Page 1

TILLER/MULCHER Electric Model 710

MULTI INTERNATIONAL GOLD MEDALS &

AWARD WINNING LAWN EDGERS & TILLERS

! NOTE

Read operators manual

Do not expose motor

to moisture

Wear eye protection

Keep bystanders away

15m (50 feet)

Blade cover label

SAFETY WARNING LABELS

ATOM Tillers have Australian and foreign Patents, Patent Pending, and Design Registrations.

FIG 2

Disconnect the

mains plug if the

cord is damaged or

entangled

ELECTRIC

PRODUCTS

ONL Y

ACN 000 583 924

160910

•

Safety Precautions

•

Assembling

•

Service

•

Operating and Tilling/Mulching Instructions

Important Manual – Do Not Throw Away

Manual always to be available for reference or

instructing new operators.

Introduction: Electric Tiller

This Atom Electric Tiller is designed to the highest standards

to ensure you many hours of uninterrupted service. Pay

special attention to the safety precautions. Only persons

who understand this Manual are to operate the Tiller.

To receive maximum performance and satisfaction from

your Tiller, it is important that you read and understand the

maintenance and safety precautions before using the unit.

Contact your Atom dealer or the Atom distributor in your

area if you do not understand or cannot carry out any of the

operating instructions in this Manual.

Atom’s philosophy is to continually improve all of its products.

As a result, engineering changes and improvements are made

from time to time. Appearances may differ between models.

This manual covers information required to operate, maintain

and service this electric Tiller.

AS WITH ANY POWER TOOL IMPROPER USE CAN CAUSE

SERIOUS INJURY. Make sure this manual is read and carefully

understood before starting or operating this equipment.

The purpose of Safety

Warnings and Notes in

this Manual is to attract your attention to possible dangers and

deserve your careful attention and understanding. The Safety

Warnings in this Manual and on the Tiller do not, by themselves,

eliminate any danger. The instructions or warnings they give are

not substitutes for proper accident prevention measures.

Failure to obey a safety warning can

result in injury to yourself and others.

Advises you of information or instructions vital

to the operation or maintenance of the equipment.

! SAFETY WARNING

! WARNING

MADE IN AUSTRALIA

FIG 1

Contents

Safety Warning Labels ....................................... 1

Safety Precautions ........................................ 2 - 3

Assembling the Tiller ...........................................3

Parts and Controls ............................................. 4

Starting and Stopping Instructions ....................... 4

Tilling & Mulching Instructions ........................ 4 - 5

Switch Adjustment ............................................. 6

Lubrication of Gears .......................................... 6

Warranty ......................................................... 6

Tine Installation & Removal ................................. 7

Parts List and Parts Illustration .......................... 7-8

The information contained in this manual is also

available at www.atomindustries.com

PAGE

Operator /

Owner Manual

63902MA-12

1711

Page 2

FIG 4

Proper eye protection is a

must. The blade cover may not

protect the operator from all moving foreign objects, even

though the discharge is directed away from the operator, as

ricochets and bouncebacks may occur during tiller operations.

Never operate an Atom Tiller unless wearing goggles or

properly fitting safety glasses with adequate front and side

protection which comply with ANSI Z 87.1.

Safe use of an Atom Tiller involves:

1.The Operator.

2.The Atom Tiller.

3.The use of the Atom Tiller.

