Auber SYL-2342, SYL-2352 Instruction Manual

AUBER INSTRUMENTS WWW.AUBERINS.COM

2016.05 P1/8

SYL-2342 PID TEMPERATURE CONTROLLER

INSTRUCTION MANUAL

Version 5.3 (May 2016)

Caution

This controller is intended to control equipment under normal operating

conditions. If failure or malfunction of the controller may lead to abnormal

operating conditions that may result in personal injury or damage to the

equipment or other property, devices (limit or safety controls) or systems

(alarm or supervisory) intended to warn of or protect against failure or

malfunction of the controller must be incorporated into and maintained as

part of the control system.

Installing the rubber gasket supplied will protect the controller front panel

from dust and water splash (IP54 rating). Additional protection is needed for

higher IP rating.

This controller carries a 90-day warranty. This warranty is limited to the

controller only.

1. Specifications

Input type

Thermocouple (TC): K, E, S, N, J, T, B, WRe5/ 26;

RTD (Resistance Temperature Detector): Pt100, Cu50

DC Voltage: 0~5V, 1~5V, 0~1V, -100~100mV, 20~20mV, -5~5V, 0.2~1V

DC current: 0~10mA, 1~10mA, 4~20mA. (Use external

shunt resistor for higher current)

Input range

Please see section 4.7 for detail.

Accuracy

± 0.2% Full scale: RTD, linear voltage, linear current and

thermocouple input with ice point compensation or Cu50

copper compensation.

0.2% Full scale or ± 2 ºC: Thermocouple input with

internal automatic compensation.

Note: For thermocouple B, the measurement accuracy of

± 0.2% can only be guaranteed when input range is

between 600~1800 ºC.

Response time

≤ 0.5s (when FILt = 0)

Display resolution

1° C, 1°F; or 0.1° C

Control mode

Fuzzy logic enhanced PID control

On-off control

Manual control

Output mode

Relay contact (NO): 250VAC/7A, 120V/10A, 24VDC/10A

Alarm output

Relay contact (NO): 250VAC/1A, 120VAC/3A, 24V/3A

Alarm function

Process high alarm, process low alarm, deviation high

alarm, and deviation low alarm

Manual function

Automatic/Manual bumpless transfer

Power supply

85~260VAC/50~60Hz

Power

consumption

≤ 5 Watt

Ambient

temperature

0~50ºC, 32~122º F

Dimension

48 x 48 x 100mm (W x H x D)

Mounting cutout

45 x 45mm

2. Available Configurations

All the models listed in Table 1 are 1/16 DIN size with dual-alarm outputs.

Table 1. Controller models.

