COMPLETE PRODUCT CATALOG | AE100

PROVEN

PROTECTION

BY DESIGN

ATTABOX INDUSTRIAL ENCLOSURES

FIBERGLASS AND POLYCARBONATE

ELECTRICAL, INDUSTRIAL

AND INSTRUMENTATION ENCLOSURES

Table of Contents

Introduction 1

General Info 2

ModRight™ 10

Heartland™ 12

Commander™ 18

BantamBox™ 32

Viking™ 42

DuraShield™ 54

Endurance™ 60

Freedom™ 64

Centurion™ 82

MachoBox™ 90

Triton™ 94

Accessories 102

Technical Info 118

Part No. Index 150

ATTABOX INDUSTRIAL ENCLOSURES

Proven Protection By Design

The Reason You Buy Enclosures: Protection.

The Reason You Should Buy AttaBox Enclosures: Proven Protection.

Many factors might influence your purchase of an enclosure, but all relate to the ultimate need for an

enclosure to reliably protect whatever you put inside.

Whether your enclosure is intended to house an electrical connection, or a control panel, or sensitive

measurement systems, the demand for uncompromised protection against diverse forces—including

moisture, dust and dirt, ultraviolet radiation, temperature extremes, and impact—is the number one

reason to put your trust in ATTABOX.

Get the protection you paid for.

AttaBox Enclosures: Designed to Match

the “Right” Enclosure to the Exacting

erformance and Protection Needs of

P

Your Specific Job.

Every application is different.

Not every enclosure is best for every use.

AttaBox offers you freedom-of-product-choice with a wide-ranging selection of non-metallic enclosures

featuring ten full product lines encompassing over 150 different sizes and 4 configurations.

AttaBox produces enclosure families representing the varying benefits of polycarbonate, fiberglass,

and polyester, ensuring breadth and depth in your ability to source and achieve protection for every

on-the-job need.

1

General Information

Standards

2

General Info

Application

The products in this catalog are designed for electrical and

electronic enclosure applications in commercial or industrial

locations that are classified as non-hazardous. Information on

the classification of hazardous and non-hazardous locations

appears at the end of this section.

The enclosure products in this publication should be applied,

installed and used only by qualified engineers, technicians or

electricians knowledgeable of the standards, laws, regulations

and ordinances associated with the respective application.

The information in this section has been condensed from

several references and is provided for guidance in selecting

the appropriate enclosure for an application. The original

reference must be consulted for detailed information.

Industry Standards

The following information is provided with permission of

the respective organizations to assist in the selection of an

enclosure:

Enclosure Ratings

What are Ratings?

As a way of standardizing enclosure performance,

organizations like NEMA, UL, CSA and IEC use rating systems to

identify an enclosure’s ability to resist external environmental

influences. These influences include falling dirt or liquids,

hose directed water to complete submersion and each

are broken out by the Type rating. While these ratings are

intended to assist you in your enclosure selection there are

differences among the organizations.

North American Standards Organizations

In North America, NEMA, UL and CSA are the more common

recognized standards organizations. Ratings between these

organizations are similar in description and performance. UL

and CSA both required enclosure testing that is conducted

in certified labs. They also conduct site evaluations or

field audits to ensure manufacturer adheres to prescribed

manufacturing methods and material specifications within the

approved UL/CSA files. NEMA publishes a standard for ratings

and testing, but does not test or list enclosures.

International Standards Organizations

IEC does not require independent testing, similar to NEMA, but

there are differences in the interpretation between the two

organizations. For example, under the IEC standards for each

level of ingress protection (IP), a certain amount of water is

allowed to enter the enclosure. Unlike UL or CSA, water-tight

means simply that. Any amount of water ingress regardless of

size or amount is considered a failure to the specification.

IEC 60529 IP ratings do not specify construction or degrees or

protection, while NEMA type ratings do specify construction

and performance requirements for most conditions. Because

of these differences in tests and evaluations, the IEC

enclosure ratings cannot be directly translated with NEMA

Enclosure Type ratings.

Reference Documents and Sources

National Electrical Manufacturers Association (NEMA)

1300 North 17th ST, Suite 1847

Rosslyn, VA 22209

www.nema.org

NEMA Standards Publication 250, Enclosures for Electrical Equipment (1000

Volts Maximum) and NEMA Standards Publication ICS6, Enclosures for

Industrial Controls and Systems.

Canadian Standards Association (CSA)

178 Rexdale Blvd.

Etobicoke, Ontario, Canada M9W 1R3

www.csa.ca

CSA Standard C22.2 No. 14 Industrial Control Equipment for Use in Ordinary

(Non-Hazardous) Locations; CSA Standard C22.2 No. 40 Cut-Out, Junction

and Pull Boxes; and CSA Standard 22.2 No. 94 Special Purpose Enclosures

Underwriters Laboratories (UL)

333 Pfingsten Road

Northbrook, IL 60062-2096

www.ul.com

Underwriters Laboratories of Canada

7 Crouse Road

Scarborough, Ontario, Canada M1R 3A9

UL 50 Enclosures for Electrical Equipment; UL 94 Tests for Flammability

of Plastic Materials for Parts in Devices and Appliances; UL 508 Industrial

Control Equipment; UL 870 Wireways, Auxiliary Gutters and Associated

Fittings; and UL 746C Polymeric Materials - Use in Electrical Equipment

Evaluations

International Electrotechnical Commission (IEC)

1 Rue de Varembei

CH-1211

Geneva 20, Switzerland

www.iec.ch

IEC 529 Classification of Degrees of Protection Provided by Enclosures

IEC 204 Electrical Equipment of Industrial Machines

American National Standards Institute (ANSI)

1430 Broadway

New York, NY 10018

www.ansi.org

ANSI Z55.1 Gray Finishes for Industrial Apparatus and Equipment

National Fire Protection Association (NFPA)

Batterymarch Park

Quincy, MA 02269

www.nfpa.org

NFPA 70 National Electric Code

NFPA 79 Electrical Standard for Industrial Machinery

2

General Information | North American Standards

NEMA, UL, and CSA Ratings

2

NEMA, UL, and CSA are standard writing organizations

commonly recognized in North America. Their ratings are

based on similar application descriptions and expected

performance. UL and CSA both require enclosure testing by

qualified evaluators. They also send site inspectors to make

Enclosure Types Non-Hazardous Location

ENCLOSURE

RATING

Type 1

Type 2

Type 3

Type 3R

Type 4

Type 4X

Type 6

NATIONAL ELECTRICAL MANUFACTURERS ASSOCIATION

(NEMA STANDARD250) AND ELECTRICAL AND

ELECTRONIC MFG. ASSOCIATION OF CANADA (EEMAC)

Enclosures are intended for indoor use primarily to

provide a degree of protection against contact with the

enclosed equipment or locations where unusual service

conditions do not exist.

Enclosures are intended for indoor use primarily to

provide a degree of protection against limited amounts

of falling water and dirt.

Enclosures are intended for outdoor use primarily to

provide a degree of protection against windblown dust,

rain, and sleet; undamaged by the formation of ice on

the enclosure.

Enclosures are intended for outdoor use primarily to

provide a degree of protection against falling rain sleet;

undamaged by the formation of ice on the enclosure.

Enclosures are intended for indoor or outdoor use

primarily to provide a degree of protection against

windblown dust and rain, splashing water, and hosedirected water; undamaged by the formation of ice on

the enclosure.

Enclosures are intended for indoor or outdoor use

primarily to provide a degree of protection against

corrosion, windblown dust and rain, splashing water, and

hose-directed water; undamaged by the formation of ice

on the enclosure.

Enclosures are intended for use indoors or

outdoors where occasional submersion is encountered.

Limited depth; undamaged by the formation of ice on

the enclosure.

UNDERWRITERS LABORATORIES INC.

(UL 50, UL50E AND UL 508)

Indoor use primarily to provide protection against contact

with the enclosed equipment and against a limited

amount of falling dirt.

Indoor use to provide a degree of protection against

limited amounts of falling water and dirt.

Outdoor use to provide a degree of protection against

windblown dust and windblown rain;

undamaged by the formation of ice on the enclosure.

Outdoor use to provide a degree of protection against

falling rain; undamaged by the formation of ice on

the enclosure.

Either indoor or outdoor use to provide a degree of

protection against falling rain, splashing water, and

hose-directed water; undamaged by the formation

of ice on the enclosure.

Either indoor or outdoor use to provide a degree of

protection against falling rain, splashing water, and hosedirected water; undamaged by the formation of ice on the

enclosure; resists corrosion.

Indoor or outdoor use to provide a degree of protection

against entry of water during temporary submersion at a

at a limited depth; undamaged by the external formation

of ice on the enclosure.

sure a manufacturer adheres to prescribed manufacturing

methods and material specifications. NEMA, on the other hand,

does not require independent testing and leaves compliance

completely up to the manufacturer.

CANADIAN STANDARDS ASSOCIATION

(STANDARD C22.2 NO. 94)

General purpose enclosure. Protects against

accidental contact with live parts.

Indoor use to provide a degree of protection against

dripping and light splashing of noncorrosive liquids and falling dirt.

Indoor or outdoor use; provides a degree of

protection against rain, snow, and windblown dust;

undamaged by the external formation of ice on the

enclosure.

Indoor or outdoor use; provides a degree of protection

against rain and snow; undamaged by the external

formation of ice on the enclosure.

Indoor or outdoor use; provides a degree of protection

against rain, snow, windblown dust, splashing and hosedirected water; undamaged by the formation of ice on the

enclosure.

Indoor or outdoor use; provides a degree of protection

against rain, snow, windblown dust, splashing and hosedirected water; undamaged by the external formation of

ice on the enclosure; resists corrosion.

Indoor or outdoor use; provides a degree of protection

against the entry of water during temporary submersion at

a limited depth. Undamaged by the external formation of

ice on the enclosure; resists corrosion.

General Info

Enclosures constructed for either indoor or outdoor

use to provide a degree of protection to personnel

against access to hazardous parts; to provide a degree of

protection of the equipment inside the enclosure against

Type 6P

Type 12

Type 13

This material is reproduced with permission from NEMA.

The preceding descriptions, however, are not intended to be

complete representations of National Electrical Manufacturers

Association standards for enclosures or those of the Electrical

and Electronic Manufacturers Association of Canada.

ingress of solid foreign objects (falling dirt); to provide a

degree of protection with respect to harmful effects on

the equipment due to the ingress of water (hose directed

water and the entry of water during prolonged submersion

at a limited depth); that provides an additional level of

protection against corrosion and that will be undamaged

by the external formation of ice on the enclosure.

Enclosures are intended for indoor use primarily to

provide a degree of protection against dust, falling dirt,

and dripping noncorrosive liquids.

Enclosures are intended for indoor use primarily to

provide a degree of protection against dust, spraying

of water, oil, and noncorrosive coolant.

Indoor or outdoor use primarily to provide a degree of

protection against hose-directed water, the entry of water

during prolonged submersion at a limited depth and

damage from external ice formation.

Indoor use to provide a degree of protection against

dust, dirt, fiber flyings, dripping water, and external

condensation of noncorrosive liquids.

Indoor use to provide a degree of protection against lint,

dust seepage, external condensation and spraying of

water, oil, and noncorrosive liquids.

This material is reproduced with permission from Underwriters

Laboratories Inc. Enclosures for Electrical Equipment, UL 50,

Copyright 1995 and Industrial Control Equipment, UL 508,

Copyright 1996 by Underwriters Laboratories Inc.

Underwriters Laboratories Inc. (UL) shall not be responsible

for the use of or reliance upon a UL Standard by anyone.

UL shall not incur any obligation or liability damages, including

consequential damages, arising out of or connection with the

use, interpretation of, or reliance upon a UL Standard.

Indoor or outdoor use primarily to provide a degree of

protection against hose-directed water, the entry of water

during prolonged submersion at a limited depth and

damage from external ice formation.

Indoor use; provides a degree of protection against

circulating dust, lint, fibers, and flyings; dripping and

light splashing of non-corrosive liquids; not provided

with knockouts.

Indoor use; provides a degree of protection against

circulating dust, lint, fibers, and flyings; seepage and

spraying of non-corrosive liquids, including oils

and coolants.

This material is reproduced with permission from the Canadian

Standards Association.

3

General Information

NA Standards continued and International Standards (IP Code)

