Page 1

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.10 P1/3

TH220 TEMPERATURE AND HUMIDITY CONTROLLER

INSTRUCTION MANUAL

Version 1.2 (Oct, 2017)

1. Overview

This plug-n-play temperature and humidity controller is designed for high

relative humidity (>85%) and condensing environments, where slight

temperature drop may cause condensation and could damage the sensor. This

controller equipped with one of the most robust humidity sensors on the

market. It can be fully recovered even immersed in water. Ideal for curing

Fridge. The controller can control both temperature (heating or cooling) and

humidity (humidifying or dehumidifying) at the same time.

2. Specification

Table 1. Specifications

Temperature Control Range

- 40 ~ 80 ° C, - 40 ~ 176 °F

Temperature Resolution

0.1 ° C (between -9.9 ~ 80 °C)

1 ° C (between -40 ~ 10 °C)

0.1 ° F (between -9.9~99.9 °F)

1 ° F (between -40 ~ 10 °F,100 ~176 ° F)

Temperature Accuracy

0.5 °C

Temperature Control Mode

On/Off Control. Heating or Cooling

Temperature Control Output

15A, 120V or 240V AC *

Humidity Control Range

0~99.9% RH

Humidity Resolution

0.1% RH

Humidity Accuracy

4% RH

Humidity Control Mode

On/off control.

Humidifying or dehumidifying

Humidity Control Output

15A, 120V or 240V AC *

Operating Temperature

0~50 °C

Dimension

91x140x46mm

Input Power

85 ~242VAC, 50Hz/60Hz

Sensor Cable Length

6 ft (2m)

Power Cable Length

3 ft (1m)

* Please note: Although both temperature and humidity output can handle up to

15A, the combined total power of the two channels are limited to 1500 Watts

due to the limitation of input power cord.