Model

Control output

Ramp/soak option

SYL-2342

Relay contact output

No

SYL-2342P

Relay contact output

Yes

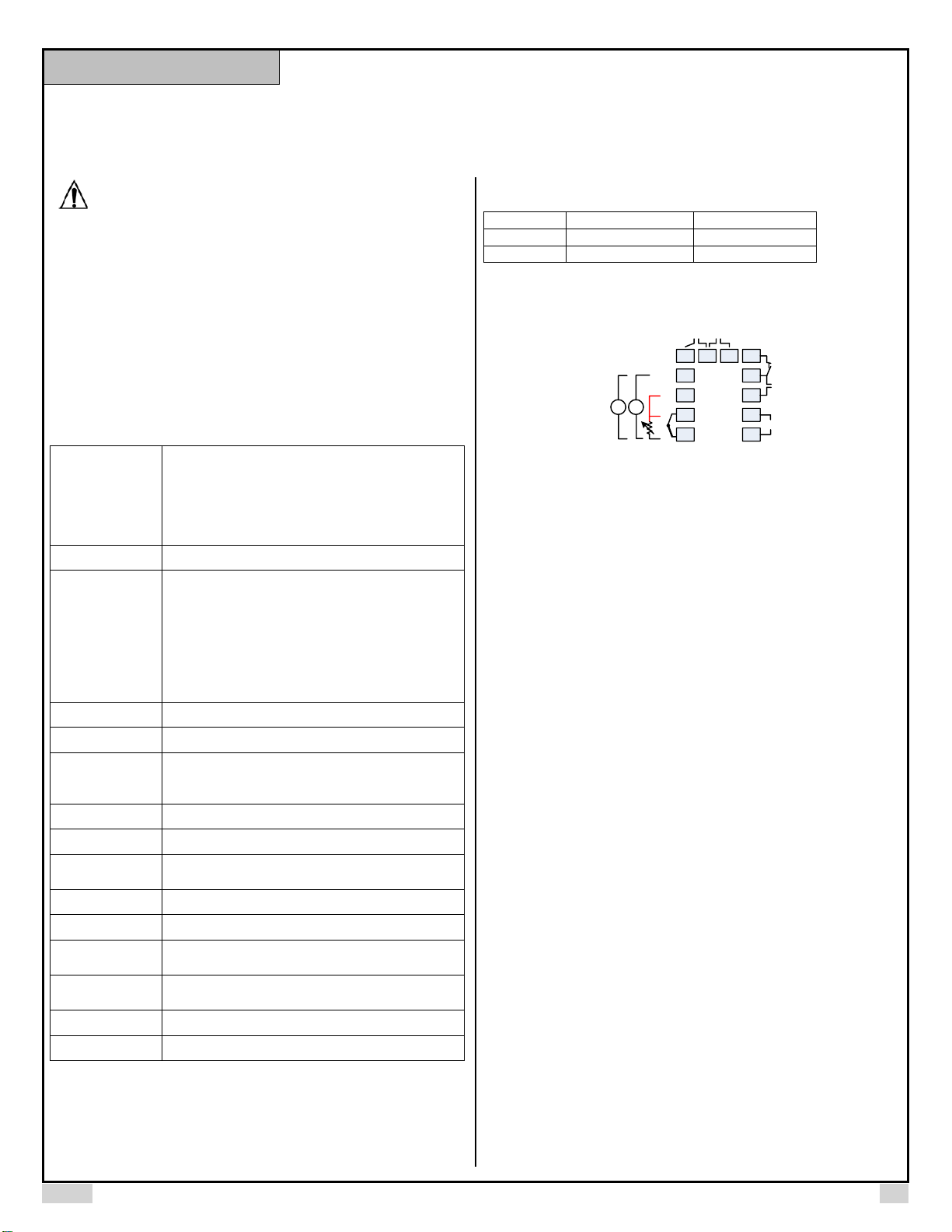

3. Terminal Wiring

1

2

3

13 14 6

7

8

9

10

4

5

RTD

R

R

W

TC

mA

V

AL1 AL2

AC

85~260V

Out

Model: SYL-2342, SYL-2342P

+

-

+

Figure 1. Wiring terminals of SYL-2342 and SYL-2342P.

3.1 Sensor connection

Please refer to Table 3 for the input sensor type (Sn) setting codes. The initial

setting for input is for a K type thermocouple. Set Sn to the right sensor code if

another sensor type is used.

3.1.1 Thermocouple

The thermocouple should be connected to terminals 4 and 5. Make sure that

the polarity is correct. There are two commonly used color codes for the K type

thermocouple. US color code uses yellow (positive) and red (negative).

Imported DIN color code uses red (positive) and green/blue (negative). The

temperature reading will decrease as temperature increases if the connection

is reversed.

When using ungrounded thermocouple that is in touch with a large conductive

subject, the electromagnetic field picked up by the sensor tip might be too large

for the controller to handle, the temperature display will change erratically. In

that case, connecting the shield of thermocouple to terminal 5 (circuit ground of

the controller) might solve the problem. Another option is to connect the

conductive subject to terminal 5.

