Page 1

AT&T System 75

and System 75 XE

Wiring

Copyright © 1987 AT&T — All Rights Reserved

Printed in U.S.A.

555-200-111

Issue 1, April 1987

Page 2

TO ORDER COPIES OF THIS MANUAL

Call:

Write:

Call:

AT&T Customer Information Center on 800-432-6600

In Canada Call 800-255-1242

AT&T Customer Information Center

2855 North Franklin Road

P. O. BOX 19901

Indianapolis, Indiana 46219

TO COMMENT ON THIS MANUAL

The AT&T Document Development Organization

Hot Line:

800-334-0404

In North Carolina Call 919-727-3167

Every effort was made to ensure that the information in

this document was complete and accurate at the time of

printing. However, information is subject to change. This

document will be reissued periodically to incorporate

changes.

Published by

The AT&T Documentation Management Organization

Page 3

INTRODUCTION

CONTENTS

Page

ORGANIZATION

Use of Guide

Equipment

GENERAL

CROSS-CONNECT HARDWARE SELECTION

WIRING HARDWARE CHANGES

PLANNING

Job Aids

Terminals

Site or Satellite Closets

Cabling Facilities

1-3

1-3

1-4

1-4

1-7

1-7

1-7

1-8

1-8

1-10

1-10

-i-

Page 4

LIST OF FIGURES

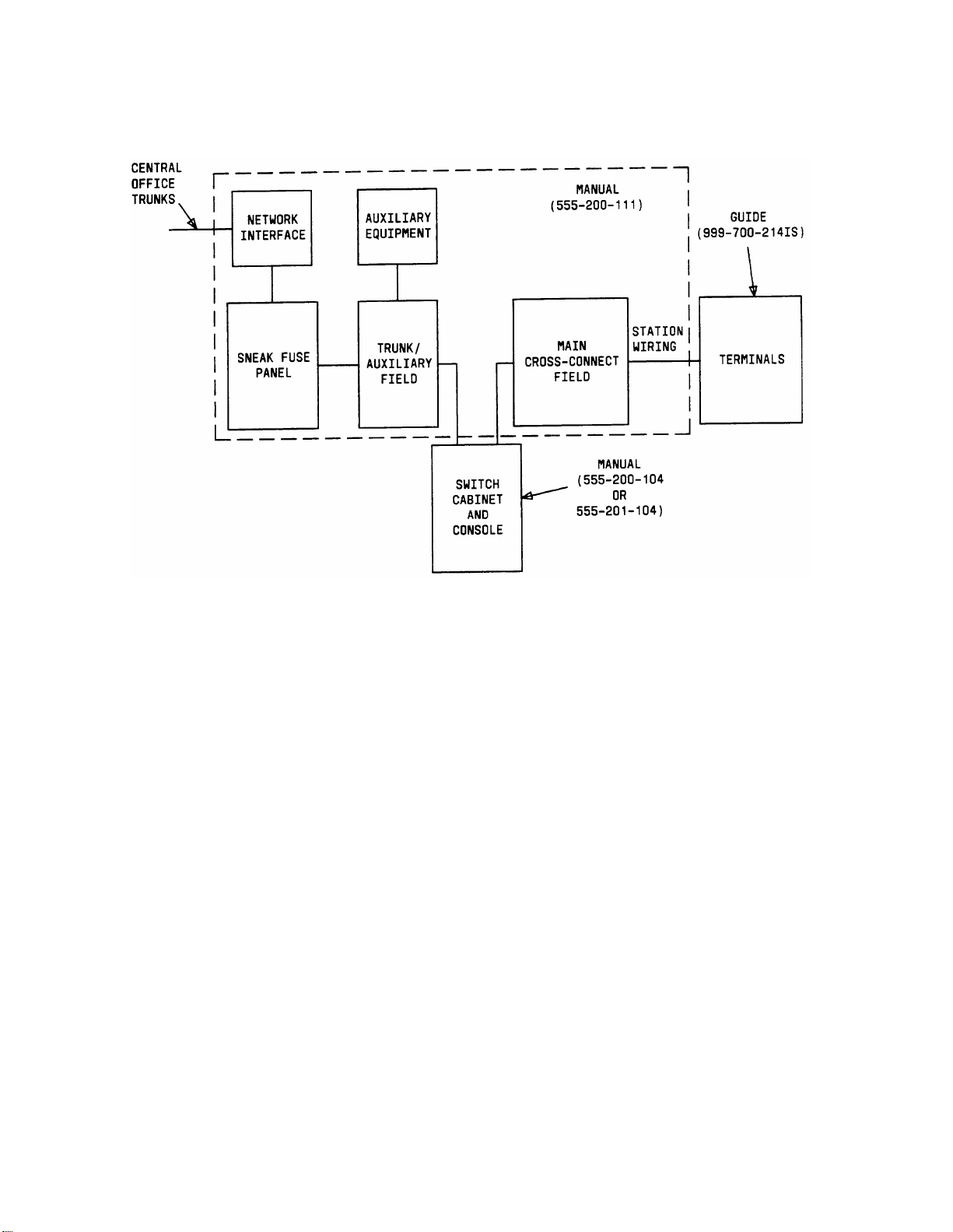

Figure 1-1. Documentation Block Diagram

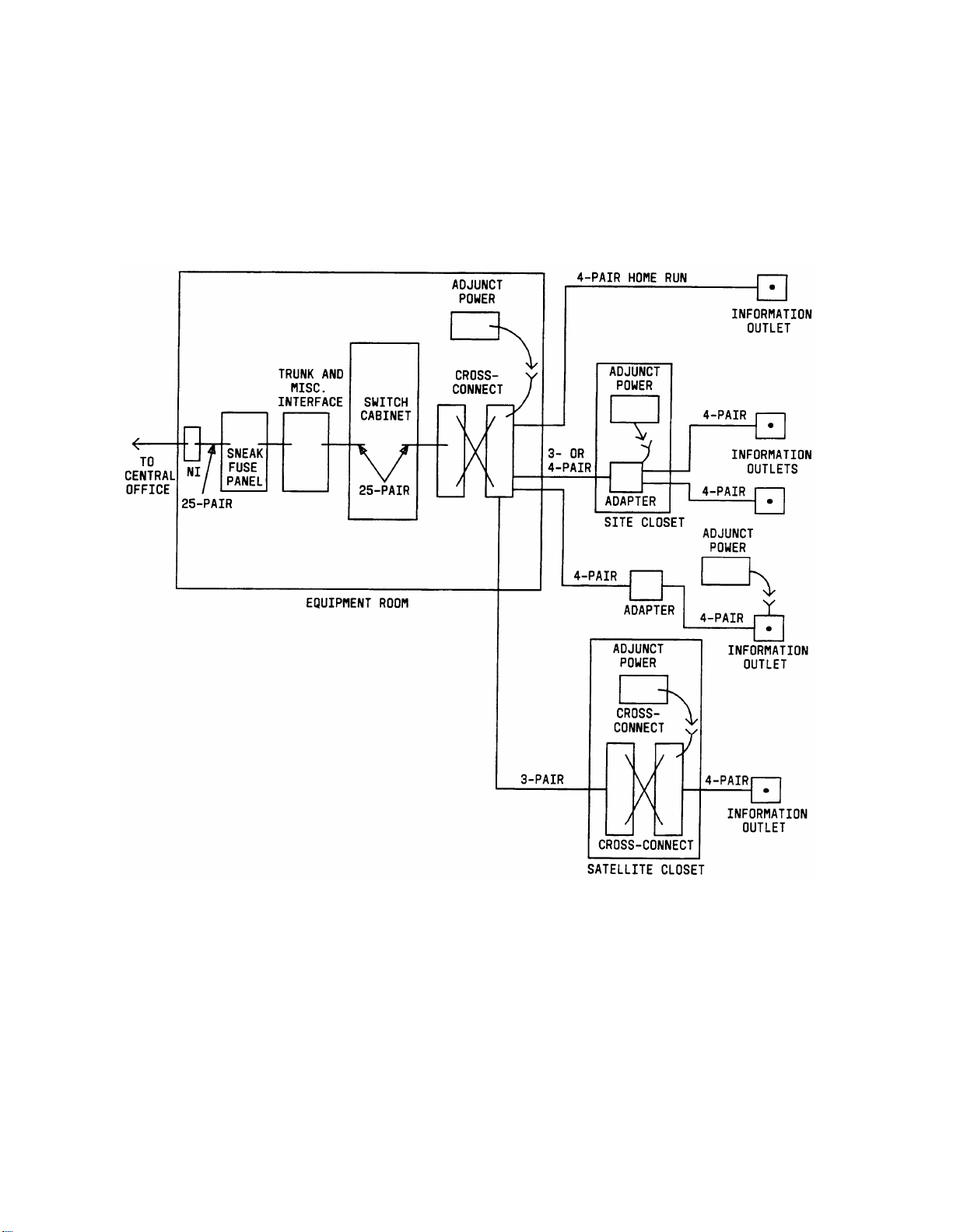

Figure 1-2. System Uniform Wiring Plan

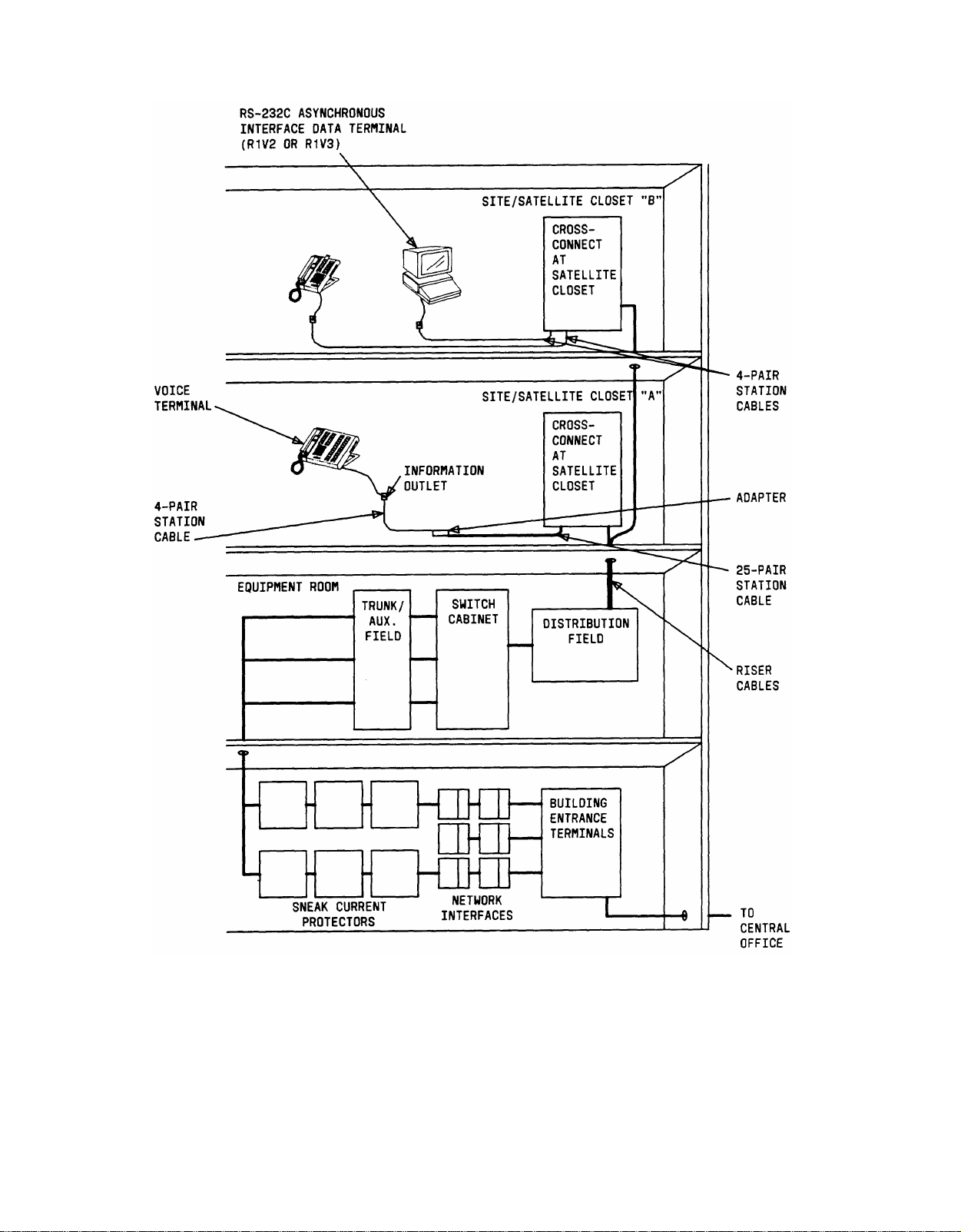

Figure 1-3. Sample Uniform Wiring Installation

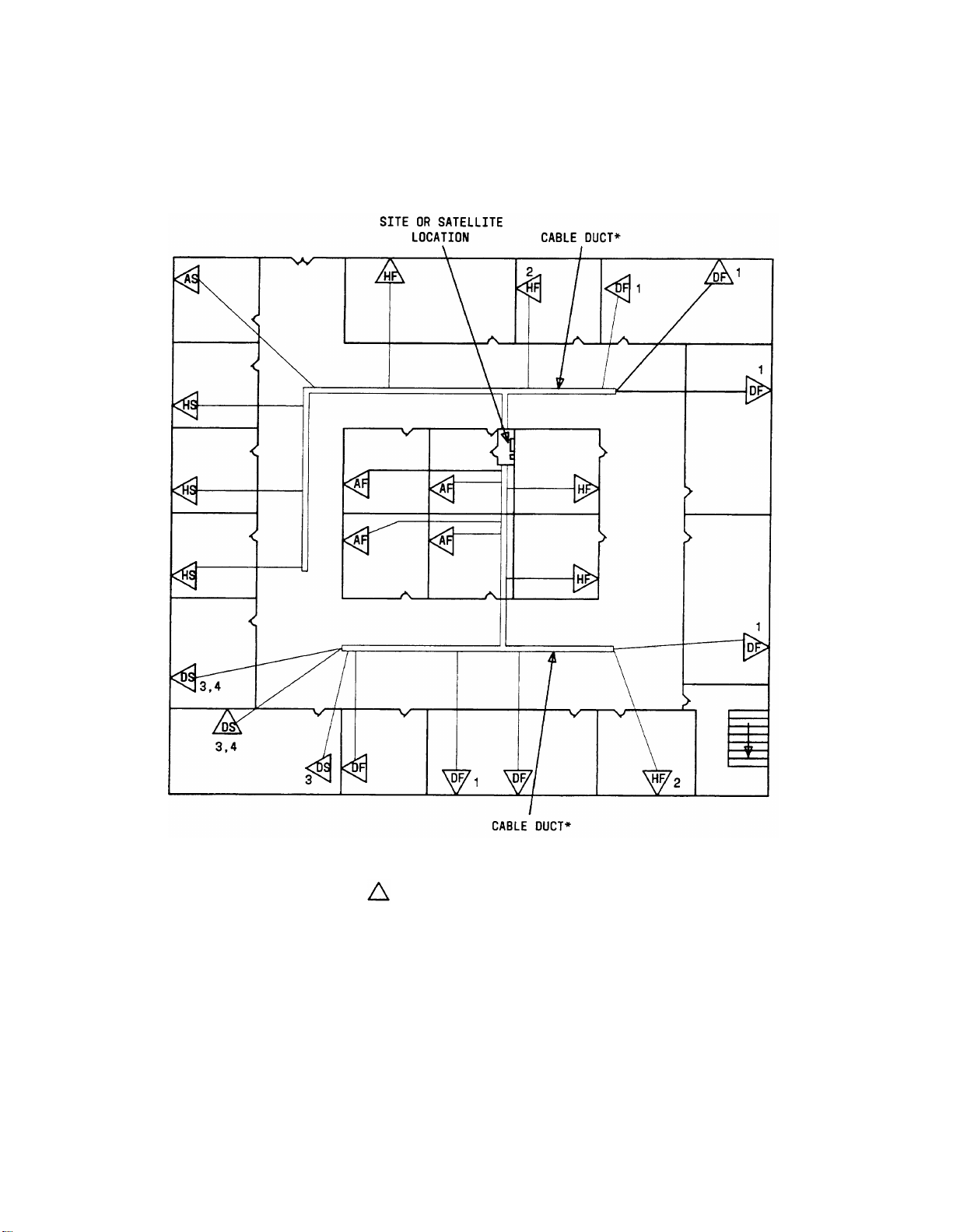

Figure 1-4. Sample Floor Plan With Terminal Locations Marked

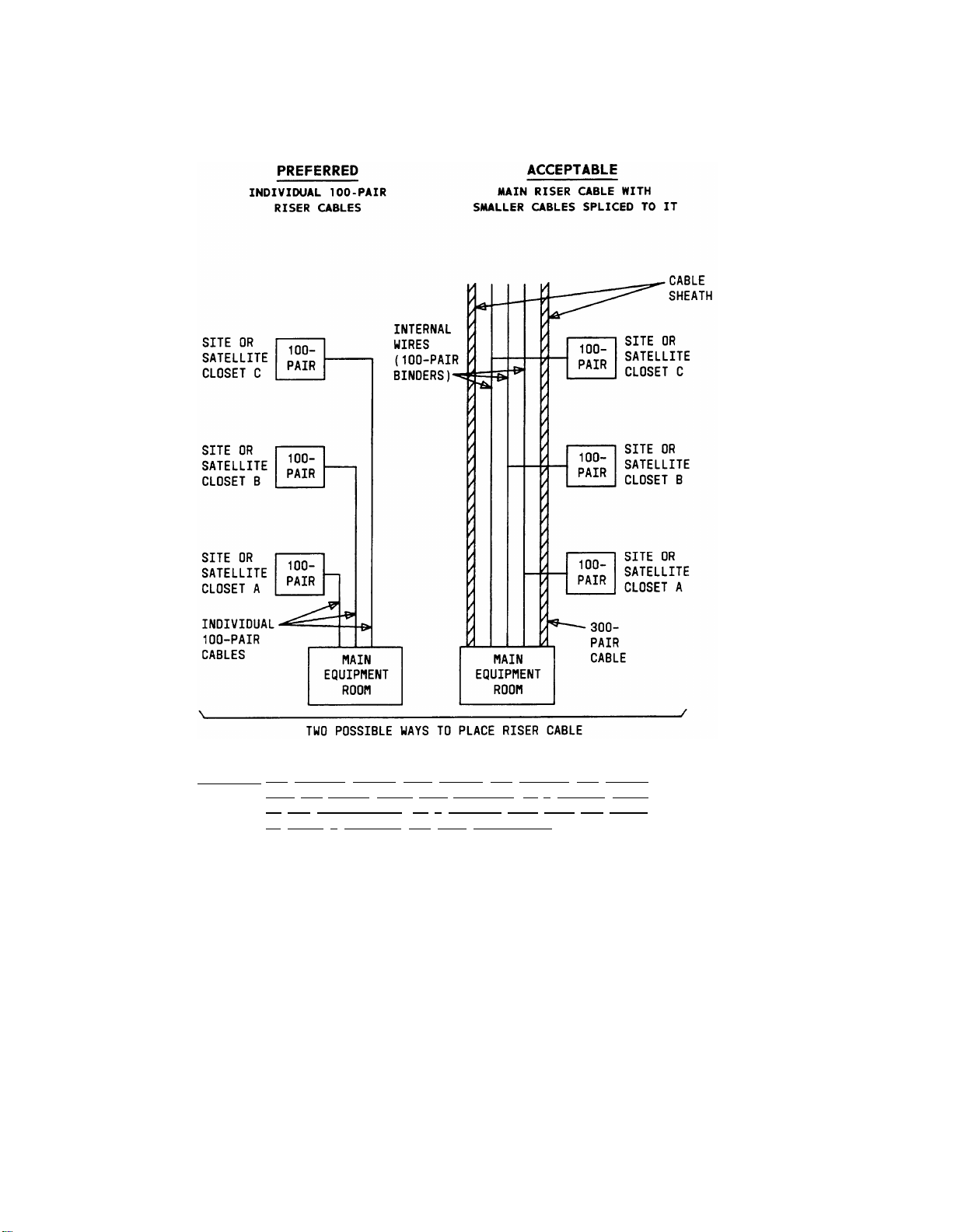

Figure 1-5. Riser Cable Placement

1-2

1-5

1-6

1-9

1-11

-ii-

Page 5

1. INTRODUCTION

This is one of three documents (Figure 1-1) required for the installation of the System 75 or

the System 75 XE. This guide explains the hardware, job planning, equipment ordering, and

installation information from:

●

The telephone company network interface up to and including the 25-pair cables that

connect directly to the switch and

●

The main equipment room cross-connect field and cabling from this field to the

switch cabinet and to the 8-pin modular wall jacks (information outlets).

Unless a statement is made that a topic is strictly for the System 75 or the System 75 XE,

all information in this document refers to both systems.

The other two documents required for the installation of the System 75 or System 75 XE are

as follows:

AT&T System 75—Installation and Test (555-200-104):

Contains information for installing and testing the System 75 switch and the

attendant console. (For continuity purposes, wiring of the attendant console is

also covered in this guide.)

AT&T System 75 XE—Installation and Test (555-201-104):

Contains information for installing and testing the System 75 XE switch and the

attendant console. (For continuity purposes, wiring of the attendant console is

also covered in this guide.)

AT&T System 75 and System 85—Terminal Installation and Test (999-700214IS):

Contains information for the installing and testing of the voice terminals and

their associated adjuncts.

1-1

Page 6

Figure 1-1. Documentation Block Diagram

1-2

Page 7

ORGANIZATION

This guide is organized into five sections:

●

SECTION 1—INTRODUCTION

