Page 1

Diamond Storage Array

S-Class

Installation, Operations, Maintenance

M anual

© 2005 ATTO Technology Inc. All rights reserved. All brand or product names are trademarks of their

respective holders. No part of this manual may be reproduced in any form or by any means without the

express written permission of ATTO Technology Inc.

2/05

6.4 PRMA-0339-000

Page 2

Page 3

Page 4

Contents

Preface

1.0 Diamond Storage Array Product Overview ..................................1

Diamond Storage Array features

Fibre Channel model

SCSI model

2.0 Diamond Storage Array Technical Overview ...............................3

ADXT Powers ATA to New Levels

3.0 Installation Instructions .................................................................5

Three major steps are required to set up the Diamond Storage Array

Step 1: physical setup

Step 2a: set up the Ethernet connection

Step 2b: connect to Ethernet

If the Diamond Storage Array is attached to a DHCP server

If the Diamond Storage Array is not attached to a DHCP server and you wish to change the

defaults

Step 3: set up RAID configuration

3.1 Components .........................................................................7

Floor model

Rack mount

Floor model

Rack mount

General instructions

3.2.1 Connecting a Fibre Channel Array .......................11

Autoconfiguration

Manual configuration

3.2.2 Connecting a SCSI Array .......................................13

To connect a SCSI array

4.0 Determining Drive and Sled Designations ...................................15

Numbering conventions

Physical numbering

Logical numbering

Examples

Unique serial number for each LUN

5.0 Accessing the Array .......................................................................17

Command Line Interface

ATTO ExpressNAV

In-band SCSI over Fibre Channel

RS-232 port

Ethernet port

SNMP

Page 5

5.1 In-band CLI Over the Fibre Channel ...................................19

I/O details

5.2 Serial Port Access ................................................................21

5.3 Ethernet Access: Telnet and SNMP Protocols ..................23

To connect to the Ethernet port

To use Telnet

To use SNMP

5.4 ATTO ExpressNAV: Browser-based Interface ...................25

Browser compatibility

To optimize ExpressNAV in Internet Explorer

Opening an ExpressNAV session

Navigating ExpressNAV

5.4.1 ExpressNAV Pages ................................................27

Status

Ethernet

SNMP

Serial Port

Fibre Channel

Storage Management

RAID

Clear Data

Logical Units

Rebuild

Configuration

Advanced

To use the advanced page CLI commands

Restart

Help

5.5 Command Line Interface Use and Guidance .....................29

5.5.1 Summary of CLI Commands .................................31

5.5.2 General Use Commands ........................................33

FirmwareRestart

Help

RestoreConfiguration

SaveConfiguration

SystemSN

VerboseMode

5.5.3 Ethernet Commands ..............................................35

EthernetSpeed

FTPPassword

IPAddress

IPDHCP

IPGateway

IPSubnetMask

SNMPTrapAddress

SNMPTraps

Page 6

SNMPUpdates

Te ln e t Pa s sw or d

TelnetTimeout

TelnetUsername

5.5.4 Fibre Channel Configuration Commands ............37

FcConnMode

FcDataRate

FcFairArb

FcFrameLength

FcFullDuplex

FcHard

FcHardAddress

FcNodeName

FcPortInfo

FcPortList

FcPortName

FcWWName

5.5.5 Serial Port Configuration Commands ..................39

SerialPortBaudRate

SerialPortEcho

SerialPortHandshake

SerialPortStopBits

5.5.6 Diagnostic Commands ..........................................41

AudibleAlarm

DiamondModel

DiamondName

DriveCopyStatus

DriveInfo

FcNodeName

FcPortList

FcPortName

Help

IdentifyDiamond

Info

LUNInfo

SerialNumber

SledFaultLED

SMARTData

Temperature

VirtualDriveInfo

5.5.7 Maintenance Commands .......................................43

FcScsiBusyStatus

FirmwareRestart

MaxEnclTempAlrm

MinEnclTempAlrm

Temperature

Zmodem

Page 7

5.5.8 Drive Configuration Commands ...........................45

ATA Di sk S t at e

AutoRebuild

ClearDiskReservedAreaData

DriveCopy

DriveCopyHalt

DriveCopyResume

DriveCopyStatus

DriveInfo

DriveSledPower

DriveWipe

IdeTransferRate

LUNInfo

LUNState

QuickRAID0

QuickRAID1

QuickRAID5

QuickRAID10

RAID5ClearData

RAID5ClearDataStatus

RAIDInterleave

RAIDHaltRebuild

RAIDManualRebuild

RAIDRebuildState

RAIDRebuildStatus

RAIDResumeRebuild

RebuildPriority

ResolveLUNConflicts

RestoreModePages

SledFaultLED

VirtualDriveInfo

6.0 Configuring Drives ..........................................................................49

JBOD (Just a Bunch of Disks)

RAID Level 0

RAID Level 1

RAID Level 10

RAID Level 5

Interleave

Hot Spare sleds

Enhancing performance

6.1 JBOD .....................................................................................51

To set up the JBOD configuration

6.2 RAID Level 0 .........................................................................53

Sled-based versus disk-based

To set up RAID Level 0 groups

To remove RAID Level 0 groups

6.3 RAID Level 1 .........................................................................57

To set up RAID Level 1 groups

To remove RAID groups

Hot Spare sleds

To set up RAID Level 1 with Hot Spare sleds

Page 8

6.4 RAID Level 5 .........................................................................59

Configuring a fully-populated array

To set up one RAID Level 5 group with one Hot Spare sled

To set up two RAID Level 5 groups with two Hot Spare sleds

Configuring a partially-populated array

To set up one RAID Level 5 group with one Hot Spare sled

Removing RAID groups

6.5 RAID Level 10 .......................................................................63

To set up RAID Level 10 groups

To remove RAID groups

Hot Spare sleds

To set up RAID Level 10 with Hot Spare sleds

6.6 Rebuilding RAID Configurations ........................................65

To reset LUN status

To synchronize mirrored drives automatically

Rebuild priority

To synchronize mirrored drives manually

6.7 RAID Interleave Parameters ................................................67

To change the RAID Interleave parameter

7.0 Hardware Maintenance ...................................................................69

To remove a management card

To remove a disk drive sled (Exhibit 7-2)

To remove a Host Interface Card

To remove the power supply (Exhibit 7-4),

To remove a blower assembly (Exhibit 7-4),

7.1 Hot Swap Operating Instructions .......................................71

Disk drives

Power supplies

Blower assemblies

To replace a blower assembly

7.2 Optional Hot Spare Sled ......................................................73

To set up RAID Level 1 with Hot Spare sleds

To set up RAID Level 10 with Hot Spare sleds

To set up one RAID Level 5 group with one Hot Spare sled

To set up two RAID Level 5 groups with Hot Spare sleds

8.0 Copying Drives ................................................................................75

Procedure

9.0 Updating Firmware .........................................................................77

Updating firmware using the RS-232 serial port

To update firmware

Updating firmware using the optional Ethernet card

Page 9

10.0 System Monitoring and Reporting ..............................................79

RS-232 monitoring port and CLI

Ethernet monitoring port and CLI

Power On Self Test (POST)

Ready LED

Audible alarm

Thermal monitoring

Power supply monitoring

System fault LED and error codes

Disk drive activity and disk fault LEDs

10.1 Troubleshooting .................................................................82

Windows 2000 special instructions

Error messages

Specific situations and suggestions

If a drive fails to respond

If a power supply fails

To determine if the problem exists with the HIC

If you can’t access the CLI via Ethernet

If LUNs do not display on the host

10.2 Resetting Defaults ..............................................................85

Default

To return to Default settings

Factory Default

To reset to factory defaults

Appendix A

Appendix B

Appendix C

Appendix D

Appendix E

..

ATA Disk Technology .....................................................i

..

Information Commands Results ....................................ii

..

Product Safety .................................................................vi

Safety compliances

EMC specifications

Radio and television interference

..

Specifications ..................................................................vii

Environmental and physical

Rack mount dimensions

Floor mount dimensions

..

Warranty ...........................................................................viii

Manufacturer limited warranty

Contact ATTO Technology, Inc.

Page 10

Preface

This guide will take the technology-savvy user through the installation and maintenance of the Diamond Storage

Array.

The Diamond Storage Array was designed to meet

your need for large amounts of easily accessible

storage using proprietary Aggregated Data Transfer

Technology (ADXT

multiple, high performance ATA disk drives with the

sustained data transfer rates required by sophisticated

computer users.

Your comments help us improve and update our

products. Contact us

J

) to merge the power of

Disclaimer

ATTO Technology, Inc.

155 CrossPoint Parkway

Amherst, New York 14068

(716) 691-1999 • voice

(716) 691-9353 • fax

http://www.attotech.com/diamond

ATTO Technology can also be reached via e-mail at

the following addresses

Sales Support

Technical Support

: sls@attotech.com

: techsupp@attotech.com

Although reasonable efforts have been made to assure

the accuracy of the information contained herein, this

publication could include technical inaccuracies or

typographical errors. Manufacturer expressly

disclaims liability for any error in this information and

for damages, whether direct, indirect, special,

exemplary, consequential or otherwise, that may result

from such error including but not limited to loss of

profits resulting from the use or misuse of the manual

or information contained therein (even if

Manufacturer has been advised of the possibility of

such damages). Any questions or comments regarding

this document or its contents should be addressed to

Manufacturer.

Manufacturer provides this publication as is, without

warranty of any kind, either express or implied,

including, but not limited to, the implied warranties for

merchantability or fitness for a particular purpose.

Information in this publication is subject to change

without notice and does not represent a commitment

on the part of Manufacturer. Changes may be made

periodically to the information herein; these changes

will be incorporated in new editions of the publication.

Manufacturer reserves the right to make

improvements and/or changes at any time in

product(s) and/or program(s) described in this

publication.

