Page 1

W W W . A T T A C K . S K

THE WOOD GASIFYING BOILER

ATTACK® SLX

PROFI / LAMBDA TOUCH

INSTRUCTIONS FOR USE

Page 2

Page 3

3

CONTENT

1INTRODUCTION ................................................................................................................................................... 5

1.1GENERAL DESCRIPTION ............................................................................................................................ 5

1.2DESCRIPTION OF MARKINGS OF THE ATTACK SLX BOILERS ........................................................ 6

1.3SAFETY ............................................................................................................................................................ 6

1.4IMPORTANT INFORMATION .................................................................................................................... 6

1.5TECHNICAL DESCRIPTION ........................................................................................................................ 7

1.6FUEL ................................................................................................................................................................. 8

1.6.1WOOD .................................................................................................................................................... 8

1.6.2ALTERNATIVE FUELS.......................................................................................................................... 8

2TECHNICAL PARAMETERS OF ATTACK SLX BOILERS ............................................................................... 9

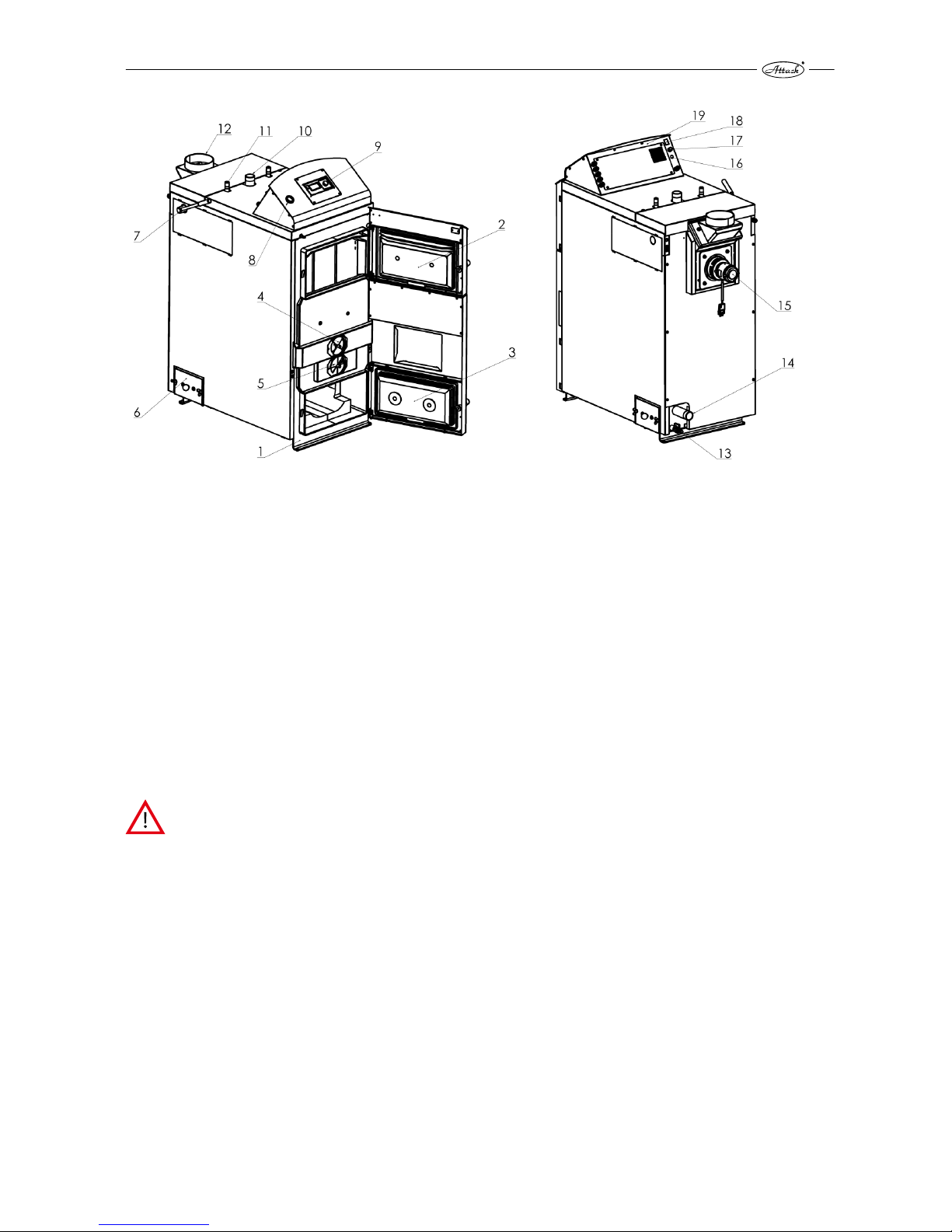

3DIMENSIONS AND MAIN PARTS OF THE ATTACK® SLX BOILERS ................................................................ 10

4PURPOSE OF USE ............................................................................................................................................. 11

5ASSEMBLY AND INSTALLATION OF THE BOILER ................................................................................... 12

5.1MANIPULATION WITH BOILER ............................................................................................................. 12

5.2GENERAL CONDITIONS OF INSTALLATION ..................................................................................... 12

5.3BOILER PLACING ....................................................................................................................................... 12

5.4CONNECTION OF THE BOILER TO THE HEATING SYSTEM .......................................................... 14

5.4.1USE OF ANTIFREEZE MIXTURE .................................................................................................... 14

5.4.2PROTECTION AGAINST CORROSION ......................................................................................... 14

5.4.3OUTFALL OF THE FLUE OUT OF THE BOILER .......................................................................... 15

5.4.4CONNECTION OF THE BOILER TO THE CHIMNEY.................................................................. 15

5.4.5CONNECTION TO THE ELECTRICITY MAINS ............................................................................ 16

5.4.6OPTION AND THE WAY OF CONNECTION OF THE CONTROL AND SAFETY ELEMENTS ......... 16

5.4.7PROTECTION OF THE BOILER AGAINST OVERHEATING ...................................................... 17

5.4.8CONNECTION TO THE ACCUMULATION TANKS ................................................................... 18

5.4.9SCHEMES OF BOILER CONNECTION TO THE ACCUMULATION TANKS ......................... 19

5.4.10STANDARDLY DELIVERED ACCUMULATION TANKS ATTACK* ......................................... 22

5.5BINDING NORMS FOR DESIGNING AND ASSEMBLY OF THE BOILERS .................................... 23

6BOILER OPERATION ......................................................................................................................................... 24

6.1OPERATING PRESCRIPTIONS ................................................................................................................ 24

6.2HEATING UP, OPERATION AND FUEL REFILLING ........................................................................... 25

6.2.1PROTECTIVE TOOLS FOR WORK WITH THE BOILER .............................................................. 30

6.3CONTROL OF THE ATTACK SLX PROFI BOILER ............................................................................... 30

6.3.1ADVANTAGES OF REGULATOR ................................................................................................... 30

6.3.2BASIC DESCRIPTION OF THE REGULATOR .............................................................................. 31

6.3.3CONNECTION OF THE PROFI PID REGULATOR BY HYDRAULIC SCHEMES ................... 32

6.3.4REGULATOR CONTROL AND OPERATING MODES ............................................................... 37

6.3.5SETTING THE USER PARAMETERS .............................................................................................. 37

6.3.6SETTING THE SERVICE PARAMETERS ........................................................................................ 39

6.3.7DESCRIPTION OF PARAMETERS .................................................................................................. 40

6.3.8ERROR MESSAGES ........................................................................................................................... 43

6.3.9DISASSEMBLY OF THE REGULATOR .......................................................................................... 44

6.3.10TECHNICAL SPECIFICATION OF THE REGULATOR ................................................................ 44

6.3.11SETTING THE AIR FLAPS AND FLUE GAS TEMPERATURE ................................................... 44

6.4ATTACK SLX LAMBDA TOUCH BOILER CONTROL ......................................................................... 46

6.4.1BASIC CONTROL ELEMENTS ........................................................................................................ 46

6.4.2THE REGULATOR WAY OF WORK: .............................................................................................. 47

6.4.3DESCRIPTION OF MAIN CONTROL MODES: ............................................................................ 48

6.4.4STARTING UP THE REGULATOR .................................................................................................. 50

6.5DISPLAYING THE INFORMATION ........................................................................................................ 53

6.5.1SETTING THE PARAMETERS.......................................................................................................... 54

Page 4

4

6.5.2LEVEL OF SETTING THE BASIC PARAMETERS ......................................................................... 55

6.5.3LEVEL OF SETTING THE ADVANCED PARAMETERS .............................................................. 56

6.5.4SPECIFIC SETTINGS ......................................................................................................................... 60

6.5.5CONNECTION TO THE INTERNET ................................................................................................ 61

6.5.6SOFTWARE UPDATE ....................................................................................................................... 62

6.5.7FACTORY SETTINGS AND RESET ................................................................................................. 62

7RISK ANALYSIS .................................................................................................................................................. 63

8BOILER MAINTENANCE .................................................................................................................................. 65

8.1BOILER CLEANING .................................................................................................................................... 66

8.2INSTALLATION AND REPLACING OF FIREPROOF PARTS ............................................................. 67

9TRANSPORT, MANIPULATION AND STORING ......................................................................................... 68

9.1INSTRUCTIONS TO PRODUCT DISPOSAL AFTER TERMINATION OF ITS LIFE-TIME ............. 68

9.2WRAPPING DISPOSAL ............................................................................................................................. 68

9.3ACCESSORIES ............................................................................................................................................ 69

10POSSIBLE FAILURES AND THE WAY OF ITS REMOVAL ......................................................................... 69

11CHARACTERISTIC OF TEMPERATURE SENSORS ..................................................................................... 70

12ELECTRICAL SCHEMES .................................................................................................................................... 71

12.1ATTACK SLX PROFI .................................................................................................................................. 71

12.2ATTACK SLX LAMBDA TOUCH ............................................................................................................. 72

NOTES ............................................................................................................................................................................ 73

Page 5

5

1 INTRODUCTION

Dear customer,

thank you for your trust and purchase of our product – wood gasifying boiler ATTACK SLX. We wish it

serves you reliably for a long time. The reliable and correct function of device is related to its operation and therefore it is necessary to read this user manual. The manual is written with respect to the

correct function of the boiler.

The correct function of the boiler particularly depends on the following:

choice of the correct boiler output and type

perfect commissioning

correct operation

regular professional maintenance

reliable service

1.1 GENERAL DESCRIPTION

Name: Wood gasifying boiler ATTACK SLX 20, 25, 30, 35, 40, 45, 50, 55

In version „PROFI“, „LAMBDA Touch“

Type: ATTACK SLX 20, 25, 30, 35, 40, 45, 50, 55

Max. operation pressure: 250 kPa

Electr. power supply: 230 V/50 Hz/10 A

Elektr. input: 20, 25, 30, 35 SLX – 42 W

40, 45, 50, 55 SLX – 78 W

Fuel: Dry wood with calorific value 15 up to 17 MJ/kg, moisture 12 up to

20 %, diameter 80 up to 150 mm

Nominal output: 20, 25, 30, 35, 40, 45, 50, 55 kW

Gasifying boiler ATTACK SLX is intended for economical and ecological heating of the family

houses, cottages, small plants, workshops and similar objects.

Prescribed fuel for ATTACK SLX is dry wood logs or chopped pieces with length according to the

type of the boiler.

Water temperature in cooling circuit has to be 8–12 °C. Water pressure is fixed: 0,25 MPa min.

and 0,6 MPa max.

ATTACK SLX boilers work in non-condensation operation. Behind the chimney connection work

in overpressure operation.

Level of the acoustic pressure A does not exceed 70 dB (A).

Immediate peak value of the acoustic pressure C does not exceed 63 Pa.

Producer ATTACK, s.r.o. reserves the right of technical changes of products without previous notification.

Page 6

6

1.2 DESCRIPTION OF MARKINGS OF THE ATTACK SLX BOILERS

ATTACK SLX 20

Profi

25

LAMBDA

Touch

30

35

40

45

50

55

Wood gasifying boiler

Boiler output

Version type

1.3 SAFETY

In this manual are used following warning symbols for ilustration of the danger importance and

important safety notifications:

CAUTION!: Immediate danger situation and it could lead to the serious health or property damage if the right steps are not taken. Take the action according to the instruc-

tions!

WARNING: Dangerous situation might occur. It could lead to the serious health or property damage if the right steps are not taken. Work with extreme caution!

NOTICE: Dangerous situation might occur. It could lead to the serious health or property

damage if the right steps are not taken.

1.4 IMPORTANT INFORMATION

Boiler is delivered with documents and components in the feeding chamber, because of that,

please ensure before first heat up, that the feeding chamber is empty.

