Page 1

INSTRUCTIONS FOR USE

W W W . A T T A C K . S K

WALL HUNG ELECTRIC BOILER

ATTACK®

ELECTRIC EXCELLENT

Page 2

Page 3

3

Contents

1. General information

1.1 . . . . . . . . . . . . . . . . . . . . . 4Description and use

1.2 . . . . . . . . . . . . . . . . . . . . . . . 4Advantages of boiler

1.3 . . . . . . . . . . . 4Important directions and advises

1.3.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.2 Putting into operation . . . . . . . . . . . . . . . . . 5

1.3.3 Boiler operation . . . . . . . . . . . . . . . . . . . . . . 5

1.3.4 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

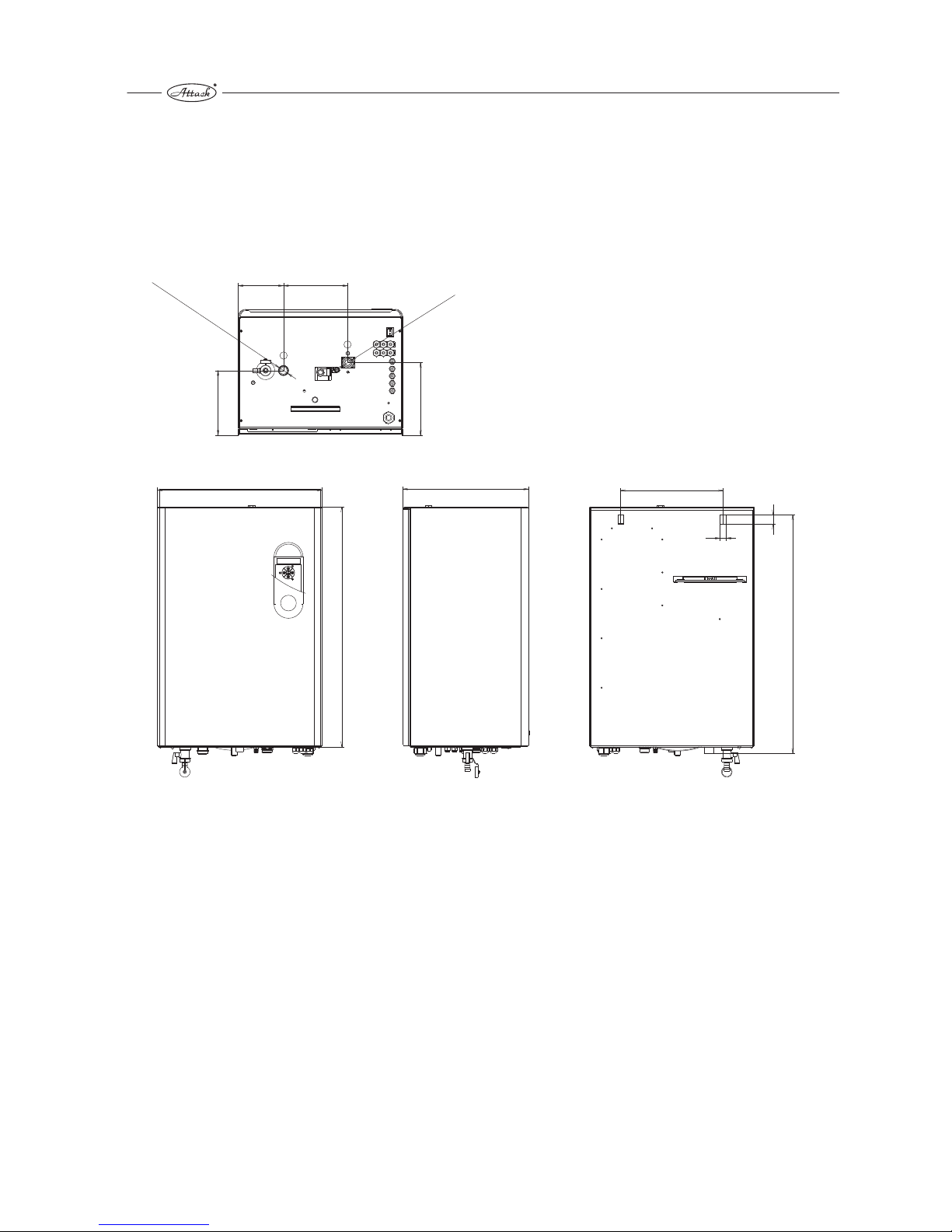

1.4 Main dimensions . . . . . . . . . . . . . . . . . . . . 6

1.5 Technical data . . . . . . . . . . . . . . . . . . . . . . 7

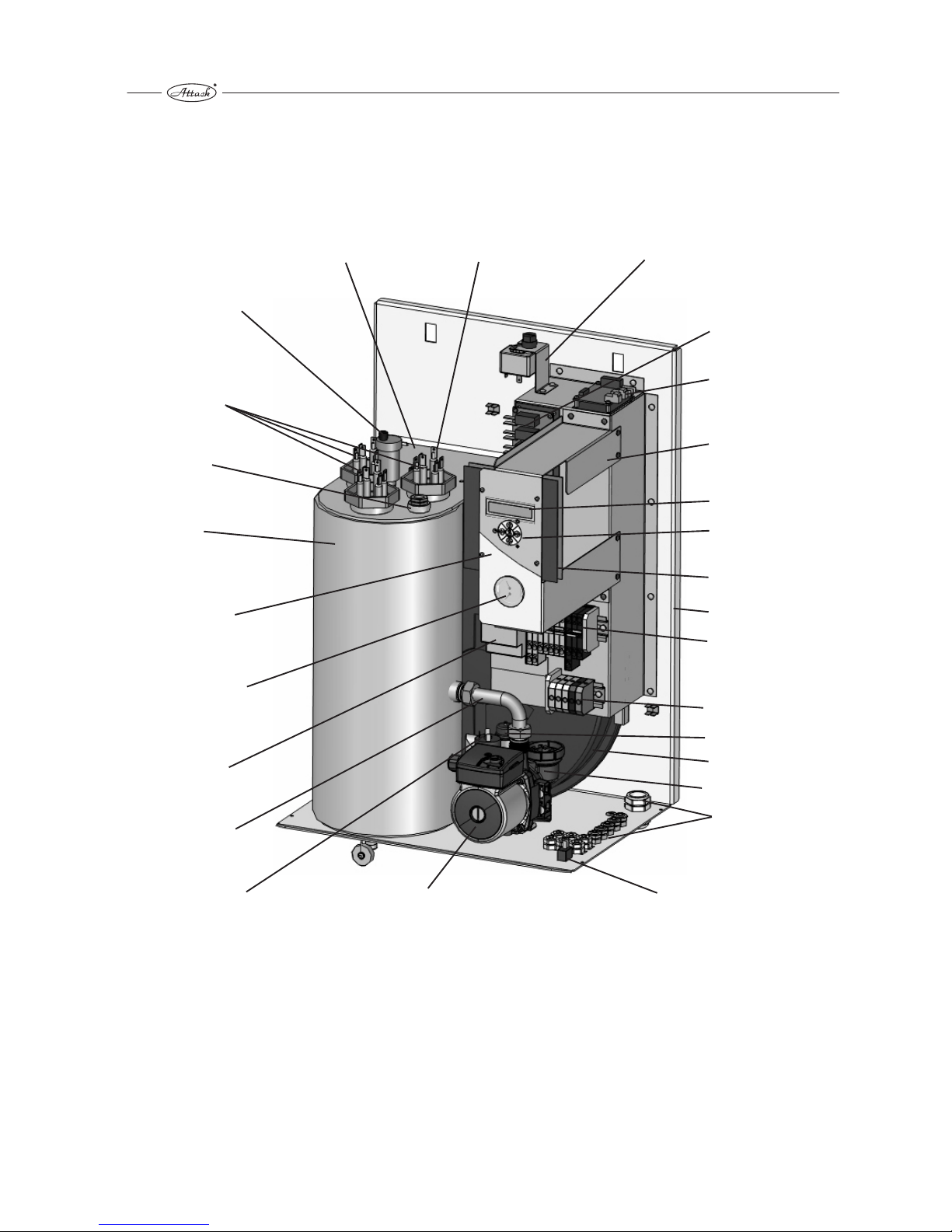

1.6 Main parts . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.7 Description of functions . . . . . . . . . . . . . . . 9

1.7.1 Technical description . . . . . . . . . . . . . . . . . . 9

1.7.2 Principle of boiler operation . . . . . . . . . . . . . . . 9

1.7.3 Control unit and control panel . . . . . . . . . . . . 9

1.7.4 Protection function of the boiler . . . . . . . . . . 10

1.7.5 Safety function of the boiler . . . . . . . . . . . . . 10

1.8 Circuit diagram . . . . . . . . . . . . . . . . . . . . . 11

2. Boiler attendance

2.1 Control panel . . . . . . . . . . . . . . . . . . . . . 16

2.2 Switch on/off . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 Operation modes . . . . . . . . . . . . . . . . . . . 18

2.3.1 Operation mode (heating water) . . . . . . . . . . . 18

2.3.2 Operation service utility water (sanitary water) . . 20

2.4 Setting of boiler parameters . . . . . . . . . . . . 21

2.5 Breakdowns . . . . . . . . . . . . . . . . . . . . . . . . 27

3. Installation

3.1 Norms and regulation. . . . . . . . . . . . . . . . . .28

3.2 Placement of the boiler. . . . . . . . . . . . . . .28

3.3 Mounting of the boiler on the wall. . . . . . . . 28

3.4 Electroinstallation. . . . . . . . . . . . . . . . . . . . 28

3.4.1 Connection of the boiler to electric supply netw. . .28

3.4.2 Installation of the room thermostat . . . . . . . . . 29

3.4.3 Installation of mode TUV . . . . . . . . . . . . . . . . 29

3.5 Heating system . . . . . . . . . . . . . . . . . . . 29

3.6 Expansion vessel . . . . . . . . . . . . . . . . . . . . . 29

3.7 Marking of working scale . . . . . . . . . . . . . . 30

3.8 Circle pump . . . . . . . . . . . . . . . . . . . . . . . . . 30

.