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Page 11

Page 12

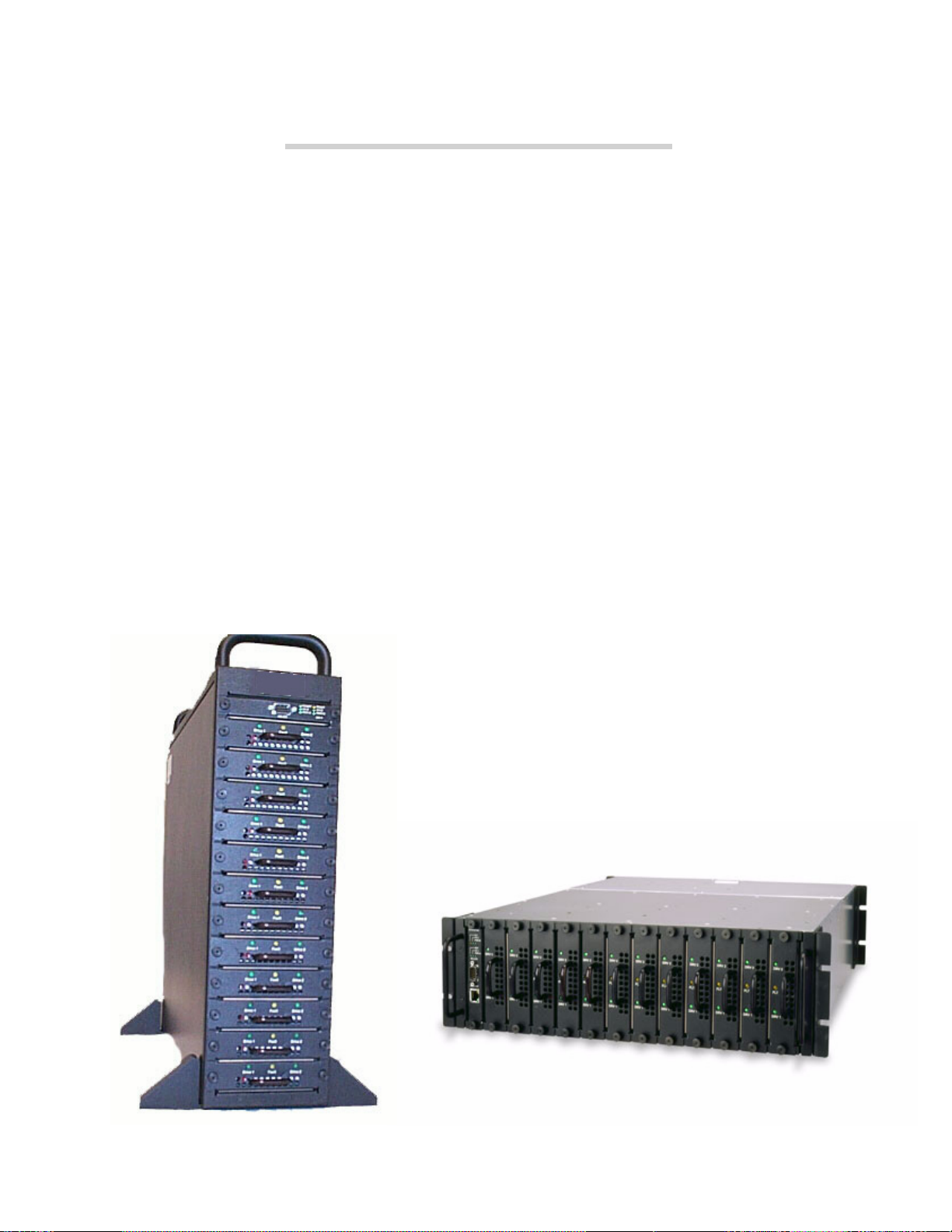

1.0 Diamond Storage Array Product Overview

The Diamond Storage Array offers up to 24 ATA disk drives in a rack mount or floor model

configuration.

The Diamond Storage Array is ideally suited for

data intensive applications such as web hosting, email servers, on-line transaction processing,

digital video editing, medical imaging and digital

audio editing. Virtually any high performance

computing system with a growing need for

storage capacity can use the power of the

Diamond Storage Array.

With the cost effective approach of using ATA

disk drives, you can add more storage capacity as

your needs grow without the budget-busting costs

of other disk storage technologies. You can also

improve the performance and capacity of the

Diamond Storage Array cabinet as technology

progresses by simply replacing disk drive sleds

and Host Interface Cards.

The Diamond Storage Array is operating system

independent and supports all popular computer

hardware platforms and network environments

with a 2-gigabit Fibre Channel interface or an

Ultra160 SCSI interface.

The Diamond Storage Array is a fully populated,

turnkey solution with drives pre-installed. It is

fully supported by highly trained customer

service and engineering staffs.

The Diamond Storage Array uses Aggregated

Data Transfer Technology (ADXT

J

) to merge

the performance of multiple ATA drives to

achieve sustained, full bandwidth data transfer

rates. ADXT provides end users with the power

and sophisticated data control needed to take

moderately priced ATA disk drives, combine

them in a disk storage array, and power them to

the performance levels of SCSI or Fibre Channel

disk arrays.

Diamond Storage Array features

• Up to 7.2 Terabytes initial configuration

(expandable with future drive technology)

• 24 ATA disk drive capacity

• Aggregated Data Transfer Technology

(ADXTJ) for high performance/scalability

• Ultra ATA 100 megahertz (Mhz)

1

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Page 13

• JBOD, RAID Level 0, RAID Level 1, RAID Level

10 and RAID Level 5 configurable

• Staggered drive spin-up to reduce peak power

demand

• Tagged command queuing to process up to 255

simultaneous data requests

• RS-232 management for local management

control; Ethernet option available for setup

connection only

• ATTO ExpressNAV

for management and information

• Two power supplies capable of 85-264 V (rated

100-240V AC) operation (340 watts each)

• UL, TUV and CE marked and compliant

• Internal thermal and power management

• Redundant hot swappable power supplies with

integrated thermal and power management

• Hot spare sleds: replace degraded sleds with

spares on the fly using software

• Floor model cabinet or 19” 3U rack mount

Exhibit 1.0-1 Back of rack mount model, Diamond Storage Array. Left: Fibre Channel. Right: SCSI.

TM

browser-based interface

Fibre Channel model

• 2 gigabit Fibre Channel Port (single or dual

channel)

• SFP-based Fibre Channel interface supports

long wave and short wave optical cables

• Built-in hub for daisy-chaining

• Up to 9,500 I/Os per second per port

• Up to 180 MB/sec. sustained Fibre Channel

transfer rates per interface

SCSI model

• Ultra 160 SCSI bus.

• Dual stacked VHDCI connectors for daisychaining and termination

• SCSI Target ID selection switch

• Support for single-ended and LVD SCSI

• No onboard termination

Product overview

2

Page 14

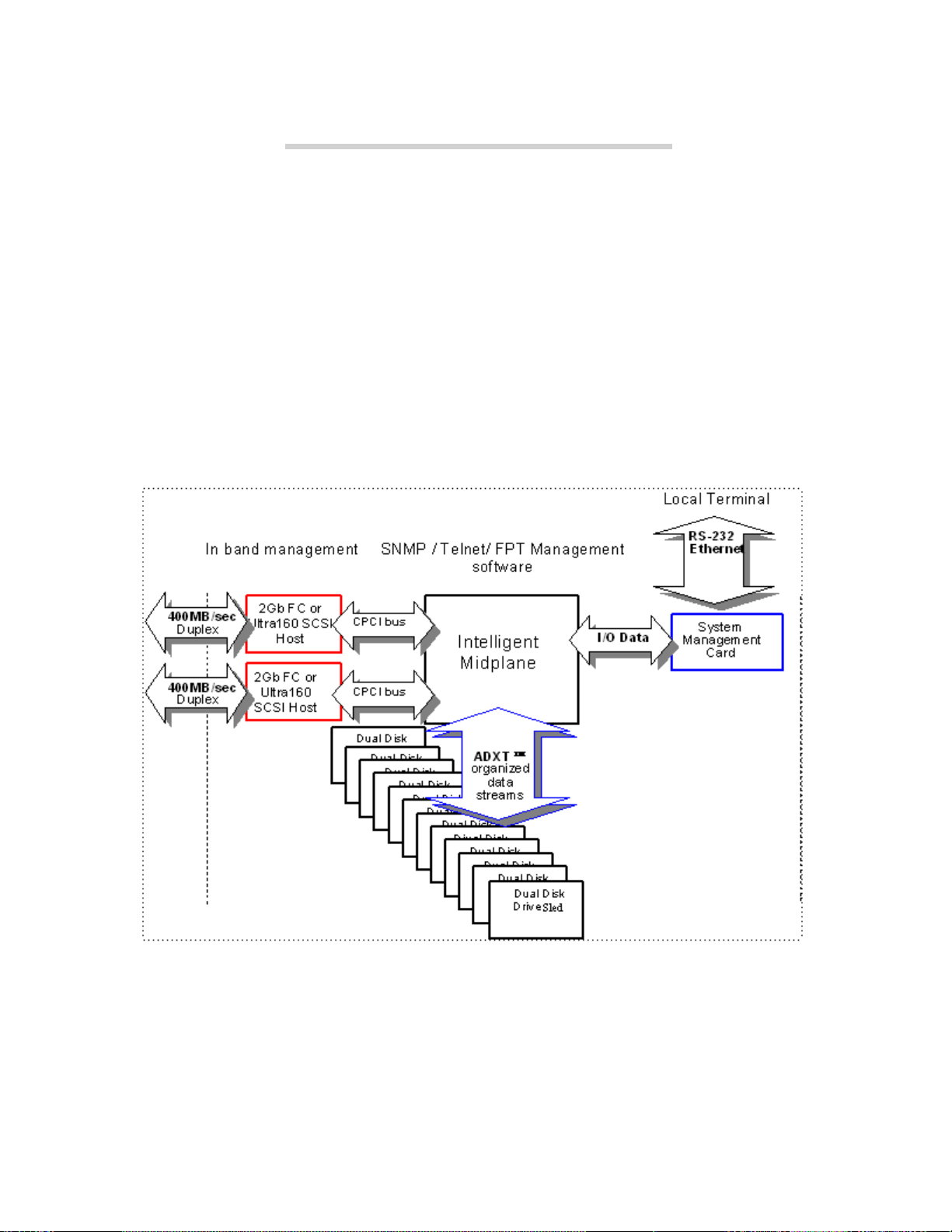

2.0 Diamond Storage Array Technical Overview

The Diamond Storage Array uses Aggregated Data Transfer Technology (ADXT) to achieve the high

data transfer performance you need. ADXT

achieve sustained, full bandwidth Fibre Channel data transfer rates.

merges the performance of multiple ATA drives together to

Unlike other storage arrays which use expensive

SCSI or Fibre Channel disk drives to achieve

performance, the Diamond Storage Array uses

lower cost ATA disk drives combined with an

intelligent midplane to create a storage array with

exceptional price and performance

characteristics.

The intelligent midplane contains hardware and

software which provide the proprietary ADXT

Exhibit 2.0-1 Data pathways and architecture for Fibre Channel operation

,

switched data management and data movement

technology, to create a higher performance

storage solution.

The Diamond Storage Array is made up of dual

SCSI or Fibre Channel Host Interface Cards, the

intelligent midplane, a system management card,

and 12 independent disk drive sleds containing up

to 24 ATA disk drives.

a

ADXT Powers ATA to New Levels

The original notion of RAID was to build high

capacity, reliable storage subsystems using large

numbers of inexpensive disk drives. Thus its

original definition:

3

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Redundant Array of

Inexpensive Drives

became

and the inherent cost advantage in a RAID system

was lost. The Diamond Series provides a high

capacity, high performance and highly reliable

Redundant Array of Independent Drives

. Over time that definition

Page 15

disk array that uses the merged power of ATA disk

drives.

enclosure management services, serverless

backup, data replication and LUN mapping.

