Page 1

AUBER INSTRUMENTS WWW.AUBERINS.COM

A

Instruction Manual

Instruction Manual for EZBoil® DSPR320

Version 1.0 (August, 2018)

Caution

This controller is intended to control equipment under normal operating

conditions. Failure or malfunction of the controller may lead to abnormal

operating conditions, which result in personal injury or damage to the equipment

or other property. Devices (limit or safety controls) or systems (alarm or

supervisory) intended to warn of or protect against failure or malfunction of the

controller must be incorporated into and maintained as part of the control system.

Installing the rubber gasket supplied will protect the controller front panel from

dust and water splash (IP54 rating). Additional protection is needed for higher

IP rating.

This controller carries a 90-day warranty. This warranty is limited to the

controller only.

1. Specifications

Table 1. Specs of DSPR320.

Input type RTD (Resistance Temperature Detector): PT100

Accuracy ± 0.2% of full scale

Sensor input range 0°F ~ 932°F, -17°C ~ 500°C

Response time ≤ 0.5 s

Display resolution 1°C or °F

Control mode temperature, power

Program step Up to 9 steps in each mode

Timer range 00 H 00 M to 99 H 00 M

Main output 12 VDC for solid state relay

Relay output 3 A for resistive load. 1 A for inductive load

Number of relays 2

Power supply 85 V ~ 260 V AC / 50 ~ 60 Hz

Power consumption ≤ 5 Watt

Working ambient

temperature

Dimensions 48 x 48 x 100 mm (W x H x D, from the front panel to the back)

Mounting cutout 45 x 45 mm

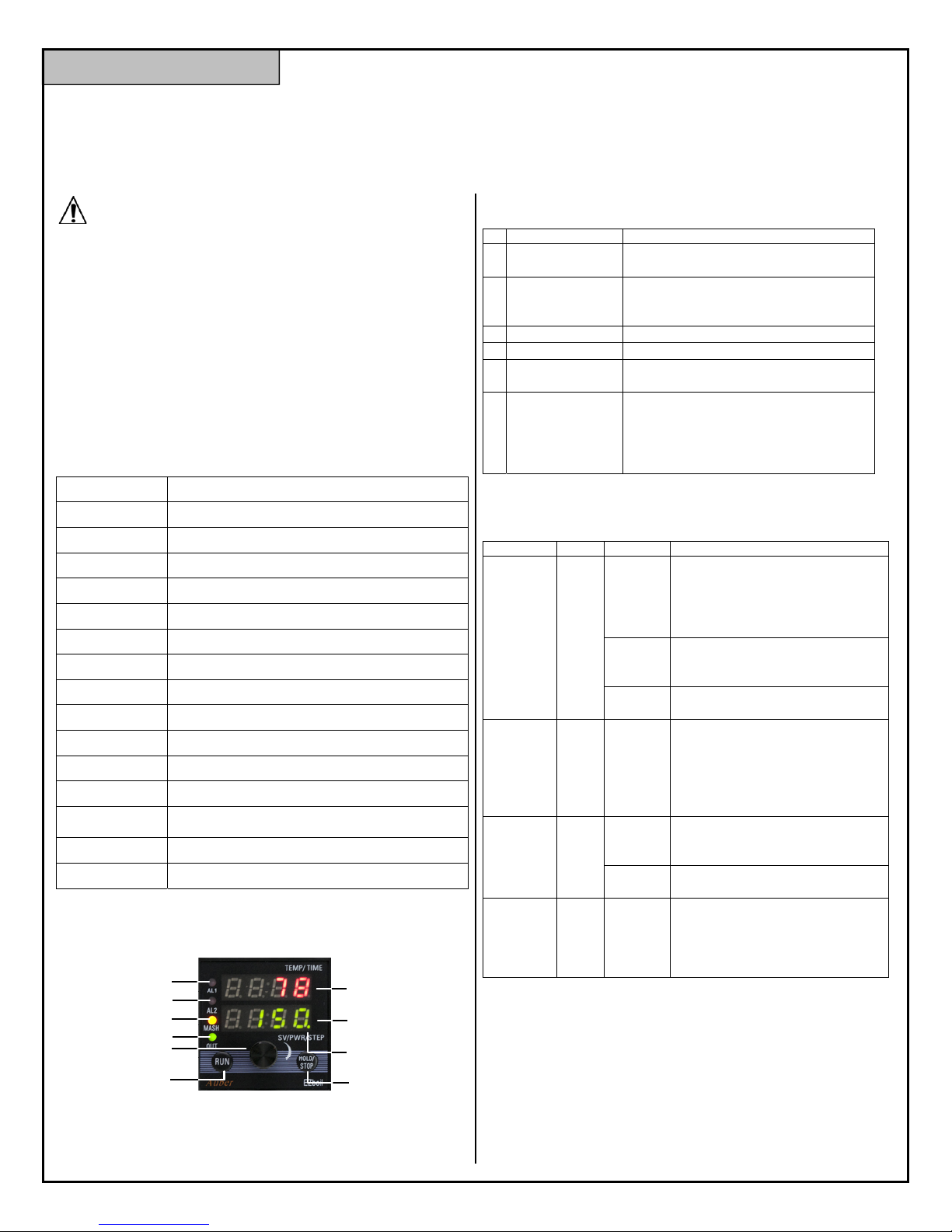

2. Front Panel

0ºC ~ 50ºC, 32ºF ~ 122ºF

4

5

6

1

2

7

8

3

9 10

Figure 1. The front panel of DSPR320.

2.1. Display

Table 2. Front panel display.

# Name

1 Top Display

2 Bottom Display

3 AL1 Indicator (red)

4 AL2 Indicator (red)

5 MASH Mode

Indicator (yellow)

6 Output Indicator

(green)

