ATSG Ford 4R100 Service Manual

FORD 4R100

INDEX

IDENTIFICATION TAG LOCATION AND INFORMATION ............................................................... 3

GENERAL DESCRIPTION AND OPERATION ..................................................................................... 4

COMPONENT AND SOLENOID APPLICATION CHART ................................................................... 5

"PTO" GENERAL REQUIREMENTS .................................................................................................... 6

ELECTRICAL COMPONENT DIAGNOSIS ........................................................................................... 8

FLUID REQUIREMENTS ....................................................................................................................... 12

SOLENOID PACK TESTING .................................................................................................................. 12

ABBREVIATION DESCRIPTION .......................................................................................................... 14

DIAGNOSTIC TROUBLE CODE CHART AND DESCRIPTION ........................................................ 15

LINE PRESSURE TEST .......................................................................................................................... 21

NON-PTO AND PTO HYDRAULIC DIFFERENCES ........................................................................... 22

PWM AND NON-PWM OIL PUMP DIFFERENCES ........................................................................... 34

CASE CHECKBALL LOCATIONS ......................................................................................................... 38

VALVE BODY CHECKBALL LOCATIONS ........................................................................................... 39

AIR PRESSURE CHECKS ...................................................................................................................... 40

TRANSMISSION DISASSEMBLY ......................................................................................................... 41

COMPONENT REBUILD SECTION

TRANSMISSION CASE ASSEMBLY ................................................................................................ 55

FRONT AND REAR PLANETARY CARRIERS ............................................................................... 64

FORWARD CLUTCH HOUSING ...................................................................................................... 66

DIRECT CLUTCH HOUSING ........................................................................................................... 69

FORWARD, DIRECT, SUN SHELL SUB-ASSEMBLY .................................................................... 76

CENTER SUPPORT ASSEMBLY ...................................................................................................... 80

INTERMEDIATE/OVERDRIVE CYLINDER ASSEMBLY ............................................................. 82

OVERDRIVE GEARSET ASSEMBLY ............................................................................................... 84

COAST CLUTCH HOUSING DIFFERENCES ................................................................................ 88

COAST CLUTCH HOUSING ASSEMBLY ........................................................................................ 90

OIL PUMP ASSEMBLY ...................................................................................................................... 94

VALVE BODY ASSEMBLY ............................................................................................................... 100

TRANSMISSION FINAL ASSEMBLY ................................................................................................. 102

MANUAL VALVE CHECK .................................................................................................................... 111

MANUAL SHIFT LEVER DIFFERENCES ........................................................................................ 112

TORQUE SPECIFICATIONS ............................................................................................................... 115

VALVE BODY BOLT CHART AND IDENTIFICATION .................................................................... 116

BOLT CHART AND IDENTIFICATION ............................................................................................. 117

SPECIAL SERVICE TOOLS ................................................................................................................. 118

AUTOMATIC TRANSMISSION SERVICE GROUP

18639 S.W. 107TH AVENUE

MIAMI, FLORIDA 33157

(305) 670-4161

Copyright © ATSG 2003

INTRODUCTION

Updated

October, 2003

FORD 4R100

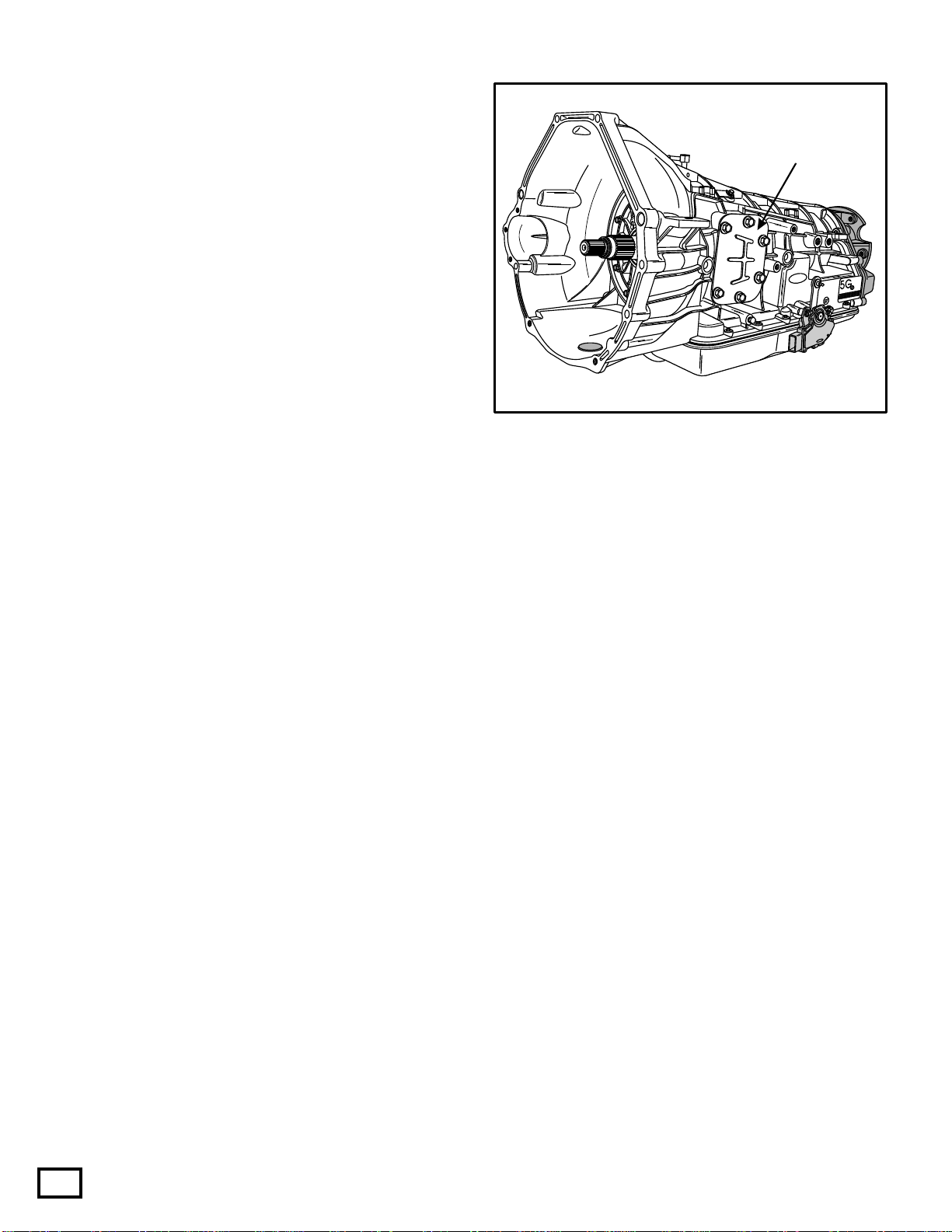

The Ford 4R100 transmission is an updated version of the E4OD and was first introduced in the 1999 model

year, and is currently found in the F250, F350, F450 and F550 Super Duty trucks, E150, E250, E350, E450 vans

and the Expedition/Navigator/Excursion vehicles equipped with the 5.4L, 6.8L, and 7.3L engines. Some of the

4R100 units are equipped with a Power-T ake-Off (PT O) window on the left hand side of the transmission case.

The revisions in the 4R100 have created many new engineering changes that have affected many of the internal

and external parts that will affect the servicing, repairing and overhaul of these units.

We wish to thank Ford Motor Company

for the information and illustrations

that have made this booklet possible.

No part of any ATSG publication may be reproduced, stored in any retrieval system or transmitted in any form or

by any means, including but not limited to electronic, mechanical, photocopying, recording or otherwise,

without written permission of Automatic Transmission Service Group. This includes all text illustrations,

tables and charts.

The information and part numbers contained in this booklet have

been carefully compiled from industry sources known for their

reliability, but ATSG does not guarantee its accuracy.

DALE ENGLAND

FIELD SERVICE CONSULTANT

WAYNE COLONNA

TECHNICAL SUPERVISOR

PETER LUBAN

TECHNICAL CONSULTANT

JON GLATSTEIN

TECHNICAL CONSULTANT

ROLAND ALVAREZ

TECHNICAL CONSULTANT

GERALD CAMPBELL

TECHNICAL CONSULTANT

Copyright © ATSG 2003

JIM DIAL

TECHNICAL CONSULTANT

ED KRUSE

TECHNICAL CONSULTANT

GREGORY LIPNICK

TECHNICAL CONSULTANT

DAVID CHALKER

TECHNICAL CONSULTANT

JERRY GOTT

TECHNICAL CONSULTANT

MIKE SOUZA

TECHNICAL CONSULTANT

AUTOMATIC TRANSMISSION SERVICE GROUP

18639 S.W. 107TH AVENUE

MIAMI, FLORIDA 33157

(305) 670-4161

1

Technical Service Information

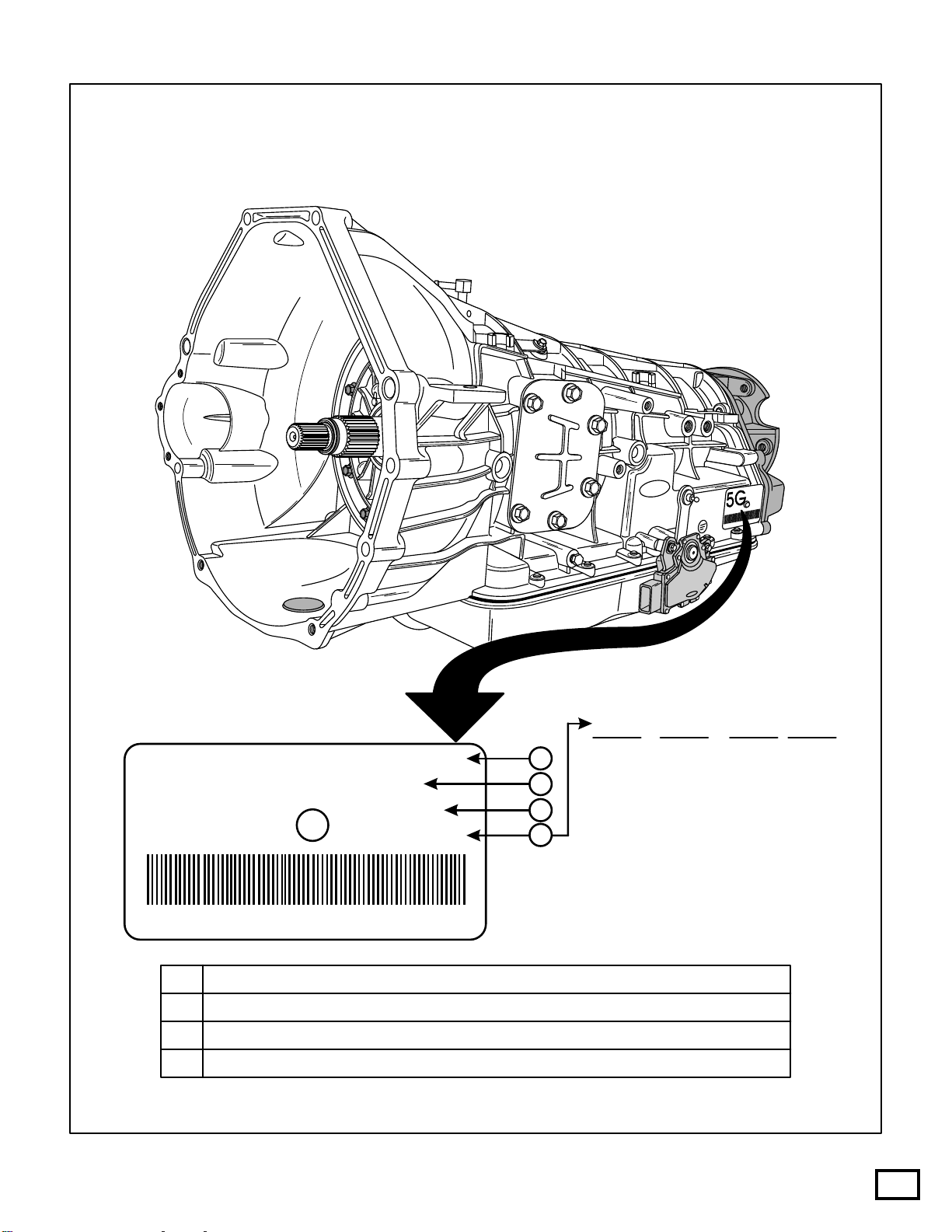

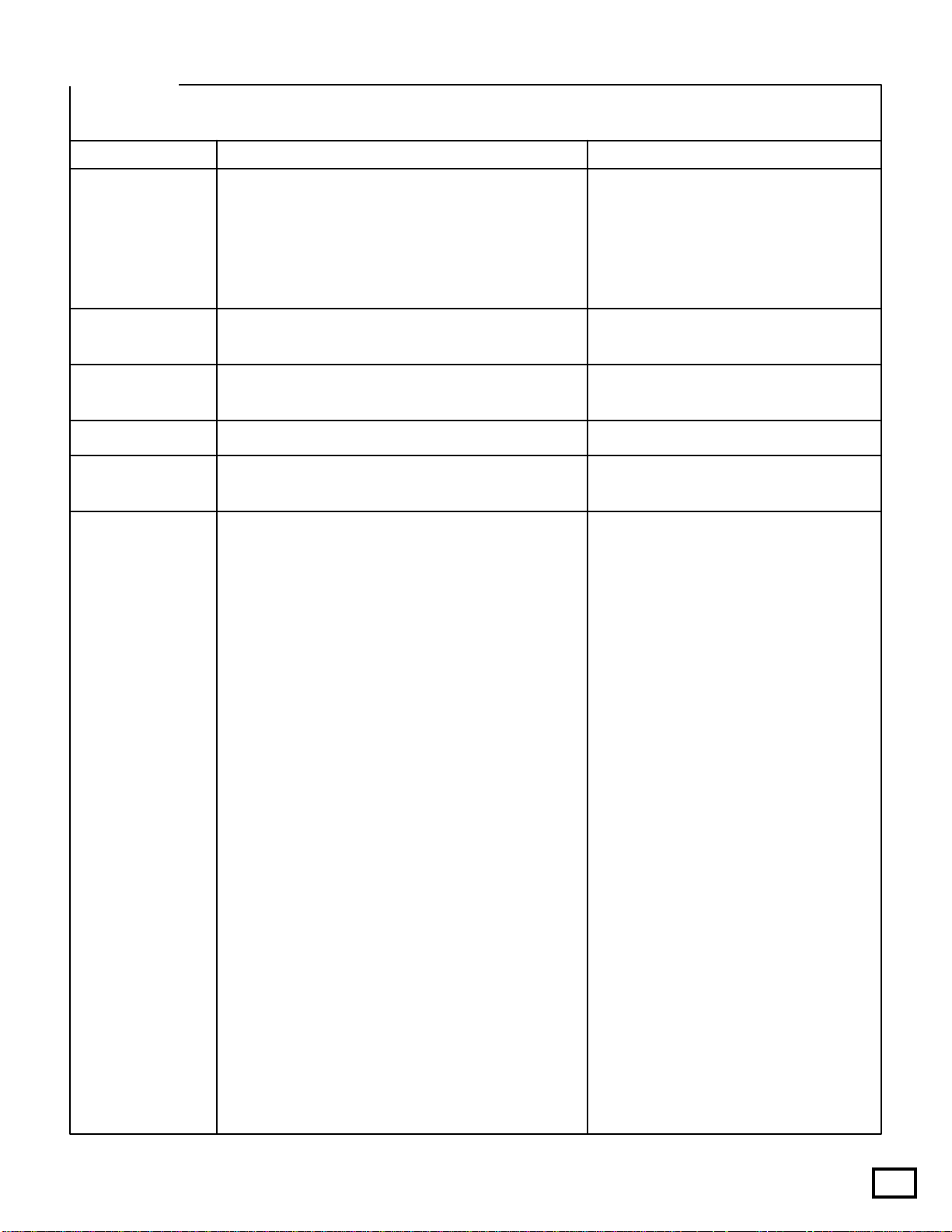

TRANSMISSION IDENTIFICATION

WITH POWER TAKE OFF OPTION

Note:

PTO is available as an option on 8500 GVW or above, Super Duty

F-Series trucks with 6.8L gasoline and 7.3L Diesel e ngines.

Ford 4R100 transmissions on other models are not PTO capable.

Ford

Ford

RFF81P-7006-BA

98

AC

-

P

4

W

X

-B

L

J

R

1

6

3

04

0

7

1

C

D-9

B

55GG

0043616520

Assembly Part Number, Prefix And Suffix1

Transmission Model

2

Serial Number

3

XW4P-AC

RJL-B

004361

BD-9C17

4 X 44 X 4

Fo

r

d

Year Month Day

17C9BD-

1

Build

Date

2

3

4

9=1999

0=2000

1=2001

2=2002

3=2003

A=Jan

B=Feb

C=Mar

D=Apr

E=May

F=Jun

G=Jul

H=Aug

J=Sep

K=Oct

L=Nov

M=Dec

Build Date (Year, Month, Day)

4

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2003 ATSG

Figure 1

3

Technical Service Information

TRANSMISSION

DESCRIPTION AND OPERATION

General Description

The Ford 4R100 automatic transmission is a four

forward speed unit with electronic shift control. It is

designed for longitudinal powertrains for rear wheel

drive vehicles.

The 4R100 transmission features a four element

torque converter design that includes Torque

Converter Clutch (TCC) and a gear train that includes

three planetary gearsets.