Contains an overview of the system Uniform Wiring Plan and presents

general guidelines on hardware selection and manual organization.

●

SECTION 2—Z100-TYPE MODULAR HARDWARE

Contains an explanation of Z100-type and associated hardware, job planning,

equipment ordering codes, and how to install the hardware.

●

SECTION 3—110-TYPE HARDWARE

Contains an explanation of 110-type and associated hardware, job planning,

equipment ordering codes, and how to install the hardware.

●

SECTION 4—66-TYPE HARDWARE

Contains an explanation of 66-type and associated hardware, job planning,

equipment ordering codes, and how to install the hardware.

●

SECTION 5—GLOSSARY

Contains a brief description of some of the terms used in this guide.

●

SECTION 6—INDEX

Contains a permuted index.

Use of Guide

This guide will be helpful in planning, designing, and installing a cost-effective wiring

installation that allows moves, changes, and additions to be made quickly and easily. To

make the best use of this guide, take the time to read it thoroughly and become familiar

with its contents and organization. For quick access to information needed to answer most

questions, simply refer to the table of contents and locate the specific item in question.

To answer questions requiring more information than this guide contains, consult the

documents listed previously in this introduction section. If you need additional help, contact

the Premises Services Consultant (PSC).

For further technical assistance, the recommended channel for AT&T System Technicians is

as follows:

1.

Contact your Field Assistance and Support Team (FAST).

2.

If a satisfactory answer is not obtained from the FAST center, contact your

supervisor.

3.

Your supervisor should contact the regional staff, if necessary.

1-3

Page 8

Equipment

Most of the items specified in this guide are available through your local AT&T Information

Systems Marketing Branch Office (MBO). However, some common use hardware items may

have to be obtained from other sources.

GENERAL

Station wiring has a significant role in today’s customers’ information systems.

Technological innovations have enabled both voice and data transmission to be provided

through communications system wiring and have simplified wiring by significantly reducing

the number of cable pairs required by terminals with enhanced feature options.

This guide provides planning, ordering, and installation guidelines for a system Uniform

Wiring Plan (Figures 1-2 and 1-3) using Z100-, 110-type, or 66-type hardware.

The system switch ports for data and voice terminals require three pairs of wire per circuit.

Voice terminal adjuncts require an additional pair for remote powering. To provide

maximum flexibility for voice terminal changes, rearrangements, and powering, all data and

voice terminal information outlets are wired with 4-pair cable. With proper administration,

this will allow any terminal to be located at any information outlet.

1-4

Page 9

Figure 1-2. System Uniform Wiring Plan

1-5

Page 10

1-6

Figure 1-3. Sample Uniform Wiring Installation

Page 11

CROSS-CONNECT HARDWARE SELECTION

The following cross-connect hardware for new wiring installations is listed for the system.

