Page 1

INSTRUCTION FOR USE

FLOOR STANDING

CAST-IRON

SOLID FUEL

BURNING BOILER

ATTACK FD

ATTACK, s.r.o. - 08/2010

EN

Page 2

Dear customer,

Thank you for buying a universal ATTACK FD boiler and trust expressed to our company --

ATTACK, s.r.o.

ATTACK FD boiler is certified for burning coke, wood and black coal.

To get used to right handling with your new product, read instructions for its use. Please follow

the further information to ensure long-time operation without breakdowns to your as well as our

satisfaction.

Important warnings

- Study the instructions to get essential information about the construction of the boiler, it's manipulation and it's

safe operation

- After unpacking the boiler check whether your delivery is complete

- Make sure that the type of the boiler corresponds to the required use

- The installation must be done only by a proffesional with permission to this operation

- Launching and putting the boiler into operation and other obligatory service inspections may be done only by a

service technician with a valid contract from the producer

- The boiler must be connected according to valid rules, standards and norms from the instructions of use

- The producer is not responsible for the damages caused by incorrect connection

- In case of a failure ask a service technician for a help, any unprofessional intervention may damage the boilerl

- For the right function, safety and long time operation of the boiler get a regular check and maintenance from one

of our service organizations at least once a year

- You must only use the original spare parts for the repairs

- If the boiler is out of order for a longer time (switched off or there is a breakdown ), it is necessary to be careful

when putting the boiler back to operation

- The producer reserves the right to make changes in the construction of the boiler and in the instructions of

use

2

Page 3

CONTENTS

1 Use and preferences of the boiler....................................................................4

2 Technical data on ATTACK FD boiler.............................................................4

3 Dimensions of ATTACK FDboiler................................................................... 5

4 Head losses.......................................................................................................5

5 Description of ATTACK FD................................. ...........................................6

6 Localization and installation of the boiler...................................................... 6-7

7 Supply and wrapping......................................................................................... 8

8 Appliance for excessive heat removal - cooling circuit................................. .8-9

9 Boiler assembly................................................................................................. 10

10 Assembly of the accessories.............................................................................. 10

11 Casing assembly............................................................................................... .10

12 Brazier grid assembly........................................................................................ 11

13 Draught regulator.............................................................................................. 12

14 Putting the boiler into operation........................................................................12

15 Attendance of the boiler by a user......................................................................13

16 Maintenance........................................................................................................14

17 Instructions for the luquidation of the product after its service life....................14

18 Warranty and responsibility for defects.............................................................15

19 Repairs.................................................................................................................15

3

Page 4

ATTACK FD boiler is a cast iron low-pressure boiler for combustion of solid fuels - coke, wood, coal:

Combustion of other substances like plastics is not allowed..

1. The use and preferences of the boiler

Four-element size of ATTACK FD is suitable for reconstructions of heat sources in dwellings, for smaller flats and recreation

facilities. Bigger size of the boiler suits to requirements for heating in family houses, shops, schools and similar..

The boiler is produced as a hot-water boiler with natural as well as forced heating water passage and working overpressure up to

4 bar. Before delivery it is tested for tightness by a testing overpressure of 8 bar.

Boiler preferences :

Modern design

High lifetime of cast iron heat exchanger, with extra low-temperature corrosion resistance

High efficiency up to 85%

Wide output range in dependance on number

of elements

5-years warranty on the cast iron heat exchanger

High reliability of regulating and safety components

Simple attendance and maintenance

Simple assembly of casing during the boiler assembly in the boiler room

Low demand on chimney draught

Good position of the output regulator

Enlarged combustion chamber for bigger wood pieces

Sophisticated production technology with a stable and verified quality of production process( ISO 9001)

