Page 1

WOOD GASIFYING

BOILER

ATTACK DPX

STANDARD, PROFI,

LAMBDA

ATTACK, s.r.o. - aktualizácia 05/2010

SK

EN

DE

RU

FR

ES

RO

Page 2

2

ATTACK DPX - Wood gasifying boiler

- Assembly, control heat up and attendance training is perfomed by field engineer trained by

producer, who also fills in the protocol about boiler installation.

- At wood gasification, it comes to formation of tar and condensates (acids) in the fuel chamber.

Therefore the mixing device has to be installed with the boiler to keep minimum temperature of the

return water into boiler at 65°C.

Operation temperature of the water has to be in the range of 80-90°C.

- The boiler cannot permanently operate in the outout range lower than 50%.

- When using the circuiting pump, its operation has to be controled by detached thermostat to

ensure prescribed minimum temperature of return water.

- Boiler operation is ecological at nominal output.

- Therefore we recommend to install boiler with accumulation tanks and mixing device, which

ensures fuel saving of 20-30% and longer boiler and chimney life-time, together with more

comfortable attendance.

- If you cannot connect the boiler into accumulation, we recommend connect the boiler at least with

one equalisation basin with approximate volume of 25l per 1kW of the boiler´s output.

- Daily heating-up is necessary, when the boiler operates at lower output (summer operation and

D.H.W. heating).

- Use only dry fuel with humidity of 12-20% (output decreases with increasing humidity and fuel

consumption is increased).

- Correct boiler choice, i.e. its heating output is very important condition for economical operation

and correct boiler function. The boiler has to be chosen by nominal output adequate to temperature

losses of heated object.

- Boiler can be used only for purpose that it is intended to and only in the way described in

this manual.

- WARNING – After disconnection of operating boiler from electricity mains, the

burning continues further in attenuation regime. Do not open boiler door, until the

boiler temperature decreases under 40°C.

Guarantee for boiler is not valid if:

-it is not operated with prescribed fuel -not with wood of humidity lower than 20% or if it is used

with the fuel that is not prescribed by producer

Page 3

3

- the mixing device Regumat ATTACK-OVENTROP is not installed in the system to ensure

temperature of return water into boiler at least at 65°C

- functional thermostatic valve is not installed in the aftercooling circuit of the boiler (WATTS

STS20), connected to the cold water source.

This device is not intended for usage by persons (including children) that are physically, sensually,

mentally or due to unsufficient experiences and knowledge unable to use it safely without being

under control or being instructed to use by person responsible for their safety. It is necessary not to

allow children to play with the boiler.

If the electrical cord is broken, it has to be replaced with special cord, available from

producer or service technician!

Be carefull while using the device! The Lambda probe works at high temperatures (300°C)

and by uncareful manipulation there is a danger of scorch!

Warning sign

This warning sign always appears in the instruction manual, when it is necessary to warn about

possible bodily injury and material damages, if this manual is not kept properly.

Two types of warning signs are used in this manual:

WARNING Warns about life-dangerous situations and situations that may cause bodily

injury and damages, in case that necessary actions were not kept.

ATTENTION warns about less safe work methods and processes that may cause bodily

injury or material damages.

Page 4

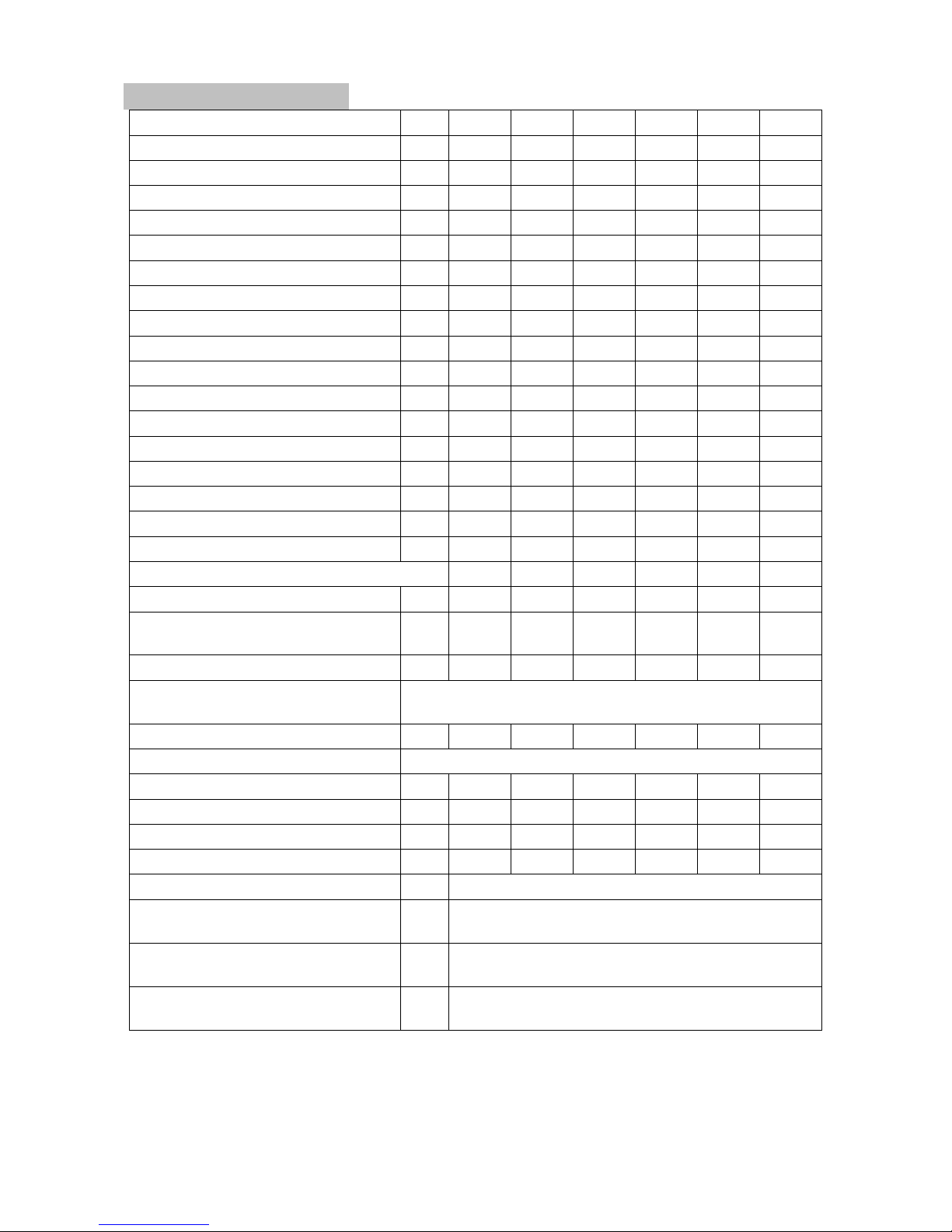

4

Manual content:

2. Important

4. Content

5. Introduction, general description

6. Technical parameters

7. Boiler dimensions

8,9, 10. Instrument panel of ATTACK DPX STANDARD, PROFI LAMBDA

11. Purpose of usage, technical description, description of the STANDARD version

11. Warning

14. Technical description of DPX PROFI

15. Boiler overheating, methods of boiler regulation, error messages

16. Technical description of ATTACK DPX LAMBDA

20. Setting and putting into operation of ATTACK DPX LAMBDA

23. Safety test of ATTACK DPX LAMBDA

25. Maintenance of the heating system, fuel

26. Assembly and installation of boiler

27. Chimney, flue gas ducting, boiler connection to electricity mains

28. Boiler protection against corrosion

30. Obligate norms for projecting and assembly of boilers

31. Installation and exchange of refractory adapting pieces

32. Connection schemes

33. Connection with heat accumulators

34. Boiler protection against overheating

34. Transport, manipulation and storaging

36. Possible faults and methods of their removal

41. Schedule of dependency of resistance on thermal probe temperature of the heating water (DPX

PROFI)

42. Electrical schemes of connection of the ATTACK DPX boilers

47. ES declaration of conformity

49. Notes

Page 5

5

Introduction:

Dear customer,

thank you for confidence that you showed us by purchasing our product - the ATTACK wood

gasifying boiler. We wish you long and reliable operation. Proper attendance of the boiler is one of

the conditions for reliable and correct operation, so please read this instruction for use carefully.

The manual is written in the way to respect the correct operation of the boiler.

The most important conditions of correct boiler operation are following:

- choice of the right type and output of the boiler

- impeccable putting into operation

- sensitive attendance

- regular technical maintenance

- reliable service

General description

Wood gasifying boiler ATTACK DPX

Name: WOOD GASIFYING BOILER ATTACK DPX 15, 25, 30, 35, 40, 45,

IN DESIGN „STANDARD“, „PROFI“, „LAMBDA“

Type: ATTACK DPX 15, 25, 30, 35, 40, 45

Max.operation pressure: 250 kPa

Water volume: 80, 100, 110, 128 l

Electr. connection: 230 V/50 Hz/10 A

Electr. output: 60 W

Fuel: Dry wood with heat value of 15 - 17 MJ/kg, humidity of 12 - 20%,

diameter 80 až 150 mm

Nominal output: 15, 25, 30, 35, 40, 45 kW

The ATTACK DPX wood gasifying boiler is intended for economic and ecological heating of

family houses, bungalows, small plants, workshops and similar objects.

Specified fuel for ATTACK DP boilers is dry wood, e.g. logs of lengths, depending on the type of

boiler.

Description of the ATTACK DPX labelling:

ATTACK DPX 15 Standard

25 Profi

30 Lambda

35

40

45

Wood gasifying boiler.

Boiler output

Version type.

Page 6

6

Technical parameters:

Boiler type

DPX15 DPX25 DPX30 DPX35 DPX40 DPX45

Boiler output kW 15 25 30 35 40 45

Surface of exchanger m² 1,98 2,52 2,78 2,78 3,03 3,03

Volume of fuel chamber dm³ 65 96 112 112 128 128

Dimension of feeding opening mm 235x445 235x445 235x445 235x445 235x445 235x445

Prescribed chimney draught Pa 23 23 23 23 23 23

Max. operation overpressure of water kPa 250 250 250 250 250 250

Pressure loss of water (∆T 10K) kPa 1,9 2,3 4,4 4,4 6,6 6,6

Pressure loss of water (∆T 20K) kPa 0,6 0,7 1 1 1,8 1,8

Boiler weight kg 370 430 460 460 490 490

Diameter of flue gas connection mm 150 150 150 150 150 150

Boiler height – „A“ mm 1240 1240 1240 1240 1240 1240

Boiler width – „B“ mm 700 700 700 700 700 700

Boiler depth – „C“ mm 840 1240 1340 1340 1440 1440

Depth of chamber – „D“ mm 400 590 690 690 790 790

Protection of electrical parts IP 21 21 21 21 21 21

Electric output W 50 50 50 50 60 60

Boiler efficiency % 89 89 89 89 90 90

Boiler class 3 3 3 3 3 3

Flue gas temperature at nominal output °C 170 170 180 180 190 190

Substantive flue gas overflow at

nominal output

kg/s 0,019 0,019 0,021 0,021 0,027 0,027

Maximum noise level dB 65 65 65 65 65 65

Prescribed fuel

Dry wood with heat value of 15-17 MJ/kg, water volume min.

