Page 1

ATTACKDP

WOODGASIFYINGBOILER

R

TECHNICALMANUAL

Page 2

ATTACKDP-Woodgasifyingboiler

-Assembly,pre-heatingandtrainingoftheattendanceisperfomedbyanassemblytechnician

trainedbythemanufacturer,whoalsofillsinadocumentontheinstallationoftheboiler

-Duringwoodgasifying,tarandcondensates(acids)arecreated.Therefore

behindtheboilerthemixingapplianceregumatortemperature-responsivevalvemustbe

installed,tokeeptheminimumtemperatureofreturnwaterof65intotheboiler.

-Operationtemperatureofwaterintheboilermustbeof80-90°C.

-Theboilermustnotbepermanentlyoperatedwiththeoutputlowerthan50%.

-Whenacirculationpumpisused,itmustbecontrolledbyaseparatedthermostatinorderto

keeptheprescribedminimumtemperatureofreturnwater.

-Ecologicaloperationoftheboilerisduringnominaloutput.

-WerecommendtoinstalltheboilerwithstoragereservoirsandRegumatwhichguarantees

economyinfuelin20až30%andlongerservicelifeoftheboileraswellascomfortable

attendance.

-Iftheboilercannotbeattachedtotheaccumulation,werecommendtoconnectitatleast

withoneequalisationbasinwiththevolumeofabout25lfor1kWoftheboileroutput.

-Duringthemodewithdecreasedoutput(summermodeandwaterheating)itisnecessaryto

startburningdaily.

-Fuelmustbeusedonlydriedof12-20%moisturecontent(withahighermoisturecontent

offueltheoutputofboilerdecreasesanditsconsumptionincreases)

inthefuelbin

°C

-Thechoiceoftherightboilersize,thatisitsheatingoutput,isaveryimportantconditionfor

economicoperationandrightfunctionoftheboiler.Theboilermustbechosensothatits

nominaloutputrespondstoheatlossoftheheatedobject.

Theguaranteedoesnotapplyfortheboilerif:

-itisoperatedwithwoodexceeding20%moisturecontentorwithfuelnotprescribedby

themanufacturer.

-IfapropermixingapplianceRegumatisnotinstalledinthesystem,whíchprovidesfor

returnwaterthetemperatureof65°C.

-afunctionalthermostaticvalve(WATTSSTS20)isnotinstalledonthecoolingcircuit

ofboilerandconnectedtothesourceofcoolingwater.

2

Page 3

Content:

2.Important

3Content

4Introduction,generaldescription

5Technicalparameters

6Dimensionsofboilers

7,8ControlboardofATTACKDPSTANDARD,PROFI

9Purposeofuse,technicalparamaters,operationalrules

10Warning

11TechnicaldescriptionofDPPROFI

12Overheatingoftheboiler,thewaysofregulation,displayingfaults

13Maintenanceofheatingsystem,Prescribedfuel

14Chimney,exhaustpipe,connectingboilertothemains

15Protectionofboileragainstcorrosion

16Recommendedconnection

17Protectionofboileragainstoverheating

18Defectsandtheirremedy

19Possiblefaultsandthemeansoftheirelimination

20Schemeofdependencyofresistanceonthetemperatureofheatingwaterbythe

thermalprobe(DPPROFI)

21-22ElectricalschemesofboilerconnectionsATTACKDP

3

Page 4

Introduction:

Dearcustomer,

Generaldescription:

DescriptionofATTACKDPbrand:

ATTACKDPwoodgasifyingboilerisdesignedforeconomicandecologicalheatingof

familyhouses,bungalows,smallplants,workshopsandsimilarobjects.

Thankyouforconfidencethatyoushowedusbypurchasingourproduct-ATTACKwood

gasifyingboiler. Wewishyoulongandreliableoperation.Properattendanceoftheboilerisone

oftheconditionsforreliableandrightoperation,sopleasereadthisinstructionforuse

carefully.Themanualiswritteninthewaytorespecttherightoperationoftheboilerin

centralheatingsystem.

Theconditionsofrightoperationoftheboiler:

-tochoosetherighttypeandoutputoftheboiler

-impeccableputtingintooperation

-sensitiveattendance

-regulartechnicalmaintenance

-reliableservice

SpecifiedfuelforATTACKDPboilersisdrywood,e.g.logsoflengths,dependingonthetype

ofboiler.Thewoodgasifyingboileristheholderof1015certificate.

ATTACKDP25Standard

35

45

75

ATTACKDP25Profi

35

45

75

Boileroutput

Woodgasifyingboiler

4

Version

Version

Boileroutput

Woodgasifyingboiler

Page 5

Technicalparameters:

Specifiedmin.temperatureofreturnablewaterinoperationis65°C.

Specifiedtemperatureofwaterduringoperationintheboileris80-90°C.

5

TypeofboilerDP75DP25DP35DP45

BoileroutputkW16-2522-3529-4548-75(verziaSTANDARD)

OutputrangekW10-2514-3518-4530-75(verziaPROFI)

Heatingsurface2,302,703,105,20m

2

Feedhoppercapacitydm105145185350

3

Dimensionoffeedingopenning235x445235x445294x544mm235x445

SpecifiedchimneyPa25252525

Max.workingwateroverpressurekPa250250250250

Boilerweightkg350390420650

Diameterofflueconnectionmm152152152219

Boilerheightmm1080132010801080

Boilerwidthmm580750580580

Boilerdepthmm1050115012651600

ShieldingofelectricpartsIP21212121

ElectricalinputW45454545

Boilerefficiency%86868686

COemisionclass3

Temp.offluegasinnominaloutput°C220220220220

Flowoffluegasinnominaloutputkg/s0,0150,0180,0210,045

Maximumnoiselevel656565dB65

Specifiedfuel

Averagefuelconsumption7,510,513,522,5kgh

-1

mm550/580650/680750/7801000/1100

Burningtimeinnominaloutputhod.3333

Watervolumeinboilerl657892160

Min.volumeofequalisationbasinl5006257501500

VoltageV/Hz230/50

Consumptionforseason

1kW=1m

3

°C65-90

°C10-27

V/A230/1,5

Drywoodof15-17Mj/kg-1calorificvalue,watercontent

min.12%-max.20%diameter80-150mm

Rangeoftemperature

ofheatingwater

Rangeofroomtemperature

(PROFIversion)

