atwood Truck Camper Jacks User Manual

LITERATURE NUMBER MPD 87903

CAMPER JACK CONTROL

WITH ATWOOD’S AUTOMATIC EXTEND

DRIVER PASSENGER

EE

RR

EE

RR

ALL JACKSFRONT

E

R

FRONT

REAR REAR

ACME & BALL SCREW

A Division of Dura Automotive Systems

ENGLISH, FRANCAIS (et Canada) •Installation •Operation •Maintenance

REFERENCE NUMBERS REFER TO ILLUSTRATIONS ON BACK PAGE

SAFETY ALERT SYMBOLS

Safety Symbols alerting you to potential personal safety hazards.

Obey all safety messages following these symbols.

WARNING CAUTION

avoid possible avoid possible

injury or death injury and/or property damage

READ ALL INSTRUCTIONS BEFORE OPERATING JACKS

Installer: Provide these instructions to the consumer.

Consumer: Keep documents for future reference.

Atwood Acme and Ball Screw Truck Camper Jacks are designed to be

used in sets of four with one at each corner of the truck camper. The

maximum static load and lifting capacity is:

SCREW SYSTEM PER JACK

Acme 2,250 lbs. 1,250 lbs.

Ball 3,900 lbs. 2,200 lbs.

Heavy Duty Ball 5,000 lbs. 2,800 lbs.

Atwood makes two types of Electric Ball Screw Truck Camper Jacks

(EBSTCJ); one with remote capability and one without. They are not inter-

changeable. Our remote control is designed for use only with Atwood Electric

Ball Screw Truck Camper Jacks (EBSTCJ) equipped for remote control capability. The camper must be wired specifically for the remote.

See Chart below for the recommended maximum loading for a four

jack system based on the bracket kit used.

Bracket Kit or less 3900 lbs. 5000 lbs.

Narrow Front

Narrow Rear X

with lower clamp

Wide Front

Wide Rear X

with no lower clamp

Wide Front

Narrow Rear X X

with lower clamp

Wide Front, Wide

Rear with lower clamp

FOR YOUR SAFETY

Truck Camper Wet Weight

2250 lbs. – 2250 lbs. – 3900 lbs. –

XXX

PERSONAL INJURY & PRODUCT DAMAGE

• Unplug the remote control when not in use.

• Store remote in a secure place, away from access by children.

INSTALLATION

NOTE: Camper manufacturer must insure camper side walls are sufficiently

reinforced at corners for mounting jacks.

1. Bolt together flat and formed pieces of each corner bracket using

3/8˝ x 1˝ grade 5 bolts, flat washers and bolt retainers (supplied) as

shown in FIG 1 or 4. Bolts must extend from the formed piece

through the flat piece.

2. Position brackets on corners so that jack will be perpendicular to

ground when camper is level. (See

lower support bracket, place it at least 12˝ below main corner bracket. See FIG 3-A.

3. On all corner brackets and lower support brackets, drive 1/4˝ diameter lag screws (not supplied) into camper’s corner through center of

each slotted hole into camper framework. Minimum length of lag

screw must be 1-1/4˝. See FIG 2-A for wide brackets and FIG 5-A for

narrow brackets.

NOTE: Holes are slotted to allow brackets to tighten up to the camper’s

corners as installation is made. Positioning lag screws in center

of slots permits bracket to shift without affecting the integrity of

the corner.

4. On wide brackets, use steel angles (not supplied) on inside of

camper’s corners to provide sufficient support. See FIG 2-B. Use four

(4) 3/8˝ bolts, lock washers and nuts (not supplied) to bolt through

each wide corner bracket, side wall and steel angle. Torque bolts to

15-20 ft. lbs.

5. Mount jacks to 3/8˝ x 1˝ long grade 5 hex bolts protruding from corner brackets (installed in STEP 1 above). Use flat washers and locknuts (SUPPLIED) to retain jack. Torque to 15-20 ft. lbs. See FIG 2-C for

wide and 5-B for narrow (bolt retainer not shown for clarity).

NOTE: Jack must be located so handle clears all obstructions when

cranked.