4. . . . . . . . . . . . 3Termination of operation 1

5. . . . . . . . . . . . . . . . . . . . . . . . 31Maintenance

6. . . . . . . . . . . 3 Full delivery . . . . . . . . . . . . . 1

7. . . . . . . . 31Transport and warehousing

8. . . . . . . . . . . . . . . . . . . . . . . 32Claims

9. . . . . . . . . . . . . . . 32Way of liquidation

10. . . . . . . . . . . . . . . . . . . . . . . 32Enclosures

10.1 Installation of room thermostat . . . . . . . 33

10.2 Face of control unit . . . . . . . . . . . . . . . . 33

Meaning of abbreviations and used symbols

OV - heating water

TUV - service utility water (sanitary water)

ZOV - storage water tank

TMV - three ways valve

Notice pay attention

Dear customer,

You have bought a modern product – the direct heated

electric boiler ELECTRIC EXCELLENT from the company

ATTACK, s.r.o., Slovak Republic. We believe that our

Page 4

4

product will serve you good and for long time. It is

necessary for you to study whole instruction manual and

hold all the principles. The declaration of conformity was

issued by the producer according to directives

2004/108/EC, 2006/95/EC,

Basic features

®

Boilers ATTACK are electric, using water for heating. It

is electric wall-hung appliance determined for heating

of family houses or flaks with heat loss to 22,5 kW.

The boiler could be used for heating of service utility

water (sanitary water) through storage water tank.

The boiler could be remote controlled by GSM.

Advantages of your boiler

SIMPLE CONTROL – you new boiler is in operation

automatically. After boiler professional putting into

operation is not necessary any additional setting. The

boiler will adapt to conditions of your heating system

DIMENSIONS – your new boiler is really small regarding

its dimensions. You can place it anywhere where is

impossible to place another type of boilers.

REMINDER!

Your new boiler is not stay alone to be useful for your

comfort, use good outside insulation of your flat or your

house, use the room thermostat for economical

consumption of electric energy.

ATTACK, s.r.o

1. General information

1.1 Description and use

The wall hung electric boiler ELECTRA EXCELLENT is

convenient for heating in heating systems with forced

circle and for heating of service utility water (sanitary

water).

The heating of heating water takes place in a boiler drum

by means of one (EXCELLENT 08), two (EXCELLENT 15)

or three (EXCELLENT 24) heaters of a power output of

4,5 kW, 6 kW or 7,5 kW. Each heater consists of three

heating rods of a power output of 1,5 kW, 2 kW or 2,5 kW

each. Heating operation is controlled by control unit with

PID regulation. PID regulation assures high efficient

operation due to minimalizing of heating water

temperature overshoots over temperature setting. This

regulation saves also your energy consumption. The

boiler could be regulated by the room thermostat and it

also able to heat sanitary water in an independent storage

water tank connected through with 3-ways motoric valve.

1.2 Advantages of boiler

small dimensions, modern design

high efficiency 99 %

silent operation

information on the display

mode relay independent to the control unit cost

saving regarding replacement

step less regulation of boiler output with continuous

switching on/off heating elements economic

operation

rotation of heating elements ensuring elongation of

lifetime

possibility of using the boiler for under floor heating

system

breakdowns diagnostic system with display indication

information about heating system pressure thermo

manometer

operation mode Stand-by ensuring termination of

boiler operation with all protective functions:

protective functions:

antifreeze

deblocking

against overheating

against pressure lost

pump running out regulated by time or temperature

possibility of remote control with GSM

possibility of equitermic operation

possibility of connection with a storage water tank

possibility of a room thermostat connection

automatic deaerating

breakdowns statement memory

function back to factory setting.

1.3 Important instructions and

advices

Regarding installation, putting the boiler into operation

and maintenance it is necessary to observe instructions

according to concrete norms and regulations and

instructions from the producer. It is also necessary for you

to read carefully instruction manual and guarantee

conditions.

Control if the boiler in the box is completed regarding

accessories etc.

Control if the boiler type is in accordance with your

request for use.

The data stated on the type label has to be

compatible with conditions for boiler connection and

mounting.

It is not allowed for user to manipulate with parts

plumbed.

1.3.1 Installing, mounting of the boiler

Safety and economic operation of the boiler requests

a technical project made by authorized heating or

civil engineer for whole heating system.

Page 5

5

Mounting of the boiler could be carried out only by

authorized company or persons.

On the boiler and 100mm before the boiler there is

not allowed a placement of things from flammable

materials.

The boiler mounted on the wall is not able to be

moved or placed to another place.

Boiler connection is allowed only with nut with flat

ring sealing.

It is necessary to put heating water inlet with a filter

and shut off valves.

It is necessary to leave a free space on both side

walls of the boiler 100 mm and minimally 400mm

from the top for after sales service. In case that you

will not observe this request for free space you have

to pay dismantling and mounting the boiler back to

the wall and to heating system, it is not a repair paid

in guarantee period!

1.3.2 Putting into operation

Putting the boiler into operation has to be carried out

only by authorized professional company or service

person that has a valid agreement signed with the

producer. The list of these companies is enclosed.

The company or person who will put the boiler into

operation has an obligation to assure repairs of

breakdowns or defects in guarantee period. In case that

this company doesn't exist anymore, the guarantee

repair will be assured by any company from the list

closed to you.

By putting the boiler into operation the authorized

person is obligated to:

control connections of the boiler to electric supply

network and to heating system

control tightness of the boiler

control all functions of the boiler

inform the user about boiler operation, its control and

maintenance

inform the user about safety dimensions from sides of

the boiler from flammable walls and its protection

according to ČSN 061008 and ČSN 730823.

To fulfil requests for boiler safety and economic

operation it is necessary to observe below mentioned

conditions:

for boiler mounting and installing the user has to get the

permission from the company who is a distributor of

electricity in your region, control the input of the boiler if

it is in accordance with the input stated in the

permission

for mounting of the boiler it is necessary to have an

authorized technical project for heating system and for

connection of electric boiler

the boiler is able to be mounted only in an environment

according to its determination and according to the

project

manipulation, operation, using, control and

maintenance of the boilers are forbidden if it is not in

accordance with rules and directions of this instruction

manual. It is forbidden mainly to disconnect any of

safety units or elements in the boiler!!!

If the guarantee list is not filling fully, it is not valid

If you take the boiler from the colder environment

to the warmer one (for example if the outside

temperature is below 0° C or 0° C and you want to

m o un t i t i ns i d e ) , p l e a s e w a i t

approximately 2 hours.

1.3.3 Operation of the boiler

The boiler has to be controlled and used only

according to advices and instructions stated

in this instruction manual, only by adult

person who was posted in maintenance of

the boiler. Putting the boiler into operation will made by

authorized service person during the heating test.

Any manipulation, operation, using and maintenance of

the boiler, which is not in accordance with instructions

and advices stated in this instruction manual, is

inadmissible. The producer is not responsible for

damages caused by wrong using and maintenance of

the boiler.

The producer recommends periodical service controls

of the boiler 1x per year before heating season. The

service control could be done only by a professional

authorized service company or person. The list of

service control steps recommend to be controlled

before heating season you will find in the chapter

“maintenance”.

The producer allows only room thermostat connection,

if the room thermostat has with potentional-free outlet

connection. The authorized service person is

responsible during putting the boiler into operation to

fill and sign guarantee card.

If you find any breakdown or any defect on an electrical

part of the boiler, please, don´t repair it by yourself,

disconnect the boiler from the electric supply network

and ask for after sales service person.

It is not allowed to use the boiler ELECTRIC-EXCELLENT

for another purposes than is stated in this instruction

manual.

1.3.4 Safety

Fire instructions:

Disconnect the boiler from the electric supply

network and take out it out of its operation according

to possibilities.

Extinguish fire using pulverized or

snows extinguish appliance flammable

and explosive materials

Don't stock any flammable and explosive

things closed to the boiler (for example

paper, colours, chemicals etc.)

