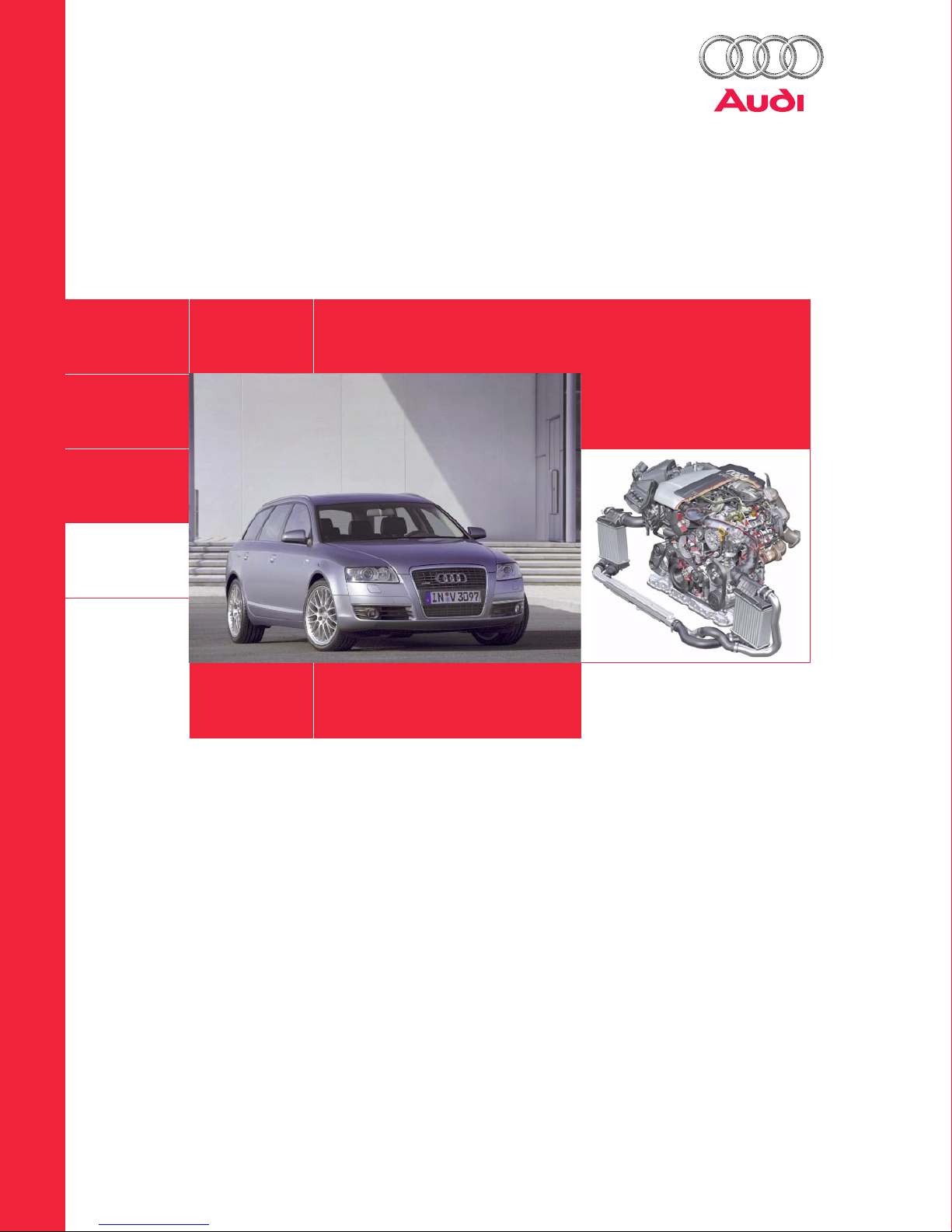

The New Audi A6 Avant ´05

Self-Study Programme 344

Service Training

Audi is adding a new chapter to the success story of

the Avant.

The new Aud i A6 Avant '05 represents a unique

blend of design and dynamism, driving pleasure

and functionality.