Assembly, checking heat up and training of the operation is performed by the assembly

technician who is trained by the producer and s(he) also fill protocol about the boiler installation.

During the gasification, tar and condensates (acids) are created in the fuel tray. That is why

the mixing device has to be installed behind the boiler, to ensure the minimum temperature

of the backflow water to the boiler 65 °C. Operation temperature of the water in the boiler

has to be in range of 80–90 °C.

Boiler must not be operated constantly in the output range lower than 50 %.

Ecological operation of the boiler is by the nominal output.

That is why we recommend to install the boiler with accumulation tanks and mixing device,

what ensures 20–30 % fuel saving and longer lifetime of the boiler and chimney with more

comfortable operation.

Page 7

7

We recommend to connect the boiler with accumulation tank with minimum volume of 70 l

to 1 kW boiler output.

Use only dry fuel with 12–20 % moisture (with higher fuel moisture is decreased boiler out-

put and increases its consumption)

Right choice of the boiler size, i.e. its heat output, is very important condition for economical

operation and correct function of the boiler. Boiler has to be chosen according to its nominal

output, which must meet the heat losses of the heated object.

WARNING: Boiler might be used only for intended purpose and only in the way described in this manual.

CAUTION!: After the boiler disconnection from electricity mains during the operation,

burning continues in the sustain mode. Do not open the boiler door until the tempera-

ture drops below 40 °C.

The boiler warranty is not valid, if:

Is not operated with prescribed fuel

In the system is not installed the mixing device ATTACK – OVENTROP, which ensures the

backflow water temperature to the boiler at least 65 °C during the operation

Functional thermostatic valve wont be installed at the aftercooling circuit of the boiler (e.g.

WATTS STS20) and then connected to the source of the cooling water.

Boiler is not installed according to the requirements stated in this manual, e.g. correct di-

mensions of the chimney etc.

Is not sufficiently cleaned according to the instructions given in this manual

This appliance is not intended for use by persons (including children) with physical, sensual or

mental disability or insufficient experience due to which they are not able to use the device in a

safe way without being supervised or instructed about the boiler operation by the person responsible for their safety. Do not to allow children to play with this appliance.

If the power supply cable is damaged, it must be replaced with the correct type of

the cable, which is available by producer or by a service technician!

Be careful during the work with this appliance! Lambda probe works by high temperatures (300 °C) and you might get burned during careless manipulation!

1.5 TECHNICAL DESCRIPTION

Boiler is constructed for wood combustion, based on the gasifying with use of exhaust fan,

which makes forced flow in the boiler and sucks the flue gas out of the boiler. Boiler body is

made as the weld from steel plates of 6 mm thickness. In the upper part of the boiler is feeding

chamber with above-standard volume, equipped with dry sheath technology, which lowers the

condensate creation and prolong lifetime of the boiler. In the bottom part of the feeding chamber is fireproof nozzle with longitudinal hole for crossing the wood gas to the combustion

chamber. Secondary air is brought by the nozzle and after mixing with wood gas creates burning in the combustion chamber. Combustion chamber is also the ashtray, where are collected

wastes after combustion (ash). In the rear part of the boiler body is tubular exchanger equipped

with turbulators, which serves for cleaning the exchanger and increasing the boiler efficiency.

Turbulators might be controlled manually or automatically (using engine) according to the

boiler version PROFI or LAMBDA Touch. In the upper part of the boiler is situated boiler regulation, which controls the wood gasification process and offers all important information about

Page 8

8

the boiler operation. Flue gas suction by the feeding is solved by the exhaust canal in the upper

part of the combustion chamber and leads directly to the chimney – go around the exchanger.

Boiler is designed for long period of combustion (4 up to 8 hrs, depending on the output) and

that is why it needs to be equipped with accumulation tank.

1.6 FUEL

1.6.1 WOOD

In the ATTACK SLX boiler is possible to use soft and hard chopped fuelwood with calorific value

in range of 15 to 17 MJ/kg. Ideal are especially beech, oak, fir, spruce, pine, popolar tree, alder,

willow, birch, ash tree, hornbeam, locust tree, always with moisture in range of 12 up to 20 %.

Suitable diameter of logs is in range of 80 up to 150 mm. Maximal lenght of the logs must not

exceed 680 mm for 20, 25, 30, 35 SLX boilers and 780 mm for 40, 45, 50, 55 SLX boilers to prevent

wood jam in the feeding chamber.

Calorific value of particular types of wood:

Units

Wood Kcal/kg

MJ/kg

kWh/kg

Spruce 3 900 16,25 4,5

Pine 3 800 15,80 4,4

Birch 3 750 15,50 4,3

Oak 3 600 15,10 4,2

Beech 3 450 14,40 4,0

WARNING: Unsuitable moisture or size of the wood might cause lowering or increasing

the output, low or high temperature of the flue gas, excessive condensation, flame loss

of the gasifying process or uncontrollable combustion.

Recommended wood storing and drying:

Hard wood: stored in dry environment for 2 years

Soft wood: stored in dry environment for 1 year

Wood must be secured against rain during storage (drying). You can help to the wood drying

effectiveness by storing the wood with as large as possible spaces between each piece of wood

to let the air flow between them. It is good to store the wood in the environment with air

draught, what ensures faster drying. If possible, store the wood at least 1 day in the warm place

(e.g. boiler room – wood will be preheated and it will lead to the combustion effectiveness) before feeding in the boiler.

1.6.2 ALTERNATIVE FUELS

It is possible to use also wood briquettes with hole, pressed from wood sawdusts without any

additional connective materials. It is necessary to mix wood briquettes with wood in particular

ratio (ratio depends on the size and shape of the briquettes), to prevent clogging of the nozzle

for wood gasifying.

WARNING: Fuels, which are not allowed increase demands on cleaning and lead to the

accumulation of aggressive sedimentation and condensation. In the end, it might lead to

lowered functionality, boiler damage and invalid warranty. Use of unallowed fuels might

lead to incorrect and uncontrollable combustion.

Page 9

9

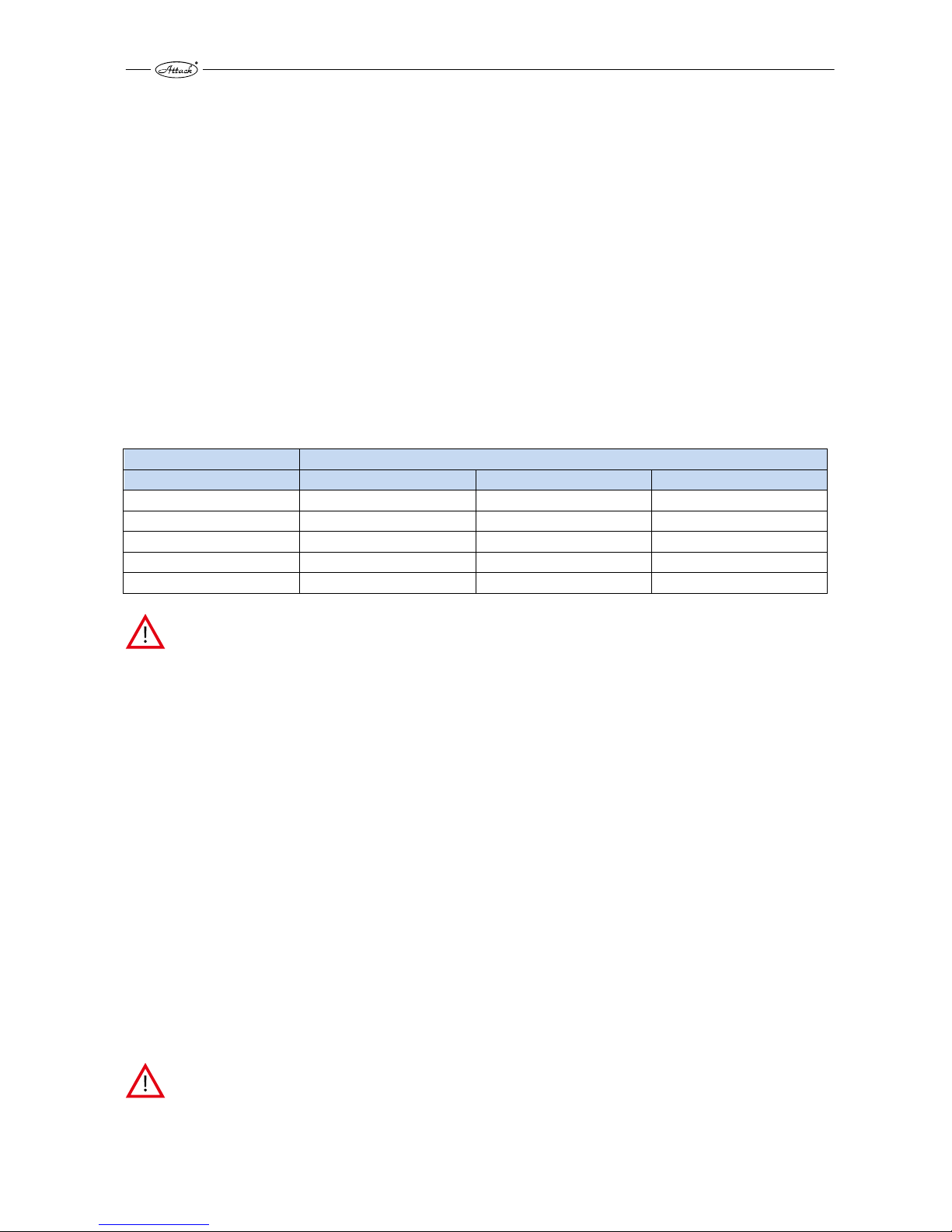

2 TECHNICAL PARAMETERS OF ATTACK SLX BOILERS

Parameter / Boiler type SLX20 SLX25 SLX30 SLX35 SLX40 SLX45 SLX50 SLX55

Nominal output of the boiler kW 20 25 30 35 40 45 50 55

Output range kW 10–20 12,5

–

25

15–30 17,5–35 20–40 22,5–45 25–50 27,5–55

Area of the exchanger m² 2,95 3,32

Volume of the feeding chamber dm³ 200 230

Dimensions of the feeding hole mm 235 × 445

Prescribed chimney draught Pa 23

Prescribed chimney draught mbar 0,23

Max. working overpressure of the water kPa 250

Pressure loss of the water (ΔT 10K) kPa 1,9 2,1 2,4 2,7 3,9 4,5 5,2 6,1

Pressure loss of the water (ΔT 20K) kPa 0,8 0,9 1,2 1,6 1,9 2,1 2,4 3,2

Weight of the boiler kg 570 650

Diameter of the flue gas outlet mm 150

Height of the boiler mm 1 472

Width of the boiler mm 703

Depth of the boiler mm

1 337

1 506

Depth of the feeding chamber mm 690 790

Diameter of the riser pipe "E" "

G 6/4"

G 2"

Diameter of the reverse "F" "

G 6/4"

G 2"

Protection class IP 21

Electrical input at the nominal output W 42 42 42 42 78 78 78 78

Electrical input at the minimal output W 31 31 31 31 52 52 52 52

Electrical input at the standby mode W < 15 < 15 < 15 < 15 < 15 < 15 < 15 < 15

Boiler efficiency % 91,8 91,6 90,3 90,4 90,3

Boiler class — 5

Temperature of the flue gas by the nominal

output

°C 165 170 175 180 165 170 170 180

Temperature of the flue gas by the minimal

output

°C 130 135 140 145 135 140 140 145

Mass flow of the flue gas by the nominal

output

kg/s 0,018 0,02 0,021 0,023 0,027 0,029 0,031 0,033

Mass flow of the flue gas by the minimal

output

kg/s 0,008 0,011 0,014 0,016 0,017 0,021 0,022 0,023

Max. noise level dB 65

Class and type of the fuel — A, Wood pieces with relative moisture of 12 % – max. 20 %, Ø 50–150 mm

Average wood consumption kg/h 5,2 6,5 7,8 9,1 10,4 11,7 13 14,3

Indicative consumption of the wood per

season

— 1 kW = 1 m

3

Max. length of logs mm 650 750

Time of burning by nominal output * h 8 7,2 6,5 5,8 6 5,1 4,6 4

Volume of the water in the boiler l 117 136

Recommended volume of the accumulation

tank

l 1500 2000 2200 2500 3 000 3 200 3 500 4 000

Voltage V/Hz ~230/50

Range of the setting the temperature of the

heating water

°C 65 ÷ 85

Capacity of the contacts of the boiler regulator (PROFI version)

— 2 A/~230 V

*depending on the type of fuel and perfection of the feeding the chamber with wood

Producer ATTACK, s.r.o. reserves the right of technical changes of products without previous notification.