THE OPERATOR

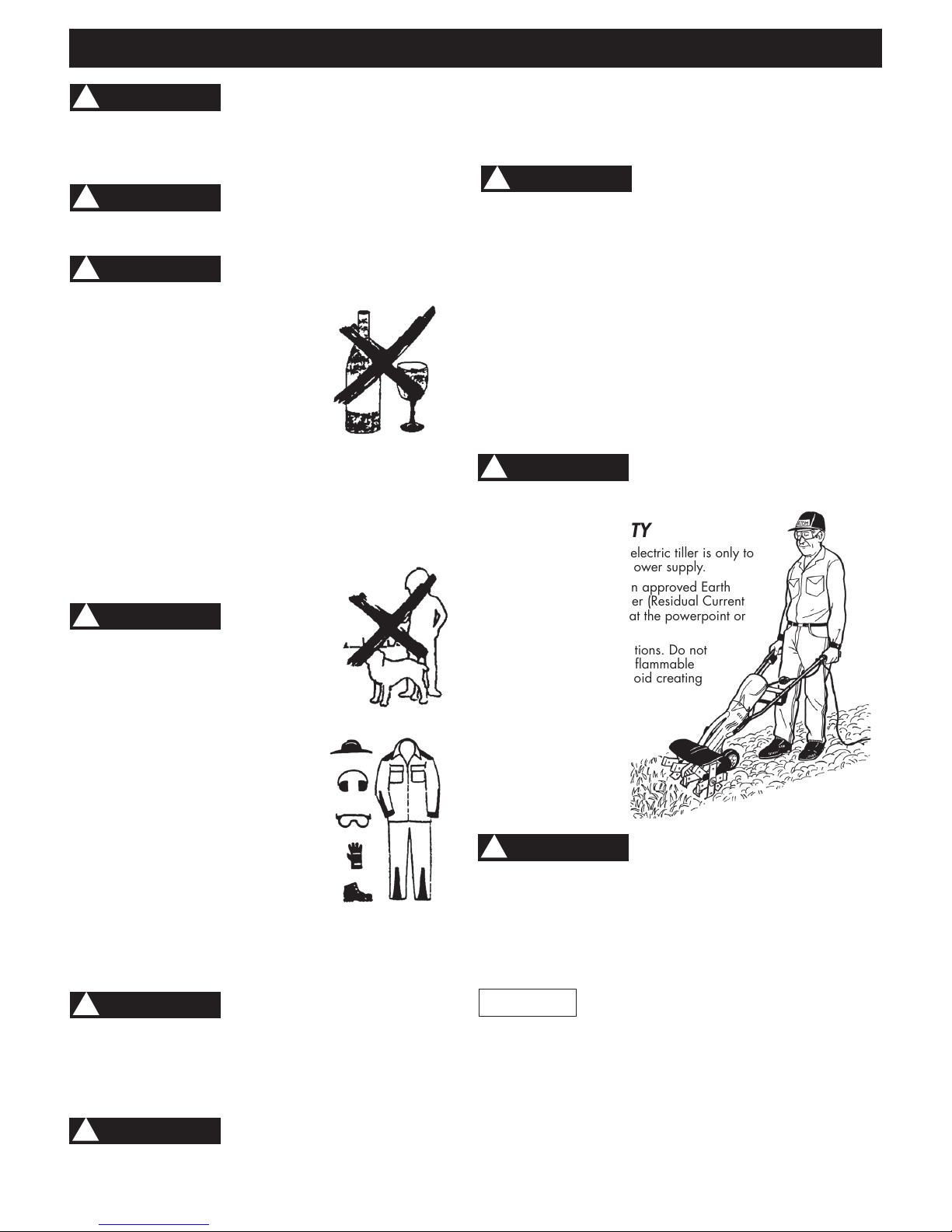

PHYSICAL CONDITION

Operator must be in good physical

condition and mental health, and not under the influence of

any substance (drugs, alcohol, etc.) which might impair vision,

dexterity or judgement (Fig 3).

Do not operate the Tiller when fatigued. Be alert – if you get tired

while operating the machine, take a break. Tiredness may result

in loss of control. Working with any power tool can be strenuous.

If you have any condition that might be aggravated

by strenuous work, check with your doctor

before operating the machine

FIG 3

PROPER CLOTHING

Clothing must be sturdy and snug-fitting,

but allow complete freedom of movement

(See Fig 5). Avoid loose-fitting jackets,

flared or cuffed pants, or anything that

could trip the operator. Wear overalls or

long pants to protect your legs. DO NOT

wear shorts. Use of gloves when working

with the Lawn Tiller is recommended.

Good footing is most important. Wear

sturdy shoes with nonslip soles. DO NOT

wear sandals, open footwear (flip-flops)

or operate with bare feet. In hot or sunny conditions, always

wear a hat and long sleeve shirt for protection against skin

cancers. Use of a good brand of sunscreen cream is also

recommended on exposed skin surfaces.

FIG 5

Replace immediately any worn or broken

debris deflector shield or blade cover.

Check from time to time that all screws are tight. Never operate

your machine if it is damaged, improperly adjusted or not

completely and securely assembled.

SAFE MAINTENENCE, REPAIR & STORING

Use only original Atom replacement parts for maintenance and

repair. Use of parts manufactured by others will void warranty

and/or may cause serious or fatal injury.

Always stop the motor, make sure

that the tines have stopped, before

adjusting tine height. Before doing any adjustment, maintenance

or repair work, or cleaning the unit or tines, disconnect extension

cord.

Follow the maintenance instructions in the appropriate section of

this manual. Any motor repairs should be carried out by a person

with suitable sevicing experience.

SAFE STARTING & WORKING CONDITIONS

Always inspect that the unit is in good working order before use.

