Page 1

W W W . A T T A C K . S K

GAS CONDENSING BOILER

ATTACK

KZT, KST, KT, KT Small, KZT Solar Plus

INSTRUCTIONS FOR USE

Page 2

2

1 Installation...........................................................................................................................

Introduction..............................................................................................................................

Control panel KST Plus, KT Plus, KT small Plus.....................................................................

Start and stop and indication during operation KST Plus, KT Plus, KT small Plus.....................

Regulation of boilers KST Plus, KT Plus, KT small Plus..........................................................

Control panel KZT Plus...........................................................................................................

Start and stop and indication during operation KZT Plus...........................................................

Regulation of boiler KZT Plus..................................................................................................

Equithermic regulation of boilers.............................................................................................

Compensation curve and transfer of curves...............................................................................

Regulation of hydraulic pressure, connection of external tank..................................................

2 Installation...........................................................................................................................

General instructions.................................................................................................................

Place of installation..................................................................................................................

Hydraulic connections..............................................................................................................

Gas connection, anti-freeze system...........................................................................................

Electrical coonections and external sensor................................................................................

Placing of external probe and access to el. terminal...................................................................

Flue gas outlets.........................................................................................................................

Accessories, Connection to outlet of condensed water..............................................................

3 Operation and maintenance................................................................................................

Regulations..............................................................................................................................

Combustion analysis and setting of CO2...................................................................................

Start-up....................................................................................................................................

Maintenance.............................................................................................................................

Table - list of errors...................................................................................................................

4 Characteristics and technical data......................................................................................

Dimensions and connections....................................................................................................

Main boiler parts.......................................................................................................................

Hydraulic circuit of boilers.......................................................................................................

Table with technical data...........................................................................................................

Electrical schemes and diagram of pressure losses....................................................................

Accessories of flue gas outlet and table of resistance.................................................................

Manual content:

3

3

3

4

5

6

7

8

8

9

10

11

11

11

11

12

12

13

14-15

16

17

17

18

19

20

21

22

22-23

24-26

27-29

30

31-32

33

Page 3

3

1. Installation

Introduction

Dear customer,

thank you for choosing the ATTACK trademark, the wall hung condensing boilers ATTACK with

modern design, equipped with modern technology, with increased reliability and construction quality.

Read this user manual properly, whereas it contents important information concerning safety at

installation, usage and maintenance of the appliance.

The ATTACK Plus boilers are intended for central heating and D.H.W. warming (with built-in 25-litres

stainless tank, instantaneous heating or external additional tank) with mixing and condensation at high

output level at operation and very low emissions. They use natural gas or propane, equipped and

controlled with modern micoprocessor control system.

Boiler body consists from multi-plate exchanger and mixing ceramic burner, equipped with electronic

ignition and ionisation flame control, venilator with modulation of rotations and modulation gas valve.

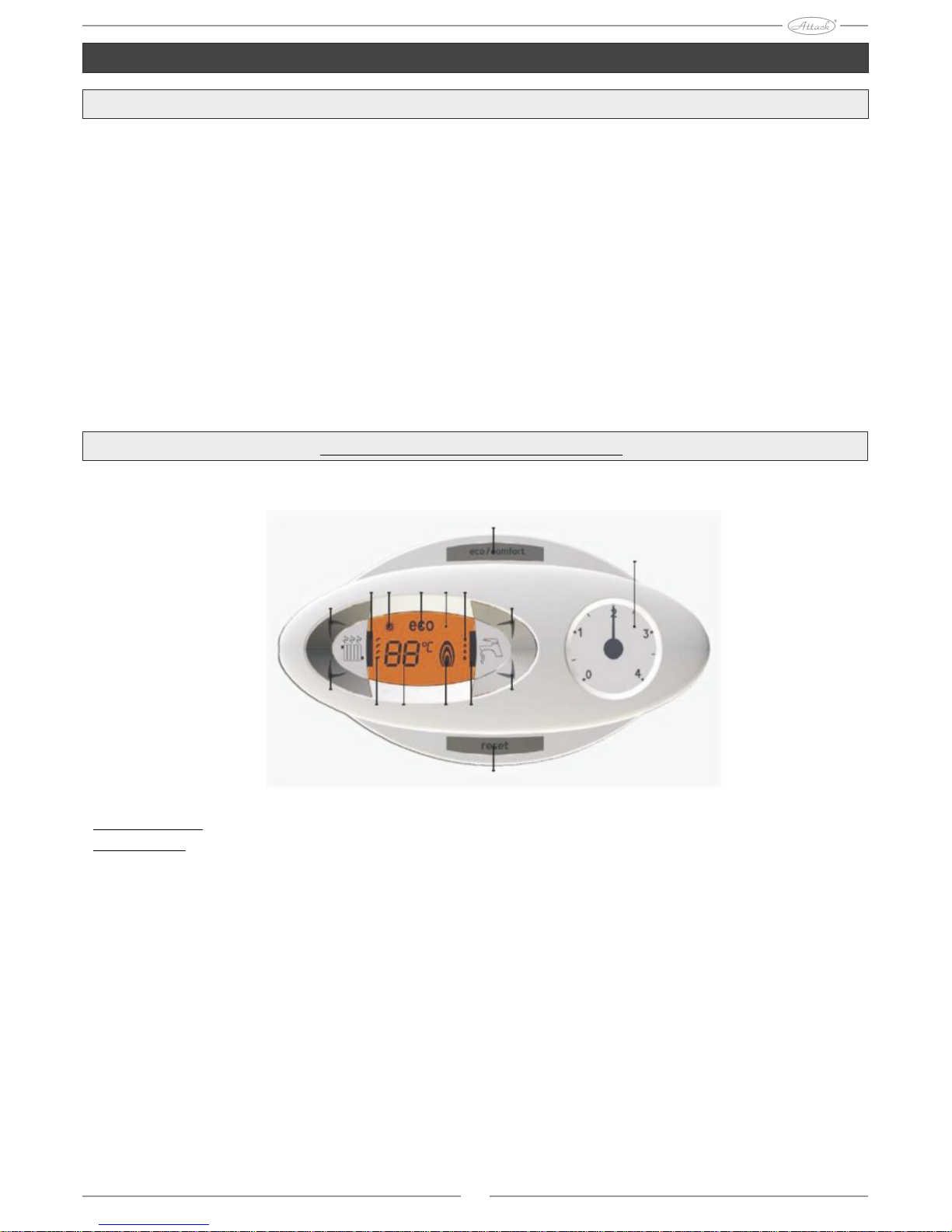

Control panel of boilers KT Plus, KT small Plus, KST Plus

Pic.1

Control panel

Description

1 = Button to decrease set temperature of D.H.W.

2 = Button to increase set temperature of D.H.W.

3 = Button to decrease set temperature of water in central heating system

4 = Button to increase set temperature of water in central heating system

5 = Display

6 = Button to recover original setting - regime option Summer/Winter

7 = Button to switch regime Economy/Comfort - Start/Stop of appliance

8 = Symbol of D.H.W.

9 = Indication of D.H.W. production

10 = Indication of regime Summer

11 = Multifunctional indication (flickers during protection function of exchanger)

12 = Indication of regime Eco (Economy)

13 = Indication of heating function

14 = Symbol of heating in heating appliance

15 = Indication of operating burner and actual output

( flickers during function of Flame protection)

7

16

14 10

4

12 5 9

2

3

13 11 15 8

1

6

Page 4

4

Indication during operation of KT Plus, KT small Plus, KST Plus

Heating

Requirement for heating (generated from room thermostat or Open therm regulator) is indicated by

flickering of LED diodes at radiator symbol (see page 13 - pic.1). Display (see page 11 - pic.1)

projects actual temperature at the inlet into heating appliance and during waiting time for heating, the

„d2“ text is displayed.

Domestic hot water

Requirement for D.H.W. (activated by taking of D.H.W. ) is signalized by flickering of LED diodes by

symbol of water tap (see page 8 - pic.1).

Display projects actual temperature at the D.H.W. outlet and during the waiting time for D.H.W., there

is a text „d1“.

Disconnection of water heater KT small Plus, KT Plus (economy)

Water warming - i.e. temperature keeping in the water heater can be turned off. In case that you turn

this function off, no D.H.W. will be produced.

User can turn the heater off (ECO regime) by pressing ECO/Comfort button (see page 7 - pic.1). In

the ECO regime, appropriate yellow control light is turned on (see page 12 - pic.1) To reactivate the

COMFORT regime, press the button ECO/COMFORT (poz. 7- obr.1 ) again.

Comfort of water heating KST Plus

Requirement for Comfort regime (comeback to original internal boiler temperature) is signalized by

flickering of LED diodes by symbol of water tap (see page 9-pic.1). Water in exchanger is

permanently warmed to temperature of 45°C. Display (see page 11-pic.1) shows actual temperature of

water in the boiler.

Start and stop of boilers KT Plus, KT small Plus, KST Plus

Boiler start

Connect appliance into electricity mains. The „FH“ is displayed within next 120 seconds, which

signalizes deareation cycle of the heating appliance. Also the version of the card software is displayed

within first 5 seconds. Open the gas valve installed on connection in front of the boiler. After

expiration of the FH text is boiler prepared for automatic operation after every usage of the DHW or

in case of requirement of the room thermostat.

Boiler stop

Hold button (see 7 - Pic.1 ) for 5 seconds.

The control electronics remains connected to the electricity mains after the boiler is shut down.

Operation of DHW warming and heating is turned off. To turn the boiler on again, hold the button for

5 seconds (see 7 - Pic.1). Boiler will be immediately ready for operation by every DHW usage or by

activation per the room thermostat. After interruption of the electrical or gas connection of device is

the antifreeze system inactive. During long-time interruption of operation, to avoid of damages caused

by frost, it is recommended to release all water from the boiler, DHW and water from supply system,

or to release only DHW and fill the supply system with antifreeze mixture that conforms to conditions

given in this manual.