Page 10

10

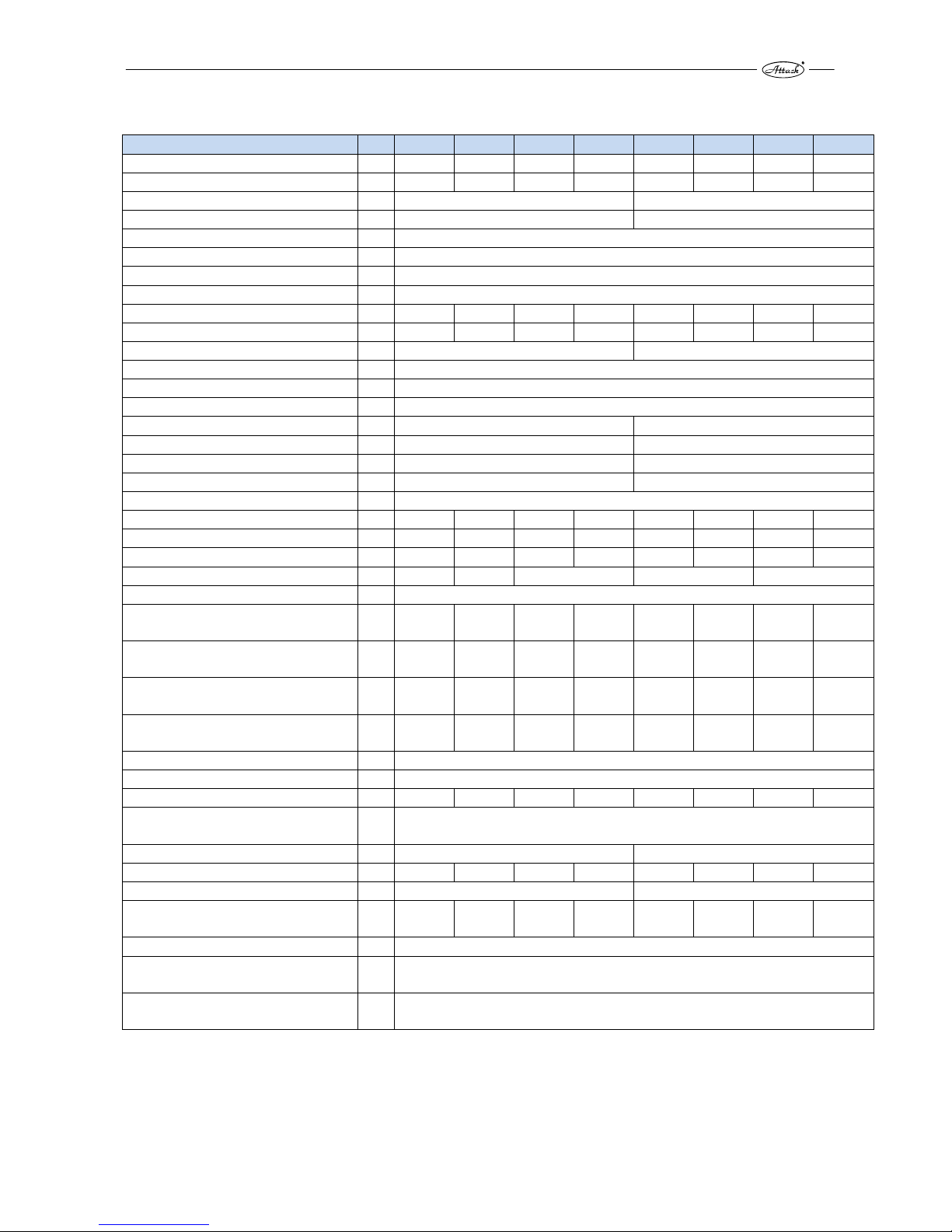

3 DIMENSIONS AND MAIN PARTS OF THE ATTACK® SLX BOILERS

Dimensions of the boilers with output of 20–35 SLX:

Dimensions of the boilers with output of 40–55 SLX:

SLX20 SLX25 SLX30 SLX35 SLX40 SLX45 SLX50 SLX55

Riser pipe – „E“ G 6/4" G 6/4" G 6/4" G 6/4" G2" G2" G2" G2"

Reverse – „F“ G 6/4" G 6/4" G 6/4" G 6/4" G2" G2" G2" G2"

Page 11

11

CAPTION:

1. Body of the boiler 6. Cleaning covering 11. Aftercooling circuit 16. Lambda fuse

2. Door of the feeding chamber 7. Lever of turbulators 12. Rotary chimney 17. Emergency thermostat

3. Door of the combustion chamber 8. Manometer 13. Release valve 18. Main switch Lambda

4. Primary air 9. Regulator of the boiler 14. Reverse 19. Control case

5. Secondary air 10. Riser pipe 15. Fan

4 PURPOSE OF USE

Ecological warm water boiler Attack SLX is intended for heating family houses and other similar

objects. Boiler is constructed for combusting wood pieces. It is possible to use any dry wood,

especially wood logs for combustion. Boiler is not intended for combustion of the sawdusts and

small wood wastes. It is possible to combust it only in small quantity (max. 10 %) together with

wood pieces. Massive fuel feeder replaces and removes hardest operation during the wood

preparation and its chopping to smaller pieces.

Placing boilers in dwelling premises (including corridors) is inpermissible!

Page 12

12

5 ASSEMBLY AND INSTALLATION OF THE BOILER

5.1 MANIPULATION WITH BOILER

Boiler is delivered on the pallet. Perform manipulation

with boiler only at the pallet. Put down the boiler form

the pallet immediately at the place of installation. It is

possible to perform this by use of manipulation cart or

by crane and handles, which are welded at the exchanger of the boiler.

Figure 1 Manipulation with boiler with use of the

welded handles

5.2 GENERAL CONDITIONS OF INSTALLATION

Only a person with valid authorization for installation and assembly of the heating technology

devices can install the boiler. The installation requires an appropriate project that is in line with

valid prescriptions. Technician must check the boiler before installing, if data given on the production label are in conformity with data in the project and the documentation attached to the

boiler. The boiler connection must be in line with the valid prescriptions, norms, regulations and

this instruction manual.

WARNING: Producer takes no responsibility for damages caused by wrong connection

or operation!

5.3 BOILER PLACING

Boiler serves for installation and operation in the space with the basic environment (AA5/AB5)

according to STN 33 2000-3.

Boiler room must meet the following requirements:

Boiler is not suitable for use in the potentially explosive environment.

The temperature in the boiler room must not drop below the freezing point.

Boiler does not provide any lighting. Customer must ensure sufficient light source according

to the local norms and regulations.

It is necessary to consult the installation with the producer, if the boiler will be installed at

height above sea level exceeding 1 800 m.

Boiler room must have sufficient ventilation and inlet of the required burning air (minimally

10 cm

2

/kW of the boiler output). Hole for the ventilation should be designed to not let the

outside weather influence its function. (rain, snow, wind)

Page 13

13

During the installation of the boiler must be ensured a safe distance of its surface from the

flammable materials depending on their flammability level:

Materials of flammability level B, C1 a C2 200 mm

Materials of flammability level C3 400 mm

Level of flammability was not proved according to STN 73 0853 400 mm

Examples of building materials division according to the level of flammability:

Level of flammability A not flammable (bricks, breez blocks, ceramic tile, mortar, plaster)

Level of flammability B partly flammable (heraclit, lignos, board made out of basaltic felt, novodur)

Level of flammability C1 hard flammable (broadleaf wood (beech, oak), plywood, werzali, hardened

paper)

Level of flammability C2 intermediate flammable (coniferous wood (pine, spruce), chipboard, so-

lodur)

Level of flammability C3 easily flammable (wood-fibre, polyurethan, PVC, soft foam, polystyrene)

The sealing board or protection covering (on the protected object) must exceed the boiler edge

at least for 300 mm. Also other items from flammable materials must be protected in this way, if

they are placed near the boiler and it is not possible to keep the safe distance.

If the boiler stands on the flammable surface, it must be protected by an inflammable, heat insulating mat, which exceeds the ground plan on the side of the feeding door and ash tray door for

at least 100 mm. All materials of the flammability level A might be used as an inflammable, heat

insulating mat.

Boiler must be placed in a such way, ensuring sufficient space of at least 1 m from the front and

0,5 m from the left (right) and rear side. It is necessary to leave the space of at least 1 m above

the boiler.

This space is necessary for basic operation, maintenance and eventual service of the boiler. It is

not allowed to place the boiler in dwelling premises (including corridors).

WARNING: Items from flammable materials must not be laid on the boiler and in the

distance shorter than the permitted (safe) one. The boiler must be put out of operation,

if there is a danger of fire or explosion during the work (e.g. work with painting materials, glues, etc.).

Page 14

14

5.4 CONNECTION OF THE BOILER TO THE HEATING SYSTEM

Boiler ATTACK® SLX has to be installed in the system, which meets the requirements of the heating water quality as follows:

Country Number of standards Country Number of standards

Slovak republic STN 07 7401:1991 Switzerland SWKI 97-1

Austria ONORM H5195-1 Italy D.P.R. no. 412

Germany VDI 2035

For filling or refilling the water in the system might be used only water which is adapted for values according to STN 07 7401: 1992. Water has to be clear, colourless, without any suspended

substances, oils and chemical agressive additives and cannot be acidic (pH has to be higher than

7,2). Water hardness cannot exceed 1 mmol/l and concentration of Ca²Ѐ 0,3 mmol/l.

NOTICE: The warranty of the boiler is not valid in case of infringement of these conditions!

5.4.1 USE OF ANTIFREEZE MIXTURE

It is not recommended to use antifreeze mixture with not suitable quality for the boiler operation. It is related especially to lowering the heat penetration, big volume expandability, aging,

rubber parts damage. If necessary, use the Alycol Termo (manufacturer Slovnaft Bratislava) antifreezing mixture – according to experiences of producer, there is no risk of lowering the safety of

use and noticeable influencing of the boiler work. If this type of protection against freezing is not

achievable in particular conditions, parameters are not fulfiled or there are some boiler failures

caused by use of other antifreezing mixtures, there is no possibility of warranty.

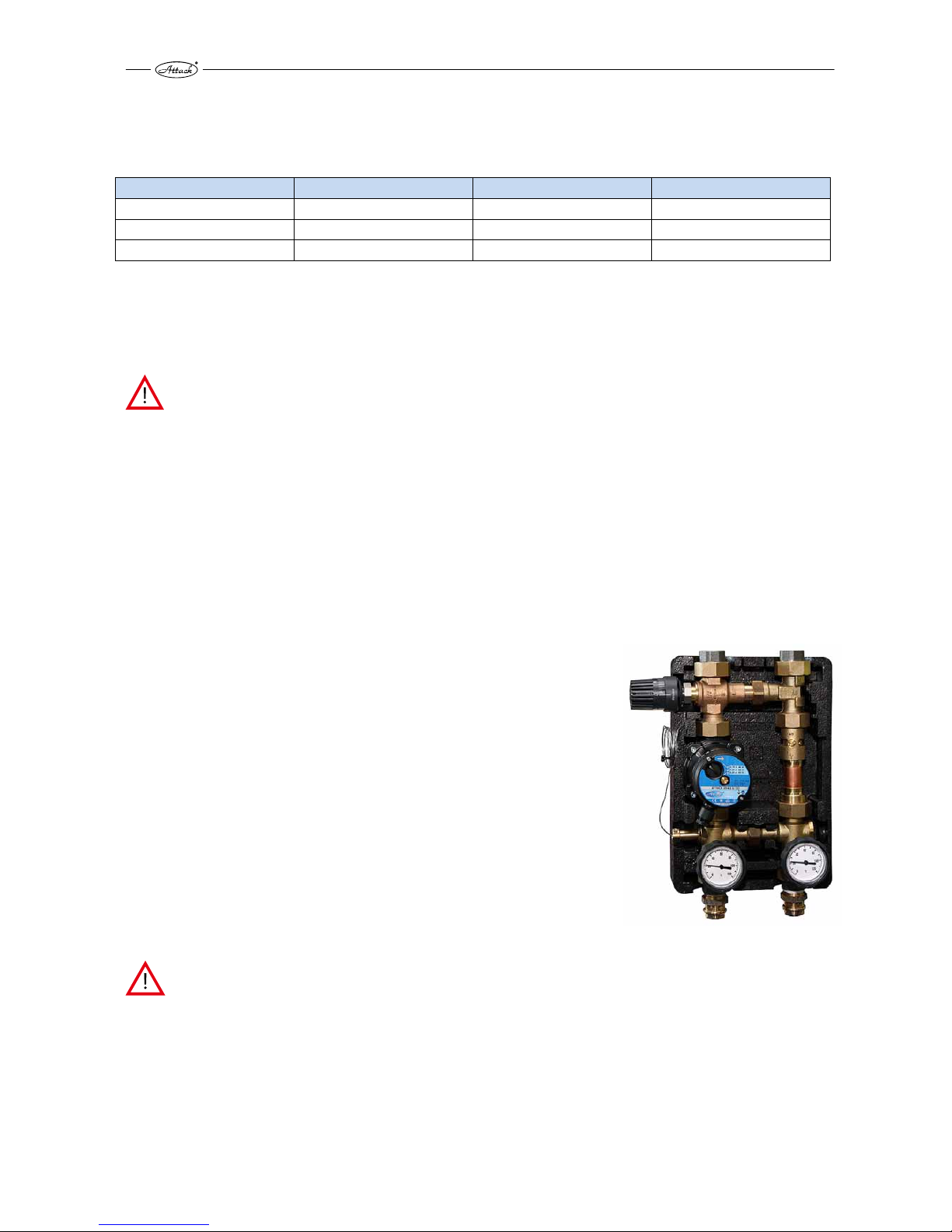

5.4.2 PROTECTION AGAINST CORROSION

Boiler must be connected with device for controlling the temperature of the boiler reverse. Suitable solution is use of mixing device

ATTACK-OVENTROP (Figure 2), which makes the temperature rise

of the return connection to acceptable level. In this way is boiler

protected against supercooling below 65 °C and creation of the

water steams, acids and tars in the feeding chamber is lowered.

