Page 1

W W W . A T T A C K . S K

Combined boiler

ATTACK Wood&PelleT

for Wood And PelleTs

insTrUCTions for Use

Page 2

2

CONTENTS

CONTENTS ...................................................................................................................................................................... 2

1. GENERAL INFORMATION ....................................................................................................................................... 4

1.1 INTRODUCTION ................................................................................................................................................. 4

1.2. SAFETY ................................................................................................................................................................. 4

1.3 BOILER OPERATION .......................................................................................................................................... 4

1.4 SAFETY ITEMS FOR WORK WITH THE BOILER ........................................................................................... 5

1.5 BOILER MODIFICATION ................................................................................................................................... 5

1.6. BASIC DESCRIPTION OF THE BOILER: ......................................................................................................... 5

1.7 FUEL ....................................................................................................................................................................... 6

1.7.1 WOOD ........................................................................................................................................................... 6

1.7.2 PELLETS ......................................................................................................................................................... 7

1.7.3 ALTERNATIVE FUELS ................................................................................................................................. 7

2. BOILER ASSEMBLY AND INSTALLATION ........................................................................................................... 8

2.1 HANDLING THE BOILER ................................................................................................................................... 8

2.2 GENERAL CONDITIONS OF INSTALLATION ............................................................................................... 8

BINDING NORMS FOR PROJECTING AND INSTALLATION OF THE BOILERS ..................................... 9

2.3 PLACING THE BOILER .................................................................................................................................... 10

2.4 BOILER CONNECTION TO THE HEATING SYSTEM ................................................................................ 11

2.4.1 PROTECTION AGAINST CORROSION ................................................................................................ 12

2.4.2 CHIMNEY ................................................................................................................................................... 13

2.4.3 FLUE GAS CONNECTION OF THE BOILER ........................................................................................ 13

2.4.4 CONNECTION TO THE ELECTRICITY MAINS ................................................................................... 13

2.4.5 CONNECTION OF THE EXTERNAL PELLET TANK........................................................................... 14

2.4.6 LEFT DOOR VERSION ............................................................................................................................. 14

2.4.7 CHOICE AND WAY OF CONNECTION OF THE CONTROL AND SAFETY ELEMENTS ........... 14

2.4.8 CONNECTION TO THE ACCUMULATION TANKS .......................................................................... 16

2.4.9 RECOMMENDED HYDRAULIC SCHEMES OF BOILER CONNECTION....................................... 18

3. BOILER START-UP .................................................................................................................................................. 19

4. WARRANTY CONDITIONS ................................................................................................................................... 19

5. TECHNICAL PARAMETERS .................................................................................................................................. 20

5.1 DIMENSIONS OF THE BOILER ATTACK WOOD&PELLET 25 ............................................................... 21

6. REGULATION OF THE BOILER AND THE HEATING SYSTEM ..................................................................... 22

6.1 IN GENERAL ...................................................................................................................................................... 22

6.2 EMERGENCY ACTIONS .................................................................................................................................. 22

Page 3

3

6.3 PREPARATION FOR THE OPERATION, FILLING THE INTEGRATED PELLET TANK ....................... 23

6.4 DESCRIPTION OF THE SAFETY DEVICES .................................................................................................. 23

6.5 BOILER CONTROL AND OPERATION ........................................................................................................ 24

6.5.1 DESCRIPTION OF THE MAIN CONTROL MODES ........................................................................... 25

6.5.2 DESCRIPTION OF THE CONTROL MODES, RELATION BETWEEN THE MODE WOOD AND

COMBI ................................................................................................................................................................... 26

6.5.3 OPERATION WITH WOOD .................................................................................................................... 26

6.5.3.1 MANUAL LIGHT UP OF WOOD........................................................................................................ 27

6.5.3.2 AUTOMATIC LIGHT-UP OF WOOD................................................................................................. 31

6.5.4 COMBINED OPERATION MODE .......................................................................................................... 33

7. DISPLAYING INFORMATION .............................................................................................................................. 35

8. SETTING THE PARAMETERS ............................................................................................................................... 37

8.1 LEVEL OF SETTING THE BASIC PARAMETERS ........................................................................................ 37

8.2 LEVEL OF SETTING THE ADVANCED PARAMETERS ............................................................................. 39

9. SPECIAL SETTINGS AND INFORMATION ........................................................................................................ 48

10. INTERNET CONNECTION .................................................................................................................................. 49

11. SOFTWARE UPDATES ........................................................................................................................................ 50

12. FACTORY SETTINGS AND RESET .................................................................................................................... 51

13. BOILER MAINTENANCE ..................................................................................................................................... 51

14. BOILER CLEANING .............................................................................................................................................. 52

15. ASSEMBLY AND DISSASSEMBLY OF THE REFRACTORY ITEMS ............................................................ 53

16. TABLE OF RELATION OF THE RESISTANCE AND THE TEMPERATURE OF THE SENSOR PT 1000 54

17. ELECTRICAL CONNECTION SCHEME ............................................................................................................ 55

18. ACCESSORIES ....................................................................................................................................................... 58

19. INSTRUCTIONS FOR DISPOSAL OF THE APPLIANCE AFTER ITS LIFETIME ENDS ............................ 58

19.1 DISPOSAL OF PACKAGING ........................................................................................................................ 58

Page 4

4

1. GENERAL INFORMATION

1.1 INTRODUCTION

Dear customer,

thank you for your trust and purchase of our product – the combined boiler ATTACK WOOD&PELLET.

The boiler construction is based on the newest knowledge of the biomass combustion and meets all

current test criteria and EU directives.

Please read this manual carefully and keep it near the boiler for reference. This manual contains

important information, including information for correct, safe and economical boiler operation.

Constant improvement of our products may mean small differences in the pictures and content and

we reserve right to make technical changes of products without previous announcement.

1.2. SAFETY

The following three warning signs are used in this manual for illustration of the threat of danger

and for important safety notifications:

DANGERNGER

There is imminent danger and serious threat to health or property. Follow the given

instructions!

WARNING

Potentionally dangerous situation that could cause serious threat to health or property if

advised actions are not taken. Take care!

CAUTION

Take care and follow the advised actions.

1.3 BOILER OPERATION

CAUTION

No unauthorized personel to enter the boiler room, there may be serious risk to health or

property. Operator of the system must ensure that no unauthorized person, particularly children,

enter the boiler room.

Page 5

5

1.4 SAFETY ITEMS FOR WORK WITH THE BOILER

To work on the boiler please use correct personal protective equipment including heat resistant

gloves, suitable cloths and safety shoes.

1.5 BOILER MODIFICATION

CAUTION

It is forbidden to make any changes to the construction of the boiler or disable any safety

and protection devices fitted to the boiler.

1.6. BASIC DESCRIPTION OF THE BOILER

The ATTACK WOOD&PELLET is a modern environmentally friendly boiler that saves environment

by efficient burning of biomass. The user gets the advantage of low operating costs from wood

combustion as well as the convenience of the heating system comparable with gas boilers when

burning the pellets. The boiler is intended for heating of dwelling houses, cottages, factories,

industrial units, etc.

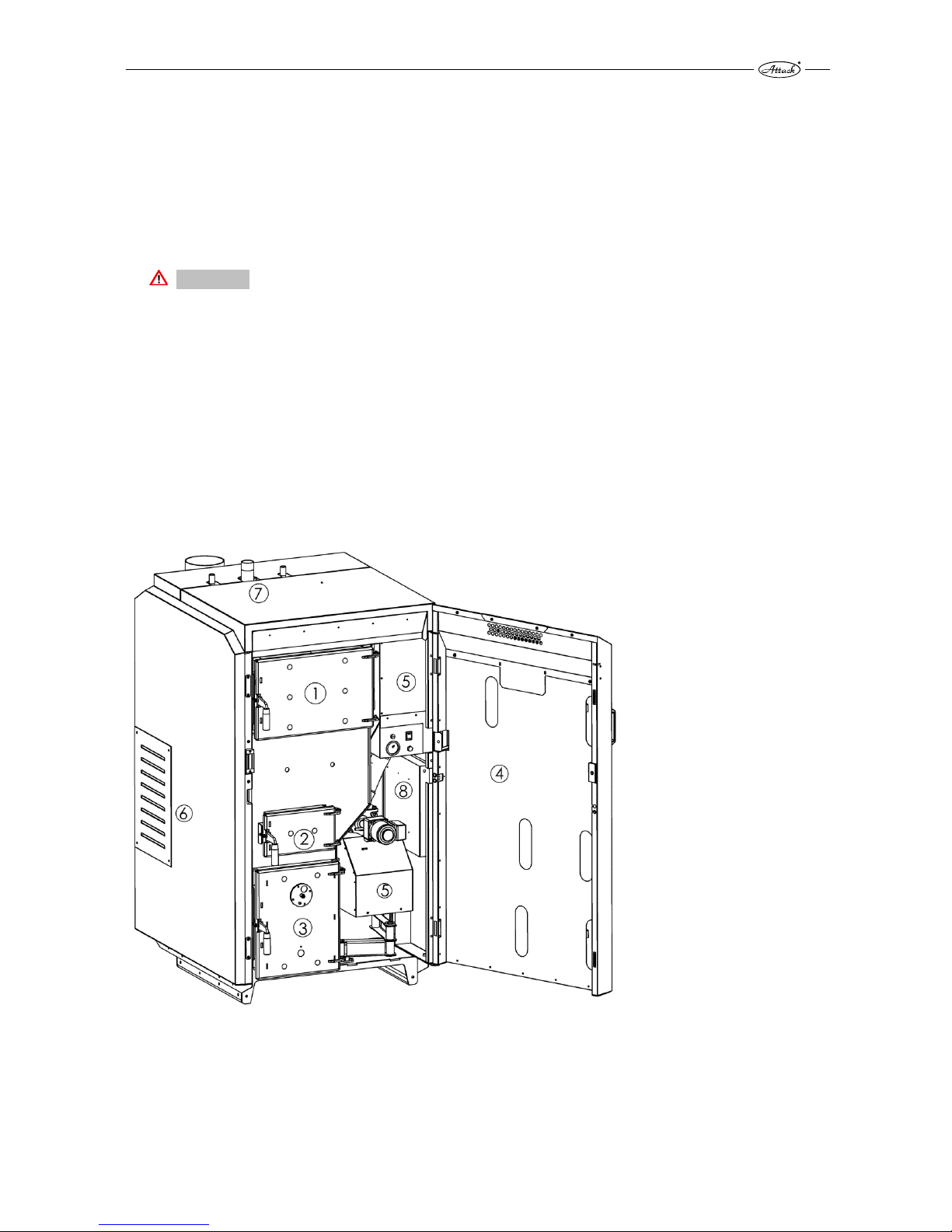

Pic. 1 Basic description of the boiler

1 –wood feeding chamber door, 2 –middle door for ignition and cleaning, 3 –combustion

chamber door with a sight-hole, 4 – main door, 5 – burner for pellet combustion, 6 – secondary

and primary air inlet for gasification, 7 – boiler flow connection, 8 – boiler control electronics.

Page 6

6

The boiler consists of the wood feeding and combustion chamber, pellet combustion chamber,

pellet burner, integrated pellet tank and heat exchanger. The boiler can be operated in either

wood mode or pellet mode, but not at the same time. The boiler is designed with reference to

the user comfort, i.e. to save time for heat-up, fuel cutting, cleaning and total time spent by the

boiler. The basic part of the boiler is a water cooled body, welded from boiler steel plate of 3–

6 mm to ensure long life time. The feeding chamber for gasification is equipped with a dry coat.