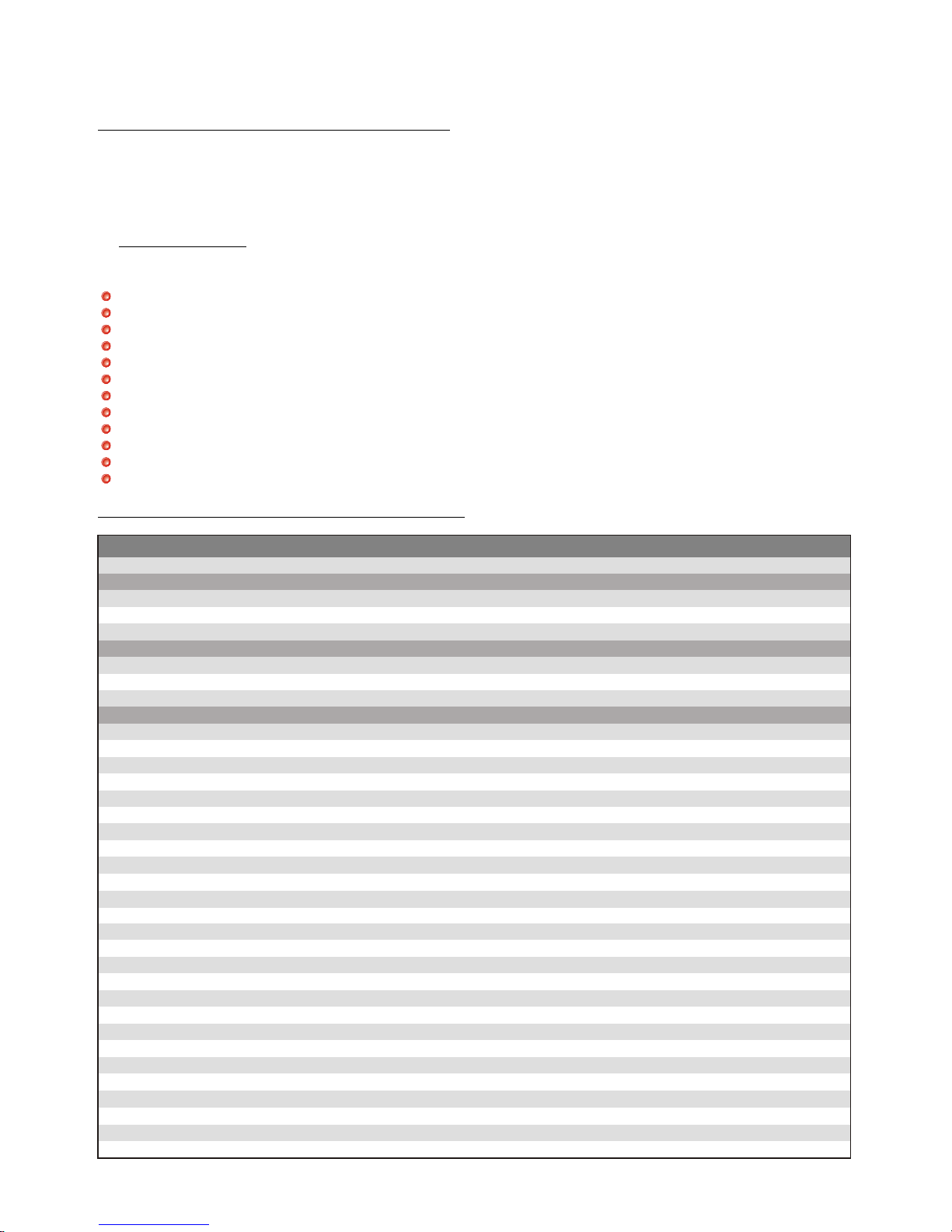

2. Technical parameters of ATTACK FD

4

3

Capacity of combustion chamber dm 25,5 34 42,5 51 59,5

Boiler type FD20 FD26 FD32 FD36 FD42

Nominal output - black coal kW (kcal/h) 18 (18000) 24 (22000) 3 0 (26000) 3 6(30000) 42(34000)

Fuel consumption at nominal output - black coal kg/h 3,6 4,6 5 ,2 6,4 7,5

minimum output - black coale kW 9 12 15 18 21

Fuel consumption at minimum output - black coal kg/h 1,9 2 ,3 2 ,6 3,2 3 ,7

Nominal output - wood kW 16 20 25 30 34

Wood consumption at nominal output kg/h 4,85 6,11 7,38 8,65 9,92

minimum output - wood k W 8 10 13 15 17

Wood consumption at minimum output kg/h 2,15 2,52 2,89 3,26 4,63

Nominal output - coke kW 20 2 6 32 3 6 42

Fuel consumption at nominal output-coke kg/h 3,7 4,8 5 ,9 6,66 7,77

minimum output - coke kW 6 8 9 ,5 11 12,5

Fuel consumption at minimum output - coke kg/h 1,11 1,48 1 ,76 2,04 2 ,31

Boiler water volume l 27 31 35 39 43

Max. working pressure bar 4

Weight kg 210 245 2 80 315 350

Height P mm 1081

Height mm 1001

Width mm 4 70

Lenght of combustion chamber mm 290 390 490 590 690

Width of combustion chamber mm 3 00

Dimensions of door (width x height) mm 230 x 310

Efficiency % 78-82

Test pressure bar 8

Connection of C.H. water inch G 2"