Mixing device ATTACK-OVENTROP allows to set temperature of

return-water in range of ca. 50–70 °C thanks to the thermostatic

head.

Figure 2 Device for protection of the reverse temperature AT-

TACK OVENTROP

NOTICE: If the device against corrosion is not installed in the system or this device does

not work properly, there is a possibility of creation of agressive condensate, which might

lead to the boiler damage. Protection against condensation must be in use during the

boiler operation, otherwise is warranty provided by producer not valid!

Use of the size of ATTACK OVENTROP devices depending on the boiler output:

ATTACK OVENTROP DN25: SLX 20–35 kW

ATTACK OVENTROP DN32: SLX 40–55 kW

Page 15

15

5.4.3 OUTFALL OF THE FLUE OUT OF THE BOILER

Flue has to have outfall to the chimney hole. If it is not possible to connect the boiler to the

chimney hole directly, then the appropriate extension should be as short as possible, of up to 1

m length, without any additional heating area and it must ascend to the chimney. It is good to

insulate the flue, to achieve sufficient flue gas temperature and prevent the chimney condensation. Flues must be mechanically firm (it is recommended to attach the flue to the boiler and bolt

them together) and tight against the flue leakage and cleanable inside. Flues must not lead

through the somebody else's dwelling or commercial premises. The internal diameter of the flue

must not taper in direction to the chimney. It is not eligible to use the elbow connectors. There

must be an „T-shaped“ connection between flue and chimney to let the condensate flow down

to the intended container and not in the boiler.

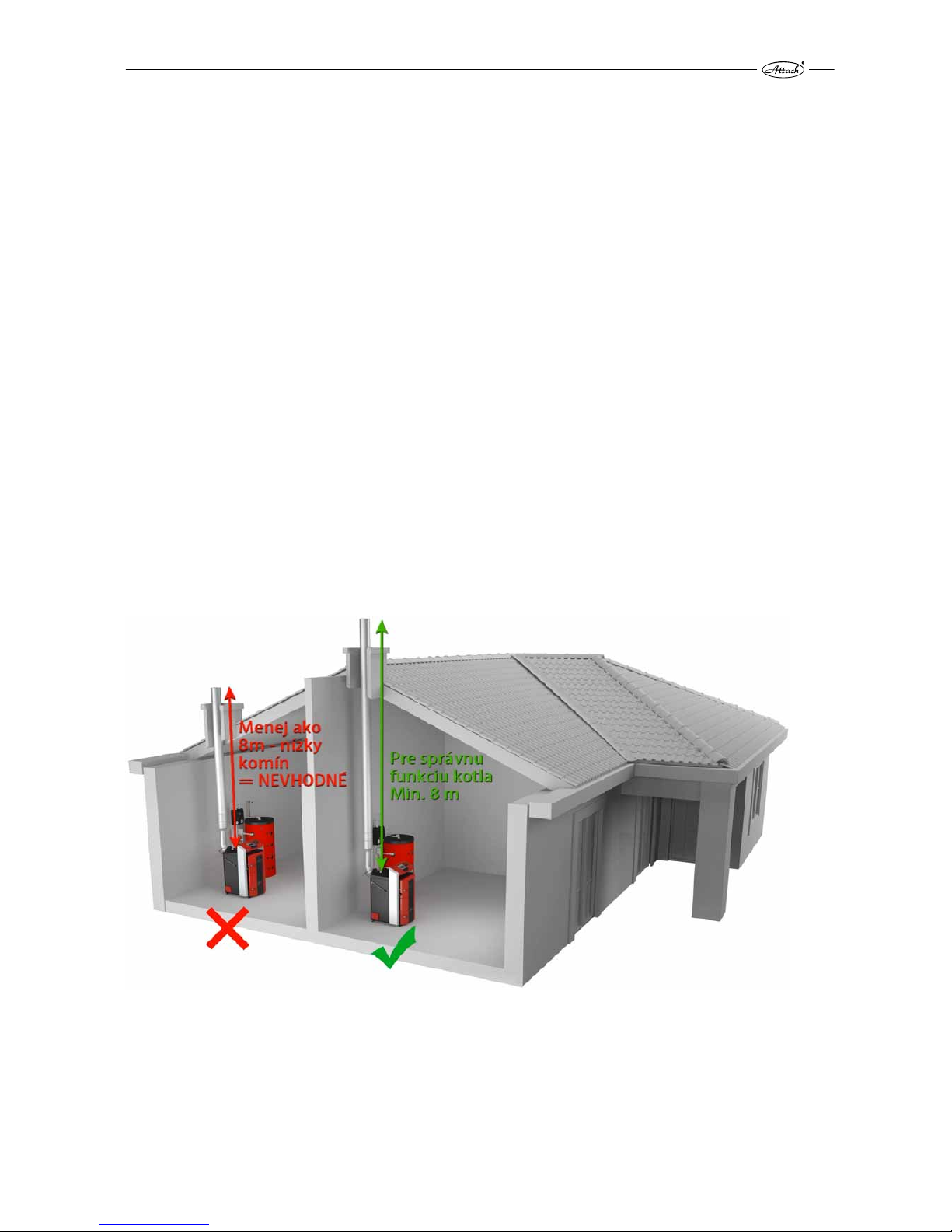

5.4.4 CONNECTION OF THE BOILER TO THE CHIMNEY

Connection of the appliance to the chimney hole must be always done with permission of the

appropriate chimney sweep association. The chimney hole must always generate sufficient

draught and take the flue gas out into the atmosphere under the all operating conditions.

Correct dimensions of the chimney hole are important for correct boiler function, because burning, output and boiler life-time are influenced by the draught. The chimney draught directly depends on its diameter, height and roughness of the internal wall. It is not allowed to connect any

other appliance to the chimney, where is the boiler connected. Diameter of the chimney must

not be smaller than the outlet part of the boiler. Chimney draught must achieve prescribed values. It cannot be too high to not decrease the boiler output and interrupt the burning (flame). If

there is too strong draught, install the throttle flap into the chimney hole between the boiler and

the chimney.

Figure 3 Correct and incorrect parameters of the chimney for connection the SLX boiler

Prescribed values of the chimney diameter and height:

20 × 20 cm min. height 7 m

20 cm min. height 8 m

15 × 15 cm min. height 11 m

16 cm min. height 12 m

Page 16

16

Exact dimensions of the chimney determines STN 73 42 10. Prescribed chimney draught is stated

in Technical parameters. Chimney draught is measured by the devices intended for this operation, minimally 40 cm behind the outfall of the chimney. Draught is measured during the boiler

operation at full output, by the same temperature of flue gas as the set one.

In case, that your chimney does not achieve prescribed parameters of the chimney, it is possible

to install additional fan ATTACK PV150 behind the boiler, which is able to make required parameters of the chimney.

It is necessary to keep in mind by choosing the type of the chimney or during the boiler operation, that stainless insulated chimney (most of the time placed externaly at the sheathing of the

building) has the best qualities of the chimney draught beginning after heat up, because it is

quickly warmed in a whole lenght. Chimney with stainless insertions has worse qualities of the

chimney draugh beginning, because it is warmed slower than insulated chimney. Worst qualities

of the chimney draught beginning has chimney without insertions (e.g. brick or ceramic), because its accumulation to operation temperature takes much longer. So, if the heat up or boiler

start up is problematic, consider recontruction of the chimney and equipping the chimney with

stainless insertions.

5.4.5 CONNECTION TO THE ELECTRICITY MAINS

The boiler is connected to the electricity mains of 230 V/50 Hz/10 A by an electrical cord with

plug. The mains input is type M and by replacing, it must by replaced with the same type by the

service organisation. Appliance must be placed with easy reach of the plug. The boiler must be

connected to the plug circuit with 10 A electrical circuit-breaker (following the STN EN 60 335-1

+ A11:1997).

5.4.6 OPTION AND THE WAY OF CONNECTION OF THE CONTROL AND SAFETY

ELEMENTS

Boiler is delivered with basic equipment, regulation and control elements. It is necessary to purchase other elements, which are not a part of delivery, but have to be installed in the heating

system. It is especially, valve against exceeding permitted pressure (figure 4) in the heating system (we prescribe 2,5 bar), valve of the aftercooling loop of the boiler for draining excess

warmth out of the boiler to the waste and bleeding valve for correct function of the boiler. Expansion tank in the system must have sufficient volume, which is set by the project architect of

the heating system according to valid prescriptions. Electrical installation with sufficient equipment of the boiler has to be performed by the specialist according to valid norms.

CAUTION! Heating system has to be equipped with safety

valve against exceeding pressure in the boiler (2,5 bar). We

recommand to place this valve on the riser pipe of the boiler,

always infront of the closing valve of the boiler (or infornt of

the OVENTROP). If the safety valve would not be func-

tional, excessive pressure would not be able to leak and

boiler might explode!

Figure 4 Safety valve against overpressure

Page 17

17

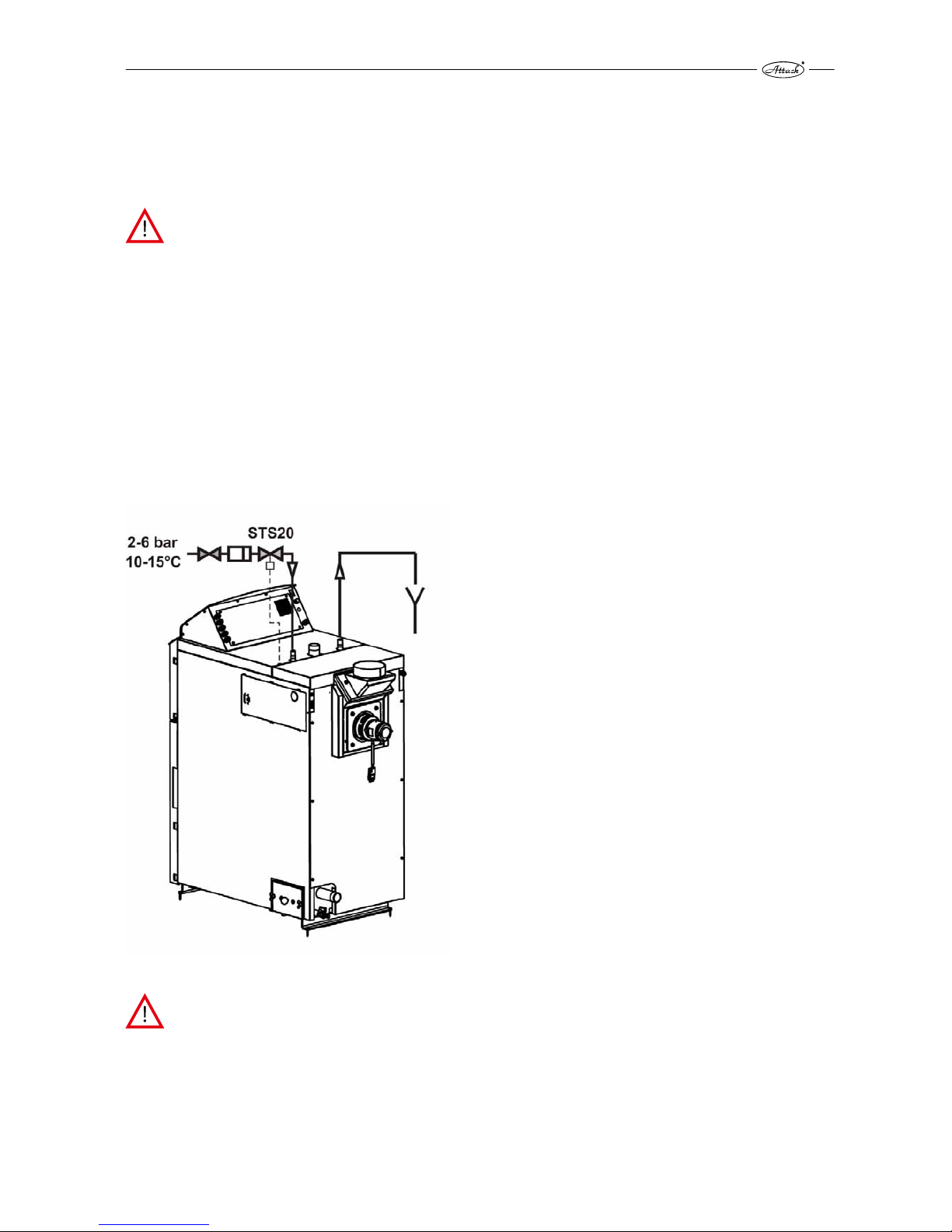

5.4.7 PROTECTION OF THE BOILER AGAINST OVERHEATING

Every gasifying boiler has to be equipped with functional aftercooling circuit. It is possible to

order correct valve for ensuring this function, as accessory. In the figure 5 you can see correct

installation of the aftercooling circuit valve.