Following each list item are considerations that should help to determine the appropriate

selection.

Z100-Type Hardware

1.

●

Designed particularly for customer participation in cross-connect

administration due to patch cord design

Does not require technical skills for cross-connect administration

●

Firm quote price list for all installations up to 150 stations

●

110P Hardware

2.

●

Customer participation in cross-connect administration due to patch cord

design

Requires some amount of technical skill for cross-connect administration

●

3. 110A Hardware

Not designed for customer participation in cross-connect administration—

●

requires technically skilled personnel due to use of jumper wires

●

Less expensive material cost than the patch cord systems, but more

expensive installation and administrative labor cost

66-Type Hardware

4.

● Not designed for customer participation in cross-connect administration—

requires technically skilled personnel due to use of jumper wires

Less expensive material cost than the patch cord systems, but more

●

expensive installation and administrative labor cost

Obviously, the customer’s degree of interest and preference for administering his or her own

cross-connections (because of likely lower total annual costs, as well as preference for

administering his or her cross-connect field at his or her convenience) should be given

primary consideration in recommending cross-connect hardware.

WIRING HARDWARE CHANGES

All jobs engineered by Premises Services Consultants (PSCs) based on customer

requirements and preferences should not be redesigned by the Field Services Organization

(FSO) without approval by the PSC/Marketing Branch Office (MBO). A change order must

be issued to affect billing.

PLANNING

The following brief introductory information will help you design a uniform wiring plan with

sufficient growth potential. The plan is flexible, simple, easy to administer, and reasonable

in cost.

1-7

Page 12

Job Aids

Blueprints (floor plans) are an important tool when planning, designing, and installing

station wiring. The floor plans (Figure 1-4) provide a complete view of all conduit and other

cabling facilities placed during construction of the building. These facilities should be

considered when planning site or satellite locations and cabling.

Terminals

The number of information outlets to be installed per terminal location should be

determined by your requirements. It may also be advantageous to initially install any

additional information outlets that may be required for future growth or terminal

rearrangements.

To begin designing the station wiring, indicate the following information on the floor

plan(s):

● Location of each information outlet and associated terminal type if known (analog,

hybrid, or digital)

●

Any associated terminal adjuncts or modules and the required powering

arrangements.

1-8

Page 13

* AN OPTION TO THE CABLE DUCT SHOWN IS TO RUN CABLES (PLENUM-APPROVED, IF

APPROPRIATE OR REQUIRED) ABOVE A DROP/FALSE CEILING.

- INFORMATION OUTLET LOCATION

A-

ANALOG TERMINAL DEVICE

H -

HYBRID TERMINAL DEVICE

D -

DIGITAL TERMINAL DEVICE

S-

SURFACE MOUNTED INFORMATION OUTLET

F-

FLUSH MOUNTED INFORMATION OUTLET

1 -

SPEAKERPHONE

2 -

AMPLIFIED HEADSET

3 -

CALL COVERAGE MODULE

4 -

FUNCTION KEY MODULE

5 -

DISPLAY MODULE

Figure 1-4. Sample Floor Plan With Terminal Locations Marked

1-9

Page 14

Site or Satellite Closets

When determining the site or satellite closets, use the following information as a guide.

Indicate the locations on the floor plan.

Keep the number of locations to a minimum.

a.

To minimize the station wiring distances, centrally locate the site or satellite

b.

closets among the information outlets.

Site or satellite closets should be easily accessible and contain sufficient ac power

c.

outlets. Terminals equipped with adjuncts that require power can be remotely

powered from a site or satellite location as well as from the main equipment room

or at information outlets. The distance between the power supply and the terminal

cannot exceed 250 feet (76.2 m) using 24-gauge wire.

Locks should be provided for the site or satellite closet to prevent tampering.

d.

Cabling Facilities

The method of riser cable distribution between the main equipment room and the site or

satellite closets is usually determined by the type of cabling facilities (riser closets, conduit

size, cabling shafts, etc.) placed during construction of the building (Figure 1-5).

a.

The preferred arrangement is to have individual cables supply each site or satellite

closet.

b.

A second method is to have one or two large cables supply all the site or satellite

closets. This method requires smaller cables to be installed between the main riser

cable and the site or satellite closet. These smaller cables are spliced into the main

cable.

Determine the type of cabling required and mark the type and routing on the blueprint or

floor plan. Also indicate any additional cabling facilities required for riser and terminal

cabling.

1-10

Page 15

CAUTION:

THE UNIFORM WIRING PLAN SHOULD NOT CONTAIN ANY BRIDGE

TAPS (AN UNUSED CABLE PAIR CONNECTED TO A WORKING CABLE

OR THE CONTINUATION OF A WORKING PAIR PAST THE POINT

AT WHICH A TERMINAL HAS BEEN CONNECTED).

Figure 1-5. Riser Cable Placement

1-11

Page 16

2. Z100-TYPE HARDWARE—SYSTEM 75 AND SYSTEM 75 XE INSTALLATIONS

CONTENTS

Page

GENERAL

Z100-TYPE HARDWARE

Connector Modules

Z100A1 Connector Module

Z100B1 Connector Module

Connecting Units

Cords

ZD6A-87 Patch Cords

ZD2A-87-10 Power Adapter Cords

Associated Hardware

Cable Slack Managers

General

Z113A Housing

Z114A Housing

NETWORK INTERFACES

RJ21X Network Interfaces

RJ2GX Network Interfaces

1.544 Mbps Digital Service Interfaces

SNEAK FUSE PANELS

575-4 Sneak Current Fuse Assembly

TRUNK/AUXILIARY FIELD

Cable Access Panels and Emergency Transfer Units

400A Apparatus Mounting

400B Apparatus Mounting

400C Apparatus Mounting

2-1

2-2

2-2

2-4

2-4

2-7

2-10

2-10

2-11

2-12

2-12

2-12

2-13

2-13

2-15

2-15

2-15

2-15

2-15

2-15

2-16

2-17

2-17

2-17

2-17

TRUNK CONCENTRATOR CABLES

WP-90929, List 2, Cable Assembly

WP-90929, List 4, Cable Assembly

16-PORT ANALOG LINE BOARD ADAPTER CABLE

4-PORT MET LINE BOARD CONCENTRATOR CABLE

ADJUNCT POWER UNITS

Individual Power Supplies

-i-

2-20

2-20

2-20

2-23

2-24

2-24

2-24

Page 17

Bulk Power Supply

346 Modular Bulk Power Supply

EQUIPMENT ROOM DESIGN

Typical System Equipment Room Floor Plans

General

Typical Floor Plans

Single-Section Cross-Connect Field

Mult-Section Cross-Connect Field

Wall Space Requirements

Single-Section Cross-Connect Field

Multi-Section Cross-Connect Field

Equipment Requirements

Connector Module, Patch Cord, and Cable Slack Manager

Requirements

Cable Access Panel Requirements

Trunk Circuit Capacities

Selecting the Cable Access Panel

EQUIPMENT ROOM HARDWARE AND CABLING INSTALLATION

Hardware Installation

Installing the Cross-Connect Field

Installing Cable Slack Managers

Labeling the Cross-Connect Field

Main Cross-Connect Field

Multi-Section Cross-Connect Field

2-26

2-26

2-29

2-29

2-29

2-29

2-29

2-33

2-34

2-34

2-34

2-35

2-35

2-36

2-36

2-36

2-38

2-38

2-38

2-40

2-41

2-42

2-47

Installing the Cable Access Panels (CAPs)

Labeling the Cable Access Panel

Installing the Sneak Fuse Panels

Cable Installation

Labels

Routing Cable Guidelines

General

Routing Cables From Switch Cabinet to Cross-Connect Field

Routing Cables From Cable Access Panel to Switch Cabinet

Installing Control Carrier Outputs Cable

Installing Trunk Cables Between Network Interface and System

Cabinet

Installing Coupled Bonded Conductor Grounding

-ii-

2-50

2-51

2-60

2-60

2-60

2-61

2-62

2-63

2-64

2-65

2-66

2-73

Page 18

Installing Cables Between Switch Cabinet and the Cross-Connect

Field

Installing Cables Between Cross-Connect Field and Auxiliary

Cabinet

STATION WIRING DESIGN

Description

Information Outlets

Station Cables

Closets

Site Locations

Satellite Locations

Station Circuit Distribution From Equipment Room

4-Pair Station Circuits

3-Pair to 4-Pair Station Circuits

Layout

Locating Information Outlets

Locating Satellites and Sites

Adapter Requirements

2-74

2-78

2-78

2-78

2-78

2-78

2-80

2-80

2-82

2-83

2-83

2-83

2-88

2-88

2-88

2-88

Z100A1 Connector Module Requirements

Sizing 4-Pair Station Cables (DIW)

Sizing 25-Pair and Multiple 25-Pair Station Cables

3-Pair Station Cable Circuits

4-Pair Station Cable Circuits

STATION WIRING AND ASSOCIATED HARDWARE INSTALLATION

Installing the Station Cables

Installing Z100-Type Hardware at Satellite Locations

Labeling

Installing the Information Outlets

ADJUNCT POWERING

Adjunct Powering From the Equipment Room

Adjunct Powering From Satellite Locations

Adjunct Powering From Site Locations

Adjunct Powering From Information Outlets

PATCH CORD INSTALLATION AND ADMINISTRATION

Equipment Room Cross-Connect Field

Installing Patch Cords

Removing Patch Cords

2-88

2-88

2-88

2-88

2-89

2-89

2-89

2-92

2-93

2-95

2-96

2-96

2-96

2-96

2-100

2-102

2-105

2-105

2-105

-iii-

Page 19

Installing and Removing Power Adapter Cords

2-106

Satellite Locations

1-Point Administration

2-Point Administration

MISCELLANEOUS WIRING INSTALLATION

Installing Attendant Console

Installing Selector Console

Installing INADS (Initialization and Administration System) Interface

Installing DS1 Tie Trunks

Collocated DS1 Tie Trunks

DS1 Tie Trunks Using 551-Type CSU

Installing Customer-Provided Alarm—System 75 XE Only

Installing Off-Premises Terminal Wiring

Installing Out-of-Building Terminal Wiring

Analog Out-of-Building Terminals

Digital Out-of-Building Terminals

Installing Emergency Transfer Units and Terminals

2-106

2-107

2-107

2-107

2-107

2-111

2-112

2-114

2-114

2-114

2-116

2-116

2-118

2-118

2-119

2-122

574-5 Power Transfer Unit

Z1A Emergency Transfer Unit

Installing External Ringing

Installing Queue Warning Indicator

AUXILIARY EQUIPMENT INSTALLATION

Auxiliary Equipment Description

Installing Loudspeaker Paging and Music-on-Hold

Installing Loudspeaker Paging Access—278A Paging Adapter

Installing Loudspeaker Paging Access—89A Control Unit

PagePac PAGING SYSTEM

PagePac 20

PagePac VS

PagePac 50/100/200

Installing Music-on-Hold Access

Installing Loudspeaker Paging With Background Music

Installing Recorded Announcement Equipment

2-122

2-130

2-137

2-138

2-139

2-139

2-140

2-142

2-144

2-146

2-146

2-146

2-146

2-152

2-156

2-157

Digital Announcer

Installing Audichron Wake-Up Announcement System—R1V3 Only

Installing Dial Dictation Equipment

-iv-

2-161

2-162

2-165

Page 20

Installing 3270 Data Modules

2-166

Installing Processor Data Modules (PDMs)

Installing Applications Processor Interface—System 75 Only

Installing Audio Information Exchange (AUDIX) Interface—V3

Only

Installing Call Management System (CMS) Interface—V3 Only

Installing Distributed Communications System (DCS)—V2 and V3

Property Management System Interface—V3 Only

Installing Customer-Provided Terminal Using Asynchronous Data Units

(ADUs)

Installing Station Message Detail Recording Interface

2-168

2-171

2-173

2-173

2-173

2-174

2-174

2-176

-v-

Page 21

LIST OF FIGURES

Figure 2-1

Figure 2-2

Figure 2-3

Figure 2-4

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-8

Figure 2-9

Figure 2-10

Figure 2-11

Figure 2-12

Figure 2-13

Figure 2-14

Figure 2-15

Figure 2-16

Block Diagram of System 75 or System 75 Reinstallation

Station Wiring Alternatives

Z100-Type Support and Panel

Z100A1 Connector Module 2-5

Z100B1 Connector Module 2-6

Z100-Type Connecting Units

Connecting Unit Installation

Connecting Unit Removal

ZD6A-87 Patch Cord 2-11

ZD2A-87-10 Power Adapter Cord 2-12

Cable Slack Managers 2-14

Model 575-4 Sneak Fuse Panel 2-16

Cable Access Panel (400C Apparatus Mounting)

