Page 1

TH1 1 3 & TH1 1 6 A/F/AF

Owner s Guide

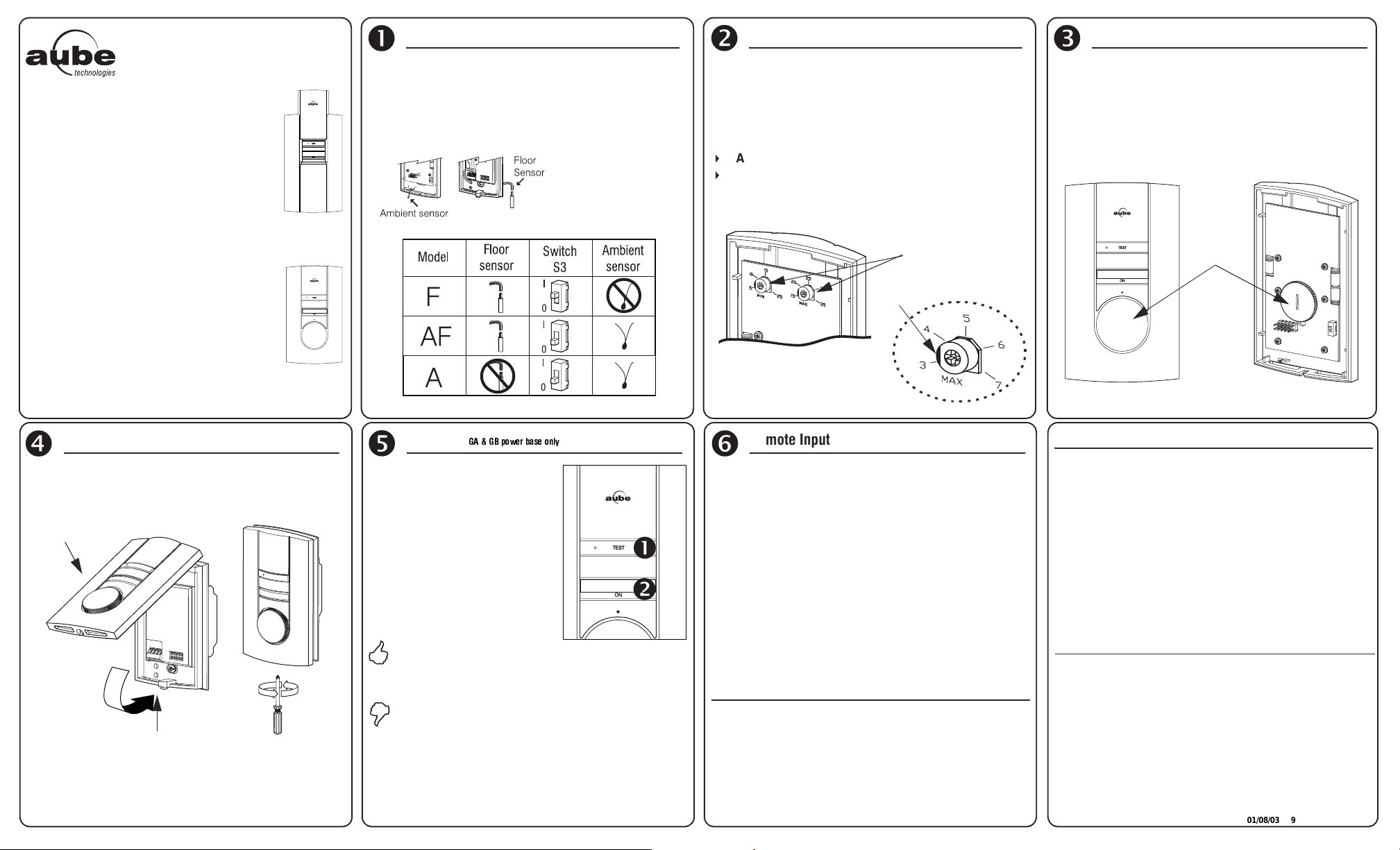

Model Selection (switch)