2.2. Key Functions

Table 3. Key functions

#

Key

8 Knob

9 RUN

10

Combination

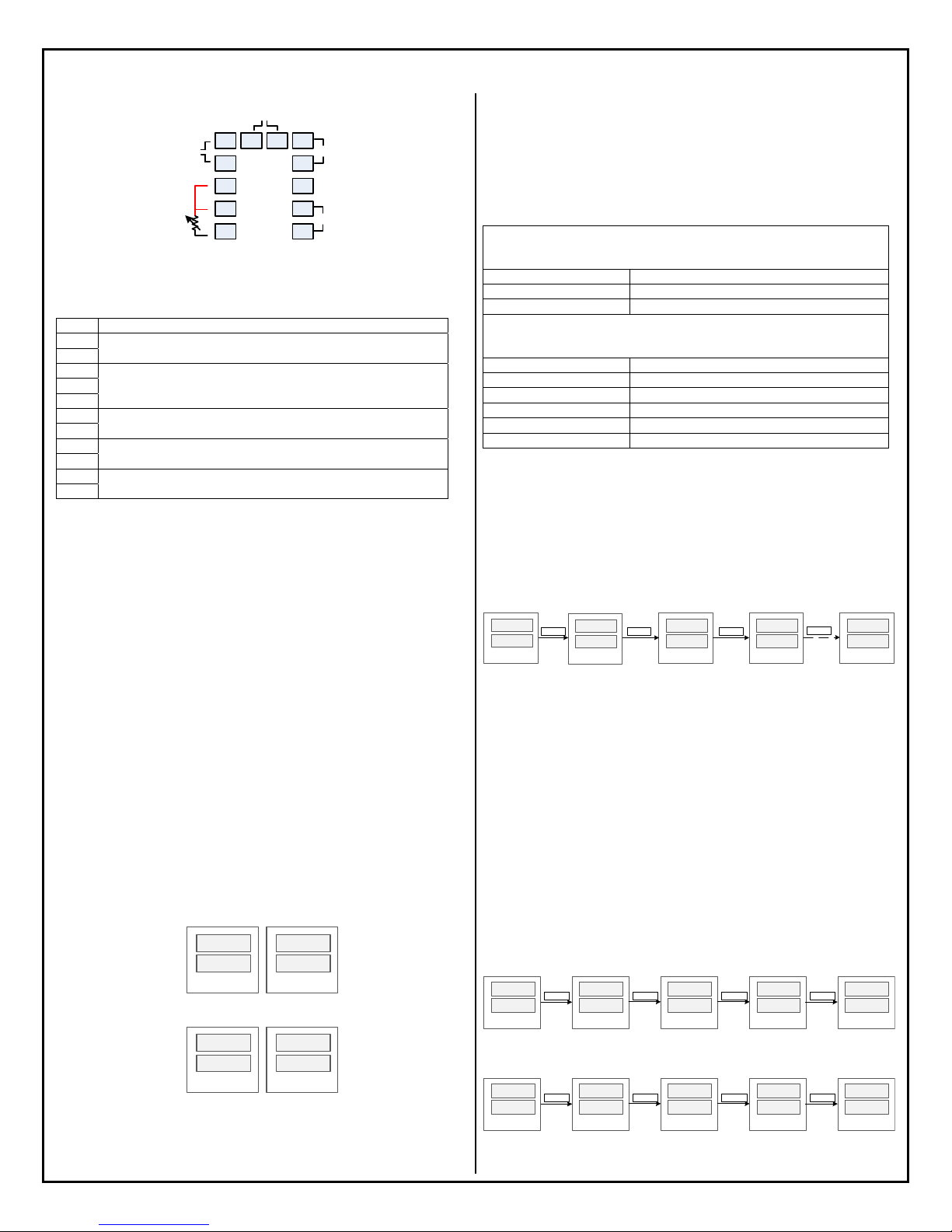

3. Wiring Terminals

The pin assignment of the back terminals of DSPR320 is shown in Figure 2 and

the descriptions of each terminal are given in the table below.

HOLD

/STOP

RUN

+

KNOB

Descriptions

Temperature reading and step-timer.

Parameter names.

Set value, step number, and program

status.

Parameter values.

Light up when Relay 1 (AL1) pulls in.

Light up when Relay 2 (AL2) pulls in.

Light up when controller is in MASH

mode.

Light up when the controller is sending

control signal to the SSRs. When it

flashes, the percentage of time of it

being lit up indicates the percentage of

power that is being sent to the SSRs.

ction

Short press

Long press

Rotate

Short press

Short press

Long press

Hold

down the

RUN key

and press

the knob

Functions

Press the knob to bring up the

Quick Access Menu.

Press the knob to select a

parameter or to save the

parameter value.

Press and hold the knob 3

seconds to bring up the Main

Menu.

Rotate the knob to browse and

change parameter values.

Start the program.

Resume the timer if timer is

paused.

Mute the on-board buzzer and/or

cancel the relay action if

temperature alarms are triggered.

Pause the timer.

Hold it down for 2 seconds to stop

the program.

End the program and stop all

outputs.

Go back to the previous

parameter in the menu list.

2018.08 P1/11

Page 2

AUBER INSTRUMENTS WWW.AUBERINS.COM

AL2

-

SS R

7

+

8

9

AC

85~260V

10

RTD

AL 1

1

13 14 6

2

3

R

4

R

5

W

Figure 2. Terminal assignments of DSPR320.

Table 4. Back terminals of DSPR320.

Pin # Descriptions

1 Relay 1 (AL1)

2

3 Probe input (PT100 RTD). Two red leads should be connected to pin 3

and 4.

4

5

6 Control output (12 VDC), pin 7 is the positive and pin 6 is the negative.

7

9 Power input (85 V ~ 260 V AC)

10

13 Relay 2 (AL2)

14

4. Getting Started

Before you start using this controller, please read the manual carefully. This

section only provides a brief description on some of the most basic operations of

this controller. Please read the later sections in this manual to understand how this

controller works and learn more about each parameter.

4.1. Power Up

To test the unit and get familiar with all the features of this controller, please

connect a PT100 RTD probe and then supply the 120 V or 240 V AC power.

4.2. Displayed Information

When the controller is powered up for the first time, the top display will show

current probe reading, and the bottom display will show the program status

“STOP”.

When the program is running but the temperature has not yet reached the setvalue of the current step (i.e., the step-timer has not started yet), the top window

shows the current temperature reading, and the bottom display will flash between

the current set-value and the current step number (Figure 3). When the step-timer

has started, the top window will show the probe reading and the time alternatively,

and the bottom window will still show the current set-value and the current step

number alternatively (Figure 4). If the set-value has the letter “P” display on its left,

that means this is a percentage value of power, not a temperature value.

7 8

1 5 0

7 8

m - 1

Figure 3. Two display screens when the step-timer has not started.

1 4 9

1 5 0

00:45

m - 1

Figure 4. Two display screens when the step-timer has started.

There are four LED indicators on the left side. The top two red LED are

synchronized with the relay AL1 and AL2 status respectively. The third LED is

yellow, and it lights up if the controller is at MASH mode. The last green indicator

is synchronized with the output signal to the external SSR.

4.3. Understand the Menu Structure

The table below shows the menu structure of DSPR320 and how to access the

menu.

Table 5. Menu structure of DSPR320.

(Short-press the knob to bring up the Quick Menu; rotate the knob to browse different

RST (n/y)

STEP (1 ~ 9)

MODE (Mash/Boil)

(Hold down the knob for 3 seconds to bring up the Main Menu; rotate the knob to

browse different menu items; press the knob again to select. )

mPRG

bPRG

mSET

bSET

RELY

SYST

Quick Access Menu

options; press the knob again to select.)

Reset the program

Jump to the selected step

Select mode

Main Menu

Mash mode program

Boil program

Mash-step settings

Boil-step settings

Relay configurations

System configurations

4.4. Select Mash or Boil Mode

There are two program modes: MASH and BOIL. By default, the controller is at

MASH mode. If you want to run the program in Boil mode, please press the knob

to bring up the Quick Access Menu. Next, rotate the knob clock-wise till you see

“MODE” in the top display and “BOIL” in the lower display. Then, press the knob

again to confirm the selection. The MASH indicator will light up if the controller is

in MASH mode, and it should turn off if the controller is in BOIL mode.

Press

KNOB

MODE

B O I L

stop

7 8

Press

KNOB

R S T

N

Keepturning

KNOB

STEP

1

Keepturning

KNOB

MODE

MASH

Figure 5. Select Program Mode on DSPR320.

4.5. Adjust Parameters

All parameters are divided into four groups in the Main Menu: mSET (mashing

step settings), bSET (boiling step settings), RELY (relay settings), and SYST

(system settings). Press the knob for 3 seconds to go the Main Menu and turn the

knob to select the desired parameter group to edit. Please refer to Section 7 of this

manual for the detailed explanation of each parameter.

4.6. Enter the Program

Press down the knob for 3 seconds to go the main menu, the first two items are

mPRG (Mash Mode Program) and bPRG (Boil Mode Program). Rotate the knob

to select which program to enter and press the knob again to confirm.

There are maximum 9 steps can be entered in each mode. For each step, the user

will be asked to enter the set-value and the step-timer. The Figure 6 below shows

the operations for how to enter the set-value of the Step 1 of the Mash Program.

And the Figure 7 shows the same operations for Boil Program.

stop

7 8

Press

KNOB

3sec

GOT O

mPRG

Press

KNOB

M1 - s

M 0

Turn

KNOB

M1 - s

M1 5 0

Press

KNOB

M1 - t

0 0:0 0

Figure 6. Entering the Mash Program.

stop

7 8

Press

KNOB

3sec

GOT O

bPRG

Press

KNOB

b1 - s

p 0

Turn

KNOB

b1 - s

P 2 5

Press

KNOB

b1 - t

0 0:0 0

Figure 7. Entering the Boil Program.

2018.08 P2/11

Page 3

AUBER INSTRUMENTS WWW.AUBERINS.COM

The set-value can either be a temperature value (with letter “M” display on the left)

or a percentage number (with letter “P” displayed on the left) of the power output.

The user can rotate the knob to select from 0% to 100% power and from 0 to

932 °F/°C. Press the knob to confirm the value and go to the timer setting.

The step-timer can be set in the HH:MM format, ranging from 00:00 to 99:00, or a

special code which can be SKIP, HOLD, END, or CONT. Please see later sections

for details. If the step-timer a step is set to END or CONT, the user won’t be

prompted with the next step.

4.7. Start the Program

Simply press down the RUN key to start the program. The top window will show

“RUN” shortly and then show probe reading and start running the first valid step.

RUN

1 5 0

Figure 8. The top window shows “RUN” when the program starts.