When working with the Atom Tiller, always wrap your fingers

tightly around each handle grip. Keep your hands in this position

to have your machine under control at all times. NEVER attempt

to operate the Atom Tiller with one hand, as a loss of control may

result in serious or fatal injury. Make sure the handle grips are

in good condition and free of moisture, oil or grease. Use both

hands, one on each handle, to operate and control the tiller.

Do not overreach. Keep proper footing and balance at all times.

PAGE 2

SAFETY PRECAUTIONS

As with any power tool, the use of the

tiller with rotating blades may be

dangerous. It is important that you read, fully understand, and

observe the following safety precautions and warnings. Re-read

this operator’s manual and the safety instructions periodically.

Read and understand all labels attached to tiller.

! WARNING

Do not lend, rent or sell this machine

without the operator’s manual. Be sure

that anyone using this unit understands the information contained

in this manual before use.

! WARNING

! WARNING

This Tiller must

not be operated

by minors. Bystanders, especially children

and animals should not be allowed in the

area where a machine is in use and be at

least 15 metres (50 feet) away (Fig 4). If

approached switch off motor immediately.

When not in use store the tiller out

of reach of children.

! WARNING

! WARNING

! WARNING

As with any power tool, some special

safety precautions must be observed to

reduce the risk of personal injury. Careless or improper use may

cause serious or even fatal injury.

! WARNING

Tiller tines can cut extension cord. Keep

the extension cord away from

the cutting tines (Fig 6). A cut extension cord is

dangerous and can be fatal to you or others.

! WARNING

ELECTRICAL SAFETY

1. This double insulated electric tiller is only to

be used on 240 volt power supply.

2. Where possible use an approved Earth

Leakage Circuit Breaker (Residual Current

Device) safety switch at the powerpoint or

switchboard.

3. Avoid dangerous situations. Do not

use in the presence of flammable

liquids or gasses to avoid creating

a fire or explosion.

4. Do not attempt to use

unit if there is any

damage. Do

not use until

damage is

repaired by

an authorised

service centre.

Do not use in rain, in damp or wet

locations, or around swimming pools,

hot tubs etc. Do not expose to water, rain, or snow to avoid the

possibility of electrical shock.

5. Damaged supply cord (on Tiller motor). This must be replaced by

an authorised service agent or similarly qualified person in order

to avoid a hazzard.

6. Never carry the unit by the extension cord or yank the extension

cord to disconnect the unit.

! WARNING

! NOTE

Use extension cords specifically marked as

suitable for outdoor appliances. These have

minimum 1mm diameter copper wire. In Australia/NZ, these are

now yellow in colour. Do not use white coloured or light gauge

undersized extension cords as these will cause a drop in line

voltage resulting in loss of power and overheating. If in doubt,

use the next heavier guage.

Inspect the extension cord before each use and

do not use if damaged in any way.

FIG 6

Page 3

PAGE 3

SAFETY PRECAUTIONS

(

CONTINUED

)