12% - max. 20% diameter 80-150 mm

Average fuel consumption Kg/h 3,9 6,5 7,8 9,1 10,4 11,75

Consumption per season 1 kW = 1 m3

Maximum length of wood logs mm 350 550 650 650 750 750

Burning time at nominal output hod 3 3 3 3 3 3

Volume of water in boiler l 80 100 110 110 128 128

Minimum volume of equalisation basin l 375 625 750 900 1000 1200

Connection voltage V/Hz

230/50

Range of settings of heat. Water

temperature

°C 65-90

Range of setting of room temperature

(PROFI version)

°C 10-27

Power handling capacity of boiler

regulator´ s contacts (PROFI version)

V/A 230/2

Acoustical pressure level A does not exceed 70dB (A).

Immediate top value of acoustical pressure C does not exceed 63 Pa.

Prescribed min. temperature of return water in operation is 65°C.

Prescribed operation temperature of water in boiler is 80-90°C. Producer, the ATTACK, s.r.o. reserves right of

technical changes of products without previous announcement!

Page 7

7

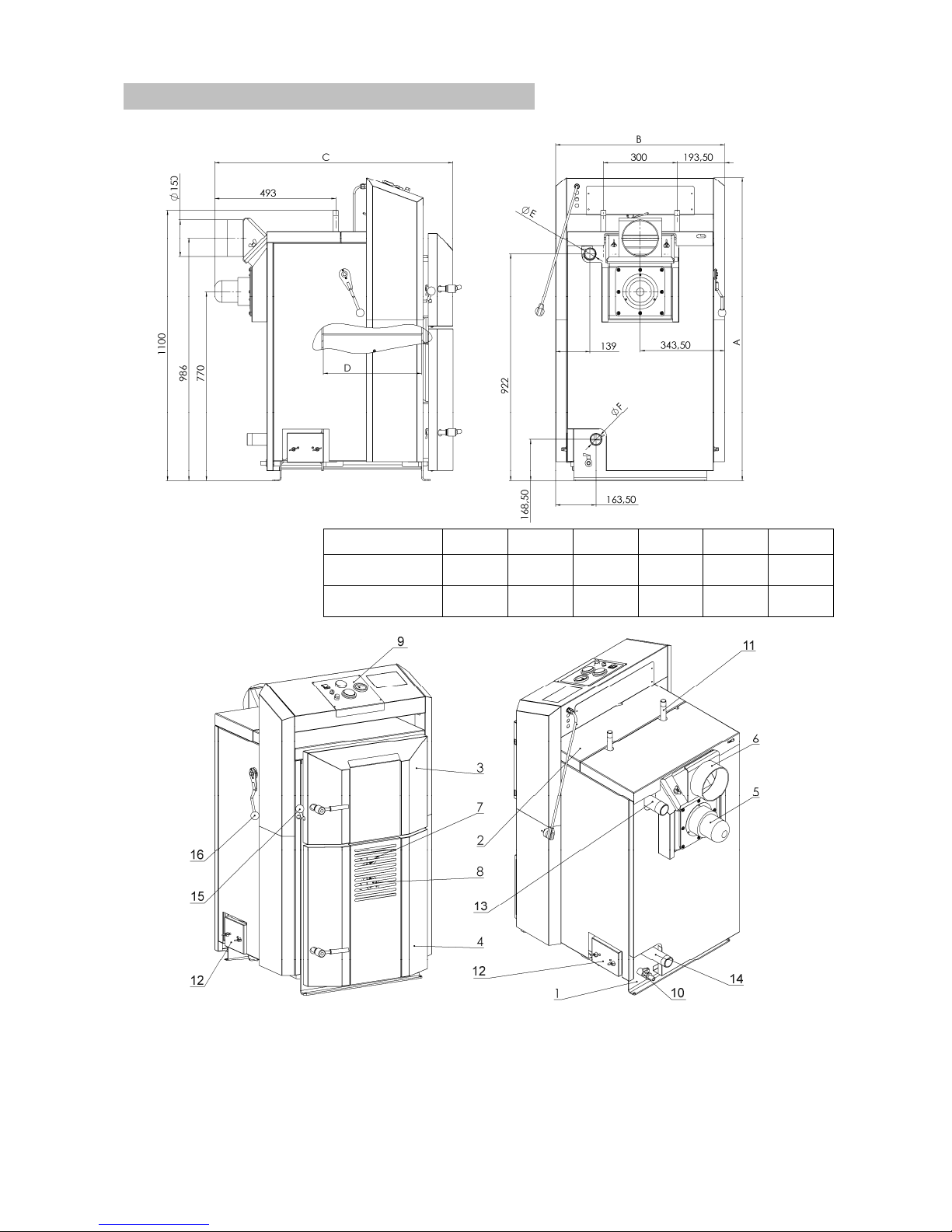

Dimensions of the ATTACK DPX boilers

DPX15 DPX25 DPX30 DPX35 DPX40 DPX45

C.H. flow

connection – „E“

G6/4“ G6/4“ G6/4“ G6/4“ G2“ G2“

C.H. return

connection – „F“

G6/4“ G6/4“ G6/4“ G6/4“ G2“ G2“

KEY:

1. BOILER BODY 2. UPPER CAP 3. FEEDING DOOR

4. ASH PAN DOOR 5. SUCTION FAN 6. CHIMNEY 7. PRIMARY AIR FLAP

8. SECONDARY AIR FLAP 9. INSTRUMENT PANEL 10. DISCHARGE VALVE

11. COOLING CIRCUIT 12. COVERING OF CLEANING OPENING 13. C.H. FLOW CONNECTION

14. C.H. RETURN CONNECTION 15. PULL ROD OF THE CHIMNEY FLAP 16. LEVER FOR EXCHANGER CLEANING

Page 8

8

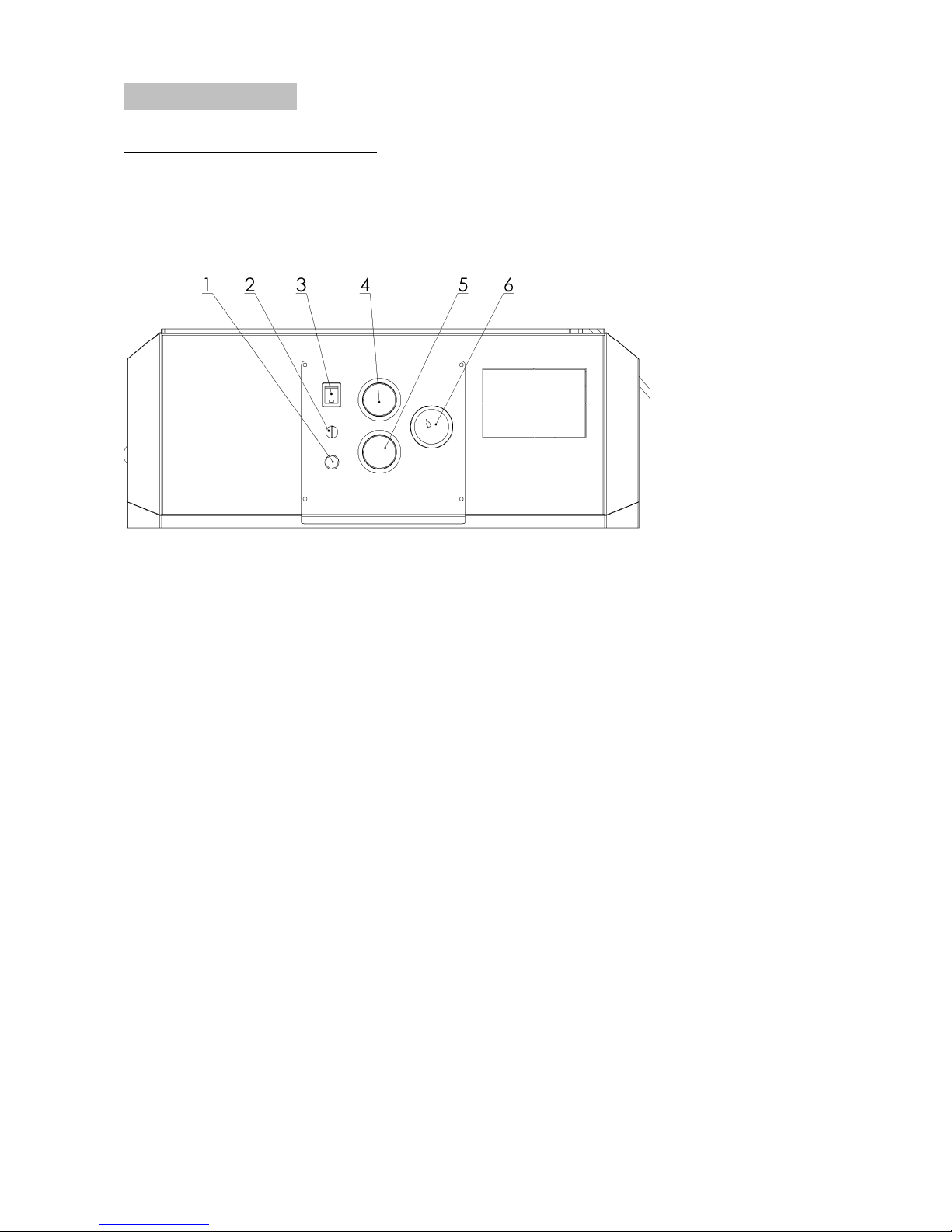

Instrument panel

ATTACK DPX STANDARD

The wood gasifying boiler "ATTACK DPX Standard" is controled by boiler and flue gas

thermostat.

1 – Emergency

thermostat with reset

2 - Fuse

3 - Main switch

4 - Flue gas thermostat

5 - Boiler thermostat

6 –Thermomanometer

Description:

1. Emergency thermostat with reset - boiler protection against overheating (after reaching

temperature higher than 110°C it comes to boiler disconnection from electricity mains) after

decrease of water temperature under 85°C it is necessary to push the restart button manually

after removing cover of reset .