Page 5

5

Regulation of the boilers KT Plus, KT small Plus, KST Plus

Switching to Summer/Winter

Hold the button for 2 seconds (see 6 - Pic.1).

The Summer sign appears on display (see 10 - Pic.1). Boiler will make only the DHW The antifreeze

system remains active. To cancel the Summer mode, hold the button for 2 seconds again (see 6 Pic.1).

Regulation of the heating water temperature

It is possible to set the temperature from the minimum of 20°C up to the maximum of 90°C by the

buttons of heating (see 3 and 4 - Pic.1).

Regulation of the DHW temperature

It is possible to set the temperature from the minimum of 10°C up to the maximum of 65°C by the

buttons of DHW (see 1 and 2 - Pic.1).

Setting of the environment temperature (with additional room thermostat)

Set the required temperature in premises by the room thermostat. If the room thermostat is not

connected, boiler will keep temperature in supply system at value that was set at the inlet into the

supply system.

Setting of the environment temperature ( additional OpenTherm regulator)

Set the required temperature in premises by the regulator. Boiler will treat water in OpenTherm

device adequately to the required temperature of environment. Farther in this manual you will find

instructions for operation with remote control.

Page 6

6

Control panel of the KZT Plus boilers

Pic.2

Control panel

Description

1 = Button to decrease adjusted DHW

2 = Button to increase adjusted DHW

3 = Button to decrease adjusted temperature of water in the central heating system

4 = Button to increase adjusted temperature of water in the central heating system

5 = Display

6 = Button for switching to Summer/Winter

7 = Button for switching to Economy/Comfort

8 = Button of reset / fill-in of device

9 = On / Off button of device

10 = Button of the „Controlled temperature“ menu

11 = Indication of achieving the required DHW temperature

12 = Sign of DHW

13 = Indication of DHW production

14 = Setting/ temperature at the DHW outlet (flickers during the „Heat exchanger protection“ operation )

15 = Indication of Eco (Economy) mode or Comfort mode

16 = Temperature of the external sensor (with additional external probe)

17 = Appears, when the external probe or the remote control is connected (optional)

18 = Temperature of environment (per additional remote control)

19 = Indication of burner operation and actual output (flickers during function „Flame protection“)

20 = Indication of operation against frost

21 = Indication of pressure in the heating device

22 = Error indication

23 = Setting / temperature at the heating device inlet (flickers during operation „Exchanger protection“)

24 = Sign of heating

25 = Indication of heating operation

26 = Indication of achieving temperature at the heating device inlet

27 = Indication of the Summer mode

Page 7

7

Start and stop of the KZT Plus

Boiler without electrical connection

Boiler is not connected to the electricity mains

When the electrical or gas connection is interrupted, the antifreeze system does not work. During

long-time interruption of operation, to avoid of damages caused by frost, it is recommended to release

all water from the boiler, DHW and water from supply system, or to release only DHW and fill the

supply system with antifreeze mixture.

Boiler start

Connect boiler to electricity mains.

The „FH“ letters will be displayed within the following 120 seconds, which means, that the air is

being released form the heating device. During the first 5 seconds is displayed also the card software

version. Open the gas valve installed on the connection with boiler.

The „FH“ text expires, the boiler is prepared for automatic operation everytime by DHW consumption

or by requirement from the room thermostat.

Boiler stop

Hold the button for 1 second (see 9 - Pic.2). When the boiler is shut down, the control electronics

remains connected to electricity. Operation of water warming and heating is turned off. The antifreeze

system remains active. To start the boiler again, hold the button for 1 second again (see 9 - Pic.2).

Boiler will be immediately ready for operation by every DHW consumption or by activation through

the room thermostat.

Indication during heating operation of the KZT Plus

Requirement for heating (activated by room thermostat or remote control) is indicated by flickering of

the warm air over space heater sign (see 24 and 25 - Pic.2).

Display (See 23 - Pic.2) shows actual temperature at the heating device inlet and the „d2“ text during

the period of waiting for heating.

Grades of heating (see 26 - Pic.2) light on sequentially, according to achieving of the value set by

thermal probe.

Domestic hot water

Requirement for water heating in the boiler is indicated by flickering of the warm water sign - marked

as water tap (see 12 and 13 - Pic.2). Display (see 14 - Pic.2) shows actual temperature at the DHW

outlet and the „d1“ during waiting for DHW. Grades of the DHW (see 11 - Pic.2) light on

sequentially, according to achieving of the temperature set by the heating device sensor.

Shutdown of the water heater (economy)

Water heating, i.e. keeping water temperature in the storage tank can be shut down. When this

function is turned off, no DHW is produced. When the DHW warming is turned on (original setting),

text „COMFORT“ is diplayed (see15-Pic.2). When it is turned off, text ECO is displayed (“See7Pic.2"). For activation of the COMFORT mode, press the button again (See 7 -Pic.2).

Page 8

8

Regulation of the KZT Plus boiler

Switching Summer/Winter

Hold the button for 1 second (see 6 - Pic.2).

The Summer sign appears on display (see 10 - Pic.1). Boiler will make only DHW. The antifreeze

system remains active. To cancel the Summer mode, hold the button for 1 second again (see 6 - Pic.2).

Regulation of the heating water temperature

It is possible to set the temperature from the minimum of 20°C up to the maximum of 90°C by the

buttons of heating (see 3 and 4 - Pic.2).

Regulation of the DHW temperature

It is possible to set the temperature from the minimum of 10°C up to the maximum of 65°C by the

buttons of DHW (see 1 and 2 - Pic.2).

Setting of the environment temperature (with additional room thermostat)

Set the required temperature in premises by the room thermostat. If the room thermostat is not

connected, boiler will keep temperature in supply system at value that was set at the inlet into the

supply system.

Environment temperature setting ( additional time remote control)

Set the required temperature in premises by the . Boiler will treat water in device time remote control

adequately to the required temperature of environment. Farther in this manual you will find instructions

for operation with time remote control.

Equithermic regulation of the KZT Plus, KST Plus, KT Plus, KT small Plus boilers

After installation of external probe (additional), the external temperature measured by the external

probe is displayed on the screen of the control panel (See 5 - Pics.1 and 2).

Boiler regulation system works with the „Controlled temperature“. In this mode is temperature of the

heating device regulated according to the external climatic conditions to ensure higher comfort and

energy savings during the whole year. Moreover, after increasing of the external temperature is the

temperature at the boiler outlet decreased according to the concrete „ compensation curve“. By

regulation of the equithermic regulation of temperature, the temperature set by the buttons of heating

(See 3 and 4 - Pics.1 and 2) represents maximum temperature at the inlet into the heating device.

It is recommended to set maximum temperature to enable system operation within the full interval.

Boiler must be set by specialist during the installation. Necessary adjustment for higher comfort can be

done by user.

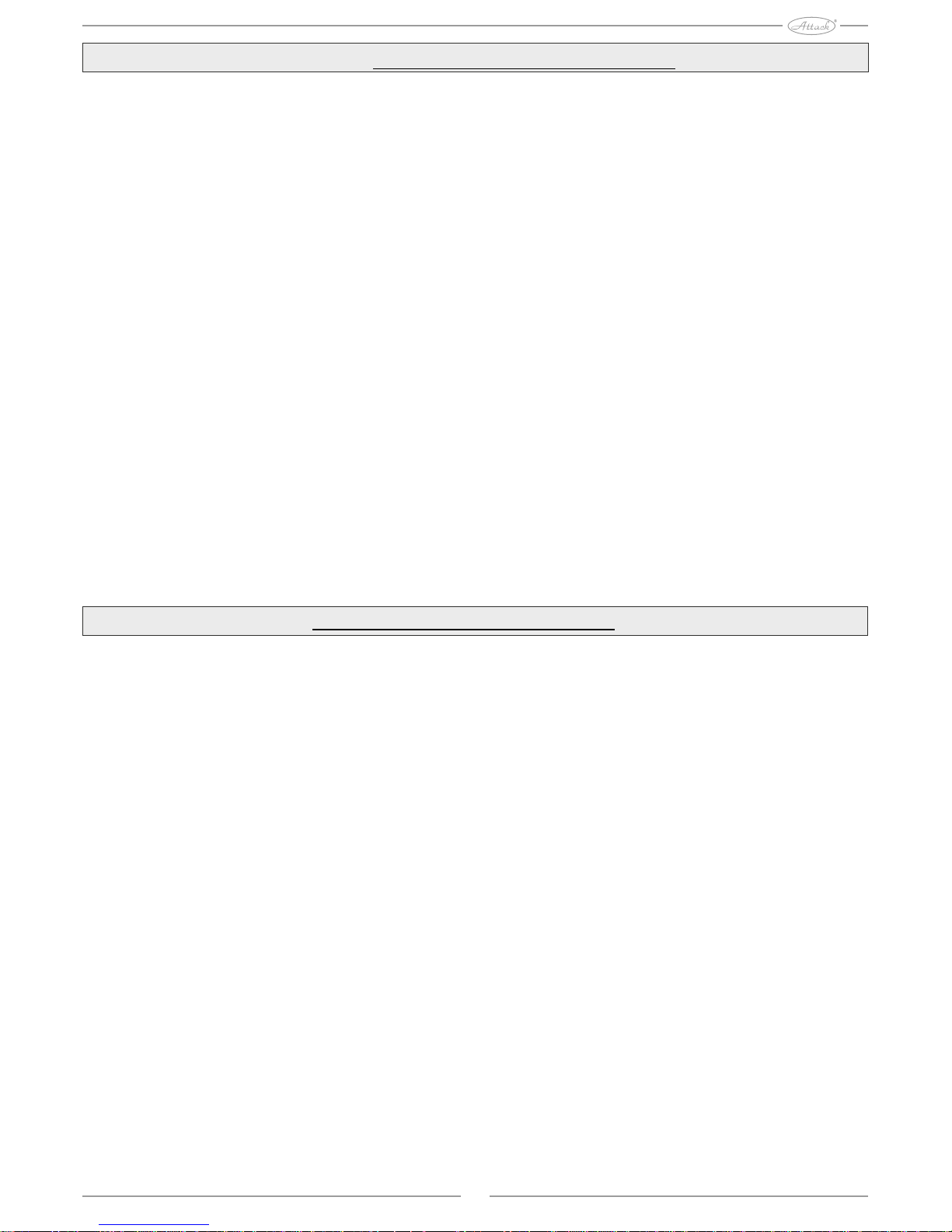

Compensation curve and shift of curves of the condensing boilers Plus

Press button once to display actual compensation curve (See 6 - Pic.1 KST, KT and See 10 - Pic2 KZT).

