Instruction Manual

for

3-Phase 1 Q-Power Controller

Temvar GDE2

ATR Industrie-Elektronik GmbH

Siempelkampstr. 50

D-47803 Krefeld

Phone: (+49) 2151 926100

Fax: (+49) 2151 926101

Internet: www.msr-elektronik.com

E-Mail: elektronik@atrie.de

TABLE OF CONTENTS

1 SAFETY AND APPLICATION NOTES FOR DRIVE CONVERTERS..............................................................2

2 DEVICE DESCRIPTION..................................................................................................................................3

2.1 General.......................................................................................................................................................3

2.2 Device Description .....................................................................................................................................3

2.3 Ambient Conditions....................................................................................................................................5

2.4 System Conditions .....................................................................................................................................5

3 PRODUCT OVERVIEW...................................................................................................................................6

3.1 Device Table ..............................................................................................................................................6

3.2 Dimensions of Chokes and Devices...........................................................................................................7

4 DEVICE CONNECTION...................................................................................................................................8

4.1 Connection Diagram...................................................................................................................................8

4.2 Sequence for Switching On/Off..................................................................................................................8

4.3 Terminal Assignment..................................................................................................................................9

4.4 Assembly..................................................................................................................................................11

4.4.1 Danger.............................................................................................................................................11

4.4.2 Mechanical Design...........................................................................................................................11

4.4.3 Wiring Instructions...........................................................................................................................11

5 LAYOUT PLANS...........................................................................................................................................12

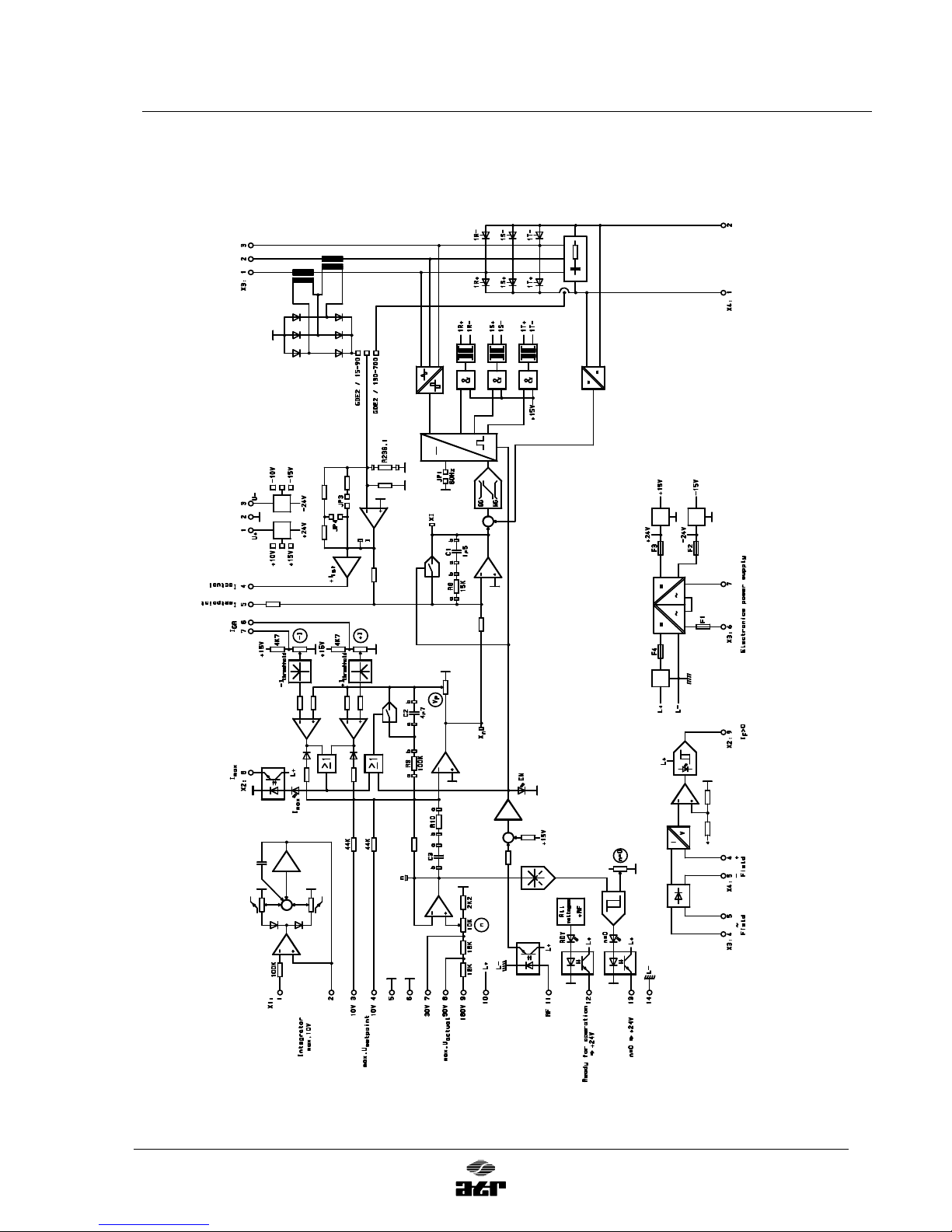

5.1 Circuit Diagram.........................................................................................................................................12

5.2 Equipment Configuration..........................................................................................................................13

5.3 Component Mounting Diagram for Electronics PCBs...............................................................................15

5.4 Potentiometer Settings.............................................................................................................................17

5.5 LED Displays............................................................................................................................................18

6 FUNCTIONAL DESCRIPTION OF THE INPUTS AND OUTPUTS ...............................................................19

6.1 Analog Inputs ...........................................................................................................................................19

6.2 Analog Outputs.........................................................................................................................................20

6.3 Control Inputs and Signal Outputs ...........................................................................................................21

7 FUNCTIONAL DESCRIPTION ......................................................................................................................23

7.1 Setpoint Value Integrator..........................................................................................................................23

7.2 Speed Controller ......................................................................................................................................24

7.3 Current Limit.............................................................................................................................................24

7.4 Current Controller.....................................................................................................................................25

7.5 Firing Pulse Formation .............................................................................................................................25

7.6 Thyristor Outputs......................................................................................................................................26

7.7 Electronics Supply....................................................................................................................................26

7.8 Field Supply..............................................................................................................................................26

7.9 System Power Supply Monitoring.............................................................................................................27

7.10 Tacho Monitoring......................................................................................................................................27

7.11 Fan Monitoring .........................................................................................................................................27

8 INSTALLATION.............................................................................................................................................28

8.1 Dangers....................................................................................................................................................28

8.2 Recommended Procedure .......................................................................................................................29

9 OPTIMISATION.............................................................................................................................................30

10 FAULT OCCURRENCE.................................................................................................................................31

Updated edition: A0254_06 - Date: July 8, 2009/KB

Temvar GDE2

July 08, 2009

2

D 96.091101E

1 SAFETY AND APPLICATION NOTES FOR DRIVE CONVERTERS

(According to the 72/73/EC Low-voltage Guideline)

10.25.96/HX/PT/BLY

1. General

Depending on their protection class, drive converters may have

non-isolated and live conductors, possibly moving or rotating

parts, and hot surfaces.

There is danger of severe personnel or equipment damage if the

required cover is inadmissibly removed, the unit is used in an

inadmissible application, improperly installed or operated.

Refer to the documentation for further information.