2. Fuse - boiler protection against short circuit

3. Main switch - boiler start and complete boiler stop for the case of need.

4. Flue gas thermostat - at decrease of flue gas temperature under adjusted value is the fan

switched off

ATTENTION! While heating-up, set this thermostat to 0°C. After fuel burn-out set the flue

gas thermostat to „Operation“. When the temperature decreases under adjusted value, the

suction fan is switched off. If you wish to turn the fan on again, set the lower temperature on

the flue gas thermostat. It is necessary to test the optimum setting for operation.

5. Boiler thermostat - serves for setting of max. temperature of water in boiler (after exceeding

of adjusted value is the fan switched off and boiler works at minimum output, after decrease of

given temperature is the fan switched on again and boiler works at maximum output).

6. Thermomanometer - indicates outlet water temperature from the boiler and operation pressure.

Pull rod of the chimney flap - serves to open and close the heat-up flap (everytime the feeding door

is opened).

Lever for exchanger cleaning - serves for cleaning of exchanger´s tubes

Page 9

9

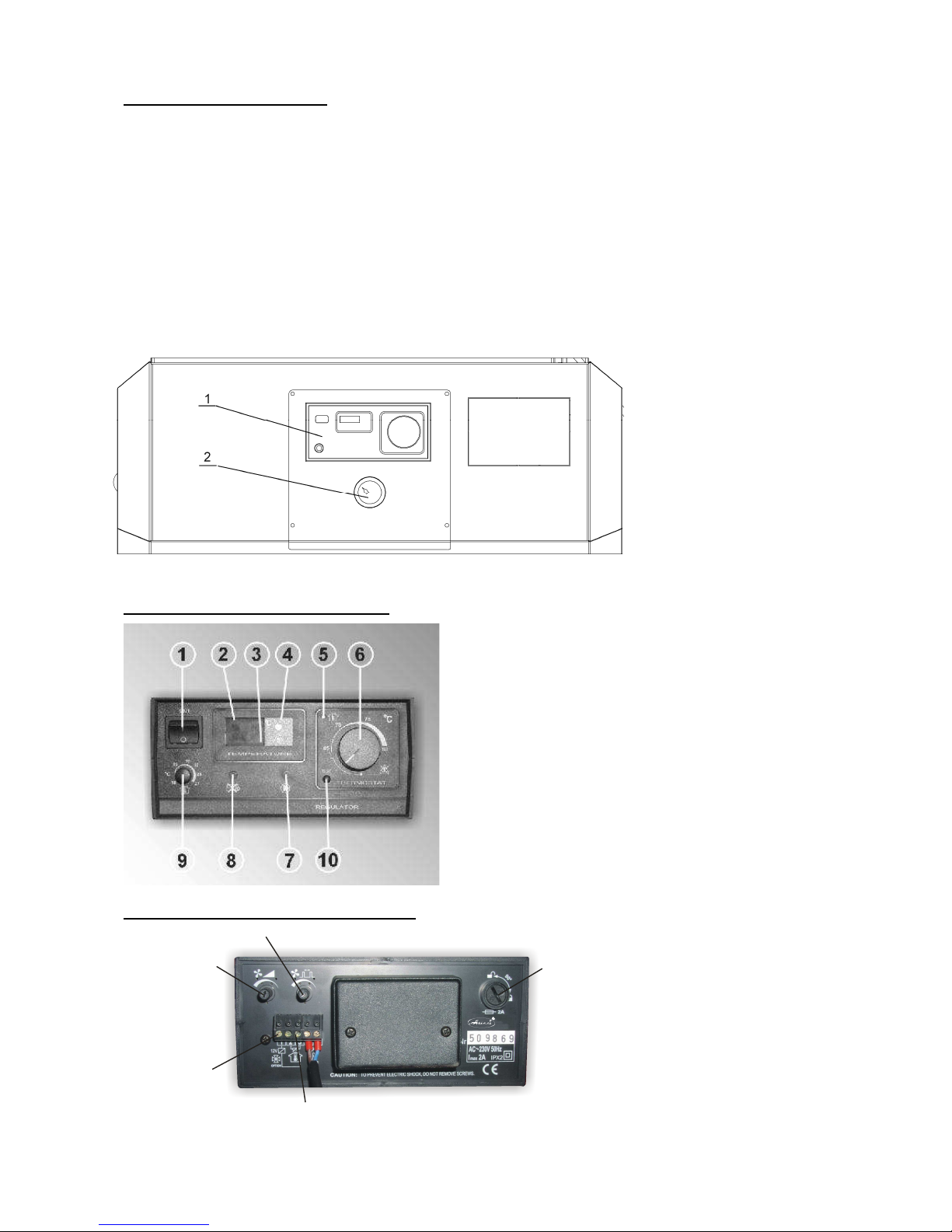

ATTACK DPX PROFI

The ATTACK DPX Profi version in comparison with Standard version represents higher attendance

comfort, possibility of output modulation and possibility of connection of control and regulation

elements.

The boiler temperature is kept at the level set by the user, by setting up number of rotations of the

flue gas fan. The ATTACK PROFI boiler regulator measures the temperature of water in the boiler

continuously and indicates its value on the display, controlling pump of central heating at the same

time. There is a possibility to connect a room thermostat to boiler regulator. The room thermostat

ensures regulation of temperature of heated rooms. Control of gear of the four-way mixing valve is

possible as well.

1 – Electronic regulator

Profi

2 - Manometer

Frontal view of electronic regulator

1 - Switch of connection

2 - Display indicating boiler temperature

3 - Control light of heating up process

4 - Control light of boiler overheating

5 - Control light of room thermostat

6 - Knob of the boiler thermostat

7 - Control light of the C.H. pump operation

8 - Control light for insufficiency of fuel

9 - Knob of room thermostat

10 -TEST button (after pressing it,

the temperature set by knob 6 appears and the flue

gas fan is switched off for the moment )

Backward view of electronic regulator:

Setting of flue gas

fan speed during

burning up mode

Setting of post purge time of fan after reaching set up temperature of heating water

Fuse

2A

Connection of

mixing valve

(12 V)

Connecting of room temperature sensor or thermostat

Page 10

10

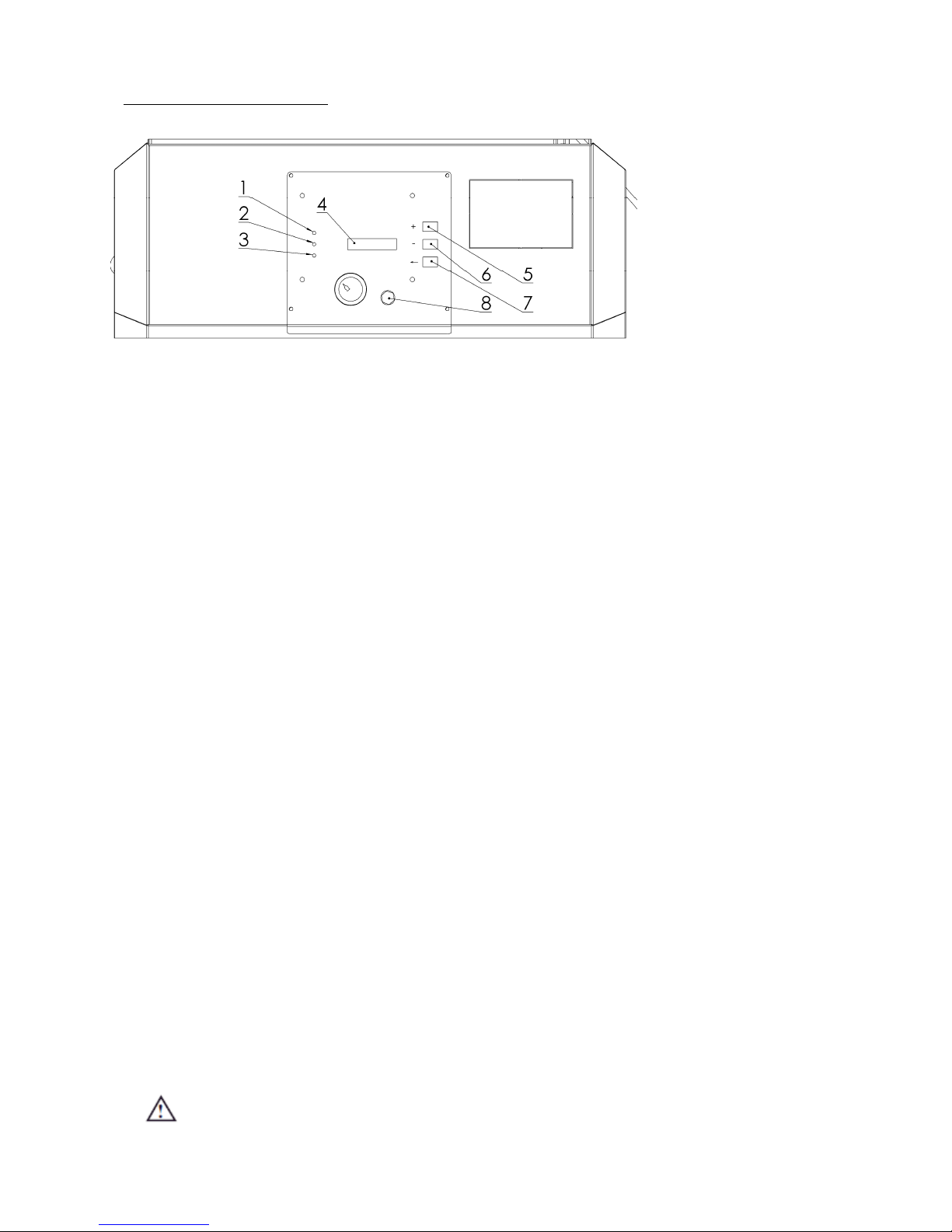

ATTACK DPX LAMBDA

1. – Green control light

2. – Yellow Green

control light

3. – Red Green control

light

4. - Display

5. – Button „+“

6. – Button „-„

7. – Button ←“

8. – Reset of emergency

thermostat

Control light 1:Lights, when the boiler was switched on by „+“(5), expires automatically after

burning out (fuel is gone and boiler is switched off). Expires also in case, when the

boiler was switched off manually by „-“ button (6).

Control light 2: Lights, when following errors occure:

o incorrectly measured values of the flue gas temperature

o see chapter Errors and warnings

Control light 3: Lights or flickers, when error or warning occurs:

o STB on - Reset (error, message (3)lights)

o incorrectly measured values of boiler temperature(error, message (3)lights)

o Too high temperature of flue gas (warning, message (3)flickers)

o Overheating – do not open! (Boiler temperature over 90°C, warning flickers

display 3)

o see chapter Errors and warnings

Display 4: Diplays operation data for different settings at errors. In case that the boiler is switched

off and no error is displayed, illumination of display expires after 15 minutes.

Button 5 (+): After first key depression, the dipslay illumination is on. Boiler is switsched on after

repeated depression of the key - heating up or loading is possible afterwards. Also

another settings given in the menu can be done via this button (see below - button 7).