Cable Access Panel (Functional Diagram)

Trunk Concentrator Cables (WP-90929, Lists 2 and 4, Cable

Assemblies) 2-21

16-Port Analog Line Board Adapter Cable (853B Adapter)

2-1

2-2

2-3

2-8

2-9

2-10

2-18

2-19

2-24

Figure 2-17

Figure 2-18

Figure 2-19

Figure 2-20

Figure 2-21

Figure 2-22

Figure 2-23

Figure 2-24

Figure 2-25

Figure 2-26

Figure 2-27

Individual Power Supplies

AC Power Strip

346 Modular Bulk Power Supply

346A1 Power Panel Circuit Breaker Locations

Typical Single-Section Cross-Connect Field Installation

(Approximately 288 Station Capacity Illustrated)

Typical 2-Carrier System 75 Cabinet or 2-Cabinet System 75 XE Floor

Plan

Typical 5-Carrier System 75 Cabinet or 3- or 4-cabinet System 75 XE

Floor Plan

Typical Multi-Section Cross-Connect Field Installation (Approximately

576 Station Capacity Illustrated)

Typical 5-Carrier Cabinet Floor Plan Using a Multi-Section CrossConnect Field

Cross-Connect Field and Cable Access Panel Installation

System Label Graphic Symbols and Designation

Nomenclature

2-25

2-25

2-27

2-28

2-30

2-31

2-32

2-33

2-34

2-39

2-41

-vi-

Page 22

Figure 2-28

Cross-Connect Field Layout

2-42

Figure 2-29

Figure 2-30

Figure 2-31

Figure 2-32

Figure 2-33

Figure 2-34

Figure 2-35

Figure 2-36

Figure 2-37

Figure 2-38

Figure 2-39

Figure 2-40

Figure 2-41

Figure 2-42

Figure 2-43

Port Labels

4-Pair Station Appearance Labels

3-Pair Station Appearance Labels

Auxiliary Labels

Section TIE Labels

Clear Plastic Label Holder (188UT1-50 Strip Designation)

Control Carrier Outputs (AUXILIARY Label)

System Port Circuit Appearances and Trunk Labels

System Port Circuit Appearances and Auxiliary Circuit

Labels

Z1A Emergency Transfer Unit Labels

574-5 Power Transfer Unit Labels

"X" Connector Label 2-60

Equipment Room Cabling Labels 2-61

Self-Stick Label Installation on 25-Pair Cable Connector

Cable Routing Through Cable Slack Manager—1-Cabinet

Installation

2-43

2-44

2-45

2-46

2-47

2-51

2-53

2-55

2-56

2-58

2-59

2-61

2-62

Figure 2-44

Figure 2-45

Figure 2-46

Figure 2-47

Figure 2-48

Figure 2-49

Figure 2-50

Figure 2-51

Figure 2-52

Figure 2-53

Figure 2-54

Figure 2-55

Figure 2-56

Figure 2-57

Cable Routing From Switch Cabinet to Cross-Connect Field and Cable

Access Panel

Typical Port Cable Installation at Switch Cabinet 2-64

Control Carrier Outputs (AUXILIARY Connector)—System

75

Control Carrier Outputs (AUXILIARY Connector)—System 75

XE

System 75 2-Carrier Slot Addresses

System 75 5-Carrier Slot Addresses

System 75 XE Carrier Slot Addresses

Installing Concentrator Cables Between the CAP and the Switch

Cabinet

Coupled Bonded Conductor Grounding Installation

Connector Module Flex Tab Latch Locations

25-Pair Cable Routing Through Connector Module

4-Pair Single Modular Plug-Ended Station Cable 2-79

Example of Extending 4-Pair Station Cables

258A and BR2580A Adapters 2-81

2-63

2-65

2-66

2-69

2-70

2-71

2-72

2-74

2-76

2-77

2-80

Figure 2-58

356A Adapter

2-82

-vii-

Page 23

Figure 2-59

4-Pair Circuit Distribution and Connectivity from Equipment Room

Cross-Connect Field Using Z100A1 Connector Modules

2-83

Figure 2-60

Figure 2-61

Figure 2-62

Figure 2-63

Figure 2-64

Figure 2-65

Figure 2-66

Figure 2-67

Figure 2-68

Figure 2-69

Figure 2-70

3-Pair to 4-Pair Circuit Distribution and Connectivity From

Equipment Room (Z100B1 Connector Modules Used at Cross-Connect

Field and Z100A1 Connector Modules Used at Satellite

Location)

3-Pair to 4-Pair Circuit Distribution and Connectivity From

Equipment Room (Z100B1 Connector Modules Used at Cross-Connect

Field and 356A adapter Used at Site Location)

25-Pair Station Cable Labels

Multiple 25-Pair Station Cable With Factory-Installed Staggered

Fingers Connected to a Connector Module

4-Pair Station Wiring Labeling From Equipment Room to Information

Outlet

Typical Satellite Installation

Satellite Location Layout

3-Pair to 4-Pair Station Wiring Labeling From Equipment Room to

Information Outlet

Typical 8-Pin Modular Information Outlets

Remote Powering From a Z100A1 Connector Module Located at the

Equipment Room or Satellite Location

Remote Powering From a 258A Adapter in a Site Closet

2-84

2-85

2-89

2-90

2-91

2-92

2-93

2-94

2-95

2-97

2-98

Figure 2-71

Figure 2-72

Figure 2-73

Figure 2-74

Figure 2-75

Figure 2-76

Figure 2-77

Figure 2-78

Figure 2-79

Figure 2-80

Figure 2-81

Figure 2-82

Figure 2-83

Figure 2-84

Remote Powering From a 356A Adapter in a Site Closet

Typical Local Powering From a 400B2 Adapter—Flush-Mounted

Information Outlet

Typical Local Powering From a 400B2 Adapter—Surface-Mounted

Information Outlet

Port Assignment Record Form

1-Point Administration

2-Point Administration

Patch Cord Plug Release Tab Removal Location

Connections for Attendant Console

Wiring Required at Cable Access Panel for Attendant Console Remote

Powering From Switch Cabinet—System 75 Only

Selector Console Installation

Connections at Cable Access Panel for INADS Trunk

Connections for DS1 Tie Trunks Between 2 System 75s or System 75

XEs

Connections for DS1 Tie Trunks Using 551 T1 CSU

Connections for Off-Premises Terminals

2-99

2-100

2-101

2-103

2-104

2-104

2-107

2-109

2-110

2-111

2-113

2-115

2-115

2-117

Figure 2-85

Connections for One to Eight Out-of-Building Analog Voice Terminals

Only

-viii-

2-120

Page 24

Figure 2-86

Connections for Each Group of Eight Out-of-Building Analog Voice

Terminals

2-121

Figure 2-87

Figure 2-88

Figure 2-89

Figure 2-90

Figure 2-91

Figure 2-92

Figure 2-93

Figure 2-94

Figure 2-95

Figure 2-96

Figure 2-97

574-5 Power Transfer Unit Option Switches

Connections at Cable Access Panel for Voice Terminal Used Only for

Emergency Transfer—574-5 Power Transfer Unit

Connections at Cable Access Panel for Voice Terminal Used for

Emergency Transfer and as Normal Extension—574-5 Power Transfer

Unit

Connections at Cable Access Panel for Optional DID Make-Busy

Trunk—574-5 Power Transfer Unit

Connections at Cable Access Panel for Voice Terminal Used Only for

Emergency Transfer (Ground Start Trunks)—Z1A Emergency

Transfer Unit

Connections at Cable Access Panel for Voice Terminal Used for

Emergency Transfer and as Normal Extension (Ground Start

Trunks—Z1A Emergency Transfer Unit)

Connections at Cable Access Panel for Optional DID Make-Busy

Trunk—Z1A Emergency Transfer Unit

Ground Wiring Example (Three Voice Terminals Used Only for

Emergency Transfer)

Ground Wiring Example (Five Voice Terminals Used for Emergency

Transfer and as Normal Extensions)

Ground Start Key Installation

Connections for External Ringing or Queue Warning

Indicator

2-123

2-125

2-127

2-129

2-131

2-133

2-135

2-136

2-136

2-137

2-138

Figure 2-98

Figure 2-99

Figure 2-100

Figure 2-101

Figure 2-102

Figure 2-103

Figure 2-104

Figure 2-105

Figure 2-106

Figure 2-107

Figure 2-108

Figure 2-109

Connections for Loudspeaker Paging and Music-on-Hold

Connections for Loudspeaker Paging Zone—278A Paging

Adapter

Connections for Loudspeaker Paging Zone—89A Control Unit

Connections for PagePac 20 Without Zone-Mate 9 or 39

Connections for PagePac 20 With Zone-Mate 9 or 39

Connections for PagePac VS

Connections for PagePac 50/100/200 Amplicenter Only

Connections for PagePac 50/100/200 System

Connections for FCC Registered Equipment Provided for Music-on-

Hold/Dial Dictation Equipment (Auxiliary Access)

Connections for Non-FCC Registered Equipment Provided for Music-

on-Hold/Dial Dictation Equipment (Auxiliary Access)

Loudspeaker Paging With Background Music Connections—278A

Adapter

Loudspeaker Paging With Background Music Connections—89A

Control Unit

2-141

2-143

2-145

2-147

2-148

2-149

2-150

2-151

2-153

2-155

2-156

2-157

-ix-

Page 25

Figure 2-110

Connections for FCC Registered Equipment Provided for Recorded

Announcement/Dial Dictation Equipment (Analog Access)

2-158

Figure 2-111

Figure 2-112

Figure 2-113

Figure 2-114

Figure 2-115

Figure 2-116

Figure 2-117

Figure 2-118

Figure 2-119

Figure 2-120

Figure 2-121

Connections for Non-FCC Registered Recorded Announcement/Dial

Dictation Equipment (Analog Access)

Connections to Digital Announcer Located in Auxiliary

Cabinet

Connections for Analog Line Port to Wake-Up Announcement

Unit

Connections for Auxiliary Trunk Circuit Pack to Wake-Up

Announcement Unit

Connections for Power Unit to Wake-Up Announcement Unit

Connections for 3270A or 3270T Data Module

Connections for 3270C Data Module

Connections for PDMs in Data Mounting—Through Cable Access

Panel

Connections for PDMs in Data Mounting—Through Cross-Connect

Field

Connections for Individual PDMs

Connections at Cable Access Panel for Applications Processor

Alarms

2-160

2-162

2-164

2-164

2-165

2-167

2-167

2-169

2-170

2-171

2-172

Figure 2-122

Figure 2-123

Figure 2-124

Figure 2-125

Connections to ADU for Data Terminal Equipment (R1V2 or

R1V3)