Currentcarryingcapacity

ofboilerregulatorcontacts(PROFIversion)

Max.lengthoflogs/Depthofcombustionchamber

Page 6

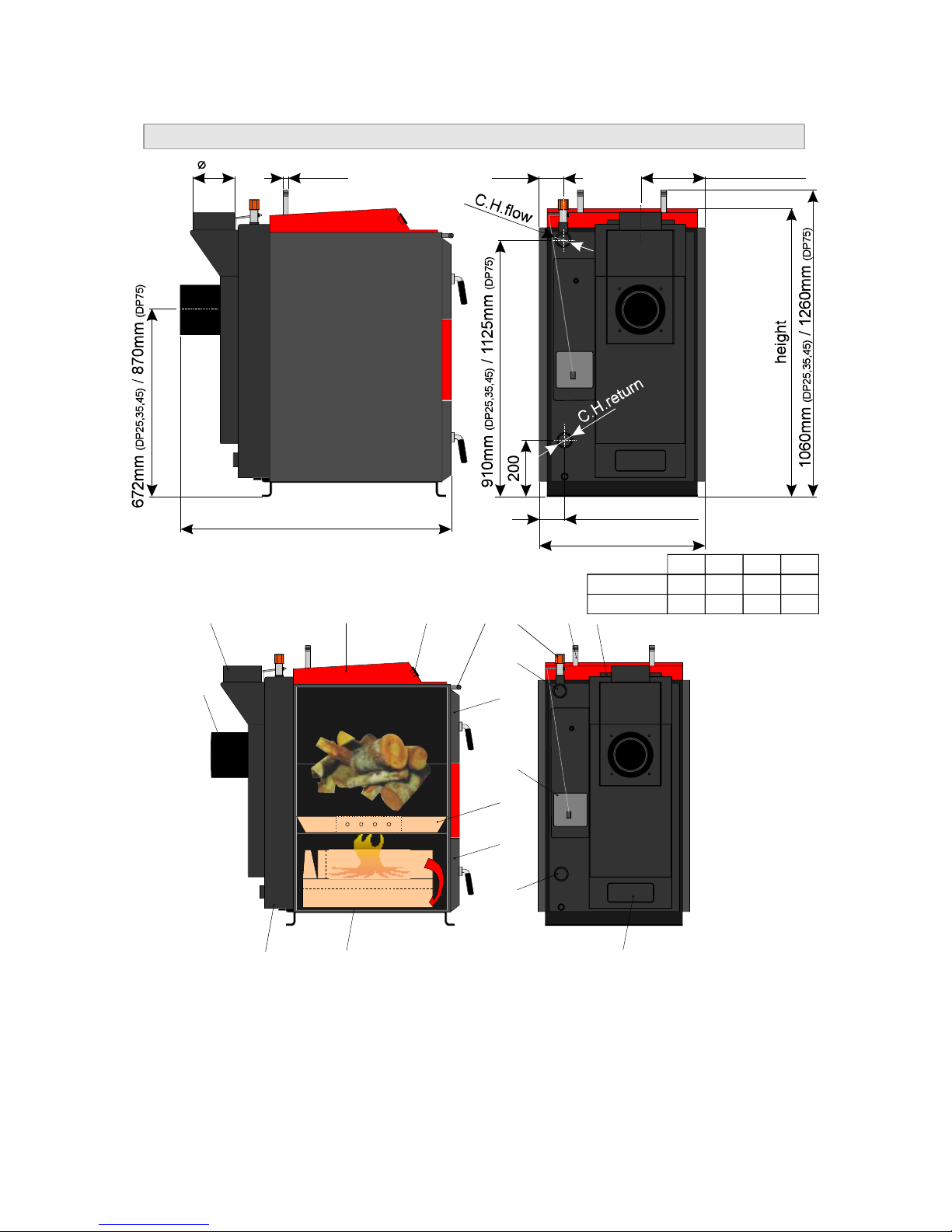

DimensionsofATTACKDPboilers

1.Boilerbody

2.Controlboard

3.Feedingdoor

4.Ashdoor

5.Suckingfan

6.Flue

7.Heatproofshapedpiece-jet

8.Heatproofshapedpiece-ashpan

9Boilerthermostat

10.Reset

11.Fluegasthermostat

12.Controlthermostatofventilator

13.Switch

14.Thermometer

15.Regulatorofoutput

16.Coolingdowncircuitagainstoverheatingofwaterinboiler

17.Coverofcleaninghole

18.C.H.flowconnection

19.

