Page 1

W W W . A T T A C K . S K

WOOD GASIFYING BOILER

ATTACK DPX

STANDARD / PROFI / LAMBDA

USER MANUAL

for correct installation,

operation and cleaning

Important! Read this manual properly before the boiler start-up!

Page 2

Page 3

3

CONTENTS

1. INSTALLATION AND CHIMNEY PARAMETERS................................................................................................. 4

2. VERIFICATION OF THE CORRECT CHIMNEY PARAMETERS ......................................................................... 5

3. DEVICES FOR CHIMNEY DRAUGHT MEASURING ........................................................................................... 6

4. OPERATION PRESSURE IN HYDRAULIC CIRCUIT ............................................................................................ 7

5. BOILER PROTECTION AGAINST EXCESSIVE CONDENSATION – ATTACK-OVENTROP ........................ 7

6. CORRECT ASHTRAYS POSITION ........................................................................................................................... 8

7. FUEL .............................................................................................................................................................................. 8

8. AFTERCOOLING CIRCUIT INSTALLATION ......................................................................................................... 9

9. CORRECT ADJUSTMENT OF AIR INLETS ............................................................................................................ 9

10. ASHTRAY CLEANING .......................................................................................................................................... 10

11. HOW TO CLEAN SPACE AROUND THE ASHTRAY ..................................................................................... 12

12. EXCHANGER PIPES CLEANING BY LEVER OF TURBULATORS ............................................................... 13

13. HOW TO CLEAN SPACE UNDER EXCHANGER ........................................................................................... 14

14. POSITION OF LEVER OF TURBULATORS BY CLEANING .......................................................................... 15

15. TOOLS FOR CLEANING OF SPACE UNDER EXCHANGER ........................................................................ 16

16. CONTROL OF TUBULAR EXCHANGER´S FUNCTIONALITY ..................................................................... 17

17. ACCESS TO TUBULAR EXCHANGER .............................................................................................................. 17

18. EXCHANGER´S COVER REMOVAL .................................................................................................................. 18

19. CONTROL OF CORRECT FUNCTION OF THE HEAT-UP FLAP ................................................................. 18

20. TURBULATOR THREADS CLEANING.............................................................................................................. 19

21. CLEANING OF THE VENTILATOR´S OPERATION AREA ............................................................................ 20

22. CLEANING OF RADIAL IMPELLER’S VANES ................................................................................................. 21

23 SUMMARY OVERVIEW OF REGULAR CLEANING OF PARTICULAR BOILER PARTS .......................... 22

24. OVERVIEW OF VENTILATORS USED IN PARTICULAR BOILERS ............................................................. 22

Page 4

4

1. INSTALLATION AND CHIMNEY PARAMETERS

By installation of chimney connection to boiler it is necessary to care about correct outlet of flue

gas and eventual condensate, not to let it fall back into the boiler. For this purpose you can use

the T-piece, see picture below. Exhaust connection comes into the chimney vent. If it is not

possible to connect boiler to chimney vent directly, then the adequate extension of exhaust

connection has to be as short as possible, and no longer than 1 m, without additional heating

surface and it has to go up in direction to the chimney. Exhaust connections must not go

through foreign dwelling or utility units. Internal cross-section of the exhaust connection must

not taper in direction to the chimney. Try to minimize usage of elbows by installation. Chimney

has to be constructed in conformity with the norms STN 73 4201 and STN 73 4210.

Prescribed values of the correct height and

cross-section chimney dimensions:

DPX15, DPX25, DPX35, DPX45

20×20 cm min height 7 m

20 cm min. height 8 m

15×15 cm min height 11 m

16 cm min height 12 m

Page 5

5

2. VERIFICATION OF THE CORRECT CHIMNEY PARAMETERS

Correct boiler function significantly depends on quality chimney with correct parameters.

Minimum chimney diameter is 150 mm, however, 200 mm is recommended. Chimney has to be

designed or regulated to achieve prescribed draught of 23–30 Pa at nominal boiler flue gas

temperature value.

ATTENTION! Chimney which does not fulfil required parameters may cause limited

boiler function (Low flue gas temperature, low output, excessive condensation of

tubular exchanger, shorter life-time, even total boiler disfunction)! Guarantee does

not relate to the boiler installed with the chimney of incorrect parameters.