SMDR Cabling for Data Terminal Equipment

SMDR Cabling for On-Premises Data Communications

Equipment

SMDR Cabling for a Remote Host

2-175

2-176

2-177

2-177

-x-

Page 26

LIST OF TABLES

TABLE 2-A WP-90929, List 2, Cable Assembly Wiring

TABLE 2-B WP-90929, List 4, Cable Assembly Wiring

TABLE 2-C Individual Power Supply Adjunct and Distance Limitations

TABLE 2-D 346A Power Unit Adjunct and Distance Limitations

TABLE 2-E Z100 Cross-Connect Hardware Requirements

TABLE 2-F Carrier Lead Appearance on Connector

TABLE 2-G System Wiring

2-22

2-23

2-26

2-28

2-35

2-67

2-86

-xi-

Page 27

Z100-TYPE HARDWARE

2. Z100-TYPE HARDWARE—SYSTEM 75 OR SYSTEM 75 XE INSTALLATIONS

GENERAL

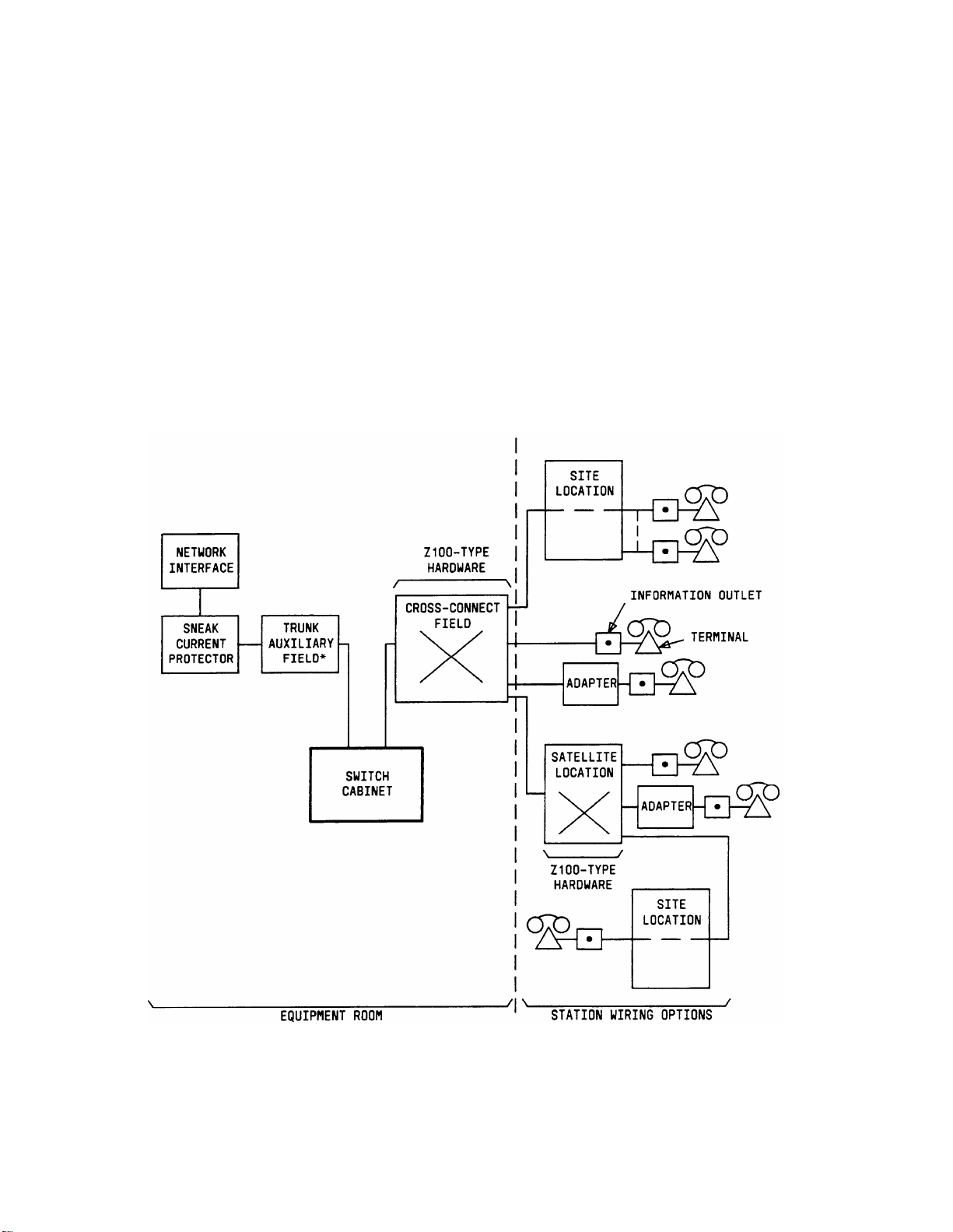

Figure 2-1 shows the equipment required to install a System 75 or System 75 XE. A

description and explanation of each piece of equipment follows. Ordering information is

provided at the end of each description.

The sites shown in Figure 2-1 are physical locations (closets) for pass-through connections

where adjunct power may be applied. The satellite is a physical location (closet) where

cross-connect administration can take place and adjunct power may be applied.

*

PROVIDED BY THE CABLE ACCESS PANEL (CAP), 110-TYPE

HARDWARE OR 66-TYPE HARDWARE

Figure 2-1. Block Diagram of System 75 or System 75 XE Installation

2-1

Page 28

Z100-TYPE HARDWARE

Z100-TYPE HARDWARE

As shown in Figure 2-1, Z100-type hardware is used for the cross-connect field and for

optional satellite locations. The Z100 hardware consists of the following:

●

Connector Modules

Connecting Units

●

Cords (Anti-Snag Modular Plug-Ended Patch Cords and Power Adapter Cords).

●

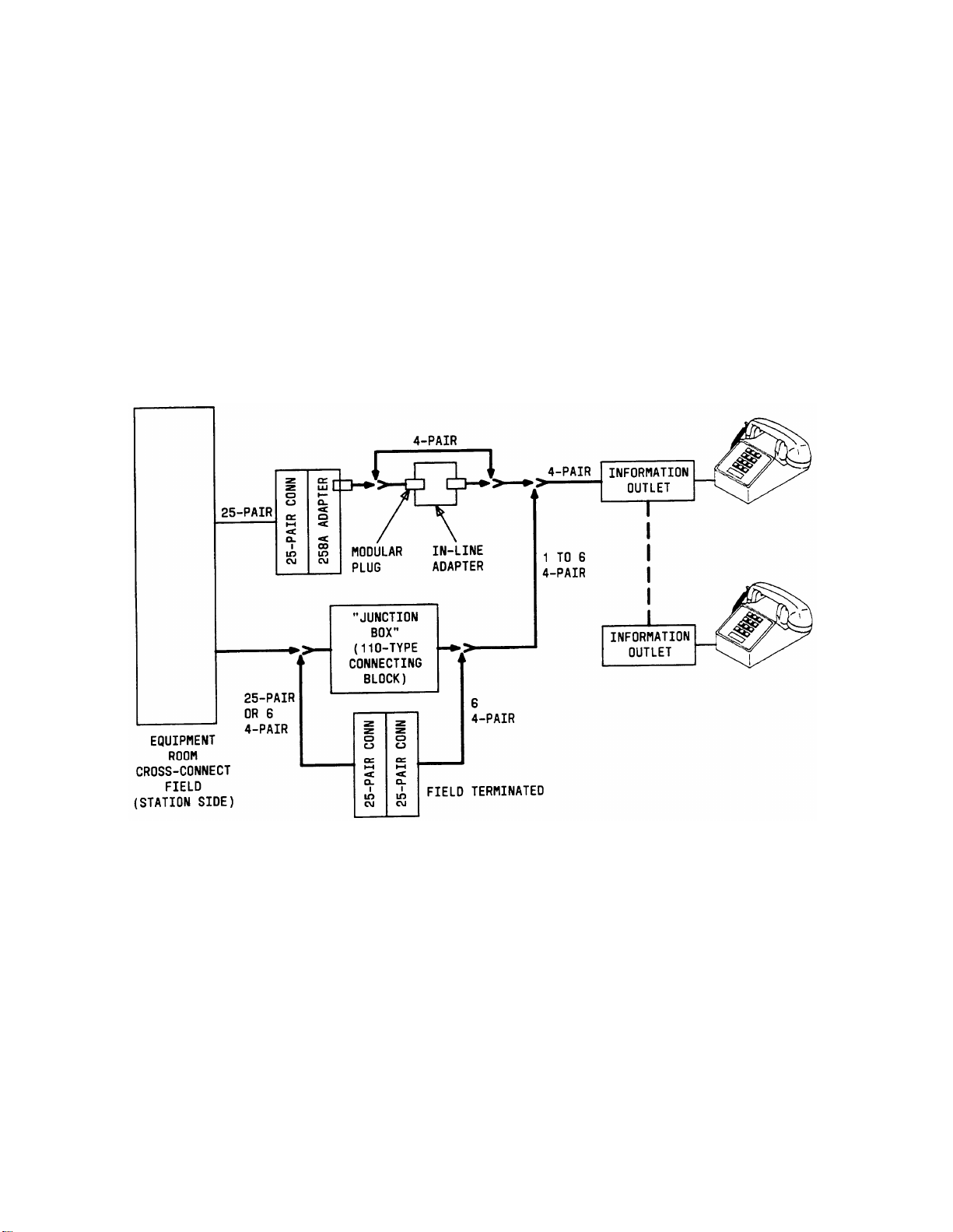

Hard-wired (punch-down) connections are not used with the Z100 hardware unless field-

applied 25-pair connectors, modular plugs, or external "junction boxes" (punch-down to 50pin miniature ribbon connector) are used (see Figure 2-2).

Figure 2-2. Station Wiring Alternatives

Connector Modules

Connectorized 25-pair cables terminate on the connector modules. Anti-snag modular plugended patch cords are used to cross-connect the circuits.

The connector modules are preassembled. Each connector module is 5 inches (12.7 cm) wide

and approximately 44 inches (111.8 cm) high. The hardware making up the assembly

consists of one Z9A support, one Z2A jack panel, seven connecting units, seven Z5A

retainers, and one MET/RJ25C connector adapter (test jack).

2-2

Page 29

Z100-TYPE HARDWARE

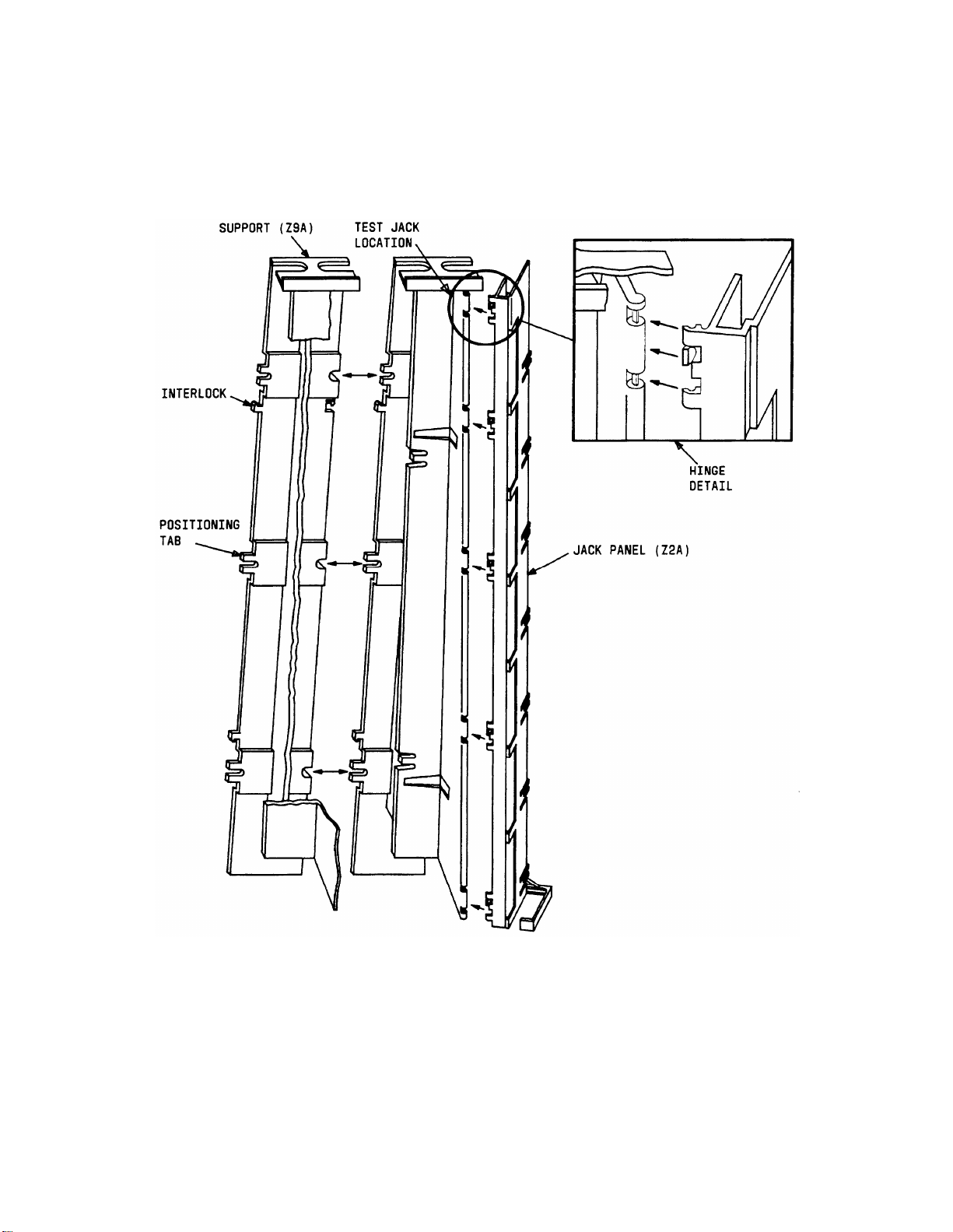

Figure 2-3 shows the connector module support and jack panel. The support has tabs that

allow adjacent connector modules to snap and interlock together to form cross-connect fields.