20.Controldoor

21.Pullrodofchimneyflap

C.H.returnconnection

22.Boilerregulator(PROFIversion)

6

ATTACK

®

C.H.flowconnection

C.H.returnconnection

1

2

3

4

5

6

7

8

9,10,11,12,13,14,15,22

21151617

18

19

20

17

width

depth

152

G1/2"

80mm/100mm

(DP25,35,45)(DP75)

80

225mm/290mm

(DP25,35,45)(DP75)

DP25DP35DP45DP75

G6/4"G6/4"G2"G2"

G6/4"G6/4"G2"G2"

Page 7

Controlboard

1.Reset

2.Fuse

3.Mainswitch

4.Fluegasthermostat

5.Boilerthermostat

6.Thermometer

7.Pullrodcontrol

Description:

1.Reset-

2.Fuse-

3.Mainswitch-

4.Fluegasthermostat-

5.Boilerthermostat-

6.Thermometer-

7.Pullrodcontrol-

protectionoftheboileragainstoverheating(incasethetemperatureishigherthan

110degreesC,theboilerisdisconnectedfromthepowernet)

protectionoftheboileragainstshortcircuit

switchingonoftheboiler,switchingoffifnecessary

whenthetemperatureoffluegasdecreasesundersetupvalue,the

fanisswitchedoff

servesforsettingupmaximumtemperatureofwaterintheboiler(after

exceedingsetuptemperaturethefanisswitchedoffandthe

boilerworkswithminimumoutput.Afterdecreasingsetuptemperature

thefanisswitchedonagainandtheboilerworkswithmaximum

output.

indicatesoutlettemperatureofwaterfromtheboiler

servesforopeningandclosingoffuelcut-offflap

7

ATTACKDPStandard

Woodgasifyingboiler"ATTACKDPStandard"iscontrolledbyaboilerandfluegasthermostat.

Page 8

ATTACKDPProfi

TheassetofProfiversionofATTACKDPboilerscomparingwithStandardversionisinmore

comfortableserviceandthepossibilityofheatoutputmodulationandadditionofcontrolelements.

Theboilertemperatureiskeptatthelevelsetbytheuser,bysettingupnumberofrevolutionsofthe

fluegasfan.ATTACKPROFIboilerregulatormeasuresthetemperatureofwaterintheboiler

continuouslyanddepictsitsvalueonthedisplay,controllingthepumpofcentralheatingatthesame

time.Thereisapossibilitytoconnectaroomthermostattotheboilerregulator.Theroomthermostat

providesthoroughregulationoftemperatureofheatedrooms.Thecontrolofdriveofthefour-way

mixingvalveispossibleaswell.

Backwardviewofelectronicregulator:

Settingoffluegas

fanspeedduring

burningupmode

Settingofpostpurgetimeoffanafterreachingsetuptemperatureofheatingwater

Fuse

2A

Connectingof

mixingvalve

(12V)

Connectingofroomtemperaturesensororthermostat

8

7-Controllightofcirculatingpumpoperation

8-Controllightoflackoffuel

9-Turningbuttonofroom

thermostat

10-TESTbutton(bypressingthebutton

thetemperaturesetupbytheturningbutton6.

appearsandatthesametimefluegas

fanswitchesoffforamoment)

1-Mainswitch

2-Displayshowingthe

boilertemperature

3-Controllightof

burningupprocess

4-Controllightofboileroverheating

5-Controllightof

roomthermostat

6-Turningbuttonofboiler

thermostat

1 2 3 4 5 6

9 8 7

10

Page 9

9

Purposeofuse

Technicaldescription

ATTENTION!

Operationrules

Ecologicalhot-waterboilerAttackDPisdesignedforheatingoffamilyhousesandsimilar

objects.Theboilerisdesignedforburningwoodonly.Anydrywoodcanbeusedfor

burning,mainlylogs.Alsowoodofbiggerdiameter,blocks,canbeused,whichreduces

nominaloutputbutprolongsburningtime.Theboilercannotbeusedforburningfiledustand

smallwoodendebris.Thiscanbeburntonlyinsmallamounttogetherwithlogs(max.10%).

Duetoitslargefeedhopperyoucanavoidthemostdemandableoperationofpreparationand

cuttingthewoodintosmallerpieces.

Theboilerisdesignedforcombustionofwoodontheprincipleofwoodgasifyingusinga

fluegasfansuckingfluegasfromtheboiler.

Thebodyoftheboilerisaweldmentofmetalsteelplatesof6mmthickness.Itincludesa

feedhopperwithaheatproofshapedpiecethathasanoblongopeningfortransitionofflue

gasandgas.Underitintheafter-combustionspacethereisanashpan.Intherearpartofthe

boilerthereisverticalfluechannelwithafuelcut-offflapintheupperpart.Thereisalsoa

suctionbranchforconnectiontotheflue.

Inthefrontwallintheupperpartthereisafeedingdoorandinthebottompartthereisan

ashdoor.Inthefrontpartoftheuppercoverthereisapullrodoffuelcut-offflap.Thebody

oftheboilerisfromtheoutsideinsulatedbymineralfleeceputunderthecoversofoutside

jacket.Intheupperpartoftheboilerthereisacontrolboardforelectromechanical

regulation.

Intherearpartoftheboilerthereisachannelforinletofprimaryandsecondaryairwitha

regulationflapwheretheairisheatedtoahightemperature.

-Thermometerindicatesoutlettemperatureoftheboiler

-Ifitisnecessary,theboilercanbeswitchedoffbymainswitch

-Electriccircuitisprotectedbyafuse

-Fancanbeswitchedoffbyafluethermostatafterburningdownfuel.

Forheatingup,setthisthermostatto0°C.Afterfuelstartsburning,setthe

fluethermostatto"Operation".Ifthetemperatureoffluegasdropsundersetuptemperature,

thefluethermostatisswitchedoff.Ifyouwantthefanstartagain,youhavetosetupalower

temperature.Theoptimumconditionforoperationmustbetried.

-Regulationthermostatcontrolstheoperationofthefanbytheoutlettemperatureofwater

fromtheboiler.

-Safetynon-returnablethermostatservesasprotectionagainstoverheatingincaseof

breakdownoftheregulationthermostatorassignalizationdeviceforovercomingsafety

temperature.Afterovercomingthetemperatureitisnecessarytopressit.