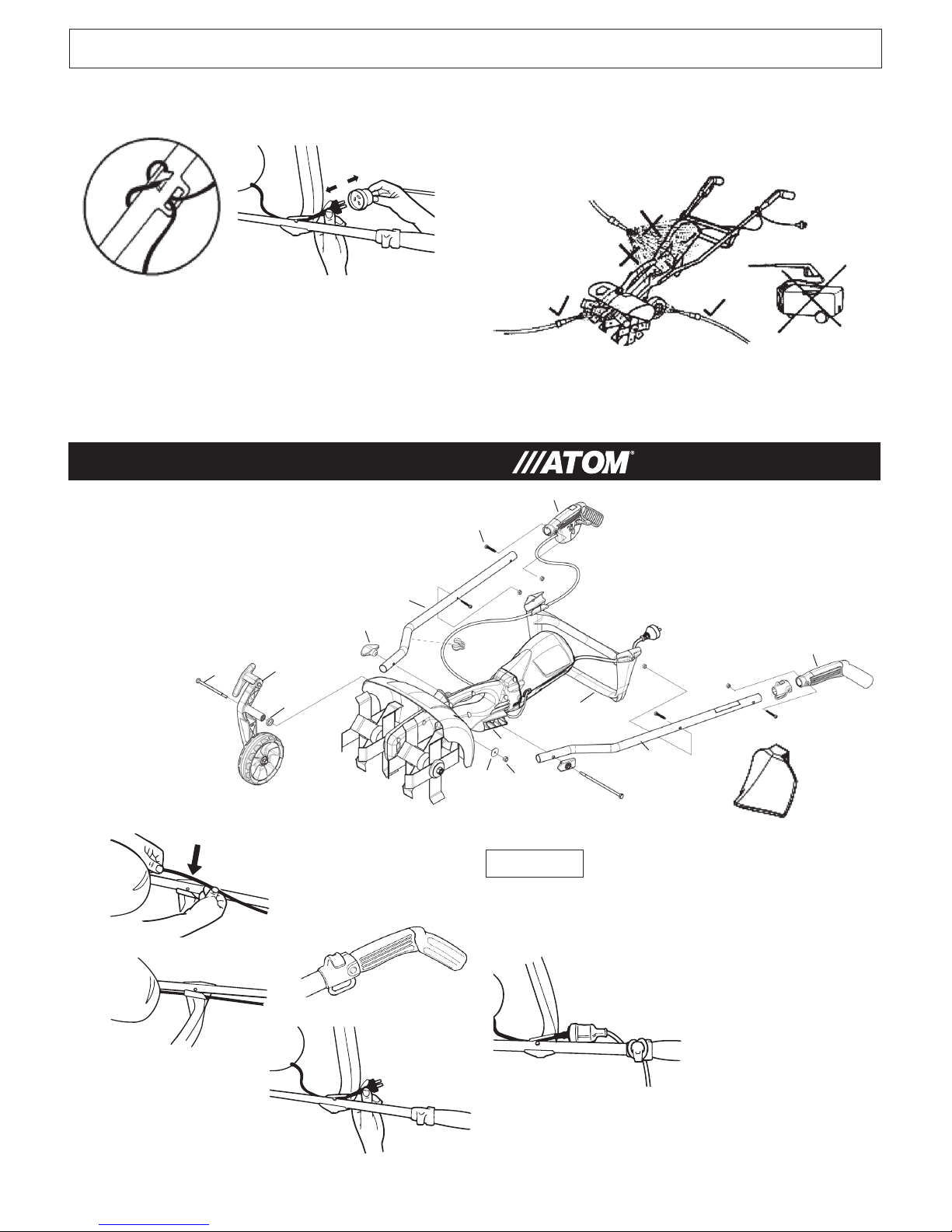

ASSEMBLING THE TILLER

Keep the extension cord clear of operator and obstacles at all times.

Do not expose the cords to heat, oil, water, or sharp edges.

Do not edge next to cord, or walk on or drive over cord.

Do not store unit outside but only indoors in secure dry place.

To reduce the possibility of the extension cord disconnecting

from the unit during operation, loop the extension cord to the

extension cord anchor as shown (Fig 8)

FIG 8

CLEANING UNIT AFTER USE

When cleaning, disconnect electrical cable (Fig 9) and do not use

water hose. Scrape dirt away. If motor accidentally wet by water,

allow to dry in the sun, inspect and ensure it is dry before use.

DO NOT USE hose water to clean machine as it could force

water into casing and motor.

Always disconnect motor power cable from extension cord

when removing tine cover, cleaning tines, adjusting wheel

depth, cleaning unit, etc.

Do not use the tiller if the switch does not turn the tiller on

and off properly. Repairs to the switch must be made by

qualified electrical service personnel.

Throttle cable #10 from motor must loop

under edger body and clip into place on

handle clip #17 then over top of cross brace #7 and clip into

place on RH top side of brace.

Attach extension cord to plug of motor and fit extension

cord to anchor (Fig 11E).

! NOTE

FIG 11A

FIG 11B

FIG 11C

FIG 11E

FIG 11D

FIG 9

TOP

VIEW

FIG 10

Slide O Ring #14 over wheel

arm #5 axle. Slide into Tiller

body. Slide Bolt #10 through

wheel arm, fitting washer #16

and screwing nylon nut #17

up tightly.

Fit cross brace #7 with base down as illustrated, to handle tubes

#3 & 5. Use 2 screws #8 and lock nuts #9 provided in

packet. Use straight blade screwdriver or torx 25

screwdriver. Screw on firmly.

Insert 175mm (6.5”) bolt #1 through the head

retainer #2 (note arrow points forward) then

through LH handle tube #3 then through edger

body #4 and RH handle tube #5.Handle tubes

are identical. Fit so label sits upwards.

Screw large wing nut #6 on

protruding bolt and

tighten.

Insert Trigger

Handle #11 onto

RH handle tube.

Use one screw #8

and one nut #9 to

fix handle to tube.

Clip throttle cable #10

into place, Fig 11A and

11B also through clip for handle #17.