4.8. Make Adjustment On-the-Fly

This controller offers a quick way for users to adjust the set-value and the steptimer of the current step without going back into the programming menu. It also

allows the program to be jumped from the current step to any other valid step in

the program.

a) Change the set-value. When the lower display shows the current set-value,

simply turn the knob in either direction to start editing the value. A flashing dot will

appear at the lower right corner to indicate the set value is being editing. Keep

turning the knob till the desired set-value is shown in the lower window. Then press

the knob to confirm the change, otherwise the new value won’t be saved.

7 8.

1 5 0.

Turn

KNOB

7 8.

1 5 0.

Turn

KNOB

7 8.

1 5 5.

Depress

KNOB

7 8.

1 5 5.

Figure 9. Changing the set-value while the program is running.

b) Change the step-timer. When the lower display shows the current step number,

turn the knob in either direction to start editing the step-timer. A flashing dot will

appear at the lower right corner to indicate the new value hasn’t been saved yet.

Press the knob again to confirm the change, otherwise the new value won’t be

saved. The Figure 10 below shows this operation when the temperature is still

being ramping up to the step’s set-value. So, the top window only shows the

current probe reading. If the step-timer had started, the top window will show the

current time.

7 8.

m - 1.

Turn

KNOB

7 8.

0 0:4 5.

Turn

KNOB

0 0:5 0.

7 8.

Depress

KNOB

7 8.

m - 1

Figure 10. Changing the step-timer while the program is running.

c) Pause the timer. When the temperature reaches the timer-start-point, the steptimer will start counting down time. The user can manually pause the timer by

short-pressing the HOLD key. When the timer is paused, the top window will show

“HOLD.”. To resume the current step- timer, press the RUN key shortly and the

controller will show “RUN” in its top window. The Figure 11 shows how to pause

the timer.

0 0:4 5.

m- 1.

Figure 11. Operations to pause and to resume the step-timer.

When the timer is paused from the key pad, a dot will also appear in the right

corner of “HOLD.” indicates that the timer is temporarily paused and it can be

resumed. This is different from setting/changing the step-timer to HOLD, where

the timer display is “HOLD” (no dot) and pressing the RUN key will make the

program continue to the next step.

d) Jump to another step. While the program is running, it can be jumped from

the current step to another step in the program. This operation is not valid if the

program is ended or stopped. The operation is shown in Figure 12. Press the knob

to bring up the Quick Access Menu. The top window will show “STEP” and the

current step number will be shown in the lower window. Turn the knob to find the

desired step number and press down the knob to confirm. If you select a valid step

number, the controller will jump to the selected step and executing the new step.

If you select the current step number or a non-valid step number, the controller will

take no action and simply return to the main operation interface. Here, a non-valid

step refers to a step whose step-timer is set to SKIP or a step behind the last step

of a program.

7 8.

1 5 0.

Press

KNOB

Figure 12. Jumping from one step to another while the program is running.

Please note that all changes that the user makes from the main interface are

temporary. It doesn’t affect the programs that have been saved in the mPRG or

bPRG. The controller will always retrieve the set-value and the step-timer value of

the next step from the saved program.

4.9. End or Stop the Program

In DSPR320, End and Stop are different status. When a program has come to its

end, whether the controller will enter the End or the Stop status depends on the

parameter EO (Ending Option for Mash Mode) and bEO (Ending Option for Boil

Mode). Please refer to section 5.7 for details.

Ways to End a program:

a) Wait till the controller finish executing all the programmed steps.

b) Change the step-timer to “END”. The program will come to its end when the

temperature reaches the timer-start-temperature.

Ways to Stop a program:

a) Press and hold the “STOP” key for about 3 seconds to end the program and

stop all outputs.

b) Reset the program by going to the Quick Access Menu and select “RST/Y”.

c) Switch the Operation Mode from one to another will also end the current

program.

d) Power off the controller and power it on again.

5. Understand the Controller DSPR320

5.1. Program Mode

In DSPR320, a Program Mode, or a Mode, can save a program with up to 9 steps.

There are two Modes on DSPR320: MASH and BOIL. The Program Mode is

indicated by the MASH LED indicator. The intended use of MASH Mode is to

control water or wort temperature during a mashing process. The default setvalues of all steps in MASH Mode are 0 degree. The temperature unit depends on

Press

HOLD

Step

1.

HOLD.

1 5 0.

Turn

KNOB

Press

RUN

STEP

RUN

m- 1.

Press

RUN

KNOB

3

1 6 0.

2018.08 P3/11

Page 4

AUBER INSTRUMENTS

the C-F setting in the SYST menu. The intended use of BOIL Mode is to bring

water or wort to its boiling point and remind the user to add hops. The default setvalues of all steps in BOIL Mode are 0% of power. It is displayed as “P 0”, where

the letter P indicates this is a percentage value of power.

Despite the difference in the default set-values, the DSPR320 controller does allow

the user to change set-values freely from temperatures to power percentages, or

vice versa. Any step in MASH mode can be a power-control step (boiling step),

and any step in BOIL mode can be a temperature-control step (mashing step).

This feature gives users a great flexibility to customize the desired heating profiles

per their brewing recipes and control automation needs.

Please note that switching Program Mode while a program is running will result in

the program being terminated immediately. This operation is not recommended.

5.2. Program

A Program refers to a series control steps that has been saved under a Program

Mode (MASH or BOIL). A program can have no more than 9 steps. When the user

edits a program, if a step’s step-timer is set to END, the user won’t be asked to

enter settings for the next step.

When the controller runs a program, it always starts from Step 1 or the first valid

step and ends at either at the step where the step-timer is set to END or at Step 9

if it exists.

The MASH Mode has a special feature that allows the controller to continue to run

the program saved in BOIL Mode automatically when the Mash program is finished.

To use this feature, the last step in the MASH Mode should be set to CONT instead

of END by turning the knob counter-clockwise for a full turn.

The user can go to mPRG (MASH mode program) and bPRG (BOIL mode

program) in the main menu to enter or edit the programs.

Step settings in mPRG and bPRG are named in this format: aX-B, where:

a: can either be letter m or b to indicate MASH mode or BOIL mode.

X: a numeric number ranging from 1 to 9.

B: can either be letter S or t where

S: set-value.

t: step-timer.

For example, the parameters of the Step 1 of MASH mode are m1-S and m1-t

while the parameter of the first step of BOIL mode are b1-S and b1-t.

5.3. Step

A step can be considered as one of many sections that consist a program. It

defines the temperature or power percentage that the controller should maintain

for a certain duration of time. A step is exclusively referring to the time period when

the temperature has reached a pre-defined timer-start-point and the step-timer is

counting time. The beginning of a step is when the step-timer starts and the end

of a step is when the step-timer ends. In a program, the sections between steps

are transition sections, or called ramp sections. The controller doesn’t regulate the

ramp-up or ramp-down speed.

The settings of a step consist of the set-value and the step-timer. The step-timer

only starts counting when the temperature has reached a pre-defined timer-startpoint (see section 5.6 for details).