1.7 Description of function

1.7.1 Technical description

The boiler is designed according to valid norms

Page 6

6

450

656

345

280

26

16

652

124 176

177

199

G3/4

G 3/4

1.4 Main dimensions

Dimensions in mm.

outlet of heating water

inlet of heating w

ater

Page 7

7

1.5 Technical data

2 x 3 x 1,5

Power output of 1 heating rod in kW

3 heating rods

2 x heater

* Y - connection

**Supply lead has tobe proposed in preference in conformity with the norms.

***

Boiler type

ELECTRIC 15

Electric parameters

EXCELLENT

Total electric input kW 15

Nominal heating output kW 15

Heater power output 2x3x2,5

Nominal current A 3x24

Electric network* V

Electric network V

Nominal current max. A 3x24

Pump input W

Main circuit breaker A 3x25

Nominal current of control fuse A

Enclosure IP

Mechanical life time of relay Electrical life time of relay

Width mm 450

Height mm 656

Depth mm 345

Boiler weight without water kg 38

Min. working overpressure of heating system

bar

Max. working overpressure of heating system

bar

Operation overpressure recommended kPa/bar

Circle pump Maximal temperature of heating water °C

Water volume of whole boiler l

Environmental kind ČSN 332000-3 Efficiency by nominal output %

Supply cable CYKY** mm

2

5x4

Supply cable AYKY** mm

2

5x6

Expansion vessel l

Surrounding temperature °C

Warehousing and transport temperature °C

Electromagnetic temperature Humidity %

Measuring accuracy % < 1

Accuracy of boiling water regulation °C ± 1

ELECTRIC 24

EXCELLENT

22,5

22,5

3x3x2,5

3x36

3x36

3x40

450

656

345

39,5

5x6

5x10

< 1

± 1

Regulation type -

Cascade Service plug Number of boilers in cascade max. -

Unit

50/60/70

0,315

Mechanical parameters

1 000 000 cycles

40

0 ÷ 90 without condensation

Regulation

Expanding temperature of thermostat

blocked, opened-closed systém

°C 100

10,6

normal AA5, AB5

99

3x230/400V+N+PE/50 Hz*

8

0 ÷ 40

-30 ÷ + 70

EN 55014-1(2006)

Environmental requests

0,4

3

100/1

UPM3 FLEX AS 15-70

80

250 000 cycles, 16 A, 250 V

PI

Remote control

with cascade controller

6 PIN

according to the cascade controller

1x230V+N+PE/50 Hz

450

656

345

36,5

5x2,5 / 1x6

5x4 / 1x10

< 1

± 1

ELECTRIC 08

EXCELLENT

7,5

7,5

3x2,5

3x12 / 1x36

3x12 / 1x36

3x16 / 1x40

Page 8

8

1.6 Main parts

boiler heating sensor

emergency thermostat

mode relay

mode sanitary water

control unit holder

display

touch control buttons

control unit

frame of the boiler

switchboard X2

switchboard X1

safety valve

expansion vessel

thermomanometer

sensor

cables bushing

main switcher on/off

pump

pressure switcher

inlet pipe

safety contactor

thermomanometer

control panel

insulation of boiler

body

reservoir of emergency

thermostat

heating elements

deaerate valve G3/8”

boiler body

Page 9

9

and rules ČSN EN and IEC. The safety of the boiler, energy

saving and sound was important matter during the boiler

designing.

1.7.2 Principle of boiler operation

The insulated boiler body with volume 10,6 l is a reservoir

where water is heated by electric heating elements

according to the boiler type, by one (08 kW), two (15 kW)

or three (24 kW). Depending on the actual heat

requirement, individual heating rods are connected, each

of them having a power output of 1,5 kW for Comfort 05

and Comfort 09 (1 heating rod = 1,5 kW, 6 heating rods 9

kW), a power output of 2 kW for Comfort 06, Comfort 12

and Comfort 18 (1 heating rod 2 kW, 9 heating rods 18 kW)

or a power output of 2,5 kW for EXCELLENT 15 and

Comfort 24 (1 heating rod = 2,5 kW, 9 heating rods 22,5

kW). Circulation of water is through the pump. Safety of

boiler operation is monitoring by several independent

sensors. Whole heating process and pump operation is

controlled by the control unit with display and push touch

control buttons. The button 0/1 is for switching off the

boiler out of operation.

1.7.3 Control unit and control board

Control unit has several functions which assure basic

characteristics, mainly:

safety functions assure protection against the of health

and property

user's functions functions set by the user

operation functions internal functions of control unit

import for sound operation of the boiler, but un-get-atable for the user

Control unit could be in below mentioned modifications:

basic only for heating = control unit + mode relay

for heating and heating of sanitary water = control unit

+ mode relay + mode TUV (sanitary water)

for heating with GSM remote control = control unit +

mode relay + mode GSM

for heating and heating of sanitary water with GSM

remote control = control unit + mode relay + mode TUV

(sanitary water) + mode GSM.

Control unit works with below mentioned inlet signals:

temperature of heating water (sensor NTC)

outside temperature (sensor NTC)

room temperature (sensor NTC)

temperature of sanitary water (sensor NTC) only if the

boiler has connected TUV (sanitary water) sensor

switching on signal of sanitary water heating 230 V

(only if the boiler has TUV (sanitary water) mode

room thermostat signal potentional free switcher

signal of relay lightening in the first level potentional

free switcher

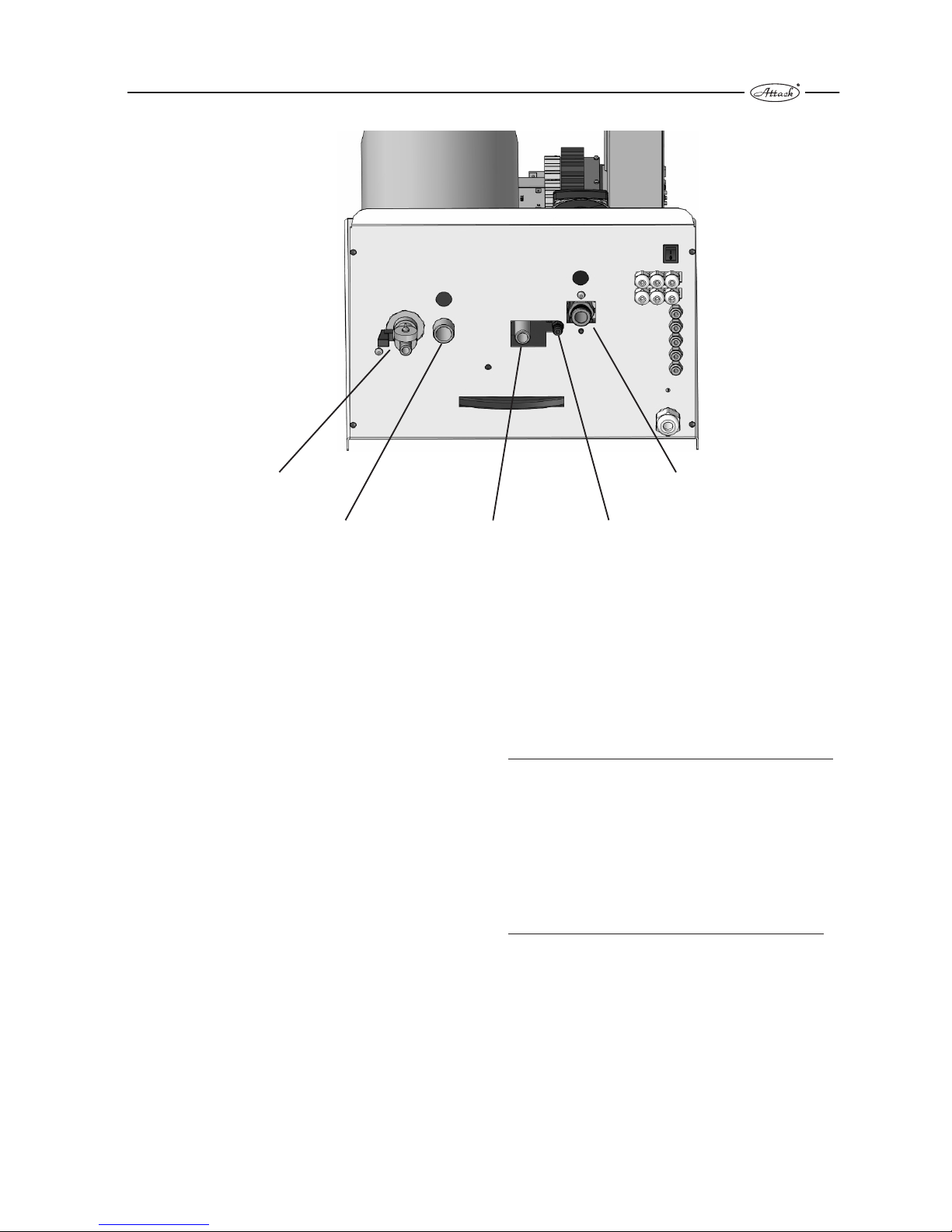

blow off valve of the boiler

body

outlet of heating wate

(warm)G 3/4”

outlet of safety valve

blow off valve of th

pump

inlet of heating water

(cold) G 3/4”

Page 10

10

signal of relay lightening in the second level

potentional free switcher

HDO (mass remote control) signal potentional free

switcher

signal HDO (mass remote control) activation of

“working zero” N

breakdown signal of floor overheating potentional

free switcher

breakdown signal of overheating 230 V

breakdown signal of pressure loss 230 V

signal of GSM mode

Control unit controls:

mode relay heating elements

mode relay pump

mode TUV (sanitary water) three ways valve for TUV

1.7.4 Antifreeze protection of the boiler

Antifreeze protection of the boiler

This function protects the boiler against freeze and is

active in the mode STAND-BY.

Circulation pump and the boiler are in operation, if

temperature of heating water decreases below 5 °C. In

this case the boiler assures minimal level o heating and

the system is mildly warm, the boiler heats to 15 °C

temperature of heating water and after that the boiler

set back to mode that it start to operate from. Pump

running of is active.

In case that the boiler is in the summer mode

(permanent heating of storage water tank) and the

temperature of heating water decreases below 5 °C

then the antifreeze protection function is activated for

heating system, after the boiler catch the temperature

15 °C, then the 3-ways valve go back to the position for

heating of sanitary water and pump running of is also

active.

If the boiler is switched off or out of electric

supply, this function is not active.