FIG 11

1

8

4

12

17

5

7

9

9

8

11

2

10

9

13

Clip cord anchor #12 onto LH handle #13

and fit together onto LH handle tube #3

(Fig 11C). Fit screw #8 with nut #9. Clip

power plug cord of motor into place on LH

topside of cross brace #7 (Fig 11D).

16

15

14

8

6

17

16

3

FURROW

PLOW

ATTACHES TO

WHEEL ARM

Page 4

PARTS & CONTROLS

1+2.The handles of the Tiller are held by both hands.

3. The throttle interlock which releases the throttle trigger which switches on

motor for automatic safety clutch to engage and thus rotate tines.

4. Handle nut for holding handle tubes onto housing.

5. Depth adjustment for adjusting wheel to regulate tine depth.

6. Tine cover reduces the risk of flying debris

and direct contact with the feet or hands.

7. Handle to lift Tiller.

8. Tines rotate when motor is switched on.

9. Tine holding nuts RH (shown) & LH thread on each

end of tine shaft.

10. Wheel for moving and guiding tiller.

11. Cross Brace, attaches downward on

handle.

12. Left and right Handle Tubes.

13. Warning label.

14. Lift knob and twist to remove cover.

15. Cable clamp.

16. Electric motor assembly.

STARTING & STOPPING INSTRUCTIONS

PAGE 4

FIG 13

Switch motor on (Fig 13)

by pushing down safety

interlock with thumb

and pulling on

trigger. To

stop, release

trigger.

1

2

3

15

12

FIG 12

15

4

7

5

14

13

6

11

10

9

8

16

COMBINATION CULTIVATING, TILLING, ROTARY HOEING

1. The Atom Tiller is very easy and simple to use. It only takes a

few minutes to become an efficient user.

2. Thoroughly inspect the area where the tiller is to be used and

remove all long grass, stones, sticks, wires and other foreign

objects.

3. Adjust tine depth (Fig. 15A or 15B). Try the third hole closest

to operator.

4. Start motor and, with both arms fully extended downwards,

(Fig. 15C), hold both handle grips firmly.

5. As tilling action begins, the tines dig and move the tiller forward.

6. NOTE: to reduce “Forward Pull” of tiller, adjust wheel arm for

shallower depth.

7. Continue at a moderate pace until you are familiar with the

controls and handling of the Atom Tiller.

NOTE: after allowing the tiller to cultivate 500mm you can pull

it back towards you and then allow the unit to move forward

again. You can repeat this procedure over the area you are

cultivating. Always have a firm footing.

8. Mulching. The tiller is ideal to mix cut lawn clippings, leaves

etc into your garden bed. This method accelerates mulching/

composting process. See page 5.

9. To go deeper adjust wheel arm adjustment forward or lift

handles. To go shallower adjust wheel arm adjustment

rearwards or push handles down.

FIG 14B

Operate unit carefully. Be very careful

walking backwards as you may trip,

fall and injure yourself. Always have a firm footing.

! WARNING

FIG 14C

FIG 14A

Very hard ground, clay or rocky conditions: The Atom

rotary tiller is NOT DESIGNED for very hard ground, hard or rocky

conditions. These kinds of soil will not make a good garden bed.

NOT recommended for ground covered with palm leaves, vines,

wire or long grass as it will clog the tines and will not till ground.

8

8

8

8

8

FURROW

PLOW

ATTACHES TO

WHEEL ARM

! NOTE

The Atom Tiller is not

designed for large

areas where heavier duty equipment

should be used.

Page 5

PAGE 5

COMBINATION CULTIVATING, TILLING, ROTARY HOEING

(

CONTINUED

)

Operate unit carefully. Be very careful

walking backwards as you may trip,

fall and injure yourself. Always have a firm footing.

! WARNING

If tines jam or stop (tines no longer rotates) pull unit back as it

could release blockage. Switch motor off. Disconnect cable.

Place machine upright with handles on ground (Fig. 15) Remove

obstruction.

Failure to disconnect lead of motor to

clean tines could lead to very serious

injury of hands if unit accidently started. Always wear gloves to

clean.

! WARNING

FIG 15

Clutch: The Atom

Tiller is equiped with a

centrifugal clutch.

DO NOT run tiller

at low speeds

(or, if jammed) as

clutch shoes will

prematurely wear

and cause damage,

Fig. 16.

! NOTE

Keep inside of tiller guard clean, especially in

wet conditions. A clogged guard can slow

down or stop tine rotation and may cause damage to automatic

safety clutch.

REMOVE ANY TANGLED GRASS OR VINES AROUND TINES.