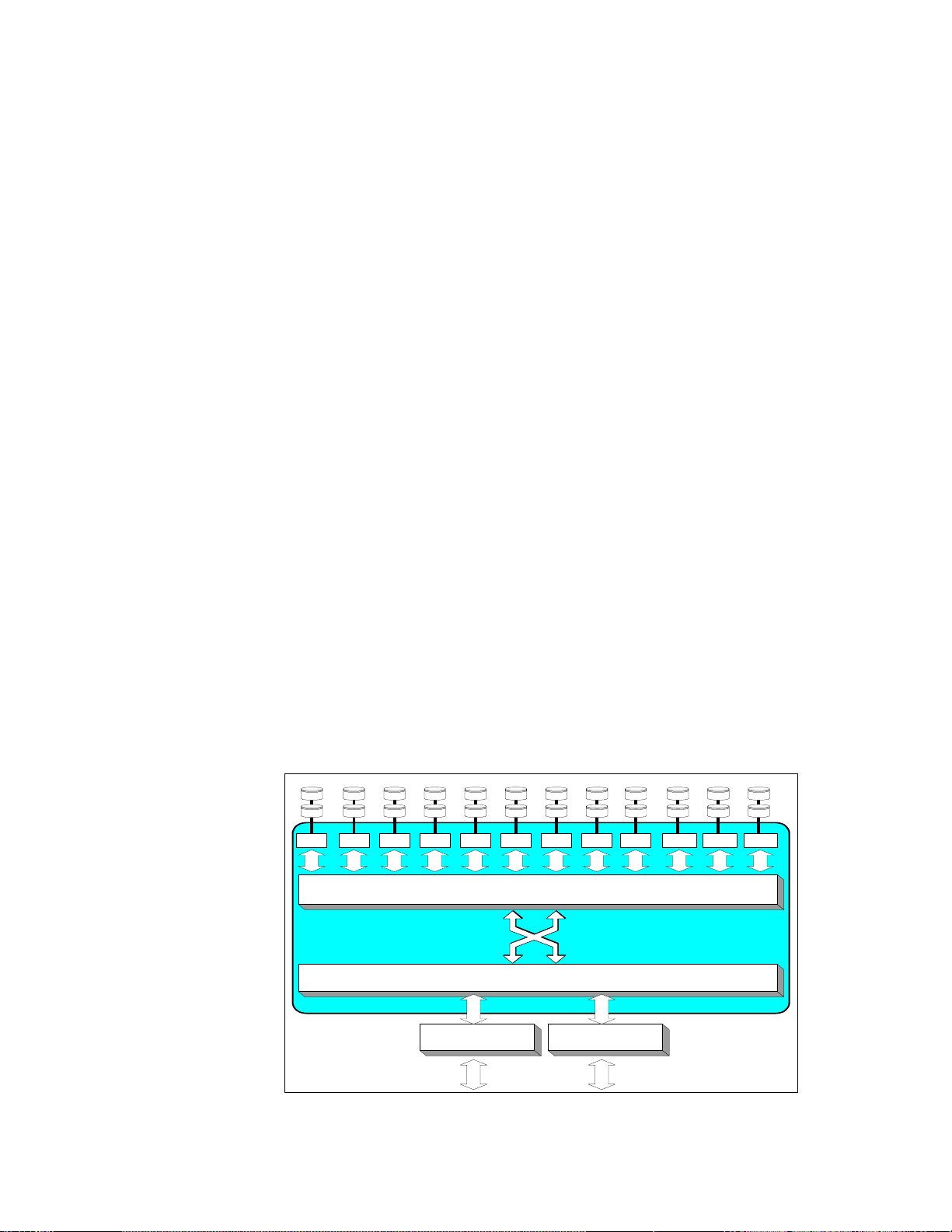

Intelligent Midplane

The heart of the Diamond

Series disk storage array is the intelligent

midplane with ADXT

to sum or

aggregate

the

data rates of individual ATA disk drives to create

high data transfer rates. This technology enables

features such as serverless backup, advanced error

protection, metadata storage techniques,

virtualization software, thermal management and

advanced enclosure services.

The midplane contains a combination of custom

Application Specific Integrated Circuits (ASICs),

processors and proprietary embedded software. It

is divided into three main processing sections

which handle the data being read or written to the

ATA disk drives from the Fibre Channel or SCSI

host interfaces. The Virtual Device Manager

(VDM), Data Routing Fabric (DRF) and ATA

Interface Engines (AIE) organize data streams for

storage or retrieval.

Virtual Device Manager

Data is accessed through

virtual devices using an implementation of the

standard SCSI protocol controlled by the Virtual

Device Manager. The VDM adds capabilities

such as RAID, data management services,

Data Routing Fabric

Incoming or outgoing data is

routed between the ATA Interface Engines (AIE)

and the Fibre Channel or SCSI interface by the

custom Data Routing Fabric ASIC, a high speed,

low latency transfer fabric with more than 2

GB/sec. of bandwidth supported by up to 512

Megabytes of memory.

ATA Interface Engine (AIE)

The interface to each

pair of drives is through a custom ATA Interface

Engine ASIC. The AIE implements the typically

software-intensive ATA interface completely in

silicon. Each AIE contains a dedicated ATA

protocol processor to completely automate

command and protocol processing. Automated

command overlapping and queuing maximizes

the performance of multi-threaded I/O. The AIE

transfers data using double-clocking technology

at 66 megabytes per second. The Diamond

Storage Array contains 12 AIEs for a parallel

transfer rate of 792 megabytes per second. In

addition to guaranteeing data transfer integrity

with automatic CRC checking, the command and

status transfers are validated using a patent

pending technology unique to the AIE.

Disk 2

Disk 2

Disk 2

Disk 2

Disk 2

Disk 2

Disk 2

Disk 2

Disk 2

Disk 1

Disk 1

Disk 1

Disk 1

Disk 1

Disk 1

Disk 1

Disk 1

Disk 1

AIE2AIE3AIE4AIE5AIE6AIE7AIE8AIE9AIE10AIE11AIE

AIE

1

DATA ROUTING FABRIC

text

VIRTUAL DEVICE MANAGER

FIBRECHANNEL

INTERFACE 1

FIBRECHANNEL

INTERFACE 2

Disk 2

Disk 1

Disk 2

Disk 1

Disk 2

Disk 1

12

4

Page 16

3.0 Installation Instructions

If you are familiar with the Diamond Storage Array, Fibre Channel, SCSI and RAID configurations, you

may set up and configure the Diamond Storage Array using these instructions. Find details, illustrations

and other guidance for more involved operations and special cases in the rest of this manual.

CAUTIONCAUTION

Before configuring the Diamond Storage

Array, ensure that any computer data to be

stored on the array is properly backed up

and verified. The operation and storage of

computer data on any disk storage array

should be accompanied by a regular

program of computer data backups and

verification for the data stored on such an

array.

The Manufacturer is not responsible for the

loss of any data stored on the Diamond

Storage Array under any circumstances

and any special, incidental, or

consequential damages that may result

thereof.

Three major steps are required to set up the

Diamond Storage Array

1 Physically set up Diamond Storage Array

2 Connect to Ethernet

3 Configure the drives

Step 1: physical setup

1 Make sure the Diamond Storage Array is

mounted properly and has adequate air flow

around it.

2 Insert the appropriate connector into the

interface card in the back of the Diamond

Storage Array.

3 Connect the Fibre Channel or SCSI cable from

your host computer system to the connector. To

use ExpressNAV browser-based management

interface and configure your Diamond Storage

Array, you must connect to the Ethernet port.

4 To set up the Ethernet connection: connect a

cross-over cable (for a direct connection to a

PC) or regular network cable from a network

device to the RJ45 Ethernet port on the

Ethernet management card on the front of the

Diamond Storage Array.

Step 2a: set up the Ethernet connection

The Diamond Storage Array supports service

operations over the RS-232 serial port using

standard terminal emulation software available

with most systems.

1 Connect a DB-9 null modem serial cable

between the port marked RS-232 on the front of

the Diamond Storage Array and the computer’s

serial port. The cable must be no longer than

three meters.

2 Make sure the power switches on the power

supplies on the rear of the unit are in the Standby position.

3 Plug in the power cords to the back of the unit,

then into an appropriate power source (100-240

VAC).

4 Reboot your host computer system.

5 Press the Stand-by power switch for each

power supply on the Diamond Storage Array to

the ON position.

6 Upon successful power up and diagnostics, the

unit displays the POST (power up self test)

information.

The Diamond is now in Command Line Interface

mode. You may modify the setup of the Diamond

Storage Array using the CLI (refer to

via ASCII-based Commands

on page 27), but the

CLI: Interface

easiest method to configure the array is by using

ATTO ExpressNAV software, a graphical user

management interface accessed through a

standard Internet browser. Refer to

ExpressNAV: Browser-based Interface

ATTO

on page 23.

Step 2b: connect to Ethernet

If the Diamond Storage Array is attached to a

DHCP server

1 At the Ready prompt after POST (refer to Step

6 above), type set IPDHCP enabled

2Type SaveConfiguration Restart

3At the Ready prompt after POST (see above),

type get IPAddress

5

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Page 17

4 Enter this address into your browser.

5 The ATTO ExpressNAV screen appears. Log in

using the Telnet defaults:

Username: Telnet

Password: Diamond

6 Follow the screens to find information about the

array or to configure the array from the factorydefault settings. The Diamond Storage Array

may be set up in a JBOD, RAID Level 0, 5 or 10

configuration with or without Hot Spare sleds

If the Diamond Storage Array is not attached to

a DHCP server and you wish to change the

defaults

1 At the Ready prompt after POST (see above),

type set IPAddress [desired IP address].

2Type set IPSubnetMask [desired IP Subnet

Mask]

3Type set IPGateway [desired IP Gateway]

4Type SaveConfiguration Restart to save the

configuration and restart the Diamond Storage

Array

5 After the powerup and POST complete, type

the IP address from step 1 above into your

browser.

6 The ATTO ExpressNAV screen appears. After

logging in (refer to Step 2b: connect to

Ethernet, Step 5 on page 6), follow the screens

to find information about the array or to

configure the array from the factory-default

settings. The Diamond Storage Array may be

set up in a JBOD, RAID Level 0, 1, 5 or 10

configuration with or without Hot Spare sleds.

Step 3: set up RAID configuration

The simplest way to set up configurations is to use

the ExpressNAV interface. Refer to

ExpressNAV: Browser-based Interface

ATTO

on page 23 for

more information on the interface. After logging

in (refer to

page 6

Step 2b: connect to Ethernet

, Step 5 on

), follow the screens to find information

about the array or to configure the array from the

factory-default settings

You may the CLI, the

.

QuickRAID

commands to

set up RAID and hot spare sleds, if required.

• Each Hot Spare sled configuration requires

a certain number of Hot Spare sleds. These

sleds, once designated as Hot Spares, are

not available for other use.

• RAID Level 10: 10 drive sleds and two Hot

Spare sleds (sleds 11 and 12).

Note

All arrays using RAID level 10 and Hot Spare

sled options must be fully populated.

• RAID Level 5: 10 drive sleds and two Hot

Spare sleds (sleds 11 and 12)

• RAID Level 5: five drive sleds (sled positions

1 through 5) and one Hot Spare sled (sled

12).

Installation

6

Page 18

3.1 Components

The Diamond Storage Array has been designed to be easy to use, maintain and upgrade. It features a

durable steel outer case and modular components in either a floor or a rack mount model.

Immediately upon receipt, check the shipping

carton for damage from mishandling. Contact us

at once via the means that is easiest for you (refer

to

Contact ATTO Technology, Inc.

on page viii) if the

carton has been mishandled or displays any signs

of damage.

The front of the Diamond Storage Array provides

access to the management card and disk drive

sleds. The rear of the unit holds the Host Interface

Cards, power supplies and blower assemblies.

CAUTIONCAUTION

All modular components must be replaced

by qualified personnel only.

