Page 1

W W W . A T T A C K . S K

DIRECT HEATED GAS TANKS FOR D.H.W.

ATTACK® PZO

INSTRUCTIONS FOR USE

Page 2

2

CONTENT

3 Introduction

3 General technical description

3 Principle of working

4 Basic dimensions of water storage tanks

4 Basic technical data on storage tanks

5 ASSEMBLY

5 Connecting the water storage tank to gas supply

5 Connecting the water storage tank to water supply

6 Connecting to flue

6 OPERATION

6 Procedure of filling the tank with water

6 Checking the tank before ignition

7 Start putting the appliance to operation

8 Regulation of water temperature

8 Putting the storage tank out of operation

8 Safety device

8 Test of the appliance

8 POSSIBLE DEFECTS

9 Condensation of vapour

9 Fume, smell of fume

9 Unfamiliar noise

9 Emergency thermostat

9 PERIODICAL MAINTENANCE

10 Warning for users

10 Installation and adjustment of gas valve

11 Notes

11 Record on putting the boiler to operation

Page 3

3

INTRODUCTION

This instruction serves mainly for the user of this storage tank. It contains basic technical

information and steps necessary for putting the boiler into operation, for its smooth

attendance and basic rules of maintenance. Some chapters and information written in this

instruction are also meant as an informative guide for specialised organisations which will

carry out assembly of the appliance at user's.

WARNING!

To ensure the operation of the appliance without failures and because of own safety, it is

necessary to study this manual thoroughly and follow the steps and instructions included. The

part of the manual is also a record on putting the appliance to operation that will be made by

an authorised company. The list of authorised service organisations and the letter of

guarantee is a part of this manual. If the record is not filled properly, it can be a reason for not

acknowledging the reclamation.

All this manual together with the letter of guarantee and record on putting to operation must

be therefore kept carefully.

GENERAL TECHNICAL DESCRIPTION

The appliance works as a gas storage heater of water with waste gas exhaust to the flue. It

operates on natural gas. The appliance consists of a steel tank with a ceramic layer, outside

cover with thermal insulation of high quality, combined gas fitting, gas burner and

accessories.

PRINCIPLE OF WORKING

When putting the heater into operation, the ignition flame is burned with the help of a

piezoelectric lighter that burns the flame of the main burner. Heat arising from gas burning is

transferred through the bottom of the steel tank and smoke tube in the storage tank. After

reaching the temperature set by a thermostat (40-72), position 4: (about 55°C), the main

burner goes off automatically and only the ignition flame stays burning which is working nonstop. The output of ignition burner is very low (about 100 W) and heat arising from burning is

used for further keeping the water temperature in the storage tank. Possible loses are

therefore minimalized.

The storage tank is equipped by a waste-gas thermostat that serves against back passage of

waste gas. When there is a failure in the waste gas exhaust, the operation of the heater is

stopped and gas supply into gas fitting is broken. Cutting out the sensor from the thermal fuse

circuit is inadmissible.

Polyurethane insulation keeps the reached water temperature with high effectivity (decrease

of water temperature is about 0.8 1°C/h). When the temperature in the storage tank decreases

in 5-6°C or when higher amount of hot water is taken off and cold water flows after, the

regulation thermostat enables reignition of the main burner and water is heated to the

temperature adjusted by a regulation button of gas fitting.

A combined safety valve (0,6 MPa) with a non-return flap valve that is activated for pressure

higher than 0,6 MPa is a part of the appliance. The valve opens when the pressure in hot water

distribution overcomes the critical value. After pressure decreasing the valve will close

automatically.