An additional support is required for each cross-connect filed to provide a patch cord guide

for the last connector module in the field.

Figure 2-3. Z100-Type Support and Panel

The connecting units and Z5A retainers are located inside the jack panel. The Z5A retainers

located at the back of the jack panel snap closed to lock the mating connectors of the 25-pair

cables in place.

2-3

Page 30

Z100-TYPE HARDWARE

The MET/RJ25C connector adapter (test jack) is located at the top of the Z9A support. An

anti-snag modular plug-ended patch cord can be plugged from it into the port jack and a

terminal connected to the station jack to test either a circuit coming from the switch or the

terminal.

There are two preassembled Z100-type connector modules available with connecting units.

The connector modules are identical except for the connecting units provided.

Z100A1 Connector Module

The Z100A1 connector module (see Figure 2-4) contains four Z200A1 connecting units and

three Z201A1 connecting units. The Z100A1 connector module is used at either the crossconnect field or at satellite locations when 4-pair station circuits are provided from the

equipment room or satellite closet to the station wiring. Each Z100A1 connector module has

a capacity of twenty-four 4-pair station circuits and twenty-four 3-pair port or station

circuits.

Z100B1 Connector Module

The Z100B1 connector module (see Figure 2-5) contains four Z203A1 connecting units and

three Z201A1 connecting units. The Z100B1 connector module is used at the cross-connect

field when 3-pair station circuits are provided from the equipment room to the station

wiring. Each Z100B1 connector module has a capacity of thirty-two 3-pair station circuits

and twenty-four 3-pair port circuits. This connector module may also be used if connections

are required for off-premises stations in an otherwise 4-pair station cross-connect field

arrangement.

The following is a listing of ordering information for the connector modules. Ordering

information for the individual connecting units is provided under the heading Connecting

Units in this manual.

CONNECTOR MODULE ORDERING INFORMATION

Description

Z100A1 Connector Module

Z100B1 Connector Module

Z2A Jack Panel

Z5A Retainer

Z9A Support

MET/RJ25C Connector Adapter

Comcode

103 961 157

103 961 165

103 961 231

103 961 215

103 961 249

403 826 928

2-4

Page 31

Z100-TYPE HARDWARE

Figure 2-4. Z100A1 Connector Module

2-5

Page 32

Z100-TYPE HARDWARE

2-6

Figure 2-5. Z100B1 Connector Module

Page 33

Z100-TYPE HARDWARE

Connecting Units

The four connecting units (Figure 2-6) that can be used in the connector modules are as

follows:

● Z200A1—Used for connectorized station cables (4-pair station circuits from

equipment room or satellite locations).

Z201A1—Used in the cross-connect field for the connectorized switch cables and in

●

satellite locations for connectorized station cables (3-pair station circuits from the

equipment room).

Z202A1—Used for Standard Serial Interface (SSI) port circuits from an Applications

●

Processor (AP) to data terminals only.

●

Z203A1—Used for connectorized station cables (3-pair station circuits from the

equipment room).

The Z202A1 connecting unit is not available in the preassembled connector modules. It can

be used as a replacement in the Z100A1 or Z100B1 connector modules. Figures 2-7 and 2-8

show how the connecting units are installed and removed.

CONNECTING UNIT ORDERING INFORMATION

Description

Z200A1 Connecting Unit

Z201A1 Connecting Unit

Z202A1 Connecting Unit

Z203A1 Connecting Unit

Comcode

103 961 256

103 961 264

103 961 272

103 961 280

2-7

Page 34

Z100-TYPE HARDWARE

(USED WITH SSI CIRCUITS ONLY)

Figure 2-6. Z100-Type Connecting Units

2-8

Page 35

Z100-TYPE HARDWARE

NOTE:

HOLD Z5A RETAINER OUT OF THE WAY WHILE

INSERTING (OR REMOVING) CONNECTING UNIT.

Figure 2-7. Connecting Unit Installation

2-9

Page 36

Z100-TYPE HARDWARE

PUSH CONNECTING UNIT

OUT WHILE PRYING

JACK PANEL SLIGHTLY

OPEN WITH SCREWDRIVER.

Figure 2-8. Connecting Unit Removal

Cords

ZD6A-87 Patch Cords

The ZD6A-87 patch cords (Figure 2-9) equipped with 3-pair anti-snag modular plugs are used

with the connector modules to provide cross-connections. This 3-pair patch cord can be

connected to both the 3- and 4-pair jacks on connecting units. Four patch cord lengths are

available. The lengths are identified by the color of the molded plastic modular plugs on

each end and can be ordered as follows (see Note):

Note: See Equipment Requirements for additional patch cord ordering quantities.

2-10

Page 37

PATCH CORD ORDERING INFORMATION

Z100-TYPE HARDWARE

Cord

ZD6A-87

ZD6A-87

ZD6A-87

ZD6A-87

Modular Plug

Color

Length

Clear 7 ft (2.1 m)

Yellow

Blue

Black

10 ft (3.0 m)

12 ft (3.7 m)

14 ft (4.3 m)

Comcode

(1 per package)

103 944 872

103 944 898

103 944 914

103 944 948

Figure 2-9. ZD6A-87 Patch Cord

ZD2A-87-10 Power Adapter Cords

The ZD2A-87-10 power adapter cord (Figure 2-10) connects an adjunct power supply to a 4pair jack on a Z100A1 connector module located at the equipment room or at a satellite

location. One end of the power adapter cord consists of a 1-pair 10-foot (3.0-m) cable

equipped with a 6-conductor modular anti-snag plug that connects to the power supply. The

other end is a combined 8-conductor anti-snag plug/6-conductor jack adapter that connects

to the 4-pair jack.

POWER ADAPTER CORD ORDERING INFORMATION

Cord

ZD2A-87-10

Comcode

(1 per package)

103 944 856

2-11

Page 38

Z100-TYPE HARDWARE

Figure 2-10. ZD2A-87-10 Power Adapter Cord

Associated Hardware

Cable Slack Managers

General

The cable slack managers (Figure 2-11) are raised floor units 32 inches (81.3 cm) wide, 38

inches (96.5 cm) deep, and 4.5 inches (11.4 cm) high. The cable slack managers are used for

cable distribution and cable slack storage between the system cabinets and the cross-connect

field. They can also accommodate a limited amount of slack in station cables. Power cables

from the system cabinets are also run through/from the cable slack managers.

Note: Cable slack managers are not required when the switch cabinet is installed on a

raised computer floor. The station cables and the cables from the system cabinets are

routed under the computer flooring to the cross-connect field.

The cable slack managers have tabs and interlocks that allow adjacent cable slack managers

to interlock together. Retainers mounted on columns inside the cable slack managers keep

the cables from protruding above the top of the base. The cable slack managers are coded as

housings and are available as follows.

2-12

Page 39

Z100-TYPE HARDWARE

Z113A Housing

The Z113A housing is used between the wall and equipment cabinets (Switch, Applications

Processor, Auxiliary, etc.). It consists of a Z8A1 base, two Z814A covers, and 25 Z6A

retainers.

Z114A Housing

The Z114A housing is designed to be used adjacent to the Z113A housing if no equipment

cabinet exists at the position or if the cabinet(s) is positioned against the wall with the

cross-connect field beside the cabinets(s). It consists of a Z8A1 base, one Z814A cover, one

Z815A cover, and 25 Z6A retainers.

CABLE SLACK MANAGER ORDERING INFORMATION

Description

Z113A Housing

Z114A Housing

Z8A1 Base

Z814A Cover

Z815A Cover

Z6A Retainer

Comcode

103 961 322

103 961 330

103 965 133

103 965 141

103 965 158

103 965 166

2-13

Page 40

Z100-TYPE HARDWARE

2-14

Figure 2-11. Cable Slack Managers

Page 41

Z100-TYPE HARDWARE

NETWORK INTERFACES

RJ21X Network Interfaces

The RJ21X network interfaces are the connection points between the local telephone

company lines (1-pair trunks) and the system. The interfaces are supplied and installed by

the local telephone company.

RJ2GX Network Interfaces

The RJ2GX network interfaces are the connection points between the local telephone

company tie-trunks and the system three-pair tie-trunks. The interfaces are supplied and

installed by the local telephone company.

1.544 Mbps Digital Service Interfaces

The 1.544 Mbps (Megabits per second) digital service interfaces are the connection points

between the local telephone company T1 carrier lines and the system DS1 tie trunks. The

interfaces are supplied and installed by the local telephone company.

SNEAK FUSE PANELS

575-4 Sneak Current Fuse Assembly

Sneak current protection is required between the RJ21X or RJ2GX network interface and the

switch. The Model 575-4 Sneak Current Fuse Assembly (Figure 2-12), or equivalent, is

recommended for sneak current protection. The panel is connectorized in and out and

equipped with 25 two-pair fuse modules. Connectorized (B25A) cables connect the network

interface to the sneak fuse panel. 157B Connecting Blocks equipped with SCP-1 protectors

may also be used for sneak current protection.

SNEAK FUSE PANEL ORDERING INFORMATION

Description

157B Connecting Block

Protector, SCP-1*

575-4 Sneak Current Fuse Assembly

Fuse Module—25A xxxxxx

Comcode

403 613 003

403 617 632

xxxxxx

*

The SCP-1 Protectors must be ordered separately and installed on the 157B Connecting Block. Twenty-four

protectors are required per block.

2-15

Page 42

Z100-TYPE HARDWARE

Figure 2-12. Model 575-4 Sneak Fuse Panel

TRUNK/AUXILIARY FIELD

The trunk/auxiliary field, located between the sneak current protectors and the switch,

primarily provides access to the trunk circuits for testing. The Z100 hardware can use cable

access panels (CAPs), ll0-type hardware, or 66-type hardware for the trunk/auxiliary field.

2-16

Page 43

Z100-TYPE HARDWARE

This section of the document only covers using the cable access panels (CAPs) for the

trunk/auxiliary field (Figure 2-13). If 110-type or 66-type hardware is used as the

trunk/auxiliary field, refer to Section 3 or 4 of this manual.

Cable Access Panels and Emergency Transfer Units

Figure 2-14 is a functional diagram of the cable access panel (CAP). As shown in Figure 214, 25-pair connectors on each side of the CAP are wired to 110-type terminals located in the

center of the panel. Five connectors on each side of the CAP provide a pass-through

connection for five 25-pair cables. An additional connector is provided on the left side for

the Emergency Transfer feature.

The connectors on the left side of the panel are labeled DISTRIBUTION CABLES: the cables

on the right side are labeled CABINET CABLES. Factory-installed straps on the 110-type

terminals connect the distribution side connectors to the cabinet side connectors.

CAPs are available with or without a power failure transfer unit mounted inside at the top

of the panel. They are coded as apparatus mountings and are available as described below.

400A Apparatus Mounting

The 400A apparatus mounting is not equipped with an emergency transfer unit. It is used

when the customer does not require the Emergency Transfer feature. It can also be used

when more than one CAP is required and/or the emergency transfer units are mounted

outside the CAP.

400B Apparatus Mounting

The 400B apparatus mountings equipped with a Z1A Emergency Transfer Unit. The Z1A

unit provides emergency transfer connections for six analog (only) voice terminals to six

trunks. If the central office trunks require ground start, a ground start switch must be

installed on each voice terminal used for emergency transfer service.

400C Apparatus Mounting

The 400C apparatus mounting is equipped with a 574-5 Power Transfer Unit. The 574-5 unit

provides emergency transfer connections for five analog (only) voice terminals to five trunks.

This unit provides automatic ground start.

