Atwood 8516, 8516-LD, 8520-LD, 9525-LD, 9531-LD Technical Lnstallation Manual

...

/iltAtwood'

Atwood

Mobile Products

LLc

1120

North Main

Street

.

Elkhart,

lN 46514

USA

:

800-546-8759

Canada & USA : 800-825-4328

lnternet:

http://www.atwoodmobile.com

/A\

(w)

\ \.--

--z<

// TM

\qSTEyy/

Literature

number

30090

hydro flamerM

8500-lV Series Furnaces

Models

8516,

8520, 8525,

8531, 8535

8516-LD, 8520-LD,

9525-LD, 9531-LD,

8535-LD

1

522, 2334, 1

522-LD, 2334-LD

Technical

lnstallation

Manual

English,

Frangais

(et

Canada)

This

instruction

manual is

for

use by an authorized

service

technician

to install

an

Atwood

-

hydro flamerM

furnace.

Should

you

require

further

information,

contact

your

dealer or nearest

Atwood

Mobile

Products

Service

Center.

This furnace

design

has

been

certified

for

installation in

recreation

vehicles

as a MSP

Category lll furnace. Follow

this

installation

instruction

to

insure

safe operation

of the furnace.

Failure

to install

furnace

according to this installation instruction

nullifies

the furnace

warranty.

Effective

10/10

A

wlnu*c

Avoid

possible

injury

or death

lmproper installation,

adjustment,

alteration, service

or

maintenance

can cause

property

damage,

personal

injury

or

loss

of life. Refer

to the

installation

instructions

and/or

owners

manual

provided

with

this appliance. lnstallation

and service must

be

performed

by a

qualified

installer,

service agency

or

the

gas

supplier.

INDEX

SPECIF|CAT|ONS.

...........2

MODELS

..,.,,.,,.2

OIMENSIONS

,,,,.2

WEIGHT

,,,,,,.,,2

MINIMUMCLEARANCETOCOMBUSTIBLES:

...

.....2

INSTALLATIONANDSAFETYCODES

,,....,2

GENERAL FURNACE

LOCATION

.,.,.,..,.,2

DOORSIDEWALLCUTOUT

.........3

DOORINSTALLATION.

.....3

LD VENT

SIDE WALL

CUTOUT

LD

VENT INSTALLATION

4

4

VERTICAL INSTALLATION

CAULKING AREAS

...,.4

DUCTING

OPTIONS

...,.,,.,4

REQUIREDMINIMUMDISCHARGE,....,...,,4

FLEXIBLE DUCTING

SYSTEMS

......5

HARD DUCTING

FLOOR

SYSTEMS

... ... ...5

HORIZONTALORVERTICALDISCHARGE

...........5

EXTENSTONBOXDISCHARGE...

..........5

FLEXADAPTER

PLATE

.....5

PROPANE

GAS

CONNECTION

.... ..6

ELECTRICALCONNECT|ONS...

...........6

CONDUCTORSIZINGTABLE

..,....,6

POWERSUPPLY

.....6

THERMOSTATINSTALLATION.....

.........6

OPERATING INSTRUCTIONS

..,

.,, ,,7

To

Shut

Down

.

.....

..7

SYSTEM CHECKS

......,.,..7

PROPANEGASPRESSURETEST

...,.,,.,,,7

STATIC

PBESSURETEST..

..

, ,.,...7

IGNITIONCONTROLDIAGNOSTICCODES

......,.,.7

STANDARD3TRIES

FOR IGNITION

CONTROLS

, ,,, ,,7

2-STAGE

3TRIES FOR

IGNITION

CONTROLS

, , . . . . . .7

WIRING DIAGRAMS

.. .......9

Bs-IVWIRING&

LADDER DIAGRAM

.........9

85-IV-LDWIRING&LADDER

DIAGRAM

......9

1522,2334LDWIRING&LADDERDIAGRAM

.. .,..10

1522,2334 WIRING

& LADDER DIAGRAM

...... ....10

Parts Drawing

....

..........11

TO THE

INSTALLEH:

.TO

THE

CONSUMER:

LEAVE THIS

MANUAL WITH

THE

APPLIANCE.

RETAIN

THIS MANUAL

FOR

FUTURE REFERENCE.

SAFETY

ALERT

SYMBOLS

Safety

Symbols alerting

you

to

potential

personal

safety

hazards

obey

all safety

messages

following

these

symbols

A

wanuxc

Avoid

possible

injury

or

death

A

caunoru

Avoid

possible

injury

and/or

propertv

damaoe

A

wanumc

FIRE

OR EXPLOSION

lf the information

in

this manual is not

followed

exactly, a

fire

or explosion may

result

causing

property

damage,

personal

injury

or loss

of

life.

FOR YOUR

SAFETY

WHAT

TO DO IF YOU

SMELL GAS:

.

Extinguish

any open flame.

r

Evacuate

all

persons

from

the

vehicle.

.

Shut off the

gas

supply

at the

gas

container

or

source.

.

Do not

touch

any electrical switch,

or use any

phone

or

radio in

the vehicle.

.

Do not

start the

vehicle's

engine or

electric

generator.

o

Contact

the nearest

gas

supplier

or

qualified

service

technician for repairs.

.

lf

you

cannot

reach

a

gas

supplier

or

qualified

service

technician, contact

the

nearest

fire

department.

.

Do

not

turn on the

gas

supply until

the

gas

leak(s)

has

been

repaired.

lnstallation

and service must

be

performed

by a

qualified

Service Technician,

Service Center

or

gas

supplier. Parts List

Models

8516-lv

8520-lv

8525-lv

8531-lV

8s35-lV

8516-LD

8520-

LD

8s25-

LD

8531-

LD

8535-

LD

BTU lnout

16,000

20.000

25,000

30,000

34,000

Duct Static

Pressure

20'wc

.10"

WC

.10"

WC

.10"

WC

.10"

WC

Amperage

(AMPS)

4.6

4.6

7.6

7.6

9.8

Watts

55

55

91

91

118

Power

Supply

(Volt

DC)

12

12

12

12

12

Recommended

Return Air

80

in2

80

in2

80

in2

80

in2

80

in2

Minimum

Return

Air

65

in2

65

in2

65

in2

65

in2

65 in2

SPECIFICATIONS

MODELS

(wc

DIMENSIONS

WEIGHT

Standard

2-Staqe

Furnace

30

lbs

31

lbs

Boxed

32

lbs

33

lbs

MINIMUM

CLEARANCE

TO

COMBUSTIBLES:

ii;o;b;;rds.

walls

&

similar

combustible

buildino

materials

must

be

prwiOeO

tne

full

length

and

width

of unit'

Soacinq

of

1/4" to

ducting

within

3

ieet

of

furnace

must

be

provided

.