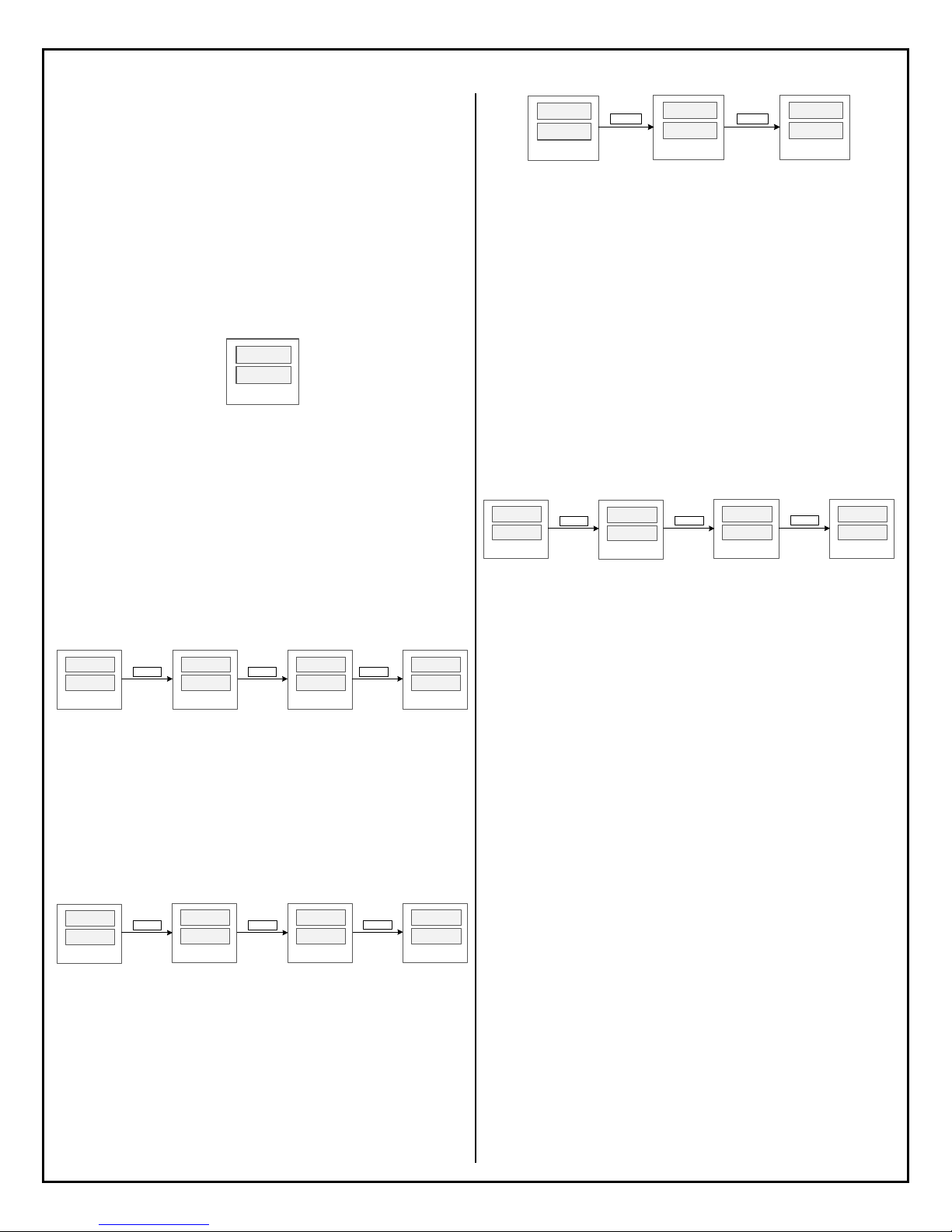

5.4. Ramp Sections

In DSPR320, program sections between steps are called ramp sections. Some of

the relay functions are closely associated with the ramp sections, hence a clear

definition of each section is necessary. A STEP section is exclusively referring to

the time period when the temperature has reached a pre-defined timer-start-point

and the step-timer is counting time. The section prior to the start of a STEP as well

as its step-timer is referred as the RAMP section of a step. A ramp section where

the temperature needs to be ramped up is called HEAT section. A ramp section

where the temperature needs to be cooled down is called COOL section. A RAMP

WWW.AUBERINS.COM

section and a STEP section together are referred as an Extended Step (EXTN)

section. The plot in Figure 13 shows a short two-step program to illustrate what

the different sections are. The description of each section is given in the table.

Please note that the controller determines whether a section is HEAT or COOL

by comparing the current probe reading and the step’s set-value instead of

comparing the set-values of two steps.

Figure 13. A two-step program to illustrate different program sections.

Table 6. Program sections of the two-step example program.

Step # Time Range Description Section

0 ~ 5 min Ramp section of Step 1, which is a HEAT

1

5 ~ 10 min

0 ~ 10 min

10 ~ 20 min Ramp section of Step 1, which is a COOL

2

20 ~ 40 min Step 2

10 ~ 40 min Extended Step 2 EXTN

To determine whether a transition section is HEAT or COOL, the controller

compares the current probe reading against the step’s set-value instead of

comparing the set-values of two steps. This comparison only happens when the

program is in a transition section, i.e., when the step-timer of the next step hasn’t

yet started.

However, the boiling steps (power-control steps) are handled differently since

there is no set-value for boiling steps. For boiling steps, the controller uses the

bTSP (boiling timer-start-point) for comparison purpose. Table 7 listed the

different situations of how the controller determine HEAT or COOL of a ramp

section.

Table 7. Determine HEAT or COOL between two steps.

To Step (n+1)

From Step

(n)

Mashing Step

Boiling Step

5.5. Step-Control Mode

The step-control mode, or control mode, refers to how the power is regulated at

a step, which can either be temperature-control or be power-control. In

temperature-control mode, the goal is to raise and maintain the water or wort

temperature at the specified value. The steps that have set values in temperature

(0 ~ 932 °F/°C) use temperature-control mode and these steps are sometimes

referred as mashing steps for convenience. In the power-control mode, the goal

is to bring water or wort to boil by raising the water or wort temperature above

section

Step 1

Extended Step 1 EXTN

section

Mashing Step Boiling Step

PV vs SV PV vs bTSP

bTSP vs SV bTSP vs bTSP (N/A)

Type

RAMP,

HEAT

STEP

RAMP,

COOL

STEP

2018.08 P4/11

Page 5

AUBER INSTRUMENTS WWW.AUBERINS.COM

No

No No

A

No No

certain threshold and then let the user to adjust the power output percentage

manually. Steps that have set values in percentage (0% ~ 100%) use power-

control mode and these steps are sometimes referred as boiling steps for

convenience.

For any step in a program, the control mode can be either temperature-control or

power-control. The MASH or BOIL mode doesn’t impose any constraint on the

control mode of any step in its program. When entering the set-value for a step,

the user can simply select either a power percentage number or a temperature

value as the set-value.

Please note that “mashing step” or “boiling step” refers to how the power is

controlled for a particular step, while the “mash mode” or “boil mode” refers to

the program mode that is intended to be used for the mash or boil process.

5.6. Set-Value

The set-value of a step can be either a power percentage value (from 0% to 100%)

or a temperature value (from 0 to 932). The percentage numbers and the

temperature values together make up a combined list of available set-values:

0%, 1%,....99%, 100%, (bo) (ma), 0, 1, 2, … 931, 932.

When editing the set value, the user can rotate the knob to select the desired value.

Turning the knob clockwise will increase the value, and turning the knob counterclockwise will decrease the value. When the value changes from percentage to

temperature, the lower window will show “MA” shortly to remind the user the set

value is temperature value for mashing. Conversely, when turning the knob

counter-clockwise and as the value changes from temperature to percentage, the

lower window will show “BO” shortly to remind the user the set value is power

percentage for a boiling step. All temperature values have the letter “M” displayed

on the left side, and all percentage values have the letter “P” will be display on the

left side to indicate these are percentage values. For example, 0% is displayed as

“P 0” and 0 degree is displayed as “m 0”.

When the program is running, temperature set-values will NOT have the letter “M”

displayed on the left, but the percentage values do have the letter “P” on the left.

5.7. Step-Timer

The step-timer defines the time duration of a step where the temperature or the

power should be maintained at its set-value. The timer can be set to anywhere

between 0 minute to 99 hours. The time duration is displayed in the format of

HH:MM.

The step-timer setting can also be a special command which tells the controller

how to handle this step instead of counting down time. The special command can

be SKIP, HOLD, END, or CONT. The meaning of a command is explained in the

table below. Please note that “CONT” is not available to the BOIL program mode.

Table 8. Special commands of step-timers.

Command Description

SKIP Bypass this step.

HOLD Hold the program at the current step. Press RUN key to continue to

the next step.

END End the program.

CONT End the MASH Program and continue to execute the first step of the

BOIL program. Only available to MASH Program.

When the controller executes a step, it won’t start the step-timer or execute the

special command until the probe reading has reached a timer-start-point. For

temperature-control steps (mashing steps), the timer-start-point is determined by

tSP, which defines a two-sided deviation band around the set-value (see Figure

14). For power-control steps (boiling steps), the timer-start-point is determined by

bTSP, which defines an absolute temperature value above which the timer should

start. Once this temperature is reached, the controller will start counting down time

until the time is reached, or execute the special command. Once the timer starts,

it won’t stop nor pause because of the probe temperature drops output of the timerstart-point. However, the user can manually pause the timer by pressing the HOLD

key, and then resume the timer by pressing the RUN key.

230

210

190

170

150

130

Tem p er a t u r e(° F)

110

90

70

Boilin gstep

bTSP

SV+tSP

Mashingstep

0 5 10 15 20 25 30 35 40 45

Time(min)

SV‐tSP

Figure 14. The timer-start-point of boiling steps and mashing steps are defined

differently.

