Page 1

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.03 P1/9

EZboil, Power Regulator for Boiling Process Automation DSPR120

Version 1.2 (Mar, 2017)

Caution

• This controller is intended to control equipment under normal operating

conditions. Failure or malfunction of the controller may lead to abnormal

operating conditions, which result in personal injury or damage to the

equipment or other property. Devices (limit or safety controls) or systems

(alarm or supervisory) intended to warn of or protect against failure or

malfunction of the controller must be incorporated into and maintained as part

of the control system.

• Installing the rubber gasket supplied will protect the controller front panel from

dust and water splash (IP54 rating). Additional protection is needed for higher

IP rating.

• This controller carries a 90-day warranty. This warranty is limited to the

controller only.

1. Specifications

Input type

RTD (Resistance Temperature Detector): Pt100

Accuracy

± 0.2% full scale

Temperature

range

-328° F ~ +932°F, -200° C ~ +500°C

Response time

≤ 0.5s

Display

resolution

1° C or °F

Control mode

Mashing, Boiling

Alarm function

Process high alarm

Power supply

85~260VAC/50~60Hz

Power

consumption

≤ 5 Watt

Working Ambient

temperature

0~50ºC, 32~122º F

Dimension

48 x 48 x 100 mm (W x H x D, from the front panel to

the back)

Mounting cutout

45 x 45 mm

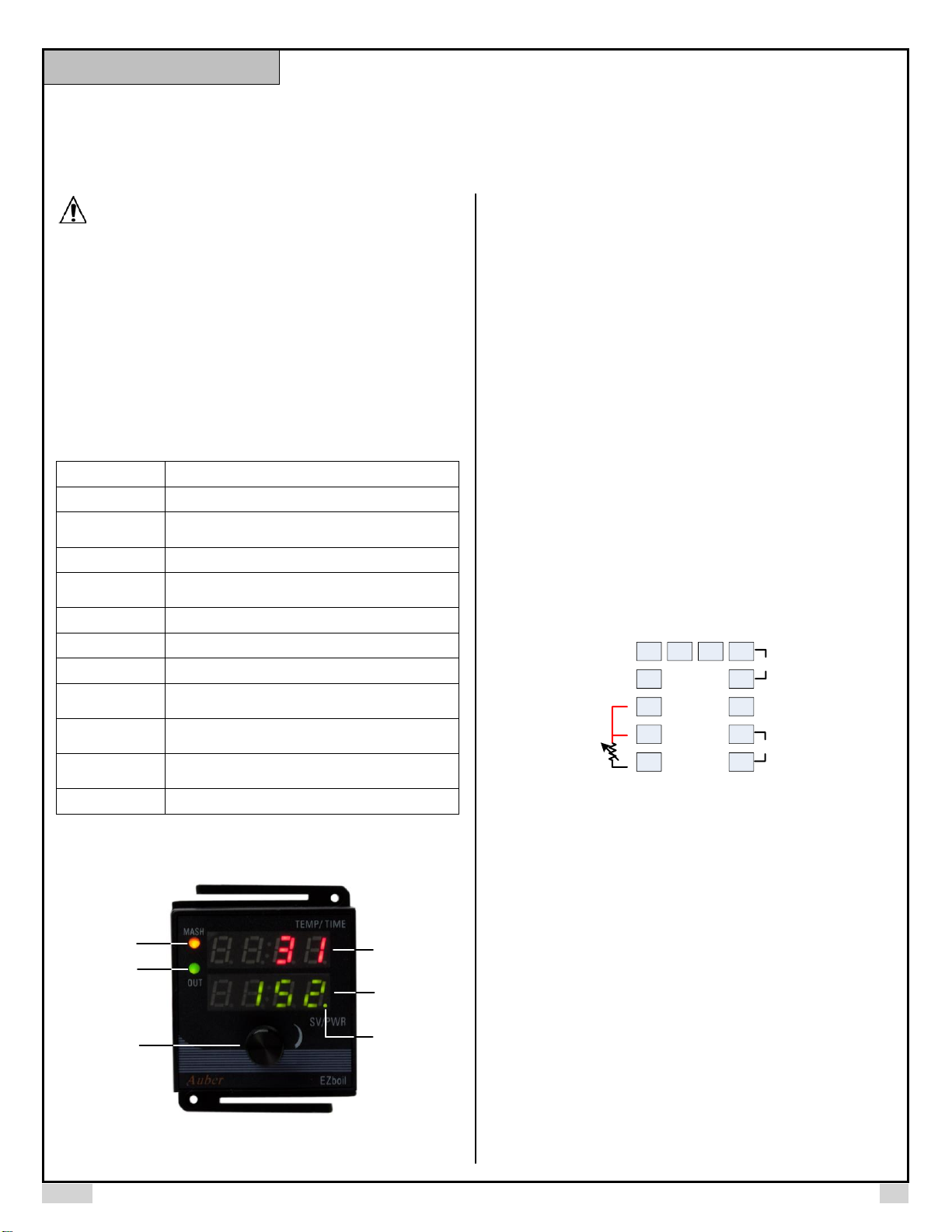

2. Front Panel

3

4

5

1

2

6

Figure 1. The front panel of EZboil

1). Top display. This display indicates the temperature sensor read out value.

When timer is activated, it will show time and temperature alternately.

2). Bottom display. In boiling mode, this display will show the percentage of

power being sent to the external SSR after the initial heat up phase. In mashing

control mode, this display will show the set temperature.

3). Rotary switch (knob). Turn it clockwise to increase the output power (or

selected parameter value); turn it counter-clockwise to reduce the output power

(or selected parameter value). Press it briefly to reset the timer (if enabled) and

to switch between mashing and boiling mode. Press and hold it for 5 seconds to

enter parameter settings menu. Please see section 6 for details.

4). Output indicator (OUT). This green LED light is synchronized with output. It

shows how much power the regulator is sending out (as a 12VDC control signal

pulse through terminal 6 and 7). When it is on solid, the output is 100% on. When

it is off, there should be no output. When it is flashing, the frequency of the

flashing is an indication of high or low power output. Higher frequency means

higher power output.

5). Mashing mode indicator (MASH). This yellow LED light indicates the

operation mode of the controller. When it is on, controller is in mashing mode;

when it is off, controller is in boiling mode.

6). Temperature setting adjusting indicator. This is the small dot at the lower

right corner. In mashing mode, when temperature set point is adjusted, it will

start to flash. It reminds you that you need to press the knob to confirm the

change. Otherwise, the temperature setting will return back in 2 seconds after

you stop the adjustment.

3. Wiring Terminals

The pin assignment of the back terminals of DSPR120 is shown in Figure 2.

1

2

3

13 14 6

7

8

9

10

4

5

AC

85~260V

SSR

+

-

RTD

R

R

W

Figure 2. Terminal assignments of DSPR120.

3.1 Sensor connection

DSPR120 only accepts Pt100 RTD temperature sensor. For a three-wire RTD

with standard DIN color code, the two red wires should be connected to the

terminals 3 and 4. The white wire should be connected to terminal 5. For a twowire RTD, the wires should be connected to terminals 4 and 5. Jump a wire

between terminals 3 and 4.

