Auber TD100 Instruction Manual

AUBER INSTRUMENTS WWW.AUBERINS.COM

Instruction Manual

TD100 TEMPERATURE CONTROLLER

INSTRUCTION MANUAL

1. Overview

This temperature controller contains one temperature probe and two

independent outputs. One output is for cooling device such as

refrigerator and the other one is for heating device. It can be used for

applications such as beer fermentation or convert a refrigerator to

kegerator. By using both cooling and heating devices, the refrigerator

can be controlled at specific temperature regardless in hot summer or

cold winter.

This controller is a plug and play controller. No wiring is needed for

the heater or cooler. Both the heating and cooling control modes are

simple on/off control, similar to a mechanical thermostat but with

much higher precision due to adjustable hysteresis band, precise

sensor and digital read out. Anti-short function is provided for cooling

to protect the compressor from being turned on with high pressure

Freon.

Different operation temperature ranges of the two outputs can be set

separately. Once the cooling range is set, the controller program will

automatically limit the heating range to prevent both heating and

cooling from being turned on at the same time.

A digital silicon band gap sensor is used . The advantage is being

much more reliable in moisture environment than thermistor sensor. It

can be immersed over extended period of time. It also has a more

uniform accuracy over an entire specified temperature range.

2. Specification

Temperature Control Range -50~125 °C, -58~257 °F

0.1 °C (between -9.9 ~ 99 °C)

Temperature Resolution

Temperature Accuracy 0.5 °C or 0.9 °F

Temperature Control Mode On/Off Control. Heating and Cooling

Temperature Control Output 10A, 120V or 240V AC *

Audio Alarm High and Low Limit

Sensor Ty pe Silicon Band Gap Sensor

Sensor Size 0.25" OD (6.35 mm) x 1" (25mm) long

Sensor Measuring Range -20~125 °C

Ambient Temperature -20~ 50 °C

Dimension 91x140x46mm

Input Power 85 ~242VAC, 50Hz/60Hz

Sensor Cable Length 3 ft (1m)

Power Cable Length 3 ft (1m)

Warranty 1 Year

1 °C (between -50 ~ 10 °C, 100~125°C)

0.1 °F (between -9.9~99.9 °F )

1 °F (between -58 ~ 10 °F,100 ~257 °F)

