Atwood Mobile Products Furnace 7916-II, Furnace MPD 32072, Furnace 8012-II User Manual

MPD 32072

ONE

side duct

BOTH

side ducts

FRONT

hydro flame

9

7900-II / 8000-II

TM

Series Furnace

Technical Installation Manual

ENGLISH, FRANCAIS (et Canada) •Installation

THIS INSTRUCTION MANUAL IS FOR USE BY AN AUTHORIZED SERVICE

TECHNICIAN TO INSTALL AN ATWOOD - hydro flameTMFURNACE.

INSTALLER

: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

This furnace design has been certified by the American Gas

Association and Canadian Gas Association for installation in

recreation vehicles as a MSP Category III furnace. Follow this

installation instruction to insure safe operation of the furnace.

Failure to install furnace according to this installation instruction

nullifies the furnace warranty.

SAFETY ALERT SYMBOLS

Safety Symbols alerting you to potential personal safety hazards.

Obey all safety messages following these symbols.

WARNING CAUTION

avoid possible avoid possible

injury or death injury and/or property damage

WARNING: If the information in this manual is

not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss

of life.

INDEX

FURNACE SPECIFICATIONS ..............................................................1

DIMENSIONS ..................................................................1

WEIGHT ........................................................................1

DUCTING CONFIGURATION................................................................1

MINIMUM CLEARANCE TO FLOORBOARDS, WALLS,

& SIMILAR COMBUSTIBLE BUILDING MATERIALS..................................2

SAFETY INFORMATION ................................................................1-2

FURNACE INSTALLATION ..............................................................2-4

CUTOUTS ..................................................................................2

DUCTING................................................................................2-3

Flexible Ducting......................................................................2

Venting Chart ........................................................................3

OPTIONAL INSTALLATION - DIRECTIONAL AIR BOX....................................3

PROPANE GAS CONNECTION ............................................................3

ELECTRICAL CONNECTIONS..............................................................3

Thermostat Installation ............................................................3

Door Installation ....................................................................3

SYSTEM CHECK TESTS ....................................................................4

PROPANE GAS PRESSURE ..............................................................4

FIGURES 1-8 (INCLUDING DC WIRING DIAGRAM) ..........................................4

REPLACEMENT PARTS LIST & DRAWING ..............................................8

DUCTING CONFIGURATIONS

Effective 1/08

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Evacuate all persons from vehicle.

• Shut off gas supply at gas container or source.

• Do not touch any electrical switch, or use any

phone or radio in vehicle.

• Do not start vehicle’s engine or electric generator.

• Contact nearest gas supplier or qualified Service

Technician for repairs.

• If you cannot reach a gas supplier or qualified

Service Technician, contact the nearest fire

department.

• Do not turn on gas supply until gas leak(s) has

been repaired.

— Installation and service must be performed by a

qualified Service Technician, Service Center or

gas supplier.