NOTE: For trucks with dual rear wheels, use Swing-Out Brackets to

allow the front jacks to swing out to a wider position to clear dual

wheel fenders. Follow Swing-Out Bracket instructions MPD

87904 for proper installation and safe use.

6. For rear jacks with lower clamps, carefully spread clamps far

enough to slip over rear jack tube. Push onto jack and attach to

lower support brackets with 3/8˝ x 1˝ long, grade 5 hex bolts, flat

washers, and locknuts provided. Torque bolts to 15-20 foot lbs.

WARNING

PERSONAL INJURY & PRODUCT DAMAGE

• Never store camper on the jacks.

• Never exceed rated jack and/or camper capacity.

Camper can collapse and tip over.

Do not operate jacks if the camper exceeds gross vehicle weight.

•

• Only operate jacks when camper is unoccupied and contents are

secured and properly distributed.

Maintain proper load distribution and a safe distance when raising

•

or lowering camper.

• Park the camper on a firm, level site.

Never walk under the camper when it is extended on the jacks.

•

• Do not lift the truck with the jacks.

Electric Ball Screw Jack

7. Locate electrical receptacles on front and rear of camper as shown

by the rear view in FIG 9 with 4-wire connectors on driver side and 2wire connectors on passenger side of camper. Receptacles must be

mounted within 5˝ from edge of camper, see FIG 9-A.

8. Make electrical connections as shown in FIG 10 with front and back

jacks on separate 30 amps circuits with fuses located within 18˝ of

battery. Use 10 gauge stranded copper wire. Wiring must met RVIA

codes.

A - Driver side D - 30 amp fuse

B - Passenger side E - Black w/White stripe

C - Red w/White stripe F - Black

WITHOUT REMOTE CONTROL - FIG 6 & 7

1

TRUCK CAMPER JACKS

INCLUDES REMOTE CONTROL

FOR ELECTRIC BALL SCREW JACKS

(4 JACK SETS)