Elements number pcs 4 5 6 7 8

Depth L mm 455 555 655 755 855

Connection of cooling loop inch G 1/2inner thread

Burning time at nominal output - black coal h 4

Burning time at nominal output - wood h 2

Max.lenght of logs at max. diameter of 150 mm mm 280 380 480 580 680

Operation drauhgt at min. and nom.output Pa 10-20 12-22 13-23 15-25 18-28

Flue gas temperature at nom. output °C 240 250 250 260 260

Flue gas flow- nom. output g/s 9,54 12,31 15,08 16,99 19,78

Flue gas temperature at min. output °C 120 130 140 150 150

Flue gas flow- min. output g/s 3,02 3,95 4,66 5,36 6,04

Page 5

How to choose the right size of a boiler

The right size of a boiler,i.e. of heat output, is a very important condition for economic operation and right work of the boier..

A boiler has to be chosen in order for its nominal output to respond to losses of a heated object.

When you choose a boiler with a too high nominal output, it can cause higher tarring and dew of the boiler.

3. Dimensions of ATTACK FD

470

1001 mm

210

190

840

150

M

S

R

L

M C.H. passage 2”

R C.H. return 2”

S Boiler drain 1/2”

4. Head losses

Flow rate

ATTACK FD 20

ATTACK FD 26

ATTACK FD 32

ATTACK FD 36

ATTACK FD 42

5

P

Page 6

5. Description

Construction of the boiler

The main part of the boiler is a cast-iron -element boiler body produced of grey cast iron..

- middle elements - quality 150

- front and rear elements - quality 200

Pressure parts of the boiler suit to the requirements for tightness by standards:

TNN EN 303- 5 : 2000 Boilers for Central Heating.

The boiler body is assembled from elements with the help of pressed nipples of 56mm diameter, ensured by anchor bolts..

convection part. Inlet and outlet of heating water is situated

in the rear part of the boiler.

The whole boiler body is insulated by a mineral insulation not harmful for health, that eliminates losses caused by heat

emission into surroundings. Steel casing is painted by a komaxit paint of a good quality.

The

elements create combustion and ash collection space, water space and

6. Localization and installation of ATTACK FD boiler

Rules and standards

Boilers for solid fuels can be installed only by a company with a valid certificate for installation and maintenance.

Installation must be designed by valid standards. Before the installation of the boiler to an older system of heating, all the

system must be cleaned by the company. The heating system must be filled with water suitable to the requirements by STN

07 7401:1991 a and its hardness must not exceed required parameters.

Recommended values

Hardness mmol/l 1

2+

Ca mmol/l 0,3

concentration of total Fe + Mn mg/l (0,3)*

*) recommended value

6

Possibilities of localization

ATTACK FD boilers is certified for installation in spaces not serving for common life (cellar, halls, etc.)

Localization of the boiler by fire regulations :

1. Localization on a floor of an incombustible material (fig.)

- Put the boiler on an incombustible pad exceeding dimensions of the lateral sides of the boiler in

20 mm and only for the lenght of combustion chamber

- If the boiler is located in a cellar, we recommend to set it up ona n elevated step

of the minimum height of 50 mm

- The boiler is located into the middle of the s stand

Page 7

location of the boiler to keep necessary manipulation space:

- Basic space AA5/AB5

- In front of the boiler there must be manipulation space of min. 800 mm

- minimum distance between the rear part of the boiler and the wall must be 800 mm

- at least form one lateral side keep space for approach to the rear part of the boiler - min. 800 mm

Location of fuels:

- to put fuels behind the boiler or keep them near the boiler in the distance shorter than 800 mm is not allowed