By elimination and moving the condensation point from the boiler body to the surface of the dry

coat is the boiler´s life extended. The dry coat can be easily exchanged, if it comes to its damage.

Turbulators in the tubular exchanger improve heat transfer into the heating water and ensure

automatic exchanger cleaning to maintain high efficiency during the operation and to extend

the boiler life. The boiler body is insulated with mineral wool. The covering is powder coated.

1.7 FUEL

1.7.1 WOOD

In the boiler ATTACK WOOD&PELLET it is possible to burn soft and hard chopped fuel wood with

the heat value 15–17 MJ/kg. Particularly suitable is beech, oak, fir, spruce, pine, poplar, alder,

willow, birch, ash, wych-hazel, locust, always within the humidity range of 12–20 %.

Recommended diameter of the wood logs is in the range of 80–150 mm. The maximum length

of wood logs is 580 mm and it must not be exceeded, otherwise they would get stuck in the

feeding chamber.

The heat value of the particular wood types:

Units

Wood Kcal/kg

MJ/kg

kWh/kg

Spruce 3 900 16,25 4,5

Pine 3 800 15,80 4,4

Birch 3 750 15,50 4,3

Oak 3 600 15,10 4,2

Beech 3 450 14,40 4,0

CAUTION

Wrong humidity or size of the wood may cause increase or decrease of output, low or high flue

gas temperature, excessive condensation, flame loss during the gasification process or

uncontrollable combustion.

Recommended storing and drying the wood:

Hard wood: 2 years in dry environment

Soft wood: 1 year in dry environment

When storing (drying) the wood, it has to be protected against rain. To dry the wood more

efficiently, stack to keep as large air gaps as possible. The wood will season faster with airflow

over the wood. If possible, store the wood for at least 1 day at a warm place (e.g. boiler room)

before loading it into the boiler (as it is warm, the efficiency of burning is increased).

Page 7

7

1.7.2 PELLETS

The pressed wood pellets wihout any additional materials can be burned in the boiler.

Parameters of the pellets should be following:

Approved pellet specification:

Measured weight: 600–750 kg/m3

Heat value: 4,7–5,0 kWh/kg

Size/diameter: 6 mm

Size/length: Caution! Max. 35 mm

Humidity – max.: 12 %

Ash content: 0,5–1 %

Content of crumble (dust:) max. 3 %

Ash melting temperature: min. 1 100°C

Norms : DIN 51 731 – HP 5, DIN Plus, or EN 14961-2 – A1

1.7.3 ALTERNATIVE FUELS

It is possible to use the wood briquettes made from pressed wood sawdust without any

additional adhesives or bidning materials.The briquettes must be always mixed in

the appropriate ratio to the wood (dependent on the size and shape of the briquettes) and must

not stuck in the refractory nozzle for wood gasification.

CAUTION

Use of unsuitable fuel types causes higher cleaning requirements and accumulation of an

agressive sediments and condensation that may lead to reduced functionality, damage to the

boiler and invalidate the warranty. Burning the wrong fuels may cause incorrect and

uncontrollable combustion.

Page 8

8

2. BOILER ASSEMBLY AND INSTALLATION

2.1 HANDLING THE BOILER

The boiler is delivered on a pallet. Handle it always on the pallet and put it down from the pallet

only at the point of installation. This can be done by a manipulation trolley or a crane and lifting

eye that is not included into the delivery (recommended specification: lifting screw with an eye

M20 ISO 3266, or M20 DIN 580). The lifting eye can be screwed into the chassis welded on the

upper cover of the boiler to hang the boiler. Carrying capacity of the hanging eye M20 is 1 200

kg, weight of the boiler is approximately 860 kg. Remove the upper boiler cover before hanging

the boiler on the hanging eye.

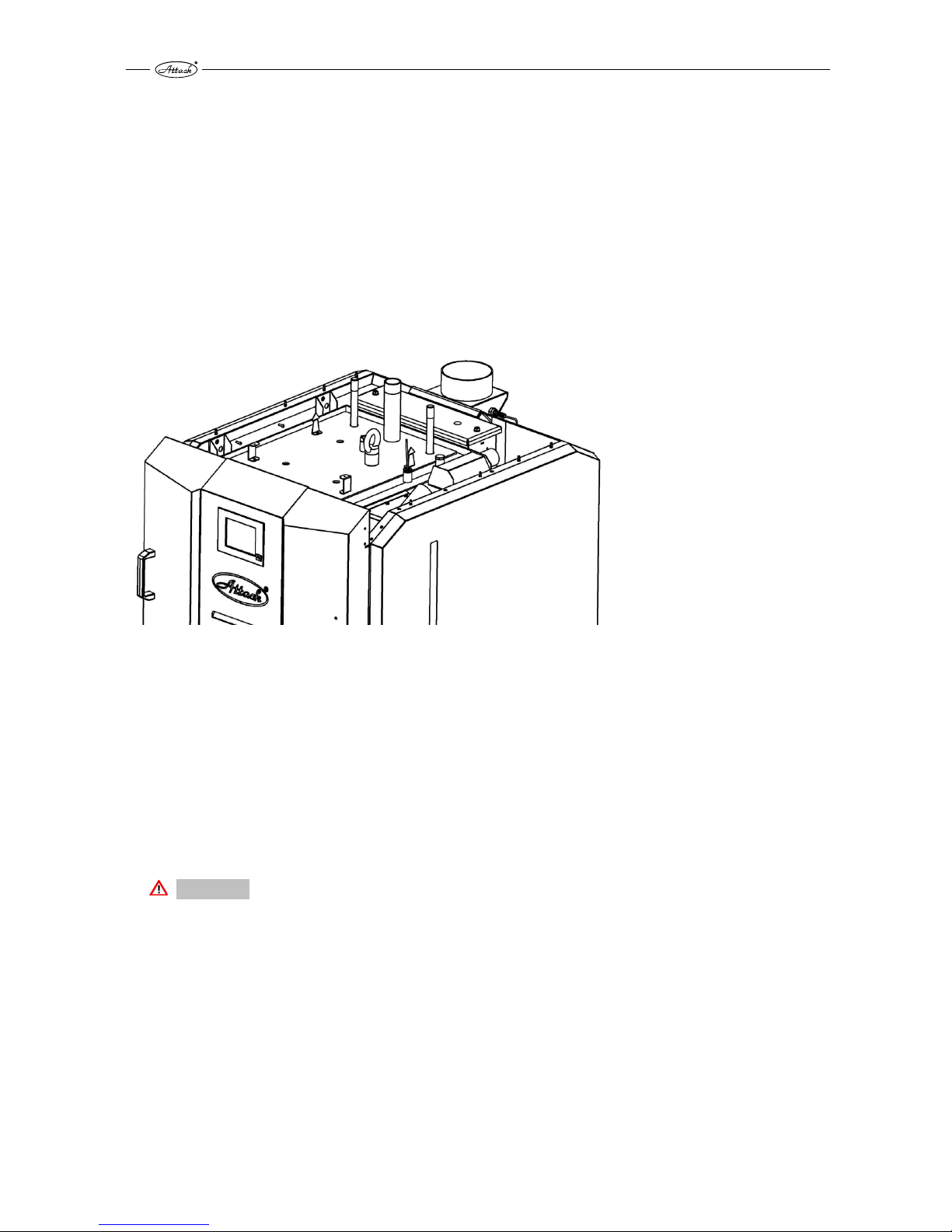

Pic. 2 Handling the boiler with the hanging screw with eye

2.2 GENERAL CONDITIONS OF INSTALLATION

The boiler can only be installed by a properly certified installer with valid certification to install

and assemble the heating appliances. Before installation, there must be a project made

following to the valid prescriptions. Before installation of the boiler, the worker must check

accordance of the data on the data plate with the data given in the project and documentation

of the boiler. Connection of the boiler must be done in conformity to the valid directives, norms,

ordinances and this instruction manual.

CAUTION

The producer takes no responsibility for damage caused by incorrect connection or

incorrect operation.

Page 9

9

BINDING NORMS FOR PROJECTING AND INSTALLATION OF THE BOILERS

Installation of the boiler must be done in conformity with the following norms:

STN EN 303-5 Heating boilers for solid fuels

STN 92 0300 Fire safety of the local appliances and heat sources

STN EN 60 335.1 +A11 Safety of the electrical appliances for household

STN 06 10 00 Local appliances for solid, liquid and gaseous fuels

STN 06 03 10 Central heating, projecting and installation

STN 06 08 30 Safety devices for central heating and D.H.W. preparation

STN 07 74 01 Water and steam for thermal energetic devices with

operation pressure of steam up to 8 MPa

STN 332000 4-46 Electrical installations of buildings – part 4: Ensuring safety

STN 332000–3 Electrical installations of buildings – part 3: Definition of the

basic characteristics

STN EN ISO 11202 Acoustics. Noise generated by machines and devices.

Definition of the emissions levels of the acoustic pressure at

a workplace and other precisely defined places by using the

approximative corrections in environment. (ISO 11202: 2010)

STN EN ISO 12100 Safety of machines. General principles of construction of

machines. Consideration and elimination of the risk (ISO

12100: 2010)

STN EN 953+A1 Safety of machines. Protection covers. General requirements

for design and construction of fixed and movable covers.

STN ISO 27574-2 Acoustics. Statistical methods for definition and verification

of the determined values of the noise emission of machines

and devices. Part 4: Methods for series of machines.

STN ISO 1819 Devices for fluent cargo transport. Safety prescriptions.

General clauses.

STN EN ISO 15614-1 Requirements for quality of the fusion welding of metal

materials

STN EN 287-1 Welding of reserved technical devices

STN 07 0240 Low pressure boilers, technical prescriptions

STN 07 0245 Warm water boiler with the output up to 50 kW. Technical

requirements, testing

STN 07 7401 Water and steam for heat energy devices with the steam

operating overpressure up to 8 MPa.

STN 73 4210 Manufacturing the chimneys and flue ways and connection

of devices

STN 92 0300:1997 Minimum distance of the external surface of the appliance or

flue way from the building constructions

Page 10

10

2.3 PLACING THE BOILER

The boiler is intended for installation and operation in an area conforming to (AA5/AB5) under

the STN 33 2000-3.

The boiler room must fulfill the above mentioned and the following requirements:

There can be no potentionally explosive environment in the boiler room, as the boiler is not

suitable for usage in such environments.

The temperature in the boiler room must not drop below freezing

Boiler itself does not provide any lighting. The user must ensure sufficient source of light,

according to the local norms and directives.

If the boiler is going to be installed above an altitude of 1 800 m, the installation has to be

consulted with the manufacturer

There must be an opening of at least 200 cm

2

in the boiler room for sufficient ventilation and

supply of the required amount of the air for combustion. The external environment should

not influence the functionality of the opening (rain, snow, wind).

When installing the boiler, it is necessary to keep a safe distance of its surface from

flammable materials, according to the degree of flammability:

from materials of flammability B, C1 a C2 200 mm

from materials of flammability C3 400 mm

from materials with the grade of flammability not approved under the STN 73 0853

400 mm

Examples of classification of the building materials by their degree of flammability:

degree of flammability A inflammable (bricks, blocks, ceramic tiles, mortar, parging)

degree of flammability B partly flammable (heraklith, lignos, board from basalt felt, novodur)

degree of flammability C1 difficult to ignite (hardwood (oak, beech), plywood, werzalit,

hardened paper)

degree of flammability C2 normal combustibility (softwood (pine, spruce), chipboard,

solodur)

degree of flammability C3 easily ignited (wood fibre boards, polyurethane, PVC, foam rubber,

polystyrene)

The sealing board or protection covering on the protected items must exceed the boiler edge

for at least 300 mm. Also other items from flammable materials must be protected in this way, if

they are placed near the boiler and it is not possible to keep the safe distance.

