Page 1

SOLAR TECHNIQUE

ATTACK® SOLARTHERM HSA 200

PARALLEL MOUNTING

BRACKETS ON THE ROOF

W W W . A T T A C K . S K

Page 2

Content

Safety warnings ...................................................................................................................... 4

Shipping instructions .............................................................................................................. 5

Installation instructions .......................................................................................................... 6

Tools Overview ....................................................................................................................... 7

Material Overview .................................................................................................................. 8

Recommended mounting points ............................................................................................10

Parallel mounting brackets on the roof .................................................................................. 11

Specifications ....................................................................................................................... 17

Recommendations for service ............................................................................................... 18

Warranty ............................................................................................................................... 20

3

Page 3

Safety warnings

In the case of mounting on the roof - before the work –

it is essential to install compliant independent

protection against falling or catching device according

to DIN 18338 on roofing work on the roof and sealing

work on roofs and in accordance with DIN 18451 for

work on scaffolding safety net! Regulation on the

protection of workers in construction BGBl 340/1994 §

7-10! It is absolutely necessary to keep other

regulations in the country!

If there are no safeguards against falling or catching

device-independent entities due to the technical

reasons, it is necessary to use a safety harness!

Use only safety harnesses, which are identified and

tested by authorized testing laboratory (safety or

webbing, connecting cords / belts, shock absorbers,

shortening ropes).

If there are no protection devices against falling or

catching independent on people, without the use of

safety harnesses there is danger of falling from great

heights and thus of severe or fatal injuries!

Safety harness must be preferably nailed above the

user. Fix safety harness only to eventually building

components or points that have sufficient capacity!

Only prescribed heat transfer medium!

Do not use damaged ladders, for example cracked

beams with a wooden ladder rungs, bent and broken

metal ladders. Do not repair brittle beams, side walls

and walls of wooden ladders!

Place the strap-on ladders safely. Be careful when

attaching the right angle (68 ° - 75 °). Strap ladders

are secured against slipping, overturning, sliding and

running, for example advanced bases, bases ladder

adapted substrate hinges.

Ladders rest only to the secure anchors. In the field of

transport ensure ladders by closures.

When using ladders, there is danger of falls caused

by slipping, fall or flip over the ladder!

Near unattached electrical lines, with which contact is

possible, work only if state was secured when they

are not under voltage and this condition is ensured

during the entire period of work, electrically conductive

parts are protected by fencing or covering them, and

there is no reduction of safety distance.

Radius of voltage

1 m ...........................1000 V voltage

2 m ...........................voltage from 1000 to 11000 V

3 m ...........................voltage from 11000 to 22000 V

4 m ...........................voltage from 22000 to 38000 V

> 5 m in the case of unknown voltage

The manufacturer hereby undertakes to take back

products marked with the ecological brand and

materials they contain, to deliver for further

processing. Only prescribed heat transfer medium can

be used!

Contact with loose electrical lines can be fatal.

In the case of drilling and handling collectors wear

goggles!

During installation, wear safety boots!

When mounting and handling collectors, wear gloves

providing protection against cuts!

During installation, wear a helmet!