Here is a car that exhibits a unity and harmony of

design.

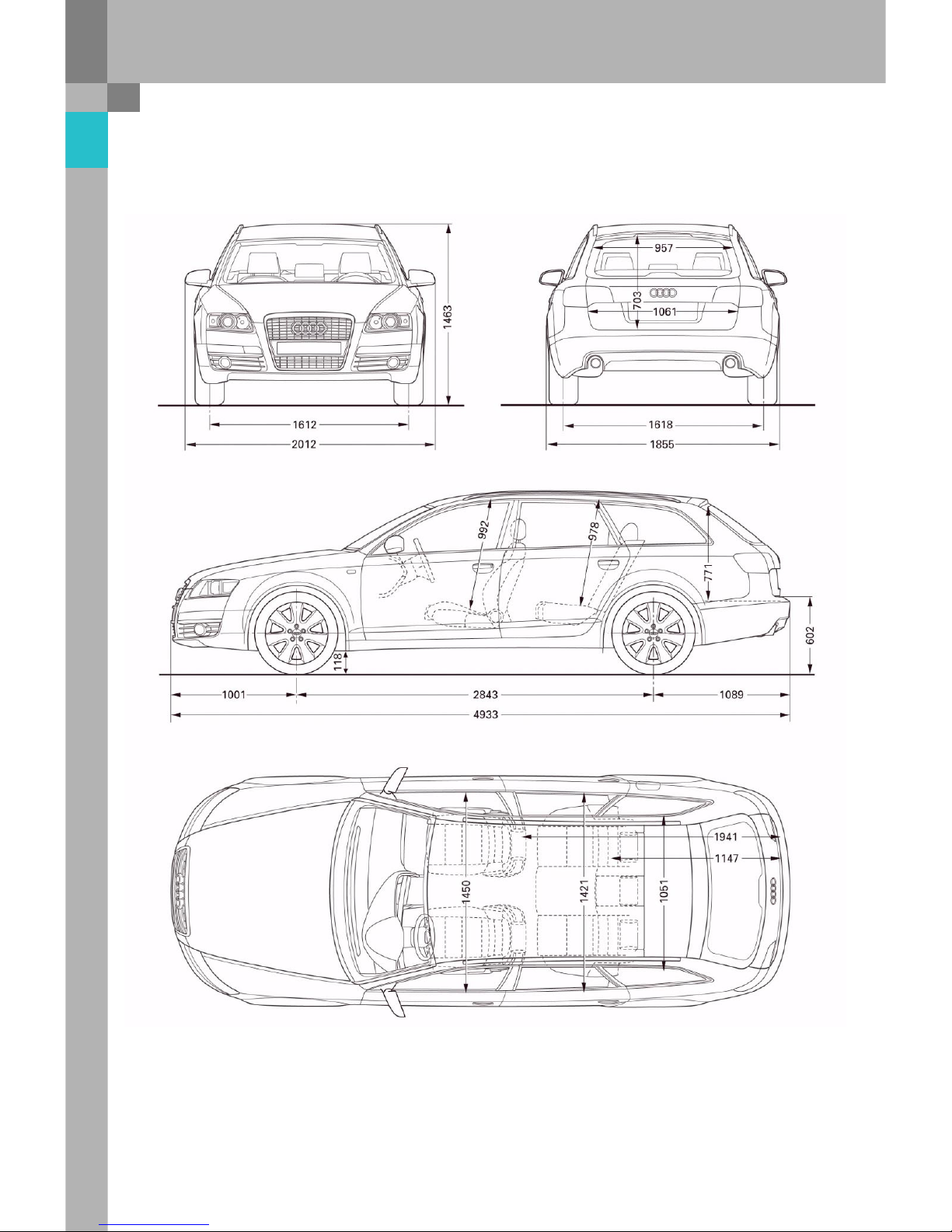

Measuring 4.93 metres in length, 1.86 metres in

width, and 1.46 metres in height, the new

Audi A6 Avant ´05 visibly sets a new standard in

terms of its proportions.