CAUTION! Cooling circuit against boiler overheating can not be used according to the

EN 303-5 norm for other purposes as is the boiler protection against overheating.

Valve at the inlet of cooling water to the cooling circuit of the boiler has to be permanently

opened and cooling circuit of the boiler has to be connected to functional distribution of cold

water (e.g. to distribution of cold water of the water network) of 10–15 °C temperature and operating overpressure 2–6 bar, which ensures safety operation even by electricity failure.

Thermostatic valve at the inlet of aftercooling circuit, which has sensor placed at the rear part of

the boiler, protects the boiler against overheating. If the water temperature in the boiler rises

above 95 °C, valve releases water from the water network in the cooling circuit which takes away

excessive warmth. In case of boiler overheating and opening a thermostatic valve, permanent

drain of warmed water from the cooling circuit of the boiler to the waste, has to be ensured.

Functionality of the aftercooling circuit and thermostatic valve might be also checked manually,

with the manual button of the thermostatic valve.

Figure 5 The way of cooling circuit connection

CAUTION! If the circulation of cooling water through the aftercooling circuit would not

be ensured during the opening of thermostatic valve, there is a danger of boiler damage.

In this case is warranty not valid!

Page 18

18

5.4.8 CONNECTION TO THE ACCUMULATION TANKS

System of the connection is based on warming the accumulation tanks, where is the accumulated warmth from accumulation tanks gradually drained according to the requirements of

heated space. During the bioler operation at full output are accumulation tanks warmed at 80–

90 °C. Heating with accumulation tanks in connection with ATTACK SLX boiler brings several

advantages. Main advantages are higher efficiency, lower fuel consumption, prolonged lifetime

of the boiler, more frequent operation, minimal creation of acids and condensates, higher comfort, lower risk of boiler overheating and fuel saving.

Recommended volume of the accumulation tank for ATTACK SLX 25 boiler is 2000 l (for other

outputs see technical parameters). Boiler is able to produce 180 kWh of energy at one loading of

the hard wood to the feeding chamber (it is ca. 7 hours of operation at full 25 kW output). It correspond to charge of 2 000 l accumulation tank from 20 °C to 90 °C if there is no energy offtake

(that is why is necessary to keep in mind by choosing the size of accumulation tank, that boiler

must be operated according to the size of accumulation tank. It means that, if you have 2000 l

tank, load the wood chamber fully. If you have 1000 l tank, load the chamber halfway – if there is

no energy offtake from the accumulation tank). If the accumulation tank is charged (bottom

temperature of the accumulation tank achieves 70 °C) and boiler achieved set boiler temperature, do not load the wood to the boiler. If you would load the wood to the boiler in this state,

wood would not be combusted (boiler has already achieved set temperature and fan has turned

off). It would get dry and condensates would create in the feeding chamber, what lowers boiler

lifetime. It is necessary to fill the wood at the time when the accumulation tank is almost discharged.

Example 1:

Outside temperature of the environment is −5 °C and heat loss of the object is 10 kW by this

temperature. Boiler has 25 kW at the full output operation. Accumulation tank with volume

2000 l is discharged (its upper and bottom temperature is 20 °C). The heating system (to cover

heat loss) drains 10 kW output from accumulation tank and boiler has 25 kW output, accumulation tank will be heated by the output of 15 kW – difference between them. 15 kW output makes

energy of 105 kWh by full loading of the chamber with hard wood and time of the operation ca.

7 hours. Energy of 105 kWh warms accumulation tank from 20 °C to 65 °C. It means, that this is

the safe economic operation without putting the boiler out of operation or draining excessive

warmth to the waste (boiler was cooled by the aftercooling circuit). Boiler is able to cover the

heat loss for up to 15 hours at one wood loading.

Example 2:

Outside temperature of the environment is +3 °C and heat loss of the object is 5 kW by this temperature. Boiler has 25 kW at the full output operation. Accumulation tank with volume 2000 l is

discharged (its upper and bottom temperature is 20 °C). The heating system (to cover heat loss)

drains 5 kW output from accumulation tank and boiler has 25 kW output, accumulation tank will

be heated by the output of 20 kW – difference between them. 20 kW output makes energy of

140 kWh by full loading of the chamber with hard wood and time of the operation ca. 7 hours.

Energy of 140 kWh warms accumulation tank from 20 °C to 80 °C. It means, that this is the safe

economic operation without putting the boiler out of operation or draining excessive warmth to

the waste. If the heat loss of the object would be constant all the time – 5 kW, charged accumulation tank would be able to cover heat loss for about 28 h, what is together with operation time

up to 35 hours without need of wood loading.

That is why it is necessary to keep in mind, that boiler should be loaded only with amount of

wood necessary for charging the accumulation tank, because pointless overheating might lead

to putting the boiler out of the operation or removing excessive warmth to the waste. This is

uneconomical and requires activation of the safety element – aftercooling loop.

Page 19

19

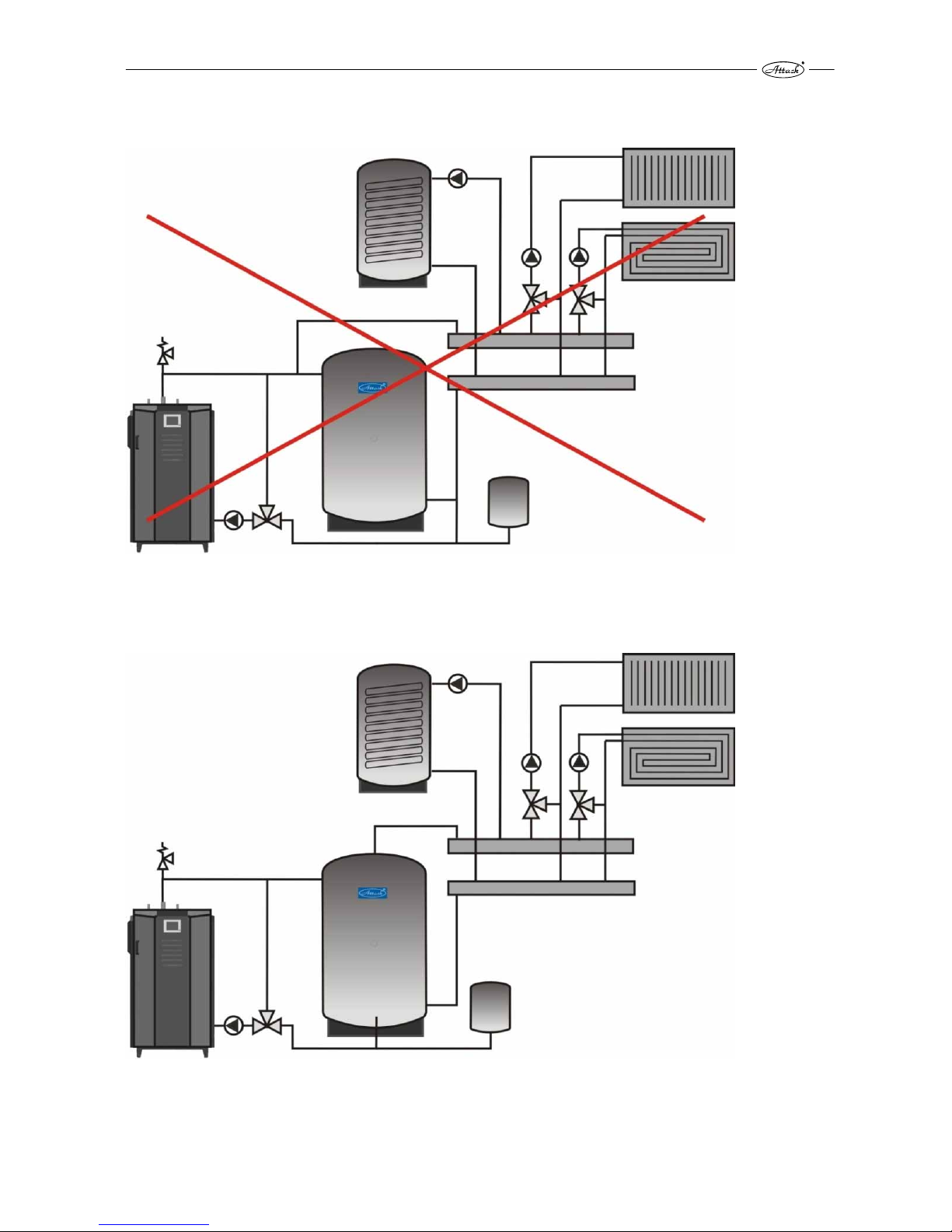

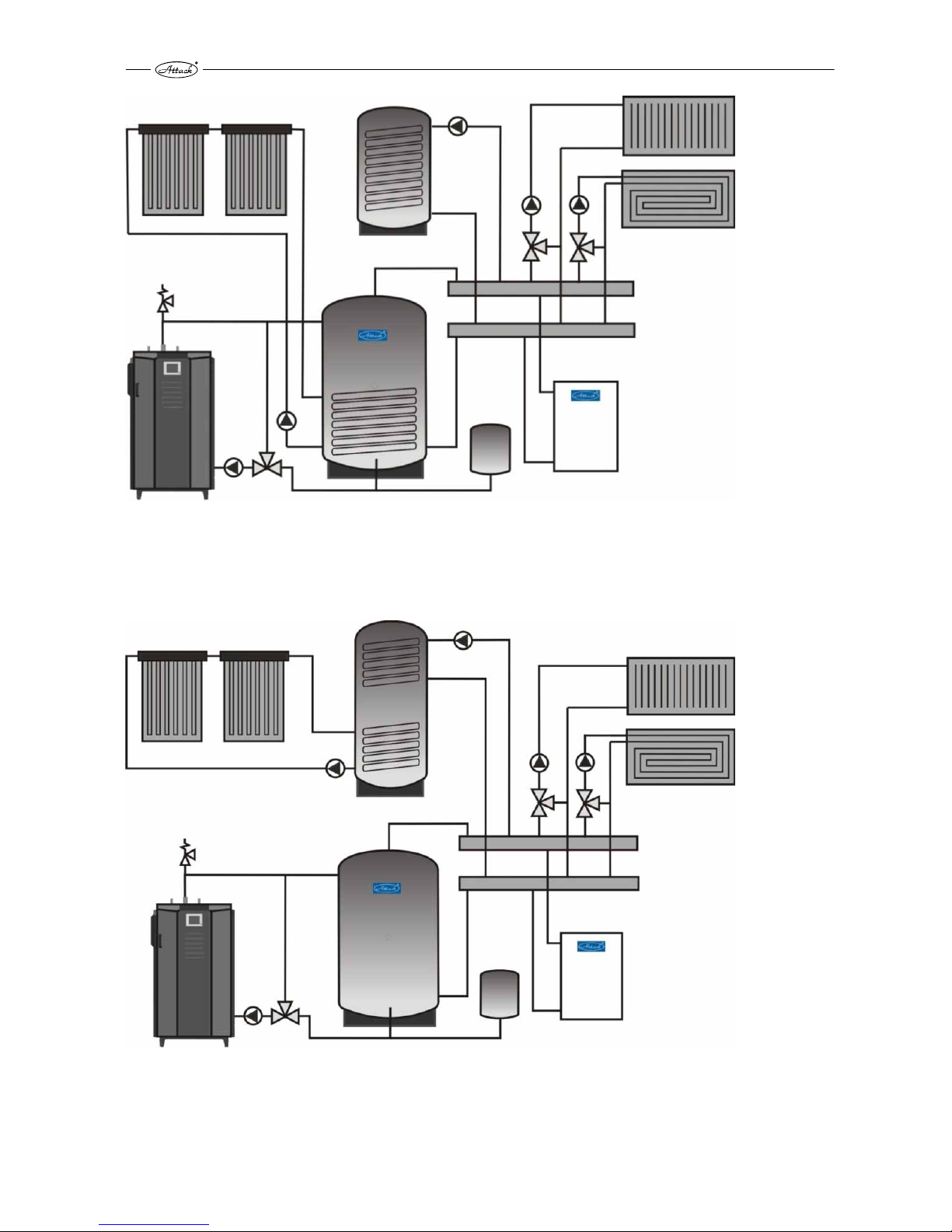

5.4.9 SCHEMES OF BOILER CONNECTION TO THE ACCUMULATION TANKS

Scheme č. 1. – Incorrect connection, where is the heating circuit connected by the T connector

infront of the accumulation tank

Scheme č. 2 – Correct connection of the gasifying boiler with accumulation tank, D.H.W. tank

and mixing heating circuits (radiator and flooring)