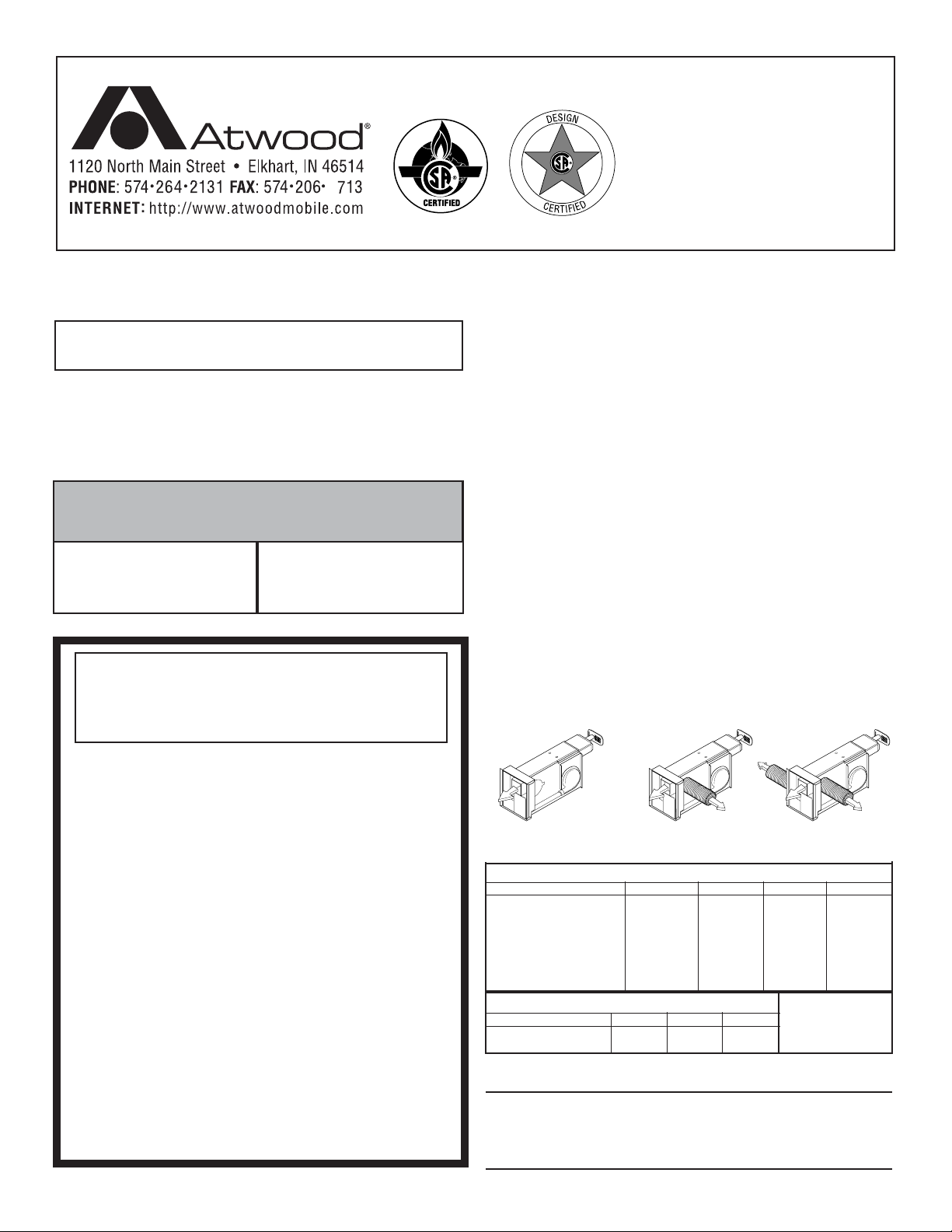

79/80 SERIES 79 SERIES 79 SERIES

80 SERIES ( 8012-II)

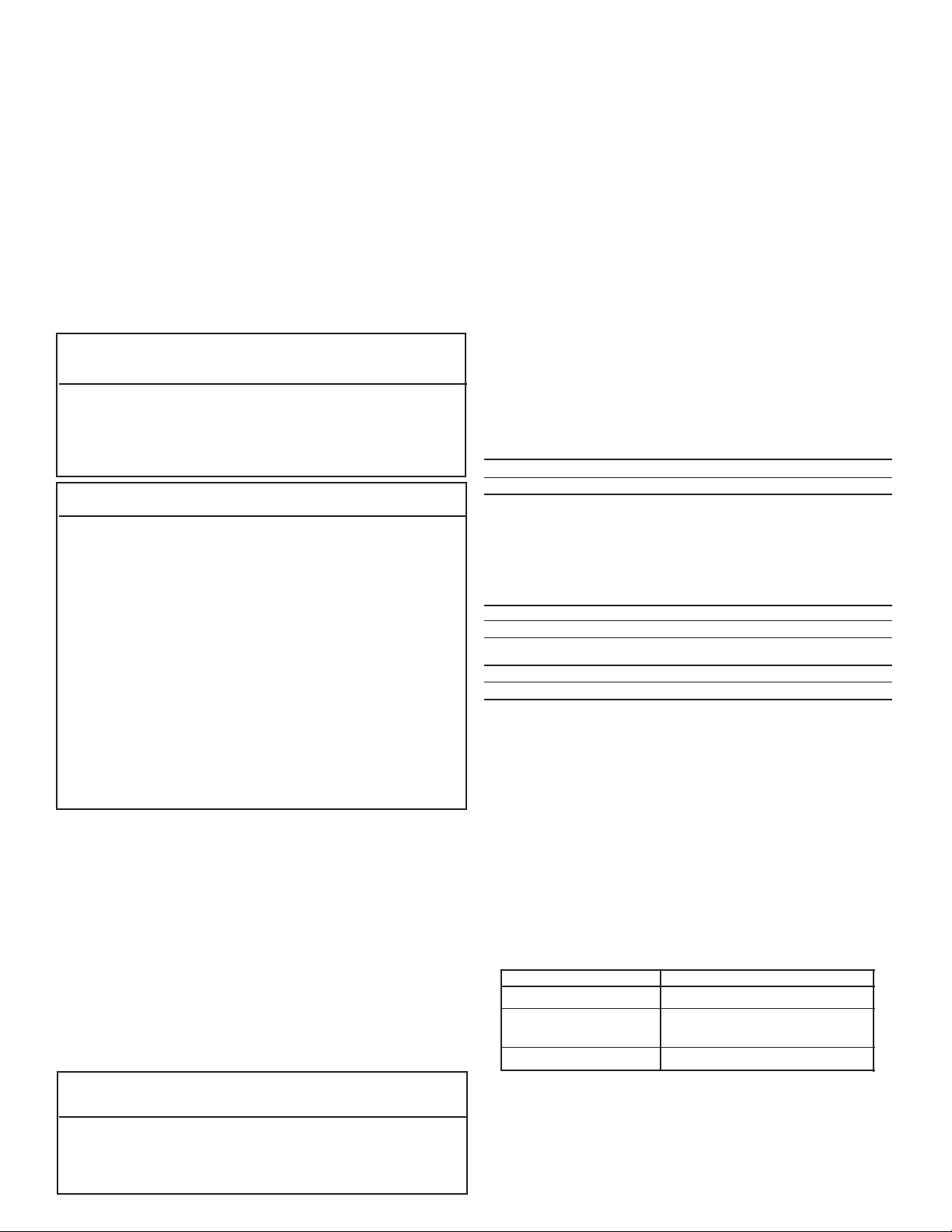

SPECIFICATIONS (W.C. = Water Column)

MODEL # 7912-II 7916-II 7920-II 8012-II

Input BTU/HR 12,000 16,000 18,000 12,000

Output Capacity BTU/HR 9,160 12,160 13,680 9,120

Duct Static Pressure - .20" W.C. .10" W.C. .10" W.C. N/A

12 Volt Amperage (AMPS) 3.4 3.4 3.4 1.8

Watts 40.8 40.8 40.8 21.6

Power Supply (Volt DC) 12 12 12 12

MINIMUM RETURN AIR 35 in

2

35 in

2

35 in

2

DIMENSIONS

ALL MODEL WIDTH HEIGHT DEPTH

Casing 8-3/8˝ 11-3/8˝ 20-5/8˝ FURNACE 23 lbs

Door 9-7/8˝ 11-1/2˝ 1-1/4˝ SHIPPING 25 lbs

WEIGHT

MINIMUM CLEARANCE TO

FLOORBOARDS

1

, WALLS & SIMILAR COMBUSTIBLE BUILDING MATERIALS

MUST BE PROVIDED THE FULL LENGTH AND WIDTH OF UNIT

Top and Sides 0˝ TO CASING SPACERS (SCREW HEADS)

Extension Box 0˝

Rear 0˝

Bottom 0˝ TO CASING SPACERS (SCREW HEADS)

35 in

2

Spacing of 1/4˝ to ducting within 3 feet of furnace must be provided

unless UL listed wire bound vinyl ducts are used. All ducting material

should be rated for continuous use of 200˚F.

NOTE: If zero clearance is maintained from furnace to cabinet structure, a

4˝ x 4˝ air intake cutout must be provided to blower wheel side of furnace

at air intake opening.

NOTE: Clearances are specifically for plywood or similar building

materials surrounding the furnace (i.e. furnace should

NOT be located

under furniture or in a closet space where clothing or other material

could be located.)

NOTE: Furnace efficiency rating is a thermal rating determined under