- to put fuels between two boilers in a boler room is not allowed

- it is recommended bez the manufacturer to keep the distance of min. 800 mm between the boiler and fuels, or to locate fuels

in a room other than where the boiler is installed

7

Podmurovka

Requirements for the boiler room

Q

S =

100

Chceck that the room has the requirements in accordance to the rules. Furthermore, the room should be aired in order to have a

regular combustion. Therefore it is necessary to practice some openings in the wallls of the room, which correspond to the

following requirements:

2

- They should have a free section of at least 6 cm for each 1,163 kW (1000 kcal/h). The minimum opening section shouldn´t be

2

smaller than 100 cm . The section can also be calculated using the following ratio:

2

- where "S" is expressed in cm

- "Q" is expressed in kcal/h

-The opening should be situated in the lower part of an outer wall, preferably opposite the combustion

gas discharge.

2. Safe distance from combustibles

- during the installation as well as during the operation of the boiler it is necessary

to keep the safe distance from combustibles

- for easy combustible substances of combustibilitz level C, that burn quickly and

go on beurning even after removing the source (e.g.. paper, cardboard,asphalt

cardboard, tar paper, wood and wood-fibre boards, palstics, floor coverings), the

safe distance is doubled

- It is also necessary to double the safe distance in the case when the

combustibility level is not known

Connection to the flue

A flue should correspond to the following parameters::

- it should be of waterproof materials,resistant to temperature of smokes and condensations

- it should be of sufficient mechanical resistance and a weak thermal conductivity

- It should be hermetic in order to avoid cooling of the flue

- it should have the most possible vertical process and the terminal part should have a static aspirator, which assures an

efficient and constant discharge of the combustion product

- in order to avoid the wind creating and a high pressure around the chimneypot, so that it prevails on the ascensional

force of the combustion gas, it is necessary that the discharge orifice hangs over at least 0,4 m of whatever structure

adjacent (including the roof ridge) and the height of the chimney itself was at least 8 meters.

- The flue shouldn´t have a diameter inferior to the boiler connection.For flues with square or rectangular sections, the

internal section should be higher than 10% compared to the boiler connection section.

- The net section of the flue can be obtained from the following ratio:

Fig. Dimensions of the elevated step.

P

S = K

H

2

S - section in cm

k - reduction coefficient - 0,045 for wood

- 0,030 for carbon

P - boiler capacity in kcal/h

H - height of the chimney in meters measured from the flame axis at the exhaust of

the chimney in the atmosphere. For the dimensioning of the flue you should

consider the effective height of the chimney in meters measured from the flame axis

to the top, adminished in:

- 0,50 m for each direction changing of the connection tube between boiler and flue,

-1 m for each horizontal meter of the connection itself.

Page 8

7. Supply and wrapping

8. Appliance for excessive heat removal - cooling circuit

( must be used in the system of closed draught )

A cooling circuit serves to excessive heat removal so that the highest water temperature in the boiler was not overreached i.e.

110°C . The cooling circuit is connected to the boiler flanges .

In case the pump stops working, discharge water is cooled by the cooling circuit, as overheating could cause opening the

thermoregulating valve by 95°C. Return water is carried with the help of an interconnection between cooling circuit and the flange

of return water.

To all the ATTACK FD boilers used in the system of closed ventilation it is NECESSARY to use a

cooling circuit and a termoregulation valve, in order to accept the warranty.

hydraulical chart of connection of cooling circuit

8

8a. ATTACK FD boiler used in the system of open ventilation and natural water

passage

In the system of open ventilation and natural water passage it is not necessary to use a cooling circuit with a

termoregulation valve.

In case of changing the open system into the closed one it is also possible to buy a cooling circuit separately..

WARNING: Keep the rules against water pollution.

Termoregulation valve “STS20”

- Min.temperature -10°C

- Set-up temperature

/initial opening/ 97°C

- Max.flow temperature 110°C

- Max.operation pressure 10 bar

3

- Max.flow 6,5 m /h

Supply of the boiler consists of::

- cast iron body

- on the cast iron body there is a set of ............and a bag with the documentation (instruction for use, waranty , list of service

organisations, manufacturing label)

- inside the cast iron body there is an ash collector and 2 bags:

1.bag contains a screw with bakelite knob for the manual adjustment of the blast gate damper, a contact spring and

a M6 lever, to be fixed at the blast gate damper..