All work concerning transportation, installation, and

commissioning as well as maintenance is to be performed by

qualified expert personnel (take also note of the IEC 364 and/or

DIN VDE 0100 and national accident prevention regulations).

Expert personnel for electrical devices

Personnel, which is based on his/her professional training,

experience and knowledge of the applicable standards and

capable to judge the tasks to be performed and to recognize

possible sources of danger.

Personnel trained for electro-technical operation

Personnel informed by the expert personnel for electrical

devices regarding the tasks assigned to him/her and the

possible danger occurring at improper acting’s and who is

trained if required and instructed about the required safety

mechanisms and protective measures.

2. Intended use

Drive converters are components supposed to be included into

electrical equipment or machines.

When installing the drive converter into a machine, its

commissioning (i.e. taking up its intended operation) is

prohibited until it is ascertained that the machine conforms to the

regulations described by the EC guideline 93/44/EC (Machine

Guideline). Take note of EN 60204.

Commissioning (i.e. taking up its intended operation) is only

allowed if the Electromagnetic Compatibility guideline

(89/336/EC) is observed.

The drive converters fulfil the requirements of the 73/23/EC

Low-voltage Guideline. Drive converters are subject to the

harmonized standards of the prEN 50178/DIN VDE 0160 in

association with EN 60439-1/VDE 0660 part 500 and EN

60146/VDE 0558.

The specifications and the data concerning the connection

conditions are stated on the rating plate and in the

documentation of the component. Meeting these data and

conditions is compulsory.

3. Transport and storage

The notes regarding transport, storage and appropriate

operation must be observed.

Climatic conditions must be complied with as detailed by prEN

50178.

4. Setting up

Setting up and cooling of the devices must be made according

to the rules described in the corresponding documentation.

Drive converters are to be protected against inadmissible

stress. Particularly, no components may be twisted and/or no

isolation distances may be changed. Touching of electrical

components and contacts is to be prevented.

Drive converters include components, which can be damaged

by electrostatic discharge. When handled improperly, these

components can be easily damaged. Electrical components

may not be damaged or destroyed by using mechanical force

(this may endanger health).

5. Electrical connection

The valid national accident prevention regulations (e. g. VGB4)

must be observed when working on drive converts which are

connected to the supply voltage.

The electrical set-up has to be performed according to the

relevant regulations (e.g. conductor diameter, fusing,

protective conductor connection). Furthermore, the

documentation contains notes concerning this subject.

Notes relevant to a proper EMC-conforming set-up (e. g.

screening, earthing, arrangement of filters, and cable routing)

are to be found in the documentation of the drive converters.

These notes must always be observed even when working

with drive converters with the CE mark. The manufacturer of

the plant or of the machine is responsible for the observance

of the required limit values as defined by the EMC regulations.

6. Operation

If applicable, plants fitted with drive converts must be equipped

with additional monitoring and safety devices according to the

currently valid safety regulations, e. g. law concerning work

equipment, accident prevention regulations, etc. Modifications

of the drive converters using the operating software are

admissible.

Touching of equipment parts that are subject to voltage in

operating conditions and of wire connections is not allowed

directly after disconnecting the supply voltage. There is the

danger of still charged capacitors! Fore this, all relevant safety

markings on the drive converter must be observed.

During operation, covers and doors must be kept shut.

7. Maintenance

The manufacturer’s documentation must be observed.

These safety notes must be kept in a safe place!

Temvar GDE2

July 08, 2009

3

2 DEVICE DESCRIPTION

2.1 General

Three-phase power controllers from the GDE series are compact devices for armature feeding of speedregulated direct current drives up to 700 A.

The device concept is characterized by the compact design.

The enclosed, galvanized housing and intelligent terminal assignment ensure that electromagnetic

compatibility of the device is excellently supported (see Section 4).

The main power connection covers the range from 210 to 550 V without switchover.

The electronics power supply is 230 V 50/60 Hz for all devices. Synchronization of the electronics power

supply with the main power supply is not necessary.

The model specification lists the main features of the device, e.g.

GDE2/15

max. output current 15 A

series 2

1-quadrant device

three-phase current connection

direct current control device

2.2 Device Description

The power section comprises a thyristor bridge without circulating current in standard modular

technology. The supply connections X3 are located on the top, the outputs and electronics connections

X4 and X1, on the bottom of the devices. The electronics consist of a closed-loop controller, an openloop controller PCB, and a power supply unit.

2.2.1 Closed-loop Controller PCB GDE2 A0114xx

This can be accessed by unscrewing the top plate. This area houses the electronic terminals

X1 (setpoint and actual values, enable and signal outputs) and X2 (potential terminals and

auxiliary inputs), and everything that is needed for installation (potentiometers, component

mounting points, LED signals). The following circuit groups are located on this printed circuit

board:

A) Setpoint value integrator

B) Actual speed value alignment

C) Speed controller with current limiting

D) Current controller

E) Signal outputs for speed > 0, current limit reached, field current > 0 and device stand-by

.

Temvar GDE2

July 08, 2009

4

2.2.2 Open-loop Controller PCB GDE2 A0095xx

This is located on the left sidewall.

The following circuit groups are located on this printed control board.

A) Switchover logic

B) Current measurement

C) DC/AC conversion limitation

D) Firing pulse formation

E) On-off logic in case of power system failure

F) Firing pulse output stages

2.2.3 Power Supply Module

Devices 15 A - 270 A GDE2 A0033xx

Devices 380 A - 700 A GDE2 A0112xx

For devices up to 270 A this module is mounted on the right-hand wall.

The following circuit groups are located on the module (A0033xx).

A) Electronics power supply with miniature fuses F1 - F4 (see circuit diagram on page 12)

B) Field current monitoring

C) Generation of synchronous voltage

D) Power system monitoring

E) Temperature monitoring

F) Armature voltage acquisition

G)

Overload protection switch with suppressor circuit for thyristors

For devices over 380 A the module (A0112xx) is located under the hinged cover. The overload

protection switch with suppressor circuit is housed on a separate PCB directly above the

thyristors.

The main elements such as the 60 Hz bridge and miniature fuses for the electronics power

supply can be accessed by lifting up the closed-loop controller PCB. Otherwise there is nothing

on these PCB's that would need to be adjusted for installation.

Danger

Dangerous voltage is present even when the system switch of the power controller is

open. The control module and supply modules contain a number of dangerous live

circuits.

Failure to observe the instructions given in this operating manual can cause death,

serious injury to persons and damage to equipment.

Temvar GDE2

July 08, 2009

5

2.3 Ambient Conditions

The specified nominal device currents are valid up to a maximum ambient temperature of

40°C. Above this level, a reduction in the device c urrent of 1% per °C must be allowed for. The

absolute temperature limit is 55°C. Heat concentrat ion above the devices should be avoided.

The devices have protection type IP 00, meaning that they have to be enclosed in control

cabinets or closed control housings.

The surrounding air must be free of electrically conductive dust particles and chemically

aggressive vapors. Vibrations can destroy the devices.

2.4 System Conditions

The devices work in a voltage range of 230 to 500 V ± 10%/50Hz. For operation connected to

a 60 Hz mains power supply, the JP2 bridge must be fitted on the open-loop controller PCB.

The device is ready for operation approx. 200 ms after connecting the electronics power

supply. Until then the closed-loop controllers and pulse generator are inhibited. The signal

"stand-by" is only given after this interval. Closed-loop controller enable is internally inhibited

until the main power is connected.