Beforeputtingtheboilerintooperationmakesurewhetherthesystemisfilledwithwaterand

deareated.Theboilercanbeoperatedonlyinaccordancewiththeseinstructionsinorderto

workproperly.Itcanbeoperatedonlybyanadult.Wheninstallingtheboiler,laysomething

undertherearparttoelevateitin10mmforbetterflushinganddeareating.

Locationoftheboilersinlivingspaces(includinghalls)isinadmissible!

Description:

Preparingtheboilerforoperation

-STANDARDversion

Page 10

Warning

CAUTION:

protectiontheboileragainstoverheating.

Afterthefirstheatingup,therecanbecondensationandcondensatemayleak.

Condensationdisappearsafterlongerheating.Whenburningsmallerwoodenwasteitisnecessaryto

checkthetemperatureoffluegaswhichovercome320°C.Otherwisethefancanbe

damaged.Creationoftarandcondensateinthefeedhopperisaphenomenonaccompanyingwood

gasifying.

Iftheboilerwasoutoforderforalongertime(switchedoff,brokedown),itisnecessarytouse

extremecautionwhenputtingintooperationagain.Innotworkingboiler,thepumpcanbeblocked,

watercanleakortheboilercouldgetfrostinwinter.

Forrefuelingfirstopenthefuelcut-offflapbythepullrod,donotstoptheventilator.Waitforsome

10seconds,thenslowlyopenthefeedingdoorsoasaccumulatedfluegascanbedraughttotheflue.

Duringheatingkeepthefeedhopperalwaysfull.Topreventsmoke,stokeotherfuelonlyafterthe

originalchargeisburntoutatleastto1/3ofthecontent.Thencoverlivecoalwithabroadlogandfill

inasusually.Thefuelmustnotbepressedoverthejetasthiscouldcauseextingiushingthefire.

Duringoperationthepullrodoffuelcut-offflapmustbeshiftedin,otherwisethefan

canbedamaged.

Thisisnotadefect

mustnot

Beforeburningthefuelopenthefuelcut-offflappullthepullrodoftheflapandsettheflue

thermostatto0°C.Throughtheupperdoorputdrywoodchipsontheheatproofshapedpiece

perpendicularlytothechanneltoleave2-4cmgapbetweenthefuelandchannelfortransitionofflue

gas.Putpaperorwoodwoolonthechips,thenchipsagainandabiggeramountofdrywood.After

burningthefuelswitchonthefanandclosethefuelcut-offflap.Onthethermoregulationvalvesetthe

demandedtemperatureofwater(80-90°C).Afterproperstartfillinthewholefuelbinandsetupthe

fuelthermostatintooperationposition.

Togasifywood,theremustbeareductionzoneintheboiler(alayerofcharcoalontheceramicshaped

pieceinthefeedhopper).Thelayercanbecreatedbycombustionofdrywoodofpropersize.When

wetwoodisburned,theboilerisnotworkingasagasifyingboilerandtheconsumptionofwood

rises,outputislowerthandemandedandtheservicelifeofboileraswellasthatofflueisshortened.

Ifthedraftisasspecified,theboilerworksupto70%ofoutputevenwithoutafan.

Outputregulationisconductedwithaflapontherearsideoftheboilerwichiscontrolledbya

thermoregulationvalve.Thevalveopensorclosestheflapautomaticlybysetupoutlettemperature

(80-90°C)ofwater.Payspecialattentiontosettingupthethermoregulatorasthisexceptof

regulationhasanotherimportantfunction-Forsetting

upfollowtheinstructionsforaseemblyandsetupoftheregulator.Checktheprotectionagainst

overheatingbyverifyingthefunctionofregulatorwith90°Cwater.Forthistemperaturethe

regulationflapmustbealmostclosed.Setupoftheregulatormustbetested.Thepositionofthe

regulationflapcanbewatchedfromthebacksideofthefan.Withtheboilerthermostatlocatedonthe

paneloftheboileryoucancontrolthefanbyoutlettemperatureofwater.Thetemperatureonthe

regulationthermostatshouldbyinlowerthantheoneonthethermoregulator.Onthepanelthere

isalsoafluethermostatservingtostopthefanafterburningoutofthefuel.Forheatingup,setitupto

0°C.Afterproperheatingupsetituptooperationpositionsothatthefanisworkingandisnot

stoppeduntilburningoutoffuel.Theoptimumpositionofthefluethermostatmustbewatchedbythe

kindoffuel,draftandotherconditions.Checkthetemperatureofoutletwateronthe

thermomanometer.Onthepanelthereisalsoasafetynon-returnablethermostat.

Heatingupandoperation

Electromechanicaloutputregulation

5°C

Refueling

Duringtheoperationthepullrodoffuelcut-offflapmustbeshiftedinotherwisethefan

canbedamaged..

CAUTION!

10

Page 11

TechnicaldescriptionofATTACKDPPROFI:

Duringtheoperation,thedisplayisshowingthecurrenttemperatureofoutletheatingwater.

Speedofthefanarecontrolledinthisway:

-ifduringburningupprocestheboilertemperatureislowerthan45°C,thefanworkswiththe

outputsetupbytheturningofburningupbuttonsituatedinrearsideofregulatorintherangeof

40-100%.(onthedisplayyoucansee),forboiler

temperaturehigherthan45°Cthefanworksupto100%.

-ifthetemperatureofheatingwaterduringtheoperationismorethan10°Clowerthantheone

setupbytheturningbutton,thefanworksin100%output.

-ifthetemperatureofheatingwaterislowerthan10°Cfromthetemperaturesetupbythe

turningbuttonoftheboilerthermostat,theregulatordecreasestheoutputofventilatoraccording

tothedifferencebetweenthesetemperaturesbutonlytotheoutputnotlowerthan40%.

-iftheboilertemperatureishigherorequaltothetemperaturesetupbytheturningbuttonofthe

boilerthermostat,thefanswitchesoff.