It is possible to change it per DHW buttons (See 1 and 2 - Pic.1 and 2). Adjust the required curve from 1

to 10, adequately to the characteristics. By adjusting curve to 0 is the regulation of the controlled

temperature cancelled.

Compensation curve of the Plus condensing boilers

Access to the paralel curves shifting is enabled through heating buttons (See 3 and 4 - Pics. 1 and 2).

Flickering text (OF) is displayed. It is possible to change it through DHW buttons. (See 1 and 2 - Pics. 1

and 2).

Parallel shift of the curves of the condensing boilers Plus

Repeated pressing of the button (See 6 - Pic.1 KST, KT ) and (See 10- Pic.2 KZT ) enables to exit

mode of the parallel curve regulation. If the environment temperature is lower than required

temperature, it recommended to set more abrupt curve and vice-versa. Decrease or increase for 1 unit

and check the result in the room.

Page 9

9

Compensation curve and curve shifting

By holding the ,,reset" button (See6 - Pic.1 KST, KT) or the ,,mode" button(See 10 - Pic.2 KZT ) for 5

seconds opens the menu of the „Controlled temperature“, the flickering „CU“ is dipslayed. Adjust the

required curve by the DHW buttons (marked as 1 and 2, pics. 1 and 2) from 1 to 10, adequately to the

characteristics. Regulation of the controlled temperature is cancelled by adjusting curve to 0.

Compensation curve

Option of the parallel curve shift, the flickering „Of“is displayed by pressing the heating buttons (See 3

and 4 - Pics.1 and 2). Set the parallel curve shift adequately to the characteristic by the DHW buttons

(See 1 and 2 - Pics. 1 and 2).

Compensation curves

Parallel curve shift

Repeated pressing of the button „Reset“ (See 6 - Pic.1 KST, KT ) and „Mode“(See 10- Pic.2 KZT ) for

5 seconds enables to exit mode of the parallel curve regulation. If the environment temperature is lower

than required temperature, it recommended to set more abrupt curve and vice-versa. Decrease or increase

for 1 unit and check the result in the room.

Regulation with time remote control

If the time remote control (additional equipment) is connected to the boiler, the above mentioned

operations are controlled per boiler display and the „FH“ text appears.

Regulation of the heating temperature

Regulation can be performed via menu of the time remote control, as well as via the boiler´s control

panel.

Regulation of the DHW temperature (with external DHW tank installed)

Regulation can be performed via menu of the time remote control, as well as via the boiler´s control

panel.

Switching Summer/Winter

The Summer mode has priority over the eventual requirement for heating from the remote control.

Selection Eco/Comfort

If the DHW warming is turned off by the remote control, boiler is switched into the Economy mode.

Therefore is the button (See 7 - Pics.1 and 2) on the boiler control panel out of order. If the DHW

warming is turned on by the remote control, the boiler is switched to the Comfort mode. Therefore it is

possible to set one of the two modes through the button (See 7 - Pics. 1 and 2).

Controlled temperature ( OPENTHERM )

The OPENTHERM communication is built into the electronic control board of the boiler. All the boiler

functions are controlled through programmable Opentherm regulator (Ordering code: OT36A).

Programmable regulator and the room thermostat are not included to the boiler accessories.

10 9 8 7 6

5

4

3

2

1

100

90

80

70

60

50

40

30

20

-20-15-10-505101520

100

90

80

70

60

50

40

30

20

-20-15-10-505101520

Page 10

10

Regulation of the hydraulic pressure of the supply device

Pressure indicated on the water-gauge, when the heating system is filled being cold, has to be 1,0 bar.

If pressure of device decreases to minumum values, boiler display shows error F 37. Increase pressure

in device to value higher than 1,0 bar by using the filling tap (See 1). Manometer indicating pressure

without electrical connection is placed in the bottom part of the boiler.When the hydraulic pressure is

recovered, boiler activates 120 seconds long ventilation cycle displayed as „FH“. Afterwards it is

always necessary to close the filling tap (See 1).

Connection to the DHW tank of the KT Plus, KT small Plus boilers

Control electronics of the boiler serves to control the external DHW tank. Make hydraulic

connections following the scheme. Make electrical connections following the instructions in the

electrical scheme (Page 13). It is always necessary to instal thermal probe for the tank. Boiler control

system detects presence of the thermal probe and automatically configures itself, activates display and

appropriate control of DHW warming.

Scheme of connection to external tank:

8 DHW outlet

9 DHW inlet

10 Inlet into the heating system (CH flow connection)

11 Return flow from the heating system (CH return

connection)

209 Inlet into the exchanger of DHW warming

210 Return flow from the exchanger of DHW warming

Page 11

11

2. Installation

General instructions

BOILER HAS TO BE INSTALLED EXCLUSIVELY BY SPECIALIZED AND TRAINED WORKERS AND ALL THE

INSTRUCTIONS GIVEN IN THIS TECHNICAL MANUAL HAVE TO BE KEPT, AS WELL AS ALL THE VALID

PRESCRIPTIONS, ALL REGULATIONS FROM THE EN NORMS, ALL STN NORMS, ALL SAFETY

PRESCRIPTIONS AND ALL WARNING SIGNS.

Place of the installation

Sphere of combustion of device is totally hermetic to the surrounding environment, and thereby it is possible to install

device in any kind of room. It is necessary to have sufficient ventilation in the room, where the boiler is going to be installed

to avoid from danger of the gas release (even if small). This safety norm is given by the Ordinance EHS Nr.90/936 for all the

gas using devices and also for devices with so called hermetic chamber. The boiler has to be installed in the dustless room,

where are no flammable materials or corrosive fumes.Room must be dry and the inside tempreture must not decrease under

0°C. Boiler has to be hung on the wall and therefore it is equipped with the console. Boiler has to be clamped in the way

ensuring its stable and efficient position. It is necessary to leave sufficient space for maintenance, in case that the boiler is

placed in the corner or if there is a furniture around. By installation , keep safe distance of the boiler surface from flammable

materials in dependence on combustibility grade:

- from materials of the combustibility grade B, C1, C2 100mm

- from materilas of the combustibility grade C3 200mm

- from materials of the combustibility grade not tested under STN 73 0853 200mm

Examples of the building materials sorting by combustible grade:

- combustible grade A - non-combustible (brick, adapting pieces, ceramic tiles, parget, mortar )

- combustible grade B -very hard combustible (heraklith, lignos, boards from basalt felt)

- combustible grade C1 - hard combustible (beech, oak, plywood, werzalit, hard paper )

- combustible grade C2 - medium combustible (pine wood, spruce chipboard, solodur)

- combustible grade C3 - easy combustible (wood-fibre-boards, polyurethane, PVC, molitane, polystyrene)

Solid materials of the combustible grade A can be used as non-combustible and isolation matters. Items made from

combustible materials must not be placed on the boiler and in the distance of 500mm from boiler.

Hydraulical connections

The ATTACK boilers are intended for heating systems with forced heating water circulation. Intensity of the water flow can

be set by switch on the pump. Before is the heating system filled with water, it is necessary to clean the system properly. It is

necessary to flush heating bodies and distribution pipes several times.To flush and clean the system properly it is

recommended to use cleansing articles. Filter must be mounted at the inlet into the heating system. It is recommended to use

copper filter with side cleaning and it has to be cleaned in regular intervals, depending on system clogging. Due to the

maintenance and servicing it is recommended to mount closing valves at the inlet and outlet of central heating and D.H.W.

Filter and valves are not delivered as accessories of the boiler. Heating system has to be also equipped with inlet valve

(installation with ATTACK KT boiler) with reverse flap, connected to water supply system to fill and pressure the heating

system. Boilers ATTACK KST and KZT Plus are equippped with filling valve with reverse flap.

Warranty is not valid for cases of clogging or stucking of exchanger or pump caused by dirts from the system!

Water callosity in the heating system cannot excess 3 mmval/l . In case of exchanger damage caused by boiler operation

with water of callosity higher than 3 mmval/l is warranty for exchanger also not valid. Expanse vessel of 7 or 8l installed in

the boiler enables connection to the closed heating system. If it is neccessary due to the size of the heating system, it is

possible to install additional expanse vessel. There should be difference of 15-20°C between outlet and inlet boiler heating

water. In case of reconstruction of the heating system or new system, it is recommended to use low-voluminous heating

appliances and distribution pipes in as small dimmensions as possible for quick system temperature reaction and

considerable flexibility of the system.

Process of filling with water: boiler has to be disconnected from electricity mains. Open deareation valves on boiler and

heating system. System has to be pressurized for at least 1 bar and deareated again. If the pressure decreases, it is neccesary

to pressurize it again.

Heating system must conform to valid norms and prescriptions:

STN 06 0310 - projection and installation of the central heating system,

STN 06 0830 - Assurance of appliance for central heating system

STN 06 0830 - Expanse vessel size

STN 07 7401 - Water in heating system

If the expanse vessel volume exceeds 7 or 8 litres it is necessary to add next expanse vessel with volume adequate to the

difference. To use maximum condensation effect it is necessary to dimensionize heating system to gradient 50/30°C. Fall

from the safety 3-bar valve has to be connected to the waste pipe. Heating system has to be equipped with suitable filter. For

maximum output of the heat exchanger, its correct function and long lifetime it is necessary to ensure minimum

overpressure of the heating system of 0,8bar. Built-in expanse vessel enables boiler connection to closed heating system.

