Page 1

555-230-894

Issue 1

September, 1995

Table of

Contents

DEFINITY® Communications

System

Generic 3 Installation

(For Single-Carrier Cabinets)

Graphics © AT&T 1988

Page 2

Blank Page

Page 3

Contents

Table of Contents i

About This Book xv

■ This Book’s Organization xv

■ Other Books xvi

■ Trademarks xvii

1 Overview and Roadmap 1-1

■ System Reliability 1-1

Standard R eliability 1-2

High Reliability 1-2

Critical Reliability 1-2

■ DEFINITY Syste m I nstal lati on Road m a p 1-3

Plan and Prepare the Site 1-3

Unpack the Cabinet s 1-3

Install and Connect the Cabinets 1-3

Install Telecommunications Cabling 1-4

Install Generic 3 Managemen t Terminal (G3-MT) 1-4

Activate the System 1-5

Test the System 1-5

Install and Wire Telephones an d Other

Equipment 1-6

Administer the D EFINIT Y System According to

Customer Requirements 1-7

Test Telephones and Other Equipment 1-7

2 Plan and Prep a re the Site 2-1

■ Check the Customer’s Order 2-1

■ Locate and Lay Out the Equi p me nt Room 2-2

Issue 1 Sept em ber 1995 iii

Page 4

Contents

Generic 3 Management Terminal

(G3-MT) Requirements 2-2

Cross-Connect Fields 2-2

Space Requirements 2-2

Room Layout 2-2

F igure Notes: 2-3

Cable Slack Manager (Optional) Requirements 2-4

Tools Need e d 2-4

Lay Out and Ensure Appropriate Power 2-6

Power Arrangements for AC Power 2-6

Power Arrangements for DC Power 2-7

■ Lay Out and Ensure Appropriate Grounding 2-8

Connect Coupled Bonding Conductor 2-8

■ Determine the Location of the Equ ipment Closets 2-9

■ Determine External Trunk Locations 2-9

■ Create a Provisioning Plan 2-9

3 Unpack the Cabinet 3-1

Unpack and Inspect for Damage 3-1

4 Install and Connect the Cabinet s 4-1

■ Install Earthq uake Mou ntin g 4-2

■ Position a nd Stac k t he Cabinets 4-2

■ Connect System Cabinet Grounds 4-3

F igure Notes: 4-4

■ Connect Battery Leads 4-5

■ Connect Power 4-6

Connect AC Power 4-6

Connect DC Power 4-6

F igure Notes: 4-8

Connect Power Plant Ground 4-9

F igure Notes: 4-9

Connect Frame Ground 4-10

Figure Notes: 4-10

Connect DC Power Distribution Box Grounding 4-11

iv Issue 1 September 1995

Page 5

Contents

Figure Notes: 4-11

Connect Single-Carrier Network Grounding 4-11

Figure Notes: 4-12

Coupled Bonding Conductor (CBC) 4-12

Figure Notes: 4-13

Connect DC Power to Networks 4-14

Connect AC Powe r to DC Power Cabinet 4-14

Test DC Power Plant 4-14

Connect Stand-by Power 4-14

■ Locate and Connect Time Division

Multiplexing (TDM) Bus 4-15

Figure Notes: 4-16

■ Locate and Connect Inter-Cabinet Cables (ICC) 4-17

Figure Notes: 4-18

■ Install Fibre-Optic Cables 4-19

Fibre-Optic Cable Operation 4-19

Locate Fibre-Optic Cable Connections 4-19

General Rules and Recommendations for

Connecting Fibre-Optic Cables 4-20

Figure Notes: 4-22

Figure Notes: 4-23

Raised Floor or Ca b le Slac k Managers 4-23

Cable Connections 4-24

Standard Reliability Fibre-Optic Cable Connections 4-25

High Reliability Fibre-Optic Cable Connections 4-26

Critical Reliability Fibre-Optic Cable Connections 4-27

■ Verify Port Cabinet Address Plug s 4-29

■ Install Back P anel s 4-30

■ Install Groun d Plates 4-30

Figure Notes: 4-30

Install Ground Plates on Systems with

Earthquake Protection 4-31

Install Ground Plates on Systems without

Earthquake Protection 4-31

Figure Notes: 4-31

■ Install Cable Clamp s 4-34

Figure Notes: 4-34

■ Install Front Plates 4-35

Issue 1 Sept em ber 1995 v

Page 6

Contents

Install Front Plates on Systems with

Earthquake Protectio n 4-35

Install Cabinet Clip On Systems without

Earthquake Protection 4-35

Figure Notes: 4-36

5 Install Telecommunications Cabling 5-1

■ Install the C ro ss-Connect Field 5-1

Typical Cross-Connect Field Using

110-Type Hardware 5-1

F igure Notes: 5-2

Hardware Installation 5-3

■ Install Cable Slack Managers 5-3

■ Route Cables from Cabinet to Cross-Connect Field 5-3

F igure Notes: 5-5

F igure Notes: 5-6

■ Connect Control Carrier Outputs Cable 5-6

Label Cables 5-7

■ Install Trunk Cables Among Network

Inter face, Sneak Current Protector, and

Switch Cabinet 5-7

6 Install Generic 3 Management Terminal 6-1

■ Generic 3 Management Terminal

(G3-MT) Requirements 6-1

■ Connect Generic 3 M anagement Term inal (G3-MT) 6-2

F igure Notes: 6-4

■ Set Up G3 Management Terminal (G3-MT) 6-6

■ Remotely Connect Generic 3

Management Terminal (G3-MT) 6-7

F igure Notes: 6-7

7 Activate the System 7-1

■ Power Up Switch 7-2

Install Translation Flash-Memory Card 7-2

vi Issue 1 September 1995

Page 7

Contents

Power up AC-Powered Switch 7-3

Power up DC-Powered Switch 7-3

Verify Messages on Terminal 7-3

■ Introduction to Terminal Screens and Com man d s 7-4

Screens 7-4

Commands 7-5

Getting Help 7-5

■ Log in to the System 7-5

■ Set Required Country Options 7-6

■ Change Craft Password 7-9

■ Set Date and Time 7-11

■ Set System Maintenance Parameters 7-14

■ Save Translations 7-15

Logoff 7-17

8 Test the Syste m 8-1

■ Check the System Status for Each Cab inet 8-1

■ Check Circuit Pack Configuration 8-4

■ Test Time Division Multiplexor (TDM)

Bus in Processor Port Network (PPN) 8-9

■ Test Tone -C lock Boards 8-10

■ Test Swit ch Processing Element (SPE)

Duplication Me mory Shadowing Link 8-11

■ Test Duplicated Switch Processing

Element (SPE) Interchange 8-12

■ Test Expansion Interface Boards 8-14

■ Test Time Division Multiplexer (TDM)

for each Expansion Port Network (EPN) 8-15

■ Test Tone-C lock for each Expansion

Port Network (EPN) 8-16

■ Test Tone-C lock Interchange for each

Expansion Port Network (EPN) 8-17

■ Test Expansion Interface Exchange for

Each Expansion Port Network (EPN) 8-17

■ Check Circuit Pack Configuration Again 8-19

■ Save Translations, if Required 8-20

Issue 1 Sept e m b er 1995 vii

Page 8

Contents

■ Re-install Front Doors 8-20

■ Next Steps 8-20

9 Install and Wire Telephones and

Other Equipment 9-1

■ Telephone Connection Example 9-1

Connect Adjunct Power 9-3

■ Analog Station or 2-Wire Digital Sta tion Example 9-5

■ Analog Tie Trunk Example 9-6

■ Digital Tie Trunk Examp le 9-9

■ Auxiliary Connector Output s 9-10

■ APP Connector and Cable Diagrams (Pinout Charts) 9-15

■ Install Init ialization and Administrat ion System (INA DS)

Interface 9-21

Figure Notes: 9-21

Figure Notes: 9-22

■ Install Emergency T ransfer Unit s and

Associated Telephones 9-23

Install the 808A Emergency Transfer Panel 9-23

■ Install External Ringing 9-24

Requirements 9-24

Installatio n 9-24

Figure Notes: 9-25

■ Install Queue Warning Indicator 9-25

Requirements 9-25

Installatio n 9-26

■ Install the 1145B 1 Power Sup ply 9-26

Wall-Mounting Plates 9-27

Figure Notes: 9-28

Mount the 1145B1 Power Supply 9-29

Figure Notes: 9-29

Mount the 1146B1 Power Distribution Unit 9-30

Battery Mounting / Wiring 9-30

Power Up and Test 9-31

Wire the 1146B1 Power Distribut ion Unit 9-32

viii Issue 1 September 1995

Page 9

Contents

Figure Notes: 9-32

Reset Light Emittin g Diodes (LED) on Power Distri b u t ion

Unit 9-33

■ Install the M SP-1 Power Sup pl y 9-34

Und erwriter’s Laboratories (UL ) Inform ation 9-34

Importan t Safety Instructions 9-35

Description of the MSP-1 Power Supply 9-36

Locate the MSP-1 Power S upply 9-36

Mount the MSP-1 Power Su pp l y 9-36

Connect the Power Supply 9-37

Figure Notes: 9-38

Figure Notes: 9-39

■ Install the Basic Rate Interface (BRI)

