Page 1

THE ACCUMULATION TANKS

ATTACK®

AK/AS, HR/HRS, TUV/TUVS, S/SS

INSTRUCTION MANUAL

W W W . A T T A C K . S K

Page 2

2

CONTENTS

1. General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Description of device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1. Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2. Thermal insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3. Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Technical data and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 11

4. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1. Connection to the heat source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2. Connection of the electrical heating bodies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6. Putting into the operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

THE ATTACK ACCUMULATION TANKS

The ATTACK, s.r.o. company is the largest manufacturer of the accumulation tanks in Slovakia

with the widest offer of these items.

1. GENERAL INFORMATION

This instruction manual is an inseparable and important part of the product. Read the instructions given in this manual carefully, as they contain important information about safety, installation, usage and maintenance. Keep this manual to be eventually used in future. This appliance is

constructed for accumulation and subsequent distribution of the heat energy from the heat sources as well as for preparation of the D.H.W.

It is forbidden to use this appliance for other purposes than given above (e.g. as a D.H.W.

tank), except of the tanks with a built-in D.H.W. tank. Producer takes no responsibility for

damages caused by unsuitable or incorrect usage.

Before starting the work on device or its maintenance, disconnect the electrical power inlet. If

there are any marks of fault on the appliance, stop the operation and call a service technician.

2. DESCRIPTION OF DEVICE

The tanks serve for accumulation and subsequent distribution of the heat energy from solid fuel boilers, heat pumps, electric boilers, etc. The accumulation tanks ATTACK AS, HRS, TUVS and SS are accessorized with an extra exchanger for a heat source with separated circuit (e.g. for solar system). The accumulation tanks ATTACK HR, HRS, TUV, TUVS are equipped with a built-in system for D.H.W. preparation.

Page 3

3

ACCUMULATION TANKS

2.1. TYPES

The AK and AS line of the accumulation tanks with the volume up to 5.000 l and option to install

the electrical heating body.

The HR and HRS line of the accumulation tanks with the volume up to 2.000 l and a built-in

D.H.W. tank and option to install the electrical heating body.

The TUV and TUVS line of the accumulation tanks with the volume up to 2.000 l, a built-in instanta-

neous D.H.W. warming through a copper exchanger and option to install the electrical heating body.

The S and SS is a line of a stratified storage tanks with the volume up to 2.000 l and option to

install the electrical heating body.

2.2. THERMAL INSULATION

The accumulation tanks are supplied with 100 mm wide soft insulation made of polyester fibers

with leatherette cover.

2.3. SPECIFICATION

Max. operating pressure in the accumulation tank: 3 bar

Max. operating temperature in the accumulation tank: 95 °C

Operating pressure in a solar exchanger: 9 bar

Max. operating pressure in the D.H.W. tank: 6 bar

3. TECHNICAL DATA AND DIMENSIONS

Accumulation tanks ATTACK AK, AS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4 – 5

A

ccumulation tanks

ATTACK HR, HRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page

6 – 7

Accumulation tanks ATTACK TUV, TUVS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8 – 9

Stratified accumulation tanks ATTACK S, SS . . . . . . . . . . . . . . . . . . . . . . . . . page 10 – 11

Page 4

D2

1 ½"

AS

RS

1 ½" 1 ½"