Page 4

4

Chart No. 2: BASIC TECHNICAL DATA ON WATER STORAGE TANKS

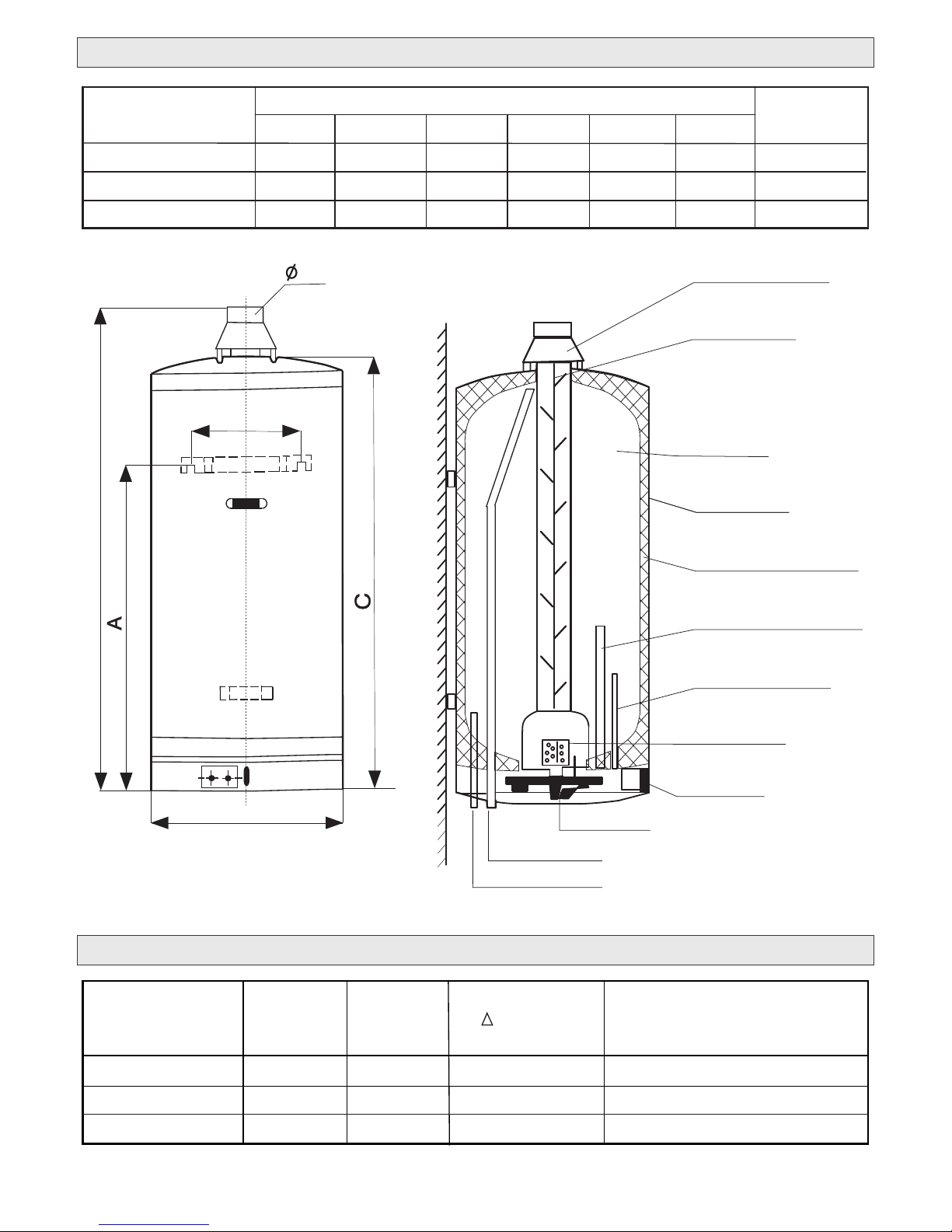

Pict.No.1: Basic dimensions

of water storage tanks

Chart No. 1: BASIC DIMENSIONS OF WATER STORAGE TANKS

Waste gas breaker

Flue deflector

Hot water

Tank coating

Polyurethan insulation

Magnesium anodal bar

Thermostat sleeve

Main burner

Gas valve

Pilot-burner

Hot water inlet

Hot water outlet

80

5,3

55 0,56

85 0,56

TYPE

ATTACK PZ 80

ATTACK PZ 120

Volume

(L)

Power

demand

(kW)

Heating time

t = 45°C

(min)

Gas consumption

3

(m /h)

5,3

104

5,3

ATTACK PZ 150

120

150

0,56

D

B

E

F

Type

ATTACK PZO 80

ATTACK PZO 120

ATTACK PZO 150

WEIGHT

(kg)

DIMENSIONS (mm)

D

A B

C

E

F

575

880

1130

985

1240

1510

860

1155

1385

520

520

520

320

320

320

100

100

100

52

65

78

Page 5

5

* Given values refer to heating without taking water and are only informative. The real values

depend on specific conditions (temperature of inlet water, intervals of water consumption

and so on).