Clean tines of grass, rocks and sticks, always use gloves as

the tines are self sharpening and are very sharp. You could

cut yourself. Remove tine cover as follows. Lift knob Fig. 17A

twist and slide cover forward Fig. 17B. If jammed cover can

be tapped off with a soft hammer.

FIG 16

FIG 17B

FIG 17A

Levelling uneven ground: The tiller if used carefully can

level uneven ground for a good garden bed. Use your arms to

work the tiller forwards and backwards.

After levelling pre-work all surfaces to prepare the new flat bed.

Use a rake to smooth out and tidy up.

The tiller can be transported by pushing it on its wheel.

Very hard ground, clay or rocky conditions: The Atom

rotary tiller is NOT DESIGNED for very hard ground, hard

or rocky conditions. These kinds of soil will not make a good

garden bed.

TO AVOID PERSONAL INJURY,

NEVER CARRY THE TILLER

WHILE IT IS RUNNING.

The Tiller can be easily moved as shown below.

! WARNING

FIG 18 FIG 19

Stop the motor prior to lifting or carrying Fig. 19

AFTER FINISHING WORK

Storing: Keep the unit in a dry place until you need it again.

MULCHING

Using an Atom Tiller is a highly efficient method of creating a

compost heap in the corner of your garden. This nutrient rich

mulch and compost can be used to improve existing beds and

stimulate rapid earth worm activity.

It only takes a few minutes to produce compost. Make a pile of

leaves, lawn cuttings and other small leafy or vegetable matter,

about 500mm high. Place some soil on top and spray with

water. Use your Tiller to break it up into small pieces. Make the

pile as big as you like.

Repeat a week later. Leave for another week and it is ready for

use. You can add to the compost any time you wish.

Adding fertilizer, animal manure and thoroughly mixing will

make a very strong and nutrient rich mulch.

BEFORE AFTER

Page 6

PAGE 6

WORKSHOP INSTRUCTIONS

NOTE: This information is for persons with suitable servicing experience should this unit ever require workshop repair.

TO REMOVE & REPLACE CLUTCH DRUM

Remove motor. Hold tines down and spin off clutch nut

anti-clockwise with impact driver. Replace parts as required.

Reverse procedure to re-install.

TO REMOVE CLUTCH

1. Remove motor pod from tiller by removing the 3 screws

(Fig. 19). Place sideways on a bench and unscrew 2 cover

screws and remove cover #63373 (Fig. 20B).

2. Insert 5mm rod through body lug and turn clutch until rod

passes through shaft hole (Fig. 20B) to lock shaft.

3. Use screwdriver and tap end of clutch hub (left hand

looking at clutch) and spin clutch off (Fig. 21).

4. To replace clutch assembly, reverse procedure above.

TO REMOVE WHEEL ARM

Undo 1/4 hex bolt and pull wheel arm thru casing. Fig. 22.

FIG 20B

FIG 21

LUBRICATION OF GEARS

There is sufficient lubricant to last the lifetime of

the Tiller.

FIG 22

FIG 19

TO REMOVE MOTOR POD

1. Use a screwdriver or preferably a

No. 25 torx screwdriver, remove 3

screws located as shown Fig. 19.

2. Pull motor out from edger casing. It is

NOT necessary to remove handles.

Original sales docket must be shown as proof and date of purchase.

Warranty exclusions:Not using genuineAtom replacement parts,

eg Tines etc,not following operator manual instructions,accidental

damage,not following service instructions,normal wear and

tear,abuse and rough handling.

Home Owner Warranty: 12 months for parts and labour from

date of purchase.

Commercial Warranty: 3 months for parts and labour from date

of purchase.

WARRANTY FOR ATOM TILLERS

TO REPAIR THROTTLE TRIGGER ASSEMBLY

1. Remove 2 screws and remove cover and all parts. Re-assemble

as follows.

2. Fit throttle inter-lock compression spring (Fig 35).

3. Fit trigger compression spring then trigger. Front of Trigger

spring fits over retainer post (Fig 35 and 36). Fit throttle cable

(note position) (Fig 37).

4. Hold trigger in place with finger until throttle cover is fitted

(Fig 38). Ensure throttle cover rear tabs (arrowed Fig 38)

engages underside of handle wall. It is then ready for screwing

tight (with 2 screws).

IF SWITCH DOES

NOT WORK

Fig.37 shows normal position

throttle cable. If inner cable

stretches in use it may be

necessary to move outer

cable forward by loosening 2

cover screws 2-3mm and then

retighten so switch can

be activated.

FIG 36

NOTE: CORRECT POSITION

OF THROTTLE CABLE.