Some models provide for Power Take Off (PTO)

operation in all transmission shift lever positions.

During PTO operation in OD, 4th gear is disabled.

The hydraulic control system of the 4R100 unit has

five electronically controlled solenoids for:

Shift feel, through line pressure control.

Shift scheduling, through shift valve position.

Engine braking during coast conditions.

TCC apply (On/Off or Modulating).

Major Internal Components

"Seven Friction Apply Elements"

Intermediate Band

Coast Clutch, Multi-disc

Overdrive Clutch, Multi-disc

Intermediate Clutch, Multi-disc

Direct Clutch, Multi-disc

Forward Clutch, Multi-disc

Low/Reverse Clutch, Multi-disc

"Three One-Way Clutches"

Overdrive Roller Clutch

Intermediate Sprag

Low Roller Clutch

Shift Quadrant Indicator

V ehicles equipped with the 4R100 transmission have

a Transmission Control Switch (TCS), also referred to

as "Overdrive Cancel Switch", and a Transmission

Control Indicator Lamp (TCIL), located on the end of

the manual gear shift lever, as shown in Figure 3. The

TCS is a momentary contact switch. When this

switch is pressed, a signal is sent to the PCM to allow

automatic shifts from 1st to 4th gear or from 1st to 3rd

gear. After the TCS has been pressed the PCM turns

on the TCIL lamp ("OFF"), to indicate that overdrive

has been canceled, as shown in Figure 3.

The shift quadrant has the following positions, as

shown in Figure 2: P , R, N, D , 2 and 1.

D position (TCS OFF) provides 1-2-3-4 automatic

upshifts and downshifts. Coast braking occurs in 4th

gear. (TCIL Not Illuminated)

D position (TCS ON) provides 1-2-3 automatic

upshifts and downshifts. Coast braking occurs in 3rd

gear. (TCIL Illuminated)

2 position provides a pull-in shift to 3rd gear with

coast braking. After an automatic downshift, a 2nd

gear hold occurs with coast braking.

1 position provides a pull-in shift to 2nd gear with

coast braking. After an automatic downshift, a 1st

gear hold occurs with coast braking.

"Three Simple Planetary Gearsets"

Overdrive

Forward

Reverse

"Typical" Shift Quadrant Indicator

P R N

Figure 2 Figure 3

4

D

2 1

Copyright © 2003 ATSG

OVERDRIVE OFFOVERDRIVE OFF

AUTOMATIC TRANSMISSION SERVICE GROUP

TCS

SWITCH

TCIL LAMP

Technical Service Information

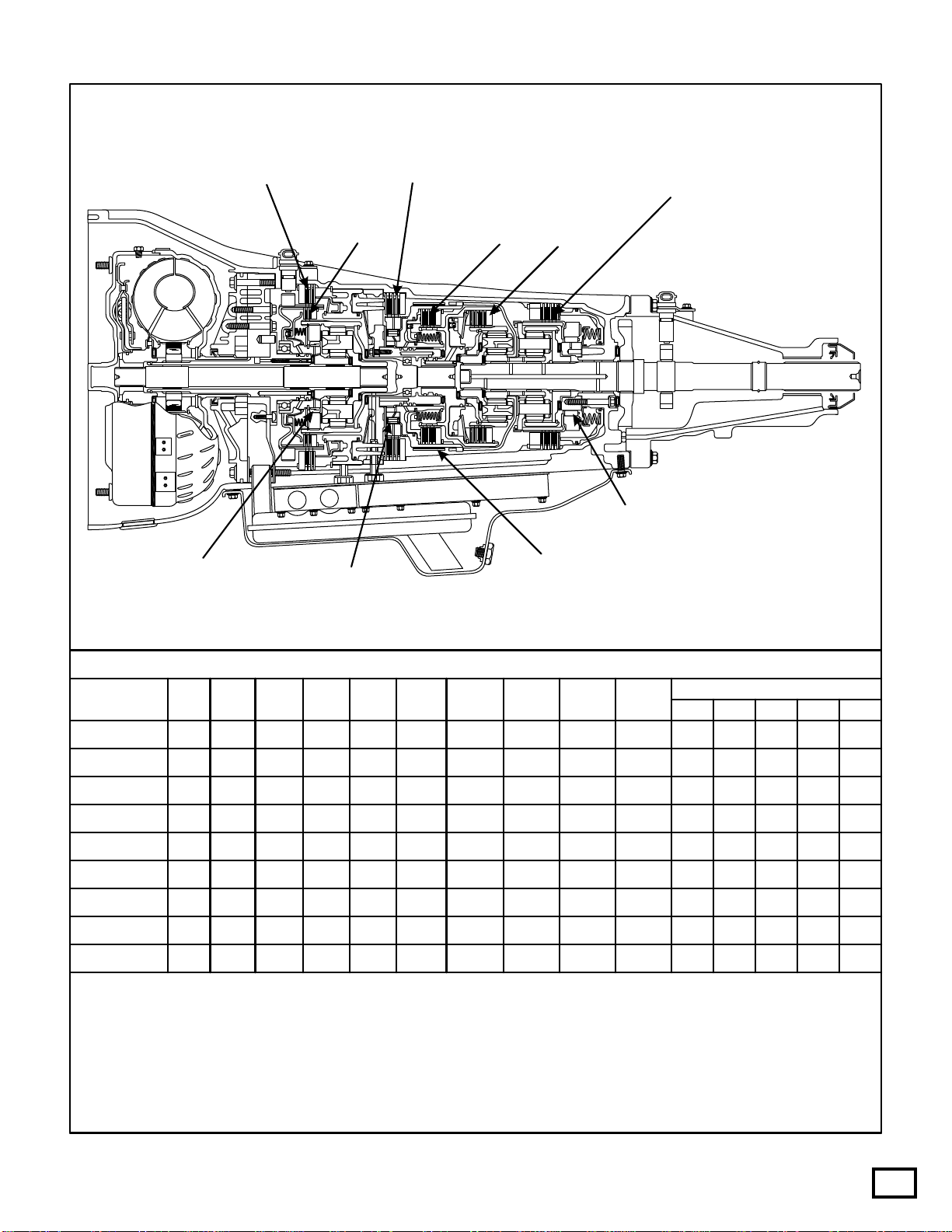

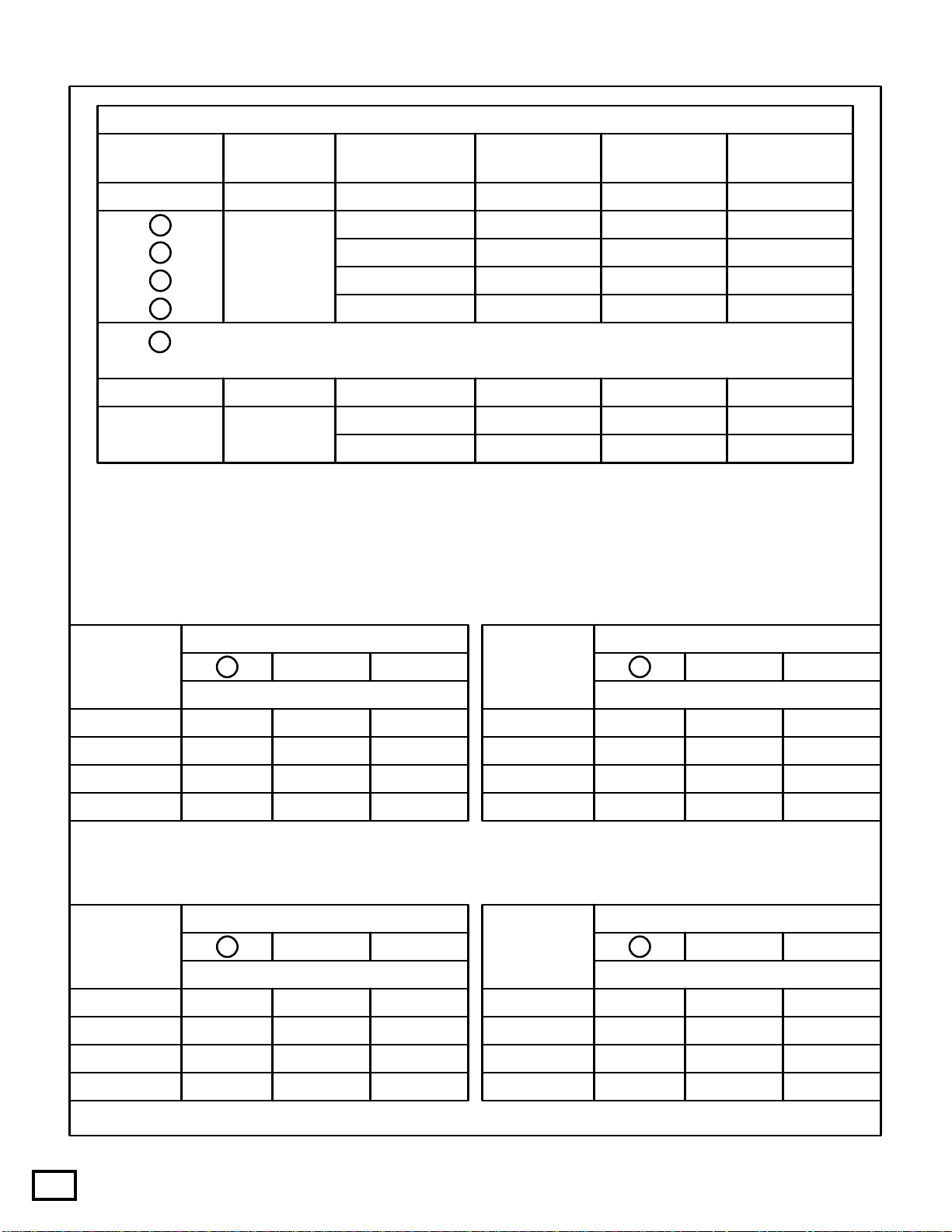

Overdrive

Clutch

FORD MOTOR COMPANY

4R100 ("PTO" Version Illustrated)

Intermediate

Clutch

Low/Reverse

Clutch

GEAR

Park/Neut

Overdrive

Roller Clutch

Fwd

Clut

Int

Clut

Coast

Clutch

Intermediate

Sprag

Direct

Clutch

Intermediate

Forward

Clutch

Low

Roller Clutch

Band

COMPONENT AND SOLENOID APPLICATION CHART

Dir

Clut

O.D.

Clut

Cst

Clut

Int

Band

L/R

Clut

O.D.

Roller

Int

Sprag

Low

Roller

SS1 SS2

On

GEAR RATIOS

Reverse - 2.18

1st Gear - 2.71

2nd Gear - 1.54

3rd Gear - 1.00

4th Gear - 0.71

SOLENOIDS

CCS

TCC EPC

Off Off

Off

Mod

Reverse

OD-1st

OD-2nd

OD-3rd

OD-4th

OD-3rd**

M-2nd

M-1st

ON ON

ON Hold

ON ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON ON

ON

ON

ON ON

ON

ON

ON

Hold

Hold Hold

Hold

Hold

Hold

Hold

Hold

Hold

Hold

On

Off Off Off

On *On

OnOnOn

Off

Off

Off

On

*Off

Off

*Off

On

*Off

Off

Off

On On

On

On

Off

*On

*On

*On

*On

*On

Off

OD-3rd** = TCS "On" with TCIL illuminated showing "Off"

*On = If the PCM determines that powertrain operating conditions exist for TCC apply, the TCC solenoid may

be On (Modulating with PWM TCC units) in any forward gear except Manual 1st.

*Off = Will be "On", if the TCS switch is pushed.

Mod = Modulating at all times by the PCM and line pressure will be regulated based on throttle position,

engine load and vehicle speed.

Copyright © 2003 ATSG

Figure 4

AUTOMATIC TRANSMISSION SERVICE GROUP

Mod

Mod

Mod

Mod

Mod

Mod

Mod

ModOn

5

Technical Service Information

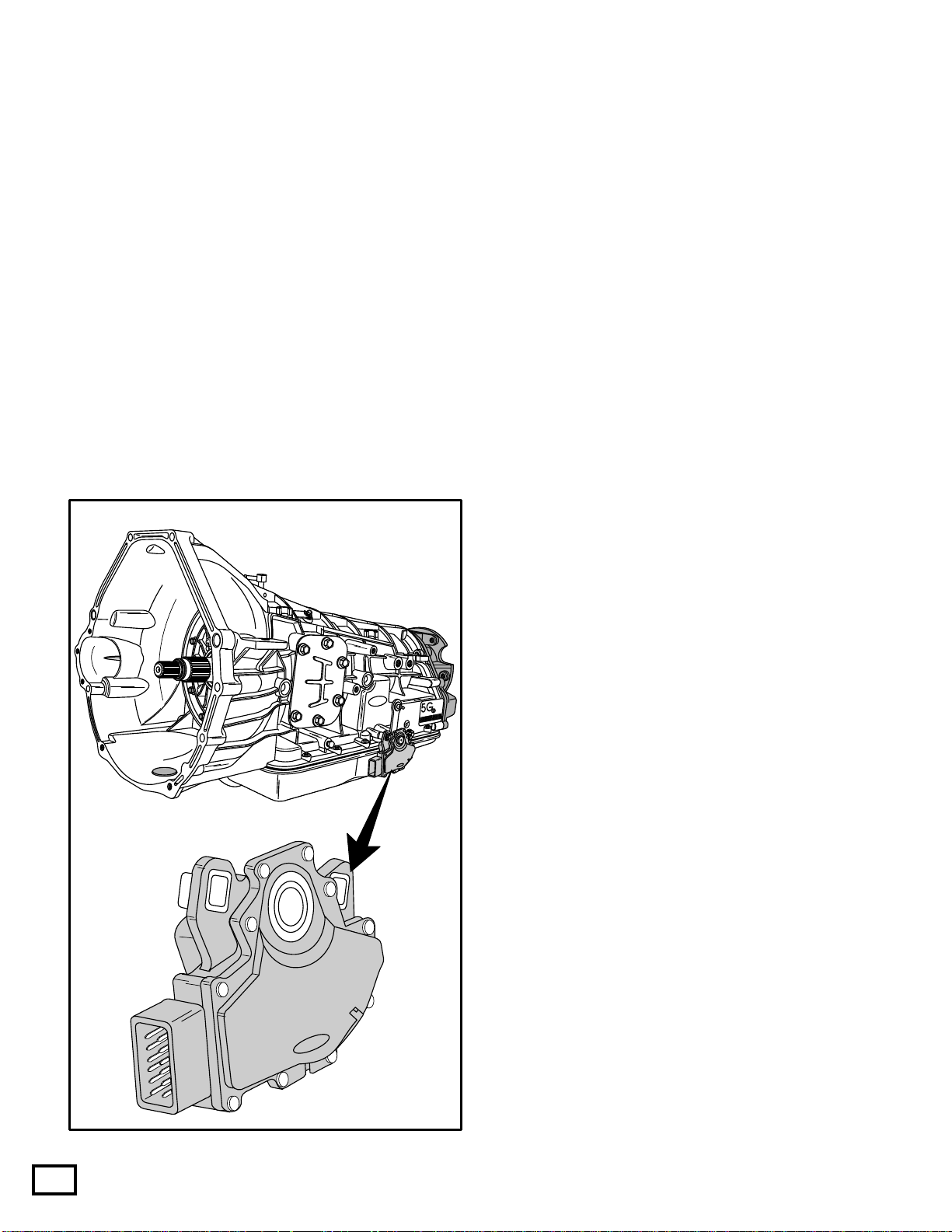

PTO "GENERAL" REQUIREMENTS:

(1)

Obviously the case must be PTO capable with

the cast-in window in the transmission where the

PTO unit mounts to the transmission, as shown in

Figure 5.

(2)

Designed for use during Mobile (Some Models)

or Stationary conditions.

(3)

PTO is available as an option only on 8500 GVW

or above, Super Duty F-Series trucks with 6.8L

Gasoline and 7.3L Diesel engines. Ford 4R100

transmissions on other models are not PTO

capable.

(4)

Battery voltage must be supplied to the

Powertrain Control Module (PCM) input pin 4

on gasoline models, or pin 66 on diesel models,

when the PTO is engaged. The processor uses

this information to raise EPC pressure to

approximately 55 PSI so that you do not burn the

coast clutch. This voltage must be provided by

the PTO installer .

(5)

Shift Solenoid 2 and the Coast Clutch Solenoid

must be energized when the PTO is turned ON.

PTO

Window

dF

d

or

or

F

006-BA

RFF81P-7

98

Fo

rd

Copyright © 2003 ATSG

Figure 5

TRANSMISSION FUNCTIONS

DURING PTO OPERATION:

(1)

Shift Solenoid 2 and Coast Clutch Solenoids are

turned on, the coast clutch activates and does not

allow 4th gear operation during PTO operation.

C

A

-

P

4

W

X

B

-

L

RJ

1

6

3

04

0

7

1

C

9

-

D

B

"GENERAL" CONDITIONS FOR OPERATION

(1)

The vehicle is not in the crank or start mode.

(2)

The transmission range selector must be in the P,

R, O.D, 2 or 1 position. The PTO will not operate

when selector is in the neutral position.

(3)

PTO operation is inhibited when in cranking

mode, neutral, or 4th gear.

(4)

Transmission only operates 1st through 3rd

gears. Computer strategy does not allow 4th

gear to engage, under any conditions.

(5)

Transmission Fluid Temperature Sensor (TFT)

reading must be up to operating temperature.