5.8. End or Stop the Program

When the last step of a program is executed, the program ends and controller will

either show “END” or “STOP”. In DSPR320, End and STOP are different status.

STOP means the controller has turned off all outputs, including the main SSR

output as well as both relays. END means the program has come to an end, but

the controller will continue to regulate the temperature or the power per the setvalue of the last step. See Table 9 for a comparison between these two statuses.

Table 9. The differences between END and STOP.

Main Output

Relay Output

larms

END

Yes

STOP

When a program has come to its end, whether the controller will enter the END or

STOP status depends on the parameter EO (Ending Option for Mash Mode) and

bEO (Ending Option for Boil Mode).

By default, both EO and bEO are set to OFF, which means that once a program

has ended, there will be no output from the controller. The controller will show

current probe reading in the top window and show “STOP” in the bottom window

(Figure 15).

7 9

stop

Figure 15. DSPR320’s display when a program is stopped. All outputs are turned

off.

If EO and/or bEO is set to ON, the controller will continue to regulate the

temperature if the last step is a temperature-control step, or to regulate power if

the last step is a power-control step. The controller will show the current probe

reading and “END” alternatively in the top bottom window. The bottom window

will show the set-value of the last step in the program (in Figure 16, the set-value

is 80). The OUT indicator will show the output status accordingly.

2018.08 P5/11

Page 6

AUBER INSTRUMENTS WWW.AUBERINS.COM

… …

…

…

…

END

8 0

7 5

8 0

Figure 16. DSPR320’s display when a program is ended. The OUT indicator is

on as the controller still tries to maintain the temperature at set-value.

Once the program has ended or stopped, pressing the RUN key won’t start the

program again. The user needs to reset the controller, by either going to RST in

the Quick Access Menu or cycle the power supply to the controller, before the

program can be started again.

5.9. Use Relays to Assist the Brewing Process

The DSPR320 is equipped with two build-in relays, Relay 1 (labelled as AL1) and

Relay 2 (labelled as AL2). They are identical in terms of their capability and

specifications. There available Relay Mode settings are: ALAM, BEEP, ALBE,

RAMP, HEAT, COOL, STEP, and EXTN. Please see section5.3 and 7.5 for more

details.

The functions of the relays can be divided into three main groups:

a) Temperature alarms: ALAM and ALBE.

b) Event remainder: BEEP.

c) Program-section control: RAMP, HEAT, COOL, STEP, and EXTN.

For the first two groups, temperature alarms or event reminder, the main

application is to use the relay to drive an external buzzer.

With the functions in the third group, the controller can complete more complexed

home brewing automation tasks, such as turning on an additional heater during

the ramp-up section of certain steps, turning on the wort pump during all mashing

steps, or turning on a circulation pump for chiller during ramp-down sections when

wort needs to be cooled down. An example of how to use the replay to control

pumps are given in the section 10.1 of this manual.

6. Quick Access Menu

The Quick Access Menu has three functions as shown below.

RST -- reset the program

STEP -- jump to another step

MODE -- select Program Mode

Table 10. Quick Access Menu.

Top

Disp.

RST

Bottom

Disp.

N

Y

(Rotate the knob to browse, press the knob to confirm the

No effect. Return to the normal operation mode.

Reset the program, stop all outputs. The user

can start the program again by press down the

Functions

selection.)

RUN key.

When a program is running, select a valid step

number to jump to the selected step.

Selecting the current step number has no

STEP 1 ~ 9

effect.

Selecting non-valid step number, i.e., a step

that doesn’t exist in the current program or a

step has been set to SKIP, has no effect.

Stop all output and switch to MASH mode if

MASH

MODE

BOIL

current mode is BOIL.

No effect if current mode is MASH.

Stop all output and switch to BOIL mode if

current mode is MASH.

No effect if current mode is BOIL.

To bring up the Quick Access Menu, simply press the knob shortly. When the

controller is not executing any program, i.e., the controller is at the END or the

STOP status, press the knob will bring up the RST function. If a program has been

started, press the knob will bring up the STEP function. The user can rotate the

knob to select the desired function. To confirm the selection, press the knob again.

The table below listed the details of each function in the Quick Access Menu.

7. Main Menu

Program settings and parameters are grouped into 6 submenus.

mPRG – the program of Mash Mode.

bPRG – the program of Boil Mode.

mSET – settings for all mashing (temperature-control) steps.

bSET – settings for all boiling (power-control) steps.

RELY – settings for relay AL1 and AL2.

SYST – system parameters.

To bring up the Main Menu, press down the knob for 3 seconds. Then the top

window will show “GOTO” (go-to) and the bottom window will show the first item

in the menu list, which is “mPRG” (mPRG). Turn the knob to find the correct submenu, and then press down the know to select the item. The parameters in each

sub-menu are listed and explained below.

7.1. mPRG – Mash Program

The user can enter or edit the Mash Program in this sub-menu. Only the settings

for Step 1 is listed and described in Table 11. Steps in the rest of the program are

identical to Step 1.

Table 11. mPRG menu.

Display Name Description Range Default Note

m1-s m1-S Set-value 0% ~ 100%, 0 ~

m1-t m1-t Step-timer CONT, END, HOLD,

…

m9-S m9-S …

m9-t m9-t …

mPRG

0 °F/°C 1

932 °F/°C

00:00 2

SKIP, 00:00 ~ 99:00.

… …

… …

… …

Note 1. Set-value can be a percentage value or a temperature value,

corresponding to a boiling step or a mashing step respectively. The unit of set

temperatures is decided by the C-F setting in the SYST menu.

Note 2. When the temperature has reached the timer-start-point of a step, the

controller will start the step-timer or execute the special command. The special

commands are explained below:

CONT – Continue executing the Boil Program when the Mash Program is over.

END – End the program.

HOLD – Hold the program at the current step till the user press the RUN key.

SKIP – Bypass this step.

However, the special command SKIP is an exception. If a step-timer is set to SKIP,

this step will be bypassed when running the program, and the step number will

become invalid in the current program. For example, in a 4-step mashing program,

if the user changes the m2-t to SKIP, the controller will only execute Step 1, 3, and

4, and the user can’t not jump to the Step 2 of this program.

The command CONT is only available in MASH program mode. To select CONT,

turn the knob counter-clockwise for a full turn when you see END. If the step-timer

is set to END or CONT, the controller won’t ask the user to enter settings for the

rest of steps. And so, the rest steps don’t exist to this particular program.

2018.08 P6/11

Page 7

AUBER INSTRUMENTS WWW.AUBERINS.COM

3

A

5

7.2. bPRG – Boil Program

The user can enter and edit the BOIL program in this sub-menu. The settings of

the BOIL program are the same as the MASH program, except that the command

CONT is not available in the BOIL Program. Only the settings for Step 1 is listed

and described in Table 12. Steps in the rest of the program are identical to Step 1.

Table 12. bPRG menu.

Display Name Description Range Default Note

b1-s b1-S Set-value 0% ~ 100%, 0 ~

b1-t b1-t Timer END, HOLD, SKIP,

b9-S b9-S … … … …

b9-t b9-t … … … …

bPRG

0% 1

932 °F/°C

00:00 2

00:00 ~ 99:00.

Note 1. Set-value can be a percentage value or a temperature value,

corresponding to a boiling step or a mashing step respectively. The unit of set

temperatures is decided by the C-F setting in the SYST menu.

Note 2. Please refer to the Note 2 of section 7.1.

7.3. mSET -- Mashing (temperature-control) Step Settings

Most of the parameters in this submenu defines how the controller runs all the

mashing steps (temperature-control steps) in both the MASH program and the

BOIL program. However, EO is a parameter that only applies to the MASH

program.

Table 13. mSET menu.

mSET

Display Name Description Range Default Note

tSP tSP

EO

oScr oScr Overshoot correction -50 ~ +50 0

mout mOUT

AtTE

Mashing step timer-

start-point

EO

Mashing program

ending option

Mashing acceleration

output power

ttE Attenuation constant -2 ~ +2 0

0 ~ 932 °F/°C 1°F 1

ON, OFF OFF 2

0% ~ 100% 100% 4

Note 1. tSP, timer-start-point for mashing steps, defines a two-sided deviation

band between the probe reading and the set temperature, within which the steptimer should start. For example, if tSP = 1 and m1-S = 150°F, then it means that

when the probe reading reaches the range between 149°F and 151°F, the Step 1

timer will start.