Inlet gas pressure: 2,0 kPa for natural gas G20

Overpressure : 1,1 kPa for natural gas

Opening pressure of safety valve: 0,6 MPa

Range of operation thermostat: about 40–72°C

ASSEMBLY

PZO water storage tank can be located in a place where for 1 kW of installed output there is 1m3

of space, according to standards. In the place where the tank is located, over the floor there

2

must an opening of 200 cm diameter. If the room is not of the minimum volume required, over

2

the floor and under the ceiling there must be vent holes, each of 600 cm area. In the rooms

3

where there are more than 2 m of space for 1 kW of installed output, no vent holes are needed.

Before hanging the storage tank on the wall i tis necessary to make sure whether the wall is

strong sufficiently to carry the weight of the tank filled with water. The wall must be from

incombustible material, otherwise it must be insulated. We recommend to balance the

storage tank.

The assembly can be performed only by a qualified company.

CONNECTING THE HOT WATER STORAGE TANK TO GAS PIPE

The assembly must be done by valid standards and precautions. On the inlet of gas to the

appliance there must be a closing element (gas valve) that should be approachable easily.

After connecting the appliance to the gas pipe the pressure test must be done and report on

first examination must be written. Gas pipe is connected directly to a gas fitting.

CONNECTING THE WATER STORAGE TANK TO WATER PIPE

- Cold water is connected to the pipe with blue marking

- Hot water outlet is connected to the pipe with red marking

On the inlet of cold water into the tank it is necessary to attach a combined safety valve with a

non-return flap that opens automatically for 0.6 Mpa pressure. After pressure decreasing the

valve closes automatically. When higher amount of water is taken and it is heated intensively,

the safety valve can open for a short time and a certain amount will flow out. To stop often

opening of the valve we recommend to take following measures:

to fit a suitable expansion tank between the storage tank and safety valve. It is not possible to

use common expansion vessels, but tanks with a rubber bag and certificate for use for water

(e.g. ZILMET expansion tanks are suitable) which are dimensioned to maximum pressure. By

using a suitable expansion tank you can totally eliminate frequent opening the safety valve.

Page 6

6

NOTE

Water must be treated by the standard. In case of deviation, an equipment for water

treatment must be installed to the tank.

WARNING

The water storage tank cannot be put into operation in any case without the safety valve fitted

and it cannot be removed.

CONNECTION TO FLUE

The appliance must be connected to a waste gas exhaust with the diameter of 100 mm. Waste

gas must be removed using the flue breaker and non-return flap against backward flow of

waste gas.

Connecting waste gas exhaust to flue must be done by the demands of standards. The flue to

which the appliance is connected must be tested by a special company. If the gas boiler and

water storage tank share operation, they can be connected to one flue only under the

condition it is dimensioned sufficiently to the output of both the appliances.

Each water storage tank works without outside source of power and it is not possible to

connect it with a flue flap electrically controlled.

Although technically it is possible to fit a bimetal flue flap due to low total savings, because of

some negative guiding signs (first of all higher noisiness of operation) it is only rarely used.

OPERATION

WARNING!

Water storage tank can be put into operation only when filled by water!

PROCEDURE OF FILLING THE TANK WITH WATER:

- Open the valve on the inlet of cold water. The valve must be always open during the

operation of the tank.

- Deaerate the tank through water-pipe fittings.

- Check the tightness of the fitting.

CHECK BEFORE IGNITION

WARNING!

* Water storage tank can be put into operation only by a trained worker of one of the service

organizations the list of which is in the supplement.

* To keep the user safe, natural gas, otherwise without smell, is mixed with aromatic materials,

so called odourisation of gas. If you smell gas in a room, do not use open faire, electric

appliances (no telephone) and do not carry out any activity which might cause sparkling. The

room must be aired, gas valve closed and the failure announced to a gas company or to a

service technician.