Terminating Resistor 9-39

Terminating Resistor Adapter 9-40

Closet Mounted (110RA1-12) 9-41

Figure Notes: 9-41

Figure Notes: 9-42

■ Install Mult i point Ada p te rs 9-42

BR851-B Adapter (T-Adapter) 9-43

367A Adapter 9-44

Basic Multipoint Installation Distances 9-45

Figure Notes: 9-46

■ Install Power Ad apters 9-47

400B2 9-47

400F2 9-48

■ Install Auxiliary Equipment 9-49

Auxiliary Equipment Description 9-49

Install Loudspeaker Paging and Music-on-Hold 9-50

Install Loudspeaker Paging Access without

Paging Adapter 9-50

Requirements 9-50

Figure Notes: 9-51

Install Loudspeaker Paging Access 9-51

Install Music-on-Hold Access 9-52

Requirements 9-52

Figure Notes: 9-53

Issue 1 September 199 5 ix

Page 10

Contents

Install Federal Communications Commission

(FCC) Registered Music Source 9-54

Install Re c o rded A nnoun c e m ent Equipment 9-54

Requirements 9-54

Figure Notes: 9-55

■ Install Proce s sor Dat a Modules (PDMs) 9-55

Requirements 9-55

Installation 9-56

Figure Notes: 9-57

Connection to Ind i vi dual Processor Data Modules

(PDMs) 9-57

Figure Notes: 9-58

■ Install Call Management Sys tem (CMS) Interface 9-58

Figure Notes: 9-59

■ Install Property Management Syste m (PMS) Interface 9-59

Requirements 9-59

Figure Notes: 9-61

■ Install Customer-Provided Terminal

Using Asynchronous Data Unit (ADU) 9-61

Requirements 9-61

Installatio n 9-61

■ Install Station Mes sag e Det ail

Recording (SMDR)/Call Detail

Recording Unit (CDRU) Interface 9-62

Interface Cabling to Station Message Detail

Recording (SMDR) Output Device 9-63

Figure Notes: 9-64

Switch Settings for Processor Data Module

(PDM), Trunk Data Module (TDM), or 21 2-Type

Mode m 9-65

212-Type Modem Switc h Setti ng 9-66

■ Imp l em e nt a nd Administer System Dat a 9-66

10 Test Telephones and Other Equip men t 10-1

■ Make Test Calls (Single-Cabinet Switch) 10-2

Description 10-2

Procedure 10-2

■ Make Test Calls (Two-Cabinet Switch ) 10-3

x Issue 1 Se p t em ber 1995

Page 11

Contents

Description 10-3

Proced ure 10-3

■ Make Test Calls (Thre e-Cabi net Switch) 10-4

Description 10-4

Proced ure 10-5

■ Test the Atten dant Console 10-8

Description 10-8

Procedure 10-8

■ Test the Selector Console 10-9

Description 10-9

Procedure 10-9

■ Test External Ringing 10-9

Description 10-9

Procedure—Ringing Device Installed 10-9

Procedure—Ringing Device Not Installed 10-10

■ Test Que u e Warning Indicator 10-10

Description 10-10

Procedure—Queue Warning Indicator Installed 10-10

Procedure—Queue Warning Indicator Not

Installed 10-11

■ Test Integrate d An nouncement 10-12

Description 10-12

Procedure — Record An n o uncemen t 10-12

Procedure — Playback Announcement 10-12

Procedure —Delete Ann ouncement 10-12

■ Test Music-on-Hold 10-13

Description 10-13

Procedure 10-13

■ Test Emergency Transfer 10-13

Description 10-13

Procedure 10-14

■ Test Remote Access Interface (know n

as Initializat ion a n d Administrat ion

System) 10-14

Description 10-14

Procedure—Remote Test 10-14

Issue 1 September 199 5 xi

Page 12

Contents

Procedure—Local Te st 10-15

■ Test Basic Rate Interface (BRI) 10-15

Description 10-15

Procedure—Dial Tone 10-15

Procedure—Make and Receive Calls 10-15

Procedure—Checking the Service Profile

Identifier (SPID) 10-16

A Approved Grounds A-1

■ Definition of Approved Ground A-1

■ Acceptable M ediums for Protective Ground A-1

■ Approved Floor Grounds A-2

B Earthquake Protection Procedures B-1

■ Install Floor Mountin g to Att ach Cabinet to Floor B-1

F igure Notes: B-2

F igure Notes: B-3

■ Install Groun d Plates on Cabinet Backs B-4

■ Install Front Plates B-4

C DEFINITY AUDIX System Power Procedures C-1

■ Manually Power Down DEFINITY AUDIX System C-1

■ Manual Power U p DEFINITY AUDI X System C-3

D Country Differences D-1

■ United States to Unite d King d om and

France Terminology Translations D-1

■ Country-Specific Ha rdware D-1

E Installing the 9400-Series Telephones E-1

■ Installi ng the 94 00-Seri es Telephones E-1

■ Wiring Information E-2

xii Issue 1 Sep tember 1995

Page 13

Contents

Distance Limitations E-4

F igure Notes: E- 5

F igure Notes: E- 5

■ Wall Mounting E-6

■ Using the Test Feature E-9

The Test Feat ure E-9

■ Button Labels E-10

F Wire Conversion Information F-1

■ Common Wire Colours F-1

■ AWG to SWG Conversion

(Stranded Wire) F-1

■ Wire Gauge Comparison

(S olid Conductor) F-4

G Electrical Code Equivalencies G-1

■ North American Electrical Code G-1

■ International Electrical Codes G-1

H Option Switch Settings H-1

■ Distributed Communications System

(DCS) Opti on Settings for G3i System s H-1

■ Mod em Pooling (Com bined) Option Settings H- 2

■ 103JR Modem Opti on Settings H-2

■ 201CR Modem Option Settings H-4

■ 202SR Modem Option Settings H-6

■ 208BR Modem O p ti on Settings H-9

■ Asynchronous 212AR Modem Option Settings H-11

■ Synchronous 212AR Modem Option Settings H-14

■ Asynchronous 2224A Modem Option Settings H-17

■ Synchronous 2224A Mo d em O p tion Settings H-18

■ 7400A Option Settin g s H-19

■ Printer Opt i o n Settings H-20

■ 475 Printer Connected to a G3 Management Terminal H-21

Issue 1 S e p t em ber 1995 xiii

Page 14

Contents

■ 475 Printe r U sed as Sys t e m Printer H-21

■ 475 or 476 Printer Used as Journal

Printer for Hospitality Feature H-21

■ 470 or 471 Printer Used as Journal

Printer for Hospitality Feature H-28

■ 572 Printer H-30

■ Station Message Detail Re c ording

(SMDR) Interface Option Settings H-34

■ Audio Information Excha nge (AUDIX)

Interface Option Settings for G3i Systems H-36

■ TN760 Tie Trunk Circuit Pack Op tion Settings H-37

■ TN464C, D, E, F Option Settings H-41

TN464C/D O p tion Setting s H-41

Figure Notes: H-42

TN464E/F Option Settings H-42

Figure Notes: H-44

I References I-1

■ Basic I-1

■ Call Center I-5

■ Networks I-6

■ App l icat ion Sp ecific I-7

ABB Abbreviations ABB-1

IN Index IN-1

xiv Issue 1 Septem b er 1995

Page 15

About This Book

This book supports DEFINIT Y® Communications Systems Generic 3 Version 3

and later. This book provides procedures and information for installing the

hardware and initially testing the DEFINITY Communications Sy s tem Generic 3,

Models G3i and G3s. The information in this b o o k a pplies to single-carrier

cabinet switches only.

DEFINITY is a registered trademark of AT &T. DEFINITY Communications System

Generic 3 is a bbreviated as G3.

This Book’s Organization

This book is organized into 10 chapters and 10 appendices. The procedures in

this book should b e read and followed sequentially.

■

Chapter 1, "Overview and Roadmap"

Provides an overview of system reliability options a nd a step-by-step

roadmap for installing and testing the system.

■

Chapter 2, "Plan and Prepare the Site"

Explains how to plan and prepare the site and includes typical floor plans.

■

Chapter 3, "Unpack the Cabinet"

Explains how to safely unpack the cabinets.

■

Chapter 4, "Install and Connect the Cabinets"

Explains how to install the cabinets, install the power, and connect the

cabinets together.

Issue 1 September 1995 xv

Page 16

About This Book

■

■

■

■

■

■

■

Chapter 5, "Install Telecommunications Cabling"

Explains how to install cabling between the sw itch and the cross-c onnect

field.

Chapter 6, "Install Generic 3 Management Terminal"

Explains how to install and bring up the Generic 3 Management Terminal.

Chapter 7, "A c tivat e the System"

Explains how to act ivat e and initialize the s ystem .

Chapter 8, "Test the Sy st em"

Explains how to test the system.

Chapter 9, " In stall a nd Wire Telephones and Other Equipment"

Explains how to install and wire telephones an d other equipment to the

switch.

Chapter 10, " Test Tel ephones and Other Equipment"

Explains how to test the e q u i p men t insta lled in Chapter 9.