2

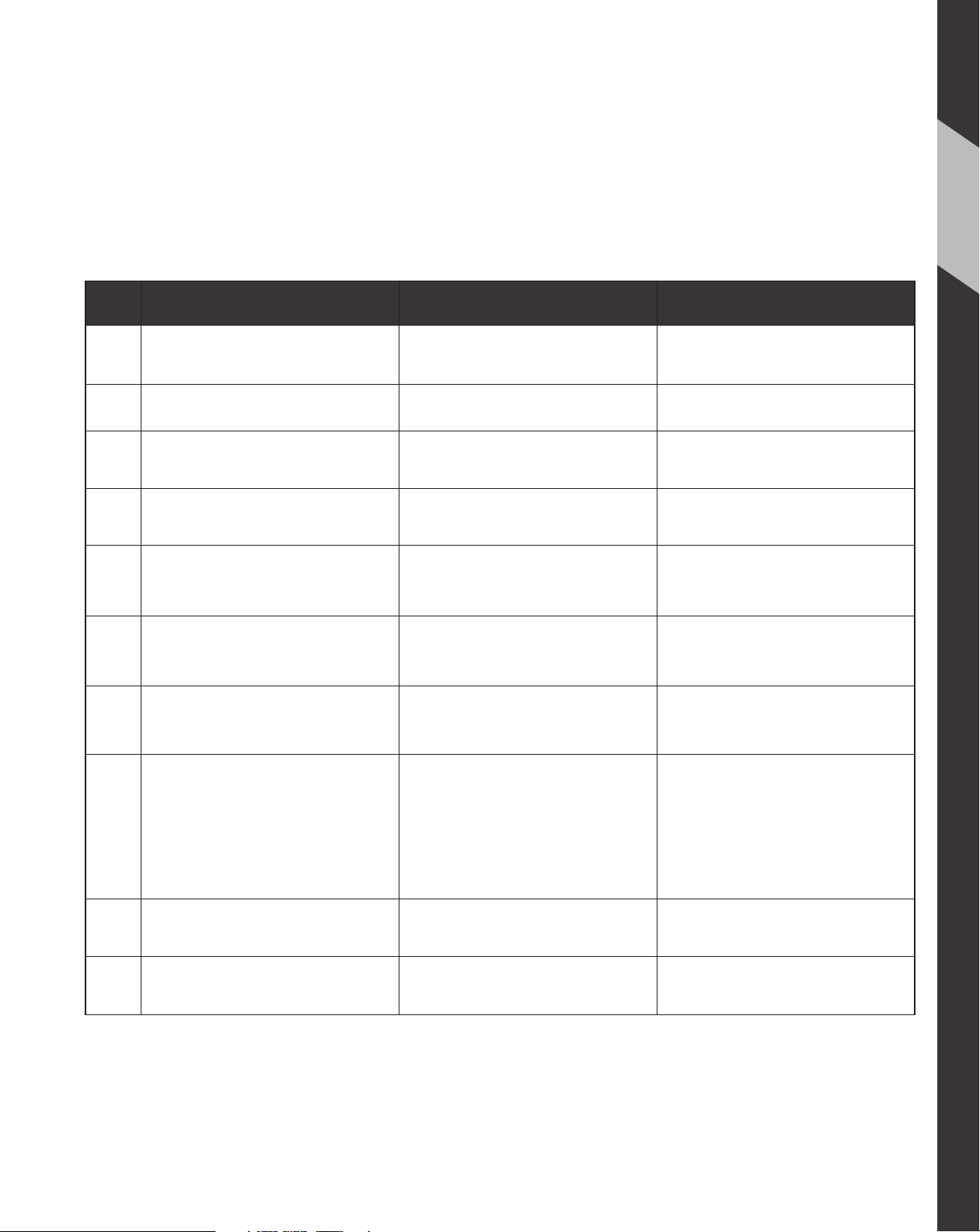

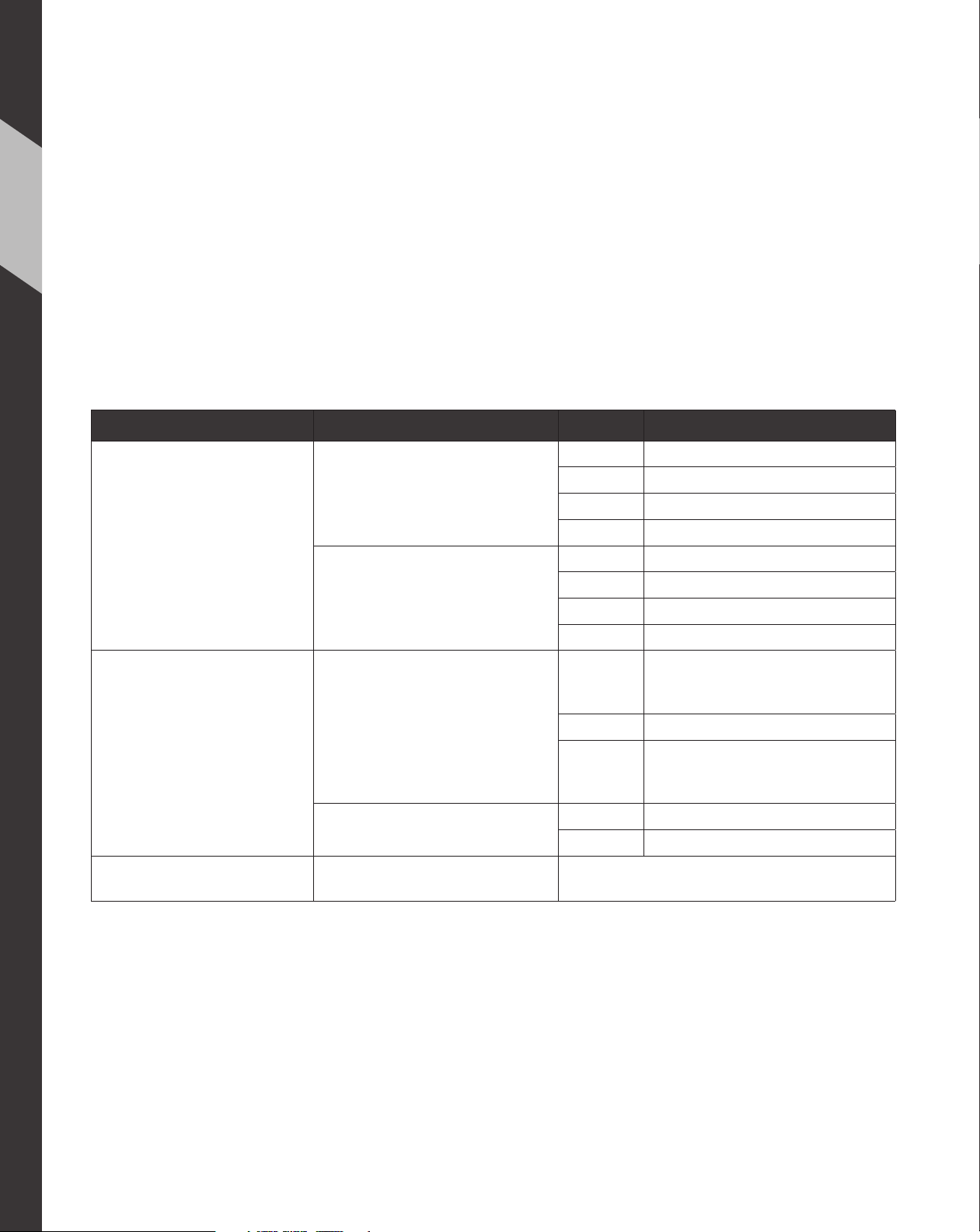

Comparison of Enclosure Types for Non-hazardous Locations

General Info

Provides a Degree of Protection Against the Type of Enclosure

Following Environmental Conditions

1 3 3R 4 4X 6 6P 12 13

Incidental Contact with Enclosed Equipment

Indoor

Outdoor

Falling Dirt

Dripping and Light Splashing Liquids

Rain, Sleet*, Snow

Circulating Dust, Lint, Fibers and Flyings

Settling Dust, Lint, Fibers and Flyings

External Ice*

Hosedown and Splashing Water

Oil and Coolant Seepage

Oil and Coolant Spraying and Splashing

Corrosive Agents

Occasional Temporary Submersion

Occasional Prolonged Submersion

*External operating mechanisms are not required to be operable when the enclosure is ice covered

A Brief Comparison Of NEMA – “Enclosure for Electrical

Equipment (1000 Volts Maximum)” and IEC 60529 – “Degrees

of Protection Provided By Enclosures (IP Code)”

This publication is intended to provide a brief comparison

and explanation of some of the basic differences between

NEMAStandard 250, Enclosures for Electrical Equipment (1000

Volts maximum) and IEC Standard 60529, Degrees of Protection

provided by Enclosures (IP Code). For a detailed comparison

of the differences between the NEMA 250 and IEC 60529

performance specifications, please refer to the respective

documents.

What is IEC 60529 and what does it cover?

IEC 60529 is a standard developed through the International

Electrotechnical Commission (IEC) that describes a system for

classifying the degrees of protection provided by an enclosure.

An “enclosure” as used in 60529 is “a part providing protection

of equipment against certain external influences and in any

direction protection against direct contact”.

What is not covered by IEC 60529?

IEC 60529 is NOT a “product standard” and does not cover

enclosure requirements other than the “degree of protection”

provided. For instance IEC 60529 does not specify the corrosion

protection and other environmental operating requirements

and tests defined in NEMA 250.

What does “degree of protection” mean in IEC 60529?

“Degree of protection” is a term used in the standard

to describe:

1. The protection of persons against access to hazardous

parts inside the enclosure.

2. The protection of the equipment inside the enclosure

against ingress of solid foreign objects.

3. The protection of the equipment inside the enclosure

against harmful effects due to the ingress of water.

• • • • • • • • •

• • • • • • • • •

• • • • • •

• • • • • • • • •

• • • • • • • •

• • • • • •

• • • • • • •

• • • • • • •

• • • • • •

• • • •

• •

• •

• •

•

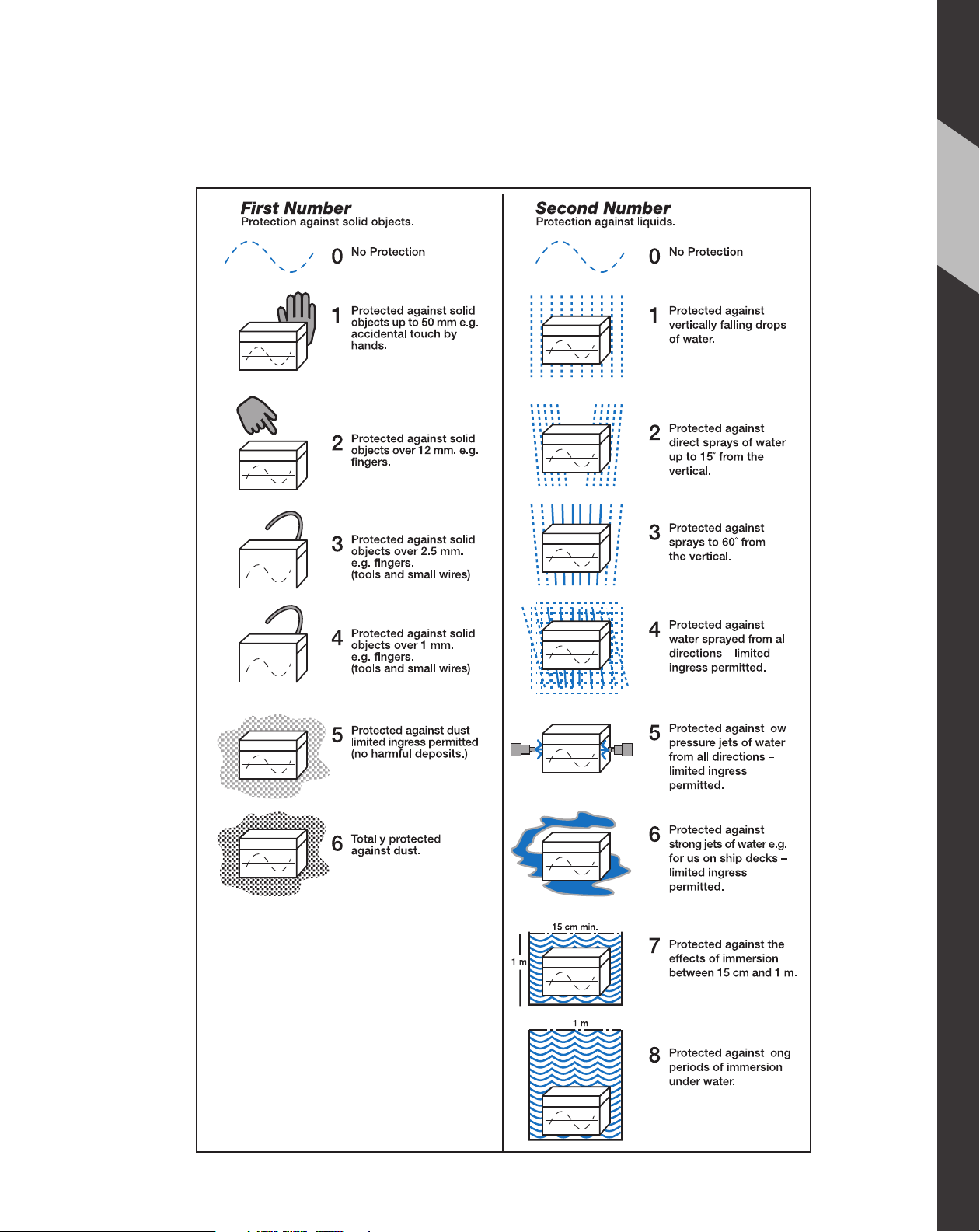

What is an “IP Code”?

The IP Code is a designation that indicates the level, or

amount, of the protection. The IPCode designation consists of

the letters IP (International Protection or Ingress Protection)

followed by two numerals. In some instances there may

be an optional letter or third digit representing protection

against access and mechanical impacts. These two items are

beyond the scope of this reference. Please consult additional

resources as required.

What does the first numeral of an IP Code indicate?

The first characteristic numeral indicates the degree of

protection provided by the enclosure with respect to persons

having access to hazardous parts and with respect to solid

foreign objects entering the enclosure. See Table 1.

What does the second numeral of an IP Code indicate?

The second numeral indicates the degree of protection

provided by the enclosure with respect to the harmful ingress

of water. See Table 2.

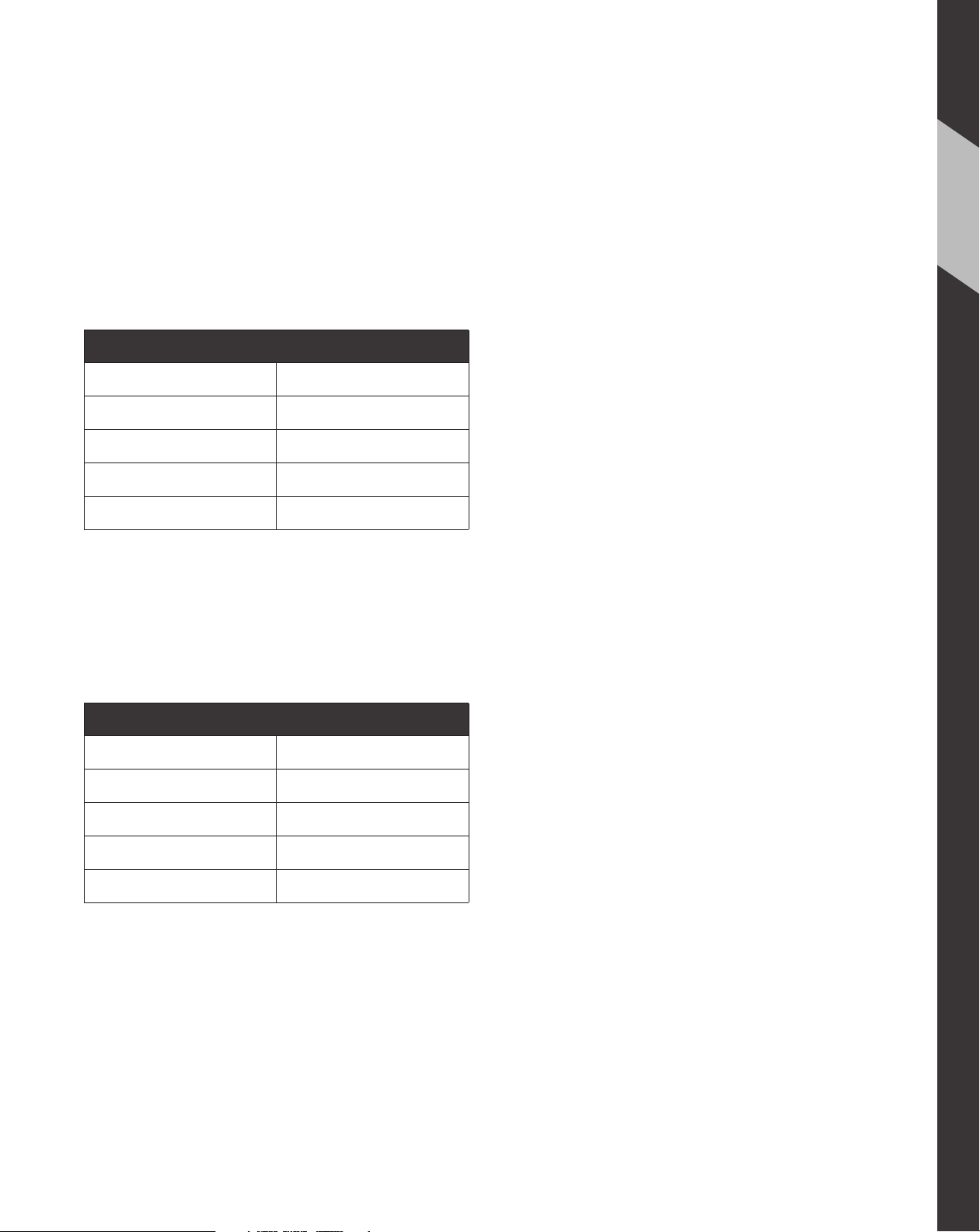

If a requirement for an enclosure Type is specified, can an

equivalent IP rated enclosure be substituted?