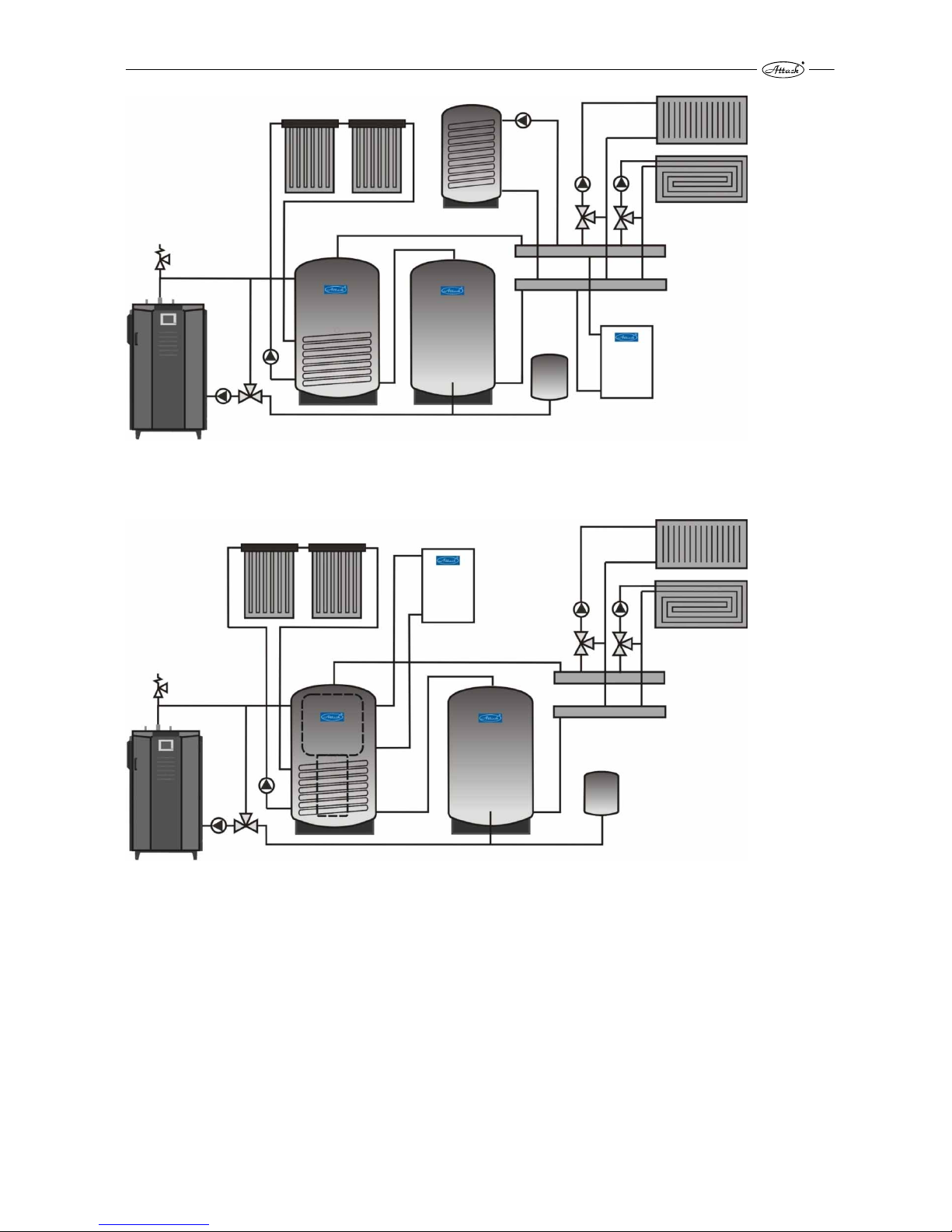

Page 20

20

Scheme č. 3 – Connection of the gasifying boiler with accumulation tank with spiral for solar

heating, D.H.W. tank, solar panels, mixing heating circuits (radiator and flooring) and automatic

boiler (e.g. gas)

Scheme č. 4 – Connection of the gasifying boiler with accumulation tank, D.H.W. tank with spiral

for solar heating, solar panels, mixing heating circuits (radiator and flooring) and automatic

boiler (e.g. gas)

Page 21

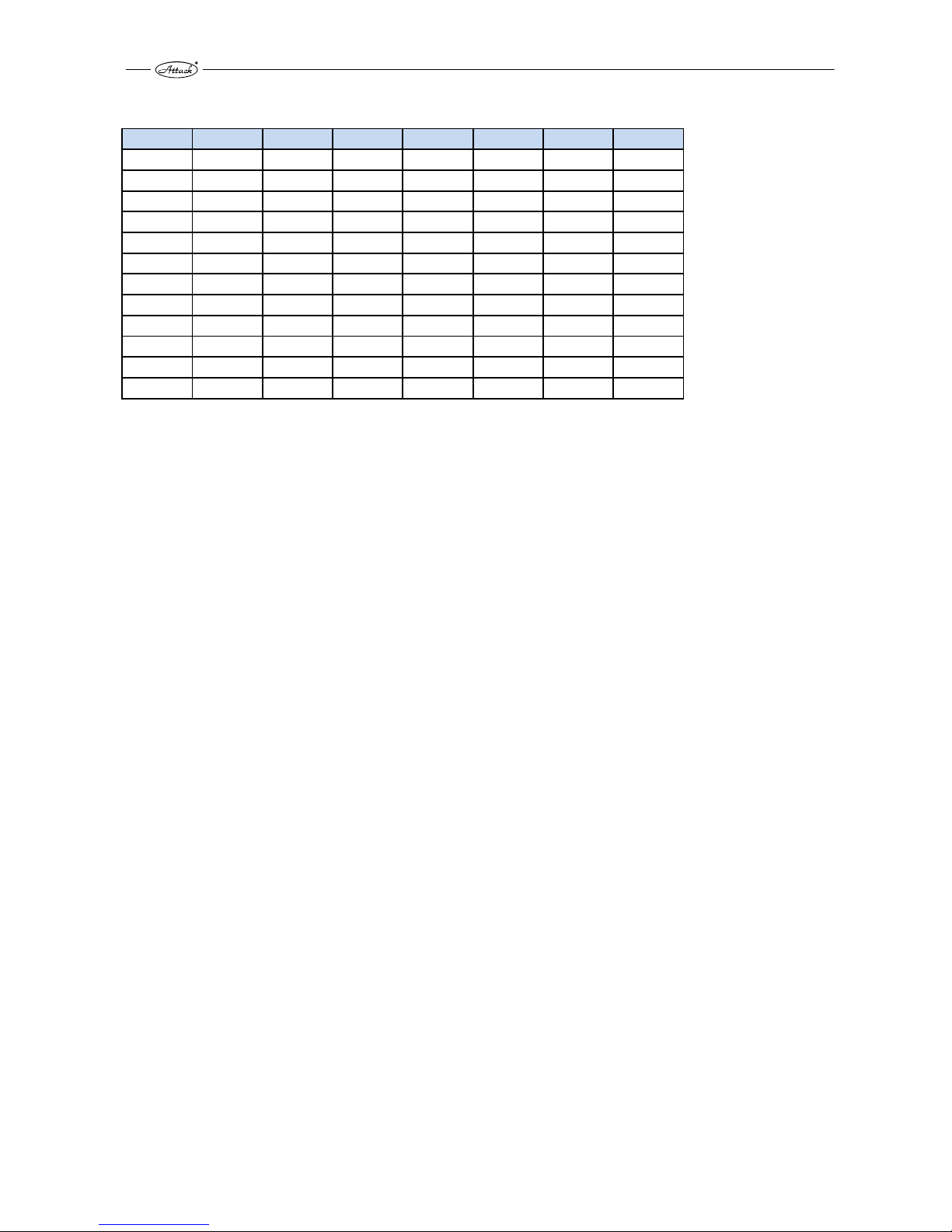

21

Scheme č. 5 – Connection of the gasifying boiler with two accumulation tanks

Scheme č. 6 – Connection of the gasifying boiler with combined accumulation tank

For other ways of connection, please visit web page www.attack.sk, where you can find wide

range of options for connection to the heating circuits.

Page 22

22

5.4.10 STANDARDLY DELIVERED ACCUMULATION TANKS ATTACK*

AK AS HR HRS TUV

TUVS

S SS

200 200 — — — — — —

300 300 — — — — — —

400 400 — — — — — —

500 500 600 600 500

500

500 500

800 800 800 800 600

600

800 800

1000 1000 1000 1000 800

800

1000 1000

1500 1500 1250 1250 1000

1000

1250 1250

2000 2000 1500 1500 1250

1250

1500 1500

2500 2500 2000 2000 1500

1500

2000 2000

3000 3000 — — 2000

2000

— —

4000 4000 — — — — — —

5000 5000 — — — — — —

AK – standard accumulation tank designed for accumulation of heating water

AS – accumulation tank for accumulating of heating water, equipped with a heating coil for

connection to solar panels

HR – combined accumulation for accumulation of the heating water as well as for preparation of

the D.H.W. by an internal enameled exchanger

HRS – combined accumulation for accumulation of the heating water as well as for preparation

of the D.H.W. by an internal enameled exchanger, equipped with a heating coil for connection to

solar panels

TUV – accumulation tank for accumulation of the heating water as well as for the D.H.W. preparation in a water coil

TUVS – accumulation tank for accumulation of the heating water as well as for the D.H.W. preparation in a water coil, equipped with a heating coil for connection to solar panels

S – accumulation tank with internal disk and stratification pipe (based on the type AK) that allows layering of water as necessary (different water temperature on inputs as well on outputs)

SS – accumulation tank with internal disk and stratification pipe (based on the type AS and S),

equipped with a heating coil for connection to solar panels

* Required volume for required accumulation of energy is possible to cover one or several accumulation tanks. Accumulation tanks can be connected together to create required volume of accumulation water. Therefore, if you decided that your accumulation volume will be 2000 l, you can buy a single accumulation tank of 2000 l or two accumulation tanks with a capacity of 1000 l and connect

them together.

Page 23

23

5.5 BINDING NORMS FOR DESIGNING AND ASSEMBLY OF THE

BOILERS

Boiler installation must be preformed in conformity with following norms:

STN EN 303-5:2012 Heating boilers for solid fuels

STN 73 42 10 Construction of the chimneys and flues

STN 92 0300 Fire safety of the local appliances and heat sources

STN EN 60 335.1 +A11 Safety of the electrical appliances for household

STN 06 10 00 Local appliances for solid, liquid and gaseous fuels

STN 06 03 10 Central heating, designing and installation

STN 06 08 30 Safety devices for central heating and D.H.W. heating

STN 07 74 01 Water and steam for thermal energetic devices with operation pres-

sure of steam up to 8 MPa

STN 332000 4-46 Electrical installations of buildings – part 4: Ensuring safety

STN 332000–3 Electrical installations of buildings – part 3: Definition of the basic

characteristics

STN EN ISO 11202 Acoustics. Noise emissions of the machines and devices. Measuring

the emissions levels of the acoustic pressure at the workplace and

other precisely defined places by use of approximate corrections for

environment (ISO 11202: 2010)

STN EN ISO 12100 Safety of machines. General principles of construction of machines.

Considering and lowering the risk. (ISO 12100: 2010)

STN EN 953+A1 Safety of machines. Protective covers. General requirements for pro-

jecting and construction of the solid and movable covers.

STN ISO 27574-2 Acoustics. Statistical methods for determination and verification of

the given noise emission value of the machines and devices. Part 4:

Methods for machine series.