App endix A, "Approved Grounds"

■

■

■

■ Appendix E, "Installing the 9400-Series Telephones"

■ Ap p e ndix F, "Wire Conversion Information"

■ Ap p endix G, "Electrical Code Equivalencies"

■ Appendix H, "Option Switch Settings"

■ Appendix I, "References"

■ Abbreviations

■ Index

Other Books

In add i t ion t o this book, other sy stem d escription, installation a n d test ,

maintenance, and administration books are available. A complete list of

DEFINITY Generic 3 books available in United States English can be found in the

Global Business Communications S ys tems Publications Catalog,

list of books relevant to this product can be found in Appendix I.

App e ndix B, "Earthquake Protection Procedures"

App e ndix C, "DEFINITY AUDIX System Power Procedures"

App e ndix D, "Country Diffe rences"

555-000-010. A

xvi Issue 1 Septem b er 1995

Page 17

Trademarks

This ca t alog and all DEFIN ITY Communications System Ge n eric 3

documentation in United States English can be ordered directly from:

General Business Communications System Publications Fulfillment Centre at

1-317-361-5353.

Trademarks

This book contains refe rences t o the following trademarked products:

■ AUDIX

■ DEFINIT Y

■ LINX

■ Shockwatch

■ Styrofoam

■ SYSTIMAX

■ Tiltwatch

®

is a registered trademark of AT&T

®

is a registered trademark of AT&T

™

is a trademark of Illinois Tool Works, Inc.

™

is a trademark of Me dia Recovery, Inc.

™

is a trademark of Styrofoam Corporation

®

is a registered trademark of AT&T

™

is a trademark of Media Recovery, Inc.

Issue 1 September 1995

xvii

Page 18

About This Book

xviii Issue 1 September 1995

Page 19

Overview and Roadmap

This chapter present s g eneral inform at ion about the methods to configure your

DEFINITY Syste m G e n eric 3 for system availability.

It also provides a roadma p (a high-level overview of the seq uence of steps) f o r

the installation of the system. The roadma p provides references to the

appropriate chapter in this book or other books for d etailed instruc tions.

1

System Reliability

The DEFINITY Syste m G 3 provides various system reliability configurations or

du plication options. These reliability configurati ons provide for dupli ca tion of G3

system co mponents for higher system availability. The f ollowi n g three types of

reliability suppl y your system’s needs:

■ Standard Reliability

■ High Reliability

■ Critical Reliability

Within these conf i g urat ion o ptions, you ca n d uplicate the following components:

■ Processor Port Network (PPN) Cont rol Carrier

■ Expansion Port Network (EPN) Control Carrier

■ Inter-Port Network (PN) Connectivity (fibre-optic cabling)

■ Tone-Clock

Chapter 4, "Install and Connect the Cabinets" provides more detail on system

reliability configurations.

Issue 1 S e p t em ber 1995 1-1

Page 20

Overview and Roadma p

Standa rd Reliab il ity

DEFINITY System G3 sta ndard reliabi lity systems p rovide the most co steffect ive product. This is the only reliability offering for a G3s system. Standard

reliability systems do not d uplicate Tone-Clock(s), the Control Carriers, or any

inter-Port Network (PN) co nnectivity.

Standard reliability systems use the fo llowi n g c o m ponents:

■ One control carrier per port network (Expansion Port Network (EPN) or

Processor Port Network (PPN))

■ One Tone-Clock per port network

■ Simplex inter-Port Network (PN) connectivity (via fibre-optic cables)

High Reliability

The G3i hi gh reliability option provides dup lication of hardware associated with

the Processor Port Network (PPN) Control Carrier.

High Reliabili ty systems use the following component s:

■ Duplicate Control Carriers in the Processor Port Network (PPN)

■ Duplicate Processor Port Network (PPN) Tone-Clocks, one in each

Control Carrier

■ One Tone-Clock per Expansion Port Network (EPN)

■ Simplex inter-Port Network (PN) connectivity

Critical Reliability

G3i critical reliability option provides the highest reliability through du p lication of

the control carrier(s), inter-Port Network (PN) connectivi ty, a n d Tone-Clocks.

Critical Reliability systems use the following comp onents:

■ Duplicate control carriers in the Processor Port Network (PPN) and

Expansion Port Network (EPN)

■ Duplicate Tone-Clocks in each port network (Processor Port Network

(PPN) and Expansion Port Network (EPN))

■ Duplicate inter-Port Network (PN) connectivity, using duplicated

Expansion Interface circuit packs and fibre optic c ables.

1-2 Issue 1 September 1995

Page 21

DEFINITY System Insta ll ation Road m ap

DEFINITY System Installation

Roadmap

This section is intended to provide a high-level sequence for th e instal lation

process and also a roadmap to the infor m ati on in thi s book. It is also noted

where specific steps are covered in othe r books.

Plan and Prepare the Site

Complete this task by following the instructions provided in Chapter 2.

1. Determine what was ordered for the customer: DEFINIT Y System

Generic 3, number of ca binets and port networks, management

terminals, adjuncts, consoles, telephones, modem s, external trunks, etc.

2. Locate DEFINITY System e quipment room and lay out equipment room

floorplan for system cabinet s, m anagement terminal and desk, crossconnect hardware and adjuncts, etc.

3. Lay out and ensure appropriate power for switch and management

terminal in equipment room and arrange for an electrician to install.

4. Lay out and ensure appropriate groundin g in equipment room (refe r to

App endix A, "Approved Grounds").

5. Determine location of e q uipmen t closets where large cables can be

connected out into smaller ones.

6. Determine where external trunk lines come into the building and where

external trunk converters and adapters will be inst alle d.

7. Determine an appropriate available port circuit on DEFINIT Y System for

each telephone, trunk, and peripheral connection needed and create a

provisioning p lan.

Unpack the Cabinets

Complete this task by following the instructions provided in Chapter 3.

1. Unpack and inspect the c abinets.

2. Check circuit packs.

Install and Con nec t the Cabin ets

Complete this task by following the instructions provided in Chapter 4.

1. Install earthquake floor mounting if needed (refer to Appendix A,

"Approved Grounds" ).

2. Posit i o n and stack cabinets.

3. Connect system cabinet grounds.

Issue 1 September 1995

1-3

Page 22

Overview and Roadma p

4. Connect battery leads.

5. Connect AC power

6. Locate and connect Time Division Multiplexer (TDM) Bus.

7. Locate and connect inter-cabinet cables, if system has duplicated Switch

Processor Elements (SPEs) in Processor Port Network (PPN) co ntrol

cabinets (high or critical reliability configurations).

8. Install fibre optic c ab les b e t ween port networks (if the syst em has mo re

than one cabinet stack).

9. Verify p ort ca binet a ddress p l u g s.

10. Replace cabinet back panels.

11. Install g round p l ates.

12. Install c a b le clamp s.

13. Install front plates (if needed for electromagnetic shielding and/or

earthquake protection

Procedures").

14. Install c a b inet clip (i f you do not have earthquake prote ct ion or

electromagnetic shielding).

or

DC power.

Install Telecom m un ication s Cab ling

Complete this task by following the instructions provided in Chapter 5.

— see Appendix B, "Earth quake Protection

1. Install cross connect equipment.

2. Install cab le slack manager.

3. Route cab les from cabinet to cross-connect field.

4. Connect control carrier ou tputs ca b le.

5. Label cables.

6. Install trunk cables among network interface, sneak fuse or circuit

breaker panel, and switch ca binet .

7. Install coupled bonding conductor grounding.

Install Gen eric 3 Management Terminal (G3-MT)

Complete this task by following the instructions provided in Chapter 6.

1. Connect Management Terminal.

2. S et up Management Terminal.

3. Connect remote Management Terminal (if included).

1-4 Issue 1 September 1995

Page 23

DEFINITY System Insta ll ation Road m ap

Activate the System

Complete this task by following the instructions provided in Chapter 7.

1. Powe r up swit c h.

2. Log in to the system.

3. Set required count ry op t ion s.

4. Change craft password.

5. Set date and time.

6. Set system maintenance parameters, if Packet Controller (TN778 Circuit

Pack) is included.

7. Save a nd b ack up translations.

Test the System

Complete this task by following the instructions provided in Chapter 8.

1. Check the system status for e ach cabinet.

2. Check circuit pack configuration.

3. Test Time Division Multiplexer (T DM) bus in Processor Port Network

(PPN).

4. Test Tone -Clock boards.

5. Test Switch Processor Element ( SPE) duplication memory shadowing link,

only for hig h an d crit ical reliability system s.

6. Test duplicated Switch Processor Element (SP E) interchange, only for

high and critical reliability systems.

7. Test expansion int erface b oards, if present.

8. Test Time Division Multiplexer (T DM) for each Expansion Port Network

(EPN) , if Expansion Port Networks (EPN) are present.

9. Test Tone-Clock for each Expansion Port Network (EPN), if Expansion

Port Networks (EPN) are present.

10. Test Tone-Clock interchange for each Expansion Port Network (EPN),

only for critical reliability systems with Expansion Port Networks (EPN)

present.

11. Test expansion int erface exchange for each Expans ion Port Network

(EPN) , if Expansion Port Networks (EPNs) are present.

12. Check circuit pack confi gurati on, again.

13. Save a nd back up translatio n s again, if required.

14. Re-install front doors on switch c abinets.

Issue 1 September 1995

1-5

Page 24

Overview and Roadma p

NOTE:

Install and Wire Telep hones an d Other Equipment

Complete this task by following the instructions provided in Chapter 9.