No! The IPCode only addresses requirements for protection

of people, ingress of solid objects, and ingress of water.

There are numerous other requirements covered by the Type

designations that are not addressed by the IEC 60529/IP Codes.

IEC 60529 does not specify:

• Construction requirements • Effects of icing

• Door and cover securement • Gasket aging and oil resistance

• Corrosion resistance • Coolant effects

The Type designation specifies requirements for these

additional performance protections. For this reason, the

IEC enclosure IPCodes designations CANNOT be converted

to enclosure Type numbers. For general cross reference

comparison see See Table 2.

•

4

General Information | IP Code

2

Table 1

General Info

5

General Information

IP Code Continued

2

General Info

Table 2

SIZE ID

NUMBER

1 IP23

2 IP30

3 IP64

3R IP32

4 IP66

4X IP66

6 IP67

6P IP68

12 IP55

OVERALL

H X W X D

13 IP65

The data contained in the table is provided for information and this table must only be used to apply NEMA ratings to IEC

designators; it should not be used inversely. The cross-reference is based on engineering judgment and is not approved by

the standards organizations.

6

General Information | IP Code

Enclosure Selection Guidelines

The Enclosure Selection is designed to enhance enclosure

selection by making the process easier, more consistent,

accurate and complete. The goal is to assure that factors

affecting enclosure selection are considered and the enclosure

specification is complete and accurate.

1. Examination of the Application

The requirements of your application must be taken into

consideration. Often the application will be associated with

the market or product. For example, does the application

require a disconnect, does it need to be wall mount or free

standing? Each application is different and needs a complete

review.

2. Environmental Considerations

Regardless of application - solar field, factory floor, chemical

plant, the environment is a critical factor for consideration.

In the proposed environment, what is the highest threat?

Based on this threat, and the use of NEMA ratings you can

determine which enclosure offers the best protection.

3. Material Considerations

Based on the environmental protection that you identify,

you will need to define the appropriate material for your

application.

Fiberglass

Polycarbonate

PVC

ABS

Carbon Steel

Stainless Steel

Aluminum

4. Size Considerations

Several factors will need to be evaluated when specifying the

size of the enclosure, such as:

Internal equipment dimensions

Service connections

External space restrictions

Mounting and access

Climate control requirements

Aesthetics

Economics

5. Standards or Ratings

Select an enclosure that has a rating appropriate for your

environment and application. Rating types from NEMA, UL,

CSA, and IEC determine an enclosures ability to withstand

environmental conditions. Keep in mind that there may

be multiple enclosures that meet the ratings which may be

reduced by material and size considerations.

6. Thermal Considerations

To maximize the life and efficiency of internal components

effective thermal management considerations need to be

evaluated. One often thinks in terms of dissipating heat

build-up, but one must also consider applications that require

addition of heat.

2

General Info

7

General Information

Hazardous Locations

2

General Info

Classification of Hazardous Atmospheres

The NEC classifies areas according to the nature, likelihood

and extent of ignitable flammable hazards that could exist

where electrical equipment is installed. The intent of area

classification is to prevent fires and explosions that could be

caused by electrical equipment serving as an ignition source

(arc, spark, high temperature, etc.).

The NEC divides the atmospheric explosion hazards into three

classes. Considerable skill and judgment must be applied

when deciding to what degree an area contains hazardous

concentrations of vapors, combustible dusts or ignitable fibers

SUMMARY OF HAZARDOUS ATMOSPHERES

and flyings. Factors such as temperature, barometric pressure,

humidity, ventilation, quantity of release, distance from the

source, etc. must all be evaluated.

An abbreviated summary of the NEC classifications appears

in the table below. For detailed information on specific

atmospheres, refer to the NEC, Articles 501-505 and 511-517.

For a more complete list of flammable liquids, gases and

solids; refer to NFPA 497A and NFPA 497B, Classification of

Gases, Vapors and Dusts for Electrical Equipment in Hazardous

(Classified) Locations.

CLASS DIVISION GROUP

I

Flammable Gases, Vapors

Flammable and Combustible

Liquids

II

Combustible Dusts

III

Ignitable fibers and flyings

1 Normally hazardous

– Always present in atmosphere

2 Not normally hazardous

– May be present in atmosphere

1 Normally hazardous

– Always present in atmosphere

2 Not normally hazardous

– Always present in atmosphere

1 & 2 No Groups

TYPICAL ATMOSPHERE, IGNITION

TEMPERATURES

A Acetylene, 305°C (581°F)

B Hydrogen, 520°C (968°F)

C Ethylene, 450°C (842°F)

D Methane, 630°C (999°F)

A Same as Division 1

B Same as Division 1

C Same as Division 1

D Same as Division 1

Combustible metal dusts, or other

E

combustible dusts of similar

hazardous characteristics

F Combustible carbonaceous dusts

Combustible dusts not included in

G

Group E or F, includes flour,

grain, wood, plastic & chemicals

F Same as Division 1

G Same as Division 1

8

General Information | IP Code

IEC methodology was added to the 1996 NEC in Article 505.

The IEC uses area classifications similar to the NEC, but with

different terms, groupings, descriptors and temperature range.

Article 505 defines only Class I areas; however, the divisions

and groupings are different as shown in the following tables:

IEC Group I is for underground mines and is not covered by

the NEC. Group IIC combines NEC Groups A and B making the

requirements for acetylene the same as for hydrogen and

other highly flammable gases.

COMPARISON OF GROUPS

NEC Group IEC Group

A IIC

B IIC

CAUTION: These methodologies are mutually exclusive and

should not be mixed and matched. Equipment

approved for the NEC classifications may be

used in the equivalent IEC area, but not vice

versa. NEC Article 500-3 requires that the area

classification, wiring and equipment selection be

under the supervision of a qualified Registered

Professional Engineer.

Enclosure ratings for hazardous locations include:

NEMA 7 Enclosures constructed for indoor use in

hazardous locations classified as Class I, Division

1, Groups A, B, C or D as defined in NFPA 70.

NEMA 8 Enclosures constructed for either indoor or

outdoor use in hazardous locations classified as

Class I, Division 1, Groups A, B, C and D as defined

in NFPA 70.

2

General Info

C IIB

D IIA

The IEC divides NEC Division 1 into Zone 0 and Zone 1. In Zone

0 the hazard is present at all times or for long periods of time.

In Zone 1 the hazard is present during normal conditions,

including repair and maintenance activities or leakage, or

where operations or processes could result in the release

of a flammable mixture or cause a simultaneous failure of

electrical equipment.

COMPARISON OF DIVISIONS WITH ZONES

NEC Division IEC Zone

1 0

1 1

2 2

Non-hazardous Non-hazardous

NEMA 9 Enclosures constructed for indoor use in

hazardous locations classified as Class II, Division

1, Groups E, F or G as defined in NFPA 70.

NEMA 10 Enclosures constructed to meet the requirements

of the Mine Safety and Health Administration, 30

C. F. R., Part 18.

9

3

ModRight

ModRight

AttaBox Enclosures prides itself in its willingness and ability

to meet the enclosure modification needs of customers. The

combination of technologically advanced equipment and a

sound procedure for handling the most detailed modification

allows AttaBox Enclosures to process modifications on time,

and to the highest quality standards in the industry.

Modifications can be mixed and matched in an endless

number of combinations. They can take the form of:

• Custom mold-in colors

• Silk screening

• EMI/RFI shielding

• Custom window sizes

• Custom cutouts/holes

• Custom size enclosures

• Other special requests

This AttaBox catalog is devoted to practical applications and

solutions to enclosure problems. A variety of off-the-shelf

products are available to solve common industry related

problems. AttaBox’s ModRight Program is designed to support

you in very uncommon or complex applications. When you

need to pick up the phone for additional assistance, think

AttaBox ModRight!

™

Services

ProRight

The ProRight Program offers the capability of prototyping a

unique design through the hand layup process or low volume

molding. Product can be pre-tested for its effectiveness before

large volumes of product are produced.

BuildRight

The BuildRight Program offers a complete range of standard

and unique modifications that make a useful configuration

right out of the carton available.

The BuildRight Program accommodates custom manufacturing

and component assembly to deliver exactly the configuration

that you desire at time of shipping.

CostRight

The CostRight Program will help you determine beforehand

how cost effective the pre-assembly can be. Prices are agreed

to up front at an industry competitive rate.

ShipRight

The ShipRight Program evaluates current shipping requirements

and offers “when-needed” and on time deliveries in an agreed

upon manner. Bulk shipping and quantity requirements are

considered under this program.

ModRight

The ModRight program is multi faceted and designed to meet

a range of unique requirements from simple hole drilling to

full custom blend of molding materials.

DesignRight

The DesignRight Program will take your custom concept,

perhaps your embossed logo or a completely custom cover

design, and conform it to an existing enclosure. The result is

your custom cover on a “standard” base.

FormRight

The FormRight Program is available for custom material

formulation to match your unique requirements. AttaBox

will work with you to custom formulate the sheet molding

compound with the attributes that you require for UV, flame

retardation, infestation resistance, you name it.

This is the total package

From the basic product through all of its custom/modified

required changes, to the moment it arrives at your doorstep

for installation into your application, AttaBox ModRight

Program offers standard and custom assistance for your

every need. To receive a quotation or further information,

please visit us at AttaBox.com.

10

3

ModRight

11

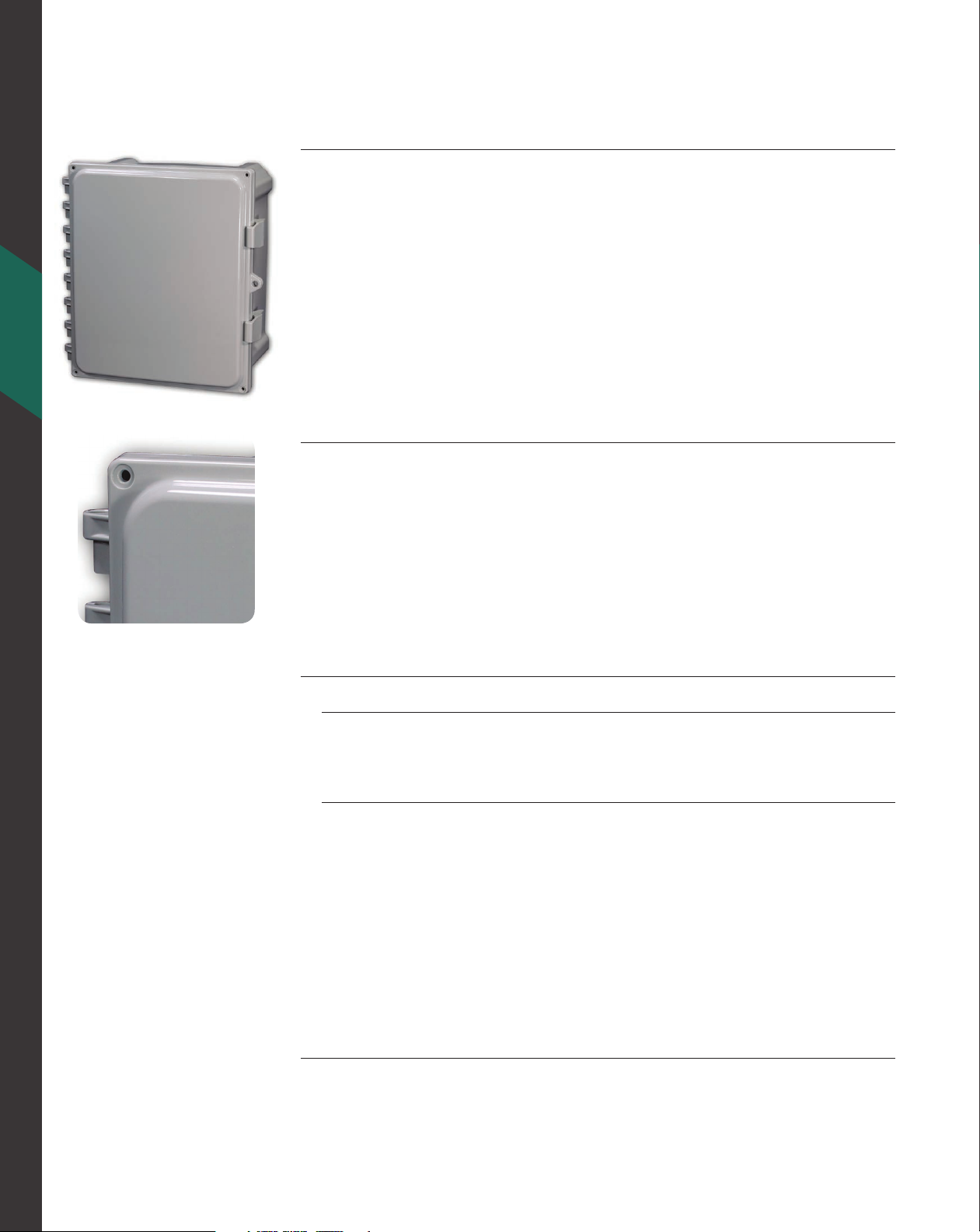

Heartland™ Series

Proven Protection From Reliable Material Performance In Aggressive Environments

The Heartland (AH) Series are high performance, polycarbonate enclosures applicable for heavy industrial

4

conditions, but with a refined style suitable for commercial, industrial and OEM design applications.

Heartland (AH)

The polycarbonate resin in the Heartland Series attained the best available “F1” rating, having passed critical tests

for UV exposure and water immersion.

Heartland Series enclosures are rain-tight and watertight rated for use in both interior and exterior applications.

Material ratings, as well as product ratings, assure the user that polycarbonate is designed to perform, without

adverse affects, in cold weather applications.

Of significant protective value: corrosion-resistant polycarbonate can be effectively used across a wide range of

aggressive environments.

HEARTLAND SERIES ATTRIBUTES

• Latches and hinges do not penetrate enclosure

• Easy to remove lid

• High performance inserts

• Integrated padlock hasp

• Flush-fit side mount swing panel and DIN rail system

• Molded in bosses

• Multi-directional mounting feet

• Available in standard opaque or clear cover options

HEARTLAND SERIES INDUSTRY STANDARDS

UL/cUL File # E319779

NEMA Ratings

(UL508A, UL50 & UL50e)

IEC 60529 Ratings IP66, IP68

Temperature Range (-20°F to +240°F) (-29°C to +115°C)

Flammability Rating UL94-5VA, UL94-V0

Self Extinguishing Non-halogenated, non-flame propagating

Certifications

Outdoor UV Exposure (UL 746C) (f1) Rated

Chemical Resistance See chart on page 120

12

cULus, CE, REACH, RoHS

1, 3R, 4, 4X, 6P, 12

Heartland | Opaque (AH)

4

Heartland (AH)

Heartland | Clear (AH_C)

13

Heartland | Opaque

HINGED, LATCHED, PADLOCKABLE

CONSTRUCTION

Material (Box & Cover) Polycarbonate with UV inhibitors

Gasket Material Neoprene rope style,

Poured polyurethane seamless gasket on select sizes

Cover Screw Material 304 Stainless Steel

4

Heartland (AH)

Mounting Bosses Panel mounting capability for fixed rear panel

Back Panel Screw Size #10-32x3/8

Metal Inserts All threaded brass inserts accepting #10-32 screws

Cover Screw Size #10-32 x 5/8

Cover Screw Torque 20-24 in.-lbs.