Temperature Lock (TH1 1 3 only)

Setpoint Definition

Thank you for choosing Aube’s nonprogrammable thermostat. Your new

electronic thermostat is equipped with a

microprocessor and proportional integral

adaptive (PIA) temperature control

technology for total comfort. Depending on

the selected model , thi s th erm os tat h as been

designed to control:

A:The Ambient temperature (using an

electric heating system)

AF:The Ambient temperature with Floor

TH116

Public Area

temperature limit (using a floor heating

system to heat the room)

F:The Floor temperature (floor heating)

NOTE: This control module must be

mounted on a PB112 Series power base.

The thermostat has an On/Standby switch

making it possible to put the thermostat in

sleep mode when its use is no longer

TH113

required (e.g. summer).

Control Module Installation

Align the bracket tabs on the control module with the

holes located on the power base.

Follow the same procedure for the TH116.

Control module

Power base

NOTE: Keep the thermostat's air vents clean and free

from obstructions.

NOTE: The screw cannot be removed completely.

FOR A AND AF MODELS ONLY

At the rear o f the control module is a switch that has been

factory-set to the applicable temperature control.

NOTE: The AF model can be used for all temperature

control types (A, F and AF).

Note: The ambient

sensor is not

operational when the

switch is set to I (u p ) .

GFCI Test

ߺߴߓߙߓ ߺߵߓ ࠣࠢࠪ࠘ࠥߓࠕࠔࠦ࠘ߓ ࠢࠡ ࠟࠬ

The GFCI monitors the electrical

flow for any loss of current; if

there is any loss, the thermostat

will cut off power to the heating

system. We reco mmend you test

the GFCI immediately after

installing the control module, and

once a month thereafter to

ensure it is operating properly. To

test:

! Press the TEST button:

• Successful: TEST warning light is ON and power to heating system is cut

off.

• Unsucessful: The TEST warning light is OFF. Cut

power to heating system from the main power

panel and call customer service.

" When successful, reset thermostat (STANDBY/ON)

to power heating system.

NOTE: If the test warning light comes ON during normal

operation, cut power to heating system from the main

power panel and hav e a n el ec tric ia n v erif y t he i ns tal lation.

At the rear of the control module are two potentiometers.

These potentiometers act like a temperature lock. Even

when occupants adjust the temperature using the dial on

the front/rear of the control module, the potentiometers

override the dial and maintain the temperature within the

locked-in minimum and maximum range.

A - ambient temperature

F & AF - floor temperature limit

Use a flat tip screwdriver to rotate the pote nti om ete rs un til

the notch points to the desired temperature.

Potentiometers

Notch

Remote Input

The TH113 and TH116 are equipped with a remote input

which allows connection of an optional telephone

controller (CT240) or any other remote control system.

When a command signal is received through this input,

the thermostat automatically lowers its setpoint by 3.5°C.

The LED lights up to indicate the signal’s presence

(except for GA and GB models).

Bypass (not available for GA and GB power base):

The TEST button can be used to bypass the signal for a

2-hour period. The LED goes off to indicate the bypass.

NOTE: When combined with a GA/GB power base, the

TEST button is used only for GFCI testing. The bypass

function is not available with these power base models.

Technical Specifications

Models: TH113 and TH116 A / AF / F

Setting range: 45°F, 59°F to 95°F (7°C, 15°C to 35°C)

Potentiometers: minimum: 41°F to 77°F (5°C to 25°C)

maximum: 59°F to 95°F (15°C to 35°C)

Accuracy: ± 0.9°F (0.5°C)

Storage: -4°F to 120°F (-20°C to 50°C)

Turn the di al to the desired temperature.

TH113: The dial is located on the front of the control

module.

TH116: The dial is located on the rear of the control

module.

The min. position indicates the minimum temperature

setpoint: 45°F (7°C).