Version 1.1

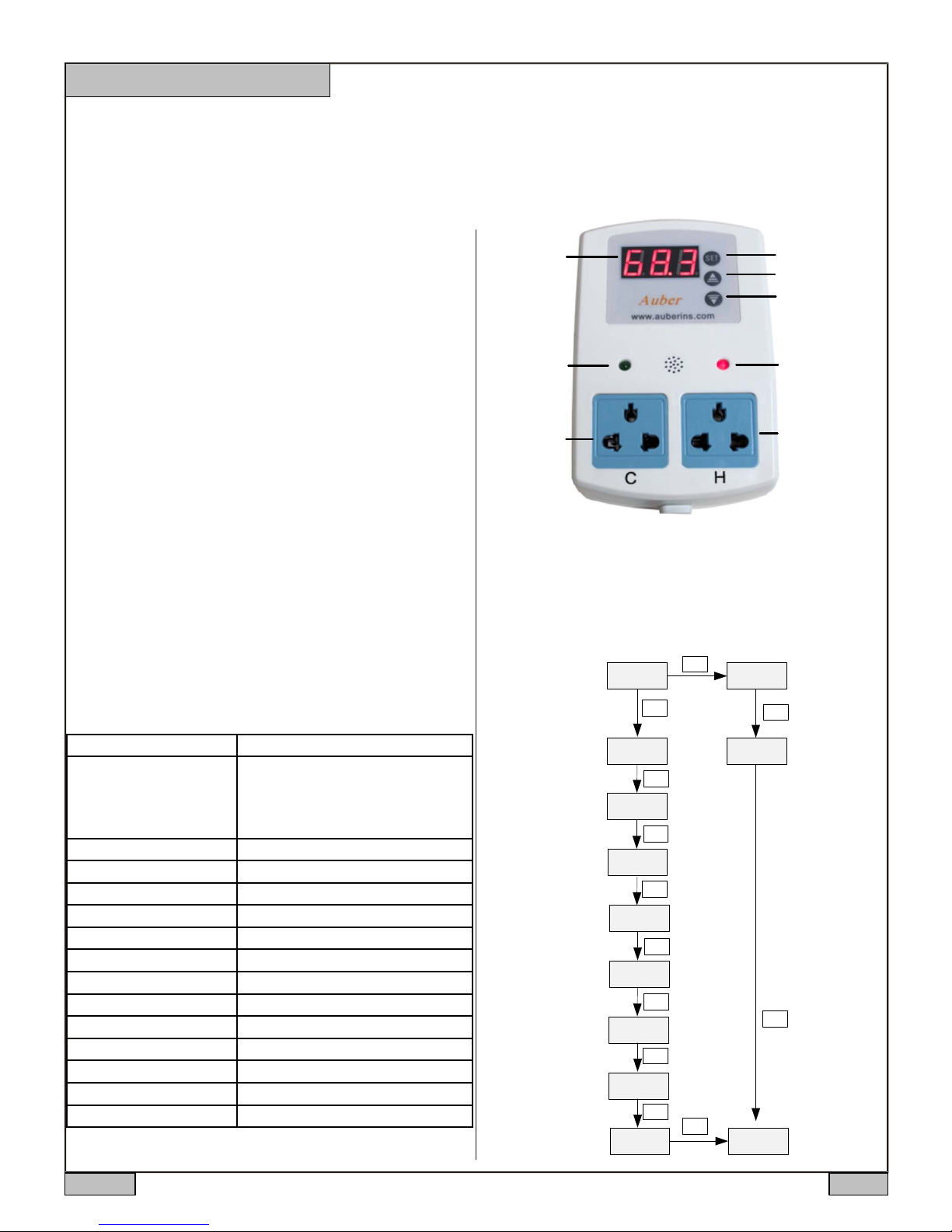

3. Front Panel

Measured

Temperature

Cooling Device

On Indicator

Cooling Device

Socket

Figure 1. Front Panel

Set Key

Up Key

Dn Key, Mute Alarm

Heating device

On Indicator

Heating Device

Socket

4. Setup Flow Chart

When the controller is powered on, it will display the measured

temperature. The controller will keep running according to the saved

setting. If the temperature sensor is shorted, the controller will display

“Err”. Please see Figure 2 for the flow chart to set the parameters.

SET

5 sec

SET

SET

SET

SET

SET

SET

SET

SET

SET

CSP

HSP

6 8.9

Cooling

Set Point

SET

Heating

Set Point

SET

Figure 2 Set

Up Flow Chart

Measured

Temperature

Alarm High Limit

Alarm Low Limit

Cooling Differential

Heating Differential

Cooling Antishort

Sensor Failure

Operation

Temperature Offset

Temperature Unit

6 8.9

AH

AL

CDF

HDF

AS

SFA

OFS

C-F

2013.05 P1/3

AUBER INSTRUMENTS WWW.AUBERINS.COM

5. Parameter Settings

To change the target temperature, press SET key momentarily. The

controller will show CSP (Cooling set point), press SET again will

show HSP (heating set point). When the controller shows CSP or

HSP, use Up or Down key to change the value. Then press SET key

to confirm the change.

To change the system parameters, press SET key for 5 seconds, the

controller will enter the parameter set up mode. The first parameter

AH will show on the display. Use Up or Down key to modify the

parameter value. Then press SET key to confirm the change. The

display will show the parameter again. Press the SET key to show

the ne x t p a r a me t e r . The instrument will automatically exit if no key is

pressed for 10 seconds. Please see the Table 1 for the parameters.