Button 6 (-): Serves to switch the boiler off. This function is used only for emergency shut down,

e.g. if there is no water in the heating system or if the sensor for overheating is not

working. . Also another settings given in the menu can be done via this button (see

below - button 7).

Button 7 (←): After first key depression, the dipslay illumination is on. Enter the „Selection“

menu via repeated depression of the key. Afterwards, by „+“ (5) or „–“(6) button it is

possible to get several information and to perform different settings.

! Buttons 5 and 6 have different functions.

Button 8: Reset of the emergency thermostat button (STB)

If the STB was switched on because of too high boiler temperature (≥95˚C) and the

boiler temperature decreased to 85°C, it is possible to reset the STB by removing cover

(8) and pressing the key underneath (8). Error is removed automatically. If fault occures

again, it is necessary to inform technician.

Reasons:low warmth offtake, power failure, circuiting pump - faulty mixing valve. To

decrease temperature to 85°C, regulators switches connecting pump on.

If the flue gas fan is not working, the boiler door must not be opened!

Page 11

11

Purpose of usage

Ecological warmwater boiler

Ecological warmwater boiler Attack DPX is designed for heating of dwelling houses and similar

objects. The boiler is designed for burning wood only. Any dry wood can be used for burning,

mainly logs. Also wood of bigger diameter, blocks, can be used, which reduces nominal output but

prolongs burning time. The boiler cannot be used for burning filedust and small wooden debris.

This can be burnt only in small amount together with logs (max. 10%). Due to its large feed hopper

you can avoid the most demandable operation of preparation and cutting the wood into smaller

pieces.Location of the boilers in living spaces (including halls) is inadmissible!

Technical description

The boiler is designed for combustion of wood on the principle of wood gasifying using a flue gas

fan sucking flue gas from the boiler.

The body of the boiler is a weldment of metal steel plates of 6 mm thickness. It includes a feed

hopper with a heatproof shaped piece that has an oblong opening for transition of flue gas and gas.

Under it in the after-combustion space there is an ash pan In the rear part of the boiler there is

there is a pipe exchanger with turbulators joined by vertical flue channel with a fuel cut-off flap in

the upper part. There is also a suction branch for connection to the flue.

In the front wall in the upper part there is a feeding door and in the bottom part there is an ash door.

Between the door, under the front cover is the flap of the primary and secondary air. In the left

cover, in the level of the feeding door, there is a pull rod of the heating up flap controlled by the

door and the exchanger cleaning lever.

The body of the boiler is from the outside insulated by mineral fleece put under the covers of

outside jacket.In the upper part of the boiler there is a control board for electromechanical

regulation.

Technical description ATTACK DPX STANDARD

Operation prescriptions

Preparation of the boiler for operation

Before putting the boiler into operation make sure whether the system is filled with water and

deareated. Make also sure, that it does not come to decrease of heating water pressure. Check

sensors of boiler, safety thermostats and manometer, placed in casings in the rear boiler part,

rearward. Check tightness and construction of flue gas ducting. The boiler can be operated only in

accordance with these instructions in order to work properly. It can be operated only by an adult.

When installing the boiler, lay something under the rear part to elevate it in 10 mm for better

flushing and deareating. Boiler must be attended only by the trained adult person with completed

elementary education.

Attention

After the first heating up, there can be condensation and condensate may leak. This is not a defect

Condensation disappears after longer heating. When burning smaller wooden waste it is necessary

to check the temperature of flue gas which must not overcome 320°C. Otherwise the fan can be

Page 12

12

damaged. Creation of tar and condensate in the feed hopper is a phenomenon accompanying wood

gasifying.

If the boiler was out of order for a longer time (switched off,broke down), it is necessary to use

extreme caution when putting into operation again. In not working boiler, the pump can be blocked,

water can leak or the boiler could get frost in winter.

Heating up and operation

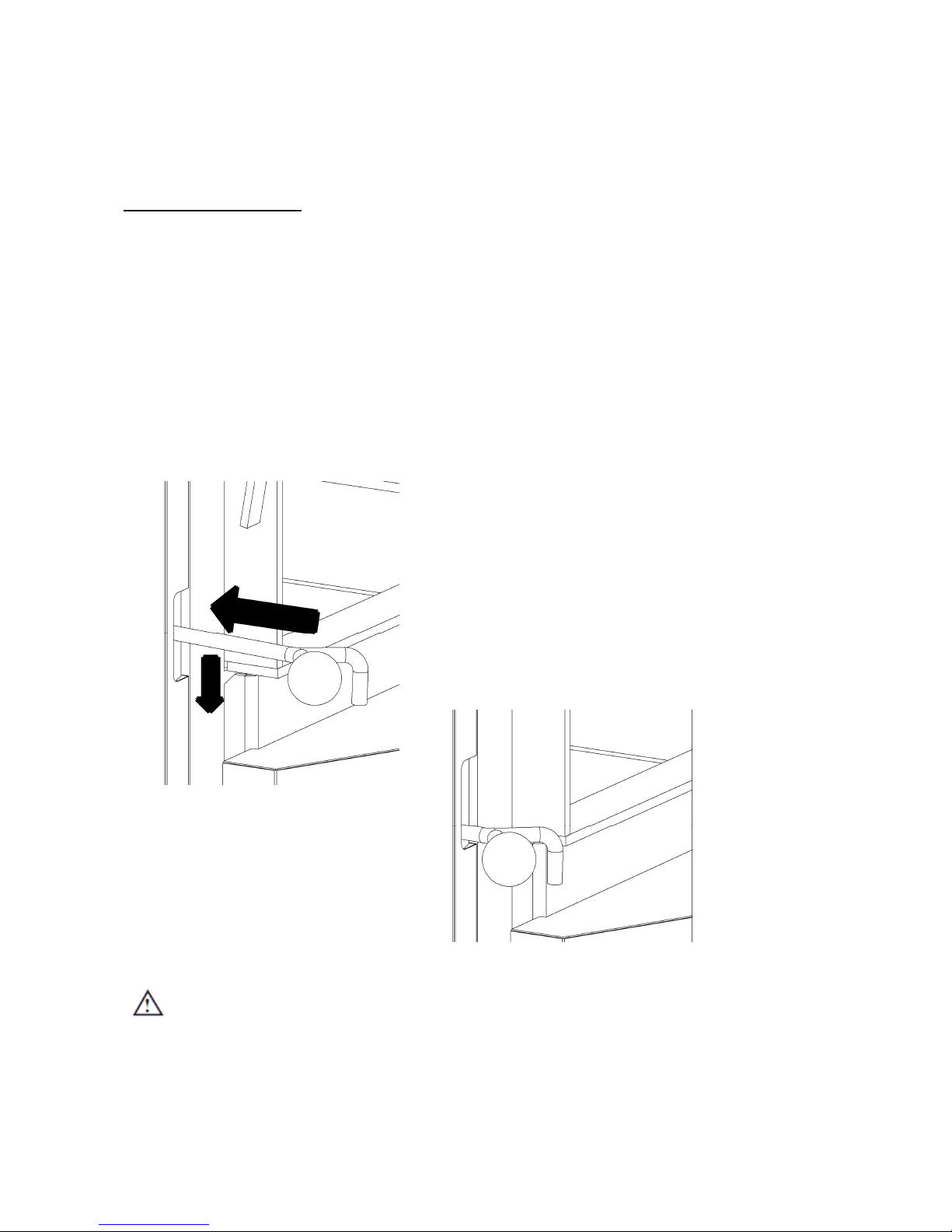

Before you fire up the fuel, open the feeding door and push the pull rod of the heating up flap,

which is pulled out, back to the basic position, until the trimmer engages (like at the closed door,

see the picture).

Set the flue gas thermostat to „0°C“. Put the refractory adapting piece on the thin layer of wood (cca

50mm) through the upper door - there should be a 4-3cm gap inbetween. Put the chippings on this

layer. Then put the paper or the fire wool on the chippings. Put cca 2 layers of thin dry wood on the

top. Fill the chamber to the top with used firewood. Turn on the suction fan and shut the feeding

door to the gap of cca 15mm. Set the required water temperature (80-90°C) on the output regulator.

When it is burning sufficiently (cca 10 minutes), close the feeding door. Set the flue gas thermostat

to the operation position (with the white mark above, cca 90° to the right form the zero position it depends on the flue gas temperature, at which is the boiler shut down required after burning out of

the fuel).

Push backwards and down

Position after pushing backwards and down

CAUTION: During the operation, the pull rod of fuel cut-off flap must be shifted in

by door into closed flap position, otherwise the fan can be damaged.

To gasify wood, there must be a reduction zone in the boiler (a layer of charcoal on the ceramic

shaped piece in the feed hopper). The layer can be created by combustion of dry wood of proper

size. When wet wood is burned, the boiler is not working as a gasifying boiler and the consumption

Page 13

13

of wood rises, output is lower than demanded and the service life of boiler as well as that of flue is

shortened. If the draft is as specified, the boiler works up to 70% of output even without a fan.

Electromechanical boiler regulation

Boiler regulation is executed by the boiler thermostat on the boiler panel, by which is the ventilator

controlled according to the set output temperature of the water.

The required boiler operation temperature should be set on the boiler thermostat. On the panel there

is also the flue gas thermostat, which serves for ventilator shut down shut after burning out of fuel.

At heating up it should be set to tehe position of „0°C“. After adequate burning up, set the flue gas

thermostat to the operation temperature - the fan has run and it has to shut down only after burning

out of fuel. It is possible to observe the optimum position of thermostat according to the sort of the

used fuel, chimney draught and another conditions. Watch the output water temperature on the

temperature scale of the thermanometer. The irreversible safety thermostat is also located on the

panel (version STANDARD and LAMBDA).

Refueling

For refueling open slowly the feeding door. The heating up flap will be thereby also opened. Do not

turn off the ventilator. During heating keep the feed hopper always full. To prevent smoke escape

into the boiler-room, stoke other fuel only after the original charge is burnt out at least to 1/3 of the

feeding content. Then cover live coal with a broad log and fill in as usually. The fuel must not be

pressed over the jet as this could cause the jet stuck and the boiler parameters would go wrong.

Technical description of ATTACK DPX PROFI:

During the operation, the display is showing the current temperature of outlet heating water.

Rotations of the fan are controlled in the following way:

- if during burning up process the boiler temperature is lower than 45 °C, the fan works with the

output set up by the turning of burning up button situated in rear side of regulator in the range of 40

- 100 %. (you can see it on the display, from r4 = 40% to r9 = 90 %, rF=100%), for boiler

temperature higher than 45°C, the fan works up to 100%.

- if the temperature of heating water during the operation is more than 10°C lower than the one set

up by the turning button, the fan works in 100 % output.