Page 6

6

3. DEVICES FOR CHIMNEY DRAUGHT MEASURING

It is possible to check correct chimney draught by some types of analysers or by exact

differential pressure-gauge. On the picture there is draught reducer too, also useful for correct

draught setting.

Page 7

7

4. OPERATION PRESSURE IN HYDRAULIC CIRCUIT

Operation pressure must not exceed limit of 2,5 bar.

ATTENTION! Expanse vessel and safety valve must be installed in the system.

5. BOILER PROTECTION AGAINST EXCESSIVE

CONDENSATION – ATTACK-OVENTROP

For correct boiler function and its long life-time it is necessary to keep return water temperature

always higher than 65 °C. Set boiler thermostat to 80-85 °C, which is ideal boiler operation

temperature. Boiler guarantee is valid only in case that the ATTACK-OVENTROP device was

installed into the hydraulic system.

ATTENTION! If the ATTACK OVENTROP device is not installed, it may cause shorter

boiler life-time.

Page 8

8

6. CORRECT ASHTRAYS POSITION

Ashtray position is important for correct boiler operation. It is not necessary to take out the

ashtray while cleaning, but it is important to check its correct position sometimes. Ashtray has to

be completely shifted rearwards.

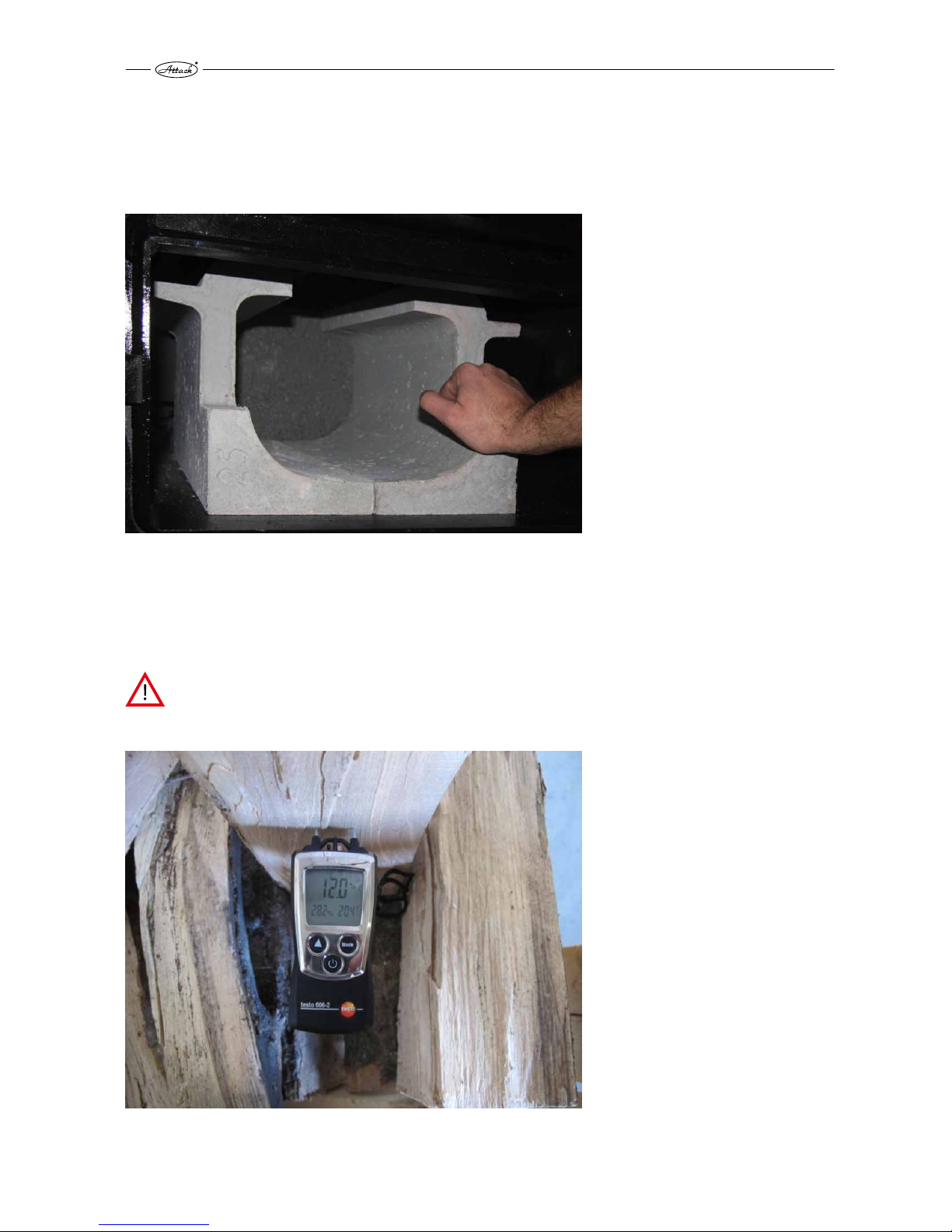

7. FUEL

Use suitable fuel for wood gasifying boiler operation – soft or hard wood logs. Wood moisture

has to be in range of 12–20 % (related to time of min. 15 month of free storing at the fresh air).

Alternatively it is possible to use wood briquets of cylindrical shape with opening in the middle.