Note 2. EO, ending-option of the MASH program, defines whether the controller

will send out the power after the Mash Program ends. If EO = OFF, no output will

be sent after the Mash Program ends; controller will show “STOP” at the bottom

display. If EO = ON, controller will continue to send out power per the set value of

the last step after the program ends; controller will show “END” at the bottom

display. To completely turn off the output, the user can hold down the STOP key

until the bottom display shows “STOP”.

The difference between STOP and END are explained in the section 4.9 and 5.8.

Note 3. oSCr, overshoot correction, is a parameter that helps users to correct the

temperature overshot if it happened during the initial heat up. For example, if the

temperature overshot 2 degrees, set oScr = 2 to remove this overshoot. Some

users may want to set oScr as negative number to purposely impose a

temperature overshot, which can reduce the temperature response delay between

the hot liquor tun and the mash tun. Please note that oScr affects the initial heating

up phase as well as the transition phase between steps. It has no effect on how

the controller stabilize the temperature at the current set temperature.

Note 4. mOUT, acceleration output power for mashing steps, determines the

maximum output power can be sent during the acceleration stage of heating up

the water or wort toward the set temperature of the next step.

Note 5. ATTE, attenuation constant, is parameter to adjust the temperature-control

stability in mashing steps. The value ranges from -2 to +2. The default value is 0.

If the temperature fluctuates more than 1 degree, user can increase the value of

this parameter. If the controller takes a long time to eliminate the gap especially

when temperature drops below the set temperature, the user can reduce the ATTE

value to make the system more responsive.

7.4. bSET -- Boiling (power-control) Step Settings

All parameters, except bEO, in this submenu defines how the controller runs all

the boiling steps (power-control steps) in both the MASH program and the Boil

Program. The parameter bEO only applies to the BOIL program.

Table 14. bSET menu.

bSET

Display Name

bAST

bOUT bOUT

btSP bTSP

bEO bEO

bAST

Description

Boiling acceleration

set temp.

Boiling acceleration

output power

Boiling timer start

temp.

Boiling ending

options

Range Default Note

0 ~ 932 °F/°C 200°F 1

0% ~ 100% 100% 2

0 ~ 932 °F/°C 208°F 3

ON, OFF OFF 4

Note 1. bAST, boiling-acceleration set temperature, defines a set point of

temperature below which the controller will use the maximum power percentage,

which is defined by parameter bOUT, to heat up the water or wort. When the

temperature rises above bAST, the controller will change the power percentage to

the step’s set-value saved in the program. By default, bAST is set at 200°F, which

means when the temperature hasn’t reached 200°F yet, the controller will send

the maximum power percentage that is allowed by parameter bOUT.

Note 2. bOUT, boiling-acceleration output percentage, defines the maximum

power percentage that the controller is allowed to use during the boilingacceleration phase of every boiling step. By default, this parameter is set to 100%.

Note 3. bTSP, timer-start-point of boiling, defines a temperature above which the

step-timer of a boiling step (power-control step) should start. By default, this

parameter is set at 208°F, which means that once the water or wort temperature

the step-timer will start.

Note 4. bEO, ending-option of BOIL program, defines whether the controller will

send out the power after the BOIL program ends. If EO = OFF, no output will be

sent after the Boil Program ends; controller will show “STOP” at the bottom

display. If EO = ON, controller will continue to send out power per the set value of

the last step after the program ends; controller will show “END” at the bottom

display. To completely turn off the output, the user can hold down the STOP key

until the bottom display shows “STOP”.

7.5. RELY -- Relay Configurations

This controller has two relays: Relay 1 (labelled as AL1) and Relay 2 (labelled as

AL2). Pparameters to configure each relay are identical. Those parameters that

have the number “1” in their names are for Relay 1, and the parameters that have

the number “2” in their names are for Relay 2. In this section, we’ll explain these

parameters in general, not particularly for Relay 1 nor Relay 2.

2018.08 P7/11

Page 8

AUBER INSTRUMENTS WWW.AUBERINS.COM

A

3

5

A

9

A

1 A 0

2 B 0

C 0

4 D 0

5 E 0

6 F 0

Table 15. RELY menu.

Display Name Description Range Default Note

rL rL Relay mode. OFF, ALAM,

rRG rRG Relay working range. MASH, BOIL,

LGC LGC Relay logic rL-C, rL-O rL-C

rLP rLP Relay programming. None, 0 ~

LAT LAT Relay latching mode N, PUL N

SIL SIL Relay

AH AH Absolute high alarm OFF, 0 ~

AL AL Absolute low alarm OFF, 0 ~

DH DH Deviation high alarm OFF, 1 ~

DL DL Deviation low alarm OFF, 1 ~

HY HY

AP AP Pulsing duration 1 ~ 100

silence/suppressing

larm hysteresis band 1 ~ 100 °F/°C 1

RELY

OFF 1

BEEP, ALBE,

RAMP, HEAT,

COOL, STEP,

EXTN

ALL 2

LL

ALON 4

511, ALON

ON, OFF OFF 6

OFF 7

932 °F/°C

OFF 7

932 °F/°C

OFF 8

100 °F/°C

OFF 8

100 °F/°C

5 10

seconds

Note 1. rL, relay mode, determines how the relay works. The available modes

are explained in the table and the figure below. Please refer to section 5.3 for

details of program-sections.

Table 16. Relay Mode menu.

Display Name Descriptions Note

OFF OFF Disable the relay.

ALAM ALAM Relay activated by temperature alarms, which are

determined by parameter

BEEP BEEP Relay is synchronized with on-board buzzer. 1.2

ALBE ALBE Relay activated by temperature alarms. The on-board

buzzer also beeps when temperature alarms are

triggered.

RAMP RAMP Relay activated during ramp-up and ramp-down

sections.

HEAT HEAT Relay activated during the ramp-up sections only.

COOL COOL Relay activated during the ramp-down sections only.

STEP STEP Relay activated during the step section only, i.e., timer-

counting sections.

EXTN EXTN Relay activated during the extended-steps, which

includes the ramp section and the step section.

rL

1.1

H, AL, DH, and DL.

1.3

1.4

1.5

1.6

1.7

1.8

Note 1.1 ALAM, temperature alarm, the relay will be activated when the alarm

conditions defined by AH, AL, DH, or DL are met.

Note 1.2 BEEP. The relay is synchronized with the on-board event buzzer. The

on-board buzzer goes off when an event happens, which are start of a program,

end of a step, start of a step-timer, end of a program, pause of a step-timer, and

resume of a step-timer.

Here is a special case. If a relay’s, for example Relay 1, rL1 is set to BEEP and

the other relay’s mode rL2 is set to ALBE, that means the on-board buzzer will

go off whenever the temperature alarms are triggered Relay 2 alarm settings,

hence the Relay 1 will also pull-in as the buzzer goes off. When the on-buzzer is

triggered by temperature alarms, the user can mute the buzzer by pressing the

RUN key. Once the buzzer is muted, the Relay 1 will also drop out.

Note 1.3 ALBE, both the relay and the on-board buzzer will be activated when

the temperature alarm conditions are met.

Note 1.4 RAMP. Relay will be activated during RAMP sections, i.e., the transition

sections when the previous step has ended and before the next step starts. A

ramp section is essentially a section between two steps when step-timer isn’t

counting time.

Note 1.5 HEAT. Relay will be activated during the HEAT sections, i.e., ramp

sections where heating is needed.

Note 1.6 COOL. Relay will be activated during the COOL sections, i.e., ramp

sections where cooling is needed.

Note 1.7 STEP. Relay will be activated during the STEP sections, i.e., when

step-timer has been started and has not yet ended.

Note 1.8 EXTN. Relay will be active during Extended Step section, which include

a STEP and its RAMP section.

Note 2. rRG, relay range, defines whether this relay works in MASH program

only, BOIL program only, or in all programs. This parameter can be set to MASH,

BOIL, and ALL. By default, it is set to ALL.

Note 3. LGC, relay logic, determines relay status before and after the alarm

conditions are met. It can be set to Logic-Close (RL-C) or Logic-Open (RL-O).

When a relay is set to RL-C, the relay is a normally open (NO) relay, i.e., the relay

stays open when it is inactive; the relay pulls in (close) when it is activated. When

a relay is set to RL-O, the relay is essentially a normally closed (NC) relay, i.e., it

stays closed when it is inactive; the relay contacts open up (drop out) when the

relay is activated. By default, LGC = RL-C, which should be used for most

applications.