Unlocking protection of heating system

It is active at all times if the circulation pump or

3-ways valve is more than 24 hours out off

operation to protect blocking of the pump or

the valve due to its small parts. This function

avoids blocking of the pump rotor in mode

STAND-BY and elongates its lifetime.

The pump works 1 time per day for 10 s.

1.7.5 Safety function of the boiler

Control unit

The control unit is designed according to valid EU norms

and is certified.

The control unit has a protection against below and

over voltage

The control unit is protected by system Watch-Dog-

Timer with time 512 ms against its processor “blocking”.

In case that the processor is blocking the automatic

reset function is activated and then the program is

going with all parameters set from the point where it

was broken

Protection against overheating

The boiler has an emergency thermostat set for 100 °C.

In case of boiler overheating heating elements are put

out of operation independently to the control unit. This

breakdown is signaling on the display as a critical

breakdown No. 5.

This breakdown could be repaired only by authorized

service man.

Protection against lost of heating water pressure

The boiler equipped with a pressure switcher which

control minimal pressure in heating system 0,4 bar,

when the function reliability of deaerate valves is

assured, it means that the boiler has sufficient volume

of water.

In case of lost of heating water pressure below 0,4 bar

the boiler signs the critical breakdown No. 4 and

heating elements are put out of operation

independently to the control unit.

This breakdown could be repaired after the control of

tightness of water ways and after water filling over 0,4

bar. After that the boiler is automatically reset and

returned to normal operation.

Boiler protection against over and below voltage

in supply electrical net

The control unit is equipped with function assuring

putting the boiler out of operation if the voltage is below

150 V or over 250 V. This stage is marked on the display

like a critical breakdown No. 8. Below voltage is not

marked on the display.

When the voltage is OK = in the scale 150 250 V, the

boiler returns to normal operation.

Boiler protection against overpressure of heating

water

The boiler pump is equipped with pressure safety valve

set for 3 bars. In case of the overpressure more than 3

bars the leakage of water occurs from the valve till the

pressure of water in heating system is not below

maximal requested level.

This valve is in its operation automatically.

Page 11

11

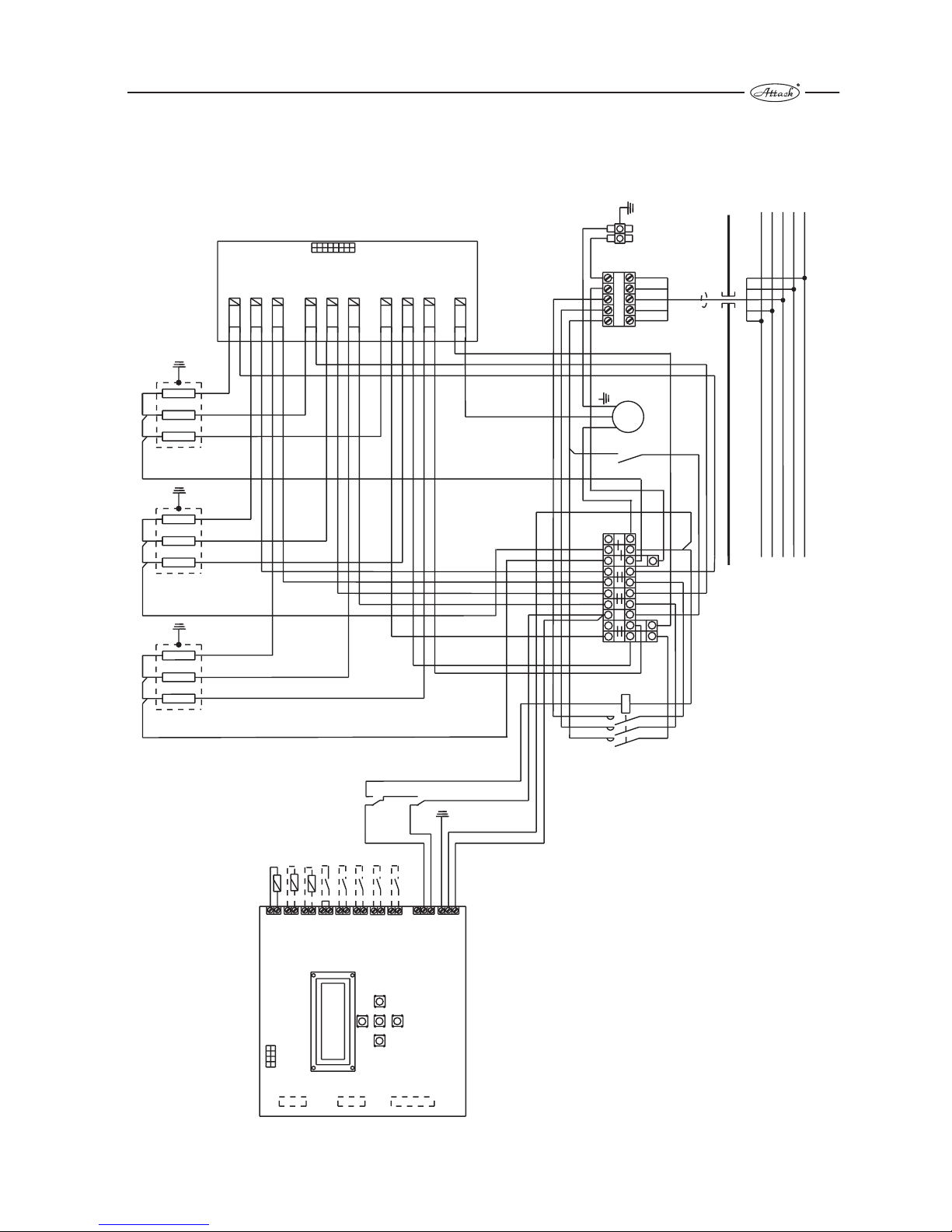

Circuit diagram for connection of the boiler EK18K, EK24K to supply electrical net 3x230V/400V

1.8 Circuit diagram

Legend:

NTC OV -

NTC sensor heating water

NTC OUT

-

NTC outside temperature sensor

NTC ROOM - NTC room temperature sensor

TER -

room thermostat 24V

FLOOR -

underfloor heating

nd

2.ST

-

external input lightening control 2 level

st

1.ST

- external input lightening control 1

leve

l

HDO -

mass remote controlí

GSM - GSM modem

HT

-

emer

gency thermostat

TS

-

pressure switcher

TUV -

service utility water (sanitary water)

KM1 -

contactor

X1, X2 - switchboard

HV -

main switcher

Č - pump

ZM -

earthing bridge

PE -

protective conductor

N -

working” conductor

L

-

phase conductor

TT1 -

heating element 1

TT2 -

heating element 2

TT3 -

heating element 3

L

N

PE

TS/230V

HT/230V

HDO/230V

HDO

FLOOR

2.ST

1.ST

TER

NTC OV

NTC OUT

NTC ROOM

1

3

5

A1

2

4

6

A2

TT1

TT2

TT3

L1

L2

L3

N

PE

1

5

1a

10a

1

1b

TT1.3

TT2.3

TT3.3

TT1.2

TT22

TT3.2

TT1.1

TT2.1

TT3.1

PUMP

mode relay

control unit

KM1

Č

ZM

TS

HT

C

X2

X1

HV

2

1

0

NC

NO

L1

L2

L3

N

PE

1

2

PG21

L

Service

GSM

TUV

REL

connection with control un

it

.

Remarks: clamps 24 V of the room thermostat ar

connected through from the factory

Connection

TUV ZOV (sanitary water

, storage water tank)

switchboard X2, clamps 2a, 10a.

N

10

TT1.3

TT1.2

TT1.1

TT2.3

TT2.2

TT2.1

TT3.3

TT3.2

TT3.1

Page 12

12

Circuit diagram for connection of the boiler EK09K,EK12K, EK 15K to supply electrical net 3x230V/400V

Legend:

NTC OV -NTC sensor heating water

NTC OUT

-

NTC outside temperature sensor

NTC ROOM -

NTC room temperature sensor

TER -

room thermostat 24V

FLOOR -

underfloor heating

nd

2.ST

-

external input lightening control 2

level

st

1.ST

- external input lightening control 1

leve

l

HDO -

mass remote controlí

GSM -

GSM modem

HT

-

emergency thermostat

TS

-

pressure switcher

TUV -

service utility water (sanitary water)

KM1 -

contactor

X1, X2 -

switchboard

HV -

main switcher

Č -

pump

ZM -

earthing bridge

PE -

protective conductor

N - working” conductor

L

-phase conductor

TT1 -

heating element 1

TT2 -

heating element 2

Remarks: clamps 24 V of the room thermostat ar

connected through from the factory

Connection

TUV ZOV (sanitary water

, storage water tank)

switchboard X2, clamps 2a, 8a.

control unit

mode relay

connection with control un

it

.

Page 13

13

Circuit diagram for connection of the boiler EK 05K,Ek 06K, EK 08K to supply electrical net 3x230V/400V

Legend:

NTC OV -

NTC sensor heating water

NTC OUT

-

NTC outside temperature sensor

NTC ROOM -

NTC room temperature sensor

TER -

room thermostat 24V

FLOOR -

underfloor heating

nd

2.ST

-

external input lightening control 2

level

st

1.ST

- external input lightening control 1

leve

l

HDO -

mass remote controlí

GSM -

GSM modem

HT

-

emer

gency thermostat

TS

-

pressure switcher

TUV -

service utility water (sanitary water)

KM1 -

contactor

X1, X2 -

switchboard

HV -

main switcher

Č -

pump

ZM -

earthing bridge

PE -

protective conductor

N -

working” conductor

L

-

phase conductor

TT1 -

heating element 1

Remarks: clamps 24 V of the room thermostat ar

connected through from the factory

Connection

TUV ZOV (sanitary water, storage water tank)

switchboard X2, clamps 2a, 6.

control unit

connection with control un

it

.