3.1.2 RTD sensor

For a three-wire RTD with standard DIN color code, the two red wires should

be connected to the terminals 3 and 4. The white wire should be connected to

terminal 5. For a two-wire RTD, the wires should be connected to terminals 4

and 5. Jump a wire between terminals 3 and 4. Set controller input type, Sn to

21.

3.1.3 Linear input (V, mV, mA or resistance)

V and mA current signal inputs should be connected between terminals 2 and

5. Terminal 2 is positive. mV signal inputs should be connected between

terminals 4 and 5. Terminal 4 is positive. For resistance inputs, short terminals

3 and 4, then connect resistance inputs between terminals 4 and 5.

3.2 Power to the controller

The power cables should be connected to terminals 9 and 10. Polarity does not

matter. It can be powered by 85-260V AC power source. Neither a transformer

nor jumper is needed to wire it up. For the sake of consistency with the wiring

example described later, we suggest you connect the hot wire to terminal 9 and

neutral to 10.

Instruction Manual

AUBER INSTRUMENTS WWW.AUBERINS.COM

2016.05 P2/8

3.3 Control output connection

The relay output of the controller SYL-2342 can be used to turn on a contactor

or a solenoid valve. It can drive a small heater directly if the heater draws less

than 10A when connected to 120V AC power source. For applications needing

two control outputs, such as one for heating and another for cooling, relays

AL1 or AL2 can be used for the second output with on/off control mode. Please

see Figure 11 for details.

3.3.1 Connecting the load through a contactor

Assuming the controller is powered by 120V AC and the contactor has a 120V

AC coil, jump a wire between terminals 8 and 9. Connect terminal 7 to one lead

of the coil and terminal 10 to the other lead of the coil. Please see Figure 7 for

example.

3.3.2 Connecting the heater (or cooler) directly from the internal relay

Assuming the controller and the load (heater or cooler) are powered by the

same voltage. Jump a wire from terminal 9 to 8. Connect terminal 7 to the one

lead of the load and terminal 10 to the other lead of the load. Please see Figure

6 and 9 for details.

3.4 For first time users without prior experience with PID controllers, the

following notes may prevent you from making common mistakes.

3.4.1 Power to the heater does not flow through terminal 9 and 10 of the

controller. The controller consumes less than 2 watts of power. It only provides

a control signal to the relay. Therefore, wires in the 18 to 26 gauge range

should be used for providing power to terminals 9 and 10. Thicker wires may

be more difficult to install.

3.4.2 The control relay outputs (for SYL-2342), AL1 and AL2, are “dry” single

pole switches. They do not provide power by themselves. Please see Figure 6,

7 and 11 for how they are wired when providing a 120V output (or when output

voltage is the same as the power source for the controller). If the load of the

relay requires a different voltage than that for the controller, another power

source will be needed. See Figure 8 for examples.

3.4.3 For all controller models listed in this manual, the power is controlled by

regulating the duration of on time for a fixed period of time. It is not controlled

by regulating amplitude of the voltage or current. This is often referred as time

proportional control. For example, if the cycle rate is set for 100 seconds, a 60%

output means controller will switch on the power for 60 seconds and off for 40

seconds (60/100 = 60%). Almost all high power control systems use time

proportional control because amplitude proportional control is too expensive

and inefficient.