2.bag contains:a thermomanometer, thermostatic draught regulator,, 2 flanges for the boiler, 2 flange packings, 8

screws with hexagonal head, 8 fan-shaped washers, return valve

Boiler casing (sidewall right and left, top cover, front panel with the logo of the manufacturer, rear cover, protective bar and 3

selftapping screws) in a cardboard box.

vstup vratnej vody do kotla

zo systému

vstup vratnej vody

z dochlazovacieho okruhu

výstup topnej vody do systému

výstup topnej vody z kotla

výtok chladiacej vody

vstup chladiacej vody

termoregulaèný ventil STS 20

Page 9

9

210 mm

160 mm

1140 mm

230 mm

530 mm

1430 mm

60 mm

210 mm

Page 10

10. Assembly of the accessories

The closing handles for the ports and the screw with the adjustment knob for the blast gate damper are supplied separately,

sence they could be damaged during the transport. Both the handles and the screws with knob are packed in a nylon bag

introduced inside the ash collection basin..

For the assembly of the handles proceed as following (fig.4):

- Take the handle(1), insert it into the opening of the load port(2), and introduce the roll(3) in the opening of the handle, block

the handle introducing the elastic split pin(4).

- Carry out the same operation for the handle of the ash box port.

To assemble the screw with the knob, proceed as follows (fig.5):

- remove the screw M8x60 fixing the air blast damper to the ash box port and fix on the screw with the bakelite knob (1),

which is supplied in the packaging. Place the blind nut with cap (2) at the end of M10 screw.

- Fix M6 lever to the air blast damper (3) placing it in a horizontal direction on the right. The lever has an opening at tis

end,where the chainlet of the thermostatic regulator will be connected.

LEGEND

1Handle

2 Load port

3 Roll

4 Elastic split pin

LEGEND

1 Screw with M10 x 70 knob

2 Blind nut with cap

3 Air blast damper

Obr. 4

Obr. 5 Obr. 5

Two superior tie rods are screwed on three nuts at the front side of the boiler: the second and the third nut serve to place

correctly the lateral sides of the casing. Two nuts, one for fixing the clamp holders for the lateral sides,are screwed on the

inferior tie rods, both form the front side and from the rear side. The assembly of the casing components has to be carried out

in the following way (fig..6):

- unscrew with some rotations the second or third nut of each tie rod,

- hook the left side of the (1) on the lower tie rod and superior of the boiler and adjust the position of the nut and locknut of

the upper tie rod,

- fix the lateral side in blocking the locknut,

- in order to assembly the right side (2) proceed in the same way,

- carry out the same operation to fix the back lower board (4)

- the protection deflector (5) is fixed to the control board (6) with three self-threading screws. Fix the board by means of the

pressure stakes.

- insert a thermomanometer into the cover

then unwind the capilary of the thermometer and introduce it in the left sheath of the posterior head., introducing the contact

spring. To the right sheath fix a return valve and screw a manometer into the return valve

- fix the cover(7) at the lateral sides of the boiler with pins and pressure stakes..

NOTE: Keep the test certification together with the boiler documents.

11. a) Casing assembly

9. Boiler assembly

Set the boiler body on the place, connect heating and return water with the help of flanges with the G2" internal thread. To the

outlet of heating water in the upper part of the boiler body, adjust a pipe on the G2 thread and a cooling loop on the pipe, then

connect to the heating system. Into the tube. in the body of the cooling loop insert a sensor of the thermostatic valve which

connect to the cooling water feed. The outlet of cooling water connect to thedrainage. Connect return water from the heaters

and cooling loop to the bottom part of the body.

Attach a discharge cock into the G1/2" opening in the rear bottom partof the boiler. Attach the boiler to the chimney with the

help of the flue pipe with 150 mm diameter..

10

Page 11

A

Ż 10 mm

B

LEGEND

1 M8 x 10 screw

2 Washer

3 Grid lever

4 Ring for lever

5 M8 x 35 screw

6 Tie rod

7 M 10 nut

8 M 10 x 50 screw

9 Hub

10 Front grid

11 Intermediate grid

12 Rear grid

Fig. 3

1

2

3

4

5

6

7

8

9

10

11

12

8

If needed ( the brazier grid is not supplied with the boiler), the assembly is carried out by following steps (fig.3):

- Preraziť the card on the side of the front element in the bottom part, between the front and intermediate element using a bit of

10

make a hole as in fig.3,

- place the back grid (12) in the combustion chamber,

- place the front (10) and block it to the hub (9) with the screws (8) and the nuts (7), block the front grid from the right

side of the boiler body with the screws (5)

- hook the tie rod (6) to the seats extracted from the front and rear grids (11).