- if the temperature of heating water is lower than 10°C from the temperature set up by the

turning button of the boiler thermostat, the regulator decreases the output of ventilator according to

the difference between these temperatures but only to the output not lower than 40%.

- if the boiler temperature is higher or equal to the temperature set up by the turning button of the

boiler thermostat, the fan switches off.

- the ventilator switches on again after decreasing the boiler temperature in o 5°C comparing to the

set up temperature.

The regulation of boiler ensures that the pump for central heating switches off when the temperature

of oulet water in the boiler decreases under 60°C. The pump switches on again by the temperature

higher than 65°C. This is a prevention against tarring and the water steam condensation in the

boiler hopper.

To prevent explosion of accumulated gas during ignition, the boiler regulator ensures purging of

gas in the boiler in 5 seconds and then each minute until 9 minutes according to the position of the

turning post-purge time button in the rear part of the regulator. During the set up there is always

information on the display which lasts 2 seconds (P1,...., P9, P-). In case you do not wish purging

of gas in the boiler, it is necessary to set up (P--).

To make the process of burning up the boiler stable, there is a burning up system installed in the

regulator. After plugging in or stopping the alarm the regulator is automatically set up to the process

of burning up and this mode is signalled by a shining dot on the display. The process of burning up

is finished when the dot stops shining and the boiler temperature reaches the value set up by the

Page 14

14

thermostat. In case the temperature in the boiler does not exceed 65 °C in 2 hours of burning up

time, the regulator stops the flue gas ventilator and switches on the control light - fuel shortage.

In the time of burning out the boiler when the temperature falls under 65 °C and this condition lasts

for more than 30 minutes, the regulator stops the flue-gas fan and the control light of fuel shortage

shines on.

Fuel shortage

When the temperature of heating water in the boiler falls under 65 °C and this condition lasts for

more than 30 minutes, the regulator stops the flue-gas fan and the control light of fuel shortage

shines on. If in the burning up process the boiler temperature does not raise to more than 65°C,

fuel shortage will be shining on the display for more than 2 hours. To start the regulation again, it is

necessary to:

- refuel the boiler;

- burn the boiler up

- turn the turning button of the boiler thermostat into the maximum left position and thus stop the

alarm;

-wait until the control light of fuel shortage flickers;

- by turning button of the boiler thermostat set up the required temperature of the boiler and the

regulator starts the process of burning up

Page 15

15

Boiler overheating

If the temperature of the boiler raises to more than 105 °C, the regulator stops the flue-gas fan and

the control light of boiler overheating shines on. For new start it is necessary to:

- wait until the boiler temperature falls

- remove the cause of boiler overheating (e.g. refill missing water into the central heating

circuit)

Warning! Water can be refilled only after the boiler temperature falls under 40°C.

- turn the button of the boiler thermostat into the maximum left position ad thus stop the

alarm

- wait until the control light of boiler overheating starts flickering;

- to start the regulator again, set up the required temperature of the boiler by the turning button of

the thermostat;

If the temperature falls under 60 °C, the regulator comes into the burning up mode.

Methods of regulation of the ATTACK DPX PROFI boiler

The boiler enables regulation of room temperature as well as connecting the sensor of room

temperature. If the room temperature is lower than the set up one, the control light near the button

of thermostat shines on, which means that the boiler must keep the set up temperature. After

reaching the required temperature the control light switchces off, the suction fan switches off and

the boiler starts burning at the temperature of 65 °C.

For the purposes of timing regulation by room temperature it is possible to connect any arbitrary

programmable thermostat with the terminals for the sensor of room temperature. In this case, the

turning button of the room thermostat is not working.

If you do not wish to use the room thermostat nor the room sensor, the inlet terminals must be

short-circuited. In this case only the boiler thermostat is working.

The mixing valve with the electric drive can be also connected to the boiler regulator . (This system

is not standardly delivered with the boiler).

Error messages

The boiler regulator constantly verifies the functions of internal systems and of the sensor of boiler

temperature. After finding out the defect, the regulator switches off the flue-gas fan, the central

heating pump and at the same time the defect shows on the display. In the case of breakdown it is

necessary to switch the boiler off by the main switch,to assure the continuous operation of the

central heating pump by plugging into the mains, the fuel must be burnt thoroughly and the

contract service company contacted.

If E1 fault appears on the display, it means the damage of the sensor of boiler temperature.

Page 16

16

Technical description of the ATTACK DPX LAMBDA:

Combustion regulation

The boiler output is regulated by means of the exhaust temperature – to the O2 value and by means

of air flaps - actuators for the primary air and secondary air. The burn-off occurs with the adjusted

exhaust temperature set value. If the boiler temperature increases to 90°C (Over temperature)

because there is too much fuel (buffer is fully loaded), the exhaust fan is switched off, the primary

air flap is closed and the secondary air flap is opened on 25%. If the boiler temperature decreases to

to less than 88.5°C, the secondary air flap is opened for 30sec on 100% (chimney cleaning),

afterwards the primary air flap is regulated following exhaust temperature requirement.

The automatic switch off of the boiler: Switching off the boiler after the fuel is used, can be

alternatively done by means of exhaust temperature (TAG) or by the O2 value (function adjustable).

Switch off by exhaust gas temperature adjustment: If the fuel is used and the exhaust gas

temperature decreases for less than 25% of the nominal exhaust temperature, the boiler is switched

off after 15 minutes. This is recommended only with very big woodlogs or with very humid fuel.

Switch off by Oxygene: If the boiler runs for longer than 45 minutes and the O2 value rises for 15

minutes over 14%, the boiler is switched off. This should be the standard function, because cooling

down of the boiler by the chimney is limited. The remaining rest of coal makes easier renewed

firing and proves the lowest issues while heating-up.

After boiler switch off, the exhaust fan is switched off, the primary air flap is closed and the

secondary air flap still remains on 25% open until the exhaust temperature sinks under 100°C.

After switching off the boiler (automatically or manually): The primary air flap V1 is closed (0%),

the exhaust temperature is >100°C, the secondary air flap (V2) stays open to min. 25% and the

automatic operation continuation remains deactivated.

Heating-up and refuelling:

Basically: Before heating up, pay attention to heating system pressure (water level)!

Fuel has to be ready in the boiler!

Ignit the fuel (use operation prescriptions of the boiler)

Check requirement for warmth and external temperature, as well as the residual supply in

the hopper

Heating-up or refuelling only:

If it is possible due to the requirement for warmth and residual supply in the hopper, check

thermometers in the hopper.

Right firing-up follow (see operating instructions to the boiler)!

Effect: Maximum exploitation of the fuel.

Introduction: Make up the fire first, when the boiler is switched off (control light 1 does not shine),

Additional fuelling in “Boiler ON” status

The fuel has to be loaded immediately and the filling door must be immediately closed!

Page 17

17

Functions and text display at heating-up or refuel

After pressing the button “+” (see button 5 in chap. 1.3), starts the process that includes following

steps:

- The boiler is switched on; control light 1 shines; the ignition mode runs.

- Display shows text:

DO NOT OPEN!

PLEASE, WAIT

- The exhaust fan and the combustion control are switched on.

- The loading pump, the return- and loading valve regulation are switched on.

- The alternative energy generator is deactivated by means of an automatic change-over contact.

- After 5 sec. appears the text is displayed:

FILLING DOOR UNLOCKED

and the electromagnetic door lock (if available) is released for 10sec.

- After 10 sec. appears the text on display:

CAUTION!

Open slowly!

- After 5 sec. appears the text on display:

Heating-up

▌▌▌▌▌▌▌▌▌▌▌▌▌▌

Prepare and ignit the fuel as it is given in the manual on the page 11, shut the feeding doors!

- If the (firing) bar is full and the filling and firing up is finished, close the doors.

- If the bar is full or the firing or filling process exceeds 15 minutes, it is switched to the operation

display.

- The controller switches off the boiler after 15 min., if: 1) was not fired, the controller, however,

start the burning mode because of mistaken actuation with the key “+”; 2) the fire goes out after

doors were closed because not enough kindling was used or too wet fuel was loaded.

Operating mode display while the boiler is switched on

The text is displayed:

Boiler temp.

[°C]

After 5 sec. appears the text on display:

Exhaust temp.

[°C]

This text is displayed every 5 sec.

Too high exhaust temperature

If the exhaust temperature increases to ≥ 300°C because the filling-, cinder- or firing door were

opened for too long time, appears the text “Exhaust temperature too high“ - (see display). In this

case please:

Close the door(s) immediately!

If the exhaust temperature exceeds 350°C, the exhaust fan is switched off for safety reasons; when

Page 18

18

Temperature reaches 299°C and less, the exhaust fan is switched on again. This is protection against

exhaust fan and/or the exhaust sensor damage.

Boiler overheating

If the buffer is completely filled because too much fuel was loaded, the boiler temperature increases

to more than 90°C. Overheating occures and the exhaust fan is automatically switched off. The

display flashes and the text display appears:

Over temp.

DO NOT OPEN!

Boiler door(s) may not be opened! Overheating brings high consumption of fuel and ecological

damages.

Operating mode display while the boiler is switched off

If the fuel is used, the controller switches off the boiler automatically; however, the boiler also can

be switched off manually with the “+” button (this serves only for the security disconnection, e.g.:

no water in the boiler). Directly after switching off, the text display occures:

After 15 min. becomes the lighting of the text display) switched off.

Operating mode display while the boiler is switched off

If the fuel is consumed, the controller switches off the boiler automatically; however, the boiler also

can by hand with the button “-” switched off (this serves only for security disconnection, e.g.: when

there is no water in the boiler). Directly after switching off, the text display occures:

BOILER TEMPERATURE

°C

After 15 min. is illumination of the text display switched off.

Automatic protection functions

If the boiler is not heated within 7 days, the exhaust fan is switched on for 2 min. and the boiler is

“rinsed” with fresh air to keep it dry. At the same time, the return valve and loading valve work and

the loading pump is switched on for 10 seconds. During this process the text display indicates:

PROTECTION FUNCTION

PLEASE WAIT

After finishing the protection functions, display is automatically switched to the operating mode.

Information about current operation staten about toperating state .

The menu button“←”allows entrance into menu “Selection” in which different submenus can be

selected and the first submenu “Information” appears immediately. With the menu button “←” you

enter into submenu “Information” where you can get different information with buttons “+” and “-”.

To exit from the menu use “ ←” button; after exit it is automatically switched to operation display.

If no button is pressed for 30 min., it is automatically switched to operation display.

If error or excessive temperature appears, the menu will be left automatically. Display shows

following information:

Page 19

19

Menu Submenu Indication

Boiler set to

°C --

Shows adjusted temperature of water in boiler.

Boiler temperature

°C ---.-

Actual value. Shows actual temperature of water in boiler.

Flue gas set to

°C ---.-

Shows adjusted temperature of flue gas.