FIG 35

Spring retainer post

FIG 38

FIG 37

Page 7

PAGE 7

639021L 1711

MODEL 710 ELECTRIC TILLER PARTS LIST

ATOM INDUSTRIES

9 Fred St. Lilyfield 2040 Sydney Australia

Tel: +61(0)2 9810 0194 Fax: +61(0)2 9810 6691

Email: sales@atomindustries.com.au

www.atomindustries.com

ATOM INDUSTRIES (NZ) Limited

FREECALL 0800 174 753 Fax: 0800 603 403

Email: sales@atomindustries.com.au

www.atomindustries.com

KEY# PART # DESCRIPTION

1 40650 SCREW M5 X 36MM

2 40651 SCREW M6 X 16

3 40652 NUT NYLOC 5MM

4 42111 WHEEL SEAL 27.2 X 12.6

5 43172 NUT NYLOC 3/8” UNC

6 43173 NUT RH M12 X 1.75MM

7 43198 TRIGGER COMP SPRING

8 43199 SPRING SMALL

9 43218 WASHER FLAT 3/8”

10 43227 GREASE AND DISPENSER

11 43452 HT ADJ ARM COMP SPRING

12 43790 SCREW 5.5MM FOR PLASTIC

13 43868 BEARING 6003-2RS 4MM SHOULDER

14 44006 NUT 1/4 UNC

15 44060 UNIVERSAL HANDLE TUBE

16 44302 HEIGHT ADJ ARM PIN

17 44318 CLUTCH DRUM CUP 54MM

18 45112 NUT M12 X 1.75 L H

19 63277 CLUTCH WASHER

20 62795 WASHER 30 X 1.6 X 1/4 HOLE

21 62843 HEX BOLT 3.5 X 1/4 BSW

22 62844 HEX BOLT 3 X 3/8” BSW

23

62851WP

TINE SPACER LARGE 45.5MM

24

62852WP

TINE SPACER SMALL 10MM

25 62891 SHAFT TINE 250MM

26 62892 SHAFT TINE 350MM

27 62903 WHEEL SPACER 41.5MM

28 62912 FLANGE HUB

29 62919 NUT NYLOC 1/4” UNC

30 62921 TINE CUP

31 62948 TILLER TINE

32 62982 BEARING WASHER 32 X 18 X 1.6

33 62983 HARDENED WASHER 54 X 12 X 2

34 63002 CABLE THROTTLE

35 63471BP RH HANDLE DOMESTIC

36 63472BP LH HANDLE DOMESTIC

37

63020WE

CROSS BRACE

38 63021BP RH HANDLE THROTTLE COVER

39

63022WN

THROTTLE TRIGGER

40

63023WN

THROTTLE TRIGGER INTERLOCK

41

63032

NUT FLANGE 3/8” UNC

42 63049

HEX BOLT 6.5 X 1/4 BSW

43

63902MA

MANUAL ELECTRIC TILLERS

44 63065 WARNING LABEL TILLER GUARD

45

63187BN

CAPTIVE PLATE 1/4” HEX

46

63488A

HANDLE KNOB & NUT

47

63217BN

CLIP FOR HANDLE CABLE & WIRE

KEY# PART # DESCRIPTION

KEY# PART # DESCRIPTION

48

63261

SPACER SHAFT 10MM

49 63269 ROLL PIN 6 X 30

50 63440 ROLL PIN 5 X 18

51 63224 O’RING 20 X 2mm

52

63016WE

ELECTRIC CORD ANCHOR

53

63368 GEAR CROWN 10/1

54

55

56

63376WP

WHEEL ARM TILLER

57

63377WP

HEIGHT ADJ HANDLE TILLER

58

63378WP

TILLER COVER KNOB

59

63380WE

COVER TINE 250MM

60

63381WE

COVER TINE 350MM

61

63384 GEAR SEAL TILLER

62

63780NN

GEAR HELICAL 48T

63

63781NN

GEAR HELICAL 12T

64 63387 SHAFT DRIVE TILLER 275.5MM

65

63018WE

HANDLE PLUG BLOCK

66

69

70 63439 SEAL U GEAR BOX TILLER

71

63445BP

WHEEL BLACK

72 63466 LABEL HANDLE

73 63474 BEARING 32 X 10 X 12 WITH SEAL

74

63533WE

HOOK EDGER CABLE BODY

75

62972

SEAL

76

63772NN

SPACER

77 63867 NUT 3/8” HOLDING

78 63868 WASHER 25 X 17 X 2

79 63275 ROLL PIN 5 X 30

LOOSE TINES

Check that all tines are in correct position and are tight

together, no gaps or foreign material between them. Tighten

nut clockwise on LH side of unit (Fig.30A) and anti clockwise

on RH side (Fig. 30B) as shown on top of tine cover.