GASOLINE ENGINE PTO OPERATION:

(1)

PTO installer must obtain a "High Idle Throttle

Control" from an aftermarket source.

(2)

Auxiliary Powertrain Control Module seen on

Page seven, does not work on the gasoline engine

models. APCM module works only on the 7.3L

diesel engine.

(3)

For stationary PTO operation an engine idle

speed of 1300 RPM is required.

(2)

Electronic Pressure Control (EPC) pressure is

raised to approximately 55 PSI. This is why the

coast clutch will be smoked in a short period of

time if a battery voltage wire is not supplied to

EEC input pin 4 (gasoline) or pin 66 (diesel)

when the PTO is engaged, as this rise in pressure

would not occur.

(3)

The Transmission Control Indicator Lamp

(TCIL) illuminates.

(4)

When the PTO is turned ON, the transmission

operates only in 1st through 3rd gears.

Overdrive 4th gear is not allowed by the PCM

strategy.

(5)

The transmission shift schedule is early and shift

feel is very firm.

(6)

PTO operation can cause transmission fluid

temperature to exceed the recommended

maximum limit of 250 degrees F. Failure mode

logic within PCM strategy prevents transmission

damage by disabling the PTO above this

temperature limit.

(4)

The Torque Converter Clutch (TCC) engages

Specific Operation For Diesel, See Page 7.

once the engine reaches 1300 RPM.

6

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

DIESEL ENGINE PTO OPERATION:

"AUXILIARY" POWERTRAIN CONTROL MODULE

7.3L DIESEL ENGINE (ONLY)

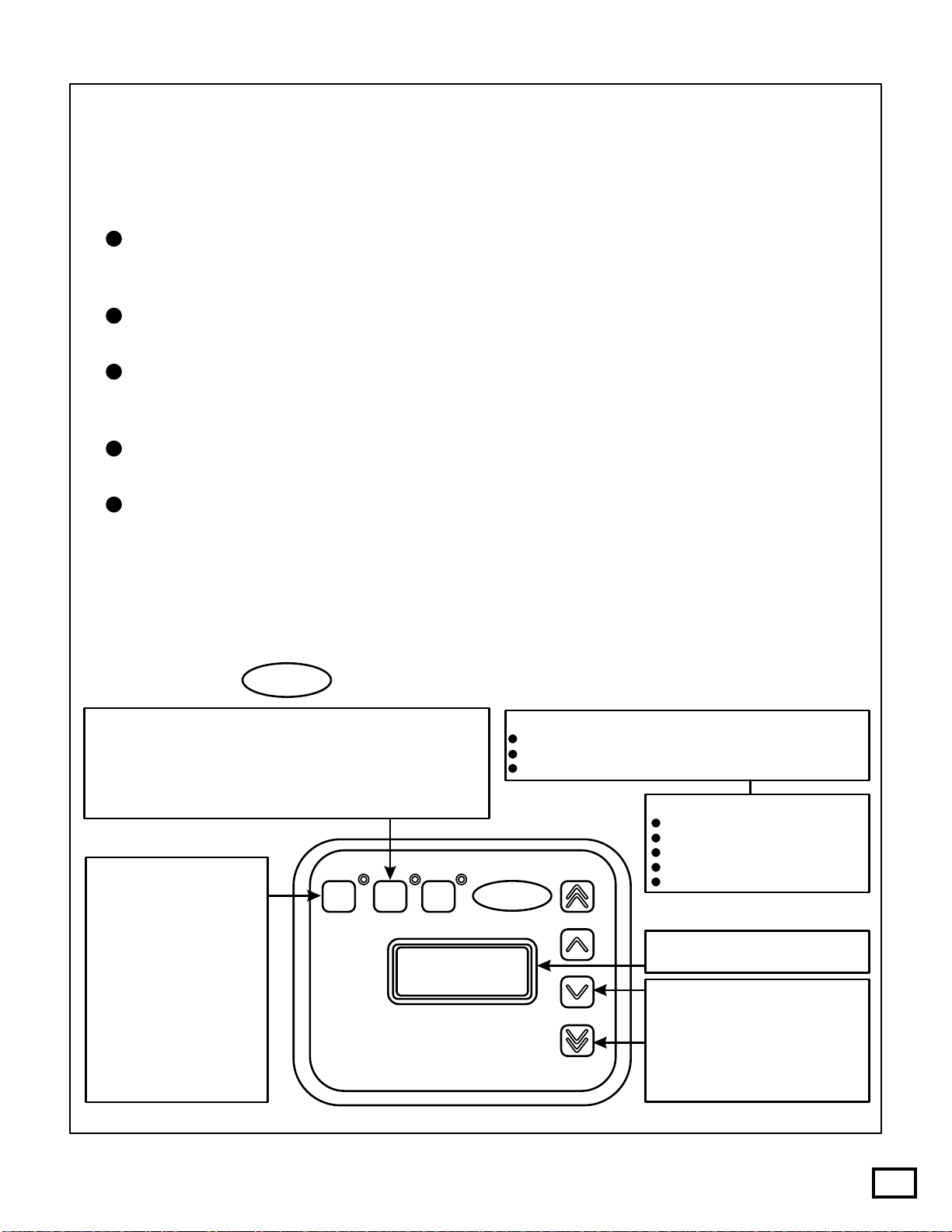

The Auxiliary Powertrain Control Module (APCM) commands the Electronic Engine Control

(EEC) module to increase the idle speed during PTO operation. The APCM controls engine

speed from 1300 to 2500 RPM.

The Auxiliary Powertrain Control Module is a seperate option, it does not come standard with a

PTO capable transmission, and is for 7.3L diesel applications only .

Intended for stationary use only, and in stationary operation the PT O requires an engine idle speed

of 1300 RPM. During stationary PTO operation on the 7.3L diesel, the EEC increases the idle to

1300 RPM automatically.

During stationary PTO operation, the Torque Converter Clutch (TCC) engages once the RPM

reaches 1200-1300 RPM.

The following conditions must be met before the idle speed is increased:

1. Parking brake must be engaged for all applications.

2. No hydraulic brake actuation.

3. Accelerator pedal must be in the idle position.

4. V ehicle speed must be zero MPH.

5. Brake lights must be functional.

FordFord

CHARGE PROTECTION APPLICATION

Charge Protection is used for maintaining battery charge.

In Charge Protection mode, the battery voltage is monitored and the

engine idle speed is increased as necessary, so the battery charge is

maintained as required.

Charge Protection can be activated from in-cab and can be

programmed to activate automatically on engine start-up.

RPM CONTROL

RPM Control is used for

RPM Control mode can be

activated from in-cab and

can be programmed to

activate automatically on

engine start-up.

The programmable speed

presets range from 1300 to

This is the recommended

method of elevating idle

speed for PTO operations.

AUXILIARY POWERTRAIN CONTROL MODULEAUXILIARY POWERTRAIN CONTROL MODULE

Exclusively for light trucks with the 7.3L Diesel Engine.

Intended for Stationary Use Only.

Order Guide Option Code 961.

RPM

RPM

CHARGE

CONTROL

CONTROL

CHARGE

PROTECT

PROTECT

POWERPOWER

FordFord

2500

KITS INCLUDE

Aux. Powertrain Control Module.

Mounting Hardware and Bracket.

Wiring Harness.

Instruction Booklet.

Operators Card.

LCD screen displays the current

engine speed or battery voltage.

Each Single Arrow key contains a

preset speed allowing for four

programmable RPM settings.

The Double Arrow keys can also be

used to manually raise or lower the

engine speed at a faster or slower

rate.

Figure 6

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2003 ATSG

7

Technical Service Information

DIAGNOSTIC CONCERNS WITH PTO

EQUIPPED VEHICLES:

(1)

Always ensure that PTO is turned OFF, before

any diagnostic procedures begin.

(2)

Never perform any transmission special tests

(i.e. pressure test, stall test etc.) when the PTO is

turned ON.

(3)

If a transmission concern or symptom goes

away with the PTO turned OFF , it is most likely

not a transmission concern.

(4)

On Board Diagnostics operate normally during

PTO operation with the exception of the engine

misfire monitor. The circuit checks made by the

PCM and Failure Mode Effect Management

(FMEM) capability will continue. The PTO

must be turned OFF to access Diagnostic

Trouble Codes (DTC's) and perform OBD tests.

Caution: If the batteries are disconnected for any

reason, the PCM "must" have a 7 mile drive cycle at

speeds above 50 MPH, before it remembers that it is

capable of running a PTO

CENTRAL JUNCTION BOX

FUSE 19

Red/Yellow

ELECTRICAL COMPONENT DIAGNOSIS

Accelerator Pedal Position Sensor (Diesel Only)

The Accelerator Pedal (AP) position sensor is

mounted on the accelerator pedal inside the vehicle

and detects the position of the accelerator pedal and

sends this information as a varying voltage signal to

the PCM. The PCM then uses the monitored voltage

level of the AP sensor for control of EPC pressure and

shift scheduling.

The Idle Validation Switch is fed voltage through

fuse number 19, as well as the Transmission Control

Switch, as shown in Figure 7.

If the Idle Validation Switch feed voltage is lost for

any reason, the engine will immediately return to

idle and stay there until feed voltage is restored.

4X4 Low Switch

The 4X4 Low Switch is used to the PCM that the

transfer case system is operating in LOW range. The

PCM receives the 4X4 Low Switch input signal and

modifies shift scheduling for the lower gear ratio

(See Figure 8).

If the 4X4 LOW indicator fuse is blown, the

transmission will shift according to the 4X4 LOW

shift schedule, regardless of transfer case lever

position.

Transmission Control Switch (TCS)

Clutch Pedal Position (CPP) (Std Trans Only)

Idle Validation Switch (IVS) (Diesel Only)

Overhead Trip Computer Module

Generic Electronic Module (GEM)

Instrument Cluster Terminal A12

Instrument Cluster Terminal B11

Copyright © 2003 ATSG

Figure 7

PCM PIN 14

Lt. Blue/Black

Figure 8

8

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

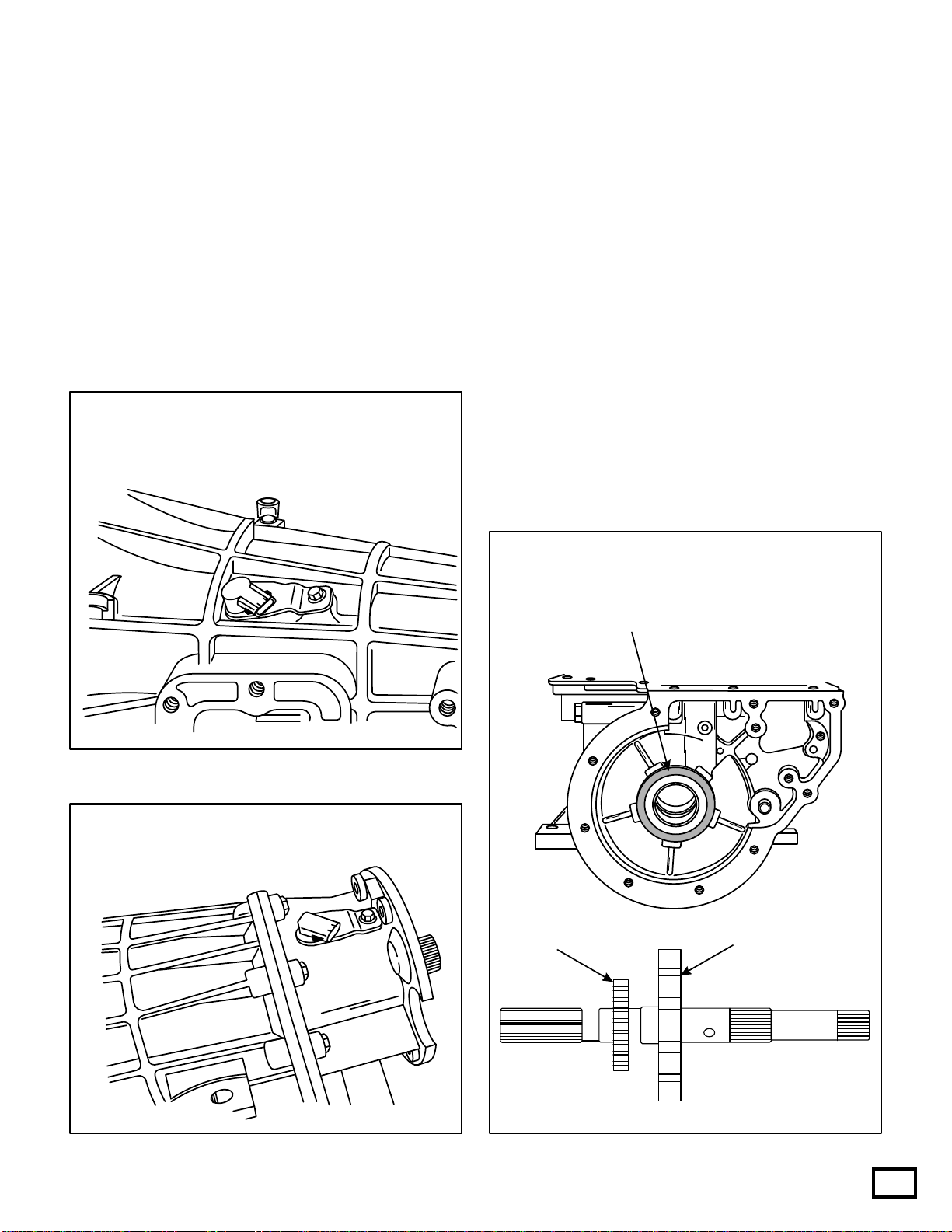

Turbine Shaft Speed Sensor Output Shaft Speed Sensor

The Turbine Shaft Speed (TSS) sensor is a magnetic

pickup that sends the PCM a frequency signal related

to the rotating speed of the transmission input shaft.

The TSS mounts on the top front of the case on some

models, as shown in Figure 9. W e have also provided

you with the resistance readings and OEM part

numbers on both Turbine Speed Sensors, as the PTO

and Non-PTO models use different sensors, as shown

in Figure 9.

The PCM uses the TSS sensor signal to control EPC

pressure and TCC strategy .

Turbine Shaft Speed Sensor

PTO Models Only = 496-1244 Ohms Resistance

Part Number F81Z-7M101-BA

Non PTO Models Only = 781-1979 Ohms Resistance

Part Number F81Z-7M101-AA

The Output Shaft Speed (OSS) sensor is a magnetic

pickup that sends the PCM a frequency signal related

to the rotating speed of the transmission output shaft.

The OSS sensor was added to the top of extension

housing, as shown in Figure 10. The OSS is triggered

by an added rotor pressed onto the output shaft. The

park gear is also now pressed onto the output shaft,

and the number 13 thrust washer has changed to a

thrust bearing, as shown in Figure 11. We have

provided you with the resistance reading and the

OEM part number for the output shaft speed sensor.

Refer to Figure 10 for output shaft speed sensor

information.

The PCM uses the OSS sensor signal to control EPC

pressure, shift scheduling and TCC strategy .

Copyright © 2003 ATSG

Figure 9

Output Shaft Speed Sensor

All Models = 781-1979 Ohms Resistance

Part Number F81Z-7M101-AA

The Park Gear is also a press fit to the output

shaft, and the number 13 thrust washer, between

the case and the park gear has been replaced

with a needle bearing.

OSS Rotor Park Gear

(Press Fit)(Press Fit)

Copyright © 2003 ATSG

Copyright © 2003 ATSG

Figure 10 Figure 11

AUTOMATIC TRANSMISSION SERVICE GROUP

9

Technical Service Information

ELECTRICAL COMPONENT DIAGNOSIS

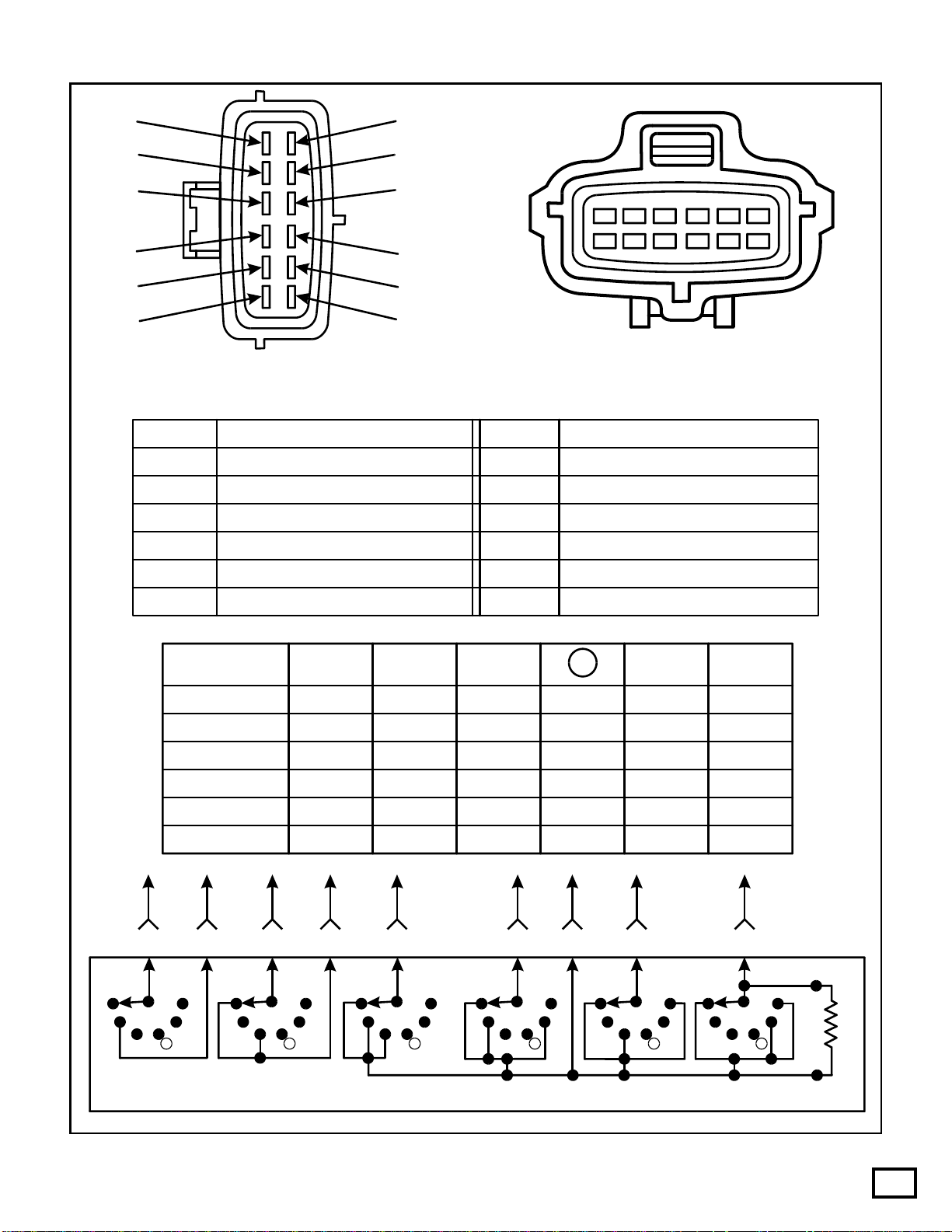

Digital Transmission Range Sensor

The Digital Transmission Range (DTR) sensor has a

twelve pin electrical connector and is located on the

outside of the transmission at the manual lever, as

shown in Figure 12.