Flue gas temperature

°C ---.-

Shows actual temperature of flue gas.

O2 set to

% --.-

Shows adjusted O2 content in the flue gas.

O2

% --.-

Shows actual O2 content in the flue gas.

CO2 set to

% --.-

Shows adjusted CO2 content in the flue gas.

CO2

% --.-

Shows actual CO2 value.Tip: for calculation, max. 20,3%

of CO2 is used as fixed value.

Suction fan

ON/OFF

Operation state of the fan.

Circulating pump

ON/OFF

Operation state of the circulating fan.

Primary motor

% --.-

Position of the primary motor shield .

Secondary motor

% --.-

Position of the secondary motor shield.

Lambda

--.-

Ratio of air (actual value) Tip: for calculation, max. 20,3%

of CO2 is used as fixed value.

Efficiency

ETA – F (%) --.-

Grade of burning efficiency – actual value

For calculation, air temperature 35°C is used.

Complete temperature

excess

(%) --.-

Represents ratio of temperature excess (%) at complete

combustion time (summary of operation hours)

Temperature excess10 refuellings (%) --.-

Represents ratio of temperature excess after refuelling

In (%) at last 10 refuellings

Operation hours

h --.-

Represents operation hours of boiler. Po 60 000 hodinách

sa počítadlo vynuluje

Software

--.--

Programm version number

Information

Serial number

---------

Serial or production number of regulator

Test of device

Safety test

Setting

FINISH

Page 20

20

Settings for the commission of the ATTACK DPX LAMBDA .

The start-up of device is enabled, when the minimum requirements for test- or heating operation

are fulfilled (see chapter 1.2). Afterwards it is necessary to carry out the following settings.

Settings with usage of the service technician´ s code

The menu button „

←“enables entrance into menu “Selection”, where it is possible to select the

„Settings“ submenu by buttons “+” or “-”. The choice of “Settings” is confirmed with the button “

„←”.

The exit from the submenu automatically occurs after setting of the "connection valve" with the

menu button “ ←”; after exit it is automatically switched to the operating display.

If no button is pressed for 1 min., it is automatically switched to the operation display.

Settings:

Menu Submenu Indication

Information

Test of device

Safety test

Code insert

---

Set the code by „+“ button. Random

number lights on the left side. Insert code

and confirm by „←“ button. Technician´s

number is available from supplier of the

boiler.

01 :Language

German DE

English GB

Italian IT

French FR

Swedish SE

Polish PL

Slovak SK

Czech CZ

Dutch NL

Danish DK

Hungarian HU

Slovenian SI

Function: Setting of national language

02 : Setting of boiler

°C 85

Function: Set boiler temperature

Producer: 85°C

Range of setting: 75°C – 85°C

03 : Setting of TAG

°C 180

Function: After setting of flue gas

temperature (nominal 180°C boiler output).

Producer: 180°C

Range of setting: 110°C up to 240°C

Tip: TAG = flue gas temperature

04 : Setting of O

2

% 6,0

Function: Setting of O2 value for

combustion 6 %

Producer 6,0 %

Range of setting: 4,0 % up to 8,0 %

Setting

05 : Start TAD

K 60

Function: to reach sufficient output before

the feeding door is closed

Producer: 60K

Range of setting: 25K up to125K

Tip: TAD= temperature difference. It is

Page 21

21

a difference between flue gas temperature

and temperature in the boilers

06 : Disconnection

O

2

TAG

Function: Boiler for wood combustion is

switched off in consequence of:

O2 – indicates higher level of coal residual.

(easier start)

TAG – indicates minimum coal residual

(recommended by combustion problems –

deformed or wet fuel)

Producer: O2

Setting: O2/TAG

10 : V1 Primary air

Air (%) 85

Function: By flue gas sensor error or

oxygen sensor error it regulates adjusted

temperature. It serves as temporary

solution, until the error is removed - it is

not a standard operation function in any

case!

Producer: 85 %

Range of setting: 0 % - 100 %

11 : V2 Secondary air

Air (%) 40

Function: By flue gas sensor error or

oxygen sensor error it regulates adjusted

temperature. It serves as temporary

solution, until the error is removed - it is

not a standard operation function in any

case!

Producer: 40%C

Range of setting: 0 % - 100%

Finish

After the settings are made, the test of device is performed, correct device functions are and the

safety test is done as well.

Page 22

22

Cancelling of the manufacturer´s function

This process requires code of manufacturer. It is possible to set operation hours of the boiler, to

reset number of overheatings, as well as last 10 combustions can be set to zero value.

Enter and exit to appropriate submenu is similar as in the Chapter 8.1. If no button is pressed

within 1 minute, regulator automatically switches to operation display.

Selection Submenu Indication

Information

Test of device

Safety test

Code

---

Set the code by „+“ button. Chnage the random

number that appears on the right to the

manufacturer´s code and confirm by „←“. Next

setting appears.

Cancel

YES/NO

Choose YES by „+“

Next explanation appears after pressing„←“ and

menu expires.

By pressing YES solution to set boiler operation

hours and complete excess temperature, while last 10

combustions are set to 0

Setting

33 : Output decrease

YES/NO

Choose YES by „+“

Next explanation appears after pressing„←“ and menu

expires.

By pressing YES solution, boiler output decreases to

20% in case that boiler temperature excesses

adjusted value for 2K

Finish

Testing

Test of device and safety test has to be done in the presence of the heating technician!

Test of device

Test of device is possible, only if the boiler is shut down!

Test is possible, only if there is no danger of overheating!

Test is selected and done by the menu button „←“ (enter into Selection menu). Next menu selection

is displayed by the „test of device“ button and confirmed by „←“ button. Then, the appropriate step

of the test is activated by the „+“ or deactivated by the „-“. Every next step is selected by „←“. Test

of device is finished with the last point of the test by the „←“ button and display is automatically

switched to operation mode. Test can be aborted also by early pressing of the „+“ and „-“ buttons at

once.

In case that no button is pressed within 15 minutes, display is automatically switched to operation

mode.

Page 23

23

Selection Submenu

Svítí

Information

Scale of O2

End of the test

(+,-)

After pressing the „+“ button, „calibrate“ appears

on dipslay. Calibration takes apporximately 600

seconds. Automatic calibration is done only, when

there was no fire in the boiler for 48 hours and

operation time of the sesor is longer than 200

hours. sa na displeji objaví „kalibrovať“

During manual setting of the scale there can be no

fire in the boiler, nor smoulder of fuel residuals! If

it is not necessary to adjust the scale, press „←“

for the next step.

Tip: Early exit from menu is possible by pressing

of „+“ and „-“.

Flue gas fan

End of the test (+,-)

By pressing + switch on the flue gas fan

By pressing – switch off the flue gas fan

By pressing ← select next point of the test

Circulating pump

End of the test (+,-)

By pressing + switch on circuiting pump

By pressing – switch off circuiting pump

By pressing ← select next point of the test

Primary motor

End of the test (+,-)

By pressing + open primary air flap

By pressing – close primary air flap

By pressing ← select next point of the test

Secondary motor

End of the test (+,-)

By pressing + open secondary air flap

By pressing – close secondary air flap

By pressing ← select next point of the test

Illumination

End of the test (+,-)

By pressing + switch on illumination of text display

By pressing – switch off illumination of text display

By pressing ← select next point of the test

Control light 1

End of the test (+,-)

By pressing + switch on control light1

By pressing – switch off kontrolku 1

By pressing ← select next point of the test

Control light 2

End of the test (+,-)

By pressing + switch on control light 2

By pressing – switch off control light 2

By pressing ← select next point of the test

Test of device

Control light 3

End of the test (+,-)

By pressing + switch on control light 3

By pressing – switch off control light 3

By pressing ← select next point of the test

Safety test

Setting

FINISH

Safety test

If the boiler is switched on, it is possible to select the safety test. However, it is necessary to let the

boiler work for 1 hour at least, to achieve output appropriate to the normal operation state.

Test is selected and performed by the ← button (enter into menu „Selection“ ), then by the button -

select from menu „Safety test“ and confirm selection by the

← button. Safety test starts

Page 24

24

automatically. During this test, it is necessary to hold the + button within 30 seconds, to prevent

automatic stop of the test (see explanation in the schedule below).

Test is time limited for 30 minutes. It is automatically stopped or aborted if:

1. Boiler temperature increases to 110°C

2. The + button was not held for 30 seconds

In this case, regulator automatically switches to operation display.

Menu Submenu Indication

Information

Test of device

Test is time limited for 30 minutes

Safety test

Safety test +

(sec.) 30

Boiler temperature

(°C ) --,-

After selection of the test, it is necessary to

hold the + button within 30 seconds,

otherwise is the test automatically stopped.

If the boiler temperature increases to 95°C

- 100°C, the STB is switched on and the

fan is switched off. After few seconds, the

text: „STB on“ appears on display. It

means, that the STB test was successfully

done.

After pressing the „+“ button again,

circuiting pump stays stopped, until

temperature of 110°C is reached, to

perform the test of overheating protection.

Boiler temperature must be kept under

110°C to confirm, that the test of

overheating protection was successfully

done or finished.

Setting

FINISH

Maintenance of the heating system and of the boiler

At least once in fortnight check or fill up water in the heating system. If the boiler is out of

operation during winter, water can be frost in the system. Therefore it is better to discharge water of

the system or fill in the antifreeze agent. Otherwise discharge water only in critical situations and

for the shortest possible time. After heating season is finished, clean the boiler thoroughly, replace

damaged parts. Twice a year clean the radial impeller of the ventilator and its air chamber.

Changing of door sealing cord

Dismantle the old sealing cord with a screwdriver and clean the rabbet where it was placed. Take

the new sealing cord and put its begining on the horizontal parts of the rabbet. Press it into the

rabbet on the circumference of the door with your hand or light knock of the hammer.

Adjustment of hinges

After some time, the sealing cord in the door gets deformed. Therefore, to ensure tightness of the

door, it is necessary to change the position of the door. The position is changed by tightening the

hinges of the door. Feeding door and bottom door are joined to the body with two hinges which are

attached to the door with a long pin. To change adjustment of hinges, it is necessary to remove the

pin and screw the hinge by turning it. Fit the door on and insert the pin into the hinge.

Nozzle body change

The body of nozzle is placed in the boiler body in a nozzle holder. In the lower part is the nozzle

body sealed by boiler lute and in the upper part by a packing cord. When exchanging the nozzle,

Page 25

25

remove the packing cord from the rabbet by a screwdriver. Remove the nozzle body and clean the

holder thoroughly from the tar and old lute. Put the nozzle body insulation on the cleaned surface.

Take the nozzle and put it on the holder, so that the shorter wall was in the rear part of the boiler.

