Attwood 3820, 3810, 3800 User Manual

®

3

3800 Series Stainless

Steel 2-Mile Sidelights

Bicolor Combination Bow Light: 3810

Sidelight Pair: 3820

Attwood marine hardware, navigational lighting, bilge pumps, and other

marine accessories are specified more than any other brand by America’s

best-known boat manufacturers as original equipment. Look to Attwood

for quality replacement parts and marine accessories.

SAVE THESE INSTRUCTIONS

Form Number 69360 Rev. A 00-01

FEATURES

The Attwood Stainless Steel sidelights provide 2-mile visibility

with advanced optics for greater visibility and safety. The housing

is corrosion-proof with an aerodynamic design for an attractive

appearance on the deck of your boat. The base gasket forms a

seal between the lens and deck for an easy, waterproof installation.

Side reflectors provide added protection even when the light is not

on. These lights exceed all requirements of ABYC A-16-97 and

COLREG 72 for boats up to 20 meters/65.6 feet (BiColor Bow

Light 3810) and up to 50 meters/164 feet (Sidelight Pair 3820).

REQUIRED FOR INSTALLATION

• Phillips screwdriver

• Drills: ³⁄₄" for wire clearance hole

Pilot drill for mounting screws

• Two #10 pan head stainless steel screws (not included)

LOCATION

1. Position light(s) on a surface of the gunwale or deck that is

horizontal (within +/-5 degrees).

2. When installing bicolor combination light, place it on the

centerline of the boat at the bow (See Figure 1a).

When installing sidelight pairs, place lights with the red lens

on the port (left) and green lens on the starboard (right) as you

stand onboard facing bow of the boat. Lights must be parallel

to centerline of the boat (See Figure 1b).

Figure 1a Figure 1b

4. Measure and mark location of wire clearance hole. If installing a

bicolor light, location must be on the boat centerline. If installing

a sidelight pair, both must be the same distance from the bow.

At the marked location(s), make a mark for a ³⁄₄" hole. This hole is

necessary for wire passage and lamp ventilation (See Figure 2).