- introduce the ring (4) and the lever (3) on the hub (9), fixing then everything with the washer (2) and the screw (1).

12. Brazier grid assembly

11

LEGEND

1 Left side

2 Right side

3 Posterior superior boardt

4 Protection deflector

5 Control board

6 Cover

Obr. 6

1

2

5

3

6

4

b) Assembly of the control rod of chimney flap

Assembly of the control rod of the chimney flap is done in this way::

- punch holes in the skeleton (in the right lateral side)

- insert the rod pos. 2 through the right lateral side

- at the end of the rod fix a ball pos. 3

- mount the lever pos.1 on the axis of the chimney flap.

- the rod pos. 2 insert into the lever pos. 1. Slip a washer pos.7 on the

rod from both sides. After slipping lock with a pin pos. 8. On the rod

put a screw, washer, and a nut pos. 4, 5 a 6. Tighten the screw slightly.

Test the function of the flap. If needed, adjust the angle of slipping and

tighten the screw firmly.

Page 12

Draught regulator

Draught regulator - thermostatic regulator is equipped with a thermosetting resin knob of an adjustment field from 30 to 100°C

(fig.7).

Screw the regulator on the 3/4“ opening of the front head and orientate the red index on the upper part. The lever with the

chainlet should be introduced in the regulator holder after removing the plastic lock. If the jopint which fixes the lever with the

chainlet is taken out, take care in assembling it again in the same position..

After adjusting the knob to 60°C, block the lever with the chainlet in a slightly inclined position downwards, miernym smerom

so that the chainlet will be in axis with the air gate damper. For the adjustment of the regulator that basicly depends on the

determination of the chainlet length, proceed in the following way:

- Adjust the knob at 60°C,

- burn the boiler with open air gate damper,

- when the temperature of heating water reaches 60°C, fix the chainlet in such a position that the air gate damper will be open

with the opening of cca.1mm

- Now the regulator is calibrated and it is possible to choose the desired operating temperature by a rotating head.

13. Draught regulator

14. Putting into operation - directions for a service organisation

Putting the boiler into operation can be performed only by a service organisation certified for this activity.

Checking activities before start

Before putting the boiler into operation it is necessary to check:

a ) Filling the heating system with water (check by a manometer) and tightness of the set

b ) connection to the chimney - this connection can only be carried out with the approval of a chimney-sweeping company ,

to measure the draught of the chimney by a chart of fuels

Putting the boiler into operation

- Start fire

- Set the boiler to a necessary operation temperature. Recommended temperature of the outlet water is 80°C.

- Adjust the lenght of the chainlet of the draught regulator (according to the instructions for the draught regulator).

-Keep the boiler in the operation state by the proper standards.

Again check tightness of the boiler.

- Get the customer acquinted with attendance.

- Make a record into the Letter of Warranty..

Filling the heating system with water:

Water hardness must correspond to standards and it is necessary to treat water ..

Heating systems with an open expansion tank enable a direct contact of heating water with the atmosphere. In the period of heating

expanding water in the tank absorbs oxygen that increases corrosive effects and in the same time water is evaporated significantly.

To refill, only water treated to values by STN 07 7401: 1992 can be used.

The heating system must be thoroughly rinsed, to wash out all the dirt..

During the heating period it is necessary to keep constant volume of water in the heating system. When refilling the heating set with

water it is necessary to avoid sucking the air in the system. Water from the boiler and heating system must never by drained or taken

for use except for unavoidable situations such as repairs and so on. Draining water and feeding with new one increases the danger of

corrosion and incrustation.If refilling is necessary, it can be done only to a cooled boiler to prevent breaking the elements.

After filling the boiler and heating system check the tightness of all joints..

Finishing the assembly and testing of heating must be recorded to the Letter of warranty..

Connection to the chimney :

Connection of the boiler to the chimney must be performed by the standard and with the approval of a chimney-sweeping company.

Boilers in the central heating system must be connected to a separated chimney vent. The chimney with the right draught is a basic

condition for a good operation. It influences the performance of the boiler as well as its effectivity.

in case of unsuitable hardness

12

Page 13

15. Attendance of the boiler by a user

COKE

The most suitable fuel is coke of 24-60mm grain-size.