Boiler has to be placed to ensure necessary operation conditions, adequately to design of the combustion air inlet and flue

gas exhaust.

V =V . v . 1,3

C

V - volume of expanse vessel

C

V - volume of water in heating system

v - appropriate volume increase by warming to t

m

t =80°C is v =0,029

m

Page 12

12

Antifrost system, frost-free liquids, additional mixtures or inhibitors

Boiler is equipped with antifrost system that activates boiler for heating, when the temperature of water at

the inlet into the heating system decreases under 6°C. Mechanism is not active, if appliance is

disconnected from electricity or gas. If it is necessary, it is possible to use frost-free liquids, additional

mixtures or inhibitors, but exclusively in case, that producer of the liquids or additional mixtures

guarantees, that his products are suitable for use and do not cause damage of the boiler exchanger or other

boiler parts and heating system. It is forbidden to use routine frost-free substances, additional mixtures or

inhibitors which are not exclusively intended for use in appliances producing heat and which are not

suitable for materials of boiler and distribution system.

Gas connection

Before boiler connecting, the gas connection has to be tested and revised. After boiler connection, all the

gas connections have to be tested for tightness, including pipes and armatures in boiler. Gas distribution

pipes in hte building must be done in conformity with valid norms STN EN 1775. Dismantable

connections of the gas pipes and D.H.W. pipes must not be strained by any other additional powers.

Connection to electricity mains

Boiler is intended for connection to electrical socket of 230V/50Hz placed near boiler by movable inlet

cable. Connection to electricity has to be in conformity with norm STN 33 2000-4-46, where the socket

has to be equipped with middle safety bar connected to the PE conductor.It is not allowed to use different

distributors and extension cords. Electrical voltage has to be 230V/50Hz. Plug installation, room

thermostat connection and service of electrical parts must be performed by person with special

electrotechnical qualification under the ordinance 50/1978 Zb.

Boiler is equipped with inlet electrical cable without plug. Connection to mains must be done tightly and

they must be equipped with bipolar switch with minimum contact distance of 3mm, with integrated fuse of

3A max between boiler and mais. By electrical connections it is necessary to keep polarity (PHASE:

brown conductor / ZERO: blue conductor / PROTECTION: yellow-green conductor).

Boiler is equipped with inlet electrical cable without plug. Connection to mains must be done stationary,

accessorized with bipole switch, with minimum 3mm distance of contacts, max 3A fuse engaged between

boiler and mains. It is important to keep polarity by electrical connections (PHASE:brown conductor /

ZERO: blue conductor / PROTECTION:yellow-green conductor). By installation or exchange of

electrical cable it is necessary to let grounding wire longer for 2cm than other wires. Inlet electrical cable

of device must not be exchanged by user. In case of cable damage, turn device off and call qualified

workers of authorized service. For the case of exchange of electrical inlet cable, use only the “HAR H05

VV-F” 3x0,75 mm2 cable with maximum external diameter of 8mm.

Room htermostat a Opentherm (boiler accessory)

ATTENTION: RO OM THER MOS TAT MUST H AVE CLEAN C ONTACTS . BY 230V

CONNECTION 230 V TO THERMOSTAT TERMINAL IS ELECTRONICS IRREVERSIBLY

DAMAGED.

It is necessary to connect room thermostat by copper conductor of 1-1,5mm2 diameter. For the

Opentherm´s contacts it is possible to use copper conductor with diameter of 1-1,5 mm2.

Conductors of external temperature sensor must not be lead parallely with conductors of the room

thermostat and mains connection.

External sensor (boiler accessory)

Connect sensor to appropriate terminals.Use casual 2-wire cable. It is necessary to connect room temperature sensor by

copper conductor of diameter.Maximum ohm resistance of conduction is 0,75 mm2 10kΩ, complete length is 30cm.

External probe should be rather installed on northern, north-western side or on side, where the living room is generally

placed. Probe must never be exposed to morning sun. Generally, it must not be exposed to direct sun radiance. If it is

necessary, protect it by cover. Probe must not be installed near windows, door, ventilation openings, chimneys, nor heat

sources, which could influence measured values.

Page 13

13

Wrong placing of external probe

Access to electrical terminal of the KZT Plus boiler

To access to boiler terminal, it is necessary to remove rear cover and then to make necessary electrical

connections, as it is given on scheme on the picture.

Access to electrical terminal of the KST Plus, KT Plus, KT small Plus boilers

To access to boiler terminal, it is necessary to remove rear cover and then to make necessary electrical

connections, as it is given on scheme on the picture. After connection of external tank through

temperature sensor it is necessary disconnect both resistances on terminal. If tank is connected through

tank thermostat, it is only necessary to disconnect resistance1,8k .

Page 14

14

Flue gas exhausts

This appliance is a C type, with hermetic chamber and forced exhaust, air inlet and flue gas outlet have

to be connected to one of the systems of outlet / suction mentioned further. Appliance is homologized for

operation with all chimneys Cxy, that are listed on label with technical data (some configurations are

given only as example in this chapter). Despite of that there is a possibility, that some configurations will

be literally limiting or they will not conform to prescriptions, norms or national regulations. Check and

strictly keep all instructions before installation. Except of that, keep instructions concerning placement

of endings on wall ot roof and minimum distances from windows, walls, ventilation openings, etc.

This appliance of C type has to be installed by usage of suction pipes and exhaust outlets supplied by

producer, in conformity with UNI-CIG 7129/92. In case, that these are not used, any warranty and

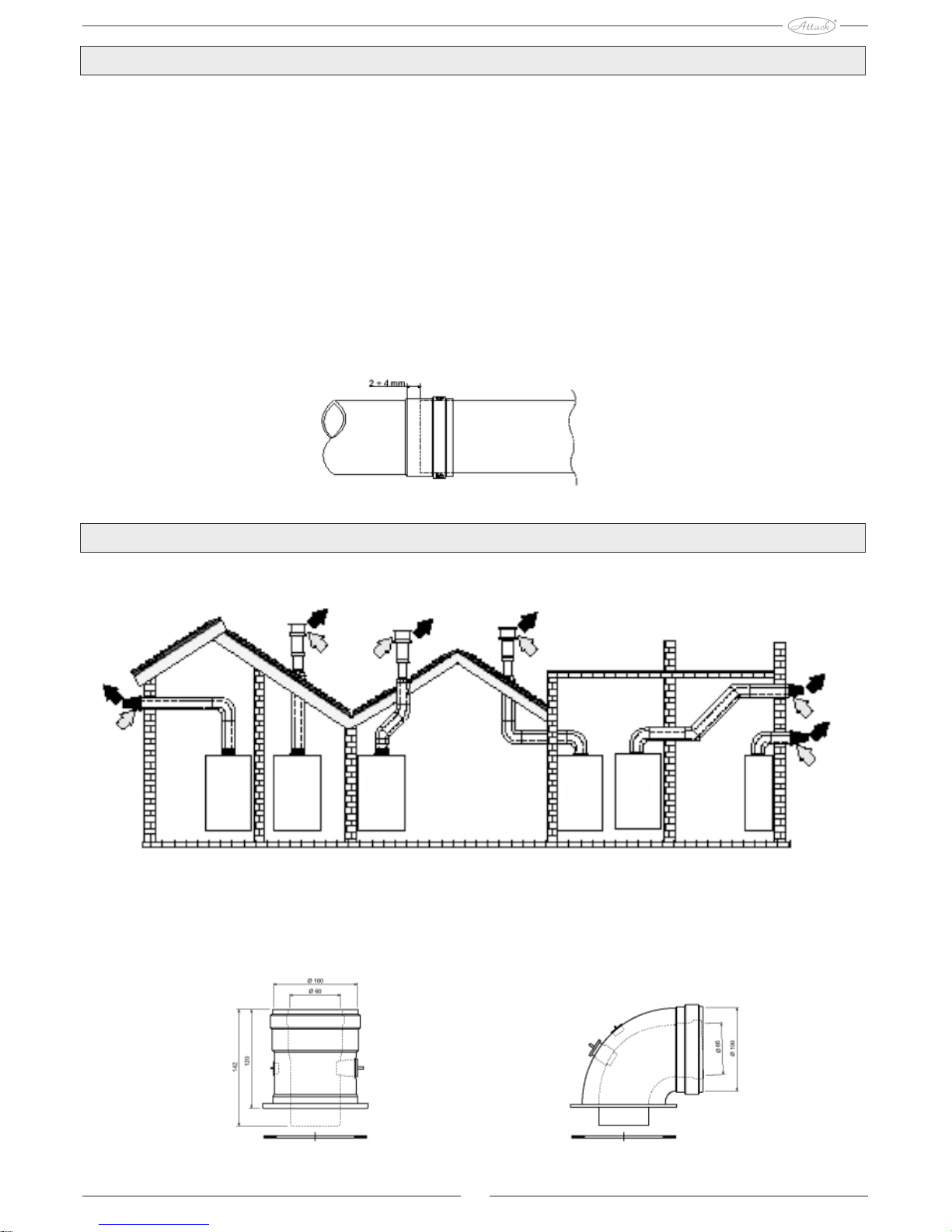

producer´s reliability expires. By installation of flue gas exhausts longer than 1m it is necessary to

consider natural material extension of materials by operation. To prevent deformations, let dilatation

space of 2 ÷ 4 mm approximately, per 1m of length.