3.2 Power to the controller

The power cables should be connected to terminals 9 and 10. Polarity does not

matter. It can be powered by 85-260V AC power source. Neither a transformer

nor jumper is needed to wire it up. For the consistent with the wiring example

described later, we suggest you connect the hot wire to terminal 10 and neutral

to 9.

3.3 SSR output connection

The SSR control output of the DSPR110 provides a 12V DC signal that can

control up to 5 SSRs in parallel. Connect terminal 7 to the positive pole of the

SSR (terminal 3 on Auber’s SSRs). Connect terminal 6 to the negative pole of

the SSR (terminal 4 on Auber’s SSRs). Please make sure the SSR is installed

on the heat sink with proper current rating.

Instruction Manual

Page 2

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.03 P2/9

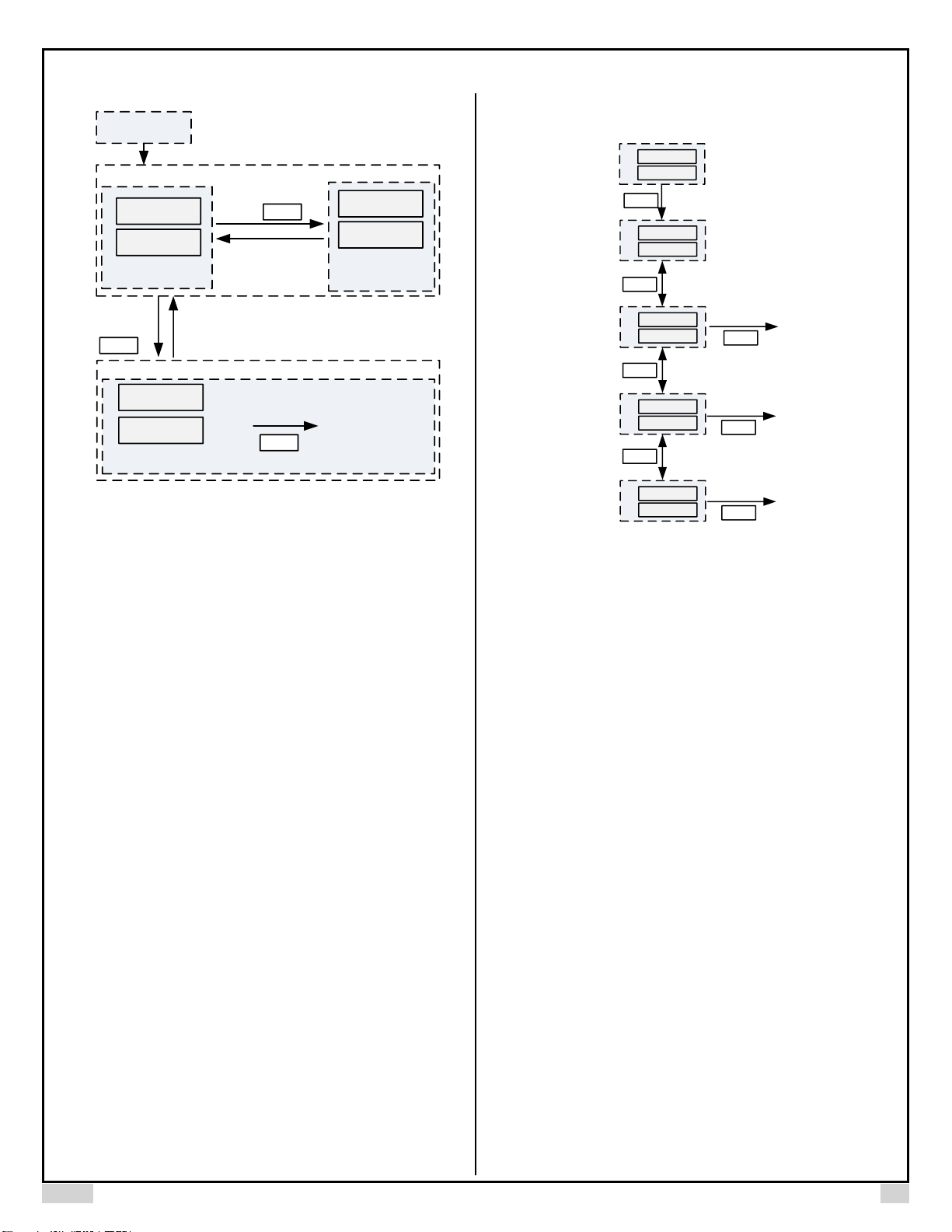

4. Display Status

Power on

80

100

Display mode 1

rst

n

Display mode 2

Mash

Parameter settings

Display mode 3

Next parameter

Goto

Timer reset /

mode selection

Knob

Press

Knob

Knob

Press down an d

Hold for 5s

Press

Exit

Exit

Figure 3. Display modes of DSPR120

Display mode 1 (Normal operating mode): When power is turned on, the top

display window shows the current sensor temperature reading. When timer is

activated, the top display will be switched between the current temperature and

current time alternately. In mashing mode, the bottom display will show your set

temperature. In boiling mode, the bottom display will show your current output

percentage (e.g. P50 for 50% power output). Please check section 5 for how to

adjust set temperature/power.

Display mode 2 (Timer reset & Operation mode selection): This display

mode allows you to reset the timer, or to switch between the mashing and boiling

operation mode.

A short press of the knob will enter this display mode.

1) The display will show “rSt” on top and “n” at the bottom. This is the exit menu.

If you enter this mode by accident, you can press the knob again to exit this

display mode without changing anything.

2) Rotate the dial clockwise for one click will change the bottom display to “y”.

This menu is to reset the timer. Press the knob will reset the timer. It has two

purposes. A) If you want to use the timer as regular timer without correlation to

the temperature, you can start the timer at any time by the reset button. B) After

timer is timed up and process ended, you can restart the process again by the

reset button instead of power off the system and power it on again.

3) Rotate the knob with two clicks, the top display will change to “Mode” and

bottom will show “Mash*”. Rotate the knob again, the bottom display will change

to “boil”. These two menus are for setting the controller to either mashing control

or boiling control mode. Press the knob will set the controller to the operation

mode displayed. Please check section 5.1 for details.

Display mode 3 (Parameter settings): Press down and hold the knob for 5

seconds to enter the display mode 3. Please check section 6 for details.

5. Operation

5.1 Operation mode selection

This controller offers two operation modes, mashing and boiling. When the

mashing mode is selected, the controller functions as a temperature controller.

It automatically adjusts the power output to hold the temperature at set point.

When boiling control mode is selected, the controller functions as a power

regulator. It allows the user to manually adjusting the power to control the

strength of the boil. Figure 4 shows how to select and switch between these two

modes.

rst

n

rst

y

80

100

Knob

Press

mode

mash

Rotate

mode

boil

Rotate

Knob

Mash Mode

Boil Mod e

Available if timer

is enabled

(TF =on)

Available if timer

is enabled

(TF =on)

Rotate

Knob

Knob

Press

Knob

Press

Knob

Timer Reset

Knob

Press

Figure 4. Flow chart for time reset & operation mode selection

Press the knob once. The display will show “rSt”. Rotate the knob with two clicks,

the top display will change to “Mode” and bottom will show “Mash*”. Press the

knob will set the controller to mashing mode. When mashing mode is selected,

the yellow indicator on the top left corner of the panel will lit. This indicator will

be off if the boiling mode is selected.