Mounting Feet Inserts 1/4-20x1/2

Mounting Feet Torque 14-16in.-lbs

Hinge and Latch Hardware Polycarbonate with UV inhibitors

Side Mount Solutions Variable height side mount capability

INDUSTRY STANDARDS

UL/cUL File # E319779

NEMA Ratings

(UL508A, UL50 & UL50e) 1, 3R, 4, 4X, 6P, 12

IEC 60529 Ratings IP66, IP68

Temperature Range (-20°F to +240°F) (-29°C to +115°C)

Flammability Rating UL94-5VA

Self Extinguishing Non-halogenated, non-flame propagating

Certifications cULus, CE, REACH, RoHS

Outdoor UV Exposure (UL 746C) (f1) Rated

Chemical Resistance See chart on page 120

ACCESSORIES

BACK PANELS

Aluminum BP__A pg. 108

Carbon Steel BP__CS pg. 108

ABS BP__ABS pg. 108

ACCESSORIES

Swing Panel Mounts (4 per kit) pg. 17

DIN Rail / DIN Rail Kit pg. 17

Vents pg. 104

4X Breather Vent pg. 102

4X Drain Vent pg. 102

PluggIt pg. 103

Cable Glands pg. 106

Thermal Accessories pg. 115

Thumb Screw Kit pg. 17

Pole Mount Kit pg. 17

All Other Accessories Pg. 102-117

MODIFICATIONS

Custom Colors pg. 10-11

Silk Screening pg. 10-11

Custom Cutouts/Holes pg. 10-11

14

Heartland | Clear

HINGED, LATCHED, PADLOCKABLE

CONSTRUCTION

Material (Box & Cover) Polycarbonate with UV inhibitors

Gasket Material Neoprene rope style,

Cover Screw Material

Mounting Bosses Panel mounting capability for fixed rear panel

Back Panel Screw Size #10-32x3/8

Metal Inserts

Cover Screw Size #10-32 x 5/8

Cover Screw Torque 20-24 in.-lbs.

Mounting Feet Inserts 1/4-20x1/2

Mounting Feet Torque 14-16in.-lbs

Hinge and Latch Hardware

Side Mount Solutions Variable height side mount capability

INDUSTRY STANDARDS

UL/cUL File # E319779

NEMA Ratings

(UL508A, UL50 & UL50e)

IEC 60529 Ratings IP66, IP68

Temperature Range (-20°F to +240°F) (-29°C to +115°C)

Flammability Rating UL94-V0

Self Extinguishing Non-halogenated, non-flame propagating

Certifications

Outdoor UV Exposure (UL 746C) (f1) Rated

Chemical Resistance See chart on page 120

Poured polyurethane seamless gasket on select sizes

304 Stainless Steel

All threaded brass inserts accepting #10-32 screws

Polycarbonate with UV inhibitors

1, 3R, 4, 4X, 6P, 12

cULus, CE, REACH, RoHS

4

Heartland (AH_C)

ACCESSORIES

BACK PANELS

Aluminum BP__A pg. 108

Carbon Steel BP__CS pg. 108

ABS BP__ABS pg. 108

ACCESSORIES

Swing Panel Mounts (4 per kit) pg. 17

DIN Rail / DIN Rail Kit pg. 17

Vents pg. 104

4X Breather Vent pg. 102

4X Drain Vent pg. 102

PluggIt pg. 103

Cable Glands pg. 106

Thermal Accessories pg. 115

Thumb Screw Kit

Pole Mount Kit pg. 17

All Other Accessories Pg. 102-117

pg. 17

MODIFICATIONS

Custom Colors pg. 10-11

Silk Screening pg. 10-11

Custom Cutouts/Holes pg. 10-11

15

Heartland

TECHNICAL DRAWINGS / DIMENSIONS

4

Heartland (AH)

HEARTLAND SERIES DIMENSIONS

SIZE ID

NUMBER

AH664

AH664C

AH864

AH864C

AH884

AH884C

AH1084

AH1084C

AH1086

AH1086C

AH10106

AH10106C

AH12106

AH12106C

AH14126

AH14126C

AH16148

AH16148C

AH181610

AH181610C

AH18164

AH181614C

AH20168

AH20168C

AH242410

AH242410C

All measures are in inches, items in parentheses are in millimeters.

* AH18164 size does not exhibit same mounting foot design. Mounting feet are molded into the box rather than installed separately.

** Panel sold separately

OVERALL

H X W X D

7.41 x 8.68 x 5.84

(188 x 223 x 148)

9.41 x 8.68 x 5.86

(239 x 223 x 149)

9.41 x 10.68 x 5.86

(239 x 271 x 149)

11.41 x 10.68 x 6.36

(290 x 271 x 161)

11.41 x 10.68 x 7.89

(209 x 271 x 200)

11.41 x 12.68 x 6.97

(209 x 322 x 177)

13.40 x 12.68 x 7.86

(340 x 322 x 200)

15.40 x 14.68 x 7.86

(391 x 373 x 200)

17.65 x 16.68 x 9.98

(448 x 424 x 253)

19.41 x 18.68 x 11.90

(493 x 474 x 302)

19.41 x 18.68 x 5.41

(493 x 474 x 137)

21.41 x 18.68 x 9.97

(544 x 474 x 253)

25.41 x 26.68 x 11.41

(645 x 678 x 290)

INSIDE

A X B X C

5.94 x 5.94 x 5.02

(151 x 151 x 127)

7.97 x 5.97 x 5.07

(202 x 152 x 129)

7.97 x 7.97 x 5.03

(202 x 202 x 128)

9.96 x 7.96 x 5.57

(253 x 202 x 142)

9.95 x 7.95 x 7.06

(253 x 202 x 179)

9.95 x 9.95 x 6.15

(253 x 253 x 156)

11.95 x 9.95 x 7.07

(304 x 253 x 180)

13.95 x 11.95 x 7.07

(354 x 304 x 180)

15.93 x 13.93 x 9.20

(405 x 354 x 234)

17.83 x 15.83 x 11.08

(453 x 402 x 281)

18.16 x 16.16 x 5.08

(461 x 410 x 129)

19.86 x 15.86 x 9.15

(504 x 403 x 232)

23.91 x 23.91 x 11.88

(607 x 607 x 302)

MOUNTING HOR.

E X F

3.64 x 8.40

(93 x 213)

5.64 x 8.04

(143 x 213)

5.63 x 10.03

(143 x 255)

7.64 x 10.04

(194 x 255)

7.63 x 10.03

(194 x 255)

7.63 x 12.03

(194 x 306)

9.64 x 12.04

(245 x 306)

11.64 x 14.04

(296 x 357)

13.64 x 16.04

(347 x 407)

15.64 x 18.04

(397 x 458)

N/A

18.75 x 19.17

(476 x 487)

N/A

MOUNTING VER.

E X F

8.04 x 3.64

(204 x 93)

10.04 x 3.64

(255 x 93)

10.04 x 5.63

(255 x 143)

12.04 x 5.64

(306 x 143)

12.03 x 5.63

(306 x 143)

12.03 x 7.63

(306 x 194)

14.04 x 7.64

(357 x 194)

16.04 x 9.64

(407 x 245)

18.04 x 11.64

(458 x 296)

20.04 x 13.64

(509 x 347)

20.50 x 13.50

(521 x 343)

23.15 x 14.75

(588 x 375)

25.69 x 18.00

(653 x 457)

MOUNTING 45

E X F

6.75 x 6.74

(171 x 171)

8.76 x 6.75

(223 x 171)

8.74 x 8.78

(222 x 223)

10.76 x 8.75

(273 x 222)

10.76 x 8.75

(273 x 222)

10.76 x 10.75

(273 x 273)

12.76 x 10.75

(324 x 273)

14.76 x 12.75

(375 x 324)

16.76 x 14.75

(426 x 375)

18.75 x 16.74

(476 x 425)

N/A

21.91 x 17.87

(557 x 454)

N/A

J K L M N

4.50

4.25

4.25

(114)

4.56

(116)

4.53

(115)

5.05

(128)

6.54

(166)

5.65

(144)

6.56

(167)

6.56

(167)

8.68

(220)

10.56

(268)

4.56

(116)

8.65

(220)

10.56

(268)

(108)

6.25

(159)

6.25

(159)

8.25

(210)

8.25

(210)

8.25

(210)

10.25

(260)

12.25

(311)

14.25

(362)

16.25

(413)

16.25

(413)

18.25

(464)

22.25

(565)

(108)

4.25

(108)

6.25

(159)

6.25

(159)

6.25

(159)

8.25

(210)

8.25

(210)

10.25

(260)

12.25

(311)

14.25

(362)

14.25

(362)

14.25

(362)

22.25

(565)

8.89

(226)

10.89

(277)

10.88

(277)

12.89

(327)

12.88

(327)

12.88

(327)

14.89

(378)

16.89

(429)

18.89

(480)

20.89

(531)

21.75

(552)

24.00

(610)

26.69

(678)

SHIPPING

WEIGHT

8.89

2.50 lbs. BP66**

(226)

8.89

3.19 lbs. BP86**

(226)

10.88

(277)

10.89

(277)

10.88

(277)

12.88

(327)

12.89

(327)

14.89

(378)

16.89

(429)

18.89

(480)

CF BP88**

4.31 lbs. BP108**

CF BP108**

CF BP1010**

6.19 lbs. BP1210**

7.99 lbs. BP1412**

10.00 lbs. BP1614**

11.25 lbs. BP1816**

PANEL

NUMBER

N/A CF BP1816**

20.02

(509)

21.86

(555)

CF BP2016**

CF BP2424**

16

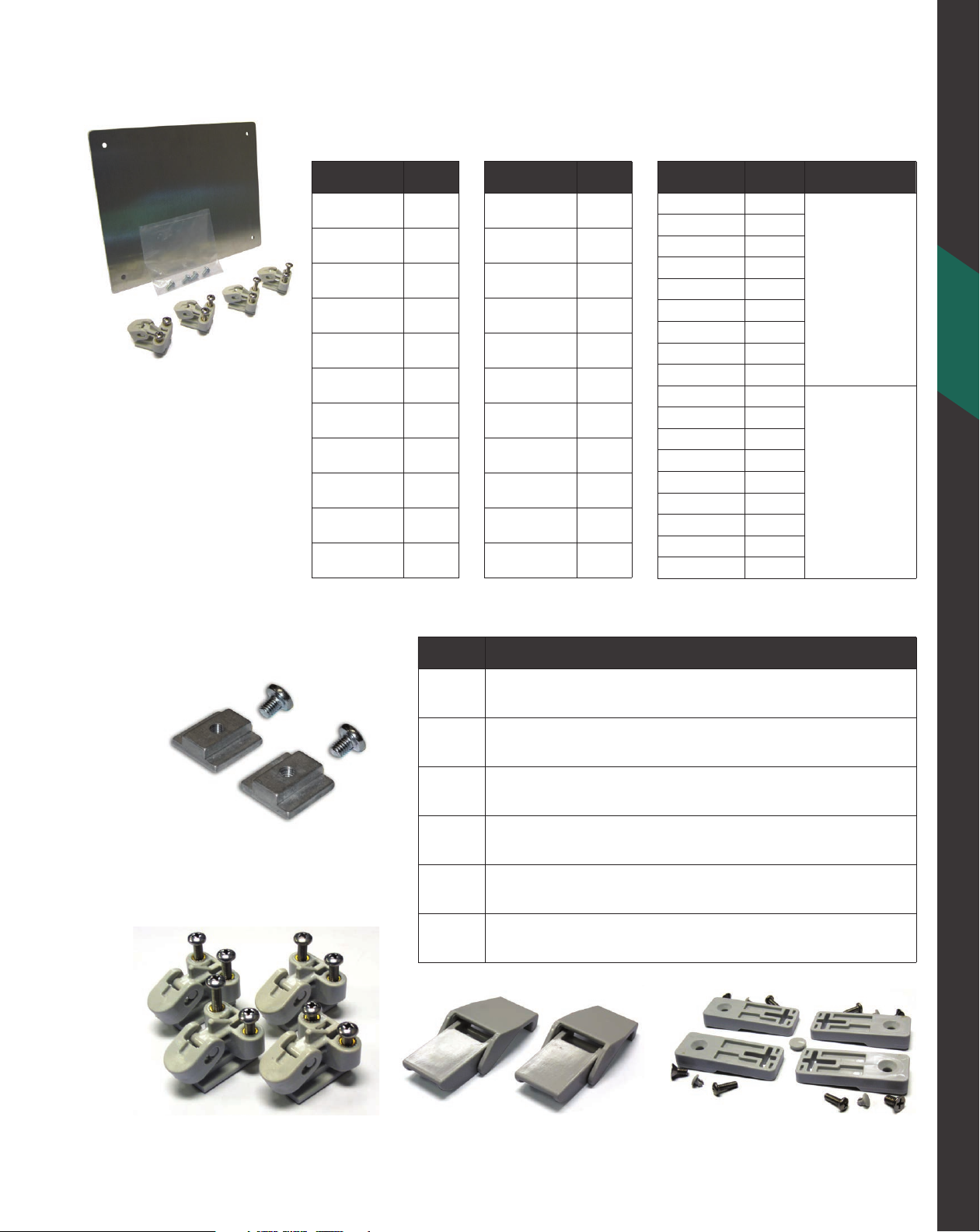

Heartland

ACCESSORIES

Includes mounts, screws and panel.

ALUMINUM

SWING PANEL KITS

CATALOG NUMBER FITS

AH66SPK 6 x 6

AH86SPK 8 x 6

AH88SPK 8 x 8

AH108SPK 10 x 8

AH1010SPK 10 x 10

AH1210SPK 12 x 10

AH1412SPK 14 x 12

AH1614SPK 16 x 14

AH1816SPK 18 x 16

AH2016SPK 20 x 16

AH2424SPK 24 x 24

ABS

SWING PANEL KITS

CATALOG NUMBER FITS

AH66SPABS 6 x 6

AH86SPABS 8 x 6

AH88SPABS 8 x 8

AH108SPABS 10 x 8

AH1010SPABS 10 x 10

AH1210SPABS 12 x 10

AH1412SPABS 14 x 12

AH1614SPABS 16 x 14

AH1816SPABS 18 x 16

AH2016SPABS 20 x 16

AH2424SPABS 24 x 24

DIN RAILS

CATALOG NUMBER FITS DESCRIPTION

AH6DRK 6”

AH8DRK 8”

AH10DRK 10”

AH12DRK 12”

AH14DRK 14”

AH16DRK 16”

AH18DRK 18”

AH20DRK 20”

AH24DRK 24”

AH6DR 6”

AH8DR 8”

AH10DR 10”

AH12DR 12”

AH14DR 14”

AH16DR 16”

AH18DR 18”

AH20DR 20”

AH24DR 24”

Kit Includes a DIN

rail that fits size

indicated, plus

two custom slot

nuts, and two

thread forming

screws used for

mounting to back

of enclosure.