If the boiler stands on a flammable surface, it must be protected by an inflammable, heat

insulating mat, which exceeds the edge on the side of the feeding door and the ash tray door for

at least 100 mm. All materials of the A flammability degree can be used as an inflammable, heat

insulating mat.

The boiler must be placed in a such way ensuring sufficient space of at least 1 m from the front

and 0,5 m from the left (right) and rear side. It is necessary to leave the space of at least 1 m

above the boiler.

Page 11

11

This space is necessary for basic operation, maintenance and eventual service of the boiler. It is

not allowed to place the boiler in dwelling premises (including corridors).

CAUTION

The items from flammable materials must not be laid on the boiler and within the minimum

distance specified for material type, the permitted (safe) one.

The boiler must be turned off, if there is a danger of fire or explosion due to flammable gases

from paints or materials in the vicinity (e.g. work with painting materials, glues, etc.).

It is not allowed to place the boiler in dwelling premises (including corridors)!

2.4 BOILER CONNECTION TO THE HEATING SYSTEM

The ATTACK WOOD&PELLET must be installed in the system that fulfils the requirements for

quality of the heating water:

Slovak republic: STN 07 7401:1991

Austria: ONORM H5195-1

Germany: VDI 2035

Switzerland: SWKI 97-1

Italy: D.P.R. no. 412

To fill or re-fill the water in the system it is possible to use only the water treated to the values

under the STN 07 7401: 1992. The water must be pure, colourless, without suspendous

substances, oils, nor chemically aggressive ingredients. The water cannot be acidic (pH must be

higher than 7,2).

Callosity of the water must not exceed 1mmol/l and concentration of the Ca²Ѐ must be lower

than 0,3 mmol/l.

CAUTION

If the above mentioned conditions are not adhered to, then the warranty provided by the

manufacturer is void!

Use of antifreeze mixtures

It is not recommended to use antifreeze mixtures as their properties that are not suitable for

operation of the boiler. This particularly concerns decreased heat transfer, large thermal

expansion, ageing, damage of the rubber parts. When it is necessary, it is possible to use the

antifreeze mixture Alicol Termo (producer: Slovnaft Bratislava) – following experience of the

producer there will not come to the decreased safety of usage, nor to the significant influence

on the boiler operation. If this way of protection against freeze is not possible under the

particular conditions and the different antifreeze mixture is used, the warranty does not relate to

the wrong functionality, nor to the eventual faults of the boiler.

Page 12

12

2.4.1 PROTECTION AGAINST CORROSION

The boiler must be connected with a device regulating the temperature of the boiler´s return

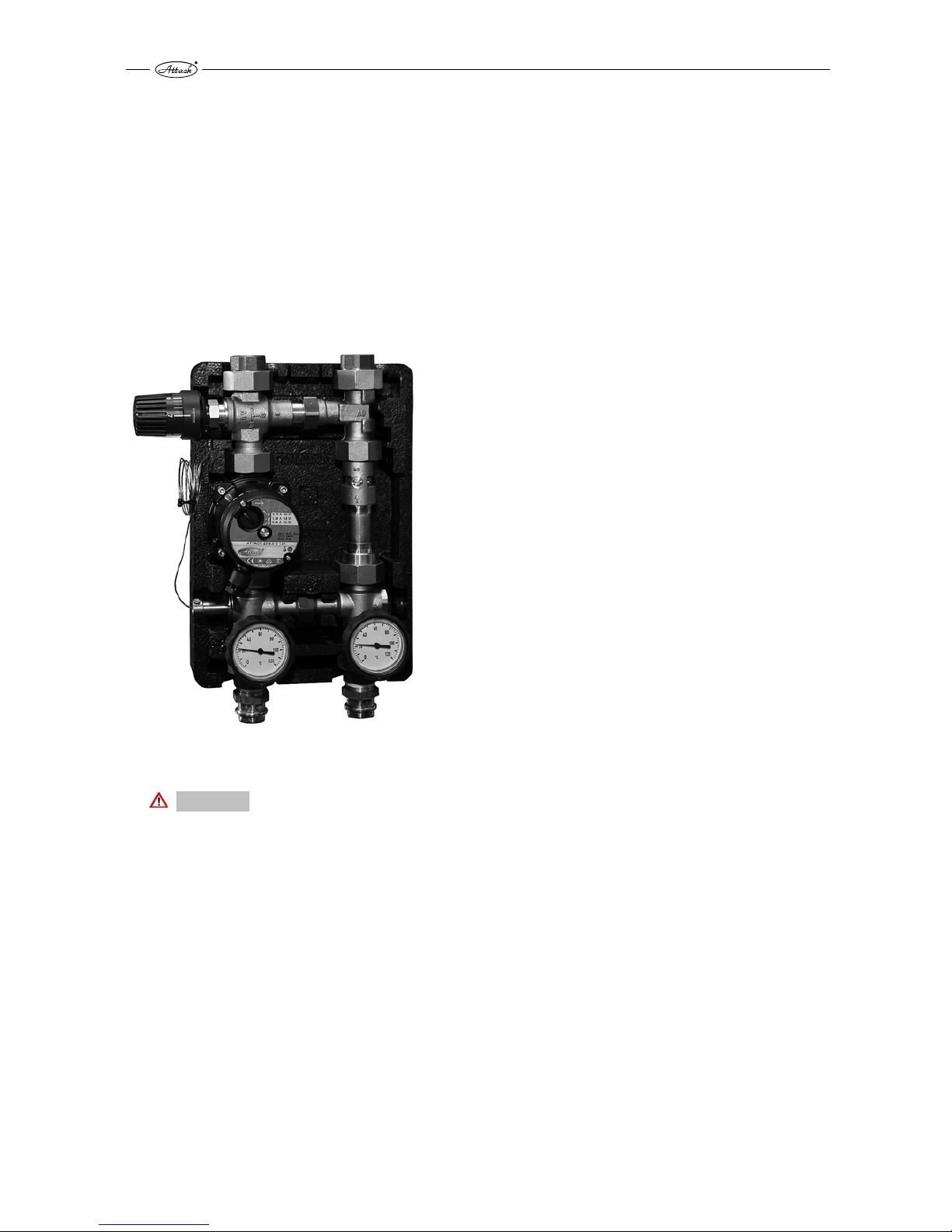

connection. It is suitable to use the mixing device Attack-Oventrop (Pic.3), which enables

creation of the separate boiler and heating circuit. Thereby is the boiler protected against

undercooling and the creation of water steam. Acids and tars in the boiler´s feeding chamber are

eliminated.

The Attack-Oventrop device keeps the constant temperature of the return heating water flowing

into the boiler over 65 °C by setting the thermostatic head to the level 5–6.When the individual

thermal regulation mixing valve is used, it is possible to control the temperature of the heating

water independently on the temperature of water in the boiler by setting the flap. The

temperature in the boiler has to be kept in the range of 80–90 °C.

Pic. 3 Device ATTACK Oventrop

CAUTION

If a protection device against corrosion is not intalled in the system or the device does not work

properly, it may lead to creation of an aggressive condensate and thereby boiler damage.

Protection against condensation must be used during boiler operation, otherwise the

warranty is void!

Page 13

13

2.4.2 CHIMNEY

Connection of the appliance to the chimney hole must be always done with in line with local

regulations and the appropriate chimney association. The chimney must generate sufficient

draught and take the flue gas out into the atmosphere under all operating conditions.

Correct dimensions of the chimney are important for correct boiler function, because the

burning, output and boiler life-time are influenced by the draught. The chimney draught directly

depends on its diameter, height and surface finish of the internal wall. It is not allowed to

connect any other appliance to the chimney, where the boiler is connected. Diameter of the

chimney must not be smaller than the connection part on the boiler. The chimney draught must

achieve the precribed values, but it cannot be too high, not to decrease the boiler output and

interrupt the burning (flame). If there is too strong draught, install the throttle flap into the

chimney hole between the boiler and the chimney.

Minimum dimensions of the chimneys:

20×20cm min. height 7 m

20 cm min. height 8 m

15×15 cm min. height 11 m

16 cm min. height 12 m

The exact chimney dimension is defined by the STN 73 42 10. The prescribed chimney draught is

given in the Technical parameters.

2.4.3 FLUE GAS CONNECTION OF THE BOILER

The flue connection must lead into the chimney hole. If it is not possible to connect the boiler to

the chimney hole directly, then the appropriate extension should be as short as possible, of up

to 1 m length, without any additional heating area and it should ascend in direction to the

chimney. It is suitable to insulate the flue connection to achieve the sufficient flue gas

temperature and to prevent the condensation in the chimney. The flue connection must be

mechanically tight (it should be mounted to the boiler and tightly fixed by screws) and tight

against the flue leakage. There must be possibility of the internal cleaning. The flue connections

must to lead through the foreign dwelling or commercial premisses. The internal diameter of the

flue connection must not taper in direction to the chimney. It is not suitable to use the elbow

connectors. There must be a „T“connection of the flue outlet to the chimney, to ensure that the

condensate must leak into the appropriate tray and not into the boiler.

The flue connection must comply with local regulations and only be conducted by authorised

and trained personel.

2.4.4 CONNECTION TO THE ELECTRICITY MAINS

The boiler is connected to the electricity mains of 230V/ 50Hz/16A by an electrical cord with

plug. In the case of need, the power supply cord of the M type must be replaced with an

adequate one by the service organization.

The appliance must be placed in such a way that enables the user to reach the connection plug.

The boiler must be connected to the 16A socket circuit by a circuit breaker (following the STN EN

60 335-1 + A11:1997).

Page 14

14

2.4.5 CONNECTION OF THE EXTERNAL PELLET TANK

The boiler is equipped by a motor for vacuum pellet feeding from an external tank. The external

tank can be placed nearby the boiler or in another room. The max. length of the suction tube is

10 m. The tank can be in the higher position, but not in the lower position than the boiler. It is

recommended to use the ATTACK vacuum tanks for the ATTACK WOOD&PELLET boiler. The

suction tubes ( 50 mm) and the vacuum tank can be ordered as accessories together with the

boiler.

Connection of the suction and blow out tube marked on the rear side boiler as „PELLET IN“and

„PELLET OUT“.

2.4.6 LEFT DOOR VERSION

There is an option of the ATTACK WOOD&PELLET boiler with the left door (door hinges on the

left side). It can be done before the boiler start-up or later, when the boiler is not in service. The

main, upper, middle and bottom door can be turned without need of the any additional tools.

Everything necessary is contained in the boiler. Use the standard tools: cross screwdriver, fork

key of 8–13 mm or nut, allan key of 6 mm, etc. The adjustment has to be done by a trained

worker.