Note *: due to the limitation of 7 segment LED display, the letter “M” is displayed as “m”.

5.2 Mashing Operation

When first powered up, make sure the controller is in the mashing mode: The

yellow colored mashing mode indicator on the upper left corner should be on,

and the bottom display has no “P” on the left. If not, please change the control

mode to mashing mode as discussed in section 5.1 above. If you were using the

controller in the mashing mode when powered off last time, the controller will

start in mashing mode.

After controller is powered up, the top LED displays the current temperature

reading from the sensor. If temperature sensor is not connected, it will show

“orAL”. The bottom LED displays your set temperature. To adjust its value, just

rotate the knob. Once the value of the setting is changed, a small dot on the right

bottom corner will be flashing. It tells you that the setting has been changed but

not confirmed. After you adjust the temperature to the desired number, push the

knob to confirm the change. After confirmation, the new setting will remain on

the display and the dot will be turned off. If you forgot to push the dial, the display

will return to original set temperature after 2 seconds. The set point will remain

unchanged. This mechanism is for preventing temperature set point change by

accident.

The Output indicator will stay on solid right after powered up. This mean the

controller is heating up the kettle at maximum speed. Once the temperature is

getting close to the set point, the output indicator will start to flash at slower rate

or take a pause. It indicates the controller is trying to modulating the power to

hold the temperature stable.

For how to set up the timer in mashing mode, please read section 6.2.

Page 3

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.03 P3/9

5.3 Boiling Operation

When first powered up, make sure the controller is in the boiling mode: the

mashing mode indicator on the upper left corner is off and bottom display has a

“P” on the left. If not, change the control mode to boiling mode as discussed in

section 5.1 above. If you were using the controller in the boiling mode when

powered off last time, the controller will start in boiling mode.

The top LED displays the current temperature reading from the sensor. If

temperature sensor is not connected, it will show orAL. The controller will not

turn on the heater if the sensor is not connected. The bottom LED displays the

boiling output in percentage of the power. For example, if you use a 5500

Watts heater, “P50” mean the heater is running at 50% of power, or 2750

Watts (5500x50%=2750). The symbol “P” on the left is for making sure that the

display does not get confused with temperature setting of the mashing mode.

You can rotate the knob to adjust the output value. The new setting will take

effect automatically. There is no need to push the knob to confirm as the

temperature setting change in the mashing mode. For the first time use, while

the controller is still in the acceleration phase, you should set the boiling output

to a value below 60%. Once the controller finished the acceleration, it will

switch to this power level automatically. After getting familiar with your system,

you can set to a higher value that produce a rolling boil without boiling over.

When the controller is powered up, the output indicator will stay on solid. This

mean the controller is in the acceleration phase. Once the temperature rise

above the acceleration phase, the power output will be reduced to the value as

shown on the bottom display. The Output indicator will start to flash at slower

rate.

Note, when adjusting the boiling output setting while the controller is still in the

acceleration phase, the new setting will be shown on the bottom display.

However, it will not take effect until the acceleration phase is finished. If you want

to manually control the power output during the entire boiling process, set bAST

to zero (see section 6.3 for details).

For how to set up the boiling mode, please read section 6.3.

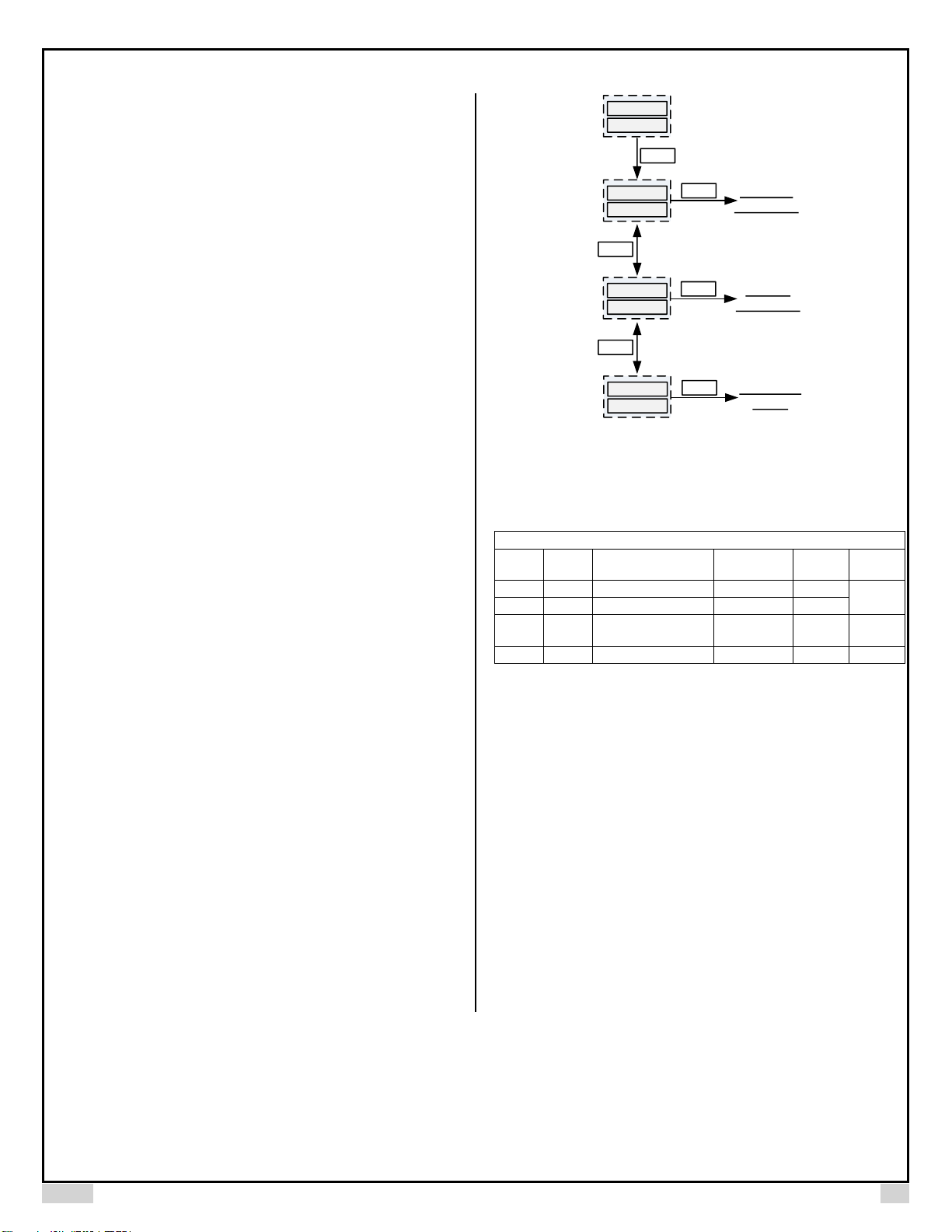

6. Control Parameters

Parameters are divided into three groups (figure 5): MASH for mashing control,

BOIL for boiling control, and SYST for system configuration. The same type of

parameter may have slightly different names when used in different mode. For

example, the timer setting in mashing mode is called “t”, while this parameter is

called “bt” in the boiling mode.