-theventilatorswitchesonagainafterdecreasingtheboilertemperatureino5°Ccomparingto

thesetuptemperature.

Theregulationofboilerensuresthatthepumpforcentralheatingswitchesoffwhenthe

temperatureofouletwaterintheboilerdecreasesunder60°C.Thepumpswitchesonagainbythe

temperaturehigherthan65°C.

Topreventexplosionofaccumulatedgasduringignition,theboilerregulatorensurespurgingof

gasintheboilerin5secondsandtheneachminuteuntil9minutesaccordingtothepositionof

theturningpost-purgetimebuttonintherearpartoftheregulator.Duringthesetupthereis

alwaysinformationonthedisplaywhichlasts2seconds(P1,....,P9,P-).Incaseyoudonotwish

purgingofgasintheboiler,itisnecessarytosetup(P--)..

Tomaketheprocessofburninguptheboilerstable,thereisaburningupsysteminstalledinthe

regulator.Afterplugginginorstoppingthealarmtheregulatorissetuptotheprocessofburningup

andthismodeissignalledbyashiningdotonthedisplay.Theprocessofburningupisfinishedwhen

thedotstopsshinigandtheboilertemperaturereachesthevaluesetupbythethermostat.Incasethe

temperatureintheboilerdoesnotexceed65°Cin2hoursofburninguptime,theregulatorstopsthe

waste-gasventilatorandswitchesonthecontrollight-missingfuel.

Inthetimeofburningouttheboilerwhenthetemperaturefallsunder65°Candthisconditionlasts

formorethan30minutes,theregulatorstopstheflue-gasfanandthecontrollightofmissingfuel

shineson.

Whenthetemperatureofheatingwaterintheboilerfallsunder65°Candthisconditionlastsfor

morethan30minutes,theregulatorstopstheflue-gasfanandthecontrollightofmissingfuel

shineson.Ifintheburningupprocesstheboilertemperaturedoesnotraisetomorethan65°C,

missingfuelwillbeshiningonthedisplayafter2hours.Tostarttheregulationagain,itis

necessaryto:

r4=40%dor9=90%,rF=100%

Missingfuel

-refueltheboiler;

-burntheboilerup

-turntheturningbuttonoftheboilerthermostatintothemaximumleftpositionandthusstop

thealarm

-waituntilthecontrollightofmissingfuelflickers,

-byturningbuttonoftheboilerthermostatsetuptherequiredtemperatureoftheboilerandthe

regulatorstartstheprocessofburningup

11

Page 12

Overheatingoftheboiler

Thewaysofboilerregulation

Displayingfaults:

Ifthetemperatureoftheboilerraisestomorethan95°C,theregulatorstopstheflue-gas

fanandthecontrollightofboileroverheatingshineson.Fornewstartitisnecessaryto:

-waituntiltheboilertemperaturefalls

-removethecauseofboileroverheating(e.g.refillmissingwaterintothecentral

heatingcircuit)

°

-Turnthebuttonoftheboilerthermostatintothemaximumleftpositionadthusstop

thealarm

-waituntilthecontrollightofboileroverheatingstartsflickering;

-tostarttheregulatoragain,setuptherequiredtemperatureoftheboilerbytheturning

buttonofthethermostat;

Ifthetemperaturefallsunder60°C,theregulatorcomesintotheburningupmode.

Theboilerenablesregulationofroomtemperatureaswellasconnectingthesensorofroom

temperature.Iftheroomtemperatureislowerthanthesetupone,thecontrollightnearthe

buttonofthermostatshineson,whichmeansthattheboilermustkeepthesetuptemperature.

Afterreachingtherequiredtemperaturethecontrollightswitchcesoff,thecircuitpumpof

centralheatingswitchesoffandtheboilerstartsburningatthetemperatureof65°C.

Fortheregulationbyroomtemperatureitispossibletoconnectwiththeterminalsforthe

sensorofroomtemperatureanyroomthermostatthatcanbeprogrammable.Inthiscasethe

turningbuttonoftheroomthermostatisnotworking.

Ifyoudonotwishtousetheroomthermostatnortheroomsensor,theinletterminalsmustbe

short-circuited.Inthiscaseonlytheboilerthermostatisworking.

Totheboilerregulatorcanbealsoconnectedamixingvalvewithan12Velectricdrive.(This

systemisnotdeliveredwiththeboiler).

Theboilerregulatorconstantlyverifiesthefunctionsofinternalsystemsandofthesensorof

boilertemperature.Afterfindingoutthedefect,theregulatorswitchesofftheflue-gasfan,the

centralheatingpumpandatthesametimethedefectshowsonthedisplay.Inthecaseoffailure

itisnecessarytoswitchtheboileroffbythemainswitch.Continuousoperationofthecentral

heatingpumpmustbeassuredbypluggingintothemains.Fuelmustbeburntthoroughlyand

thecontractservicecompanycontacted.

IfE1faultappearsonthedisplay,itmeansthedamageofthesensorofboilertemperature.

Warning!Watercanberefilledonlyaftertheboilertemperaturefallsunder40C.

12

Page 13

Permanent-heatoperation

Cleaningtheboiler

Permanent-heatoperationoftheboilermeansfirecanbekeptduringthenightwithoutheatingup

Thiswayofoperationshortenstheservicelifeoftheboiler.Forpermanent-heatoperationpreparethe

boilerthisway:

-Pntheglowinglayer

-Getthemixingvalveready.Afterclosingthevalvethetemperatureofwaterrisesto80-90°C.

-Regulationflapcontrolledbythethermoregulatorisclosedautomaticlyandthefanisswitchedoff.

Intheboilerpreparedlikethisburningiskeptformorethan12hours.Duringpermanent-heatoperationthe

temperatureofwaterintheboileris.