Page 14

14

Circuit diagram for connection of the boiler EK 05K, EK 06K, EK 08K to supply electrical net 1x230V

Legend:

NTC OV -

NTC sensor heating water

NTC OUT

-

NTC outside temperature sensor

NTC ROOM -

NTC room temperature sensor

TER - room thermostat 24V

FLOOR -

underfloor heating

nd

2.ST

-

external input lightening control 2

level

st

1.ST

- external input lightening control 1

leve

l

HDO -

mass remote controlí

GSM -

GSM modem

HT

-

emer

gency thermostat

TS

-

pressure switcher

TUV - service utility water (sanitary water)

KM1 -

contactor

X1, X2 -

switchboard

HV -

main switcher

Č -

pump

ZM - earthing bridge

PE -

protective conductor

N -

working” conductor

L

-

phase conductor

TT1 -

heating element 1

Remarks: clamps 24 V of the room thermostat ar

connected through from the factory

Connection

TUV ZOV (sanitary water

, storage water tank)

switchboard X2, clamps 2a, 6.

control unit

mode relay

connection with control un

it

.

Page 15

15

Circuit diagram TUV ZOV (sanitary water, storage water tank) of the boiler EK 24K

Legend:

NTC OV -NTC sensor heating water

NTC OUT

- NTC outside temperature sensor

NTC ROOM - NTC room temperature sensor

TER - room thermostat 24V

FLOOR - underfloor heating

nd

2.ST

- external input lightening control 2

level

st

1.ST

- external input lightening control 1

leve

l

HDO -mass remote controlí

GSM - GSM modem

HT

-

emer

gency thermostat

TS -

pressure switcher

TUV - service utility water (sanitary water)

KM1 -contactor

X1, X2 -

switchboard

HV - main switcher

Č - pump

ZM - earthing bridge

PE - protective conductor

N - working” conductor

L

-phase conductor

TT1 - heating element 1

TT2 - heating element 2

TT3 - heating element 3

Remarks: clamps 24 V of the room thermostat ar

connected through from the factoryConnection

TUV ZOV

(sanitary water

, storage water tank)

switchboard X2, clamps 2a, 10a.

control unit

mode relay

connection with control un

it

.

THER.TUV

1 2 N L3

orange

green

PE

Not included

Connection of DHW tank thermostat

TUV

Module TUV

Connection control unit

TMV

TMV - three way vale

Page 16

16

2. Maintenance

2.1 Control panel

information display

- temperature setting in

the reference room

change of the requested

parameter -

change of the requested

parameter +

- sanitary water temperature

setting

- information about

instantaneous stage

- going to mode STAND-BY

- parameters enter

- selection confirmation

i

0

0 C

0

--0 C

0

--0 C

ZI

22,5 kW

- going from the mode

STAND-BY the mode of heating

+

-

Thermomanometer

Page 17

17

Display

- Information display

- use for editing of instantaneous values of the electric boiler

- enter to information display is available after long (approx. 4s) pushing or 4x short pushing

0

TVS + 10 C

0

OVP35 C

CSQ:20

PP:3

instantaneous temperature of outside sensor

( )only if it is connected

requested and calculated temperature of the heating water

( )according to an equithermic curve

last breakdown in the boiler memory

GSM signal intensity (1- 30)

( )only if GSM mode is connected

- Basic information displayed

0

40 C

0

55 C

0

21 C

WI

10 kW

instantaneous temperature

of heating water

instantaneous temperature of sanitary

water in the storage water tank

(only if the boiler has TUV (sanitary water) mode

and TUV (sanitary water) sensor connected)

instantaneous temperature in referring room

(in case of reffering room sensor connection)

pump operation

- marking is lightining and the pump is in an operation

- marking is not lighting and the pump is switched off

signalizing of instantaneous stage of the boiler

- the boiler is in an operation of storage water tank heating

( )only if the boiler has TUV mode

- the boiler is in and operation of heating water

signalizing of instantaneous stage of GSM

( )only if the boiler has GSM mode

- - GSM in an operation

- @ - receiving/sending SMS

signalizing of the instantaneous boiler mode

WI - mode “WINTER” (heating water and

storage water tank heating)

SU - mode “SUMMER” (only storage water tank heating,

if the boiler has TUV (sanitary water) mode connected)

instantaneous output

of the boiler in kW

- S - (Soft start) SOFT START - see parameter P11

HDO

- vysoký tarif

- nízký tarif

Page 18

18

2.3 Modes

Important information for setting

during editing “help” is lighting in the low line for the

value to be set

during the first pushing of each button the editing is not

active

in delay in setting more than 10 s the editing is without

the change, it means that the setting is going back to

the starting position (only if the editing was not

confirmed )

each value set has to be confirmed by button .

if the value setting is not wanted or wrong (for example

entering the parameters setting), wait 10 s and the

boiler is automatically going back to starting basic

display or it is also possible to “enter” the parameter by

pushing the button , .

By holding the button , the setting value will

automatically rolls up or down

In case of wrong parameters setting it is possible to go

back to “factory setting” according to these steps:

switch off the boiler using the main switcher, push

together and switch on the boiler. On the

display there is “reset of factory parameters” and after

OK is displayed then the parameters are according to

factory setting.

Main operation modes

Operation mode “winter”

on the display there is “WI”

this operation mode is active always when the

temperature of heating water is set (it means the

operation mode “SU” is not lighting). In this operation

mode the boiler is heating the system and also the

storage water tank (if it is connected through)

Operation mode “summer”

on the display there is “SU”

this mode is possible to activated by reducing the

temperature of heating water using the button - below

25° C and confirmed this by .In this operation mode

the boiler is heating only the storage water tank (3ways valve is permanently in position in position

“tank”). It is possible to go from this operation mode to

operation mode “Winter” by increasing of heating water

temperature using and confirm it by .

Operation mode “stand by”

on the display there is

this operation mode is activated by long pushing (3 s)

the button and deactivated by short pushing .

Concerning this operation mode there are only active

protective functions described in the chapter 1.7.4

2.3.1 Mode heating (heating water)

on the display there is the symbol

this manual mode is active in operation mode

“WINTER” “WI”“

+

-

+

-

+

2.2 The boiler switching ON/OFF

Use the switcher 0/1 placed on the right corner of bottom side of the boiler (see the picture 1.6 Main parts)

On the display there is displayed introductory information after boiler's switching on.

E - KOMFORT: 22,5 kW

TUV: NE VER.1.20

- electric boiler ELECTRIC EXCELLENT with output 22,5 kW

- TUV mode is not connected, SW version 1.20

Switchboard of the boiler and inlet conductors and clamps of the contactor and inlet conductor

of the switcher are under voltage!

Disconnect the boiler from the main electric inlet supply!

Example::

Page 19

19

Without the room thermostat connected

Regulation is depended on the temperature of boiler water

requested by the user and hysteresis set by the parameter

P20 in the scale 1 - 10 °C. (This parameter could be set

only by authorized service person).

Steps for temperature setting of heating water:

Set the temperature requested by pushing , on the

control panel , on the display is temperature and “OV

TEPLOTA” and confirm by .After confirmation you will

go back to the basic display. The boiler is now heating to

the temperature requested by you. The scale of

temperature setting is 25 80 °C (regarding the setting

below the temperature value 25 °C the marking of

operation mode “SUMMER” = “SU” is lighting, going back

to heating mode is possible only by increasing the

temperature of heating water by the button ) .

If you don't confirm the value during editing till. 10 s, the

boiler is automatically goes back to the previous setting.

We recommend you to use the room thermostat for

economical operation of your heating system

With the room thermostat

In case that the room thermostat is connected the

regulation of temperature is the same as in case

without the room thermostat connected till the moment

when the request for heating is stopped by the room

thermostat.

With the room sensor connected (on the display there is

marked by the symbol .

In case that the room sensor is connected (the order

number of set is 4050485) the boiler is heating according

to the temperature in a reference room with hysteresis 1

°C. Actual temperature in the reference room is displayed

under the symbol .The room sensor is connected on the

clamps of the control unit marked NTC ROOM.

Steps for setting of temperature in a reference room

Press the button , on the control panel, for setting of the

temperature requested press for its increasing or

for its decreasing and confirm it by . After this

confirmation you will go back to main display.

Temperature could be set in scale from 5 to 35 °C, if the

temperature is decreased below 5°C the regulation

function is switched off on the basis of reference room

temperature. The boiler is controlled by the same way as

in previous 2 samples without the importance of the

temperature in reference room. The temperature will not

be shown on the display.

Remarks: if you have reference room temperature

regulation activated then this regulation is priority (and

the boiler will not reply to room thermostat).

Steps for setting of temperature in a reference room with

GSM modem (Only if you have GSM modem order No.

9566.2010 connected to the boiler)

The temperature in a reference room it is possible to set

also like a remote control through SMS in a format

example *22 (star, temperature in °C without spaces)

according to the way described in a instruction manual of

GSM modem.

GSM module works only in the nets

with standardized GSM protocol.

With equithermic regulation

equithermic regulation is not depended on instruction

from control elements of the boiler, it is determined

only for setting the temperature of heating water on

the basis of outdoor temperature.

this mode it is possible to be activated by connection of

outdoor sensor (set of outside sensor order No. 4841815

of control unit “NTC OUT”) and setting of equitermic

curve regulation is done by the parameter P8.

