atwood Wheel Leveling IOM User Manual

Table of Contents

Installation 2-10

Leveler legs……………………………………………………….....……… 2

Controller………………………………………………………………........ 4

Dip-switch Configurations…………………………………………………. 5

Wire Harness Installation………………………………………………….. 7

Operation 11-14

Program HOME Position...................................................................... 12

Program/Reprogram AUTO Level Position / Keypad Function............ 13

Unhooking from Tow Vehicle & Leveling/Hooking to Tow Vehicle... 14

Leveling Features…………………………………………………………. 15

System Protection Features...................................................................... 16

Maintenance / Warranty............................................................................. 17

Troubleshooting ……………………………………………………………….. 18-21

Index……………………………………………………………………………… 22

- 1 -

LEVELER LEGS

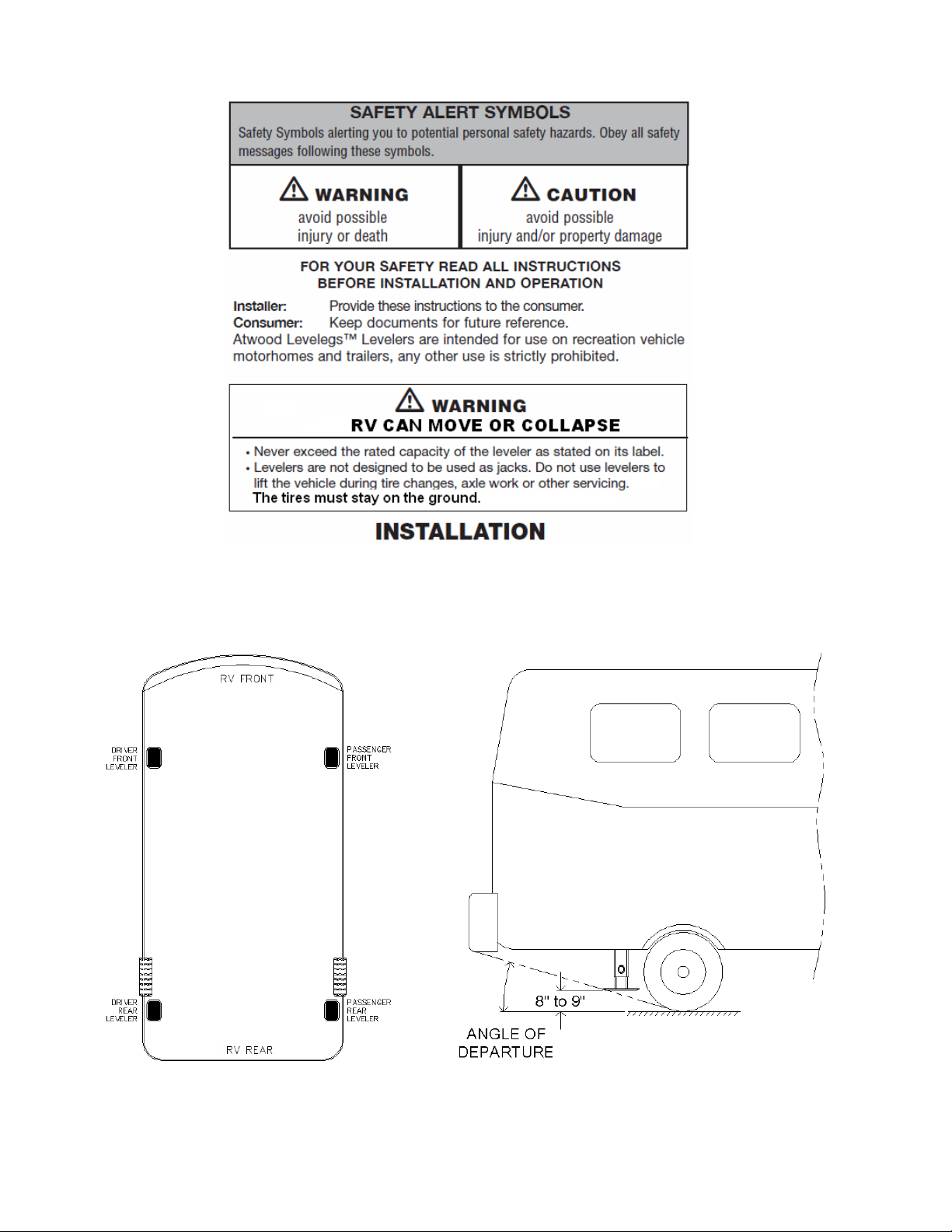

1. Install direct drive levelers as close to the front bulkhead, and the rear levelers as close to

the rear wheels as possible in a rectangular formation. If the levelers are installed

unevenly, the effectiveness of the system will be compromised.