To enter parameter setting mode, press and hold the knob for at least 5s. Then

you will see “GOTO” on the top display. Rotate the knob, you will see the bottom

display changes with three different names: MASH (for mashing parameters,

figure 7), BOIL (for boiling parameters, figure 8) and SYST (for system settings,

figure 6). The parameter values are stored in the controller memory. All the

settings remain unchanged if you power it off.

Push the dial to enter the selected parameter group. Then top display shows the

current selected parameter name, and the bottom display shows its

value/options. Rotate the knob clockwise to increase the value, and rotate it

counter-clockwise to reduce the value. Faster rotating speed will change the

value rapidly. Once finished, press knob again to confirm and go to next

parameter. You can press the knob repeatedly to exit the setting quickly.

Press down

and hold the

knob for 5s

80

100

Knob

goto

mash

goto

boil

goto

syst

Enter Mash

mode settings

Enter Boil

mode settings

Enter System

settings

Knob

Press

Knob

Press

Rotate

Knob

Rotate

Knob

Knob

Press

Figure 5. Parameter group selection

6.1 System settings

Parameters that are shared by both control modes are under this group.

Table 1. System configuration parameters

System Configuration

Display

Code

Description

Setting

Range

Initial

Setting

Remark

tF

tF

Timer function

ON, OFF

ON

Note 1

tdIr

tdIr

Timer counting direction

dn, uP

dn

Pb

Pb

Temperature reading

offset

-100~+100 ° C

or ° F

0

Note 2

C-F

C-F

Temp. display unit

° C, °F

°F

Note 3

Note 1. Timer settings. tF, tdIr

tF: The timer function is controlled by a master parameter tF. When it is set to

ON, the timer function (for both mashing and boiling modes) is enabled. When

tF is set to OFF, the timer function is disabled.

tdIr: Timer direction parameter. Set it to up for timer counting up and dn for timer

counting down.

Note 2. Input offset. Pb

Pb is used to set an input offset to compensate the error produced by the sensor

or input signal itself. For example, if the controller displays 2ºC when probe is in

ice/water mixture, setting Pb = -2, will make the controller display 0ºC.

Note 3. Temperature unit setting. C-F

C-F determines the temperature unit. It can be set to C (Celsius, ˚C) or F

(Fahrenheit, ˚F).

Page 4

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.03 P4/9

goto

syst

Knob

tf

on

Knob

tdir

dn

Knob

pb

0

Knob

C-f

f

Knob

80

100

Timer function

Timer

counting

direction

Temperature

reading offset

Temp. display

unit

Press

Press

Press

Press

Press

End

Figure 6. Flow chart of setting system parameters

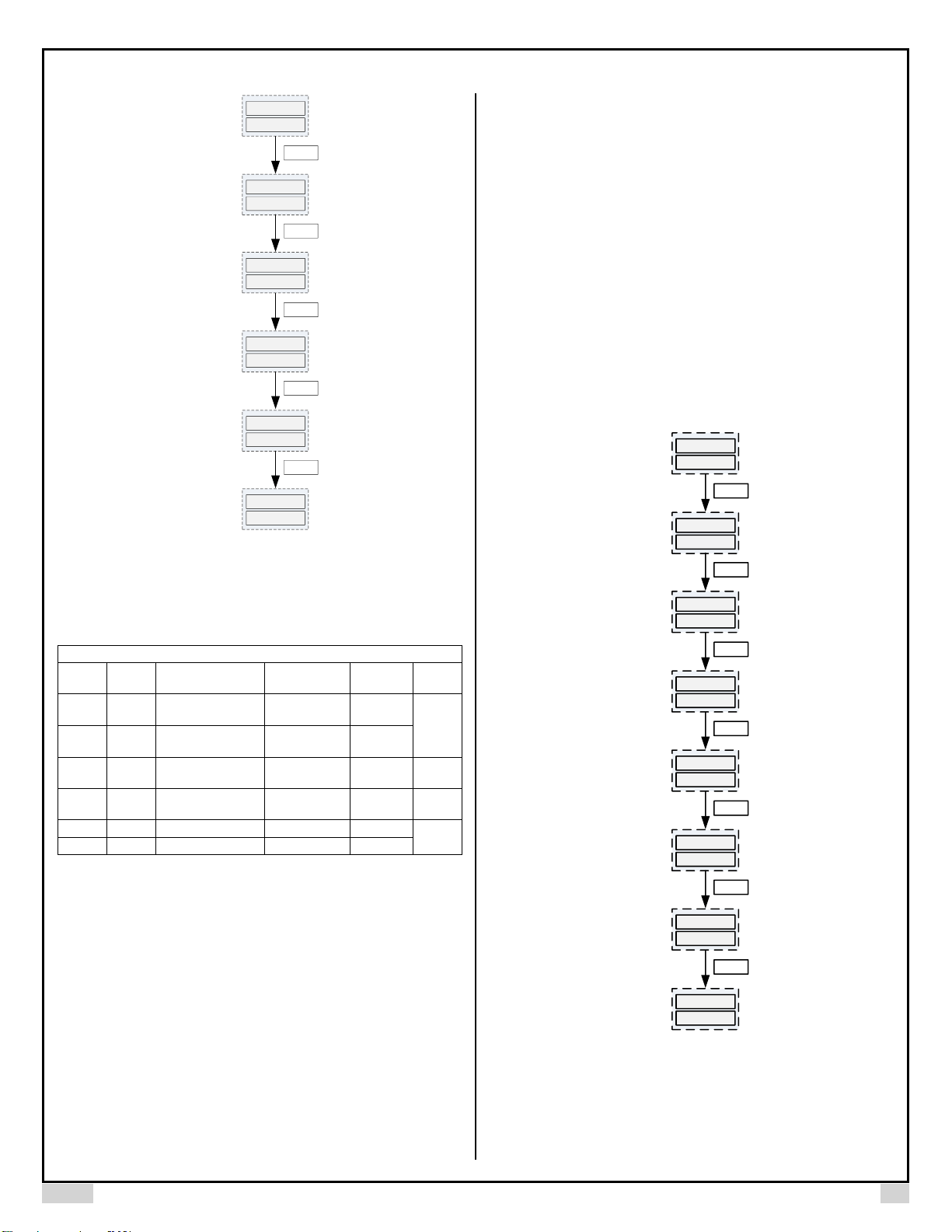

6.2 Mashing Parameters

Table 2. Mashing parameters

Mashing Mode Parameters

Display

Code

Description

Setting Range

Initial

Setting

Remark t t

Mashing time set

value

00:00~99:99

(hour: minute)

1:00

Note 5

tSP

tSP

Mashing timer start

temp.

-999~+9999 ° C

or ° F

151

ALH

ALH

Mashing alarm set

temp.

-999~+9999 ° C

or ° F

150

Note 6

EO

EO

Mashing ending

options

ON, OFF

OFF

Note 5

oScr

oScr

Overshoot correction

-100~+100

0

Note 7

AttE

AttE

Attenuation constant

-2~+2

0

Note 5. Timer Function: t, tSP, EO

This timer function allows the controller to show the mashing time. It makes a

beeping sound when timed out and will display the process is ended. It can also

automatically shut off the controller’s power output after time out. The time

duration is set by the t parameter for mashing mode. The unit is hour: minutes.