ATTENTION! Wood with moisture exceeding 20 % shortens boiler life-time, causes

lower output, excessive condensation in tubular boiler exchanger, which may

require additional out-of-warranty service!

Page 9

9

8. AFTERCOOLING CIRCUIT INSTALLATION

Boiler warranty is valid only in case, that functional thermostatic valve, connected to the cold

water source, is installed in the boiler aftercooling circuit. If the cold water source depends on

electricity (home water plant), whole device can be out of order in case of power failure. In this

cases, use water tanks placed higher than boiler, connected to thermostatic valve. Tank volume

has to be appropriate to the boiler outuput.

ATTENTION! If there is no aftercooling circuit on the boiler and it comes to boiler

overheating, serious and non-recurring damage or even fire may occure.

9. CORRECT ADJUSTMENT OF AIR INLETS

Correct adjustment of primary and secondary air by STANDARD and PROFI boilers is marked on

tin-plate and it is not necessary to manipulate with that. Correct setting of primary air (upper

butterfly) is 100 %, secondary air (bottom butterfly) is set to 35 %. This relates to all outputs of

DPX boilers (15, 25, 35, 45).

Page 10

10

10. ASHTRAY CLEANING

Internal space of ashtray has to be cleaned from accumulated ash at least 1× a day. Cleaning

with scoop is very effective and easy. Cleaning can be done very easily and fast also by full boiler

operation.

ATTENTION! Hot ash from ashtray can still smoulder, therefore it is not supposed to

be put into trash bin, however into appropriate tin-plate bin, not to cause the fire.