+

-

+

+

-

4

5

5

6

1 - boiler

4 - heating system

5 - closing valve

6 - filter

1

1 -boiler

4 - heating system

5 - closing valve

6 - filter

10 - temperature sensor

in reference room

4

5

5

6

10

1

9

4

5

5

6

1 - boiler

4 - heating system

5 - closing valve

6 -filter

9 -room thermostat

1

Page 20

20

Temperature of heating water for heating will be

automatically calculated on the basis of the outdoor

temperature according to the curve chosen and change

of starting point (parameter P9) without dependency of

heating water temperature setting.

Steps for setting are described in a chapter “Setting of

parameters”.

Disconnecting of equitermic regulation is necessary to

carry out with the parameter P8 and with decreasing of

the equitermic curve number value under the value “1”

till the text “NE” is displayed.

2.3.2 Mode TUV (sanitary water) is displayed

This mode is able to be activated after connection of

TUV mode order No. 9566.2000,

This mode is active in operation mode “summer”,

“winter” and is activated after request for heating

into the storage water tank.,

Temperature of water in the storage water tanks is

controlled directly by connection of TUV sensor in

the TUV mode or indirectly with storage thermostat

which gives information to the boiler heat/don´t heat

through the connection of connection of contactors

to the clamps on the mode TUV.

With connection of TUV sensor

1 - boiler

2 - storage water tank

3 - 3-ways valve

4 - heating system

5 - closing valve

6 - filter

7 - back flap

8 - treatment place

for water

9 - room thermostat

10 - reference room

temperature sensor

11 - consumption place

12 - safety valve for TUV

(sanitary water)

13 - expansion valve

14 - sensor of storage

water tank

9

M

AB

A

B

13

2

3

4

5

6

7

8

11

12

14

5

5

5

5

10

1

curve No.

1

2

3

20

25

4

5

6

7

9

10

65

70

75

80

85

30

35

40

45

50

55

60

4

5

678

9

10

1

2

3

outside temperature (°C))

temperature of heating water (°C))

equitermic curves of control panel

curve No.

curve No.

curve No.

curve No.

curve No.

curve No.

curve No.

8

curve No.

curve No.

Below mentioned equitermic curves are calculated for room reference temperature 20 °C.

Page 21

21

the boiler will hold the temperature set in the storage

water with hysteresis set by the parameter 21 in a scale

1 10 °C (Remarks this parameter is able to be set only

by service authorized person).

Steps for setting of TUV (sanitary water) temperature:

Press , on the control panel and for setting of the

temperature requested press for increasing and

for decreasing of temperature and confirm it by .After its

confirmation you go back to the main display. Temperature

is able to be set in a scale 30 - 65 °C, if temperature is

reduced below 30 °C then the boiler will switch off heating

of TUV. On the display there is displayed “VYP” instead of

temperature value. The boiler will not answer to the

temperature in the storage water tank.

With connection of thermostat clamps to the storage

water tank

The boiler is controlled by potential-free signal ON/OFF

connected to the clamps of TUV mode. In case of the

request for TUV/sanitary water heating “ON” the

temperature regulation is carry out for the before set

temperature 80 °C. After termination of operation the

boiler automatically goes back to the mode before

setting. Going back to this mode is automatically, it is

not possible to active it by a user.

Attention!

In the case of combination of boiler (hot water

heating and floor heating it is always

necessary to intall proctectionagainst the

overheating of the floor heating (f.e. mixing

valve).

2.4. Setting of par ameter and

functions of the boiler

Parameters P20 to P28 and P33, P34 are possible to be

displayed and to be set after rebuilding of service

jumper on the back side of the control unit.

Change in setting of the boiler could be

carried out only by authorized service

person!

After cover removing there is threat of

emergency of electric shock!

For your easy orientation and setting is enclosed

a help table of parameters:

+

-

1 - boiler

2 - storage water tank

3 - 3 ways motoric valve

4 - heating system

5 - closing valve

6 - filter

7 - back flap

8 - treatment of sanitary

water

9 - room thermostat

10 - reference room

temperature sensor

11 - consumption place

12 -safety valve

TUV/sanitary water

13 - expansion vessel

15 - thermostat of storage

water tank

M

AB

A

B

13

2

3

4

5

6

7

8

9

11

12

5

5

5

5

10

15

1

Page 22

22

max. output

according to parameter P35

max. boiler output

according to parameter P35

Parameter

marking

Information/value

displayed in English

Importance Setting value

Factory

setting

Autorization

Min.

version of

the boiler

- HW setting

Setting of heating water tempeature, going to

"summer" opeation mode under 30 °C (symbol of

summer = tap)

30 to 80, step 1 60 User 1

- DHW setting

Setting of sanitary (domestic hot water) tempeature,

going to switch off mode under 30°C ("-" is lihtening

on the display instead of temperature value)

30 to 65, step 1 50 User 2

- Room setting

Setting of temperature requested in reference room

under 5°C, termination regulation on basis of temperature in reference room ("-" is lightening on the display

instead of temperature value)

5 to 35, step 1 Ooff User 1+A2

P1 Language Language CZ, EN,FR,SK,DE EN User 1

P2 Backlighting Permanent backlightening of display YES, NO Yes User 1

P3 Pump runout set Pump running out Time, temperature Temperature User 1

P4 Time pump runout Time of pump runing out 1 to 30, step 1 min 10 User 1

P5

Temperature pump

runout

Temperature of pump running out 25 to 70,step 1°C 40 User 1

P6 Floor temp. limit Underfloor heating - temperature limitation No, 20 to 55, step 1°C No User 1

P7 Antifrost Antifrost protection YES, NO Yes User 1

P8 Equithermic curves Selection of equitermic curve No, 1 to 10, step 1 No User 1+A1

P9

Equithermic curve - start

Moving of start point of equitermic curve 20 to 30 °C, step 1 °C 20 User 1+A1

P10 Tempering Tempering - outside temperature No, 0 to 10, step 1°C No User 1+A1

P11 Soft start temp. Temperature setting delay with soft start No, 30 to 80, step 1 °C 40 User 1

P12 Soft start time Time settling delay 1 to 60, step 1 min 1 User 1

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

P18 P-constant Regulation constant P 0 to 99, step 1% 50 Producer 1

P19 I-constant Regulation constant I 0 to 99, step 1% 50 Producer 1

P20 HW hysteresis Hysteresis of heating water temperature 1 to 10, step 1°C 5 Service 1

P21 DHW hysteresis Hysteresis of TUV/sanitary water temperature 1 to 10, step 1°C 5 Service 1

P22 High T - max P HW Maximal output for heating systém with HT 0 to 22,5 step 2,5 kW 0 Service 1

P23 High T - max P DHW

Maximal output for storage water tank heating with HT

0 to 22,5 step 2,5 kW 0 Service 1

P24 Low T - max P HW

Maximal output for heating system with HDO (mass

remote control)

0 to 22,5 step 2,5 kW 22,5 Service 1

P25 Low T - max P DHW

Maximal output for storage water tank heating with

HDO (mass remote control)

0 to 22,5 step 2,5 kW 22,5 Service 1

P26 EIC 1

External lightening of boiler input 1 - lightening of input

0 to 12,5, step 2,5 kW 0 Service 1

P27 EIC 2 External lightening of boiler input 2 0 až 12,5, krok 2,5 kW 0 Service 1

P28 Manual low T

Manual HDO (mass remote control)switching on,

after 10 min. going back NO

HDO?(mass remote control), O.K. HDO? Servis 1

P29 PIN PIN Number in a format of 4 place 1234 User 3

P30 User 1 User 1

Phone number according to country

------------- User 3

P31 User 2 User 2

Phone number according to country

------------- User 3

P32 User 3 User 3

Phone number according to country

------------- User 3

P33 Errors - memory Errors/breakdowns memory - Service 1

P34 Errors - memory erase Errors/breakdowns memory deletion O.K. - Service 1

P35

1 ROD POWER OUTPUT

1 heating rod power output setting 1 kW to 4 kW, step 0.1 2,5 Producer 1

Version of boiler Version of boiler 1 = basic (control unit + relays mode)

Version of boiler 2 = TUV/sanitary water = (control unit + relays mode + TUV mode)

Version of boiler 3 = GSM = (control unit + relays mode + GSM mode)

Version of boiler 4 = Full = (control unit + relays mode + TUV mode + GSM mode)

Accessories A1 - Outside sensor (Order No.: 4841815)

A2 - Reference room sensor ( Order No.: 4050485)

TUV set/mode (Domestic hot water/sanitary water) - Order No.: 9566.2000

GSM mode/set - Order No.: 9566.2010

Page 23

23

Function and its setting

The electric boiler is equipped with several useful functions

assuring its comfort and economical operation. Putting the

boiler into operation it is necessary to set carefully boiler´s

function by setting of parameters for right function of the

boiler and heating system. On the lower line of display

there is “help” lighted for easy operation and setting of the

parameter.

Setting of parameters

Press shortly and now you are in the display for setting

the parameters. Use , and list the number of

parameter which you want to change. It is necessary to

press for editing of the parameter (editing is shown by

±on the right lower corner), now you can change the value

of the parameter setting by or , or move in the

parameter by , or during setting the phone numbers

or PIN code (parameters 29, 30, 31, 32).

Value set or chosen by you is necessary to confirm by for

its saving (> is blinking shortly).Now you are able to

change the next parameter by pressing or , or wait

approximately 10 s and the boiler goes automatically back

to the basic display.