STN ISO 1819 Devices for continuous transportation of the freight. Safety prescrip-

tions. General enactments

STN 92 0300 Fire safety of local appliances and heat sources

STN EN ISO 15614-1 Requirements for the quality of the fusible welding of the metal ma-

terials

STN 73 4210 Manufacturing the chimneys and flues and connection of appliances

STN 92 0300:1997 Minimum distance of the external surface of the appliance or flue

from the building constructions

Page 24

24

6 BOILER OPERATION

6.1 OPERATING PRESCRIPTIONS

WARNING: Serious health or property damage might occur, if an unauthorised person

enters the boiler room. An operator of the system have to secure the boiler room

against the entrance of unauthorised people or children

Boiler preparation for operation

Ensure before putting the boiler into operation, if the system is filled with the water, bleeded

and if there is no decrease of the heating water pressure. Check if the chimney piping is tightly

connected (the best bolted together) and if there wont be a smoke leakage. Check, if the manometer, boiler and safety thermostat sensors are placed in the boiler probes and if they show

real values. To achieve the correct function, boiler must be operated in compliance with the instructions given in this manual. During the boiler installation, underlay rear part for 10 mm, to

ensure easier flush out and bleeding. Operation may be performed only by an

adult, trained person with finished primary education.

WARNING: By the first heating up might occur condesation and leakage of the condensate – it is not failure. After longer heating condensation disappears. It is necessary to

check the flue gas temperature during the combustion of small wood waste, which

must not exceed 320 °C. In this case fan might get damaged. Partial creation of tar and

condensates in the feeding chamber of the boiler is common attendant effect by the

wood gasifycation and does not have negative influence on the boiler operation.

If the boiler was longer out of order (turned off, in failure), it is necessary to pay higher caution

by restarting it up again. If the boiler was out of operation, there is possibility of pump blockage,

water leakage out of system or boiler freezing in the winter period.

Page 25

25

6.2 HEATING UP, OPERATION AND FUEL REFILLING

WOOD IGNITION

1. Open the door of the feeding chamber. Check height of the ash in the feeding chamber. If the

height of ash exceeds 50 mm from the chamber bottom, clean the feeding chamber (figure 6). If there are wood coals in the chamber, it is not necessary to remove them, they make

heating up easier. But it is always necessary to remove the ash. For cleaning is ideal to use fire

poker and push the ash to the nozzle to make it fall to the combustion chamber (ashtray) of

the boiler. Clean the combustion chamber always before every heating in the boiler!

Figure 6 Correctly cleaned feeding chamber

NOTICE! If the combustion chamber would be insufficiently cleaned, volume of the

combustion chamber would be rapidly lowered and it might lead to imperfect combustion and dangerous states. Do not operate the boiler without cleaned combustion

chamber by no means!

2. Put the refractory shaped brick, one layer of medium-thick logs (ca. 40–60 mm) into the feed-

ing chamber, to not block the inlet of air to the nozzle and primary air. (figure 7)

Page 26

26

Figure 7 Basic layer of wood during heat-up

3. Put the paper or cardboard (figure 8) on the prepared wood, or other suitable means for

wood ignition (e.g. solid spirit firelighter)

Figure 8 Put the twisted cardboard on the wood

4. Put fine splinters on the cardboard or paper, which create basic layer (coals) after ignition, to

ignite pieces of wood.

Page 27

27

Figure 9 Splinters for creating the basic layer

5. Switch on the regulator. You can find the the way of starting up in part 6.3.4 – PROFI, 6.4 –

LAMBDA Touch

6. Ignite prepared layer at the bottom of front part (figure 10) and close the door partly for ca.

15 mm.

Figure 10 Ignition of the basic layer

7. Wait 10–15 minutes until the basic layer sufficiently burn, to make it possible to stoke wood

pieces (pict. 11)

Page 28

28

Figure 11 Sufficiently flaming basic layer

8. Stoke the wood pieces in full (figure 12)

Figure 12 Stoking in full.

9. Close the door. Heat up is done. If you are not sure, whether heat up was successful or not,

watch the flue gas temperature. If the heat up was done correctly, temperature of flue gas will

rise

Page 29

29

OPERATION

Bioler is during the common operation controled according to several parameters depending on

the boiler version (PROFI, LAMBDA Touch). It is ideal to operate the boiler on 100 % output.

Boiler achieves the highest efficiency, stability of burning, minimal wastes from burning and

trouble –free operation. This type of operation is best achievable when is the boiler connected

to the accumulation tank with suitable volume, which is gradually charged. Difference between

set boiler temperature and temperature of the reverse must be minimally 15 °C to not let boiler

achieve set boiler temperature during the charging of accumulation tank. Otherwise the boiler

would put to the sustain mode before charging the accumulation tank. Operation and boiler

control is described more in details below, according to the boiler version PROFI or LAMBDA

Touch.

FUEL REFILLING

CAUTION! Door of the feeding chamber has to be opened gradually during the opera-

tion, to not let potential smoke which comes out of the chamber hit your eyes.

Refill the fuel only when the wood is almost consumpted and in the feeding chamber are only

coals. (figure 13). We do not recommend to refill the wood during the common operation, when

is the chamber filled for more than 1/5 of its volume, because in the chamber takes place the

pyrolysis without the oxygen inlet, which creates the smoke and it is not possible to suck it out

well after you open the door. Perform refilling by opening the door partly (ca. 15 mm), wait until

the smoke will be sucked out and open the door fully. Then stoke the wood to the chamber as

fast as possible. Wood has to move in the feeding chamber freely and between each log has to

be at least 1–2 cm space. You can close the door after stoking the wood to the chamber

Figure 13 Height of the live coals suitable for stoking.

Page 30

30

LAMBDA Touch version of the boiler can keep remaining coals longer, because after burn out

of the fuel is closed the flap of primary air by the servoengine, what prevents their burning out.

In this way is possible to keep coals up to 24 hours and make the futher heat up easier.

6.2.1 PROTECTIVE TOOLS FOR WORK WITH THE BOILER

It is necessary to use the protective tools according to valid regulations of the work safety, during the work with the boiler. During the operation, cleaning and inspection of the boiler is necessary to pay attention to protection of the health. It is necessary to use gloves with higher fireproofness, eligible clothes and hard shoes.

6.3 CONTROL OF THE ATTACK SLX PROFI BOILER

Boiler regulation offers high comfort of the control, possibility of output modulation and possibility of connection of the control and regulation elements. Regulator controls the operation on

the basis of boiler and flue gas temperature. Regulator tries to achieve required boiler temperature by set temperature of the flue gas, which is controlled by changing the fan rotations. In this

way regulator ensures, that temperature of the boiler will be reached by as high as possible efficiency. If the temperature of the boiler is coming near to the set value, regulator modulates output of the boiler. If the set boiler temperature is reached, regulator switches the fan off.

Technical description and the way of regulation of ATTACK PROFI boiler:

Connection

Connect the regulator, fan, circuit pump and supply cords to appropriate plugs in the rear part

of the device before switching on the device by main switch. Sensor of the boiler temperature

has to be placed in the boiler probe.

CAUTION! Before connecting the regulator to the electricity mains, check, if it is properly grounded and screws of the clamp are tightened enough.

WARNING: Maximal total output of devices connected to the regulator can not be

higher than 700 W.

WARNING: It is possible to connect UM-1 module for expanded function of regulator,

which allows to control switching on of other automatic boiler.

6.3.1 ADVANTAGES OF REGULATOR

Regulator is able to control:

1. Rotations of the exhaust fan

2. Circuit pump of heating circuits

3. Pump of D.H.W. charging or pump of accumulation tank charging (always only one)

4. Switching on the other, automatic boiler in case of fuel burn out in the boiler. (module UM-1

delivered as accesories)

Regulator is able to scan:

1. Boiler temperature

2. Flue gas temperature

3. Temperature in the D.H.W. tank or in the accumulation tank (always only one)

4. Room thermostat and on the basis of its switch on, controls circuit pump.

Page 31

31

6.3.2 BASIC DESCRIPTION OF THE REGULATOR

Figure 14 Particular buttons and displaying the information on the regulator

1. main switch

2. icon for D.H.W. temperature indication

3. icon for temperature of accumulation tank indication

4. icon for flue gas temperature indication

5. icon for current boiler temperature indication

6. current boiler temperature (or temperature of D.H.W., flue gas, etc.)

7. symbol, which informs about the operating mode of the boiler

8. setting the boiler temperature

9. button to enter to the information menu, service menu and confirmation of parameters

10. icon displaying fan operation

11. operation of the pump for D.H.W. or of the pump for the accumulation tank charging

12. icon displaying circuit pump operation

13. icon displaying entrance to the service menu

14. icon indicating overheating or sensors damage

15. icon indicating that the room thermostat is turned on

16. button to stop the boiler or to move backward in menu

17. button to start the boiler or to move forward in menu

Page 32

32

6.3.3 CONNECTION OF THE PROFI PID REGULATOR BY HYDRAULIC SCHEMES

The regulator can control several types of hydraulic schemes. Parameters in the service menu

must be correctly set adequately to the type of the hydraulic scheme.

Note: The additional thermal sensor for controlling the additional output is connected by production and it is rolled in the control panel of the boiler. To use the sensor, it is necessary pull it

out from the control panel through the prepared plastic bushing. This action can be performed

only by a qualified person or by a person trained by producer. Regulator is set by production for

the simplest control of heating circuit according to the scheme 7. Schemes show connection of

pumps and sensors. There is not shown connection of the fan and connection to the mains on

the schemes.

Scheme 7: Gasifying boiler + heating circuit

Setting parameters for hydraulic scheme 7:

Page 33

33

ur = ur0

Scheme 8: Gasifying boiler + heating circuit + D.H.W. charging

Setting parameters for hydraulic scheme 8:

ur = ur1 – for priority charging of D.H.W. tank

ur = ur2 – for parallel charging of D.H.W. tank

Page 34

34

Scheme 9: Gasifying boiler + heating circuit + charging of accumulation tank

Setting parameters for hydraulic scheme 9:

ur = ur4

Page 35

35

Scheme 10: Gasifying boiler + heating circuit + charging of accumulation

tanks connected in serie

Setting parameters for hydraulic scheme 10:

ur = ur4

Page 36

36

Scheme 11: Gasifying boiler + heating circuit + charging of combined accumulation tank

Setting parameters for hydraulic scheme 11:

ur = ur4

Page 37

37

6.3.4 REGULATOR CONTROL AND OPERATING MODES

By turning on the main switch are shown on the display all icons for responsible check of their

functionality. If the regulator gets suddenly disconnected from electricity mains (e.g. by power

failure), regulator returns to the last mode, by which the interruption of electricity supply occurred. Regulator saves all the settings even after the power failure.

Basic control of the regulator lay in setting the boiler temperature by the knob. Other functions

are controlled on the basis of service parameters set in service menu.

The boiler is turned on by pressing the START (17) button that starts the operation of exhaust fan. The STOP (16) button put the boiler out of operation by turning the exhaust fan off.

The sign displayed behind the numeric temperature indication (7) indicates the current

mode of the PID regulator

[50°–] – indicates the stand-by mode

[50 °C] – indicates the winter operating mode

[50 °C] – indicates the winter operating mode when the boiler temperature is achieved

[50°U] – indicates summer operating mode intended only for D.H.W. warming

[50°u] – indicates summer operating mode when the boiler temperature is achieved

[70°d] – indicates mode of elimination of the legionella bacteria, when the temperature of

D.H.W. is increased to 75 °C

[50°P] – indicates that regulator is blocked by pellet burner of the COMBI Pellet boiler or connection between clamps 10 and 11 is incorrectly connected.

The PROFI PID regulator has an advantage of regulating the flue gas temperature to the set, required value. Regulator tries to achieve set flue gas temperature and after reaching this temperature is switched to the mode of reaching the required boilers temperature. Thereby is the

fuel used in the most effective way and also high efficiency is ensured.

6.3.5 SETTING THE USER PARAMETERS

The menu for displaying and setting the user parameters is accessible after short press of the OK

button. The „+“ and „–“ buttons are used to browse in settings and parameters. After selecting

appropriate parameter is possible to enter to this parameter by pressing the OK button. Successful entrance to this parameter is signalized by flickering of this parameter. Then setting can be

changed by the „+“ and „–“ button and confirmed by „OK“ button. Some of the parameters are

only informative and they can not be changed. To exit the menu, confirm the [End] by „OK“ button. After remaining more than 1 minute without the user´s intervention, the regulator switches

to the basic display.

Page 38

38

Table 1. User parameters:

Display Parameter Min Max Step

Fac.

sett.