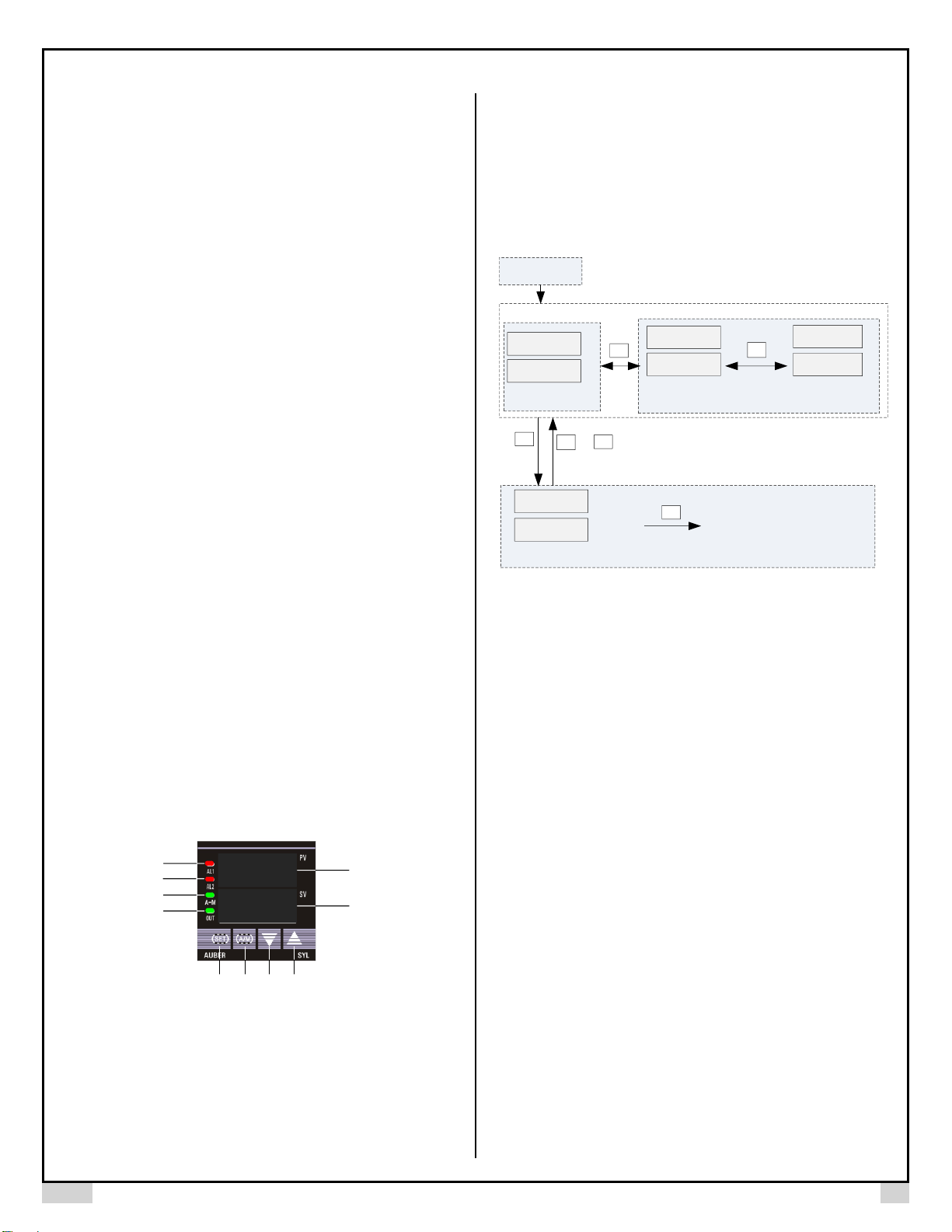

4. Front Panel and Operation

3

4

5

6

1

2

7 8 9 10

8 8 8 8

8 8 8 8

Figure 2. Front panel

① PV display: Indicates the sensor read out, or process value (PV).

② SV display: Indicates the set value (SV) or output value (%).

③ AL1 indicator: It lights up when AL1 relay is on.

④ AL2 indicator: It lights up when AL2 relay is on.

⑤ A-M indicator: The light indicates that the controller is in manual mode. For

the controllers with the Ramp/Soak option, this light indicates that the

program is running.

⑥ Output indicator: It is synchronized with control output (terminal 7 and 8),

and the power to the load. When it is on, the heater (or cooler) is powered.

⑦ SET key: When it is pressed momentarily, the controller will switch the

lower (SV) display between set value and percentage of output. When

pressed and held for two seconds will put the controller into parameter

setting mode.