J[[.i

LL

ri.t.d

wire

boLind

vinyl

ducts

are

used

All

ducting

material

,..Jt

O"

rated

ior

continuous

use

at

minimum

of

200"F'

.

Clearances

are

specilically

for

plywood

or similar

building

materials

sriiornOing

the

furnace

(i.e. Furnace

should

not

be

located

under

furniture

oiin

a closet

space

where

clothing

or other

material

could

be

located).

.

Furnace

"ifi.i.n.y

rating

is a thermal

rating

determined

under

continuous

operaiing

co-nditions,

independent

of

any

installation.

Etti.i.n.v

rate

ls

giv-en

at

77%

minimum;

actual

elficiency

rating

may be

higher.

.

Reiurn

airls

supplied

through

openings

in

furnace

casing.

All

return

"ii

p".*g".

,Lit

o"

kept

cleai

for

furnace

to

function

properly'

n"t",

to

frini.r,

clearance

to

floorboards,

walls

&

similar

combustible

building

material'

The

total

unobstructed

return

air

opening

size(s)

muit

not be

less

than

specified

in

specification

-

minimum

return

air.

Failure

to

meet

minimum

return

alr

requirements

nullif

ies f urnace

warranty.

When

frrnuces

are

installed

to

minimum

clearances,

an

additional

t

6

in'

of

return

air

must

be

provided to

blower

side

of

furnace'

or

a

2i ciearance

the

full

length

and

height

on

blower

slide

must be

maintained.

INSTALLATION

AND

SAFETY

CODES

USA

and

Canada

-

follow

all

applicable

state

and

local

codes

-

in the

absence

of

local

codes

or

reguiations,

refer

to

current

standards

o1:

.

Recreation

Vehicles

ANSI

A1

19.2/NFPA

501C

.

National

Fuel

Gas

Code

ANSI

2223'1

andlor

CAN/CGA

B149

lnstallation

Codes

Federal

Mobile

Home

Construction

& Safety

Standard'

fille

24

CFn,

patt

3280,

or

when

this

Standard

is

not applicable'

the

Siunblio

ror.

Manufactured

Home

lnstallations

(Manufactured

Home

SiG.,

C".rr.ities

and

Set-ups),

ANSI

A255'1

and/or

CAN/CSA-

Z24O

MH Series,

Mobile

Homes.

Ground

National

Electrical

Code

ANSI/NFPA

No'

70 and/or

CSA

c22.1

Park

Trailers

ANSI

119.5

UMN)

GENERAL

FURNACE

LOCATION

a

a

lnstall

furnace

through

an exterior

wall'

DO

NOT

install

furnace

near

iilt-out

rooms,

slide-outs'

doors

or

other

projection

that

could

obstruct

furnace

exhaust'

A

wannrnc

CARBON

MONOXIDE

POISONING

.

Furnace

must

be

installed

and

vented

to

these

lnstructions.

.

lmproper

installation,

adjustment,

alteration,

service

or

maintenance

can

cause

injury

or

property damage'

.

lmproper

installation

location

may

cause

furnace

to

produce

negative

pressure,

affecting

combustion

air

or

venting

of

other

aPPliances.

Models #

't522

2334

Low

Hiql'

Low

Hiqh

BTU

lnput

15 000

22,000

23,000

34,000

Duct

Static

Pressure

.10'w.c

.10"

w.c.

.10'w.c.

.10"

w.c.

Amperage

(AMPS)

4.8

10.2

6.5

13.2

Watts

58

122

ao

158

Power

Supply

(Volt

DC)

12

12

12

12

Recommended

Return

Air

80

in2

80

in2

80

in2

B0

in2

Minimum

Return

Air

65 in2

65 in2

65

in2

65

in2

A

"*,r,"oL

'NSTALLATI.N

*ARN'NGS

a

a

a

DO

NOT

install

furnace

on

material

that

restricts

return

air,

like carpet

or any

soft

material

such

as

vinyl'

DO

NOT

install

furnace

where

clearance

to

combustibles

cannot

be

maintained.

DO

NOT

modifY

furnace

in anY

waY'

DO

NOT

alter

furnace

for

a

positive

grounding system'

DO

NOT

hi

pot

furnace

unless

electronic

ignition

system

(circuit board)

has been

disconnected'

bO

ruOr

use

battery

charger

to

supply

power

to

DC

model

furnace

even

when

testing.

DO

NOT

use

12O-volt

AC

current

with

DC

models'

DO

NOT

use

furnace

cabinet

area

as

a storage

compartment

DO

NOT

vent

furnace

with

venting

system

servlng

another

appliance.

DO

NOT

vent

furnace

to

an

outside

enclosed

porch

area.

DO

NOT use

for temporary

heating

of

buildings

or

structures

under

construction.

Protect

building

materials

from

degrading

from

flue

gas

exhaust.

Protect

furnace

electrical

components

from

water'

a

a

a

a

Compartments

must

be

closed

when

operating

unit'

All

Models

widrh

Height

Depth

/lac

16-112"

7-318"

'18',

Door

19-114"

9-114

114"

Vent

LD

5-3/8"

Horizontal

ToP

and

Sides

1/2"

Rear

1

Bottom

3/16"

Vertical

Top

and

Sides

1/2"

Rear

1

Bottom

0"

(slide

plate

end)

Locate furnace near midpoint of coach

for

single

furnace

applications.

lnstallation must

provide

accessibility

if any repairs are

necessary

to

the furnace. Failure

to

meet

this

requirement will create additional

labor

costs that

will

be the

responsibility

of the

installer.

DO NOT install vent in

areas

where

projection

or door openings

come

within

6" of

vent

tube opening.

DO NOT

install furnace

in

an area

where wires,

pipes

or other

ob.jects will interfere

with installation

or operation

of furnace.

DO

NOT install furnace on material that

restricts return

air, such as

directly

on carpet,

or soft material

(like

vinyl). lf

you

must install

furnace

on carpet or soft

material, install furnace on

cleats,

or on a

wood

or metal

panel

extending the

full width and depth of furnace

plus

minimum

clearance

to combustibles.

DO NOT

use

peiroleum

or cilrus

type cleaner on

plastic parts,

as

damage may

occur.

A

*o*wrttc

CARBON

MONOXIDE POISONING

Properly

seal door/vent assembly to

prevent

carbon

monoxide from

entering coach.

o

DO

NOT draw combustion air

from living

area.

.

DO NOT vent

exhaust air

into

the

living

area or an

enclosed

porch.