Temperature

dial

TH113 TH116

Warranty

AUBE TECHNOLOGIES INC. ONE (1) YEAR LIMITED WARRANTY

This product is guar anteed against workmansh ip defects for a one year

period following the initial date of purchase. During this period, AUBE

Technologies Inc. will repair or replace, at our option and without charge,

any defective product whic h has been use d under normal condition s. The

warranty does not cover del ivery costs and does not apply to products

poorly installed or randomly damaged following installation. This war ranty

cancels and replaces any other manufacturer's express or implied

warranty as well as an y other compa ny comm itm ent. AU BE Te chnolog ies

Inc. cannot be held liable for related or random damages following the

installation of this product. Th e defective product as well as the purchase

invoice must be returned to the place of purchase or ma iled, prepaid an d

insured, to the following address:

Aube Technologies Inc.

705 Montrichard

Saint-Jean-sur-Richelieu, Quebec, Canada J2X 5K8

If you have any questions concerning the TH113 or the TH116

thermostat, call our technical support team at:

Phone: Montreal area: (450) 358-4600

Canada / U.S.: 1-800-831-AUBE

Fax: y(450) 358-4650

Email: service@aubetech.com

Monday to Friday from 8:30 AM to 5:00 PM EST.

For more information on our products, visit us at:

www.aubetech.com

01/08/03 920-113-001-00-1-A

(2823)

Page 2

Installation Instructions

MASTER THERMOSTATS

TH113-A/F/AF (12VDC)

TH114-A/F/AF (12VDC)

TH115-A/F/AF (12VDC)

TH116-A/F/AF (12VDC)