Extension

Connection by coaxial pipes

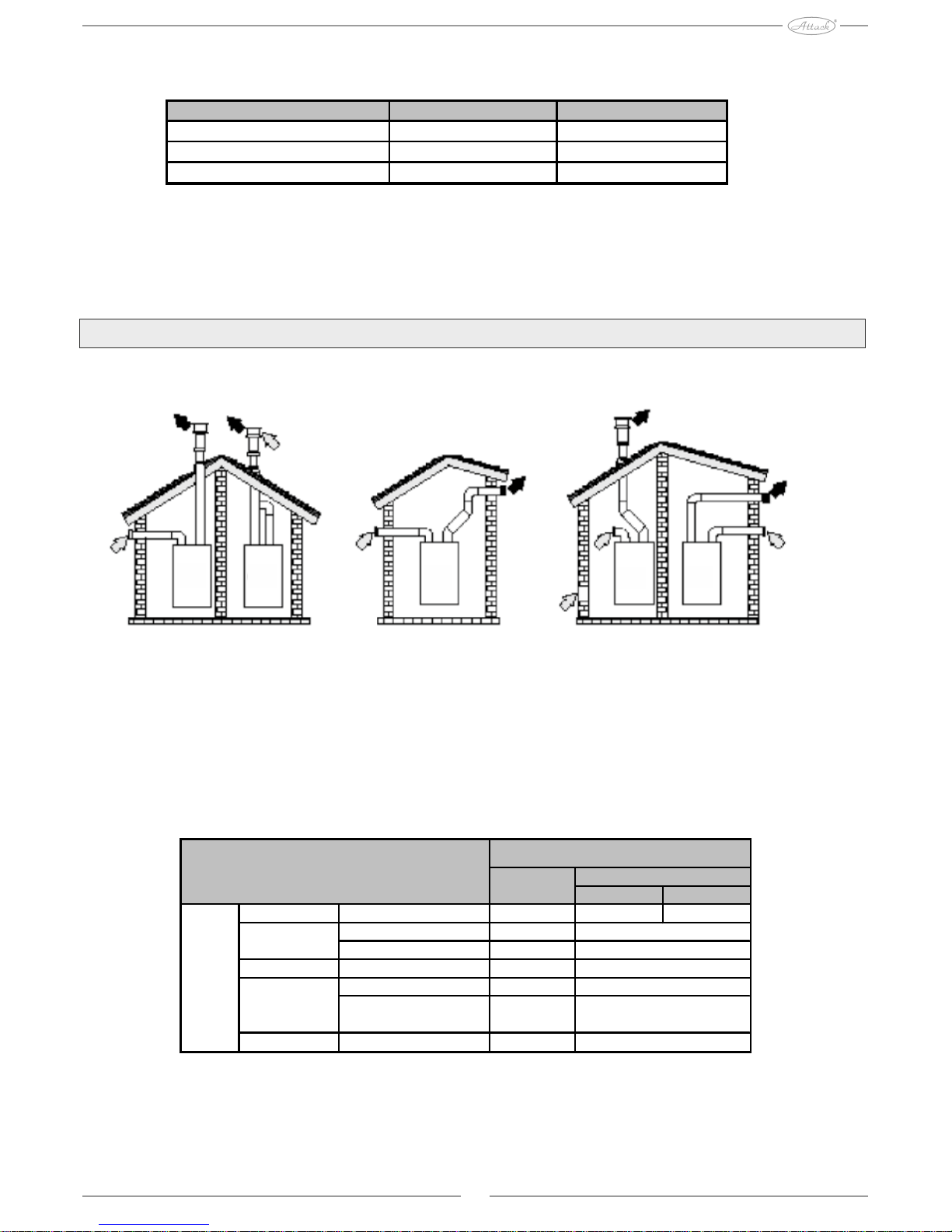

Examples of connection by coaxial pipes

By coaxial connection, mount one of the following accessory pieces to appliance. It is necessary to keep

slight downgrade of horizontal parts of flue gas exhaust to boiler, in order to prevent eventual condensed

water leaks out and drops.

Accessories by coaxial connection

C

13

C

33

C

33

C

33

C

13

C

13

Page 15

15

C

53

C

33

C

53

C

23

C

13

Air suction

Vertically Horizontally

Pipe 1m O/M 1 1,6 2

45° O/M 1,2

90° O/M 1,5

Distribution with control opening 0,3

air to wall 2

Chimney Air/flue gas 80/80

2

0,3

Losses in m/eq

Flue gas outlet

1,8

Elbow

Ø 80

Endpiece

12

5flue gas to wall

Maximum length of coaxial outlets

Before installing it is necessary to check, if the maximum permitted length has not been exceeded.

Every coaxial arc means length reduction, as it is given in the table. For example, connection 60/100

with elbow of 90° + 1m of horizontal outlet means equivalent length of 2m. Before installation it is

necessary to check, if the max.permitted length was not exceeded (concern, that every coaxial bow

causes length reduction as it is given in the table).

Connection by separate tubes

Examples of connection with separate tubes

Before installing, check by simple calculation, if total length does not exceed maximum length:

1. Make final calculation of scheme of double chimneys, including accessories and endings.

2. Check table 4 - losses in meq (equivalent meters) for every item, in dependence from its position in

installation.

3. Check, if total amount of losses is lower or equal to the maximum permitted length given in the table.

Maximum length of separate tubes

Separate tubes

Maximum permitted length 75 meq

Coaxial 60/100 Coaxial 80/125

Max. permitted length

5m 10m

Factor of elbow reduction

90° 1m 0,5m

Factor of elbow reduction 45° 0,5m 0,25m

Page 16

Accessories

Connection to mutual chimneys

Examples of connection to chimneys

If you decide to connect boilers ATTACK Plus to mutual or separate chimney with natural exhaust,

mutual or separate chimney has to be projected exclusively by specialized worker in conformity with

valid norms for appliances with hermetic chamber, equipped with fan.

Moreover, it is necessary to keep following characteristics of mutual / separate chimneys:

- dimensionised by calculation method given in valid norms

- proof against flue gas, resistant against smoke and heat, proof against condensed water

- circular or quadrilateral diameter, vertical , without reductions

- with pipe, that takes hot flue gas out, they are adequately remote or isolated from flammable materials

- with connection to single appliance on 1 floor

- with connection to same appliances (or different, but all appliances only with forced flue gas outlet or

only with natural flue gas exhaust)

- without mechanical means for suction in main pipes

- with underpressure in all their length, in conditions of stationary operation.

- in their platform they have collection tank for solid material or eventual condense water, equipped with

metal door with airtight closing.

Connection to condense water outlet

Boiler is equipped with internal syphon for condence water outlet. By first installation, mount inspection

connection (A). Mount flexible pipe of condense outlet (B) to outlet of boiler´s syphone by extending it

for 3cm approximately and fit it by fixing bolt. Fill syphone for 0,5l of water (2) approximately and

connect flexible pipe to outlet device (3).

Outlet of condense water

16

C

83

C

43

C

43

Page 17

3. Operation and maintenance

All operations for regulation and adjustment according to type of gas must be done by qualified and

trained workers (professional technicians, that respect valid technical norms) - the authorized

servicemen. ATTACK takes no responsibility for damages on properties, nor injuries of persons that are

caused by incorrect manipulation with appliance by unqualified or unauthorized persons.

Regulation

Adjustment according to type of gas

Appliance works on natural gas (G20) or propane (G31). Adjustment of appliance for concrete gas type is

performed by producer, as it is given on the serial label. In case that it is necessary to use appliance with

another type of gas, than it is intended, it is necessary to ensure appropriate set for transformation. Then it

is necessary to make the following steps:

1. Remove covering

2. Open hermetic chamber

3.Hang down fixing clip C and pick gas pipe A out of the fan unit - Venturi.

4. Exchange nozzle B laid inside the gas pipe for nozzle from boiler transformation set.

5. Fix the gas pipe A back by clip and check, if the sealing is tight

6. Mount hermetic chamber and covering again.

7.Modify parameter related to the gas type:

switch boiler into the stand-by mode, hold DHW buttons pressed (pos. 1 and 2 - pic. 1 and 2) for 10

seconds: flickering „PI01“ is displayed

by pressing DHW button (pos. 1 - pic.1 and 2), set parameter 00 (by operation for natural gas) or 01 (by

operation for propane). Hold DHW button pressed (poz.1 - pic. 1 and 2) for 10 seconds. Boiler gets back

to stand-by mode.

8. Check inlet operation pressureat the gas valve inlet.

9. Use combustion analyser, connected to the exhaust outlet from boiler to check, if the CO2 content in

flue gas, by max. and min. boiler output, is adequate to the supposed content given in the table with

technical data for appropriate gas type.