90°

45° 45°

4

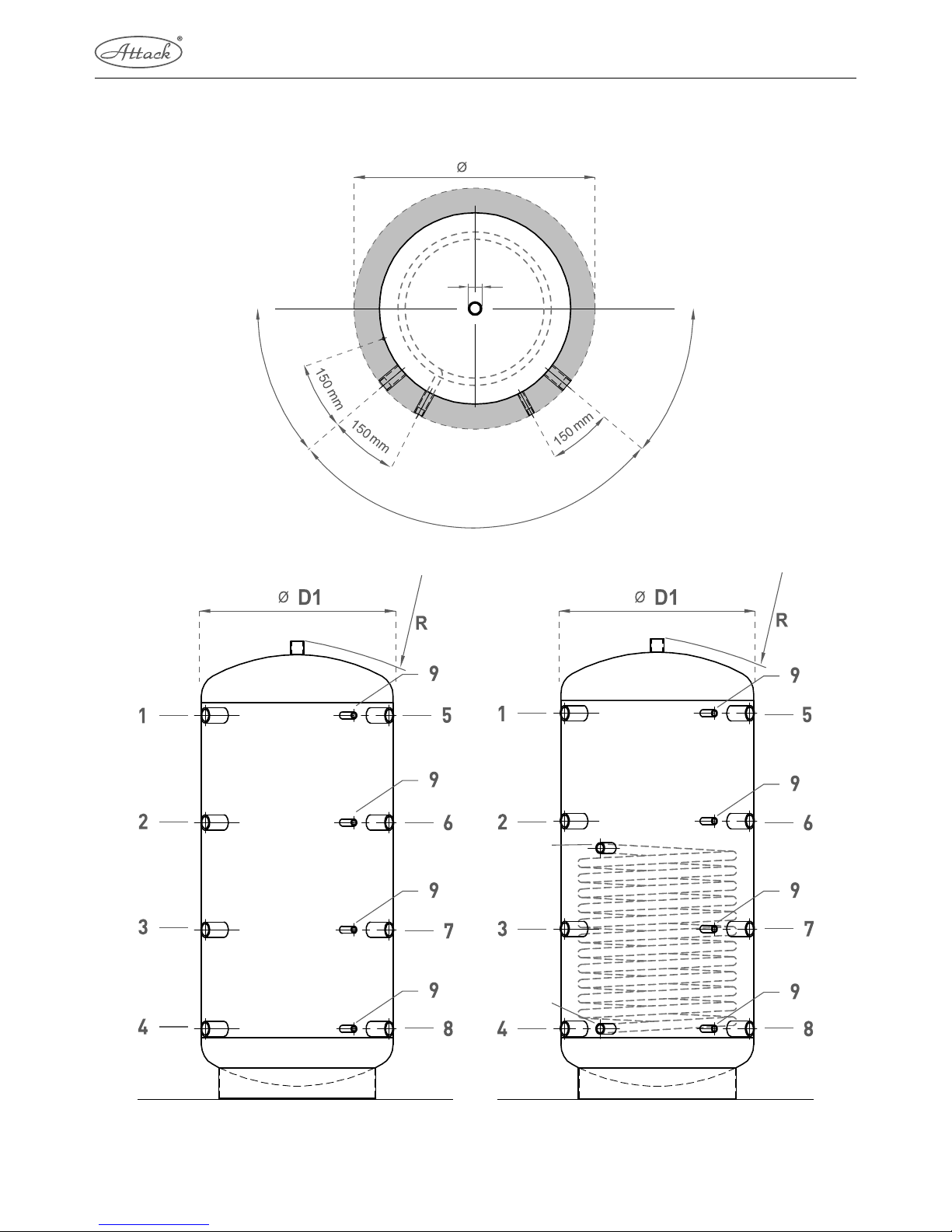

ATTACK AK ATTACK AS

ACCUMULATION TANKS ATTACK AK, AS

Page 5

5

ACCUMULATION TANKS

DESCRIPTION

The accumulation tanks ATTACK AK, AS made from the quality steel serve for ac-

cumulation and subsequent distribution of the heat energy from the biomass boiler

(e.g. SLX, DPX, DP, PELLET 30 AUTOMATIC Plus, WOOD&PELLET). The ATTACK AS

model is accessorized with an extra exchanger to be connected to the solar system.

ATTACK AK: 9× socket G 1 ½", 4× socket G ½"

ATTACK AS: 9× socket G 1 ½", 4× socket G ½", 2× socket G 1" – solar circuit

KEY FOR THE ACCUMULATION TANKS

1 – Flow connection – boiler . . . . . . . . . . . . . 1 ½"

2 – Freely disposable . . . . . . . . . . . . . . . . . . 1 ½"

3 – Freely disposable . . . . . . . . . . . . . . . . . . 1 ½"

4 – Return connection – heating circuit . . . . . . 1 ½"

5 – Flow connection – heating circuit (radiators) . 1 ½"

6 – Flow connection – heating circuit (floor) . . . 1 ½"

7 – Return connection – gas, oil and pellet boiler . . 1 ½"

8 – Return connection – wood boiler . . . . . . . 1 ½"

9 – Sensor of solar system or heating . . . . . . . . ½"

AS – Flow connection of solar system . . . . . . . . 1"

RS – Return connection of solar system . . . . . . . 1"