continuous operating conditions, independent of any installation. Eff.

rate is given at 77% minimum, actual efficiency rating may be higher.

*When furnaces are installed to minimum clearances, an additional 16 in

of return air must be provided to blower side of furnace, or a 2˝ clearance

the full length and height on blower side must be maintained.

WARNING

CARBON MONOXIDE POISONING

• Furnace must be installed and vented to these instructions.

• Improper installation, adjustment, alteration, service or maintenance

can cause injury or property damage.

• Improper installation location may cause furnace to produce negative

pressure, affecting combustion air or venting of other appliances.

CRITICAL INSTALLATION WARNINGS

• DO NOT install furnace on material that restricts return air, like carpet

or any soft material such as vinyl.

• DO NOT install where clearance to combustibles cannot be maintained.

• DO NOT modify furnace in any way.

• DO NOT alter furnace for a positive grounding system.

• DO NOT HI-POT furnace unless electronic ignition system (circuit

board) has been disconnected.

• DO NOT use battery charger to supply power to DC model furnace

even when testing.

• DO NOT use 120 volt AC current with DC models.

• DO NOT use furnace cabinet area as a storage compartment.

• DO NOT vent furnace with venting system serving another appliance.

• DO NOT vent furnace to an outside enclosed porch area.

• DO NOT use for temporary heating of buildings or structures under construction.

• Protect building materials from degrading from flue gas exhaust.

• Protect furnace electrical components from water.

