Auber TD400P Instruction Manual

AUBER INSTRUMENTS WWW.AUBERINS.COM

2015.06 P1/5

TD400P Programmable Temperature Controller

Version 1.1 (Oct, 2017)

1. Overview

This is a dual-output temperature controller with 8 programmable steps. It

contains one temperature probe and two independent outputs. One output is

for cooling device such as refrigerator and the other one is for heating device.

The temperature control can be programmed to vary with different time step

setting. Up to 8 temperature-time steps covering 33 days can be programmed.

It can be used for applications such as beer fermentation or convert a

refrigerator to kegerator. By using both cooling and heating devices, the

refrigerator can be controlled at specific temperature regardless in hot summer

or cold winter.

This controller is a plug and play controller. No wiring is needed for the heater

or cooler. Both the heating and cooling control modes are simple on/off control,

similar to a mechanical thermostat but with much higher precision due to

adjustable hysteresis band, precise sensor and digital read out. Anti-short

function is provided for cooling to protect the compressor from being turned on

with high pressure Freon.

Different operation temperature ranges of the two outputs can be set

separately. Once the cooling range is set, the controller program will

automatically limit the heating range to prevent both heating and cooling from

being turned on at the same time.

A digital silicon band gap sensor is used. The advantage is being much more

reliable in moisture environment than thermistor sensor. It can be immersed

over extended period of time. It also has a more uniform accuracy over an

entire specified temperature range.

2. Specifications

Table 1. Specifications

Temperature Control Range

-50 ~ 105° C, -58 ~ 221°F

Temperature Resolution

0.1° C (between -9.9 ~ 99°C)

1° C (between -50 ~ 10°C, 100 ~ 120° C)

0.1° F (between -9.9 ~ 99.9°F)

1° F (between -58 ~ 10° F, 100 ~ 248° F)

Temperature Accuracy

0.5 ° C or 0.9 °F

Temperature Control Mode

On/Off Control. Heating and Cooling

Temperature Control Output

10A, 120 V or 240 VAC *

Timer Range

Each step: 0.1 to 99.9 Hours or 1 to 999

Minutes

Timer Resolution

0.1 Hours or 1 Minute

Max Programmable Time

799.2 hours or 33.3 days (for total 8 steps)

Audio Alarm

High and low limit

Sensor Type

Silicon Band Gap Sensor

Sensor Size

0.25" OD (6.35 mm) x 1" (25mm) long

Ambient Temperature

-20 ~ 50° C (0 ~ 120°F)

Dimension

91 x 140 x 46mm

Input Power

85 ~ 242 VAC, 50 Hz / 60 Hz

Sensor Cable Length

6 ft (2 m)

Power Cable Length

3 ft (1 m)

Warranty: One (1) year.

*: Either heating or cooling device is limited to 10 Amps. The output voltage is

same as input voltage. When the controller is plugged into 120V AC, the

output will be 120VAC. If the controller is connected to 240 VAC, the output will

be 240VAC also.

3. Front Panel

Up Key

Down Key

Set Key

Cooling Device

Socket

Heating Device

Socket

Heating Device

Indicator

Cooling Device

Indicator

Display

Start Key

Pause/Stop Key

Mute Key

Prog. Step Key

Run indicator

Figure 1. Front Panel.

Display window: display temperature reading and parameters.

RUN indicator: the green LED indicator is on when the program is running.

START key: start executing the program.

PAUSE/STOP key: short press it to pause the program; long press it for 4

seconds to stop the program (only when the program is already been paused).

MUTE key: silent the alarm buzzer.

STEP key: jump to different step; check the running step.

SET key: access the program settings and parameter settings.

UP key: increase the value.

DOWN key: decrease the value.

Cooling device socket: supply power to cooling device.

Cooling device indicator: green LED indicator; it is on when the cooling

device socket is energized.

Heating device socket: supply power to the heating device.

Heating device indicator: red LED indicator lit; it is on when the heating

device socket is energized.

4. Basic Operation

Here are the basic operating procedures to use this controller. To fully

understand the functions on this controller, please read the entire manual.

1) Connect the temperature sensor to the sensor socket that is located on the

top of the controller. Please check the alignment of the slot on the plug with the

key on the socket. (See section 12 for details.)

2) Plug the controller’s power cord to a wall outlet.

3) Set up the program and system parameters. Please read the rest of this

manual for details.

4) Connect the cooling device and/or heating devices to the output sockets on

this controller.

5) Press START key to start running the program.