The lines of the car combine the clear architecture

typical of Audi with other core elements of the

brand's progressive design.

The a lready classic proportions of the Avant's

silhouette, with its high shoulder line, narrow

windows all round, coupé-like roofline and shallow

sloping tail end, have been infused with added

dynamism.

The New Audi A6 Avant ‘05

Into the lead: With Design & Performance

Self-study programmes on the Audi A6 Avant

344_056

344_057

NoteReference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

The self -study programme provides introductory information regarding the design and function of new

models, automotive components or technologies.

The self-study programme is not a Repair Manual!

All values given are intended as a guideline only and refer

to the software version valid at the time of publication of the SSP.

For maintenance and repair work, always refer to the current technical literature.

Table o f contents

Occupant protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Running gear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Infotainment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Convenience electronics. . . . . . . . . . . . . . . . . . . . . . . . . . 32

4

Overview

Dimensions of the Audi A6 Avant ´05.

Introduction

344_062

5

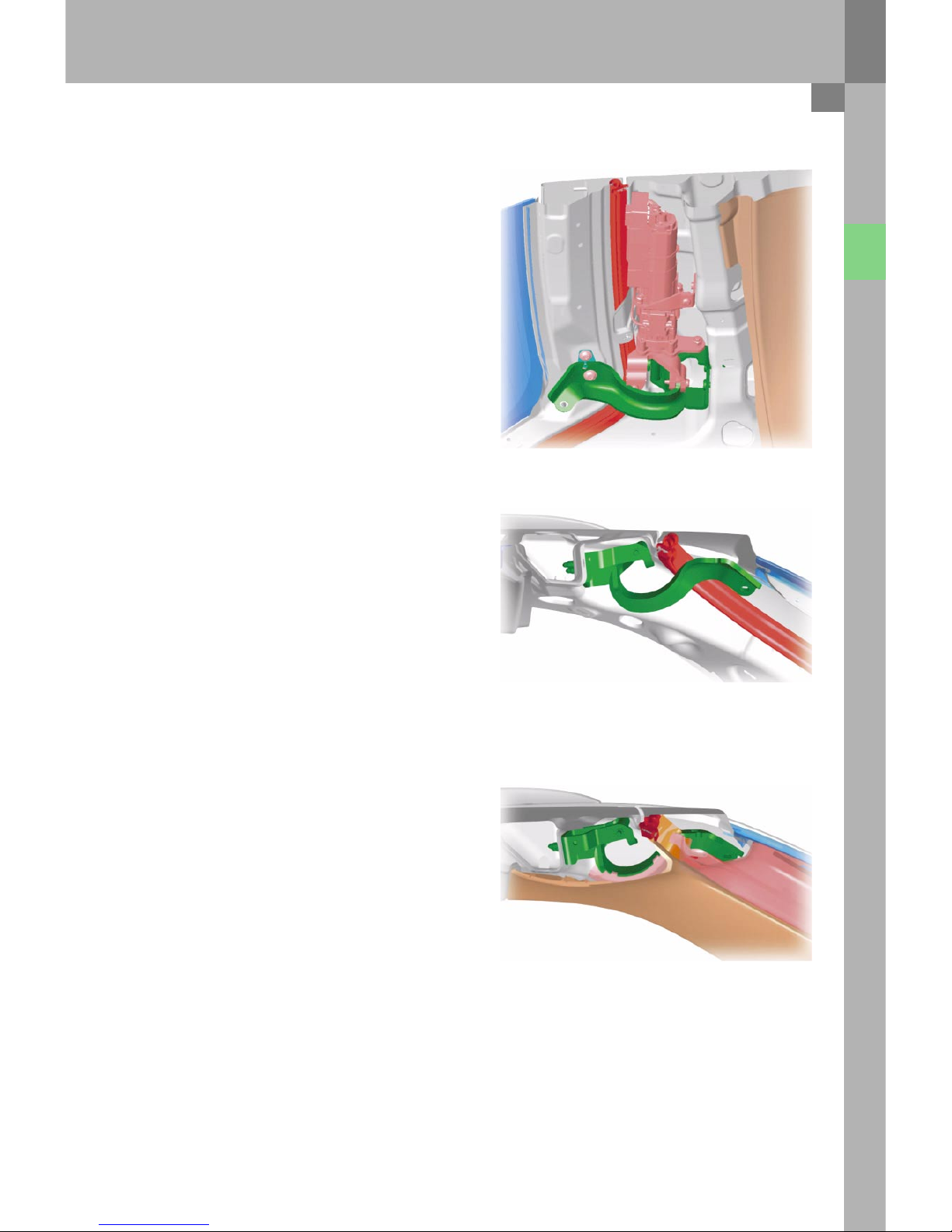

Tai lg at e

In the new Audi A6 Avant ´05 , an inner tailgate hinge

is implemented for the first time.

The hinge is attached to the upper roof crossrail at

the rear so that it is located behind the tailgate seal,

and thus inside the occupant cell.

When the tailgate is closed, the hinge is concealed

behind the trim panel and is not visible from the

interior.

This hinge arrangement and function has the

following advantages:

–no corrosion,

–no sealing problems,

–internal wiring,

–no grommets are needed to seal through-holes

in the body,

–larger cargo area

possibility for electric tailgate drive.

Body

344_046

344_047

344_048

6

Occupant protection

Reference

For further information on the safety

system, please refer to Self-Study

Programme 323 - Audi A6 ´05.

Front passenger front airbag

–Airbag igniter 1, front passenger side N131

–Airbag igniter 2, front passenger side N132

The front p assenger airbag consists of a casing in which are housed two pyrotechnic gas generators

separated by a partition. A propellant in the form of tablets and hollow tabs is used.

Safety system

The g oal was to implement a protection system that offers a very high level of safety, thereby raising still

further the high safety standard set by the current Audi fleet.