2.4.7 CHOICE AND WAY OF CONNECTION OF THE CONTROL AND SAFETY

ELEMENTS

The boiler is delivered with the basic regulation and control equipment. This equipment must be

completed with other items (not delivered with the boiler) in line with local regulations, that

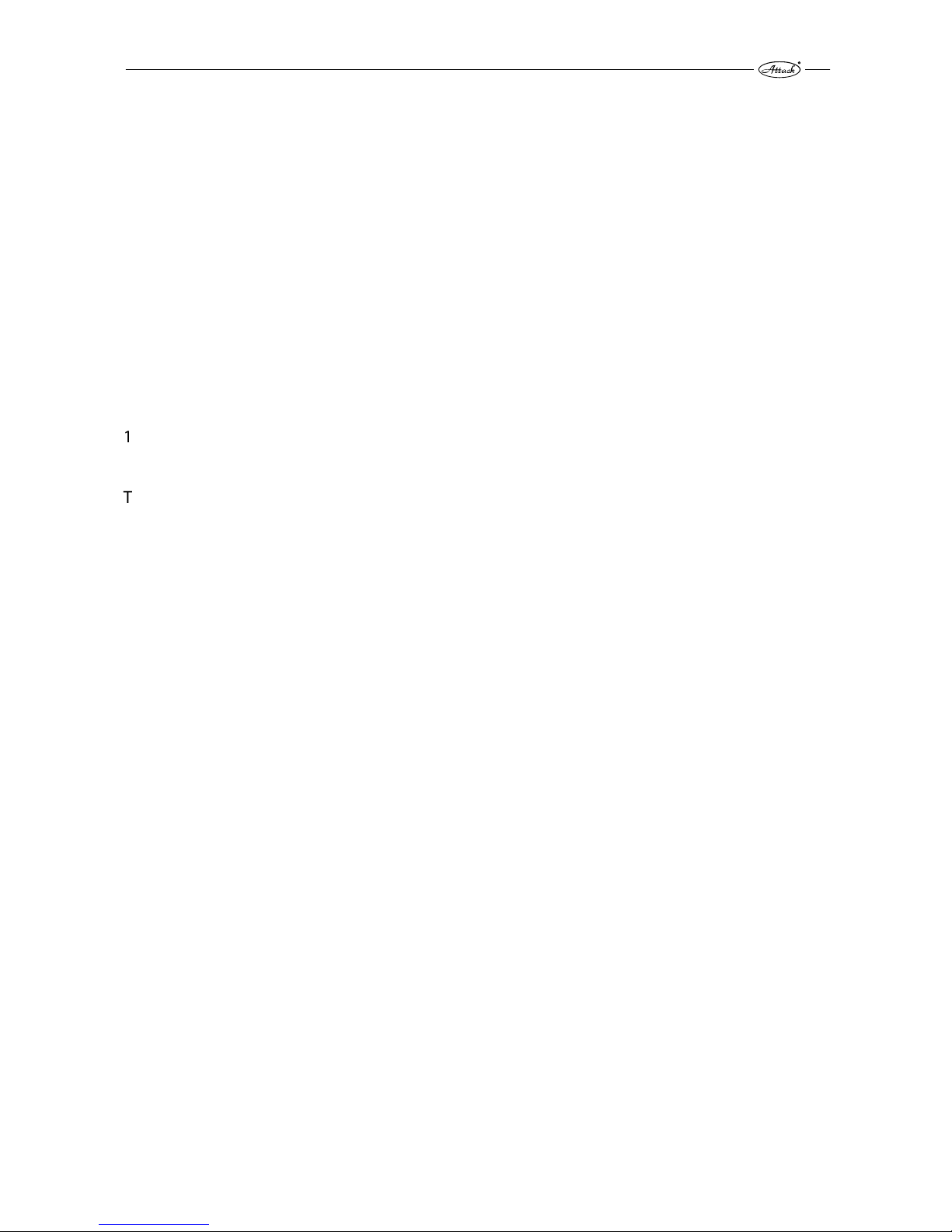

have to be installed in the heating circuit – particularly the following ones: safety valve (Pic. 4)

against exceeding the permitted pressure in the heating system (prescribed value: 2,5 bar), valve

of the boiler aftercooling loop to take the excessive heat from the boiler into the waste and

deaeration valve for the correct boiler function. The volume of the expanse vessel in the system

has to be defined by a designer of the heating system according to the system design and local

regulations. The electrical installation related to the additional boiler equipment has to be done

by a specialist and following the valid regulations.

DANGER

The heating system must be equipped with a safety valve against

exceeding the pressure in the boiler (2,5 bar). This valve should

be placed on the flow connection of the boiler, always installed in

front of the boiler closing valve (or in front of the Oventrop –

scheme 1). If the safety valve is not functional, the excessive

pressure will not be eliminated and it may cause an explosion

of the boiler.

Pic. 4 Safety valve against the overpressure

Page 15

15

Boiler protection against overheating

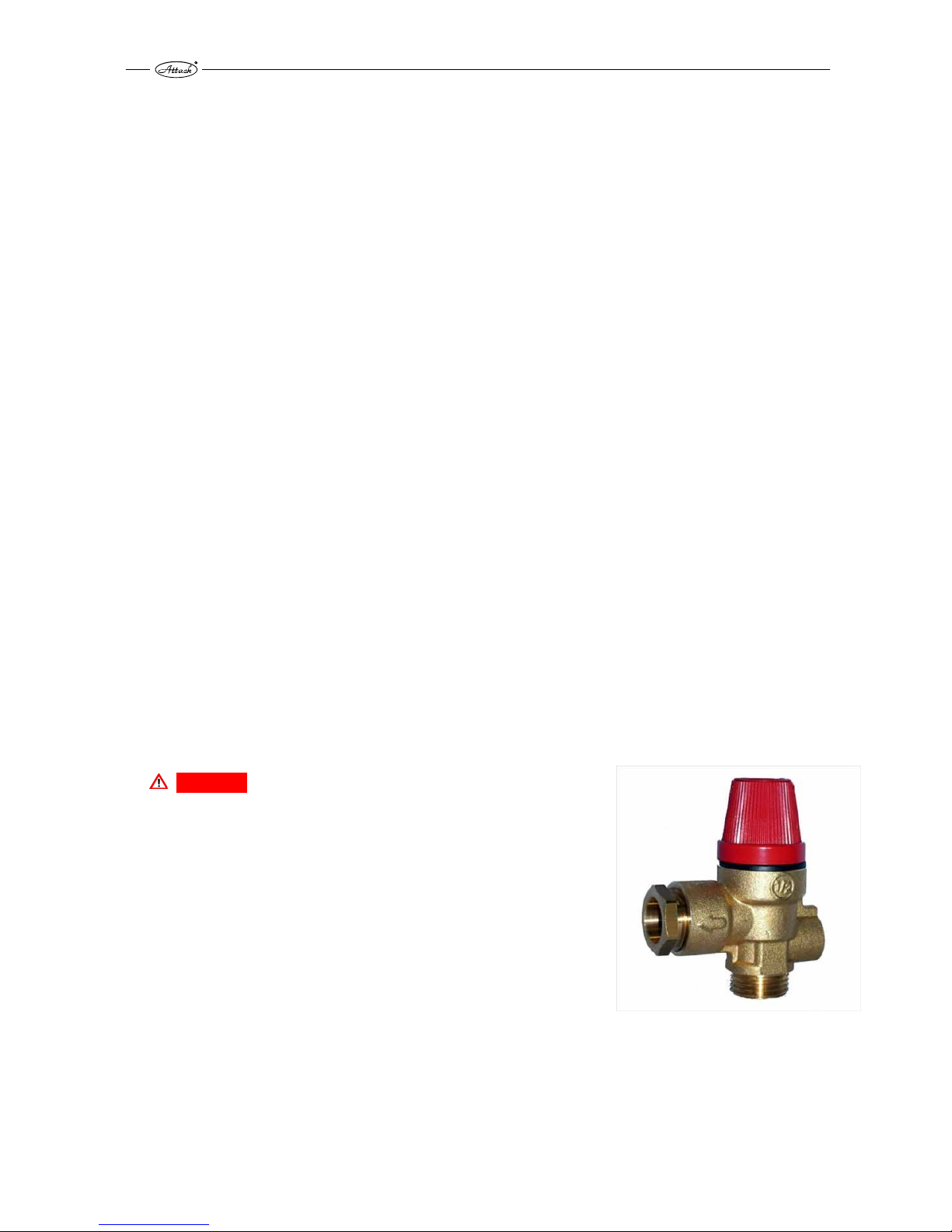

Every wood gasifying boiler must be fitted with a functional aftercooling circuit. The appropriate

valve ensuring this function can be ordered as an accessory. On the pic. 5 you can see the correct

installation of the valve of the aftercooling circuit.

DANGER

Following the norm EN303-5, the aftercooling circuit against overhetaing must not be

used for other purpose than the boiler protection against overheating.

Pic. 5 Connection of the thermostatic valve to the aftercooling loop

The valve must be permanently opened at the cold water inlet into the boiler aftercooling

circuit. The aftercooling circuit must be connected to the functional distribution of the cooling

water (e.g. to the distribution of the cold water in the water supply network) with the

temperature of 10–15 °C and operating overpressure of 2–6 bar, ensuring the safe operation

even by a power failure.

The thermostatic valve at the outlet of the aftercooling circuit with the sensor placed in the rear

side of the boiler protects the boiler in the following way. If temperature of the water in the

boiler exceeds 95 °C, the valve fills the aftercooling circuit with the water from the water supply

network to absorb the excessive heat. For the case that the boiler gets overheated and the

thermostatic valve is open, it is necessary to ensure the permanent outtake of the warm water

from the aftercooling circuit into the waste. Functionality of the aftercooling circuit and the

thermostatic valve can be checked manually, by the manual button of the thermostatic valve.

DANGER

If the circulation of the cooling water through the aftercooling circuit is not ensured, when

the thermostatic valve is open, there is a danger of the boiler damage! The warranty is not

valid in such a case.

Page 16

16

2.4.8 CONNECTION TO THE ACCUMULATION TANKS

The accumulation tanks are connected to be warmed and the accumulated heat is continually

used according to the requirements of the heated space. When the boiler operates at full output,

the accumulation tanks are heated to 80–90 °C. Usage of the accumulation tanks together with

the boiler ATTACK WOOD&PELLET brings several advantages. The main advantages are:

prolonged life of the boiler, cleaner operation, minimal creation of acids and condensate, smaller

frequency of the fuel loading, lower probability of the boiler overheating and fuel saving.

The recommended volume of the accumulation tank for the boiler ATTACK WOOD&PELLET 25 is

2.000 l (the min. volume is 1.250 l). By full load of the hardwood (i.e. 6 hours of operation at full

output of 25 kW), the boiler produces 150 kWh of energy. This is adequate to the loading of the

2.000 l accumulation tank from 20 °C to 80 °C, if there is no other energy consumption. Thereby

it is necessary to consider the boiler usage and operation as well, when you are choosing the

accumulation tank: by the accumulation tank of 2.000 l it is necessary to load the full chamber,

by 1.000 l there is half of the chamber to be loaded (if there is no energy outtake from the tank).

Example 1:

The external temperature of environment is -5 °C and the heat loss of the building is 10 kW. The

boiler output by full operation is 25 kW. There is an accumulation tank of 1.250 l, that is

discharged (its upper and bottom temperature is 20 °C). As the heating system (to cover the heat

loss) takes 10 kW from the accumulation tank and the boiler has the output of 25 kW, the

accumulation tank is heated by the remaining 15 kW. The output of 15 kW, by the full load of

hard wood and during the 6 hours of operation, creates the energy of 90 kWh. This energy heats

the accumulation tank from 20 °C to 62 °C despite of the fact, that the 10 kW are being taken.