Instruction Manual

AUBER INSTRUMENTS WWW.AUBERINS.COM

2015.06 P2/5

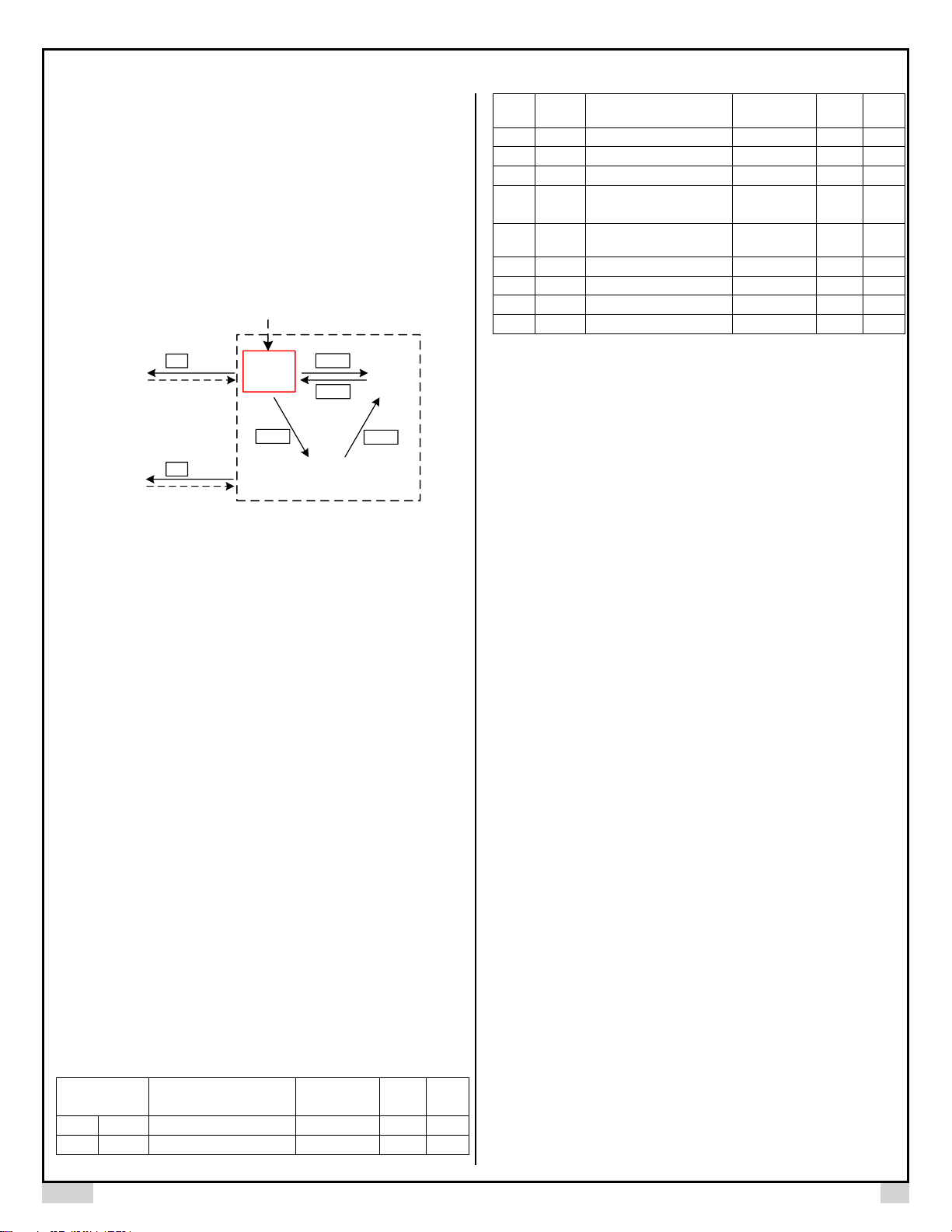

5. Mode Selection

This controller has 5 different modes: program run, program hold, program

stop, parameter setting, and programming mode. Before powering on the

controller, please connect the sensor cable to it. If no sensor is connected, the

controller will show error code “Err”, indicating no sensor is detected. When the

controller is powered on, it enters the Program Hold mode. It will flash

measured reading temperature value and “hold” alternatively. The controller

will start controlling temperature according to the saved setting, but the timer is

paused.

Program

Hold

Parameter

Setting Mode

Program

Run

Program

Stop

Programming

Mode

2 s

4 s

START

START

STOP

SET

PAUSE

Controller

Power Up

SET

Figure 2. Switching between different modes.

Program Running: The controller executes the saved program. The green

indicator RUN is lit, and the timer is running. The display window should show

the current temperature reading. The controller will send power to its

heating/cooling sockets to regulate temperature. When the program is running,

press PAUSE key will put the controller to Program Hold mode.

