Attwood 4137, 4138 User Manual

®

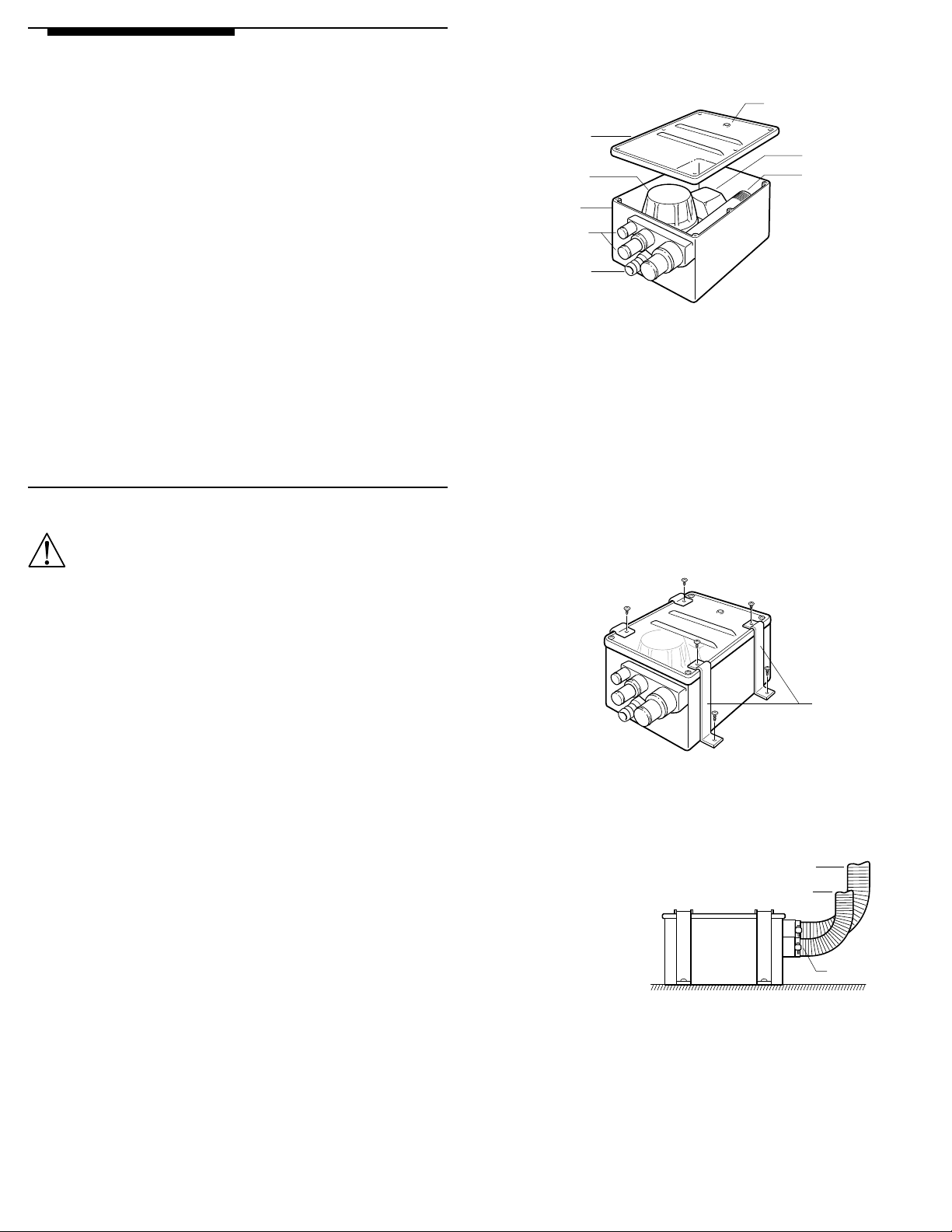

Cover

Optional 1/4" Vent

Hole Location

Float Switch

FilterPump

Box

Inlets

Outlet

•

•

•

•

•

•

•

•

•

3

Deluxe Shower Sump System

4137, 4138 Mounting Instructions

Attwood marine hardware, navigational lighting, bilge pumps, and other

marine accessories are specified more than any other brand by America’s

best-known boat manufacturers as original equipment. Look to Attwood

for quality replacement parts and marine accessories.

