sensors (front left G78 and rear left

G76) is supplied by the headlamp range

control unit J431. Power is supplied to the

right-hand level sensors (front right G289 and

rear right G77) by the 4-level air suspension

control unit J197.

This ensures that if control unit J197 fails, the

headlamp range control system can continue

to operate (see also Self-levelling control unit

page 34)

Level sensor on rear axle

Level sensor installation

position

Pin assignment for the level sensor

J431 Control unit for

HeadampRangeControl

J197 Self-levelling suspension control unit

Pin

1 Earth

(left from J431, right from J197)

2 Vacant

3 Vacant

4 Analogue signal output,

Voltage signal

(left only for HRC)

5 5 Volt power supply

(left from J431, right from J197)

6 Digital signal output,

PWM signal

(right and left for J197)

25

The rotor consists of a closed conductor loop

connected to the sender arm (rotates with the

sender arm). The conductor loop has the

same geometric shape as the receiver coils.

Construction/design

The angle sensor consists essentially of the

stator and the rotor.

The stator consists of a multilayer circuit

board comprising the exciter coil, three

receiver coils and the control/evaluation

electronics. The three receiver coils have an

angular geometrical star shape and are

arranged out of phase. The exciter coil is

mounted on the back of the circuit board.

243_035

Operating lever

Conductor loop/rotor

Front of multilayer circuit board

with view of the receiver coils

Circuit board

connectors

Rear of multilayer circuit board

with view of the exciter coil

Control/evaluation

electronics

26

System components

Function

The exciter coil is subjected to an alternating

current which produces an electromagnetic

alternating field, the induction of which is

penetrated by the rotor.

The current induced in the rotor produces a

second electromagnetic alternating field

around the conductor loop (rotor).

Both alternating fields, from the exciter coil

and from the rotor, act on the receiver coils

and induce corresponding alternating

currents in them.

While the induction of the rotor is

independent of its angle position, induction

of the receiver coils depends on their

distance from the rotor and thereby on its

angle position.

As the rotor, depending on its angle position,

overlaps differently with regard to each

receiver coil, their voltage amplitudes vary in

accordance with the angle position of the

rotor.

The evaluation electronics compensate the

alternating currents of the receiver coils,

amplify them and produce proportional

output voltages for the three receiver coils

(proportional measurement). After voltage

evaluation, the result is converted into output

signals for the level sensors and transmitted

to the control units for further processing.

0

0

0

243_036

243_037

Exciter coil

Stator

Rotor

3 receiver coils

Conductor loop

(induced current)

U

1

U

2

U

3

Voltage amplitudes depending on the position of

the rotor with regard to the receiver coil

(example of a rotor position)

U

1

U

2

U

3

Time

Time

Time

1st magnetic

field at the

exciter coil

2nd magnetic

field in the

conductor loop

27

Warning lamp K134...

... illuminates for one second when

terminal 15 is ON (self-test).

... is constantly illuminated in the

case of relevant system errors or

when the system is switched off.

... is constantly illuminated during

basic system setting and when

basic system setting has not been

performed successfully.

... flashes in the case of extremely

low or high levels.

... flashes during final control

diagnosis.

242_050

Warning lamp K134

As no magnetic materials are required,

temperature and age cause only minimal

variances in the measured values. Such

variances are caused by a reduction in the

strength of the magnetic field of permanent

magnets over time or due to temperature

changes.

Level sensors, summary

The advantages of the angle sensor are the

proportional measurement process along

with their contact-free and therefore wearfree operation.

The generation of ratios (proportional

measurement) means that the output signal

proportional to the angle is largely

independent of mechanical tolerances such

as distance changes, axle movement or

inclination errors. Magnetic interference is

also largely suppressed due to the generation

of ratios.