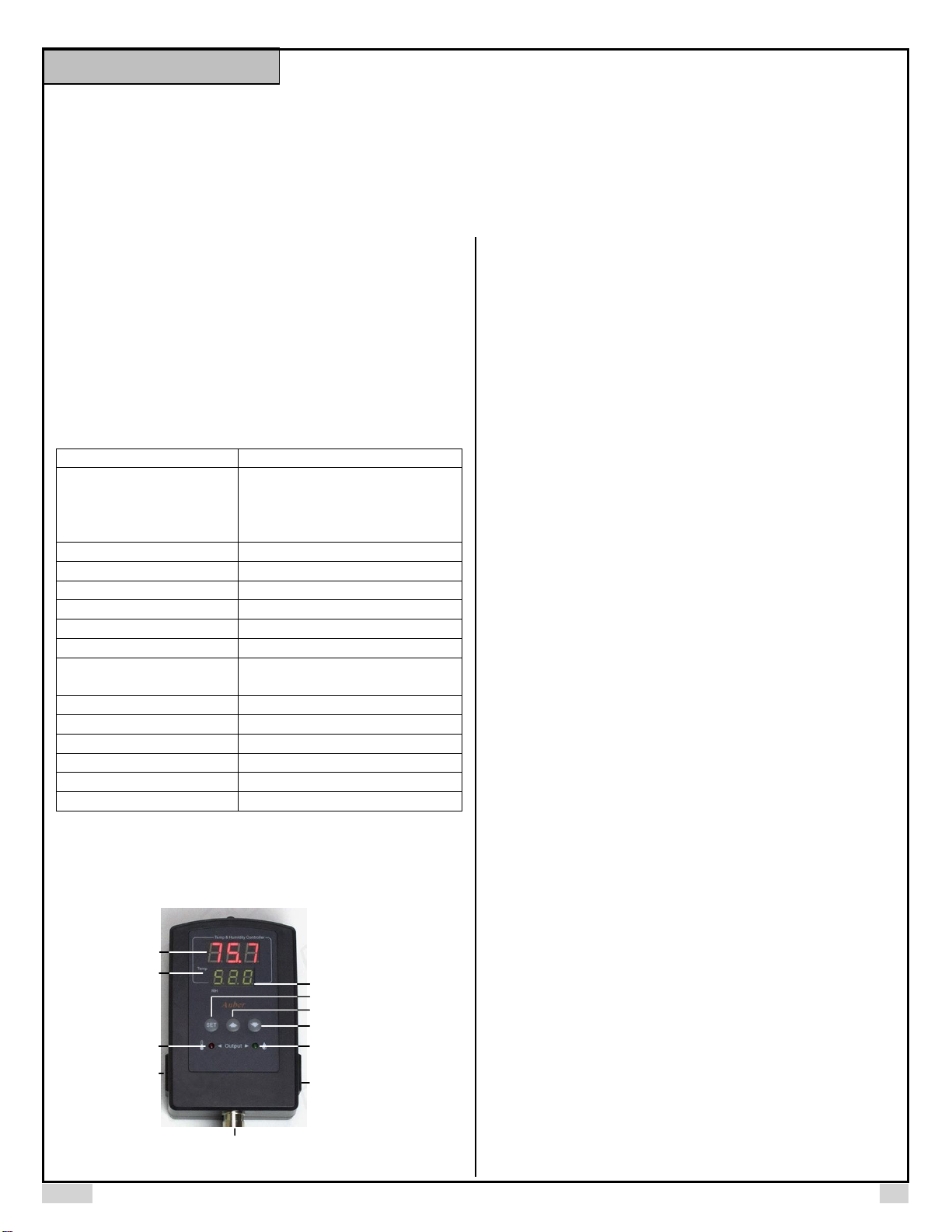

3. Front Panel

Up Key,Unmute Alarm

Dn Key, Mute Alarm

Set Key

Heating/

Cooling

Device Socket

Humidifier/

Dehumidifier

Device Socket

Humidifier/Dehumidifier

On Indicator

Heating/Cooling

Device On Indicator

Measured

Humidity

Measured

Temperature

Alarm Indicator, On

when Alarm Muted

Sensor Socket

Figure 1. Front Panel

Measured temperature window: In normal operating mode, this window

shows measured temperature. In parameter setting mode, this window shows

parameter name.

Measured humidity window: In normal operating mode, this window shows

measured humidity. In parameter setting mode, this window shows parameter

value.

Alarm indicator: When the alarm is muted, the alarm indicator (the small dot

on the last digit) will be on.

SET key: Access the program settings and parameter settings.

UP key (Unmute): Increase the value. Press down momentarily to unmute the

alarm.

DOWN key (Mute): Decrease the value. Press down momentarily to mute the

alarm.

Temperature socket: Supply power to heater/cooler.

Temperature indicator: Red LED indicator; it is on when the temperature

socket is energized.

Humidity socket: Supply power to the humidifier/dehumidifier.

Humidity indicator: Green LED indicator; it is on when the humidity socket is

energized.

