Page 1

LITERATURE NUMBER MPD 87840

JACK SCREWS

FIXED MOUNT JACKS

9

ENGLISH, FRANCAIS (et Canada) •Installation •Operation •Maintenance

SAFETY ALERT SYMBOLS

Safety Symbols alerting you to potential personal safety hazards.

Obey all safety messages following these symbols.

WARNING CAUTION

avoid possible avoid possible

injury or death injury and/or property damage

Installer: Provide these instructions to the consumer.

Consumer: Read and keep documents available for future reference.

Capacity Definition: The supporting, or support, capacity is the maxi-

mum vertical load that the jack can support.

WARNING

Never exceed the rated capacity stamped or labeled on jack tube.

•

• Jacks must be installed according to instructions provided to ensure

safe operation.

HANDLE MAY INJURE OR DAMAGE PROPERTY

PERSONAL INJURY / PRODUCT DAMAGE

• BEFORE INSTALLATION, JACK HANDLE MUST CLEAR ALL OBSTRUCTIONS WHEN

THEY ARE IN USE

• Install jacks in accordance with provided instructions.

• Adequate ventilation must be provided when welding.

.

WELDING INSTRUCTIONS

• M.I.G. OR STICK - 5/32˝ fillet weld minimum.

.I.G. WELDING

• M

diameter of .035 - .045. The recommended shielding gas mixture is

75% - 95% Argon & 25% - 5% CO

• STICK WELDING - Use E6011 A.W.S. welding rod or equivalent.

Recommended machine settings for specific electrode diamterer are

as follows: 1/8” electrode set power between 115-130 Amps DC or

5/32” electrode set power between 140-160 Amps DC.

- Use A.W.S. ER 70S-3 or 6 wire or equivalent with a

Jack Screws

Jack screws are jacks with no mounting plates or brackets. Atwood

Mobile Products Engineering Department (574-262-2655) must authorize all

mounting (except U-Bolt Mounting) of jack screws for each application.

WELD-ON APPLICATION:

Supporting Capacity 1,000 lbs.

1. Weld jack to backing plate following

length of bracket on both sides.

Fixed Mount Jacks

Fixed mount jacks are only for use on 3˝, 4˝ or 5˝ frame or channel.

1. Install bolts through top holes in jack bracket and mounting strap,

then attach nut and lock washer

2. Position jack on trailer tongue and repeat Step 1 for bolts below

trailer tongue

3. Torque to 25 ft. lbs.

INSTALLATION

CAUTION

CAUTION

HAZARDOUS FUMES

2

.