Going back to the factory setting

In case that you set the parameter wrongly or not

requested, it is possible to go back to the factory setting as

follows: Switch off the boiler using the main switcher and

press in one time and switch on the boiler. On the

display there is “RESET TOVARNICH PARAMETRU” lighted

and after O.K., the factory parameters are in the factory

setting.

Description of parameters

Heating water temperature, sanitary water temperature

and temperature in a reference room were described in

previous chapters.

P1- Language (CZ, EN,FR,SK,DE)

setting of language for communication of the boiler on

its display and for sending SMS about breakdowns (GSM

mode)

CZ Czech language, EN English language, FR French,

SK Slovak, DE German language

P2- Possibility of permanent lighting of display

(Y/N)

Y the display is lighting permanently

N the display is lighting only during its activation by

pressing of a button, for 30 s

Remarks: if you press firstly and shortly, editing is not

in a process only the display is lighting.

P3-Pump time running out (time, temperature)

Setting of time running out after termination of request

for heating

Time for time pump running out with time set by the

parameter P4

Temperature for temperature pump running out with

temperature set by the parameter P5.

P4-Time pump running out (1- 30 s)

Time setting for pump running out after termination of

request for heating.

Remarks: In case that the request for heating of sanitary

water is terminated in winter operation mode there is

activated time pump running out set previously 1 min. into

heating system. In case of the summer operation mode

there is time running out 1 min. into storage water tank.

P5-Temperature pump running out (25 - 70° C)

temperature setting , if the temperature will be over

the temperature set, the pump will be in a operation.

Remarks: In case that the request for hating of sanitary

water is terminated in winter operation mode there is

activated time pump running out set previously 1 min. into

heating system. In case of the summer operation mode

there is time running out 1 min. into storage water tank.

P6-Temperature limit for underfloor heating (NO,

25 - 55°)

limitation of maximal temperature of heating water with

using the boiler for underfloor heating without the

priority of heating water set.

Remarks: In case of active equithermic regulation the

boiler will “cut” by this temperature the equitermic curve

set.

Always it is necessary to assure the

protection of underfloor heating system

circle against overheating using the

external equipment (for example mixture

valve or limit thermostat for underfloor

heating, its clamps are able to be

connected to the control unit on the

position of emergency thermostat of

underfloor heating).

Remarks: The boiler has the clamp for underfloor heating

thermostat connection (on the control unit there is

marking “FLOOR”). In case that temperature is higher than

the temperature set by this thermostat then control unit

will disconnect or output levels and stop the pump

operation.

We recommend you installation of this thermostat to avoid

overheating of undefloor heating system

P7-Antifrost protection (Y/N)

This function protects the boiler against boiler icing.

In case that the boiler water temperature falls down

below 5° C the boiler will switch on the pump

operation and will heat to 15 ° C. After that the boiler

goes back to the stage before antifrost protection

starting. The pump running out is activated for 1 min.

This function is active in all the modes.

Y function is active according above mentioned steps.

N function is not active (for example in systems there

are the antifreeze liquid additives.

In case of deactivation of this function

there is a threat of property damages.

The boiler is not able to protect rooms

there is the temperature lower than the

temperature in the room there is the

boiler placed (for example the boiler is

placed in a cellar and the coldest room is in

an attic.).

+

-

+

-

+

-

Page 24

24

P8- Equithermic regulation (NO, 1 to 10)

this function actives the boiler regulation on the basis

of dependency of heating water temperature calculated

and outdoor temperature according to an equitermic

curve and its movement.

NO equitermic regulation is not active

Number 1- 10 number selection of a optimal curve for

heating system. Description of equitermic regulation

see the point 2.3.1

P9- Selection of equitermic curve start-point

movement (20 - 30 °C)

You set the start-point of the curve, it means that it is

possible to increase the temperature till for 10 °C.

The number 20 - 30 °C = temperature of start-point

equitermic curve.

P10-Tempering function (NO, 1 to 10 °C)

This function is the same as antifrost protection (P7)

with a difference that the temperature after function

activation is measured by outside sensor. If the outside

temperature is lower than the temperature set then the

boiler will hold the boiler water on 15 ° C till the moment

when the outside temperature will increase over the

temperature set.

NO this function is not active

The number 0 - 10 °C outside temperature for

activation/deactivation of tempering fuction

P11-Selection of soft start function (NO, 30 - 80

°C)

This function assures stabilization of heating system in

cold stage (during switching on with the main switcher)

in dependency on temperature requested by the

parameter 12. During activation “S” is lighting on the

display.

NO function is not active

The number 30 - 80 °C heating water temperature

which the boiler operation is hold on set by the

parameter P12.

P12- Selection of lag (delay) in soft start (1 -60

min.)

If the function of soft start is activated, it is possible to

set the time for staying the boiler in the temperature set

by the parameter P11. If the function is deblocated by

the parameter P11 then the parameter P12 is not

active.

The value 1 to 60 = time in minutes for setting of lag

(delay).

P18- Selection of regulation constant P

selection of regulation constant has an influence for

boiler water temperature regulation

This parameter could be set only by

authorized service technique!

This constant could be changed only

according to producer instructions!

P19- Selection of regulation constant I

selection of regulation constant has and influence for

boiler water temperature regulation

This parameter could be set only by

authorized service technique!

This constant could be changed only

according to producer instructions!

P20 -Selection of hysteresis of heating water

temperature (1 - 10 °C)

if you use this parameter you will be able to set

temperature difference between switching on

temperature of boiler water and temperature

requested.

The value = 1 to 10 °C hysteresis in °C.

If you select the lower hysteresis of heating water then

you increase the number of heating cycles that could

cause reducing of life time of relays!

This parameter could be set only by

authorized service technique!

P21- Selection o hysteresis of TUV (sanitary

water), (1 - 10 °C)

if you use this parameter you will be able to set

temperature difference between switching on

temperature of water in the storage water and

temperature requested.

The value = 1 to 10 °C hysteresis in °C.

If you select the lower hysteresis of heating water then

you increase the number of heating cycles that could

cause reducing of life time of relays!

This parameter could be set only by

authorized service technique!

P22- Selection of maximal output for heating of

whole system with high price tariff (HT),(0- 22, 5

kW)

Using this parameter you are able to limit output of

the boiler for heating system during its operation

with high price tariff (HT).

Value 0 to 22.5 maximum power output in kW, the

step according to the mounted heating rod type (see

Parameter Tab., P35).

Page 25

25

This parameter could be set only by

authorized service technique!

Operation of the boiler in HT is possible

only on the basis of permission of

official electricity network distributor!

P23-Selection of maximal output for heating of

TUV (sanitary water) with high price tariff (HT), (0

- 22,5 kW).

Using this parameter you are able to limit output of

the boiler for heating into the storage water tank TUV

(sanitary water) with high price tariff (HT).

Value 0 to 22.5 maximum power output in kW, the

step according to the mounted heating rod type (see

Parameter Tab., P35).

This parameter could be set only by

authorized service technique!

Operation of the boiler in HT is possible

only on the basis of permission of

official electricity network distributor!

P24-Selection of maximal output for heating of

whole system with low price tariff (NT), (0- 22, 5

kW)

Using this parameter you are able to limit output of the

boiler for heating system during its operation with low

price tariff (NT) HDO (mass remote control) signal.

Value 0 to 22.5 maximum power output in kW, the

step according to the mounted heating rod type (see

Parameter Tab., P35).

This parameter could be set only by

authorized service technique!

P25-Selection of maximal output for heating of

TUV (sanitary water) with low price tariff (NT),

(0 - 22, 5 kW)

Using this parameter you are able to limit output of the

boiler for heating into the storage water tank TUV

(sanitary water) with low price tariff (NT) HDO (mass

remote control) signal.

Value 0 to 22.5 maximum power output in kW, the

step according to the mounted heating rod type (see

Parameter Tab., P35).

This parameter could be set only by

authorized service technique!

P26-Selection of lightening relay function in 1st

level (0 - 12, 5 kW)

Using this parameter you are able to set how the

nominal output will be lighted in case of the signal of 1st

level from the lightening relay placed in consumer

board unit.

Value 0-half the max. power output, a step by the set

value of parameter P35.

This parameter could be set only by

authorized service technique!

P27-Selection of lightening relay function in 2nd

level (0- 12, 5 kW)

Using this parameter you are able to set how the

nominal output will be lighted in case of the signal of

2nd level from the lightening relay placed in consumer

board unit.

Value 0-half the max. power output, a step by the

set value of parameter P35.

This parameter could be set only by

authorized service technique!

P28- Selection of manual switching on of HDO

(mass remote control) signal

Using this parameter it is possible to simulate the HDO

signal (activation of low price tariff NT). This parameter

is automatically deactivated after 10 min. This

parameter is only for service and after sales service

purposes including boiler setting.

HDO (mass remote control) it is not active.

O.K. HDO is activated after its confirmation for 10 min.

This parameter could be set only by

authorized service technique!

P29- Selection of safety PIN code

Using this parameter it has to be set PIN SIM card

inserted in GSM mode. In case that SIM card is not

by PIN protected, this number could each one.

The value xxxx four places number.

For this possibility of remote GSM control

of the boiler it is necessary to buy a GSM

model!

If you insert the wrong number of PIN

then you could block the SIM card!

P30-Selection of the user No. 1 responsible for

remote GSM communication with the boiler

Using this parameter it has to be inserted GSM mobile

phone number of the user responsible for remote GSM

communication with the boiler through SMS. The

number has to be inserted in the international number

format and if the number is shorter than 13 places then

it is necessary to insert for free ending place “N”.