CABLE ACCESS PANEL ORDERING INFORMATION

Description

400A Apparatus Mounting

400B Apparatus Mounting

400C Apparatus Mounting

Z1A Emergency Transfer Unit

Comcode

103 969 663

103 969 671

103 969 689

103 961 363

574-5 Power Transfer Unit

(With Automatic Ground Start)

Apparatus Mounting Door

403 890 940

844 176 164

2-17

Page 44

Z100-TYPE HARDWARE

2-18

Figure 2-13. Cable Access Panel (400C Apparatus Mounting)

Page 45

Z100-TYPE HARDWARE

Figure 2-14. Cable Access Panel (Functional Diagram)

2-19

Page 46

Z100-TYPE HARDWARE

TRUNK CONCENTRATOR CABLES

Trunk concentrator cables are used for the following purposes:

Match 1-pair local telephone company trunks to 3-pair circuits that connect to the

●

switch.

●

Match 1-pair local telephone company trunks provided for off-premises lines to 3-pair

circuits that connect to the cross-connect field.

●

Split eight 3-pair analog tie trunks into two groups of four 3-pair tie trunks that

connect to the switch

The trunk concentrator cables are 25 feet (7.6 m) in length. They are coded as cable

assemblies and are available as described below.

WP-90929, List 2, Cable Assembly

The WP-90929, List 2, Cable Assembly (Figure 2-15 and Table 2-A) is used to connect local

telephone company trunks to the system switch. It is also used to connect off-premises

analog circuits to a Z100B1 connector module in the equipment room cross-connect field. The

3-fingered end of the cable assembly contains male ribbon connectors; the other end contains

a female ribbon connector. Each cable assembly can match 24 one-pair trunk circuits to 24

three-pair trunk circuits.

WP-90929, List 4, Cable Assembly

The WP-90929, List 4, Cable Assembly (Figure 2-15 and Table 2-B) is used to connect tietrunk circuits to the system switch. The 2-fingered end of the cable assembly contains male

ribbon connectors; the other end contains a female ribbon connector. Each cable assembly

can match eight 3-pair tie-trunk circuits to two groups of four 3-pair tie-trunk circuits.

TRUNK CONCENTRATOR CABLE ORDERING INFORMATION

Description

WP-90929, List 2, Cable Assembly

WP-90929, List 4, Cable Assembly

Comcode

405 065 012

405 075 540

2-20

Page 47

Z100-TYPE HARDWARE

Figure 2-15. Trunk Concentrator Cables (WP-90929, Lists 2 and 4, Cable

Assemblies)

2-21

Page 48

Z100-TYPE HARDWARE

TABLE 2-A. WP-90929, List 2, Cable Assembly Wiring

Conn. 0

Pin

No.

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Cable

No. 1

W-BL

W-BR

R-O

R-S

BK-G

Y-BL

Y-BR

V-O

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

V-S

Cable

No. 2

-

-

-

-

-

-

-

W-BL

W-BR

R-O

R-S

BK-G

Y-BL

Y-BR

V-O

-

-

-

-

-

-

-

-

-

Cable

No. 3

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

W-BL

W-BR

R-O

R-S

BK-G

Y-BL

Y-BR

V-O

-

Conn. 0

Pin

Numbers

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Cable

No. 1

BL-W

BR-W

O-R

S-R

G-BK

BL-Y

BR-Y

O-V

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

S-V

Cable

No. 2

-

-

-

-

-

-

-

-

BL-W

BR-W

O-R

S-R

G-BK

BL-Y

BR-Y

O-V

-

-

-

-

-

-

-

-

-

Cable

No. 3

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

BL-W

BR-W

O-R

S-R

G-BK

BL-Y

BR-Y

O-V

-

2-22

Page 49

Z100-TYPE HARDWARE

TABLE 2-B. WP-90929, List 4, Cable Assembly Wiring

Conn. 0

Pin

No.

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Cable

No. 1

W-BL

W-O

W-G

W-BR

W-S

R-BL

R-O

R-G

R-BR

R-S

BK-BL

BK-O

-

-

-

-

-

-

-

-

-

-

-

-

V-S

Cable

No. 2

-

-

-

-

-

-

-

-

-

-

-

-

W-BL

W-O

W-G

W-BR

W-S

R-BL

R-O

R-G

R-BR

R-S

BK-BL

BK-O

-

Conn. 0

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Cable

No. 1

BL-W

O-W

G-W

BR-W

S-W

BL-R

O-R

G-R

BR-R

S-R

BL-BK

O-BK

-

-

-

-

-

-

-

-

-

-

-

-

S-V

Cable

No. 2

-

-

-

-

-

-

-

-

-

-

-

-

BL-W

O-W

G-W

BR-W

S-W

BL-R

O-R

G-R

BR-R

S-R

BL-BK

O-BK

-

16-PORT ANALOG LINE BOARD ADAPTER CABLE

The 16-port Analog Line circuit pack (TN746) has an output of sixteen 1-pair circuits that

appear on a 25-pair connector at the switch. The 16-port analog line adapater cable

(Figure 2-16) separates the 1-pair circuits into 3-pair circuits that appear on two 25-pair

connectors at one end of the cable.

The adapter cable is 8 feet (2.4 m) long and can be ordered with the TN746 circuit pack. The

adapter cable is coded as an adapter and can also be ordered as described below.

16-PORT ANALOG LINE

ADAPTER CABLE ORDERING INFORMATION

Description

853B Adapter

Comcode

104 305 834

2-23

Page 50

Z100-TYPE HARDWARE

NOTE:

A B25A MUST BE USED BETWEEN THE

ADAPTER CABLE AND THE CONNECTOR

MODULE.

Figure 2-16. 16-Port Analog Line Board Adapter Cable (853B Adapter)

4-PORT MET LINE BOARD CONCENTRATOR CABLE

The MET Line circuit pack (TN735) has an output of four 3-pair circuits that appear on a

25-pair connector at the switch. The WP-90929, List 4, Cable Assembly (Comcode 405 075

540) described previously and shown in Figure 2-15 combines the MET line circuits that

appear on two 25-pair connectors onto one 25-pair connector that connects to the crossconnect field.

ADJUNCT POWER UNITS

There are two types of power supplies used for adjunct powering—individual and bulk. The

power supplies are specified by the Field Services Organization (FSO) for firm quote price

lists. For all other quotes, the power supplies are specified by the Premises Services

Consultant (PSC).

Individual Power Supplies

Individual power supplies (Figure 2-17) can be used for powering from the equipment room,

site or satellite locations, or information outlets. An individual power supply can power only

one voice terminal. Table 2-C contains the individual power supply limitations for distance,

wire gauge, and adjuncts.

When a number of individual power supplies are used at the equipment room or at a site or

satellite location, an ac power strip (Figure 2-18) is installed to accommodate the various

2-24

Page 51

Z100-TYPE HARDWARE

sized power supplies. The outlets on the ac power strip must be spaced 3.5 inches (8.89 cm)

to 4 inches (10.16 cm) apart with the plug inserts perpendicular to the strip.

Note: A 543A power unit (Comcode 104 034 541) may be required for inrush protection

for a 20 amp 120-volt ac line serving multiple 329A Power Units. Contact your PSC for

details. Most multiple powering requirements should be served by the 346 modular

bulk power supply.

NOTES:

1.

THE 329A AND THE KS-22911, L1

ARE SIMILAR IN APPEARANCE.

2.

THE 2012D TRANSFORMER AND 248B

TRANSFORMER MUST BE ORDERED

SEPARATELY AND FIELD ASSEMBLED

AS SHOWN.

Figure 2-17. Individual Power Supplies

NOTE: THIS AC POWER STRIP MUST BE

LOCALLY PROVIDED.

Figure 2-18. AC Power Strip

2-25

Page 52

Z100-TYPE HARDWARE

TABLE 2-C. Individual Power Supply Adjunct and Distance Limitations

Power Unit

Adjunct Limits

2012D Transformer One speakerphone

(18-volt ac) With or headset only

248B Adapter

KS-22911, L1 Power One digital module plus

Supply (48-volt dc) speakerphone or headset

One digital module plus

speakerphone or headset

329A Power Supply

Two digital modules plus

(-48 volt dc) speakerphone or headset

Three digital modules plus

speakerphone or headset

INDIVIDUAL POWER SUPPLY ORDERING INFORMATION

Description Comcode

2012D Transformer

248B Adapter

KS-22911, L1 Power Unit

Wire

Gauge

24

24

24

24

24

102 600 517

102 802 103

403 242 639

Distance

Feet (Meters)

150 (45.7)

300 (91.4)

500 (152.4)

350 (106.7)

250 (76.2)

329A Power Unit

Bulk Power Supply

103 873 998

346 Modular Bulk Power Supply

The 346 modular bulk power supply consists of a 346A1 power panel and up to three 346A

power units (see Figure 2-19). The panel has three 2-ampere resettable circuit breakers, one

for each 346A power unit (see Figure 2-20). Power panels are used with one, two, or three

power units connected.

A standard 5-foot (1.52-m) double-ended (male, female) power cord connects the 346A1 power

panel to an ac outlet. Service to the ac outlet must be a dedicated (nonswitched) 20-ampere

line. A maximum of four power panels can be connected to the 20-ampere line.

Note: The city of Chicago and Cook County Illinois electrical codes require the use of a

fused ac power cord POP-6/217 by JDS Products and a metallic 346B1 power panel.

Each 346A power unit provides four power jacks. A slide switch is located between the top

two and bottom two jacks. When the slide switch is in the down position, 10 watts of power

are provided at the jacks above and below the switch.

When the slide switch is in the up position, the power from the jack above the switch and

below the switch are combined. This provides 20 watts of power at the jack above the

switch. The jack below the switch will have no power.

2-26

Page 53

Z100-TYPE HARDWARE

Figure 2-19. 346 Modular Bulk Power Supply

2-27

Page 54

Z100-TYPE HARDWARE

Figure 2-20. 346A1 Power Panel Circuit Breaker Locations

Table 2-D lists adjunct powering limitations for each individual 346A power unit.

TABLE 2-D. 346A Power Unit Adjunct and Distance Limitations

Slide Switch

Position

Adjuncts Powered

(Maximum per Unit)

Wire

Gauge

Distance

Feet (Meters)

Any four terminals equipped

with one speakerphone or one

headset

Down (10 w)

Any four digital voice

terminals equipped with

one digital module and a

24

260 (79.2)

speakerphone or headset each

Any two digital voice terminals

Up (20 w)

equipped with up to three digital

modules and a speakerphone or

headset each

BULK POWER SUPPLY ORDERING INFORMATION

Description Comcode

346A Power Unit

346A1 Power Panel

104 174 768

104 174 750

2-28

346Bl Power Panel

104 174 768

Page 55

Z100-TYPE HARDWARE

EQUIPMENT ROOM DESIGN

The AT&T System 75—System Description (555-200-200) or AT&T System 7.5 XE—System

Description (555-201-200) provide equipment room specifications for temperature, humidity,

air purity, lighting levels, and grounding. They also provide information on the floor and

wall space required for the system equipment and associated peripheral equipment installed

in the equipment room. For completeness, some of the information contained in these

documents is repeated in this manual.

Typical System Equipment Room Floor Plans

General

The equipment room floor plan must be provided by the Field Services Organization (FSO)

for firm quote price lists. For all other quotes, the equipment room floor plans must be

provided by the Premises Services Consultant (PSC). Factors that influence the design are

as follows:

●

Size and layout of the equipment room

●

Number of equipment cabinets

●

AC outlet locations

●

Size of the system.

Typical Floor Plans

Single-Section Cross-Connect Field

Figure 2-21 shows a typical single-section cross-connect field installation. The cross-connect

field is located directly behind the switch cabinet. This is the preferred cabinet and crossconnect field location.

Figure 2-22 is a typical floor plan for a 2-carrier System 75 cabinet or a 2-cabinet System 75

XE. Figure 2-23 is a typical floor plan for a 5-carrier System 75 cabinet or a 3- or 4-cabinet

System 75 XE. The maximum capacity for a 2-carrier cabinet is approximately 200 stations.

All cross-connect fields for the 2-carrier cabinet should be handled by a single section as

shown in Figure 2-22.

The maximum capacity for a 5-carrier cabinet is 800 stations. For large systems using the

5-carrier cabinet, the size and layout of the equipment room may require that the crossconnect field be separated into two or more sections. Also, all large systems requiring more

than 20 connector modules (480 stations) require multi-section cross-connect fields. (See

Multi-Section Cross-Connect Field for details.)