D1 – Diameter without insulation

D2 – Diameter with insulation

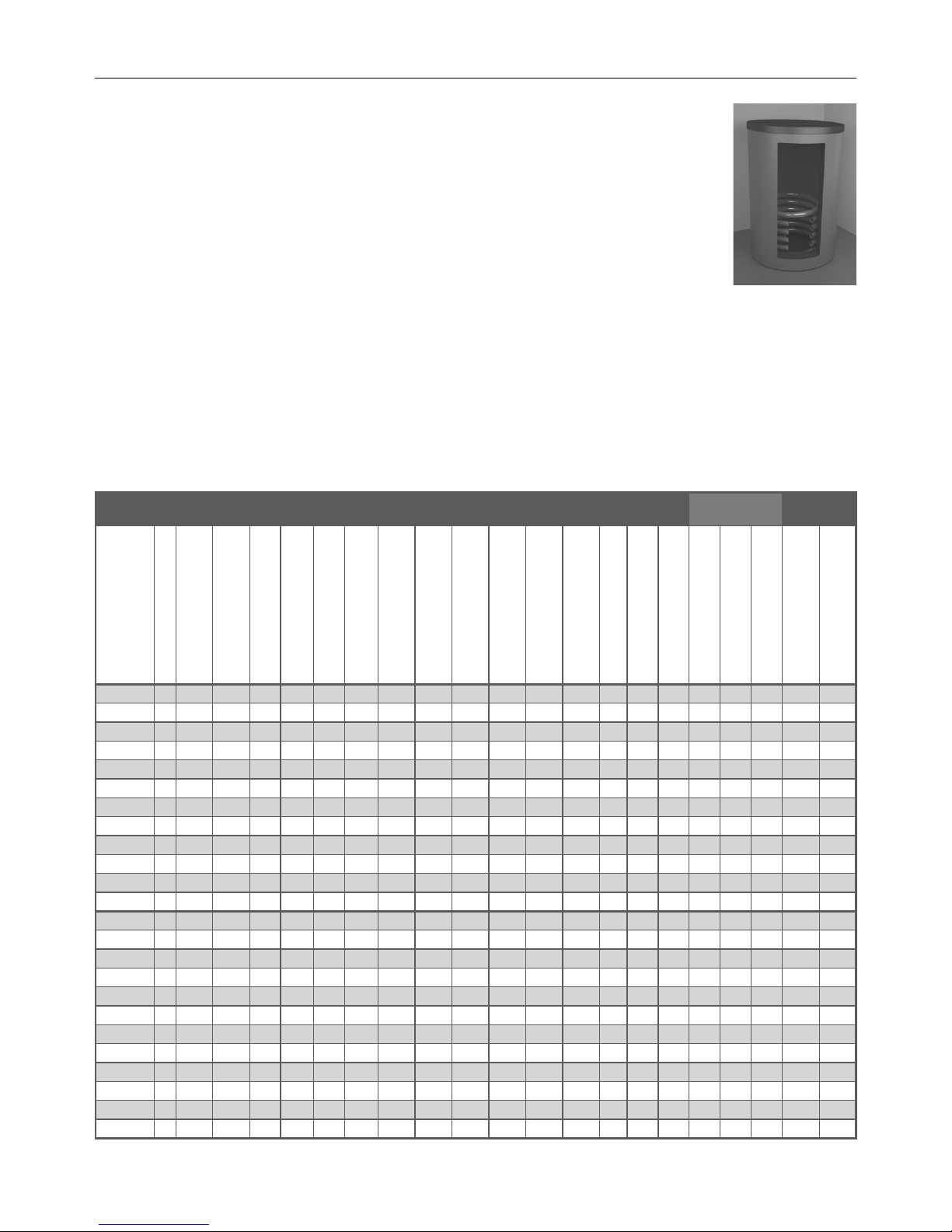

TECHNICAL PARAMETERS

Tank

Solar

excha nger

Tank

Type

Energy efficiency c lass

Position 1–5

Position 2–6

Position 3–7

Position 4–8

Position RS

Position AS

L – max. length of the ele ctric

heating body

∅ D1 – Diameter without

insulation

∅ D2 – Diameter with insula -

tion of 100 mm

Height

Height with insulation of

100 mm

R – Slope dimension wit hout

insulation

Max. operating pressure (bar)

Static loss (W )

Max. operating temperature (°C)

Area of exchanger (m²)

Volume of e xchanger (l)

Max. operating pressure (bar)

Volume (l)

Weight (kg)