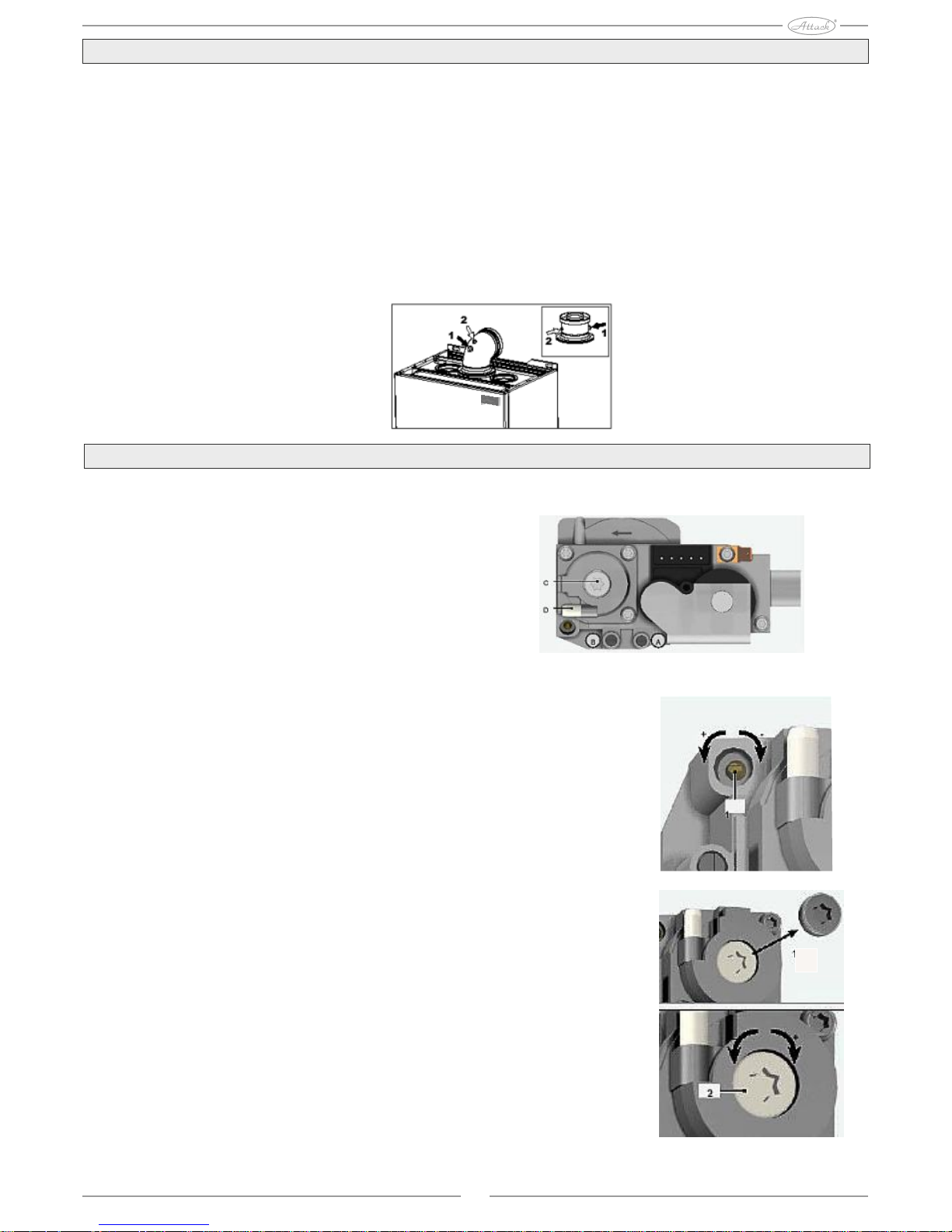

Gas nozzle exchange

17

Page 18

Analysis of combustion

Combustion is analysed in air (2) and flue gas (1) exemption areas as it is given on the picture. For

measuring it is necessary to:

1.Open exemption areas of air and flue gas

2.Put probes in

3.Press buttons "+" and "-" by heating sign for 5 seconds to activate the TEST mode

4.Wait 10 minutes until boiler gets into stable operation

5.Measure

Value of CO2 has to be in interval of 8,7 - 9% by natural gas (G20). By propane (G31) it is 9,5-10%.

In case, that analysis is done, while boiler is not in stable operation, errors in measuring may occur.

Combustion analysis

Setting of CO2 value by combustion

Setting and check of the CO2 on gas valve can be only by qualified service technician!

Description of gas valve:

A - Inlet pressure

B - Outlet pressure

C - Regulation screw - min. output setting

D - Regulation screw - max. output setting

By max.output is CO2 set by regulation screw D, by max.output is CO2 set by regulation screw C

Co2 test by max. output:

1- Put device for combustion analysis into flue gas outlet pipe.

2- Start boiler and test mode by pressing "+" and "-" buttons by heating

sign for 5 seconds.

3- Use "+" button to set heating to max output (100%)

4- Check, eventually set CO2 values by screw (1) for the range of

8,7 - 9,2 % for natural gas (G20) and 10 - 10,5 % for propane (G31)

5- Exit test mode after correct setting.

CO2 test by min output:

1- Put device for combustion analysis into flue gas outlet pipe.

2- Start boiler and test mode by pressing "+" and "-" buttons by heating

sign for 5 seconds.

3- Use "-" button to set heating to min. output (0%)

4- Check, eventually set CO2 values by screw (1) for the range of

8,7 - 9,2 % for natural gas (G20) and 10 - 10,5 % for propane (G31)

5- Set back to 100% and exit test mode after correct setting.

18

Page 19

Activation of the TEST mode

Press heating buttons together for 5 seconds to activate the TEST mode (see 3 and 4 - pics.1 and 2). Boiler

is started by maximum output of the set heating and actual value, as it is given in the text below.

Signs of heating and DHW flicker on display and temperature of heating. Values of actual heating output

and actual value of flame flow (uA x 10) are also displayed.

To exit TEST mode, repeat same process as by activation. TEST mode is everytime automatically

stopped after 15 minutes.

Regulation of heating output

To make regulation of heating output, set boiler into the TEST mode. Press buttons of heating (see 3 and

4, pics. 1 and 2) to increase or to decrease output (Minimum = 00 - Maximum = 100). If the RESET button

is pressed for 5 seconds, maximum output stays at the level that was actually set.Exit TEST mode.

Operation start-up

Before start and after all installation actions that required disconnection from distribution network or

works on safety mechanisms or boiler parts, it is necessary to check the following:

Before boiler start

- open eventual control valves installed between boiler and distribution network.

- check tightness of connections, if there is no gas leakage; be carefull and use soap water solution

- check pressure of expanse vessel overfill

- fill hydraulic devices and ensure absolute deareation of boiler and heating system - open deareation

valve on boiler, eventually deareation valves of distribution system

- check pressure in heating system, cca 1bar. in cold state

- fill outlet syphone and check correct connection to outlet device for condense water

- check, if there is no water leakage in the heating system, DHW circuit, connections or in the boiler

- check accuracy of connection of electrical device and functionality of grounding

- check if pressure value and gas overflow for heating are adequate to requirements

- check, if there are no flammable liquids or other materials in near surrounding of boiler

Checking during operation

- Turn device on

- Check tightness of gas circuit and heating system

- Check tightness of chimney and air-flue gas exhausts during boiler operation

- Check correct tightness and functionality of syphone and device of outlet of condensed water

- Check correct water circulation between boiler and heating system

- Check correct modulation of gas valve by heating and also by DHW preparation

- Check correct boiler start by several tests of start and stop by room thermostat or by remote time

controller

Use combustion analyser, connected to the flue gas outlet from the boiler to check, if the CO2 content in

flue gas - by max. and min. boiler output - is adequate to the supposed content given in the table with

technical data for appropriate gas sort, eventually adjust it , as it is given in the instructions in chapter

about CO2 adjustment on page 18.

-Check, if fuel consumtion, displayed on counter, is appropriate to consumption given in the table with

technical data.

- Check correct parameter programming and make eventual adjustments according to your needs

(compensation curve, output, temperatures, etc.)

19

Page 20

Maintenance

Regular check

To keep long-time functionality and effectivity of device, qualified worker must regularly perfom the

following tests:

- Control and safety elements (gas valve, flow sensor, thermostats, etc.) must work correctly

- Circuit of flue gas exhaust must be perfectly tight

- Closed chamber has to be tight

- Pipes and ending air-flue gas must have no barriers, nor leakage

- System for condense water outlet must be functional, without barriers and it cannot leak

- Burner and exchanger must be clean and without sediments. By eventuall cleaning, do not use

chemical means, nor steel brushes.

- Electrode must be placed correctly, with no sediments

- Gas and water supply connections must be ensured against leakage

- Pressure of water in distribution device in cold state must be approximately 1 bar. If pressure is

different, adjust this value.

- Circulation pump must not be blocked

- Expanse vessel must be filled

- Flow and gas pressure must correspond to data given in appropriate tables

Cover, control panel and external parts of boiler can be cleaned by soft wet cloth, eventually soak in water

with cleaner. Do not use abrasive cleaners nor dissolvents.