SLAVE UNITS

CT230-120GA

CT230-120GB

CT230-240GA

CT230-240GB

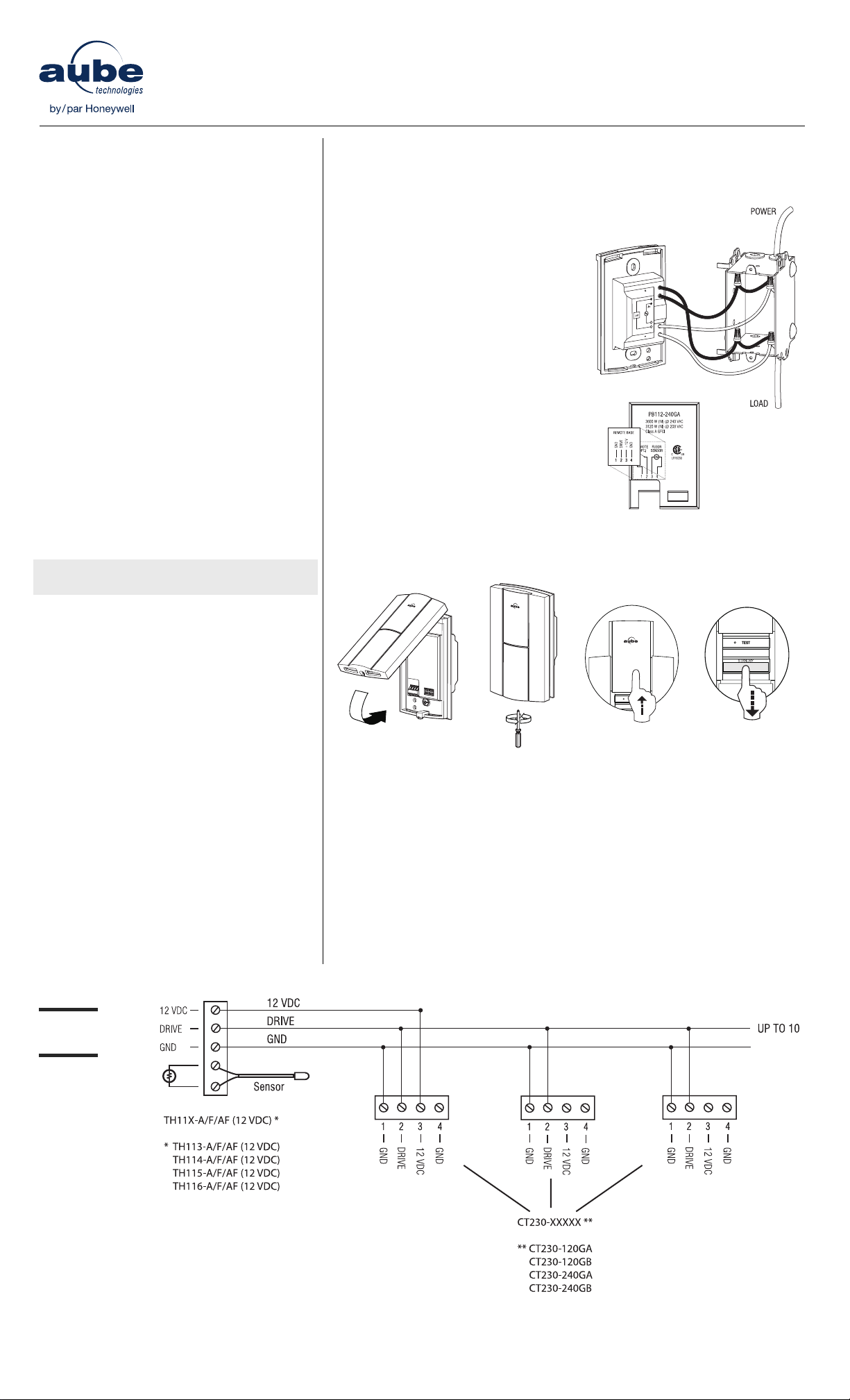

1. Introduction

This master and slave unit system is specially

designed for large floor heating applications

exceeding 15 A.

The master thermostat controls a single or

multiple floor heating zones driven by slave units.

The master thermostat can control up to 10 slave

units.

Each slave unit drives its own zone and is

equipped with a GFCI test button and warning

light as well as an On/Standby switch to facilitate

maintenance on specific zones of the floor

installation.

2. Operation

Master Thermostat

The master unit controls the temperature and

sends a signal to slave units when heating is

required. The floor sensor is connected to the

master unit. The master unit is powered by the

slave units.

Slave Unit

The slave unit receives the signal sent by the

master unit and activates its load.

NOTE: There must be a minimum of one slave

unit ON to power the master unit.

3.2 Slave Units - Installation and Wiring

The slave units can operate on different voltages (e.g. 5 units @ 120 V and 5 @ 240 V).

• Required parts: CT230-120GA, -120GB, -240GA or -240GB

• Installation: On an electrical box

• Location: Installation near the master

thermostat is not required (i.e. can be

installed in a utility room).

• Wiring: The power bases are joined

through a daisy chain connection.

n Connect the 120 V or 240 V power

base wires to the power (line) and to

the load (floor) using solderless connectors for copper wires, and secure

the base to the electrical box.

o Affix the wiring sticker (in the CT230

box) to the base.

p Connect the slave power bases

together as per FIGURE 1.

q Once installation and wiring is com-

plete, mount the CT230 interface:

a) Align the bracket tabs of the

CT230 with the holes located on

top of the power base.

b) Secure the CT230 interface using the screw (captive).

3. Installation

Turn off power to the heating system at the

main power panel to avoid electrical shock.

Installation should be carried out by an

electrician.

3.1 Wiring Guidelines

• The wire distance between the master thermostat and slave unit should not exceed 500 ft.

(150 m).

• The floor sensor cable should not exceed

200 ft. (60 m).

• A 3-wire 20 AWG cable is recommended.

FIGURE 1

Connections

r Switch all slave power bases to STANDBY by sliding the protective door upwards

and positioning the switch to STANDBY.

Install and connect the master unit (see 3.3).

400-230-000-C 5/12/05 1/2

Page 3

3.3 Master Thermostat - Installation and Wiring

WARNING: Make sure all slave units are in STANDBY mode.

•Required parts: TH113-A/F/AF (12VDC),

TH114-A/F/AF (12VDC),

TH115-A/F/AF (12VDC) or

TH116-A/F/AF (12VDC)

• Location: anywhere easily accessible to users.

Temperature control: AF (ambient with floor limit) / A (ambient)

• Install the master thermostat in the controlled area.