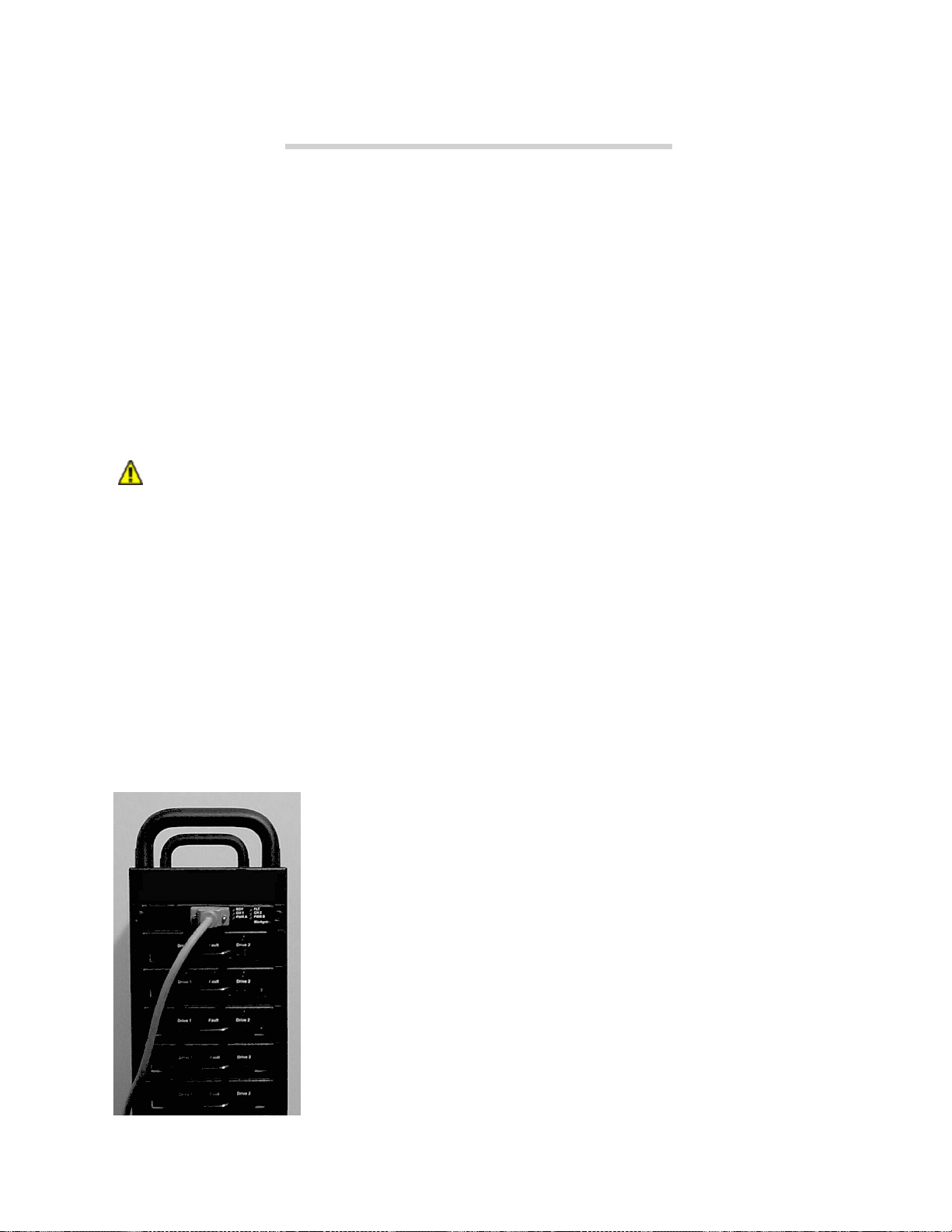

Floor model

The management system card is at the top front of

the case. At its center is a DB-9 serial RS-232

port, a connection for setup, monitoring and

upgrade of the unit from any computer system

with an RS-232 interface. The optional 10/100

BaseT Ethernet management services card

enables Telnet-based monitoring and

management. It also provides the ability to update

the firmware in the array via FTP.

LEDs to the port’s

right indicate fault,

unit ready, Host

Interface Cards A

and B installation

status, and the power

status for each power

supply.

sled contains two hard drives. Up to 24 hard

drives may be installed on the 12 sleds. Empty

bays should be covered by blank faceplates or

empty sleds. Access is provided by loosening two

screws and gently pulling on the sled handle.

On the rear of the unit are blowers which support

hard drive, cabinet and power supply cooling. The

blowers are held in by removable screws. Correct

operation is displayed by a LED at the top of each

panel.

The power supplies for the array, also in the rear

of the unit, are accessible by loosening two screws

and pulling on the power supply module handle.

The power standby on/off switch is at the top of

each module. A yellow LED indicates

and a green LED indicates

on

. The power cord

caution

socket is at the bottom of each power supply.

Between the power supplies and blower

assemblies are two slots that hold the Host

Interface Cards. The HIC is the connection point

into the array and is available in three options: 1Gigabit Fibre Channel, 2-Gigabit Fibre Channel,

or Ultra 160 SCSI. Host Interface Cards have

and

on-line

or

fault

and

activity

LED indicators,

fault

depending on the model.

SCSI

The SCSI card faceplate has a rotary

binary-coded hex switch to set the SCSI ID of the

array. The SCSI card also has an in channel, to

connect via cable to the unit’s communication

source, and an out channel, available for daisychaining arrays together or to complete

termination using an external LVD terminator.

Below the

management system

card are individual

disk drive sleds

which also have

LEDs for each

drive’s status. Each

7

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Rack mount

The system management card is at the left front of

the case. At its center is a DB-9 serial RS-232 port

which allows a connection for setup, monitoring

and upgrade of the unit from any computer system

with an RS-232 interface. The optional 10/100

Page 19

BaseT Ethernet

management services card

enables Telnet-based

System Management Card

monitoring and

management. It also

provides the ability to

update the firmware in the

array via FTP. LEDs

farthest to the left indicate

fault, unit ready, Host

Interface Cards A and B

installation status, and the

Disk drive sleds (12)

power status for each

power supply.

Power supplies

To the right of the system

management card are

individual disk drive sleds

which also have LED

indicators for each drive’s

status. Each sled contains

two hard drives. Up to 24

hard drives may be

installed on the 12 sleds.

Empty bays should be

covered by blank faceplates or filled with empty

sleds. Access is provided by loosening two screws

and pulling on the sled handle.

In the rear of the unit are the blower assemblies

which support hard drive, cabinet and power

supply cooling. Correct operation is displayed by

a LED at the top of each panel. The blowers are

held in place by removable screws.

The power supplies for the array are accessible by

loosening two screws and pulling on the power

supply module handle. The power standby on/off

switch is at the top of each module. A yellow LED

indicates

caution

and a green LED indicates on.

The power cord socket is at the bottom of each

power supply.

Intelligent midplane (internal)

Host interface cards

Blower assemblies

Between the power supplies and blower

assemblies are two slots that hold the Host

Interface Cards. The HIC is the connection point

into the array and is available in a 2-Gigabit Fibre

Channel or Ultra 160 SCSI. Host Interface Cards

fault

and

have

on-line

or

fault

and

activity

LED

indicators, depending on the model.

SCSI

The SCSI card faceplate has a rotary

binary-coded hex switch which allows you to set

the SCSI ID of the array. The SCSI card also has

an in channel, to connect by a cable to the unit’s

communication source, and an out channel,

available for daisy-chaining arrays together or to

complete termination using an external LVD

terminator.

Components

8

Page 20

3.2 Physical Set Up

The Diamond Storage Array is shipped completely assembled with two 120 VAC power cords for use in

the United States and Canada.

Immediately upon receipt, check the shipping

carton for damage from mishandling. Contact us

at once by the means easiest for you (refer to

Contact ATTO Technology, Inc.

on page viii) if the

carton has been mishandled or displays any signs

of damage.

Floor model

The Diamond Storage Array is heavy (about 92

pounds fully loaded) and requires two people to

lift and carry it safely. Place the array on a level

surface and make sure there is adequate space in

the front and back of the unit for proper cooling

and airflow. Continue with the general

instructions.

Rack mount

The array fully loaded is heavy (about 86 pounds).

The unit should be handled with care and requires

two people to lift, carry and/or install it safely.

The Diamond Array can be mounted via several

different methods in a 19” rack with 3U (5.25”) of

vertical space required. Air flow should not be

restricted in any way.

Installation in a rack may create a differential

between the room ambient temperature and the

internal ambient temperature in the rack. While

the maximum internal operating temperature of

the array is 47°C, you should not run the system

at the maximum temperature for extended

periods. Therefore, ensure that the room ambient

temperature is kept below 30°C for best

operation.

Spaced rail pairs in some rackmount cabinets.

You can mount the array using two sets of rail

pairs spaced to accommodate the overall length of

the unit (approximately 23 inches). Mount using

the rack mount brackets on the front and rear of

the unit fastened to the rail pairs using 10/32 pan

head screws with lock and flat washers.

Rack mount cabinets with stationary shelf or tray

system.

The shelf or tray must be able to support

at least 125 pounds. The shelf or tray must be

installed and secured to the rack before installing

the array. Secure the front of the array to the rack

with 10/32 screws, locks and flat washers.

Sliding shelf or tray type systems

should never

be used under any circumstances.

Two point open rack system.

The rack must be

strong enough to support the Diamond Array

properly. Mounting brackets should be moved to

the centermost mounting holes and secured using

10/32 screws.

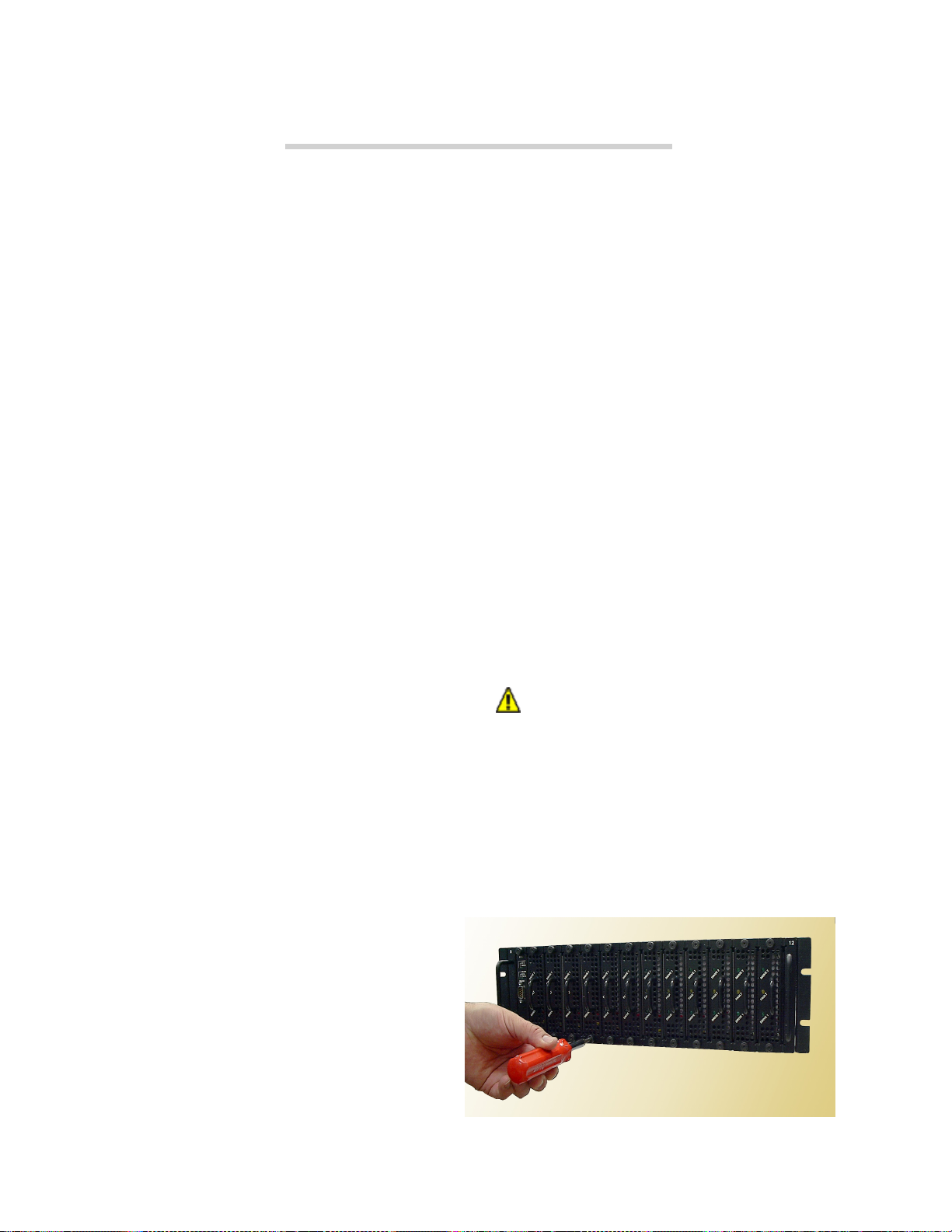

CAUTIONCAUTION

Do not mount multiple arrays on a two-rail

rack or mount the array above the midpoint

of a two-rail rack system. Do not mount the

array on any kind of rail-type system. The

array is too heavy and does not have the

proper hole pattern for rails.

Insure the array has adequate air flow and

continue with the general instructions.

Each side of the rack mount array chassis has

three pairs of mounting holes. One is located near

the front of the rack, one near the unit’s center of

gravity, and one near the rear of the rack. The

holes will accommodate 10/32 screws but the

screws can protrude no farther than .375 inches

into the rack.