Kit Includes a DIN

rail that fits size

indicated, plus two

tribolar screws.

4

Heartland (AH)

AHSNK

ACCESSORIES

CATALOG

NUMBER

AHSNK Slot Nut Kit (includes two nuts & two screws)

AHSPMK Swing Panel Mounts (4 per kit)

AHLK

AHAK

AHTSKSS

AHTSKAL

Accessory Kit (includes all screws, inserts

and mounting feet) - replacement only

Kit includes two stainless steel thumb screws,

Kit includes two aluminum thumb screws,

DESCRIPTION

Latch Kit (2 latches per kit)

- replacement only

and two plastic backers.

and two plastic backers.

AHSPMK AHLK AHAK

17

Commander™ Series

Proven Protection From A Complete Environmental Seal

FIBERGLASS OPTION:

Commander (CO) Series slim-line enclosures are designed from fiberglass-reinforced polyester and feature

a continuous polyurethane gasket that provides the critically reliable, long-term protection of a complete

environmental seal.

5

Commander (CO)

POLYCARBONATE OPTION:

The Commander Series offers an all-polycarbonate product with blank covers and a choice of one-or-two-hole

pushbutton openings for both 22mm and 30mm hardware. These enclosures include the external flush wall design,

unobstructed sidewalls internally, polymer cover screws, watertight seal and other standard features of the

Commander Series.

Commander Series enclosures, in a full range of sizes, are ideal for compact or portable control or simply as a small

junction box.

Commander Series Fiberglass Enclosures are available in two cover versions:

The first style is a flush cover for unobstructed enclosure sides and a continuous cover gasket producing a watertight

seal. Attributes include soft, rounded edges and virtually no pocket areas to trap dust or debris. These enclosures

feature a mounting foot option versus bosses for a mounted back panel.

The second style offers a lift-off overhang cover design with molded-in panel mount inserts.

Both versions of the Commander Series enclosures feature a slim style with flush sidewalls. Both also include captive

stainless steel cover screws.

COMMANDER SERIES ATTRIBUTES

• Memory retaining continuous polyurethane gasket

• Captive stainless steel cover screws on fiberglass option

• Captive polymer cover screws on polycarbonate option

• Chemically resistant fiberglass reinforced polyester or polycarbonate

• Submersible, non corrosive, environmental design

• High impact resistance

18

COMMANDER SERIES INDUSTRY STANDARDS

UL/cUL File # E64358 / E319779

NEMA Ratings 1, 3R, 4X, 6P, 12

(UL508A, UL50 & UL50e)

CSA Std. C22.2 File # LR069014 (Fiberglass only)

IEC 60529 Ratings IP66, IP67, IP68

UL 1741 File # E333478 (Fiberglass only)

Temperature Range (Fiberglass) (-76°F to +274°F) (-60°C to +134°C)

Temperature Range (Polycarbonate) (-20°F to +240°F) (-29°C to +115°C)

Flammability Rating UL94-5V

Self extinguishing Non-halogenated, non-flame propagating

NFPA No. 101 Flame Spread Class A (1)

Impact Rating IK10

Certifications cULus, CSA, IEC, REACH, RoHS

Outdoor UV Exposure (UL 746C) (f1) Rated

Plenum Space Rating (UL 2043) Yes (Fiberglass only)

Chemical Resistance See chart on page 120

Commander (CO)

5

Commander (CO)

BLANKBLANK

22MM INLINE

30MM MULTIHOLE POLYCARBONATE30MM INLINE

19

5

Commander (CO)

Commander | Fiberglass | Blank

4 COVER SCREWS, LIFT OFF COVER

CONSTRUCTION

Material (Box & Cover) Hot compression molded fiberglass reinforced polyester (thermoset)

Gasket Material Poured polyurethane seamless gasket

Cover Screw Material Recessed captive 304 stainless steel

Cover Screw Size #10-24 x 3/4

Cover Screw Torque 20-24 in.-lbs.

Enclosure mounting Mounting wells located under the cover/outside the gasket area

Soft Edge Design Rounded edges, minimal protrusions or exposed pocket areas for

assembly of dust and debris

INDUSTRY STANDARDS

UL/cUL File # E64358

NEMA Ratings 1, 3R, 4X, 6P, 12

(UL508A, UL50 & UL50e)

CSA Std. C22.2 File # 1, 3R, 4X, 6P, 12 per CSA File# LR069014

IEC 60529 Ratings IP66, IP67, IP68 per UL file# E362920

UL 1741 File # E333478

Temperature Range (-76°F to +274°F) (-60°C to +134°C)

Flammability Rating UL94-5V

Self extinguishing Non-halogenated, non-flame propagating

NFPA No. 101 Flame Spread Class A (1)

Certifications cULus, CSA, IEC, REACH, RoHS

Outdoor UV Exposure (UL 746C) (f1) Rated

Plenum Space Rating (UL 2043) Yes

Chemical Resistance See chart on page 120

ACCESSORIES

Accessory Kit (Screws) pg. 104

Mounting Feet COMTGFTKIT

All Other Accessories Pg. 102-117

MODIFICATIONS

Custom Colors pg. 10-11

Silk Screening pg. 10-11

Custom Cutouts/Holes pg. 10-11

20

Commander | Fiberglass | Blank

TECHNICAL DRAWINGS / DIMENSIONS

5

Commander (CO)

COMMANDER SERIES FIBERGLASS BLANK CONFIGURATION DIMENSIONS

SIZE ID NUMBER

*CO332

CO532

CO644

CO832

CO844

CO932

CO1144

CO1432

CO1732

*Flat Cover

All measures are in inches, items in parentheses are in millimeters

OVERALL

H X W X D

3.72 x 3.63 x 2.95

(95 x 92 x 75)

5.97 x 3.63 x 3.14

(152 x 92 x 80)

6.63 x 3.81 x 3.89

(168 x 97 x 99)

8.41 x 3.63 x 3.14

(214 x 92 x 80)

8.88 x 3.81 x 3.89

(225 x 97 x 99)

9.35 x 3.63 x 3.14

(237 x 92 x 80)

11.13 x 3.81 x 3.89

(283 x 97 x 99)

13.78 x 3.63 x 3.14

(350 x 92 x 80)

17.35 x 3.63 x 3.14

(441 x 92 x 80)

INSIDE

A X B X C

3.13 x 3.03 x 2.70

(79 x 77 x 69)

5.38 x 3.03 x 2.87

(137 x 77 x 73)

6.00 x 3.19 x 3.63

(153 x 81 x 92)

7.82 x 3.03 x 2.87

(199 x 77 x 73)

8.26 x 3.19 x 3.63

(210 x 81 x 92)

8.75 x 3.03 x 2.87

(222 x 77 x 73)

10.51 x 3.19 x 3.63

(267 x 81 x 92)

13.19 x 3.03 x 2.87

(335 x 77 x 73)

16.75 x 3.03 x 2.87

(426 x 77 x 73)

I J K L M N P Q SHIPPING WEIGHT

0

(0)

4.72

(120)

5.31

(135)

7.16

(182)

7.56

(192)

8.10

(206)

9.81

(249)

12.53

(318)

16.10

(409)

0

(0)

2.38

(61)

2.50

(64)

2.38

(60)

2.50

(64)

2.38

(60)

2.50

(64)

2.38

(60)

2.38

(60)

2.31

(59)

4.56

(116)

4.88

(124)

7.00

(178)

7.13

(181)

7.94

(202)

9.37

(238)

12.37

(314)

15.94

(405)

2.75

(70)

2.75

(70)

2.94

(75)

2.75

(70)

2.94

(75)

2.75

(70)

2.94

(75)

2.75

(70)

2.75

(70)

1.59

(40)

3.84

(98)

4.13

(105)

6.28

(160)

6.38

(162)

7.22

(183)

8.63

(219)

11.66

(296)

15.22

(387)

2.03

(52)

2.03

(52)

2.19

(56)

2.03

(52)

2.19

(56)

2.03

(52)

2.19

(56)

2.03

(52)

2.03

(52)

2.2

(56)

2.2

(56)

2.2

(56)

2.2

(56)

2.2

(56)

2.2

(56)

2.2

(56)

2.2

(56)

2.2

(56)18(458)

4.4

(112)

6.7

(169)

7.3

(186)

9.1

(231)

9.6

(243)

10.1

(256)

11.8

(300)

14.5

(368)

0.9 lbs.

1.2 lbs.

1.5 lbs.

1.5 lbs.

1.8 lbs.

1.6 lbs.

2.1 lbs.

2.1 lbs.

2.8 lbs.

21

5

Commander (CO)

Commander | Fiberglass | Blank

4 COVER SCREWS, LIFT OFF COVER

CONSTRUCTION

Material (Box & Cover) Hot compression molded fiberglass reinforced polyester (thermoset)

Gasket Material Poured polyurethane seamless gasket

Cover Screw Material Recessed captive 304 stainless steel

Cover Screw Size #10-24 x 3/4

Cover Screw Torque 20-24 in.-lbs.

Enclosure mounting Mounting wells located under the cover/outside the gasket area

Back Panel Screw Size #10-32x3/8

Panel Mounting Raised bosses with brass inserts accepting #10-32x3/8 screws

for optional panel mounting

Soft Edge Design Rounded edges, minimal protrusions or exposed pocket areas for

assembly of dust and debris

INDUSTRY STANDARDS

UL/cUL File # E64358

NEMA Ratings 1, 3R, 4X, 6P, 12

(UL508A, UL50 & UL50e)

CSA Std. C22.2 File # 1, 3R, 4X, 6P, 12 per CSA File# LR069014

IEC 60529 Ratings IP66, IP67, IP68 per UL file# E362920

UL 1741 File # E333478

Temperature Range (-76°F to +274°F) (-60°C to +134°C)

Flammability Rating UL94-5V

Self extinguishing Non-halogenated, non-flame propagating

NFPA No. 101 Flame Spread Class A (1)

Certifications cULus, CSA, IEC, REACH, RoHS

Outdoor UV Exposure (UL 746C) (f1) Rated

Plenum Space Rating (UL 2043) Yes

Chemical Resistance See chart on page 120

ACCESSORIES

Aluminum Back Panel BP_A pg. 108

Carbon Steel Back Panel BP_CS pg. 108

All Other Accessories Pg. 102-117

MODIFICATIONS

Custom Colors pg. 10-11

Silk Screening pg. 10-11

Custom Cutouts/Holes pg. 10-11

22

Commander | Fiberglass | Blank

TECHNICAL DRAWINGS / DIMENSIONS

5

Commander (CO)

COMMANDER SERIES FIBERGLASS BLANK CONFIGURATION DIMENSIONS

SIZE

ID NUMBER

CO763

CO963

*Panel ordered separately

All measures are in inches, items in parentheses are in millimeters

OVERALL

H X W X D

7.63 x 6.63 x 3.19

(194 x 168 x 81)

9.87 x 6.63 x 3.19

(251 x 168 x 81)

INSIDE

A X B X C

6.90 x 5.90 x 2.88

(175 x 150 x 73)

9.15 x 5.90 x 2.88

(232 x 150 x 73)

MOUNTING

E X F

5.37 x 5.63

(137 x 143)

7.62 x 5.63

(194 x 143)

J K L M N SHIPPING WEIGHT PANEL NUMBER

2.48

(63)

2.48

(63)

5.37

(137)

7.62

(194)

4.25

(108)

4.25

(108)

4.52

(115)

6.77

(172)

4.9

(124)

4.9

(124)

2.5 lbs. BP76*

2.6 lbs. BP96*

23

5

Commander (CO)

Commander | Fiberglass | 30mm In-Line Configuration

4 COVER SCREWS, LIFT OFF COVER

CONSTRUCTION

Material (Box & Cover) Hot compression molded fiberglass reinforced polyester (thermoset)

Gasket Material Poured polyurethane seamless gasket

Cover Screw Material Recessed captive 304 stainless steel

Cover Screw Size #10-24 x 3/4

Cover Screw Torque 20-24 in.-lbs.

Enclosure mounting Mounting wells located under the cover/outside the gasket area

Soft Edge Design Rounded edges, minimal protrusions or exposed pocket areas for

assembly of dust and debris

INDUSTRY STANDARDS

UL/cUL File # E64358

NEMA Ratings 1, 3R, 4X, 6P, 12

(UL508A, UL50 & UL50e)

CSA Std. C22.2 File # 1, 3R, 4X, 6P, 12 per CSA File# LR069014

IEC 60529 Ratings IP66, IP67, IP68 per UL file# E362920

UL 1741 File # E333478

Temperature Range (-76°F to +274°F) (-60°C to +134°C)

Flammability Rating UL94-5V

Self extinguishing Non-halogenated, non-flame propagating

NFPA No. 101 Flame Spread Class A (1)

Certifications cULus, CSA, IEC, REACH, RoHS

Outdoor UV Exposure (UL 746C) (f1) Rated

Plenum Space Rating (UL 2043) Yes

Chemical Resistance See chart on page 120

ACCESSORIES

Accessory Kit (Screws) pg. 104

Mounting Feet COMTGFTKIT

All Other Accessories Pg. 102-117

MODIFICATIONS

Custom Colors pg. 10-11

Silk Screening pg. 10-11

Custom Cutouts/Holes pg. 10-11

24

Commander | Fiberglass | 30mm In-Line Configuration

TECHNICAL DRAWINGS / DIMENSIONS

5

Commander (CO)