Figure 2

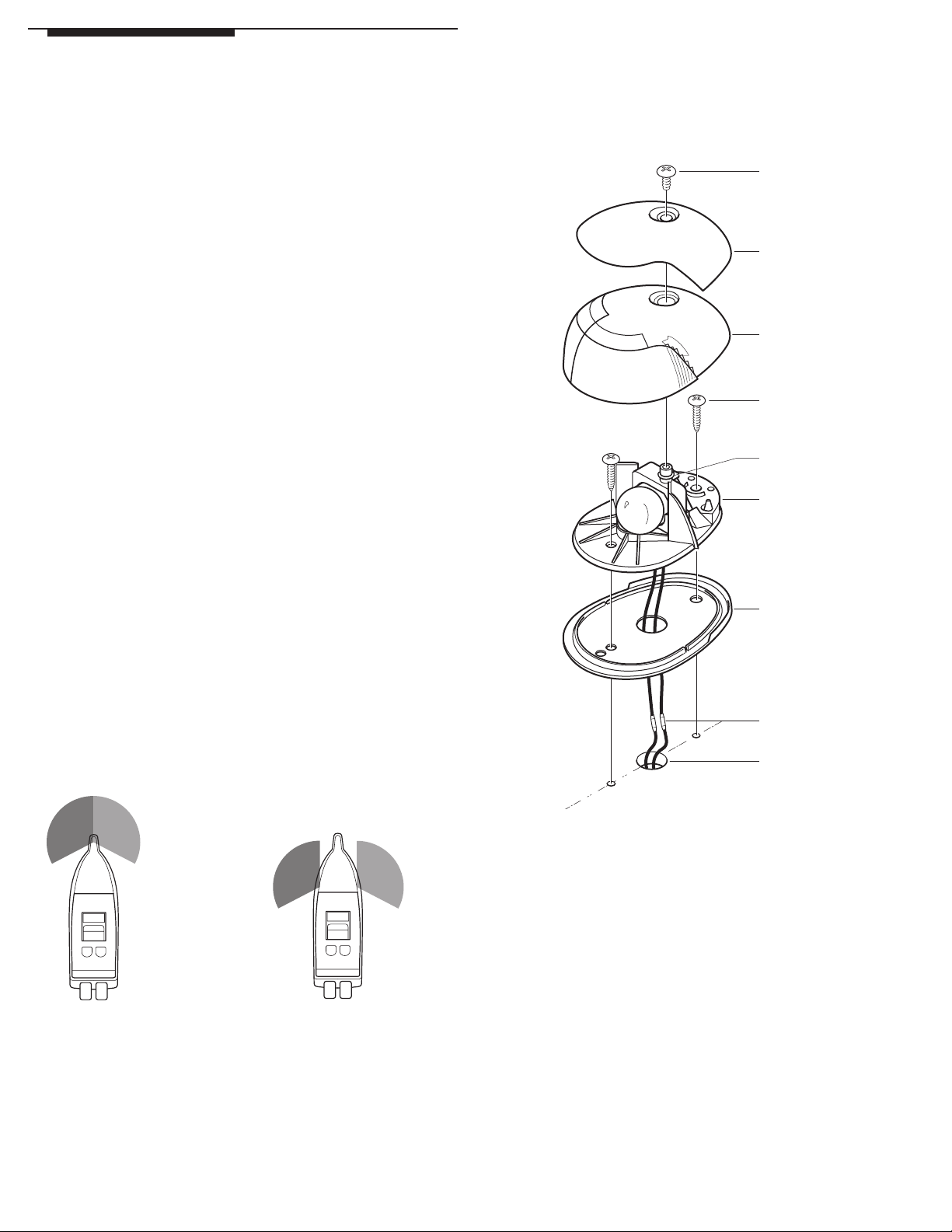

•

•

•

•

•

Cover Screw

•

Lens Cover

•

Lens

#10 Stainless Steel

Mounting Screws

O-Ring

•

Base

•

Gasket

Butt-Joint

Connectors

3/4" Hole Aligned

with Boat Centerline

Red

(Port)

3. Make sure there are no obstructions at the front or side such as

rail stanchions, chocks, anchors, cleats, etc. within the light’s arc

of visibility (112.5 degrees each side).

Green

(Starboard)

Red

(Port)

Green

(Starboard)

MOUNTING INSTRUCTIONS

1. Remove the cover and lens by removing the Phillips head screw

in the cover and lifting off (See Figure 2).

2. Align hole beneath light base with the position you’ve marked for

the clearance hole. Set lens toward the bow and align arrow on

base with the boat centerline. Use the light base as a template

to mark locations for the mounting screw pilot holes (use at least

2 #10 stainless steel screws).

CAUTION:

Position holes carefully on aluminum boats so that wires do not

contact the hull.

3. Drill clearance hole and pilot holes for the mounting screws.

WIRING INSTRUCTIONS

The power supply must be 12-volt DC ONLY. Use crimp type

marine-grade connectors with suitable insulation. Protect all

connections with suitable materials.

NOTE:

Failure to make proper connections and fuse the light properly (see

back page) will void the product warranty.

1. Connect one lead to the negative (-) post of the 12-volt supply.

Gasket

Lens Cover

Connect the other lead to a fused and switched positive (+) 12-volt

supply. Sidelights require 1-amp fusing per lamp: a 1-amp fuse

for the Bicolor Combination light, a 2-amp fuse for the Sidelight

Pair. Note that navigation rules require sidelights to be operated

separately from anchor lights. Use either two switches or a single

switch with three positions for off/anchor/running (See Figure 3).