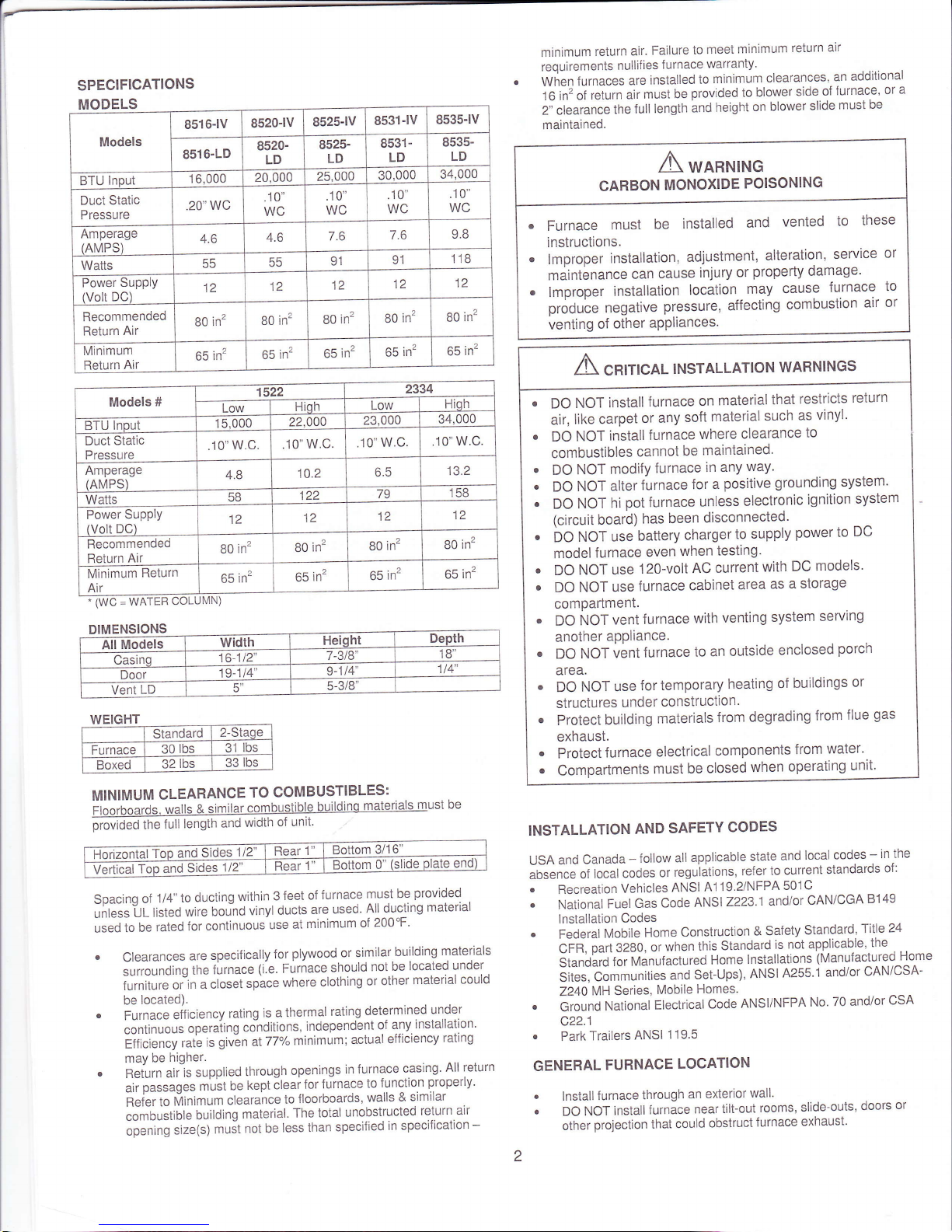

DOOR

SIDEWALL CUTOUT

*

Recommended

exterior

wall

thickness

0" 1o 1-112"

-

2-112'maximum.

ABC

Figure 1

DO NOT

oversize

hole

-

over sizing can

result in water leakage.

A

*o*,u'rc

CARBON

MONOXIDE POSISONING

Properly

seal door to

prevent

carbon

monoxide

from entering

coach.

A

wlnu*c

CARBON

MONOXIDE POSIONING

Properly

adjust draft cap to

prevent

carbon

monoxide from

entering

coach.

DOOR

INSTALLATION

.

Standard Door

or

Deluxe Door may

be used alone or

with

optional

Recessed Bezel.

See

instructions

supplied

with

bezel

for cutout

hole

and mounting instructions.

.

The

furnace

must always be

installed level

(front

to back, side to

side) to

prevent

water intrusion lnto the interlor.

.

To

prevent

moisture f rom

entering

inside

of coach, apply

RTV type

sealant.

.

The

door bezel

must fit

tightly, to

prevent

water leakage.

o

Doors are designed

to

allow water drainage in either horizontal or

vertical installations. Proper location

of

Vent Assembly is important

for

proper

exhausting of

fumes

and

proper

function

of

furnace.

.

With

wing

nut

(C)

loosen on draft cap assembly, close door

(A)

and

pull

draft cap

assembly

(D)

fonntard until it

pushes

against the

screen

(B).

.

Open door and tighten

wing nut.

Close door and check to

insure

draft cap

is

against door screen.

RIGHT

SIDE

LEFT

SIDE

Figure 2

Pull furnace

forward until mounting tabs

protrude

through exterior

wall.

The

edge of control box must be flush with

coach's outer

skin

(VERTICAL

installation

-gas

connection must be on bottom).

Apply RTV

type sealant to entire back flange of bezel creating a

watertight

seal.

Secure by

inserting

door bezel onto

furnace

tabs through

notches

on door bezel.

The

gas

inlet

plug

and slide

plate

must

be installed in the closed

position

and door bezel

flange inside

of slide

plate.

lnsert six

mounting tabs lhrough slots

provided

in

door bezel.

Bezel must be

tight against casing and cuiting

into RTV

sealant.

Bend

tabs

flush with

door bezel, aligning holes

in

tabs

with

slots

in

door

bezel.

lnstall 12

mounting screws. DO NOT deform bezel.

The door bezel must fit tightly against sidewall to

prevent

water

leakage.

Fill tab slots with

caulking

after

securing

wlth

screws.

Remove

excess sealant

from

around door bezel and

visually

inspect

door bezel to make sure

it

is completely sealed.

Secure mounting legs to floor for horizontal installation. For

vertical

units use

vertical mounting

bracket and self{apping screws to

hold

furnace to floor

(tabs

on

control

box can be used to secure

furnace).

For Vertical Kit Part No.

see

parts

list.

Fasten

door with fasteners

provided.

t.

2.

4.

5.

b.

7.

8.

o

10.

11.

CAUTION

Personal lnjury

DO NOT

allow furnace tabs to

protrude

through sidewall

cutout

opening during

installation

process

until door

is

installed

and tabs are bent over.

Take

care

when handling

or brushing against all sheet

metal

edges to avoid

personal

!njury.

RIGHT

SIDE

12.