For easier reference, installation steps and test steps are grouped in

separate chapters. It may be better to install each hardware component,

administer it, and then test it before going on to install another component.

As an exampl e , install the Atten dant Console using the procedures in

Chapter 9, " Inst all a n d Wire Telephones an d Other Equipment", administer

it using the procedures in "Administer the DEFINITY System According to

Customer Requirements" on page 1-7, and test it using the procedures in

Chapter 10, "Test Telephones and Other Equipment".

1. Make and label wiring cross connections for this cu stomer, using

provisioning p lan a s d irected in Step 7 of Chapter 2, "Plan and Prepare

the Site" .

2. Install and label equipment.

3. Install the attendant c onsoles.

4. Install the telephones.

5. Install the trunks.

6. Install the interface for the remote management terminal (known as

INADS).

7. Install the emergency transf er units and associated telephones.

8. Install external ringing.

9. Install queue warning indicator.

10. Install auxiliary power.

11. Install Basic Rate Interface (BRI) telephone, Basic Rate Interface (BRI)

terminatin g resistor, multipoint a d apter, and power adapter.

12. Install auxilliary equipment

13. Install the Processor Data Module (PDM).

14. Install the Call Manage ment System (CMS) interf ace.

15. Install Property Management System (PMS).

16. Install any customer-provided terminals using Asynchronous Data Units

( ADUs).

17. Install Station Mes sag e Det ail Recording (SMDR)/Call Detail Recording

Unit (CDRU) interface.

1-6 Issue 1 September 1995

Page 25

DEFINITY System Insta ll ation Road m ap

Adminis ter the D EFIN I T Y Syst em Ac cord in g to

Customer Requi remen ts

After the hardware is installed and the system is activate d , the d ata for system

and telephone features must be a d m in istered, using the provisioning plan

created for this customer in Step 7 in Chapt er 2, "Plan an d Prepare the Site". All

steps for the administration of the system are provided in the United Ki ng d om

English bo o k,

555-230-655.

DEFIN ITY Co mmunicat ions System Generic 3 Im p lementation

Test Telephones and Other Equip ment

Complete this task by following the instructions provided in Chapter 10.

1. Make test calls (single-port-network switch).

2. Make test calls (two-port-network switch).

3. Make test calls (three-port-network switch).

4. Test the a tt e ndant console and selector console.

,

5. Test ex t ernal ringing .

6. Test queue warning indicator.

7. Test inte g rate d announcement.

8. Test m usic-on-hold .

9. Test emergency transfer.

10. Test r emote access interface (known as INADS).

11. Test Basic Rate Interface (BRI).

Issue 1 September 1995

1-7

Page 26

Overview and Roadma p

1-8 Issue 1 September 1995

Page 27

Plan and Prepare the Site

This chapter describes tasks required to plan, prepare, and p ro vision the site

de pe n ding upon which DEFINITY Syst e m G eneric 3 was ordered. Perform the

following:

■ Check the customer’s order.

2

■ Locate and lay out the equipment room.

■ Lay out and ensu re appropriate p ower.

■ Lay out and ensure appropriate groundin g.

■ Determine location of equipmen t closets.

■ Determine location of external trunk lines.

■ Create a provi sioning plan.

Check the Customer’s Order

Determine what was ordered for the customer: DEFINITY System Generic 3 , the

number of cabinets, p o rt netw or ks, management terminals, a d juncts, consoles,

telephones, modems, external trunks, etc.

NOTE:

One port net work is e q u ivalent to one single-carrier-cabinet stack.

Throughout this document, “cabinet” sometimes refers to one single-carr ier

cabinet an d some times refers to one

accor ding t o the context. An attempt has been made to use “single-carrier

cabinet (SCC)” to mean exactly that and to use the more general term,

“cabinet,” to mean a stack of one or more sin g l e-carrier c abinets or a port

network. A “system” is one or more single carrier cabinet stacks.

stac k

of single-carrier cabinets,

Issue 1 S e p t em ber 1995 2-1

Page 28

Plan and Prepare the Site

Locate and Lay Out the Equipment Room

Determine where the DEFINITY Syste m G eneric 3 equipment room is located ,

and then lay out the equipment room floor plan for DEFINITY System cabinets,

management terminal and desk, cross-connect hardware and adjuncts, etc.

Generic 3 Management Term inal

(G3-MT) Requirements

In general, the Management Terminal must be directly connected to the cabin et

with the shortest possible cable. For maintenance purposes, the terminal must

be located in the same equipment room as the cabinet, or in sight of the cabinet.

Power fo r t h e terminal must be obtained from a single-phase standard 120 Volt

60 Hz or 230 Volt 50 Hz AC receptacle in the equipment room.

Cross-Connect Fields

Recommended hardware is the wall-mounte d 110 SYSTIMAX premises

distribution equipment for structured cabling systems.

Space Requirements

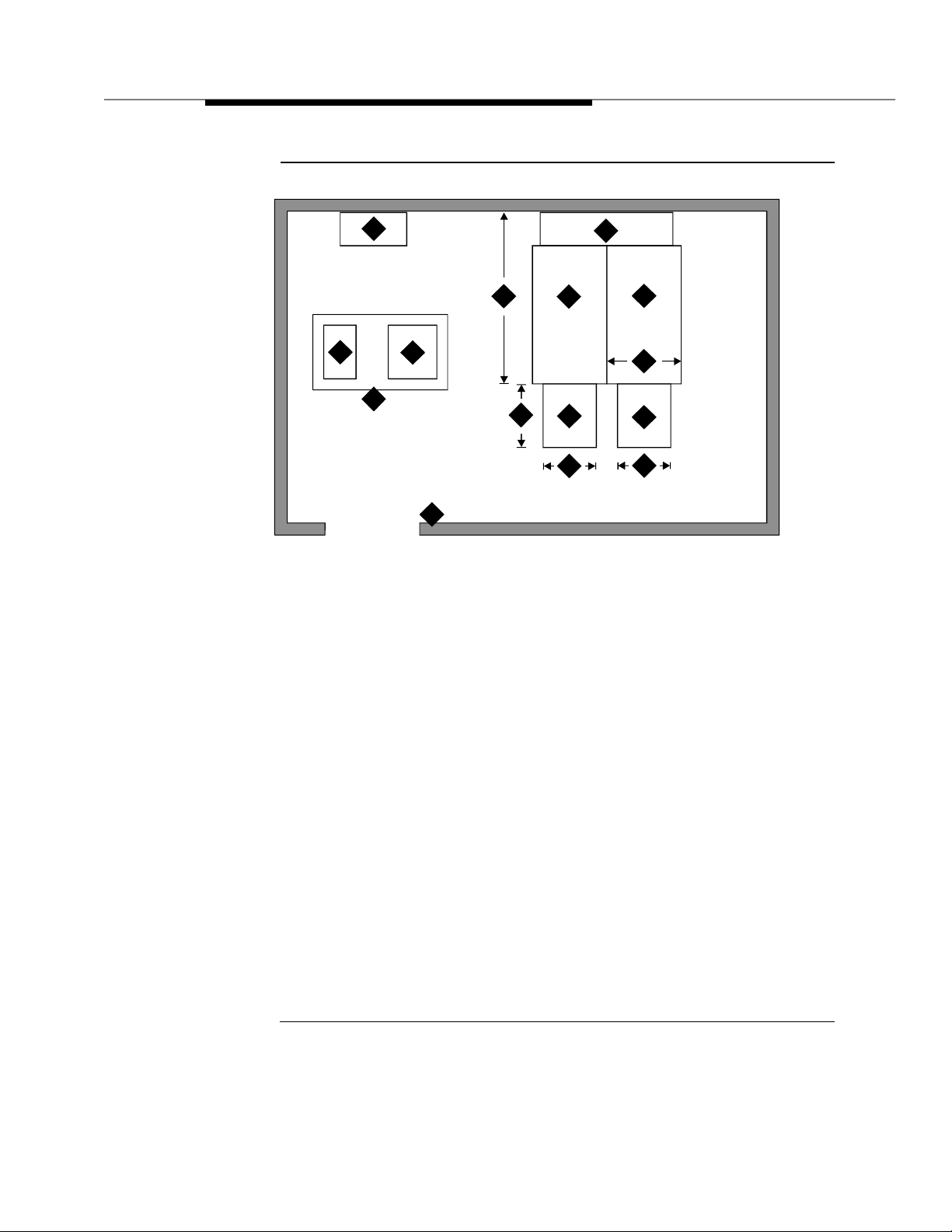

The floor plan shown in Figure 2-1 p ro vides dimensions for the Processor Port

Network (PPN) cabinets and Cable Slack Managers.

Room Layout

Typical floor plans for a single-carrier cabinet are shown below:

2-2 Issue 1 September 1995

Page 29

Locate and Lay Out the Equip men t Room

4

1

5

3

2

Figure Notes:

1. Printer (Optional)

2. Wall

3. Table

4. Trunk/Auxiliary Field. May be Located

within Cross-Connect Field.

5. G3 Management Terminal (G3-MT)

6. Processor Port Network (PPN) Cabinets

7. Cable S lack Manager

14

8

7

11

6

12

8. Cross-Connect Field

9. Cable Slack Manager (Op tional)

10. Expansion Port Network ( EPN) Cabinets

(opti on al). S pace indica ted by callo uts 9

and 10 needed for e ach Expansion Port

Network (EPN) in system .