SAVE THESE INSTRUCTIONS

Form Number 69274 Rev. K 98-08

2. For hook-up to multiple inlets/hose sizes, determine opening sizes needed

and saw ends off the correct fittings (sizes and cut locations are marked

on the fittings). File around the fitting inside diameter to remove burrs and

rough edges. Figure 1

Figure 1

The Attwood Deluxe Shower Sump System is an efficient, low cost system

incorporating an Attwood 750 GPH Pump and an Attwood Automatic Float

Switch. This system is designed to satisfy the needs of the boater for a

functional means of transferring “gray” water from the shower, or other

water drains. Multiple inlets can be hooked up to more than one drain with

different hose size options. The see-through top on the box allows you to

see when the filter needs cleaning.

Refer to the chart below to ensure that you have selected the proper shower

sump for your boat application:

Shower Sump D.C. Voltage D.C. Amps Max Fuse

Model Amperages

4137 12.0 2.7 4

4138 24.0 1.8 2

WARNING:

To prevent personal injury, never use 120/240 VAC power tools while

working in water or a wet environment.

To prevent personal injury, always disconnect the power source before

servicing or installing this product.

Always use the fuse amperage rating specified for this shower sump model.

Failure to do so could result in serious personal injury or fire hazards.

To prevent possible injury and water damage, shut off all water before servicing.

REQUIRED FOR INSTALLATION

• Fine-tooth hacksaw or

band saw

• File

• Drill and suitable drill bit

• Four #8 screws for

hold-down clamps

Optional:

• Attwood model 7615 switch or equivalent

Note:

Switch is recommended to allow the pump to be turned off in

an emergency

The following materials are needed if no sump pump mounting pad is in place:

• 1/2" (1.27) thick marine plywood

block large enough to mount

sump pump

• Hand-held roller

INSTALLATION INSTRUCTIONS

1. Determine location of sump system, making sure system is lower than the

shower drain. Ensure there is enough structure and room to accommodate the sump system before drilling.

Note:

For correct operation of the automatic float switch, the box should be

mounted level. If the box cannot be mounted level, the end without fittings

can be raised up to 1/2" from level.

Note:

Because sailboats tend to heel, install sump system parallel lengthwise

with the bow-to-stern line. Fitting end can face either fore or aft.

• Phillips screwdriver

• One hose clamp for each

hose used

• Wire connectors for

16-gauge wire

• See amperage in chart above

• Fiberglass—18 oz. mat or woven

roving

• Polyester resin and catalyst

3. To install mounting pad:

Locate mounting pad area according to guidelines in Step 1.

4. Sand gelcoat or paint off the mounting surface to create an area that

is 3" wider than the mounting pad on each side.

Completely cover the mounting pad with fiberglass. Saturate the

fiberglass with resin, and press the fiberglass edges down against

the hull to adhere the pad in place. Roll out the fiberglass to remove

any uneven surfaces, air bubbles, or excess resin.

5. Place the box in desired location. Position the hold-down clamps (two

on each side) so the top of the clamps are between the two raised ribs.

Figure 2

Mark the screw hole locations and drill the pilot holes.

the hull!

Note:

If possible, pre-wire the sump system before fastening clamps down. See

wiring diagram. Figure 4

Figure 2

•

•

6. Connect 3/4" I.D. outlet hose from thru-hull connector to the outlet fitting.

Secure the connection with a hose clamp.

Note:

The outlet hose must rise smoothly from the fitting, up to the thru-hull.

Any downward dip will trap water and air inside the pump. Figure 3

Figure 3

For correct operation, outlet

hose must continually rise

above pump outlet to

prevent air-lock

Inlet Hose(s)

Outlet Hose

Do not drill through

Hold-Down Clamps

•

•

•

Hose Clamp

7. Connect inlet hoses from the drains to the inlet fittings. Secure each

connection with a hose clamp.

Note:

The inlet hoses must rise smoothly from the fitting, up to their Drains.

Also, using a shower drain with a trap will not allow air to vent out of the

box, and the rising water will not activate the float switch.

If the hose cannot be routed upward, or a drain with trap is desired:

Vent the sump system box by removing the system cover and drilling a 1/

4" hole where indicated. File away any rough edges, and replace the

cover (position hole toward the box end with no fittings). See Figure 1

8. Fasten sump system in place with the four hold-down clamps and four screws.

WIRING INSTRUCTIONS

WARNING:

Model 4137: Use 12-volt DC power source. Model 4138: Use 24-volt DC

power source. Higher DC voltage or AC voltage may cause serious damage

and/or personal injury.