LD VENT

SIDE

WALL

CUTOUT

c_r

C

a':

Figure

3

B

Side

Wall

Cutout

2-3t8"

1-1

12"

J- llz

Diameter

hole

*

Recommended

wall

thickness

0" 1o

2-112"

OOfrf

Ot

oversize

hole

-

over

sizing

can

result

in

water

leakage'

LD VENT

INSTALLATION

VERTICAL

INSTALLATION

CAULKING

AREAS

I

,/

Figure

4

You

Must

Caulk-

all

areas

shown'

.

Around

entire

red

gas inlet

plug

"C"'

.

Around

entire

black

stiJe

plateldges

were

it mates

with

sheet

metal

D

A

B

t-

L

a

"8".

Alound

entire

gas line

where

it

enters

gas inlet

plug

"D"

ni..g

*"fJ.O

ioints

"A'

of

two

bottom

corners

of sheet

metal

casing

and

irere

door

tlange

covers

slide

plate'

DUCTING

OPTIONS

REQUIRED

MINIMUM

DISCHARGE

Models

8516,8520

8s25,

8s31

otretr

1522

2334

All

Models

using

toP

or

bottom

discharge

oPtions

All vertical

installations

Required

Discharge

Area

24 in'

36

in2

48

inz

36

in2

48

in2

48

in2

48

in2

--a--

i

A

B-

A

1.

2.

J.

4.

tr

6.

Locate

vent

hole

cutout

as

called

out

oiirii-rlz"

dlameter

hole

through

sidewall

of

coach'

Remove

vent

and

vent

ring

from

furnace'

l;;;;iir;;;.lrom

backsi-de

of

wall,

lining

up

hole

in

wall

with

hole

for

vent

in

furnace.

ippty

seatant

to

back

of

vent

ring

and

vent

cap

base'

inllu'ir

u"nt

assembly

with

HOT

it top

on

horizontal

installations

and

iloT

".ligr,t;ide

for

vertical

installations

Vent

ring

must

slip

i.Jil"

."rinrittn

air

intake

tube'

Secure

to

wall

with

four

(4)

screws

not

Provided.

ili,.i*."rrlUfy

must

maintain

minimum

overlap

ot

1'114"

on exhaust

trne

unO

1/2"

minimum

on

combustion

air

tube'

DO

NOT exceed

maximum

wall thickness.

$;;;;i;;;"

to

floor

with

two

(2)

screws'

through

legs

on

back

ol

J"ri.g.

f;t

vertical

units

use

veriical

mounting

bracket

and

self-

i*oin"o

screws

to

hold

furnace

to

floor

(tabs on

control

box can

be

;t:Ji

i;

t..r,"

irtnu.").

For

Vertical

Kit

Pan

No

see

parts list'

Prooer duct

installation

is critical

to

operation

of

furnace

When

i;r,!ili.;

,il.i;,'u*se

muter,iars

rated

for continuous

use

at

200'F'

See

minimum

clearance

to

floorboards'

walls

&

similar

combustible

building

materials.

Fach 4-inch duct

openinq

provides 12

in2

of

discharge

area'

Provide

I"

"-tir'iz

i.'"oi

n[n-.rot'""ole

duct

discharge

area

ior

each

closeable

register

used

Use

ol

2"

ducting

does

not

count

toward

achleving

minimum

;.;;;g.lA;ir"ements.

Ducting

into

dead

air

spacewith

no

return

;i;,

;;.i;h;lding

tank

areas,"do"s

not

count

toward

achievins

minimum

discharge

requirements'

nJir.iJr.tlng

insltallation

to

obtain

air

rise

of

100'F-130"F'

Figure

5

1.

2.

a

4.

E

.

Horizontally

installed furnaces

-

using side duct

options - must

have

a minimum of one

duct

from

both lelt

and

right

side of casing

FLEXIBLE

DUCTING

SYSTEMS

When designing

flexible duct

systems:

.

Avoid

sharp bends or

crushed ducts.

.

Stretch

all ducts and run

them directly to outlets, keeping

quantity

and angles

of bends to a minimum.

Remove

knockout

plates

from

desired outlets.

Attach

a duct

adapter to each opening

by

inserting

flange over

casing, locking

the tab into

casing slot and turning

adapter 90"

Attach

and

secure

lour-inch

flexible

ducts to adapters.

Run

ducts to

desired

location

within RV,

secure to registers.

Additional

ducting may

be

needed

to maintain

correct static

pressure.

HARD DUCTING

FLOOR

SYSTEMS

When

designing hard

ducting

systems:

o

Undersized

ducting

will

cause high

temperature limiting.

.

Oversized

ducting

will

cause inadequate

air

flow

from registers.

.

When

hard ducting is 1-112"

in depth, an

additional

flex

duct may

be

needed

to maintain installation

duct

static

requirements.

.

DO NOT

install floor registers

within 2 feet

of

return

air openings.

-

See ducting

option

from

casing

top and bottom areas. These

options

can

be

with flex

ducting

or by

hard

ducting installations.

Hard

ducting can be sealed

using an optional

gasket

and

plenum

plate

kits.

See

parts

list.