11. 22 Inches (55 cm)

12. 27 Inches (68 cm)

13. 32 Inches (81 cm)

14. 40 Inches (101 cm)

9

13

10

12

Additional Notes:

AC receptacles must be s ep ara te l y cu rre nt p rotecte d (fuse or circuit breaker) and n ot unde r the

cont rol of a wall switc h . Rec ep t acles must not be sh ar ed with othe r eq u ipment and s h ou ld be

located away from the cross-connect field.

System must be grounded by one of the approved methods. See Appendix A.

Earthquake protection and/or electromagnetic shielding may be required. See Appendix B.

Figure 2-1. Typical Floor Plan for G3i Single-Carrier Processor

Port Network (PPN) with Expan sion Port Network

(EPN) Cabinets

Issue 1 September 1995

2-3

Page 30

Plan and Prepare the Site

Cable Slack Manager (Optional) Requirements

A cable slack manager (optional) is 32 inches (81 c m) wide and 40 inches (102

cm) deep. Normally, one slack manager is needed for each cabinet stack. Extra

slack managers may be ordered, if necessary.

Tools Needed

Table 2-1 lists the tools and te st equip m ent required to install the switch. Make

sure all tools are available before inst alli n g th e DEFINITY System Generic 3.

2-4 Issue 1 September 1995

Page 31

Locate and Lay Out the Equip men t Room

Table 2-1. Tools and Tes t Equipm e n t In ventory

Recommended

Tasks Equipment Required

Unpacking

Cabinet

Installing

*

Cabinet

Checking

Com m e rcial Power

Circuit Pack

Voltage Check

Initia l izing S witch Generic 3 Management Te r mi na l 715 Management

Installing cables

and tele phon es

Ti n Snips

Utility Knife

Adjustable Wrench 6- or 8-inch

Electric Drill Impact type

Masonry Bit 1/2-inch

Drill Bit

(for Computer Floors only)

Drift Punch Length as required to

Cha lk Line

Rul e 30-inch

Adjustable Wrench 6- or 8-inch

Ratchet 1/2-inch 1/2-inch

Sockets 5/16-, 1/2-, and 3/4-

Nut d river 1/4-inch 1/4-in ch

Screwdriver 8-inch flat blade

All en Wr ench

Dig ital Multimeter KS-20599

Voltage Tester TN2036 (optional)

Diagonal cutters

Phillips screwdriver

Electric drill for install ing

information outlets

Impact tool for cross-connect

hardware

Test (telephone) set

‡

Type

5/8-inch

reach from computer

floor to concrete floor

inch

1/8-inch

Terminal

Recommended

Types for Europe

†

5/16-, 1/2-, and 3/4-

†

inch

†

* Electric drill and dril l bi ts are required for earthquake mounting.

† Since U.S./English fasteners are used, U.S. /English tools are required unless an exact match can

be found among metric tools.

‡ Required when installing an AC powered switch.

Issue 1 September 1995

2-5

Page 32

Plan and Prepare the Site

Lay Out and Ensure Appropriate Power

1. Lay out and ensure appropriate power for switch cabinets and

management terminal in equipment room.

2. Provide one power outlet per single-carrier cabinet.

3. Have an electrician check the commerci al power and verify p ower is

available and present.

Power Arrangements for AC Power

The fol lowing procedures appl y t o both the Processor Port Network (PPN)

cabinet(s) and Expansion Port Networks (EPN) cabinet(s) (as provided), except

where noted.

The fol lowin g illu strat ion sh ows a typical power and grounding layout, and the

illustration after tha t shows the AC p ower rec ep tacle req uirements. The power

circuit must be d e dicated to the DEFINITY System Generic 3 only and must be

on a separat ely current limited (fuse or circuit breaker) circuit. It must not be

shared with other equipment and must not be under th e control of a wall switch.

The power supply for the Generic 3 Management Terminal (G3-M T), however,

does not have to be dedicated

Locate and/or arrange the cross-connect field so all power receptacles are

accessible.

2-6 Issue 1 September 1995

Page 33

Locate and Lay Out the Equip men t Room

Power Arrangements for DC Power

The followin g table shows the i n p ut DC requirements for the system -48 VDC

Input Power Requirements

Parameter Requirements

Static Voltage -48 VDC nominal, -42.5 VDC minimum, -52.5 VDC maximum

(measured at inp ut to System cabinet) under normal

operating co nditions.

Dynamic

Voltage

AC Ripple

Voltage

Low Voltage

Disconnect

Overvoltag e

Protection

Voltage Drop Maximum drop—Must not exceed 0.5 V DC one way on

Current Draw The b attery p l a nt rectifiers must be capable of providing

Circuit Breaker An Underwriter Laboratories (UL) listed and Canadian

Redundancy Redundancy of the battery chargers/rectifiers should be

Transient change in volt age— +/- 5% of steady state

voltage . Al lowed tran sient d urati on— U p to 200

milliseconds.

Maximum wideband AC ripple — 4 50 mvpp (millivolts peakto-peak) in the 3 kHZ to 20 MHZ band.

Automatic disconnect—Occurs when input voltage is less

than -42.5 VDC (control provided with battery plant).

Input voltage at switching c abinets shall not exceed -52.5

VDC.

feeder cables between the power board and the System

cabinet. Feeders must be U n d erwriter L aboratories (UL)

approved (or e q uivalent) and Canadian Safety Association

(CSA) certified. Recommended -48 VDC feeder cable—

Royal Electric #X4905 or equivalent No. 1 AWG is required

for distances up to 50 feet (15 meters). Cab le resistance

must be equal to or less than 0.1290 ohms per 1000 f eet

304 meters).

current for the System including that required for System

holdover and for charging the batteries. In addition, this may

include DC curre nt required for an inverter that provides

Occupier to peripheral e qu ip ment if it is installed and for

future growth.

Safety Assoc iat ion (CSA ) ce rt ifie d ci rcuit breaker must be

provided at the battery plant power board for each System

cabinet feeder. The recom mended c ircuit breakers are 75

amp ere Airpax UPL-1-1REC2-52-753 or Heinemann AM1B2-A-75-2.

considered. This would also provide the ad di t iona l c u rrent

necessary to recharge the batteries after being fully

discharged.

Issue 1 September 1995

2-7

Page 34

Plan and Prepare the Site

Parameter Requirements

Electrical

Noise

Grounding A single point ground must be maintained. A ground

Lig htni ng

Protection

Voice band noise from the bat tery plant to the system must

be less than 32 dBrnC (decibels above reference noise wi th

C-filter or -58 dB mp (decibels below 1 milliwatt

psophometric).

conductor must be installed from the battery plant GROUND

DI SCH AR GE BAR to the closest “Approved Ground” via the

shortest and most direct route as required by the National

Electrical Code or applicable electrical co de in your area.

The gauge must be no smaller than the largest condu c tor in

the System an d larg er than 6 AWG. Ground i ng between the

system cabinet and th e b att ery p lant should be connected

using the procedures given later in this chapter.

There must b e adequate lightning prote ction in the b attery

plant to insure that the system will not be dama g e d .

Lay Out and Ensure Appropriate Grounding

Grounding is relat ively simple for an AC-powered switch. First, connect the

cabinets to each other. Then, c onnect a single ground wire from the Processor

Port Network (PPN) to th e approved prote ctive ground .

Grounding of the system must com ply with the general rules for grounding

contained in Article 250 of the National Electrical C o de (NEC), National Fire

Protection Agency (NFPA) 7 0 , or the appli cable electric code in your country.

See Appendix A for a description of “approved ground.”

Conne c t Cou pled Bonding Conductor

The Coupled Bonding Conductor connects to the single-point-ground-block and

runs adjacent to pairs in an associated telecommunications cable. The mutu a l

coupling between the bonding conductor and the pairs reduces potential

differences in terminating e q u i p me nt. The conductor consists of a 10 AWG wire

that must be tie-wrapped to the inside wiring ca b le and terminated at the

coupled bonding conductor terminal bar at the switch cross-connect field.

Refer to Ap p e ndix F for wire conversion information.

Refer to Figure 4-9 on page 4-13 for an illustration of a Coupled Bonding

Conductor.

If the approved protective ground or approved floor ground can only be

accessed inside a dedicated po wer equ ipment room, you should have an

electrician make the connections to this ground.

2-8 Issue 1 September 1995

Page 35

Determine the Location of the Equipment Closets

NOTE:

Check location of the AC power receptacle. The receptacle must be on a

separately current limited (fuse or circuit breaker) circuit not controlled by

a wall switch .

Determine the Location of the

Equipment Closets

Determine the location of the eq uipm ent closets where larg e cables can be

connected out into smaller ones. Determine locations of terminating resisters for

Basic Rate Interface (BRI) station circuits to be installed in equipment closets.

Determine External Trunk Locations

Determine where external trunk lines come into the building and be routed to the

equipment room. Determine where external trunk converters and adapters as

well as sneak-current fuse panels will be installed in the switch room (preferably

close or next to the cross connect fields).

Create a Provisioning Plan

Determine an appropriate available port circuit on the DEFINITY System for each

telephon e , trunk, and p eripheral connection needed, and, in addition, p lan for

auxiliary p ower for Basic Rate Interface (B RI) and certain d isplay sets.