Circuit must be properly fused to prevent possible fire hazard and/or damage

to pump and switch should the pump become jammed.

Caution:

All connections should be made using crimp-on connectors.

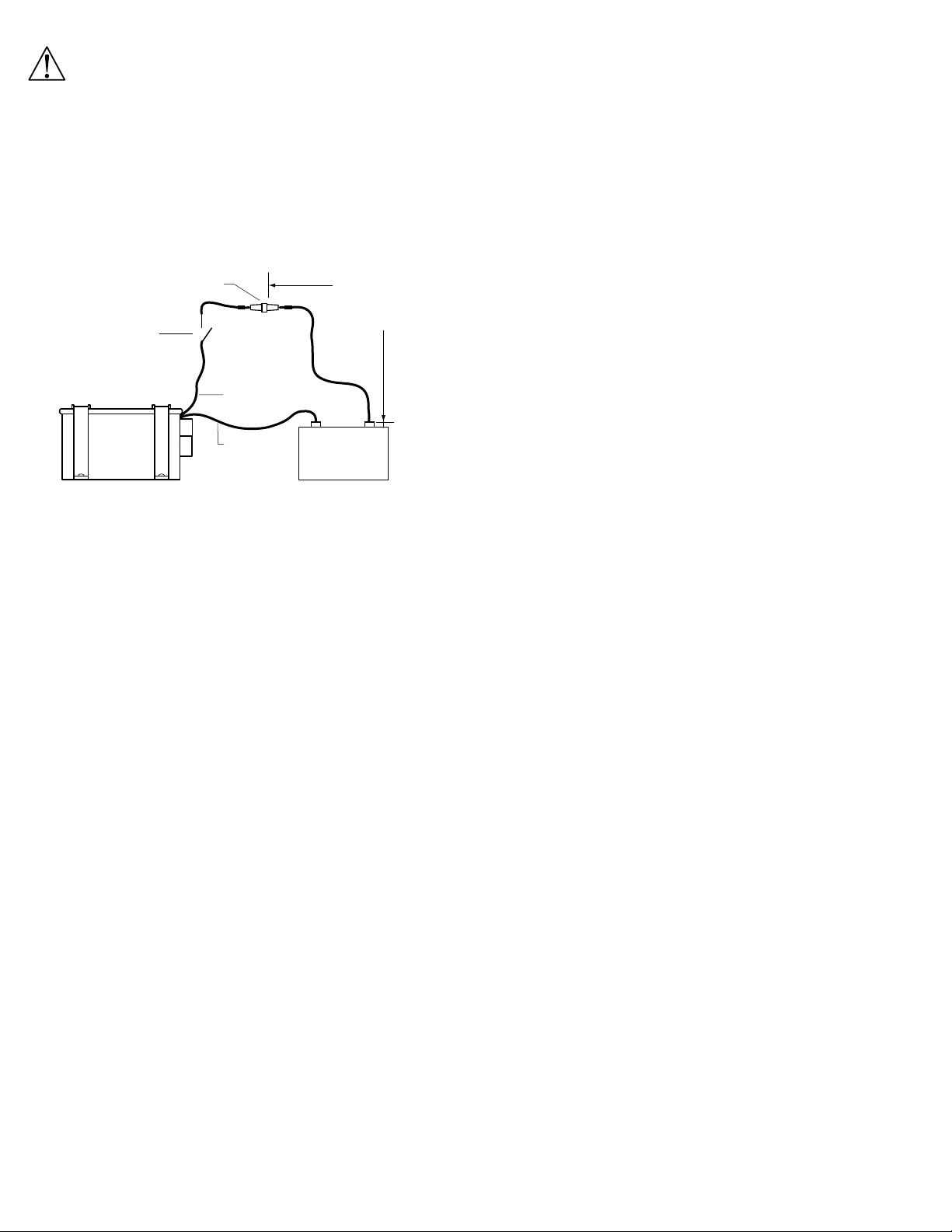

1. Electrical connections should be made as shown in Figure 4.

Figure 4

4-Amp. Model 4137

2-Amp. Model 4138

Two-Terminal, “On-Off” Type

Switch Can Be Attwood

Rocker, Push-Pull, or

Toggle Type

Sump System

•

•

•

•

Brown Wire

•

Black Wire

•

72" (183 cm)