The many sa fet y requirements for the new Audi A6 Avant ´05 included meeting all current legislation, as well

as achieving a top rating in consumer tests.

Audi's internal specifications often increase the challenges to the development team.

This was the case with the Audi A6 saloon introduced to the market in the 2005 model year; likewise with the

new Audi A6 Avant ´05.

The occupant protection system in the Audi A6 Avant ´05 was largely adopted from the saloon. Due to the

modifications to the body, however, several components were adapted to the new parameters.

A new gas generator with dual threshold deployment for the front passenger front airbag will be implemented

in the Audi A6 saloon in early 2005. This module will be fitted to all models world-wide.

The new Aud i A6 Avant ´05 will be equipped with this airbag from rollout.

Rupture disc

344_001

Metal filter Partition Metal filter

Outlets

Prim ing charge 2

Rupture disc

Prim ing charge 1

Igniter 2 Igniter 1

Housing

Metal filter Metal filterPrope llant cha rge 2

Outlets

Prope llant cha rge 1

Compensating material

344_001

7

Airbag igniter 2, front passenger side N132

The a irbag control unit defines the time interval between the deployment of airbag igniter 1, front passenger

side N131 and airbag igniter 2, front passenger side N132 according to the type and severity of the accident.

The task of the second gas generator is to inflate the airbag to its full size.

The second gas generator has exactly the same function as the first gas generator.

Airbag igniter 1, front passenger side N131

If igniter I is electrically activated by the airbag control unit J234, it ignites priming charge I. Under the

resulting pressure, the flame passes through the rupture disc and ignites propellant charge I.

On account of the hollow propellant tabs, the complete propellant charge ignites more quickly.

The metal filter cools and treats the developing gas before it flows through the outlets to the airbag.

The task of the first gas generator is to inflate the airbag.

Outlet

Partit ion

Metal filter

Prope llant cha rge 2 Outlet Compensating material

344_005

Metal filter

Rupture disc

Outlet

Compensating material

344_004

Rupture discMetal filter

Metal filterOutlet Propellant charge 1

Part ition Igniter I

Housing

Primi ng ch arge 2

Igniter 2

344_004

8

The 3.0l V6 TDI was modified in several respects to

fill the gap between the 2.5l V6 TDI with distributor

injection pump and the 3.0l V6 TDI with common rail

injection. A wide range of diesel engines in various

sizes is therefore available to the customer.