Effective 5/22/07

WARNING

FIG 3) On rear corners with a

G - Red

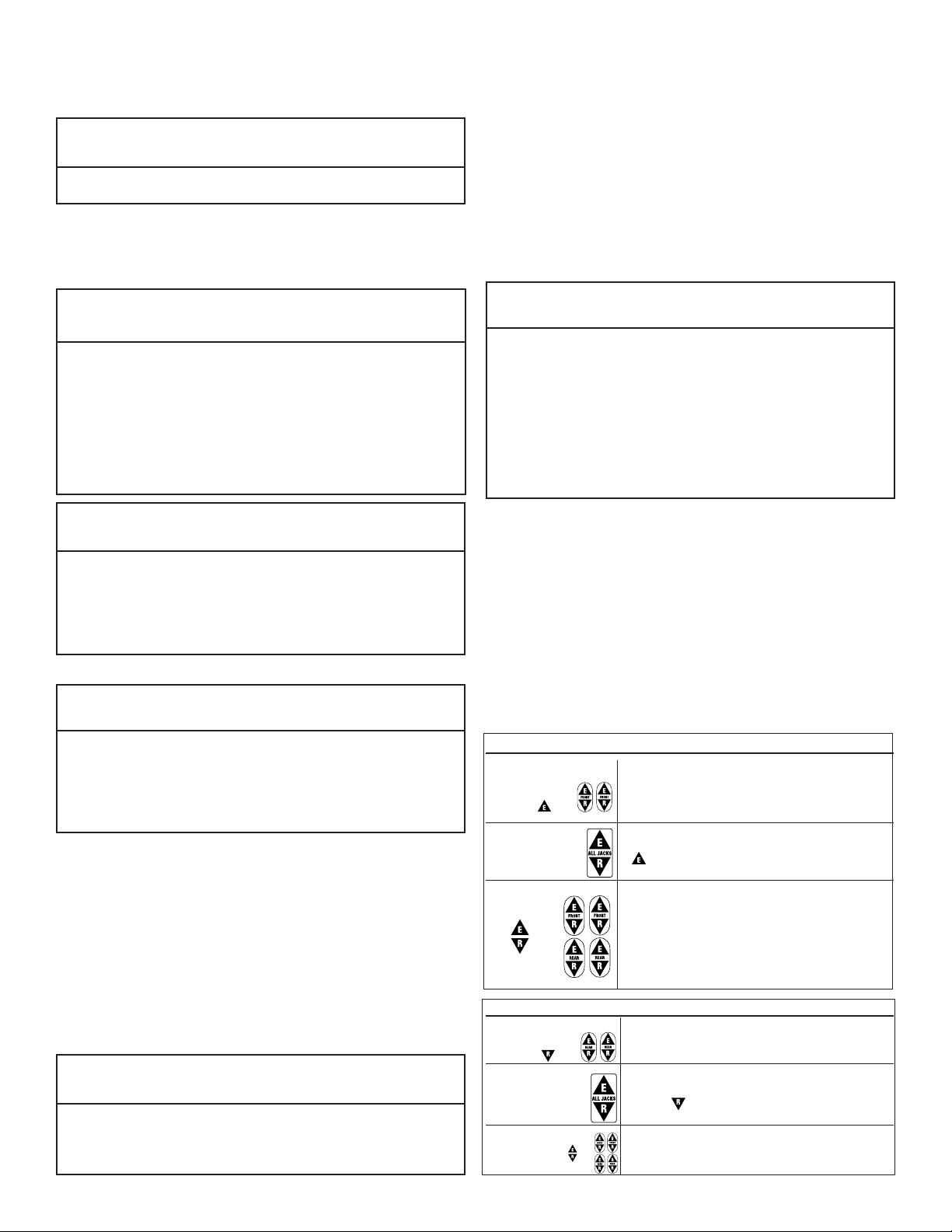

Electric Ball Screw Jack WITH REMOTE CONTROL - FIG 7

Press and hold

Extends single jack.

Press and hold.

Retracts single jack.

Press and hold.

Retracts single jack.

Press and hold

Extends single jack.

Press and hold.

Retracts single jack.

Press and hold

Extends single jack.

7. Mount two wire connectors on front and rear of camper within 5˝

from edge of camper.

CAUTION

PRODUCT DAMAGE

• Disconnect power to the power relay module prior to HiPot testing

of the camper or the microprocessor will be damaged.

TO INSTALL THE WIRELESS REMOTE CONTROL, REFER TO INSTRUCTION

MPD 87920.

OPERATION

To remove handle, hold plastic push collar in place with one hand

and back handle off with the other hand until the pin is engaged in

the middle of handle “T” slot. Release bar should audibly and visually

spring back into position. To do so the handle must be in the vertical

position (

NOTE: If jack is supporting camper, it may be necessary to rotate han-

FIG 17).

dle clockwise slightly to relieve load on Release Bar before

Release Bar can be disengaged.

Manual Ball Screw Jacks have a quick-to-ground feature. To drop

jack foot quickly to ground: push in both sides of Release Bar, then

step down on jack foot to drop it to the ground.

NOTE: Quick-to-ground feature may not work freely until jack has been

used several times because of close tolerances built into jack.

ELECTRIC JACKS

WARNING

CAMPER CAN TIP OVER

• Soft or spongy areas may cause jacks to sink, causing camper to

tip over. Park the camper on a firm, level site.

• Insure area below and around jack is clear of obstructions.

• Do not place blocks under the jack for additional ground clearance.

• Always keep the front of camper higher than or equal to the rear

of the camper. Never allow either side or end of camper to be more

than 4˝ out of level. See FIG 12 and 13.

• Do not use the jacks to raise the truck, such as to change a tire.

The jacks are designed only for lifting and lowering the camper

onto the truck and for stabilization of camper.

CAUTION

PRODUCT DAMAGE

• Do not over extend or over retract jacks. Each jack has built in stops.

Excessive force applied against the stops will cause damage.

Do not use pneumatic tools to operate any jack. They can over-extend

•

or over-retract the jack.

• Do not use the jacks to level the truck and camper. This will overload

the jacks.

ACME JACK — FIG 14

CAUTION

PERSONAL INJURY/PRODUCT DAMAGE

• Do not use pneumatic tool to run drill adapter.