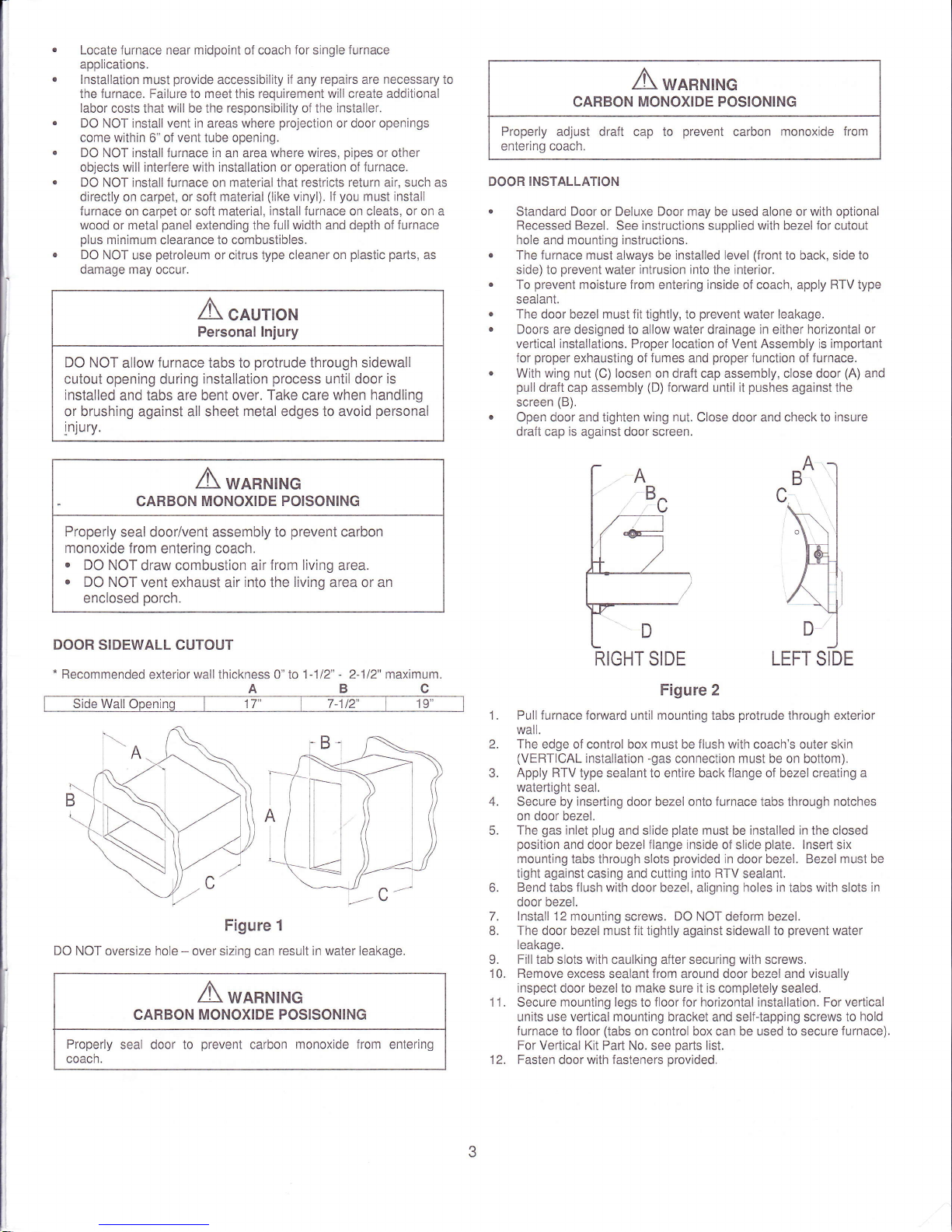

HORIZONTAL

OR

VERTICAL

DISCHARGE

Figure

6

Units

can be installed

as bottom/top

or

vertical

bottom

discharge

systems.

Remove

bottom

/ top discharge

or side cover

plate,

these

ducting

options must

be connected

to a ducting system.

lnsure

sealing of

all

joints

when

use of a

gasket

and

plenum plate

for hard

ducting configurations.

Other

methods

of sealing

furnace

to the floor

are acceptable

as

long

as

clearances

and seals meet requirements

of clearances

and

temperature.

Fasten

plenum

plate

over floor

cutout.

lf

a

gasket

and

plenum plate

is not

used

seal

furnace

to hard

duct system making

sure seal

is

airtight.

Position

gasket

on

plenum

over

hole

opening.

Set

furnace

on

gasket;

make

sure

gasket

remains in

position.

Additional

ducting

can be used to maintain

correct static

pressure

or

as desired.

EXTENSION

BOX DISCHARGE

INSIDE

WALL

Figure 7

A

plenum

plate

may

be used for

top or bottom discharge

installation.

A

casing extension

box adds

6" of depth

to

furnace

casing. To order

see

parts

list.

Remove

three knockouts from

rear of furnace.

Place

extension

box with foam

gasket

against furnace,

making sure

the

three openings

are enclosed within

extension

box.

With

extension

box held in

place,

secure with

lwo 112"

sheet metal

screws not

provided.

3.

Fasten

plenum plate

over cutout.

4. Position

gasket

on

plenum plate.

5. Set furnace

on

gasket;

make

sure

gasket

remains in

position.

6. Fasten

extension

box to

floor

with 1i4"

sheet metal

screws or

staples.

7. Additional

ducting

can be used

to

maintain

correct

static

pressure

or

as

desired.