The devices require a mains power source with UK = 4% at nominal device current. This is

achieved by preconnecting the recommended commutation chokes DD15-700.

For the electronics and fan supply an auxiliary voltage of 230 V ±10%, 50/60 Hz is required.

Attention! The power controller is not suitable for an operation at earth-free supply systems

(IT systems). Please do not hesitate to ask for customized execution when required.

Temvar GDE2

July 08, 2009

6

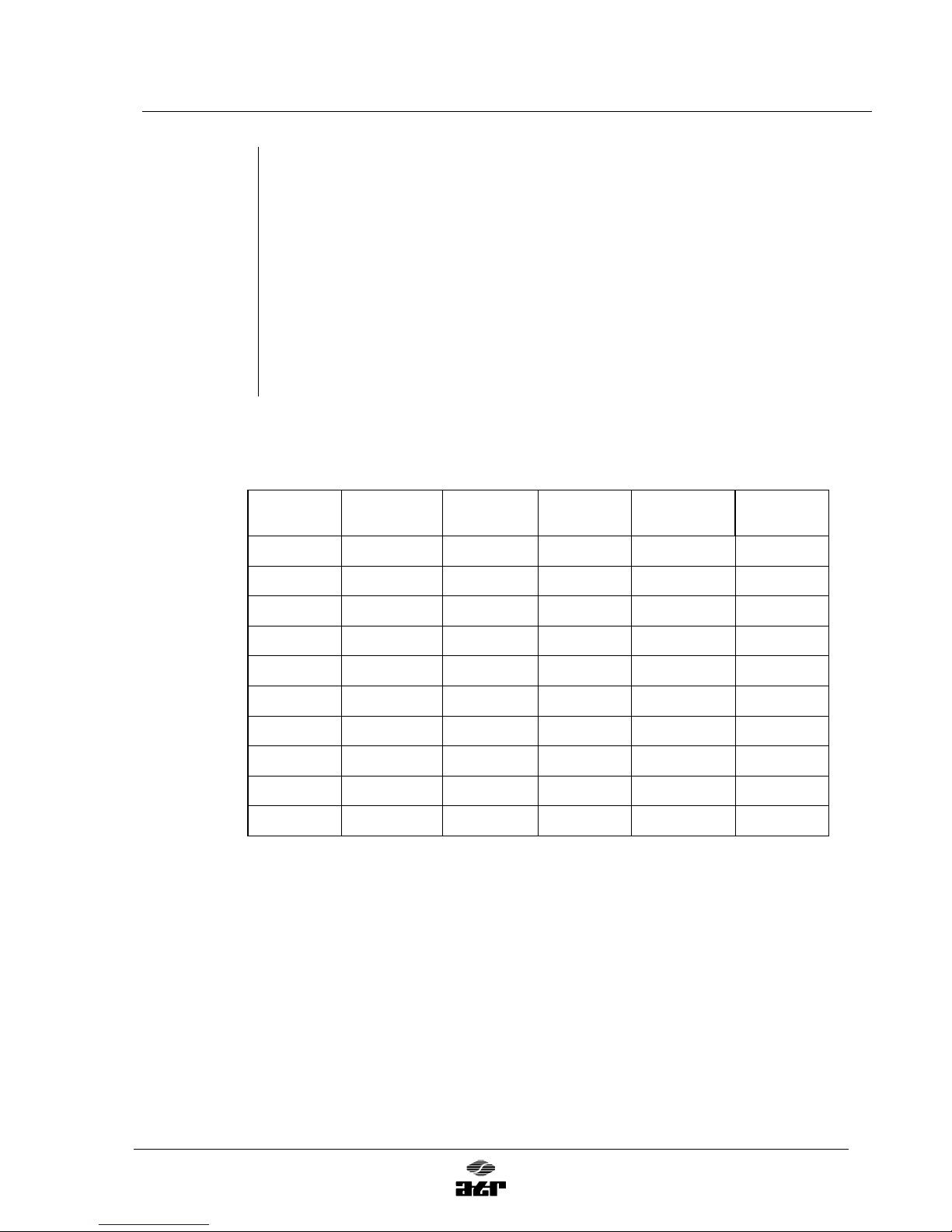

3 PRODUCT OVERVIEW

3.1 Device Table

Type Input

Current/fuse

Output

Current/fuse

Power

loss

Current

consumption

electronics

Input

choke

GDE2/15

GDE2/30

GDE2/60

GDE2/90

GDE2/130

GDE2/190

GDE2/270

GDE2/380

GDE2/500

GDE2/700

12 A

25 A

49 A

74 A

107 A

156 A

221 A

312 A

410 A

574 A

16 A

35 A

63 A

80 A

125 A

160 A

250 A

400 A

450 A

630 A

15 A

30 A

60 A

90 A

130 A

190 A

270 A

380 A

500 A

700 A

150 W

200 W

300 W

320 W

350 W

630 W

760 W

1100 W

1400 W

2000 W

0,2 A

0,2 A

0,2 A

0,2 A

0,6 A

0,6 A

0,6 A

1 A

1 A

1 A

DD 15

DD 30

DD 60

DD 90

DD130

DD190

DD270

DD380

DD500

DD700

3 x

For 500V connection 2 x in series

Shared data:

Supply voltage - main power : 207 - 550 V / D 230 - 500 V ± 10%

Supply voltage - electronics : 207 - 253 V / 0,2 A E 230 V ± 10%

Supply voltage - field supply : max. 400 V / E 400 max.

Frequency of supply voltage : 48 - 63 Hz

Output - field supply : 0.9 x UE / DC / max. 7 A

From GDE2/130 : 0.9 x UE / DC/ max. 15 A

Temvar GDE2

July 08, 2009

7

3.2 Dimensions of Chokes and Devices

For 15 - 90 A devices

Type Rated

a.c.