When timer function is enabled, the timer counting will be started by timer start

temperature, tSP. When temperature reaches timer start temperature, the timer

starts to count. After timer started counting, it will continue even if the

temperature drops below this start temperature. The timer can be reset to start

from beginning again. To reset the timer, press the knob momentarily, the display

will show rSt on top and “n” at the bottom, rotate the dial clockwise will change

the bottom display to “y”. Press the knob again will reset the timer (Figure 4)

After the timer starts, the top display will be switched between the current

temperature and current time alternately in every 6 seconds. The temperature

and time display can be easily differentiated with their appearance. The

temperature reading has two or three digits. For example, 212 degrees will be

displayed as “212”. The timer display has four digits with flashing colon in the

middle. For example, “01:20” for 1 hour 20 minutes.

When time counting ends, the controller will generate six long beeps. The top

display will switch between the current temperature and “End” alternately. After

timer ends, the power output can be configured either to continue heating, or

shut off. It is controlled by the parameter called ending options, EO. Set it to

ON for continue heating, set it to OFF to turn off the output.

If you want to use the timer as a regular timer without correlating to the

temperature setting, you can set the tSP below the ambient temperature (or

zero). The timer will start as soon as the regulator is powered up. You can use

the reset button (rSt) to reset the timer at any time.

Note 6. Alarm Function: ALH

EZboil has a built-in buzzer that can be programmed to beep when temperature

reaches the alarm set temperature, ALH. The alarm will generate four short

beeps every time the temperature rise from below ALH to higher than ALH. The

alarm function can be used to notify the operator when temperature is approach

the boil. The alarm function does not affect the heating or the time function, it

only provides the alarm sound.

goto

mash

Knob

t

1:00

Knob

Tsp[

151

Knob

alh

150

Knob

eo

off

Knob

oscr

0

Knob

atte

0

Knob

80

100

Press

Press

Press

Press

Press

Press

Press

Mashing time

set value

Mashing timer

start temp.

Mashing alarm

set temp.

Mashing ending

options

Overshoot

correction

Attenuation

constant

End

Figure 7. Flow chart of setting mashing parameters

Note 7. Temperature Control Tuning Parameters: oScr, AttE

The mashing control mode utilizes AI algorithm instead of the commonly used

PID or On/off control algorithm. The program is optimized for beer mashing. For

most system, there is no need to tune. It allows the system to heat up at

maximum speed, then hold the temperature stable with one-degree precision. If

Page 5

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.03 P5/9

you are not satisfied with the control result, these two parameters will help you

to fine tune the system. The overshot correction, oScr is for adjusting the

temperature overshot during the initial heat up. For example, if the temperature

overshot 3 degrees, set oScr = 3 should remove the overshoot. This parameter

has no effect after the temperature reach the set point. The attenuation

constant, AttE is for adjusting the temperature stability during mashing. The

value is from -2 to +2. The default value is 0. If the temperature fluctuates more

than one degree, user can increase the value. If the controller takes too much

time to correct the temperature drop, user can reduce the AttE to make the

system more responsive.

6.3 Boiling Parameters

For the easy of discussion, we divide the boiling mode into two phases, the initial

heating phase and boiling phase. During the initial heating phase, power

output is set high to accelerate the temperature rise. During the boiling phase,

the power output is lowered to prevent the boiling over. We name the output

setting for the boiling phase as “Boil Output” setting. Its value is always

displayed on the bottom LED display and can be adjusted by turning the knob.

The acceleration power output setting is not displayed at bottom display during

initial heating, because it rarely set to less than 100%.

Table 3. Boiling parameters

Boiling Mode Parameters

Display

Code

Description

Setting Range

Initial

Setting

Remark

bAST

bAST

Boiling acceleration

set temp.

-999~+9999 ° C

or ° F

200

Note 8

bOUT

bOUT

Boiling acceleration

output power

0~100%

100

bt

bt

Boiling time set value

00:00~99:99

(hour: minute)

1:00

Note 9

btSP

btSP

Boiling timer start

temp.

-999~+9999 ° C

or ° F

208

bALH

bALH

Boiling alarm set

temp.

-999~+9999 ° C

or ° F

200

Note 10

bEO

bEO

Boiling ending

options

ON, OFF

OFF

Note 9

Note 8. Acceleration heating function: bAST, bOUT

EZboil accelerates heating speed of the initial heating phase by running the

heater at high power, then reduce the power once the temperature is getting

close to the boil. The heating acceleration is controlled by two parameters,

Boiling acceleration set temperature, bAST and Boiling acceleration output

power, bOUT. The bAST set the temperature limit that below this temperature,

the controller will output at a power determined by the bOUT. When temperature

rise to the bAST, the output will automatically reduce to a lower level to prevent

a messy boiling over. The boiling over is caused by several factors including the

amount of foam on the surface and the power of the heater. The more foams

there is, the easier it is to boil over. The vigorous the boil is, the easy it is to boil

over. To preventing the boiling over, operator should skim the foam out and

reduce the power as the temperature approaching the boiling. Since the heater

power and liquid volume varies between each application, we suggest the bAST

to be set at least 5 degree (Fahrenheit) below the boiling point for the first time

use. As you getting familiar with your system, you can change this setting to

higher or lower. The bOUT is the power used during initial heating phase. The

unit is in percent of power. It should be set to 100% unless you have a very

powerful heater with very small amount of liquid. The bOUT setting does not limit

the power regulation range for boiling phase. If you don’t need to use this

feature, set bAST to 0, so this controller will work as a manual mode

controller over the entire temperature range.

Note 9. Timer Function: bt, btSP, bEO

This timer function allows the controller to show the boiling time. It makes a

beeping sound when timed out and will display the process is ended. It can also

automatically shut off the controller’s power output after time out. The time

duration is set by bt parameter for boiling mode. The unit is hour: minutes.

When timer function is enabled, the timer counting will be started by timer start

temperature, btSP. When temperature reaches timer start temperature, the

timer starts to count. After timer started counting, it will continue even if the

temperature drops below this start temperature. The timer can be reset to start

from beginning again. To reset the timer, press the knob momentarily, the display

will show rSt on top and “n” at the bottom, rotate the dial clockwise will change

the bottom display to “y”. Press the dial again will reset the timer (Figure 4)

After the timer starts, the top display will be switched between the current

temperature and current time alternately in every 6 seconds. The temperature

and time display can be easily differentiated with their appearance. The

temperature reading has two or three digits. For example, 212 degrees will be

displayed as “212”. The timer display has four digits with flashing colon in the

middle. For example, “01:20” for 1 hour 20 minutes.

When time counting ends, the controller will generate six long beeps. The top

display will switch between the current temperature and “End” alternately. After

timer ends, the power output can be configured either to continue heating, or

shut off. It is controlled by the parameter called ending options, bEO. Set it to

ON for continue heating, set it to OFF to turn off the output.

goto

boil

Knob

bast

200

Knob

bout

100

Knob

bt

1:00

Knob

btsp

208

Knob

balh

200

Knob

beo

off

Knob

Press

Press

Press

Press

Press

Press

Press

Boil acceleration

set temp.