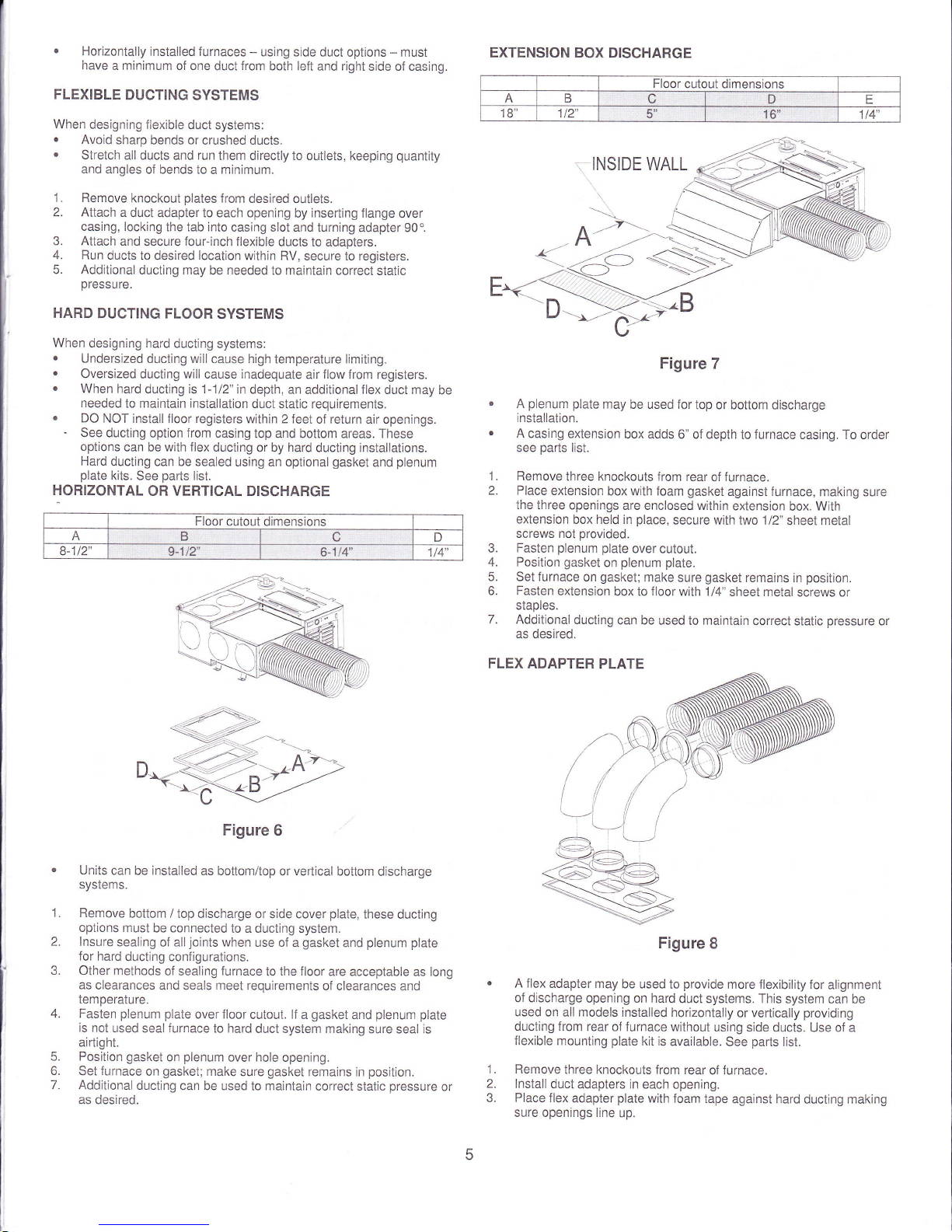

FLEX

ADAPTER

PLATE

Figure

8

A flex

adapter may

be used

to

provide

more flexibility

for alignment

of discharge

opening on hard

duct systems. This

system can be

used on

all

models

installed horizontally

or vertically

providing

ducting from

rear

of

furnace

without

using side

ducts. Use of a

flexible mounting

plate

kit is

available.

See

parts

list.

Remove

three knockouts from

rear

of

furnace.

lnstall

duct adapters in

each opening.

Place

flex

adapter

plate

with foam

tape

against hard ducting making

sure openings line

up.

1.

2.

1.

J.

4.

5.

6.

7.

Floor

cutout dimensions

B

c

D E

18" 1t2"

5"

to

114"

Floor cutout dimensions

A

B

c D

8-1t2 s-'t/2"

6-1t4" 1t4"

4.

(

6.

7.

With

plate

held

in

place,

fasten

plate

to ducting

using

screws

or

staples

as

need to

keeP

it flat.

lnstall three

duct adapters

into

flex adapter

plate.

Attach

flexible ducting

from

furnace to

ilex adapter

plate

and secure

ducting

in

place

on both

ends.

Additional

ducting

can

be used

to

maintain

correct

static

pressure

or

as desired.

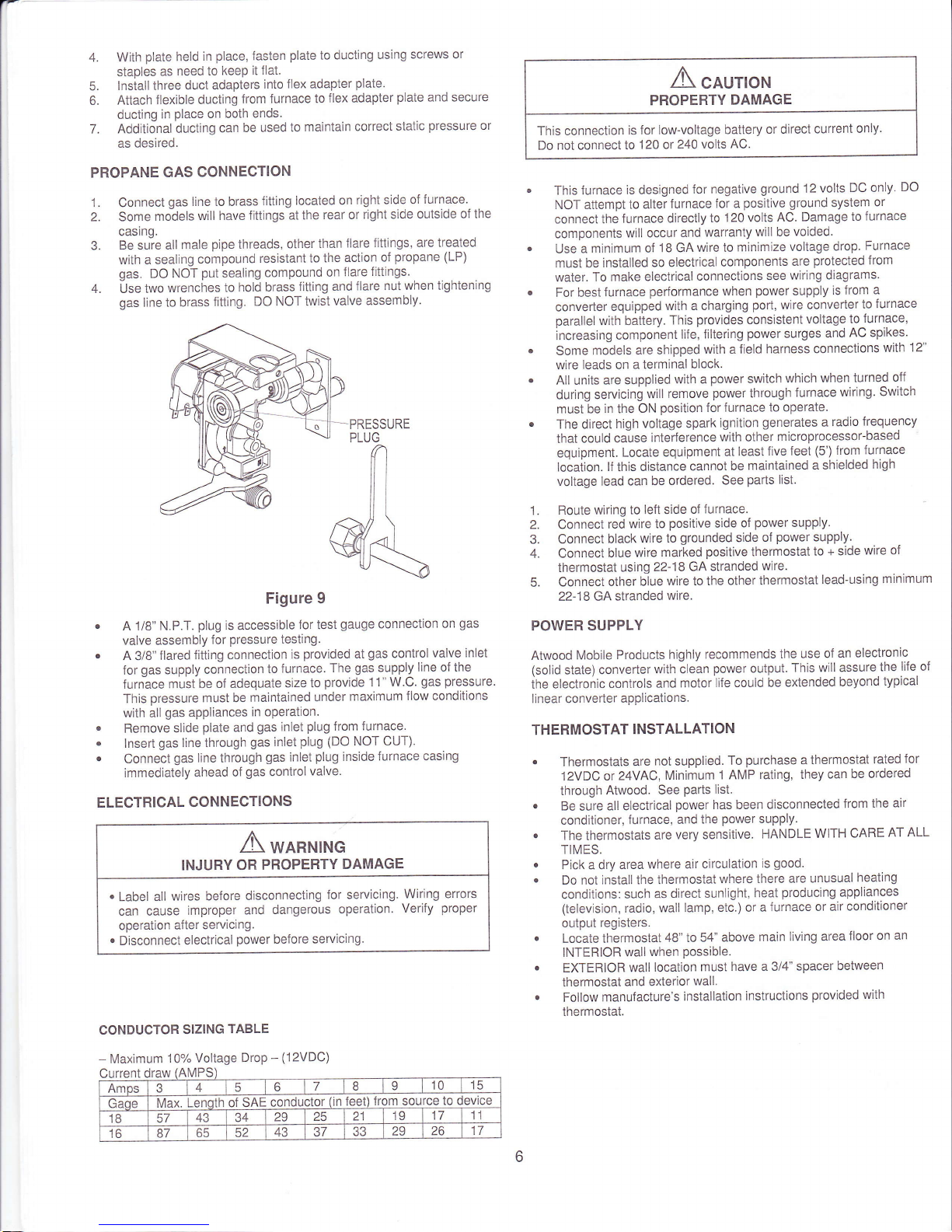

PROPANE

GAS

CONNECTION

1.

Connect

gas

line to brass

fitting

located on

right

side

of Jurnace.

2. Some

models

will have

fittings at

the

rear or

right side

outside of the

casing.

3.

Be suie all

male

pipe

threads,

other

than

llare

fittings, are

treated

with a sealing

compound

resistant

to the

action

of

propane

(LP)

gas.

DO NOT

put

sealing

compound

on

flare

fittings.

4. Use two

wrenches

to

hold brass

fitting

and

flare

nut when tightening

gas

line to brass

fitting.

DO NOT iwist

valve assembly.

Figure 9

.

A 1/B"

N.P.T.

plug

is accessible

for

test

gauge

connection

on

gas

valve assembly

for

pressure

testing.

r

A 3/8"

flared

fitting

connection

is

provided

at

gas

control

valve inlet

for

gas

supply

connection

to

furnace.

The

gas

supply

line of the

furnace

must

be of adequate

size to

provide 1 1" W.C.

gas pressure.