Note 4. rLP, relay programming, is a parameter that determines at which steps in

a program the relay is allowed to function per its relay mode (rL, see note 1 in

this section) setting. This parameter has a numeric value ranging from 0 to 511,

where “0” means the relay is not allowed to function at any step in a program,

and “511” means the relay is enabled for all 9 steps in a program. Any other

value in between 0 and 511 indicates that the relay is only allowed to function at

certain specified steps. The calculation method is explained later in this section.

Two special codes, NONE and ALON, are added to the rLP values, where

” is equivalent to “0”, and “ALON” is equivalent to “511”. By default, rLP

“NONE

= ALON, which allow the relay functioning for the entire program.

To use this feature, the user should decide at which steps the relay is enabled,

and then use the equation below to calculate the value of rLP:

rLP = A×1 + B×2 + C×4 + D×8 + E×16 + F×32 + G×64 + H×128 + I×256,

where the letter A, B, C, and etc. are binary numbers, 0 or 1, representing

whether the relay function is allowed at a particular step. The Table 17 shows the

letter code, the code value, and the multiplier of each step. For instance, if the

user wants to enable the relay function only at step 1 and 5, the rLP value should

be 17 (rLP = A×1 + E×16 = 1×1 + 1×16 = 17). The value of rLP can be

calculated by this online relay programming calculator here.

Table 17. rLP calculation table.

Step # Letter Code

3

Letter Code Value

Disabled Enabled

1 1

1 2

1 4

1 8

1 16

1 32

Multiplier

2018.08 P8/11

Page 9

AUBER INSTRUMENTS WWW.AUBERINS.COM

2

5

6

8

7 G 0 1 64

8 H 0 1 128

9 I 0 1 256

Special Note

1) This parameter rLP imposes a hard constraint on at which steps the relay

function is enabled. However, whether the relay will be actually activated

depends on the relay mode (rL) setting and whether the activating condition is

met. This parameter applies to all relay modes.

2) The “step” here refers to the “extended step”, which includes a step and the

ramp section prior to the step. Please see section 5.4.

Note 5. LAT, latching mode, determines how should a relay returns back to its

deactivated status once it is activated. It only affects the relay if the Relay Mode

rL is set to ALAM or ALBE. This parameter can be set to N (normal/nonlatching) or to PUL (pulsing).

When LAT = N (normal), the relay will be activated when the alarm condition is

met, and it will be deactivated when as the alarm condition is removed. When LAT

= PUL (pulsing), once the alarm is triggered, the replay will stay in the activated

status for a pulse duration that is defined by parameter AP (please see Note 10 in

this section). This function is useful in situations where the user only needs to

energize the buzzer for a short period of time once the alarm is triggered.

Note 6. SIL, alarm-silence/suppression, determines whether to suppress the

Absolute Low Alarm (AL) when the controller just starts running the program and

the water or wort temperature is still lower than the Absolute Low Alarm (AL). By

default, SIL is set to OFF. If SIL = ON, controller will suppress the relay action at

the very first time that the Absolute Low Alarm (AL) is triggered. If the Absolute

Low Alarm (AL) is turned off, the SIL setting has no effect on the relay actions.

Note 7. AH (Absolute High Alarm) and AL (Absolute Low Alarm), defines the

high and low temperature alarms that applies to the entire control process from

the beginning of a program till the end of a program. When the temperature is

higher than AH, the alarm relay will be activated; it will be deactivated when

temperature drops below (AH - HY). Similarly, when the temperature is lower

than AL, the alarm relay will be activated; and it will be deactivated when the

temperature rises above (AL + HY). However, please note, absolute alarms

won’t work in situations where a program is ended or stopped.

AL+HY

Temp.

AL

AlarmOn

AbsoluteLowAlarm

Time

AH‐HY

Te mp.

AH

AlarmOn

AbsoluteHighAlarm

Time

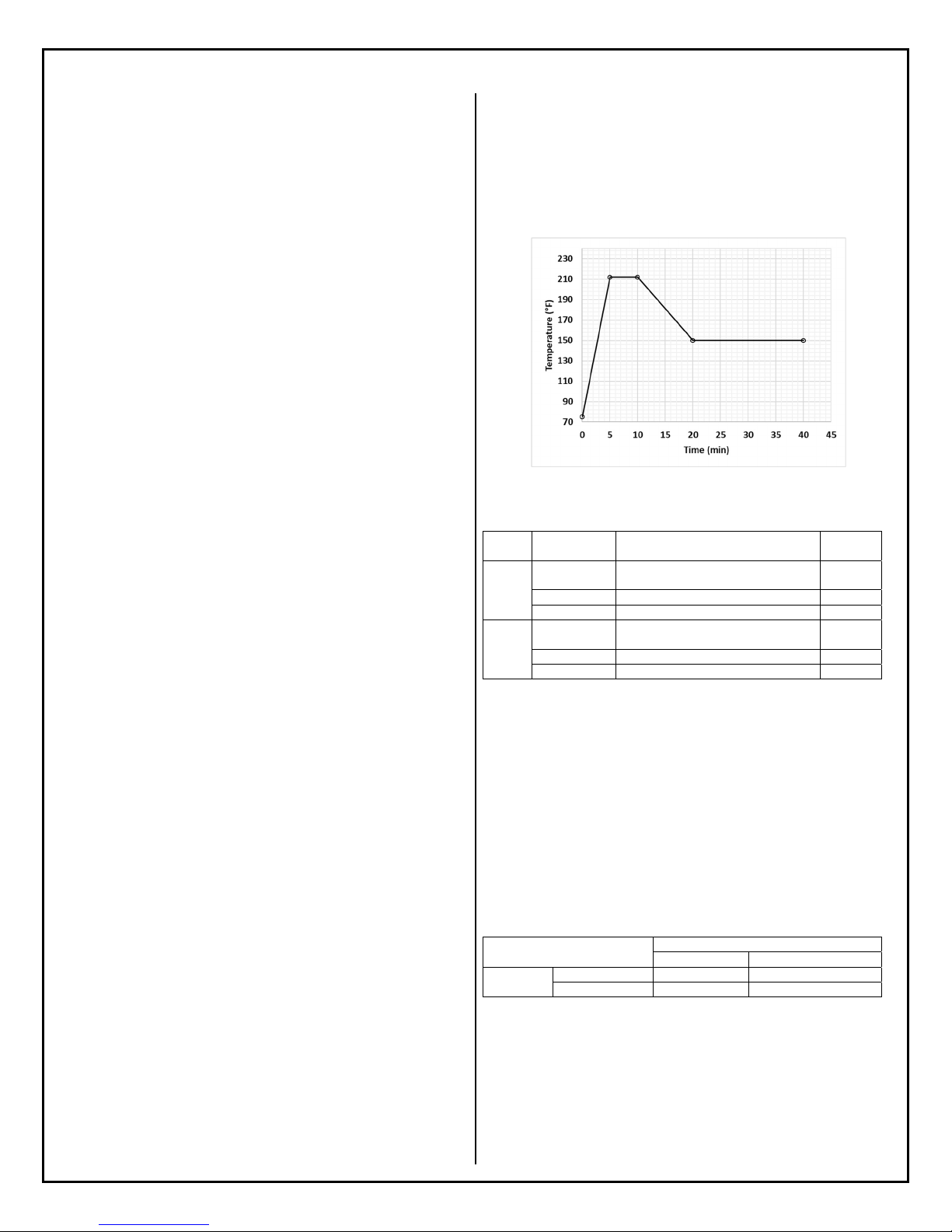

Figure 17. Absolution alarms.

Note 8. dH (Deviation High Alarm) and dL (Deviation Low Alarm), defines the

how much temperature deviation from the set temperature (SV) is allowed before

the alarm is triggered. For mashing steps, the set values are temperatures. When

the temperature is higher than (dH + SV), the alarm relay will be activated; it will

be deactivated when temperature drops below (dH + SV - HY). Similarly, when

the temperature is lower than (SV - dL), the alarm relay will be activated; it will be

deactivated when the temperature rises above (SV - dL + HY).

SV+dH‐HY

Special Note: deviation alarms only applies to mashing steps and only when the

step-timer has started; it doesn’t apply to the ramp sections of a program nor

applies to boil-steps.