Page 11

11

Page 12

12

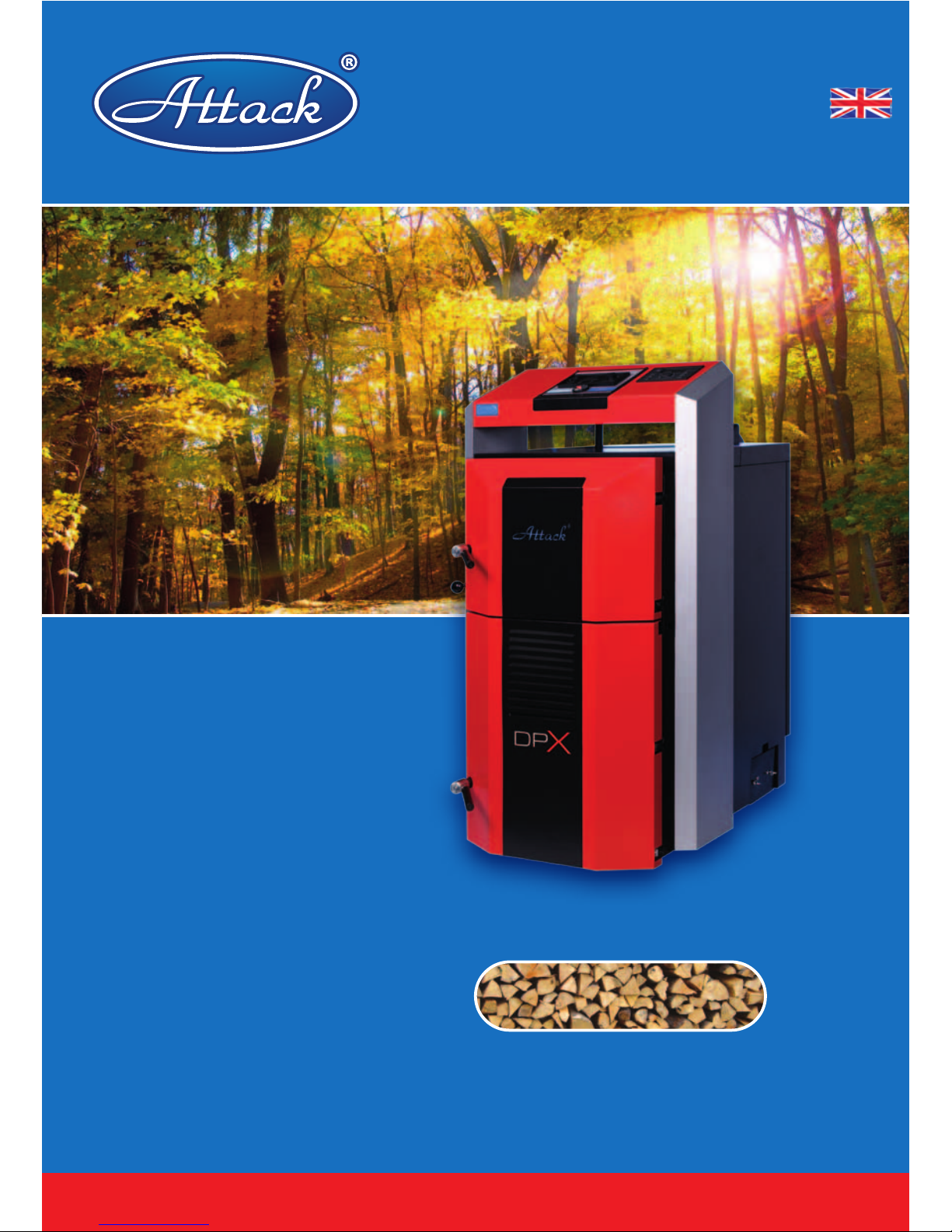

11. HOW TO CLEAN SPACE AROUND THE ASHTRAY

Space around the ashtray has to be cleaned regularly, at least 1× a week. Use suitable tool, fire

hook delivered with boiler is ideal for this purpose. It is not necessary to take out the refractory

pieces from the boiler´s ashtray.

ATTENTION! Unsufficiently cleaned space around ashtray may cause limited boiler

function.

Page 13

13

12. EXCHANGER PIPES CLEANING BY LEVER OF

TURBULATORS

It is necessary to move lever of turbulators cleaning regularly, preferably by every boiler loading,

at least 3 times a day. It is necessary to move it by full lever uplift, 5–6 times upwards and

downwards.

ATTENTION! If it is not moved with the lever regularly, exchanger pipes may clog

and therefore cause turbulators blockage, lower efficiency, decreased output and

incorrect boiler function. In this case is boiler warranty not valid. If you cannot

move the lever of turbulators, stop the boiler and call specialized service.

Page 14

14

13. HOW TO CLEAN SPACE UNDER EXCHANGER

It is necessary to clean space under exchanger pipes in regular intervals. This interval depends

on boiler operation time, but it has to be done at least 1× a week. Remove cover of the opening

for cleaning carefully, not to damage the sealing. After cleaning of space under exchanger,

install the cover – it has to be sufficiently screwed and air-proof.

ATTENTION! Otherwise there may come to insufficient air circulation in the boiler

and thereby to incorrect boiler function (ineffective combustion, decreased output,

low flue gas temperature, etc.).

Page 15

15

14. POSITION OF LEVER OF TURBULATORS BY CLEANING

To clean space under exchanger of the DPX 15, 25, 35 boilers, it is necessary to lift lever of

turbulators fully up, turbulators go into the pipes and thereby there is free space for cleaning. By

the DPX 45 boiler it is ideal to lift the lever into middle position.