⑧ Automatic/Manual function key (A/M) /Data shift key.

⑨ Decrement key ▼: Decreases numeric value of the setting value.

⑩ Increment key ▲: Increases numeric value of the setting value.

4.1 Display Status

Power on

8 0 0.0

8 0 0.5

Display mode 1

8 0 0.0

A 6 0

8 0 0.0

“M 60” means

output value=60%

on manual mode

Display mode 2

1 0 0 5

ALM1 (high limit alarm)=1005

Display mode 3

2S

+

Next parameter

M 6 0

A L M1

SET

SET

SET

A/M

SET

A/M

“A 60” means

output value=60%

on Automatic mode

PV

SV

PV

PV

Figure 3. Display modes

Display mode 1: When the power is turned on, the upper display window

shows the measured value (PV) and the lower window shows the four-digit set

value (SV).

Display mode 2: Press the SET key to change the display status into mode 2.

The upper display window shows the measured value (PV) and the lower

windows shows the output value. This picture shows the output percentage is

60% when in Automatic (PID) control mode. If parameter A-M = 1 (see table 2),

pressing the A/M key will switch the controller between PID and Manual control

mode with the output unchanged. This bumpless transfer allows the controller

to be switched between manual and automatic mode without the output

suddenly 'bumping' to a different value.

Display mode 3: Press the SET key for 2 seconds to enter the display mode 3.

This mode allows users to change the system parameters.

4.2 Basic Operation

4.2.1 Changing set value (SV)

Press the ▼ or ▲ key once, and then release it. The decimal point on the

lower right corner will start to flash. Press the ▼ or ▲ key to change SV until

the desired value is displayed. If the change of SV is large, press the A/M key

to move the flashing decimal point to the desired digit that needs to be

changed. Then press the ▼ or ▲ key to start changing SV from that digit. The

decimal point will stop flashing after no key is pressed for 3 seconds. The

changed SV will be automatically registered without pressing the SET key.

4.2.2 Display change

Press the SET key to change the display mode. The display can be changed

between display modes 1 and 2.