WOOD

To reach the nominal output it is necessary to keep the max. 20% moisture content of wood

Fuel must be stored in dry place..

Cleaning of the grid is made so as not to let burning fuel drop down to the ash collection basin. do popolníka

BLACK COAL

The most proper fuel is black coal of 24-60mm grain-size.

How to start fire

1. Check the amount of water in the heating system on the thermomanometer.

2. Open boiler fittings between the boiler and heating system.

3. Clean the grid, ash collection basin, flues, and walls of the boiler. ( after cleaning the boiler check the tightness of the cowl )

4. Spread wood through the ash port and chamber port along all the lenght on the cleaned grid.

5. Flue flap in the cowl adjust into the position of open and close the load port..

6. Inflame wood thorugh open ash port and chamber port.

7. Close the chamber port and ash port and open the fuel cut-off slide fully.

8. On burning wood load a thin layer of basic fuel..

9. After inflaming it, load other dose of fuel up to the bottom edge of a load port and arrange the fuel into an even layer.

10. As soon as fuel gets deep red glare, open a little the air disk of secondary air inlet on the load port by means of a tool.

11.After the flame turns yellow, close the air disk of secondary air.

Operation

1.After reaching the temperature of heating water adjust the inlet of combustion air. The boiler output is regulated by the change of

draught with the help the flue flap in the cowl. A slight output regulation is carried out with a fuel cut-off slide that regulates the air

inlet under the grid either manually or with a draught regulator. Adjust the draught regulator so that the cut-off slide in the ash port

was almost closed in the moment when the required temperature is reached.

2. Reloading the boiler during operation depends on the need for heat and burning intensity. When realoading, the layser of fule must

be equally thick.

3. When using coke, black coal, wood, it is necessary to open partially the air rose of secondary air inlet in the loading port during all

the time of inflamation of reloaded fuel. (The air rose must be controlled by a tool due to the surface temperature.)

4.When starting the night operation, clean the grid, let the reloaded fuel burn thoroughly and then decrease the boiler output by

cutting off the draught by the cut-off slide and turning down the air rose of the secondary air inlet. The level of opening of the cut-off

slide and air rose must be tested and it is necessary to prevent escape of flue gases into the boiler room. The draught regulator should

be turned off (close the cut-off slide)..

5. To restart operation of the boiler in the morning, open the cut-off slide and air rose and rake the grid after opening the ash port.

6. The ash port must be permanently closed during the operation of the boiler.

7. If necessary, deplenish the ash collection basin (use protective gloves).

Dew formation and tarring of the boiler

After first burnings in a cold boiler water condenses on the walls and flows down into the ash collection space which can make the

impression that the boiler is leaking. This dew disappears after setting ashes down on the inner walls of the boiler. When the boiler

runs with low temperature of water under 65°C and with wet wood, water condensates in flue gases, condensate flows down cold

walls of the boiler. Heating with low temperatures is also not suitable for the service life of the chimney body.

Tarring of the boiler occurs under similar conditions (low output, low temperature) furthermore during insufficient burning (lack of

combustion air) Tar from the boiler can be removed best under the minimum temperature of 90°C in the boiler. This temperature can

be reached fast by turning off the radiator. To prevent dew formation and tarring of the boiler, it is recommended to run the boiler with

the temperature over 65°C and choose the boiler according to the needed output of the heating system.

Interrupting the operation of the boiler

The operation is interrupted when the fuel in the boiler is let to burn up. We do not recommend to haste the interruption of the

operation in any way..

Shorttime interruption of the operation

For shorttime interruption of the operation clean from burnt fuel, empty the ash collection basin, clean surfaces of load port,

clean the ash collection space and close the load and ash port..

Longtime interruption of the operation of the boiler

For longtime interruption of the operation (e.g. end of heating season) clean the boiler properly, so as moisture causing excessive

corrosion is not kept in soot and ash..

13

Page 14

16. Maintenance

1. Remove ashes from the ash collection basin during the operation even more times a day by the kind of the used fuel, because a

full ash collection basin interferes with right distribution of combustion air under fuel and causes unequal burning of fuel on the

grid. All the residuals, especially cinder, are removed before each new ignition and during restartin the boiler in the morning. Ashes

need to be put into incombustible containers with covers. During the work it is necessary to use protective aids and regard

personal safety.