WELDING INSTRUCTIONS. Weld full

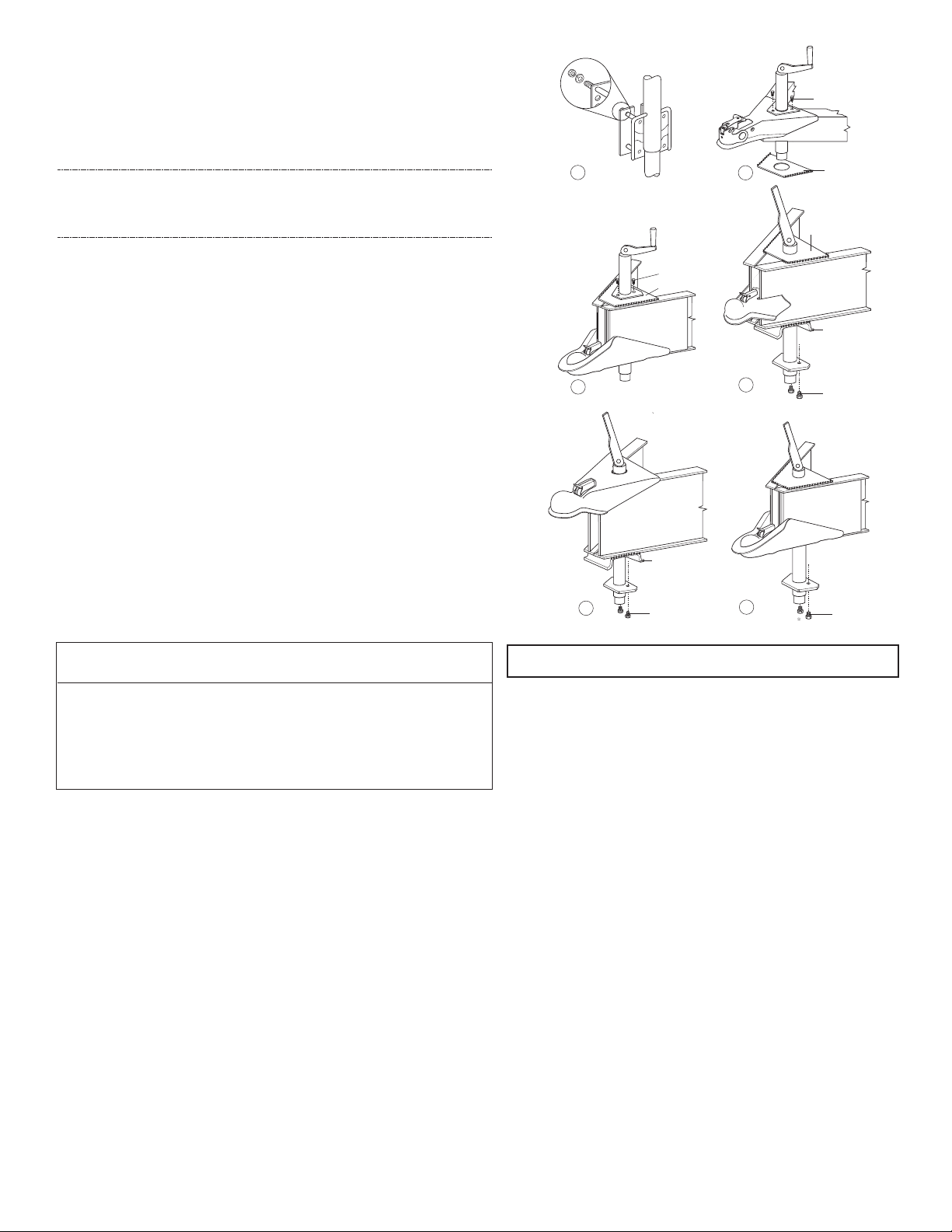

FIG 1.

A-Frame Top Mount Jacks- 1,000 - 5,000 lb. Jack Capacity

COUPLER OR FRAME DAMAGE

• A bottom support plate must be used with all A-Frame Top Mount

Jack Screws.

BOLT-ON APPLICATION:

1. Use 3-3/8˝ - 16 UNC Grade 5 bolts to attach A-frame jack mounting

plate to coupler

20 ft. lbs.

2. Weld top or bottom support plate to trailer frame following

INSTRUCTIONS

2 & 3-B.

WELD-ON APPLICATION:

1. Follow

2. Weld top or bottom support plate to trailer frame following

WELDING INSTRUCTIONS and completely weld around A-frame jack

mounting plate.

INSTRUCTIONS

FIG 2-A or top support plate FIG 3-A. Torque to 15-

. Weld completely around support plate to trailer frame FIG

. Weld completely around support plate to trailer frame.

MOBILE HOME

A-Frame Bottom Mount Jack -

The following installation instructions vary according to the type of coupler mounted on the trailer frame.

STRADDLE MOUNT COUPLER (FIG 4)

For complete Atwood Straddle Mount Coupler Installation, Operation,

and Maintenance instructions please see MPD 87985.

PRODUCT DAMAGE

• Straddle mount couplers are to be used only on mobile homes.

• Top and bottom support plates MUST be used with all Straddle

Mount Couplers.