Boil

acceleration

output power

Boil time set

value

Boil timer

start temp.

Boil alarm

set temp.

Boil ending

options

80

100

End

Figure 8. Flow chart of setting boiling parameters

If you want to use the timer as a regular timer without correlating to the

temperature setting, you can set btSP below the ambient temperature (or just

zero). The timer will start as soon as the regulator is powered up. You can use

the reset button (rSt) to reset the timer at any time.

Page 6

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.03 P6/9

Note 10. Alarm Function: bALH

EZboil has a built-in buzzer that can be programmed to beep when temperature

reaches the alarm set temperature, bALH. The alarm will generate four short

beeps every time the temperature rise from below ALH to higher than ALH. The

alarm function can be used to notify the operator when temperature is

approaching the boil. The alarm function does not affect the heating or the time

function, it only provides the alarm sound.

7. Application examples:

1. Timer operation example:

The timer can be used for several ways to help the boiling process.

1) Use it to automatically control the boiling time (boiling mode).

Set the parameter as following

tF=on, btSP=210, tdIr=dn, bEO=OFF, bt=1:30,

The timer will start to count when temperature reaches 210 degrees. The timer

will count down from 1:30, when time out, the controller will stop heating, beeps,

and flash “End”.

2) Use the timer as a regular timer (boiling mode).

Set btSP below the ambient temperature so that timer is available, set bt to a

very long time so that it will not end before operator decide to end the boil. The

counting direction should be up. Use the reset button (rSt) to reset the timer at

any time

tF=on, btSP=50, tdIr=up, bEO=on, bt=60:00.

3) Use the timer as a regular timer (mashing mode).

Set tSP below the ambient temperature so that timer is available, set t to a very

long time so that it will not end before operator decide to end the mash. The

counting direction should be up. Use the reset button (rSt) to reset the timer at

any time

tF=on, tSP=50, tdIr=up, EO=on, t=60:00.

4) Use EZboil as a manual regulator (similar to DSPR1)

To use it as manual regulator with temperature reading, please set it to boiling

mode. Disable timer, and set boiling acceleration set temperature below ambient

temperature (or just zero).

Mode=boiling, tF=off, bAST=0

8. Wiring Examples

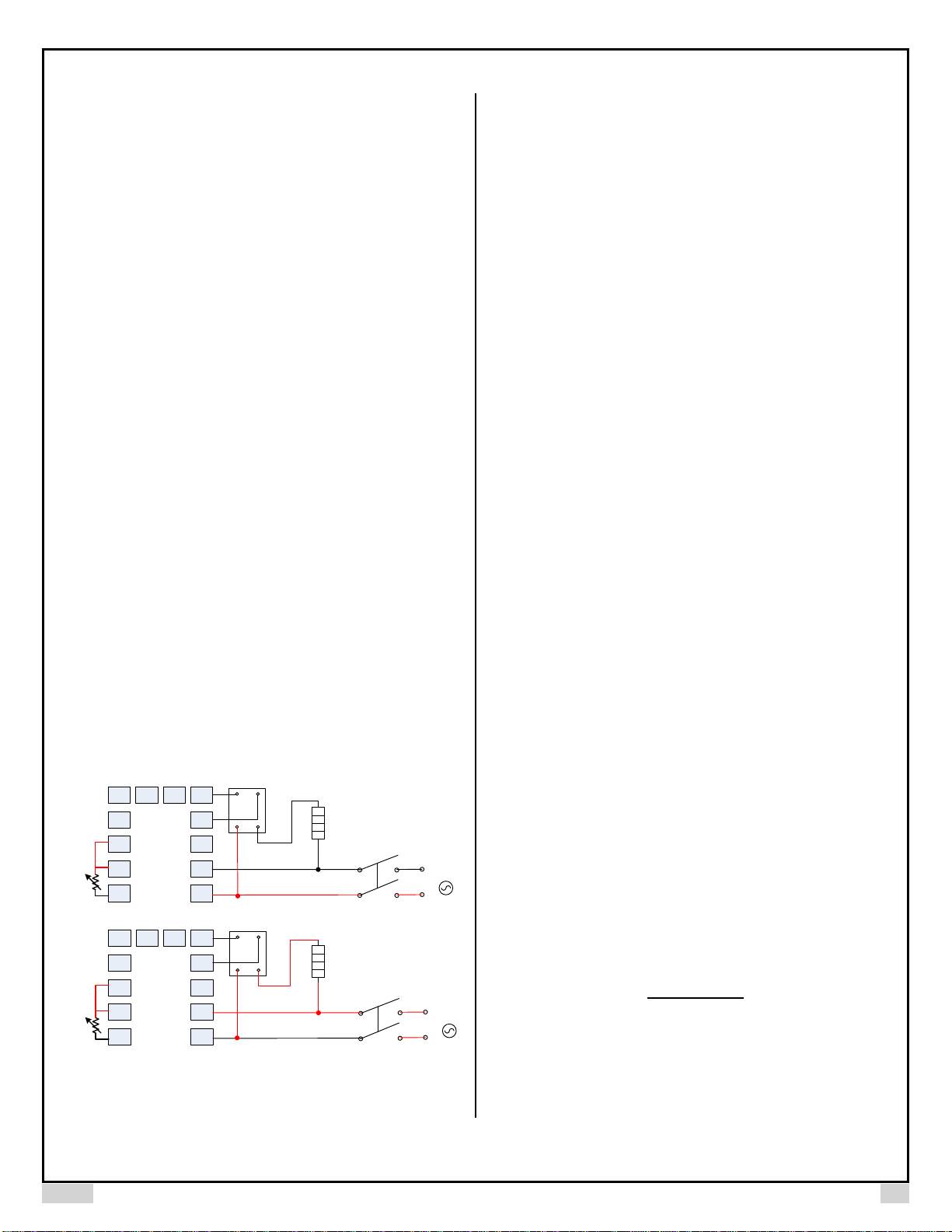

Example 1. Here are two wiring diagrams of how to connect a DC triggered AC

SSR with this power regulator.

1

2

3

13 14 6

7

8

9

10

4

5

RTD

R

R

W

-

+

34

120V AC

L

N

Heater

+

-

SSR

1

2

3

13 14 6

7

8

9

10

4

5

RTD

R

R

W

Heater

240V AC

L1

L2

-

+

34

+

-

SSR

Figure 9. Wiring examples of controlling a heater with SSR and DSPR120 in a

120VAC system (upper) and in a 240VAC system (lower).

9. Common sensor errors:

This regulator will display error message or incorrect temperature reading if your

sensor is not connected, or your sensor is bad. Top display will flash “orAL” and

“932” alternately, if you set it to Fahrenheit display (C-F = ° F); or “orAL” and “500”

alternately, if you set it to Celsius display (C-F = ° C).

Auber Instruments

5755 North Point Parkway, Suite 99

Alpharetta, GA 30022

www.auberins.com

Email: info@auberins.com Tel: 770-569-8420

Copyright 2007-2017, Auber Instruments All Rights Reserved.

No part of this manual shall be copied, reproduced, or transmitted in any way

without the prior, written consent of Auber Instruments. Auber Instruments

retains the exclusive rights to all information included in this document.