AK200K C 925 705 455 205 - - 550 500 700 1 140 1 190 1 157 3 65 95 - - - 204 46

AK300K C 1 110 790 4 60 210 - - 600 550 750 1 350 1 400 1 368 3 78 95 - - - 289 60

AK400K C 1 120 815 515 210 - - 700 650 850 1 380 1 430 1 402 3 87 95 - - - 405 73

AK500K C 1 4 05 1 013 621 230 - - 700 650 850 1 660 1 710 1 678 3 94 95 - - - 488 81

AK800K - 1 545 1 135 725 315 - - 84 0 79 0 990 1 8 40 1 890 1 864 3 108 95 - - - 732 109

AK1000K - 1 735 1 255 775 295 - - 840 790 990 2 030 2 080 2 052 3 127 95 - - - 915 118

AK1500K - 1 755 1 345 820 375 - - 1 050 1 000 1 200 2 095 2 145 2 142 3 162 95 - - - 1 449 201

AK2000K - 1 955 1 4 09 862 315 - - 1 150 1 100 1 30 0 2 310 2 360 2 353 3 189 95 - - - 1 980 235

AK2500K - 2 005 1 4 65 915 375 - - 1 250 1 200 1 400 2 387 2 437 2 438 3 - 95 - - - 2 435 271

AK3000K - 2 205 1 600 985 375 - - 1 300 1 250 1 450 2 596 2 646 2 643 3 - 95 - - - 2 915 363

AK4000K - 2 385 1 730 1 065 405 - - 1 450 1 400 1 6 00 2 819 2 869 2 872 3 - 95 - - - 3 819 475

AK5000K - 2 285 1 6 80 1 065 455 - - 1 650 1 600 1 800 2 770 2 820 2 845 3 - 95 - - - 4 940 578

AS200K C 925 705 455 205 205 545 550 500 700 1 140 1 190 1 157 3 6 4 95 0,9 6 10 198 63

AS300K C 1 110 790 460 210 210 610 60 0 550 750 1 350 1 400 1 368 3 77 95 1,2 7,9 10 283 83

AS400K C 1 120 815 515 210 210 610 700 650 850 1 380 1 430 1 402 3 84 95 1,5 10 10 388 103

AS500K C 1 405 1 013 621 230 230 710 700 650 850 1 660 1 710 1 678 3 92 95 1,8 11,9 10 474 118

AS800K - 1 545 1 135 725 315 315 725 840 790 9 90 1 84 0 1 890

1 864 3 105 95 2,4 15,9 10 713 157

AS1000K - 1 735 1 255 775 295 295 860 840 790 990 2 030 2 080 2 052 3 121 95 3 19,8 10 891 172

AS1500K - 1 755 1 345 820 375 375 895 1 050 1 000 1 200 2 095 2 145 2 142 3 161 95 3,6 23,7 10 1 420 265

AS2000K - 1 955 1 409 862 315 315 843 1 150 1 100 1 300 2 310 2 360 2 353 3 188 95 4,2 23,7 10 1 960 296

AS2500K - 2 005 1 465 915 375 375 1 095 1 250 1 200 1 40 0 2 387 2 437 2 438 3 - 95 4,2 27,7 10 2 410 345

AS3000K - 2 205 1 600 985 375 375 1 095 1 300 1 250 1 450 2 596 2 646 2 643 3 - 95 4,2 27,7 10 2 890 446

AS4000K - 2 385 1 730 1 065 405 405 1 125 1 450 1 400 1 600 2 819 2 869 2 872 3 - 95 5 33 10 3 779 568

AS5000K - 2 285 1 680 1 065 455 455 1 175 1 650 1 600 1 800 2 770 2 820 2 845 3 - 95 6 39,6 10 4 880 687

Page 6

1

2

3

EL EL

4

5

6

7

8

9

6

7

8

9

10

10

10

RS

AS

10

10

10

10

10

1

2

3

4

5

AF

AC

MA

CN

14°

D2

∅

D1

∅

D1

∅

R

R

100

28°

17°

17°

EL

28°

6

ACCUMULATION TANKS ATTACK HR, HRS

ATTACK HRSATTACK HR

Page 7

7

ACCUMULATION TANKS

DESCRIPTION

The accumulation tanks ATTACK HR, HRS are made from the quality steel

and serve for accumulation of the heating water as well as for preparation of

the D.H.W. by an internal enameled exchanger. The ATTACK HRS model is

accessorized with an extra exchanger to be connected to the solar system.

Tanks of this type have a built-in magnesium anode in the D.H.W. tank

to increase resistance against corrosion. The manual deaeration valve is installed in the upper part.

ATTACK HR: 9× socket G 1 ½", 6× socket G ½"

ATTACK HRS: 9× socket G 1 ½", 6× socket G ½", 2× socket G 1" – solar circuit

KEY FOR THE ACCUMULATION TANKS

1 – Flow connection – boiler . . . . . . . . . . . . . 1 ½"

2 – Freely disposable . . . . . . . . . . . . . . . . . . 1 ½"

3 – Electrical heating coil (EL) . . . . . . . . . . . . 1 ½"

4 – Freely disposable . . . . . . . . . . . . . . . . . . 1 ½"

5 – Return connection – heating circuit . . . . . . 1 ½"

6 – Flow connection – heating circuit (radiators) 1 ½"

7 – Flow connection – heating circuit (floor) . . . 1 ½"

8 – Return connection – gas, oil and pellet boiler 1 ½"

9 – Return connection – wood boiler . . . . . . . 1 ½"

10 – Sensor of solar system or heating . . . . . . . ½"

AS – Flow connection of solar system . . . . . . . . 1"

RS – Return connection of solar system . . . . . . . 1"

D1 – Diameter without insulation

D2 – Diameter with insulation

CN – Pump of the circulation tank . . . . . . . . . . ¾"

AF – Cold drinking water . . . . . . . . . . . . . . . . ¾"

AC – Hot drinking water . . . . . . . . . . . . . . . . . ¾"