The DTR sensor completes the start circuit in Park

and Neutral, the backup lamp circuit in Reverse, and

the neutral sense circuit (4WD Only) when in Neutral.

The DTR sensor also opens or closes a set of four

different switches that are monitored by the

Powertrain Control Module (PCM) to determine the

position of the transmission manual lever. Refer to

Figure 13.

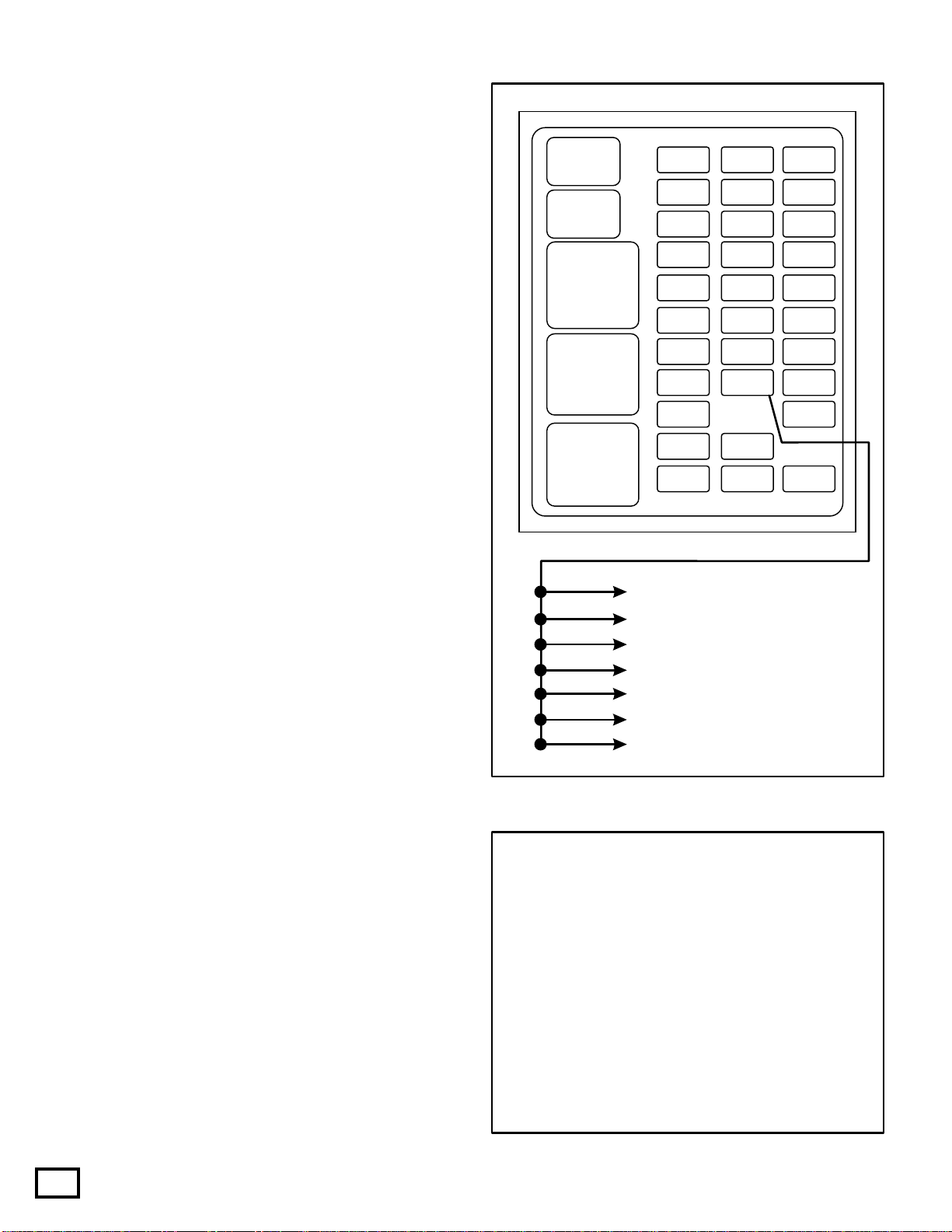

DTR TESTING PROCEDURE

In Figure 13 we have provided you with pin number

identification for both the transmission range sensor

and the vehicle harness. We have also provided a

chart that will give you the open/closed state of each

internal switch, dependent on selector position, and

notice that three positions read a 270W resistor, that is

also internal.

Note: All testing that we have provided for you is

done with a DVOM, set to the ohms position, and all

tests are performed with the ignition switch in the

"OFF" position.

(1)

Testing the transmission range 3A switch, and

the 270W internal resistor is done across pins 2

and 3 of the DTR sensor, and must be checked in

each selector position to determine the switch

and resistor integrity. Refer to Figure 13.

(2)

Testing the transmission range 1 switch is done

across pins 2 and 4 of the DTR sensor, and must

be checked in each selector position to

determine switch integrity. Refer to Figure 13.

(3)

Testing the transmission range 2 switch is done

across pins 2 and 5 of the DTR sensor, and must

be checked in each selector position to

determine switch integrity. Refer to Figure 13.

(4)

Testing the transmission range 4 switch is done

C

A

-

P

4

W

X

-B

RFF81P-7

ordFord

F

006-BA

98

L

J

R

1

6

3

4

0

0

7

1

C

9

-

D

B

across pins 2 and 6 of the DTR sensor, and must

be checked in each selector position to

determine switch integrity. Refer to Figure 13.

F

or

d

(5)

Testing the reverse lamp circuit is done across

pins 9 and 11 of the DTR sensor, and must be

checked in each selector position to determine

switch integrity. Refer to Figure 13.

(6)

Testing the neutral start circuit is done across

pins 10 and 12 of the DTR sensor, and must be

checked in each selector position to determine

switch integrity. Refer to Figure 13.

NEUTRAL

L

C

AA

293

-7F

TP

F7

Ford

10

Copyright © 2003 ATSG

Figure 12

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

126

115

104

1 7

23456 1

12 11 10 9 8

7

93

82

View looking into DTR Sensor

Pin No.

1

2

3

4

5

6

Not Used Ground

Signal Return (Ground)

TR3A (5 Volts from PCM)

TR1 (10-12 Volts from PCM)

TR2 (10-12 Volts from PCM)

TR4 (10-12 Volts from PCM)

P R N 2 1TERMINALS

2 AND 3 CLOSED

2 AND 4

2 AND 5

2 AND 6

CLOSED CLOSED CLOSED

CLOSED

CLOSED

CLOSED

OPEN

Pin No.Function

10

11

12

OPEN

View looking into DTR Sensor

harness connector-terminal side

Function

7

8

9

Neutral

Battery Voltage Feed

Fuse 21, Hot In Start

Back-up Lamps

Starter Relay

D

270 W270 W270 W

OPEN OPEN

OPEN

CLOSED

CLOSED

OPEN

CLOSED

OPEN

OPENOPEN

CLOSEDCLOSED

9 AND 11

10 AND 12

OPEN OPEN

CLOSED

CLOSED

OPEN

CLOSED

9 11 12 10 4 5 6 32

P

N

1

P

2R

D

N

1

P

2R

D

N

1

P

2R

D

DIGITAL TRANSMISSION RANGE SENSOR

Figure 13

AUTOMATIC TRANSMISSION SERVICE GROUP

N

OPEN

OPEN

2R

D

OPEN

OPEN

1

P

N

2R

D

OPEN

OPEN

1

P

N

Copyright © 2003 ATSG

1

2R

D

270 W

11

Technical Service Information

ELECTRICAL COMPONENT DIAGNOSIS

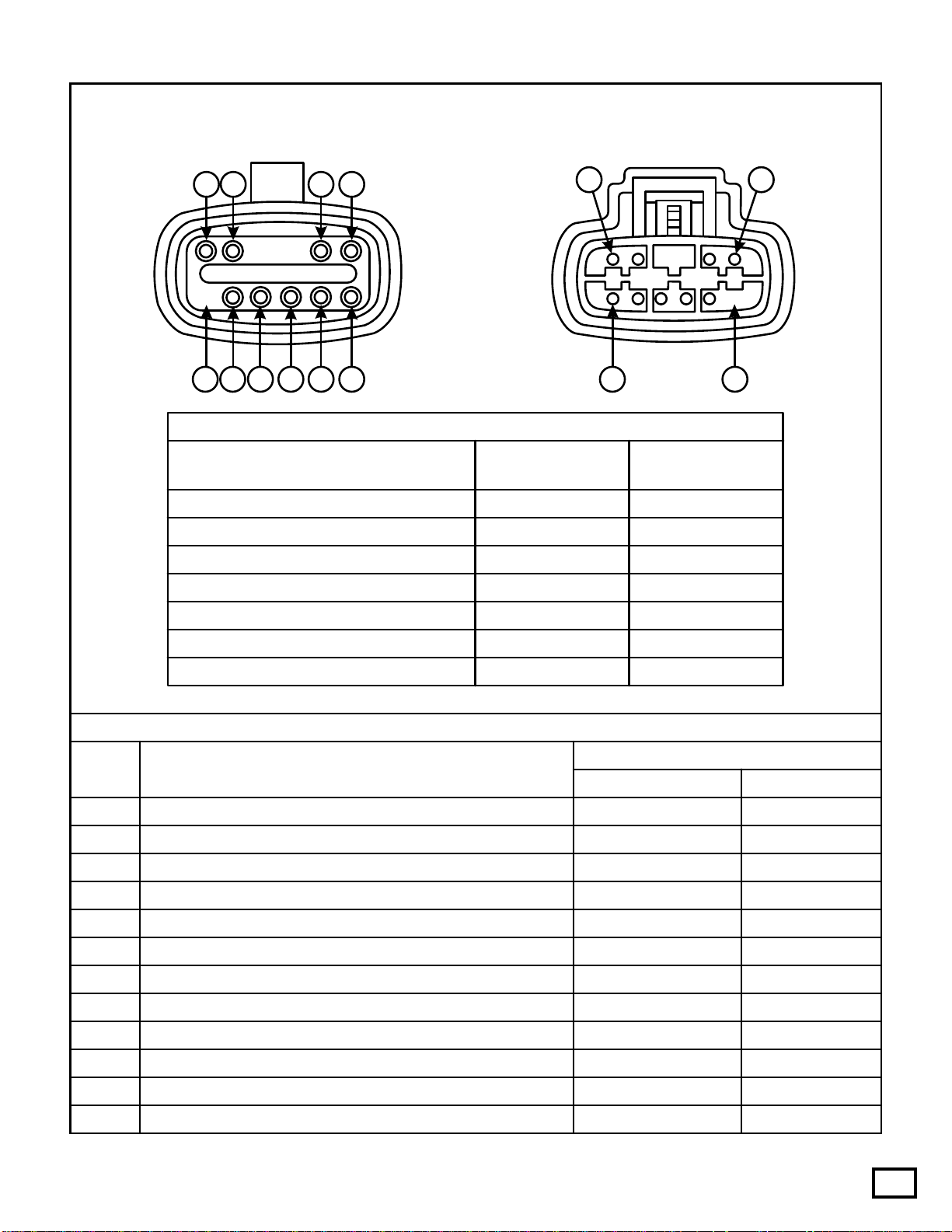

Solenoid Assembly

The Solenoid Assembly is bolted to the case and

located inside the bottom pan. The Solenoid

Assembly contains shift solenoid 1, shift solenoid 2,

coast clutch solenoid, TCC solenoid, EPC solenoid

and the TFT sensor. The solenoids are not serviced

individually. Y ou must replace the entire assembly, as

shown in Figure 14. Some of these units are equipped

with an ON/OFF TCC solenoid and some are

equipped with a PWM TCC solenoid, so it is

important to determine which you have.

SOLENOID PACK ASSEMBLY

SOLENOID PACK TESTING PROCEDURE

In Figure 16 we have provided you with pin number

identification for both the transmission case

connector and the vehicle harness. We have also

provided a chart that will give you the function of

each and the ohms readings you should see on each of

the solenoids and the TFT sensor .

Note: All testing that we have provided for you is

done with a DVOM, set to the ohms position, and all

tests are performed with the ignition switch in the

"OFF" position.

(1)

Shift Solenoid 1 is tested across pins 1 and 3,

and should read 20-30 ohms resistance. Refer

to Figure 16.

(2)

Shift Solenoid 2 is tested across pins 1 and 2,

and should read 20-30 ohms resistance. Refer

to Figure 16.

(3)

TCC On/Off Solenoid is tested across pins 1 and

4, and should read 20-30 ohms resistance.

Refer to Figure 16.

Copyright © 2003 ATSG

Figure 14

Transmission Fluid Temperature

°C °F Resistance

-40 to -20

-19 to -1

0 - 20

21-40

41-70

71-90

91-110

111-130

131-150 267-302

-40 to -4

-3 to 31

32-68

69-104

105-158

159-194

195-230

231-266

1062k - 284k W

284k - 100k W

100k - 37k W

37k - 16k W

16k - 5k W

5k - 2.7k W

2.7k - 1.5k W

1.5k - 0.8k W

0.8k - 0.54k W

(4)

TCC PWM Solenoid is tested across pins 1 and

4, and should read 10-20 ohms resistance.

Refer to Figure 16.

(5)

Coast Clutch Solenoid is tested across pins 1

and 5, and should read 20-30 ohms resistance.

Refer to Figure 16.

(6)

EPC Solenoid is tested across pins 11 and 12,

and should read 3.0-5.0 ohms resistance. Refer

to Figure 16.

(7)

TFT sensor is tested across pins 7 and 8. Refer

to the chart provided in Figure 15.

4R100 FLUID REQUIREMENTS

Only Motorcraft Mercon® multi-purpose automatic

transmission fluid XT-2-QDX or an equivalent

Mercon® fluid should be used in all Ford 4R100

transmissions. Before adding any fluid, ensure that it

is the correct type.

Checking Fluid

Always use the transmission fluid level indicator

(Dipstick) to set the correct fluid level. Set the fluid

level at normal operating temperature which is 150°

to 170°F, engine at idle in Park.

12

Figure 15

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

SOLENOID BODY PIN IDENTIFICATION AND FUNCTION

SOLENOID BODY

CONNECTOR

121187

16 2345

VEHICLE HARNESS

CONNECTOR

12 7

1

6

Solenoid Resistance Chart

Solenoid Body

Solenoid

Shift Solenoid "B" (2) 1 and 2 20-30 Ohms

Shift Solenoid "A" (1)

TCC Solenoid, (On-Off)

Pin Numbers

1 and 3

1 and 4

Resistance

20-30 Ohms

20-30 Ohms

TCC Solenoid, (PWM)

Coast Clutch Solenoid

Electronic Pressure Control Solenoid

Transmission Fluid Temp Sensor

Solenoid Connector Pin Identification and Function

DescriptionPin No.