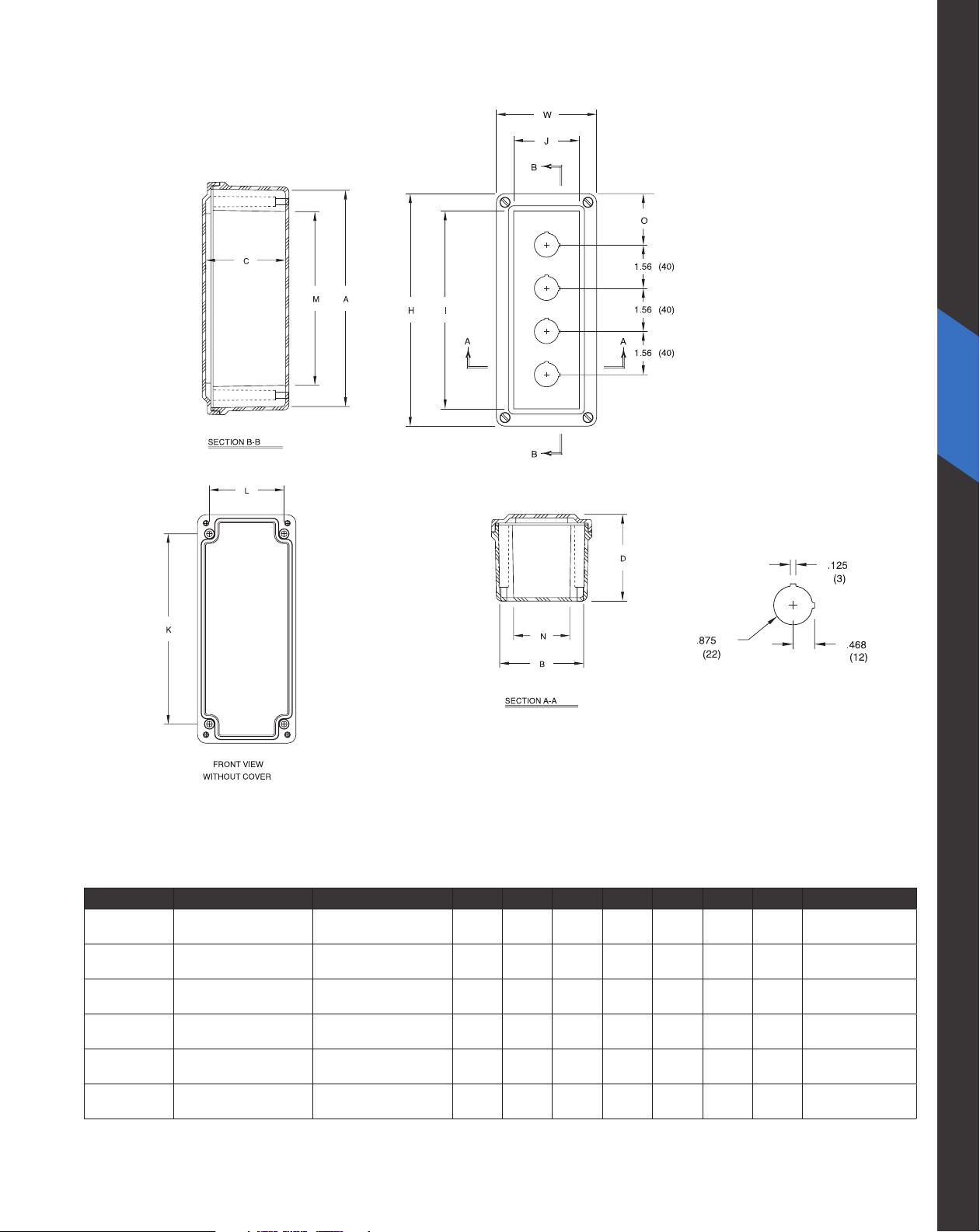

COMMANDER SERIES FIBERGLASS 30mm INLINE CONFIGURATION DIMENSIONS

SIZE ID NUMBER OVERALL H X W X D INSIDE A X B X C I J K L M N O SHIPPING WEIGHT

CO1PB

CO2PB

CO3PB

CO4PB

CO5PB

CO6PB

All measures are in inches, items in parentheses are in millimeters.

Note: Shown CO3PB for Reference.

6.63 x 3.81 x 3.89

(168 x 97 x 99)

6.63 x 3.81 x 3.89

(168 x 97 x 99)

8.88 x 3.81 x 3.89

(225 x 97 x 99)

11.13 x 3.81 x 3.89

(283 x 97 x 99)

13.78 x 3.63 x 3.14

(350 x 92 x 80)

17.35 x 3.63 x 3.14

(441 x 92 x 80)

6.00 x 3.19 x 3.63

(153 x 81 x 92)

6.00 x 3.19 x 3.63

(153 x 81 x 92)

8.26 x 3.19 x 3.63

(210 x 81 x 92)

10.51 x 3.19 x 3.63

(267 x 81 x 92)

13.19 x 3.03 x 2.87

(335 x 77 x 73)

16.75 x 3.03 x 2.87

(426 x 77 x 73)

5.31

(135)

5.31

(135)

7.56

(192)

9.81

(249)

12.53

(318)

16.1

(409)

2.5

(64)

2.5

(64)

2.5

(64)

2.5

(64)

2.38

(60)

2.38

(60)

4.88

(124)

4.88

(124)

7.13

(181)

9.37

(238)

12.37

(314)

15.94

(405)

2.94

(75)

2.94

(75)

2.94

(75)

2.94

(75)

2.75

(70)

2.75

(70)

4.13

(105)

4.13

(105)

6.38

(162)

8.63

(219)

11.66

(296)

15.22

(387)

2.19

(56)

2.19

(56)

2.19

(56)

2.19

(56)

2.03

(52)

2.03

(52)

3.31

(84)

2.19

(56)

2.19

(56)

2.19

(56)

2.39

(61)

3.05

(77)

1.5 lbs.

1.5 lbs.

1.8 lbs.

2.0 lbs.

2.1 lbs.

3.0 lbs.

25

5

Commander (CO)

Commander | Fiberglass | 22mm In-Line Configuration

4 COVER SCREWS, LIFT OFF COVER

CONSTRUCTION

Material (Box & Cover) Hot compression molded fiberglass reinforced polyester (thermoset)

Gasket Material Poured polyurethane seamless gasket

Cover Screw Material Recessed captive 304 stainless steel

Cover Screw Size #10-24 x 3/4

Cover Screw Torque 20-24 in.-lbs.

Enclosure mounting Mounting wells located under the cover/outside the gasket area

Soft Edge Design Rounded edges, minimal protrusions or exposed pocket areas for

assembly of dust and debris

INDUSTRY STANDARDS

UL/cUL File # E64358

NEMA Ratings 1, 3R, 4X, 6P, 12

(UL508A, UL50 & UL50e)

CSA Std. C22.2 File # 1, 3R, 4X, 6P, 12 per CSA File# LR069014

IEC 60529 Ratings IP66, IP67, IP68 per UL file# E362920

UL 1741 File # E333478

Temperature Range (-76°F to +274°F) (-60°C to +134°C)

Flammability Rating UL94-5V

Self extinguishing Non-halogenated, non-flame propagating

NFPA No. 101 Flame Spread Class A (1)

Certifications cULus, CSA, IEC, REACH, RoHS

Outdoor UV Exposure (UL 746C) (f1) Rated

Plenum Space Rating (UL 2043) Yes

Chemical Resistance See chart on page 120

ACCESSORIES

Accessory Kit (Screws) pg. 104

Mounting Feet COMTGFTKIT

All Other Accessories Pg. 102-117

MODIFICATIONS

Custom Colors pg. 10-11

Silk Screening pg. 10-11

Custom Cutouts/Holes pg. 10-11

26

Commander | Fiberglass | 22mm In-Line Configuration

TECHNICAL DRAWINGS / DIMENSIONS

5

Commander (CO)

COMMANDER SERIES FIBERGLASS 22mm INLINE CONFIGURATION DIMENSIONS

SIZE ID NUMBER OVERALL H X W X D INSIDE A X B X C I J K L M N O SHIPPING WEIGHT

CO1PB22

CO2PB22

CO3PB22

CO4PB22

CO5PB22

CO6PB22

All measures are in inches, items in parentheses are in millimeters.

Note: Shown CO4PB22 for Reference.

6.63 x 3.81 x 3.89

(168 x 97 x 99)

6.63 x 3.81 x 3.89

(168 x 97 x 99)

6.63 x 3.81 x 3.89

(168 x 97 x 99)

8.88 x 3.81 x 3.89

(225 x 97 x 99)

11.13 x 3.81 x 3.89

(283 x 97 x 99)

11.13 x 3.81 x 3.89

(283 x 97 x 99)

6.00 x 3.19 x 3.63

(153 x 81 x 92)

6.00 x 3.19 x 3.63

(153 x 81 x 92)

6.00 x 3.19 x 3.63

(153 x 81 x 92)

8.26 x 3.19 x 3.63

(210 x 81 x 92)

10.51 x 3.19 x 3.63

(267 x 81 x 92)

10.51 x 3.19 x 3.63

(267 x 81 x 92)

5.31

(135)

5.31

(135)

5.31

(135)

7.56

(192)

9.81

(249)

9.81

(249)

2.5

(64)

2.5

(64)

2.5

(64)

2.5

(64)

2.5

(64)

2.5

(64)

4.88

(124)

4.88

(124)

4.88

(124)

7.13

(181)

9.37

(238)

9.37

(238)

2.94

(75)

2.94

(75)

2.94

(75)

2.94

(75)

2.94

(75)

2.94

(75)

4.13

(105)

4.13

(105)

4.13

(105)

6.38

(162)

8.63

(219)

8.63

(219)

2.19

(56)

2.19

(56)

2.19

(56)

2.19

(56)

2.19

(56)

2.19

(56)

3.31

(84)

2.53

(64)

1.75

(44)

2.09

(53)

2.44

(62)

1.66

(42)

1.6 lbs.

1.6 lbs.

1.6 lbs.

1.8 lbs.

2.1 lbs.

2.1 lbs.

27

5

Commander (CO)

Commander | Fiberglass | 30mm Multi-Hole Configuration

4 COVER SCREWS, LIFT OFF COVER

CONSTRUCTION

Material (Box & Cover) Hot compression molded fiberglass reinforced polyester (thermoset)

Gasket Material Poured polyurethane seamless gasket

Cover Screw Material Recessed captive 304 stainless steel

Cover Screw Size #10-24 x 3/4

Cover Screw Torque 20-24 in.-lbs.

Stainless Steel Hardware 300 series stainless steel used on all external hardware

Cover Retention Stainless steel beaded cover retention chain

Back Panel Screw Size #10-32x3/8

Panel Mounting Raised bosses with brass inserts accepting #10-32x3/8 screws

for optional panel mounting

Mounting Feet Integral Mounting Flange

Soft Edge Design Rounded edges, minimal protrusions or exposed pocket areas for

assembly of dust and debris

INDUSTRY STANDARDS

UL/cUL File # E64358

NEMA Ratings 1, 3R, 4X, 6P, 12

(UL508A, UL50 & UL50e)

CSA Std. C22.2 File # 1, 3R, 4X, 6P, 12 per CSA File# LR069014

IEC 60529 Ratings IP66, IP67, IP68 per UL file# E362920

UL 1741 File # E333478

Temperature Range (-76°F to +274°F) (-60°C to +134°C)

Flammability Rating UL94-5V

Self extinguishing Non-halogenated, non-flame propagating

NFPA No. 101 Flame Spread Class A (1)

Certifications cULus, CSA, IEC, REACH, RoHS

Outdoor UV Exposure (UL 746C) (f1) Rated

Plenum Space Rating (UL 2043) Yes

Chemical Resistance See chart on page 120

ACCESSORIES

Aluminum Back Panel BP_A pg. 108

Carbon Steel Back Panel BP_CS pg. 108

Accessory Kit (Screws) pg. 104

All Other Accessories Pg. 102-117

MODIFICATIONS

Custom Colors pg. 10-11

Silk Screening pg. 10-11

Custom Cutouts/Holes pg. 10-11

EMI/RFI Shielding pg. 10-11

28

Commander | Fiberglass | 30mm Multi-Hole Configuration

TECHNICAL DRAWINGS / DIMENSIONS

5

Commander (CO)

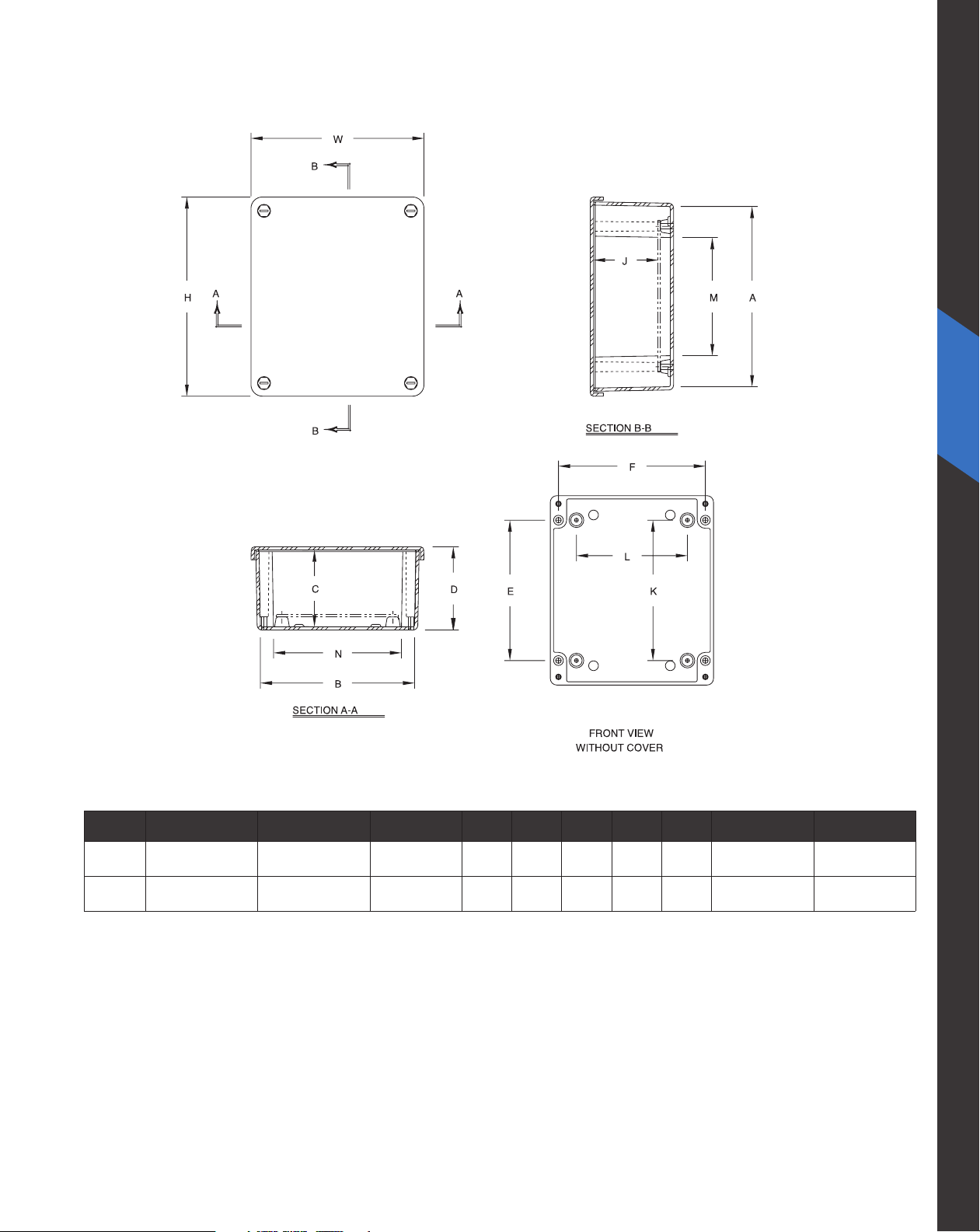

COMMANDER SERIES FIBERGLASS 30mm MULTIHOLE CONFIGURATION DIMENSIONS

CATALOG

NUMBER

CO4PBW 2 x 2

CO6PBW 3 x 2

CO9PBW 3 x 3

All measures are in inches, items in parentheses are in millimeters.

Note: Shown CO6PBW for Reference.

* Panel ordered separately.

HOLE

CONFIG.