- 2 -

2. Position leveler vertically against frame so base of foot has 8-9" minimum ground clearance

when RV is loaded to its maximum GVWR (NOTE: the clearance of a raw rail is different than

the clearance of a fully completed unit).

3. For all Leveleg installations, refer to the diagram with the correct configuration.

A. For 5K Direct Drive Landing LegsTM,

i. Attach mounting brackets to legs using 3/8” – 16 carriage bolts and nuts. Torque bolts

to 18-20 ft-lbs. On each leg, position one bracket above and one below mounting tabs

welded to landing leg housing.

ii. Position legs against frame in a vertical position. Legs should not be more than 1/4˝

out of parallel with each other. Locate foot pads and lock pins for maximum ground

clearance and to clear lower edge of trailer.

iii. Mark mounting bracket location on trailer frame. Weld mounting bracket to trailer

frame on both vertical sides and across

either top or bottom. DO NOT weld edges

that contact mounting tabs on landing

legs.

NOTE: Due to different frame configurations, it

may be necessary to weld angle bracket tubing

to upper and/or lower part of frame to locate

landing legs vertically and plumb.

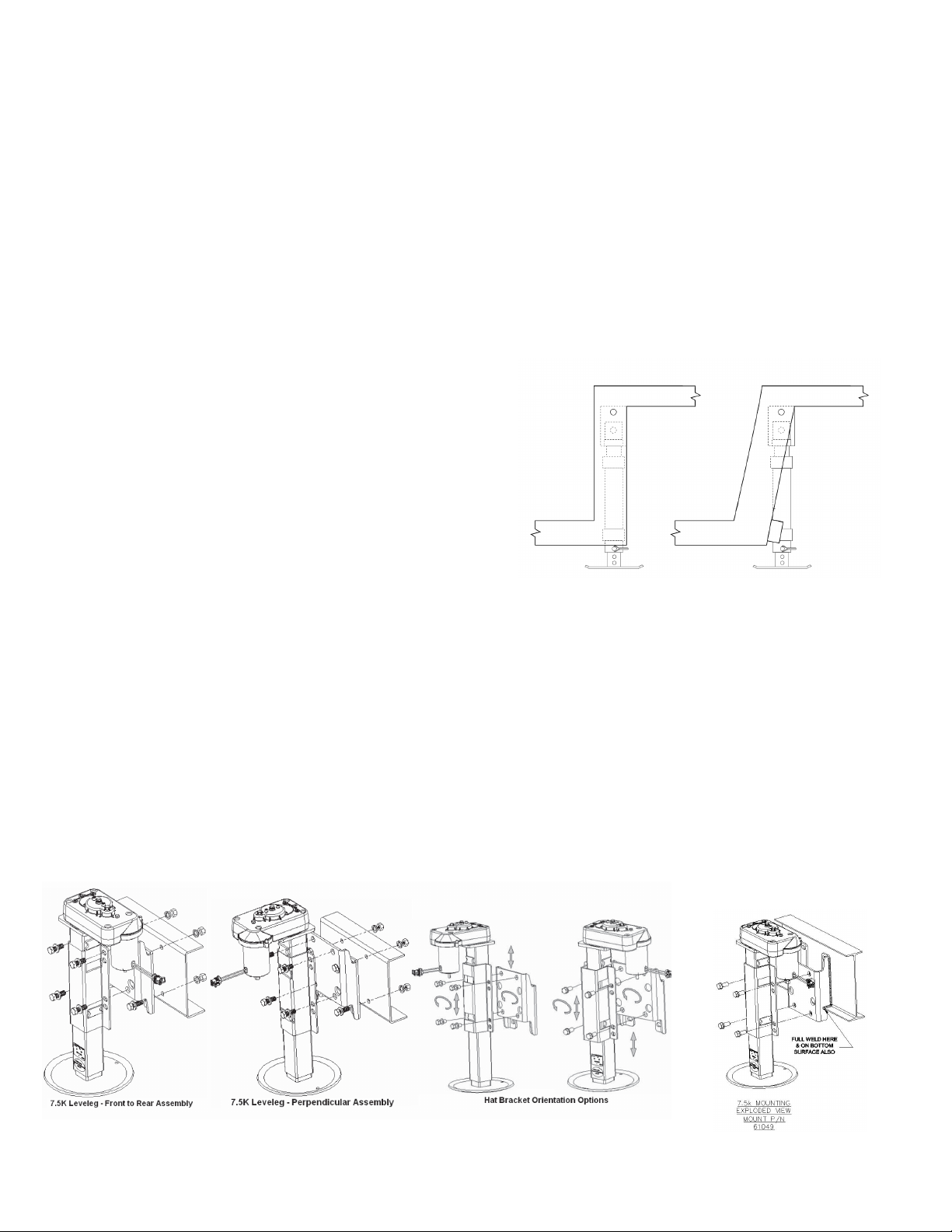

B. 7.5K LevelegsTM. There are different ways

to mount the 7.5k Levelegs. The hat

bracket shown below left attaches the

Leveleg oriented to the front or rear of the RV, and the hat bracket shown below middle

attaches the Leveleg oriented perpendicular to the frame.

i. For bolt on assembly, attach the frame bracket to the frame using 4 sets of 1/2”-13

grade 5 nuts and bolts and 1/2” flat and locking washers. This bracket can also be

welded to the frame on some units.

ii. Fit the hat bracket around the Leveleg and attach to the frame bracket using 4 sets

of 1/2” – 13 grade 5 bolts and 1/2” flat washers.

NOTE: The hat brackets used for the 7.5k Levelegs can be oriented in multiple ways to

best fit the RV. The hat bracket can be rotated 180° to bolt the Leveleg higher or lower

to the frame bracket. Also the top tab of the Leveleg can either fit through the slot of the

hat bracket, or rest on the top of the hat bracket in order to offer more options for

assembly. These options are illustrated in the figure below right.