Page 7

7

Control button

of regulation thermostat

Piezoelectric lighter

Gas supply

to the main burner

Main gas supply

START AND PUTTING WATER STORAGE TANK TO OPERATION

Open the gas valve before the appliance.

Turn the control button of the gas fitting anticlockwise to the position of ignition burner („ “

pilot).

Press the control burner to stop and light the ignition burner by pressing the piezoelectric

lighter. It is necessary to keep the control button pressed for 10–15 seconds (pict. No.1).

Release the control button and make sure whether flame of the ignition burner keeps on

burning. If not, repeat the procedure again.

Set up the temperature required by the control button of the regulation thermostat.

Regulation of water temperature

By a regulation button, switch-off temperature can be set up in the range of 40-70°C. We

recommend to set the regulation button to 4-5 position. In this position we can reach the

temperature of 55-60°C. For this temperature only minimum of incrustation is created. For fast

heating of water in the tank it is possible to set up the button to level 7. At this level the

incrustation is higher, so it is recommended only oaboutsionally. If flame of ignition burner is

burning, thermal insulation of the heater enables keeping the temperature of heated water

for a longer period without repeated ignition of the main burner.

Water temperature can be set up by the control button of the regulation thermostat like

following:

Position 1 (about 40°C); position 2 (about 45°C); position 3 (about 50°C);

Position 4 (about 55°C); position 5 (about 60°C); position 6 (about 66°C);

Position 7 (about 72°C)

SIT 630 EUROSIT GAS VALVE

Page 8

8

WARNING!

Because of possible condensation of vapour it is not recommended to set up water

temperature to a value lower than 50°C. For running water it is necessary to mix water in the

fitting.

PUTTING THE WATER TANK OUT OF OPERATION

The procedure is following:

Turn the control button into the position OFF

Stop gas supply to the appliance

For putting the appliance back to operation it is necessary to follow previous chapters

WARNING!

Control elements of the gas fitting can not be manipulated violently. Damage can cause gas

release and even explosion. If turning the control element causes problems, service should

be called immediately.

SAFETY DEVICE

The procedure of burning is protected by flame fuse that closes gas supply automatically

when ignition flame goes off. Opening time of the fuse is about 8 seconds but it can not

overcome 15 seconds. Closing time is about 45 seconds but it can not overcome 60 seconds.

TEST OF THE DEVICE

When putting the device to operation the organization is obliged to check:

safety times of flame fuse

adjustment of the appliance to a certain thermal output

the procedure of burning the main burner from ignition flame (must be continuous)

whether the operation thermostat is working

whether the safety valve is working

whether the device is gas resistant and water resistant

whether the draught breaker is working and waste gas is exhausted properly

documentation of the device

POSSIBLE FAILURES – CONDENSATION OF VAPOUR

Vapour present in waste gas can condensate and then drop on hot surfaces. In this case some

hiss and crackle can be heard. After heating water this sound will stop.

CONDENSATION OF VAPOUR CAN HAPPEN IN FOLLOWING CASES:

New storage tank is filled with cold water for the first time.

Gas burning starts but water is still cold.

If in a short time a big volume of water was released and water coming into the boiler is too

cold. If this occurs too often, it is necessary to set up the regulator of temperature to a higher

value.

Page 9

9

FUME, SMELL OF FUME

Smell of fume after ignition of the storage tank is not a defect or anything unusual. It is just a

result of possible burning out of oil deposit on metal parts of the tank and the smell will stop in

a short time.

UNFAMILIAR NOISE

This can be sensed in case of expansion of metal parts when heating and cooling down

periodically.

EMERGENCY THERMOSTAT

The storage tank is equipped with an emergency thermostat which in case of failure of

regulation thermostat followed by higher temperature in the tank closes gas supply to main

and ignition burners. If both the burners go off, it is necessary to wait until water in the tank

cools down under 40°C and then relight the ignition flame again. If it is not possible to put the

storage tank to operation again, service must be called immediately.

PERIODICAL MAINTENANCE

Periodical maintenance is important to make the storage tank reliable. User is

recommended to sign a contract with a service company on regular checks and

maintenance of the storage tank which can prolong life and ensures operation without

failures.

To make repairs and maintenance possible and easy, there must be free approach to the

storage tank. Air supply must not be limited.