AUBER INSTRUMENTS WWW.AUBERINS.COM

2016.05 P3/8

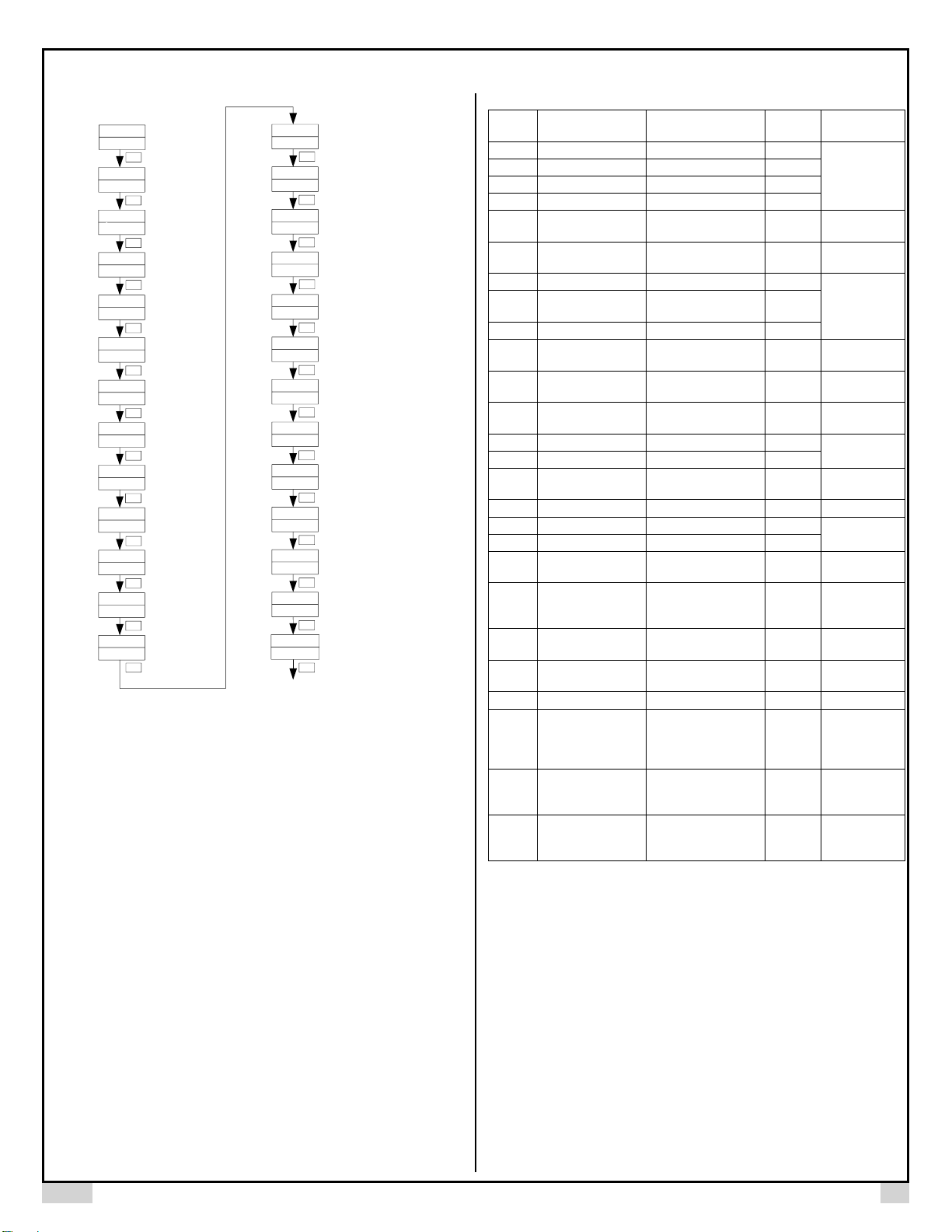

SET

PV

SV

2S

SET

SET

SET

SET

SET

SET

SET

ALM1

Process high alarm

HY-1

9 9 9 9

Hy-1

Deviation high alarm

HY-2

9 9 9 9

Hy-2

Deviation low alarm

HY

0.3

Hy

Hysteresis band

AT

3

At

Control mode

I

1 0 0 0

I

Integral time

P

5 0 0

P

Proportional constant

SET

SET

SET

SET

SET

SET

SET

SET

t

2

t

Cycle time

SN

0

Sn

Input type

DP

0

dP

Decimal point position

Baud

9 6 0 0

Baud

Communication baud

filt

0

FILT

PV input filter

A-M

2

A-M

Running status

SET

SET

SET

SET

SET

SET

SET

SET

P-SH

2 5 0 0

P-SH

Display high limit

Pb

0.0

Pb

Input offset

Op-A

0

OP-A

Output mode

outL

0

OutL

Output low limit

OUtH

1 0 0

OutH

Output high limit

AL-P

1 7

AL-P

Alarm output definition

COOL

1 0

Cool

System function selection

Addr

1

Addr

Communication address

d

1 2 0

d

Derivative time

P-SL

- 1 0 0

P-SL

Display low limit

SET

SET

EP1-EP8

ALM1

1 0 0

ALM2

5 0

ALM2

Process low alarm

Locw

8 0 8

Lock

Configuration privilege

Figure 4. System setup flow chart

4.2.3 Manual/Automatic mode switch

Bumpless switching between PID mode and Manual mode can be performed

by pressing the A/M key. The A-M LED will light up when the controller is in

Manual mode. In Manual mode, the output amplitude can be increased or

decreased by pressing ▲ and ▼ (display mode 2). Please note that manual

control is initially disabled (A-M = 2). To activate the manual control, set

A-M = 0 or 1.