9

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Page 21

General instructions

1 Insert the proper connector into the Host

Interface Card in the back of the array. (Refer to

Connecting a Fibre Channel Array

Fibre Channel and

page 13 for SCSI).

2 Connect the cable (Fibre Channel or SCSI)

from your host system to the Host Interface

Card connector on the back of the array. The

cable you use depends upon your application,

the environment and distance.

3 Make sure the power switches on the power

supplies on the rear of the unit are in the standby position. Plug in the power cords to the back

of the unit, then into an appropriate power

source (100-240 VAC). The power source must

be connected to a protective earth ground and

comply with local electrical codes. Improper

grounding may result in an electrical shock or

damage to the unit.

Exhibit 3.2-1 Back side of a rack mount Fibre Channel Diamond Storage Array.

Connecting a SCSI Array

on page 11 for

on

4 Press the stand-by power switch for each

power supply to the ON position. When the

green power LED on the back of the unit is lit,

the power supply is fully operational and

delivering power to the system. The power LED

on the front of the array will light once the

firmware begins to execute.

When the power is turned on, the LEDs on the

front of the array will flash twice. Drives will spin

up in groups of three, about every one to two

seconds. The individual LEDs will blink. After all

available drives have spun up, the individual

drive LEDs will stay lit. When all available

drives are operational, the ready LED on the

top front panel of the management card will

remain lit.

5 Reboot your computer

6 Determine the best configuration for your needs

(i.e. JBOD, RAID, etc.) and refer to the rest of

this manual for more detailed explanations and

configuration information.

10

Installation

Page 22

3.2.1 Connecting a Fibre Channel Array

The Diamond Storage Array supports up to two Fibre Channel Host Interface Cards (HIC). Physical

connections and CLI commands contribute to the Fibre Channel topology.

The cable you use depends

upon your application, the

environment and the

distance required for your

2 Gb HIC uses

2 SFPs to connect up

to 2 FC cables

storage area network.

To comply with FCC and

CE EMI for the 2-gigabit

Host Interface Card, use fiber optic cables.

Exhibit 3.2-2 Fibre Channel cable options

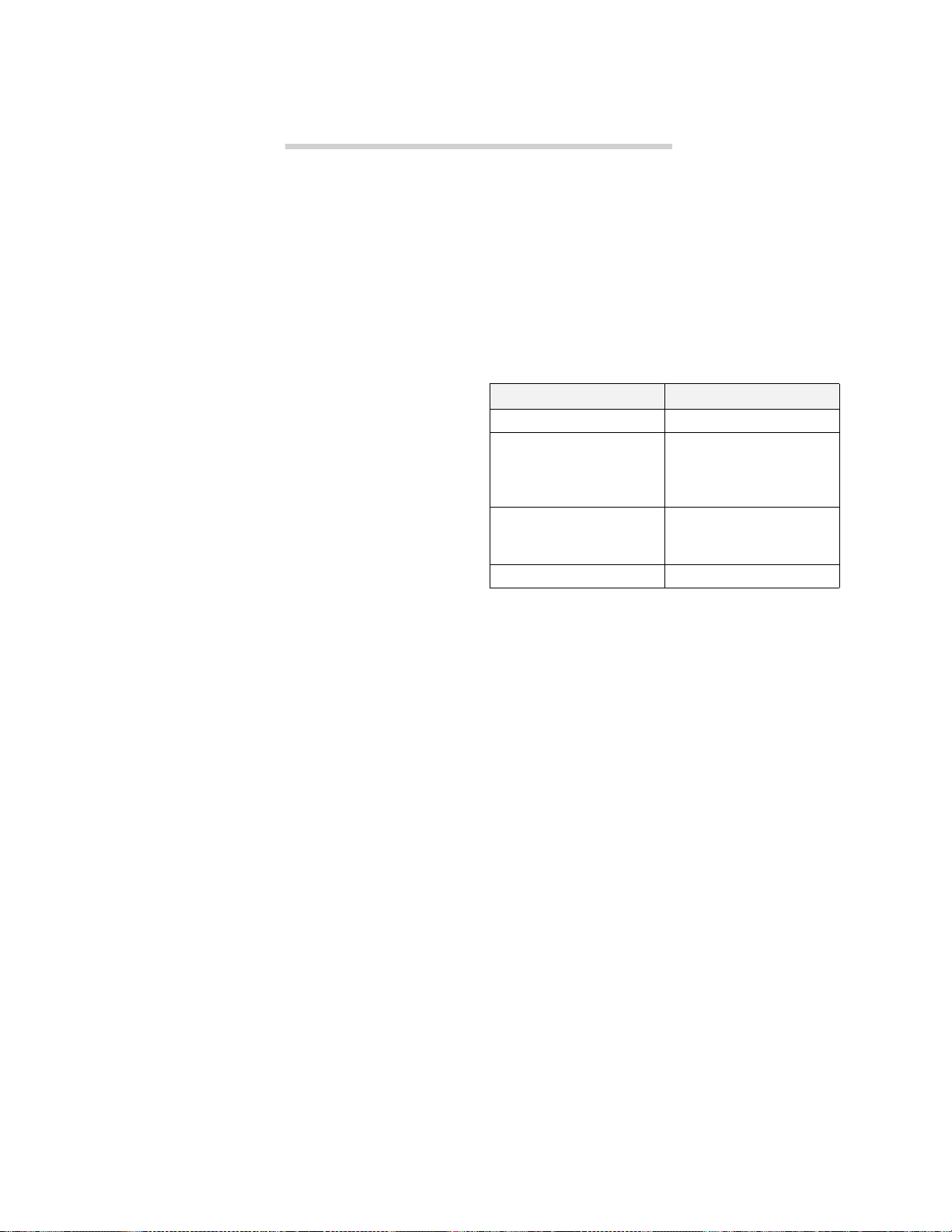

Cable length Cable type Cable size

<10 meters Unequalized copper

>10 <30 meters Equalized copper

Up to 175 meters multi mode fiber optic 62.5 micron

Up to 500 meters multi mode fiber optic 50 micron

Up to 10 kilometers single mode fiber optic 9 micron

The Diamond Storage Array may have two Fibre

Channel Host Interface Cards (HIC). In 2 gigabit

Fibre Channel arrays, each HIC is connected by a

Fibre Channel cable via a SFP (small form factor

pluggable) module into a point-to-point or loop

Fibre Channel topology.

Install the SFP according to the manufacturer’s

instructions.

Each HIC has two ports and an on-board hub.

Each port has an SFP module to connect to Fibre

Channel. Each HIC is independent of the other, so

that one may be connected into a point-to-point

topology and the other into a loop. However, if

one port in a HIC is connected into a point-topoint topology, the other port cannot be used.

One of the advantages of using loop topology for

Fibre Channel connections is that it allows arrays

to be daisy-chained together.

Autoconfiguration

The array automatically determines which HICs

are installed and if they are in loop or point-topoint topologies.

If you wish to see how the unit has been set up, go

to the CLI commands and type

Info or go to the

Status page of the ExpressNAV interface. The

return displays the data rate and connection mode

for each HIC (FC 0 and FC 1).

Manual configuration

You may manually configure the array using CLI

commands (refer to

Guidance

Channel

(refer to

on page 29.) or access the

page of the ExpressNAV interface

ATTO ExpressNAV: Browser-based Interface

Command Line Interface Use and

Fibre

on page 25).

•

FCConnMode

topology for both HICs on an array. Options are

loop only (loop), point-to-point only (ptp), loop

preferred (loop-ptp) or point-to-point preferred

(ptp-loop).

Loop connects to either an FC-AL arbitrated loop or

a fabric loop port (FL_Port) on a switch.

Point-to-point (ptp) connects to a direct fabric

connection, such as an F port on a switch.

Loop-ptp allows the array to determine what kind of

connection to use, but tries to connect in loop mode

first, then point-to-point mode.

Ptp-loop allows the card to determine what kind of

connection to use, but tries to connect in point-topoint mode first, then loop mode.

• FcDataRate specifies the Fibre Channel data

rate at which both HICs on a Diamond operate.

Choices are 1 gigabit, 2 gigabit and

autodetection.

specifies the Fibre Channel

11

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Page 23

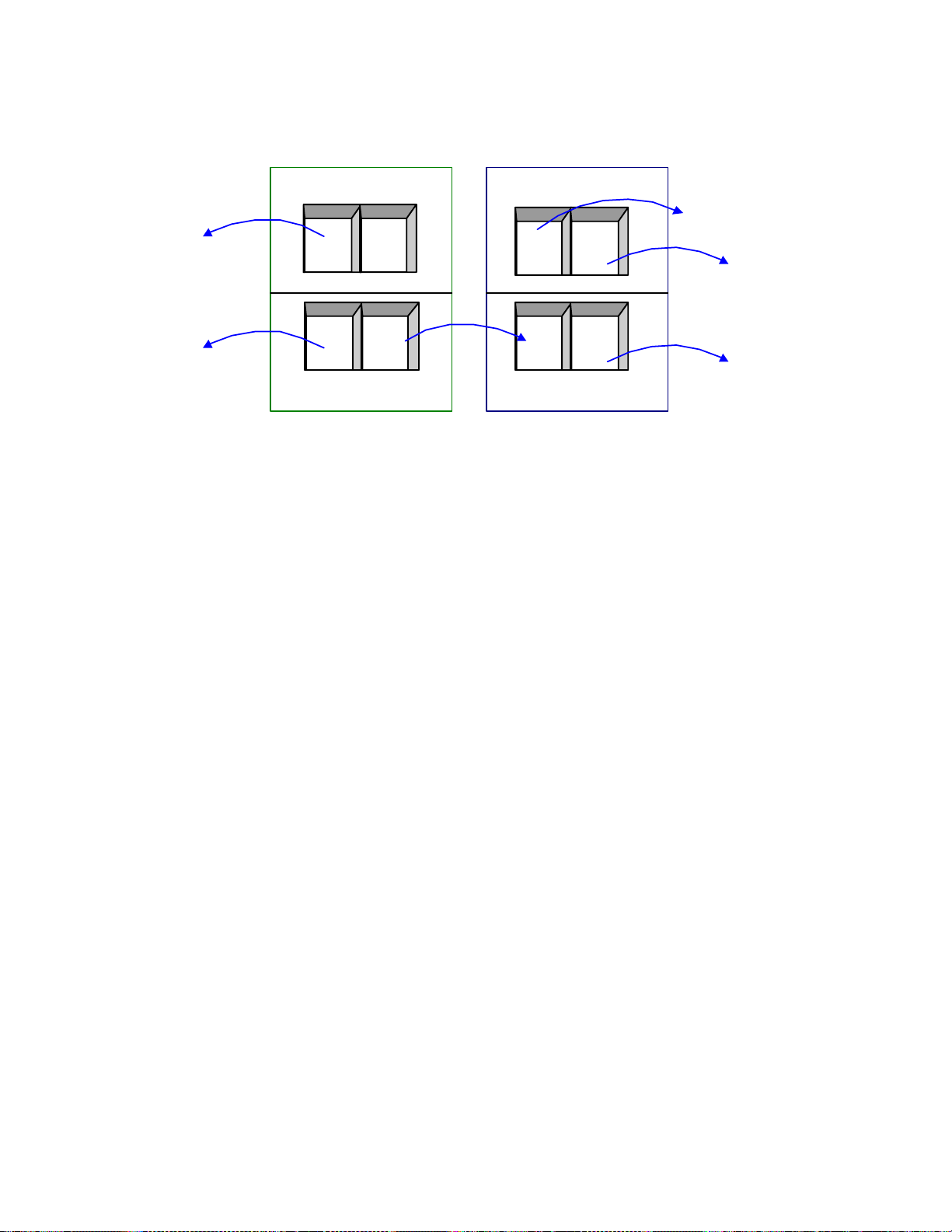

Exhibit 3.2-3 Possible 2 gigabit Fibre Channel physical connections depending on which Fibre Channel connection mode has been selected.

point-to-

point mode

loop

mode

Diamond Storage Array A Diamond Storage Array B

no

connection

possible

loop

mode

daisy -chain

loop

mode

loop

mode

loop

mode

loop

mode

12

Fibre Channel connections

Page 24

3.2.2 Connecting a SCSI Array

The SCSI Diamond Storage Array uses a VHDCI connector and SCSI cables to connect to a host. It will

automatically detect the type of Host Interface Card it is using without any intervention.