Page 7

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.03 P7/9

Appendix

Technical Talk -- How does it Work? v1.1

There are three commonly used methods for AC power control.

1) Phase angle firing. In this method, the AC power control is achieved by firing the SCR at different phase angle. This is how our SSVR works. This method offer the

most uniform power output. But the output is very difficult to be adjusted linearly due to the shape of the sine wave. Because of the sharp cut off, there is a potential

electromagnetic interference (EMI or RFI) if there are inductive devices on the power line. Some of the inductive devices cannot be controlled by this method.

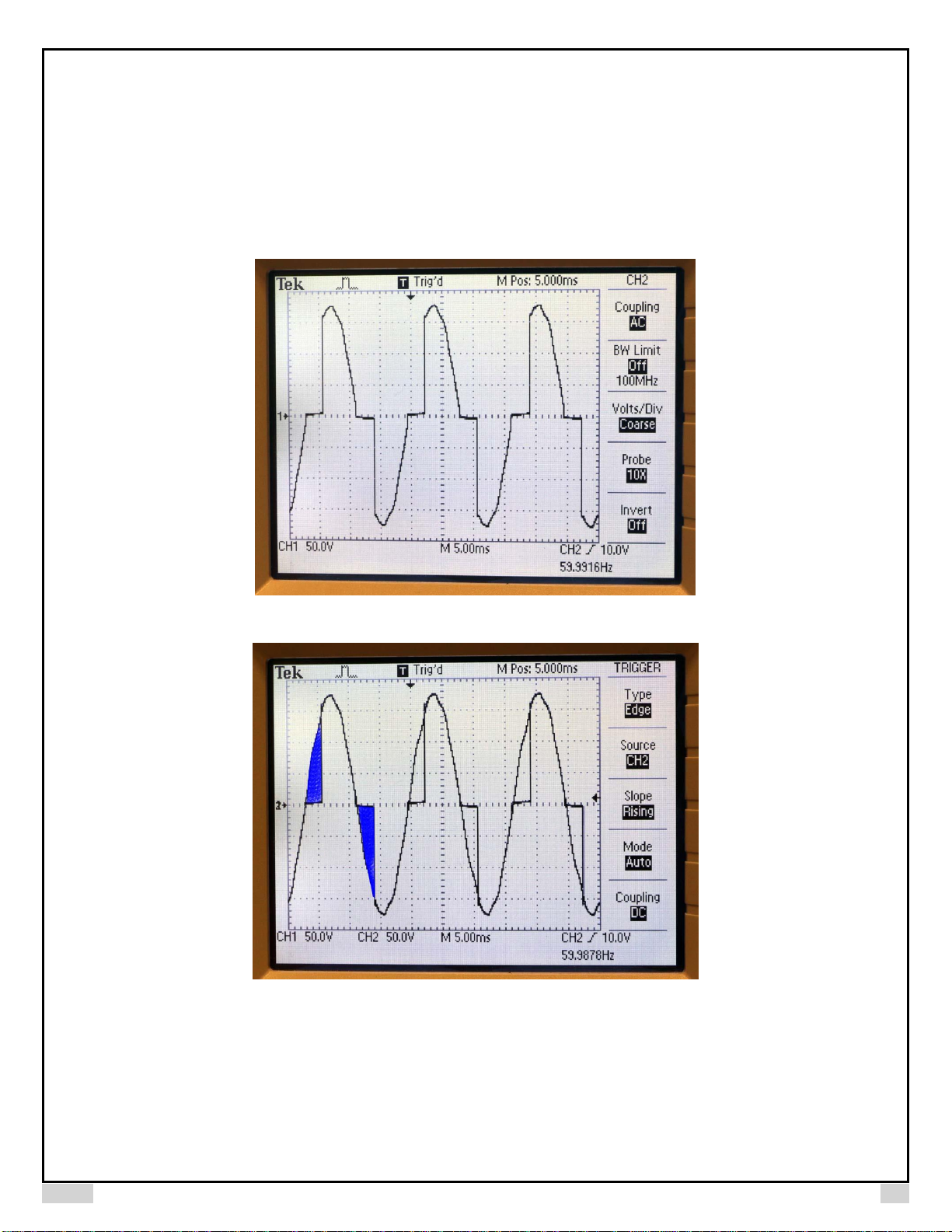

Figure 4. SSVR and TRIAC use phase-angle firing to regulate the power.

Figure 5. Original AC sine wave is overlaid with SSVR output wave form. The blue colored area shows the power output that has been blocked.

2) Time proportional firing. A fixed cycle time needs to be defined in this method. Then, the controller or regulator adjusts the on time during each cycle to achieve

the power control. For example, if the cycle time is 1 second, turn on the power for 0.25 second for every 1 second means a 25% power output. Most of PID controllers

use this method to control SSRs. This is also how the manual mode of Auber's PID controller works, except the cycle time has to be 2 second or longer.

Using this method, the user can linearly adjust output. But the power output is pulsed at each cycle. The shortest cycle time for most PID is either 1 or 2 second.

Therefore, power is pulsed at 1 or 2 seconds. When heating a liquid, heat is not transferred as smooth as the phase-angle fire method.