4.2.4 Parameter Setup Mode

When the display mode is 1 or 2, press SET and hold for roughly 2 seconds

until the parameter setup menu is displayed (display mode 3). Please refer to

4.3 for how to set the parameters.

4.3 Setup flow chart

While in the parameter setup mode, use ▲ and ▼ to modify a digit and use

A/M to select the digit that needs to be modified. Press the A/M and SET key at

the same time to exit the parameter setup mode. The instrument will

automatically exit if no key is pressed for 10 seconds. Figure 4 is the setup flow

chart. Please note the changed parameter will be automatically registered

without pressing the SET key. If the controller is locked (see 4.17). Only limited

parameters (or no parameters) can be changed.

4.4 Parameter Setting

Table 2. System parameters.

Code

Description

Setting Range

Initial

Setting

Remarks

ALM1

Process high alarm

-1999~+9999° C or °F

100

See 4.4.1

ALM2

Process low alarm

-1999~+9999° C or °F

50

Hy-1

Deviation high alarm

0~+9999° C or °F

9999

Hy-2

Deviation low alarm

0~+9999° C or °F

9999

Hy

Hysteresis Band

0~200° C or ° F or

0~2000 for linear input

0.3

See 4.4.2

At

Auto tuning

0~3. Set to 1 or 2 to

start Auto tuning

3

See 4.4.3

I

Integral time

0~9999

1000

See 4.5.1

P

Proportional

Constant

1~9999%

500

d

Derivative Time

0~2000

120

t

Cycle time

2~125

20 for

relays

See 4.6

Sn

Input type

0~37

0 (K type

TC)

See 4.7

dP

Decimal point

position

0~3

0

See 4.8

P-SL

Display low limit

-1999~+9999° C or °F

-100

See 4.9

P-SH

Display high limit

-1999~+9999° C or ° F

2500

Pb

Input offset

-1999~+4000

-1999~+9999° C or °F

0.0

See 4.10

OP-A

Output mode

0~2

0

See 4.11

OUTL

Output low limit

0~100%

0

See 4.12

OUTH

Output high limit

0~100%

100

AL-P

Alarm output

definition

0~31

17

See 4.13

COOL

System function

selection

0~15

10

For heating

and ° F display,

see 4.14

Addr

Communication

address

s 0~20

1

Ignore this

setting

bAud

Communication baud

rate

0~19200

9600

Ignore this

setting

FILt

PV input filter

0~20

0

See 4.15

A-M

Automatic/Manual

status

0. Manual

1. Automatic

2. Manual suppressing

2

Manual control

is disabled. Set

to 1 to active.

See 4.16

LocK

Configuration

privilege

0~9999

808

All parameters

are unlocked.

See 4.17

EP1-

EP8

Field parameter

definition

nonE ~ A-M

nonE

To be defined

by user. See

4.17

4.4.1 Alarm parameters

This controller offers four types of alarm, “ALM1”, “ALM2”, “Hy-1”, “Hy-2”.

ALM1: High limit absolute alarm. If the process value is greater than the

value specified as “ALM1+Hy” (Hy is the Hysteresis Band), then the alarm

will turn on. It will turn off when the process value is less than “ALM1-Hy”.

ALM2: Low limit absolute alarm. If the process value is less than the value

specified as “ALM2-Hy”, then the alarm will turn on, and the alarm will turn

off if the process value is greater than “ALM2+Hy”.

Hy-1: Deviation high alarm. If the temperature is above “SV+Hy-1 +Hy”, the

alarm will turn on, and the alarm will turn off if the process value is less than

“SV+Hy-1 -Hy” (we will discuss the role of Hy in the next section)

Hy-2: Deviation low alarm. If the temperature is below “SV-Hy-2 -Hy”, the

alarm will turn on, and the alarm will turn off if the temperature is greater

than “SV-Hy-2 +Hy”.

Loading...

Loading...