Whenthereistoomuchash,thereisnotenoughspaceforburningoutoffuelandaholderof

ceramicjetaswellasthewholeboilercanbedamaged.Whencleaningtheboiler,firstlyturntheventilatoron,

openthefeedingdoorandwipetheashthroughaslotintobottomspace.Leavelongunburntlogsinthefeed

hopper.Opentheuppercleaningcoverandcleaninsidewithabrush.Afteropeningthebottomcleaningholetake

ashandsootout.Afteropeningthebottomdoorcleanthebottomspace.Cleaningintervaldependsonthequalityof

wood(moisturecontent),heatingintensity,draftoftheflueandothercircumstances.Werecommendtocleanthe

boileronceaweek.Onceayearminimallycleanthe

movingwheelofthefanandcheckthroughthecleaningholefoulingofregulationofprimaryandsecondaryair

flowingintofeedchamberandcleanwithascrewdriverifnecessary.Itinfluencestheoutputandqualityof

burning.Regularandpropercleaningisimportantforpermanentoutputandservicelifeoftheboiler.

Incaseofinsufficientcleaningtheboilercanbedamagedand

Atleastonceinfortnightcheckorfillupwaterintheheatingsystem.Iftheboilerisoutofoperationduringwinter,

watercanbefrostinthesystem.Thereforeitisbettertodischargewaterofthesystemorfillinwithantifreeze

agent.Otherwisedischargewateronlyincriticalsituationsandfortheshortesttimepossible.

,replacedamagedparts.Twiceayearcleanthemovingwheelofthe

ventilatoranditsairchamber.

Specifiedfuelisdriedcutwoodandlogsof80-150mmdiameter,withmin.12%andmax.20%moisturecontent

andcalorificvalueof15-17MJkg.Itisalsopossibletoburnbigpiecesofwoodenwastewiththicklogs.

butonly

inwinter.

80-90°C

Theboilermustbecleanedregularlyandproperlyevery3-5daysbecauseashsettleddowninthefeed

hoppertogetherwithcondensatesandtardecreasesoutputandservicetimeoftheboilerandisolatesheatexchangingsurface.

Donotpullthefireclayshapedpieceoutwhencleaning.

guaranteeexpires.

Afterheatingseason

isfinished,cleantheboilerthoroughly

daily,

utafewbiggerlogs(4-6)o

Dismantletheoldpackingcordwithascrewdriverandcleantherabbetwhereitwasplaced.Takethenewpacking

cordandputitsbeginingonthehorizontalpartsoftherabbet.Withyourhandorlightknockofthehammerpressit

intotherabbetonthecircumferenceofthedoor.

Aftersometimethepackingcordinthedoorgetsdeformed.Torepackthedoor,itisnecessarytochangethe

positionofthedoor.Thepositionischangedbytighteningthehingesofthedoor.Feedingdoorandbottomdoorare

joinedtothebodywithtwohingeswhichareattachedtothedoorwithalongpin.Ifwewanttochangethe

adjustmnentofhinges,itisnecessarytoremovethepinandscrewthehingebyturningit.Fitthedooronandinsert

thepinintothehinge.

Thebodyofnozzleisplacedintheboilerbodyinanozzleholder.Inthelowerpartisthenozzlebodysealedby

boilerluteandintheupperpartbyapackingcord.Whenexchangingthenozzle,removethepackingcordfromthe

rabbetbyascrewdriver.Removethenozzlebodyandcleantheholderthoroughlyfromthetarandoldlute.Onthe

cleanedsurfaceputthenozzlebodyinsulation.Takethenozzleandputitontheholdersothattheshorterwallwas

intherearpartoftheboilerpushedtothestop.Thelateralclearancemustbethesame.Takethenewsetofpacking

cordsofthenozzlesandwithalightknockpressitintothegapsoastobeatthesamelevelwiththenozzle.

WARNING-

Maintenanceofheatingsystemandboiler

Prescribedfuel

Changingthepackingcordofthedoor

Adjustmentofhinges

Exchangeofthenozzlebody

Settingoftheboilercombustion

Settingoftheboilercombustionisexecutingthroughtheregulationsflapsoftheprimaryandsecondaryair.

Boilersarefromtheproductionsetforthemostoptimalburningconditionsintermoftheemissionsandthe

tempertatureofexhaustgas.Settingcanbeexecutedonlybyproducerorbytrainedserviceman.

Themostoptimalsettingoftheregulationflaps:

-1

13

flapofthesecondaryair:

DP25backstop+2mm

DP35backstop+2mm

DP45backstop+4mm

DP75backstop+4mm

flapoftheprimaryair:

DP25totallyclosed/backstop/

DP35totallyclosed/backstop/

DP45totallyclosed/backstop/

DP75backstop+5mm

Page 14

Note

Logsofbiggerdimensionsisnecessarytocutintohalvesorquarters(becauseofthe

requirementofoperationtonominaloutput).Youcanburnhardaswellassoftwood.Wood

mustbedried!

Attachmentoftheappliancetothefluemustbealwaysdonewithapprovalofauthorized

chimney-sweepingcompany.Theremustalwaysbesufficientdraftintheflueandfluegas

mustbedraughttotheatmosphereinallpossibleoperationconditions.Fortherightoperation

oftheboilertheindependentfluemustbedimensionedintherightway,

Thedraughtisinfluencedbythe

sectionofflue,heightandroughnessoftheinternalwall.Intothefluewheretheboileris

attached,nootherappliancecanbeattached.

Fluedraughtmusthavethespecifiedvalues.Butitmustnotbetoohighso

asnottodecreasetheefficiencyofboilerandinterruptburning.Ifthedraughtistoostrong,

installathrottlevalvebetweentheflueandboiler..