To connect a SCSI array

1 Insert a SCSI VHDCI connector into the Host

Interface Card in the back of the array.

2 Connect the cable from your host system to one

of the VHDCI connectors on the Host Interface

Card connector on the back of the array.

3 If the SCSI array is the last device on the bus,

you must attach a VHDCI terminator to one

connector of the SCSI Host Interface Card or

Exhibit 3.2-3 SCSI cable options.

Bus speed, MB/sec.

max.

SCSI-1 5 8 6 - 8

Fast SCSI 10 8 6 - 8

Fast Wide SCSI 20 16 6 - 16

Wide Ultra SCSI 40 16 3 - 4

Wide Ultra SCSI 40 16 1.5 - 8

Wide Ultra 2 SCSI 80 16 - 12 16

Ultra 3 or Ultra160 SCSI 160 16 - 12 16

Bus width,

bits

connect a cable between the second connector

and the next device on the SCSI bus.

4 The SCSI Host Interface Card has a rotary

binary-coded hex switch which allows you to

set the SCSI ID of the HIC. Be sure the selected

ID is different from all other SCSI devices on

the bus.

Note

If slower devices are connected on the same

SCSI bus as the Ultra 160 array, the bus will

communicate at the rate of the slowest device.

Max. bus lengths,

meters

Single-ended LVD

Max. device

support

Exhibit 3.2-4 SCSI interface cards: left without terminators attached; right with a terminator attached.

13

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Page 25

14

SCSI connections

Page 26

4.0 Determining Drive and Sled Designations

g

The Diamond Storage Array has been designed with 12 sleds, each holding two drives. The easiest way

to configure a array is to use all the drives on all the sleds. The firmware uses a numbering system to

determine which drives and sleds it is affecting.

We recommend that all sled slots are filled

contiguously, starting with the first slot next to the

management card.

When configuring a Diamond Array with fewer

than 12 drive sleds, you must consider several

factors: RAID level, number of physical

drives/sleds and the end configuration you are

trying to achieve. Review the information about

each configuration to determine how each

configuration would be affected by using fewer

sleds.

Numbering conventions

The Diamond Storage Array with firmware

version 3.1 and newer uses a unique numbering

convention to orient its drives and sleds to the

controlling firmware. Older versions do not use

this convention. (Refer to

Updating Firmware

on

page 77 for information about updating the array

firmware.)

Physical

refers to the physical drives in the array,

the hardware that actually exists in a physical

sense.

Logical (or virtual)

refers to what the host

operating system recognizes as an entity. Two

physical drives may be seen as one logical drive

by the operating system.

Logical disks do not always map one-to-one with

physical disks.

In RAID configurations, for

example, several physical disk drives (or portions

of several physical drives) are grouped into a

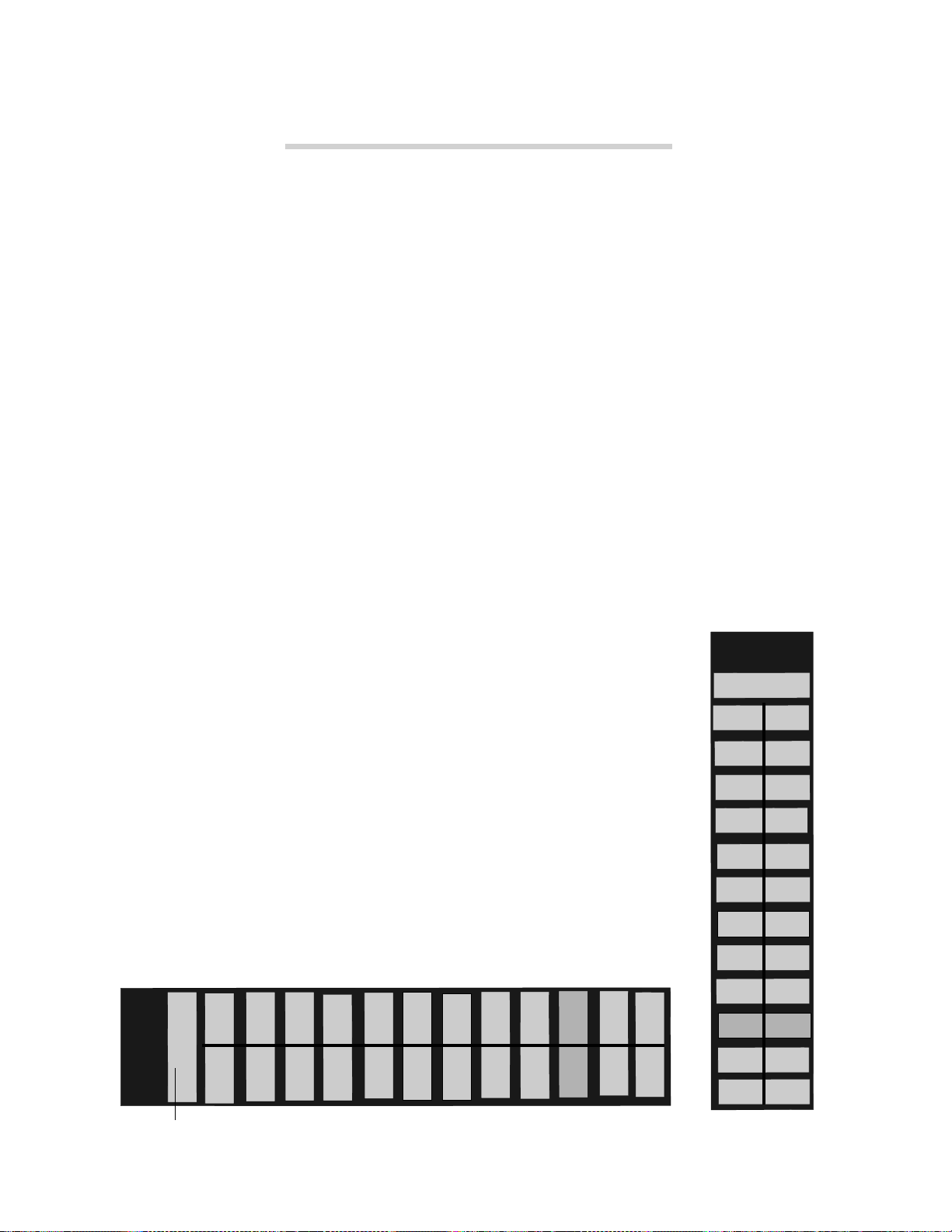

1 2 3 4 5 6 7 8 9 10 11 12

Disk 2

Disk 2

Disk 2

LUN 13

LUN 14

LUN 15

Disk 2

LUN 16

Rack Mount Drive Sleds

LUN 17

Disk 2

LUN 16

LUN 17

Disk 2

LUN 18

Disk 2

LUN 19

LUN 20

LUN 19

logical disk or Logical Unit (LUN). Each LUN is

broken into logical blocks of 512 bytes each,

numbered 0 through n (the Logical Block Number

or LBN). A 100 GB LUN has approximately

200,000,000 logical blocks.

Physical numbering

The Diamond RAID Storage Array contains

• Up to 24 physical disk drives

• Two drives mounted on 12 physical drive sleds

• Sleds are numbered 1-12, starting at the top

(floor units) or the left (rackmount units).

• Each sled is connected to its own internal ATA

bus with two disk drives, numbered 1 and 2.

• Two green LEDs, labeled Drive 1 and Drive 2,

indicate activity for the two drives. They remain

solidly lighted when there is no activity.

Logical numbering

Logical numbering depends on

the RAID configuration of the

storage array. S Class firmware

includes RAID Level 0, RAID

Level 1, RAID Level 10 and

RAID Level 5 capability. A

variety of configurations may

be selected using the

QuickRAID0 command. The

default configuration is

QuickRAID0 0 or JBOD (Just

a Bunch of Disks).

Disk 2

Disk 2

Disk 2

Disk 2

LUN 20

LUN 21

LUN 22

LUN 23

Disk 2

LUN 24

Mana

Drive 1

LUN 1

Drive 1

LUN 2

Drive 1

LUN 3

Drive 1

LUN 4

Drive 1

LUN 5

Drive 1

LUN 6

Drive 1

LUN 7

Drive 1

LUN 8

Drive 1

LUN 9

Drive 1

LUN 10

Drive 1

LUN 6

ement car d

Drive 2

LUN 16

Drive 2

LUN 17

LUN 18

Drive 2

LUN 19

Drive 2

LUN 20

Drive 2

LUN 21

LUN 22

Drive 2

LUN 13

Drive 2

LUN 14

Drive 2

LUN 15

Drive 2

LUN 20

LUN 19

Drive 1

LUN 12

Drive 2

LUN 17

1 2 3 4 5 6 7 8 9 10 11 12

Floor Model Drive Sleds

Drive 2

Drive 1

LUN 11

Drive 1

LUN 12

LUN 23

Drive 2

LUN 24

Management Card

15

Disk 1

LUN 1

Disk 1

LUN 2

Disk 1

LUN 3

Disk 1

LUN 4

Disk 1

LUN 5

Disk 1

LUN 6

Disk 1

LUN 7

Disk 1

LUN 8

Disk 1

LUN 9

Disk 1

LUN 10

Disk 1

LUN 11

Disk 1

LUN 12

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Page 27

Examples

JBOD

mode uses 24 LUNs. Each LUN is

equivalent to one physical drive. The array will

operate with several sleds missing, but the empty

sled(s) will be treated as offline and will not be

configurable.

RAID Level 0 (

QuickRAID0 [n]

)

With a fully

populated array, RAID 0 may be configured as 1,

2, 3, 4, 6, or 12 LUNs. As

QuickRAID0 1

, all 24

physical drives are configured as a single stripe

group or LUN. You may also configure two LUNs

of 12 drives each, three LUNs of eight drives

each, four LUNs of six drives each, six LUNs of

four drives each and 12 LUNS of two drives each.

(See Exhibit 6.2-3 in

RAID Level 0

on page 53). The

command assumes there are 24 drives available to

configure the specified number of LUNS.

configured as six mirrored pairs, then striped into

two LUNs.

RAID Level 5 (

QuickRAID5

)

with a fully

populated Array may be configured as 1, 2, 3 or 4

LUNs. As

QuickRAID5 1

, all 24 physical drives are

configured as a single RAID 5 LUN. You may

also configure two LUNs of 12 drives each, three

LUNs of eight drives each, or four LUNs of six

drives each. RAID Level 5 parity will reduce the

usable capacity of each LUN by the equivalent of

one drive sled.