4. Lubricate the bolts and torque to 65 ft-lbs.

- 3 -

- 4 -

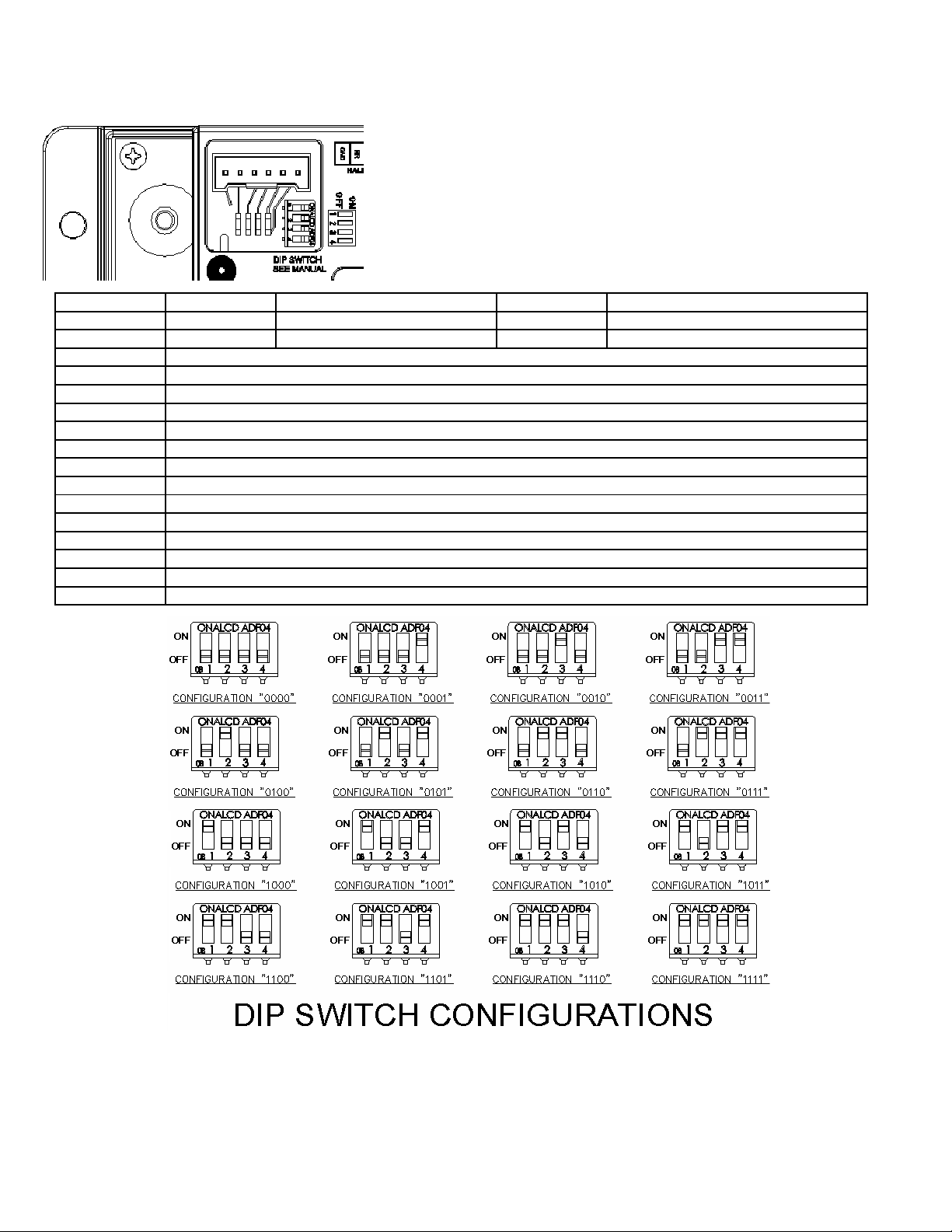

Dip Switch Configuration

• In order to accommodate as many units as possible, there

is a set of four small “dip switches” on the control board

that must be configured. Refer to the following table and

figure for the required configuration for your RV.

NOTE: If any of the blank configurations are used (noted by

“DEAD POSITION) in the table below), the Controller will not

work. In this case, the Control Pad Leveler position LEDs will

flash up and down.

Configurations Rear Levelers Rear Levelers Stroke Length Front Levelers Front Levelers Stroke Length

0000 7.5K 15" of travel 5K Direct Drive 24" of travel

0001 7.5K 13" of travel 5K Direct Drive 24" of travel

0010 DEAD POSITION

0011 DEAD POSITION

0100 DEAD POSITION

0101 DEAD POSITION

0110 DEAD POSITION

0111 DEAD POSITION

1000 DEAD POSITION

1001 DEAD POSITION

1010 DEAD POSITION

1011 DEAD POSITION

1100 DEAD POSITION

1101 DEAD POSITION

1110 DEAD POSITION

1111 DEAD POSITION

NOTE: These switches MUST be configured correctly. Incorrect configuration can result in

poor performance or damage to the system.