The lateral clearance must be the same. Take the new set of packing cords of the nozzles and with a

light knock, press it into the gap to be at the same level with the nozzle.

Setting of the boiler´s combustion

The boiler´s combustion is set by the regulation flaps of primary and secondary air. Boilers are from

the production set for the most optimal burning conditions according to emissions and flue gas

tempertature. Setting can be executed only by producer or by trained serviceman.

Optimum setting of the regulation flaps:

Permanent-heat operation

Permanent-heat operation of the boiler means that the fire can be kept during the night without

heating up daily, but only in winter. This way of operation shortens the service life of the boiler. For

permanent-heat operation prepare the boiler in the following way:

Put a few bigger logs (4-6) on the glowing layer

- Shut the mixing valve. After closing the valve the temperature of water rises to 80- 90°C.

- Suction fan turns off.

- Regulation flap controlled by regulator shuts automatically and the fan is switched off.

In the boiler prepared like this, burning is kept for more than 12 hours. During permanent-heat

operation, the temperature of water in the boiler is 80 - 90°C.

Boiler cleaning

The boiler must be cleaned regularly and properly every 3-5 days because ash subsided in the

feed hopper together with condensates and tar decreases output and lifetime of the boiler and

isolates heat-exchanging surface. When there is too much ash, there is not enough space for

burning out of fuel and a holder of ceramic jet as well as the whole boiler can be damaged. When

cleaning the boiler, firstly turn the ventilator on, open the feeding door and wipe the ash through a

slot into bottom space. Leave long unburnt logs in the feed hopper. Move the lever for exchanger

cleaning for several times. After opening the bottom cleaning hole, take ash and soot out. After

opening the bottom door clean the bottom space. Cleaning interval depends on the quality of wood

(moisture content), heating intensity, draft of the flue and other circumstances. We recommend to

clean the boiler once a week. Do not take the refractory adapting piece out when cleaning. Once a

year minimally clean the radial impeller of the fan and check fouling of regulation of primary and

secondary air flowing into feeding chamber through the cleaning hole and clean with a screwdriver,

if it is necessary. It influences the output and quality of burning.

WARNING - Regular and proper cleaning is important for permanent output and service life of the

boiler. In case of insufficient cleaning, the boiler can be damaged and guarantee expires.

Prescribed fuel

Specified fuel is dried cut wood and logs of 80-150mm diameter, with min. 12% and max. 20%

moisture content and calorific value of 15 - 17MJ/kg. It is also possible to burn big pieces of

wooden waste with coarse wood logs.

Note

It is necessary to cut the logs of bigger dimensions into halves or quarters (because of the

requirement of operation to nominal output). You can burn hard as well as soft wood. Wood must

be dried! Boiler output depends on the moisture content of wood. Output and function of the boiler

Primary air flap:

DPX25 open wide

DPX35 open wide

DPX45 open wide

Secondary air flap:

DPX25 open to the 3rd mark

DPX35 open to the 4th mark

DPX45 open to the 5th mark

Page 26

26

is guaranteed for maximum moisture content of 20%. Guarantee expires at boiler operation with

cut wood with humidity over 20%.

Energy content of mostly used kinds of wood

Wood Thermal capacity per1 kg

kcal MJ kWh

Spruce 3900 16,25 4,5

Pine 3800 15,80 4,4

Birch 3750 15,50 4,3

Oak 3600 15,10 4,2

Beech 3450 14,40 4,0

Assembly and installation of the boiler

Boiler installation

Boiler can be installed only by person with valid certificate for installation and assembly of heat

technology devices. The project in conformity with valid prescriptions has to be made out for

installation. Before installation of boiler, the assembly worker has to check all data given in the

production label for their conformity with data in the project and attached documentation. Boiler

connection has to be in conformity with valid prescriptions, norms, regulations and this manual for

attendance.

Producer is not responsible for damages caused by faulty connection, respectively by

incorrect operation.

Placing of boiler

Boiler is designed for installation and operation in the premises with basic enviroment (AA5/AB5)

under STN 33 2000-3. For the installation it is necessary to keep safe distance of its surface from

flammable materials by the degree of flammability and combustibility:

- from materials of flammability B, C1 a C2 200mm

- from materials of flammability C3 400mm

- from materials with degree of flammability not tested by STN 73 0853 400mm

Examples of building material devided by the degree of flammability:

- degree A non-combustible (bricks, blocks,ceramic linings, morter, plaster)

- degree B partially flammable (heraklith, lignos, boards from bazalt felt)

- degree C1 very difficult to ignite (broadleaves - beech, oak; plywood, werzalit, hard paper)

- degree C2 intermediate flammable (coniferous species -wood, pine, spruce pulpboard, solodur)

- degree C3 easy flammable (wood pulpboards, polyurethane, PVC, foam rubber, styrofoam)

Non-combustible board or protecting fire- screen ( on the protected subject) must exceed the boiler

dimensions for at least 300mm. All the other subjects from combustible materials, which are

situated near the boiler, have to be protected by non-combustible board or fire-screen, if it is

impossible to keep the safe distance.

If the boiler is located on the floor from combustible materials, the floor must be covered with the

non-combustible, thermal insulating pad exceeding the boiler planview for at least 100mm on the

side with feeding door and ash door . All the solid materials of "A" degree of combustibility can be

used as a fireproof thermal insulation.

If the boiler is placed in the boiler room, there must be a free space of min.1 meter in front of the

boiler and of 0,5m from the side walls and from the rear side. Above the boiler there must be a free

Page 27

27

space of min. 1meter. This space is necessary for basic operation, maintenance and service of the

boiler. Location of the boiler in the dwelling spaces (including halls) is not allowed! The cross

section of opening for air inlet to the boiler room is recommended to be at least 200 cm²,

depending on the boiler output.

ATTENTION!

The objects from easily combustible materials cannot be placed on the boiler or the nereby

in the distance shorter than the safe distance.

If there is a danger of fire or blow up during the work (e.g. the work with texture materials, sizing

materials, etc.) the boiler must be out off operation.

Air inlet

For correct boiler operation, it is necessary to provide sufficient air inlet for combustion. Minimum

cross section of the opening for fersh air inlet is 200 cm².

Connection of boiler to the heating system

Only trained service technician is allowed to install the ATTACK DPX boiler and to do the service

actions. Before boiler installation into older heating system, it is necessary to wash (to clean) the

whole system. Heating system has to be filled with water, conforming to requirements of the STN

07 7401:1991, particularly its callosity cannot exceed 1mmol/l and concentration of Ca2+ must not

exceed 0,3 m mol/l.

In case that these conditions will not be kept, the boiler warranty expires!

Chimney

Connection of the appliance to the flue must be always done with approval of authorized chimneysweeping company. There must always be sufficient draft in the flue and flue gas must be draught

to the atmosphere in all possible operation conditions. For the correct operation of the boiler, the

independent flue must be dimensioned in the right way, because combustion, output and service life

of boiler depends on the draught. The draught is influenced by the section of flue, height and

roughness of the internal wall. Into the flue where the boiler is attached, no other appliance can be

attached. The flue diameter must not be smaller than the outlet on the boiler. Flue draught must

have the specified values. But it must not be too high so as not to decrease the efficiency of boiler

and interrupt burning. If the draught is too strong, install a throttle valve between the flue and

boiler.

Information values of the chimney´s cross section:

20 x 20cm min. height 7m

O 20cm min. height 8m

15 x 15cm min. height 11m

O 16cm min. height 12m

Exact chimney dimension is stated by the STN 73 42 10. Prescribed chimney draught is given in the

Technical parameters.

Exhaust pipe

Exhaust pipe must have the outlet into the chimney. If the boiler cannot be attached to the chimney

directly, the exhaust pipe must be as short as possible and not longer than 1m without heating

surface and it must rise in direction to the flue. Exhaust pipes must be tight and resistant against flue

gas leakage and cleanable from inside. Exhaust pipes must not lead through other´s dwelling and

utility premises and the internal section of the exhaust pipe must not taper in direction to the flue.

Usage of bents is not suitable.

Page 28

28

Boiler connection to the electricity mains

The boiler is connected to the mains of 230 V/50 Hz by a supply cord and plug. The voltage is of M

type and when replaced, the same type must be used by a service oragnization.The appliance must

be located in such a way that the plug was within the reach of the attendance.

(under STN EN 60 335-1 + A11:1997).

Selection and method of connection of regulation and control elements

Boiler is supplied with basic equipment of regulation and control elements. Connection of these

elements is given in the scheme of connection. It is recommended to extend boiler regulation with

other regulation elements that enable more comfortable and more economical operation. Every

pump in the systme must be controlled by individual thermostat to prevent boiler undercooling at

the return water inlet (C.H. return connection) under 65°C.

Connection of these additional elements is planned by projectant, adequately to specific conditions

of the heating system. Electric installation connected to sufficient boiler equipment must be done by

specialist, in conformity with valid norms.

Warning: heating system must be equipped with safety valve against overpressure.

Boiler protection against

corrosion

Suitable solution of this problem is

usage of mixing device (Regumat

Attack-Oventrop). Both solutions enable

creation of separate boiler and heating

circuit. Thereby it is prevented from

boiler undercooling under 65°C and the

condensation of water steams, acids and

tars in the boiler hopper is eliminated.

Mixing device Regumat keeps constant

temperature of return heating water,

enetring into boiler at 65°C, when the

thermostatic head is set to 5th-6th

degree. At usage of individual thermal

regulation valve, it is possible to

regulate heating water temperature by

setting of the flap, independently from

temperature of water in the boiler. Temperature in the boiler has to be kept in the range of 80-90°C.

Technical parameters REGUMAT ATTACK OVENTROP:

Clarity DN 25

Maximum pressure 10 bar

Maximum temperature 120°C

Value kvs 3,9

Clarity DN 32

Maximum pressure 10 bar

Maximum temperature 110°C

Value kvs 0

Page 29

29

Regumat consists from three way mixing valve, circuitingpump, closing valve, thermometers and

isolation. This solution is advantegeus because its compactness, simple attendance and guaranteed

protection of boiler´s heat exchanger

Regumat for boiler Ordering code

ATTACK DPX15, DPX25, DPX30, DPX35 (DN25) DPP25003

ATTACK DPX40,

DPX45 (DN32) DPP25006

Page 30

30

Obligate norms for projecting and assembly of boilers:

STN EN 303-5 Solid fuel boilers for heating

STN 73 42 10 Manufacturing of chimneys and flue connections

STN 92 0300 Fire safety of local appliances and heat sources

STN EN 60 335.1 +A11 Safety of electroappliances for household

STN 06 10 00 Local devices for solid, liquid and vapour fuels

STN 06 03 10 Central heating, projecting and assembly

STN 06 08 30 Security facilities for central heating and D.H.W. warming

STN 07 74 01 Water and steam for thermal energetic appliances with operation steam

pressure tp to 8 MPa

STN 332000 4-46 Electrical building installations – part 4: safety ensurance

STN 332000–3 Electrical building installations – part 3: Determination of

basic characteristics

EN ISO 11202:2009 Measuring of emission levels of acoustical pressure at

attendance work place and other determined places.