This

pressure must be

mainiained

under

maximum

llow conditions

with

all

gas

appliances

in operation.

.

Remove slide

plate

and

gas

inlet

plug

from

furnace.

.

lnsert

gas

line ihrough

gas

inlet

plug

(DO

NOT CUT).

o

Connect

gas line

through

gas

inlet

plug

inside

furnace

casing

immediately

ahead

of

gas

control

valve.

ELECTRICAL

CONNECTIONS

A

wanNrNrc

INJURY

OR

PROPERTY

DAMAGE

.

Label

all

wires before

disconnecting

for servicing.

Wiring errors

can cause

improper

and

dangerous

operation.

Verify

proper

operation

after servicing.

.

Disconnect

electrical

power

before

servicing.

CONDUCTOR

SIZING

TABLE

-

Maximum

10%

Voltage

Drop

-

(12VDC)

A

"ou,o*

PROPERTY

DAMAGE

This connection

is for

low-voltage

battery

or direct

current

only.

Do

not connect

to

120 or 240

volts

AC.

.

This furnace

is designed

for negative

ground

12

volts

DC only.

DO

NOT attempt

io alter

lurnace

for a

positive

ground

system

or

connect the

f

urnace

directly

to

120 volts

AC.

Damage

to

furnace

components

will occur

and

warranty

will be

voided.

.

Use

a

minimum of

1B GA

wire to

minimize

voltage

drop.

Furnace

must be

installed

so electrical

components

are

protected from

water.

To make

electrical

connections

see

wiring diagrams.

.

For

best

furnace

performance when

power

supply

is from

a

converter

equipped

with a charging

port,

wire converter

to

furnace

parallel

with battery.

This

provides

consistent

voltage to-furnace,

increasing component

life, filtering

power

surges

and

AC spikes'

.

Some

models

are shipped

with a

lield

harness connections

with

12"

wire leads on

a terminal

block.

.

AII units

are supplied

with a

power

switch

which

when turned

off

during servicing

will

remove

power

through

furnace

wiring.

Switch

must be

in

the

ON

position

for furnace

to operate.

.

The direct

high

voltage spark

ignition

generates

a

radio

lrequency

that

could cause

interference

with

other

microprocessor-based

equipment.

Locate equipment

at

least

five

feet

(5')

from

furnace

locaiion.

lf this distance

cannot

be

maintained

a shielded

high

voltage

lead can

be ordered.

See

parts

list.

1.

Route wiring

to

left

side

of

lurnace.

2. Connect

red

wire to

positive

side

of

power

supply.

3. Connect

black

wire to

grounded

side

of

power

supply.

4. Connect

blue

wire marked

positive

thermostat

to + side

wire of

thermostat

using

22-18

GA stranded

wire.

5.

Connect

other

blue

wire to the

other thermostat

lead-using

minimum

22-18 GA

stranded

wire.

POWER SUPPLY

Atwood

Mobile

Products

highly

recommends

the

use of

an

electronic

(solid

state) converter

with clean

power

output.

This will assure

the

li{e of

ihe

electronic

controls

and

motor

life could be

extended

beyond

typical

linear converter

applications.

THERMOSTAT

INSTALLATION

o

Thermostats are

not

supplied.

To

purchase

a thermostat

rated

for

12VDC

or

24VAC,

Minimum

1 AMP

rating, they

can

be ordered

through

Atwood. See

Parts

list.

o

Be

sure

all electrical

power

has been

disconnected

lrom

the

air

conditioner,

furnace, and

the

power

supply.

.

The

thermostats

are

very sensitive.

HANDLE

WITH

CARE

AT ALL

TIMES.

.

Pick a dry area

where air

circulation

is

good.

.

Do not

install the thermostat

where there are

unusual

heating

conditions:

such

as

direct sunlight,

heat

producing

appliances

(television, radio,

wall

lamp, etc.) or a

furnace

or air

conditioner

output

registers.

Locate thermostat

48" to

54" above

main

living area

iloor

on an

INTERIOR

wall

when

possible.

EXTERIOR

wall

location

must

have a 3/4"

spacer

between

thermostat

and exterior

wall.

Follow

manufacture's

installation

instructions

provided with

thermostat.

Current

draw

(AMPS

Amps

4 5

b

7

8 9

10

iE

Gaqe

Max.

Lenqth of SAE

conductor

(ln

feet)

from source

18

F,7

43

34

29

25

21 19

17

'1

1

16

87

65

az

/a

ca

29 26

17

OPERATING INSTRUCTIONS

A

wnnrurruc

FIRE

OR EXPLOSION

Do not

operate furnace while vehicle is in motion or being towed.

.

During

initial firing of this furnace, a burn-off of excess oils

remaining

from manufacturing

process

may cause smoking or

fumes

for 5-10

minutes.

.

NOTE: if furnace

should

lock

out, the

blower will

go

off in 3 minutes

and

remain

off until unit

is

reset by

reactivating

the thermostat.

STOP! Read

Users

lnformation Manualsupplied with

furnace.

'1

. Turn

the

manual valve

(if

so equipped) or the

valve

at the outside

LP

tank to the

"OFF""

position

DO NOT force. NOTE: This furnace

is

equipped with a valve

shut-off switch

with switch in

"OFF"

position.

Gas will

not flow

to burner

nor will

the

furnace

operate.

Turn

switch to

"ON"

position.

2. Set

thermostat above

room

temperature to begin blower operation.

A slight

delay

will occur before

the

blower comes on. Allow blower

to run for 1 minute for

combustion chamber

purge

cycle.

lf blower

does

not

come on

go

to shut down and contact

your

dealer or a

'

Iocal

recreational vehicle

service agency.

3. After 1 minute,

the blower

may not

be

running

at this time,

move

thermostat lever below room temperature. Wait approximately 2

minutes for

blower to

go

otf.

4.

Open manual

shut-off

valve

(if

so equipped) or the

valve

at the

'

outside LP tank. Correct operation characteristics depend on the

valve

being

positioned

fully

open.

Never

attempt to operate

with

a

valve

partially

closed.

Turn

shut-off switch to

"ON"

position.

5. Set thermostat lever to desired

setting.

lf set above room

temperature, blower

will

come on.

6. Allow

30 seconds for main burner to light after blower comes on.

This

furnace is

equipped

with

an

ignition

device

which

automatlcally

lights

the burner.

DO NOT

try to

light

the burner by

hand.

7. lf

burner does not

light,

repeat Steps 1 through 5.

B. lf

after three

(3)

attempts

with no ignition,

go

to shut down and

contact

your

dealer or a

local recreational vehicle

service agency.

Do

not

continue to

cycle furnace

through thermostat

in

an attempt to

get

ignition.

To

Shut Down

1.

Set the thermostat to

lowest

setting,

move

lever to

"OFF"

position.