4

Page 4

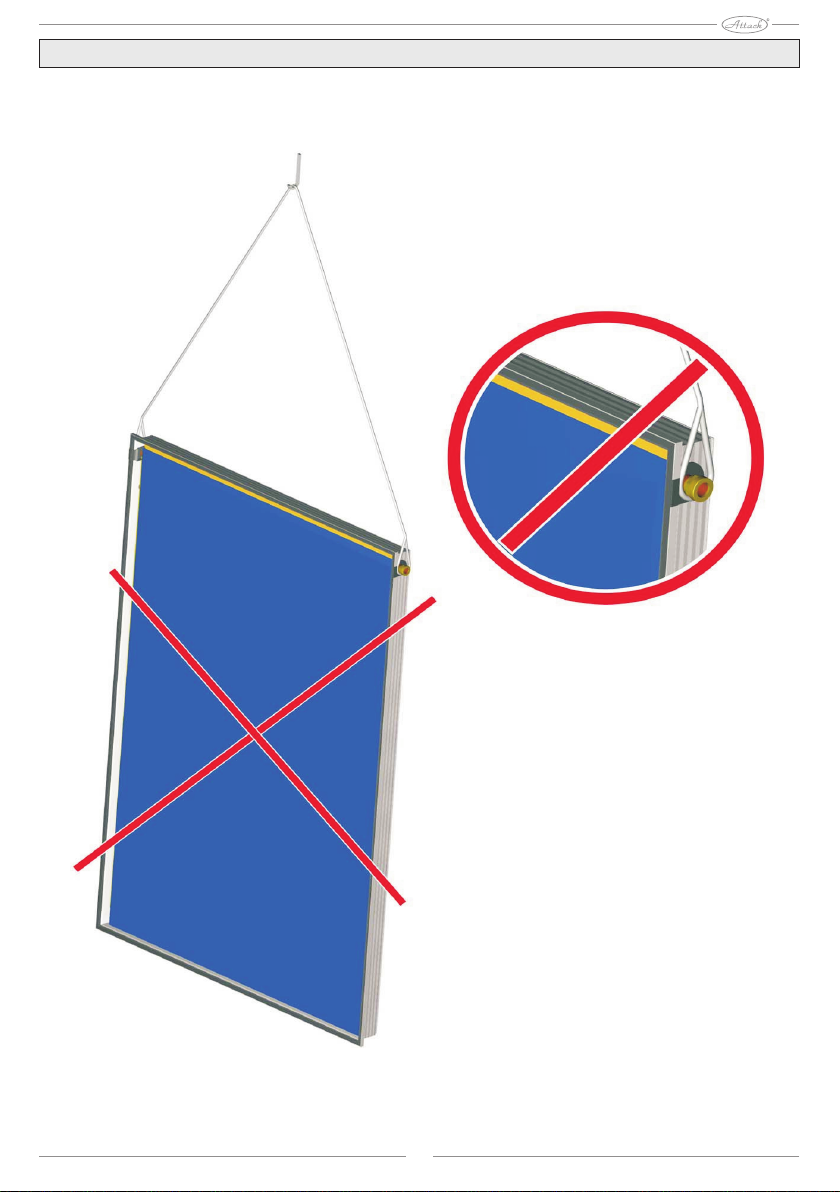

Shipping instructions

Do not lift the collector for the connector or a threaded screw connections!Attention:

5

Page 5

Installation instructions

General warnings and warnings of carriage

The mounting system is only suitable for roofs with tiled roofing. Installation can be performed only by specialized

personnel. All work in this guide apply only to such specialized personnel. When installing in principle be used the

supplied material. Before installation and operation of solar collectors with a view to inform the applicable local rules

and regulations. When transporting the collector is advised to use the conveyor belt. The collector may not be lifted for

a connection or threaded screw connections. Avoid shock and mechanical impact on the collector, especially for solar

glass, rear wall and pipe connections.

Statics – roof with tiled roofing

Installation may be done only on flat roofs or bearing constructures with sufficient capacity. Before mounting the

collectors should definitely check the static load capacity of the roof or bearing constructure, in each case the call

should be static, to examine local and regional features. In doing so, it is necessary to pay particular attention to the

quality (wood) of bearing constructure - strength bolting consolidating assembly plant collectors. Inspection of the

structures collectors at their place of installation according to DIN 1055, part 4 and 5 or under the law of the country is

necessary especially in areas with high snow precipitation (note: 1 m3 of snow dust ~ 60 kg / 1 m3 of wet snow ~ 200 kg)

or in areas with strong winds. It should be taken of all the specific location of installation of equipment (warm Alpine

wind, the effects of flow turbulence wind, etc.) that could result in an increased burden on the device. When selecting

the installation site must be ensured in order for not to exceed the maximum loads or forces acting due to wind or snow

precipitation. In principle, the collector arrays have to be installed so that if any snow accumulation in the catchment

grid (or accumulated due to the specific situation of the installation) can not reach the collector. Collectors may not be

installed on the roof edge (it should be observed marginal zone E/10 on flat roofs according to EN 1991, at least 1 m).