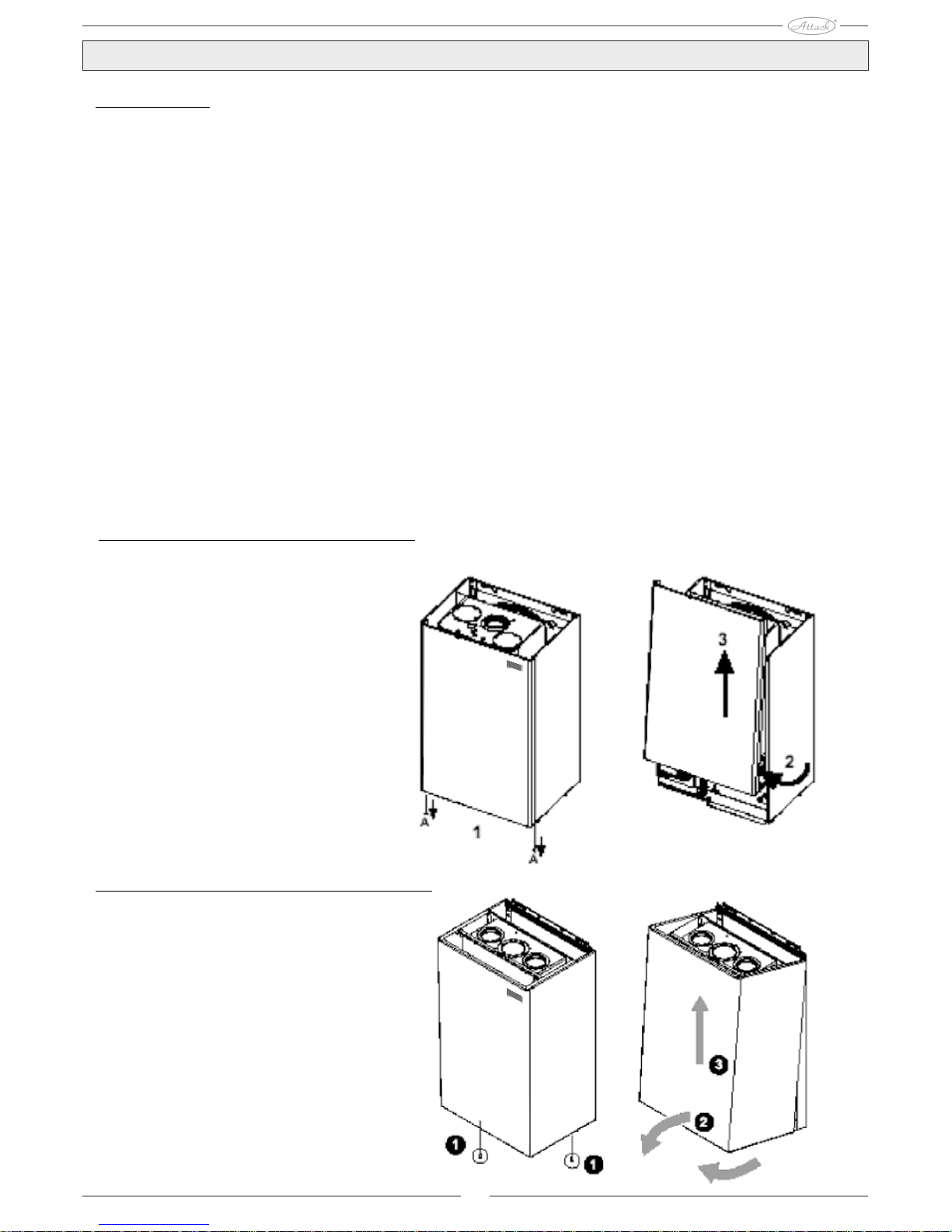

How to open cover of the KZT Plus boiler

To open cover of boiler:

1. Dismantle screws A (1)

2. Pull cover to open (2)

3. Lift up and remove cover (3)

How to open cover of the KST Plus, KT Plus, KT small Plus boilers

To open cover of boiler:

1. Dismantle screws (1)

2. Pull cover to open (2)

3. Lift up and remove cover (3)

20

Page 21

Table of error messages

Diagnostics

Boiler is equipped with modern system for autodiagnostics. In case of boiler error, display flickers

together with the sign of error and number indicating error code.

There are errors, that cause permanent blockage (marked by „A“ letter): to get boiler back to normal

operation, press RESET button for 1 second or use RESET on remote time controller (additional), if

it is installed; if boiler does not come to operation, it is necessary to remove the fault. Errors (marked

by „F“ letter) cause often blockages, that are automatically removed, immediately after the value gets

back into the interval of normal boiler operation.

21

Code Error Possible cause Solution

Check, if gas inlet into boiler is balanced and if pipes are deareated

Error of ignition and ionisation electrode

Check cable connection of electrodes, their correct placing and

if there are no sediments on them

Damaged gas valve Check and change gas valve

Insufficient gas pressure in network Check gas pressure in distribution network

Blocked syphon Check and clean syphon, if necessary

Signal of flame presence

by extinguished burner

Error of electrode Check cable connection of ionisation electrode

Damaged sensor of heating Check correct placing and operation of central heating sensor

Water in device does not circulate Check circuiting pump

Areated heating system Deareate heating system

Intervention of fuse of flue

gas and smoke exhaust

Error F07, that occured 3-times

in last 24 hours

Action of ventilator fuse

protection

Error F15 that remained for 1 hour

period

Error of ionisation electrode Check position of ionisation electrode or exchange it

No flame in start-up phase Unstable pressure Check burner

(6-times within 4 min.) Error Check setting of gas valve by min. output

Flue gas outlet clogged Remove barries from piping of flue gas outlet

Syphon clogged Check and eventually clean the syphon

Damaged sensor

Sensor failure at the entry

Cabling under shortage

into distribution device 1

Aborted cables

Damaged sensor

Failure of sensor of return flow

Cabling under shortage

Aborted cables

Damaged sensor

Sensor failure at the entry

Cabling under shortage

into distribution device 2

Aborted cables

Supply voltage lower than

170V

Incorrect frequency in

electrical mains

Incorrect water pressure in Too low pressure Refill system with water

device Damaged sensor/ switch of pressure Change the RZT sensor or RT,RST pressure sensor

F39 External probe error Damaged sensor or shortage Change sensor or check connection of cables

Incorrect water pressure in Check safety valve

device Check pressure in expanse vessel

A41 Placing of sensors Sensor disconnected from pipe Check correct placing of sensor

F42 Error of heating sensor Damaged sensor Change sensor

Water in device does not circulate Check circuit pump

F43 Safety action of exchanger Areated distribution device

F47 Error of pressure sensor Aborted cables Check connection of cables

F50 Error of modulation reel Aborted cables Check connection of cables

Check connection of cables or change sensor

F14

Check connection of cables or change sensor

Problems with electricity mains Check electricity mains

F34

F11

See error F15

A05

A06

F10

Check connection of cables or change sensor

Boiler overheating

A03

A04

See error F07

No gas is supplied

Burner did not ignit

A01

Check electronicsError of control electronics

A02

Deareate heating system

F40

Too high water pressure

Problems with electricity mains Check electricity mains

F35

F37

Page 22

400330

700

4. Characteristics and technical data

Dimensions and connections of the KZT Plus

boiler

Dimensions and connections

1 = Inlet into heating system (c.h. flow connection)

2 = Outlet of supply water

3 = Gas inlet

4 = Inlet of supply water

5 = Return flow from heating system (c.h.return flow)

Dimensions and connections of the KT Plus

boiler

Dimensions and connections

1 = Inlet into heating system (c.h. flow connection)

3 = Gas inlet

5 = Return flow from heating system (c.h.return flow)

6 = Safety valve release

22

80 120 120 130

1 2 3 4 5

460

302

362

97 94,5 51 54 80 73,5

80 120 120 80

82 74 56 48 84 56

229

180

118

180

232

1 3 6 5

195

362

841

809

10,5

32

198

120

360

45

200 200

450

450

460

45

70 52 52 116 63,5 106,5

44

318

Page 23

Dimensions and connections of the KST Plus

boiler

Dimensions and connections

1 = Inlet into heating system (c.h. flow connection)

2 = Supply water outlet

3 = Gas inlet

4 = Supply water inlet

5 = Return flow from heating system (c.h.return flow)

6 = Safety valve release

Dimensions and connections of the KT small

Plus boiler

Dimensions and connections

1 = Inlet into heating system (c.h. flow connection)

3 = Gas inlet

5 = Return flow from heating system (c.h.return flow)

6 = Safety valve release

1 2 3 4 5 6

82,5 76 54 51 80,5 56

231

179

80 120 120 80

195

700

400

330

1 3 6 5

32,5 50 78,8 79,5 53,7

300

320

700

23

165

68 120 132

25,5

Page 24

Main parts of the KZT Plus boiler

5 Hermetic chamber

7 Gas inlet

8 Supply water outlet

9 Supply water inlet

10 Inlet into heating system (c.h.flow connection)

11 Return flow from heating system (c.h.return connection)

14 Safety valve

16 Ventilator

19 Combustion chamber

22 Ceramic burner

29 Collector on flue gas outlet

32 Circuit pump of heating

36 Automatic deareation valve

37 Filter on cold water inlet

40 Expanse vessel of supply water

44 Gas valve

56 Expanse vessel

74 Tap to fill distribution device

82 Ionisation electrode

95 Three-way valve

130 Pump of supply water

145 Manometer

161 Heat exchanger

186 Sensor of heating water return connection

188 Ignition electrode

191 Sensor of flue gas temperature

193 Syphon

194 Exchanger of supply water

195 Stainless steel tank for supply water 25lit.

196 Condensate collector

243 Sensor of supply water temperature

246 Pressure sensor

250 Filter on inlet into heating system

278 Double sensor (Safety + Heating)

24

Page 25

Main parts of the KST Plus boiler

5 Hermetic chamber

7 Gas inlet

8 Supply water outlet

9 Supply water inlet

10 Inlet into heating system (c.h. flow connection)

11 Return flow from heating system (c.h. return

connection)

14 Safety valve

16 Ventilator

19 Combustion chamber

22 Cearmic burner

29 Collector at flu gas outlet

32 Circuit pump of heating

36 Automatic deareation valve

37 Filter at cold water inlet

39 Regulator of supply water flow

42 Temperature sensor of supply water

44 Gas valve

56 Expanse vessel

74 Tap to fill distribution device

82 Ionisation electrode

95 Three-way valve

114 Sensor of water sensor

136 Flow sensor

161 Heat exchanger

186 Sensor of heating water return connection

188 Ignition electrode

191 Sensor of flue gas temperature

193 Syphon

194 Heat exchanger of supply water

196 Collector of condensate

201 Mixing Venturi pipe

250 Filter at inlet into heating system

278 Double sensor (Safety + Heating)

25

Page 26

5 Hermetic chamber

7 Gas inlet

10 Inlet into heating system (c.h.flow connection)

11 Return flow from heating system (c.h.return

connection)

14 Safety valve

16 Ventilator

19 Combustion chamber

22 Main burner

29 Collector at flue gas outlet

32 Circuit pump of heating

36 Automatic deareation valve

44 Gas valve

56 Expanse vessel

74 Tap to fill distribution device

82 Ionisation electrode

95 Three-way valve

114 Sensor of water pressure

161 Heat exchanger

186 Sensor of return connection of heating water

188 Ignition electrode

191 Sensor of flue gas temperature

193 Syphon

196 Collector of condensate

201 Mixing venturi pipe

209 Outlet into water tank

210 Return flow from water tank

250 Filterat inlet into heating system

278 Double sensor (Safety + Heating)

26

Main parts of KT Plus, KT small Plus boilers

Page 27

Hydraulic circuit of the KZT Plus boiler

7 Gas inlet

8 Outlet of domestic hot water

9 Inlet of domestic hot water

10 Inlet into heating system (c.h.flow connection)

11 Return flow from heating system (c.h. return

connection)