1

Vehicle Power In For Solenoids (VPWR)

2

Shift Solenoid "B" (2) Ground from PCM

3

Shift Solenoid "A" (1) Ground from PCM

4

Converter Clutch Solenoid Ground from PCM

5

Coast Clutch Solenoid Ground from PCM

6

Not Used

7

Transmission Fluid Temp Sensor

8

Transmission Fluid Temp Sensor (Signal Return)

9

Not Used

1 and 4

1 and 5

11 and 12

7 and 8

10-20 Ohms

20-30 Ohms

3.0-5.0 Ohms

See Chart Below

PCM Connector Pin

Gas & Diesel (Cal) Diesel (49 State)

71, 97

11

6

54

20

37

91

71, 97

1

27

28

53

37

91

10

11

12

Not Used

Electronic Pressure Control (EPC)

Vehicle Power In For EPC Solenoid (VPWR)

Figure 16

AUTOMATIC TRANSMISSION SERVICE GROUP

81

71, 97

81

71, 97

13

Technical Service Information

FORD 4R100

Abbreviation Description

Abbreviation AbbreviationDescription Description

4X4L

ABS

A/C

ACCS

AP

APGND

ARPMDES

BARO

BOO

BPA

BPP

BUS +

BUS -

CASE GND

CCS

CID

CMP

4X4 Low Switch

Antilock Brake System

Air Conditioning

Air Conditioning Clutch Status

Accelerator Pedal Position Sensor

Accelerator Pedal Sensor Ground

Ancillary Engine Speed Desired

Barometric Pressure Sensor

Brake ON/OFF Switch

Brake Pressure Applied

Brake Pedal Position

Data Link Connector

Data Link Connector

Case Ground

Coast Clutch Solenoid

Cylinder Identification

Camshaft Position Sensor

ICP

IPR

IVS

KAM

KAPWR

KOEO

KOER

MAF

MAP

MIL

OCT ADJ

OSS

PBA

PCM

PIP

ROM

RPM

Injector Control Pressure Sensor

Injector Pressure Regulator

Idle Validation Switch

Keep Alive Memory

Keep Alive Power

Key On Engine Off

Key On Engine Running

Mass Air Flow Sensor

Manifold Absolute Pressure Sensor

Malfunction Indicator Lamp

Octane Adjust

Output Shaft Speed Sensor

Parking Brake Applied

Powertrain Control Module

Profile Ignition Pickup

Read Only Memory

Engine Speed

CPP

CRUISE

DLC

DTC

DTC CNT

DTR

EBP

ECT

EOT

EPC

EPR

FEPS

FUEL PW

GP

GPC

GPL

IAT

Clutch Pedal Position

Cruise Control Mode (Driving)

Data Link Connector

Diagnostic Trouble Code

Diagnostic Trouble Code Count

Digital Transmission Range Sensor

Exhaust Back Pressure

Engine Coolant Temperature

Engine Oil Temperature

Electronic Pressure Control

Exhaust Pressure Regulator

Flash EPROM Power Supply

Fuel Pulse Width

Glow Plug

Glow Plug Control Duty Cycle

Glow Plug Lamp

Intake Air Temperatur e

SCCS

SS1

SS2

SSA

SSB

SPOUT

TAC

TCC

TCIL

TCS

TFT

TP

TSS

VPWR

VREF

VSS

WOT

Speed Control Command Switch

Shift Solenoid "1"

Shift Solenoid "2"

Shift Solenoid "A"

Shift Solenoid "B"

Spark Output

Tachometer Signal

Torque Converter Clutch

Trans Control Indicator Lamp

Transmission Control Switch

Transmission Fluid Temperature

Throttle Position Sensor

Turbine Shaft Speed Sensor

Vehicle Power Supply

Vehicle Reference Voltage

Vehicle Speed Sensor

Wide Open Throttle

14

Figure 17

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

FORD 4R100

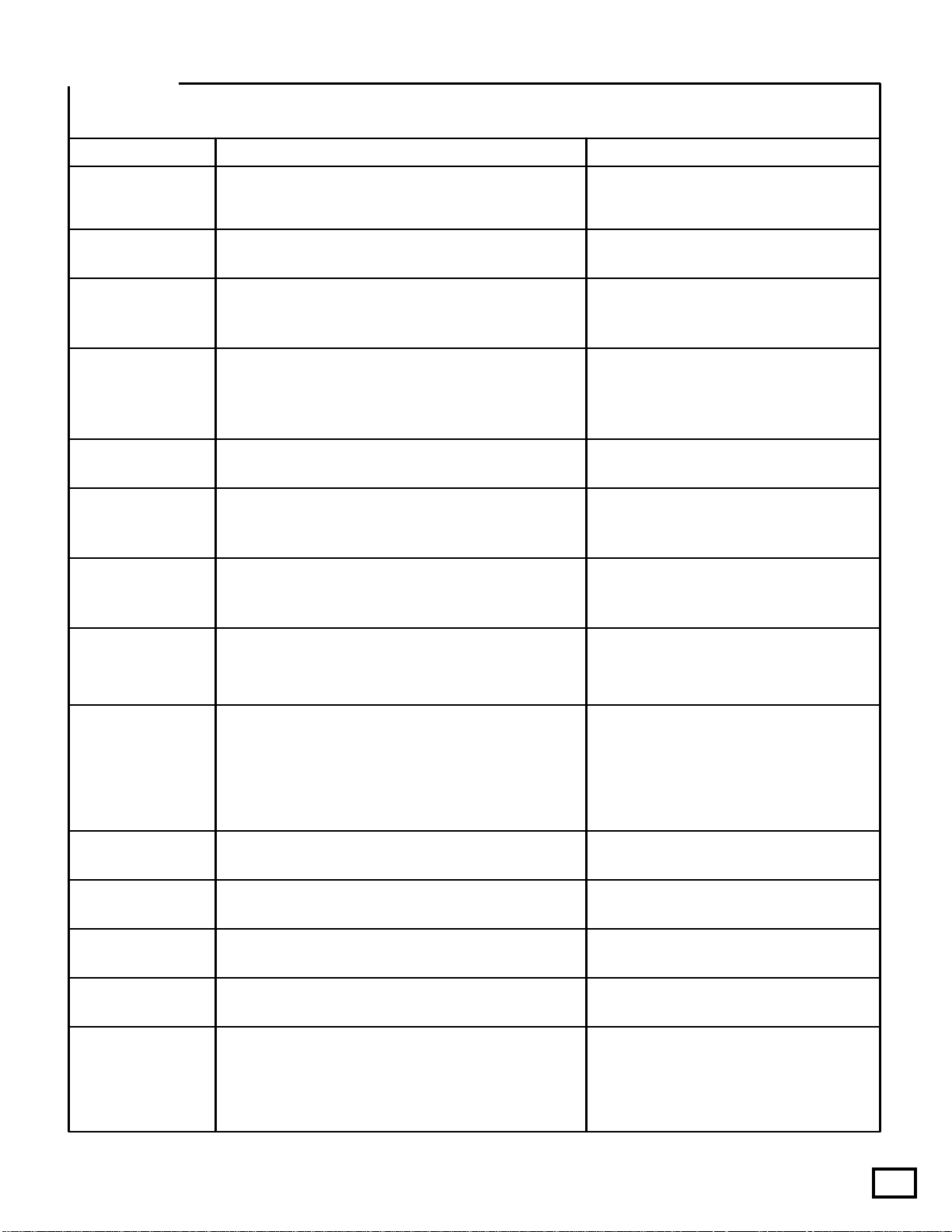

Diagnostic Trouble Code Chart

Diagnostic Code Description Symptom

P0102

P0103

P0107

P0108

P0122

MAF sensor system fails to operate in a

normal manner, which may cause a

transmission concern.

BARO sensor circuit signal higher or lower

than expected.

(TP) Throttle Position sensor or (AP)

Accelerator Pedal Position sensor below

specification during normal operation.

High EPC pressure. Firm shifts

and engagements. May flash TCIL.

Firm shift feel, late shifts at higher

altitudes.

Harsh engagements, firm shift feel,

abnormal shift schedule, abnormal

TCC operation or does not engage.

P0123

P0235

P0236

P0237

P0340

P0341

P0344

P0500

P0503

P0571

(TP) Throttle Position sensor or (AP)

Accelerator Pedal Position sensor above or

below normal specifications during normal

operation.

MAP sensor or circuit open, shorted to ground

or to 5V .

MAP sensor signal higher or lower than

expected or no response due to vacuum hose

circuit damaged, disconnected or restricted.

MAP sensor out of On-Board Diagnostics

range. No response during Dynamic

Response (Goose) test.

(DI) Distributor Ignition circuit concern or

(CKP) Crankshaft Position sensor failure.

Insufficient or intermittent vehicle speed

input from VSS/ABS.

(BPP) Brake Pedal Position switch failure, or

not connected.

Harsh engagements, firm shift feel,

abnormal shift schedule, abnormal

TCC operation or does not engage.

Firm shift feel, late shifts at higher

altitudes.

Firm shift feel, late shifts at higher

altitudes.

Rerun On-Board Diagnostics and

perform "Goose" test when asked.

Engine will stall or will not run.

May flash TCIL.

Harsh engagements, firm shift feel,

abnormal shift pattern, unexpected

downshifts may occur at closed

throttle, abnormal TCC operation or

engages only at WOT. May flash

TCIL.

Failed off. TCC will not disengage

when brake is applied.

P0703

P0705

P0708

P0712

(BPP) Brake Pedal Position switch failure, or

not connected.

(DTR) Digital Transmission Range sensor

circuit malfunction.

(DTR) Digital Transmission Range sensor

circuit malfunction.

TFT sensor circuit grounded, exceeds scale set

for temperature of 315°F .

Figure 18

AUTOMATIC TRANSMISSION SERVICE GROUP

Failed off. TCC will not disengage

when brake is applied.

Harsh engagements, firm shift feel.

May flash TCIL.

Slight increase in EPC pressure.

Harsh engagements, firm shift feel,

abnormal shift schedule, abnormal

TCC operation or does not engage.

15

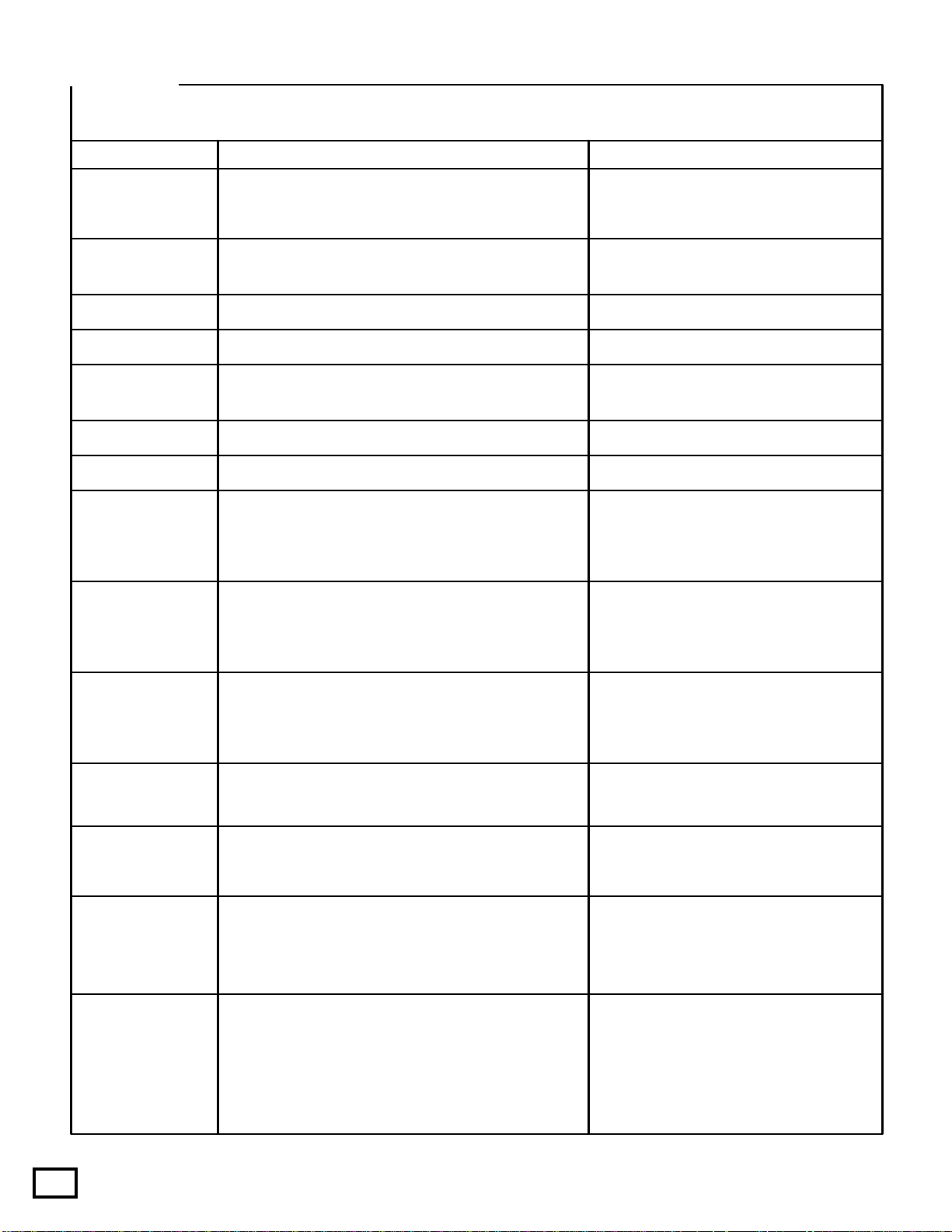

Technical Service Information

FORD 4R100

Diagnostic Trouble Code Chart

Diagnostic Code Description Symptom

P0713

TFT sensor circuit open, exceeds scale set for

temperature of minus 40°F .

TCC and stabilized shift schedule

may be enabled sooner after cold

start. May flash TCIL.

P0715

P0717

P0718

P0720

P0721

P0722

P0731

P0732

P0733

Insufficient input from TSS sensor .

TSS sensor signal intermittent.

TSS sensor signal noisy.

Insufficient input from OSS sensor .

OSS sensor signal noisy.

OSS sensor signal intermittent.

1-2 shift error because of SSA, SSB, or

internal transmission components.

2-3 shift error because of SSA, SSB, or

internal transmission components.

3-4 shift error because of SSA, SSB, or

internal transmission components.

Set DTC, Flash TCIL and Flash

MIL.

Set DTC, Flash TCIL.

Set DTC.

Set DTC, Flash TCIL and Flash

MIL.

Set DTC.

Set DTC, Flash TCIL.

Improper gear selection depending

on failure mode and transmission

range selector position. Refer to

shift solenoid operation chart.

Improper gear selection depending

on failure mode and transmission

range selector position. Refer to

shift solenoid operation chart.

Improper gear selection depending

on failure mode and transmission

range selector position. Refer to

shift solenoid operation chart.

16

P0741

P0743

P0750

P0755

The PCM picked up an excessive amount of

TCC slippage during normal operation.

TCC Solenoid circuit failure.

SSA circuit failur e.

SSB circuit failure.

Figure 19

AUTOMATIC TRANSMISSION SERVICE GROUP

TCC slippage/erratic or no torque

converter clutch operation. Flash

TCIL.

Short Circuit: Engine stalls in "D"

or "2" at idle with brake applied.

Open Circuit: TCC never engaged.

Improper gear selection depending

on failure mode and transmission

range selector position. Refer to

shift solenoid operation chart.

Improper gear selection depending

on failure mode and transmission

range selector position. Refer to

shift solenoid operation chart.

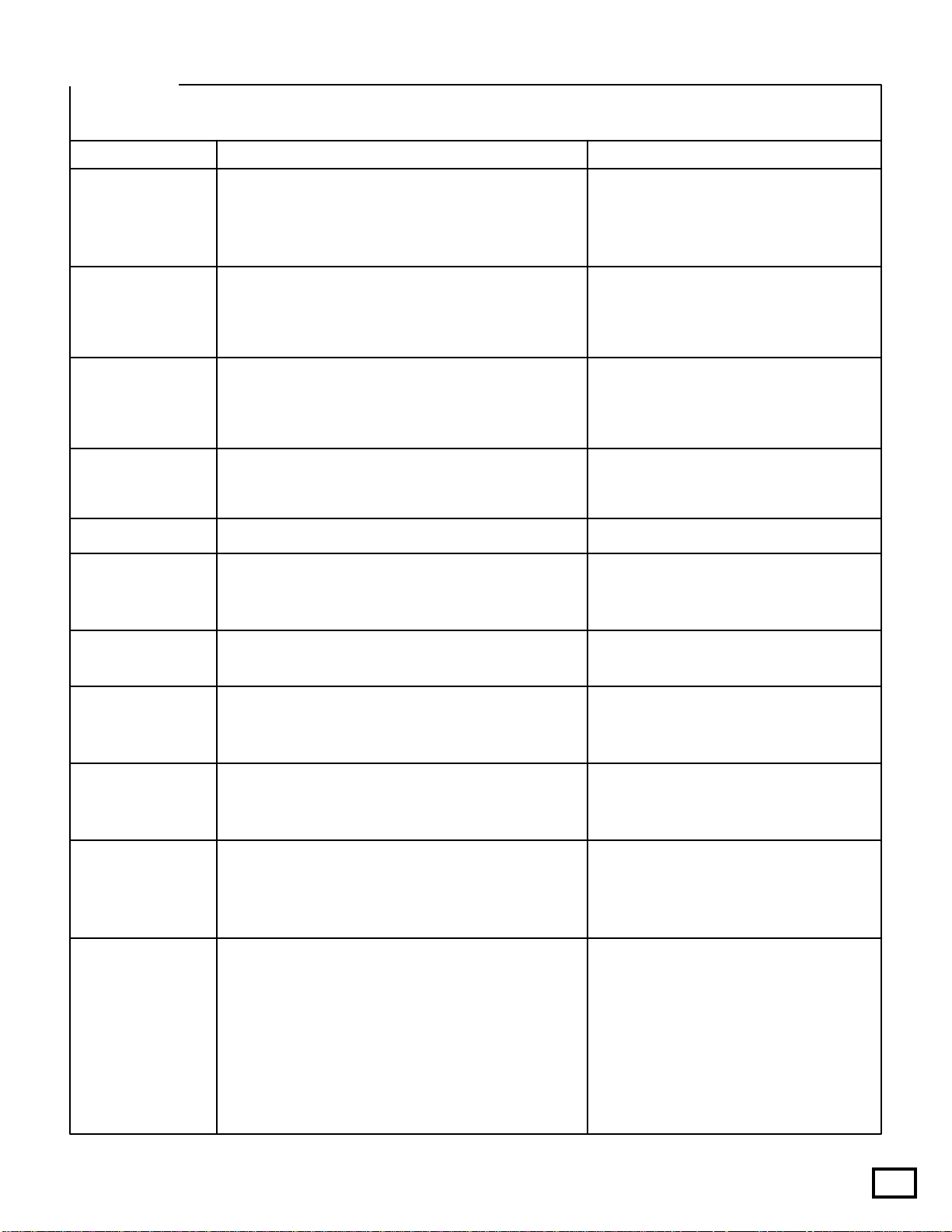

Technical Service Information

FORD 4R100

Diagnostic Trouble Code Chart

Diagnostic Code Description Symptom

P0781

P0782

P0783

P1100

P1101

P1111

P1120

1-2 shift error because of SSA, SSB, or

internal transmission components.