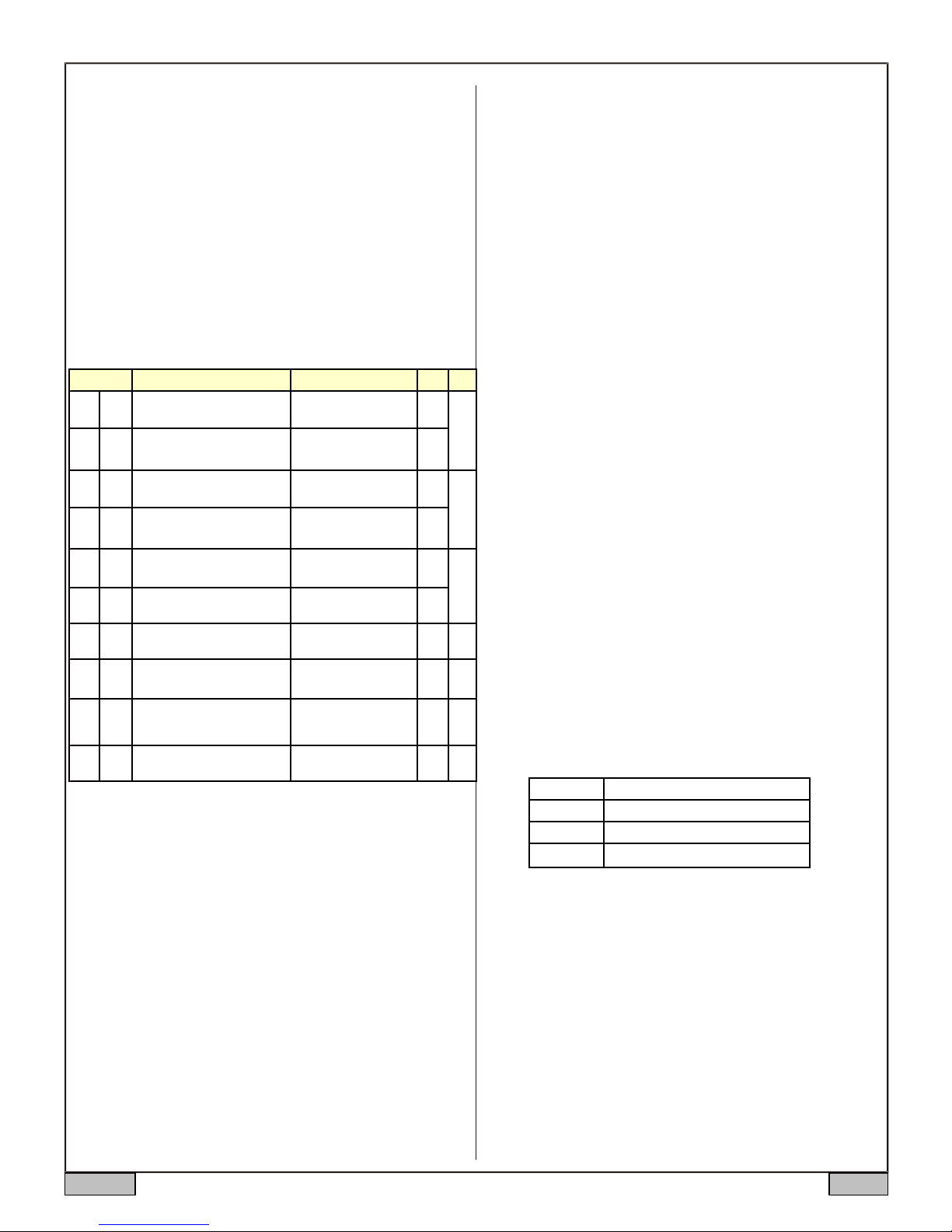

Table 1. Parameters Description

CSP

HSP

AH

AL

CdF

HdF

AS

SFA

oFS

Code

CSP

HSP

AH

AL

CDF

HDF

AS

SFA

OFS

Des cription S etting range Initial Note

C ooling Set Point

Heating Set Point

A l ar m High Li m it

A l ar m Low Lim i t

Cooli ng Differential 0~50.0 ºF 3.0

Heating Differntial 0~50.0 ºF 1.0

Cooling Antishort 0~12 mi n 0 3

S ensor F ai lure Operation 0-0, 0- 1, 1-0 0-0 4

Temperature Offset 0~10.0 0 5

-58~ 248 ºF

-50~125 ºC

-58~CS P ºF

-50~ CS P ºC

-58~ 248 ºF

-50~125 ºC

-58~ AH ºF

-50~A H ºC

67.0

62.0

95.0

32

Note 2. When the measured temperature is higher than AL, the high

limit alarm will be on; when the measured temperature is lower than

AL, the low limit alarm will be on.

When alarm is on, the display will be flashing between the measured

value and alarm type. To mute the alarm when it is on, press the

Down key momentarily. If the measured value gets out of the alarm

zone then gets back to the alarm zone again, the alarm will be on

again. To disable the alarm, set AH=AL.

The maximum value of the AL can be set is the current value of AH.

But AH can be set to the value between -58~248 ºF or

-50~125 ºC. When AH is set to a value lower than current AL, the AL

will be adjusted to the AH value automatically.

For example, when AH=95.0 ºF, AL=32 ºF, AL can be set to any

value between -58 and 95.0. For AH, it can be set to any value

between -58 and 248. If you set it to 25.0, the AL will be set to 25.0

1

automatically.

Note 3. The Cooling Antishort is the delay the time to turn the

coo l i ng load on .

2

compressor, it should not turn on the compressor when it is at high

pressure (just after turned off). Otherwise, It may shorten the life of

compressor. The Anti-Short cycle delay function can be used to

prevent the rapid cycling of the compressor. It establishes the

1

minimum time that the NO contacts remains open (after reaching

cutout) before closing again. The delay overrides any Load Demand

and does not allow the NO contacts to close until the set time-delay

value has elapsed. It gives time to release the refrigerant pressure