28

F

F

F

F

F

S

F

S

S

F

3

1

7

5

2/25

2/50

2/49

2/05

2/04

2/01

2/02

9

10

4

8

System components

Control unit J197 transmits the information

concerning the vehicle level and the system

status back to the E281 via the K wire,

whereupon the electronic unit actuates the

relevant LEDs.

For self-diagnosis reasons, the “raise” button

is designed as a redundant additional

interface.

Operating unit for selflevelling E281

The operation and displays of the operating

unit are described on page 7. In this section,

the function of the operating unit will be

described.

The interface to control unit J197 is

performed by means of a data

communication wire (K wire)

An electronic unit integrated into the

operating unit evaluates the signals from the

level button and transmits these as a

corresponding data protocol via the K wire

to control unit J197.

243_013

The K wire between E281 and J197

bears no relation to the self-diagnostic

K wire between J197 and the

diagnostic testers.

Electronic unit

Control unit J197

Terminal 30Terminal 15

Raise button

K wire

Operating unit E281

Terminal 58s

Terminal

58d

to the ESP control unit

from the ESP control unit

HL2

HL1

NL

LL

man

High

Low

Lower button

ESP button

F = LEDs for functional illumination

S = LEDs for switch illumination

29

CAN information exchange

In the case 4-level air suspension, the

information exchange between control unit

J197 for the self-levelling system and the

networked control units is performed via the

CAN drive with the exception of a few

interfaces.

Interfaces

The system overview shows the information

provided by the gearbox control unit via the

CAN bus which is received and used by the

networked control units.

Information sent by the J197

control unit.

Information received and

evaluated by the J197 control

unit.

Engine control unit:

Engine speed

Self-levelling suspension control

unit J197

System status (OK or not OK)

Warning lamp (on/off)

Self-diagnosis

Fault memory entry

Type of vehicle (e.g. allroad

quattro):

Level status

Intermediate level

Parking level

Impending adjustment

Adjustment active

Raising level

Lowering level

Switching to FR

Switching to FL

Switching to RR

Switching to RL

ESP influence

CAN drive high

CAN drive low

ESP control unit:

Driving speed

ESP status

For detailed information on the CAN

bus, please refer to SSPs 186 and 213.

30

The driving speed signal …

... is a square-wave signal produced by the

dash panel, the frequency of which is

changed in accordance with the vehicle

speed.

... is required in the evaluation of the driving

condition (stationary/driving mode) and

thereby for selection of the control criteria

(see “Control concept”).

The interface for the driving speed signal is

redundant, as the information regarding

speed is also transmitted by the CAN bus.

K wire

Communication for self-diagnosis between

control unit J197 and the diagnostic tester

takes place via the familiar K wire by means of

conventional data messages.

The self-diagnosis K wire must not be

confused with the K wire connecting

operating unit E281 to control unit J197.

Power supply to the headlamp range control

system

In the case of 4-level air suspension in the

allroad quattro, the headlamp range control

system voltage is supplied by the air

suspension control unit J197. Further

information can be found under Control unit

J197 on page 34.

Additional interfaces

The door contact signal …

... is an earth signal from the control unit for

central locking. It indicates that the door or

boot lid/tailgate is open.

... serves as a “wake-up pulse” for transfer

from sleep mode to run-on mode (see

“Control concepts”).

Terminal 50 signal...

... signals actuation of the starter and is used

to switch off the compressor during start-up.

If a low position is detected following a wakeup pulse, the compressor is activated

immediately in order to allow the vehicle to

drive off as quickly as possible.

The compressor is switched off during startup in order to save battery power and ensure

starting power.

The vehicle locking signal …

... is used as information for parking level

control

... is an earth pulse coming from the control

unit for central locking J429

... is not detected by the self-diagnosis.

Parking level control is not performed if this

signal fails.

Interfaces

The vehicle locking signal is not

required for vehicles without parking

level control (see pages from 10

onwards and 34 onwards).