2-3 shift error because of SSA, SSB, or

internal transmission components.

3-4 shift error because of SSA, SSB, or

internal transmission components.

MAF sensor system fails to operate in a

normal manner, which may cause a

transmission concern.

System Pass. No Codes Detected.

Throttle Position Sensor voltage lower than

expected.

Improper gear selection depending

on failure mode and transmission

range selector position. Refer to

shift solenoid operation chart.

Improper gear selection depending

on failure mode and transmission

range selector position. Refer to

shift solenoid operation chart.

Improper gear selection depending

on failure mode and transmission

range selector position. Refer to

shift solenoid operation chart.

High EPC pressure. Firm shifts

and engagements. May flash TCIL.

Harsh engagements, firm shift feel,

abnormal shift schedule, abnormal

TCC operation or does not engage.

P1124

P1280

P1281

P1460

P1463

P1464

P1500

Throttle Position Sensor out of On-Board

Diagnostics range during KOEO test.

Injection Control Pressure (ICP) sensor

circuit failure (Diesel Engine), or out of range

low.

Injection Control Pressure (ICP) sensor

circuit failure (Diesel Engine), or out of range

high.

A/C switch error .

Insufficient or intermittent vehicle speed

input from VSS/ABS.

TP sensor (Gas Engines) not at idle

position during KOEO test.

May result in firm shifts.

May result in firm shifts.

Failed On: EPC pressure slightly

low with A/C off.

Failed Off: EPC pressure slightly

low with A/C on.

Harsh engagements, firm shift feel,

abnormal shift pattern, unexpected

downshifts may occur at closed

throttle, abnormal TCC operation or

engages only at WOT. May flash

TCIL.

Figure 20

AUTOMATIC TRANSMISSION SERVICE GROUP

17

Technical Service Information

FORD 4R100

Diagnostic Trouble Code Chart

Diagnostic Code Description Symptom

P1702

Digital Transmission Range (DTR) sensor

signal intermittent.

Erratic harsh shift engagements.

P1703

P1704

P1705

P1711

P1713

P1714

P1715

(BPP) Brake Pedal Position switch not

actuated during KOER test.

Digital Transmission Range (DTR) sensor

misaligned or failed electronically .

Digital T ransmission Range (DTR) sensor not

run in park or neutral during On-Board

Diagnostics KOEO or KOER tests.

Transmission not at operating temperature

during On-Board Diagnostics.

No change in TFT sensor - Low range.

SSA mechanical failure detected.

SSB mechanical failure detected.

Failed on or not connected, TCC

will not engage at less than onethird throttle opening.

Increase in EPC pressure.

Rerun On-Board Diagnostics.

Warm vehicle to normal operating

temperature and rerun On-Board

Diagnostics.

May flash TCIL.

Improper gear selection depending

on failure mode and transmission

range selector position. Refer to

shift solenoid operation chart.

Improper gear selection depending

on failure mode and transmission

range selector position. Refer to

shift solenoid operation chart.

P1718

P1728

P1729

P1740

P1744

P1746

P1747

No change in TFT sensor - High range.

Excessive amount of transmission slippage

has been detected.

4X4 Low switch circuit failure.

TCC solenoid mechanical failure detected.

The PCM picked up an excessive amount of

TCC slippage during normal operation.

Failure of the EPC control pressure driver

located inside the PCM.

EPC shorted circuit failure, or PCM.

May flash TCIL.

Transmission slippage, erratic or no

TCC operation. May flash TCIL.

Early or delayed shift schedule.

Harsh shift, may flash TCIL.

TCC slippage/erratic or no torque

converter clutch operation. Flash

TCIL.

Open circuit causes maximum EPC

pressure, harsh engagements and

shifts. May flash TCIL.

Shorted circuit causes minimum

EPC pressure, limits engine torque

with partial fuel shut off and heavy

misfire. Flashing TCIL.

18

Figure 21

AUTOMATIC TRANSMISSION SERVICE GROUP

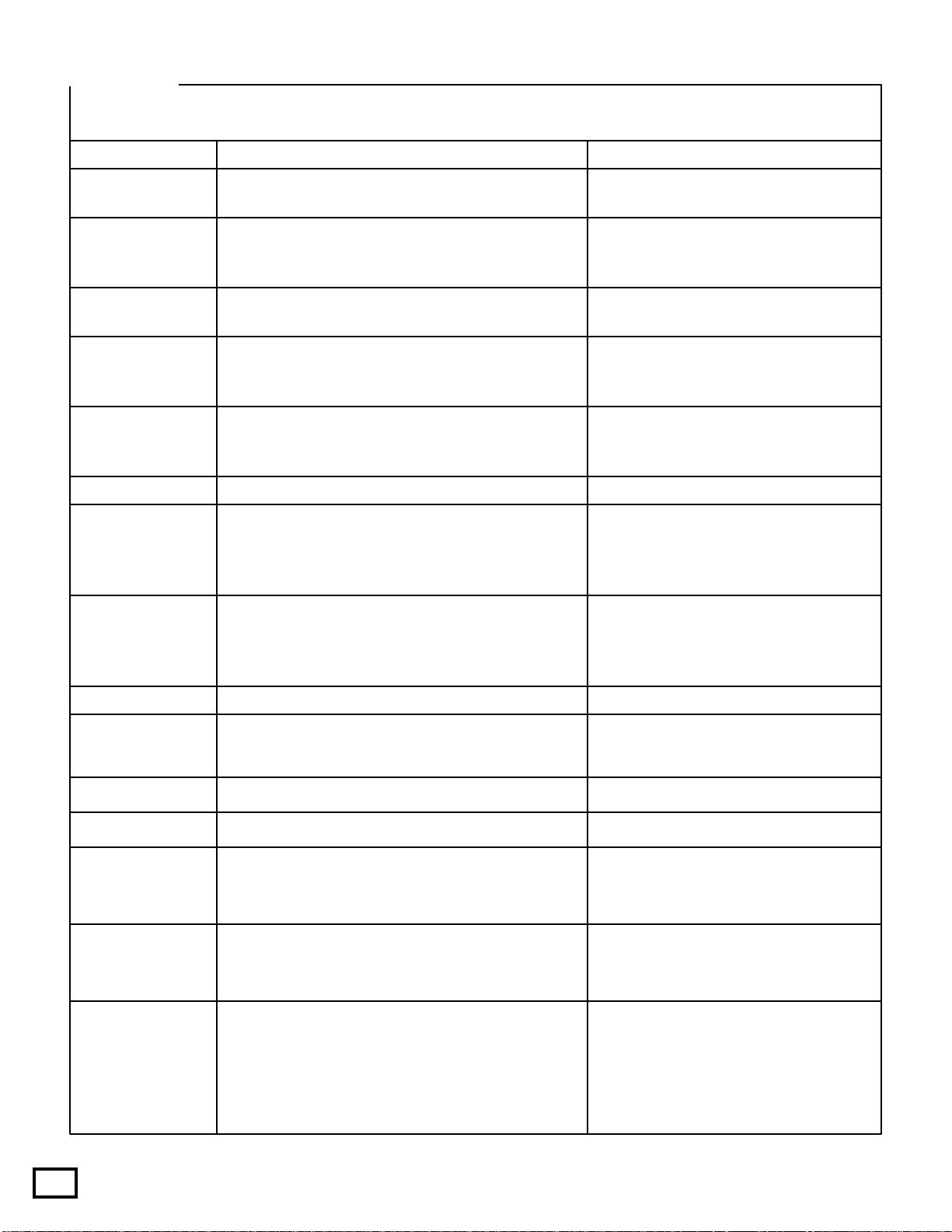

Technical Service Information

FORD 4R100

Diagnostic Trouble Code Chart

Diagnostic Code Description Symptom

P1754

P1760

P1780

P1781

P1783

CCS circuit failure.

EPC signal intermittent short.

TCS not cycled during the On-Board

Diagnostics or the circuit is open or shorted.

4X4 Low switch circuit failure.

Transmission Fluid Temperature has

exceeded 270°F .

Failed Off: No third gear engine

braking in O.D. cancel.

Failed On: Third gear engine

braking in O.D. range. Coast clutch

may be damaged causing eventual

failure.

Short circuit causes minimum EPC

pressure.

No overdrive cancel when switch is

cycled.

Early or delayed shift schedule.

Slight increase in EPC pressure.

May flash TCIL.

Figure 22

AUTOMATIC TRANSMISSION SERVICE GROUP

19

Technical Service Information

Shift Solenoid Application Chart

Selector Lever

Range

P/R/N 1

D

D

D

D

D

Cancel

MANUAL 1

MANUAL 1

Controlled by PCM

*

Commanded

Gear

1

2

3

4

First Through 3rd Gear Only, SSA, SSB, TCC, Same as Overdrive, CCS Always On.

2MANUAL 2

2

1

Shift

Solenoid "A"

ON

ON

ON

OFF

OFF

OFF

ON

Shift

Solenoid "B"

OFF

OFF

ON

ON

OFF

OFF

OFF OFF

TCC

Solenoid

* *

* *

* *

* *

*

***

OFF

Coast Clutch

Solenoid

*

ON

ON

ON

SHIFT SOLENOID TROUBLE CHART GUIDE

SHIFT SOLENOID "A" ALWAYS OFF

Selector Lever Position

PCM Gear

Commanded

1st

2nd

3rd

4th

SHIFT SOLENOID "A" ALWAYS ON

PCM Gear

Commanded

1st

2nd

3rd

D

Actual Gear Obtained

4

3

3

4

Selector Lever Position

D

Actual Gear Obtained

1

2

2

2 1

2

2

2

2 2

2 1

2

2

2

SHIFT SOLENOID "B" ALWAYS OFF

Selector Lever Position

PCM Gear

Commanded

1

2

2

1

1

1

1st

2nd

3rd

4th

SHIFT SOLENOID "B" ALWAYS ON

PCM Gear

Commanded

1st

2nd

3rd

D

Actual Gear Obtained

1 1

4

4

Selector Lever Position

D

Actual Gear Obtained

2 2

2

3

2 1

2

2

2

2 2

2 1

2

2

11

2

1

1

2

20

4th

1

2

1

Figure 23

4th

3

2

2

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

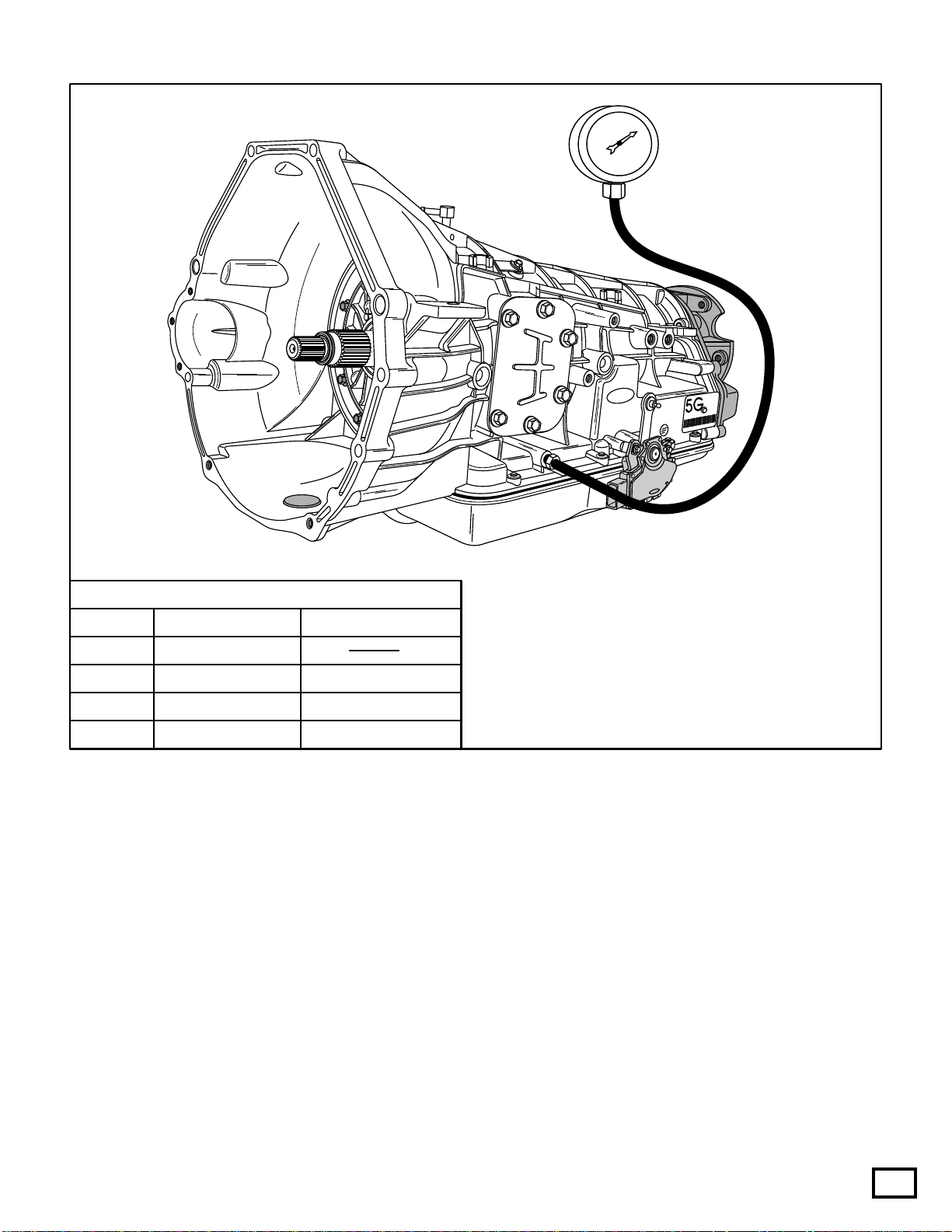

LINE PRESSURE TEST

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

FordFord

RFF81P-7006-BA

98

Fo

rd

C

A

-

P

W4

X

B

-

L

J

R

1

6

3

4

0

0

7

1

C

9

-

BD

LINE PRESSURE SPECIFICATION CHART

Gear

P, N

R

OD, M2

M1

Idle

50-65 psi

70-100 psi

50-65 psi

70-115 psi

Stall

220-240 psi

136-156 psi

175-210 psi

Figure 24

LINE PRESSURE TEST

NOTE: Perform the line pressure test before

performing the "Stall" test. If the line pressure is

low at "Idle", DO NOT perform the "Stall" test or

further transmission damage will occur.

Do Not Maintain Wide Open Throttle in any gear

range for more than "5 Seconds" or transmission

damage may occur.

NOTE: If equipped, turn "Off" the PTO unit to

ensure proper test results.

NOTE: On vehicles equipped with PTO units,

access to the line pressure port may require that you

remove the PTO unit depending on the type of unit

installed. If required, remove the PTO unit and

install PTO cover and gasket "Before" doing the

line pressure test.

Copyright © 2003 ATSG

1. Install a 300 psi line pressure gauge to the line

pressure tap, as shown in Figure 24.

2. Start the engine and check line pressure in all

ranges at "Idle". Refer to the chart shown in

Figure 24 to determine if they are within the

specifications.

3. If the line pressures are within the specifications

at "Idle", now you can perform the "Stall" test

to determine if specifications are okay there.

4. Once again, refer to the chart in Figure 24, to

determine proper specifications at "Stall".

AUTOMATIC TRANSMISSION SERVICE GROUP

21

Technical Service Information

FORD 4R100

"NON-PTO" AND "PTO"

HYDRAULIC DIFFERENCES

CHANGE:

REASON:

PAR TS AFFECTED:

Begining at the start of production for 1999 models, Ford Motor Company made available a "Power

Take Off" option for some F250, F350, F450 and F550 Super Duty Trucks, equipped with 5.4L,

6.8L and 7.3L engines.

The "PTO" option addition, to the 4R100, required many changes to the transmission to make the

"PTO" function. The "PTO" window, added to the case, the "PTO" drive gear and other cosmetic

changes were covered on Page 6 in this manual. Hydraulic changes also had to be made to make

the coast clutch operate in ranges other than the Drive ranges (See Figure 35).