Program Holding: Controller pauses the time but it still regulates the

temperature at the current set value. The RUN indicator is off. The display

window flashes between the reading temperature and “Hold”. To resume the

program, press START key. To completely stop the program, hold the STOP

key for 4 seconds.

Program Stop: The execution of the program is terminated. Controller outputs

are deactivated and timer is also stopped. The RUN indicator is off. The display

window flashes between the reading temperature and “Stop”. To start the

program, press the START key. The controller will start regulating the program

from the first step.

Programming Mode: Review and edit temperature set value and set time for

each steps. When the controller is in Program Run, Hold, or Stop mode, press

SET key to enter the Programming mode. Please see Figure 4 for details.

Parameter Setting Mode: Review and edit system parameters. When the

controller is in Program Run, Hold, or Stop mode, hold the SET key for 2

seconds to enter the Parameter Setting mode. Please see Figure 3 for details.

6. Parameter Setup

Please see Table 2 for a list of parameters and see Figure 2 for the flow chart of

how to set the parameters. Please note that parameters will remain unchanged

unless you press set key to confirm the change.

Table 2. Parameters Description.

Code

Description

Setting

Range

Initial

Note

AH

AH

Deviation high alarm

0.5~999.9

20.0 1 AL

AL

Deviation low alarm

0.5~999.9

20.0

1

Hy

HY

Temp. Control Hysteresis

Band

0.5~99.9

1.0

2

CdF

CDF

Cooling Differential

0.5~99.9

5.0 3 HdF

HDF

Heating Differential

0.5~99.9

5.0 4 oFS

Ofs

Temp. Offset

-99.9~99.9

0

5

AS

AS

Anti-short Cycle Delay (only

for cooling socket)

M 0~ M99

(0~99 min)

M 0

6

A-M

A-M

Power Outage/Startup

Modes

S,M,C

S

7

PrG

PrG

Program Modes

on, off

ON 8 SFA

SFA

Sensor Failure Operation

0-0, 0-1, 1-0

0-0 9 Time

time

Time unit

H, M

H

10

C-F

C-F

Temperature unit

ºF, º C

ºF

11

Note 1. AH, deviation high alarm; AL, deviation low alarm:

Assuming measured temperature is PV and set temperature is C. When PV - C

is above AH, the built-in buzzer will turn on (deviation high alarm); when H –

PV is above AL, the built-in buzzer will turn on (deviation low alarm). User can

mute the alarm by momentarily pressing the Mute key. The alarm will remain

inactive until the process value moves out of the alarm zone. Both alarms are

deviation alarms, i.e., if AH = 20, AL = 30, and the Set Temperature (C) is 50F,

the alarm will be activated if the temperature is above 70F or below 20F. The

alarm function is suppressed at powering up or when the program is jumped

from one step to another step. It will be activated automatically once the

measured temperature enters the none-alarm zone (between C - AL and C +

AH).

Note 2. Hy, Temperature Control Hysteresis Band, or Temperature Control

Dead Band:

This parameter set up a dead band (between C - Hy and C + Hy) within which

either the heating device or cooling device will not work. The minimum value

for Hy is 0.5. The Hy value should not be too small if the system has sluggish

response. Otherwise, it may result in the heating device and the cooling device

working against each other, wasting energy and causing oscillation.

Note 3. CdF, Cooling Differential:

This is the differential band between turn on and turn off the cooling device. It

is set to the higher side of the temperature set point (C + Hy). The cooling

device will turn on when temperature is above (C + Hy + CdF), and turn off

when temperature is below (C + Hy). For compressor based cooling device, the

CdF value should not be set too small to prevent frequent cycling.

Note 4. HdF, Heating Differential:

This is the differential band between turn on and turn off the heating device. It

is set to the lower side of the temperature set point (C - Hy). The heating

device will turn on when temperature is below (C - Hy – HdF), and turn off

when temperature is above (C – Hy).

For example, if Set Temperature C = 50, Hy = 5, CdF = 3, HdF = 2, then the

heating device will turn on when process temperature is lower than 43 (C - Hy HdF) and turn off when process temperature rise above 45 (C - Hy). The

cooling device will turn on when process temperature is above 58 (C + Hy +

CdF) and turn off when process temperature drop below 55 (C + Hy).

Note 5. oFS, Temperature Offset:

oFS is used to compensate the error produced by the sensor or input signal

itself. For example, if the unit displays 37 when the actual temperature is 32.

Set parameter oFS = - 5 will make the controller display 32.The displayed

process temperature = actual measured temperature + oFS.

Loading...

Loading...