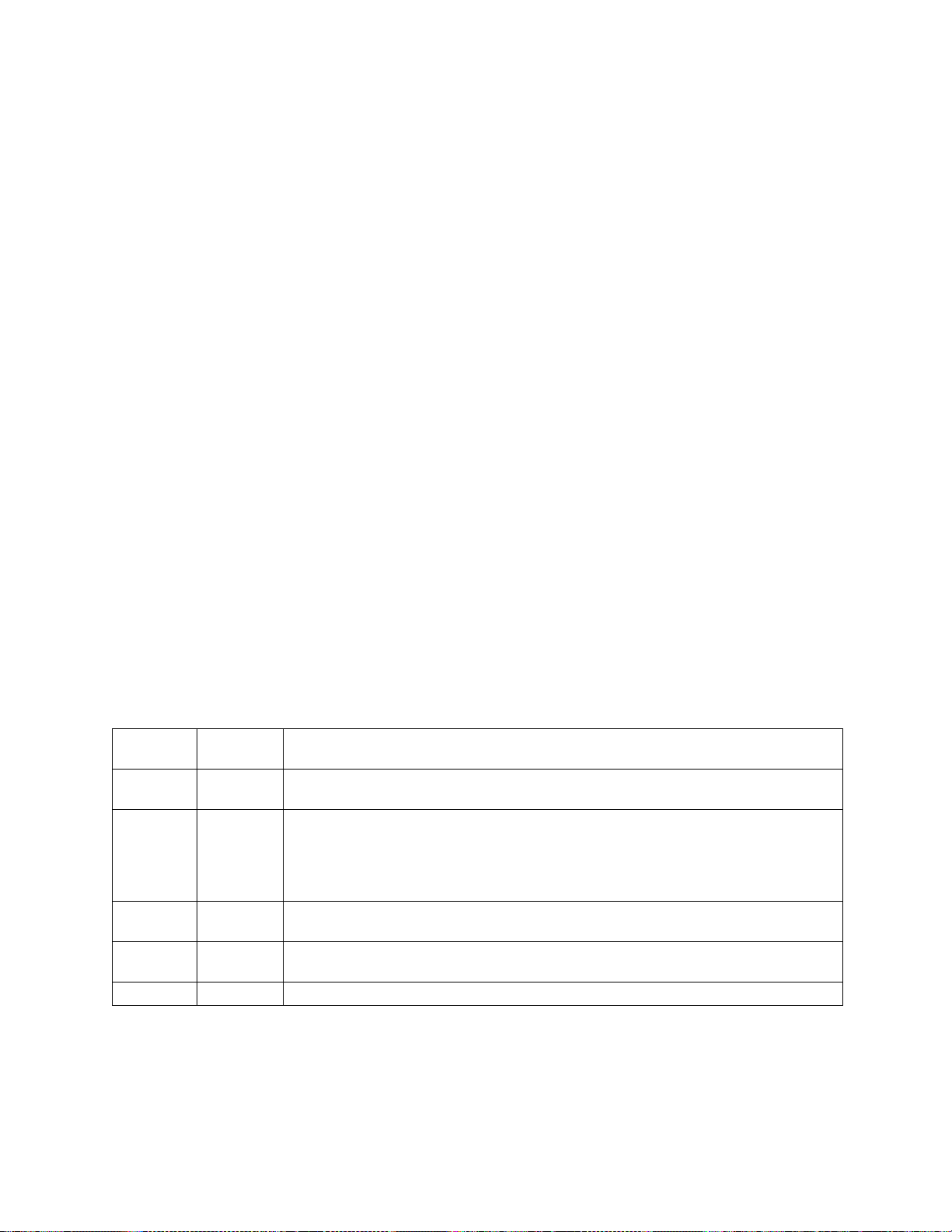

Unique serial number for each LUN

Each LUN in a system has a unique 24-character

serial number which is updated when a system

configuration changes. It is stored in a Device

Association Table on each drive.

RAID Level 1 (

array will be configured into six groups, LUNs 16, with each LUN containing two physical sleds;

each sled in the LUN will be a mirror image of the

other sled in the LUN.

RAID Level 10 (

command first creates six mirrored groups, then

stripes them into groups of one, two or three

RAID 10 groups. Each group is a LUN. Issuing

QuickRAID10 2

Character

Placement

0-19 Any ASCII

20 1 for Raid1

21 A – Z LUN Configuration Iteration Character: starts at A and increments every time a member drive is

22 A – Z Generation Character: starts at A and increments every time a new configuration is stamped on the

23 0 Reserved for future use

QuickRAID1

QuickRAID10

)

has no options: the

)

The

QuickRAID10

, the 12 physical sleds are

Valid values

char

A for Raid10

0 for Raid0

5 for Raid5

X for JBOD

Example of unique serial number for a JBOD configuration:

Drive Serial Number

RAID Configuration Character

replaced in a RAID Group. Reverts back to A any time the Generation Character is updated

system. When it reaches Z, rolls over to

When a drive or sled is replaced in

QuickRAID

configurations that allow for hot swap, a new

serial number will be computed and will in turn be

stamped onto all member drives of the RAID

group. The CLI command

ExpressNAV interface page

LUNInfo

or the

Logical Units will

display the serial number for each drive.

Format of the 24 characters is defined in the chart

below:

1231231231231231231XAC0

A

.

16

Numbering conventions

Page 28

5.0 Accessing the Array

Communicate with the Diamond Storage Array through the Fibre Channel link, the RS-232 port or the

Ethernet port using Command Line Interface commands.

You may configure and tune the Diamond Storage

Array for different environments and

applications, update the firmware, monitor

internal power and temperature status, report on

hardware diagnostics and log failures.

Three avenues are available

• In-band SCSI over Fibre Channel and over SCSI

• RS-232 port

• Telnet and SNMP over Ethernet

The rest of this manual describes how to access

the array and use the Command Line Interface or

the ExpressNAV interface.

Command Line Interface

The Command Line Interface provides access to

the array through ASCII command lines.

An initial display, after powering up the unit or

restarting the firmware, will contain the

information in Exhibit 5.0-1. Once the initial

display is complete, with the word

Ready

,

you are

in the Command Line Interface mode.

• In-band CLI over SCSI, where ASCII CLI

commands, may be issued via

CLI commands except

• ID/value, where the application program uses a

SCSI CDB (command descriptor block) to select

the buffer ID of the configuration parameters to

be affected, and the new value of the parameter.

Most configuration options are available.

Zmodem

Write Buffer.

are supported.

All

RS-232 port

The array provides remote service operations over

the RS-232 serial port using standard terminal

emulation software available with most systems.

You will need to set the following serial

parameters in your terminal program

• Bits per second: 115200

• Data Bits: 8

• Parity: None

• Stop Bits: 1

• Flow Control: None.

• Terminal type: ASCII

• Echo: on

Help

Type

available.

ATTO ExpressNAV

ATTO ExpressNAV is an integrated configuration

tool accessible through an Ethernet connection.

Platform independent, ExpressNAV contains all

the current capabilities of the CLI in a userfriendly GUI console. A menu on each page

provides access to information and configuration

operations.

Refer to

on page 25 for more information.

to display a list of all commands

ATTO ExpressNAV: Browser-based Interface

Ethernet port

The 10/100 BaseT Ethernet port provides Telnetor SNMP-based monitoring and management.

The default IP address is 10.0.0.1; the default

subnet mask is 255.255.255.0. These parameters

can be changed using the RS-232 port or Telnet.

The array should first be configured for the

network using the RS-232 port to establish the

correct IP address.

SNMP, or Simple Network Management

Protocol, is an application layer protocol that

allows network devices to exchange management

information. Through a combination of standard

In-band SCSI over Fibre Channel

In-band SCSI commands (

Buffer

) may be issued to the array Fibre Channel

Write Buffer

and

Read

port to manage configuration via two mechanisms

17

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

and custom MIBs (Management Information

Base), the array provides status and error

indications to an SNMP server, allowing the array

to be managed with other devices in a complex

Page 29

system through a common interface. You use CLI

commands or the

SNMP

page of the

ExpressNAV interface to configure up to six

unique Trap addresses. A trap is a way for the

array to tell the SNMP server that something has

happened.

SNMP

SNMP, or Simple Network Management

Protocol, is an application layer protocol that

allows network devices to exchange management

Exhibit 5.0-1 An example of the POST information on screen after boot

Diamond Storage Array

(c) 2004 ATTO Technology, Incorporated.

Firmware version 5.40 release date Mar 30 2004, 10:43:06 Build 021G

Power-On Self-Test Completion Status: GOOD

64 Megabytes of RAM Installed.

Interface Port 0 is not installed.

Interface Port 1 is 1.0624 Gb/s Fibre Channel.

information. Through a combination of standard

and custom MIBs, the array provides status and

error indications to an SNMP server, allowing the

array to be managed with other devices in a

complex system through a common interface.

You use CLI commands or the

ExpressNAV interface to configure up to six

unique Trap addresses. A trap is a way for the

array to tell the SNMP server that something has

happened.

SNMP

page of the

Interface 0 World Wide Name = 20 00 00 10 86 10 02 DC

Interface 1 World Wide Name = 20 00 00 10 86 10 02 DC

Diamond Array Serial Number = "MIDP100197"

Diamond Array Name = " "

System Serial Number = ""

Active Configuration = ATTO

DiamondClass = (S)83

Internal Temperature = 26 C [5 - 47]

ErrorLog Contents: NO ERRORS

For help, type HELP.

Ready.

18

Interfaces

Page 30

5.1 In-band CLI Over the Fibre Channel

In-band Command Line Interface (CLI) configures and manages the Diamond Storage Array using

SCSI-based CLI commands over a Fibre Channel port connection.

In-band CLI allows a programmer to configure

the Diamond Storage Array while it is moving

data. Using a programmer’s interface, CLI

commands as described previously in this manual

may be implemented.

In-band CLI is implemented as part of LUN 0. It

uses a different LUN than the array, and reports as

a Storage Enclosure Services (SES) device

(device type 0x0D).

LUN 0 is visible on all Fibre ports but is actually

a single unit. The default value for LUN 0 is 0x00.

LUN 0 must be reserved for each Write

Buffer/Read Buffer pair, using the SCSI Reserve

command to insure integrity of the in-band CLI

session.

1 An initiator (host) sends a SCSI Reserve

command to LUN 0.

• If LUN 0 is not reserved by another initiator,

LUN 0 is now reserved and ready to begin a

new CLI session.

• If the array configuration is reserved by a

different CLI session (i.e. serial or Telnet),

the in-band session will not be allowed to

modify the array configuration. If you try, the

results buffer of LUN 0 will return

Process X has the configuration

reserved.

ID of this session = Y

Ready.

2 The initiator issues a SCSI Write Buffer

command to LUN 0. A

must be accompanied by an ASCII buffer

representing the CLI command string such as

set DiamondName Omega1

3 LUN 0 will execute the command line and

create feedback in the form of ASCII characters

into a buffer. This buffer is 8 KB and circular.

Retrieve the results by issuing a Read Buffer

command before issuing another Write Buffer

command.

Write Buffer

command

4 A subsequent Write Buffer command will

execute the new command line and overwrite

the previous results in the buffer with new

results.

5 LUN 0 can be released by issuing a SCSI

Release command to the LUN after each

Write/Read Buffer

Buffer pairs.

Initiator (Host) Diamond Array

Reserve LUN 0 return: “ok”

Write Buffer

LUN 0

bid ‘AA’

“get Temperature”

Read Buffer

LUN 0

bid ‘AA’

Release LUN 0 return: “ok”

pair, or multiple

executes the CLI command,

stores output in buffer

return:

”Temperature=28C\r\n\Ready

.\r\n\0”

Write/Read

I/O details

The buffer sent to the Services LUN during the

data out phase of a Write Buffer command must

be

• ASCII data

• maximum 80 bytes length

• terminated with either a carriage return

character (0x0D), line feed character (0x0A) or

NULL character (0x00)

• Characters following the first carriage return

character, line feed character or NULL character

are ignored.

The buffer retrieved from the Services LUN

during the data-in phase of a Read Buffer

command will be

• ASCII data

• 8 KBytes (8192 bytes) in length

• terminated with a NULL character (0x00)

• Characters following the NULL character are

meaningless.

19

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Page 31

A

CHECK_CONDITION,

INVALID_PARAMETER_IN_CDB

will be returned

to an initiator that specifies an incorrect Buffer

Exhibit 5.1-1 The SCSI command process: reserve the Diamond Storage Array, send the command, release the Diamond Storage Array.