MA – Magnesium anode . . . . . . . . . . . . . . . . . –

TECHNICAL PARAMETERS

Tank

Solar

excha nger

Internal

tank

Tank

Type

Position 1–6

Position 2–7

Position 3

L-max. length of th e el. heating

body

Position 4–8

Position 5–9

Position RS

Position AS

∅ D1 – Diameter without

insulation

∅ D2 – Diameter with insula -

tion of 100 mm

Height

Height with insulation of

100 mm

R – Slope dimension wit hout

insulation

Max. operating temperature (°C)

Static loss (W )

Max. operating pressure (bar)

Area of exchanger (m²)

Volume of e xchanger (l)

Max. operating pressure (bar)

Volume (l)

Max. operating temperature (°C)

Max. operating pressure (bar)

Volume (l)

Weight (kg)

HR600K

1 515 1 123 794 650 684 245 - - 70 0 900 1 754 1 854 1 841 95 99 3 - - - 160 95 6 445 157

HR800K

1 545 1 135 8 46 735 725 315 - - 790 9 90 1 806 1 906 1 898 95 105 3 - - - 160 95 6 553 157

HR1000K

1 735 1 255 1 036 735 775 295 - - 790 9 90 1 996 2 096 2 081 95 121 3 - - - 160 95 6 731 172

HR1250K

1 655 1 175 988 880 695 285 - - 950 1 150 1 948 2 048 2 064 95 142 3 - - - 160 95 6 1 079 172

HR1500K

1 755 1 345 1 072 920 820 375 - - 1 00 0 1 200 2 032 2 132 2 160 95 161 3 - - - 160 95 6 1 260 265

HR2000K

1 955 1 408 1 314 1 000 862 315 - - 1 100 1 300 2 274 2 374 2 390 95 188 3 - - - 160 95 6 1 800 296

HRS600K

1 515 1 123 794 650 684 245 245 725 700 900 1 754 1 854 1 841 95 99 3 1,8 11,9 10 160 95 6 445 157

HRS80 0K

1 545 1 135 8 46 735 725 315 315 725 790 9 90 1 806 1 906 1 898 95 105 3 2,4 15,9 10 160 95 6 553 157

HRS1000K

1 735 1 255 1 036 735 775 295 295 860 790 9 90 1 996 2 096 2 081 95 121 3 3 19,8 10 160 95 6 731 172

HRS1250K

1 655 1 175 988 880 695 285 285 850 950 1 150 1 948 2 048 2 064 95 142 3 3 19,8 10 160 95 6 1 079 172

HRS1500K

1 755 1 345 1 072 920 820 375 375 895 1 0 00 1 200 2 032 2 132 2 160 95 161 3 3,6 19,8 10 160 95 6 1 260 265

HRS200 0K

1 955 1 408 1 314 1 000 862 315 315 843 1 100 1 300 2 274 2 374 2 390 95 188 3 4,2 23,7 10 160 95 6 1 800 296

Page 8

R

AS

RS

R

90°

12°

12°

AC

AF

½"

D2

8

ACCUMULATION TANKS ATTACK TUV, TUVS

TECHNICAL PARAMETERS OF THE D.H.W. EXCHANGER

Material Stainless steel

Heated area 3,9 m

2

Volume 13 l

Connec tion 3/4"

Max. operating pressure 10 bar

ATTACK TUV ATTACK TUVS

Page 9

9

ACCUMULATION TANKS

DESCRIPTION

The accumulation tanks ATTACK TUV, TUVS are made from a quality steel

and they serve for accumulation of the heating water as well as for the D.H.W.

preparation in a water coil. The ATTACK TUVS model is accessorized with an

extra exchanger for connection to the solar system.

ATTACK TUV: 9× socket G 1 ½", 5× socket G ½", 2× socket G 1" – D.H.W.

ATTACK TUVS: 9× socket G 1 ½", 5× socket G ½", 2× socket G 1" – solar circuit,

2× socket G 1" – D.H.W.

KEY FOR THE ACCUMULATION TANKS

1 – Flow connection - boiler . . . . . . . . . . . . . 1 ½"

2 – Freely disposable . . . . . . . . . . . . . . . . . . 1 ½"

3 – Electrical heating coil (EL) . . . . . . . . . . . . 1 ½"

4 – Freely disposable . . . . . . . . . . . . . . . . . . 1 ½"

5 – Return connection – heating circuit . . . . . . 1 ½"

6 – Flow connection – heating circuit (radiators) . 1 ½"

7 – Flow connection – heating circuit (floor) . . . 1 ½"

8 – Return connection – gas, oil or pellet boiler . 1 ½"

9 – Return connection – wood boiler . . . . . . . 1 ½"

10 – Sensor of solar system or heating . . . . . . . ½"