14 Safety valve

16 Ventilator

32 Circuit pump of heating

36 Automatic deareator

40 Expanse vessel of supply water

44 Gas valve

56 Expanse vessel

74 Tap to fill distribution device

95 Three-way valve

97 Magnesium anode

130 Pump of supply water

154 Pipe for condensed water outlet

161 Heat exchanger

186 Sensor of heating water return connection

191 Sensor of flue gas temperature

193 Syphon

194 Exchanger of supply water

195 Stainless tank of supply water 25lit.

196 Collector of condensate

241 Automatic by-pass

243 Sensor of supply water temperature

246 Pressure sensor

250 Filter at inlet into heating system

278 Double sensor (Safety + Heating)

27

Page 28

Hydraulic circuit of the KST Plus boiler

7 Gas inlet

8 Domestic hot water outlet

9 Domestic hot water inlet

10 Inlet into heating system (c.h.flow connection)

11 Return flow from heating system (c.h. return

connection)

14 Safety valve

16 Ventilator

32 Circuit pump of heating

36 Automatic deareator

37 Filter at cold water inlet

42 Temperature sensor of supply water

44 Gas valve

56 Expanse vessel

74 Tap to fill distribution device

95 Three-way valve

114 Water pressure sensor

136 Sensor of supply water flow

154 Outlet pipe of condensed water

161 Heat exchanger

186 Sensor of heating water return connection

193 Syphon

194 Heat exchanger of supply water

196 Condensate collector

241 Automatic by-pass

250 Filter at inlet into heating system

278 Double sensor (Safety + Heating)

28

Page 29

Hydraulic circuit of the KT Plus, KT small Plus boilers

7 Gas inlet

10 Inlet into heating system (c.h.flow connection)

11 Return flow from heating system (c.h. return

connection)

14 Safety valve

16 Ventilator

32 Circuit pump of heating

36 Automatic deareator

44 Gas valve

56 Expanse vessel

74 Tap to fill distribution device

95 Three-way valve

114 Water pressure sensor

154 Condensed water outlet

161 Heat exchanger

186 Sensor of heating water return connection

193 Syphon

196 Collector of condensate

209 Inlet into water tank

210 Return flow from water tank

241 Automatic by-pass

250 Filter at inlet into heating system

278 Double sensor (Safety + Heating)

29

Page 30

Technical data KZT Plus, KST Plus, KT Plus, KT small Plus

30

Data Unit

KZT Plus KST Plus KT Plus KTsmall Plus

Max. thermal power of central heating

kW 25,2 25,2 25,2 18

Min. thermal power of central heating kW 5,3 5,3 5,3 3

Max. thermal output of central heating (80/60°C) kW 24,6 24,6 24,6 17,7

Min. (80/60°C)thermal output of central heating kW 5,2 5,2 5,2 2,9

Max. (50/30°C)thermal output of central heating kW 26,6 26,6 26,6 19

Min. (50/30°C)thermal output of central heating kW 5,7 5,7 5,7 3,2

Max. thermal power of DHW kW 27 27

Min. thermal power of DHW kW 5,3 5,3

Max. thermal output of DHW kW 26,5 26,5

Min. thermal output of DHW kW 5,2 5,2

Pressure of gas connection G20 mbar

Max. gas flow G20 m3/h 2,86 2,86 2,86 1,9

Min. gas flow G20 m3/h 0,56 0,56 0,56 0,32

Pressure of gas connection G31 mbar

Max. gas flow G31 kg/h 2,11 2,11 2,11 1,41

Min. gas flow G31 kg/h 0,41 0,41 0,41 0,23

Max. substantive flue gas overflow

kg/h 30,3

Min. substantive flue gas overflow kg/h 5,3

Max. flue gas temperature °C 63

Min. flue gas temperature °C

Class of efficiency by directive 92/42EHS

Emissions class Nox

Max. operation pressure by heating bar

Min. operation pressure by heating bar

Max. temperature into heating °C

Water volume in boiler in central heating litre 1,5 1,5 1,5 1

Volume of expanse vessel of central heating

litre 8 8 8 7

Pressure of central heating expanse vessel overflow

bar

Max. pressure of central heating bar 9 9

Min. pressure of central heating bar 0,25 0,25

Water volume in boiler in DHW litre 25 0,3

DHW flow t 25°C l/min 15,2

DHW flow t 30°C l/min 12,7

DHW flow t 30°C l/10min 160

DHW flow t 30°C l/hod 790

Volume of DHW expanse vessel litre 2

Pressure of DHW expanse vessel overflow bar 1

Protection of electrical parts IP

Voltage of electrical mains V/Hz

Electrical input W 180 120 120 115

Electrical input by DHW production W 180 120

Weight of empty boiler kg 53 37 36 31

Sort of appliance

Value

5

C13-C23-C33-C43-C53-C63-C83-B22

230/50Hz

X5D

95

0,8

3

20

1

37

60

41,2

9,4

62

Page 31

31

Electrical scheme of the KZT Plus boiler

16 Ventilator

32 Circuit pump of heating

42 Sensor of supply water temperature

44 Gas valve

72 Room thermostat

82 Ionisation electrode

95 Three-way valve

130 Circuit pump of water tank

138 External sensor

139 Remote time controller

186 Sensor of return flow of heating water

188 Ignition electrode

191 Sensor of flue gas temperature

246 Pressure sensor

256 Signal of pump of modulation heating

278 Double sensor (Heating + Safety)

A Contact EKO/KOMFORT

OPENED = mode eco/comfort enabled by

control panel or remote controller

CLOSED = mode eco/comfort disabled;

comfort mode remains active

Electrical scheme of the KST Plus boiler

16 Ventilator

32 Circuit pump of heating

42 Sensor of supply water temperature

44 Gas valve

72 Room thermostat

82 Ionisation electrode

95 Three-way valve

114 Switch of water pressure

136 Flow sensor

138 External sensor

139 Remote time control

186 Sensor of return flow of heating water

188 Ignition electrode

191 Sensor of flue gas temperature

278 Double sensor (Heating + Safety)

A Contact ON/OFF of flow sensor

Page 32

Electrical scheme of the KT Plus, KTsmall Plus boilers

6 Ventilator

32 Circuit pump of heating

42 Sensor of supply water temperature

44 Gas valve

72 Room thermostat

82 Ionisation electrode

95 Three-way valve

114 Switch of water pressure

138 External sensor

139 Remote time controller

186 Sensor of return flow of heating water

188 Ignition electrode

191 Flue gas temperature sensor

278 Double sensor

(Heating + Safety)

Diagram of pressure losses by filling and height differences of pumps of boilers KZT

Plus, KST Plus, KT Plus, KTsmall Plus

A Losses of boiler infill

1-2-3 Speed of circuit pump

32

Page 33

33

Accessories of flue gas exhaust

Accessories of coaxial flue gas exhaust with diameter of 60/100mmÆ

Code Name

PR37 extension 1m D60/100 paint

Pr38 0,5m D60/100 paintextension

PR39 chimney 60/100 paint

PR40 elbow 90° D60/100 paint

PR41 elbow 45° D60/100 paint

PR42 elbow with flange + service opening D60/100

PR43 vertical flange + service opening D60/100

PR44 endpipe D60/100 paint

Accessories of double flue gas exhaust and air suction with diameter of 80 mmÆ

Code Name

PR45 pipe of exhaust and suction 1m D80

Pr46 1 m D80extension

Pr47 0,5 m D80extension

PR48 elbow 90 D80 O/M °

PR49 elbow 45° D80 O/M

Pr50 chimney D80

PR51 vertical distributor D60/100 - D80/80

Temperature sensors of heating, hot water heating and flue gas

Table of temperature dependence of resistivity

Temperature ( °C ) 100 90 80 70 60 50 40 30 25 15 5

Resistivity ( K Ohm ) 0,68 0,92 1,25 1,7 2,5 3,6 5,3 8 10 15,6 25,3

Sensor of central heating inlet Flue gas sensor Double sensor

Page 34

34

Page 35

Stamp, signature of service organization : ......................................................

Obligatory service examination after the 1st year of operation

Date : ........................................

Stamp, signature of service organization : ......................................................

Obligatory service examination after the 2nd year of operation

Date : ........................................

Stamp, signature of service organization : ......................................................

Obligatory service examination after the 3 rd year of operation

Date : ........................................

This page serves for confirming service examinations and is kept by a customer ! ! !

RECORD ON PUTTING THE BOILER TO OPERATION

Data on the customer (llegible)

Production number.............................. Name and surname:

Date of putting to operation................ .........................................

Service organization: Street: .............................

............................ Post code, town:.

.Stamp, signature ........................................

........................................................ Tel. No. ..........................

Page 36

ATTACK, s.r.o.

Dielenská Kružná 5020

038 61 Vrútky

Slovakia

Tel: +421 43 4003 103

Fax: +421 43 4003 116

E-mail: export@attack.sk

Web: www.attack.sk

Výrobca ATTACK, s.r.o. si vyhradzuje právo technických zmien výrobkov bez predchádzajúceho upozornenia. • ATTACK, s.r.o. producer reserves the right to change

technical parameters and dimensions of boilers without previous warning. • Der

Hersteller ATTACK, s.r.o. behält sich das Recht der technischen Veräderungen an

Produkten ohne eine vorige Warnung. • Изготовитель АТТАCK, s.r.o. оставляет

за собой право изменения технических параметров и размеров котла без

предыдующего предупреждения. • Le producteur ATTACK, s.r.o. réserve le

droit des modifications techniques sans l‘avertissement précédent. • Produc tor

ATTACK, s.r.o. reserva el derecho de cambios técnicos sin advertencia anterior.

ATTACK, s.r.o. – 12/2013

Loading...

Loading...