31

123

1 2378496513

BL NSL 31 58l RF BR 30 34 58r 31

10 11 12

The trailer operation signal …

..... comes from the F216 contact switch in the

trailer socket.

When the plug is connected, contact switch

F216 connects control unit J197 to earth.

See also “Trailer operation”.

Headlamp range control signal

As changing vehicle levels is axle-based (i.e.

for both sides of an axle at once), this would

produce a short-term visibility range

reduction when driving at night.

For this reason, the allroad quattro is fitted

with an automatic dynamic headlamp control

system (also without gas-discharge

headlamps). The automatic dynamic

headlamp range control system maintains the

light beam at a constant angle while the

vehicle level changes.

In order to prevent irregularities in the road

surface, such as bumps or potholes, from

causing the headlamp range to alter

unnecessarily, long reaction times are set

when the vehicle is travelling at relatively

constant speeds (little or no acceleration).

If level change takes place (e.g. motorway

mode), the 4-level air suspension control unit

J197 transmits a voltage signal to the

headlamp range control unit J431.

This activates the HRC immediately and

controls the bodywork movements.

Level change process:

Raising - rear axle first, then front axle

Lowering - front axle first, then rear axle

243_014

Trailer socket

to the self-levelling suspension

control unit J197 (pin 2/10)

from the rear fog light

switch

F216

32

Interfaces

p

t°

M

1

ABC

D

2 3 4

IV III II I

5 6 7

9 12

8

M

M

31

Functional diagram

Terminal 15 Terminal 30

T.3 4

Terminal 30

SSS

N150

N151

N311

N148

N149

G291

V66

G290

N111

J197

G76 G77 G78 G289

J431

V48 V49

E281

243_038

J403

F216

33

Key to function diagram

E281 Self-levelling suspension operating

unit

F216 Contact switch for switchable rear fog

light

G76 Self levelling suspension sender, RL

G77 Self levelling suspension sender, RR

G78 Self levelling sender, FL

G289 Self levelling suspension sender, FR

G290 Compressor temperature, self-

levelling suspension sender

G291 Self-levelling suspension pressure

sender

J197 Self-levelling suspension control unit

J403 Relay for self-levelling suspension

compressor

J429 Control unit for central locking

J431 Control unit for headlamp range

control

N111 Discharge valve for self-levelling

suspension

N148 Valve for FL suspension strut

N149 Valve for FR suspension strut

N150 Valve for RL suspension strut

N151 Valve for RR suspension strut

N311 Valve for self-levelling suspension

pressure accumulator

K134 Self-levelling suspension warning

lamp

V48 Left headlamp range control motor

V49 Right headlamp range control motor

V66 Self-levelling suspension compressor

motor

= Input signal

= Output signal

= Positive

= Earth

= Bi-directional

= CAN bus/signal wire

Auxiliary signals:

CAN low

CAN high

Door contact signal

Diagnostic connector for K wire

Vehicle locked signal

Trailer operation signal (F126)

Terminal 50 signal

Driving speed signal

Terminal 56

Diagnostic connector for K wire

to the instrument cluster

Driving speed signal from ABS control unit,

speed sensor output, rear left

1

2

3

4

5

6

7

8

I

II

III

IV

Terminal 58s

Terminal 58d

ESP button

ESP button

A

B

C

D

Headlamp range control signal

9

Power supply J431

10

34

However, all level sensors (left and right) are

required in the air suspension system run-up

and run-on mode (ignition OFF).

To allow the left-hand level sensors to deliver

measured values in the case of the 4-level air

suspension in the allroad quattro, power is

supplied to control unit J431 (HRC) from

control unit J197).

This ensures that voltage is supplied to all

level sensors when control unit J197 is active.

Self-levelling suspension

control unit J197

The central element of the system is the

control unit which, in addition to its control

functions, enables the monitoring and

diagnosis of the entire system.