• Battery operated drills, 9.6V to 18V, are powerful. Hold drill with

both hands to protect your wrist. Keep loose clothing and body

parts away from drill as the reaction torque from the drill may

cause it to kick back.

• Refer to your drill manufacturer’s operation manual.

To extend or retract jack, push handle onto drive shaft and rotate

slightly until drive pin is engaged in handle slot. Rotate handle clockwise to raise camper or counterclockwise to lower

instructions in TO LIFT OR LOWER TRUCK CAMPER section. To remove handle,

reverse above procedure. A drill adapter is provided, for even faster setup or tear-down (

OR LOWER TRUCK CAMPER section.

FIG

15 and caution above). Follow instructions in TO LIFT

MANUAL BALL SCREW JACK — FIG 16

To extend or retract jack, push handle onto alignment tube and depress

release bar with plastic push collar (

place with one hand and rotate handle slightly with the other hand

until black pin engages

clockwise

to raise camper or counter clockwise to lower camper.

Follow instructions in T

at either end of handle “T” slot. Rotate handle

O LIFT OR LOWER TRUCK CAMPER

FIG 17). Hold plastic push collar in

camper. Follow

section.

CAUTION

PRODUCT DAMAGE

• Do not over-extend or over-retract jacks. The electric jack has an

internal slip clutch to help prevent damage; when clicking sound is

heard, release switch. Continuing to hold the switch will wear out

the slip clutch or cause damage to the motor.

• If the motor will not extend/retract the jack and the motor is mak-

ing a ratcheting sound (clutch slipping), do not use the manual

override. Immediately contact an Atwood Service Center and have

jack replaced. Do not use the jack until replaced.

• If grinding operation should occur or any indications of improper or

inadequate performance, have a trained service professdional

inspect the jack set.

Electric Ball Screw Jack WITHOUT REMOTE CONTROL — FIG 6 & 7

Press switches on driver side jacks to raise and lower camper. Press

top of switch to retract jack (RET) or bottom of switch to extend jack

(EXT). You may need to first turn on power to jacks using switch inside

your camper.

Manual Override Operation: To manually extend or retract jack, place

manual override handle (

engage drive pin. Rotate handle counter-clockwise to raise or clockwise to lower camper.

Electric Ball Screw Jack

Remove the hand held remote control from its secure compartment.

Push activation switch to energize for wireless remote. Operator and

all spectators must stand a safe distance from the camper.

To LIFT Truck Camper WITH REMOTE CONTROL

EXTEND FRONT Disconnect the front and rear tiedowns.

JACKS FIRST

EXTEND ALL JACKS

INDIVIDUAL JACK

ADJUSTMENT

To LOWER truck camper WITH REMOTE

RETRACT REAR JACKS

FIRST

Follow instructions in TO LIFT OR LOWER TRUCK CAMPER section.

FIG 8-A) into alignment tube (FIG 8-B) and

WITH REMOTE CONTROL— FIG 7

Extend front jacks so camper is 4˝ higher in

front than in the rear. (see FIG 12).

Once the camper front is higher than the rear,

press and hold the ALL JACKS BUTTON, extend

( ). Release when the camper is at the

desired height.

Use the individual jack buttons to adjust an

individual jack. Press and hold the extend or

release buttons for the individual jacks as

needed to keep the front of the camper 4˝

higher than the rear, to prevent tipping over

the camper. Keep all corners within 4˝ of

level with each other.

Retract rear jacks so camper is 4˝ lower in

rear than in the front. (see FIG 13).

WARNING

PERSONAL INJURY & PRODUCT DAMAGE

• Always maintain positive pressure on handle until the release bar

is completely back into place, engaging the drive pin.

• Do not use quick-to-ground feature with handle in place. Handle

will spin and can cause property and bodily injury.

RETRACT ALL JACKS

INDIVIDUAL JACK

ADJUSTMENT

2

Once the camper has the rear lower than the

front, press and hold the ALL JACKS BUTTON,

retract ( ). Release when the camper is at

the desired height.

Use the individual jacks buttons to adjust an

individual jack. Keep all corners within 4˝ of

level with each other.

Loading...

Loading...