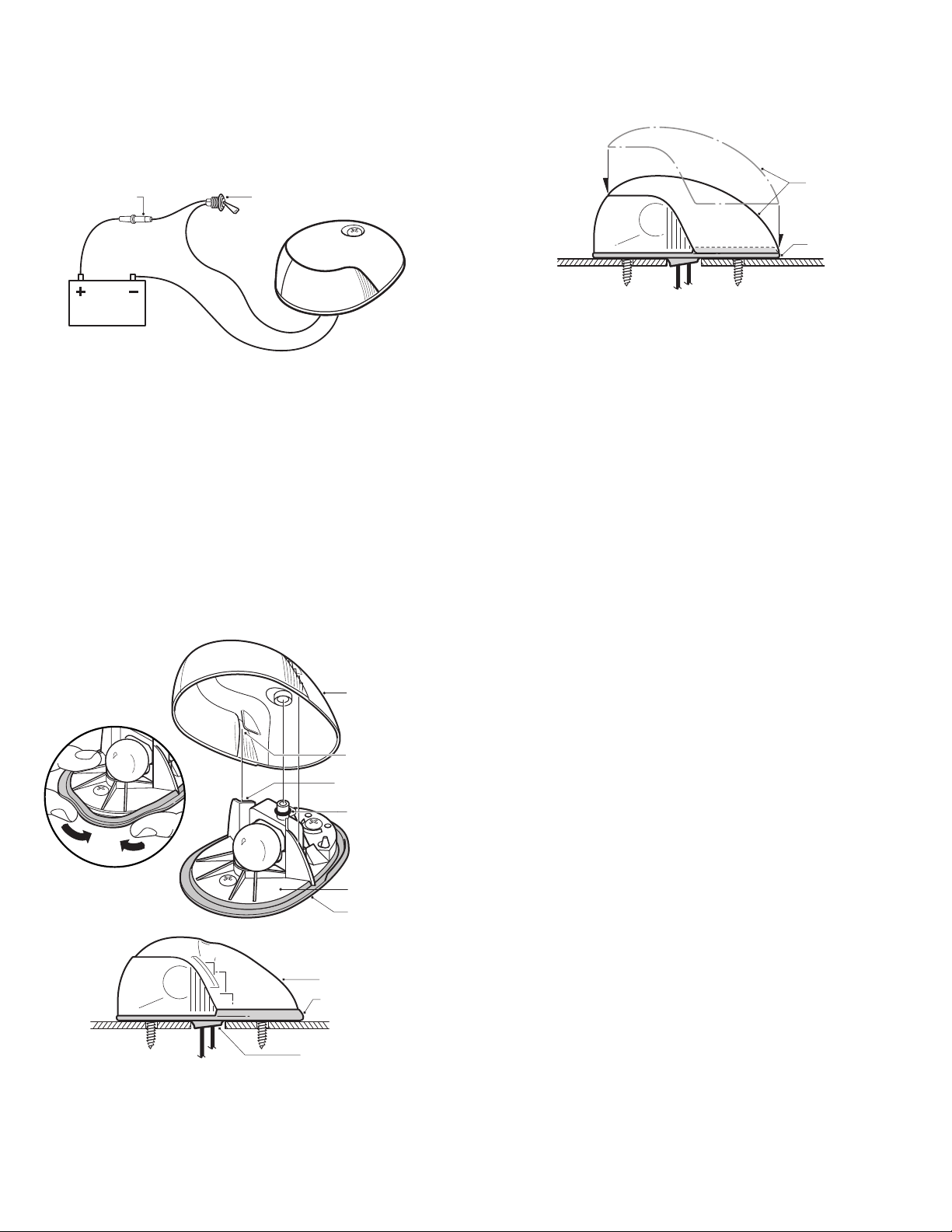

Figure 3

6. Place stainless steel cover over lens. Be sure gasket is

inside

the stainless steel cover at the back. Reinstall screw into cover

(See Figure 5).

Figure 5

2-Amp Fuse

Switch

2. Check gasket to be sure the hole lip is down. Feed wires and

connectors down through the gasket (See Figure 4).

3. Be sure base is seated into the gasket ring all the way around

(See Figure 4 Detail).

4. Align base so the hole lip fits down into the wire clearance hole.

Insert two #10 stainless steel mounting screws and fasten them

to the deck. Note: Do not fasten screws so tightly that the gasket

is deformed.

5. To replace lens: Be sure O-ring is seated on the base screw

mount. Seat lens so the base tabs fit in the lens grooves and

base screw mount lines up with the lens screw hole. Be sure

outside

the gasket is

the lens at the back.

Figure 4

Lens

Lens

Groove

Base Tab

O-Ring

Detail

Hole Lip

Base

Gasket

Lens

Gasket

MAINTENANCE

To replace lamp: Remove the cover screw, cover, and lens.

You may need to pry the lens from the gasket with a small flat

screwdriver, starting in the front of the light.

Remove old lamp by rotating 1/8 turn counterclockwise and pulling

forward. Replace lamp with the proper bayonet bulb (Attwood Part

Number 912717). Check position of O-ring on the base screw mount.

Carefully replace lens and cover on gasket to maintain the waterproof

seal. Reinstall cover screw.

ATTWOOD LIMITED WARRANTY

ATTWOOD CORPORATION, 1016 North Monroe, Lowell, Michigan 49331

(“Attwood”) warrants to the original consumer purchaser that Attwood brand

products will be free from defects in materials and workmanship under normal

use and service for one year from the date of original consumer purchases.

This limited warranty is not applicable if the product has been damaged by

accident, improper installation, unreasonable or improper use, lack of proper

maintenance, unauthorized repairs or modifications, normal wear and tear,

or other causes not arising out of defects in materials or workmanship.

Attwood products are warranted for use on pleasure boats. Any other use—

including but not limited to commercial, racing, or non-marine use—are not

covered under this warranty. Attwood’s obligation under this warranty is limited

to repair of the product at Attwood’s plant or replacement of the products at

Attwood’s option without expense to the original consumer purchaser. Any

expenses involved in the removal, reinstallation or transportation of the

product are not covered by this warranty.

The product must be returned to Attwood’s plant at the address above,

postage pre-paid, and insured with proof of original purchase including date.

If Attwood is unable to replace the product and repair is not commercially

practical or cannot be timely made, or if the original consumer purchaser

is willing to accept a refund in lieu of repair or replacement, Attwood may

refund the purchase price, less an amount for depreciation. The acceptance

by Attwood of any product returned or any refund provided by Attwood shall

not be deemed an admission that the product is defective or in violation of

any warranty. Products that are replaced or for which a refund is issued

become the property of Attwood.

THIS WARRANTY IS ATTWOOD’S ONLY EXPRESSED WARRANTY OF

THESE PRODUCTS. NO IMPLIED WARRANTY INCLUDING, WITHOUT

LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, SHALL BE EXTENDED BEYOND

THE WARRANTY PERIOD STATED ABOVE FOR EACH PRODUCT.

ATTWOOD SHALL NOT BE LIABLE FOR ANY DAMAGES, FOR LOSS

OF USE OF THIS PRODUCT, NOR FOR ANY OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES, COSTS, OR EXPENSES.

Some states do not allow limitations on how long an implied warranty lasts

or the exclusion or limitation of incidental or consequential damages, so the

above limitations and exclusions may not apply to you. This warranty gives

you specific legal rights, and you may have other rights which vary from

state to state.

© 2000

Attwood

Subsidiary Steelcase Inc.

1016 N. Monroe Street, Lowell, MI 49331-0260

Loading...

Loading...