20x20cmmin.height7m

O20cmmin.height8m

15x15cmmin.height11m

O16cmmin.height12m

ExactdimensionsoffluearespecifiedbythestandardSTN734210.Fluedraughtisspecified

intechnicalparameters.

Exhaustpipemusthavetheoutletintothechimney.Iftheboilercannotbeattachedtothe

chimneydirectly,theexhaustpipemustbe

withoutheatingsurfaceanditmustrisetotheflue.Exhaustpipesmustbetightandresistant

againstfluegasleakageandcleanablefrominside.Exhaustpipesmustnotcomethroughhome

andutilityspacesandtheinternalsectionoftheexhaustpipemustnotbenarrowingtotheflue.

Usingofbentsisnotsuitable.

Theboilerisconnectedtothemainsof230V,50Hzbyasupplycordandplug.Thevoltageisof

Mtypeandwhenreplaced,thesametypemustbeusedbyaserviceoragnization.Theappliance

mustbelocatedinsuchawaythattheplugwaswithinthereachoftheattendance.

(accordingtoSTNEN60335-1+A11:1997).

Boileroutputdependsonthemoisturecontentofwood.Outputandfunctionoftheboiler

isguaranteedformaximummoisturecontentof20%.

Chimney

becausecombustion,

outputandservicelifeofboilerdependsonthedraught.

Thefluediametermustnotbesmallerthanthe

outletontheboiler.

Exhaustpipe

asshortaspossibleandnotlongerthan1m

Connectingtheboilertothemainsnet

Informativevaluesoffluesection:

14

Page 15

Attachmentofregulationandcontrolelements

theboilerwasnotundercooledontheinletofreturnablewaterunder65°C

Protectionofboileragainstcorrosion

Theboilerisdeliveredtoaconsumerequippedwithbasicregulationandcontrolelements.

Attachmentoftheseelementsisindicatedonthechartofconnection.Werecommendtoextend

theregulationofboilerwithotherregulationelementswhichenablemorecomfortableand

economicoperation.Eachpumpinthesystemmustbecontrolledbyanindividualthermostat

soas.

Attachmentoftheseelementscanbesuggestedbyadesignerduetospecificconditionsofthe

heatingsystem.Electricinstallationtogetherwiththeproperequipmentoftheboilermustby

donebyaspecialistincompliancewithvalidstandards.Thebasicversionofboiler(Standard)

doesnothaveathermostatforpumpbuilt.

Suitablesolutiontothisproblemismixingappliance(RegumatATTACK-OVENTROP)ora

thermoregulationvalvewhichenablesseparatedboilerandheatingcircuit.Thiswayyoucan

preventundercoolingofboilerunder65°Candalsodecreasecondensationofsteam,acidsand

tarsinthefeedhopper.Withaflapofthree-wayvalveyoucanregulatethetemperatureof

heatingwaterindependentlyontemperatureofwaterintheboiler.Waterintheboilermustbe

permanentlyof80-90°C.

Standardsfordesignandassemblyofboilers:

Installationandexchangeoftheheatproofshapedpieces:

Sectioncrossboiler-combustionchamber

STNEN303-5-Heatingboilersusingsolidfuel

STN734210-Productionoffluesandexhaustpipes

STN920300-Firesafetyoflocalappliances

STNEN60335-1+A11-Safetyofdomesticelectricalappliances

STN061000-Localappliancesofsolid,liquidandgaseousfuels

Thebackpartoftheashpanpos.1insertintothelowerchamber

andpushtostoptothebackplate.Insertthefrontpartoftheash

panpos.2andpushtostoptothebackpartoftheashpan.

Ontheashpanputthesuper-structureofashpanpos.3andpush

ittostoptotherear.Theashpanshouldbesituatedinthecentre

lineofboileratthefrontsight.

Bytheexchangeofthedamagedjetpos.4orcubepos.5follow

thenext:Jetandcube/cubeonlybyDP35andDP45/takeout

aftertheeliminationofgaskets.Theninsertnewjeteventually

cubeandbackwardssealupwithgasket.Ifitisnecessary,gaskets

alsochangewithnew.Thejetisinsertedwiththesign,whichis

situatedonthelowerpartofthejetintothebackpartoftheboiler.

15

Page 16

Recommendedconnections

16

Recommendedconnectionofboilerwith4-waythermoregulationvalve

RecommendedconnectionofboilerwithREGUMATATTACK-OVENTROP

BOILER

ATTACK

DP

Expansionvessel

4-waythermoregulation

valve

Heatingsystem

BOILER

ATTACK

DP

Expansionvessel

Pump

Regumat

ATTACK-

-OVENTROP

Heatingsystem

Checkvalve

Page 17

17

Boilerhastobeoperatedwiththenominaloutput.Incaseofthewarmthtakingbytheoutput,whichis

lowerthanthenominal,itisnecessarytoconnecttheboilerwiththeaccumulationtankwithvolumeof

min.460l(STNEN303-5,clause4.2.5).

1.ATTACKOventropkeepsthetemperatureofreturnheatingwatercomingtotheboileron

65.Temperatureofreturnheatingwaterunder60°Ccausesthecondensationofsteams,

acidsandtarsinthefeedchamberanditisthereasonoftheboilerusefulllifeshortening.

Technicalparameters:

ClarityDN25

Max.pressure10bar

Max.temperature120°C

Valuekvs3,9

ATTACKOventropconsistsofthree-waymixingvalve,pumpWilo,2thermometers,

thermoregulationvalve,thermostatichead,by-pass,distanceunitandisolation.The

adventageofthissolutionconsistsincompactness,simpleattendanceandguaranteed

protectionofboilerheatingexchanger.