Page 16

16

15. TOOLS FOR CLEANING OF SPACE UNDER EXCHANGER

To clean space under exchanger it is possible to use fire hook delivered with the boiler.

Page 17

17

16. CONTROL OF TUBULAR EXCHANGER´S FUNCTIONALITY

Check regularly correct functionality of tubular exchanger – at least 1× a month. Firstly, remove

rear upper cover.

17. ACCESS TO TUBULAR EXCHANGER

Release wing matrices.

Page 18

18

18. EXCHANGER´S COVER REMOVAL

Check correct functionality fo turbulators, while the boiler is out of order. Remove the cover to

get to the tubular exchanger.

ATTENTION! Cover must be sufficiently tighten and air-proof. Otherwise it may

cause incorrect boiler function

19. CONTROL OF CORRECT FUNCTION OF THE HEAT-UP FLAP

For correct function of the heat-up flap it is necessary to check and clean bearing surfaces

regularly.

Page 19

19

20. TURBULATOR THREADS CLEANING

If the boiler was from any reason

operated in incorrect way, it is

possible, that the turbulators were

clogged and thereby the flue gas

transition was decreased. In this case

it is necessary to demount

turbulators and to clean the space

between particular threads, for

example by wire brush. Put the

turbulators back into the pipes, not

to decrease efficiency of the boiler.

(This is not related to the 15 DPX

model).

Page 20

20

21. CLEANING OF THE VENTILATOR´S OPERATION AREA

Operation space of the ventilator´s radial impeller has to be cleaned at least 1× a year. To do so,

release matrices of the ventilator´s flange and demount ventilator. Clean the operation area

from soot and mud. By demounting, take care to tighten matriaces of the ventilator´s flange

sufficiently.

ATTENTION! Demount ventilator, while boiler is out of order. Insufficiently cleaned

ventilator´s operation area may cause its limited function.

Page 21

21

22. CLEANING OF RADIAL IMPELLER’S VANES

Vanes of ventilator have to be cleaned from dirt at least 1× a year by suitable tool (wire brush).

ATTENTION! Too dirty vanes of ventilator decrease its efficiency and thereby cause

limited boiler function.

Page 22

22

23 SUMMARY OVERVIEW OF REGULAR CLEANING OF

PARTICULAR BOILER PARTS

Cleaning* Point Daily Weekly Annually

Ash removing 10 1×

Space around ash tray 11 1×

Space under exchanger 15 1×

Lever of turbulators 12 5–6×

Flap 19 1×

Space of ventilator 21 1×

Radial impeller of ventilator 22 1×

* Minimal recommended cleaning intervals. According to intensity of heating they can be also

shorter.

24. OVERVIEW OF VENTILATORS USED IN PARTICULAR

BOILERS

Ventila

tor

Boiler type FCJ4C52S FCJ4C82S R2E180-CG82-01

DPX

15 •

25 •

30 •

35 •

40 •

45 •

DP

15 •

25 •

35 •

45 •

75 •

95 ••

Page 23

Page 24

ATTACK, s.r.o. – 01/2015

ATTACK, s.r.o.

Dielenská Kružná 5020

038 61 Vrútky

Slovakia

Tel: +421 43 4003 103

Fax: +421 43 4003 116

E-mail: export@attack.sk

Web: www.attack.sk

Výrobca ATTACK, s.r.o. si vyhradzuje právo technických zmien výrobkov bez predchádzajúceho

upozornenia. • ATTACK, s.r.o. producer reserves the right to change technical parameters and dimensions

of boilers without previous warning. •Der Hersteller AT TACK, s.r.o. behält sich das Recht der technischen

Veräderungen an Produkten ohne eine vorige Warnung. • Изготовитель AT TACK, s.r.o. оставляет за собой

право изменения технических параметров и размеров котла без предыдующего предупреждения.

• Le producteur ATTACK, s.r.o. réserve le droit des modifications techniques sans l‘aver tissement

précédent. • Productor ATTACK, s.r.o. reserva el derecho de cambios técnicos sin advertencia anterior.

Loading...

Loading...