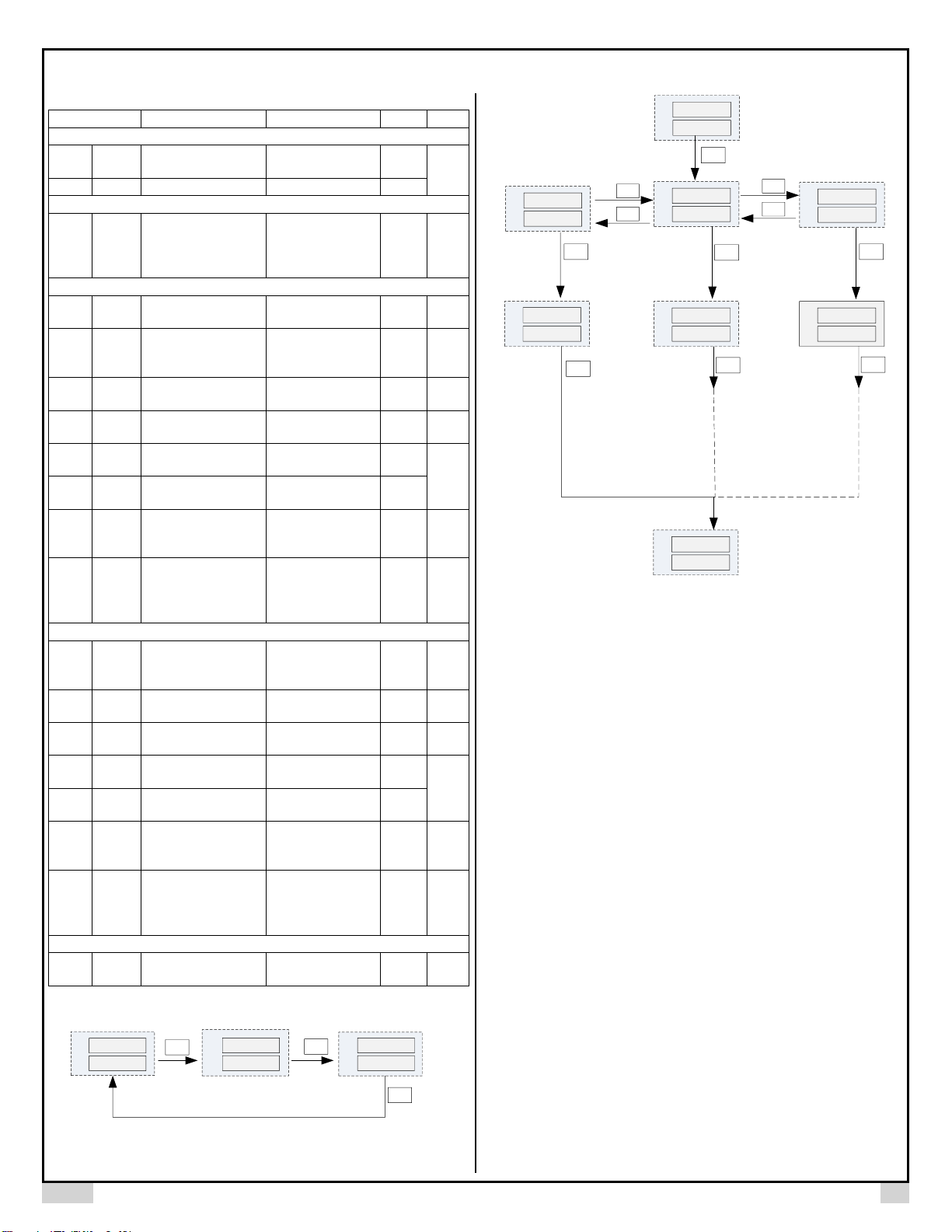

4. Setup Flow Chart

When the controller is powered on, it will display the measured

temperature and humidity. The controller will keep running according to the

saved setting. If the humidity or temperature sensor is shorted/disconnect, the

controller will display “Err”. Please see Figure 2 and 3 for the flow chart to set

the parameters.

5. Parameter Settings

To change the target temperature or humidity, press SET key momentarily.

The controller will show tSP (temperature set point), press SET again will show

HSP (humidity set point). Use Up or Down key to change the tSP or HSP. See

Figure 2 for details.

To change the other parameters, press SET key for 3 seconds, the RH window

(bottom window) will show tE, Hu or SYS* (depending on which menu was set

last time). tE menu is for temperature control settings; Hu menu is for humidity

control settings and SYS* is for system settings. Press Down (or Up) key to

change the RH window to Hu (or tE, SYS), which is the current selected menu,

then press SET key to enter.

To change parameter settings, in the parameter setup mode, use Up or Down

key to modify the parameter value. Then press SET key again to confirm the

change. This instrument will automatically exit if no key is pressed for 10

seconds. Please see the Table 1 for the parameters.

* Menu SYS and parameter PSD are only applicable for TH220-W model.

Instruction Manual

Page 2

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.10 P2/3

Table 1. Parameters Description

Code

Description

Setting Range

Initial

Note

Menu for set point (Figure 2)

tSP

tSP

Temp. Set Point

-40~176 ºF

-40~80 ºC

75.0

1

HSP

HSP

Humidity Set Point

0~99.9 %RH

40.0

Menu for parameters (Figure 3)

Edt

EDT

Menu Selection

tE: Temp. Menu

Hu: Humidity Menu

SYS*: System

Menu

TE

6

Temp. control settings (Edt = tE)

C-F

C-F

Temp. Unit

C: Celsius

F: Fahrenheit

F

tCM

tCM

Temp. Control Mode

Ht: Heating Control

CL: Cooling

Control

CL

TdF

TDF

Temp. Control

Differential

0~50.0

3.0 1 toF

toF

Temp. Calibration

Offset

-10.0~10.0

0

2

tAH

TAH

Temp. High

Limit Alarm

-40~176 ºF

-40~80 ºC

95.0

3

tAL

TAL

Temp. Low

Limit Alarm

-40~176 ºF

-40~80 ºC

32.0

TAS

TAS

Temp. Anti-short

Cycle Delay (only for

cooling)

0~12 min

0

4

TSF

TSF

Temp. Sensor

Failure Operation

ON: Output

energized

OFF: Output de-

energized

OFF

5

Humidity control settings (Edt = Hu)

HCM

HCM

Humidity Control

Mode

deH:

Dehumidifying

H: Humidifying

H

HdF

HDF

Humidity Control

Differential

0~50.0

3.0 1 HoF

HoF

Humidity Calibration

Offset

-10.0~10.0

0 2 HAH

HAH

Humidity High Limit

Alarm

0~99.9

90.0 3 HAL

HAL

Humidity Low Limit

Alarm

0~99.9

10.0

HAS

HAS

Humidity Anti-short

Cycle Delay (only for

dehumidifying)

0~12 min

0

4

HSF

oFF

Humidity Sensor

Failure

operation

ON: Output

energized

OFF: Output de-

energized

OFF

5

System setting (Edt = SYS*)

PSD

PSD

Device Access

Password

100 ~ 999

666

7

SET

T

RH

tSp

5 4.2

T

RH

1 5.0

HSp

RH

T

6 8.9

3 6.8

SET

Humidity Set PointTemp. Set Point

SET

Figure 2. Flow Chart Part 1

6 8.9

3 6.8

3 sec

T

RH

Edt

tE

T

RH

Edt

Hu

T

RH

C-F

F

T

RH

HcM

deH

T

RH

Dn

Up

6 8.9

3 6.8

T

RH

SET

SET

SET

SET

Temp.

