Page 1

LITERATURE NUMBER MPD 71074

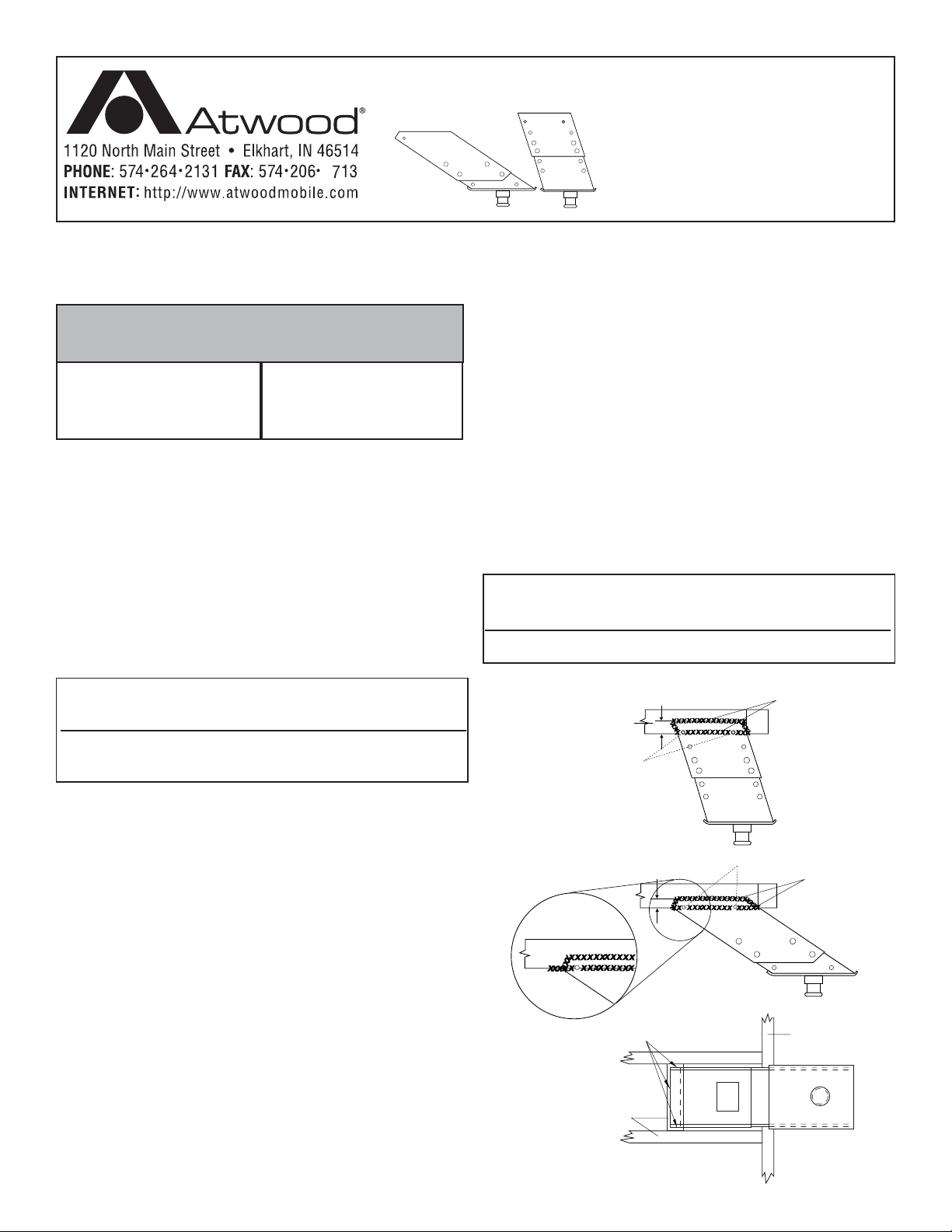

Frame Penetration

1-1/2" minimum

Model AB-72

Model AB-34

Bottom View

Frame Penetration

1-3/4" minimum

Model AB-34HD

holes for locating

weld depth

holes for locating

weld depth

Weld here full length

both sides

TRAILER FRAME

TRAILER FRAME

TRAILER FRAME

Weld sides and rear of

horizontal flange

Weld here full length

both sides

5TH WHEEL

9

ENGLISH, FRANÇAIS (et Canada)

SAFETY ALERT SYMBOLS

Safety Symbols alert you to potential personal safety hazards. Obey all safety

messages following these symbols.

WARNING CAUTION

avoid possible avoid possible

injury or death injury and/or property damage

FOR YOUR SAFETY READ ALL INSTRUCTIONS

BEFORE INSTALLATION AND OPERATION

Installer: Provide these instructions to the consumer.

Consumer: Keep documents for future reference.

The Atwood 5th Wheel Pin Box is intended for use on recreation

vehicle 5th wheel-type trailers only.

CAPACITY

AB-72 75690 72° 18,000 lbs. SAE/CSA

AB-34 75700 34° 10,000 lbs. SAE/CSA

AB-34HD 75705 34° 18.000 lbs. SAE/CSA

DO NOT EXCEED THIS CAPACITY

PIN BOX

•Installation •Operation •Maintenance

Effective 11/21/07

OPERATION

1. See the 5th Wheel hitch manufacturer’s operating instructions for

coupling and uncoupling procedures.

MAINTENANCE

1. Inspect nuts, bolts, king pin, skid plate and bolt holes at least every

2,000 miles of operation for signs of stress or cracking. Torque the

bolts to 50-55 ft. lbs.

2. Skid plate surface may need to be cleaned in order to evaluate

condition. If skid plate or any portion of the pin box connection

shows bending or cracking, replace the pin box immediately.

3. Grease contact surface of pin box with a lithium base grease every

2,000 miles of operation or monthly during use to reduce wear and

provide easier turning.

4. Contact Atwood Mobile Products for warranty information.

CAUTION

PERSONAL INJURY AND/OR PRODUCT DAMAGE

• Do not repair worn or damaged pin box. Pin box must be replaced.

Do not make alterations to pin box.

•

TRAILER CAN MOVE OR COLLAPSE

• Know the vehicle weight and all added payload. DO NOT exceed the

gross vehicle weight rating indicated on the pin box.

• Use only with 5th wheel hitches designed for use with SAE 2˝ kingpin.

WARNING

INSTALLATION

1. Assemble pin box before welding to the trailer frame. Use eight

(four per side) 1/2˝ x 13˝ UNC x 1˝ long, grade 5 bolts with lock nuts

that are supplied and assemble to the desired height. Tighten bolts

to 50-55 ft. lbs. torque.

2. Place 3/8˝ diameter rods through the holes in the sides of the pin

box to provide stops for locating the correct depth in the frame.

3. AB-72 pin box must penetrate trailer frame a minimum of 1-3/4˝.

AB-34 and AB-34HD must penetrate trailer frame a minimum of

1-1/2˝.

4. Pin boxes must be welded full length along trailer frame on both

sides and also across front of pin box to front frame member as

shown. Use 5/16˝ fillet weld No. E601 AWS welding rod 5/16˝

diameter, machine amps (AC or DCRP) @ 160-180 with 50 volts.

5. AB-34HD has a flanged, reinforcing plate on the rear of the pin box.

Weld the flange to the frame, also.

Loading...

Loading...