(1)

TRANSMISSION CASE: The transmission case was changed to accommodate the "PTO"

window, as shown in this manual. All 4R100 Cases, "NON-PTO"and "PTO,"also had a "Dam"

added to seperate "Rear Lube" and to incorporate "Central Lube"as shown in Figure 25.

(2)

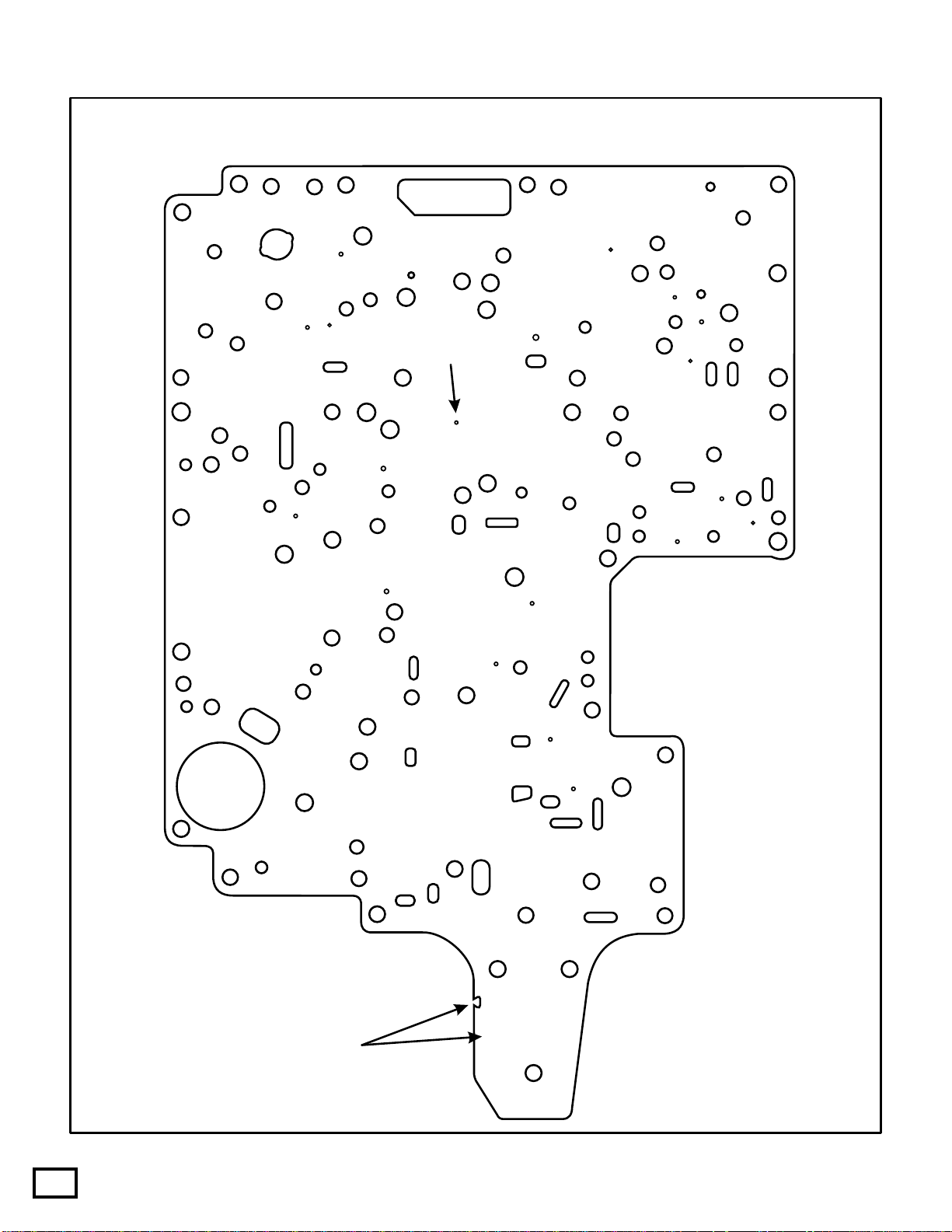

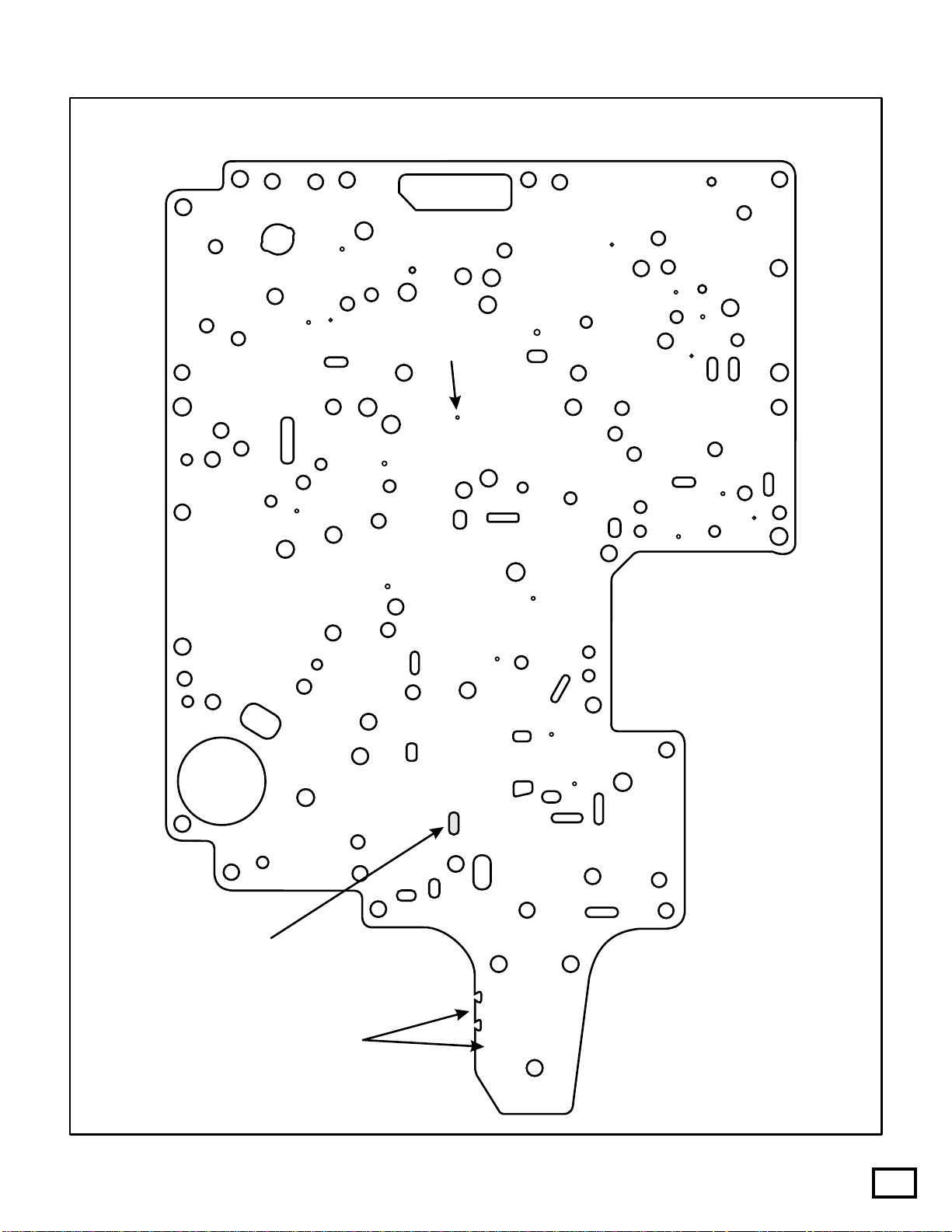

VALVE BODY TO CASE SPACER PLATE: The Valve Body to Case Spacer plate on the "PTO"

versions had a hole added to supply the 3-4 Shift V alve with Line Pressure, as shown in Figure 27. A

hole was also added to the Spacer Plate on "NON-PTO" and "PTO" versions to connect "Solenoid

Regulator Valve" oil to supply "Central Lubrication." Refer to Figures 26 and 27 for identification

of "NON-PTO"and "PTO" Valve Body T o Case Spacer Plates.

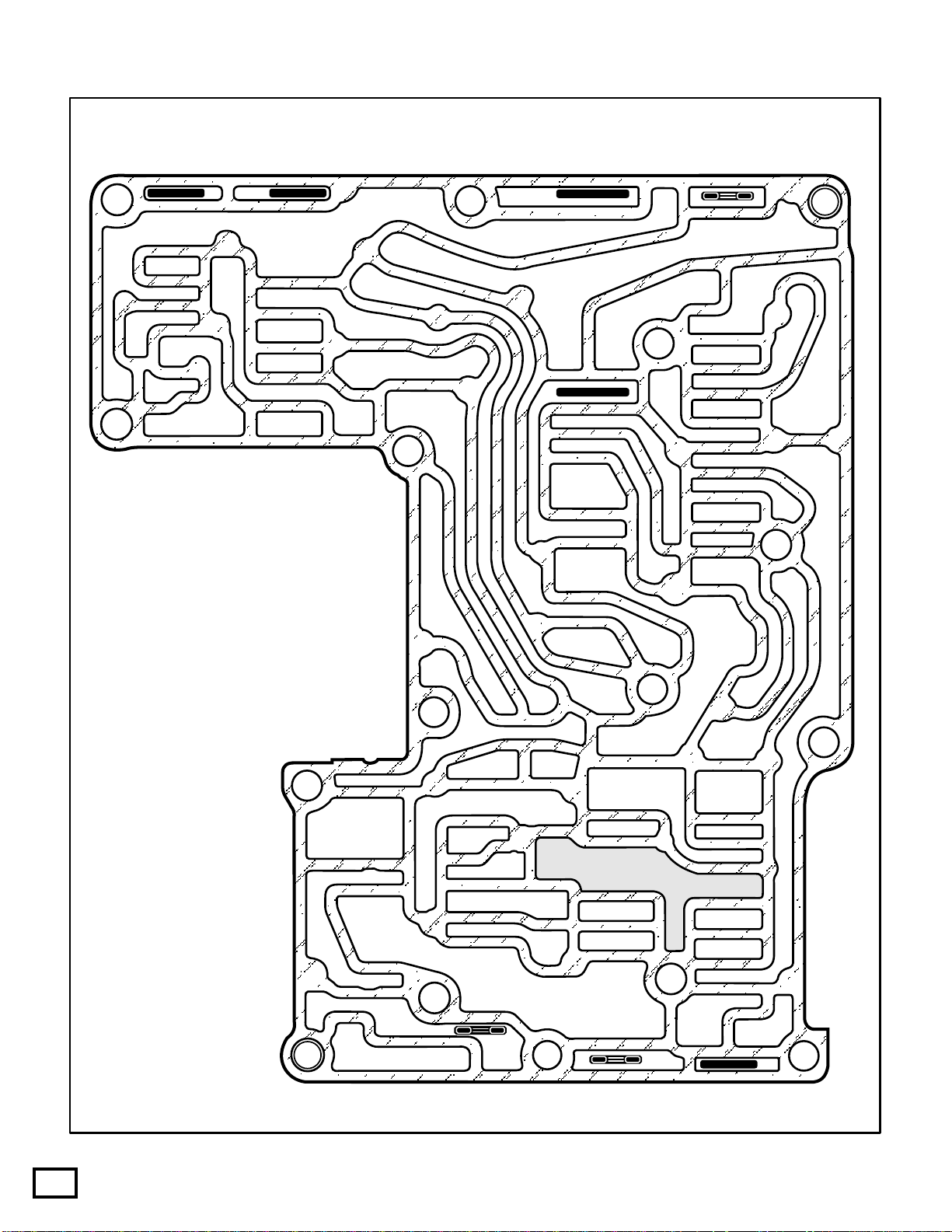

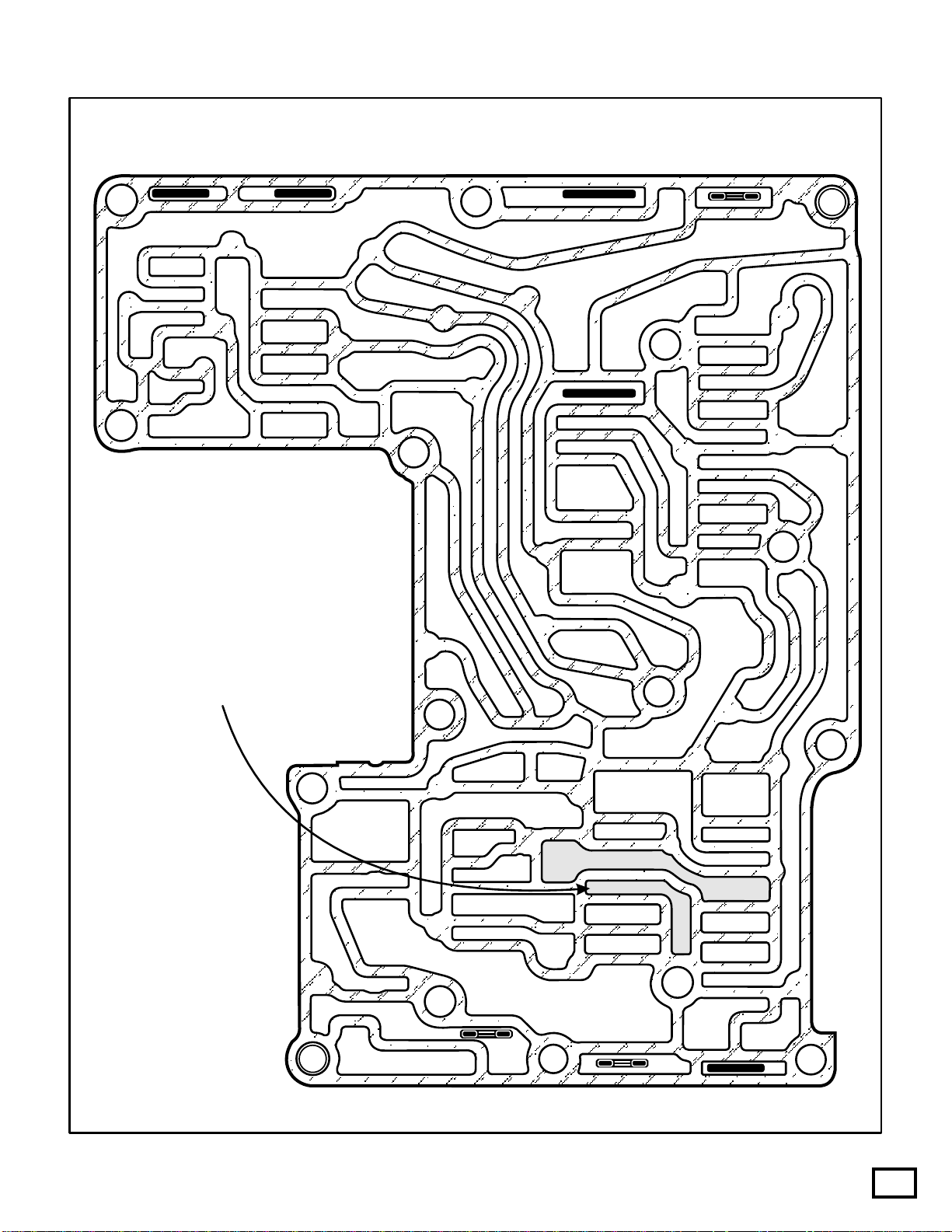

(3)

MAIN VALVE BODY: A passage was added on the "Upper Side" of the Main Valve Body on

"PTO" versions, as shown in Figure 29, to supply Line Pressure to the 3-4 Shift Valve. A passage

was also added, on the "Lower Side" of the Main Valve Body, to connect the 3-4 Shift Valve (Coast

Clutch Circuit) to an exhaust as shown in Figure 31. The spring side of the 3-4 Shift Valve was also

seperated from the Low/Reverse circuit as shown in Figure 31. Refer to Figures 28 thru 31 for

identification of "NON-PTO" and "PTO" Main Valvebody's.