AS – Flow connection of solar system . . . . . . . . 1"

RS – Return connection of solar system . . . . . . . 1"

D1 – Diameter without insulation

D2 – Diameter with insulation

AF – Cold drinking water . . . . . . . . . . . . . . . . 1"

AC – Domestic hot water . . . . . . . . . . . . . . . . 1"

TECHNICAL PARAMETERS

Tank

Solar

excha nger

Tank

Type

Energy efficiency c lass

Position 1–6

Position 2–7

Position 3 (EL)

L – max. length of the

elec tric heating body

Position 4–8

Position 5–9

Position RS

Position AS

∅ D1 – Diameter without

insulation

∅ D2 – Diameter with

insulation

Height

R – Slope dimension

without insulatio n

Mini. in stallation height

Max. operating tempera-

ture (°C)

Static loss (W )

Max. operating pressure

(bar)

Area of exchanger (m²)

Volume of e xchanger (l)

Max. operating pressure

(bar)

Max. operatind tempera-

ture (°C)

Area of D.H.W. exchanger

(m²)

Volume (l)

Weight (kg)

TUV500K C

1 405 1 013 771 600 621 230 - - 650 850 1 631 1 717 1 831 95

-

3 - - - - 4,54 474 157

TUV600K -

1 515 1 123 794 650 684 245 - - 700 900 1 754 1 841 1 954 95

99

3 - - - - 4,54 605 157

TUV800K -

1 545 1 135 846 735 725 315 - - 790 990 1 8 06 1 898 2 006 95

105

3 - - - - 4,54 713 157

TUV1000K -

1 735 1 255 1 036 735 775 295 - - 790 990 1 9 96 2 081 2 196 95

121

3 - - - - 4,54 891 172

TUV1250K -

1 655 1 175 988 880 695 285 - - 950 1 150 1 94 8 2 064 2 148 95

142

3 - - - - 4,54 1 239 172

TUV1500K -

1 755 1 345 1 072 920 820 375 - - 1 000 1 20 0 2 032 2 160 2 232 95

161

3 - - - - 4,54 1 420 265

TUV200 0K -

1 955 1 408 1 314 1 000 862 315 - - 1 100 1 30 0 2 274 2 390 2 474 95

188

3 - - - - 4,54 1 960 296

TUVS500K C

1 405 1 013 771 600 621 230 230 710 650 850 1 631 1 717 1 831 95

-

3 1,8 11,9 10 110 4,54 474 157

TUVS600K -

1 515 1 123 794 650 684 245 245 72 5 70 0 900 1 754 1 841 1 954 95

99

3 1,8 11,9 10 110 4,54 605 157

TUVS800K -

1 545 1 135 846 735 725 315 315 725 790 990 1 806 1 898 2 006 95

105

3 2,4 15,9 10 110 4,54 713 157

TUVS1000K -

1 735 1 255 1 036 735 775 295 295 860 790 990 1 996 2 081 2 196 95

121

3 3 19,8 10 110 4,54 891 172

TUVS1250K -

1 655 1 175 988 880 695 285 285 850 950 1 150 1 948 2 064 2 148 95

142

3 3 19,8 10 110 4,54 1 239 172

TUVS1500K -

1 755 1 345 1 072 920 820 375 375 895 1 000 1 20 0 2 032 2 160 2 2 32 95

161

3 3,6 19,8 10 110 4,54 1 420 265

TUVS2000K -

1 955 1 408 1 314 1 000 862 315 315 843 1 100 1 300 2 274 2 390 2 474 95

188

3 4, 2 23,7 10 110 4,54 1 960 296

Page 10

D2

1 ½"

1 ½" 1 ½"

90°

10°

10°

45°

45°

10

ATTACK S ATTACK SS

STRATIFIED STORAGE TANKS ATTACK S, SS

Page 11

11

ACCUMULATION TANKS

DESCRIPTION

ATTACK S – is based on the ATTACK AK type. Disk and stratified pipe

installed in the exchanger enable creation of water layers according to

the temperature. This construction ensures different temperature layers

at the inlets and outlets.

ATTACK SS – is based on the ATTACK AS and the ATTACK S types. It is

accessorized with an extra exchanger for connection to the solar circuit.