ČSN EN ISO 12100-2:2004 Safety of machine appliances - Basic terms, general rules for

construction, Part 2: Technical rules

ČSN EN 953+A1 Safety of machine appliances – protection covers

ČSN ISO 7574-2 Acoustics. Statistical methods for determination and

verification of stated values. Emission of noise of machines

and appliances. Part 2: Methods for individual machines.

ČSN ISO 1819:1993 Institution for continual costs transfer. Safety prescriptions.

ČSN 06 1008:1997 Fire safety of thermal appliances.

STN EN ISO 15614-1 Requirements for quality of fusion welding of metal materials.

STN EN 287-1 Welding of reserved technical appliances

STN 07 0240 Low-pressure boilers, technical prescriptions

STN 07 0245 Warm water boilers with output up to 50 kW. Technical

requirements, testing

STN 07 7401 Water and steam for thermal energetic appliances with

operation steam overpressure pu to 8 MPa.

STN 73 4210 Construction of chimneys and flue connections and

connection of devices

STN 92 0300:1997 Minimum distance of external surface of device or flue gas

connection from building constructions... …

Page 31

31

Installation and exchange of fireproof adapting pieces

Put the rear part into the lower chamber, the intagliated part backwards. It is necessary to put it in

horizontal position and then turn it. Put it into the center of the chamber and push it closely to the

rear steel plate. Insert the left front part pos.2 into lower chamber. It is necessary to insert this part

horizontally and then turn it. Use the same method for the right front part of the ash pan pos. 3. Put

both these parts together and then push them closely to the rear part of the ash pan.

Slit of boiler – combustion chamber

Page 32

32

Connection schemes

Scheme of connection with regulation system REGUMAT ATTACK-OVENTROP

BOILER

ATTACK

Expansion tank

Pump

Regumat

ATTACK-

-OVENTROP

Heating system

D.H.W.

TANK

1 2

43

Return flap Return flap

Scheme of connection with accumulation heat tank

BOILER

ATTACK

Regumat

ATTACK-

-OVENTROP

Heating

system

ACCUNULATION

HEAT

TANK

D.H.W.

TANK

Pump

Expansion tank

Return flap

1 2

43

Boiler must permanently work at nominal output. For the case of heat offtake, when the boilers

works at output lower than the nominal, it is necessary to connect the boiler to heat storage tank

with minimum volume of 460 l (STN EN 303-5, article 4.2.5 )

.

Page 33

33

Connection with heat accumulators

Connection system is based on principle of heating up of water in accumulation tanks, where the

warmth is gradually taken away from the tanks according to the request from the heating system.

By the operation with several heating ups at full performance, accumulation tanks will be

heated for the temperature of 90-100°C. Heating with accumulation tanks in connection with the

ATTACK DPX boiler brings more advantages. To the main advantages belongs longer boiler lifetime and also lower consumption of fuel. Recommended volumes of accumulation tanks according

to boiler output are following:

DPX25 - 1500 - 2000 l

DPX35 - 2000 - 2500 l

DPX45 - 2500 - 3000 l

Operation with accumulation tanks

After heat-up phase, the boiler heats the water in the accumulation tank to 90 - 100°C by full output

in 1-3 feedings. After burn-out, the heat is taken through the three-way valve only from the

accumulation tank. The offtake period depends on the tank volume and external temperature. In

heating season it can be 1 - 3 days (if the prescribed min. volume is respected). If it is not possible

to use the prescribed volume of the tank, it is recommended to use at least one tank of 500l volume

for start and finish boiler operation. Minimum volume of accumulation tank is given in the tabel

of technical parameters.

Standardly delivered accumulation tanks

Type of tank Volume (l) Diameter (mm) Height (mm) Heat-exchange surface

(m2)

AK 500 500 650 1650

AK800 800 790 1730

AK1000 1000 790 2050

AS500 500 650 1650 2,0

AS800 800 790 1730 2,4

AS1000 1000 790 2050 2,8

Tank isolation

Accumulation tanks ATTACK AK500, AK800, AK1000, AS500, AS800 and AS1000 are delivered

with detachable isolation of soft polyurethane with red leatherette surface.

Page 34

34

Advantages

Boiler installation with accumulation tank brings several advantages:

- lower fuel consumption (up to 30%). Boiler works at full output, until the fuel is burned-out, while

optimum efficiency is kept

- long chimney and boiler life-time and minimum creation of acids and condensate

- option to combine with other heat sources - solar collectors, etc.

- combination of boiler with underfloor heating

- comfortable and ecological heating

Boiler protection against overheating

ATTENTION: Following the norm EN

303-5, the aftercooling circuit against

boiler overheating cannot be used for

other purposes than boiler protection against

overheating. Valve at the cooling water inlet

into cooling circuit must be permanently open

and boiler cooling circuit must be connected to

functional distribution of cooling water (e.g. to

cold water distribution of water supply system)

with temperature of 10-15°C and operation

pressure of 2-6 bar. The STS20 valve at the

aftercooling circuit outlet with sensor in the boiler

rear part. Protects boiler against overheating in the

following way. If water temperature exceeds

95°C, it lets the water from water supply system

into aftercooling circuit to absorb the warmth. In

case of boiler overheating and opening of the

STS20 valve, the permanent outlet of warmed

water from boiler´s aftercooling circuit into flow-off has to be ensured.

In case that circulation of cooling water through aftercooling circuit is not ensured at opening of

the thermostatic valve STS20, there is a danger of boiler damage! In this case the warranty for

boiler expires.

Transport, manipulation and storaging

Producer puts the article on pallet and fits it on with technological screws. It is packed in the paper

box, binded by sticky tape and wrapped into stretched foil.

Transport, manipulation and storaging of packed product is permitted only on this pallet. For

manipulation to boiler´s standpoint there are suspension eyes for manipulation with elevator,

available after removing of upper cover.

Only approved person can ensure manipulation with the boiler.

Instructions to liquidation of the product after its life-time expiration

Ensure the liquidation of the product (boiler) by repurchase / collection of raw materials,

respectively use regulated dumping ground, controlled by appropriate municipal office.

Liquidation of packaging

Page 35

35

Liquidate the packaging by repurchase / collection of raw materials, respectively use regulated

dumping ground.

Accessories

The ATTACK DPX boiler is delivered functionally tested, wrapped, packed on wooden pallet.

Delivery contents following attachments:

- User manual

- Guarantee letter

Page 36

36

Possible faults and methods of their deletion

Fault Cause Solution

Control light „Net“ does

not lighti

No voltage in mains

Incorrectly plugged craddle into

socket

Faulty network switch

Broken inlet conductor

Check

Check

Replace

Replace

Boiler does not reach

required parameters

Water shortage in the system

High pump output

Boiler output is not sufficiently

dimmensioned for concrete system

Low quality wood

Heat-up flap does not seal

Low chimney draught

Long heating-up or operation with

opened heat-up flap

Deformed fan wings

Unsufficiently cleaned boiler

Blocked air inlet into combustion

chamber.

Refill

Set overflow and switching

Matter of project

Combust dry and cut wood

Repair

New chimney, unsuitable

connection

Put throttle into flue gas

connection

Close heat-up flap

Replace

Clean

Clean

Door do not seal Damaged glass cord

Jet gets blocked

Low chimney draught

Replace, adjust door hinges

Do not burn small wood pieces

and wood crust

Faulty chimney

Fan has no rotations or it

is noisy

When using irreversible safety

thermostat, it comes to overheating

Blocked radial impeller

Faulty condensator

Faulty motor

Faulty contact in the socket of

motor inlet conductor

Push reset button

Clean the fan

Replace

Replace

Check

Page 37

37

Errors and warnings with the ATTACK DPX LAMBDA system

By following errors and warnings it is not possible to burn in the boiler:

- red display 3 lights (error), operation of the wood boiler is not possible

- red display 3 flickers (warning), correct operation of the wood boiler is not possible. This text

automatically expires after the cause is removed.

Boiler operation is possible by emergency programm, if:

- yellow display 2 (warning) lights

All emergency programs in the regulator menu are automatically expalined and serve for the shorttime keeping of the heating operation. Thereby:

Immediate error removal is recommended!!

Too long operation by appropriate emergency program may cause chimney and boiler damage - the

warranty is not valid.

Emergency thermostat is switched on (error)

Cause:

Temperature in the boiler >95°C is caused by

fuel surplus, power shortage, fault at warmth

offtake (or in circuiting pump)

Control light 3 red lights

Correction:

Use less fuel! Check warmth offtake!

Reset:

Screw out the cover (8) and press STB button

placed underneath, when the text „boiler

temperature 85°C appears“! Error is

automatically removed within few seconds.

Emergency program:

Actions of regulator:

No

Automatic boiler stop.

Boiler temperature > 86°C, offtake of residual

warmth is switched off

V1 and V2 are adjusted after setting

STB on

reset

Boiler temperature

(°C)

If the error repeats, it is necessary to inform the service technician.

Incorrectly measured values of boiler temperature (error)

Cause:

Control light 3 red

Measured values < -20°C, or > +150°C

Lights

Correction:

Reset:

Check sockets and conductors! Replace

sensors, if necessary!

Automatically after removing the cause

Error in measuring

of boiler temperature

Boiler temperature

(°C)

Emergency program:

Actions of regulator:

No

Automatic stop of flue gas fan and circuiting

pump

V1=0 %, V2= min. 25 % open

Page 38

38

Too high flue gas temperature (warning)

Cause:

Control light 3 red:

Flue gas temperature > 300°C

Flickers

Temperature of flue

gas is too high

Boiler temperature

(°C)

Correction:

Reset:

Emergency program:

Actions of regulator:

By heating-up and refuelling, close the door

immendiately

In operation: After burning-out, clean the

boiler

Automatically at flue gas temperature <299°C

No

Flue gas temperature > 350°C, flue gas fan

stop

Flue gas temperature < 299°C, flue gas fan

start

Overheating (warning)

Cause: Boiler is on and its temperature is > 90°C

Fuel surplus, circuiting pump error

Overheating

DO NOT OPEN!

Boiler temperature

(°C)

Control light 3 red:

Correction:

Reset:

Emergency program:

Actions of regulator:

Flickers

Load less fuel or remove error

Automatically at boiler temperature < 89°C

No

Boiler temperature > 90°C, flue gas fan stop

V1=0 %, V2=min. 25 % open

Boiler temperature < 89°C, flue gas fan start.

V1 and V2 are adjusted after setting.

Incorrectly measured values of flue gas temperature (error)