a b c d e f

DD15 12 A

123

70 125

4,8 123

49

DD30 24 A 153 74,5 150 4,8 153 54,5

DD60 48 A 180 100,5 175 7,0 180 70,5

DD90 72 A 180 120 175 7,0 180 90

GDE2-15

GDE2-30

GDE2-60

GDE2-90

For 130 - 700 A devices

Type Rated

AC

a b c d

e f g

h

DD130 160 A 219

150

160

201

115,5

136

90,5

7x12

DD190 160 A 267 170 200 249 133 176 103 7x12

DD270 315 A 316 195 235 292 138 200 98 10x16

DD380 315 A 316 200 235 292 152 200 112 10x16

DD500 500 A 316 215 235 292 164 200 124 10x16

DD700 630 A 352 230 270 328 184 224 144 10x16

GDE2/130 GDE2/380

GDE2/190 GDE2/500

GDE2/270 GDE2/700

Temvar GDE2

July 08, 2009

8

4 DEVICE CONNECTION

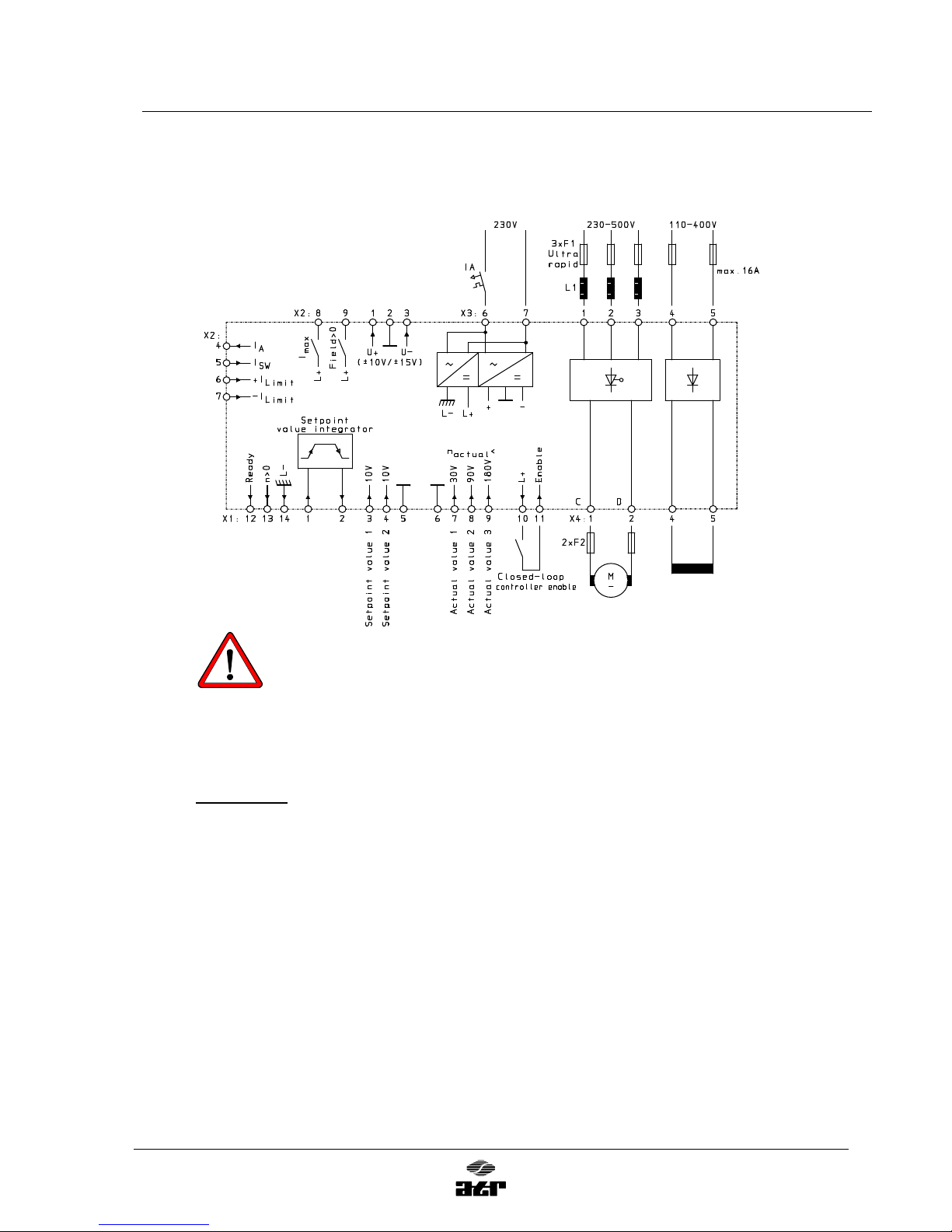

4.1 Connection Diagram

Danger

Incorrect connection of the device can lead to damage or destruction.

4.2 Sequence for Switching On/Off

Switching on

1. Field supply X3: 4 + 5

2. Electronics supply X3: 6 + 7

3. Main power X3: 1 + 2 + 3

4. Closed-loop controller enable X1: 10 + 11

5. Setpoint value X1: 1 or 3 or 4

Points 2 to 5 can be switched together, as the device is fitted with an internal inhibition of

approx. 200 ms after the electronics supply has been switched on. The "stand-by" signal is

also only given after this interval, however.

Point 1 must be switched on at least one second earlier than point 3.

The electronics supply can remain switched on permanently, it does not have to be switched

on and off with the drive.

Temvar GDE2

July 08, 2009

9

Switching off

1.) Setpoint X1: 1 or 3 or 4

2.) At standstill closed-loop controller enable X1: 10 + 11

3.) Main power X3: 1 + 2 + 3

4.) Field supply X3: 4 + 5

5.) Electronics supply

Points 1 and 2 can be switched together.

Points 3 to 5 can be switched together, but at least one second after point 2.

The electronics supply must not be switched off. The motor is safely isolated when points 1 - 4

have been switched off.

4.3 Terminal Assignment

X1: Electronics plug-in terminal 14-pole

1 Input setpoint value integrator max. ± 10 V. Input resistance 100 K.

2 Output setpoint value integrator max. ± 10 V. Output resistance 44 Ohm.

3 Setpoint value input max. + 10 V. Input resistance 44 K.

Filter time constants 22 ms.

4 Setpoint value input max. + 10 V. Input resistance 44 K.

Filter constants 22 ms.

5 Closed-loop controller ground

6 Closed-loop controller ground

7 Actual value input max. - 30 V. Input resistance 12 K.

8 Actual value input max. - 90 V. Input resistance 30 K.

9 Actual value input max. - 180 V. Input resistance 48 K.

10 L+, potential-free auxiliary voltage + 24 V for closed-loop controller enable, signal

outputs and auxiliary electronics. Load capacity max. 50 mA.

11 Input closed-loop controller enable via optocoupler + 18 to 30 V corresponds to >

12.5 V corresponds to closed-loop controller enable. Input resistance 3K3.

12 Output operational signal. + 24 V corresponds to "device stand-by".

Max. load capacity 20 mA.

13 Output operating signal. + 24 V corresponds to "drive turning".

Max. load capacity 20 mA.

14 L-, reference point of potential-free auxiliary voltage 24 V for closed-loop controller

enable, signal outputs and auxiliary electronics. Load capacity 50 mA.

X2: Electronics plug-in terminal 9-pole

1 Output + 15 V or + 10 V stabilized for auxiliary electronics and setpoint value

formation.

Max. load capacity 30 mA. The voltage can be determined using the jumper

(+15/+10).

2 Closed-loop controller ground

3 Output – 15 V or - 10 V stabilized for auxiliary electronics and setpoint value

formation. Max. load capacity 30 mA. The voltage can be determined using the

jumper (-15/-10).

Temvar GDE2

July 08, 2009

10

4 Output current actual value. Nominal device current corresponds to + 10 V.

Output resistance 220 Ohm.

5 Auxiliary input to current controller. + 10 V corresponds to 100% current setpoint

value.

Input resistance 44 K. Filter time constants 2.2 ms.

6 Input for external current limit setting + or - 10 V corresponds to 100% (R5 right

stop) current limit for positive speed setpoint value and drive operation.

Input resistance 4K7.

7 Input for external current limit setting for 4Q-device (R6 left stop).

Input resistance 4K7.

8 Signal output "current limit“ . + 24 V corresponds to device at current limit.

Max. load capacity 20 mA.

9 Signal output "field current“. + 24 V corresponds to field current larger than 0.2 A.

For devices above 380 A, field current larger than 0.4 A

Max. load capacity 20 mA.