ATTACK S: 10× socket G 1 ½", 5× socket G ½"

ATTACK SS: 10× socket G 1 ½", 5× socket G ½", 2× socket G 1" – solar circuit

KEY FOR THE ACCUMULATION TANKS

1 – Flow connection – boiler . . . . . . . . . . . 1 ½"

2 – Freely disposable . . . . . . . . . . . . . . . . 1 ½"

3 – Electrical heating coil (EL) . . . . . . . . . . 1 ½"

4 – Freely disposable . . . . . . . . . . . . . . . . 1 ½"

5 – Return connection – heating circuit . . . . 1 ½"

6 – Flow connection – heating circuit (radiators) 1 ½"

7 – Flow connection – heating circuit (floor) . 1 ½"

8 – Return connection, gas, oil or pellet boiler 1 ½"

9 – Return connection – wood boiler . . . . . 1 ½"

10 – Sensor of solar system or heating . . . . . . ½"

AS – Flow connection of solar system . . . . . . . 1"

RS – Return connection of solar system . . . . . . 1"

SF – Upper solar sensor . . . . . . . . . . . . . . . . ½"

SU – Bottom solar sensor . . . . . . . . . . . . . . . ½"

D1 – Diameter without insulation

D2 – Diameter with insulation

TECHNICAL PARAMETERS

Tank

Solar

excha nger

Tank

Typ

Energy efficiency c lass

Position 1–6

Position 2–7

Position 3

L – max. length of the ele ctric

heating body

Position 4–8

Position 5–9

Position SU

Position SF

Position RS

Position AS

∅ D1 – Diameter without

insulation

∅ D2 – Diameter with insulation

of 100 mm

Height

Height with insulation of 100 mm

R – Slope dimension wit hout

insulation

Max. operating temperat ure (°C)

Static loss (W )

Max. operating pressure (bar)

Area of exchanger (m²)

Volume of e xchanger (l)

Max. operating pressure (bar)

Volume (l)

Weight (kg)

S500K C 1 405 1 013 871 700 621 230 461 1 209 - - 650 850 1 680 1 730 1 698 95 - 3 - - - 488 81

S800K - 1 545 1 135 946 84 0 725 315 491 1 340 - - 790 990 1 842 1 892 1 898 95 105 3 - - - 713 157

S1000K - 1 735 1 255 1 036 840 775 295 577 1 495 - - 790 990 2 031 2 082 2 0 81 95 121 3 - - - 891 172

S1250K - 1 655 1 175 988 1 000 695 285 565 1 415 - - 950 1 150 1 975 2 025 2 064 95 142 3 - - - 1 239 172

S1500K - 1 755 1 345 1 072 1 050 820 375 653 1 545 - - 1 00 0 1 200 2 100 2 150 2 160 95 161 3 - - - 1 420 265

S2000K - 1 955 1 408 1 314 1 150 862 315 685 1 682 - - 1 100 1 300 2 309 2 356 2 390 95 188 3 - - - 1 960 296

SS500K C 1 4 05 1 013 871 700 621 230 4 61 1 209 230 710 650 850 1 680 1 730 1 698 95 - 3 1,8 11,9 10 4 88 81

SS800K - 1 545 1 135 946 8 40 725 315 491 1 340 315 725 790 9 90 1 842 1 892 1 898 95 105 3 2,4 15,9 10 713 157

SS1000K - 1 735 1 255 1 036 84 0 775 295 577 1 495 295 860 790 990 2 031 2 082 2 081 95 121 3 3 19,8 10 891 172

SS1250K - 1 655 1 175 988 1 000 695 285 565 1 415 285 850 950 1 150 1 975 2 025 2 064 95 142 3 3 19,8 10 1 239 172

SS1500K - 1 755 1 345 1 072 1 050 820 375 653 1 545 375 895 1 000 1 200 2 100 2 150 2 160 95 161 3 3,6 23,7 10 1 420 265

SS2000K - 1 955 1 4 08 1 314 1 150 862 315 685 1 682 315 6 65 1 100 1 300 2 309 2 356 2 39 0 95 188 3 4,2 27,7 10 1 960 296

Page 12

12

4. OPERATION

Tanks accumulate heat from the heating systems for domestic or industrial use. Different types of

boilers and heating systems, renewable energy sources (heat pumps, sun collectors) or electricity

can be used to heat the water in the accumulation tank.

Heat in the tank is accumulated either by flow of the heating liquid from the heat source or by

flow of the heating liquid and the heat transfer (e.g. from solar system) through the tubular exchanger, or by warming by the electrical bodies installed inside the tank.

In the built-in D.H.W. tank or built-in instantaneous D.H.W. warming is the warmth accumulated

from the water in the accumulation tank.

5. INSTALLATION

The installation must be in conformity with the valid regulation and it can be done only by

a qualified specialist.

Faults caused by the incorrect installation, usage and operation cannot be considered as a warranty case.

5.1 CONNECTION TO THE HEAT SOURCE

Place the accumulation tank on the ground, as close as possible to the heat source. Install the insulation. Connect the heating circuits to all inlets and outlets as it is given in the table in the chapter 3.

Mount the deaeration valve at the highest place of the system and insulate all the connection

distributions.