This is a safe and economical operation, when the heat is not taken into the waste (the boiler

was cooled down by the aftercooling circuit). The boiler is able to cover the heat loss for 15

hours just by a single load of the wood.

Example 2:

The external temperature of the environment is +3 °C and the heat loss of the object by this

temperature is 5 kW. The boiler output at full operation is 25 kW. There is an accumulation tank

of 1.250 l, that is discharged (its upper and bottom temperature is 20 °C). As the heating system

(to cover the heat loss) takes 5 kW from the accumulation tank and the boiler has the output of

25 kW, the accumulation tank is heated by the remaining 20 kW. The output of 20 kW, by the full

load of hard wood and during the 6 hours of operation, creates the energy of 90 kWh. This

energy heats the accumulation tank from 20 °C to 82 °C despite of the fact, that the 10 kW are

being taken. This is a safe and economical operation, when the heat is not taken into the waste,

but if the heat loss was smaller, the boiler could get overheated, because it would not be cooled

down. In such case it would come to activation of the aftercooling circuit and the excessing heat

would be taken into the waste. In case of the constant heat loss of the object (5 kW), the charged

accumulation tank would cover the heat loss approximately for the next 24 h. It means that by

a single load of wood and under the above mentioned conditions it would be possible to cover

the heat loss of the building for 30 hours.

Thereby it is very important to load just the amount of wood, adequate for heating the

accumulation tank and not to overheat it, because the excessive heat would be taken into the

waste unused. Such operation would not be economical and the safety element, the

aftercooling circuit would have to be activated.

The bigger volume of the accumulation tank decreases the risk of overheating and the

frequency of loading the wood.

Page 17

17

Note:

The above mentioned fact is relevant by the operation with WOOD.

By the operation with PELLETS it is not relevant, as the boiler does not have to be

connected to the accumulation tank, if ONLY PELLETS would be used.

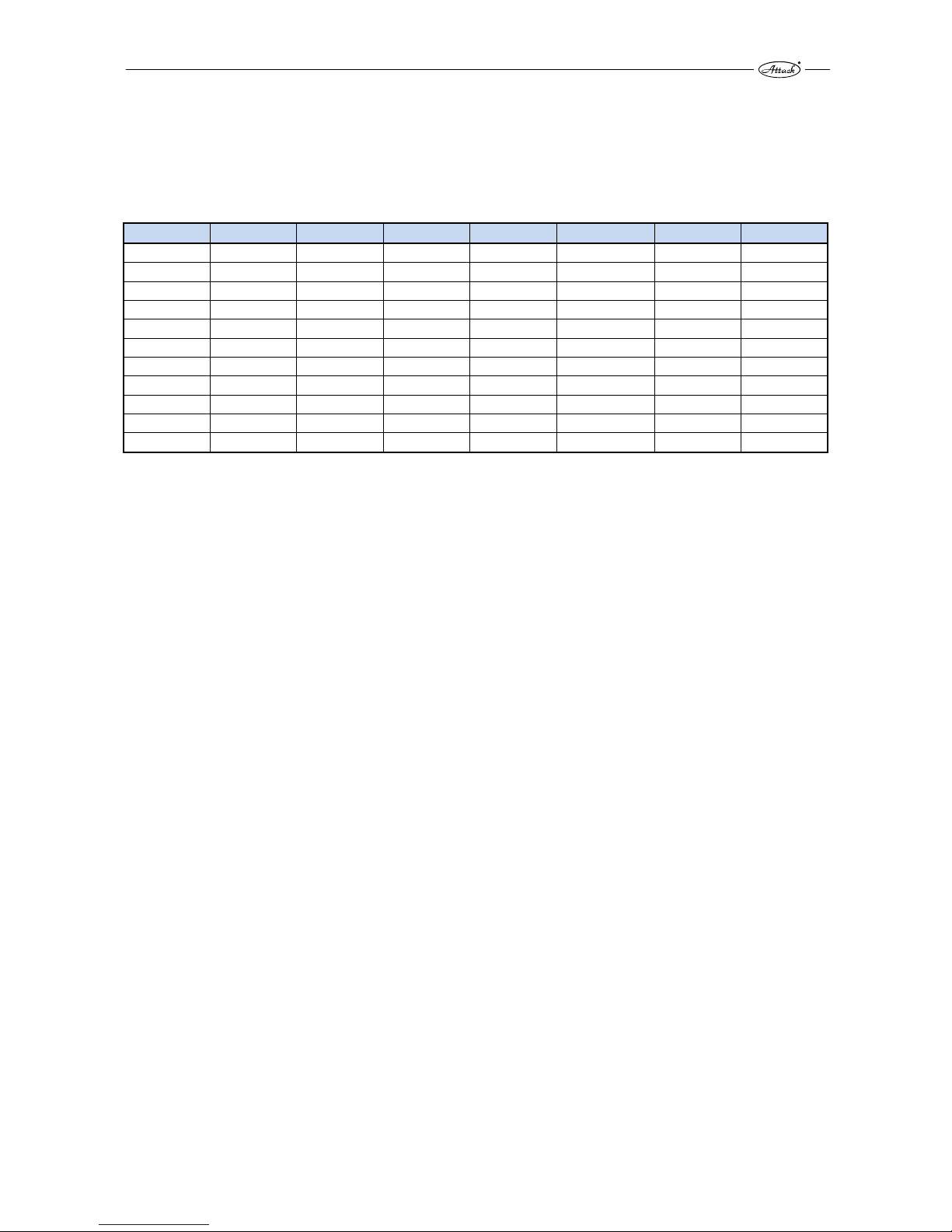

Standardly delivered accumulation tanks ATTACK*

AK AS HR HRS

TUV

TUVS S SS

300 300 — —

300

300 — —

400 400 — —

400

400 — —

500 500 600 600

500

500 500 500

800 800 800 800

600

600 800 800

1000 1000 1000 1000

800

800 1000 1000

1500 1500 1250 1250

1000

1000 1250 1250

2000 2000 1500 1500

1250

1250 1500 1500

2500 2500 2000 2000

1500

1500 2000 2000

3000 3000 — —

2000

2000 — —

4000 4000 — — — — — —

5000 5000 — — — — — —

AK – standard accumulation tank intended for the accumulation of energy of the heating water

AS –standard accumulation tank intended for the accumulation of energy of the heating water,

equipped with a coil for connection of the solar panels

HR – combined accumulation tank for accumulation of energy of the heating water and the

domestic hot water preparation

HRS – combined accumulation tank for accumulation of energy of the heating water and the

domestic hot water preparation, equipped with a coil for connection of the solar panels

* The volume necessary for the accumulation of energy can be covered by one or by several

accumulation tanks. The accumulation tanks can be connected together to create the sufficient

volume of water for accumulation. Thereby, if you decide for a volume of 2.000 l, it is possible to

use one tank of 2.000 l or two tanks of 1.000 l connected together. The required way of

connection is given in the chapter „Recommended hydraulic schemes of boiler connection“.

Page 18

18

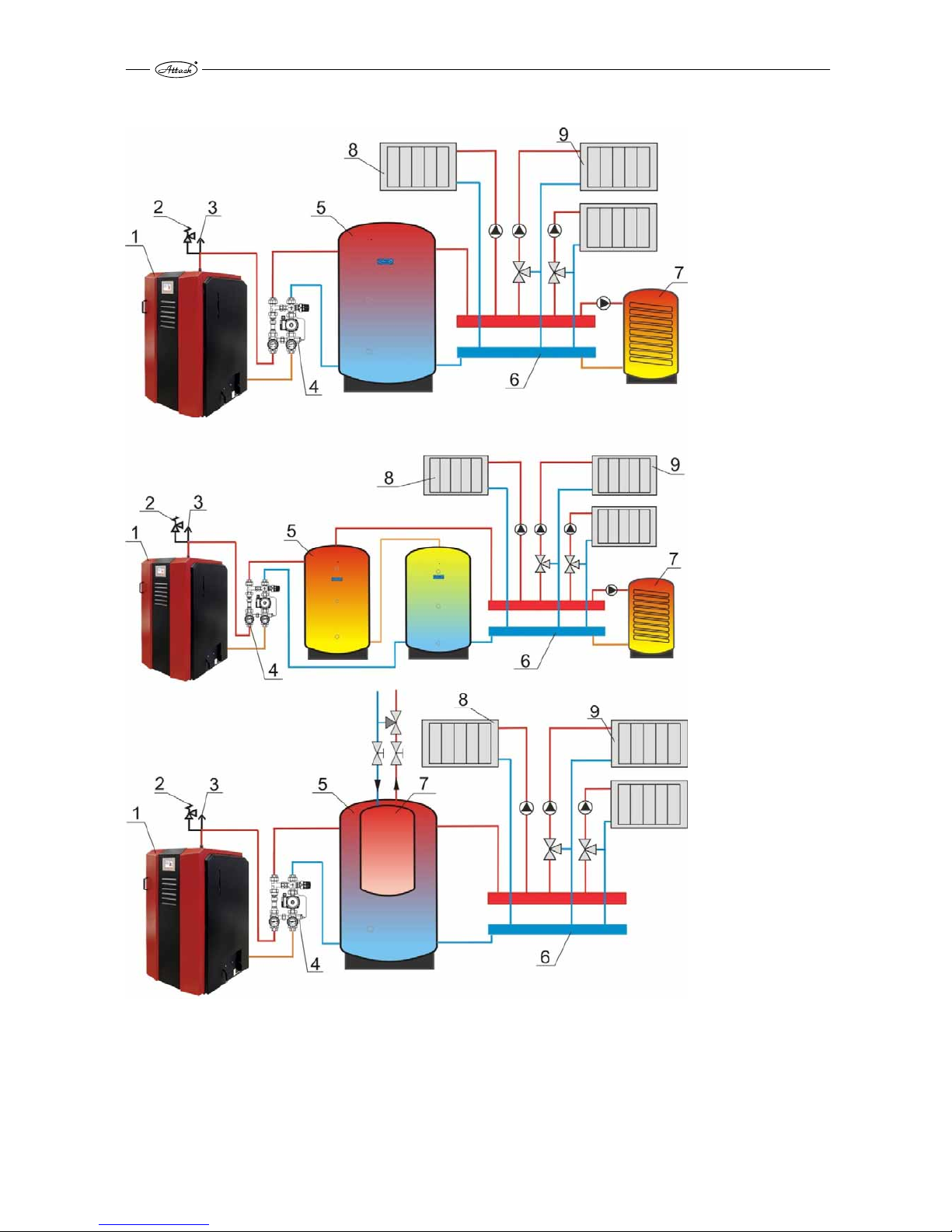

2.4.9 RECOMMENDED HYDRAULIC SCHEMES OF BOILER CONNECTION

Pic. 6. Hydraulic connection of the boiler into the heating system

1 – boiler, 2 – safety valve, 3 – deaeration valve, 4 – Attack Oventrop, 5 – accumulation tank

Attack AK or HR, 6 – distributor, 7 – tank for domestic hot water, 8 – direct heating circuit, 9 –

mixing heating circuit

Page 19

19

3. BOILER START-UP

Boiler preparation for operation

The boiler must be assembled, installed and started-up only by an installer certified for the

installation of the heating appliances. Before starting the boiler, it is necessary to check, if the

hydraulic system is filled with water by the correct pressure, deaerated and without decreasing

pressure of the heating water. Check tightness and strength of the flue construction and

functionality of the aftercooling circuit by pressing the valve manually. The boiler must be

operated in conformity with the instructions given in this manual to achieve the quality function.