! NOTE

Tines are self tightening. Excessive tension is not

required.

RIGHT HAND SIDE

(Standing behind tine cover)

FIG 30A

LEFT HAND SIDE

(Standing behind tine cover)

FIG 30B

NOTE: Tine

assembly sequence.

WARNING: When using air tools to remove nut,

do not overtighten when refitting.

TILLER BODY LH + RH WITH 3 SCREWS63968GP

GEAR PINION WITH SHAFT 69 AND PIN 50

63411A

ELECTRIC POD MOTOR

12 43790 SCREW 5.5 FOR PLASTIC

73 63474 BEARING 32 X 10 X 12 SEALED

34 63002 THROTTLE CABLE 925mm

102 62944 NUT M8 X 1.25

103

63008GN

POD SWITCH LEVER

104 63015 ELECTRIC MOTOR

105

106

107 63079 DRIVE BELT

108

63080GN

POD SMALL PULLEY 14T

109

63083GN

BEARING NEST

110 63228 POD PULLEY SHAFT

50 63440 ROLL PIN 5 X 18

112

63373GN

AIR INTAKE COVER POD

113 63390 SPRING CLUTCH ELECTRIC

114

63365GN

ASSY BIG PULLEY WITH FLANGE

BODY UPPER/LOWER POD SET

63966GN

115 63458 LABEL COMPLIANCE

116 63466 LABEL ELECTRIC

*201 63871A ASSY WHEEL ARM AND WHEEL

*202 63812A ASSY RH HANDLE WITH CABLE

*203

63872AWE

ASSY COVER 250MM

*204

63873AWE

ASSY COVER 300MM

*205 63208 SET OF 8 TINES

*206 63209 SET OF 12 TINES

*208 63411A ASSY GEAR WORM & SHAFT

*209 63874A ASSY GEAR CROWN/250MM SHAFT

*210 63875A ASSY GEAR CROWN/350MM SHAFT

*213 63880A ASSY WHEEL SHAFT AND SEALS

*214 63881A

ASSY SHAFT GEAR AND CLUTCH DRUM

*215 63035A ASSY CLUTCH ELECTRIC

*216 63459A ASSY SWITCH, PLUG, CABLE & WIRES

*218 63978A ASSY SPIRAL GEAR AND SHAFT

*250 63222 FURROW ATTACHMENT KIT

*211

63876GP

ASSY MAIN CASE 250MM WITH ALL

PARTS GREEN COLOUR

*212 63877GP

ASSY MAIN CASE 350MM WITH ALL

PARTS GREEN COLOUR

*217 63446A

ASSY MOTOR POD COMPLETE WITH

CLUTCH AND CABLE (NO HAND GRIP)

SERVICE ASSEMBLIES NOTE

We recommend factory produced assemblies for

replacements as they are more economical by

substantially reducing labour costs and time to repair.

OPTIONAL EQUIPMENT

*251 63204

8 TINE COMBINATION AERATOR

AND DETHATCHING BLADE

*252 63205

12 TINE COMBINATION AERATOR

AND DETHATCHING BLADE

Page 8

ELECTRIC TILLER MODEL 710 – 4 or 6 TINE

= Factory made assembly module.

See parts list.

*

*

*

*

*

*

*

*

*

*

*

*

*

*

43

10

22

9

4

27

71

4

9

5

21

16

11

57

35

8

7

39

38

12

65

34

6

33

24

31

78

30

13

75

51

20

29

1

2

55

73

76

28

17

19

9

5

63

79

73

74

32

73

73

13

70

54

78

30

23

24

33

18

31

44

2

58

11

16

3

46

47

15

3

1

1

3

37

15

45

42

72

1

3

36

35

3

1

217

56

2

48

53

49

48

25

75

26

*

*

211

212

203

204

214

208

209

210

213

201

202

250

251

252

205

206

*

*

202

63902ME -010711A

59 (4T)

60 (6T)

ATOM ELECTRIC MOTOR POD IS ILLUSTRATED

IN UPSIDE-DOWN ASSEMBLY POSITION. ALL

PARTS DROP INTO TOP COVER. BOTTOM COVER

SCREWED DOWN TO CLAMP ALL PARTS.

ATOM ELECTRIC TILLER MODEL 710

*

115

112

12

105

106

7

34

103

73

109

107

104

108

102

113

102

215

73

110

114

79

216

105

106

116

52

*

*

205

206

12

41

*

215

*

*

207

Loading...

Loading...