- 5 -

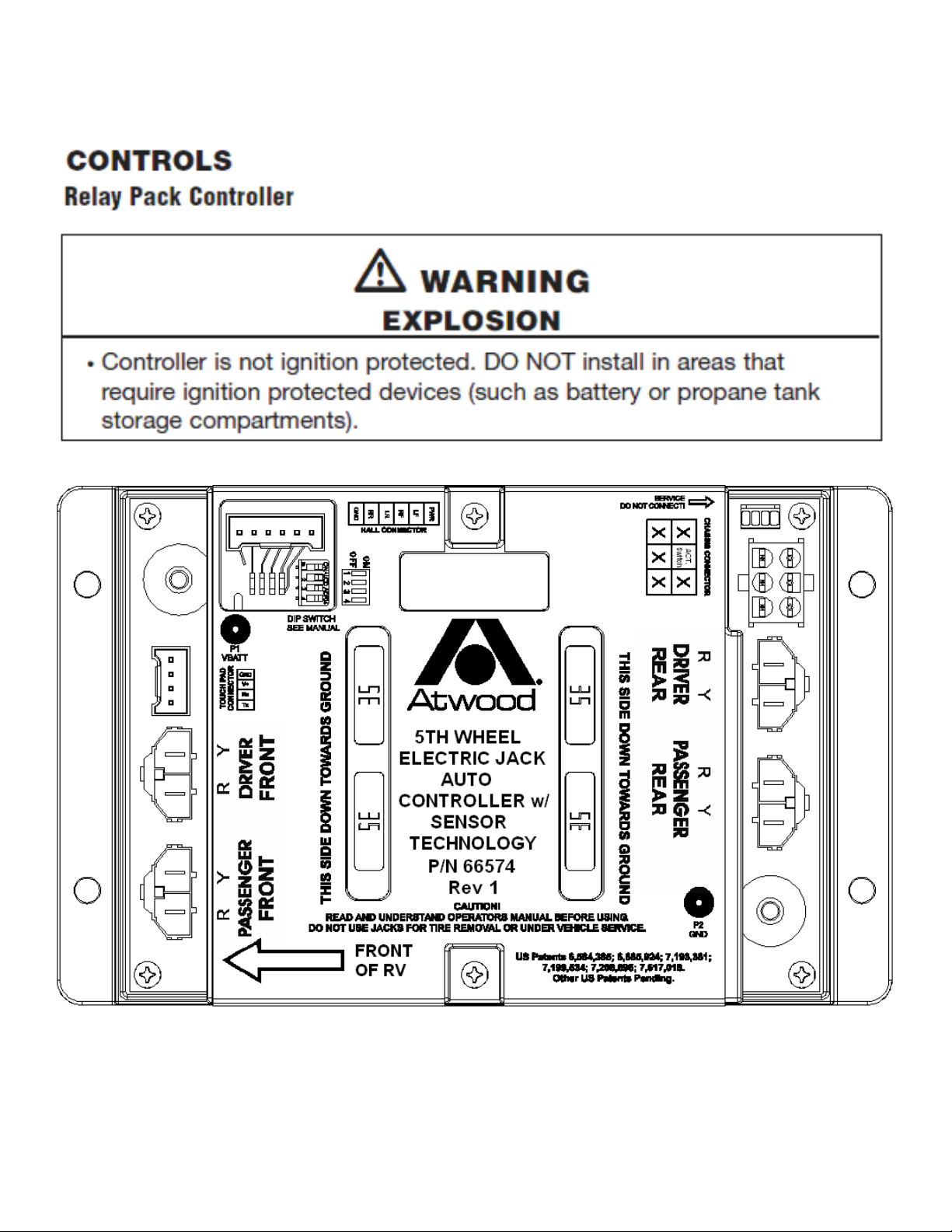

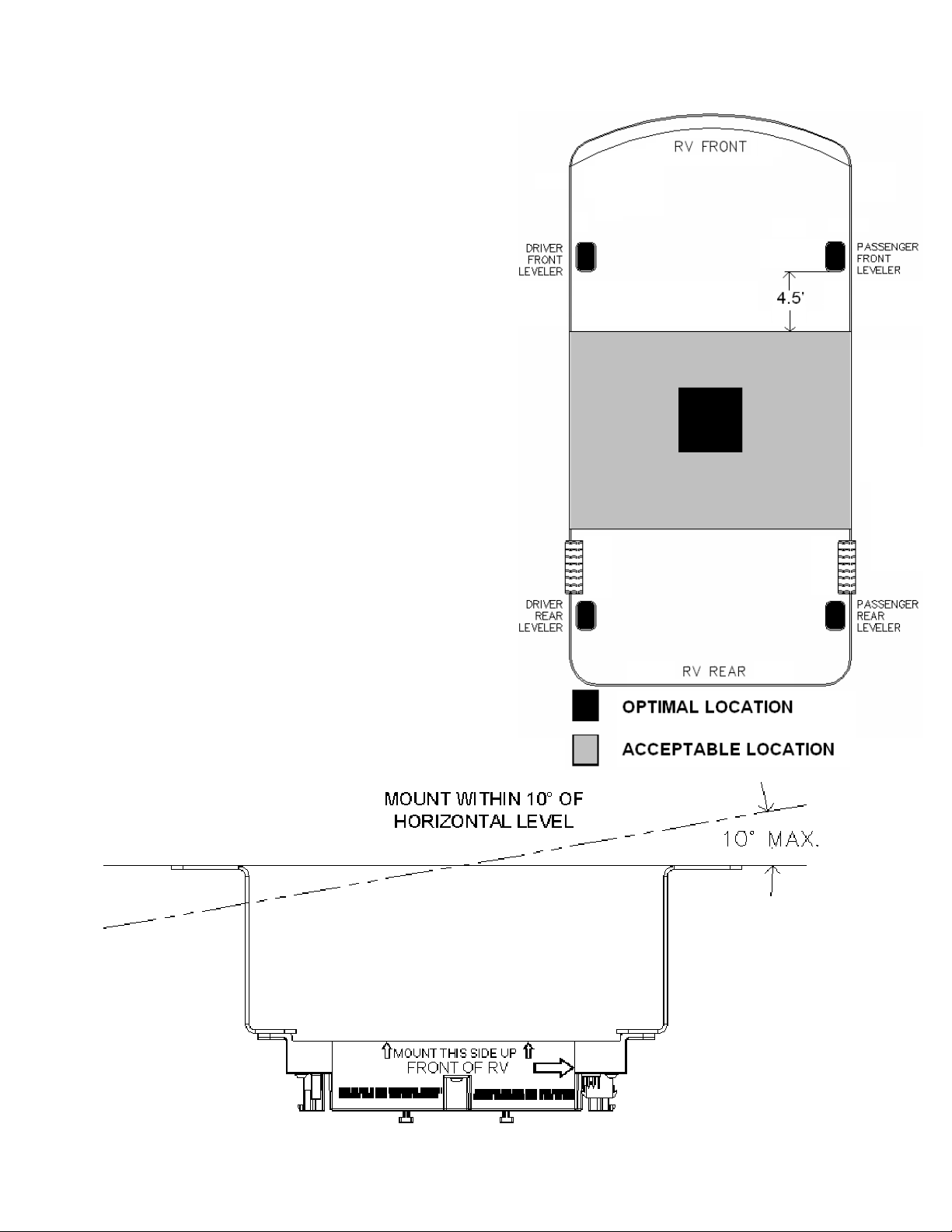

Controller Location

1. To optimize the effectiveness of the Controller,

it should be mounted as close to the center of

the RV as possible. There is an optimal zone

and an acceptable zone to install the Controller

as shown to the right. Any other place will

compromise the operation of the Controller.

2. Install Controller in a clean, dry interior area

protected from moisture. Use corner holes of

unit to fasten base horizontally to mounting

surface, using appropriate hardware for

surface.

3. Install the AUTO POSITION Controller so the

forward arrow points toward the front of the

RV. The controller must be hung upside down

to match the arrows on the side of the

Controller, within 10° of horizontal level

(parallel with mounting surface) as shown

below. Sufficient space below the board must

be provided for the wires to be connected.

NOTE: Any control board installed outside the

acceptable area (defined to the right) will

void warranty

- 6 -

CONTROLLER WIRING

All information below pertains to the diagram on the page 10

NOTE: Atwood recommends using the Plug n’ Play harness kit

• If modifications to the harnesses must be made, please mimic the Atwood harnesses, and

follow the guidelines provided by the manufacturer of the harness terminals. Be sure any wire

crimps are strong enough as defined by the manufacturer. Poor connections can hurt system

function. Refer to the wire harness index for the pin outs of each harness. Do not

make any wires longer than specified below.

• For any extra wire after installing a harness, fold end to end (do not coil) and tie as

shown. (see right)

• Atwood does not guarantee wiring functionality if wires are modified and/or new or

different harnesses are made.

NOTE: For all wires, use strain relief clamps to reduce damage to the terminals.