Main power connections X3 + X4

Main current

supply

X3: 1 + 2 + 3

Field

supply

X3: 4 + 5

Electronics

supply

X3: 6 + 7

Armature

connection

X4: 1 + 2

Field

connection

X4: 4 + 5

GDE2-15 42 * 2.52 * 2.52 * 42 * 2.52 *

GDE2-30 42 * 2.52 * 2.52 * 42 * 2.52 *

GDE2-60 162 * 2.52 * 2.52 * 162 * 2.52 *

GDE2-90 162 * 2.52 * 2.52 * 352 * 2.52 *

GDE2-130 20 x 3/M8 ** 42 * 2.52 * 20 x 5/M8 ** 42 *

GDE2-190 20 x 3/M8 ** 42 * 2.52 * 20 x 5/M8 ** 42 *

GDE2-270 20 x 5/M8 ** 42 * 2.52 * 20 x 5/M8 ** 42 *

GDE2-380 40 x 5/M10 ** 42 * 2.52 * 40 x 5/M10 ** 42 *

GDE2-500 40 x 5/M10 ** 42 * 2.52 * 40 x 5/M10 ** 42 *

GDE2-700 40 x 5/M10 ** 42 * 2.52 * 40 x 5/M10 ** 42 *

* = Line-up terminals ** = Conductor rails

Temvar GDE2

July 08, 2009

11

4.4 Assembly

4.4.1 Danger

Incorrect lifting can lead to injury and damage to the equipment.

The device should only be lifted by qualified personnel using suitable equipment.

The device must be assembled in accordance with safety regulations (e.g. DIN, VDE)

and all other relevant national or local regulations. The device must be properly

grounded, with sufficient phase-to-ground clearance and corresponding short-circuit

protection, to ensure that a high level of operating safety is maintained.

4.4.2 Mechanical Design

For reasons of electromagnetic compatibility

(EMC), the devices have a galvanized steel

housing. For the same reason, a galvanized

mounting plate is recommended, along with

connecting the ground lead to a copper bus

connected to the mounting plate via a broad,

conductive surface area (see construction

suggestions).

In order to ensure an unimpeded flow of cooling

air, an interval of at least 100 mm above and

below the device must be kept clear of

obstruction.

Failure to observe this may lead to the device

overheating!

The main power fuses must be ultra fast

blowing semiconductor fuses.

4.4.3 Wiring Instructions

All leads connected to terminal strips X1 and X2

must be shielded. The shielding should be firmly

attached using terminals, clips, or binders,

across a broad contact surface on the bus bar

provided for that purpose. Analog signal leads

should only be grounded at one point. Leads

with binary control signals can be grounded at

several points. The wiring paths should be kept

short and the electronics wiring should be

strictly isolated from the main current wiring.

(see the construction suggestions).

The closed-loop controller ground should be

connected to the protective circuit by a short

2.52 stranded wire.

Temvar GDE2

July 08, 2009

12

5 LAYOUT PLANS

5.1 Circuit Diagram

Temvar GDE2

July 08, 2009

13

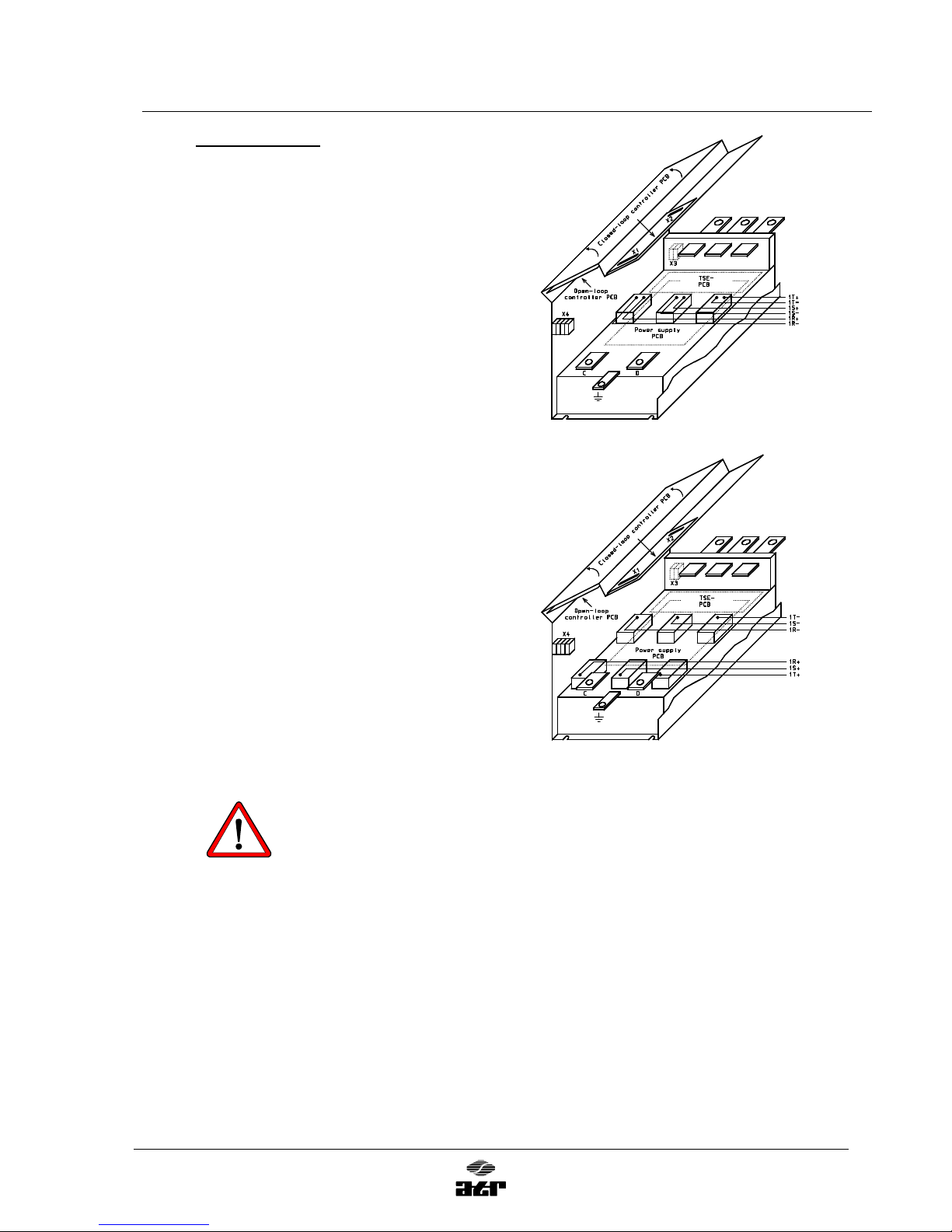

5.2 Equipment Configuration

Thyristor module:

GDE2-15 3 x MCC 19-16io8B

GDE2-30 3 x MCC 19-16io8B

GDE2-60 3 x MCC 44-16io8B

GDE2-90 3 x MCC 44-16io8B

The miniature fuses for the electronic supply are

located on the supply module.

This module can be accessed when the closedloop controller PCB is lifted out the way in the

direction of the arrow.

X1: Electronics terminal strip

Main function

X2: Electronics terminal strip

Main function

X3: Input terminals

Main power

X4: Output terminals

Main power

Thyristor module:

GDE2-130 3 x MCC 95-16io8B

GDE2-190 3 x MCC 95-16io8B

GDE2-270 3 x MCC 132-16io8B

The miniature fuses for the electronics supply

are located on the supply module.

This module can be accessed when the closedloop controller PCB is lifted out of the way in the

direction of the arrow.