• Choose a location about 5 ft. above the floor in an area where the temperature is stable.

• Avoid locations where there are air drafts (top of staircase, air outlet), dead air

spots (behind a door), direct sunlight or concealed chimneys or stove pipes.

Temperature control: F (floor)

• Can be installed anywhere.

s Wire the 12 VDC base to the nearest slave unit.

The floor sensor must be installed in an area where average temperature can be

read. The cable must follow the wall down to the floor and must not cross any

heater wires or be directly on or adjacent to a heating wire.

For maximum performance, the sensor probe should be centered between the

wires in the mat (max. 80°C).

t Push the excess wire into the wall, secure the base using the provided screws

and wall anchors, and install the TH11x thermostat onto the base.

u Once the thermostat is installed, return power to heating system and switch all

slave units and the master thermostat to ON.

Technical Specifications

Temperature:

- Operation: 32°F to 122°F (0°C to 50°C)

- Storage: -4°F to 122°F (-20°C to 50°C)

TH113/TH114/TH115/TH116 (A/F/AF-12VDC)

Power supply 12 V from remote unit

Maximum

slave units

Wire gauge 20 AWG

Size (H • W • D)

BASE

NOTE: Refer to the TH11x user guide for techni-

cal specifications.

CT230-120GA/120GB/240GA/240GB

Supply

- PB112-120

- PB112-240

GFCI GA=5 mA / GB=30 mA

Certification c CSA us

Size (H • W • D)

BASE

up to 10 slave units per

master thermostat

4.63 x 2.7 x 0.61 in.

(117.5 x 68.3 x 15 mm)

1800 W @ 120 VAC

60 Hz, 15 A resistive

3600 W @ 240 VAC

60 Hz, 15 A resistive

4.63 x 2.7 x 1.45 in.

(117.5 x 68.3 x 37 mm)

3.4 Slave Units - GFCI Test

We recommend you test the GFCI immediately after installing the thermostat, and

once a month thereafter to ensure it is operating properly.

If the test warning light comes ON during normal operation, cut power to heating

system from the main power panel and verify the installation.

n Slide the protective door upwards and make sure the switch is ON.

o Press TEST.

• The test is successful if the TEST warning light is ON and power is cut off.

• If the test fails (first installation test):

a. Verify installation

b. Check the load wires

c. Once you've identified the problem, run the GFCI test again

• If the test fails (monthly maintenance):

a. Cut power to heating system from the main power panel and call customer

service

p When the test is successful, reset the slave unit by switching from ON to

STANDBY then back to ON.

q Repeat steps 1 to 3 for all slave units.

Size (H • W • D)

INTERFACE

4.67 x 2.74 x 0.67 in.

(118.6 x 69.6 x 17 mm)

Service

If you have any questions concerning the

installation of the master thermostat or slave

units, contact our technical support team at:

Montreal area: (450) 358-4600

Canada / U.S.: 1-800-831-AUBE (2823)

Fax: (450) 358-4650

Email: service@aubetech.com

Monday to Friday from 8:30 AM to 5:00 PM EST.

For more information on our products, visit us at

www.aubetech.com

Warranty

AUBE TECHNOLOGIES INC.

ONE (1) YEAR LIMITED WARRANTY

This product is guaranteed against workmanship

defects for a one year period following the initial

date of purchase. During this period, AUBE

Technologies Inc. will repair or replace, at our

option and without charge, any defective product

which has been used under normal conditions.

The warranty does not cover delivery costs and

does not apply to products poorly installed or

randomly damaged following installation. This

warranty cancels and replaces any other

manufacturer's express or implied warranty as

well as any other company commitment.

AUBE Technologies Inc. cannot be held liable for

related or random damages following the

installation of this product. The defective product

as well as the purchase invoice must be returned

to the place of purchase or mailed, prepaid and

insured, to the following address:

Aube Technologies Inc.

705 Montrichard

Saint-Jean-sur-Richelieu, Quebec,

Canada J2X 5K8

400-230-000-C 5/12/05 2/2

Loading...

Loading...