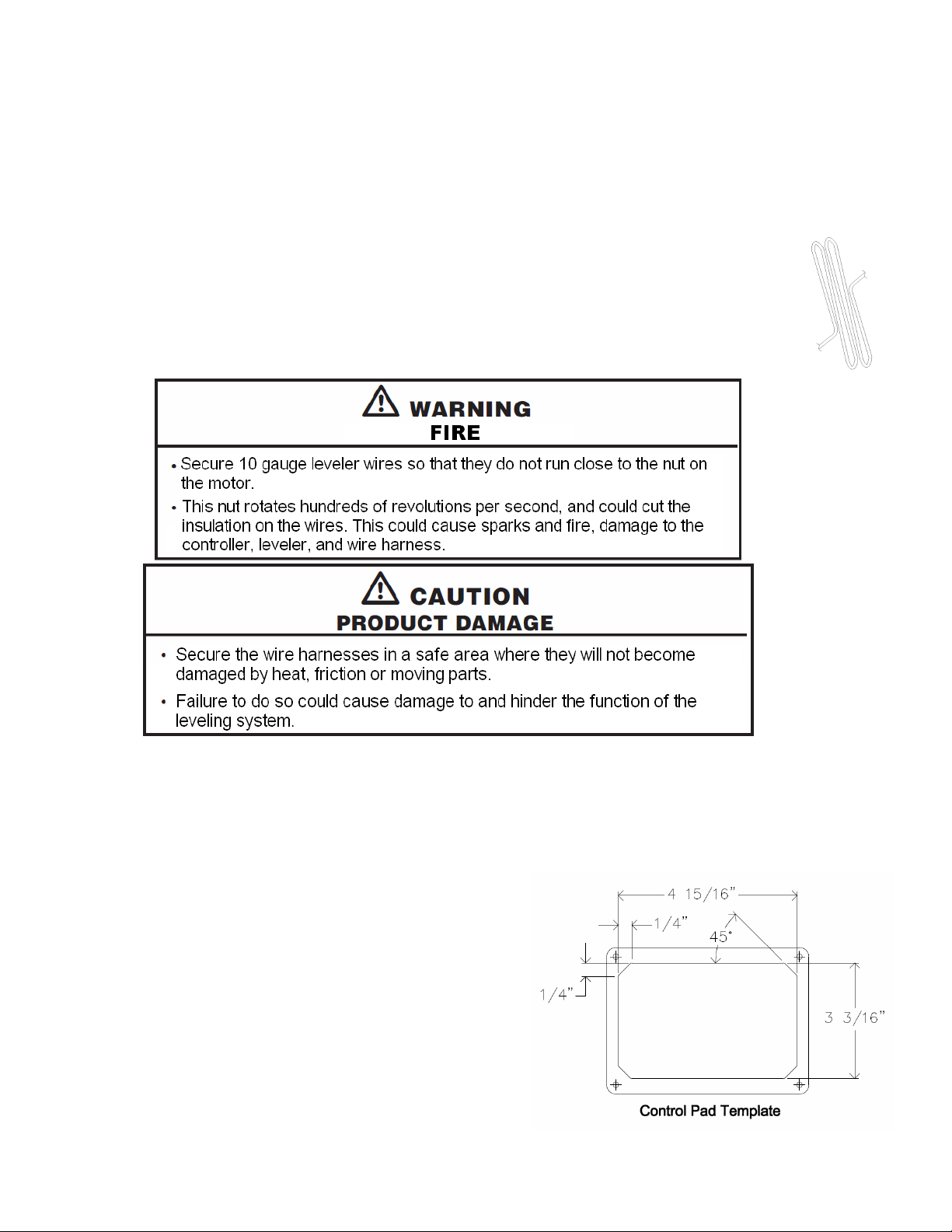

Auto Position Control Pads

NOTE: Mount the control pad in a clean, dry, and lockable compartment.

1. Provide a space with the dimensions shown in the figure to the right for the control pad at

desired location.

Note: Reference control pad when making cutout;

there is tight clearance. Also to ensure the longevity

of the product, mount keypad away from potential

sources of moisture: windows, cup holders, etc.

2. Use the corner holes to fasten control pad to

mounting surface using appropriate hardware for

surface.

3. Connect control pad wire harness to control pad.

4. Route the control pad wire harness to controller

and connect the two.

5. Fasten a strain relief clamp (not included) within

12” of the control pad. This is to prevent the wire

harness connection from being damaged at the

- 7 -

Loading...

Loading...