Note 9. HY, hysteresis/differential band, determines the difference between the

temperatures of activating and deactivating an alarm. By default, HY = 1.

Note 10. AP, alarm pulsing duration, determines the time duration of which a

relay should stay activated if a relay’s LAT is set to PUL. The unit is in second,

and the range is from 1 to 100 seconds.

7.6. SYST – System Settings

System parameters for the controller.

Table 18. SYST menu.

Display Name Description

Pb Pb Probe offset -20.0 ~

C-F C-F Temperature unit °F, °C °F

PUS PUS Power-up setting. INST,

ART ART Auto-return time, unit in

Knob KNOB Knob operation.

MUAL MUAL Mute alarm relay. n / y n

VER VER Firmware version. Display

INIT INIT Initialization, factory reset. n / y n

Note 1. Pb, probe offset. Pb is a value added to the probe reading to

compensate the error produced by the sensor or input signal itself. Normally it

should be left at zero. For example, if the controller reads 33ºF from a probe

immersed in well prepared ice bath which is supposed to be 32°F. Set Pb = -1.0

and so the controller should show 32°F. The resolution of Pb is 0.1°F or °C,

which enable the user to calibrate the probe reading with high resolution

thermometers.

Note 2. C-F, temperature unit, can be set to °F (Fahrenheit) or °C (Celsius).

Changing the temperature unit only affects the probe reading. The numerical

values of set temperatures and other temperature related settings will not be

changed or converted.

Note 3. PUS, power-up setting, determines how should the controller start the

program and send out control signal. When PUS = INST, controller starts

executing its program once it is powered up. PUS = DELY, program won’t be

executed until the user press the RUN key to start the program.

Note 4. ART, auto-return time, determines how long should be the controller

wait, if no key is pressed, before it returns from the menu list to the normal

operation mode. The unit is in seconds, and the default value is 30 seconds.

Note 5. KNOB, knob operation, determines whether the controller allows the

user to change the set-value and the step-timer using the knob from the main

interface while the program is running. When KNOB = Y, this operation is

allowed. When KNOB = N, this operation is not allowed.

SV+dH

Te mp.

SV

DeviationHighAlarm

SV–dL+HY

AlarmOn

Time

Figure 18. Deviation alarms.

SYST

seconds

only.

Temp.

SV

SV‐dL

AlarmOn

DeviationLowAlarm

Range Default Note

20.0

DELY

10 ~ 60

sec

y / n y

7

0.0 1

DELY 3

30 sec 4

Time

2018.08 P9/11

Page 10

AUBER INSTRUMENTS WWW.AUBERINS.COM

A

2

A

3

A

A

80

V

ALL

A

Note 6. MUAL, mute alarm-relay option, determines whether the user can cancel

the relay action by pressing the RUN key when a relay is activated by

temperature alarms. This setting only applies to Relay Mode ALAM and ALBE.

And this parameter setting only affects the relay action, not the on-board buzzer.

In situations where the on-board buzzer is triggered by temperature alarms, i.e.,

one of the relay’s rL is set to ALBE, pressing down the RUN key will always mute

the on-board buzzer.

Note 7. VER, firmware version.

Note 8. INIT, initialization, allows all parameters to be reset back to factory

default values if the user select INIT = Y.

8. On-board Buzzer Sound

The on-board buzzer will give different sound at different program events. The

table below listed different sounds and the corresponding events. The programrelated sound cannot be muted. When the buzzer is triggered by temperature

alarms, the user can use the RUN key to temporarily mute the on-board buzzer.

The alarm buzzer will be re-activated once the temperature moves out from the

alarm-zone.

Table 19. Buzzer sound.

Buzzer Sound Event

One short beep

Start of a program

Pause/resume a step-timer

Three short beeps

Temperature reaches the timer-start-

point, i.e., a step-timer starts counting

down time.

Two long beeps

A step-timer is reached, i.e., the end of

a step.

Four long beeps

Long beeps, continuously

A program is ended or stopped.

Temperature alarm is triggered (only

applies to situations where Relay Mode,

RL1 or RL2, is set to ALBE.

9. Sensor Error

If there is no sensor connected or the sensor input signal is out of range, the

controller will show Out of Range Alarm on the top window, i.e., flash “ORAL” and

932°F (or 500°C) in the top window. When the controller detects sensor error, it

will stop all outputs and pause the program if a program is running. The program

will be resumed if the sensor error is removed.

10. Application and Wiring Examples

10.1. Using DSPR320 for low-oxygen brewing in a BIAB setup.

In this example, a DSPR320 is used to control the heater in a BIAB kettle. The

Relay 1 will be used to control the wort-circulation pump during mashing, and the

Relay 2 will be used to control a smaller pump for circulating cold water through

an immersion chiller to cool the wort. The program we used in this example is

fictional but based on a real recipe.

In the Main Menu, go to mPRG and enter the MASH program.

Step # mX-S mX-t Note

1 P 25% 00:05 Boil water for 5 min.

2 P 25% HOLD Prepare a mineral/additive addition.

3 200 00:01 Reminder for adding mineral/additive.

4 150 00:00 Cool water temperature to 150°F, add grain.

5 144 HOLD Stop heater while adding grain.

6 144 00:45 Mashing at 144°F for 45 min.

7 160 00:45 Mashing at 160°F for 45 min.

8 170 00:15 Mash-out rest.

9 170 CONT Continue to the Boil Program.

Then, go to bPRG and enter the BOIL program.

Step # bX-S

1

4

5

P 25% 00:30

P 25% 00:15

P 25% 00:10

P 25% 00:05

bX-t Note

dd hops for bittering, boiling for 60 min.

dd hops for flavoring, boiling for 30 min.

dd hops for flavoring, boiling for 15 min.

dd hops for aroma, boiling for 5 min.

END Cool the wort.

In the RELY menu, the following parameters need to be changed from their default

values. Other unchanged parameters are not listed in this table.

Name

rL1

rRG1

rLP1

rL2

rRG2

rLP2

alue

EXTN

MASH

480

COOL

LON

Note

Relay 1 controls the wort pump, which runs during step 6,

7, 8, and 9 in Mash Mode.

Relay 2 controls a small pump to circulate cold water

through a chiller during all the ramp-down sections of both

Mash and Boil programs.

10.2. Wiring Examples

Example 1. Using DSPR320 with 120 VAC or 240 VAC to drive a DC triggered

AC SSR to control a heater.

-

4

-

SSR

+

7

3

+

8

9

Heater

N

120V AC

L

RTD

R

R

W

1

13 14 6

2

3

4

5

10

-

4

-

SSR

+

7

3

+

8

9

10

Heate r

L1

L2

240V AC

RTD

R

R

W

1

13 14 6

2

3

4

5

Figure 19. Using DSPR310D in a 120 VAC system (top) and in a 240 VAC

system (bottom) to drive an SSR and control a heater.

Example 2. Using the Relay 1 and Relay 2 on DSPR320 to drive an external

buzzer.

120 VAC

buzzer

RTD

1213 14 6

3

R

4

R

5

W

‐

4

‐

7

8

9

10

SSR

+

+

3

Heater

N

120VAC

L

L1

L2

240 VAC

Figure 20. Use the Relay 1 (pin 1 and 2) on DSPR320 to drive an external

buzzer.

2018.08 P10/11

Page 11

AUBER INSTRUMENTS WWW.AUBERINS.COM

Example 3. Using the Relay 1 on DSPR320 to control a relay and control the 120

VAC power to a NEMA 5-15R socket.

RTD

R30ARelay

(120VCoil)

NC

NO

COM

C1 C2

1213 14 6

3

R

4

R

5

W

NEMA5‐15R

Socket

N

L

G

‐

7

+

8

9

10

N

120VAC

L

4

3

1

‐

SSR

+

Heater

2

N

120 VAC

L

Figure 21. Using the Relay 1 (pin 1 and 2) on DSPR320 to control a R30A (120V

coil) relay which supplies power to a 15A socket.

(End)

Auber Instruments

5755 North Point Parkway, Suite 99

Alpharetta, GA 30022

www.auberins.com

Email: info@auberins.com Tel: 770-569-8420

Copyright 2007-2018, Auber Instruments All Rights Reserved.

No part of this manual shall be copied, reproduced, or transmitted in any way

without the prior, written consent of Auber Instruments. Auber Instruments retains

the exclusive rights to all information included in this document.

2018.08 P11/11

Loading...

Loading...