The storage tank should be cleaned of dust and can not be covered by towels, rags and other

flammable materials. Outside coat can be cleaned with a rag soaked with soapy water and

dried with a towel.

If in the room, where the storage tank is located, some works concerning to change of

surroundings are done, all the storage tank including ignition flame must be put out of

operation.

When the storage tank is off and the outside temperature drops under 0°C, water must be

released from the tank.

WARNING!

If the storage tank is put out of operation for a longer time (2 weeks and more) including

ignition burner, hydrogen, that is highly incombustible, can be released from hot water

distribution. When putting the tank back to operation, we recommend to open hot water

taps for several minutes.

If hydrogen release occurs, during water running some strange noise can be heard. When

the noise stops, the burner can be ignited and there will be no danger of spontaneous

ignition.

Page 10

10

WARNING FOR USER!

When taking the storage tank over make sure whether the letter of guarantee is confirmed

properly.

Reclaim defects immediately otherwise you lose your right for guarantee. Check whether

the equipment was not damaged during transport and if it was, claim the guarantee at the

transporter.

Reclamation of the completeness of the delivery is carried out in compliance with

Commercial Code and Civil Code at the deliverer.

Assembly of the product can be done only by a qualified worker or organization with a valid

certificate. Repairs of the storage tanks can be performed only by service organizations

included in the list. Unqualified intervention into the storage tank can cause losing the right

for a guarantee repair free of charge!

INSTALLATION AND ADJUSTMENT OF GAS VALVE

Only for qualified workers!

Adjustment of the outlet pressure

All the adjustments must be done according to technical

parameters of the appliance. Inlet and outlet pressure are

checked by A and B outlets.

Maximum pressure: Set up the control button to maximum

level of 7, by C screw set up pressure of 10 mbar.

Setting up gas flow to ignition burner

By gradual screwing D screw the flow decreases, by

releasing it increases.

If you want to put gas flow adjustment to ignition burner out

of operation, screw the D screw up to stop.

WARNING:

After finishing all the activities it is necessary to check

tightness of gas fitting and verify whether the appliance is

working.

BOILER ACCESSORIES, DOCUMENTATION

A part of the gas storage tank is a safety valve (0,6 mbar)

and draught breaker

Instruction for use

Because of permanent development of products we reserve the right to change

technical data.

A

measuring

outlet gas

pressure

B

measuring

inlet gas

pressure

+

-

+

-

C

setting up

the outlet

of main burner

D

setting up

the output

of pilot-burner

Page 11

11

Stamp, signature of the service organization: ....................................

Obligatory service inspection after the 1st year of operation

Date: .............................

Obligatory service inspection after the 2nd year of operation

Stamp, signature of the service organization: .................................Date: ..........................

Data of the customer: (legibly)

Name and surname:

...........................................................................

Street: ................................................................

ZIP code, town: ..................................................

Tel.: ....................................................................

Device commissioning report

Serial number: ...............................................

Date of commission: ......................................

Service organization:

.......................................................................

Stamp, signature

This page serves for confirming the service inspections and is kept by the customer!

NOTES

Page 12

ATTACK, s.r.o. – 05/2014

ATTACK, s.r.o.

Dielenská Kružná 5020

038 61 Vrútky

Slovenská republika

Tel: +421 43 4003 101

Fax: +421 43 3241 129

E-mail: kotle@attack.sk

Web: www.attack.sk

Výrobca ATTACK, s.r.o. si vyhradzuje právo technických zmien výrobkov bez predchádzajúceho upozornenia. • ATTACK, s.r.o. producer reserves the right to change technical parameters and dimensions of

boilers without previous warning. •Der Hersteller ATTACK, s.r.o. behält sich das Recht der technischen

Veräderungen an Produkten ohne eine vorige Warnung. •Изготовитель ATTACK, s.r.o. оставляет за

собой право изменения технических параметров и размеров котла без предыдующего предупреждения. •Le producteur ATTACK, s.r.o. réserve le droit des modifications techniques sans l‘avertissement

précédent. •Productor ATTACK, s.r.o. reserva el derecho de cambios técnicos sin advertencia anterior.

Loading...

Loading...