The value 0, 1, 2, …9, N + - marking of phone number

Page 26

26

For this possibility of remote GSM

control of the boiler it is necessary to

buy a GSM model!

GSM module works only in the nets

with standartized GSM protocol.

P31-Selection of the user No. 2 responsible for

remote GSM communication with the boiler

Using this parameter it has to be inserted GSM mobile

phone number of the user responsible for remote GSM

communication with the boiler through SMS. The

number has to be inserted in the international number

format and if the number is shorter than 13 places then

it is necessary to insert for free ending place “N”.

The value 0, 1, 2, …9, N + - marking of phone number

For this possibility of remote GSM

control of the boiler it is necessary to

buy a GSM model!

GSM module works only in the nets

with standartized GSM protocol.

P32 -Selection of the user No. 3 responsible for

remote GSM communication with the boiler

Using this parameter it has to be inserted GSM mobile

phone number of the user responsible for remote GSM

communication with the boiler through SMS. The

number has to be inserted in the international number

format and if the number is shorter than 13 places then

it is necessary to insert for free ending place “N”.

The value 0, 1, 2, …9, N + - marking of phone number.

For this possibility of remote GSM

control of the boiler it is necessary to

buy a GSM model!

GSM module works only in the nets

with standartized GSM protocol.

P33 - Selection of breakdowns archive view

Using this parameter you are able to display 4

breakdowns history with its description and

frequency. Last breakdown it is possible to display on

the information display (see description information

display).

This parameter could be set only by

authorized service technique!

P34- Selection of breakdowns clearing

Using this parameter you are able to delete the

history of breakdowns.

This parameter could be set only by

authorized service technique!

P35 - Heating rod power output selection

A heating rod power output can be selected by selecting

this parameter the actual power output will be shown

on the display on the basis of this value.

Only the manufacturer is authorized to

set this parameter!

Page 27

27

2.5. Errors/breakdowns

Others errors/breakdowns non displayed

In case that the boiler has an error/breakdown and it is necessary to call service, don't try

to remove the breakdown by yourself. There is a dangerous of a threat of electric shock!

Critical

defect

Importance Reset Possible cause Elimination

Archive of

breakdowns

symbol

1

Invalid sensor of heating water

(shunt fault).

Automatic Invalid sensor or cable fault. Call service Err3

2

Invalid sensor of TUV

temperature (shunt fault)

Automatic Invalid sensor or cable fault. Call service Err3

3

Invalid sensor of temperature in

the reference room (shunt fault)

Automatic Invalid sensor or cable fault. Call service Err3

4

Loose of pressure in the

heating system

Manual reset of

the boiler

Water underpressure of heating system = under

0,4 bar.

Control tightness of heating

system, fill the water ane reset

the boiler.

Err1

5

Boiler overheating

Manual reset of the

emergency

thermostat

The temperature in the boiler is higher than

emergency one - for example the pump

breakdown, breakdownof heating element,

aeration...

Call service Err2

6

Electronics breakdown Automatic

Wrong connection of realy mode or TUV mode

or invalid control unit.

Call service Err4

7

Floor overheating Automatic

Temperature of heating water set by limitation

thermostat of underfloorheating is higher.

Call service Err2

8

Breakdown in inlet supply

(overvoltage in the network)

Automatic

Overvoltage on the inlet clamps of the control

unit.

Call service Err4

99

More than 1 breakdown in one

time.

-

More than 1 breakdown in one time, failures are

displayed in turns.

Call service -

Table of errors/breakdowns displayed

Breakdown Possible cause Elimination

The text „Rele Modul Error“ is displayed after the

boiler start.

Wrongly connected relay mogul, defective relay modul,

defective control system

Restart the boiler, in case that the breakdown has not been

eliminated, call service.

Boiler display is not lightening

Mistake in inlet supply of the boiler, network undervoltage, invalid control unit or software is missed.

Restart the boiler, in case that the breakdown has not been

eliminated, call service.

Temperature displayed is not in accordance with

real temperature value

Sensor is disconnected or invalid or broken. Call service.

It is not possible to connect GSM modem

The net falls short of GSM protocol, wrong PIN,

defective GSM modul

Control the PIN code edited by the parameter P29.

Wrong format of user phone number.

Control the format of phone number edited by the

parameter P30, P31, P32.

Wrong format of SMS´ s instruction.

Control the format SMS according to the description in the

chapter "Installing" including interspaces.

Wrong receiver´s data (SIM card in the boiler).

Control if the phone number of SIM card of the boiler is

correct written.

SIM card has not a free memory capacity for receiving

of SMS.

Delete all SMS from the SIM card of the boiler.

SIM card is blocked by the GSM operator. Call your GSM operator SIM card of the boiler.

It is not possible to control the boiler by

GSM SMS instruction

Page 28

28

3.Installation

3.1.Norms and regulations

For safety operation, projection, mounting, operation and

service of boiler is valid below mentioned norms and

regulations:

ČSN 06 0310:2006 Heating systems in buildings

projection and mounting.

ČSN 06 0830:2006 Heating systems in buildings safety

and protection equipment.

ČSN 06 1008:1998 Fire safety of heating appliances.

ČSN 07 0240:1993 Water and low pressure steam

boilers basic rules.

ČSN 07 7401:1992 Water and steam for heating

energetic equipments.

ČSN 33 1310:1990 Electrotechnical rules. Safety rules

for electric equipments used by person without electric

qualification.

ČSN 33 2000 - …Electrotechnical rules.

ČSN 33 2130:1985 Electrotechnical rules. Inside

electrical distribution system.

ČSN 33 2180:1980 Electrotechnical rules, connection

of electric appliances.

ČSN EN 50110-1:2005 Service and work with electrical

appliances.

ČSN EN 55014:2001 Electromagentic compatibility

requirements for home appliances, electric tools and

similar appliances.

ČSN EN 60355-1+A55:1997 Safety of home electric

appliances and for similar purposes.

ČSN EN 61000 - …Electromagentic compatibility (EMC)

Law No. 22/1997 Technical requirements for products.

Government direction No. 178/1997 defined technical

requirements for construction products + enclosure No.

1 basic requirements.

Notice No. 48/1982 basic requirements to assure labour

protection and safety of technical equipments.

3.2 Placement of the boiler in the

room

Room where the boiler will be placed and mounted on the

wall has to be in accordance with normal environment

AA5/AB5 according to ČSN 33 2000 3.

It is not allowed for boilers to be installed in bathrooms,

wash rooms, shower rooms in place 0, 1, 2, 3 according to

the rule ČSN 33 20007701.

Concerning fire protection and safety the rule ČSN 06 1008

is valid and there is stated minimal distance from

flammable objects.

We recommend enlarging these distances to have minimal

space easier service and manipulation:

- 500 mm from the front side

- 600 mm from the top

- 200 mm from the side

3.3. Mounting of the boiler on the wall

Mounting is carried out by 2 screws or hooks which the

boiler is hanged on through 2 inlets with spacing of holes

280 mm on the frame of the boiler.

3.4. Electroinstallation

3.4.1 Boiler connection to electric supply net

For boiler connection to electric supply net it is

necessary for user to have a license from the local

energetic distribution organization. Boiler input is not

allowed to be bigger than the input stated in the

license.

Before mounting of the boiler it is necessary to be

installed supply electric cable with main switcher and

with over current circuit breaker including starting

inspection revise and to have confirmed application for

electric power take-off.

Electric boilers ELECTRIC EXCELLENT are ranged in

appliances continuously connected to electric circuit of

network voltage. In the fix supply cable of the boiler

there has to be in-built main switcher with distances of

all disconnected cables min. 3 mm. The boiler is

connected by corresponding cables to switch board X1

according to the diagram 1.7. Inlet of cables through

the cover of boiler is carried out with bushings. The

bushing PG21 is for main supply inlet of the boiler.

Recommended size of circuit breaker and diameters of conductors:

2

Maximal diameter for switch board X1 EK is 10 mm .

Type of boiler

Type of connection

Size of circuit Cu full conductor Cu – wire

1x230V+N+PE 1x40A 1x6 1x10

3x230/400V+N+PE 3x16A 3x2,5 3x4 3x25A

3x4 3x6 3x40A

3x6 3x10

Unavailable

Unavailable

ELECTRIC EXCELLENT 8

Size of circuit Cu full conductor Cu – wire

ELECTRIC EXCELLENT 15 ELECTRIC EXCELLENT 24

Size of circuit Cu full conductor Cu – wire

Page 29

29

Other bushings PG9, PG7 are for other signals of the

room thermostat and the 3-ways valve.

3.4.2 Installation of the room thermostat

Connection of the room thermostat is necessary to do

with twin core cable with recommended diameter min.

Cu 0,5 mm2 and length to 25 m.

The cable for the room thermostat is not allowed to be

placed in the same way with supply cord or another

electric or industrial installation. Minimal separation is

10 cm.

The switch board for the room thermostat connection

(24V) is placed in the right part of the control unit from

the front face, the clamp with marking TER, the room

thermostat has clamps with bridge from the factory

setting.

3.4.3 Installation of mode TUV (heating of

sanitary water) and the storage water tank

If you want to heat TUV (heating of sanitary water), it is

necessary to connect through the electric boiler with

TUV connection set and extend the control unit with

TUV mode.

The complete set consists of:

mode TUV

sensor TUV

3-ways valve

connection cable of TUV mode to the control unit

connections parts and materials

instruction manual

Connection of TUV mode is carried on with the flat

conductor to the connector on the left side of the control