X1: Electronics terminal strip

Main function

X2: Electronics terminal strip

Auxiliary function

X3: Input terminals

Main power

X4: Output terminals

Main power

Temvar GDE2

July 08, 2009

14

Thyristor module:

GDE2-380 3 x MCC 170-16io8B

GDE2-500 3 x MCC 255-16io8B

GDE2-700 6 x MCC 312-16io8B

The miniature fuses for the electronics supply

are located on the supply module.

This module can be accessed when the closedloop controller PCB is lifted out of the way in the

direction of the arrow.

X1: Electronics terminal strip

Main function

X2: Electronics terminal strip

Auxiliary function

X3: Input terminals

Main power

X4: Output terminals

Main power

Danger

Dangerous voltage is present even when the system switch of the power controller is

open. The control module and supply modules contain a number of dangerous live

circuits.

Failure to observe the instructions given in this operating manual can cause death,

serious injury to persons, and damage to equipment.

Temvar GDE2

July 08, 2009

15

5.3 Component Mounting Diagram for Electronics PCBs

Open-loop controller PCB Closed-loop controller PCB

GDE2 GDE2

(A0095xx) (A0114xx)

Temvar GDE2

July 08, 2009

16

SUPPLY PCB

For devices up to 270 A

SUPPLY MODULE

For devices above 380A

Temvar GDE2

July 08, 2009

17

5.4 Potentiometer Settings

+B Setpoint value integrator. Acceleration time for positive setpoint value.

Left stop approx. 1.5 seconds, right stop approx. 15 seconds.

R1 Acceleration time from 0 to 10 V.

-B Setpoint value integrator. Delay time for positive setpoint value. Effect as with + B.

R2

Vp Proportional gain for the speed controller. Left stop = x2.

Right stop = x20. This area is determined by R9 as delivered.

R3

n 25-turn spindle potentiometer for speed adjustment. Setting range approx. 1 : 4

R4 Right-hand rotation means higher speed.

+I Current limit for motor-driven operation and positive speed setpoint value or

generator-driven operation and negative speed setpoint value. Left-hand stop

R5 causes current limit 0, right-hand stop 100% of the nominal device current.

-I R6 Current limit for 4 Q device (left-hand stop).

n > 0 Threshold of operating signal 0 to 15% of the maximum speed can be set.

R7 Right stop is equal to 15%.

Temvar GDE2

July 08, 2009

18

5.5 LED Displays

STAND-BY

LED lights up when all internal electronic voltages are okay.

As soon as the closed-loop controller is enabled, the system voltage is also

checked.

Main power with clockwise rotating field, phase failure and tacho monitoring.

CLOSED-LOOP CONTROLLER ENABLE

LED lights up when the device is ready and the closed-loop controller on terminal

11 is enabled by the + 24 V signal.

n > o

LED lights up if the drive rotates faster than the threshold value set on the

potentiometer n > 0.

Current direction "+"

LED indicates 1Q operation.

Current direction "-"

This signal is only in use for the 4 Q device.

Current limit

LED lights up if the motor is driven at the set current limit for at least 15 seconds,

i.e., the speed controller is operated up to the stop, which is set with the

potentiometer +I.

Tacho

LED lights up when the tacho voltage is not at the ratio to the armature voltage

specified.

System power

LED lights up if the system power is not with clockwise rotating field, in the event

of phase failure or overheating of the heat sink.

⊗⊗⊗⊗

⊗⊗⊗⊗

⊗⊗⊗⊗

⊗⊗⊗⊗

⊗⊗⊗⊗

⊗⊗⊗⊗

⊗⊗⊗⊗

⊗⊗⊗⊗

Temvar GDE2

July 08, 2009

19

6 FUNCTIONAL DESCRIPTION OF THE INPUTS AND OUTPUTS

6.1 Analog Inputs

The analog inputs may only be connected using shielded leads. The shield should only be

connected to the grounding system at one point, across a broad contact surface in close

proximity to the device. For reasons of electromagnetic compatibility, these leads may never

be operated open-circuit, they must be connected with respect to the electrical ground when

the device is switched off.

Setpoint value integrator

The input voltage range is ± 0 to 10 V.

Setpoint value inputs

The two inputs are equal and are added together.

The maximum input voltage range is ± 0 to 10 V.

Input resistance and filter time constant are 44 KOhm and 22 ms respectively.

Actual value inputs

The potentiometer "speed adjustment" is a 25speed spindle potentiometer with a setting range

of approx. n = 4.

Right-hand stop means highest speed.

The filter time constant is selected at a very low

level of approx. 2.2 ms for reasons of dynamics,

the tacho voltage must therefore be very clean.

Inputs "external current limit"

The maximum motor current is set using

potentiometer +I (right stop 100% nominal device

current).

An external voltage of 0 to 10 V at X2: 6 means 0

to 100% motor current.

The input is equipped with an active rectifier and

can therefore process + 10 V or - 10 V (input

resistance 4K7).

The set current limit can also be reduced by

connecting a resistor to ground.

There is only a negative current limit for the 4 Q

device. For this device, the potentiometer -I is set

to the left stop.

Temvar GDE2

July 08, 2009

20

Auxiliary input - current controller

A voltage of + 10 V at terminal X2: 5 means

nominal device current.

Caution!

This auxiliary setpoint value is added to the main

setpoint value from the speed controller. The

current limit must be set low enough to ensure that

the sum of the two setpoint values does not

exceed + 10V. This input has a very low filter time

constant (2.2 ms), the voltage at terminal X2: 5

must therefore be very clean.

6.2 Analog Outputs

Setpoint value integrator

The output is protected against reverse

interference voltage by a lowpass filter and pull-up

diodes. This leads to a minimum influence of load

variation, which is however completely irrelevant if

the load is constant (e.g. with a connection to

setpoint value inputs X1: 3 or 4).

Actual current value

With a nominal device current, a voltage of + 10 V

is supplied.

Output resistance 220 Ohm.

Temvar GDE2

July 08, 2009

21

6.3 Control Inputs and Signal Outputs

Inputs and outputs are separated from the electronics potential by optocouplers. They have

their own 24 V system power supply, designated with +L and -L.

The reference potential -L, terminal X1: 14, is to be connected to the reference potential of the

system controls. It is recommended that these inputs and outputs also be connected with

shielded wire.

Danger

When controlling the binary control and selection inputs from an external voltage

source which is not connected to the device ground (X1: 14 not connected to X1: 5 or 6)

the potential difference between device ground and ground of the external voltage must

not exceed 50 V (danger for optocouplers).

Input - closed-loop controller enable

Closed-loop controller enable means: connect

voltage +L to terminal X1: 11, or apply an external

voltage of +15 to +30 V, with its reference point

connected to -L (terminal X1: 14). For a voltage

which is smaller than +10 V, the closed-loop

controller is safely inhibited. With an inhibited

closed-loop controller, the firing pulses are also

suppressed, the drive does not drift at a standstill,

but neither can it create torque. When the drive is

switched off, the closed-loop controller must be

inhibited at least 200 ms before the main power is

switched off.

Temvar GDE2

July 08, 2009

22

Signal output "stand-by"

Terminal X1: 12 is supplied with voltage +L if the

electronics power supply is present. As soon as the

closed-loop controller is enabled, the main power

is also checked at terminals X3: 1 + 2 + 3. For

devices with fans, this stand-by signal also

incorporates a temperature switch.

The stand-by signal is cancelled at a heat sink

temperature of more than 85° C. The output is

short-circuit proof.