Maximum Length

From (+) Terminal

to Fuse Holder

–

DC Battery

+

Problem Probable Cause

Pump will not turn off • System improperly wired

• Float switch is jammed in

“on” position

• Box not mounted level

• Air is trapped in box—cover

needs to be vented

Pump output is low • System wired backwards

• Line is plugged/restricted

System leaking at top • Air is trapped in box—cover

System is leaking at

inlet/outlet connection

Pump turns on but does not pump • Line is plugged

Water returns to sump from

outlet hose

needs to be vented

• Hose clamp is missing

• Hose clamp is loose

• Pipe connection is loose

• Outlet hose does not rise

continuously to thru-hull

• Check value plugged

or damaged

12-Volt DC Model 4137

24-Volt DC Model 4138

2. Using butt connectors for 16-gauge wire, splice fuse holder into positive

lead (brown) in a location easily accessible for changing fuses. Install

the specified fuse.

3. Run brown wire from sump system directly to the positive (+) battery

terminal. If using manual on/off switch, run brown wire from sump system

to the switch, then to the positive (+) battery terminal.

4. Connect black wire from the sump pump system to the negative (-)

battery terminal to complete the circuit.

5. Re-connect power and water, and test unit for proper installation.

Feed water into the sump; if the flow appears to be too low, check

wire connections.

Note:

Reversed connections will result in opposite impeller rotation, which

drastically reduces capacity and can cause premature pump failure.

MAINTENANCE INSTRUCTIONS

Drain the unit during the winter months when not in use. Disconnect and

drain all lines to the unit. Remove hold-down clamps and empty the unit.

In some installations, it may be impossible to completely drain the system.

Add a non-toxic RV/marine antifreeze to the shower drain and circulate it

throughout the system.

For improved performance, periodically clean the filter. Remove the

cover and slip the filter out for easy cleaning. Re-install the filter and

cover when finished.

TROUBLE SHOOTING

Problem Probable Cause

Pump will not turn on • Line is plugged

• Line is broken

• No power to the pump

• Fuse is blown

• System improperly wired

• Manual switch is not turned on

• Air is trapped in box—cover

needs to be vented

• Float Switch is jammed in

“off” position

ATTWOOD LIMITED WARRANTY

ATTWOOD CORPORATION, 1016 North Monroe, Lowell, Michigan 49331

(“Attwood”) warrants to the original consumer purchaser that Attwood brand

products will be free from defects in materials and workmanship under normal

use and service for one year from the date of original consumer purchases.

This limited warranty is not applicable if the product has been damaged by

accident, improper installation, unreasonable or improper use, lack of proper

maintenance, unauthorized repairs or modifications, normal wear and tear,

or other causes not arising out of defects in materials or workmanship.

Attwood products are warranted for use on pleasure boats. Any other

use — including but not limited to commercial, racing, or non-marine

use — are not covered under this warranty. Attwood’s obligation under this

warranty is limited to repair of the product at Attwood’s plant or replacement

of the products at Attwood’s option without expense to the original consumer

purchaser. Any expenses involved in the removal, reinstallation or transportation

of the product are not covered by this warranty.

The product must be returned to Attwood’s plant at the address above,

postage prepaid, and insured with proof of original purchase including date.

If Attwood is unable to replace the product and repair is not commercially

practical or cannot be timely made, or if the original consumer purchaser is

willing to accept a refund in lieu of repair or replacement, Attwood may refund

the purchase price, less an amount for depreciation. The acceptance by

Attwood of any product returned or any refund provided by Attwood shall not

be deemed an admission that the product is defective or in violation of any

warranty. Products that are replaced or for which a refund is issued become

the property of Attwood.

THIS WARRANTY IS ATTWOOD’S ONLY EXPRESS WARRANTY OF

THIS PRODUCT. NO IMPLIED WARRANTY SHALL EXTEND BEYOND

ONE (1) YEAR FROM THE DATE OF ORIGINAL CONSUMER PURCHASE.

ATTWOOD SHALL NOT BE LIABLE FOR ANY DAMAGES FOR LOSS OF

USE OF THIS PRODUCT, NOR FOR ANY OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES, COSTS OR EXPENSES.

Some states do not allow limitations on how long an implied warranty lasts

or the exclusion or limitation of incidental or consequential damages, so the

above limitations and exclusions may not apply to you. This warranty gives

you specific legal rights, and you may have other rights which vary from

state to state.

© 1998

Attwood

Subsidiary Steelcase Inc.

1016 N. Monroe Street, Lowell, MI 49331-0260

Loading...

Loading...