OVERALL

H X W X D

7.50 x 7.50 x 4.75

(191 x 191 x 121)

9.62 x 7.50 x 4.74

(244 x 191 x 121)

11.62 x 9.41 x 4.25

(295 x 239 x 108)

INSIDE

A X B X C

5.72 x 5.72 x 4.45

(145 x 145 x 113)

7.73 x 5.74 x 4.45

(196 x 146 x 113)

9.73 x 7.73 x 3.98

(247 x 196 x 101)

MOUNTING

E X F

6.75 x 4.00

(171 x 101)

8.88 x 4.00

(225 x 101)

10.75 x 6.00

(273 x 152)

J K L M N O P

4.00

4.25

4.25

0.25

7.52

(101)

4.00

(101)

3.50

(89)

(108)

6.25

(159)

8.25

(209)

(108)

4.25

(108)

6.25

(159)

(6)

0.25

(6)

0.25

(6)

(191)

9.5

(242)

11.35

(288)

2.64

(67)

2.64

(67)

3.43

(87)

2.64

(67)

2.51

(64)

2.45

(62)

HOLE

SHIPPING

DIA.

0.31

2.7 lbs. BP66*

(8)

0.31

3.5 lbs. BP86*

(8)

0.31

5.0 lbs. BP108*

(8)

WT.

PANEL

NUMBER

29

5

Commander (CO)

Commander | Polycarbonate

4 COVER SCREWS, LIFT OFF COVER

CONSTRUCTION

Material (Box & Cover) Polycarbonate with UV inhibitors

Gasket Material Poured polyurethane seamless gasket

Cover Screw Material Custom polycarbonate screw

Cover Screw Size Custom screw size

Cover Screw Torque 16 in.-lbs

Enclosure Mounting Mounting wells located under the cover/outside the gasket area

Soft Edge Design Rounded edges, minimal protrusions or exposed pocket areas for

assembly of dust and debris

INDUSTRY STANDARDS

UL/cUL File # E319779

NEMA Ratings 1, 3R, 4X, 6P, 12

(UL508A, UL50 & UL50e)

IEC 60529 Ratings IP66, IP67, IP68

Temperature Range (-20°F to +240°F) (-29°C to +115°C)

Flammability Rating UL94-5VA

Certifications cULus, IEC, REACH, RoHS

Outdoor UV Exposure (UL 746C) (f1) Rated

Chemical Resistance See chart on page 120

ACCESSORIES

Accessory Kit (Screws) pg. 104

All Other Accessories Pg. 102-117

MODIFICATIONS

Custom Colors pg. 10-11

Silk Screening pg. 10-11

Custom Cutouts/Holes pg. 10-11

EMI/RFI Shielding pg. 10-11

30

Commander | Polycarbonate

TECHNICAL DRAWINGS / DIMENSIONS

5

Commander (CO)

COMMANDER SERIES POLYCARBONATE DIMENSIONS

CATALOG NUMBER HOLE CONFIG.

COPC432 Blank

COPC533 Blank

COPC1PB 1

COPC2PB 2

COPC1PB22 1

COPC2PB22 2

All measures are in inches, items in parentheses are in millimeters.

Note: Shown CO6PBW for Reference.

* Panel ordered separately.

OVERALL

H X W X D

4.34 x 3.16 x 2.79

(110 x 80 x 71)

5.12 x 3.16 x 3.54

(130 x 80 x 90)

4.34 x 3.16 x 2.79

(110 x 80 x 71)

5.12 x 3.16 x 3.54

(130 x 80 x 90)

4.34 x 3.16 x 2.79

(110 x 80 x 71)

5.12 x 3.16 x 3.54

(130 x 80 x 90)

INSIDE

A X B X C

3.92 x 2.74 x 2.51

(100 x 70 x 64)

4.71 x 2.74 x 3.26

(120 x 70 x 83)

3.92 x 2.74 x 2.51

(100 x 70 x 64)

4.71 x 2.74 x 3.26

(120 x 70 x 83)

3.92 x 2.74 x 2.51

(100 x 70 x 64)

4.71 x 2.74 x 3.26

(120 x 70 x 83)

K L M N P

3.62

(92)

4.41

(112)

3.62

(92)

4.41

(112)

3.62

(92)

4.41

(112)

2.44

(62)

2.44

(62)

2.44

(62)

2.44

(62)

2.44

(62)

2.44

(62)

2.85

(72)

3.63

(92)

2.85

(72)

3.63

(92)

2.85

(72)

3.63

(92)

1.66

(42)

1.66

(42)

1.66

(42)

1.66

(42)

1.66

(42)

1.66

(42)

HOLE

SHIPPING WT.

DIA.

N/A N/A CF

N/A N/A CF

N/A

1.97

(50)

N/A

1.97

(50)

1.20

(31)

1.20

(31)

0.89

(23)

0.89

(23)

CF

CF

CF

CF

31

6

BantamBox (BB)

W

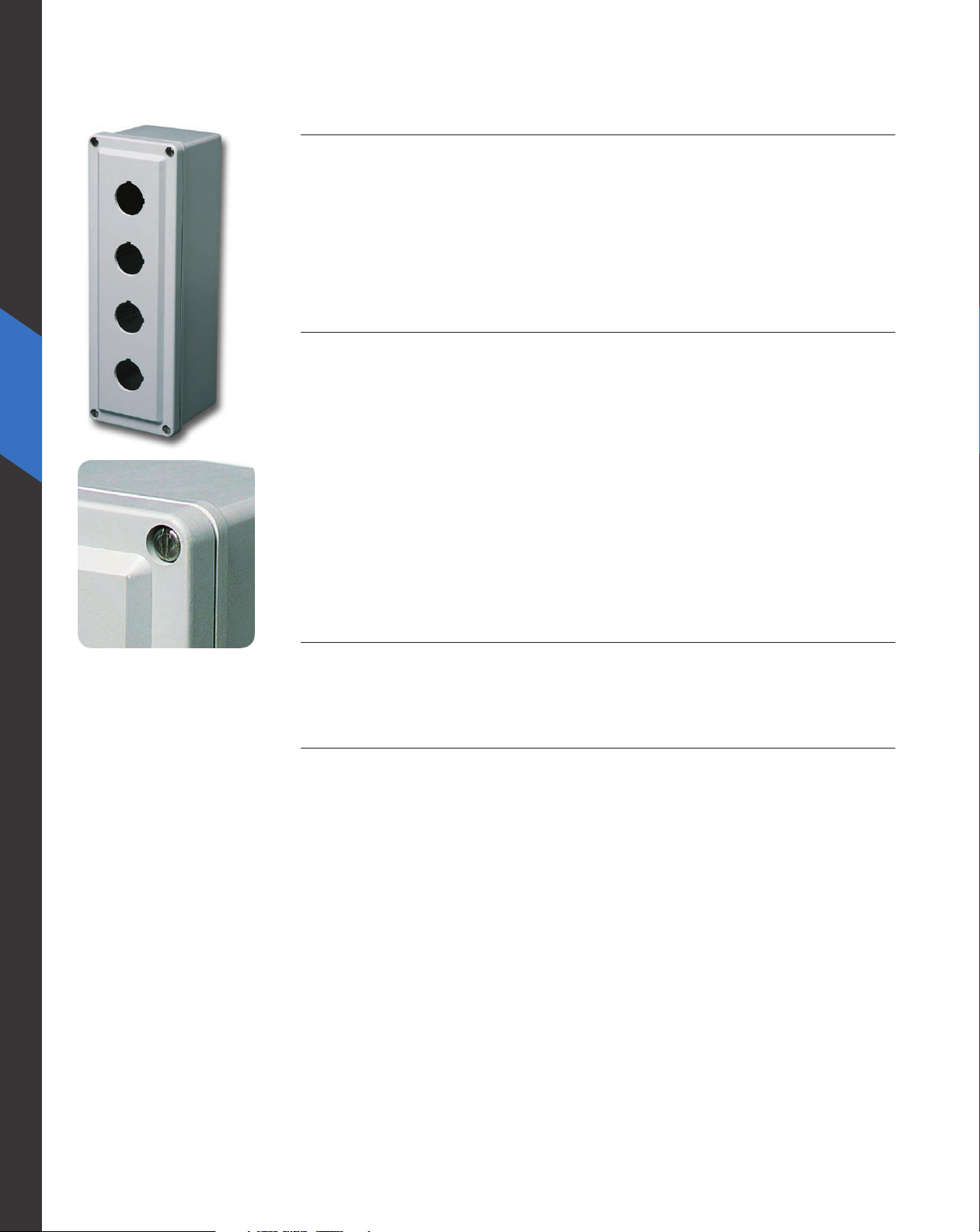

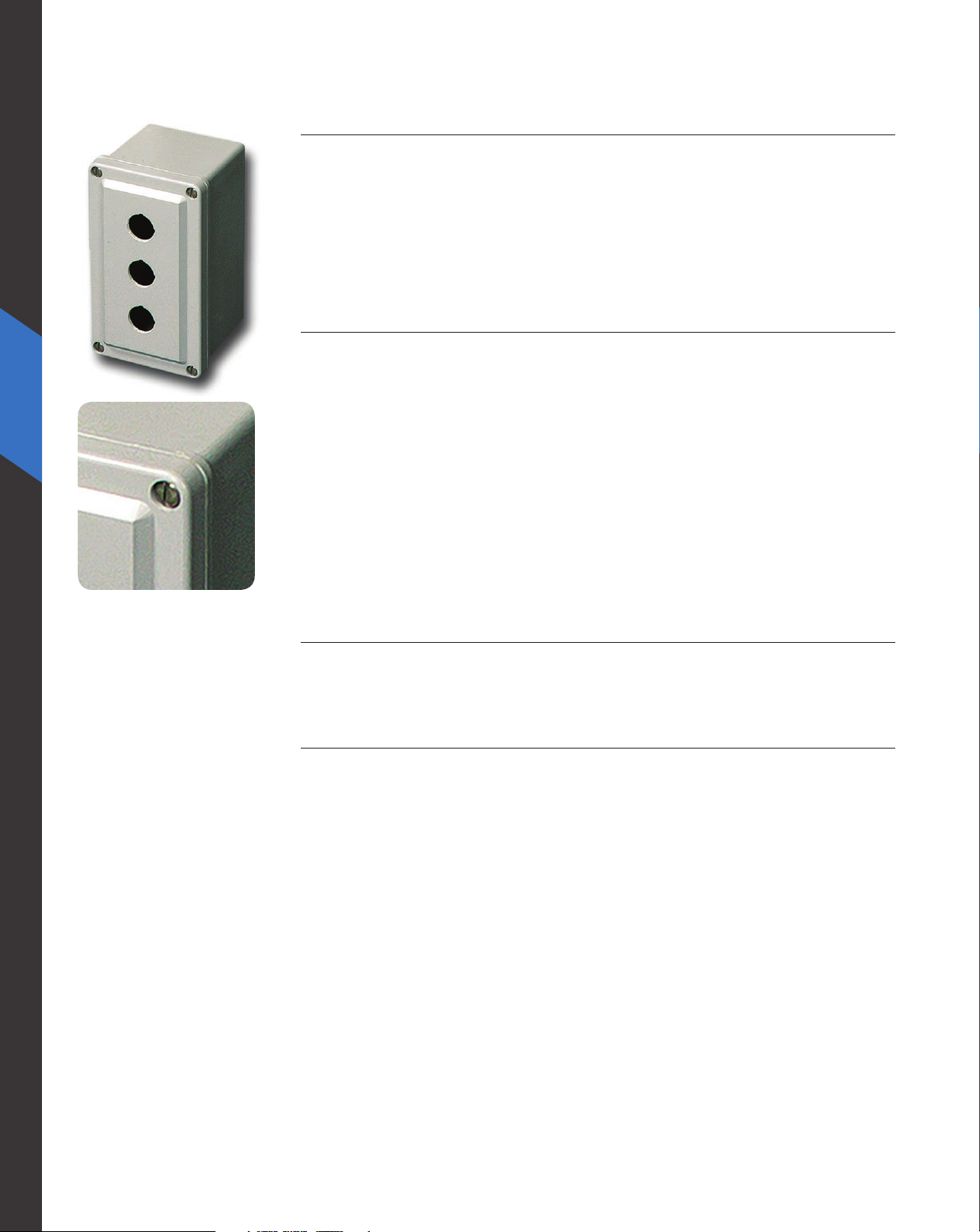

BantamBox™ Series

Proven Protection When “Small Is A Big Advantage!”

BantamBox is a polycarbonate enclosure series in either opaque (BB) screw cover or clear (BBCC) screw cover versions.

The flush sides of the enclosure make it a sought-after OEM design product. Raised bosses accommodate back panel

mounting and are successfully used for remote sensor mounting and small electronic controls in any environment.

These modular enclosures offer a broad range of 72 sizes and are ideal as project boxes in both their opaque

and clear forms.

BANTAMBOX SERIES ATTRIBUTES

• Available in 2 cover options

1. Opaque Cover

2. Clear Cover

• Multiple depths available in most sizes

• Resistant to harsh environments

• Flush sides for that perfect fit

• Multiple molded in bosses for a variety of mounting solutions

BANTAMBOX SERIES INDUSTRY STANDARDS

UL/cUL File # E319779

NEMA Ratings 1, 3R, 4, 4X, 12

(UL508A, UL50 & UL50e)

IEC 60529 Ratings IP66 Per UL File# E362920

Temperature Range (-40°F to +212°F) (-40°C to +100°C)

Flammability Rating UL94-V2

Self Extinguishing Non-Halogenated

Certifications cULus, IEC, REACH, RoHS

Outdoor UV Exposure (UL 746C) (f1) Rated

Chemical Resistance See chart on page 120

32

BantamBox | Opaque Cover (BB)

6

BantamBox (BB)

W

W

BantamBox | Clear Cover (BBCC)

W

33

6

BantamBox (BB)

BantamBox | Opaque Cover | W

4 COVER SCREWS, LIFT OFF COVER

CONSTRUCTION

Material (Box & Cover) Polycarbonate

Gasket Material Poured polyurethane seamless gasket

Cover Screw Material 304 Stainless Steel

Cover Screw Size Various

Cover Screw Torque M4: 9 - 17 in.-lbs., M6: 17-22 in.-lbs.