Signal output n > o

Terminal X1: 13 is supplied by +L if the drive

turns faster than the threshold value set on the

potentiometer n > 0.

The signal is independent of the rotational

direction. The output is short-circuit proof.

Signal output "I max."

Terminal X2: 8 is supplied by +L if the drive is

operated at the maximum set current limit for

more than 15 seconds. The output is short-circuit

proof.

Signal output " field current present"

This output is only relevant if the field rectifier in

the device - terminals X3: 4 + 5/ X4: 4 + 5 - is

used.

Terminal X2: 9 is supplied by +L, if the field

current is greater than 0.2 A. For devices above

380 A, for a field current greater than 0.4 A. This

signal is not displayed by a light-emitting diode.

The output is short-circuit proof.

Temvar GDE2

July 08, 2009

23

7 FUNCTIONAL DESCRIPTION

7.1 Setpoint Value Integrator

With a positive setpoint step-change at terminal X1: 1, the comparator (1) inverts into the

negative. The capacitor C is charged via resistor R+. The rate of charge depends on the

position of the potentiometer +B. When the output voltage on integrator (2) reaches the level of

the setpoint value at X1: 1, the comparator (1) returns to 0 and the capacitor C is no longer

charged.

With a negative setpoint value, the same applies via potentiometer -B and charging resistor R-.

If a positive setpoint value is reduced abruptly, the comparator (1) tips into the positive range,

capacitor C is discharged via potentiometer -B and resistor R-.

Temvar GDE2

July 08, 2009

24

7.2 Speed Controller

The speed controller is a standard PI-controller. Proportional gain is determined by R9 and

potentiometer VP and the integral-action time by C2. Right-hand stop of the potentiometer VP

is equal to the largest gain. The closed-loop controller output can be measured at test point

"Xn". The PI-controller can be expanded to a PID-controller by means of C3 and R10. The

current speed, normalized at the level of the setpoint value, can be measured at test point "n“.

7.3 Current Limit

Comparators (1) and (2) are set to a bias voltage of between 0 and 10 V via potentiometers +l and l. Comparator (1) is tipped to positive, comparator (2) to negative. If the speed controller output

(point 3) exceeds the bias voltage set, the corresponding comparator is tipped up. Via the

corresponding diode and the relatively low resistor 4K7 on the merge point of the speed controller

(point 1) the closed-loop controller output is lowered again. At the same time, comparator (3) will tip

into the positive and, with a FET-switch, will short circuit capacitor C2 via the speed controller. This

circuit is designed for 4Q operation. As the GDE device series only allows 1Q operation, the

potentiometer -I is turned to the left-hand stop. The bias voltage of maximum 10 V can also be

connected externally to terminals X2: 6 (input resistor 4K7).

Temvar GDE2

July 08, 2009

25

7.4 Current Controller

T

he current controller is a standard PI-controller. Proportional gain is determined by R8, the

integral-action time by C1. When using auxiliary input X2: 5, it must be taken into consideration

that the two setpoint values add up. Together they must not exceed + 10 V. The current

controller output can be measured at test point -XI. Terminal X2: 4 is supplied with the actual

current value + 10 V at nominal device current. The voltage is equalized with a time constant of

200 ms.

The actual current value is created on the open-loop controller PCB. By increasing the

effective load resistance R161/R161.1 and relocating jumpers J3/J4, all values can be kept

below the nominal device current level. Decreasing the effective load resistance is not

permitted.

Danger

If auxiliary input X2: 5 is used, the device and the motor can be overloaded or the drive

run up to excessive speeds. The current limit is not effective at input X2: 5.

7.5 Firing Pulse Formation

The output voltage of the current controller is added to the actual armature voltage. This

relieves the current controller and causes the controller to act more dynamically. The

integrated firing pulse module is controlled with the sum of these two voltages. The firing

pulses last for approx. 1 ms and are chopped at a 100 µs rate.

The rectifier limit (GG) is fixed, the inverter limit (WG) is set ex works and must not be

changed. For 60 Hz operation, bridge JP2 must be fitted on the open-loop controller PCB.

Temvar GDE2

July 08, 2009

26

7.6 Thyristor Outputs

The selected current direction +I activates

the corresponding pulse transformers and

clears the AND-gates for the firing pulses.

The thyristors require a holding current of

approx. 100 mA. If this current is not

achieved during the firing phase, the

thyristor blocks again after the firing pulse

has been removed.

7.7 Electronics Supply

To supply the electronics, a system power

source of 230 V/50-60 Hz is required. ± 10%

tolerance is permissible. Slow blowing

subminiature fuses are used. The ± 15 V

and L+ /L- are stabilized with linear

regulators.

The ± 24 V are only filtered.

7.8 Field Supply

The rectifier can be connected to a

maximum 400 V and carry a maximum load

of 5 A (above GDE2/380 max. 15 A). At a

current of greater than 0.2 A (for devices

above 380 A greater than 0.4 A) potential +L

is present at signal output X2: 9. The output

is short-circuit proof.

Temvar GDE2

July 08, 2009

27

7.9 System Power Supply Monitoring

In the case of an anti-clockwise rotating

field or phase failure, a fault alarm flag is

set, the closed-loop controller and firing

pulse formation are blocked. The "standby" signal is cancelled and the red warning

lamp "mains“ lights up. The signal flag is

reset by switching off the electronics

supply for at least 2 seconds or by

actuating reset button S2 on the closedloop controller PCB.

7.10 Tacho Monitoring

The tacho and the closed armature circuit

are monitored by the armature voltage

being compared with the tacho voltage,

normalized at 10 V. With a constant field

excitation the tacho voltage is directly

proportional to the armature voltage. At

the initial set-up, the 10 V tacho voltage

has not yet been normalized to 100%

armature voltage. Therefore, the device

should be switched on for the first time

with a speed setpoint value of approx. 1 V.

The speed adjustment with 10 V setpoint

value can only be made when the tacho

monitor is switched off. This is achieved by

closing the Dip-Fix switch S1 on the

closed-loop controller PCB. If the

normalized tacho voltage is approx. 30%

below the armature voltage (100% UA =

10 V) or the tacho is incorrectly poled, the

fault alarm flag is set (see Section 7.9).

7.11 Fan Monitoring

With the exception of the 15 + 30 A

devices, all devices have a fan for cooling

purposes. The heat sink temperature is

monitored on these devices by an 85°

bimetallic thermal switch. The actuated

(opened) switch has the same effect on

the device as the system power supply

monitoring (Section 7.9).

Temvar GDE2

July 08, 2009

28

8 INSTALLATION

8.1 Dangers

When this device is operated, certain parts of it are automatically under dangerous

voltages, which can lead to serious bodily injury or death. The following precautionary

measures must be followed to minimize the risk of injury or death.

1. Only qualified personnel who are familiar with the device and the information

supplied are permitted to assemble and operate the device, to seek and rectify faults

and carry out repairs.

2. The device must be fitted in accordance with safety regulations (e.g. DIN, VDE) and

all other relevant national or local regulations. The device must be properly

grounded, with adequate wire sizing, and corresponding short-circuit protection, to

ensure that a high level of operating safety is maintained.

3. During normal operation, all covers and doors must remain closed.

4. Before carrying out checks and maintenance work, it must be ensured that the AC

power supply is switched off and locked.

Both the power controller device and the motor are live before the AC power supply

is switched off. Voltage is present even if the contactor of the power controller is

open.