The upper edge of the collector shall not protrude above the roof.

Attention:

shingles and slate, especially furnished and habitable attic or roofs with insufficient slope (with respect to their

roofing) requires the implementation of construction protections (for example support construction) as a hedge

against the ingress of water due to wind pressure and drifting snow.

Installation of a solar collector field represents interference in the (existing) roof. Roofing such as tiles,

Protection against lightning / settlement potential building

In accordance with current standards for protection against lightning ÖVE / ÖNORM EN 62305 part 1-4, the collector

array may not connect the lightning conductor buildings. It is necessary to keep a safety distance min. 1 m from

possible neighboring conductive object. For mounting on a metal support structure is generally necessary to consult

with a qualified electrician. In order to realize the potential of settlement building by an authorized electrician must

connect metal pipe solar circuit as well as all caps or holders of collectors with the main rail for bonding in accordance

with standard ÖVE / ÖNORM E 8001-1 or standards applicable in the country.

Connections

Collectors must be interconnected, depending on their design screw connections (1 "IG / AG) or by connecting

pipe so that the surfaces of joints sealed. It is necessary to ensure the proper imposition of gaskets. If you are not

connecting elements as scheduled no flexible hoses, it must be ensured in order to have the connecting pipes take

appropriate steps to compensate for thermal expansion due to temperature fluctuations, for example.: Expansion bends

and flexible pipes (see link collectors / operational recommendations). For larger collector fields is necessary to insert

the expansion bends or flexible joints (Attention: need to check the sizing of the pump). When tightening the

connections necessary to follow from the other side (control) or other tick-key, to avoid damage to the absorber.

Inclination angle / general information

The collector is suitable for slope min. 15 ° max. 75 °. Connections collectors and ventilating / air vent openings should

be protected from water penetration and dirt and dust ingress, etc.

Warranty

The warranty arises only use the original means of frost protection from the supplier and properly carried out

installation, commissioning and maintenance. A precondition for entitlement to guarantee the installation of qualified

personnel, without exception, adherence to instructions in the manual.

6

Page 6

Tools Overview

Measuring tape

Hexagonal wrench

Ratchet with extension

Drill Allen handpiece

Angle Grinder

Hammer

7

Page 7

Material Overview

Roof Mount Roof mount bracket Screw 6*60

ClampSelf-locking hex nut M8Screw hinges M8*25

Clutch bearing profiles Mounting flange Mounting bracket

Wascher M8

8

Hexagon nut M8T Bolt M8x25

Page 8

Carrier rail

Mounting template

Gasket

9

Page 9

Recommended mounting points

Collectors

2

3

4

5

6

In areas with large snowfall or high wind areas, it is

necessary to schedule additional fasteners! (DIN 1055

follow eventually. Of force in the country).

Total length

239 cm

361 cm

482 cm

603 cm

724 cm

Mounting

points

6

8

10

12

14

10

Page 10

Parallel mounting brackets on the roof

General Warning: Points 8 - 11, 16 and 17 are needed only for installation of more than two collectors!

1 )

1: The vertical dimension of the collector -> A = 125 - 155 cm

2 )

2: Focus attachment points (see recommendation from previous

page), remove the slate / roofing

Generally: for one collector is needed one Fasteners.

3 )

3: Connect the roof mount bracket with umbrella holder, flatten

them and fasten with screws 6 * 60th

4 )

4: Place the slate / roofing, if necessary, adjust it.

11

Page 11

5 )

5: The roof mount insert screws with a flat head and tighten them

first hand only.