5.2 CONNECTION OF THE ELECTRICAL HEATING BODIES

The accumulation tank can be accessorized with the electrical heating bodies. The electrical

heating bodies can be connected to the electricity mains directly (body with an own thermostat)

or through the regulator of the whole heating system.

6. PUTTING INTO THE OPERATION

Fill the heating circuits with the appropriate liquids and deaerate the whole system. Check the

tightness of all the joints and the pressure in the system.

CAUTION: Accumulation tanks HR/HRS are filling as follow. The first, will be filled inside

tank and then remainder of accumulation tank. In case of nonobservance of process the

inside tank can be damaged.

Set the parameters of the regulation of the heating system as it is given in the documentation and recommended by the producer. Check the correct function of all control and regulation elements regularly.

Quality of the heating water significantly influences the lifetime of the heating systems. Unsuitable

quality of water may cause problems like the corrosion of device and creation of the limescale, especially

Page 13

13

ACCUMULATION TANKS

on the heat-exchange surfaces of device. Quality of the heating water depends on the quality of the

water filled into the system by starting the operation and quality and amount of the water additionally

filled into the system. Quality of the water additionally filled into the system is defined in the STN 07 7401.

To prepare the D.H.W. in a built-in tank or an instantaneous system, it is necessary to install the

safety valve of 6 bar on the cold water inlet. It is also necessary to ensure the treatment of the

D.H.W. against the limescale and dirts from the water distribution network.

Hardness of water cannot exceed 5 mval / l. Warranty does not relate to the blockage of the tank

or the flow copper exchanger by a limescale.

7. MAINTENANCE

To clean the external parts of the tank you need a wet cloth and a suitable detergent. Never use

abrasive cleaners, diluents, petroleum-based cleaners, etc.

Check the tightness of joints on the flange of the HR, HRS tank at least once a year, eventually

fix the nuts. If there is untightness even after fixing the nuts, replace the sealing under the flange.

Maintenance of the accumulation tank HR, HRS concerns test and replacement of the anode rod.

The magnesium anode adjusts the electric potential inside the tank to the value preventing corrosion of the tank. Theoretical life-time of the anode takes 2 years of operation, but it changes according to the callosity and the chemical composition of water at the place, where the tank is used.

It is recommended to make a test every 6 months and in the case of need, to replace the anode rod.

This additional protection element should be considered as important.

Procedure of replacement of the anode rod:

1. Discharge approximately 1/3 of the water in the tank

Procedure: close the valve at the water inlet into the tank,

open the valve of hot water on the mixing tap,

open the discharge valve of the tank.

2. Undo the upper cover of the accumulation tank.

3. Use a suitable tool to screw the anode out.

4. Install a new anode and mount the dismantled parts back.

5. Fill the tank with water, pressurize it and check the tightness.

The anode must be replaced only by a specialized service company!

8. DISPOSAL

Packaging must be disposed following the valid prescriptions.

After expiration of the lifetime it is necessary to dispose the product in conformity with the legal

prescriptions.

Page 14

14

SPECIFICATION OF THE ANNUAL CHECKS OF THE ACCUMULATION TANKS

(performed by the authorized service)

1. CHECK OF THE STATE OF THE TANK

The accumulation tank does not need a maintenance indeed, it is only necessary to make a check

of the pressure and tightness of all the joints. In case of the water leakage from the tank or leakage

of the liquid from the heating circuits, stop the operation of device and seal the joints to ensure the

stated operating conditions.

2. CLEANING AND MAINTENANCE OF THE TANK

To clean the external parts, use a wet cloth and a suitable detergent. Never use abrasive cleaners,

diluents, petroleum-based cleaners, etc.

It is not necessary to clean the internal side of the tank, because it is connected to the closed

heating circuit with a permanent filling.

3. ELECTRICAL HEATING BODIES IF THEY ARE CONNECTED

If there are electrical heating bodies installed in the tank, it is necessary to make a check of the

function of thermostats, state of the contacts and fixation of the screws of all terminals.

Annual test no. 1 Annual test no. 2

Date: Date:

Stamp and signature of the service technician: Stamp and signature of the service technician:

Annual test no. 3 Annual test no. 4

Date: Date:

Stamp and signature of the service technician: Stamp and signature of the service technician:

Page 15

15

ACCUMULATION TANKS

NOTES:

Page 16

ATTACK, s.r.o. – 03/2017

ATTACK, s.r.o. • Dielenská Kružná 5020, 038 61 Vrútky • Slovakia

Tel: +421 43 4003 101 • Fax: +421 43 3241 129 • E-mail: kotle@attack.sk

Export – tel: +421 43 4003 103 • Fax: +421 43 3241 129 • E-mail: export@attack.sk

Výrobca ATTACK, s.r.o. si vyhradzuje právo technických zmien výrobkov bez predchádzajúceho upozornenia.

Loading...

Loading...