CAUTION

There may come be condensation and condensate leakage by the first firing of the boiler. This

will disappear after the the first burn. It is a natural effect.

WARNING

It is necessary to be more careful, if the boiler was out of order for a longer period (in summer or

in case of failure). The pump could get blocked (and the boiler could get overheated and the

aftercooling circuit would be started), or the water could leak out of the system. Check the

correct pump function and the pressure of water in the heating system!

See the chapter „BOILER CONTROL“about putting the boiler into operation (heating up, loading,

filling the tank with pellets, etc.).

4. WARRANTY CONDITIONS

The warranty for the boiler is valid only if the boiler installation was done by a person certified

under the valid norms and following the instruction manual. The company who performed the

installation must completely and clearly fill the form. If the boiler is damaged by an inexpert

installation, the company who installed it has to carry the costs for repair, only use approved and

properly trained installers.

The user has to respect the instructions for operation and maintenance given in the manual. If

the instructions for operation and maintenance are not kept, the use of the boiler is

unauthorised and careless or incorrect fuel is used, the warranty is not valid and the customer

has to carry the costs by damage.

The warranty is valid only in the case, that the boiler was installed and operated in the

following way:

together with device for the boiler protection against condensation ATTACK-OVENTROP

with prescribed fuel given in the chapter „FUEL“

with the thermostatic valve installed against the boiler overheating

with the chimney of appropriate parameters (diameter, height) given in the chapter

„CHIMNEY“

the boiler was regularly and sufficiently cleaned as it is given in the chapter „CLEANING“

the boiler was operated following the instructions given in this manual and not in the

different way.

The warranty is valid for a complete boiler ATTACK WOOD&PELLET, except of wearing boiler

parts that are usually worn, and therefore they cannot be included into the warranty:

glass sealing cords of the door and ash tray.

refractory nozzle

Page 20

20

5. TECHNICAL PARAMETERS

Parameter Units AWP 25

Nominal output by wood kW 25

Nominal output by pellets kW 30

Range of the output by wood kW 12,5 ÷ 25

Range of the output by pellets kW 9 ÷ 30

Heat-exchange area m² 2,18

Volume of the feeding chamber l 160

Volume of the integrated pellet tank l 48

Dimension of the feeding door mm 230×445

Prescribed chimney draught Pa 23

Max. operation overpressure of water kPa 250

Pressure loss of water (T 10 K)

kPa 2,1

Pressure loss of water (T 20 K)

kPa 0,6

Boiler weight kg 860

Diameter of the flue outlet mm 150

Boiler height "A" mm 1620

Boiler width "B" mm 940

Boiler depth "C" mm 1220

Length of the feeding chamber "D" mm 580

Diameter of the flow connection " G 6/4"

Diameter of the return connection " G 6/4"

Grade of protection IP 21

El. input by a nominal output W 90

El. input by a minimal output W 32

El. input in the standby mode W < 15

Efficiency of the wood boiler % 90,5

Efficiency of the pellet boiler % 90,4

Boiler class EN 303-5:2012 — 5

Flue gas temperature by the nominal output by wood °C 156

Flue gas temperature by the min. output by wood °C 92

Flue gas temperature by the nominal output by pellets °C 130

Flue gas temperature by the min. output by pellets °C 86

Flue gas flow by nominal output kg/s 0,019

Flue gas flow by min. output kg/s 0,005

Max. noise level dB 65

Wood consumption by nominal output kg/h 7,2

Pellet consumption by nominal output kg/h 6,8

Max. length of wood logs mm 560

Time of operation by max output by wood h 6

Volume of water in the boiler l 126

Min. volume of accumulation tank l 1250

Connection voltage V/Hz/A 230/50/16

The producer, ATTACK, s.r.o. reserves right of technical changes of the products without any previous

announcement!

Page 21

21

Pic. 7 Description of particular boiler parts

1 – boiler body, 2 – main door, 3 – cover of the air inlets into the wood gasifying section, 4 –

display cooling, 5 – touch display, 6 – cover of electronics, 7 – flow connection, 8 – aftercooling

circuit, 9 – cover of turbulators, 10 – lambda probe, 11 – flue connection, 12 – exhaust fan, 13 –

return connection

426

312

G 6/4"

G 1/2" G1/2"

1

2

5

9

1

0

0

50

50

1

6

4

1

6

0

4

1

6

4

G

6

/

4

"

1

5

0

8

611

776

1125

150

1

6

0

4

568

904

951

3

0

0

1207

13

12

11

7

8

9

10

1

2

4

5

6

7

8

5.1 DIMENSIONS OF THE BOILER

ATTACK WOOD&PELLET 25

Page 22

22

6. REGULATION OF THE BOILER AND THE HEATING SYSTEM

6.1 IN GENERAL

DANGER

If you tun the main switch off during the boiler operation, it has no regulation. Then, any

dangerous states may cause the serious health or property damage. Always let the fuel

completely burn out and the boiler cool down before turning the main switch off!

WARNING

Opening the upper and middle door of the feeding chamber or the bottom door of the

combustion chamber during the operation may cause accumulation of the flammable gases and

their explosion, this may cause serious damage to health or property. It is forbidden to open

any door behind the main door during the operation!

CAUTION

6.2 EMERGENCY ACTIONS

Boiler overheating

If the boiler is in WOOD mode and it starts to overheat and the functionality of the aftercooling

loop fails from any reason, do the following:

Do not open any door of the boiler!

Turn the boiler off by the STOP button and confirm the red emergency message „I really

want to stop the boiler“

Start all the pumps, heating circuits, open all the 3-way valves (attention, the max.

temperature by the floor heating is 40 °C), to ensure the max. heat energy outtake from the

boiler

Leave the boiler room and close the door.

Open the thermostatic heads on all radiators (the heating season does not make

a difference), eventually let the domestic hot water flow - run hot water tap, if the boiler is

connected for the D.H.W. preparation as well

Contact your installer

DANGER

Never turn the main switch off, nor disconnect the boiler from the electricity mains, when

the boiler gets overheated!!

Page 23

23

6.3 PREPARATION FOR THE OPERATION, FILLING THE INTEGRATED

PELLET TANK

CAUTION

Check, that the hoses of the vacuum suction are connected correctly and airtight, before

starting the pellet suction into the integrated tank.

Before starting the operation of the boiler ATTACK WOOD&PELLET for pellets, it is necessary to

suck the pellets into the integrated tank manually. Use the TEST mode, by clicking on the

„vacuum suction“. Watch the level of the pellets sucked through the side control opening or in

the information menu of the PELLET SENSOR. The sufficient amount of pellets in the integrated

tank is visible through the full pellet indicator and by the green light of the PELLET SENSOR.

After this, the pellets will be sucked automatically. In the case of error you can always fill the tank

by the TEST mode.

6.4 DESCRIPTION OF THE SAFETY DEVICES

Description of the main regulation of the boiler (Pic. 8):

1. Emergency thermostat with reset – boiler protection against overheating (when the

temperature of 110 °C is exceeded, all the electrical devices in the boiler are disconnected,

except of the circulation pump; when the temperature of the water in the boiler decreases

under 85 °C, it is necessary to demount the cover and to manually press the thermostat

button.

2. Main fuse – boiler protection against the electrical short circuit

3. Main switch – start/stop of the boiler. Unplug the whole boiler from the electrical mains.

4. Combined thermo manometer. Actual information about the temperature and pressure,

independent of power supply.

Pic. 8 Description of the main regulation of the boiler

Page 24

24

6.5 BOILER CONTROL AND OPERATION

The combustion process in the boiler ATTACK WOOD&PELLET is controlled by the modern

electronics, equipped with software operating on the basis of the latest knowledge in the field of

the biomass burning. There is an advanced touch screen, displaying multiple information to

enable the quick identification of the state of the boiler and its parameters. On the pic. 9 there is

the basic data display.

Pic. 9 The basic data display

1 – boiler temperature, 2 – flue gas temperature, 3 – actual fan output, 4 – operation mode, 5 –

boiler state, 6 – state of regulation, 7 – records of errors and error messages, 8 – time remaining

until the cleaning starts (of the burner, of the exchanger), 9 – setting of parameters (basic,

service ones), 10 – general settings, 11 – information, 12 – indicator of the actual pellet level, 13 –

language, 14 – actual boiler output (relevant for wood and pellets)

The regulation of the WOOD burning is ensured by the Lambda probe together with the

controlled rotations of the exhaust fan, controlled inlet of the primary and the secondary air,

measuring the temperature of the boiler and flue gas.

The regulation of the PELLETS burning and feeding is ensured by the integrated vacuum feeder

(pellet suction from the main tank into the built-in integrated tank), sensor of the pellet

presence, turnstile auger, ignition coil, photocell, fan with controlled rotations and by the

automatic cleaning.

11

13

14

Page 25

25

6.5.1 DESCRIPTION OF THE MAIN CONTROL MODES

Pic. 10 The main control modes

The way of the boiler operation can be changed in dependence on the operation mode in

the following way (Pic.10):

HEATING OFF – select this mode, if the boiler is going to be unused for a longer period. It is

usually in summer, if the boiler is not used to prepare the domestic hot water. Then, the boiler

will be switched into the STANDBY mode.

TESTMODE – under this mode you can test the functionality of particular devices in the boiler

(fans, grate cleaning, coil, vacuum suction, turbulator cleaning, pump, etc.).

AUTOMATIC – under this mode is boiler working automatically and it is regulated by the boiler

temperature. Always, when the temperature decreases under the adjusted temperature

decreased by hysteresis, the boiler is started (if the boiler works under the mode WOOD, it will

not be started automatically, as it is possible only under the COMBI mode).

TIME – this mode determines the particular time intervals, when the boiler is going to work (this

is related only to the COMBI mode for the PELLET burning). The time mode does not influence

the boiler operation for WOOD, because the purpose of such operation is to keep the output of

100 % and to produce as much energy as possible to be stored in an accumulation tank.

PUFFER/BOILER – this mode serves to control the discharging of the accumulation tank. The

external module is required.

EXTERNAL START– this mode works under the room thermostat. If you connect the room

thermostat into the electronics and select this mode, then boiler in the COMBI mode, operating

for PELLETS, will work according to the requirement for heat from the room thermostat.

Page 26

26

6.5.2 DESCRIPTION OF THE CONTROL MODES, RELATION BETWEEN THE

MODE WOOD AND COMBI

The ATTACK WOOD&PELLET boiler belongs to the combined boilers indeed, without for user

interaction with the boiler after the wood is burned out, to start the pellet burning process. The

boiler automatically detects, that the wood is burned out and if there is a requirement for

heating, the pellet combustion is started.

The boiler can work under two control modes: the WOOD and the COMBI. The WOOD mode is

especially intended for the wood burning and the combined boiler works as the standard wood

gasifying boiler. After starting the WOOD mode, the boiler controls the wood combustion

process, which is stopped, when the wood burns out. In this mode is the accumulation tank

charged to use the heat during the next day and night, while the pellets are not being burned.

This mode is advantageous within the periods like autumn and spring, because the heat loss of

the building can be covered by the heat from the accumulation tank for a couple of hours or

days. The WOOD mode cannot be interrupted anytime – it is necessary to wait, until the wood

burns out. Then it is possible to get into the COMBI mode.