Order: screw with a flat head - roof mount - washer – nut

6: Install the lower bearing rail (6a, 6b)

Order: Bearing rail – screw with a flat head - roof mount - washer

- nut

6b )

6a )

7: Install the upper bearing rail (7a, 7b)

Order: Bearing rail – screw with a flat head - roof mount - washer

- nut

12

7a )

Page 12

Attention: The upper and lower bearing rail must fit together

perfectly straight and parallel!

8 )

8: Install additional mounting points under 1 – 4.

9: Push and pull terminal extension until the middle of the inner

matrix of the bearing rails (top and bottom).

Order: Bearing rail - terminal extension - washer – nut

7b )

9 )

10 )

10: Put another bearing rail (top and bottom) and attach it to an

extension terminal.

Order: Bearing rail - terminal extension - washer – nut

13

Page 13

11a )

12a )

11: Attach the bearing rails (top and bottom) with roof bars

or terminal extension.

Order: Bearing rail – screw with a flat head - roof mount

washer – nut

11b )

12: Hang the first collector to the lower bearing rail and

straighten it (12a + 12b!).

Warning:

The distance between the collector and the end of the

bearing rails = 45 mm. A dimension = dimension B!

12 b )

14

Page 14

13: Place the clamp on the upper bearing rail and tighten them

first hand only.

Order: Top bearing rail – screw with a flat head - washer - clamp

- washer – nut

14a )

14: Hang the second collector. (Dimension A = dimension B in

FIG. 12b). Please use the mounting template (14b).

13 )

14b )

15 )

15: Turn the clip 90 degrees and firmly tighten with a long socket

wrench.

15

Page 15

16 )

16: For each affecting bearing rails slide and place the mounting

part extending into the upper bearing rail.

17: Install additional terminal / other collectors, according to

point 12 – 16.

18 )

18: Replace the fixing unit to the left and right upper end of the

collector box.

Order: Bearing rail – screw with a flat head - fitting parts washer – nut

17 )

19: Connect the collectors with and torque.

19 )

16

Page 16

Specifications

Gross area

Net area

Surface hole

m2

m2

m2

2,02

1,84

1,91

Weight

Capacity

Maximum operating

pressure

kg

bar

31

l

1,4

10

1221

83

1170

70

117

1730

17

Page 17

Recommendations for service

Rinsing and performance

For security reasons, the device must perform when collectors are not exposed to sunlight, where it is

necessary to cover collectors. Especially in areas where there is danger of frost, facility has to be filled

with a mixture of water containing up to 40% of frost protection. To protect the materials from excessive

heat load device is to be filled and placed in service as soon as possible, but not after 4 weeks. If this is not

possible before putting into operation is necessary to replace gaskets to prevent leaks.

Attention:

water!

Recommended means of frost protection for flat plate collectors: TYFOCOR-L

40% of the means of frost protection (60% / water) - frost point of - 22 ° C / FREEZING POINT: - 26 ° C

50% of the means of frost protection (50% / water) - frost point of - 32 ° C / FREEZING POINT: - 44 ° C

It is possible that filled collectors can no longer be completely removed. For this reason the threat of frost

collectors may also be carried out in order to perform pressure and functional testing only a mixture of

water and frost protection. Alternatively, you can also do a pressure test using compressed air and spray

the leak search jobs.

Mounting the sensor

The temperature sensor should be mounted in the outlet collector box located next to the sensor housing.

In order to ensure optimal contact, the gap between the housing and a sensor with adequate heatconductive paste. When installing the sensor may be used only material with sufficient resistance to high

temperatures (250 ° C) (body sensor, contact paste, wire, sealants, insulation).

Operating pressure

Max operating pressure is 10 bar.

Ventilation

Equipment must be vented:

- when it is placed in service (after filling),

- 4 weeks after commissioning,

- if necessary, for example in case of disturbances.

Warning:

The ventilation valve handle only when the heat transfer fluid temperature < 60 °. In the discharge device

may be hot collectors! Cover Collectors and let out device preferably in the morning.