Create a provisioning plan to include the following (see the example on the

following pag e):

■ Station or trunk type or feature/service.

■ Building loc ation (floor/room/desk/in form ation out let ).

■ Extension number or trunk group and member number.

■ Port c ircuit location on the switch for each endpoint (DEFINITY System

Generic 3 c a b inet /carrier/ slot/circuit.

■ Route from switch room through equ ip ment closets to each endpoint.

■ Auxiliary power supply, if re quired.

Issue 1 September 1995

2-9

Page 36

Plan and Prepare the Site

.

Table 2-2. Example of a Provisioning Plan

Building

Location

Extension

Number or

Trunk Group

and Member

Station or Tru nk

Type or

Feature/Service

8410

8403

Attendant Consol e

Analog CO

Digital Tie

.....

Music on Hold

(floor/room/

desk/

information

outlet

DEFINITY

G3 cabinet/

carrier/slot/

circuit

Route

from

equipment

closets

Auxiliary

Power

Required?

2-10 Issue 1 Sep t em ber 1995

Page 37

Unpack the Cabinet

This chapter describes the system unpacking procedures.

The DEFINITY Syst em Ge neric 3 (G3) single-carrier cabinet s are shipped in a

pol yethyle n e b a g , packed in a cardboard container. The cabinet is fastened to a

wood/Styrofoam p allet with two metal bands. The cardboard container is

strapped to the p a llet with anot her m etal b and.

3

!

DANGER:

Liftin g the cab inet requires two people, as it may wei g h as much as 130

pounds/60 kilograms. Use caution to avoid injury.

Unpack and Inspect for Damage

Unpacking the Cabinets

To unpack the cabinets, c o mplete the followi n g steps:

1. Check the status of the SHOCKW A TCH and / o r TILTWATCH i n dicators on

the ca rdbo ard c ont ainer. These indicators are white under normal

conditions. If the co ntai ner ha s b een shaken or tilte d beyond

specifications, the indicators will b e r e d , indicating potential damage.

Report any damage according to local shipping instructions.

2. Remove the cabinet from the c a rdboard container.

!

DANGER:

Take care to avoid injury while cutting and removing bands.

3. Remove all cardb oard, tape, and plastic.

September 1995 Issue 1 3-1

Page 38

Unpack the Cabinet

4. Op en an d rem o ve the front door a nd b ack panels from cabinet. The

screw location is shown in the following figures.

!

CAUTION:

Deep knife penetration may d ama g e the c a binet.

1

Figure Notes:

1. Screw tha t op e ns front cabinet doo r

Figure 3-1. Front Cabinet Door Latch Screw Location

Figure 3-2 shows the b ack panel screw locations.

3-2 Sep tember 1995 Issue 1

Page 39

1

1

2

3

Figure Notes:

1. Screws to remove

2. Screws to loosen

3. Screws to remain

22

1

2

3

1

Figure 3-2. Back Cabinet Panel Screw Locations

1. Remove all packing material from inside the cabinet.

Inspect Cabinet

2. Inspect cabinet for any damage that may have occurred during shipping.

Report any damages according to local shipping instructions.

Septem b er 1995 Issue 1 3-3

Page 40

Unpack the Cabinet

3. Verify the label near the circuit breaker on the power supply toward the

rear of each cabinet co rre spon d s to your local voltage type.

Check Circuit Packs

4. Ensure all c i rcuit p acks are fully inserted into the proper slots according

to the Customer Service Document (CSD). Report any discrepancies in

circuit pack type or quantity to your AT&T representative.

!

DANGER:

If the label i s d ifferen t than the volt age typ e at your site, notify your

A T & T representative immediately for a replacement power supply.

Do not, under any circumstances, connect the system to p ower!

3-4 Sep tember 1995 Issue 1

Page 41

Install and Connect the Cabinets

This chapter describes how to install the Processor Port Network (PPN) and

Expansion Port Network (EPN) single-carrier cabinets for DEFINITY System

Generic 3. Directions are provided for the following c onfigurat ions:

■ Standard reliability

4

■ High reliability

■ Critical reliability

Refer to About This B ook for a description of each configuration.

This chapter discusses single-carrier cabinets only. For information on multiple-

carrier cabinets, refer to the

Generic 3 Installation a n d Test

To install the ca b inet s, c omp l ete the fol lowing steps as detailed in this chapter:

1. Install earthquake floor mounting (if earthquake protection is required)

2. Posit i o n and stack cabinets

3. Connect grounds and Connect AC power or DC power

4. Connect Time Division Multiplexing (TDM) cables

5. Connect inter-cabinet cables (ICC)

6. Verify address plug settings

7. Install b ack plates

8. Install g ro und pl ates

9. Install front cabinet clips or ground plates

10. Connect fibre-optic cables

DEFINITY Communica t ions System Generi c 1 a nd

document.

11. Install d oors

Issue 1 S e p t em ber 1995 4-1

Page 42

Install an d Connect the Cabinets

Install Earthquake Mounting

If earthquake protection i s re q uired for your area, install earthquake floor

mountin g a s d irecte d in Appendix B.

Position and Stack the Cabinets

Follow the diagram in the Customer Service Document (CSD) shipped with each

cabinet, and stack the DEFINITY System G eneric 3 cabinets using these steps:

1. Place the control ca b inet in p ositi on at the locat ion de t ermined when

room layout was planned.

NOTE:

Check location of the AC/DC p ower recep t acle. The receptacle

must be on a se p arat ely f used circuit

switch. It must be located within 10 feet (3 meters) of the c a binet,

and shoul d b e l o c ated outside the cross-connect field area.

2. Stack the single-carrier cabinets by letter, according to the serial

numbers and lettered designation strips in the Customer Service

Document ( CSD), and as shown in Figure 4-1.

not

controlled by a wall

D

C

B

A

Figure 4-1. Cabinets Stacked by Letter

3. Remove the front cabinet door and back cabinet panel. See " Unpack and

Inspect for Damage" on page 3-1 for more information.

4-2 Issue 1 September 1995

Page 43

Connect System Cabinet Grounds

Connect System Cabinet Grounds

To connect ground, refer to Figure 4-2 on page 4-4 and perf orm the foll owing:

1. At lower left rear of the P rocessor P ort Network (PPN) cabinet (Control

Cabinet A), connect a 6 AWG ground wire to the cabinet ground block.

See Appendix F for in ternational wire conversions for outside North

America.

NOTE:

A screwdriver is required to loosen and tighten the screws securing

the ground wire to the ground bloc k.

2. Run the ground wire to an ap p roved ground . Refer to Appendix A.

3. At the Expansion Port Netwo rk (EPN) cabinet(s) (as provided), connect a

6 AWG ground wire t o the A-c abinet ground block.

4. Run the ground wire from the Expansion Port Netwo rk (EPN) to the

Processor Port Network (PPN) cabinet and connect it to the cab inet

ground block.

NOTE:

If the Expansion Port Network (EPN) cabinet is remotely located

from the Processor Port Network (PPN) ca b inet (in a separate room

or building), run the 6 AWG cabinet ground wire to an ap proved

protective ground.

5. At the Processor Port Net work (PPN) cabinet, connect a 10-AWG wire t o

the cabinet ground block. At a later time, tie-wrap the ground wire

(coupled bonding conductor) to the trunk cables, termin ati n g it at the

coupled bonding conductor terminal bar at t he cross-connect field for the

switch. Refer to Figure 4-9 on pa g e 4-1 3 for an illustratio n of the c o u pled

bonding conductor.

Issue 1 September 1995

4-3

Page 44

Install an d Connect the Cabinets

3

2

1 1

ON ON

OFF OFF

7 7

12

13

ON ON

OFF OFF

4

ON ON

OFF OFF

12

9

5

ON ON

OFF OFF

11

6

7

7

8

10

Figure Notes:

1. Expansio n Port Network (EPN) Contro l

Cabinet A

2. Circuit breaker

3. Power sup p l y

4. Power receptacle in powe r su p p l y

5. Processor Port Network (PPN) Control

Cabinet A

6. Cabinet-stack single-point ground block

7. Power cord 2.5 meters

Figure 4-2. Typical AC Power and Groundin g Arrangement

for Single-Carrier Cabinet (Rear View)

8. National Electrical Manufacturer’s

Ass o ciation (NEMA) 5- 1 5 o r Na tional

Electrical Manufacturer’s Association

(NEMA)5-20 recep tacle or equivalen t

locally provided receptacles

9 . 6 AWG ground wire to approved ground

10. Generic 3 Management Terminal (G3-MT)

11. 1 0 AWG C oupled Bondi ng Con ductor

12. 6 AWG cabinet-stack ground conductor

13. Port cabinet

4-4 Issue 1 September 1995

Page 45

Connect Battery Leads

Connect Battery L eads

To prevent the batteries from discharging, the co n trol ca b inet is shipped with

the battery lead di sc onnect ed. To connect the batteries, perform the following:

At cabinet(s):

1. Ensure the c ircuit b reakers on ea c h c a binet are OFF.

Each ca b inet has its own power supply and the circuit breaker is located

on the rear of each power supply. See Figure 4-3.

2. Connect the battery lead:

See Fig ure 4-3. The ba ttery is near the top of the carrier toward the fro nt-

right. The battery leads should be immediately next to the ba t tery, on the

left side, and accessible from the front of the cabinet.