The control unit detects the signal from the

level sensors and uses it to determine the

current vehicle level. This is compared with

the reference level and corrected if necessary,

depending upon further input variables

(interfaces) and its internal control

parameters (reaction times and level

deviations).

It differentiates between various control

situations and controls them via the relevant

control concepts (see Control concept).

Comprehensive self-diagnosis facilitates

inspection and service of the system (see

Workshop Manual).

There are two control units currently in use,

depending on the country.

Control units with the part numbers

4Z7 907 553A and 4Z7 907 553B have different

control strategies (see page 10 onwards).

A common control strategy for all countries

(as for Index “B”) is planned for the future.

Control concepts

243_039

The system can be tested via the selfdiagnosis or test adapter 1598/35.

For further information, see “Service”

chapter.

Address word 34

Power supply to the headlamp range control

system

As previously described in the “Level sensors”

section, voltage is supplied to the left-hand

level sensors by the headlamp range control

unit J431)

Headlamp range control requires neither runup nor run-on times, so the voltage is

normally supplied to control unit J431 via

terminal 15 (ignition ON) (see function

diagram, page 32).

35

Level change process:

Raising - rear axle first, then front axle

Lowering - front axle first, then rear axle

Modes

Height mode/driving mode

Reaction times upon level deviation

Control characteristics during level change

Level change is basically performed axle by

axle, whereby level differences between the

left and right sides are compensated (e.g. if

loaded on one side).

Driving speed Reaction time

<5 km/h

Height mode

approx. 5 seconds

approx. 1 second at

extremely low level

>10 km/h

Driving mode

approx. 50 seconds or

15 minutes

depending on the level

deviation

Run-on mode/run-up mode

The run-on mode enables the compensation

of level deviations after the vehicle has been

parked (e.g. caused by passengers leaving the

vehicle or unloading the vehicle) and before

driving off (e.g. caused by intense cooling,

leakage or loading).

In this mode, delay times before commencing

a journey are kept to a minimum.

After “Ignition OFF”, the control unit is in the

so-called run-on mode. The control unit

remains active for a maximum of 15 minutes

(via terminal 30) until it goes into sleep mode.

Due to the limited energy available when the

engine is switched off, control limits are

extended and controls are limited in both

number and duration.

36

Control concepts

The system can switch between sleep mode

and run-on/run-up mode, triggered via the

door contact signal, a maximum of 15 times.

For the 15 subsequent wake-up procedures,

the system switches to sleep mode after only

1 minute.

The system can then only be activated via

terminal 15 and/or the speed signal.

Sleep mode

To minimise electricity consumption the

control unit switches to “system idle” (sleep

mode) after 15 minutes.

There is no level adjustment in sleep mode.

“Wake-up” is primarily triggered by the door

contact signal. If the door contact signal fails,

the system is activated when the ignition is

switched “ON” or by the driving speed signal.

The vehicle should be raised as quickly

as possible in order for the control unit

to recognise the lifting-platform mode.

It is often advisable to switch off the

system during repair work (e.g. during

axle measurement or if the pressure

lines have been detached, in order to

prevent the compressor running

unnecessarily).

242_010

Lifting platform mode

The control unit evaluates the level signals

while a stationary vehicle is being lowered

and thereby initiates lifting platform

operating mode.

The aim of the lifting platform mode is to

prevent excessive discharge of the air springs

when the vehicle is completely raised.

37

In trailer operation, normal mode must

always be selected and care must be

taken that the system is switched to

manual mode (e.g. no automatic

switching to manual mode if trailer

operation signal fails).

In difficult driving conditions, high

level 1 or high level 2 can be selected,

however, normal level must be selected

before a driving speed of 35 km/h is

exceeded.

Driving at low level or in automatic

mode is not permitted.

Trailer operation

The correct position of the tow bar on the

trailer attachment during trailer operation is

indicated in normal mode.

Contact switch F216 in the 13 pin trailer

socket is used to signal that the trailer plug is

inserted, i.e. indicates trailer operation (see

description “Trailer operation signal”.