Page 8

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.03 P8/9

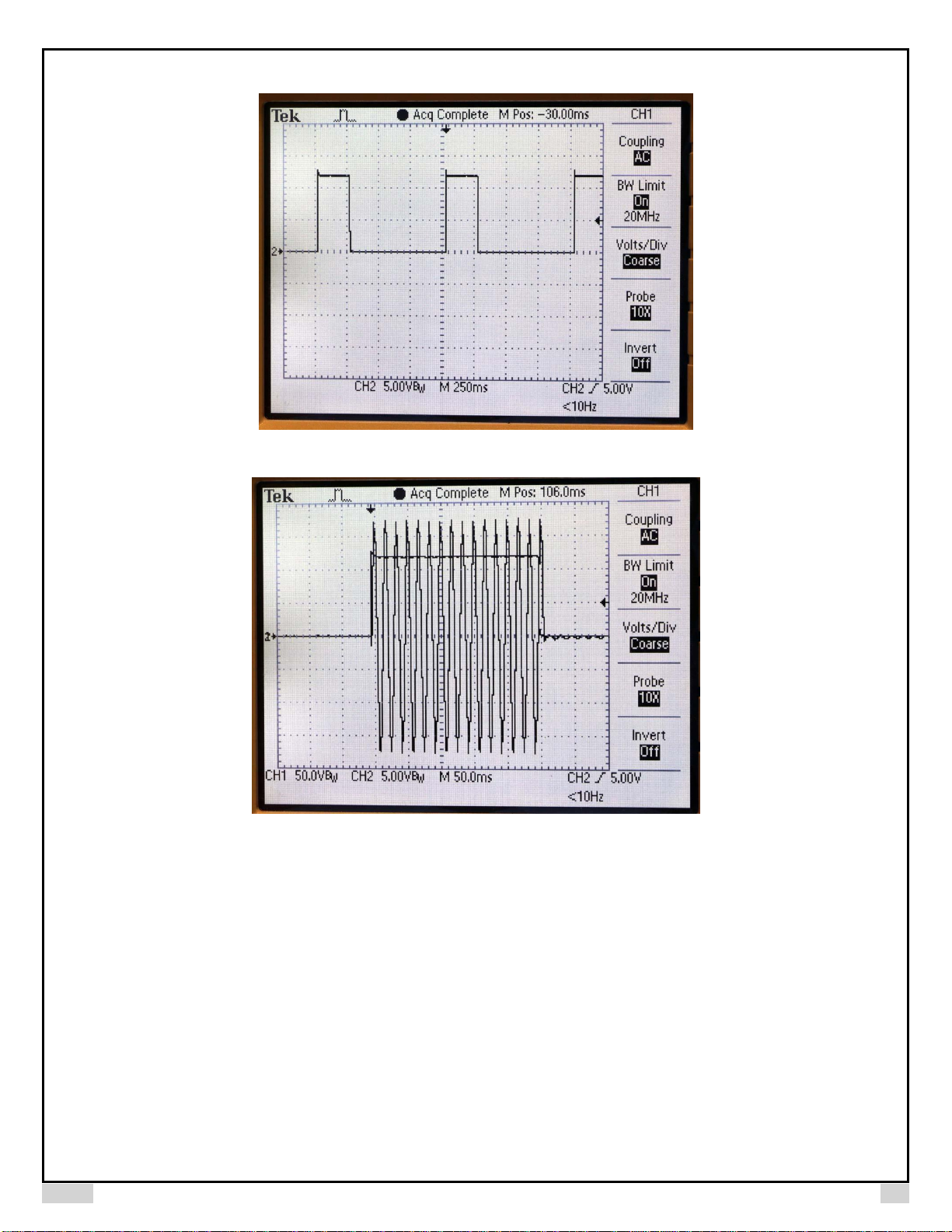

Figure 6. A 25% output control signal from a PID controller in the time proportional firing mode. Cycle time is 1 second. The output signal is 250 millisecond (ms) on,

and 750 ms off during each cycle period.

Figure 7. The control signal and SSR output waveform overlaid. When the DC signal (Channel 2, square wave) is on, the AC power can go through (Channel 1).

When the DC signal drop to zero, the AC power is blocked.

3) Burst firing. This method is similar to time proportional firing (section 2). But in contrast to the time proportional mode, where the SSR is fired once for each fixed

cycle period (which are usually 2 seconds or longer), the regulator will find the minimum cycle time to achieve the desired output percentage. The on pulse can be as

short as one AC cycle. So power is distributed more evenly over cycle time. This leads to of a more uniform power output. Several PID controllers on the market use

this mode. Our DSPR also uses this approach as the default mode to regulate power.

Page 9

AUBER INSTRUMENTS WWW.AUBERINS.COM

2017.03 P9/9

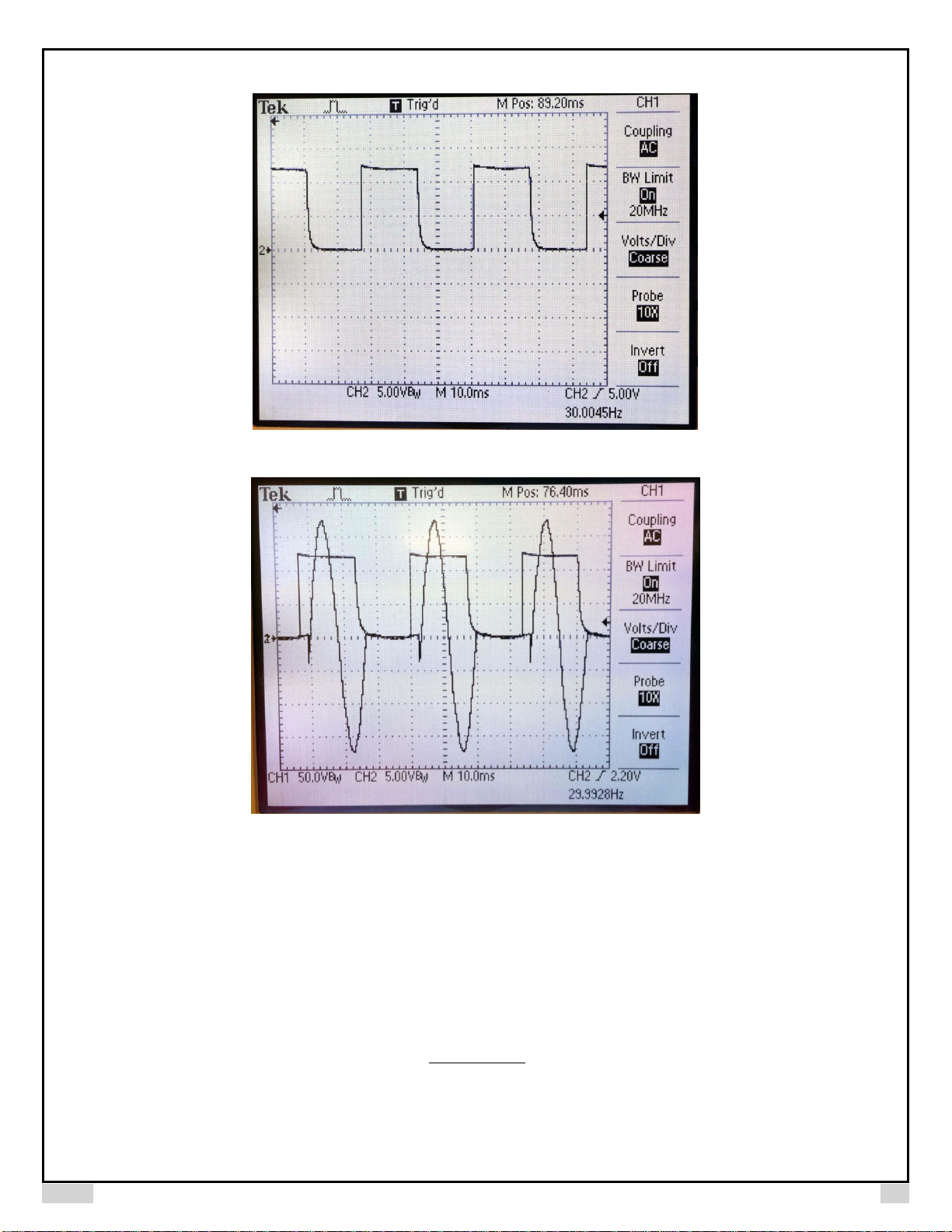

Figure 8. A 50% output control signal from DSPR when it is operating in the bust firing mode. Each pulse is 16.67 ms long, which is the same as a 60 Hz AC cycle.

So one pulse on and one pulse cycle off is equal to 50% output.

Figure 9. The DSPR control signal and SSR output waveform overlaid. The DSPR detects the frequency and phase of the AC power line, so that the pulse width and

firing time is synchronized with AC cycle.

Auber Instruments

5755 North Point Parkway, Suite 99

Alpharetta, GA 30022

www.auberins.com

Email: info@auberins.com Tel: 770-569-8420

Copyright 2007-2017, Auber Instruments All Rights Reserved.

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior, written consent of Auber Instruments. Auber Instruments retains the

exclusive rights to all information included in this document.

Loading...

Loading...