5. If measurements have to be made when the power supply is switched on, contact

with the electrical connection points must be avoided at all times. Remove all

jewellery from wrists and fingers. Ensure that the testing equipment is in full and

safe working order.

6. When working on the live machine, stand on insulated flooring, i.e. make sure that

there is no ground connection.

7. Follow the instructions given in this manual closely and observe all danger, warning

and caution advisories.

8. This list is not a comprehensive list of all measures required for the safe operation of

the machine. If you require further information or if particular problems arise, please

contact the manufacturer.

Temvar GDE2

July 08, 2009

29

8.2 Recommended Procedure

Dangers

Up until installation point 4 the device must remain isolated from the power supply. The

drive will start once the closed-loop controller is enabled!

1. Check that all main power ground wires and electronic terminals are connected

correctly. Check fuses in accordance with the device table in 3.1.

2. Use an ohmmeter to check the armature connection (1 - 10 OHM),

field connection (100 - 500 OHM) and tacho connection (approx. 80 OHM).

3. Set potentiometer +I to approx. 30%, all other potentiometers to the left-hand stop.

Release the connection for closed-loop controller enable terminal X1: 11.

Disconnect setpoint value (terminal X1: 1 or 3 or 4) and manual potentiometer to

terminal X2: 1 + 2.

Connect collector ring to X1: 3. Voltage selection terminal X2: 1 to 10 V.

Determine the maximum tacho voltage expected and check that the correct actual

value input is being used. Connect volt meter to this terminal.

4. Switch on the device and measure the main power at terminal X3: 1 + 2 + 3, field

supply X3: 4 + 5, electronics supply X3: 6 + 7, field voltage X4: 4 + 5. Set the setpoint

value to approx. + 1 V using the manual potentiometer.

5. Briefly tap the free wire "closed-loop controller enable" against terminal X1: 11. The

volt meter on the actual value input must deflect negatively. In this case the wire can

be fixed in position and the rotational direction of the machine checked. If the rotational

direction is incorrect reverse the poles of the field and tacho connections.

6. Set the current limit to the nominal motor current. Set the setpoint value potentiometer

to +10 V and deactivate tacho monitoring function (S1). Adjust the speed using spindle

potentiometer "n". The armature voltage must not exceed the value on the type plate,

if necessary reduce the field current. After adjusting the speed, reactivate the tacho

monitoring function.

Danger

Too large an overshoot can lead to the permissible armature voltage being exceeded.

Abrupt changes to the setpoint value in the field weakening range can lead to the

armature current overshooting.

7. Pinch off the manual potentiometer, apply device setpoint value and test the

emergency off function with the device setpoint value.

Temvar GDE2

July 08, 2009

30

9 OPTIMISATION

For most applications, the standard assignment for the current and speed controllers is fully

sufficient. It is advisable, however, to check the transient response of the motor in the event of

abrupt changes in the setpoint value and to optimize this using potentiometer VP . If a critical

drive requires more precise optimization, the following procedure is recommended after the

drive has been placed in operation.

The speed controller should be optimized with a machine connected.

A) Optimizing the current controller

1. Connect the potentiometer for the setpoint value and switch for closed-loop

controller enable according to the following diagram

2. Connect the speed controller according to diagram. VP-potentiometer to lefthand stop.

3. Connect RC decade according to diagram. Begin with the standard

assignment. Connect oscilloscope to test point "I".

4. Pinch off the field supply. Bridge the field current monitoring function.

5. Switch on the drive, enable the closed-loop controller. Use the potentiometer

at terminal 3 to set the even, ripple-free current. Use switch SW to set setpoint

value change. Optimize current controller first with R8, then with C1 so that the

oscillogram appears similar to the one shown in the diagram.

B) Optimizing the speed controller

1. Connect potentiometer for speed setpoint value, switch for closed-loop

controller enable and RC decade according to the following diagram.

Temvar GDE2

July 08, 2009

31

2. Connect the field supply. Set the RC decade to standard assignment

V

P

-potentiometer to center point.

3. Switch on the drive, enable the closed-loop controller.

Set approx. 30% of the maximum speed and enter the setpoint value change

using switch SW. Optimize speed controller first with R9, then with C2 so that

the oscillogram appears similar to the one shown in the diagram. The transient

response of the speed controller can often be improved using a D-element

R10/C3, particularly when accelerating or positioning large masses.

Dimensioning guidelines are in the range of 22 K and 1µF.

10 FAULT OCCURRENCE

Dangers

During operation of electrical devices, certain parts are subject to dangerous voltage.

The signal relay of the customer can be subject to dangerous voltage.

Incorrect use of these devices can therefore lead to death or serious injury as well as

serious material damage.

For this reason, observe all the instructions in this section and on the device itself

when carrying out maintenance work.

Maintenance on the device may only be carried out by authorized personnel, who are

fully versed in the safety instructions, assembly, operating and servicing instructions

contained in this manual.

Before carrying out checks and maintenance work, it must be ensured that the AC

power supply is switched off and locked and that the device is grounded.

Both the power controller device and the motor are live before the AC power supply is

switched off. Voltage is present even if the contactor of the power controller is open.

Only spare parts allowed by the manufacturer may be used.

A) Main power fuse defective.

Check the thyristors : Take measurements at terminals X3: 1 + 2, X3: 2 + 3 and X3: 1

+ 3 using an ohmmeter.

Resistance must be above 40 K-Ohm.

Measure from X3: 1 to X4.1, then X3: 2 to X4.1 and X3: 3 to X4.1, resistance must be

more than 100 K-Ohm.

Measure from X3: 1 to X4.2, then X3: 2 to X4.2 and X3: 3 to X4.2, resistance must be

more than 100 K-Ohm.

Temvar GDE2

July 08, 2009

32

B) Drive is not turning. Assuming:

Wiring and fuses are okay.

Switch on drive - positive setpoint value.

Light-emitting diodes:

⊗

Stand-by On Off On On On Off Off

⊗

Cl.-loop controller

enable

On Off Off On On Off Off

⊗

n > 0 Off Off Off Off Off Off Off

⊗

Current direction + On Off Off On On On On

⊗

Current direction - Off Off Off Off Off Off Off

⊗

Current limit Off Off Off Off On Off Off

⊗

Tacho Off Off Off Off Off Off On

⊗

Power system Off Off Off Off On On Off

Case

1

2

3

4

5

6

7

Case 1: Setpoint value at terminal X1: 3 or 4 against reference point X1: 5 or 6

probably missing.

Case 2: Measure electronics supply ± 15 V or ± 10 V at terminals X2: 1 + 3. If

missing, check supply at X3: 6 + 7 and miniature fuses F1, F2, F3 on the

supply module.

Case 3: Closed-loop controller enable missing. Measure + 24V at terminal X1: 11

against reference point X1: 14. If not available, check the miniature fuse F4

on the supply module.

Case 4: Potentiometer current limit +I is turned to zero.

Case 5: Potentiometer current limit +I is not turned up enough. Measure output

voltage at X4: 1 + 2. If present, armature line is interrupted.

Case 6: Phase failure, rotational field incorrect, measure main connection voltage at

X3: 1 + 2. Check the thermal contact for GEV2/40.

Case 7: Normalized tacho actual value 30% smaller than normalized armature

voltage, tacho input line interrupted, drive mechanically blocked.

Loading...

Loading...