Initiator/Host Diamond Storage Array

Goal

: reserve the Diamond Storage Array for an in-band CLI command

SCSI cdb: Reserve LUN 0 =>

Goal

: retrieve the Diamond Storage Array temperature via in-band CLI

1. Issue the command:

SCSI cdb: WriteBuffer LUN 0, bid=’AA’, “get Temperature\n” => places “Temperature=28C\n\r” into

2. Retrieve the results:

SCSI cdb: ReadBuffer LUN 0, bid=’AA’ =>

Goal

: release the Diamond Storage Array for other in-band users

SCSI cdb: Release LUN 0 =>

ID, Mode, Length or Buffer Offset. The Mode is

always Data (0x2), the Buffer ID is always 0 and

the Buffer Offset is always 0.

<= SCSI success

the read-data buffer

<= SCSI success

<= Returns “Temperature=28C\n\r”

from the read-data buffer

<= SCSI success

<= SCSI success

20

In-band CLI

Page 32

5.2 Serial Port Access

The Diamond Storage Array provides remote service operations over the RS-232 serial port using

standard terminal emulation software available with most systems.

The Diamond Storage Array supports service

operations over the RS-232 serial port using

standard terminal emulation software available

with most systems.

1 Connect a DB-9 null modem serial cable

between the port marked RS-232 on the front of

the array and one of the computer’s serial ports.

A gender changer or DB-9 to DB-25 converter

may be needed depending on the cables you

are using. The cable must be no longer than

three meters

2 Boot the computer terminal or terminal

emulator.

3 Start a terminal emulator program such as

Windows HyperTerminal. Set the emulator to

use the COM port with cable attached, then the

following settings:

• 115200 baud

• 8 bit ASCII

• no parity

• ASCII terminal type

• 1 stop bit

• flow control none

• echo typed characters locally

4 Turn on the array. Upon successful power on

and diagnostics, the unit should display the

POST (power on self test) information found in

Exhibit 5.0-1.

5 You should now be in the CLI mode. To see a

list of available commands, type help at the

Ready prompt or refer to this manual’s Index.

6 Use the CLI to configure the unit as a JBOD,

RAID Level 0, RAID Level 1, RAID Level 10 or

RAID Level 5 array with or without hot spare

sleds as described later in this manual.

21

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Page 33

22

Serial port access

Page 34

5.3 Ethernet Access: Telnet and SNMP Protocols

The optional 10/100 BaseT Ethernet port provides Telnet- or SNMP-based monitoring and management.

The 10/100 Base T Ethernet management services

card provides Telnet-based monitoring and

management, including firmware update using

FTP.

Remote system monitoring is also available using

Simple Network Management Protocol (SNMP).

An agent resides in the array which takes

information from the Array and translates it into a

form compatible with SNMP. If certain conditions

arise, the agent sends asynchronous notifications

(traps) to a client.

To connect to the Ethernet port

1 Connect a cross-over cable (for a direct

connection to a PC) or regular network cable

from a network device to the optional RJ45

Ethernet port on the Ethernet management

card on the front of the array.

2 If using a direct connection, power on and boot

up the host computer.

3 Attach a DB-9 null modem serial cable (the

cable must be no longer than three meters)

from the RS-232 port of the array to a host

computer and open a terminal emulator

program on the host to set the Ethernet

parameters. Turn on the array.

4 First time use: Upon successful power up and

diagnostics, set the host computer with the

appropriate settings.

The host computer must have appropriate

network settings to allow it to communicate with

the array. Please see your system

administrator for more information.

• Port type: telnet

• Terminal type:

3 If you make any changes to the network setting

on the Diamond Array, use the

SaveConfiguration and FirmwareRestart

commands.

4 Username/password: You will be prompted for

a username and password, up to eight

characters each, case insensitive. Only one

username/password combination is available

per array.

• You may change the telnet username and/or

password after entering a CLI session using

the commands

set TelnetUsername [username]

set TelnetPassword [password]

• Or change the telnet username and/or

password using the ExpressNAV interface

Configuration page.

• RestoreConfiguration default sets the

telnet username and password to the default

values.

• The username default is telnet.and

password default is diamond.

5 You should now be in the CLI. To see a list of

available commands, type help at the

prompt or refer to this manual’s Index. Or,

access the ExpressNAV interface (refer to

ATTO ExpressNAV: Browser-based Interface

page 25).

6 Configure the unit as a JBOD, RAID Level 0,

RAID Level 1, RAID Level 10 or RAID Level 5

array with or without hot spare sleds as

described later in the manual.

vt100

Ready

on

To use Telnet

1 If you have not already done so, change the IP

address from the default by first accessing the

serial connection and changing it using the CLI.

Change the IP address to a network specific

value or, if the local network uses DHCP, you

may enable automatic IP addressing (set

IPDHCP enabled) using the CLI.

2 Open a Telnet session on the host computer.

• IP address

23

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

To use SNMP

1 Enter the CLI through the serial port or

Ethernet.

2 Change the IP address to a network specific

value or, if the local network uses DHCP, you

may enable automatic IP addressing.

3 Set the number of trap client addresses by

typing

set SNMPTrapAddress [1-6] [IPAddress]

[Level]

Page 35

4Type

set SNMPUpdates enabled

5Type

set SNMPTraps enabled

6Type SaveConfiguration restart to reboot the

array.

7 Install SNMP management software on each

client you wish to receive traps (messages).

8 Call technical support (refer to

Technology, Inc.

appropriate MIB file for your array.

9 For each client, copy the MIB file to the

directory containing the SNMP management

software.

10 From within the SNMP management software,

compile the file

the software’s procedures.

on page viii) to get the

attodmnd-mib.mib

Contact ATTO

according to

11 Unload any default MIBs.

12 Load the Diamond MIB ATTODIAMOND

13 When requested, enter the array’s IP address

as the Remote SNMP Agent.

14 The SNMP management software will contact

the agent in the array. The screen will reply with

system information.

15 Status will be monitored and reported through

the SNMP management software.

.

Traps are generated for the following situations

• Temperature status changes in any of the

sensors located on the array mid-plane.

• A drive or a sled is physically removed from the

array or put into the array.

• The power supply is turned on or off.

• The fan is physically stopped.

24

Ethernet access

Page 36

5.4 ATTO ExpressNAV: Browser-based Interface

The easiest way to communicate with the Diamond Storage Array is to use ATTO ExpressNAV, a userfriendly GUI interface accessed through a browser to control the most common capabilities of the array.

Access ATTO ExpressNAV from any browser

that supports the latest standards for XHTML 1.0

and CSS1. To take full advantage of the

ExpressNAV interface you should have Java

script enabled through your browser.

Browser compatibility

All pages are written in pure XHTML 1.0 and

CSS1 to be compatible with the latest versions of

Internet Explorer, Netscape, Mozilla (including

K-Meleon, Camino, Mozilla Firefox, Epiphany

and Galeon), and KHTML (including Konqueror

and Safari).

Minimum requirement is for Internet Explorer 5.5

and Netscape 6.2.

To optimize ExpressNAV in Internet Explorer

1 Go to the browser toolbar and click on Tools

2Click on Internet Options

3 Click on the Security tab

4 Click on the Custom Level button.

5Click on Microsoft VM, Java permissions

6 Ensure Disable Java is not selected.

7 Click on the Miscellaneous tab.

8Click on Metarefresh

Opening an ExpressNAV session

1 Obtain the IP address of the array.

2 Type the IP address of the array into the

browser address window.

3 The ExpressNAV interface splash screen is

displayed. Click on Enter.

4 Enter the username and password set

previously in

Interface

The

•

• The default password is Password

5 The product faceplate display appears. Click

the component you want to manage on the lefthand side menu or go to the Advanced screen

to use the CLI.

ATTO ExpressNAV: Browser-based

on page 25.

default username is Diamond

Navigating ExpressNAV

All pages are accessible by clicking on their titles

on the left side of the page. You may also go back

one page or go to the

Home

page via the titles on

the left side of the page.

Clicking on any of the red option names will bring

up a help window. After making changes on a

page, click the

Submit button at the bottom.

Clicking this button is equivalent to typing in all

the CLI commands and then the command

saveconfiguration norestart.

25

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Page 37

Exhibit 5.4-1 Atypical page in the ATTO ExpressNAV configuration tool.

Sidebar:

select the

item you

wish to

view

Information

Parameter name

Red print links to

help text

Configure choices: red type links to

another page to change configuration

options unavailable

because of previous

Submit button

same as typing all

CLI commands and

saveconfiguration

Reset button

return to previous

setting without

making any changes

norestart

choice

26

ExpressNAV

Page 38

5.4.1 ExpressNAV Pages

Each page in the ATTO ExpressNAV interface provides information and/or configuration parameters

based on a specific topics. Each page can be reached through the menu on the left hand side of each

page.

Status

Contains general array information.

• Unit Information including Vendor ID, Product

ID, Firmware Revision and Serial Number

• Environmental Information

• World Wide Identifiers including Node Names

and Port Names

• Host Interface Card Status

• Fan Status

• Power Supply Status

• Storage Status including ATA Disk Errors and

Logical Unit Conflicts

Ethernet

Configures the Ethernet port.

• IP Address

• IP Gateway

• IP Subnet Mask

• Ethernet Speed

• Use DHCP

Refer to

on page 23 and

Ethernet Access: Telnet and SNMP Protocols

Ethernet Commands

on page 35 for

details.

SNMP

Remote system monitoring is available using

Simple Network Management Protocol (SNMP).

• Updates

• Traps

• Trap Recipient IP Addresses

Refer to

Access: Telnet and SNMP Protocols

Ethernet Commands

on page 35 and

on page 23 for

Ethernet

details on each parameter.

Serial Port

Contains the necessary information to configure

the serial port including baud rate and echo.

Refer to

Configuration Commands

Serial Port Access

on page 21 and

Serial Port

on page 39 for more

information on each parameter.

Fibre Channel

Contains parameters and information to manage

the Fibre Channel port.

• Data rate

• Full duplex mode

• Connection mode

Refer to

and

Connecting a Fibre Channel Array

Fibre Channel Configuration Commands

on page 11

on page

37 for more information.

Storage Management

Shows information about the drives and their

status. Information includes

• Sled Number

• Capacity of each sled

• Number of errors

• Configuration type (JBOD, RAID5, etc.)

• Virtual ID

You may place sleds on or off line by selecting or

de-selecting a check box.

Refer to

page 15 and

Determining Drive and Sled Designations

Drive Configuration Commands

on page

on

45 for more information.

Once you open this page, several other

configuration pages are available on the menu on

the left hand side of the page.

RAID

Contains the necessary information and

parameters to configure RAID groups.

Information provided includes

• Type of configuration (RAID5, JBOD, etc.)

• Virtual Disk ID

• State of sleds

• Capacity of sleds

• Interleave values

You may change the configuration of these

parameters

• Configuration Type (JBOD, RAID5)

• Number of Groups (when applicable)

• Interleave

• Striping method (sled or drive)

• Rebuild priority

27

ATTO Technology Inc. Diamond Storage Array Installation and Operation Manual

Page 39

Refer to

Configuration Commands

Configuring Drives

information.

on page 49 and

Drive

on page 45 for more

Advanced

Allows you to input any CLI command available

through the array.

Clear Data

Allows you to

• view the status of any Clear Data commands in

progress

• view the rebuild state of each sled

• initialize a RAID Level 5 Clear Data command

• set a rebuild state for each sled

• change the RAID Interleave.parameter

• Enable/disable AutoRebuild

Refer to

Drive Configuration Commands

on page 45

for more information.

Logical Units

Gives information on the logical units which have

been configured on the array and allows you to

change the status from online or offline or

degraded.

Refer to

page 15 and

Determining Drive and Sled Designations

Drive Configuration Commands

on page

on

45 for more information.

Rebuild

Shows the current status of rebuilds on the array

and allows you to halt, resume or initiate rebuilds.