USA AND CANADA - FOLLOW ALL APPLICABLE STATE AND LOCAL CODES -

IN THE ABSENCE OF LOCAL CODES OR REGULATIONS, REFER TO CURRENT STANDARDS OF:

• Recreation Vehicles ANSI 1192/NFPA 1192.

• National Fuel Gas Code ANSI Z223.1 /CAN/CGA B149 Installation Codes

• Federal Mobile Home Construction & Safety Standard, Title 24 CFR, part

3280, or when this Standard is not applicable, the Standard for Manufactured

Home Installations (Manufactured Home Sites, Communities and Set-Ups),

ANSI A255.1 and/or CAN/CSA-Z240 MH Series, Mobile Homes.

• Ground - National Electrical Code ANSI/NFPA No. 70 and/or CSA C22.1

• Park Trailers ANSI 119.5

NOTE: The direct high voltage spark ignition generates a radio frequency

that could cause interference with other microprocessor based equipment.

Locate equipment at least five feet from furnace location. If this distance cannot be maintained, purchase KIT MPD 37773 (a shielded high voltage lead).

Return air is supplied through openings in furnace grille. The return air passage

must be kept clear for furnace to function properly. Refer to

TO FLOORBOARDS

, WALLS & SIMILAR COMBUSTIBLE BUILDING MATERIAL.

MINIMUM CLEARANCE

STANDARD FURNACE INSTALLATION

General Installation -

• Install extension box and vent cap through an exterior wall.

• DO NOT install furnace near tilt-out rooms, slide-outs, doors or other

projections that could obstruct furnace exhaust.

• Locate furnace near midpoint of coach for single furnace applications.

• DO NOT install vent in areas where projections or door openings come

within 6˝ of vent tube opening.

• DO NOT install furnace in an area where wires, pipes, or other objects

2

will interfere with installation or operation of furnace.

• It is not recommended to install furnace on material that restricts

return air, such as directly on carpet, or soft material (like vinyl).

• If you must install furnace on carpet or soft material, install furnace on

cleats, or on a wood or metal panel extending the full width and depth

of furnace plus minimum clearances to combustibles.

LOCATION

Installation Procedure

ZERO CLEARANCE - AIR INTAKE CUTOUT

AIR INTAKE OPENING SIDE OF THE BLOWER WHEEL

CUT OUT DIMENSION ABCD

CABINET WALL 2-3/4˝ 3-5/8˝ 4˝ 4˝

A 4˝ x 4˝ cabinet cut out must be provided when there is zero clearance

between furnace and cabinet structure.

1. Set aside combustion air box and exhaust tube extensions for installation from outside coach.

(FIG 1)

FURNACE / VENT - CUTOUTS (FIG. 2)

CUT OUT DIMENSION AB

INTERIOR CABINET WALL 8-3/8˝ 11-1/4˝

DO NOT OVERSIZE HOLE - OVERSIZING CAN RESULT IN WATER LEAKAGE

CUT OUT DIMENSION CDE

COACH EXTERIOR WALL FOR VENT 4-7/8˝ 2-1/2˝ 1-3/4˝

DUCTING (FIG. 3)

Proper duct installation is critical to operation of furnace. When

installing ducts, use materials rated for continuous use at 200˚F. Front

discharge temperature should not exceed 250˚F.

Flexible Ducting System

When designing Flexible Duct Systems:

• avoid sharp bends or crushed ducts

• stretch all ducts and run them directly to outlets, keeping quantity

and angles of bends to a minimum

2. A variety of vent kits are available to provide the correct venting from furnace to outside of vehicle. To determine

distance from the back of furnace casing to outside vehicle side wall. For

proper vent kit check your V

DIM on VENTING CHART.

3. Ducting available:

TYPE OF DISCHARGE REMOVE

SIDE ONLY duct covers from both sides

COMBINATION front discharge cover plate

& SIDE and side duct cover plate

FRONT

FRONT ONLY front discharge cover plate

VENT LENGTH (V DIM), measure the

WARNING

CARBON MONOXIDE POISONING

• Properly seal vent cap to side wall to prevent carbon monoxide from

entering coach.

• DO NOT draw combustion air from living area. DO NOT vent exhaust air

into the living area or an enclosed porch.

See DUCTING CONFIGURATIONS for covers and their locations.

4. Install the furnace through cutout in cabinet area. Secure furnace

with two screws

FIG 5-A.

OPTIONAL - Installation: The 79-II furnace may be installed in a

cabinet behind a return air grille

Return air grille must supply a minimum of 35 in2of open area and

2

FIG 4-I. Door MUST be on furnace.

Loading...

Loading...