Pre-mixed composition frost protection is necessary before filling in device mixed with

Danger of scalding hot steam or heat transfer fluid!

Control of heat transfer fluid

Every two years, it is necessary to check the frost protection and heat transfer medium pH.

- Frost protection, check with measuring means frost protection and if necessary replace or add the means.

Required value of protection is approx. - 25 ° C to - 30 ° C or by weather conditions.

- Check the pH with indicator sticks pH (nominal value is approx. PH 7.5):

In case of fall below a threshold pH L 7 replace heat transfer medium.

Maintenance collector

Collector or collector array must be visually inspected every year - if they are not damaged, the seal,

pollution, etc. Other recommendations for operation and maintenance can be found in the general

instructions for commissioning and maintenance / rules from the supplier.

18

Page 18

Link collector

A possible link can be seen in the attached sketch. Based on the structural characteristics of the

situation, however, may be different in practice. If the collector field consists of more than 6

collectors (vertically aligned) or 4 collectors (arranged horizontally) in the series, it is necessary to

plan appropriate measures to compensate for thermal expansion due to temperature fluctuations

(expansion bends or flexible pipe) or a field to be multiple times in parallel run.

Output

Reverse

Flow rate

In order to achieve good performance collector, should be the size of the field around the collector about

25 m² to choose a specific flow rate 30 l / m² h.

Pipe cross-section

Table sizing, specific flow rate 30 l / m2 h

The size of the collector field

Diameter pipe / copper

Diameter pipe / corrugated

stainless steel pipes

pribl. 5

10 - 12

DN16

pribl. 7,5

15

pribl. 12,5

18

pribl. 25

22

DN20

The pressure loss in one collector in the case of a mixture of antifreeze agent / water (40% / 60%)

where the heat transfer fluid temperature 50 ° C.

Pressure loss curve: p = 0,0000106x² + 0,0137580x

Flow rate

Pressure loss

0

50

0,70

100 150

1,5

200 250

2,3 3,2

19

300 350

4,1 5,1

400 450

6,1 7,2

500

8,3 9,5

Page 19

Warranty

For cases using the device for the purpose for which it is not intended or alterations assembly components

and the consequences resulting from such proceedings are not covered by warranty. All information and

instructions in this guide apply to the current state of development. Please always use the appropriate

assembly instructions supplied with collectors. Photographs of symbols are used as pictograms. They are

based on the potential rate of error in a press, but also due to the need of constant technological changes,

please understand, that we can not assume any liability for the accuracy of the content of the document.

We refer you to the validity of the General Conditions in their amended version. This installation manual

contains its own information, subject to copyright protection. All rights and changes in this assembly

manual are reserved.

20

Page 20

ATTACK, s.r.o.

Dielenská Kružná 5020

038 61 Vrútky

Slovak republic

Výrobc a ATTACK, s.r.o. si vyhradzuj e práv o tech nických zmien v ýrobkov bez p redchádzajú ceho

upozorn enia. • ATTACK, s.r.o. producer rese rves the right to change technical parame ters and dimensions

of boiler s without previous wa rning. •Der Herstell er ATTACK, s.r.o. be hält sich das Recht der techni schen

Veräderu ngen an Produkten ohne eine vorige Warnung. • И зготовител ь AT TACK, s.r.o. остав ляет за с обой

право измене ния технических парам етров и размер ов котла без предыд ующего предупре ждения.

• Le pro ducteur ATTACK, s .r.o. réserv e le droit d es modifica tions techn iques sans l ‘avertissemen t

précéd ent. • Pr oductor AT TACK, s.r.o. reser va el derecho d e cambios técnicos sin adver tencia ante rior.

Tel: +421 43 4003 103

Fax: +421 43 3241 116

E-mail: export@attack.sk

Web: www.attack.sk

ATTACK, s.r.o. – 06/ 2015

Loading...

Loading...