• Must use 50˚ coupler with a 50˚ A-frame only.

•

Must use 60

• Larger beam reinforcements and improved attachments may be nec-

essary for adequate structural capacity.

COUPLER P/N # 83461, 84102 - 50˚ mount 32,000 lb. CAP.

COUPLER P

Top Support Plate P/N #82740 83480 (50˚), or 83670 (60˚)

Bottom Plate P/N 82672, 83400, 83470, 83511, 84150, 84151, 84160,

COUPLER P/N # 84140 - 50˚ mount 40,000 lb. CAP.

COUPLER P/N # 83462 - 50˚ mount 44,000 lb. CAP.

COUPLER P/N # 84060 - 60˚ mount 40,000 lb. CAP.

COUPLER P/N # 83549 - 60˚ mount 44,000 lb. CAP.

Top Support Plate P/N #83480 (50˚), or 83670 (60˚)

Bottom Support PlateP/N

1. Align bottom support plate so that jack is as far forward as possible, but still clears the edges of the A-Frame members and the top

back of coupler. Outside edges of bottom support plate must

extend to or past web of beam.

2. Follow

frame

3. Weld full length both sides and around the corners to inside edges

of the A-Frame beam.

1

˚ coupler with a 60˚ A-frame only.

/N # 83551 - 60˚ mount 32,000 lb. CAP.

84161, 86081

WELDING INSTRUCTIONS

FIG 4 -B.

A-FRAME JACKS

Effective 12/11/07

CAUTION

WELDING

WELDING

6,000 - 11,000 lb. Jack Capacity

CAUTION

#82672, 83511, 84150, 84160, 84151, 84161

. Weld bottom support plate to bottom of

Page 2

4. Align hole in top support plate with hole in bottom support plate and

weld to A-Frame inside or outside of flanges

FIG 4-C.

5. Insert jack through bottom support plate and top plate.

6. Bolt jack to bottom support plate with two 3/8˝ - UNC Grade 5 hex

head bolts

FIG 4-A.

7. Torque 3/8˝ bolts to 15-20 ft. lbs.

TOP MOUNT COUPLER (FIG 5)

COUPLER P/N # 81911, 81915 10,000 25,000

COUPLER P/N # 88007, 88010 10,000 25,000

COUPLER P/N # 81912 13,000 25,000

SAE RATING MOBILE HOME USE ONLY

Bottom Support Plate P/N #83400

For complete Atwood Top Mount Coupler Installation, Operation, and

Maintenance instructions please see MPD 87985.

1. Align hole in bottom support plate with hole in coupler FIG 5.

2. Follow

WELDING INSTRUCTIONS.Weld bottom support plate to bottom of frame

FIG 5-B.

3. Weld full length both sides and around the corners to inside edge of

A-Frame beam.

4. Insert jack through bottom support plate and coupler.

5. Bolt jack to bottom support plate with two 3/8˝ - 16 UNC x 5/8˝ long

Grade 5 hex head bolts

FIG 5-A.

6. Torque 3/8˝ bolts to 15-20 ft. lbs.

UNDERSLUNG COUPLER (FIG 6)

For complete Atwood Underslung Coupler Installation, Operation, and

Maintenance instructions please see MPD 87985.

Coupler P/N # 82680, 82681, 82682 13,000 lb. Capacity

USING TOP PLATE MPD 82740

1. Align hole in top support plate with hole in coupler.

2. Weld plate to top of frame. Follow

WELDING INSTRUCTION.

3. Weld full length all sides FIG 6.

4. Insert jack through bottom of coupler and to support plate.

5. Bolt jack to coupler with two 3/8˝ - 16 UNC x 5/8˝ long Grade 5 hex head

FIG 6-A.

bolts

6. Torque 3/8˝ bolts to 15-20 ft. lbs.

OPERATION

A

1

A

B

3

B

5

A

2

4

6

B

C

B

A

A

WARNING

PERSONAL INJURY / PRODUCT DAMAGE

• Never exceed the rated capacity stamped or labeled on jack tube.