If trailer operation is recognised, the manual

mode is automatically activated (LED “man”

lights up) whereby the automatic raising

process is stopped.

Normal level is set by the driver via control

unit E281.

243_015

Normal level

38

Special tools

Adapter cable 1598/35 with test box 1598/14

are used for fault finding and function testing

of sensors and signals of the 4-level air

suspension system.

As the pin assignment of the test box is not

compatible with the pin assignment of

control unit J197, pin template

V.A.G 1598/35-1 must be used.

Pin assignment is only possible by means of

pin template V.A.G 1598/35-1.

Service

Due to the limited number of

connections to test box V.A.G. 1598/14,

not all interfaces in control unit J197

are wired.

243_016

243_017

Adapter cable 1V.A.G 598/35

Pin template V.A.G. 1598/35-1

Test box

V.A .G. 1598/14

39

Basic system setting

The basic system setting of the reference

level in the 4-level air suspension system is

performed by inputting body-level measured

values at normal level.

The measured value, the vertical dimension

from the wheel centre to the wheel cut-out,

must be input into the control unit using a

diagnostic tester in function 10 “Adaption”.

(Procedure, see Workshop Manual).

The codes serve to define the reference value

for normal level (allroad quattro 402 mm).

This means that design-specific values of the

level sensors are adjusted for this dimension.

Due to the tolerances of the components

involved, there is a certain deviation between

actual (measured) and reference (defined)

values.

By the inputting of the actual value, control

unit J197 recognises a potential difference to

the reference value. based on which the

design-specific values from the level sensors

are adapted.

Advantages of the measurement method:

• No influence of the correct basic setting

due to …

... different tread depths and tyre pressures.

... minor unevenness of the road surface.

... different tyre sizes.

• Simple to perform.

Codes for the allroad quattro

25500

Position Meaning

X0000 1 = Headlamp control not

installed

2 = Headlamp control installed

0X000 5 = Reference height, front

axle 402 mm

00X00 5 = Reference height, rear axle

402 mm

000X0 0 = Vacant

0000X0 = Vacant

243_018

402 mm

402 mm

40

Self-diagnosis

Address word: 34 Self levelling suspension

Both generations of diagnostic tester

(V.A.G. 1551/1552 and VAS 5051) are suitable

for communication with the 4-level air

suspension control unit.

Due to the limited capacity of the tester

program cards, there are display text

limitations in the case of diagnostic testers

V.A.G. 1551 and 1552 (see. e.g. Workshop

Manual, Self-diagnosis function 03, Final

control diagnosis).

Service

198_039

41

Allroad quattro control strategies

4-level air suspension + additional shift stage

02035 8060

5

100 120 130 20030

General overview

Control unit 4Z7 907 553A/B

ESP safety-switching

Automatic lowering

Parking level

control

v >70 km/h: Engine intervention

v >50 km/h: Acoustic and visual warning in low range

Air supply: control primarily via

pressure accumulator <36 km/h

Vehicle speed v

in km/h

v <30 km/h: shift to low range possible

Additional shift stage

Air supply: control primarily via compressor >36 km/h

Pressure accumulator filled >36 km/h

Motorway mode:

Lowering: >120 km/h >30 seconds

Raising: <70 km/h >120 seconds

<35 km/h >30 seconds

<5 km/h immediately

Manual mode:

- no parking level control

- no motorway mode

- automatic lowering from HL2

and HL1; ESP safety-

switching remains active

Automatic mode:

- parking level control (HL1)

- motorway mode:

- automatic lowering from HL2 and HL1.

- ESP safety-switching

LL

NL

HL1

HL2

243_040

Control unit 4Z7 907 553B: Automatic mode:

- no parking level control

- automatic raising to HL1

<60 km/h >30 seconds

<30 km/h immediately

42

Notes

43

Loading...

Loading...