2. For heating with coke, black coal and wood , clean the walls of the boiler in the grate, draughts and the cowl regularly. (with

brushes - a small brush for small holes, a brush with a handle for other superficies).

3. If after the use of some fuels with more gas released tar creates on the walls of the combustion space, remove it with a scraper or

by burning dry hard wood (or coke) with the boiler set on maximum operation temperature.

4. Measure the draught (by a service oragnization) according to the chart.

17. Directions for the liquidation of the product after its service time

As this product is made of common metal materials , we recommend to liquidate single parts in this way :

- heat exchanger (grey cast iron) - through a company dealing with collection and liquidation of waste

- piping, casing - through a company dealing with collection and liquidation of waste

- other metal parts - through a company dealing with collection and liquidation of waste

-insulting material - to common waste

Dispose of the wrapping following these rules:

- plastic foil, cardboard wrapping and wooden palette - to common waste

- metal tape - through a company dealing with collection and liquidation of waste

IMPORTANT WARNING :

1. Attendance of the bboiler can be only carried out by adults familier with this instruction. To leave children without a

supervision of adults near the boiler is not allowed. Any interventions endangering the health of people attending or

aothers are not allowed.

2. If there is a danger of creating or coming of combustible vapours into the boiler room or during works when there is a

temporary danger of fire or explosion (glueing of floor coverings, painting by inflammable paints), the boiler must be put

out of the operation before startingthe works.

3. For ignition of the boiler it is FORBIDDEN to use inflammable liquids..

4. During theoperation it is FORBIDDEN to overheat the boiler..

5. No combustible objects can be put on the boiler as well as in the distance shorter than the safe one from it..

6. When taking ashes out of the boiler,there can be no combustible materials within the minimum distance of 1500 mm from

the boiler..

7. When the boiler runs with the temperature lower than 65 °C, dew formation can occur on the boiler body as well

ascorrosion that shortens the service life of the boiler body. Therefore we recommend to run the boiler with the

temperature over 65 °Cí.

8.After ending the heating season, it is necessary to clean the boiler, flues and a cowl thoroughly. Grease swivel pins, the

chimney flap and other movable parts of the boiler with graphite grease. Keep the boiler room clean and dry.Mai

14

Page 15

18. Warranty and responsibility for defects

User is obliged to order putting into operation in a specialized company , for defects is responsible a service company certified by

the manufacturer and only maintenance should be performed by the user himself..

Maintenance of the boiler must be performed regularly by the user.

Each defect must be always announced immediately after the detection in written form and its removal agreed later by

phone..

If these rules are not kept, the warranty will not be accepted by the manufacturer.

The manufacturer reserves the right for changes made as the innovation of the product that are not involved in this

instruction for use.

The warranty does not apply to:

- defects caused by a wrong assembly and attendance of the product

- damaging the product during transportation or other mechanical damage

- defects caused by inapropriate storage

- defects caused by water of inferior quality in heating system

More information on warranty conditions in the Letter of Warranty.

19. Repairs

A person performing the attendance of the boiler can carry out only the repairs consisting of simple exchange of parts like packing

cord.

Other necessary defects can be only removed by a service company from the list that is delivered as a supplement of the

instructions for use. For the repairs, use only original spare parts.

Defect Cause Removal

Insufficient output of the boiler

Boiler cannot be regulated

High temperature in boiler,

low one in radiators

Low fuel efficiency

Low pressure

Heat exchanger and flue branch with

flap covered by soot

Use fuel with higher efficiency

for lower outside temperatures

Adjust chimney

Clean the elemnets of exchanger

as well as the flue branch

Strong draught

Check and adjustment of

packing cords

Adjust chimney

High hydraulical resistance

mainly in systems with gravity circulation

Strong draught, high fuel

efficiency

Decrease hydraulical resistance.

by a circuit pump

Decrease the draught with a flap

15

Ash port is not tight

Page 16

Tel: 00421 43 4003 101

Fax: 00421 4 3 4003 106

E-mail: kotle@attack.sk

export@attack.sk

http: www.attack.sk

ATTACK, s.r.o.

Dielenská Kružná 5

038 61 Vrútky

SLOVAKIA

Producer:

www.attack.sk

Loading...

Loading...