(4)

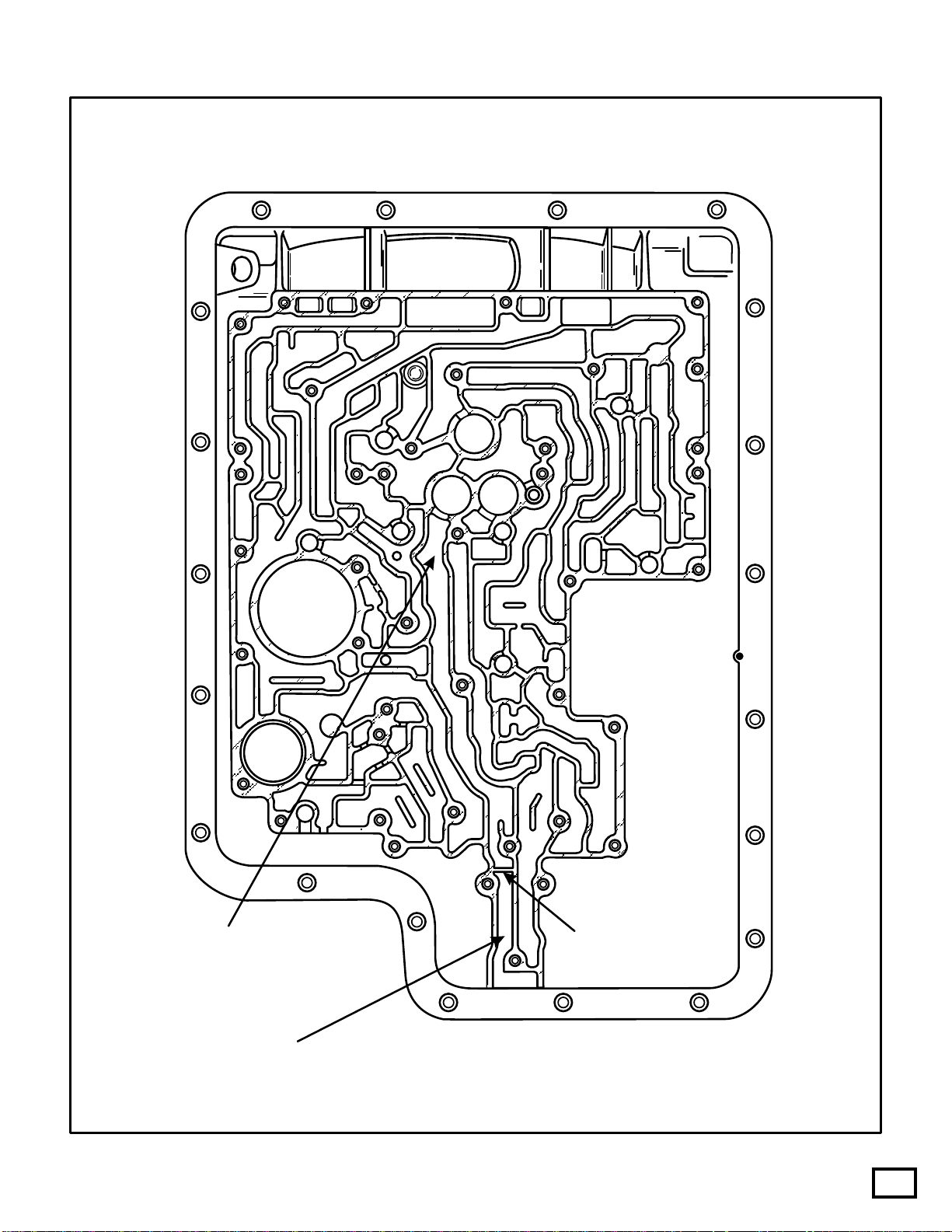

LOWER VALVE BODY: The Lower Valve Body has a passage added, as shown in Figure 33, to

connect to the "new"exhaust passage in the Main Valve Body. Refer to Figures 32 and 33, for

identification of "NON-PTO" and "PTO" Lower Valvebody's.

(5)

LOWER VAL VE BODY SPACER PLATE: The Lower Valve Body Spacer Plate had a hole added

to connect the "new" exhaust passage in the Main Valve Body to the "new" exhaust passage in the

Lower Valve body a shown in Figure 34. Refer to Figure 34 for "NON-PTO" and "PTO" Lower

V alve Body Spacer Plate identification.

INTERCHANGEABILITY :

None of the parts listed above will interchange between "NON-PTO" and "PTO" versions.

SERVICE INFORMATION:

Valve Body To Case Spacer Plate (Non-PTO) .................. ................................F81Z-7A008-DA

Valve Body To Case Spacer Plate (PTO) ...........................................................F81Z-7A008-BA

22

Copyright © 2003 ATSG

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

4R100 CASE ASSEMBLY

"NON-PTO" AND "PTO" MODELS

CENTRAL LUBE

REAR LUBE

ADDED OIL

DAM

Figure 25

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2003 ATSG

23

Technical Service Information

4R100 MAIN SPACER PLATE

"NON-PTO" MODELS ONLY

1212

CENTRAL LUBE

ORIFICE

9797

24

I.D.- 1 DOVE TAIL

PART NUMBER

F81Z-7A008-DA

AUTOMATIC TRANSMISSION SERVICE GROUP

F81P-DAF81P-DA

Copyright © 2003 ATSG

Figure 26

Technical Service Information

4R100 MAIN SPACER PLATE

"PTO" MODELS ONLY

66

CENTRAL LUBE

ORIFICE

9898

ADDED MAIN LINE PRESSURE HOLE

FROM PRESSURE REGULATOR VALVE

I.D.- 2 DOVE TAILS

PART NUMBER

F81Z-7A008-BA

AUTOMATIC TRANSMISSION SERVICE GROUP

F81P-BAF81P-BA

Copyright © 2003 ATSG

Figure 27

25

Technical Service Information

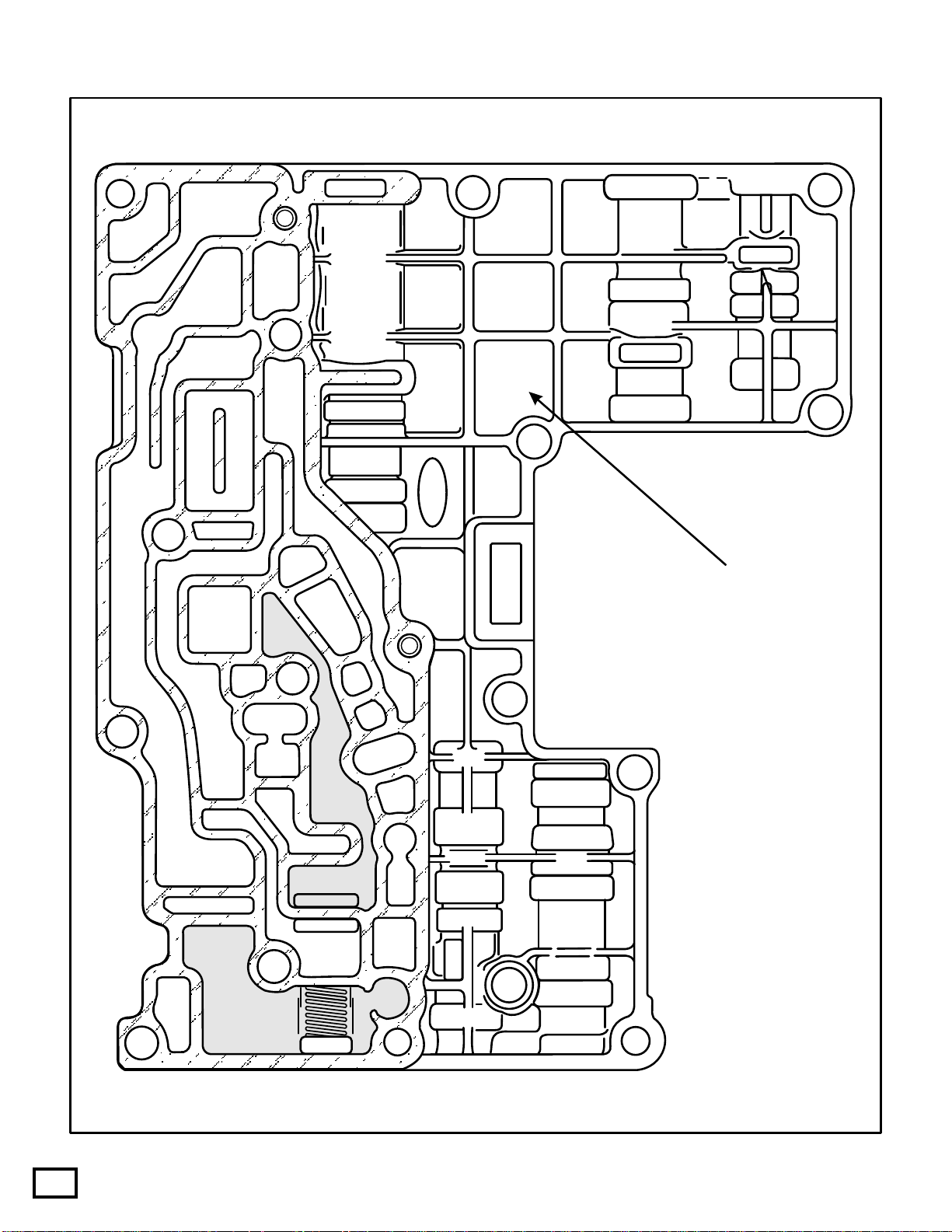

"UPPER SIDE" 4R100 MAIN VALVE BODY

"NON-PTO" MODELS ONLY

26

Copyright © 2003 ATSG

Figure 28

AUTOMATIC TRANSMISSION SERVICE GROUP

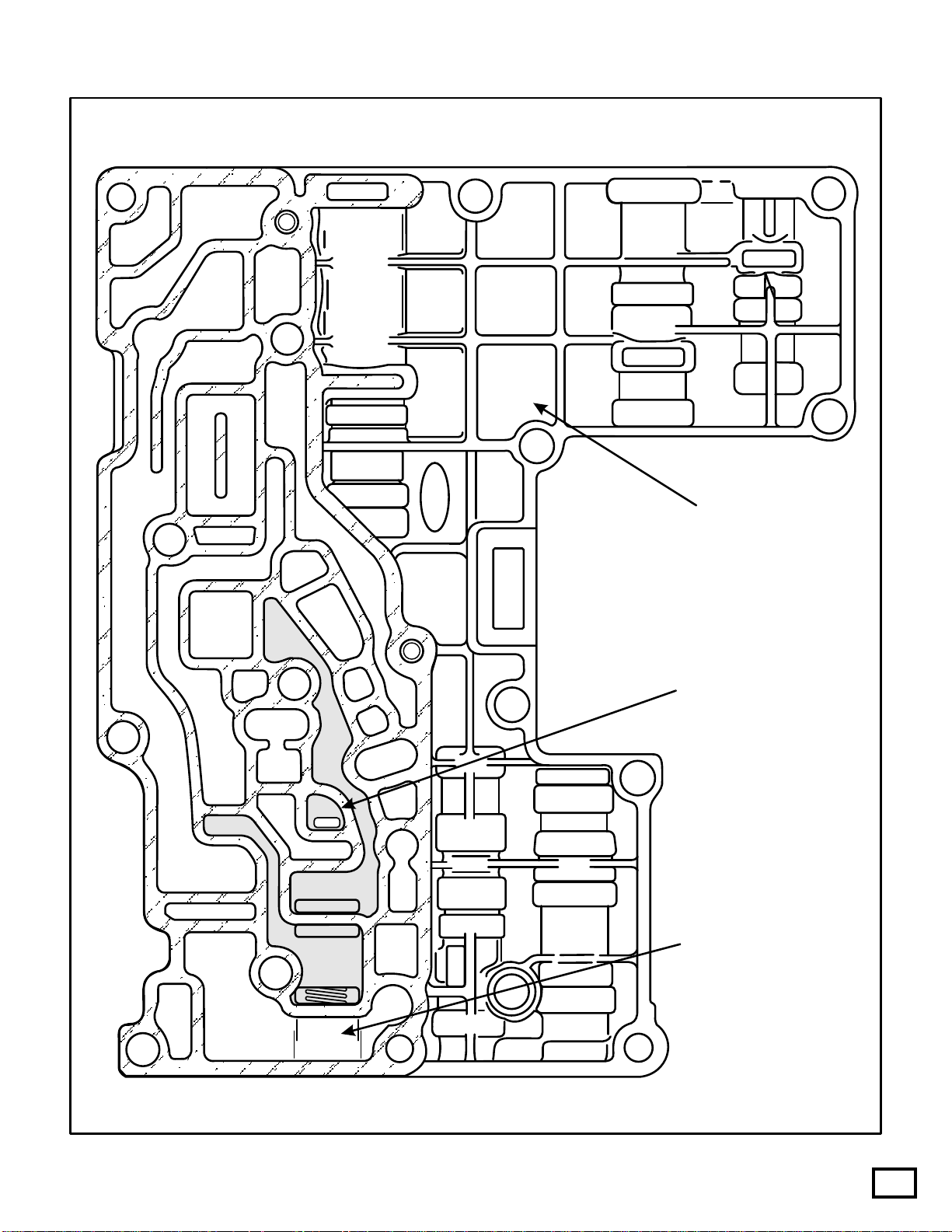

Technical Service Information

"UPPER SIDE" 4R100 MAIN VALVE BODY

"PTO" MODELS ONLY

PASSAGE ADDED TO

FEED LINE PRESSURE TO

THE 3-4 SHIFT VALVE

Figure 29

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2003 ATSG

27

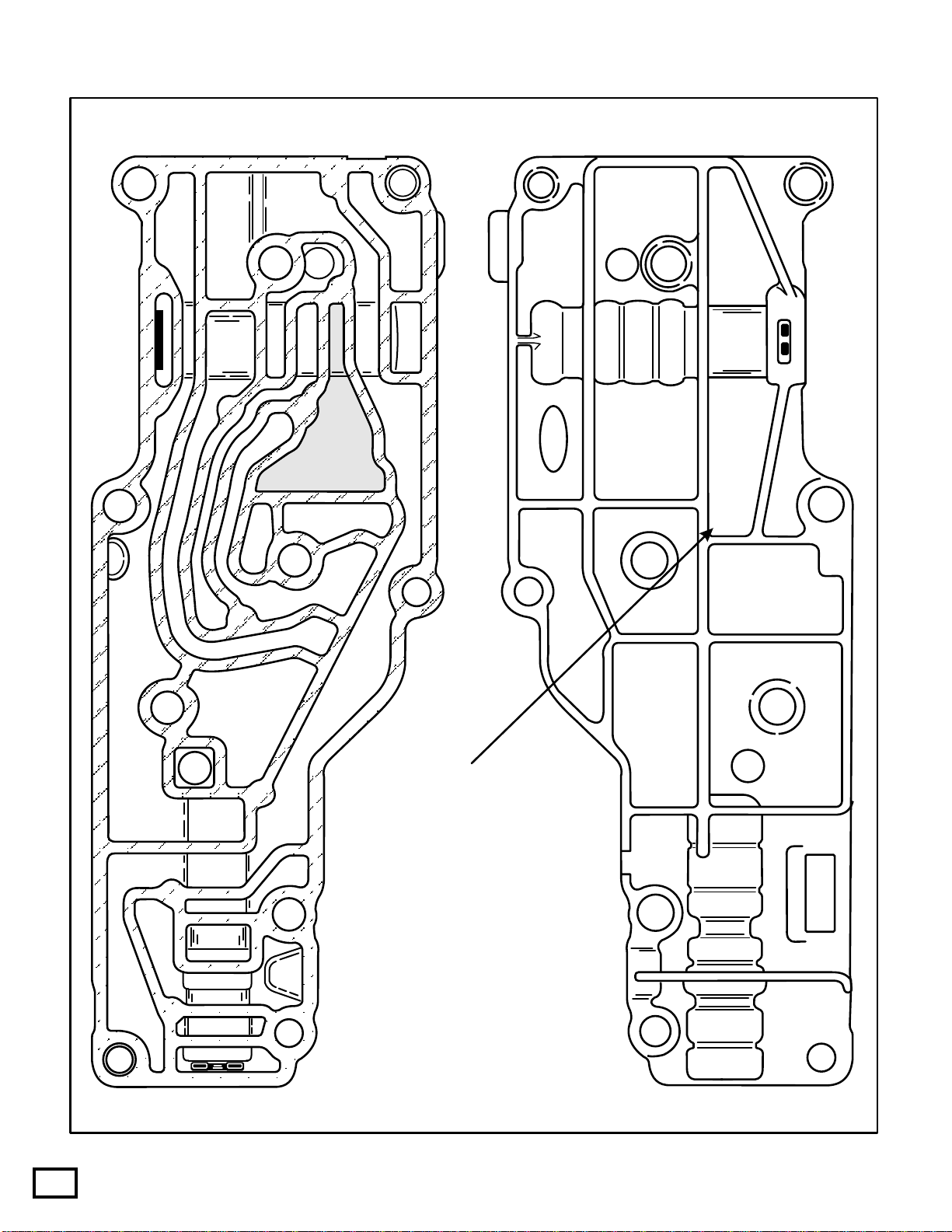

Technical Service Information

"LOWER SIDE" 4R100 MAIN VALVE BODY

"NON-PTO" MODELS ONLY

7A092-AB

7A092-AB

RFF61P-

RFF61P-

FordFord

Du PageDu Page

66

0932809328

I.D.-ROUGH FORGING

NUMBER OF "RF-F6" WHICH

INDICATES "96"

28

LOW/REVERSE

CLUTCH

Copyright © 2003 ATSG

Figure 30

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

"LOWER SIDE" 4R100 MAIN VALVE BODY

"PTO" MODELS ONLY

PP

7A092-AA

7A092-AA

RFF81P-

RFF81P-

FordFord

Du PageDu Page

11

1953819538

I.D.-ROUGH FORGING

NUMBER OF "RF-F8" WHICH

INDICATES "98"

PASSAGE ADDED

LEADING TO THE

EXHAUST IN THE

LOWER VALVE BODY

LOW/REVERSE

PASSAGE RE-MOVED

FROM SPRING SIDE

OF 3-4 SHIFT VALVE

LOW/REVERSE

CLUTCH

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2003 ATSG

Figure 31

29

Technical Service Information

4R100 LOWER VALVE BODY

"NON-PTO" MODELS ONLY

FordFord

AA

I.D.-ROUGH FORGING

NUMBER OF "RF-F6" WHICH

INDICATES "96"

RFF61P-7A101RFF61P-7A101

Du PageDu Page

55

0982809828

30

Copyright © 2003 ATSG

Figure 32

AUTOMATIC TRANSMISSION SERVICE GROUP

Loading...

Loading...