• Body and feet must be clear of the trailer tongue when raising or lowering

the jack.

• ALWAYS FULLY RETRACT AND/OR SWIVEL JACK TO HORIZONTAL POSITION BEFORE TOWING TRAIL-

ER.

• Do not use blocks for additional ground clearance, trailer can tip and fall.

• Replace jack if worn, damaged or not operating freely.

Top Wind Jacks

1. Pull handle up to horizontal position.

2. Turn handle clockwise to raise tongue and counterclockwise to lower.

3. Push handle down along jack tube for storage.

Side Wind Jacks

1. Turn handle clockwise to raise.

2. Turn handle counterclockwise to lower.

MAINTENANCE

1. Lubricate jack at least every six months in the following manner.

a. Extend jack as far as possible.

b. Lubricate entire length of outside inner ram with SAE 30 heavy oil.

. Squirt oil in oil hole or grease in grease fitting provided at top of outer

ram.

d. Clean dirt, mud or tar from jack.

2. For side wind jacks, follow procedure in

applicable and top cover and lubricate gears with wheel bearing grease.

3. When lowering jack, always provide footing such as caster wheel or a

jack foot beneath jack preventing dirt from entering center of ram.

4. Should jack become difficult to operate: remove, clean and oil. Inspect

for bent or worn parts. Use only factory supplied parts for replacement.

Replace all bent or worn parts.

5. If it is not possible to get jack to operate freely, replace jack.

6. Should problems or questions arise, contact your dealer, the trailer man-

ufacturer or Atwood Service Department, 574-264-2131.

STEP 1. Then remove clip when

2

Any jack screw, fixed mount jack or A-frame jack that has a part

number starting with a four (4) is a product that has been produced in China.

ATWOOD HARDWARE SYSTEMS & COMPONENTS LIMITED WARRANTY

Atwood Mobile Products warrants to the original owner this product will be

free of defects in material and workmanship for a period of two years from the

date of purchase. Atwood’s liability hereunder is limited to the replacement of

product, repair of product or replacement of product with a reconditioned

product, at the discretion of the manufacturer. The warranty is void if the product has been damaged by accident, unreasonable use, neglect, tampering or

other causes not arising from defects in material workmanship. The warranty

extends to the original consumer purchaser of the product only, and is subject

to the following conditions:

1. For two (2) year commencing with the date of purchase, Atwood will

replace or repair any Hardware System & Components that are found to be

defective by Atwood in material or workmanship.

2. In the event of a warranty claim, the Original Purchaser must contact the

Atwood Consumer Service Department,

1120 North Main St., Elkhart, IN 46514, Telephone:

574-264-2131 Fax: 574-206-9713. Warranty claim service must be performed as approved by the Atwood Consumer Service Department.

Warranty replacement hardware systems and components or parts will be

furnished freight prepaid. Labor cost to repair or replace will be limited to

the amount of the original purchase price of the systems and components.

The replaced warranty products or parts become the property of Atwood

Mobile Products and must be returned to the Atwood Consumer Service

Department freight prepaid, unless prior arrangements have been made.

3. This limited warranty is valid only when the product is applied, installed,

maintained and operated in accordance with this Atwood Installation,

Maintenance and Operating Manual (MPD 87984). Any deviation from these

recommended specifications must be approved in writing by Atwood.

4. Any implied warranties are limited to the duration of this limited warranty as

stated above. Atwood does not assume responsibility for consequential

damage or loss, including loss of use of vehicle, loss of time, inconvenience, expense for gasoline, telephone, travel, lodging, loss or damage to

personal properties, or loss of revenues. Some states do not allow limitations on how long an implied warranty lasts or limitations on consequential

damages, so the above limitations may not apply to you. This limited warranty gives you specific legal rights which may vary from state to state.

Loading...

Loading...