Under the COMBI mode you can select the fuel for the start of operation (WOOD or PELLETS). If

you select the WOOD operation, the boiler controls the process of wood gasification and the

process of pellet burning is started, when the wood burns out and there is a requirement for

heating.

Under the COMBI mode, the boiler starts the process of pellet burning and it works as a standard

pellet boiler. If the boiler currently burns pellets, this operation can be anytime interrupted (it

takes approximately 5 min, until the pellets are burned out) and the wood combustion can start.

As it is given above, the opposite process is not possible.

DANGER

Under the COMBI mode, when you are starting the operation with pellets, always check that

there is no wood or other fuel in the feeding chamber. Otherwise, you may cause the

uncontrolled burning and there is a risk of the serious injury or property damage.

6.5.3 OPERATION WITH WOOD

Use this mode, if:

You wish to operate the boiler as a WOOD gasifying boiler. When the WOOD is burned out in the

feeding chamber, the boiler is stopped (the pellet part will not be automatically started to work).

The ways to light the boiler up:

The manual mode of lighting up the wood is used, if the boiler was heating during the day

before or if there are cinders remained in the feeding chamber.

The automatic mode of lighting up the wood can be used after the boiler is cleaned and

there are no cinders to make it easier. The automatic mode of lighting up the wood needs

more electrical energy than the manual mode and it requires the sufficient amount of pellets

in the integrated tank.

Page 27

27

6.5.3.1 MANUAL LIGHT UP OF WOOD

1. Turn the main switch on, if it has not been done yet.

2. Open the main door and the door of the feeding chamber. Check the level of ash in the

feeding chamber. If it exceeds 50 mm, clean the feeding chamber – it is not necessary to

clean the feeding chamber every day, if the ash still contains the solid cinders. The cinders

that remain in the ash contain the usable energy and they enable faster lighting up the

wood. The feeding chamber is cleaned through the middle door by the fire hook (See the

chapter 14. Boiler cleaning).

3. Open the door of the feeding chamber and clean it. It is the best to use a fire hook and to

remove the ash ash in direction to you. Always clean the combustion chamber before

heating the boiler up!

CAUTION

If the combustion chamber is not cleaned properly, its volume is rapidly decreased and it may

cause imperfect burning and dangerous states. Never operate the boiler with the uncleaned

combustion chamber!

4. Put the paper or cardboard (the best material), rolled into tubes (Pic. 11). If there are cinders

on the bottom of the feeding chamber, put the paper or the cardboard on them.

Pic. 11 Preparation for lighting up the wood

5. Put the wood of a smaller diameter (chips of 20×20 mm) on the cardboard (pic. 12) to make

the process of lighting up faster and more stable. Put the casual wood on the fine wood in

the way enabling the free air flow. Try to use the feeding chamber in the best way to load as

much wood as possible. Load the full chamber (Pic. 13).

Page 28

28

Pic. 12 The way to prepare the wood for lighting up

Pic. 13 Loading the full chamber

6. Close the upper and the bottom door, manually light up through the middle door only.

7. Enter the WOOD mode via display and confirm it by click (Pic. 14).

Page 29

29

Pic. 14 Starting the WOOD mode.

8. After selecting the wood operation mode, activate the lighting up process by the START

button (Pic.15).

Pic. 15 Activation of the wood operation mode

Page 30

30

9. There are two options of lighting up under the WOOD operation mode (Pic. 16) – the manual

and the automatic way. Under this mode, select the manual ignition. The exhaust fan will

start to work and the boiler will be prepared for lighting up.

Pic. 16 Lighting up the wood in the wood gasification part:

1 – manual ignition (by wood chips, newspaper, cardboard or a liquid fire starter 2 – automatic

ignition, 3- period of lighting the wood up by the pellet part, 4 – delayed start, 5 – output of the

pellet burner, while the wood is being ignited

10. Light the paper or the cardboard through the middle door by a lighter (Pic. 17). Keep the

middle door partly open, until the cardboard and the wood chips light up (approximately for

5 min) and the chimney gets the draught. Afterwards, close the door. This way of heating is

very quick and it enables to heat the boiler up without any smoke. Through the pivot control

opening on the bottom door you can watch the flame created by the process of gasification.

Close the main door after verifying, that the flame was created and the boiler correctly

gasifies.

Pic. 17 Manual light-up of the wood

Page 31

31

6.5.3.2 AUTOMATIC LIGHT-UP OF WOOD

The wood can be automatically ignited by pellets, with no need to prepare the lighting-up with

paper, nor cardboard. However, it is necessary to use the wood of small diameter (wood chips of

20×20 mm).

CAUTION

The automatic light-up of the wood is a complicated process and the first trial requires the

attention of the customer. It is necessary to select the parameters of the automatic light-up

carefully, to avoid the uncontrolled wood burning in the feeding chamber of the boiler. Do not

use the automatic light-up of wood, if the parameters of your chimney do not achieve the

values given in this manual. The problems with the automatic wood ignition may occur due to

the cold chimney or in summer, when there is a chimney draught naturally decreased. Thereby it

is necessary to consider the automatic wood ignition carefully in summer and by the cold

chimney.

Procedure of starting up the automatic wood ignition:

1. Repeat the procedure under the 6.5.2.1, points 1–3.

2. Put the wood of small diameter (wood chips of 20×20 mm) on the bottom of the chamber to

make the process of heating-up faster and more stable. Put the ordinary wood on the fine

wood in the way enabling the free air flow. In the ¼ of height should be the wood laid crosswise to make a tunel to light the wood up from the pellet part (Pic. 18). Try to use the loading

chamber in the best way to feed as much wood as possible. Load the full chamber.

Pic. 18 Loading the wood into the chamber by the automatic light –up

3. Close all door (upper, middle, bottom, main ones).

7. Use display to enter into the WOOD mode following the chapter 6.5.2.1, point 7 and 8.

8. After the “start options” are displayed, select the parameters to start the automatic WOOD

light up (Pic. 19). The “starting time” defines how long the flame from the pellet part will be

igniting the wood. The “start in” defines the time delay of start. Here you can set, that the

boiler will not start the automatic light up immediately, but with a time delay given as the

“start in” parameter. The value of the output for the wood ignition by the pellet part must be

considered carefully. Too high output may cause an inappropriate emission of the gas

substances from wood and to leak of the smoke from the loading chamber into the primary

air of the boiler. Thereby we recommend to try the automatic wood light up by the lower

output as first (approximately 30 %).

Page 32

32

Pic. 19 Parameters of the automatic wood light up

2 – start of the automatic wood light up, 3 – starting time, 4 – start in, 5 – output

Page 33

33

6.5.4 COMBINED OPERATION MODE

The combined operation mode is a fully automatic mode that is able to operate the WOOD

burning or the PELLET burning, but not both at the same time.

DANGER

The combined mode serves for operation with either of the fuel types – the WOOD or the

PELLETS. Never try to burn WOOD and PELLETS at once, because it may cause uncontrolled

burning, a health hazard or property damage.

Use this mode, if:

1. You are going to load the full loading chamber with wood and you wish to cover the

requirement for heat with the pellet burning, after the wood burns out.

2. You wish to operate the boiler with PELLETS only.

Start the COMBI mode through the mode options (Pic. 20) by a double-click on the COMBI.

Pic. 20 Start of the COMBI mode

The combined mode can start with burning the wood or burning the pellets. It is not possible to

burn both fuels (i.e. the wood and the pellets) at the same time.

Page 34

34

After selecting the COMBI mode it is necessary to choose the fuel that will be burned as first.

(Pic. 21).

Pic. 21 Selection of the fuel to start the COMBI mode

If the WOOD is in the loading chamber, the PELLET mode must not be started!

If the boiler was started with wood, pellets can be used after it burns out. The operation with

wood cannot be interrupted by the operation with pellets. The boiler struggles to burn all wood

before it starts to burn pellets. The operation with pellets can be anytime interrupted (the pellets

must automatically burn down in the burner) and the wood can be loaded and burned.

DANGER

It is very dangerous to load the WOOD and to start the PELLET burning at the same time. It

may cause an uncontrolled burning, health hazard or damage of health or property.

CAUTION

ATTENTION! It is not allowed to put any flammable materials or objects into the loading

chamber of the boiler during the operation with pellets. The pellet operation is stopped in

15 seconds, if the feeding door is opened.

Page 35

35

7. DISPLAYING INFORMATION

During and also out of the boiler operation it is possible to read the information from the touch

display about the state of the boiler and particular devices (ventilators, heating coils, flaps, etc.).

By pressing the “i” button you get into the menu (Pic. 22). There are three pages in the

information menu.

The first page – the “Information 1” – gives the basic information about the boiler state: boiler,

temperature, flue gas temperature, actual value of the oxygen in the flue gas, presence of the

flame in the combustion chamber – the photocell, cycle of the pellet feeding and duration of the

feeding in one cycle) (Pic. 22)

Pic. 22 Display with the basic information, page 1

The second page – the “Information 2” – displays the actual output of the exhaust ventilator and

the burner ventilator, actual rotations of the burner ventilator, position of the primary and

secondary flap serving to control the wood gasification process (Pic. 23).

Page 36

36

Pic. 23 Display with the basic information, page 2

The third page – the “Information 3” – displays the state of start or stop of the particular outputs

(if they work or not) and of the particular inputs (if they are connected or disconnected). It is

well-readable, whether the door of the loading chamber is closed properly, whether the

integrated pellet tank is fully loaded, whether the emergency thermostat is connected or

disconnected, etc. (Pic.24).

Pic. 24 Display with the basic information, page 3

Page 37

37

8. SETTING THE PARAMETERS

The ATTACK WOOD&PELLET boiler enables to set the parameters in two levels. The first level is

intended for the end user to set the basic parameters of the boiler (the boiler temperature, flue

gas temperature, temperature of the pump start, etc.).

To set the advanced parameters that control the boiler operation it is necessary to enter the

second level by using the access code. Thereby it is protected against access of the unauthorized

person that could negatively affect the boiler operation.

CAUTION

Only the authorized technician can change the parameters at the advanced level. The

incorrectly given parameters may cause the wrong boiler operation or boiler damage. Any

parameter changes must be consulted with your installer or with the producer.

8.1 LEVEL OF SETTING THE BASIC PARAMETERS

It is always possible to change the basic parameters without need to enter the code. The access

to the basic parameters is under the button 9 (pic. 25). The basic parameters are on the pages 1

and 2.

Pic. 25 Setting the basic parameters for the end user

Decription of the basic parameters:

Boiler temperature – enables to set the temperature that should be achieved by boiler. This

parameter is related to the both modes – the WOOD and the COMBI.

Difference temperature Start (Pellet)- the boiler temperature must be decreased by this value

to start the boiler operation again. This is related to the PELLET mode.

Page 38

38

Difference temperature Stop (Pellet) – the pellet mode is stopped, when this temperature is

achieved. The burner starts to decrease the output after achieving the boiler temperature, until

this limit is achieved and the burner is stopped.

Exhaust temperature Stop (Woodbrick) – if the flue gas temperature under the WOOD mode

is lower than this value during the period of 15 min., or the oxygen content in the flue gas is

higher than 14 % during the period of 15 min., the boiler stops the wood gasifying part and

indicates the fuel shortage. If you set this temperature to higher value, you can influence the

amount of cinders remaining in the loading chamber of the boiler and they can ensure easier

heat-up. The higher is the temperature, the more cinders remain.

Start boiler pump – temperature to start the pump for accumulation tank.

Difference temperature Start (Woodbrick) – the excessive boiler temperature must be

decreased for this value to start the boiler operation again. This is related to the WOOD mode.