Unit

Humidity

Control

Settings

Humidity

Control

Mode

Temp.

Control

Settings

Edt

sys

T

RH

Dn

Up

SET

System

Setting*

psd

666

T

RH

Access*

Password

SET

SET

Figure 3. Flow Chart Part 2

Note 1. For heating (or humidifying), the output will be off when the

temperature (or humidity) reaches the set point; it will be on again when the

temperature (or humidity) drops down to tSP - tdF (or HSP - HdF).

For cooling (or dehumidifying), the output will be off when the temperature (or

humidity) reaches the set point; it will be on again when the temperature (or

humidity) rises to tSP + tdF (or HSP + HdF).

Small differential gives tight control. Large differential reduces the frequency of

cycle on and off, and it will extend the life of relay and compressor.

Note 2. The offset is used to set an input offset to compensate the error

produced by the sensor or input signal itself.

For example, for temperature reading, if the unit displays 37 ºF when the actual

temperature is 32ºF, setting parameter toF = - 5 will make the controller display

32ºF.

Note 3. The low limit alarm will be always lower than the high limit alarm. When

the measured temperature (humidity) is higher than tAH (HAH), the

temperature (humidity) high limit alarm will be on; when the measured

temperature (humidity) is lower than tAL (HAL), the temperature (humidity) low

limit alarm will be on.

When alarm is on, the display will be flashing between the measured value and

alarm type. To mute the alarm when it is on, press the Down key momentarily.

When the alarm is muted, the alarm indicator (see Figure 1, the small dot on

the last digit) will be on. If the measured value gets out of the alarm zone then

Page 3

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.10 P3/3

gets back to the alarm zone again, the alarm will be on again. To resume the

alarm, press the Up key, the alarm indicator will be off.

To disable the alarm, set High Limit Alarm = Low Limit Alarm.

Note 4. When The controller is used for cooling (or dehumidifying control) and

load is a compressor, it should not turn on the compressor when it is at high

pressure (just after turned off). Otherwise, it may shorten the life of

compressor. The Anti-Short Cycle Delay function can be used to prevent the

rapid cycling of the compressor. It establishes the minimum time that the output

contact remains open (after reaching cutout) before closing again. The delay

overrides any load demand and does not allow the output contact to close until

the set time-delay value has elapsed. It gives time to release the refrigerant

pressure through evaporator. It is typically set to 4-6 (minutes).

Note 5. The TSF (HSF) can be set to ON or OFF. When it is set to ON, the

output will always be on when the sensor fails; when it is set to OFF, the output

will always be off when the sensor fails.

For example, when the unit controls a refrigerator for food, you may want to set

the TSF to ON if the sensor fails to keep the food cold. When it controls a

heater, you may want to set the TSF to OFF for safety purpose.

Note 6. Menu selection parameter. tE menu is for temperature control settings;

Hu menu is for humidity control settings and SYS is for system settings. SYS

setting is only available to TH220-W model.

Note 7. Device access password (only available to TH220-W model). This

parameter is used to lock the access to parameter settings on AuberSmart

app. Please refer to figure 3.

6. How to install the sensor to the unit.

The connector of sensor contains a slot for fitting pin connection. It locates at

the bottom of the controller. It also has a spring lock to prevent disconnections

from accidental pulling on the cable.

To install the sensor to the controller: 1) Identify the key on the male sensor

connector (Figure 4, a) and the notch on the female connector (Figure 4, b). 2)

Hold the tail of the female connector, align the notch and the key, and push the

female connector forward.

To remove the connector, hold the spring-loaded collar on the female

connector and pull it back. Please see Figure 5.

(a)

(b)

(c)

Figure 4. Install the sensor.

Figure 5. Remove the sensor.

Auber Instruments

5755 North Point Parkway, Suite 99

Alpharetta, GA 30022, USA

www.auberins.com

E-mail: info@auberins.com Tel: 770-569-8420

Copyright 2007-2017, Auber Instruments All Rights Reserved.

No part of this manual shall be copied, reproduced, or transmitted in any way

without the prior, written consent of Auber Instruments. Auber Instruments

retains the exclusive rights to all information included in this document.

Loading...

Loading...