1

Figure Notes:

1. Battery

2. Circuit Breaker

3. Ground block

Figure 4-3. S ingle Carr i er Cabinet Control Cabinet

Battery Location, Right Side View

2

3

Issue 1 September 1995

4-5

Page 46

Install an d Connect the Cabinets

Connect Power

Connect either AC or DC power as described in this section.

Verify the label near the circuit breaker on the power supply toward the rear of

each ca b inet c orrespon ds to your local voltage type.

!

DANGER:

If the label is different than the voltage type at your site, notify your A T & T

representative immediately f o r a replacement power supply . D o not, under

any circumstances, connect to power!

Connect AC Power

Figure 4-2 applies to multiple Processor Port Networks (PPN) and Expansion

Port Network (EPN) c abinet arrang e m ent s. If mul ti p le Exp ansion Port Network

(EPN) c abinets are required, you must provide the recept acles f or the 4-cabinet

Processor Port Network (PPN) arrangement in addition to the receptacles for a

2-, 3-, or 4-cabinet Ex pansion Port Network (EPN) arrangem ent. Provide one

receptacle per single-carrier cabinet.

1. Verify the circuit breakers are OFF .

2. Connect cabinet AC line cords to the AC power rece pt acles. The AC line

cords for the cabinets must first be connected to the cabinets and then to

the AC power receptacles.

Conne c t DC Po wer

The fol lowing procedures appl y t o both the Processor Port Networks (PPN) and

Expansion Port Networks (EPN).

Figure 4-4 shows a typical power and groundi ng layout for a D C -powered

single-carrier cabinet. The size of the wire required for the -48 VDC and -48 volt

return must ensure the -48 VDC supplied by the battery plant to the cabinets will

be m aint ained between -42.5 and -5 2.5 volt DC. This ensures proper operation

and prevents hardware damag e.

4-6 Issue 1 September 1995

Page 47

Connect Power

GRD

15

2

1

5

-48V

-48VRTN

16

1

GRD

15

2

1

-48V

-48VRTN

16

1

GRD

15

2

1

-48V

-48VRTN

16

1

GRD

15

1

2

-48V

-48VRTN

17

5

1

1

1

1

6

3

4

7

-48V

RTN

1

9

12

1

7

10

(-48VRTN & GRD)

GRD

1

-48V

-48V

18

75A

75A

1

-48V

8

11

GRD

13

GRD

-48V

-48VRTN

11

7

14

Issue 1 September 1995

4-7

Page 48

Install an d Connect the Cabinets

Figure Notes:

1. Ground plat e (three required)

2. 3 Conductor No. 10 line co r d (on e per

cabinet)

3. Plug (male)

4. J58890CG DC Distribution Unit

5. Receptacle (female)

6. Cabinet single-point ground block

7. 6 AWG wire

8. 25 Amp Fuse (4 re q uir e d )

9. Coupled bond i n g co n duc tor to te rmi na l

bar at cross-connect field

10. Groun d discharge bar

11. 1 AWG wire

12. Ap p rove d grou n d

13. To cabine t singl e -p oint groun d b loc k in next

port cabinet

14. To DC distrib ution unit for next port network

15. 676B DC Power Supply

16. Port Cabinet

17. Control Cabinet

18. Ba ttery Plant

Figure 4-4. Typical Single-Carrier Cabinet System Direct

Current (DC) P ower and Grounding Wiring

!

CAUTION:

Grounding of the system shall comply with the g eneral rules for grounding

contained in Article 250 of the National E lectrical Code (NEC), National F ire

Protection Agency (NFPA) 7 0 , or th e applicable code in your area. See

App e ndix G for more information.

Determine the approved ground in the building to be wired. See A ppendix A.

Connect your system to an approved ground as described below.

4-8 Issue 1 September 1995

Page 49

Connect Power

1. 1 AWG wire

2. App roved gr ound. Must be conne c ted

to an approved ground using the correct

ga uge c able, te rminated with a listed

clam p, and identifi ed with an AT&T

gro un d tag or e quivalent.

3. DC Power Cabinet

4. Ground discharg e bar

Figure Notes:

Connect Power Plant Ground

To connect the power plant ground, complete the following steps:

1. At the DC power cabinet, connect a 1 AWG ground wire to the GROUND

DISC HARGE bar.

2. Route the ground wire out of the cabinet and terminate it on the approved

ground (see Figure 4-5). The ap proved ground must be identifie d with a

grounding tag (AT&T FORM 15657NR, or equivalent).

1

4

2

Figure 4-5. Power Plant Groundin g

3

Issue 1 September 1995

4-9

Page 50

Install an d Connect the Cabinets

Connect Frame Ground

Connect the 6 AW G frame ground cable to the cabinet frame b y following these

steps:

1. Measure and cut a length of 6 AWG cable. Use the p rovided cable or

measure and cut a length of 6 AWG cable long enough to reach between

the GROUND CONNECTION terminal in the DC Battery Cabinet and the

G ROUND DISCHARGE b a r in the DC Power Cabinet.

2. Crimp terminal lugs on each end of the wire. Terminal lugs are furnished

as part of D-181895, Kit of Parts.

3. At DC power cabinet, connect wire to the GROUND DISCHARGE bar.

4. Route the wire through one of the holes in the side of the ca b inet an d

terminate it on the GROUND CONNECTION te r min al i n the DC Ba ttery

Cabinet (see Figure 4-6).

4

Figure Notes:

1. 6 AWG wire

2. Ground discharg e bar

3. DC battery cabinet

1

3

4. Groun d c onne ct ion terminal

5. Power distribution unit

5

2

Figure 4-6. Frame Ground Groun ding

4-10 Issue 1 Sep t em ber 1995

Page 51

Connect Power

Connect DC Pow er Distribution Box Groundi ng

Run the 6 AWG ground c a ble from the DC Power Cabinet to each DC Power

Distribu t ion Unit , using the following steps:

1. At the DC Power Cab inet , c o n nect 6 AWG wire to the GROUND

DISCHARGE bar. Route the cable to the DC Power Distribu t ion Uni t.

Connect the cable to t he GRD Terminal Block in t he DC Power

Distribu tion Unit (see Figure 4-6).

2. Repeat Step 1 for each remaining DC Power Distribution Unit.

4

3

Figure Notes:

1. 6 AWG wire

2. To additional J588 90CG as p rovi ded

3. DC power cabi net

1

2

4. Ground discharg e bar

5. Power distribution unit

6. Ground terminal strip

6

5

Figure 4-7. DC Power Distribution Unit Groundin g (J58890CG)

Connect Single-Carrier Network Grounding

Each port cabinet must have a 6 AWG ground cable connected fro m t he ground

blo c k o f C ontrol C a b inet A to the DC Power Cabinet.

Use the following instru ctions to connect each network ground:

Issue 1 Septemb er 1995

4-11

Page 52

Install an d Connect the Cabinets

1. At the DC Power Cab inet , c o n nect a 6 AWG cable to the GROUND

DISCHARGE bar. Route the cable to the port Cabinet Carrier A. Connect

the cable to the single-point ground block in the Control Carrier (see

Figure 4-7).

2. Repeat Step 1 for each port Cabinet Carrier A in the system.

6

7

1

8

9

2

5

Figure Notes:

1. 6 AWG wire

2. Ground plate

3. C abinet stack single point g round bl ock

4. To additional Port Cabinet as provided

5. DC Power Cabinet

Figure 4-8. Ground Connection for Single-Carrier Network

Coupled Bonding Conductor (CBC)

The coupled bonding conductor (CBC) connects the cabinet single-point

ground block to the approved protective ground located nearest the (telephone

company owned) protector block at the building entrance facility. Fol low the se

steps to connect the coupled bonding conductor:

10

3

4

6. Ground discharg e bar

7. Port Cabinet D

8. Port Cabinet C

9. Port Cabinet B

10. Port Cabinet A

4-12 Issue 1 Sep t em ber 1995

Page 53

Connect Power

1

3

1. Connect a 10 AWG wire to the power cabinet ground discharge bar. See

Figure 4-9).

2. Repeat for each p o rt network c abinet .

NOTE:

A Coupled Bonding Conductor (CBC) must be t ie-wrapped to all

trunk c ables and termin ated at the co upled bonding conductor

terminal bar.

3

15

2

3

7

12 12

4

14

8

5

6

11

10

9

14

Figure Notes:

1. 25-Pair tip and ring cables to network

cabinets.

2. Coupled bonding conductor terminal

block

3. Tie wraps

4. Cable shield or six spare pairs

5. Ground on carbon block protector or

equivalent

6. To external trunk interface

7. 10 AWG wire

13

8. Trunk cable

9. To network cabinets

10. Battery plant ground discharge bar for

DC or AC system single point ground

11. Cross-co nnect gr ound bloc k

12. Cross-co nnect fiel d

13. To other cross-connect ground blocks

14. Approved G r ound

15. Couple Bonding Conductor

Figure 4-9. Coupled Bonding Con ductor

Issue 1 Septemb er 1995

4-13

Page 54

Install an d Connect the Cabinets

!