C 45 Set boiler temperature L65 H90 1 °C –

co C

Operating mode of the circuit pump (´C´ – WINTER, ´-´ SUMMER

C – C

cu u

Operation of the D.H.W. pump (´u´ – common mode, ´d´ –

elimination of legionella bacteria)

u d u

u50°

Current temperature measured in the accumulation tank or

D.H.W. tank

150°

Current flue gas temperature

End

Exit from user parameters

[C 45] – Adjusted boiler temperature – this is the value of the water temperature in the boiler,

which should be reached by the boiler in work mode. It is set by turning the knob manually (8)

and shown on the display (6).

[co C] – WINTER/SUMMER mode – the winter mode is indicated by the ‘C’ letter. In this mode is

the circuit pump controlled by the room thermostat and distributes heat into the heating circuit.

The summer mode is indicated by the „–“ symbol. In the summer mode is the circuit pump out of

order and the heat generated by the boiler is only used to charge the D.H.W. tank. If there is not

D.H.W. tank in the system (additional sensor is not connected), it is not possible to select the

SUMMER / WINTER mode.

[cu u] – Mode of D.H.W. tank charging – regulator enables common D.H.W. tank charging „u“

or the mode with elimination of the legionella bacteria „d“. After selecting „d“ mode , the temperature of 75 °C is achieved in the D.H.W. tank. When is this temperature achieved, regulator

switches in the mode of the common D.H.W. tank charging „u“. The option of elimination the

legionella bacteria is not available, if the additional outlet and sensor are not set for the D.H.W.

charging.

CAUTION! To not to get hurt by the hot water, it is recommended to start this mode,

when the D.H.W. is not being used (e.g. during the night).

[u50°] Temperature of additional sensor – this is the value of current temperature of the

D.H.W. tank or temperature of the accumulation tank of the heating system. This temperature is

not displayed in the user menu, in case, that the additional output is not used.

[150°] Flue gas temperature – this value represents current temperature of flue gas, if the parameter for flue gas temperature control is set in the service parameters

Page 39

39

6.3.6 SETTING THE SERVICE PARAMETERS

By holding the OK button you get access to the service menu to the parameter settings. The buttons „+“ and „–“ are used to browse between particular parameters. After selecting the appropriate parameter, confirm it by „OK“ button and it starts to flicker. By using the „+“ and „−“ buttons

is possible to change the setting of appropriate parameter. To confirm the set parameter, press

the OK button. To exit the service menu, confirm the [End] by „OK“ button. After remaining for

more than 1 minute without the user´s intervention, controller switches display to the basic

mode.

Table 3. Service parameters:

SERVICE MENU (available by holding the OK button)

Display Parameter Min Max Step Prod. set.

Π100 Maximum fan output 1 100 1 % 100

n 40 Minimum fan output 1 100 1 % 40

Πh 5 Ratio of change of the fan rotations 2 20 1 5

Πr 0 Automatic regulation of change of the fan rotations -, 0 10 1 0

Πt 1 Delay of change of the fan rotations 0 99 1 1

Πn 5 Frequency of exhaust fan blow-through --, 5 60 1 s 5

Πu 6 Duration of exhaust fan blow-through 1 99 1 min 6

Πd3 Duration of manual fan operation for 100 % --, 1 99 1 min 3

r100 Fan output by ignition 1 100 1 % 100

rh 5 Hysteresis of boiler stop by ignition 1 45 1 °C 5

P 30 Temperature for starting the circulatory pump --, 20 70 1 °C 30

Ph 2 Hysteresis of circuit pump 1 40 1 °C 2

Pc -- Interval of unblock function of circulatory pump --, 1 99 1 min 2

Ur0 Operation of additional output 0 4 1 0

u30 Operating temperature of D.H.W. tank or accumulation tank 30 60 1 °C 30

uh 5 Hysteresis of D.H.W. tank or accumulation tank 1 30 1 °C 5

uP 5 Boiler temperature increase by D.H.W. warming 1 20 1 °C 5

L65 Minimum boiler temperature 30 65 1 °C 65

H 85 Maximum boiler temperature 80 95 1 °C 85

h 2 Boiler temeprature hysteresis 1 10 1 °C 2

A 99 Temperature of boiler overheating 90 99 1 °C 99

Fd60 Duration of boiler stop by ignition and fuel shortage --, 1 99–4 h 1 min 60

Fb30 Duration of boiler stop by flue shortage and burn-down --, 1 99–4 h 1 min 30

Ar 0 Control of multifunctional additional output 0 1 1 0

C

240

Set flue gas temperature -0,5 250 1 °C 240

C

h5 Flue gas temperature hysteresis 1 99 1 °C 5

C

t 5

Time constant of stabilization the flue gas temperature 1 99 1 min 5

C

F10 Blower speed jump while stabilizing flue gas temperature 1 20 1 °C 10

C

90 Flue gas temperature by fuel shortage 30 150 1 °C 90

C

300 Maximum flue gas temperature 250 400 1 °C 300

Prod Return to the production settings

outΠ Test of fan relay outΠ out1

outP Test of circulatory pump relay outP out2

outu Test of optional pump relay outu out3

outr Test of additional output outr out4

End Exit to main menu

Page 40

40

6.3.7 DESCRIPTION OF PARAMETERS

[Π100] Maximum fan output – the highest allowed fan output

[n 40] Minimum fan output – the lowest allowed fan output

[Πh 5] Ratio of change of the fan rotations – this parameter influences lowering the fan rota-

tions, if the set boiler temperature is going to be achieved in a short time. For example, if the

value 4 is set, the fan will work at maximum output [Π100] (if the function of flue gas temperature control is not active), up to 4 degrees before achieving the set boiler temperature. Then, by

every increase of the boiler temperature for 1 °C, the fan rotations are gradually decreased until

the minimum fan output [n 40] is reached.

[Πr 0] Automatic regulation of change of the fan rotations – the fan rotations are increased /

decreased by setting this parameter within the range of 0–10 to ensure the required boiler temperature. If this parameter is set to „- -“, regulation of rotations is not active and the fan works

always at full output according to the parameter [Π100]. Setting the parameter within the range

of 0–10 relates to the time period (in minutes), during which are the fan rotations gradually increased from the parameter of the minimum fan rotations [n 40] up to the parameter [r 100].

This ensures fluent heat-up of the boiler.

[Πn 5] Frequency of exhaust fan blow-through – this frequency defines, how often has to be

the fan started to the full output operation [Π100] to take the flue gas out from the boiler, if the

fan was stopped due to achievement of boiler temperature.

[Πu 6] Duration of exhaust fan blow-through – during this period must the fan exhaust the

flue gas following the parameter [Πn 5].

[r 100] Fan output during ignition – this parameter defines the fan output by boiler heat-up. If

the parameter " Πr " is set to [Πr 0], then this parameter is not available.

[rh 5] Hysteresis of boiler stop during ignition – defines, how many degrees before reaching

the set boiler temperature is the heat-up phase deactivated or (if the flue gas temperature sensor is connected), how many degrees before reaching the set flue gas temperature. Deactivation

of heat up phase leads to the switching to common operation mode.

[P 30] Temperature to start the circulatory pump – if there is not D.H.W. tank in the system [ur

0] or it is in the mode [ur 2], then the parameter defines the boiler temperature for starting the

circulatory pump of the heating system. If the parameter is set to „- -“, then too low temperature

does not influence the operation of the circulatory pump. Anyway, the pump always starts,

when the boiler temperature exceeds the parameter [H 85] of the maximum boiler temperature.

If there is accumulation tank in the heating system (parameter [ur 4]), then this parameter defines the temperature measured in the accumulation tank by which is the circulatory pump of

the heating system started on.

[Ph 2] Hysteresis of circulatory pump – defines the temperature difference, below which must

the boiler temperature or temperature in the accumulation tank decrease in comparison with

the temperature defined by the parameter [P 30] to stop the circulatory pump.

[Pc --] Interval of antiblocking function of circulatory pump –when is the regulator in standby mode or the room thermostat is disconnected, the circulatory pump is started for 30 seconds

Page 41

41

after each [Pc --] minutes to prevent the pump blockage caused by its inactivity. The antiblocking pump function is deactivated, when the Pc is set to „- -“.

[ur 0] Operation of the additional output – this parameter defines the operating mode of the

additional output (pumps for D.H.W. tank charging or accumulation tank).

[ur 0] Additional output without function – defines that additional sensor and pump are not

connected and additional output is not used in this case.

[ur 1] Priority charging of D.H.W. tank by this setting is the pump for D.H.W. tank charging

connected to the additional output and the sensor of this tank is connected to the additional

inlet. Then, if the temperature in the D.H.W. tank drops below the value of hysteresis

[uh 5] from adjusted temperature [u 60], the pump of D.H.W. tank charging starts its operation.

When the temperature in the D.H.W. tank reaches the set value [u 60], the pump is put out of

operation. The pump is also stopped, when the temperature in boiler is lower than the temperature in D.H.W. tank. The [ur 1] mode means that the D.H.W. preparation has priority, i.e. the circulatory pump of the heating circuit is started, after charge of D.H.W. tank.

[ur 2] Parallel charging of the D.H.W. tank – works similar to the [ur 1] setting, but D.H.W. is

prepared in the parallel mode of joint operation with the circulatory pump of the heating circuit.

[ur 3] Not in use

[ur 4] Charging the accumulation tank – this setting defines, that the additional output serves

as a pump of charging the accumulation tank and the additional sensor measures its temperature. In this mode, if the temperature in the boiler exceeds the hysteresis [uh 5] over the current

temperature of accumulation tank, the pump for charging is put into operation. The pump is

stopped, if the temperature in the boiler is same or lower than the temperature in the accumulation tank, or when the temperature in boiler drops below the minimum boiler temperature defined by the parameter [L 65].

[u 30] Operating temperature of the D.H.W. tank or accumulation tank – temperature to

control the additional output [ur ].

[uh 5] Hysteresis of the D.H.W. tank or accumulation tank – this parameter defines hysteresis

of the additional output [ur ].

[uP 5] Boiler temperature rise during D.H.W. warming – this parameter is relevant, when additional output works in the mode of D.H.W. tank charging. It defines, for how many degrees will

be set boiler temperature higher than parameter [u 50] during the D.H.W. tank charging.

[L 65] Minimum boiler temperature – defines the minimum boiler temperature that can be set

by the knob.

[H 85] Maximum boiler temperature – defines the maximum boiler temperature that can be

set by the knob.

[h 2] Hysteresis of boiler temperature – defines the difference between set and the current

boiler temperature for which must the boiler temperature decrease to start the regulator again

after the set boiler temperature is achieved.

Page 42

42

[A 99] Temperature of boiler overheating – defines the value of boiler temperature to activate

the alarm of the boiler overheating.

[Fd60] Duration of the boiler stop by ignition and fuel shortage – this parameter defines the

maximum time between starting the regulator by the START button and achieving the regulator´s operating mode (reaching the flue gas temperature of [c 90]). If the temperature of [c 90] is

not reached during the heating up, fan is stopped and the alarm FUEL (fuel shortage) is displayed.

[Fb30] Duration of the boiler stop by flue shortage and burn-down – the fuel amount test is

activated in the operating mode, when the flue gas temperature drops below the parameter [c

90] or (if the flue gas sensor is not connected) when the boiler temperature drops below the set

parameter [L 45]. If the temperature does not exceed the necessary limit during this period,

regulator displays FUEL alarm.

[Ar 0] Controlling of the multifunction additional output – regulator has additional multifunction output which is compatibile with options mentioned below ( for controlling these options is necessary to use additional module UM-1):

[Ar 0] parameter – indicates start up of the automatic boiler (e.g. gas or pellet boiler). When

is the regulator started and gasifying boiler generates heat, the automatic boiler is put out of

operation. Operation of the automatic boiler is blocked by the regulator in the operating

mode. Regulator put automatic boiler into operation, if the fuel is burned down in the boiler

and the FUEL alarm is displayed.

[Ar 1] parameter – indicates that the additional multifunction output will be used for sig-

nalization of error messages like boiler sensor failure, overheating or fuel shortage.

[c 240] Adjusted flue gas temperature – is the flue gas temperature, the regulator will struggle

to reach and keep this value. The flue gas temperature sensor is turned off, if this parameter is

set to „- -“.

[c h5] Hysteresis of flue gas temperature – defines the difference, for which must the flue gas

temperature decrease, to increase the fan rotations.

[

c

t 5] Time constant of stabilization the flue gas temperature – defines the period of adjusting the fan rotations during the stabilization of the flue gas temperature. If the flue gas temperature exceeds the value given by the parameter [

c

240], regulator starts to decrease the fan rotations gradually, until the flue gas temperature decreases to the adjusted value. If the flue gas

temperature decreases to the value of flue gas temperature hysteresis, regulator starts to increase the fan rotations gradually.

[c F10] Fan rotations step of stabilization the flue gas temperature – defines the value of fan

rotations step, for which will regulator change the rotations of the fan to achieve the adjusted

flue gas temperature.