INDUSTRY STANDARDS

UL/cUL File # E319779 Per UL File# E362920

NEMA Ratings 1, 3R, 4, 4X, 12

(UL508A, UL50 & UL50e)

IEC 60529 Ratings IP66

Temperature Range (-40°F to +212°F) (-40°C to +100°C)

Flammability Rating UL94-V2

Self Extinguishing Non-Halogenated

Certifications cULus, IEC, REACH, RoHS

Outdoor UV Exposure (UL 746C) (f1) Rated

Chemical Resistance See chart on page 120

ACCESSORIES

W

BACK PANELS

Phenolic Resin Hard Paper

Back Panel BPB__P pg. 110

All Other Accessories Pg. 102-117

MODIFICATIONS

Silk Screening pg. 10-11

Custom Cutouts/Holes pg. 10-11

34

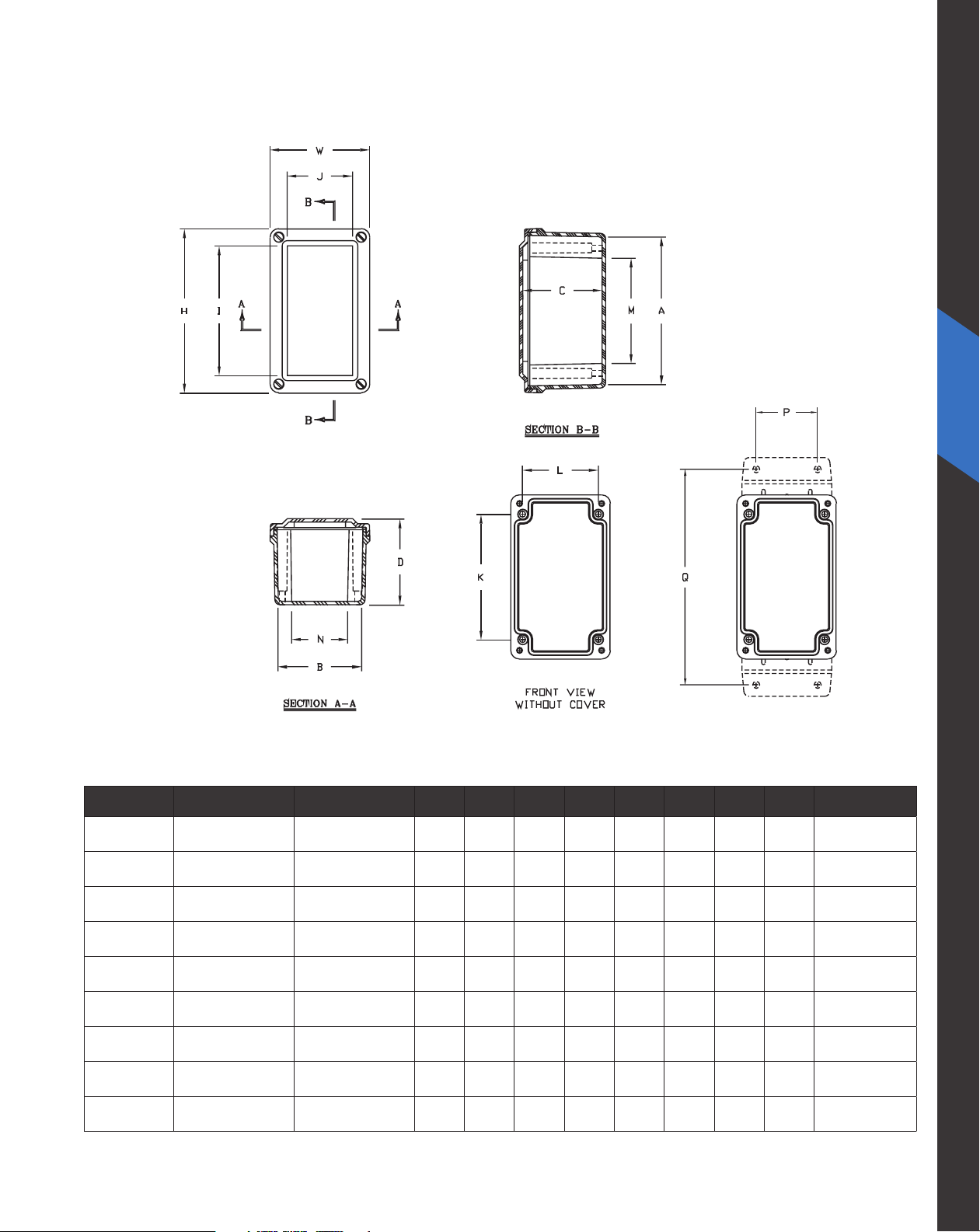

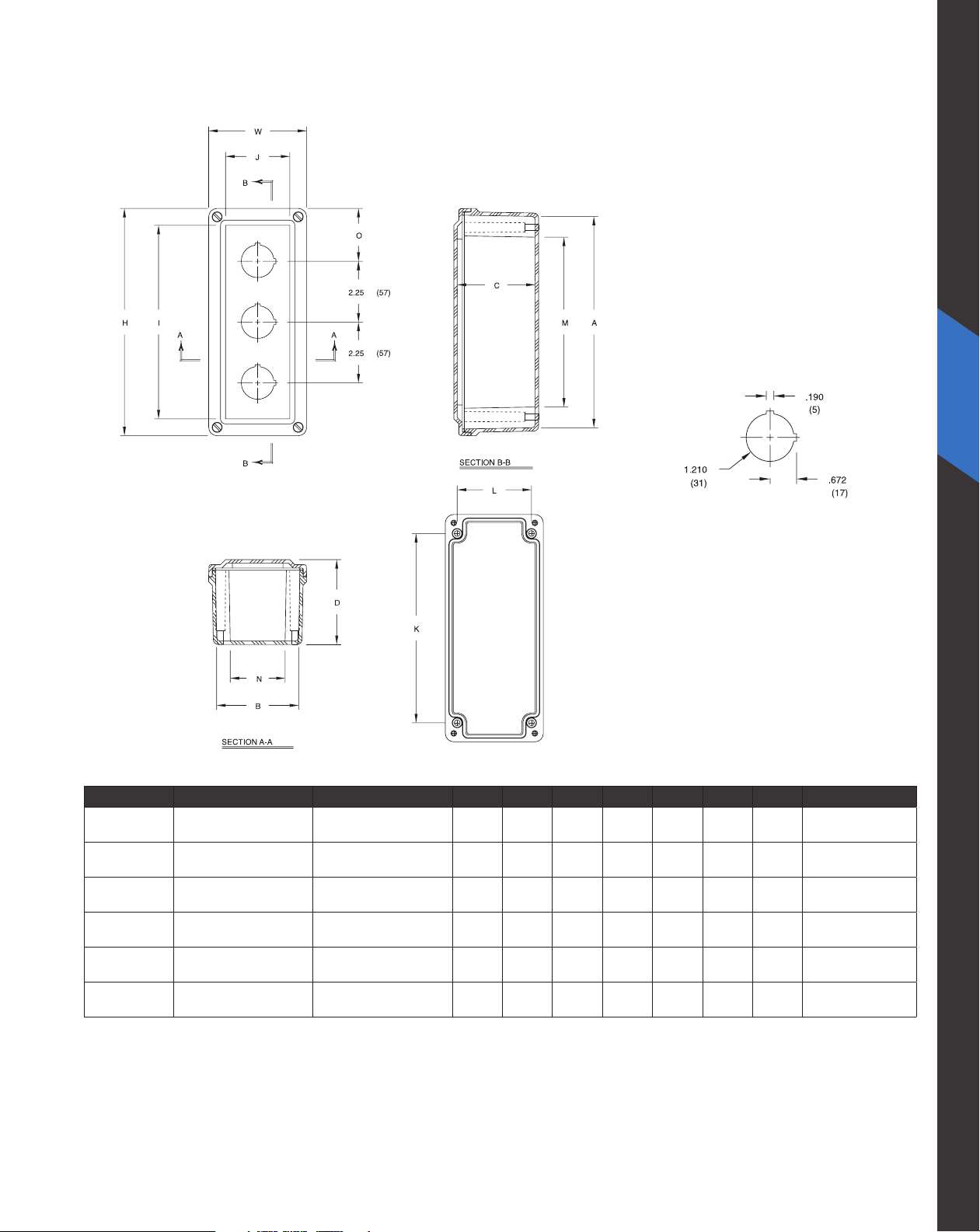

BantamBox | Opaque Cover | W

TECHNICAL DRAWINGS

6

BantamBox (BB)

W

35

BantamBox | Opaque Cover | W

DIMENSIONS

6

BantamBox (BB)

W

PART NUMBER

BB050504W

BB060504W

BB060505W

BB060545W

BB060555W

BB060603W

BB090603W

BB080805W

BB080807W

BB080809W

BB080810W

BB128035W

BB128040W

BB128045W

BB128050W

BB128055W

BB128060W

BBR128060W

BB128065W

BB128070W

BBR128070W

BB128080W

BBR128080W

BB128085W

BB128090W

BB128010W

BB168035W

BB168055W

BB168060W

BB168085W

BB168090W

BB208055W

BB121255W

BB121275W

BB121285W

BB121211W

“OVERALL

W X H X D”

2.05 x 1.97 x 1.38

(52 x 50 x 35)

2.56 x 1.97 x 1.38

(65 x 50 x 35)

2.56 x 1.97 x 1.77

(65 x 50 x 45)

2.56 x 1.97 x 1.77

(65 x 50 x 45)

2.56 x 1.97 x 2.17

(65 x 50 x 55)

2.52 x 2.28 x 1.46

(64 x 58 x 37)

3.86 x 2.52 x 1.46

(98 x 64 x 37)

3.23 x 3.15 x 2.17

(82 x 80 x 55)

3.23 x 3.15 x 2.56

(82 x 80 x 65)

3.23 x 3.15 x 3.35

(82 x 80 x 85)

3.23 x 3.15 x 3.74

(82 x 80 x 95)

4.72 x 3.15 x 1.42

(120 x 80 x 36)

4.72 x 3.15 x 1.61

(120 x 80 x 41)

4.72 x 3.15 x 1.85

(120 x 80 x 47)

4.72 x 3.15 x 1.97

(120 x 80 x 50)

4.72 x 3.15 x 2.17

(120 x 80 x 55)

4.72 x 3.15 x 2.36

(120 x 80 x 60)

4.72 x 3.15 x 2.36

(120 x 80 x 60)

4.72 x 3.15 x 2.56

(120 x 80 x 65)

4.72 x 3.15 x 2.79

(120 x 80 x 70)

4.72 x 3.15 x 2.79

(120 x 80 x 70)

4.72 x 3.15 x 3.15

(120 x 80 x 80)

4.72 x 3.15 x 3.15

(120 x 80 x 80)

4.72 x 3.15 x 3.35

(120 x 80 x 85)

4.72 x 3.15 x 3.54

(120 x 80 x 90)

4.72 x 3.15 x 3.94

(120 x 80 x 100)

6.30 x 3.15 x 1.46

(160 x 80 x 37)

6.30 x 3.15 x 2.17

(160 x 80 x 55)

6.30 x 3.15 x 2.36

(160 x 80 x 60)

6.30 x 3.15 x 3.35

(160 x 80 x 85)

6.30 x 3.15 x 3.54

(160 x 80 x 90)

7.87 x 3.15 x 2.17

(200 x 80 x 55)

4.80 x 4.72 x 2.17

(122 x 120 x 55)

4.80 x 4.72 x 2.95

(122 x 120 x 75)

4.80 x 4.72 x 3.35

(122 x 120 x 85)

4.80 x 4.72 x 4.13

(122 x 120 x 105)

“INSIDE

A X B X C”

1.85 x 1.77 x 1.22

(47 x 45 x 31)

2.40 x 1.81 x 1.18

(61 x 46 x 30)

2.40 x 1.81 x 1.57

(61 x 46 x 40)

2.36 x 1.77 x 1.57

(60 x 45 x 40)

2.36 x 1.77 x 1.93

(60 x 45 x 49)

2.28 x 2.05 x 1.18

(58 x 52 x 30)

3.54 x 2.20 x 1.93

(90 x 56 x 49)

3.03 x 2.95 x 1.93

(77 x 75 x 49)

3.03 x 2.95 x 2.32

(77 x 75 x 59)

3.03 x 2.95 x 3.11

(77 x 75 x 79)

3.03 x 2.95 x 3.50

(77 x 75 x 89)

4.49 x 2.91 x 1.18

(114 x 74 x 30)

4.49 x 2.91 x 1.38

(114 x 74 x 35)

4.49 x 2.91 x 1.57

(114 x 74 x 40)

4.49 x 2.91 x 1.73

(114 x 74 x 44)

4.49 x 2.91 x 1.93

(114 x 74 x 49)

4.49 x 2.91 x 2.13

(114 x 74 x 54)

4.49 x 2.91 x 2.13

(114 x 74 x 54)

4.49 x 2.91 x 2.32

(114 x 74 x 59)

4.49 x 2.91 x 2.52

(114 x 74 x 64)

4.49 x 2.91 x 2.52

(114 x 74 x 64)

4.49 x 2.91 x 2.95

(114 x 74 x 75)

4.49 x 2.91 x 2.95

(114 x 74 x 75)

4.49 x 2.91 x 3.15

(114 x 74 x 80)

4.49 x 2.91 x 3.35

(114 x 74 x 85)

4.49 x 2.91 x 3.74

(114 x 74 x 95)

6.10 x 2.95 x 1.22

(155 x 75 x 31)

6.10 x 2.91 x 1.93

(155 x 74 x 49)

6.10 x 2.91 x 2.09

(155 x 74 x 53)

6.10 x 2.91 x 3.11

(155 x 74 x 79)

6.10 x 2.91 x 3.31

(155 x 74 x 84)

7.64 x 2.91 x 1.93

(194 x 74 x 49)

4.57 x 4.49 x 1.97

(116 x 114 x 50)

4.57 x 4.49 x 2.72

(116 x 114 x 69)

4.57 x 4.49 x 3.15

(116 x 114 x 80)

4.57 x 4.49 x 3.94

(116 x 114 x 100)

“MOUNTING

E X F”

1.57 x 1.50

(40 x 38)

2.07 x 1.50

(53 x 38)

2.07 x 1.50

(53 x 38)

2.07 x 1.50

(53 x 38)

2.07 x 1.50

(53 x 38)

2.05 x 1.81

(52 x 46)

3.39 x 2.05

(86 x 52)

2.76 x 1.97

(70 x 50)

2.76 x 1.97

(70 x 50)

2.76 x 1.97

(70 x 50)

2.76 x 1.97

(70 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

4.25 x 1.97

(108 x 50)

5.83 x 1.97

(148 x 50)

5.83 x 1.97

(148 x 50)

5.83 x 1.97

(148 x 50)

5.83 x 1.97

(148 x 50)

5.83 x 1.97

(148 x 50)

7.40 x 1.97

(188 x 50)

4.33 x 3.54

(110 x 90)

4.33 x 3.54

(110 x 90)

4.33 x 3.54

(110 x 90)

4.33 x 3.54

(110 x 90)

J K L

1.06

(27)

0.98

(25)

1.34

(34)

1.38

(35)

1.73

(44)

0.98

(25)

1.10

(28)

1.73

(44)

2.09

(53)

2.91

(74)

2.91

(74)

0.98

(25)

1.18

(30)

1.38

(35)

1.54

(39)

1.73

(44)

1.93

(49)

1.93

(49)

2.13

(54)

2.36

(60)

2.32

(59)

2.76

(70)

2.76

(70)

2.95

(75)

3.15

(80)

3.58

(91)

0.98

(25)

1.73

(44)

1.89

(48)

2.91

(74)

3.11

(79)

1.65

(43)

1.73

(44)

2.52

(64)

2.95

(75)

3.74

(95)

0.67

(17)

1.50

(38)

1.50

(38)

1.50

(38)

1.50

(38)

1.57

(40)

3.19

(81)

2.28

(58)

2.28

(58)

1.73

(44)

1.73

(44)

3.23

(82)

3.23

(82)

3.23

(82)

3.78

(96)

3.78

(96)

3.23

(82)

3.23