2-29

Page 56

Z100-TYPE HARDWARE

Figure 2-21. Typical Single-Section Cross-Connect Field Installation

(Approximately 288 Station Capacity Illustrated)

2-30

Page 57

Z100-TYPE HARDWARE

NOTES:

THE POWER OUTLET MUST NOT BE UNDER SWITCH CONTROL AND MUST NOT BE SHARED WITH OTHER

1.

EQUIPMENT. THE POWER OUTLET SHOULD BE LOCATED OUTSIDE THE CROSS-CONNECT FIELD AREA.

ALSO, ANY CONDUIT SERVING THE OUTLET CANNOT RUN THROUGH OR BELOW THE AREA WHERE THE

CONNECTOR MODULES ARE TO BE MOUNTED.

2.

ALLOW AT LEAST 36 INCHES (91.4 cm) OF SPACE IN FRONT AND 6 INCHES (15.4 cm) ON THE

RIGHT OF THE CABINET TO PERMIT THE DOOR TO SWING OPEN.

CABINET IS LOCATED ALONGSIDE THE CROSS-CONNECT FIELD WHEN CABLE SLACK MANAGER IS NOT

3.

USED.

Figure 2-22. Typical 2-Carrier System 75 Cabinet or 2-Cabinet System 75 XE

Floor Plan

2-31

Page 58

2-32

Z100-TYPE HARDWARE

Page 59

Z100-TYPE HARDWARE

Mult-Section Cross-Connect Field

A multi-section cross-connect field consists of two or more sections of connector modules

physically separated. The sections should be equal if possible (eight to ten connector

modules each). A multi-section cross-connect field is always required when the cross-connect

field consists of more than 20 connector modules due to patch cord length limits.

A multi-section cross-connect field can also be required due to the size and shape of the

equipment room (see Figure 2-24). Figure 2-25 shows a typical equipment room floor plan

using a multi-section cross-connect field.

Figure 2-24. Typical Multi-Section Cross-Connect Field Installation

(Approximately 576 Station Capacity Illustrated)

2-33

Page 60

Z100-TYPE HARDWARE

Figure 2-25. Typical 5-Carrier Cabinet Floor Plan Using a Multi-Section Cross-

Connect Field

Wall Space Requirements

Single-Section Cross-Connect Field

As shown in Figures 2-22 and 2-23, the cross-connect field and trunk/auxiliary field are

mounted on a common wall. A maximum of 20 connector modules, plus a Z9A Support to

complete the field, can be mounted continuously on the wall. Each connector module and the

Z9A Support are approximately 5 inches (12.7 cm) wide.

If CAPs are used for the trunk/auxiliary field, each column of CAPs mounted to the left or

right of the cross-connect field requires approximately 26 inches (66.0 cm) of horizontal wall

space. Approximately 8 inches (20.3 inches) of horizontal wall space is required for each

column of sneak fuse panels. Wall space must also be provided for emergency transfer units

when they are mounted outside the CAPs. If 110-type or 66-type hardware is used as the

trunk/auxiliary field, refer to Section 3 or 4 of this manual.

Multi-Section Cross-Connect Field

As shown in Figure 2-25, the multi-section cross-connect field allows you to tailor your

cross-connect field to fit in an equipment room with limited horizontal wall space on one

continuous wall (no corners) for the size system being installed. The size of each cross-

2-34

Page 61

Z100-TYPE HARDWARE

connect field section is strictly dictated by the horizontal wall space required. The sections

may be located on several walls in the room.

Equipment Requirements

Connector Module, Patch Cord, and Cable Slack Manager Requirements

Table 2-E lists the Z100 cross-connect hardware requirements based on station capacity for

one cross-connect field section providing 4-pair (Z100A1) or 3-pair (Z100B1) distribution from

the equipment room to the station wiring (see Note).

Note: An additional Z9A support must be ordered to complete the field. Also, Z100B1

Connector Modules or Z203A1 Connecting Units are required for connecting offpremises stations.

TABLE 2-E. Z100 Cross-Connect Hardware Requirements

Number

of Z100A1 Patch Cords* Number

or Z100B1†

Station Connector 7 Ft.

Range Modules (2.1m)

1-24

25-48

49-72

73-96

97-120

121-144

145-168

169-192

193-216

217-240

241-264

265-288

289-321

313-336

337-360

361-384

385-408

409-432

433-456

457-480

1

2

3

29

58

87 - - -

4 116 - - 5

144 - - - 1

6 173 - - 7

8

9

10

11

12

13

202 - - - 2

230

257

280

302

320

333

14 348

25

16

17

18

19

20

359

369

378 107

386

393

399

Number of ZD6A-87

10 Ft. 12 Ft. 14 Ft.

(3.0m) (3.7m)

(4.3m)

- - -

-

-

-

2 - 3 - - 2

9 - -

16

- 27 - 40 - 56 - 72

2 -

90 3 -

5 124

138

152

10

17

26

-

- 4

2 4

of Cable

Slack

Managers

1

1

1

1

1

2

2

2

2

3

3

3

3

3

3

*

Includes 20% spares rounded up.

†

Includes eight spare station jacks per module.

Based on 24 port jacks per Z100B1 connector module.

2-35

Page 62

Z100-TYPE HARDWARE

Cable Access Panel Requirements

The number of cable access panels (CAPs) required is based on the number of through

connections required at the CAP. Each CAP provides five 25-pair through connections, in

and out. The primary circuits that pass through the CAP are 1-pair central office trunk

circuits and 3-pair tie trunk circuits.

The trunk cables connect from the network interface through the sneak fuse panel and CAP

to the system cabinet. Concentrator cables are used between the CAP and the system

cabinet. The connections are described under the heading Installing Trunk Cables

Between Network Interface and System Cabinet in this manual.

Trunk Circuit Capacities

Because concentrator cables are installed between the CAP and the system cabinet, the

capacity for each pass-through connection is 24 one-pair trunks or 8 three-pair trunks.

Procedure:

Divide total number of 1-pair circuits by 24.

1.

2.

If there is a remainder, round up to the next highest number. Let this number

equal PR1.

3.

Divide total number of 3-pair circuits by 8.

4.

If there is a remainder, round up to the next highest number. Let this number

equal PR3.

Add PR1 and PR3. Let this number equal CR (total number of pass-through

5.

connections for trunk circuits).

6.

Determine the total number of pass-through connections (X) required for the

following auxiliary and miscellaneous circuits:

—

Analog voice terminals used for emergency transfer service and as normal

extensions. Divide total number provided by eight. If there is a remainder,

round up to the next highest number.

—

Digital out-of-building voice terminals. Divide total number provided by

eight. If there is a remainder, round up to the next highest number.

—

Analog out-of-building voice terminals. Divide total number provided by

24. If there is a remainder, round up to the next highest number.

—

Each 71A data mounting or 3270C data module that connects directly

through the CAP to a system circuit pack.

7.

Add CR, X, and 1*. Divide this number by 5. If there is a remainder, round up to

the next highest number. This is the total number of CAPs required.

Selecting the Cable Access Panel

Once the number of CAPs required is known, a choice has to be made as to what

combination of the three available codes to order. This selection is based solely on the

emergency transfer requirements.

If ground start trunks are used for the emergency transfer stations, the 400C apparatus

mounting equipped with the 574-5 Power Transfer Unit is recommended. The 574-5 unit

* Auxiliary connection always required on initial CAP for control carrier outputs.

2-36

Page 63

Z100-TYPE HARDWARE

provides automatic ground start (no ground start switches are needed). Each 574-5 unit can

accommodate up to five voice terminals used for emergency transfer service.

If loop start trunks are used for the emergency transfer stations, the 400B apparatus

mounting equipped with the Z1A Emergency Transfer Unit is recommended. Each Z1A unit

can accommodate up to six voice terminals used for emergency transfer service (see Note).

Note: One of the emergency transfer positions is occupied by the optional DID makebusy trunk, if provided.

If there are no emergency transfer stations, the 400A apparatus mounting is recommended.

It is also recommended when more than one CAP is required and the emergency transfer

units are located in another CAP or outside the CAP.

If the number of analog stations required for emergency transfer service exceeds the

capacity of the CAPs, additional emergency transfer units should be ordered separately and

mounted on the wall near the CAP. Each wall-mounted emergency transfer unit requires an

additional CAP pass-through connection.

2-37

Page 64

Z100-TYPE HARDWARE

EQUIPMENT ROOM HARDWARE AND CABLING INSTALLATION

Hardware Installation

The procedures provided in this manual for installing hardware are written so that one

System Technician can do the installation. Procedures are provided for installing the

following:

●

Cross-Connect Field

●

Cable Slack Managers

●

Labels for Cross-Connect Field

●

Cable Access Panels

Labels for Cable Access Panels

●

Sneak Fuse Panels.

●

Installing the Cross-Connect Field

The preferred cross-connect field location is directly behind the switch cabinet. The first

connector module is aligned with the left side of the switch cabinet (see Figure 2-21). This

arrangement allows for growth on the right side of the cross-connect field.

When off-premises stations are required and you are installing a cross-connect

field using Z100A1 connector modules, Z100B1 connector modules provided for

off-premises stations are installed last in the field.

To install the cross-connect field, proceed as follows:

1.

Locate the position of the first connector module on the floor plan.

2.

Position the bottom of the first connector module 35 inches (88.9 cm) above the

floor as shown in Figure 2-26 (see Note).

Note: The first module must be mounted accurately in a vertical position

(plumb) because all other modules are positioned from this one.

3.

Mark the upper-left slotted mounting screw opening in the support.

4.

Remove the module, drill a hole in the backboard for No. 10 wood screw, and start

the 1-1/4 inch (32-mm) screw.

5.

Move the module back in place and carefully align with a level.

6.

Mark the remaining five slotted openings located in the support and remove the

module.

7.

Drill holes in the backboard for No. 10 wood screws and move connector module

back into place.

8.

Using 1-1/4 inch (32-mm) No. 10 wood screws, fasten the cross-connect module into

place. Do not tighten the screws on the right side until the next connector module

is in place.

2-38

9.

Using the positioning tabs, align the next connector module to the right of the

previously installed module.

10.

Push the supports together until the top and bottom interlocks snap together.

11.

Tighten the screws on the left side for the previously installed connector module.

Page 65

Z100-TYPE HARDWARE

Drill the pilot holes for the upper- and lower-slotted openings on the right side of

12.

new support and start the screws.

13.

Repeat steps 9, 10, 11, and 12 until all connector modules (20 maximum) and the

Z9A support (see Note) are installed.

Note: The Z9A support provides a patch cord channel for the last connector

module installed.

If you are installing a multi-section cross-connect field, locate the position of the

14.

first connector module on the floor plans and repeat the procedure from step 2 for

each section.

NOTES:

1.

EACH CONNECTOR MODULE AND THE Z9A

SUPPORT IS 5 INCHES (12.7 CM) WIDE.

2.

THIS DISTANCE IS FROM THE FLOOR TO

THE BOTTOM OF THE Z9A SUPPORT

Figure 2-26. Cross-Connect Field and Cable Access Panel Installation

2-39

Page 66

Z100-TYPE HARDWARE

Installing Cable Slack Managers

To install the cable slack managers, proceed as follows:

1.

Position the first cable slack manager against the wall under the cross-connect

field aligning the side of the manager with the first module installed.

Position the next cable slack manager under the cross-connect field and alongside

2.

the previously installed manager insuring that tabs and interlocks align and fit

together.

Repeat step 2 until all the cable slack managers are installed.

3.

Note: Nine 1/4-inch (6.4-mm) diameter holes are provided in the cable slack

manager bases for earthquake mounting if required. Also, if the cable slack

managers are mounted on an uneven floor, shims may be required to keep the

cable slack managers level and insure proper fit of the covers. Holes are also

provided in the sides of the base for bolting the cable slack managers

together. Bolts and shims must be locally provided.

2-40

Page 67

Z100-TYPE HARDWARE

Labeling the Cross-Connect Field

Figure 2-27 shows graphic symbols used (instead of words) on labels for switch, crossconnect, information outlets, and cables for the system. The labels are color-coded to

identify the system wiring as follows:

●

Green—Leads to central office

●

Purple—Leads to switch ports

●

Yellow—Leads to auxiliary equipment and miscellaneous switch leads

●

Blue—Leads to information outlets

●

White—Leads from the cross-connect field to satellite locations (3-pair)

●

Grey—Leads between cross-connect field sections and between satellite locations.