ATTACKOventropforboilers:Ordercode:

ATTACKDP25,DP35,DP45DPP25003

°C

,DP75

Protectionandusefulllifeextentionoftheboiler

12

43

Recommendedconnectionofboilerwithaccumulationtank

BOILER

ATTACK

DP

Regumat

ATTACK-

-OVENTROP

Heating

system

ACCUMULATION

TANK

D.H.W

Tank

Expansionvessel

Page 18

2.Connectionwiththreewaythermoregulationvalve

3.Connectionwithaccumulationtank

OperationalprincipleisthesameastheconnectionwithATTACKOventropregulation

system.Whenthetemperatureishigherthat65°Cthethermoregulationvalveopensthe

circuitinheatingsystem.Whenthetemperatureislowerthan65°Cmakesthiscircuitclosed

andtheboilerworksintheshortboilercircuit.Thisappliancekeepsthereturnheatingwater

commingtotheboileratthemin.temperatureof65°C.

Recommendedthreewayregulationvalve:

ForBoiler:Type:Ordercode:

ATTACKDP25,DP35DN32DPP25004

ATTACKDP45,DP75DN50DPP45001

Connectionsystemconsistsinheatingupofwaterinaccumulationtanksandthewarmthis

graduallytakingawayfromthetanksaccordingtotherequestfromtheheatingsystem.Bythe

operationwithseveralheatingupsatfullperformance,accumulationtankswillbeheatedfor

thetemperatureof90-100°C.Heatingwithaccumulationtanksinconnectionwiththe

ATTACKDPboilersbringmoreadvantages..Amongthemainadvantagesbelong

enlargementoftheboilerlifeandintheendresultalsolowerconsumptionoffuel.

Recommendedvolumesofaccumulationtanksaccordingtoboileroutput:

DP25-1500-2000l

DP35-2000-2500l

DP45-2500-3000l

DP75-4000-4500l

ODPAD

STS20

Protectionoftheboileragainstoverheating

Instructionsforliquidationoftheproductafteritslifetime

Liquidationofwrapping

CAUTION:Coolingcircuitagainstoverheating

mustnotbeusedbySTNEN303-5

forotherusethanprotectionagainstoverheating.

STS20valvewhichhasasensorplacedintherear

partoftheboilerprotectstheboileragainst

overheating.Ifthetemperatureofwaterinthe

boilerovercomes95°C,thevalveletswaterinto

acoolingcircuitwhichovertakesexcessingheat

anddischargesitintothedrain.

Theproductshouldbeliquidatedbysellingtoascrap-materialdealerortoadumpmanaged

byalocalauthority.

.Thewrappingshouldbeliquidatedbysellingtoascrap-materialdealerortoadump

managedbyalocalauthority.

18

Watersupply

Fromwaterpiping

Pressure2-6bar

10-15°C

Page 19

19

Page 20

Schemeofdependencyofresistanceonthetemperatureofheatingwaterbythethermalprobe(DPPROFI)

Teplota

°C

-55

-50

-40

-30

-20

-10

0

10

20

25

30

40

50

60

70

80

90

100

110

120

125

130

140

150

951

1000

1105

1218

1338

1467

1603

1748

1901

1980

2057

2217

2383

2557

2737

2924

3118

3318

3523

3722

3815

3901

4049

4153

Odpor

kOhm

980

1030

1135

1247

1367

1495

1630

1772

1922

2000

2080

2245

2417

2597

2785

2980

3182

3392

3607

3817

3915

4008

4166

4280

1009

1059

1165

1277

1396

1523

1656

1797

1944

2020

2102

2272

2451

2637

2832

3035

3246

3466

3691

3912

4016

4114

4283

4407

MINMAX

20

Page 21

Mainswitch

Fluegas

thermostat

thermostat

Boiler

thermostat

Highlimt

WIRINGDIAGRAMOFGASIFYINGBOILERDP25,DP35,DP45,DP75

WITHCAPACITOR

Fuse

2A/250V

thermostat

pump95°C

Capacitor

2514

Page 22

Capacitor

red

230V/50Hz

WIRINGDIAGRAMOFGASIFYINGBOILERDP25,DP35,DP45,DP75

"PROFI"WITHCAPACITOR

Page 23

RECORDONPUTTINGTHEBOILERTO

OPERATION Dataonthecustomer(llegible)

Productionnumber..............................

Nameandsurname:

Dateofputtingtooperation.........................................................

Serviceorganization:Street:.............................

............................Postcode,town:.

.Stamp,signature........................................

........................................................Tel.No...........................

Obligatoryserviceexaminationafterthe2ndyearofoperation

Stamp,signatureofserviceorganization

.:................................................

Obligatoryserviceexaminationafterthe3rdyearofoperation

Date:....................................

Obligatoryserviceexaminationafterthe1styearofoperation

Stamp,signatureofserviceorganization

.:................................................

Date:....................................

Stamp,signatureofserviceorganization

.:................................................

Date:....................................

Page 24

DOCUMENTontestingandcompletness

ofATTACKgasifyingboiler

BoilerproductionNo.:

Theproductdeliveredwiththiscertificatesuitstotechnical

standardsandtechnicalconditions.

Theproductwasmanufacturedbyitsdrawingdesigninrequested

qualityandisapprovedbySZÚBrnoundertheNo.ofcertificate

Technicalinspection

InVrútky,date:.....................................................................................

Stampandsignatureofthefinalinspection:........................................

SKCZATCHDKESFIFRGBGRIEITNLNOPTSE

Thecountryofdeliveryoftheappliance:

Producer:

Tel:operator043/4003101

Fax:043/4003106

E-mail:kotle@attackslovakia.sk

http:www.attack-sro.sk

Tel./fax:infoline043/4003104

Tel:service0905410204

ATTACK,s.r.o.

DielenskáKružná5

03861Vrútky

SLOVENSKO

STANDARDPROFI

DP25DP35DP45DP75

Loading...

Loading...