2. Turn

manual shut off

valve

(if

so equipped) to the

"OFF"

position.

Do not

force.

SYSTEM CHECKS

A

wannrnc

FIRE

OR EXPLOSION

Never

check

for leaks with

an open

flame. Turn

on the

gas

and apply soapy

water

to all

joints

to see

if

bubbles are

formed.

PROPANE

GAS PRESSURE TEST

The furnace

and any individual shut-off

valve

must be disconnected from

gas

supply

piping

system during any

pressure

testing of

system

at test

pressures

of

more

than

1/2" PSl.

Before

furnace is

connected,

piping

systems

must

be tested to be

leak

free. The test must maintain

air

pressure

of a least 6"

of

mercury

or

3"

PSI for

at

least 10 minutes.

The

entire

piping

system must be

maintained

within a range

of

10

to

14"

WC when

all appliances are

in

operation. Test

gas

connections

for

leakage with a leak

test solution.

STATIC

PRESSURE

TEST

.

Special tools required

to take casing static

pressures.

Please refer

to

Engineering

addendum when installing

the {urnace.

This

will

provide you

with

allowable

maximum

case static

pressures

with each

possible

variation

of duct configurations. The

addendum

is

available

from

you

Atwood Field

Service

Representative

or by calling Atwood Service.

Reducing

the

number

of duct turns and stretching

the ducts

will increase

airflow

and reduce

static

pressure.

Adding

ducts or

increasing

the

discharge

(hard

duct) system will also reduce

static

pressure.

You must

follow

the manufacture's recommendations

and specifications

for

optimum

performance

and

proper

operation.

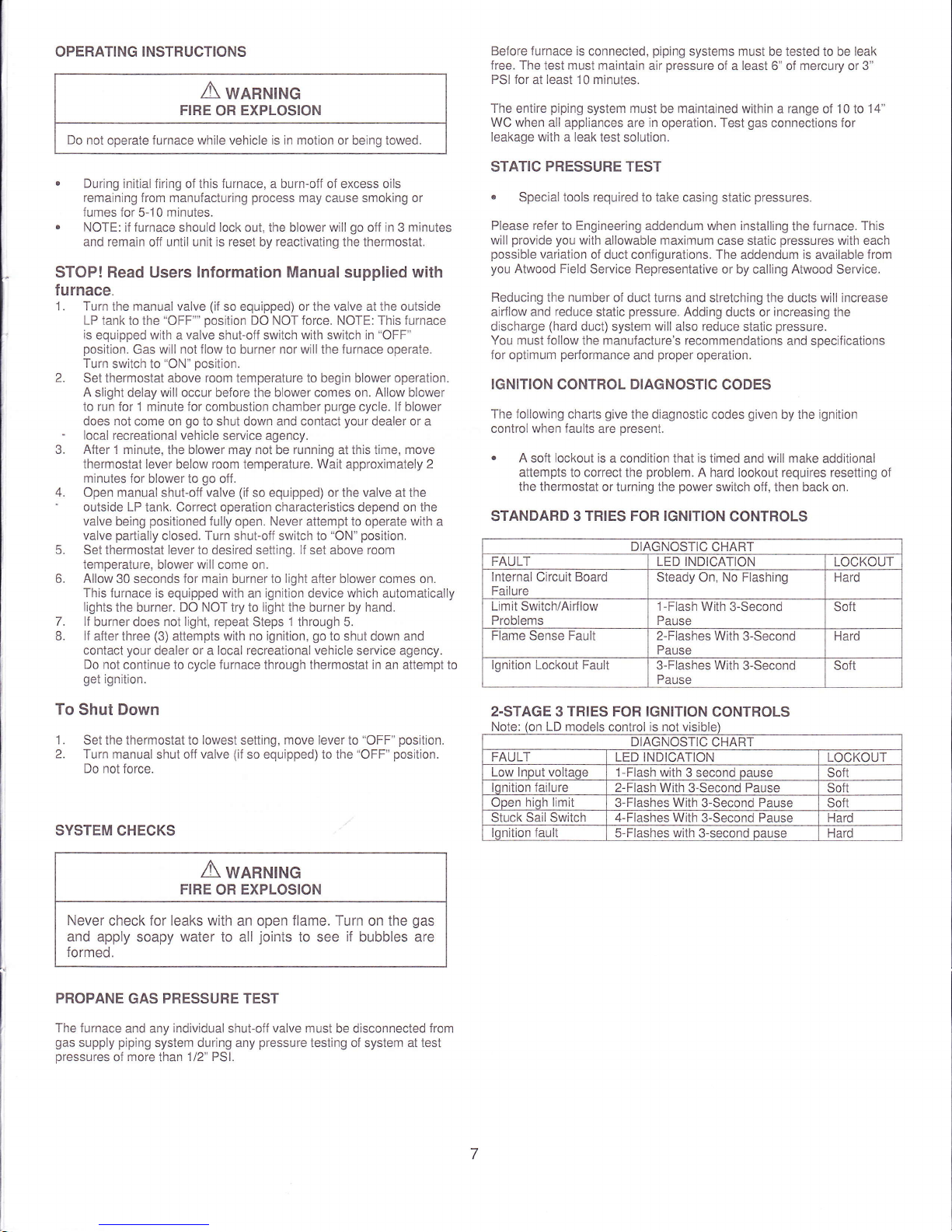

IGNITION

CONTROL DIAGNOSTIC

CODES

The following charts

give

the diagnostic codes

given

by the

ignition

control

when faults

are

present.

.

A

soft

lockout

is

a condition that

is

timed and

will make

additional

attempts to correct the

problem.

A hard lookout requires resetting oJ

the thermostat

or turning the

power

switch oJf, then back on.

STANDARD 3

TRIES FOR IGNITION

CONTROLS

DIAGNOSTIC CHART

FAULT LED INDICATION

LOCKOUT

lnternal Circuit Board

Failure

Steady On,

No

Flashing Hard

Limit Switch/Airflow

Problems

1-Flash

With

3-Second

Pause

Soft

Flame

Sense

Fault

2-Flashes With

3-Second

Pause

Hard

lgnition Lockout Fault

3-Flashes With

3-Second

Pause

Solt

2.STAGE 3

TRIES

FOR IGNITION

CONTROLS

Note:

(on

LD models

control

ts not vtstble

DIAGNOSTIC

CHART

FAULT

LED INDICATION LOCKOUT

Low lnout voltaoe 1-Flash with 3 second oause

Sofl

lonition failure

2-Flash With

3-Second Pause Soit

Open

hiqh limit

3-Flashes

With

3-Second Pause Soit

Stuck Sail Switch 4-Flashes With 3-Second Pause Hard

lonition fault

5-Flashes

with

3-second

pause

Hard

Loading...

Loading...