Engine

The 2.7l V6 TDI with common rail

344_011

9

The engine number is located on the cylinder block

at the front right adjacent to the vibration absorber.

Specifications

Engine code BPP

Typ e of eng ine V6 diesel engine

Displacement 2698 cm

3

Powe r ou tpu t 132 kW (180 bhp)

To rq ue 380 Nm at 1400-3300 rpm

Bore 83 mm

Stroke 83.1 mm

Compression ratio 17:1

Weight 220 kg

Firing order 1 - 4 - 3 - 6 - 2 - 5

Engine management Bosch EDC-16CP+ common rail injection system

with max. 1600 bar operating pressure and 8-port piezo injectors

Exhaust emission control Oxidising catalytic converter, maintenance free diesel particulate filter

(optional), lambda probe and cooled exhaust gas recirculation

Exhaust emission standard EU 4

344_012

Torque / p o we r cu r ve

Max. torque in Nm

Max. power output in kW

Engine speed in RPM

10

–The stroke was reduced from 91.4 mm to

83.1 mm by modifying the crankshaft, con-rod

and piston

–Cast exhaust manifold and steel compensator

without air-gap insulation

–Deletion of the shield plates above the manifolds

–Piezo injectors with eight-port nozzles instead of

seven-port nozzles

–An inlet restrictor has been integrated into the

fuel rail for each injector

Engine

Modifications to the 2.7l engine

The basi s is the 3.0l V6 TDI CR engine, i.e. the engine

block with 90 mm cylinder spacing was adopted,

likewise the 83.0 mm cylinder bore.

The crankshaft, the con-rod and the pistons were

modified so that a swept volume of 2698 cm

3

was

obtained by changing the stroke.

Crankshaft drive

344_003

11

The closin g of th e injector produces a pulse which

propagates from the injector to the fuel rail and is

reflected back to the injector. In this connection, the

injector pintle and injector pintle seat are subjected

to a high mechanical load (bounce). A restrictor is

installed upstream of each injector to dampen the

pulses in the fuel rail. This restrictor dampens the

incoming and outgoing pulses and so prevents the

injector pintle from colliding with the injector pintle

seat.

The restricto r is mechanically press-fitted into the

fuel rail.

In-rail restrictor

to injector

Rail

Fuel line

Inlet restrictor

344_061

Note

When replacing the injector, pay attention

to the genuine parts number!

Piezo injector

To red u c e p a rt i cu l ate emissions still further and to

optimise combustion, 8-port injectors are used in

place of 7-port injectors. This enables the fuel to be

more finely atomised and provides a smoother

combustion process.

12

Running gear

A steel-spring suspension is used in the basic version of Audi A6 Avant `05. In comparison with the running

gear in the A6 saloon, the set-ups for the springs, dampers and anti-roll bars have been revised. In the Avant,

too, there are suspension systems for front-wheel-drive and quattro versions. The dynamic suspension

system is available in the basic version. A sport suspension, which lowers the overall car's ride height by

15 mm compared to the dynamic suspension system, is available as an optional extra. Heavy-duty running

gear, which raises the car's ride height by 15 mm compared to the dynamic suspension system, is also

optional.

13

344_029

14

Running gear

Adaptive air suspension (aas)

A modified aas system is optional in the Audi A6 Avant `05. By comparison with the aas in the A8, there is no

distinction to be made between the aas standard suspension and the aas sports suspension. The following

fundamental differences exist between the aas in the A6 and the aas in the A8:

the control was adapted for the A6, with modified ride

heights compared to the A8

modified mechanical design of the dampers and

modified damping control

the solenoid valve block and compressor are installed

mounted on a common bracket

aas is also available in combination with MMI Basic

body acceleration senders are integrated in the wheel arch

15

separate spring/damper arrangement

modified pressure accumulator design,

mounted to luggage compartment floor

344_030

Loading...

Loading...