CAUTION:

System grounding shall comply with the general rules for grounding

contained in Article 250 of the National E lectrical Code (NEC), National F ire

Protection Agency (NFPA) 70, or your applicable local electrical code. See

App endix A for a description of “ a pproved ground. ”

Connect DC Power to Networks

Each port cabinet stack must have a DC Power Distribution Unit associated with

it. Each DC Power Distribution Unit furnishes DC power for four single-carrier

cabinets. The DC Power Distribution Unit c ome s equipped with four p ower

cords. Each 10 foot (3 meter) cord is equipp ed with the appropriate connectors.

Perform the following to connect each network to the DC Power Distribution Unit:

1. Connect 1 AWG wire for -48V and -48V ret urn from DC Battery Plant to

each DC Power Distribu t ion Uni t.

2. At the J58890CG DC Power Distribution Unit, connect the power cable to

an available receptacle. Route the cable to the rear of Cabinet A.

Connect the power cord to the DC connector on the rear of Cabinet A.

3. Repeat Step 1 for Cabinets B, C, an d D as required.

4. Repeat Steps 1 and 2 for all remaining port cab inets.

Connect AC Power to DC Power Cabinet

Connect the A C power to the DC Power Cabinet by performing the following:

1. Ensure the associated circuit breakers at the AC power panel OFF.

2. Have an electrician connect AC power leads to the rectifiers using the

instructions provided with the rectifiers in the DC Power Cabinet . Each

rectifier should have its own branch circuit. Terminate leads on the AC

INPUT terminal block of each rectifier.

Test DC Power Plant

To test the DC p ower p l a nt, refer to the Inst allat ion Test Procedure (ITP) in t he

LINEAGE 2000 ECS Power System Battery Plant Product Manual

Conne c t St and-by Power

An external, commercial Uninterruptible Power Supply (UPS) or a bat tery

backup arrangement may be provided. Stand-by power is engineered to

customer needs depending on the size and configuration of th e system.

, 167-790-020.

The AT&T GBCS Power System is recommended; use the installatio n

instructions provided. See your AT&T representative for more information.

4-14 Issue 1 Sep t em ber 1995

Page 55

Locate and Connect Time Division Multiplexing (TDM)

Bus

Locate and Connect Time Division

Multiplexing (TDM) Bus

Locate the white fabric-covered Time Division Multiplexing (TDM) bus cable.

Refer to Table 4-1 for slot information.

Follow these instructions to connect the bus to the appropriate slots.

1. Remove the Time Division Multiplexing (T D M) bus terminator on Slot 22 of

A

Control Cabinet

(TDM)/Local Area Network (LAN) pinfield at the equipment location ( EQL)

on the top port cabinet. See Figure 4-10.

2. Connect the bus cables as shown in Figure 4-10. The cable is located

behind the lower panel when the cabinet is shippe d.

Table 4-1. Time Division Multiplexing (TDM) Bus Connections

Configuration Cabinet/Slot

Processor Port Network

(PPN),

High or Critical

Reliability

Expansion Port

Network (EPN),

Standard, High or

Critical Reliability

Processor Port N etwork

(PPN),

Standard Reliability

and move it to the Time Division Multiplexing

A/22 B/02

B/22 C/00

C/17 D/00

A/18 B/00

B/17 C/00

C/17 D/00

A/22 B/00

B/17 C/00

C/17 D/00

Backplane Time Division

Multiplexing (TDM)/Local

Area Network (LAN)

Pinfield at EQL

Cabinet/Slot

Issue 1 Septemb er 1995

4-15

Page 56

Install an d Connect the Cabinets

AAAA

AAAA

AAAA

AAAA

AAAA

A

A

A

A

A

AAAA

AAAA

AAAA

AAAA

AAAA

A

A

A

A

A

A

AAAA

AAAA

AAAA

AAAA

AAAA

A

A

A

A

A

A

A

A

A

A

1. Time Divisio n Multiplexing (TDM) bus

terminator AHF 110 on Time Division

Multiplexing)/Local Area Network

p in fie l d (TDM/LA N )

2. Time Division Multi p l exin g / L o c al Area

Networ k pinfield (TDM/LAN) at

equipment location (EQL) (see Table 4-1

on page 4-1 5)

3. Time Division Mult i pl exin g (TDM) bus

cable WP91716 L3

4. Port cabi ne t (sta ndar d reliabi lit y), or

duplicate control cabinet (high or critical

reliability)

5. Co ntrol c abinet

Figure Notes:

1

3

3

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

2

4

2

4

2

4

3

Figure 4-10. T im e Division Multiplexing (TDM) Bus

Connections for Standard-Reliability Processor

Port Network (PPN )

4-16 Issue 1 Sep t em ber 1995

1

AAA

AAAA

AAAA

AAAA

AAAA

AAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAA

AAA

AAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

5

Page 57

Locate and Connect Inter-Cabinet Cables (ICC)

Locate and Connect Inter-Cabinet

Cables (ICC)

Connect the Inter-Cabinet Cables (ICC) using these steps:

1. Remove the Inter-Cabinet Cable (ICC) from the lower back shelf of the

cabinet.

2. Connect the cables as shown in Figure 4-11 and Table 4-2.

Table 4-2. Inter-Cabinet Cable Connections

From Cabinet A To Cabinet B

Cabinet Carrier Connection Carrier Connection

Processor

Port

Network

(PPN)

Expansion

Port

Network

(EPN)

J58890L (ICC) A J58890M (ICC) A

(ICC) B (ICC) B

(ICC) C (ICC) C

J58890N (ICC) A J58890H (ICC) A

(ICC) B (ICC) B

Issue 1 Septemb er 1995

4-17

Page 58

Install an d Connect the Cabinets

A

A

A

A

A

A

A

AAAA

AAAA

AAAA

AAAA

AAAA

A

A

A

A

A

A

AAA

Figure Notes:

1. Pi nfield per Table 4-2

2. Cabinet in Position B

3. Inter-Cabinet Cables

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

4. Backplane

5. Control Cabinet A Position

■ Rear of Cabinets Shown

1

2

3

4

5

Figure 4-11. In ter-Cabinet Cabl e (ICC) Connections for

4-18 Issue 1 Sep t em ber 1995

Standard Reliability Expansion Port Network

(EPN) Cabinet S tack

Page 59

Install Fibre-Optic Cables

Install Fibre-Optic Cables

This section discusses the hardware and methods required to connect and

route fibre-optic cables.

The Expansion Port Network (EPN) ca binet is normally positioned next to the

Processor Port Network (PPN) cabinet(s), but may also be installed in a different

room or a different building. Fibre-optic cables connect the cabinets tog et her.

Fibre-Optic Cable Operation

Fibre-optic cables carry signals between the cabinets that compose your

switch. To do this, the electronic signals at the connectors on the back of a

cabinet are converted into optical signals. The optical signals from another

cabinet are then converted back into electronic signals. AT&T provides optoelectronic devices, the 9823-typ e lightwave transceivers, that perform this task.

A completed signal from one cabinet goes through a transceiver, a fibre-optic

cable, and another transceiver to reach another ca b inet . If the two cabinets are

close together, the optical signal may go through a single, directly connected

fibre-optic cable. If th e two cabinets are far a p art, it may b e c o nvenient to

connect the cabinets through the cross-connect field.

Figure 4-13 shows how to connect fibre-optic cables for direct connections.

Figure 4-14 shows how to connect fibre-optic cables through a cross-connect

field. .

Locate Fibre- Op tic Cab le Co n necti on s

Packed with the system is a Customer Service Document (CSD) that includes a n

“Inter-Cabinet Cable Running List . ” Each ro w on the list represents a fibre-optic

cable connection.

The list includes the AT&T comcode of the cable to be used, it s length (in fe et)

and the addresses of each c a ble’ s source a nd destination. These addresses

include the nu mbers o f t he cabinets, carrier positions, and slots to which you are

to connect the cables. Use the information from the Running List to determine

where to connect each fibre-optic cable.

Figure 4-12 illustrates an example Running List.

Issue 1 Septemb er 1995

4-19

Page 60

Install an d Connect the Cabinets

Connection

From

SD67975-01

CAD3 104266465 20 ft. 01 C 02 02 B 02

CAD3 104266465 20 ft. 01 D 02 02 A 01

Cable

Code Length From To

Cabinet Position Slot Cabinet Position Slot

Figure 4-12. Typical Fibre-Optic Cable Running List

In the example Ru nning List in Figure 4-12, connect a cable labeled 104266465

(20 feet long) from Cabinet 1, Carrier C, Slot 2 , t o Ca binet 2, Carrier B, Slot 2.

NOTE:

The followin g ta sks refer to the Running List and offer ty p ical install atio n

instructions. If any conflict between specific details in the Running List and

the instructions given i n the following procedures arise, cable your system

accor ding t o the Running List provid ed with your system.

General Rules and Recommendations for

Connecting Fibre-Optic Cables

Although fibre-optic ca bles withstand some misuse, it d oes re quire caref ul

handling and routing.

Follow these rules and recommendations when installing fibre-optic cables:

Rule 1

Cross-connect the fibre-optic cable between two 9823-type lightwave

transceivers. That is, run the cable from th e connector marked TX on one

transceiver to the connector marked RX on the other transceiver, and in reverse

for the other c able.

Do this for each connection (row) on the Running List contained in the Customer

Service Doc ume nt (CSD) shipped with your system. See Figure 4-12 for a

sample Running List.

Rule 2

Use the 9823A (shortwave) transceiver for distances of up to 4900 feet. Use the