Pic. 26. Setting the basic parameters for the end user

Difference temperature Stop (Woodbrick) – the wood gasification part (i.e. is stopped) by this

temperature. The boiler will modulate its output between the adjusted temperature and the

temperature increased by this value.

Exchanger cleaning interval – this time interval defines the frequency of the automatic

exchanger cleaning by turbulators. Only the time of the boiler operation is considered.

Max. combustion time – this is the max. time of the boiler operation. When this time expires,

the burner is automatically cleaned. This time serves to shorten the burner operation period

with the pellets of lower quality.

Page 39

39

8.2 LEVEL OF SETTING THE ADVANCED PARAMETERS

Settings of the advanced parameters are available only with the access code. Click on the upper

blue batten to get the keyboard for entering the code. There is the “MAIN PAGE” text (Pic. 27).

After entering the code, the inaccessible parameters become adjustable. If you need to change

the advanced parameters, contact your installer or producer to give you the access code.

Pic. 27 Access to the advanced parameters

The advanced parameters of the boiler become adjustable after enetering the access code of the

service technician.

Page 40

40

Pic. 28 Advanced parameters, page 2

Description of the advanved parameters (Pic. 28):

Ignit during filling – starts to heat the coil by ignition, while the pellets are fed into the burner.

It reduces the time of the pellet ignition.

Maximum ignition time – defines the max. acceptable time, when the heating coil and the

ventilator work to ignite the pellets. If the pellets are not ignited during this time, the ignition

process will repeat or the error will be indicated.

Starting feeding time 1 – the amount of pellets that are loaded into the burner for the first

time.

Starting feeding time 2 – the amount of pellets that are loaded into the burner, if it does not

come to ignition within the max. ignition time.

Page 41

41

Pic. 29 Description of the advanced parameters, page 3

Photocell Fire – after exceeding this value, the boiler detects the pellet ignition in the burner

Photocell Fire off – if the value of the flame intensity in the burner decreases under this value,

the boiler detects the flame loss in the burner and thereby the burn down. This is considered as

an error.

Burn-On time after ignition – this is the time necessary for creation of the stable layer in the

burner that enables an increase in output

Burn-Off time – this is the max. time after which will the burner be cleaned, despite of the fact

that the pellets did not burn out.

Exhaust fan regulation max. power (Pellet) – output of the exhaust fan by the max. output of

the burner

Exhaust fan regulation min. power (Pellet) – output of the exhaust fan by the min. output of

the burner

Page 42

42

Pic. 30 Advanced parameters, page 4

Exhaust fan max. power – the max. output of the exhaust fan

Exhaust fan min. power – the min. output of the exhaust fan

Pellet fan during ignition – the output of the ventilator by the pellet ignition

Pellet fan during Starting – the output of the ventilator during the stable burning after ignition

Pellet fan max. power – the max. output of the burner fan

Pellet fan min. power – the min. output of the burner fan

Exchanger cleaning work time – within this period will be the exchanger tubes cleaned by

turbulators

Page 43

43

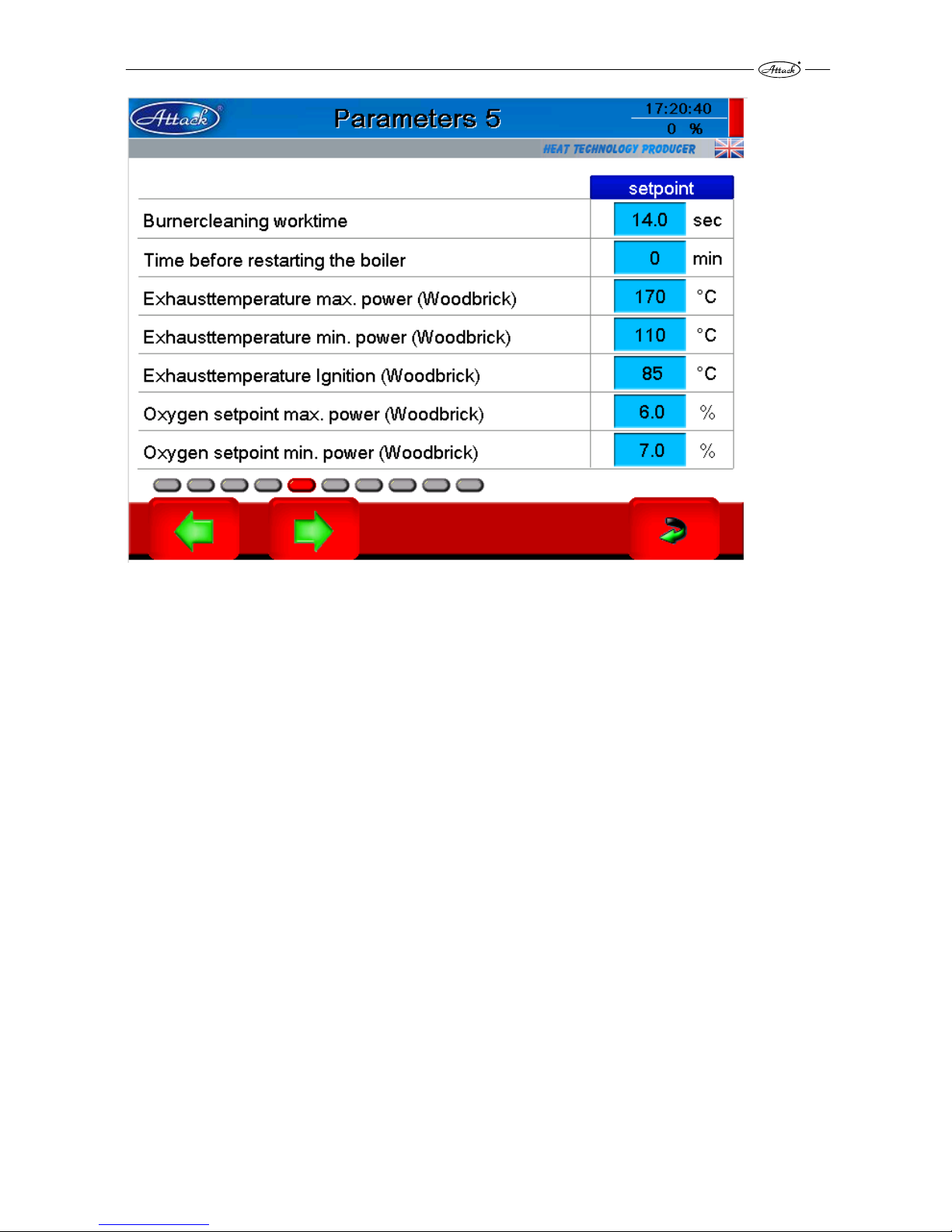

Pic. 31 Advanced parameters, page 5

Burner cleaning work time – time of moving the grate of the burner in and out to be cleaned

Time before restarting the boiler – when the wood or pellets burnm out, it is possible to set

the time, after which will the boiler start to work again.

Exhaust temperature max. power (Wood brick) – the boiler has to achieve this flue gas

temperature during its max. output by wood burning

Exhaust temperature max. power (Wood brick) – the boiler has to achieve this flue gas

temperature during its min. output by wood burning

Exhaust temperature ignition (Wood bricks) – after achieving this flue gas temperature the

boiler considers the wood ignition as successful

Oxygen setpoint max. power (Wood bricks) – the boiler will control the burning process

according to this value for the max. output

Oxygen setpoint min. power (Wood bricks) – the boiler will control the burning process

according to this value for the min. output

Page 44

44

Pic. 32 Advanced parameters, Page 6

Feeding cycle at 100 % power – the cycle of the pellet feeding into the burner

Feeding time at 100 % power – cycle time of pellets loaded into the burner

Difference temp. power regulation (Wood brick)– when the actual temperature decreases in

comparison with the adjusted temperature for this value, the boiler is started again.

Exhaust temperature regulation start – by this flue gas temperature will the boiler start to

control the wood burning process by the Lambda probe.

Maximum power (Pellet) – the max. output of the burner operation

Page 45

45

Pic. 33 Advanced parameters, page 7

Primary – airflap max. open– max. opening of the primary flap

Secondary – airflap max. open– max. opening of the secondary flap

Secondary airflap ignition (Wood brick) – position of the flap during wood ignition

Secondary airflap pre-heating (Wood brick) – position of the secondary flap for the phase of

the wood pre-heating

Ignition max. time (Woodbrick) –the flue gas temperature must achieve this value of flue gas

during wood ignition. If this temperature is not reached, the boiler is stopped and the fuel

shortage is indicated.

Page 46

46

Pic. 34 Advanced parameters, page 8

Exhaust Fan Autom. Ignition (Wood) – the fan output during the automatic wood light up by

pellets

Primary Air Flap Autom. Ignition (Wood) – position of the primary flap during the wood light

ignition by pellets

Secondary Air Flap Autom. Ignition (Wood) – position of the secondary flap during the wood

light up by pellets

Power regulator worktime – time of conversion of the PID control model

Power regulator P – part – a proportional part of the PID control model

Power regulator D – part - difference part of the PID control model

Power regulator I – part – integral part of the PID control model

Page 47

47

Pic. 35 Advanced parameters, page 9

Pump delay – time of the pump over run, when the temperature gets back under the safety

temperature of the pump start

Pump safety temperature – when this temperature is be exceeded, the pump will run

Turbine max runtime – time limit for the max. period of operation of the vacuum motor

Turbine rest time – time to cool down the vacuum motor

Number of suction retries – max. number of repeating the suction of the vacuum motor into

the integrated tank

Automatic pellets suction – option to turn the automatic pellet feeding off

Size of pellet tank – given in seconds (during this period the auger feeder is able to empty the

integrated pellet tank)

Pic. 36 Advanced parameters, page 10

Ignition retry numbers – if the pellet ignition in the burner fails, it is possible to repeat it again.

The number of trials can be set.

Page 48

48

9. SPECIAL SETTINGS AND INFORMATION

The following special settings can be made in the boiler ATTACK WOOD&PELLET (Pic. 37)

Pic. 37 The special settings are displayed after pressing the key sign.

Set Time, Set Date – it is possible to set the date and time. If the boiler is disconnected from the

electricity mains or the power supply fails, the date and time are in the memory for

approximately 3 days.

Screen saver – defines the time, when the screen saver is activated.

Program version – information about the actual program version

PLC Serial No. – the serial number of electronics

Alarms messages – enables the sound notification of errors and notifications of the boiler.

Automatic quit – if it comes to errors like a fail of ignition, flame loss or failure of the pellet feed,

they can be automatically erased and the boiler can be started again. This is possible only by

small errors. The problems like the damaged boiler temperature sensor or damaged flue gas

temperature sensor cannot be automatically erased. The time, after which will be the error

erased can be defined by the “after” parameter.

Page 49

49

10. INTERNET CONNECTION

The boiler can be connected to the internet by the LAN and it can be regulated through the

remote control. The control is available via the local network and via internet as well. It is

necessary to have the IP address from the internet provider to have an access from internet.

The LAN cable has to be connected in the following way:

1. Prepare the LAN cable of appropriate length. The length of the cable in the boiler is

approximately 2,6 m.

2. Disconnect the boiler from the electricity mains.

3. Undo the rear covering.

4. Undo the cover of electronics.

5. Undo the internal zinc plate on the upper door to get an access to the touch display.

6. Lead the cable from the rear side of the right covering, around the electronics and through