through evaporator. It is typically set to 4- 6 (minutes).

when the controller is used for cooling and load is a

Note 4. The SFA defines how the output would be if the sensor fails.

It can be set to 0-0, 0-1 or 1-0. Please refer to table 2 for details.

C-F

C-F

Temperature Unit

C : Celsius

F:Fahrenheit

F

Note 1. For cooling (or heating), the output will be off when the

temperature is blow (or over) the set point; will be on again when the

temperature rises up (or drops down) to CSP+CdF (or HSP-HdF).

Table 2. Output of the controller when sensor fails:

SFA Controller output when sensor fails

0-0 cooler off, heater off

1-0 cooler on, heater off

0-1 cooler off, heater on

For example, when the unit controls a refrigerator for food, you may

The maximum value of the HSP can be set is t he current value of

CSP. But CSP can be set to the value between -58~248 ºF or

-50~125 ºC. When the CSP is set to a value lower than current HSP,

want to set the TSF to ON if the sensor fails to keep th e food cold.

When it controls a heater, you may want to set th e ou tpu t to OFF fo r

safety purpose .

the HSP will be adjusted to the CSP value automatically.

For example, when CSP=67.0 ºF, HSP=62 ºF, HSP can be set to any

value between -58 and 67.0. For CSP, it can be set to any value

between -58 and 248. If you set it to 55.0, the HSP will be set to 55.0

automatically.

Small differential gives tight control; large differential reduces the

frequency of cycle on and off. It will extend the life of relay and

compressor.

Note 5. The offset is used to set an input offset to compensate the

error produced by the sensor or input signal itself.

For example, for temperature, if the unit displays 37 ºF when the

actual temperature is 32 ºF, setting parameter toF= - 5 will make the

controller display 32 ºF.

6. How to install the sensor to the unit.

The connector of sensor contains a slot for correct pin connection. It

also has a spring lock to prevent disconnections from accidental

pulling on the cable. To install the to the unit, please align the slot of

2013.05 P2/3

Loading...

Loading...